FOREST MACHINE MAGAZINE

Hola, , Espero que a todos ustedes les este yendo bien. Apologies, all this good weather has left me so confused that I forgot that I was in Scotland!

I have just got back home after visiting the Swedish Forestry Expo and have to say it was a well organised and interesting event. I was fortunate to go with a few other forestry contractors, which made for a fun and enjoyable time.

We arrived in Oslo with an hour and twenty minutes to make our connecting flight. We thought we had plenty of time, only to find that as non-European status Brexiteers, we had to join a few hundred other nonEuropeans in a mile long queue for passport control. Alas, it was lunch hour for the two Immigration officers who had closed their booths and nipped out for an hour to the pub for a pie and a pint. We left the queue to ask an official lady, who was trying her best to prevent the queuing travellers from rioting and storming the passport offices, whether we could get processed quicker. We were told to re-join the back of the now even longer queue, as just about everyone was in the same boat (or plane), all hoping to catch their connecting flights.

After almost two hours we made it through to the departure lounge and were just in time to wave at our flight as it took off for Arlanda Airport in Stockholm. We trapsed about the huge airport to find the Norwegian Air help desk, and were impressed with the way they dealt with our dilemma. The clerk got all seven of us booked onto the next flight, he was really helpful considering the delays at passport control undoubtedly hadn’t made his day any easier. Our spirits were lifted again as we were only going to be a few hours late so would still manage a couple of pints before bed in Stockholm. We had some time to kill so we got something to eat and a drink, and this sunk us back into the depths of depression, it was £11.60 for three quarters of a pint of Heineken and near on £20 for a chicken burger and chips. We made our flight and got a taxi to our hotel where the beer, although still more expensive than back home, meant that we could enjoy ourselves without having to sell body parts or re-mortgage our houses.

Get a regular dose of forestry on our Facebook page. Share your photos and experiences.

Stay in the loop with the latest news from the forest industry. We love to see your photos too!

Subscribe to our YouTube channel to enjoy our dedicated forestry videos.

#homeoflogging

July 2023 Issue 41

ISSN 2398-8568

YES! I would like to subscribe to Forest Machine Magazine

Online

www.forestmachinemagazine.com

A quick, easy and secure way to subscribe

BY POSTName:

Address:

Editor and Publisher

Robert Easton

Advertising

Rab Easton

Social Media Manager

Rab Easton

Layout and Design

Wendy Easton

Subscriptions

Wendy Easton

Photography

Wendy Easton

Postcode:

Email Address:

Tel No:

GIFT?

If you are taking out this subscription as a gift for someone else. Please complete the gift recipient’s details.

Name:

Address:

forestmachinemagazine@mail.com

+44

(0)7582055748 / +44 (0) 7951 473 846

Website: www.forestmachinemagazine.com

Address: 33 Holm Gardens, Bellshill, ML4 2PB. UK

Forest Machine Magazine assumes no liability or responsibility for any inaccurate information, errors or omissions. Forest Machine Magazine considers its sources reliable and verifies as much data as possible. However, reporting inaccuracies can occur and consequently readers using this information do so at their own risk. The opinions expressed in each article are those of its author and do not necessarily reflect the opinions of Forest Machine Magazine. Therefore, Forest Machine Magazine carries no responsibility for the opinions expressed thereon. Through the magazines you are able to link to other websites which are not under the control of Forest Machine Magazine. We have no control over the nature, content and availability of those sites.

The inclusion of any links does not necessarily imply a recommendation or endorse the views expressed within them. No part of this publication and/or website may be reproduced, stored in a retrieval system or transmitted in any form without prior written permission of the Publisher.

© 2023 Forest Machine Magazine. All rights reserved.

Postcode:

Email Address:

Tel No:

UK only - I wish to pay £15 p&p for 6 issues of Forest Machine Magazine

Europe - I wish to pay £35 p&p for 6 issues of Forest Machine Magazine

Rest Of World - I wish to pay £45 for 6 issues of Forest Machine Magazine

Please make cheques payable to: Robert Easton Ltd

Please return your completed form to: Forest Machine Magazine, 33 Holm Gardens, Bellshill, ML4 2PB.

Respecting Nature: PONSSE to use SSAB fossil free steel from 2026.

First Of Its Kind: New £4 million UK facility to be first-ever owned premises by Komatsu Forest sales company.

A growing business: Tigercat launch the 630H Silvicultural Carrier.

Good To Go: The trials and tribulations of harvesting next to main roads with Jim Wilmer & Sons.

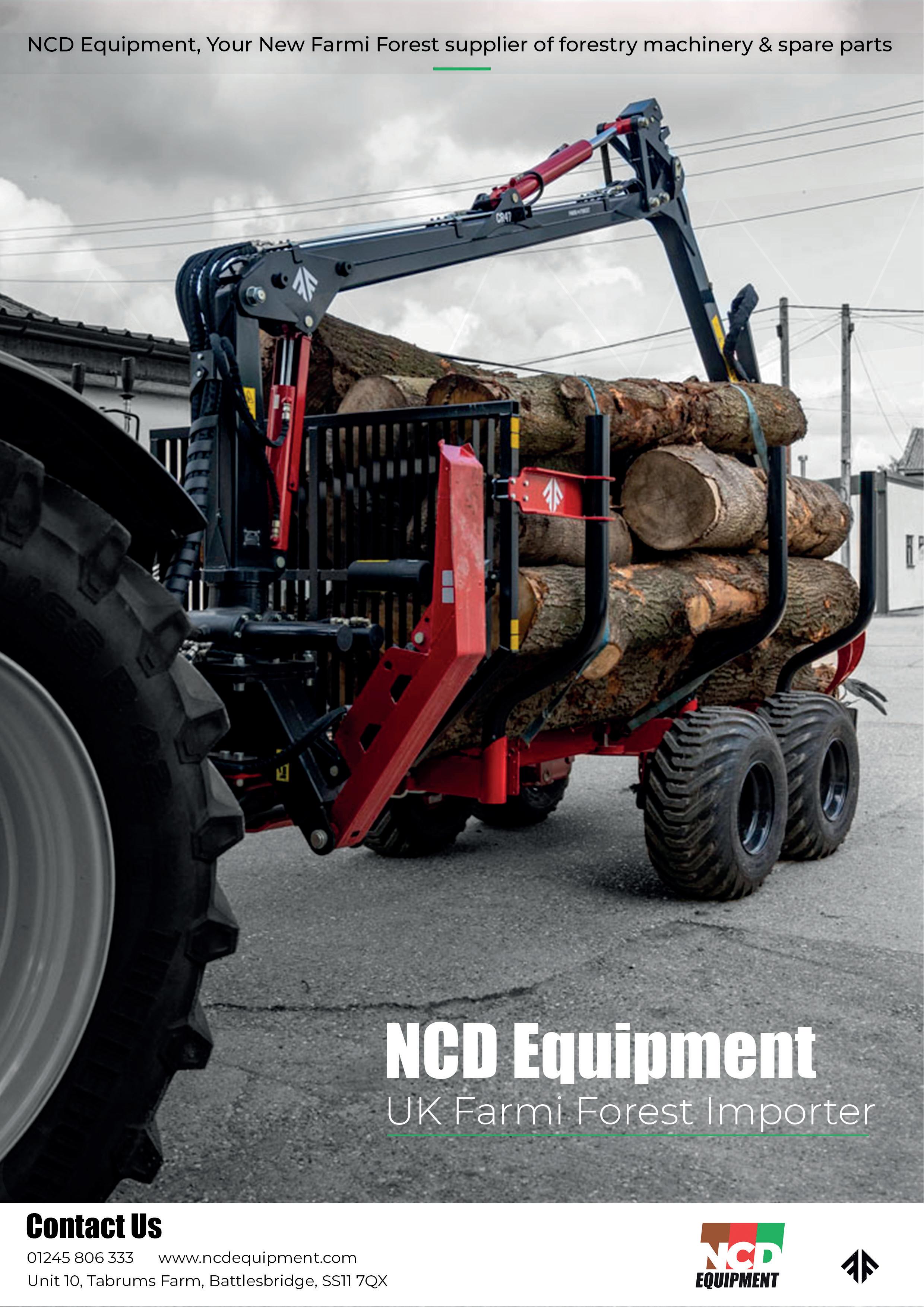

New Distributer For Farmi: NCD Equipment are now the sole importers for the comprehensive range of Farmi forestry products.

Photo Gallery: Did your picture make it onto our wall of fame.

There’s A Lot Going On At The Mill: A visit to Ridings Sawmill and their forestry contractor Gary Sheppard.

Lightening The Load: PALFINGER EPSILON ’s new generation 3 timber cranes

Another Munro Found!: New second model electric pick up designed for tough forestry and farming conditions revealed.

Classified: See if there is anything to tempt your wallet in our classified section.

FIND US ON

SSAB and Ponsse Plc, one of the world’s largest manufacturers of cut-tolength forest machines, have joined forces in a partnership in which SSAB is to deliver fossilfree steel to Ponsse gradually beginning in 2026.

This partnership will further solidify Ponsse’s position as a provider of sustainable forest machines and bring SSAB closer to its goal of establishing a fossil-free value chain.

“It’s great to have a reliable partner like Ponsse now joining our fossil-free journey. Joint efforts are needed to meet the challenging CO2 reduction targets in forest machines. Both companies prioritize sustainable solutions and will strive to make a positive impact on forest machines using SSAB Fossilfree™ steel, fostering innovation while respecting nature,” says Lotta Ruottinen, Sales Director at SSAB Europe.

“Our products and services will

play a crucial role in assisting our customers in achieving their climate objectives during the transition to a low-carbon economy. Our PONSSE EV1 forwarder concept with completely electric drive and our partnership with SSAB regarding fossil-free steels will lead our development towards carbon neutral forestry,” says Juha Inberg, Chief R&D and Technology Officer, Ponsse Plc. SSAB plans to revolutionize the entire steelmaking process. SSAB aims to deliver fossil-free steel to the market at a

Ponsse sell and refurbish used machines and spare parts in an increasing number of market areas.

Used machines refurbished by professional mechanics can be

updated using various performance packages to meet modern standards. In the PONSSE Scorpion Second Life program, more than 160 control points will be inspected.

commercial scale during 2026 and to largely eliminate carbon dioxide emissions from our operations in around 2030. SSAB works with iron ore producer LKAB and energy company Vattenfall as part of the HYBRIT initiative to develop a value chain for fossil-free iron- and steelmaking, replacing the coking coal traditionally used for iron ore-based steelmaking with fossil-free electricity and hydrogen. This process virtually eliminates carbon dioxideemissions in steel production. ponsse.com / www.ssab.com

Components will be replaced or repaired according to their condition to make sure that the machine will be reliable and that the customer will not have expensive costs and breakdown to come.

• Machines will have warranty for 6 months or 1000h.

• Available for Scorpions and Scorpion Kings.

Forestry machinery manufacturer, Komatsu Forest UK Ltd., established in Longtown, Cumbria, is engaged in the significant development project of a new UK facility to be based at Carlisle Airport; this is notably the firstever premises to be owned by a Komatsu Forest sales company.

The £4 million investment project began in January 2023, with Cubby Construction leading the build. The new facility demonstrates Komatsu’s commitment to its customers, the UK forestry industry, Cumbria, and its employees. In addition to safeguarding 35 roles, Komatsu Forest has made two new appointments to enhance its service further; Lana Andrews has been appointed Parts – Procurement & Systems Coordinator, and Elliott Brown joins the business as Financial Accountant.

Stephen Bellas, Managing Director at Komatsu Forest UK Ltd., said, “This is a significant time of change and growth for us, and it is essential that we have the right team on board to facilitate this. I am delighted with the appointments of both Lana and Elliott into these key roles; they have already demonstrated their professionalism and positive attitude to the work ahead of them.”

Mr Bellas continued, “The new site development is progressing

very well, thanks to a huge team effort from Architects Plus, Cubby Construction, Donley’s Limited, and our team at Komatsu. Our colleagues are working hard to support the project and have seamlessly managed the move to our temporary premises at Eastriggs, combined with home working. I am very proud of the team’s adaptability and commitment to providing uninterrupted customer service.”

Forest in 2004. Over the years, the teams at Komatsu Forest UK have built strong relationships with both customers and suppliers by providing topnotch high-performance machinery and parts, efficient maintenance, and exceptional customer service. At Komatsu, customer satisfaction is at the forefront of the business, as they aim to create mutual value.

The new premises is

track to open at the beginning of September and will be marked with an open day allowing guests to look around the new facility.

With a history of over 30 years in the UK, Komatsu Forest UK has evolved through various guises, starting with Caintract in 1989, which received the first Valmet 828 forwarder. It was followed by Logmec, Sisu Logging, Valmet - Partek, and finally acquired by Komatsu

Komatsu Ltd., established in 1921, is a diversified provider of industrial-use products and services. While remaining an international leader in construction and mining equipment, the company engages in other business, such as industrial machinery and vehicles, logistics, electronics and other solutions-based operations. Based in Tokyo, Japan, Komatsu employs 47,017 globally on a consolidated basis.

For more information visit www. komatsu.com.

The palettes are the most important interface the operator has with the forestry machine.

Hydraulkompaniet, together with Rottne Industri, are now launching new palettes that facilitate the work and improve the ergonomics considerably. The finished product is a breakthrough innovation. Improved ergonomics, displays in the palettes, more functions as well as more buttons on the joysticks. The working environment will now be better, more flexible and, of course, everything is manufactured to comply with relevant standards and regulations.

“We have spent a lot of time on the ergonomics and we’ve really optimised the placing of the buttons and the functionality. It’s not just that there are more buttons but we have also used them in a way that means they will never be too few,” David Selstam at Rottne’s Development Department says.

The 630H silviculture carrier replaces modified ag tractors with a purpose built carrier to pull mounding and plow implements in preparation for replanting operations.

Tigercat, a company that has contributed significantly to increased efficiencies in timber harvesting operations, is putting focus on gaining efficiencies in the silviculture side of the forest industry. Many forestry companies struggle to prepare post-harvest sites for replanting with modified ag tractors. These machines are not up to the task, often suffering from insufficient power, cooling capacity and structural durability.

Tigercat recently released the 630H silviculture carrier to address these deficiencies. Based on Tigercat’s skidder platform, the machine is equipped with hydraulic

connectors and several drawbar receiver variations to adapt to a variety of plow or mounding implement connection points. In addition, the carrier can be equipped with an optional winch and bolt-on fairlead system. The whole package is factory equipped and ready to work.

Initial studies conducted by Mexican forestry company,

Proteak indicate that the 630H carriers are quicker, more productive, and more fuel efficient than the ag tractors that they are replacing. Operators are safe and comfortable in a climate controlled cab equipped with an air ride suspension seat and ergonomic armrest mounted controls.

www.tigercat.com

Scottish Forestry is to invest up to £1 million in a comprehensive skills training programme for its front line staff in a drive to ramp up tree planting levels in Scotland.

The move is part of a delivery action plan announced by Rural Affairs Secretary Mairi Gougeon to help the private and public sectors to “step up their game”

on woodland creation and ensure forestry plays its part in tackling and mitigating climate change.

Providing more of our own stock will help to lower the sector’s own carbon footprint, deliver more biosecurity, help us meet planting targets and create more jobs and businesses.

Scottish Forestry has been

supporting Akre tree nursery through forestry grants to help them buy vital equipment to help them expand.

Woodland creation will also be boosted through Forestry and Land Scotland, which is set to increase its yearly programme from the current 500 hectares a year to 900 hectares by 2027/8 www.forestry.gov.scot

The Komatsu 951XC is a new harvester for final logging in steep terrain and on soft ground. The eight-wheel design, combined with the stable Komatsu concept, ensures a machine with great stability, excellent manoeuvrability, and low ground pressure. The Komatsu 951XC is also optimised for use with the Komatsu C164 – a harvester head specially designed for logging large trees – although naturally it works just as well with a range of other heads.

The Komatsu 951XC is part of Komatsu Forest’s product series of machines specially designed for challenging conditions.

“Now we have a complete range of eight-wheeled machines, specially designed for demanding conditions,” Joakim Johansson, Product Manager Harvesters at Komatsu Forest says.

The machine design is much like that of the Komatsu 951, although there are some differences. The Komatsu 951XC has the same wheel size as the 931XC, lending the machine a more compact design and giving the 951XC a total machine length that is shorter than that of the Komatsu 951.

The Komatsu 951XC has 242 kN of underlying tractive force and

unique interaction between engine, control system and power transmission. The hydrostatic transmission enables engine power to be fully utilised, providing considerable advantages in difficult terrain as well as excellent climbing ability. This is much due to the machine’s large hydrostatic pump, which can maintain higher speeds at high tractive forces.

“What is special about the 951XC is that it combines the strength of a 951 with an extremely compact design. Since it has about the same dimensions as the 931XC it can be used in denser stands,” Joakim explains.

951XC is also equipped with hub reductions. They provide an advantage when working in challenging conditions, such as steep, snowy, or wet terrain, as

they increase the life of the bogie and thereby machine reliability.

The Komatsu 951XC has new working hydraulics to better utilise the diesel engine. The new hydraulics also provide faster feeding from start to maximum speed and allow the saw motor to work even more efficiently.

“The new working hydraulics contribute to a feeling of an even stronger engine according to the test operators that have been working with 951XC,” Joakim states.

Although the working hydraulics are new, in all other respects the Komatsu 951XC shares the same proven design as other Komatsu harvesters, meaning 3PS.

“This enables several crane and head functions to be used

simultaneously with retained maximum hydraulic power, all thanks to the machine’s hydraulic power coordination,” Joakim continues.

All Komatsu harvesters are equipped with parallel cranes, this has been the case since 1999. With the Komatsu Forest design concept, the lifting booms and outer booms are linked, thereby eliminating an entire aspect of crane control. This concept simplifies crane operation by ensuring that the head is always level regardless of crane cycle stage. The parallel crane is also cleverly designed to be fast in its outward movements, when the head is unloaded, and powerful in its return movements, when the head is heavily loaded.

Compared to the 951, the Komatsu 951XC has a significantly shorter distance from the centre of the crane to the front wheels. This creates a larger working area in front of the machine, that enables the operator to work at shorter reaches. “The new larger working area in front of the

machine means more powerful crane movements. And for those who equipes their machines with Smart Crane they get an even more easily manoeuvred crane with excellent precision,” Joakim explains.

The Komatsu 951XC, just like all other Komatsu harvesters, features a high-performance operator environment. Examples of the many advantages include the spacious cab, good visibility and comfortable cab climate.

Thanks to the machine’s stability and levelling cab, the operator is always seated level without the need to stretch and strain to maintain a good seating position. The 951XC is, as all Komatsu harvesters, based on the tried-and-tested Komatsu concept that offers favourable weight distribution and has a low centre of gravity. In addition, the eight-wheeled XC series harvesters have a double oscillating bogie on the rear frame giving the machines completely unique handling characteristics.

“Our double oscillating bogie on the rear frame is an innovation of which we’re very proud. As well as increasing stability by lowering the machine’s centre of gravity, the machine follows irregularities in the terrain in a forgiving manner while delivering excellent manoeuvrability in challenging terrain conditions,” Joakim ends.

The work to develop a new machine is a massive team effort. Before a new machine model is launched prototypes are thoroughly tested first with Komatsu’s own test operators and then by contractors working in environments suitable for the specific machine model. One of the contractors, Henrik Lysebäck at Lysebäcks Skogsentreprenad, tested a prototype of the 951XC in the fall of 2022 and concludes the test like this;

“The 951XC is a good machine, stable and comfortable to operate. It is a machine you can trust, and you feel secure working at a long reach. This is definitely a machine I would like to continue to work with.”

www.komatsuforest.co.uk

While driving to a meeting in Dumfries and Galloway, I got held up by road works on the Carsphairn to Castle Douglas road. I couldn’t see what the problem was until traffic started moving and I spotted a Jim Wilmer and Sons Timber Harvesting road traffic management (RTM) vehicle next to the traffic lights.

An area of Sitka Spruce adjacent to the busy A713 was being clearfelled and required traffic management. This is standard for felling any trees which are

less than two tree lengths away from the main road.

After passing the site I started to think about the logistics of this type of work and it prompted me to speak to Jim Wilmer, who arranged for me to meet up with David, his son and right-hand man. David has taken a good percentage of the workload off Jim and spends much of his time liaising with landowners and foresters and walking and pricing jobs so that there is always plenty of work in front of their large fleet of harvesters and forwarders.

Arriving on site, I could see straight away that this was quite a tricky job. Not only were the trees quite close to the road, but there was an electricity powerline running through the middle of the site. This privately owned forest was being managed and marketed by Tilhill and there was approximately 3,000m³ of timber being harvested, with an average tree size of 0.7m³. Chatting to David he thought that this would be the final day where traffic management was needed, as all the trees up to two tree lengths away from the road would be

felled and processed by that evening. If everything went to plan, it would have only taken five days to complete the roadside work.

Iain McCulloch was operating the John Deere 1470 harvester and to be fair he was doing a cracking job. The stumps were nice and low and his presentation for the forwarder was spot on. I saw that the John Deere 1510 forwarder was parked up and offered my services. This job was a forwarder operators dream but Eric Kirkland who normally operates the forwarder was helping out on another site and due back later that day ☹

Iain managed to cut most of the trees within reach of the road but a deep drain at the edge of the compartment meant that some of the trees were just out of reach and were being cut and wedged over by chainsaw operators. Both chainsaw operators, Scott Rodger and Jim

Gilmour, had completed their LANTRA Road Traffic Management training courses.

When any edge, or trees within reach of the road, were being felled, traffic was stopped in both directions, and both sets of lights automatically on red. The lights were manned so that workers could stop work

immediately if a vehicle stupidly decided to jump a red light. Everyone on site was working quickly, efficiently and safely to cause as little disruption as possible to the road users. This type of work is labour intensive and requires skilled operatives that can work and communicate well together.

Martyn Henry, operations manager for Jim Wilmer and Sons Timber Harvesting, oversees the smooth running of the site, alongside Iain McMurtrie, harvesting manager for Tilhill. Iain called in while I was on site and was delighted with the quality and the speed at which the work was progressing.

After Iain McMurtrie left, I quizzed David about the complexities of putting a job like this together, he explained that it involved four or five site meetings between the relevant parties to co-ordinate the plans prior to commencing work. This harvesting site was just outside

← ↑ Traffic management is necessary as it provides a safe environment for those working on, or near the roads and for the general public using the road system.the Ayrshire Councils border and was the responsibility of Dumfries and Galloway Council regarding traffic management. David has worked regularly with both Councils and has found them brilliant to work along with as they have proven to be extremely helpful and do their utmost to make sure the work runs smoothly. Carrying out this type of work successfully is no easy task, having the right operatives, correct equipment, staff training, up to date certification, insurance and being able to work to tight deadlines are just some of the hurdles to be overcome.

I can see why Jim puts so much trust in David though, he is a good-natured young man with a good business head on his shoulders. He has an affable personality which is a great asset when liaising with so many people.

“Nothing is easy in forestry” stated David with a wry smile

as he explained yet another challenge they faced on this site “We had a live powerline running through the middle of the job and the direction we needed to fell some of the trees in was across a tarmac road which had to remain undamaged. We all got together and came up with a good

solution. We stacked a few layers of sawlogs either side of the tarmac road and felled the standing trees onto the logs so that the trees or branches never touched the road.”

Looking around the site there was a good breakout of sawlogs – 85% - and the timber was nice and straight. Ground conditions were good and firm and once harvesting has been completed the brash will be recovered and delivered to Land Energy in Girvan to be turned into biomass fuel.

This was a well organised job being undertaken by a good team of professionals with exceptional communication skills. If you have any timber harvesting that requires Road Traffic Management, please contact David Wilmer on 07879 417170.

info@jimwilmer.co.uk

www.jimwilmer.co.uk

↑ Ian McCulloch at the controls of the John Deere 1470.100mm double paddle spikes to provide the most agressive grip.

FXS is the most aggressive model in the FX series. Designed to support Skidders and heavy Forwarders tackling arduous terrain.

Euan Mellis of Mellis Forestry Contractor offers his customers a sensitive and low impact solution for the harvesting of thinnings. The company is based in Elgin in the northeast of Scotland and works throughout Moray and Aberdeenshire.

Euan’s fleet consists of a Komatsu 901 harvester with a C93 harvesting head, a Komatsu 825TX forwarder and a digger winch - built and supplied by Forest Machine Services based near Hexham in Northumberland - for any awkward or steep areas which are unable to be mechanically

harvested.

I met up with Euan just outside of Elgin on an upland first thinnings site, he was harvesting for Gordons sawmill of Nairn. Normally Euan operates the Komatsu harvester and Ian Garden extracts behind him on the forwarder, but on this particular day, he had a temporary operator working for him, as Euan had a few errands to run.

This gave me the opportunity to chat and discover a bit more about Euan’s aims and ambitions for his business. Almost immediately I

understood where he was coming from. Euan is a thinning contractor who cares deeply about the quality of his work and the impact his harvesting has on the environment. His choice of equipment reflects this, his Komatsu harvester is an 8WD low impact fuel efficient machine. It was specified with smaller bogies to narrow the overall width so he could use low ground pressure 710mm tyres and still be able to harvest in tightly planted crops. The 11m reach crane offers precise and responsive crane operation. The main boom to the tip of the telescopic arm is controlled by the operator with a single

smooth lever movement. This allows operators to concentrate solely on the harvesting head which reduces operator fatigue making a more relaxing working environment.

Euan finds the cabin a comfortable and spacious workplace, the rotating and levelling cabin with good soundproofing eases the stresses of long working hours. The side mounted crane offers fantastic visibility to the felling head. When you are working in first thinnings on dull or wintry days you are having to constantly use the harvesters’ lights to see properly. An unobstructed view to the head is hugely beneficial for keeping stumps low and preventing equipment and remaining crop damage. Another advantage is the stability, Euan pointed out that even with the long crane reach, the machine sits solid on its wheels. The C93 harvesting head is a good all-rounder for all types of thinnings and premature clear fells. It has

600mm felling diameter and an impressive feeding speed of up to 5m/second.

The block of spruce was quite heavily branched and in all fairness the head was doing an excellent job of de-limbing. The 3.7m chip cutting size was good for both the harvester and forwarder. The ground was reasonably firm on the finished racks, the machine was able to work easily without tracks or chains, certainly not the usual wet peaty ground usually found on the west coast.

As it was quite a gritty soil, Euan was changing his chainsaw chains about three times a day, he prefers to swap chains over rather than sharpen them on the head. Around 65-70% of the harvesting work requires the use of stump treatment and the Komatsu’s urea guide bars have proved to work effectively.

The reliability and performance of the harvester has been exceptional, the 0.9 litre of

AdBlue and 14 litre of Diesel produce on average 8.5m³ per hour.

This is the first Komatsu 825TX forwarder in Scotland and is compact and agile machine for this type of work. The forwarder is 2,700mm wide with 710mm tyres and is easily capable in tightly spaced crops. It is currently set up for single bays of 3m chip or double bays of up to 2.4m lengths. The 825TX is fitted with Smart Crane for improved productivity, Komatsu Comfort Ride - which offers exceptional operator comfort by dampening jolts and vibrationsand provides excellent visibility in all directions. The fourcylinder EU Stage V engine also packs plenty of punch at 173hp.

Euan opted for non-balanced bogies - balanced bogies can also be fitted - as they minimise damage on softer ground conditions. An advantage of this forwarder is that a tracking frame can be specified. The front and rear axles are equidistant from the centre joint, and this ensures both front and rear wheels follow the same path. This enables narrower routes between trees and reduces the risk of damage to standing trees when manoeuvring in tight spaces.

This forwarder has the 7.7m single reach extension 105F crane (9.5m and 10m reach double extension options are also available with Smart Crane) and a G.28 Grapple. I agree with Euan’s choice of crane, as I find the shorter crane is less cumbersome and has better manoeuvrability, which I find

makes loading easier in confined thinnings (that’s just my opinion, some others might prefer the extra reach).

I watched Ian extract a few loads of chip with the forwarder and was greatly impressed with what I saw. This is an agile forwarder, it had plenty of room in the single rows of removed trees and was quick across the ground, and it didn’t need traction aids either. The crane looked smooth and well set up

and took hardly any time to put a load on.

After both machines had travelled in all the extracted racks, there was barely a mark. I never saw any damage whatsoever to roots or to the remaining standing crop. Once out of the racks, the forwarder had to travel along the forest road to the stacking area to unload and it was hardly leaving a dent.

The forwarder has been using just under 0.6ltr of AdBlue and 11.25ltr of diesel while extracting 10m³ per hour.

Euan is delighted with his choice of equipment, they are the right size for line thinning and have a light footprint for softer areas. Both machine have proven to be exceptionally reliable and the back up service from Komatsu exceptional.

“At Komatsu Forest Ltd, we prioritise customer service above all else. We understand that reliable and high-quality service is vital for our customers to meet their deadlines and generate profits. That’s why we introduced Proact 2.0 maintenance agreements and XP (extra protection warranty) to ensure our customers’ expensive machinery is wellmaintained and operates efficiently. Our team of engineers is strategically located to provide prompt responses to machine breakdowns, minimising any downtime. Additionally, our Komatsu Forest telematic system, Maxifleet, delivers further support to customers, allowing them to access live data straight from

↑ All Komatsu forwarders can be equipped with Smart Crane.the machine and receive remote assistance from our Service team.

“We continuously work to improve our parts support and logistics, ensuring we have the right parts at the right time. Our new Komatsu Forest Ltd HQ, set to open this summer, will allow us to expand our inventory, providing our customers with Komatsu-specific parts and consumables at competitive prices. As a global group, we are always exploring new ways to enhance our after-market customer service. Stay tuned for exciting developments in this area!” said Stephen Bellas, Managing Director of Komatsu Forest UK.

Both machines are under the

MaxiFleet service contract which Euan has found really works well. Komatsu have a great system for delivering spare parts to customers by using Menzies newsagents as pick up points. Even though the areas Euan works is quite a distance from Komatsu Forests base he was quick to point out that they have never let him down and they use Frasers, a local engineer from Inverness if an emergency arises.

It’s a long time since I have seen as tidy thinnings as Euan does. He carries out silvicultural thinnings by selectively removing the trees that should be removed to allow room for the healthiest trees to flourish and mature. He is a passionate contractor working to incredibly

high standards using only the equipment that fits in with his work ethos.

“Euan’s investment in specialist thinning machinery along with the care & skill taken by him & his operators, allows us to carry out sensitive, selective thinning in our client’s woodlands. It is very important to us that thinning is carried out without damaging the crop or the site & with careful tree selection. We’ve all seen the effect of using inappropriate machinery and it is refreshing to see someone taking the care to do the job properly, with a result that we can all be proud of”, concluded Steve Conolly, managing Director at Cawdor Forestry Ltd.

www.mellisforestry.co.uk

Navigating through dense stands is a challenge. Komatsu 825TX offers features that makes thinning easier and more productive. With the tracking frame the tracking deviation is decreased by 50%. The load area is optimised with a special gate and special bunks that are angled inwards at the top to be as agile as possible in tight spaces. As always in Komatsu forwarders, visibility is excellent in all directions – as well over the hood and down towards the wheels load space and tree tops. Allowing the operator to feel safe not to damage any remaining

makes the decreased angled 5 degrees forwarders, the wheels as over the remaining stock.

komatsuforest.co.uk

READ ABOUT THE ORIGINS OF TMK:

Artur Bury

Greg Watkins

Derek Duff

Derek Mair

Jonah Dixon

Davy Wilson

Jonathan Rudd

Artur Bury

Greg Watkins

Derek Duff

Derek Mair

Jonah Dixon

Davy Wilson

Jonathan Rudd

Dwayne Lloyd, a timber haulier from Sundre AB in Canada was the winner of our July front cover photo competition.

Dwayne sent in a photo of the 2020 Western Star 4900sb Tri-drive tractor and B-train trailer complete with a 600hp ISX15 Cummins motor and an 18-speed manual transmission. Although the majority of the newer trucks are 9 axles, which allows them to haul larger loads of up to 71,200kg gross weight, this one is an 8-axle setup, enabling Dwayne to haul 63,500kg of weight, which works out to be around a 40-ton payload.

Canada is the largest exporter of wood in the world, almost half of the land area is covered in trees, this equates to 2.4 million km/0.93 million square miles. In 2020 Canada harvested 143 million m³ of roundwood

Over 90% of Canada’s forests are owned by the public (Crown Land and Provincial Forest) with about half of this area allocated for sustainable logging. This ensures a fair trade between sustaining the forest, while protecting the biodiversity of the ecosystem and providing legal methods for harvesting to benefit the economy. From the outset, foresters called for the woods to be managed prudently. This approach entailed both improving the efficiency with which trees were

harvested and investing in regenerating them to ensure that the forest’s productivity would be sustained forever.

Dwayne is 44 years old and has been hauling timber for the last 10 years, the company he works for harvest around 300,000 m³ each year in Alberta. The photo was taken in an area where he manages two trips per day to the mill and works on average 13.5-14-hour days. He travels for around two hours on the highway from the mill to the start of the forest road then its another 55 km each way to the harvesting site on rough gravelly forest roads. There is a John Deere tracked loader that loads him in the forest and at the mill he is unloaded by a wheeled loader or a Sennebogen Highlift for decking timber.

During

Please

The site that Ridings sawmill stands on has been home to sawmilling for over one hundred years.

Lindsay McKechnie and Amanda Bradley are the current custodians of the independent softwood sawmill, and the third generation of the Riding Family to run the mill.

Ridings has been in the family since the early 1970’s when the duo’s Grandfather, Fred Riding, bought shares in the privately owned sawmill. Fred originally owned the locally renowned 7 stars sawmill in Wigan, Lancashire from the early 1950’s

to the 1980’s, which predominantly produced pit props for coal mines. Both Fred’s sons, Alfred and Frank worked with him at the sawmill.

In 1976 Fred bought out the remaining shares of the Cardross sawmill so it was owned outright by the Riding family. Fred and his sons continued running both sawmills until the early 1980’s when the decline in coal-mining had an adverse effect on their sawmill in Wigan.

Up until 1970, the deep coal mining industry employed

500,000 miners at their 483 pits producing 177million tonnes of coal per year. As the railways moved into diesel and electric power, output slumped to 114 million tonnes and the workforce was reduced to 300,000 - over 240 pits closed, sparking the beginning of the end for deep coal mining. The strikes in 1972 caused blackouts and much of the UK’s industry was forced to go onto a three-day week. The decline continued with cheap coal arriving from low wage economies in Russia. By the 1990’s, just 21 million tonnes was mined from privatised deep

mines using 13,000 miners.

Those sawmills in mining areas began to suffer as many produced just one product, pit props for the National Coal Board. With the pit prop market drying up and the UK in the grips of a recession, alternative markets for timber were hard to find, many sawmills fell by the wayside. In 1980 when the Sawmill at Wigan fell into administration, Frank began working at the sawmill in Cardross and moved his family up at the end of 1981. Fred stayed in Wigan but remained heavily involved in the sawmill right up until he died aged 89.

Frank immediately set about modernising the mill for new markets, including fencing, so that they would never be solely dependent on one customer again. Under Frank’s leadership it wasn’t long before there were major changes at the Cardross site. An EWD Quad Reducer Bandsaw was installed in 1991 and in 1995 an EWD Optimising Edger line, both of which are still in use today! The bandsaw is an extremely productive saw which converts large pieces of lumber into smaller sections while minimizing waste. This was the start of a long-lasting relationship with the German Company EWD, who specialise in sawmilling technology and equipment.

Frank had a hands-on approach to all installations, which was no mean feat as the aerial photo shows the many constraints the site has. Expansion is not an option as the site is in a triangular shape and hemmed in on all three sides by the

seafront, a potato field and the railway line. Frank constantly sought ways to improve efficiency, he installed a Brodbaek pallet crosscut and tray sorting lines in the mid 1990s, a Stenner seven-head resaw line in 2003, a Costa second pass line in 2009 and a Holtec log line incorporating a Valon Kone de-barker and a Jorg Electonik 3-D Scanning system in 2015. In 2016 Riding’s were the first sawmill in the UK to use a Portal Crane to service the log yard. Frank had successfully filled every gap and utilised to its full potential every square inch of the mill at Cardross.

Sadly, Frank died in 2018, just months before a Triple Stenner Horizontal Resaw was commissioned to reduce one pass at the quad, which would increase productivity up to 20%. This again was Frank’s idea and he carried out all the planning and designed the groundworks despite being seriously unwell. However, the modernisation

never stops, a new office block including a meeting room and staff canteen have been built. Although I was told Frank would have kept his office in the old block, as the new offices are too well insulated and he wouldn’t have been able to hear the saws when having to do administration work. Frank will always be in the hearts and minds of Ridings Sawmill and his legacy will be felt there for an exceptionally long time.

Further modifications are planned for the near future, the main mill’s computer system uses outdated components which are becoming more and more difficult to source. A new system is earmarked to be installed but this will involve a complete shutdown, so the timing has to be carefully planned.

I was invited to visit the sawmill by Lindsay McKechnie and Kirsty Robb, the log procurement and

harvesting manager, and was looking forward to seeing what happens to our sawlogs after leaving the forest.

Kirsty met me when I arrived, and we decided we would start our tour at the automated weigh bridge and then go on to the log deck/sorting line. The log deck office was up two flights of stairs with a commanding view of the whole sawmill. Everything was tidy and spotlessly clean - the whole of the mill and the log yard.

Lorries loaded the 3.7m logs straight on to the log deck. The lorry crane operators do their best to keep all the buttresses in one direction but the Cranab FC12 crane that is mounted to the side of the log deck, turn any that are the wrong way round. The reason for the logs being in one direction is so that if there are any large toes sticking out the butt reducer will grind them off leaving the log in a cylindrical shape. Once

through the butt reducer the logs continue their journey down the log sorting line.

Allan McErlean, the operations manager, has worked at the mill for over 30 years, he joined us to explain more about the workings of the sawmill. The mill only takes in two lengths of saw log’s, 3.7 and 4.9m which are re-sawn to the desired lengths. The sorting line has 10 bins on the left for 3.7’s and the same on the right for 4.9.s. As they travel down the sorting log line, they are scanned at top and mid-diameter and ejected into the specified bin. This increases productivity as the saws can be set up for a specific diameter class. The overhead portal crane then empties the individual bins and stacks them so that the mill can have a run of specific diameter logs. There is zero waste in the mill, bark, shavings, woodchip and sawdust are used for biomass and manufacturing chipboard and MDF. Container lorries remove

the residue which is stored separately and under cover. Another good market for sawdust is from farmers, horse owners and stables who use a substantial amount of sawdust on the floor when cows and horses are kept inside during the winter months.

Kirsty and Alan then took me to the main building which houses the sawmill, this process is almost impossible to explain as everything happens so quickly. The sawn timber heads off in a multiple of directions to be resawn for different uses. It was incredible watching the wood being sawn and stacked and the waste being removed to the appropriate areas. Any larger waste particles are fed directly into a chipper via a conveyor feed so that the woodchip is a uniformed size.

There is a full time saw doctor with his own workshop for taking care of all the bandsaw blades. Alan explained that the

↑ The view from the log deck.main blades are changed each lunchtime while the mill is on a break. This way they work at their optimum performance and use less energy to process the timber.

There are some standalone saws for specific tasks, the Stenner horizontal 7 head resaw, which is used for producing thin slats and feather edged boards from block cut in the mill and a Kalin Multi rip with planer heads for producing framing.

The sawmill produces fencing products for the garden markets, framing and slats for shed markets, ungraded carcassing, arris rails, pallet wood, blocks and bearers. 95% of the products head south into England, with a small amount, and all residues, sold locally.

Ridings employ 50 people on site, 35 man the sawmill, 14 office staff and Kirsty who spends her time between the mill and the forest making sure

↑ Logs being processed. ↓

↑ Logs being processed. ↓

the mill has a constant supply of timber. Most of the employees I spoke to had been in the job for a considerable amount time and staff turnover was exceptionally low.

All timber is locally sourced from West Argyll and Cowal forest districts. The Sawmill uses their own contractor who harvests the timber. They purchase standing and buy in the surplus of round timber required from local merchants. Ridings bring in around 70,000 tonnes of

roundwood per year, it is predominately spruce with the remaining 10% being of mixed species softwoods.

The mill aims to be cutting 6,000 tonnes per month but has the capacity to go higher if needed. When I visited there was a good stock of round wood sorted into top diameters ready to be processed. I did notice that there was not much stock of sawn timber in the yard, which is a particularly good sign of a well-run sawmill.

Getting good quality timber is important to running a successful sawmill and this is where Kirsty Robb and their sole harvesting contractor Gary Sheppard come into play. Gary has been contracting to Riding’s for the last five years and it was a chance meeting between the two that started the ball rolling. Gary’s daughter and Kirsty are both keen horse women and it was at an equestrian event Gary and Kirsty got chatting and the rest, as they say, is history.

I have been helping Gary off and on since December last year by operating his forwarder until he was able to find a full-time forwarder operator. It didn’t take long to realised that Gary is a conscientious and productive operator who takes a lot of pride in his work and equipment. The first site I extracted was in West Argyll and it was perfect timber for the mill as it was predominately spruce saw logs with a very small percentage of chipwood. Kirsty

explained that using their own contractor is a massive asset to the mill. If Ridings need a specified amount of a certain product quickly, a phone call to Gary gets the ball rolling and the timber to roadside in record time. This isn’t so easy to organise when you are dealing with a larger contracting company running multiple harvesting sites. Kirsty also pointed out that Gary has a good eye when harvesting and is able to maximise log production without sacrificing quality when harvesting crops of a poorer form.

Gary is a big fan of John Deere harvesters and Komatsu forwarders. The very first harvested he operated when he started out in forestry was a 1470D and although he has tried other types on occasions, he hasn’t found one so far that would make him want to switch brands. The 1270G with a 415 harvesting head is two years old and was purchased new from John Deere. The forwarder is a different story though and was

bought second hand from Komatsu. The is one of the only mid-range forwarders that is capable of carrying around 18 tonne of 4.9 logs. This is beneficial in increasing production and reducing running costs when you have long extraction distances.

This was a fantastic visit as I was given an insight into not just how the sawmill operates but the pride and passion that Lindsay and Amanda have for the business.

Although Frank is no longer physically there to offer guidance, he has left his daughters, Lindsay and Amanda and Amanda’s daughter Erica, who has recently started in the business, with the knowledge, grit and determination to keep Riding’s sawmill at the forefront of the timber industry for years to come.

Ridings Sawmills (Cardross) Ltd, Clyde Sawmills, Cardross, Dumbarton, G82 5NP. 01389 841263

Aplanning application has been lodged with Powys County Council to expand BSW’s Newbridge Sawmill in Newbridge on Wye.

The proposed development will allow BSW Timber to increase their log output capacity from 200,000m³ to 360,000m³ with the construction of two new buildings. It is considered that the proposal will create around 30 new full-time jobs and will have the potential to increase log output to around 450,000m³.

The location of the two new buildings will be within the grounds of the existing operations and will allow a more efficient means of working; a new drop sorter building and a new operations building is proposed which will increase the capacity and productivity of the business, creating the first ‘super mill’ in Wales.

Well, Global Machinery Solutions Ltd

believe it is the uncapped potential and versatility that quite literally allow dreams to become a reality.

The team at Norwood Sawmills understand this and have created a sawmill range that is built on three staple principles: innovation, quality, and integrity.

The HD36v2 delivers high performance and high output for those looking to mill logs up to 36” in diameter. The mill comes available in static and mobile configurations.

What makes this model different from its predecessor, the HD36? From a functional perspective, the wider throat allows you to make a 30” cut versus the HD36’s 28” limit. From a structural perspective, the HD36v2 log deck is completely new. A patented design, Norwood’s proprietary Duradeck® system is constructed of twin laminated, roll formed, high strength steel rails with vertically installed steel plate track. Debossed steel is much stronger and more rigid than flat, unformed steel. Combined with the boxed front & rear-end frames, this log deck gives you greater strength, stiffness, lighter weight, and ultimately greater structural integrity.

As the overall dimensions of both log decks are identical, all existing log-deck mounted HD36 attachments are compatible with HD36v2, making this sawmill ideal for those looking to upgrade.

The HD36v2 accepts all the same manual, hydraulic and power attachments as its predecessor, the HD36. This ensures the spirit of Norwood’s build-as-you-grow philosophy is kept alive. The HD36v2 is fully customizable which means features and attachments can be added at your pace and as your milling needs evolve.

The HD36v2 features a bold new guard design that incorporates steel blade deflection shield inserts and an integrated dust extraction-compatible sawdust exhaust port; the vacuum hose compatible port is a handy feature, especially if you are operating indoors.

Andy Dudley, Technical Sales Consultant at Global Machinery Solutions Ltd, comments “Customers have been impressed with the HD36v2. The mills come with complete concise build instructions, but we’re always at the end of the phone if the customer has any queries when assembling the mill. The HD36v2 is very accurate when milling and can even produce a 3mm veneer!”

Norwood was the very first company to develop affordable personal band sawmills and is the only company to focus entirely on this class of sawmills. Since Norwood launched the first LumberMate, other companies followed suit, selling their own lines of personal band sawmills, but only as an afterthought to their main focus of super-sized, and super expensive, hydraulic mills.

No other company has more

portable sawmill patents than Norwood. Every Norwood is quality built in the USA and Canada. They are designed, and built, to mill millions of board feet reliably and smoothly. Original Norwood mills from 1993, over 25 years ago, are still running strong today. Many of which are operating two 8-hour shifts a day, milling even the hardest exotic hardwoods in Africa, South America, and Australia.

Every component of a Norwood sawmill is made of top-quality steel by highly skilled operators with cutting-edge fabrication and machining technologies. Norwood sawmills are designed and manufactured so that you will be able to rely on yours for the rest of your life. Industrialgrade powder-coating protects the sawmill better, and longer, than old-fashioned spray-paint, which chips, scratches, and rusts. It costs a considerable amount more to powder-coat steel and this sets Norwood apart.

Norwood have created sawmills that are going to work hard

and look good for years to come. That’s why they finish every critical component on the portable sawmills with the very best powder-coating money can buy. Norwood’s philosophy is to remove the need for replacement parts so they design and manufacture all components for trouble-free reliability.

Andy comments “Wear parts are kept on the shelf at Global for the mills, ensuing downtime can be kept to a minimum. Same day dispatch can be advised by our Parts department.”

Norwood has the only sawmill that can take you from manual to hydraulic whenever you are ready. Even Norwood’s manualonly models have more optional attachments and time-saving upgrades than any other brand. Integrity, honesty, loyalty and hard work are at the heart of Norwood.

Rory Willcocks is a name and face that readers may well recognise from hit TV show Trucking Hell. After leaving

school, Rory started as a farm worker with the Youth Training Scheme and this took him to take part in an New Zealand exchange scheme in 1987. Whilst over there, one of the farms Rory was working on had a little block of forestry there, with contractors working on the land. Seeing old timber jack skidders working, saws on the back of tractors and timber being cut fascinated Rory and ignited the start of a lifelong passion. After returning back to England, Rory spent a winter in 1989 working for a timber man on the Lincolnshire/ Leicestershire border. Although he absolutely loved the work, he didn’t find it financially supportive enough and this led a career change into plant, which then took to lorry driving and then a move to recovery, for Crouch Recovery, where Rory stayed for over 9 years and which saw his TV debut. Throughout Rory’s road based career, he never gave up on his dream of working outside with timber and milling.

In 2021, Rory decided he was nearing a position in life that would finally allow him to follow his dream of full time milling.

Rory comments “Some years ago I was working for a powered access hire firm and had to deliver a MEWP to some tree surgeons. When I returned to collect it, I saw that they had cut the stem of the tree they were working on into rings for firewood. It was a beautiful Walnut and I could have cried at the waste. I never forgot it and thought that there really should be a way to make saw milling

available to tree surgeons, farmers and landowners without them having to invest large sums in machinery”.

Rory looked at various types of “Alaskan mill” over the years and, although economical, it appeared they were more suited to the hobbyist; they all seemed too slow for professional work on site or production work.

Having previously collected machinery some years earlier from Global Machinery Solutions, then Global Recycling Solutions, as a recovery driver, Rory remembered seeing some forestry winches at the depot and thought to look the company up regarding sawmills. There, he got in touch with Andy Dudley, Sales Consultant, who helped advise Rory on a Norwood Sawmills mill that would not only suit his needs now but could also grow as his business did, with hydraulic options that could be added along the way.

Andy Dudley comments

“Customers have been impressed with the Norwood Sawmills LumberPro HD36v2 due to not only the milling accuracy but also the ability to add hydraulics. Although the mills come in kit form, we also offer the option of them being built by our workshop and being made road legal, meaning that the mill is delivered with an IVA certificate. This is the option that suited Rory’s needs best and we delivered his mill in January last year, milling on it just minutes after delivery”. The HD36v2 delivers high performance and high output

for those looking to mill logs up to 36” in diameter, with a wider throat allowing you to make a 30” cut.

Rory comments “I liked that Andy really believed in the product he was selling and took my needs seriously. He explained everything and it gave me confidence to invest in the model, it couldn’t have been more perfect. Whenever I’ve needed anything, even on a Sunday, Andy has picked up the phone. The Aftersales service has been outstanding, anytime I’ve needed any parts, I’ve called in at the Global office by chance and the parts have been there on the shelf”.

2022 saw Rory leaving Crouch Recovery, to start up his own milling business, Boundary Mobile Milling, using the HD36v2 full time. Rory is interested in not only extending his own customer base but also helping other millers outside of his radius by setting up a network, where potential job information in a different demographic can be passed to another miller who can fulfil the job. To create a community of millers that support the

needs of customers around the UK.

Rory comments “When I was a digger driver and my boss had a job in Mansfield, he’d ring up and say to a firm in Mansfield can you cover this and likewise, if they had a job in Leicester, they’d ring up and say can you cover that. It’s all about supporting each other as the killer on any job when your business is busy is always the travel”.

Louise Bradshaw-Black, Marketing Manager at Global Machinery Solutions comments

“Rory is a pleasure to help whenever he has needed any support and we wish him all the very best with Boundary Mobile Milling. It’s wonderful to see one of our mills help create not only a business but also allow Rory the opportunity to get back working outside, which is something he’s been wanting to do for 30 years”.

To learn more about any of the Norwood Sawmills range, contact our Sales office on 01476 568384, option 1 or visit our website www. globalmachinerysolutions.co.uk.

Imet up with Ian Valentine, Sales Director - North, and Dave Wadby, Product Manager, of Palfinger UK in Larbert to find out more about this new generation of cranes.

To develop the new cranes

PALFINGER EPSILON listened to their customers so that they could incorporate the best features of their previous models while integrating the latest technology. PALFINGER EPSILON’s aim was to provide a cost-effective, environmentally friendly range of cranes which

are reliable, helping to make their customer’s work much easier.

• REACH. With up to 10.9m reach the Generation 3 cranes offer the longest reach in their class. This provides a significantly larger working arc for fewer lorry repositioning manoeuvres. PALFINGER EPSILON wanted to offer customers a longer and

• stronger crane without adding extra weight. The steel structure has been completely redeveloped and optimized, so that longest, refers to both reach and service life.

• COMFORT DRIVE. This newly developed system is designed to reduce operator fatigue and increase ergonomics. These include the new Grammar seat, which features suspension for superior operator comfort and the Hydraulic Pilot System for precise crane operation with new joystick options. For night operation the new cranes offer a 360° lighting concept with new LED floodlights which turns night into day.

• CENTRALISED GREASING OPTIONS. Greasing can be done either automatically or manually. With the automatic system, it applies grease to the main axes of rotation from a dedicated grease pot (a quick visual check of the level of the grease, is all the maintenance that is required) and the manual system lubricates the crane from a central greasing point using a grease gun.

• OUTRIGGER OPTIONS. With the longer reach, optimum stability is required. PALFINGER EPSILON has achieved this by offering new outrigger options with a support width of up to 5.4m while still maintaining a compact design in the retracted position. Internal hose routing reduces the risk of damage to the hydraulics.

• SMART CONTROL. I had

• the opportunity to try this out for myself at Interforst while it was still being developed and was impressed at how easy it was to use. It works by using integrated sensors to operate the separate functions on the crane while the operator concentrates on the positioning of the crane tip. This system makes it much easier to control the crane, lowers operator fatigue and increases productivity. It is also beneficial in decreasing the time it takes new operators to get up to speed.

Other upgrades include moving the spool valves to a new location under the seat platform for better protection and the hydraulically operated Epshood weather guard.

The Generation 3 cranes are 250kg lighter than their predecessors and this can have a significant financial benefit over the life of the crane. Ian and Dave pointed out that the new cranes offer so many individual customisation options available for the customer.

Palfinger UK is the official UK distributor for Palfinger lorry cranes, Epsilon construction, recycling and forestry cranes plus branded ancillary equipment. Although the recent pandemic and Brexit have significantly increased the challenges they faced, Ian pointed out that “It’s good to see some normality returning to the world”.

Palfinger UK (Falkirk) formally Outreach has undergone many

changes over the last few years, most important was that in 2018 it became part of the TH White Group and in 2021 the retirement of product manager James V Stronach. James had been with the company for almost 50 years. Firstly, when it was owned by the James Jones and Sons Engineering Division, then through the Outreach era and finally Palfinger UK. James started out as an apprentice draftsman, before moving into sales, he is a highly respected individual, so finding a replacement for him was always going to be a difficult task for Palfinger UK.

Fortunately, Dave Wadby proved to be the ideal candidate to carry the mantle. Dave has worked for TH White for many years, he started as a welder/ fabricator moving onto crane installations before travelling around the UK helping to familiarise customers with their new cranes and offering operator training. Dealing with customers on a one-to-one basis has given Dave a good foundation for his new position as the product manager. James was a massive help and stayed on at Palfinger UK temporarily as a consultant, helping Dave to settle in and introducing him to customers. Although retired, James is still available on the end of the phone if Dave ever finds he needs a little bit of advice.

This is Dave’s first foray into the forestry sector, there wasn’t that much of a demand for timber lorries in Bradford,

and he is enjoying learning about the industry and the challenges it brings. He was

quick to point out that his forestry customers have been more than friendly and welcoming in helping him settle into his new position which he is thoroughly enjoying. Whilst the overall UK numbers are modest in comparison to the overall levels of Sales & installation activity in the Palfinger-Epsilon construction and Palfinger PK ranges, Palfinger UK continues to regard the forestry crane sector as a key market and an area they want to continue growing, hence Dave’s appointment.

DAve understands that being able to offer a first-class aftersales service to customers is equally as important as the sale and installation of the equipment, an area Palfinger UK are looking to strengthen as the year progresses.

I have met Dave on a few occasions since taking over from James and I enjoy spending time with him, he has a friendly

demeanour and is an intelligent and interesting person to talk to I am impressed with the depth of knowledge he has gained regarding timber haulage in such a short period of time.

“The order books are full” he explained “which proves we must be doing something right. Our partnership with Palfinger stretches back 50 years so we have built up a fantastic relationship. Our current lead

time for a forestry crane from the date of ordering to arriving in our depot is an average of 1620 weeks.”

The facility was a hive of activity when I visited with every single workstation utilised to its full potential. The company has continued to flourish and increase its presence in the market, but this creates another problem, staffing. To combat this Palfinger UK have a constant recruitment drive in all departments in all areas of the business. Apprenticeships are also available to people of all ages, so whether you are starting on your career journey or looking for a change, it is well worth getting in touch.

PALFINGER EPSILON is a forward-thinking company with dynamic leaders at the helm and an excellent global dealership, they are not a company to sit on their laurels and strive to be at the forefront of timber haulage by adapting to customers’ requirements as they arise.

www.palfinger.co.uk

Dave Wadby. ↑

Palfinger UK is the UK importer and distributor of Palfinger Epsilon, providing a seamless specification, design, assembly and after-sales service on a wide range of models and boom systems which are perfect for heavy grab operation, high-speed working and heavy load capacity within forestry applications. We can supply:

Timber loaders, for truck and trailers (top seat and cabin options)

Forwarder cranes

Skidder cranes

Harvester cranes

Tractor mounted cranes

Woodchipper mounted cranes

Alucar timber bunks & superstructures

Munro unveils allelectric MK_1 PickUp at Fully Charged Live North 2023 to meet global demand for zero-emission offroad mobility

The ultra-capable, ultrautilitarian pick-up follows swiftly in the wheel tracks of the Munro MK_1 Truck launched last December. The MK_1 Pick-Up signifies the next milestone of Munro’s strategic mission to fulfil significant global market demand. Like the Munro MK_1 Truck, the MK_1 Pick-Up’s unique abilities enable customers operating in challenging sectors such as mining, construction, utilities, agriculture, and defence to meet imminent decarbonisation targets without compromising on performance.

“Priced from £49,995 Ex VAT with deliveries commencing later this year, we have already secured more than 200 orders for the MK_1 Pick-Up, three of which have come from FTSE 100 companies and ten from FTSE 250 companies” confirmed Munro CEO and Co-Founder Russell Peterson. “With a full two-year order book for both the MK_1 Pick-Up and the MK_1 Truck, Munro is having to expedite its search for larger premises to meet customer demand.”

Unveiled in ‘Performance’ guise in striking Munro yellow paint

finish, the Munro MK_1 PickUp creates an purposeful visual presence. As with all models and variants of the Munro MK_1 range, the new pick-up combines the rugged reliability and easy repairability of a fulltime 4x4 mechanical drivetrain to provide uncompromising ability in all weathers and all terrains, with a state-of-the-art electric powertrain to ensure no tailpipe emissions are left in the vehicle’s wake.

The spacious, easy-to-load rear bed of the Munro MK_1 PickUp accommodates a 1050kg Euro Pallet payload, while the Performance model has a 3,500kg maximum braked towing capacity for effortless haulage of any cargo from farm implements and livestock to construction and disaster relief equipment.

Producing a prodigious peak

power output of 375 / 280kw combined with instantly available 700Mn / 516ft-lb of torque, the Munro MK_1 Pick-Up dispenses the sprint to 60mph in a mere 4.9 seconds. A 220KW electric motor and a choice of Utility and Range variants are also offered.

Replenishing the 82.4kWh battery from 15 to 80% can be swiftly undertaken using a 100kW DC charger in just 36 minutes. With a fully charged battery, the MK_1 has a range of more than 190 miles, enabling it to operate off-road for up to 16 hours on a single battery charge. Designed, engineered, and built in Britain, the Munro is the first light vehicle to enter production in Scotland in more than four decades.

“We launched Munro to fill the significant gap in the market for an electric-powered,

four-wheel-drive, utilitarian workhorse. Our vehicles are designed and engineered without compromise from clean sheet principles unimpeded by any existing architecture. The result is a rugged construction created for decades of service delivering ultimate, goanywhere, off-road ability,” continues Peterson.

“The levels of positive feedback we have experienced from media and customers who have test driven the MK_1 Truck has been unprecedented and the response to the new MK_1 PickUp has been equally positive. This, and the 200 plus pre-orders we have taken across both the truck and Pick-Up models, gives us great confidence that the vehicles Munro has created are precisely what the market wants and needs and that we can play a key role in assisting those operating in challenging environments such as mining, construction, utilities, agriculture, and defence to meet imminent decarbonisation targets.

“This represents a significant global market opportunity and one which, with our financial partners, we are poised to fully exploit as we take the next strategic step and move towards the pre-production prototype stage.”

Like the Scottish mountains the brand is named after, the Munro has been conceived to last a lifetime and is cleverly engineered to be simple and low-cost to maintain, with the extensive use of existing components. munro-ev.com

10XL Mobile Chipper

Year 2016. 1731 Hours

£130,000.00 + Vat

Shear bar, 3 set of blades and wear plates in spout recently replaced. Good chipper still being used every day and ready to go to work

Contact Stephen Clark

Eagle Asset Finance Ltd

Tel: 07967 588739

Grinder

Year 2014

Under 1,000 Hours

Open to reasonable offers

Fiat Iveco Engine

Remote Control

Roller Head Magnet

Vermeer Smart Feed

Contact Stephen Clark

Eagle Asset Finance Ltd

Tel: 07967 588739

King GTS 44/3 Tri-axle Low loader trailer. Year 2013

£18,000.00 + Vat

44 Tonne Capacity

In very good order - hardly used in the past year.

Contact Stephen Clark

Eagle Asset Finance Ltd

Tel: 07967 588739

Articulated Boom Lift

135 Hours worked

Immaculate - as new

£55,000.00 + Vat

Contact Stephen Clark

Eagle Asset Finance Ltd

Tel: 07967 588739

Year 2004

Height restrictor fitted to allow work via power lines/ highways

Suitable for fitment to Unimogs etc

Ready to go to work

£12,000.00 + Vat

Contact Stephen Clark

Eagle Asset Finance Ltd

Tel: 07967 588739

Pronar T285/1 Hook Lift Trailer. Year 2018. 17 tonne capacity

Flatbed body. Complete with 3 skeleton chassis (2 x 20ft, 1 x 22ft)

Heavy duty axles, Rear steering axle

Only travelled c. 50 miles since new. £33,000.00 + Vat

Contact Stephen Clark, Eagle Asset Finance Ltd

Tel: 07967 588739

TMS Cancela-280 Front & Rear Mount Mulching Topper

Year 2022 £9500.00 + Vat ono

100 hours worked - only used three times since new.

Contact Stephen Clark

Eagle Asset Finance Ltd

Tel: 07967 588739

Set of four used Nokian forest rider, Tyres size 650-45-24.5. Set of 4 never had tracks on looking for 450+vat each contact Kris on 07738217742

Vermeer HG4000 Horizontal

Year 2022 Manitou ATJ160

Mus-Max Wood Terminator

Ducker GMK 12 Front Mount Flail Mower/Mulcher

Vermeer HG4000 Horizontal

Year 2022 Manitou ATJ160

Mus-Max Wood Terminator

Ducker GMK 12 Front Mount Flail Mower/Mulcher

�orestr� �arvesting �nvestment �tilities � �andscaping

�e are currentl� inviting applications for the follo�ing full time positions�

As a �e� mem�er of a high performing team� operating in a competitive� commercial environment �e are see�ing an �����S�AS��C A�� S��� �����A��� ��������A�S to �oin our e�isting SP�� vegetation management teams. �or�ing throughout �ife� �din�urgh and Central Scotland.

As a �e� mem�er of a high performing team� operating in a competitive� commercial environment �e are see�ing an �����S�AS��C A�� S��� �����A��� ��������A�S to �oin our e�isting SP�� vegetation management teams. �or�ing throughout �ife� �din�urgh and Central Scotland.

As �usiness in the �tilities division continues to gro�� �e have a continuous recruitment drive open for ��perienced Ar�orists� �orestr� �peratives� Surve�ors� �arvester � �or�arder �peratives to �oin our e�panding team.

As �usiness in the �tilities division continues to gro�� �e have a continuous recruitment drive open for ��perienced Ar�orists� �orestr� �peratives� Surve�ors� �arvester � �or�arder �peratives to �oin our e�panding team.

�ased from home and travelling to client locations� �ou �ill �e responsi�le for carr�ing out high �ualit� ar�oricultural �or�s across a �ide variet� of sectors – from �or�ing on trainlines and po�erlines to assisting �ith harvesting sites �� operating tractors and harvesters. �o �e successful in this role� �ou must �e self motivated and hard �or�ing individual� sho� initiative and �e capa�le of �or�ing as part of our professional team. �hile e�perience is preferred� candidates �ho demonstrate the right �ualities ma� �e accepted and full training �ill �e provided.

�ased from home and travelling to client locations� �ou �ill �e responsi�le for carr�ing out high �ualit� ar�oricultural �or�s across a �ide variet� of sectors – from �or�ing on trainlines and po�erlines to assisting �ith harvesting sites �� operating tractors and harvesters. �o �e successful in this role� �ou must �e self motivated and hard �or�ing individual� sho� initiative and �e capa�le of �or�ing as part of our professional team. �hile e�perience is preferred� candidates �ho demonstrate the right �ualities ma� �e accepted and full training �ill �e provided.

All applicants �ill �e re�uired to undergo an emplo�ment medical e�amination including a drugs and alcohol screening. Applicants should also hold a full driver’s licence. ��pical �or�ing pattern is �onda� to �rida� and attracts overtime� �ith occasional night shift �or�ing.

All applicants �ill �e re�uired to undergo an emplo�ment medical e�amination including a drugs and alcohol screening. Applicants should also hold a full driver’s licence. ��pical �or�ing pattern is �onda� to �rida� and attracts overtime� �ith occasional night shift �or�ing.

An attractive salar� and �enefits pac�age commensurate �ith e�perience. �his includes pension scheme� life assurance� emplo�ee assistance programme� c�clescheme� and the opportunit� for e�uit� participation.

An attractive salar� and �enefits pac�age commensurate �ith e�perience. �his includes pension scheme� life assurance� emplo�ee assistance programme� c�clescheme� and the opportunit� for e�uit� participation.

�he compan�� recentl� ran�ed ����00 of Scotland’s top Private Companies and is 80% o�ned �� staff. Applicants �ill also �e given e�cellent personal and career development opportunities and �ill �e part of a highl� professional� motivated team.

�he compan�� recentl� ran�ed ����00 of Scotland’s top Private Companies and is 80% o�ned �� staff. Applicants �ill also �e given e�cellent personal and career development opportunities and �ill �e part of a highl� professional� motivated team.

�mail� hr�scottish�oodlands.co.u�

�mail� hr�scottish�oodlands.co.u�

�o appl� for this role�

�o appl� for this role�

more information� visit�

Scottish �oodlands is a leading forestr� management compan� �ith a long tradition of serving forest o�ners and investors in Scotland and the rest of the ��. �or more information� visit�

�or details of information gathered during our recruitment process� please see our �o� Applicant Privac� �otice on the careers section of our �e�page.

�or details of information gathered during our recruitment process� please see our �o� Applicant Privac� �otice on the careers section of our �e�page.

Scottish �oodlands is a leading forestr� management compan� �ith a long tradition of serving forest o�ners and investors in Scotland and the rest of the ��. �or

�or details of information gathered during our recruitment process� please see our �o� Applicant Privac� �otice on the careers section of our �e�page.

Scottish �oodlands is a leading forestr� management compan� �ith a long tradition of serving forest o�ners and investors in Scotland and the rest of the ��. �or

THINGS TO COLLECT ON A WALK THROUGH THE FOREST

• Pulling force: from 45kN to 90kN

• 3-plate clutch

• AUTOSTOP

• TERRA Remote control

• Uniforest Connect

• Pulling force: from 35kN to 85kN

• Up to 3-plate clutch

• Plenty of storage space

• With or without gear reducer

• Pulling force: from 65kN to 120kN

• From 4- to 8-plate clutch

TERRA Remote control

• Uniforest Connect