FOREST MACHINE MAGAZINE

READ ABOUT WENDY AND DARREN SMITH ON PAGE 30

FROM THE FOREST FLOOR DELIVERED DIRECT TO YOUR DOOR MAy 2023 + ISSUE 40 + ISSN 2398-8568 + FREE PUBLICATION

a Timbermax Jacket from RJ Fukes Forestry Services FREE PUBLICATION: THE MAGAZINE FOR THE FOREST INDUSTRY

CUTTINGS

Win

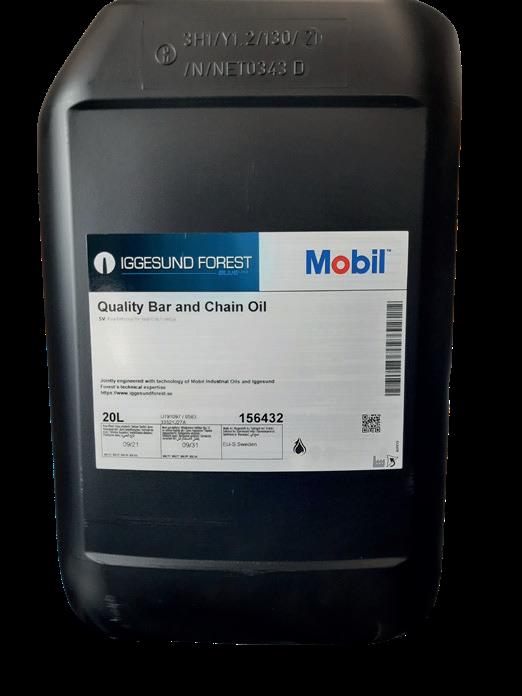

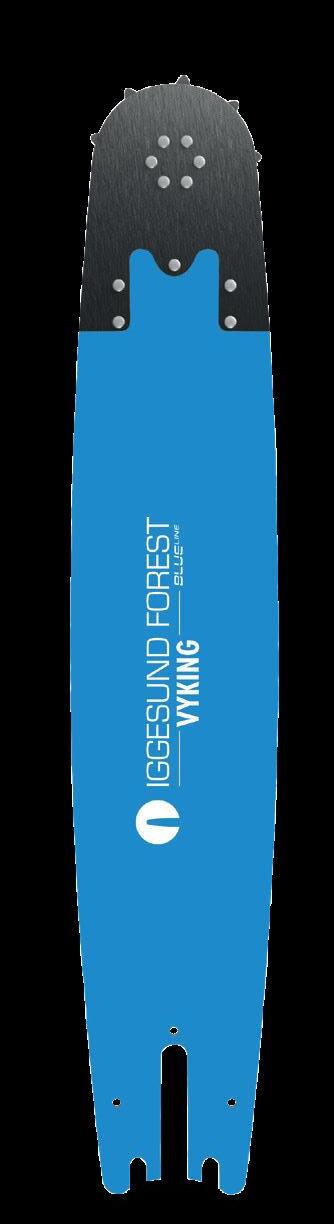

EXHIBITS ON SWEDISH FORESTRY EXPO ON SOLVALLA COME AND VISIT US ON STAND N:02

WE WILL DISPLAY OUR WORLD-LEADING HARVESTER BARS

OUR HIGH QUALITY MACHINE CHAINS

ACCESSORIES SUCH AS DRIVE WHEEL, MARKING PAINT, OUR BAR AND CHAIN OIL AND ALSO PRODUCTS FOR CHAIN MANAGEMENT

WE WILL BE INTRODUCING A BRAND NEW PRODUCT THAT WILL CHANGE THE MARKET ALMOST AS MUCH AS BLUELINE DID!

WELCOME

RAB EASTON Editor

Ilike this time of year, the cold dark winter days fade into a distant memory as they are replaced with longer daylight hours and warmer rain, with the added bonus

that the midges, which are still in hiding, are not due to start feasting on us mortals for at least another couple of months. It is also good to see our home-grown timber markets improving too, now that the construction and building trade is picking up and DIY enthusiasts are starting to plan their gardening projects.

We got some great feedback from some of our readers on the new free magazine. We were a little worried as there is less pages and we had to drop the glossy front cover, but printing and postage costs have gone up dramatically since we started. We felt that this was the best way forward and are trying our hardest to make sure it is a good informative read with a mix of news and features. There is no fooling you lot either lol, quite a few of you contacted me about the Komatsu forwarder feature where a couple of AdBlue usage figures had been corrected with Tippex. I hold my hands up and admit I got it wrong; it has been so long since operating a forwarder I forgot the difference in sizes between a 10ltr and 20ltr drum, so in effect I had doubled the amount of AdBlue the forwarder was using.

For all of you who showed great concern for the time it must have taken to correct them, rest assured it took me no time at all. When the magazine came back, I realised the mistake I’d made and immediately had an “oh S**t” moment. But, upon looking out of my window for divine inspiration, I realised the gods were smiling on me that day. The teachers were on strike and the streets were full of children out playing, this was the perfect opportunity to rectify my problem and save myself time and money on a re-print by using cheap child labour. Tables and chairs were set up in the garden, pens and Tippex laid out and with Wendy supervising we were all done in jig time.

FACEBOOK

Get a regular dose of forestry on our Facebook page. Share your photos and experiences. Stay in the loop with the latest news from the forest industry. We love to see your photos too!

INSTAGRAM

YOUTUBE

Subscribe to our YouTube channel to enjoy our dedicated forestry videos.

��

www.forestmachinemagazine.com Page 3 May 2023

Grabbing Your Attention: Hultdins launch their new Multigrip 16-V Grapple.

Expansion: Merlo increases network with new Scottish Dealer.

Sprucing Up Dinner: Scottish Spruce tips to be used in a range of Italian Pesto products.

FEATURES

The High Road: Creating new forest roads in Aberdeenshire with Boyd Plant Hire.

When The Going Gets Tough: Tigercat introduce a new skidder series for steep ground.

Blown Away: Find out how Harold Taylor deals with storm damaged trees.

Open Day: Forest Machine Services Ltd showcase there products and services.

Cool Runnings: MAN test their new eTruck in polar conditions.

Brand Spanker: Jonah takes delivery of S & D Smith’s new timber lorry.

Jobs For The Boys & Girls: James Jones & Sons host skills day.

FIND US ON

#writtenbyloggersforloggers | #loggingallovertheworld #homeoflogging | #sustainablelogging:poweringtheplanet

ISSUE AVAILABLE

SUBSCRIBE ON PAGE 14

NEXT

From 28th June 2023

8 58 34 7 15 50 32 11 40 48 NEWS EQUIPMENT CONTENTS 30 44 10 56 www.forestmachinemagazine.com Page 4 May 2023

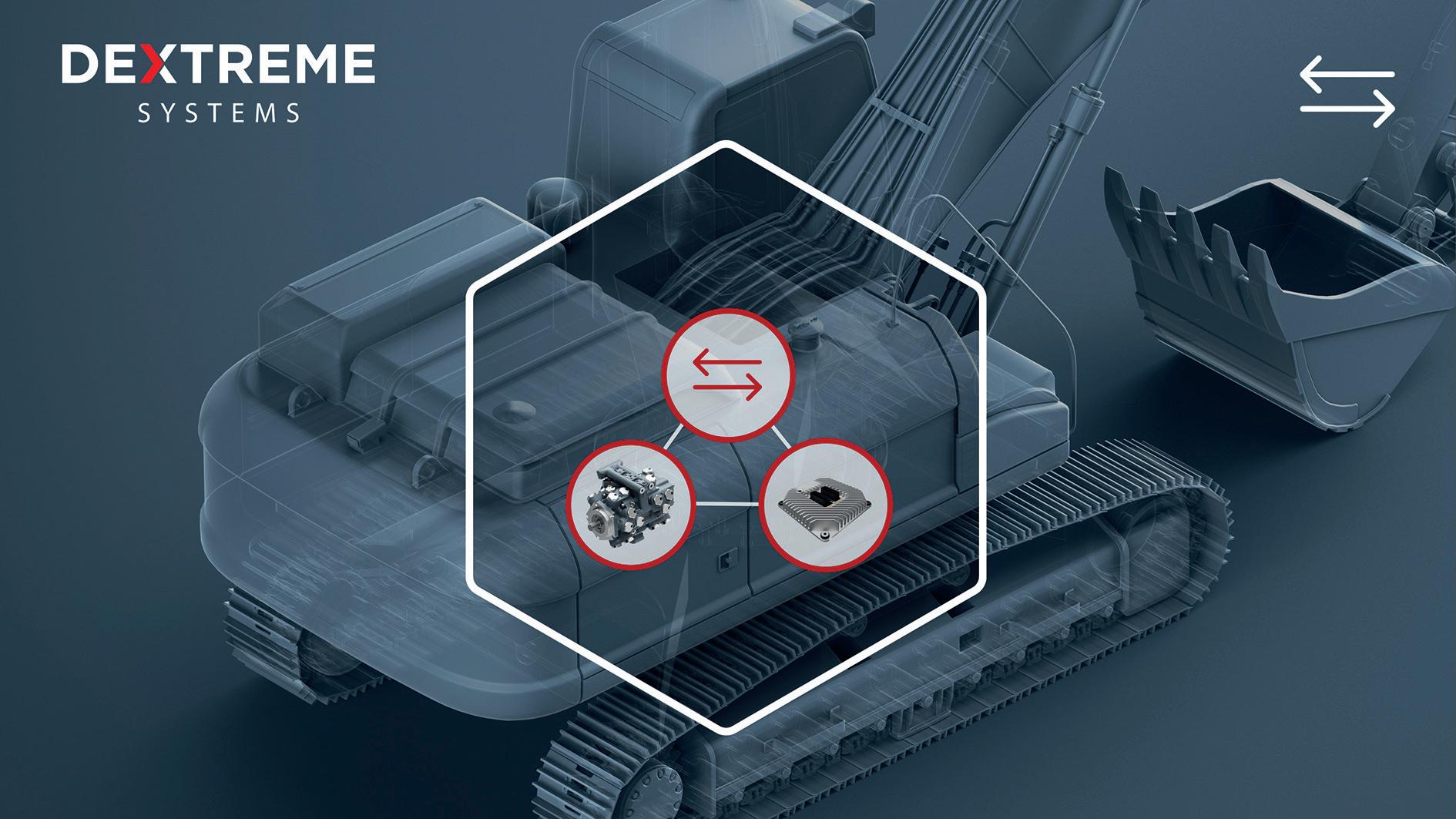

BUSINESS FINLAND FUNDING BOOSTS PRODUCT DEVELOPMENT OF PONSSE & EPEC

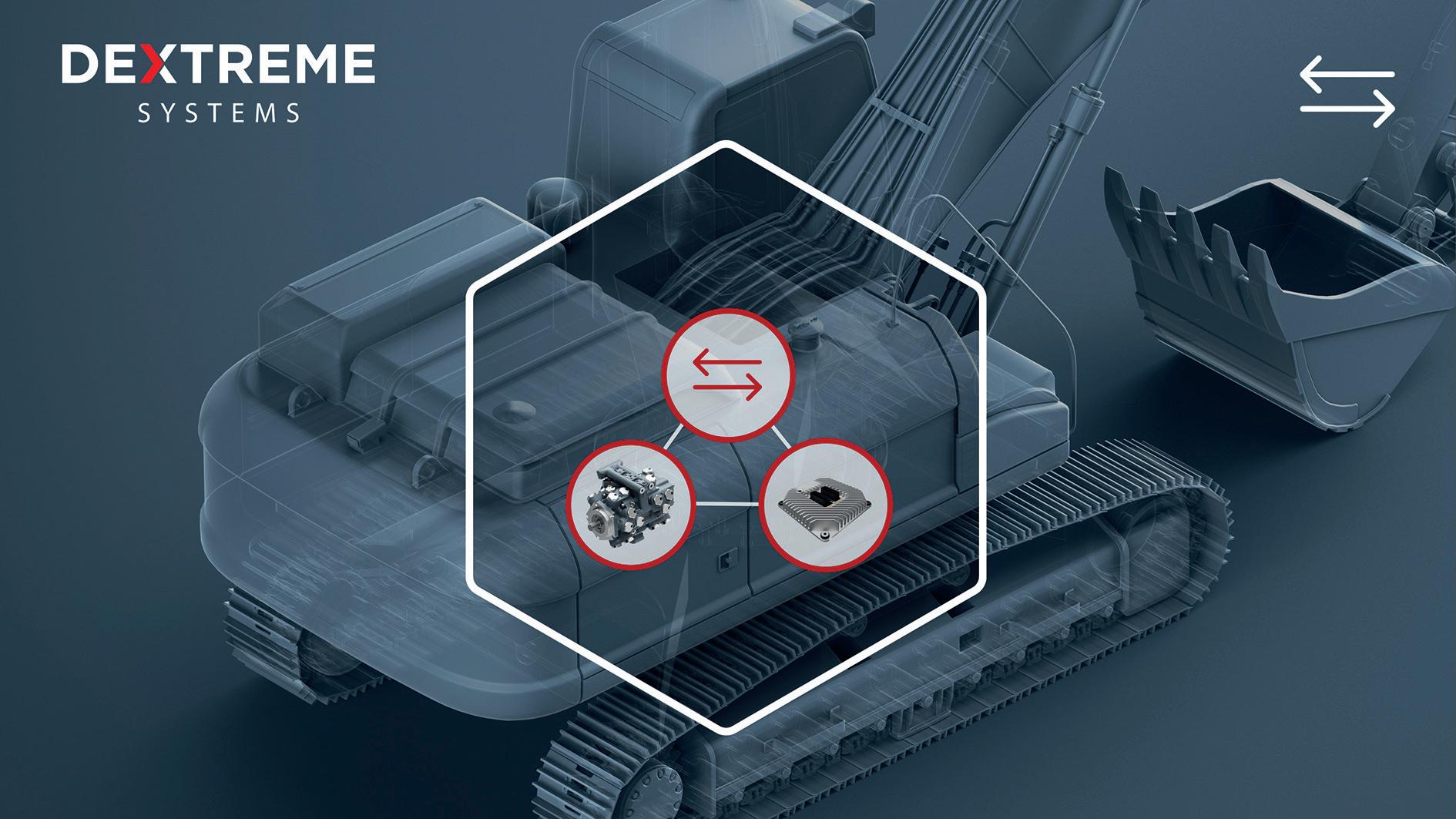

Forest machine manufacturer Ponsse and technology company Epec believe that the emissions and environmental impact of mobile work machines can be significantly reduced with new technology. In the field of mobile work machines, there are several development targets towards sustainable development.

Business Finland has granted ten million Euro in funding to Ponsse’s FORWARD’27 programme in its challenge competition for leading companies. The funding is used to accelerate the product development of mobile work machines. The aim of Ponsse’s FORWARD’27 programme is to significantly reduce emissions from mobile work machines, reduce their energy consumption and improve

productivity. Improving operator working conditions with auxiliary functions and automation are also among the key components of the programme.

“Ponsse aims to be a technological pioneer in CTL forest machines and it aims at producing carbon neutral,

sustainable and increasingly competitive solutions. With funding granted by Business Finland to leading companies, we can accelerate our development of sustainable and digital solutions for mobile work machines”, says Juho Nummela, Ponsse’s President and CEO.

In addition, Business Finland

GB LUBRICANTS MANAGING DIRECTOR STUDYING TO DELIVER SUSTAINABILITY GOALS

GB Lubricants Managing Director, Paul Booth, is celebrating after recently completing the University of Cambridge’s Business Sustainability Management Certificate and gaining its highest mark with a high pass.

The 10-week programme was

specially designed by experts from the University’s Institute of Sustainability Leadership. Its aim being to equip global business leaders in a comprehensive range of Sustainability and Social Responsibility aspects including innovation, collaboration, digitisation, social impact, and effective communication. The course

NEWS www.forestmachinemagazine.com Page 6 May 2023

has granted 20 million Euro in funding to the ecosystem companies associated with the programme.

TOWARDS SUSTAINABLE MOBILE WORK MACHINES

Ponsse and Epec will implement the FORWARD’27 together and will invest more than 25 million Euro to developing sustainable mobile work machines in the next few years. The companies will create an extensive ecosystem around the development work. The first partners have already been selected.

“Epec innovates and develops technological solutions for future work machines to enable zero emission. The joint competence of Ponsse and Epec develops continuously and FORWARD’27 programme will take our abilities even further. The group of companies and partners included in the ecosystem created also play a key part”, says Jyri Kylä-Kaila, Epec’s Managing Director.

HULTDINS NEW MULTIGRIP 16-V

The new model

MG16-V with the grapplearm from RG16-V is now available in the MultiGrip assortment.

The grapple comes with many types of excavator mountings such as OilQuick, EC-Oil, Open-S connector or a regular S- or B-mount etc.

load-holding valve.

What’s more, it’s equipped with an accumulator on the grapple cylinder that enables the arms to follow if, for example, a rock starts to slip and you risk losing your grip.

The MG16-V will be implemented in production from now.

www.ponsse.com

our business. The completion of the course and the qualification is another piece in the jigsaw of helping to continue to develop GB Lubricants’ sustainability strategy and ensure it is integrated in to a wider business plan.”

The MG-V is stronger than Hultdins strongest log grapple. With expander pins and sturdy bushings, the MG-V is a grapple that lasts! The two push rods are solid cast metal and the MG-V also eatures an integrated was a mixture of online led and independent study, group work, written coursework, live discussions via video link and a final project. Using relevant up to date case studies, the course pulled together insights and tutorials from world-leading experts in the field.

Paul commented “I realised last year I needed more tools at my disposal to help drive GB Lubricants forward with its sustainability goals and help steer the best possible route for

He added “This was a short but very intensive course and certainly the most rigorous study I have undertaken since my degree, which made achieving the qualification even more rewarding. It was a lot of

www.hultdins.se

late nights and lost weekends but it was worth it.

The volume of knowledge gained over such a relatively short period of time was incredible and the ability to link in with fellow students from around the world in tutorial groups was insightful. We have maintained a strong alumni link following the study period and continue to share ideas and best practice.”

www.gblubricants.co.uk

www.forestmachinemagazine.com Page 7 May 2023

MERLO DIVERSIFIES ITS SCOTTISH DEALER NETWORK

New to the Merlo dealer network are Fife based J Low Agri Services Ltd. Established by Jimmy & Karen Low in 2002 as a tractor hire business, J Low Agri Services quickly expanded into an agricultural engineering service business in the Fife area following Jimmy’s decision to become self-employed. Now based off Junction 4 of the M90 at Kelty, J Low Agri Services looks to continue their trend of consistent growth as a Merlo dealer.

Owen Buttle, National Sales Manager of Merlo UK, commented, “Fife is a key agricultural area of Scotland and we are extremely happy to have J Low Agri joining the Merlo network. Their location and facilities are well placed to serve farmers and contractors across the region with Merlo products & services”.

EXPANDING DEALER

Expanding to become a

combined Merlo dealer with the upcoming launch of RAS Plant Sales, Ross Agri Services Ltd will grow the Merlo offering they have provided to their customers since 2020.

Ross Agri Services Ltd (RAS), established by Bill and Ethel Ross in 1972 as a farm machinery hire business, RAS quickly grew into a major player amongst Scottish dealers when they focussed on machinery sales over hire in 1976. Bill and Ethel’s son Martin joined the business in 2000 to take responsibility for sales, administration, maintenance and the workshops. Twentythree years later, Martin has established himself as one of the most versatile dealer principals in Scotland.

The newly formed division of RAS Plant Sales will operate alongside Ross Agri Services

from their existing St Cyrus, Turriff depots plus the newly acquired Muir of Ord location, enabling RAS to carry Merlo construction products such as the ROTO and Panoramic ranges.

Shaun Groom, General Manager of Merlo UK, remarked about his experience with the RAS team, “Having known Martin, Bill & Ethel for many years, I am confident that the Merlo brand will only continue to grow further with the high level of customer support that RAS are renowned for”.

J Low Agri Services

www.jlowagriservices.co.uk

Ross Agri Services/RAS Plant Sales here.

www.rossagri.co.uk

Merlo UK

www.merlo.co.uk

NEWS www.forestmachinemagazine.com Page 8 May 2023

TreEmme MM250X

Don’t settle for second best

ENGINE 245

SPEED KM/H 40

WHEEL DRIVE 4

For operators who need multi-purpose and high-performance machines that are easy to use but are not afraid of demanding work, the TreEmme MM250X is the machine for you. This versatile machine is intended for use with a wide range of attachments. A key application is that of high output mulching in conjunction with a heavy duty mulcher, shredding post-harvest debris, tree stumps, soil reconditioning and more. Find your local Merlo Dealer at merlo.co.uk to find out more.

merlo.co.uk

KOMATSU FOREST LIMITED RELOCATION PROJECT

As you may be aware Komatsu Forest Limited have undertaken the exciting project of moving to a brand new and improved location at Carlisle Airportestimated completion during summer of 2023.

Komatsu want to ensure that your business is not interrupted

and that their service continues to meet your expected standards. It is therefore essential that they keep you informed of some key information.

The relocation to a temporary site whilst the new building is being constructed has now started.

The Service and Workshop teams will begin to depart the current site and operate from the temporary location on Tuesday, 11th April 2023. Finance and Sales will leave from Monday, 22nd April 2023

The new addresses are as follows:

Temporary Site: ( Parts Deliveries and Collections ) Komatsu Forest Limited, Elmside, Eastriggs, ANNAN, DG12 6TF.

https://goo.gl/maps/ rqA4nN43ySaMQTha6

Correspondence Address: Komatsu Forest Limited, PO Box 452, Carlisle, CA1 9JR.

Please continue to Komattsu Forest via telephone line 01228 792018.

www.komatsuforest.co.uk)

BUILD YOUR OWN ADVENTURE:

LEGO® ICONS LAUNCHES CLASSIC DEFENDER 90 SET

The LEGO® Group and Defender are celebrating 75 years of Land Rover with a build-your-ownadventure: the new LEGO® Icons Classic Land Rover Defender 90. The 2,336-piece set is complete with all the accessories for an off-road expedition.

The set has a two-in-one format, allowing builders to create an everyday road-ready model or customise it for adventures.

Defender has racked up 75 years of all-terrain expeditions. Instantly recognisable around the world, it has a unique record of adventure, humanitarian aid and hard work.

The 32cm-long LEGO® model reflects this with accessories including a roof rack, raised air intake, front bumper with working winch, side rails and toolbox, plus traction plates for crossing mud and sand. It also

has working steering and suspension, opening doors and bonnet and an interior with details based on the full-size Classic Defender.

“Bringing the Classic Defender to life in bricks was no easy challenge. Defender can take you anywhere, so during the design process we wanted to infuse the set with that sense of adventure. We can’t wait to see fans’ reactions” said Kurt

NEWS www.forestmachinemagazine.com Page 10 May 2023

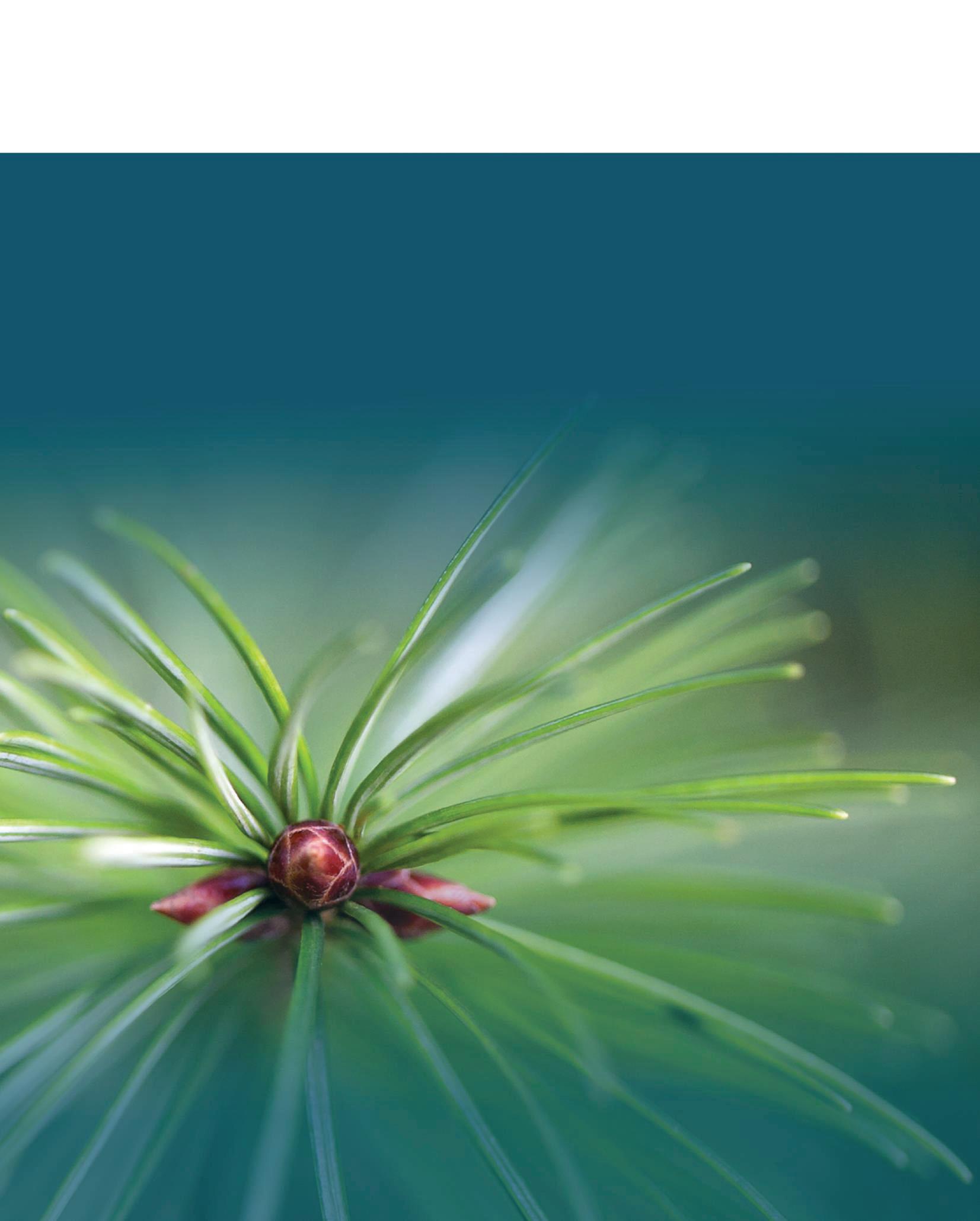

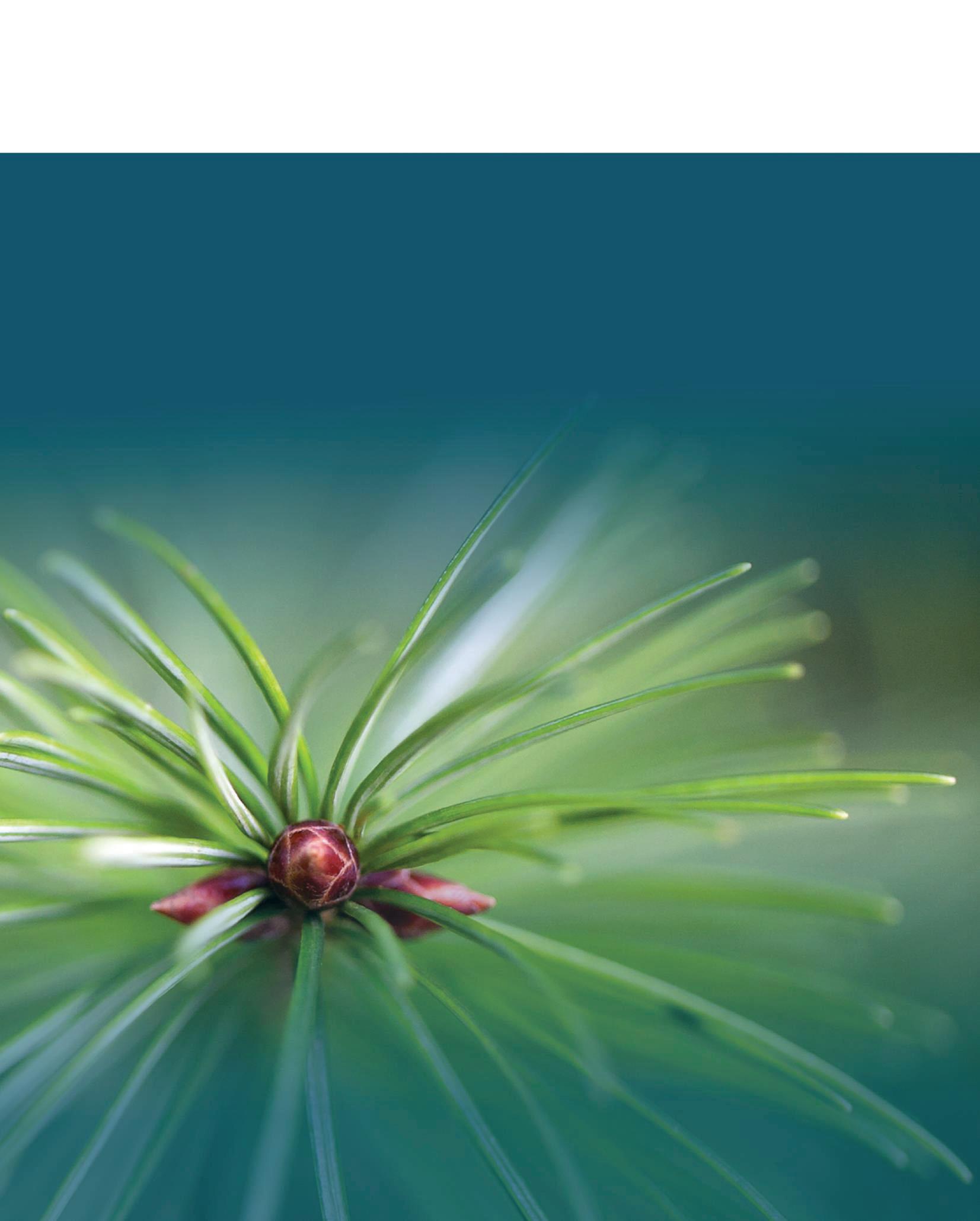

BSW TIMBER PARTNERS WITH ITALIAN FOOD MANUFACTURER

BSW Timber has partnered with Italian food manufacturer SprestoItalia to aid in the production of a new range of commercial condiment products.

Spruce tips from BSW Group’s Scottish forests will be used for the first time in a range of pesto products, produced by the Brescia based business. Aprile D’Fulsilli, spokesperson at Spresto said: “Here at Spresto, we’re always on the lookout for new and exciting flavours to add to our range of delicious pesto products. That’s why we’re thrilled to announce the launch of our latest range of pesto made from Scottish spruce tips!”

A statement on the Spresto

Italia website read: “What are spruce tips? Spruce tips are the fresh, new growths on the tips of spruce trees that appear in the spring. They have a subtle,

Kristiansen, LEGO® Design Master.

The LEGO® Icons Classic Land Rover Defender 90 set is available from 1 April in LEGO® stores and online at www.lego.com/Defender, priced at £209.99 in the UK (€239.99/$239.99).

www.landrover.com www.LEGO.com

citrusy flavour that’s reminiscent of pine and lemon, making them the perfect addition to our pesto.

We carefully pick the spruce tips from the forests of Scotland, ensuring that only the freshest and most flavourful tips make it into our pesto. We then combine them with garlic, pine nuts, olive oil, and other carefully selected ingredients to create a unique and delicious pesto that’s bursting with flavour.

Our Scottish spruce tip pesto is not only delicious, but it’s also vegan and gluten-free, making it the perfect addition to any meal. Use it as a dip for vegetables or crackers, as a spread on sandwiches, or as a sauce for your favourite pasta dishes. The possibilities are endless!

We’re proud to support sustainable and environmentally friendly practices, and our

Scottish spruce tip pesto is no exception. By using spruce tips that are naturally occurring and abundant in Scottish forests, we’re helping to reduce waste and support the local ecosystem.

We’re excited to share our new range of pesto made from Scottish spruce tips with food lovers everywhere. Try it for yourself and experience the unique and delicious flavour that only spruce tips can bring to your meals. Shop our range online or find us at a local store near you.” www.bsw.co.uk

www.forestmachinemagazine.com Page 11 May 2023

UK’S FIRST AGROFORESTRY SHOW EXPLORE THE PERKS OF FARMING WITH TREES

The event, hosted by the Woodland Trust and Soil Association and sponsored by lead partner Sainsburys, will explore the boost that trees can deliver for nature and climate as well as delivering resilience and productivity for farm businesses. It will bring together a thousand guests spanning across farmers, foresters, tree nurseries, growers, graziers, advisors, funders, food businesses, policy makers and agroforesters.

Soil Association Chief Executive Helen Browning will be hosting the event at Eastbrook Farm, in Wiltshire, where she runs a mixed farm with an agroforestry project that has been running for seven years. She said: “We are delighted to be working with the Woodland Trust to host the UK’s first ever

Agroforestry Show. Agroforestry has been proven to boost farm productivity. Trees improve soil health, provide habitats for wildlife including beneficial insects, give shelter and forage to livestock, and cut carbon emissions. And they do all this while providing additional funding streams through fruit, nuts and timber. Much more than a trade show, this twoday gathering will inspire hundreds of land stewards to collaborate and get involved with agroforestry.”

Agroforestry offers huge opportunities to the forestry sector and this show will be a catalyst to strengthen the relationships between the forestry and farming sectors. Working together the two sectors can identify solutions to help overcome the current

knowledge and financial barriers to widescale up take of agroforestry.

The Woodland Trust has a decade of experience in supporting agroforestry and at the show they will highlight how they support landowners and farmers to adopt agroforestry on their land, via a range of subsidised tree offers and expert advice. Helen Chesshire, Lead Farming Advocate at the Woodland Trust said: This event is about making trees work for farm businesses and the local environment that they operate within and rely on. It is a sign of hope that there are solutions to grasp - if we take them. We will highlight this and more at September’s show.”

The event, also sponsored by the Forestry Commission, Defra,

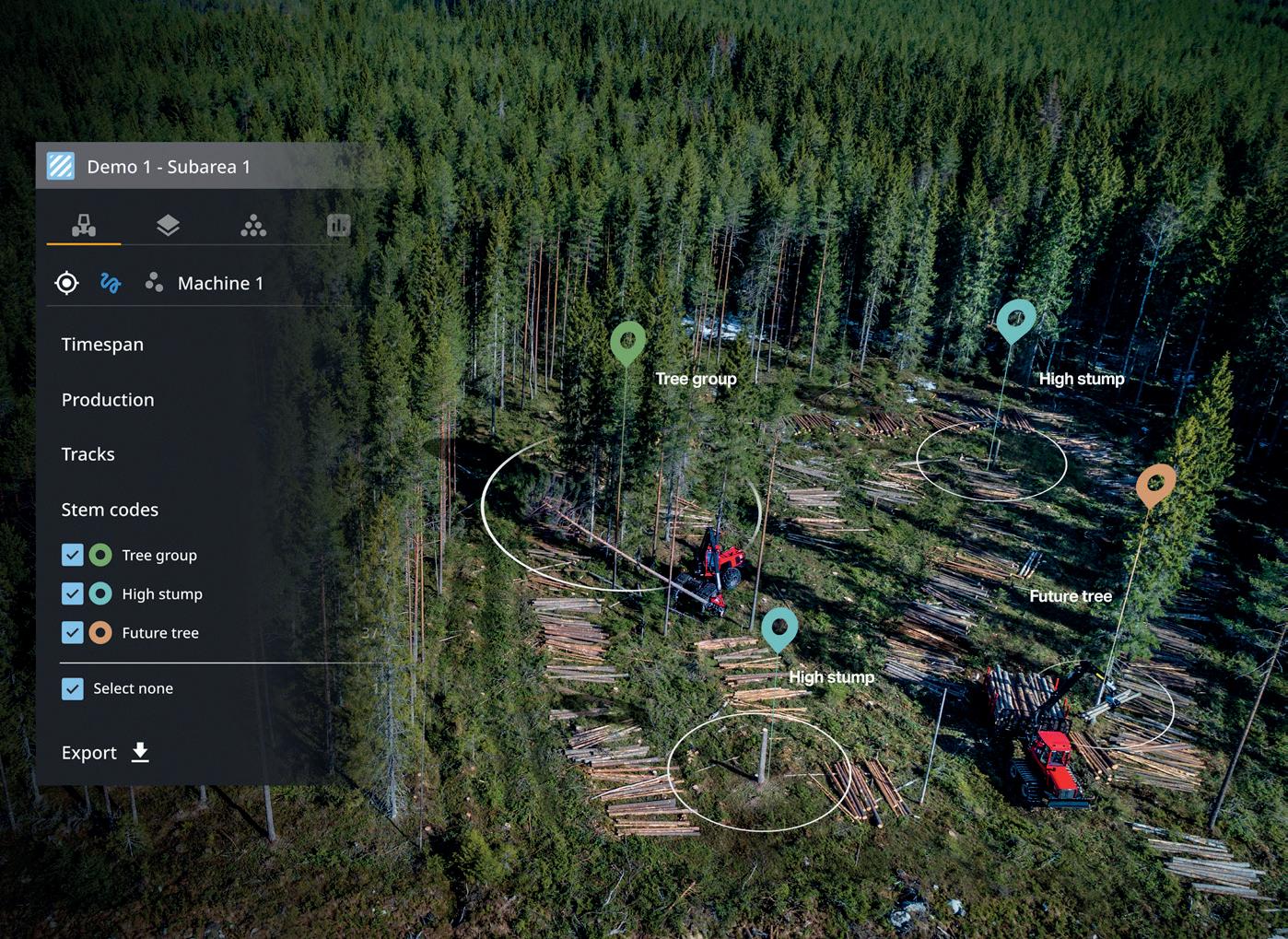

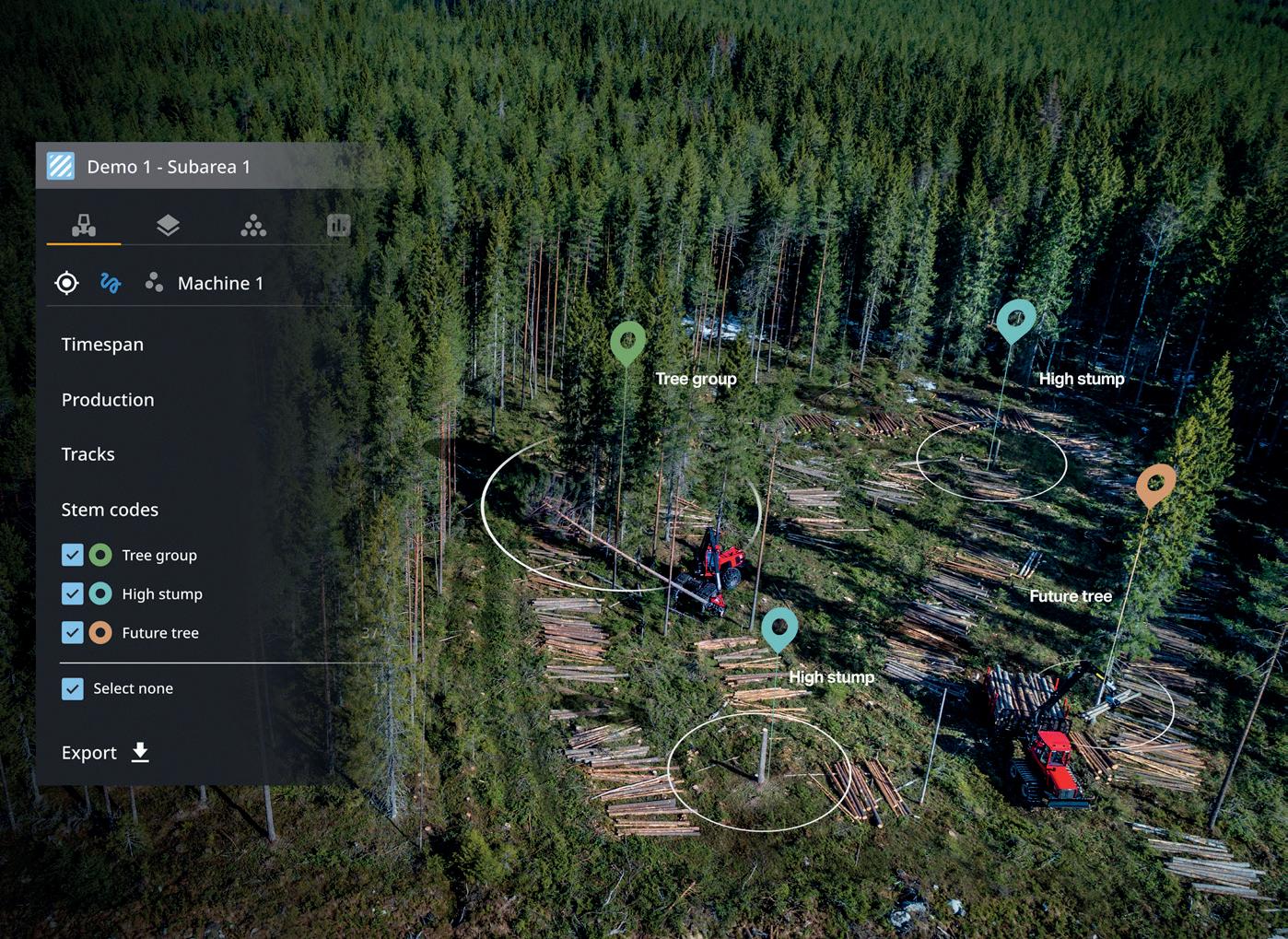

EASIER TO CLASSIFY STEMS BASED ON CONSIDERATIONS

There is now a new feature in Maxifleet called stem code visualization. With this feature, individual stems can be visualized with stem codes based on, for example, biodiversity considerations. The feature provides operator support and makes it easier to make good decisions.

Stem coding allows the operator to classify individual trees based on the premises that apply to the object. In addition to “high stumps”, the operator can select “future tree” or “tree group” to view saved trees. The position of the coded trees is stored in Maxifleet, and they are clearly marked in the map of the object. The new feature makes

it easier to follow directives, such as distances between future trees.

Maxifleet can also, based on previously coded trees, provide support for where the operator should cut a high stump or save a tree. The system can also show when it is time to save a future tree, which makes it

NEWS www.forestmachinemagazine.com Page 12 May 2023

Tillhill, Farm Carbon Toolkit and Royal Forestry Society, comes hot on the heels of a groundbreaking report, funded by the Woodland Trust, which showed how a major increase in agroforestry – farming with trees - in England, is essential if the country is to meet nature and climate targets, whilst at the same time securing long term food production.

Buy your tickets now (https:// www.agroforestryshow.com/ tickets)

Two-day tickets are offered on a tiered ticket scale to make this event as accessible and affordable as possible. Single day tickets will become available when the event program is launched. Early bird tickets are available now but will go fast. A limited number of bursary funded places are also available for those who require additional support to attend the event. Get in touch for more information at: info@agroforestryshow.com

Exhibitor details here: (https:// www. agroforestryshow.com/ sponsor-and-exhibitor-info

easier for the operator. It is also possible to track the number of high stumps made, so that the operator does not need to keep track of that. Note that the stem codes in the picture are examples, the codes are set based on the specifications of the assignment.

In addition to making the operator’s work easier, the visualization of stem codes helps to report that the job has been completed correctly based on the forest owner’s assignment. www.komatsuforest.com

RED DIESEL AMENDMENTS

These amendments will: Add arboriculture to the list of activities for which

machines and appliances (other than vehicles) can use rebated fuel, a clarification which will allow those working in this sector to use rebated fuel in the same machines and appliances as they did before April 2022.

www.forestmachinemagazine.com Page 13 May 2023

FOREST MACHINE MAGAZINE

#homeoflogging

May 2023 Issue 40

ISSN 2398-8568

YES! I would like to subscribe to Forest Machine Magazine

HOW TO ORDER

Online

www.forestmachinemagazine.com

A quick, easy and secure way to subscribe

BY POST

Name:

Address:

Editor and Publisher

Robert Easton

Advertising

Rab Easton

Social Media Manager

Rab Easton

Layout and Design

Wendy Easton

Subscriptions

Wendy Easton

Photography

Wendy Easton

Postcode:

Email Address:

Tel No:

GIFT?

If you are taking out this subscription as a gift for someone else. Please complete the gift recipient’s details.

Name:

Address:

CONTACT US

forestmachinemagazine@mail.com

+44

(0)7582055748 / +44 (0) 7951 473 846

Website: www.forestmachinemagazine.com

Address: 33 Holm Gardens, Bellshill, ML4 2PB. UK

Forest Machine Magazine assumes no liability or responsibility for any inaccurate information, errors or omissions. Forest Machine Magazine considers its sources reliable and verifies as much data as possible. However, reporting inaccuracies can occur and consequently readers using this information do so at their own risk. The opinions expressed in each article are those of its author and do not necessarily reflect the opinions of Forest Machine Magazine. Therefore, Forest Machine Magazine carries no responsibility for the opinions expressed thereon. Through the magazines you are able to link to other websites which are not under the control of Forest Machine Magazine. We have no control over the nature, content and availability of those sites.

The inclusion of any links does not necessarily imply a recommendation or endorse the views expressed within them. No part of this publication and/or website may be reproduced, stored in a retrieval system or transmitted in any form without prior written permission of the Publisher.

© 2023 Forest Machine Magazine. All rights reserved.

Postcode:

Email Address:

Tel No:

UK only - I wish to pay £15 p&p for 6 issues of Forest Machine Magazine

Europe - I wish to pay £35 p&p for 6 issues of Forest Machine Magazine

Rest Of World - I wish to pay £45 for 6 issues of Forest Machine Magazine

Please make cheques payable to: Robert Easton Ltd

Please return your completed form to: Forest Machine Magazine, 33 Holm Gardens, Bellshill, ML4 2PB.

SUBSCRIPTIONS

Page 14 May 2023

www.forestmachinemagazine.com

Talking about forest roads to anyone involved in timber harvesting or timber haulage, gets a similar reaction to someone waving a red rag to a bull.

“The roads are in a shocking state with deep ruts and potholes the size of craters, they are too narrow for timber lorries to travel on or not wide enough to get their stabilising legs fully

extended or have loads of sharp stones causing punctures and damage to tyres.”

Another gripe you hear frequently “They have millions to spend on cycle tracks and footpaths but sod all to invest in the bit that makes the money!”

The lack of maintenance to roads might make a foresters books look more profitable,

but to us who work in the forest, it creates untold hag. Maintenance vehicles have difficulty accessing sites, some fuel suppliers will not deliver, and we end up having to track machines for miles to take our diesel tanks to the nearest tarred road for refilling. Most importantly though is that emergency vehicles will struggle to get to sites in the case of accidents or fires.

From the 1970’s to the turn of the century most forest districts had a road squad. Each squad was tasked with keeping the roads in good order and building new ones. The infrastructure and conditions of the forest roads was excellent as each

ESTABLISHMENT www.forestmachinemagazine.com Page 15 May 2023

squad was comprehensively equipped with tipper lorries, excavators, dozers and road graders.

I recently visited Durris Forest near Stonehaven in the Northeast of Scotland where a huge contract was underway to create many miles of new forest roads. The new roads were being built for access so that all the cables on the electricity pylons could be replaced.

The forests on the Northeast coast of Scotland usually have a mineral podzol type of soil which is quite dry and acidic making them ideal for growing pine trees. Durris forest was not typical of the area, it was predominately Sitka Spruce planted on wet, peaty soil with visual evidence of vast areas of windblown trees caused by recent storms. I was quite interested to find out how the roads were made and the pitfalls that had to be overcome when working on boggy ground.

From the main road, it was an uphill drive of about two miles,

to where Ayrshire based company Boyd Plant Hire, was sub-contracting to John Marshall & Sons, a plant and fencing contractor also based in Ayrshire.

Allan Marshall of JMS Ltd, had two ten tonne Wacker Neuson Dual View dumpers carrying the six-inch stone - which was brought in by lorry from a local quarry - to Chris Boyd, Boyd Plant hire, who was working on a new section of road. Chris was using a CASE CX130D 13.8 tonne excavator with an X hitch, Engcon tilt rotator and a height restrictor. The height restrictor is a safety device where pre-set height limits can be set with an audible alarm or motion cut off to safeguard operators when working under electricity cables or other overhead obstacles. This is unfamiliar territory for me, I have only operated excavators a handful of times and those mostly with a dangly bit stuck on the end of the dipper boom that felled and processed trees. ��

Boyd Plant Hire has two CASE

CX130D excavators, the one working in Aberdeenshire and the other operated by Chris’s brother, John. The other CASE is currently on hire at a building site in Kilmarnock. Both are full-sized, conventional excavators, loaded with features and plenty of power from the Isuzu engine, making them well suited for a wide range of utility, groundworks and residential work.

Chris has currently three years’ work in front of him in the Northeast and it was easy to see why as he was one of the best excavator operators I have seen yet. He has over 15 years’ experience on excavators prior to establishing Boyd Plant Hire in 2019. He is highly experienced in forestry work as has carried out a lot of work at the Douglas Windfarm excavating the bases and constructing access roads. He has also carried out all types of groundworks during his career including Drainage and Sewer works, Pipe and Cable tracks and building site excavations.

www.forestmachinemagazine.com Page 16 May 2023

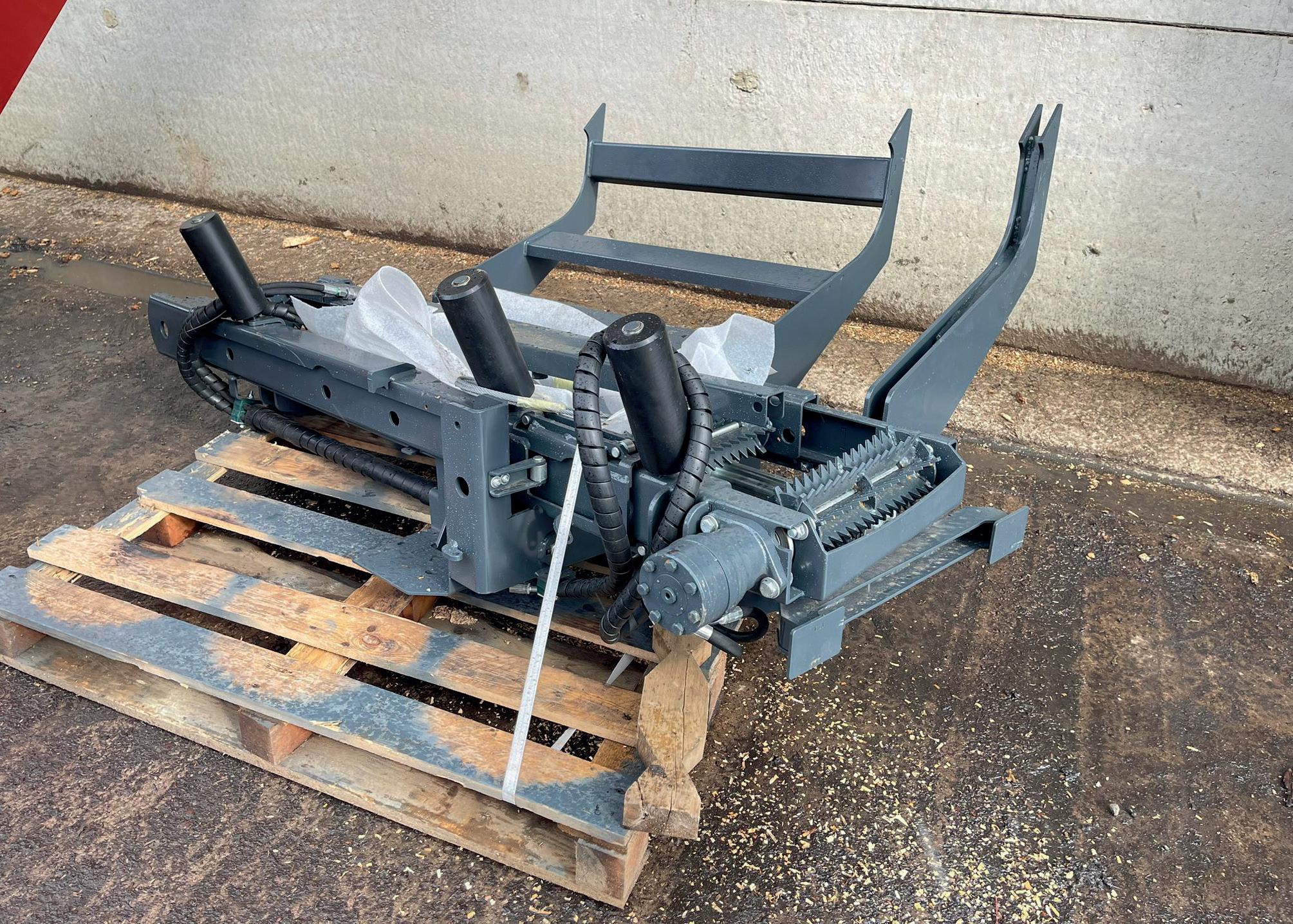

New grading beam

www.forestmachinemagazine.com Page 17 May 2023

His excavator was three years old (the other excavator working in Kilmarnock is brand new) but looked in showroom condition, the paintwork was immaculate and there was not a visible scratch or dent to be seen anywhere. When I questioned Chris on the pristine condition he admitted to washing, waxing and polishing it on a regular basis. He is delighted with CASE and has used their machines for many years. They have proved to be exceptionally reliable, have an excellent back up service and are a great all-round versatile tool for the work they carry out.

Chris was smooth but quick on the controls and made laying the road look easy when in effect maintaining a constant depth and width of is much more difficult than it looks. Prior to the road being laid, he opened a drainage channel on both sides and removed the top layer of humus and peat. Plastic cundies were put in to assist with drainage from the high to the low side wherever they were needed. The drainage channel on the low side of the road joined up with the many main forest drains to prevent any accumulation of water. The heavy-duty Doram sheeting was expertly rolled out without damage using the excavator bucket. The sheeting prevents water and peat coming up through the stone and swamping the road. Once the layer of stone was spread on top of the sheeting, a dual plastic grid sheet was rolled out which is designed to lock in and confine the aggregate. It sounds quite complicated, but in fact it was a quick process.

ESTABLISHMENT www.forestmachinemagazine.com Page 18 May 2023

The dumpers were not carrying the aggregate far and there never appeared to be a break in the stone arriving. Many operators would have been stressed out at working under this kind of pressure, but Chris was taking it in his stride and was actually enjoying himself. I was surprised at just how quickly the road was being formed, Chris was completing a remarkable 100m of road per day. With it being such a long distance from home Chris stays away for two weeks at a time working twelve on and two off and usually works 12 hours each day.

My only gripe would be that the road was just 3.5m wide. This is nothing to do with the contractor as they carry out what is stipulated in the contract. This usually comes direct from the landowner who is trying to save a few bob. At 3.5m it is a bit tight for manoeuvring articulated timber lorries, especially in the dark or in wintry conditions, even wagon and drags will struggle to get their stabilising legs fully extended when using the crane for loading. An extra half meter would make the world of difference to our hauliers! There was a few thousand tonne of blown timber needing to be cleared up that I could see, and this road would eventually be used for timber lorries as well, so it would of made sense to fact this in.

This was an interesting trip and I enjoyed broadening my horizons and learning a bit more regarding another side of the industry.

www.boydplanthire.co.uk

FORESTRY ENGLAND TO PLANT NEW WOODLAND

Plans to plant a brandnew woodland in Wing have been given the green light in a joint project between Forestry England and Buckinghamshire Council. The new Wing Wood will see 132,000 trees planted on land owned by Buckinghamshire Council, creating an inspiring green space for local people, a valuable habitat for wildlife and a sustainable source of timber.

The decision to create the new woodland on the 51-hectare site follows a public consultation last year and local and national organisations were also involved in discussions over the woodland plan. Wing Wood will include a mix of tree species suited to the locality, five new wildlife ponds and a community orchard as well as accessible paths for walking and cycling. As part of the woodland design, Forestry England hope to link the new Wing Wood with Long Spinney Wood, creating clear paths and an easy connection between the two areas. Forestry England will begin planting this year and aim to get most of the trees in the ground before the end of April with the rest planted in the autumn and winter. The 132,000 trees will form part of the council’s pledge to plant 543,000 trees, one for every resident in Buckinghamshire by 2031, as part of its Climate Change Strategy.

Gareth Williams,

Buckinghamshire Council’s Cabinet Member for Climate Change and Environment, said: “We are really pleased to be able to join forces with Forestry England to develop this new countryside space in Wing. Not only will it provide an additional green space for people to enjoy, but it will also create a welcome new haven for wildlife and enhance and enrich the existing countryside.”

Bethany Cambridge, Head of Woodland Creation at Forestry England, commented: “We are delighted to be partnering with Buckinghamshire Council to grow an inspiring woodland for local people to explore and enjoy.”

Forestry England will hold volunteer planting days in the autumn for local people to help plant the community orchard trees and learn more about the woodland design and plans. News and updates on Wing Wood will be shared at www. forestryengland.uk/wing-woodcommunity-woodland.

Wing Wood is the second woodland Forestry England is creating through their Forestry England Woodland Partnership which offers a guaranteed rental income to landowners in return for a long-term lease. York Community Woodland was the first site under the scheme and planting is well underway to create the 78-hectare woodland west of York.

www.forestmachinemagazine.com Page 19 May 2023

CLAIM FREE TREES IN THE WOODLAND TRUST’S LATEST TREE-PACK GIVE-AWAY

The Woodland Trust is urging schools and communities to plant more trees by taking advantage of its latest tree-pack giveaway.

Applications for the charity’s ever-popular free tree packs scheme are open now and schools and community groups are needed to push up the numbers of trees planted by 800,000 to reach a whopping five million.

Woodland Trust senior project lead Vicki Baddeley said: “We’re so proud of the numbers of free trees we’ve been able to give

away. Applying is easy and all saplings are fully funded for those receiving the trees in our autumn delivery in November. All you need is time and a small piece of land to plant on.”

The last round of the Trust’s free tree-packs scheme in the spring of 2023 delivered a total of 540,630 saplings to 3,272 organisations across the UK:

• England: 452,055 trees to 2,811 schools and community groups

• Scotland: 54,570 trees to 288 schools and community groups

• Wales: 33,105 trees to 173 schools and community groups

The Woodland Trust is committed to planting another 50 million native trees across the UK by 2030 and is urging people to get behind our mission to plant more trees.

The Woodland Trust’s tree packs have been generously funded by lead partners Sainsbury’s, Lloyds Bank, OVO Energy, Bank of Scotland and Sofology.

www.woodlandtrust.org.uk

OVER 300 TREES PLANTED ACROSS INVERCLYDE

AMASSIVE tree planting exercise is underway across Inverclyde with over 300 added to local greenspaces.

Grounds staff from Inverclyde Council have been adding species including rowan, field maple and silver birch to Murdieston Park, Greenock. Trees are being proactively planted throughout the area to replace ash trees which have had to be removed or cut back due to infection by ash dieback, an incurable fungal disease that causes instability and death of the tree.

Over 300 trees in total will have been planted come the end of April 2023 to make up for roughly the same amount lost through disease.

Councillor Michael McCormick, Inverclyde Council’s convener of environment and regeneration, said: “Nobody wants to lose any trees and it’s a real shame that so many have had to be removed or cut back due to ash dieback, but the nature of the disease means it kills trees from the inside making them unstable and poses a serious safety risk for people and property. There is currently no cure for the

infection and ash dieback is an issue affecting the whole of the UK.

“But it’s great to see our grounds staff out and about trying to offset that by replanting trees in so many areas, including here in Murdieston Park. There’s also a great mix of species being added which are more disease resistant. This work will only enhance what we already have in our many wonderful parks and outdoor spaces and is part of the council’s overall strategy to encourage and promote biodiversity.”

ESTABLISHMENT www.forestmachinemagazine.com Page 20 May 2023

GRANT TO BOOST DOMESTIC TREE PRODUCTION RE-OPENS

Investment in domestic tree production in England will be accelerated, with applications re-opening for the Forestry Commission’s Tree Production Capital Grant. The funding will drive the production of tree seed and saplings through developments in machinery, automation and the expansion of facilities.

In line with the aims of the England Trees Action Plan and Government ambitions to treble tree planting rates by the end of this Parliament, the Tree Production Capital Grant will support efforts to build nursery capacity and grow long-term tree seed and sapling supply.

The grant will enable suppliers to boost production rates at pace and has been designed to complement the Tree Production Innovation Fund, which provides support for research projects that enhance UK tree production methods.

Previous funding rounds have provided machinery for projects such as the Emmaus Community Tree Nursery in Cornwall to help it meet the need for locally grown trees and provide employment opportunities for homeless people. Funding has also supporting Warwickshire County Council expand and improve their tree nursery expansion and improvement so they can diversify the species they grow and adapt to future

climate conditions.

Successful projects will be awarded up to £175,000 in grant funding to cover up to 50% of costs, with money coming from the Tree Production Capital Grant as part of the Government’s £750 million Nature for Climate Fund. In comparison to the 2022 application process, the minimum grant value which can be applied for has reduced from £10,000 to £5,000 enhancing accessibility for smaller projects.

Examples of eligible projects include investments in seed trays, developments in machinery such as transplanting systems and grading machines, improved polytunnel infrastructure and irrigation systems, or in biosecurity through improved water treatment and refrigeration equipment. Applications are encouraged from tree seed and sapling suppliers of all sizes and sectors, as well as new entrants looking to diversify into the area.

Forestry Minister Trudy Harrison said: “This Government is committed to bolstering domestic tree production and fostering a robust forestry industry – actions that are necessary to realise our longterm tree- planting goals.

“Not only does the Tree Production Capital Grant allow

us to modernise and enhance the sector, but it also helps to create new green jobs and to tackle climate change, amongst myriad other benefits.”

Forestry Commission Chief Executive Richard Stanford said: “Funding projects that enhance our woodlands and treescapes is fundamental to achieving Government’s tree planting ambitions and building an innovative and robust forestry sector.

“Through the Tree Production Capital Grant we have been able to support existing tree and seed suppliers of all sizes, and also provide funding to those wishing to make a start in the sector. With the application window now open, I encourage those with relevant projects to apply.”

The second round of the Tree Production Capital Grant is now open until 31st May 2023, and will provide up to £1.76 million of funding during 2023/24 and £3.43 million during 2024/25, subject to successful bids. Applicants can apply for projects up to two years long, ending in March 2025.

The Forestry Commission will be hosting a webinar on the grant application process on Friday 28 April.

For more information and to apply, go to: https://www.gov. uk/guidance/tree-productioncapital-grant

www.forestmachinemagazine.com Page 21 May 2023

FRONT COVER PHOTO COMPETITION

Send your photo in by the 14th May 2023 E: photos@forestmachinemagazine.com | Whatsapp: 07951 473 846 Please mark photos with the heading comp. Winning photo features on our front cover and wins a £100 Amazon voucher.

Timber Transport

Subject:

Connor Hanan

Eifion Glyn Jones

Stephen Robinson

HARVESTING www.forestmachinemagazine.com Page 22 May 2023

Kelly Doran

Magnus Burd

Magnus Burd

www.forestmachinemagazine.com Page 23 May 2023

Aaron Ferguson

Mihai Andronicl

Rich Edwards

Kelly Doran

HARVESTING www.forestmachinemagazine.com Page 24 May 2023

Jeff

Malcolm

Low Impact Forestry

Morgan

Kieran Anders

www.forestmachinemagazine.com Page 25 May 2023

Benvin

HARVESTING

Patrick van Wijk

Heinrichs-Drabancz

Rob Will Service Ltd Agnes

www.forestmachinemagazine.com Page 26 May 2023

Pellum Wilkins

BM

Pty Ltd

Logging

Phil Cole

Michal Misiek www.forestmachinemagazine.com Page 27 May 2023

Jason Van Overwaelle

HARVESTING

Aleksi Kyngäs

John Parker

www.forestmachinemagazine.com Page 28 May 2023

Luke Allan Peter Guest Rowland

Rowland

Ana Boscheti

Repson Timber Limited www.forestmachinemagazine.com Page 29 May 2023

Filippo Longa

COVER PHOTO WINNERS

Our cover photo for this issue is of a Logset 12H GTE Hybrid harvester and 6F Forwarder which was submitted by Darren and Wendy Smith.

Darren and Wendy are a husband-and-wife forestry contracting team who work in the Somerset and Devon areas. Darren operates the harvester and Wendy the forwarder. Both machines are just over two years old but this is the fourth Logset harvester Darren has owned. Wendy was happy to provide a brief insight regarding their work.

Which areas do you work in and what type of work do you carry out?

“We work throughout Somerset and Devon harvesting and extracting timber on all types of terrain. Our contracts vary in size from 500 tonne up to 10,000 tonne. Although the Logset 12H GTE Hybrid Harvester is a big machine it is surprisingly nimble and is capable of all types of work from first thinnings to mature clear cuts. The type of ground we work on varies from flat to quite steep - we have an excavator winch for skidding timber off very steep ground that is unsafe to harvest with machines.”

What made you decide on Logset machines?

“Many years ago, Darren had a harvester (not a Logset) with a

problem that no one was able to repair. We decided to contact John from RJ Fukes Forestry Services to see if he would come out and have a look. It took him 10 minutes to find and repair the problem, need I say more ��

Are you pleased with the Hybrid?

“It’s a good all-round machine with loads of power but still fuel efficient. The TH75 harvesting head and 10m reach powerful crane work well together, if the tree fits in the head it will process it. When harvesting large trees on steep downhills the crane has no problem pulling them back up towards the harvester. It’s very stable even when harvesting on steep ground. The harvester had a minor teething problem when

new which John was quick to remedy, since then it has proved to be reliable and productive.”

And your forwarder?

“I operate the 6F forwarder, this is a 14- tonne load capacity forwarder with a Stage V 230hp Agco engine. My forwarder has been great from day one, it starts every morning and extracts timber all day long, week in week out. What more could you ask for!

“I opted for the smooth ride Cabin suspension; this is well worth the extra cost as it just makes your day so much better with a comfortable ride when manoeuvring over rough terrain. It has a good-sized bunk with an excellent payload and the vision out of the cab for picking up

HARVESTING www.forestmachinemagazine.com Page 30 May 2023

Win a Timbermax Jacket from RJ Fukes

How to win: Find the word that is not in the word search and WhatsApp your answer to 07582 055 748.

Closing Date: 31st May. All correct answers will be put in a hat and the winner will be picked at random. The Judges decision is final.

FRONT COVER PHOTO COMPETITION

Send your photo in by the 31st May 2023 to be in with a chance of featuring on our front cover and winning a £100 Amazon voucher. Topic: Timber Transport

+44 (0) 7582 055 748 | E: photos@forestmachinemagazine.com

LOGSET TIMBERMAX NEUSON TST FORESTRY LUDWIG CHOKER HYDRAULIC WINCH WELDING FABRICATION SPARE PARTS HARVESTER FORWARDER HYBRID HARVESTING HEADS SERVICING SALES DEX CUSTOM BUILDS LLANDOVERY REPAIRS PLASMA CUTTING O D W E E K T I V U N B F G N A W P A T F W D R C T U G F R B F N C G D K F M D I A M E E L U B R B C S F K E W E Y A P Z H L W L I S N N R B O S T L Y E R H U A C V V S D D V O Y I R X U L R I K B S W R Y R R T N X R E H K Z T O A V N X E S C Y X W E W E I U R K K P V T C Y W O X I U E N R R R W M B O E N N T I C E T K D S F D D V L O C L V D A E Y N R Y R E N R H O T X P Y O S E E I W L O D T E E L W S B L S K G P G E L Z V Z W D R R R Y D M E E E R V S E S H T F W S D B A O I T A X C N M S V N T M E I N A R I Y C U R T D S A H D H R B R A H A R U M A X C G D T R H E E U R N E M S L D C Y S N U W H T A E H I R S L R T A F L R N W Y C F W W O T M T H N U M E V E I I H E O R D K T Y R W D D S R T D D G G S R O S E U U Y B E E A O S R L C N K E F T R C H V S W Y L S E R Y W P M P T S L R H

COMPETITION

WhatsApp

www.forestmachinemagazine.com Page 31 May 2023

wood and loading lorries (which we do a lot of) is excellent.”

Do you have to travel far for work?

COVER PHOTO WINNERS

Have you and Darren always worked in forestry?

ur cover photo for this issue is of a Logset 12H GTE Hybrid harvester and 6F Forwarder which was submitted by Darren and Wendy Smith.

O“Darren has worked in the woods from leaving school, he started out as a timber faller with a chainsaw working alongside his family. He progressed onto processors and then harvesters before setting up on his own. I started forwarding about 9 years ago and I’ve never looked back.”

“Our maximum travelling distance is about one hour from home, if we work further than that we stay on site in our RV. We both thoroughly enjoy timber harvesting and I couldn’t see us doing anything else.”

Neuson Forest, TST Forestry and Ludwig Chokers. They also offer Welding and Fabrication, Plasma Cutting, Line Boring, Milling and Custom Winch Builds.

Darren and Wendy are a husband-and-wife forestry contracting team who work in the Somerset and Devon areas. Darren operates the harvester and Wendy the forwarder. Both machines are just over two years old but this is the fourth Logset harvester Darren has owned. Wendy was happy to provide a brief insight regarding their work.

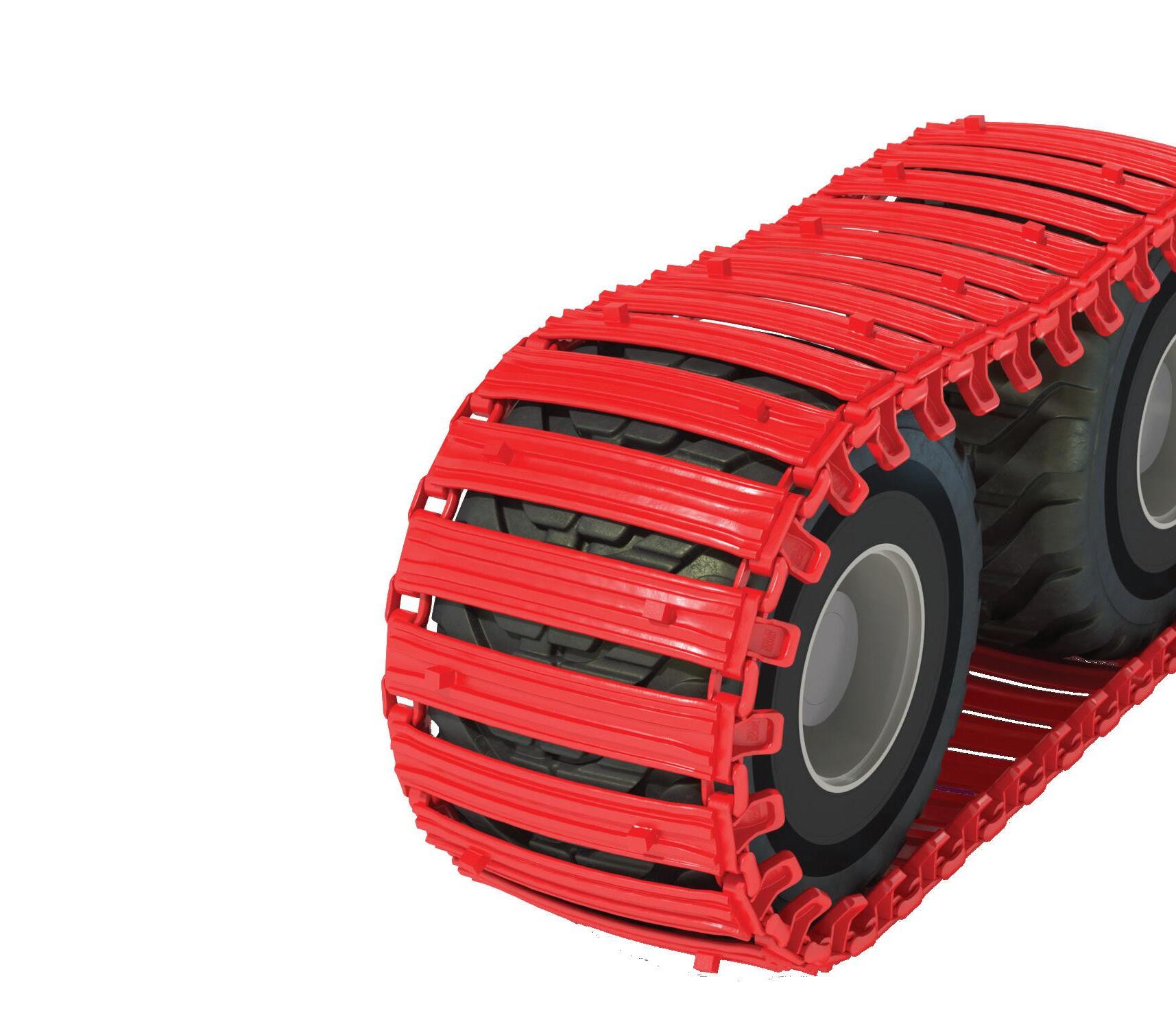

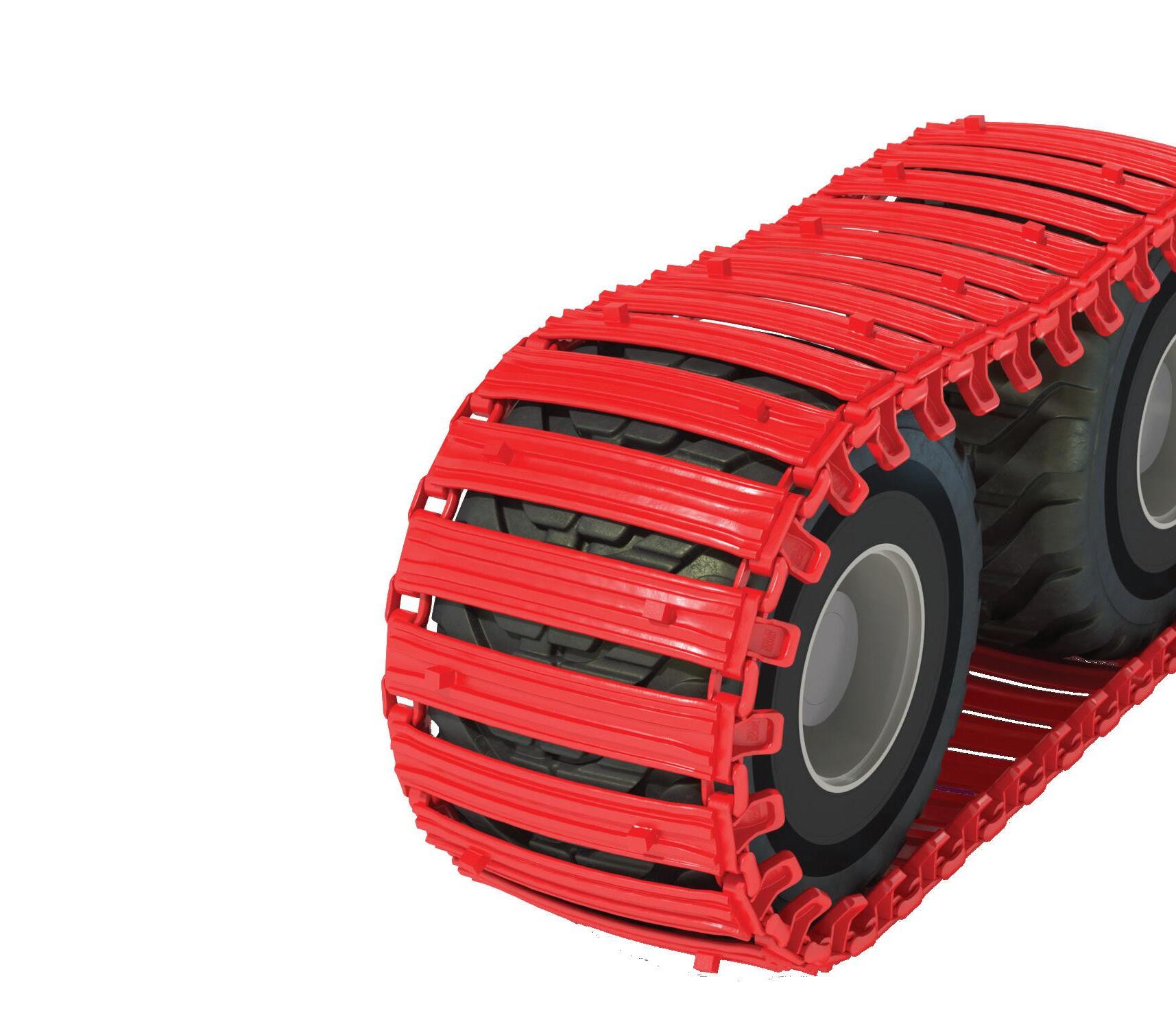

RJ Fukes Forestry Services are the UK sales and service distributers for Logset harvesting equipment, Timbermax Traction Winches,

TIGERCAT 612 SERIES: NEW NICHE SKIDDER

Which areas do you work in and what type of work do you carry out?

“We work throughout Somerset and Devon harvesting and extracting timber on all types of terrain. Our contracts vary in size from 500 tonne up to 10,000 tonne. Although the Logset 12H GTE Hybrid Harvester is a big machine it is surprisingly nimble and is capable of all types of work from first thinnings to mature clear cuts. The type of ground we work on varies from flat to quite steep - we have an excavator winch for skidding timber off very steep ground that is unsafe to harvest with machines.”

problem that no one was able to repair. We decided to contact John from RJ Fukes Forestry Services to see if he would come out and have a look. It took him 10 minutes to find and repair the problem, need I say more ��

Are you pleased with the Hybrid?

Fukes cover the UK and Ireland from their workshops in Llandovery and Carlisle and have mobile engineers with fully equipped service vehicles for carrying out on-site servicing and repairs.

www.rjfukes.co.uk

What made you decide on Logset machines?

“Many years ago, Darren had a harvester (not a Logset) with a

Introducing the 612 dual winch skidder. It is specially designed to operate in selective harvesting applications, extracting high value timber in steep or sensitive terrain conditions. The Tigercat 612 series skidder platform was created to manage the extraction function in challenging terrain selective felling applications, while preserving the value and quality of the residual stand. The

machine can be equipped with a dual winch, a movable back shield and fairlead system, as well as a crane, and front blade tongs.

The 612 is equipped with the Tigercat FPT N67 Stage V engine, delivering 155 kW (208 hp). Combined with Tigercat’s efficient drive system, the 612 impressively handles adverse terrain while minimizing wheel spin.

“It’s a good all-round machine with loads of power but still fuel efficient. The TH75 harvesting head and 10m reach powerful crane work well together, if the tree fits in the head it will process it. When harvesting large trees on steep downhills the crane has no problem pulling them back up towards the harvester. It’s very stable even when harvesting on steep ground. The harvester had a minor teething problem when

new which John was quick to remedy, since then it has proved to be reliable and productive.”

And your forwarder?

A narrow stance allows easy navigation through tight trails and rough ground conditions. The movable shield can be used as an anchor while winching. The dual winch and moving fairlead system allow the operator independent control over two separate cables when operating in tight stand conditions. The optional heavyduty crane and blade tongs offer even more versatility for extracting, manoeuvring and sorting logs.

“I operate the 6F forwarder, this is a 14- tonne load capacity forwarder with a Stage V 230hp Agco engine. My forwarder has been great from day one, it starts every morning and extracts timber all day long, week in week out. What more could you ask for!

The operator’s cab is spacious with generous sized windows providing clear sight-lines. Creature comforts include a climate-controlled cup holder and dedicated storage. Key to ergonomics and operating the machine effectively is the Turnaround seat. Turnaround provides increased comfort, clear sight-lines, and easy entry and exit from either side of the machine. The operator enjoys full control of all machine functions in any position within the 220° range.

“I opted for the smooth ride Cabin suspension; this is well worth the extra cost as it just makes your day so much better with a comfortable ride when manoeuvring over rough terrain. It has a good-sized bunk with an excellent payload and the vision out of the cab for picking up

www.tigercat.com

www.forestmachinemagazine.com Page 32 May 2023

HARVESTING

The light-weighted grip saw

• actively suspended saw unit

The suspension prevents clamping of the saw even at high-risk force.

• automatic chain tensioner

The working process is not interrupted by a jumped off chain

• grease lubricated chain Avoids oil fogging, which would cause contamination of the driver’s cab and is also economical and longer lasting.

• the powerful gripper retains the cut material safely Developed for tree fellings due to safety reasons.

• made of high-strength Hardox® steel Low maintenance and wear, highly rugged and durable.

• strong Tiltator: machine is endlessly rotatable For efficient and flexible operation.

learn more about the efficient Woodcracker ® forest machines www.westtech.at

15 t - 25 t 75 cm

for attachment to rotatable telescopic handlers.

SHEAR BRILLIANCE

As our forests mature and trees increase in height and girth, they become susceptible to damage from extreme windstorms.

Storm Arwen arrived on the 25th of November in 2021 and caused devastation throughout the UK, Ireland and France as strong winds and snow battered the country. It was unusual as winds arrived from the northeast instead of the predominant south-westerly winds, we normally experience in the UK. Gusts of up to 100mph - Settle in North Yorkshire recorded the highest gust in the UK of 110mph - were responsible for the deaths of three people by falling trees, collapsing buildings, overturning lorries and left over 225,000 UK homes

without power. Waves over 10m high were responsible for the extensive damage to towns and villages along the eastern coast of Scotland and many roads were closed with vehicles stranded due to fallen trees, heavy snow and freezing conditions.

Once the weather settles the damage can be assessed and the clear up work can be begin. The forest industry is one of the worst hit when severe windstorms land and Storm Arwen was no exception. Scotland lost 8,000 hectares of commercial forests, around 16 million trees and England lost 3,300 hectares, the northeast taking the brunt of the damage. The damage is relatively shortterm as once the forests are

cleared, they are re-stocked, so the area of forestry in the UK does not actually decrease.

I have worked on many clearfells where you leave a perfectly good standing crop at night, only to return the next morning after a storm, to utter devastation as thousands of trees are uprooted or snapped off partway up the stem. In my early years in forestry, it was a nightmare working in windblow, having to butt trees off with a chainsaw and drag them out with a skidder winch to try and clear areas. I can’t begin to tell you the number of close calls I’ve had (and I still have the scars to prove it) trying to figure out which way trees will spring when butting them off while under compression from other

HARVESTING www.forestmachinemagazine.com Page 34 May 2023

blown trees laying across them. No wonder we called them Widow Makers.

Root plates were a serious problem and although I had done my windblow course where you secure the root plate with a Tirfor hand winch so it can’t fall on you, in reality this wasn’t practical. It was very time consuming and as everyone was working on piece work and not by the hour, corners were often cut to make a living wage. Cutting corners is a discussion for another day! Felling rates back then were basically piss poor and chainsaw operators were at the bottom of the food chain. Taking short-cuts and calculated risks was the only way to make a living wage.

Mechanised forestry has made dealing with windblown trees a much safer prospect. Operators carry out the work from the safety of a ROPS and FOPS cabin and drag out the trees using the harvester crane. This is a giant leap forward in dealing with large areas of windblow. Excavator-based harvesters are better equipped to deal with windblow especially when trees are all tangled up together as they are able to lift the root plates out of way of the main extraction routes. Excavators benefit from more stability

due to heavier undercarriage and tracks, more powerful slewing gear and much stronger booms.

Even using mechanisation on windblown trees has its pitfalls, the uprooted tree stumps tend to have a lot more stones embedded in the base, so keeping the harvesters cutting chains sharp is a problem. Guide bars are more prone for being damaged due to trees being under compression and the harvesting head is vulnerable as it is difficult to assess which way trees buttresses will spring once cut while under pressure. A harvester operator needs to be extra vigilant while working in windblow which is more tiring than harvesting standing trees. Pulling out tangled trees, changing saw chains more frequently and clearing an extraction route results in lower timber production, operator fatigue and increased fuel consumption.

Harold Taylor Timber is based in Insch Aberdeenshire. The company harvests and hauls a lot of timber from

along the northeast coast of Perthshire and Aberdeenshire. A considerable amount of Harold’s work over the past two years has been clearing up the aftermath of Storm Arwen and a good proportion of the trees have been large pine and spruce trees in excess of 1m³.

Harold has a large LH855C Tigercat tracked harvester with a LogMax 10,000 head and experienced operator Bobby Melvin at the controls. The harvester is easily capable in this sized timber but the ground on many of the recent sites has been gritty. This has been playing havoc with production by repeatedly dulling the cutting chain. Bobby carries spare chains as its much quicker to change them over rather than try and sharpen them on the bar, but he still has to stop the harvester to swap them over.

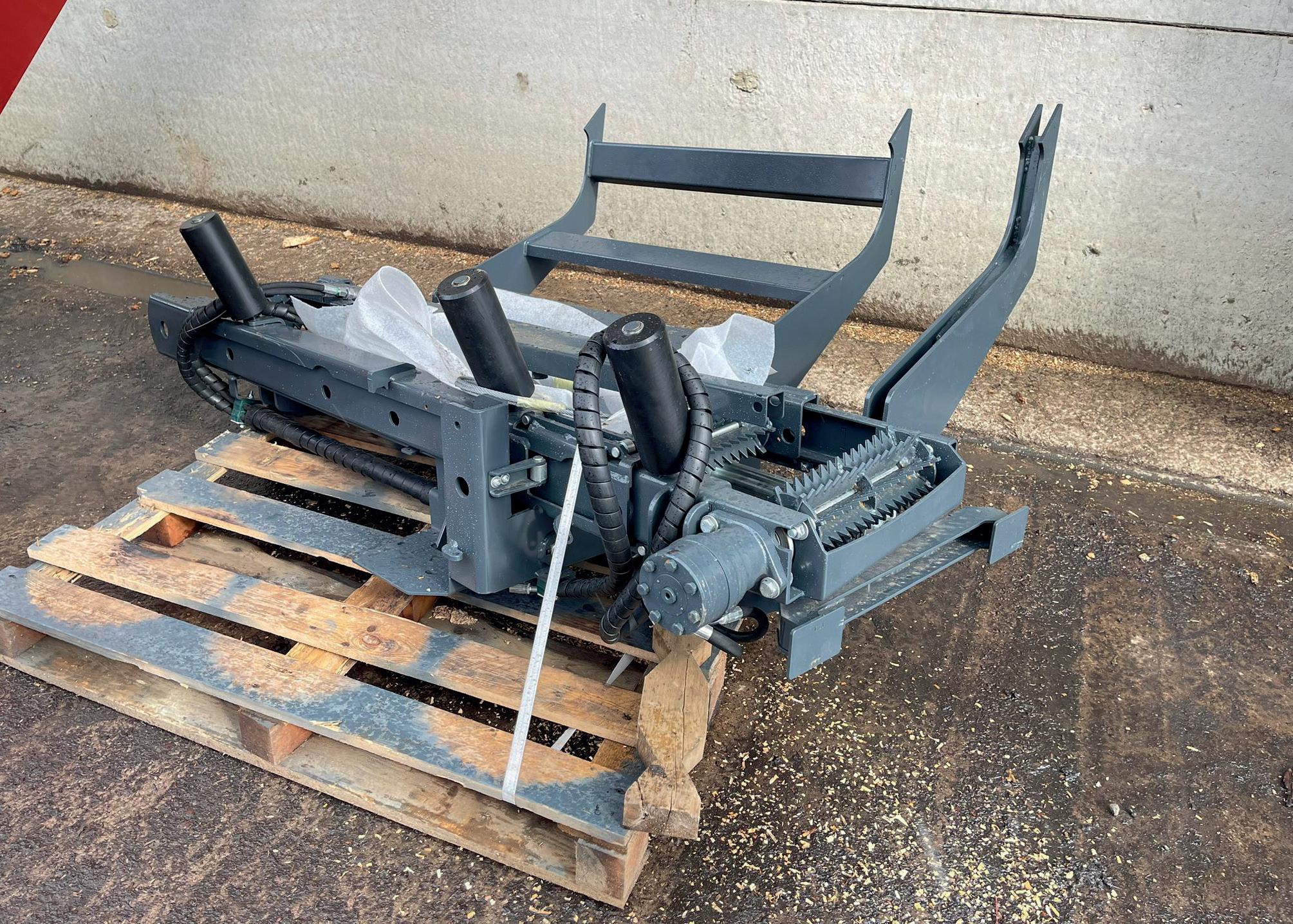

Harold could see the dip in production and the increase in downtime when working in wind blow and pondered over alternatives that would increase productivity. After a good deal of thought, he

www.forestmachinemagazine.com Page 35 May 2023

decided that a large powerful excavator with a tree shear could be the answer. Once butted off by the shear the harvester could process the tree without worrying about blunting chains. It would also speed up production as the tree shear excavator would not just cut them off but would lay the trees out in an orderly manner and direction that would boost the harvester’s production.

Harold approached RJ Hall Engineering at Innerleithen and together they decided on using a used Hyundai 430LC with a new OMEF B1600 tree shear.

The OMEF shear is designed for excavators in the 30-50 tonne class and requires a hydraulic flow of 250 to 300 l/min. The strongly built shear weighs 2400kg. It has a maximum shearing diameter of 700mm with a massive hydraulic cylinder that offers 140 tonne of shearing force. The Hyundai 430LC is a 44-tonne excavator and has an oil flow of 330 l/ min. The Hyundai ticks all the boxes, there is plenty of power from the six-cylinder Cummings 280hp engine and it is a large robust excavator that would stand up to working in demanding forestry conditions.

There was little needing done to the excavator for the conversion. Window protection was added for operator protection and a switch over valve installed for oil flow to the rotator. A heavy duty XR rotator from Indexator was the final piece required and the excavator shear was ready to go. When I visited Harold in

Aberdeenshire the excavator had not long been moved to a new site and the operator was on a day off, so Harold offered to demonstrate it for me. This forest had been a mature stand of spruce trees that had been devastated by Storm Arwen, the whole area was flat with only the odd tree left standing.

Although Harold hadn’t much experience of using the shear it was easy to see that this is the way forward as a safe and efficient way of clearing windblown trees. The shear cut through the tree butts like a knife through butter and had the crane power to drag each tree out of a tangled mess effortlessly. It was surprising just how quick it was at clearing an area. The harvester and forwarder’s main extraction route was clear of stumps as the shear had the power to lift and move them out of the way.

This tree shear will only deal with windblow as it doesn’t have a tilt ram to work in an upright position for felling standing timber. This is not an issue for Harold as it was purchased to increase productivity while working in windblow. It is easy to remove the shear and fit other attachments so the excavator can still be used for other tasks when there is no windblow to clear up. Harold wishes that he had thought of doing this years ago as he is delighted with the boosted production figures.

After watching for a while and being in awe of the area it cleared in a short time, we set of to the previous site it had

been working on. This site was another victim of Storm Arwen and Bobby was on the final furlong with the finishing line in sight. The forest road ran through the middle of the job and Harold pointed out that the right-hand side had been mostly done with the harvester prior to the Shear arriving with the left-hand side all done with the shear and harvester.

The difference was considerable, the shear and harvester had left an incredibly tidy harvesting site with almost no evidence that it had been a windblown area. Most of the uprooted stumps were back in the ground as the shear was able to cut the butts off close to the root plate without worrying about stones dulling chains. Looking at the butts I was surprised at how clean a cut the shear makes, I thought there would have been damage to the wood fibres from crushing, but I couldn’t see any. This system is still in its early days but so far is highly successful. The extra production is more than justifying the excavator and operator costs and has reduced the harvester’s running costs.

Bobby stated that this has certainly made his job easier, production on this side of the job was up by 100m³ per day compared to the other side (both were the same sized crop with similar wind damage) and more volume of the timber was salvaged due to butting off closer to the root plate. I will publish an update on this system in a few months.

Harold Taylor: 07778 357088

HARVESTING www.forestmachinemagazine.com Page 36 May 2023

www.forestmachinemagazine.com Page 37 May 2023

O ering MORE 4 1 1 O ering MORE 1 6 4 1 11 1 O MORE 1 6 4 1 11 1 O MORE 2 1 6 4 1 91 11 1 O MORE 2 1 6 4 1 91 11 1 O MORE 1 6 1 11 1 O ering the forestr MORE 2 1 6 4 1 91 11 1 O ering the MORE O ering the MORE rjfukes.co.uk Llandovery: 01550 721 641 Longtown: 01228 791 111 DEMONSTRATIONS

2023 we will be demonstrating the Neuson 264HVT throughout the Uk and Ireland. Please get in touch for more details!

During

TMK TREE SHEAR IS NOW TMK MACHINERY

READ MORE & GET TO KNOW OUR PRODUCTS:

TMKMACHINERY.COM

Having an open day or demo tour has got to be the best way to get your products and services noticed. It is a great way to connect with customers as you are not inundated with hundreds of visitors just having a look. You can actually spend more time one on one with customers who are actually interested in the equipment you have.

From a manufacturer/ distributer’s point of view you are not having to spend a fortune moving equipment vast distances, paying expensive stall fees, or restricted to what you can actually show on your allocated space. Nor do you have the added expense of

accommodation and meals while exhibiting. There is also the lost production time of being away from your premises and on some occasions, this could be up to a week.

At an open day, all the equipment and services are on display and not cordoned off, giving potential customers the opportunity to get up close and hands on with equipment. Demonstrations are not policed by marshals where you can only see a fraction of what’s going on and from a distance.

I attended the Forest Machine Services Ltd (FMS) open day at their premises not far from Bellingham in Northumberland

at the end of March. Stephen Wills and Graham Johnston, co-owners of FMS, have built up a first-class reputation for the quality of their work and excellent after sales service on the equipment they supply. They remain the only company in the UK to design and manufacture “in house” their own stroke head, the FMS 575.

Graham and Stephen offer customers a bespoke design and fabrication service for all industries and are a lifeline for replacement hydraulic hoses and many other bits and pieces. The duo are the Northern England/Southern Scotland agents for Fuelwood (Warwick) Ltd.’s forestry, biomass, firewood and arboriculture range of equipment. Plus, they have a comprehensive product range including AFM harvesting heads, woodchip containers and stores, cable winches, timber trailers and cranes, Firewood machinery, tractors and

WOOD PROCESSING www.forestmachinemagazine.com Page 40 May 2023

excavator harvesters.

There were already quite a few people mingling about when I arrived shortly after 9am. John Blacklock from Blacklock Harvesting, Robert Nelson, a fellow forwarder operator/ firewood merchant I hadn’t seen for many years - I still can’t decide if that was a good or bad thing lol - Stu Liddle of Liddle Forestry, Darren Turnbull of Turnbull Contracting and quite a few others I knew by sight but not name.

After a coffee with Graham and a look at a Komatsu excavator FMS were currently converting to a harvester, we went around the back to where the firewood processors and log splitters were laid out.

The first processor was the largest one there and Stephen was hosting the demonstrations. This was the Uniforest Titan 53/40 Premium, it is a commercial processor for the serious firewood merchant which can be powered by an electric motor, tractor PTO or PTO and electric motor. This Titan was working off a tractor

PTO. The 53/40 has built in drive feed rollers on a hydraulically adjustable feed in table and is able to cut logs at lengths of 25, 33, 40, 50, or 60 cm lengths and will cut diameters up to 53cm. It has 40 tonne of splitting force, and the knife can be adjusted to split logs into 2-4-8 or 18 pieces, it quickly filled up the large trailer with logs.

BoomSpeed is also offered as standard - Double-piston cylinders for two movement speeds: the working speed is utilised for normal splitting of resistant wood, but for less resistance or the “free run” of the cylinder, its speed is increased. This way the splitting cycle can be shortened for up to 40% which also contributes to higher efficiency.

The compact design of the 53/40 also allows simple transport by tractor while the patented protective shield moves the circular saw into the cover and folds it to transport safely.

Two other Uniforest Titan’s were on display, the 43/20 and 40/20. Graham demonstrated the

www.forestmachinemagazine.com Page 41 May 2023

FMS 575 TECH SPECS

Delimbing 35kn 800mm F11-10 64cm 8T Excavator 100Lpm 180bar 600kg 650mm 450mm

40/20 with some large diameter gnarly hardwood lengths. This model can cut logs up to 40cm diameter and has the same length options as the other two processors. The splitting force is 20 tonne and there are splitting options from two pieces up to 12.

Robert Nelson has the older version and is over the moon with it. Like every machine it takes a little while to master the technique to get the best performance, but Robert easily manages six tonne per hour driven by the tractor PTO.

There was other smaller splitters and saws for firewood production as well as an immaculate Ford 400 tractor and a Timberjack 1470D. At the front of the building there was a selection of Uniforest three-point linkage winches, Lasco cone splitters, timber and brash grapples, Kindlet kindling machine, a Vreten 1000 10 tonne forwarding trailer with a 65/40 timber crane, and an FMS 575 stroke head. The 600kg head has a 64cm saw bar, an 800mm de-limbing stroke and the knives open to 450mm, which is ideal for first and second thinnings. The head is simple and robustly built and is designed to be efficient in both hard and softwood.

WOOD PROCESSING www.forestmachinemagazine.com Page 42 May 2023

I had thoroughly enjoyed myself, there was lots to see, and it was great catching up with so many people I hadn’t seen in years. Stephen and Graham put on a brilliant display and everyone I spoke to was delighted that they had decided to make the journey to attend. forestmachineservices.com Force: Stroke: Saw Motor: Saw Bar: Ideal Carrier: Optimum Oil Flow: Max Pressure: Weight: Grip Opening: Knives Opening:

| gblubricants.co.uk | sales@gblubricants.co.uk | 0191 490 4312 GB Lubricants has a specially formulated range of oils designed to meet the high standards of forestry equipment. Maximising performance, service life and reliability. Want more from your forestry equipment? Tel: 01434 230852 info@forestmachineservices.com www.forestmachineservices.com Forestry Equipment Sales & Service Guerra Full Drive Forwarding Trailers & Grabs UNIFOREST Winches & Log processing Equipment Design & Manufacture of Bespoke Equipment info@forestmachineservices.com www.forestmachineservices.com Forestry EquipmentSales & Service Guerra Full Drive Forwarding Trailers &Grabs UNIFOREST Winches& Log processing Equipment Design & Manufacture of Bespoke Equipment FORESTRY ENGINEERS AND LOW GROUND PRESSURE CONTRACTORS www.howieforestry.co.uk M: 01292 541145 | E: info@howieforestry.co.uk | Allan Glen, Tarbolton, KA5 5NU www.forestmachinemagazine.com Page 43 May 2023

HOW CHIPPER MAINTENANCE AFFECTS EFFICIENCY

Richard Newton, forestry lead for CRJ Services, explains how chipper maintenance is essential to producing wood chips that meet customer requirements. However, it also reduces fuel consumption, makes the most of operators’ time and ensures a long life for high-value machines.

Most wood chips in the UK are produced for biomass energy production in thermal power stations or combined heat and power (CHP) units. A challenge with chipping is that it is a tough job in a harsh environment.

Components in machines can experience excessive wear, especially when logs, brash or roots have become

contaminated with sand or mud. Even though wood is a lot softer than the steel components inside chippers, the large throughput of material will eventually wear the steel away.

Most customers in the UK need chips in the G30, G50 or G100 grades, with larger generators requiring larger sized chips. However, other grades also exist – for example, there was a trend for very small micro-chips, while other chips are used in horticulture. The size of the chips is important for efficient burning and power production. It’s also important for handling that chips have a consistent shape. If they are too large, they could bridge across a duct and block it, whereas wood dust and

fines can choke up pipework. A lot of chipping operations are carried out at remote sites in the field, so chippers often need to be mobile machines that have their own diesel engine.

Beyond that, successful chipping often depends on site-specific factors, such as the conditions on site, the type of soil and whether it has contaminated the wood or brash to be chipped, accessibility and whether the material to be chipped is a neat stack of logs or a tangled pile of tops and branches. Availability of trucks to transport chipped material in a timely manner is also important to avoid the chipper and its operator sitting idle while they wait for a truck.

WOOD PROCESSING www.forestmachinemagazine.com Page 44 May 2023

HOW WEAR AFFECTS OPERATIONS

There are two basic types of chipper. At the smaller end of the market, machines are based on a single disc that spins to break up material. When it comes to medium and large industrial chippers, these have working parts based on a rotating cylinder with knives mounted into it. The knives catch material fed into it at right angles and cut it into chips against a static counter-knife.

In general, the smaller the chip size, the faster the wear on a chipper and the higher the fuel consumption. That is because it takes more energy to break wood and brash into smaller chips. In addition, components can experience damage if foreign objects find their way into the machine.

Once components experience wear, knives lose their sharpness and clearance distances become larger. This makes the resulting chips larger in size. As a result, operators may need to pass chips through a machine more than once. Not only does this take longer but it also burns additional fuel.

Operators can prevent this by performing maintenance when they see excessive wear building up on critical components.

KEEPING KNIVES SHARP

Knife inspection and sharpening is one of the most important maintenance tasks on a chipper. Operators should carry out a visual inspection of the knives on the rotor and the leading edge of the counter-knife at least once or twice every day.

It’s fairly straightforward to open up the machine in the field and sharpen the rotor knives with an angle grinder or replace them with spares. Typically, counter-knives need to be changed every 200-300 hours.

The operator should also take care to maintain a good clearance distance of 0.2 –0.5 mm between the rotor and counter-knife, which will increase as a result of wear or sharpening. Some chippers are designed with this in mind as they come with a set of

shims that the operator can fit underneath the knives on the cylinder to maintain the overall diameter.

IMPACT OF WEAR ON ACCESSORIES

It’s not just the chipping mechanism itself that experiences wear. Components such as chutes and blower hoods can be worn away by abrasion from fast-moving wood chips and airborne fines. Excessive wear of these types of chip handling equipment will also have a big impact on

www.forestmachinemagazine.com Page 45 May 2023

productivity as they ensure chips are fed into trucks and are not spilled onto the ground, where they can get dirty or lost.

Welding on a hardened steel wearplate of a hardfacing coating can prevent this. These are made from hardened steel rather than a more general-use carbon steel. The hardened steel is formulated to be tougher and more resilient to impact and abrasion, and in turn this enables these component to provide a service life of 2,000 hours or more.

Another area where hardened steel can be helpful is around the edges of the rotor. Foreign material can find it’s way into the sides of a rotor, where it presses into the cylinder and wears away the steel that supports the knives. This can be avoided by adding sacrificial wearblocks at the edges of the rotor. These are much quicker to replace than the cylinder itself and can be reversed or replaced

when their outer surface becomes worn.

MACHINES DESIGNED FOR HIGH AVAILABILITY

When specifying a large mobile chipper, every operator has preferences in terms of the type of rotors, tyres, cranes and grabs. In addition, they might prefer a chipper that is truckmounted, trailer-mounted or tractor-driven.

Other features can also help to ensure high availability of a machine in the field. For example, some chippers have been designed with systems that slow down the infeed of material when sensors detect that the counter-knife has experienced excessive force, impact or vibration.

Similarly, it’s possible to get chippers that will stop feeding material in when the rotor RPM slows down when needs to handle an excessive quantity of material or particularly hard or

tough material. This prevents the likelihood of a chipper stalling during operation so that it can recover and keep operating throughout the shift.

LIFETIME OF 20 YEARS

The high cost of diesel has made it more important than ever to control the cost of operations in the field and keep machines running for longer. With good maintenance in the field and main servicing after every 250 hours of operation, operators can minimise power consumption, ensure highquality chips are produced and extend the service life and availability of equipment.

As a service contractor, we provide support to sites anywhere in the UK, as well as scheduled main servicing and spares. We see all sorts of equipment and provide support to machines that are still operating successfully after a life of more than 20 years.

www.crjservices.co.uk

WOOD PROCESSING www.forestmachinemagazine.com Page 46 May 2023

AHWI RAPTOR 500 Tracked Mulcher 550hp self contained Off Road Chipper AWESOME POWER | LOWER GROUND PRESSURE | PROFESSIONAL SERVICE WE CAN CHIP AND EXTRACT IN ONE OPERATION Machines available on operated hire or subcontract basis www.pracbrownEC.co.uk treeclearance@pracbrown.co.uk | 01753 652022 MULCHING AND CHIPPING CONTRACTORS SINCE 1985 First in the UK!

ICY TESTS: MAN eTRUCK COPES WITH POLAR WINTER

process, they tested the overall energy management, the cooling and thermal management of the battery packs, the interaction and control of the powertrain components as well as the charging behaviour under the extreme winter conditions, among other things, on four prototypes with different battery, e-motor, transmission, axle and cab configurations of the later series production range.

From December to March, MAN integrated the upcoming large-series e-truck into its annual winter testing in northern Sweden. There, the MAN eTruck, which is suitable for daily ranges of between 600 and 800 kilometres, proved that it also works without problems in ice, snow and temperatures as low as minus 40 degrees. Driving functions and range, air conditioning and charging behaviour were the focus of thousands of successful electric test kilometres under Arctic conditions.

“The winter tests were a complete success. Our engineers literally put the new eTruck

through its paces day and night under the toughest conditions. The maturity level is already extremely high and the development team is working with great passion on the further trials to provide our customers with an optimal product for the switch to CO2free road freight transport,” says Dr Frederik Zohm, Executive Board Member for Research and Development at MAN Trucks & Bus.

Around 30 test engineers braved the polar winter with freezing cold, snowstorms and only a few hours of daylight for around four months to bring the new MAN eTruck further towards series production readiness. In the