FOREST MACHINE MAGAZINE

What a disappointment this recent weather has been. After three weeks of glorious sunny weather we are back to the wind and rain. I had hoped that this

year would be an improvement on previous ones, but we have hardly seen the sun at all in July and August. Mind you it’s not all doom and gloom as it has saved me a fortune on charcoal!

I haven’t seen many midges so far this year, but the cleggs have certainly made up for them. I was bitten a few times in the forest above Beattock in Dumfries and Galloway in August and it appears they have somewhat mutated. Their bites are much more potent than previous years, to the point I ended up in A&E, my left arm from my wrist to elbow was swollen and very sore. I was diagnosed with Cellulitis that required a course of antibiotics to fix. At first, I thought it could be me just getting older, but I have heard of others suffering from bad reactions this year. If you do experience painful swelling from bites, please make sure you get it checked out by a doctor, as if it is left untreated you could become seriously ill and need hospitalization.

The Confor Woodland Show is back this year. For those northern residents heading to the Bath & West showground on the 21 and 22 here is a good travel tip. To drive, it’s almost 800 mile round trip and will take roughly seven hours each way. The train also takes seven hours and costs £245.60. A return flight from Glasgow to Bristol with EasyJet is £55 and takes 1 hour 10 minutes. That’s a no brainer as far as I’m concerned, the showground is less than 25 miles from the airport. Even with car hire, one night’s accommodation and a couple of beers I’m still cheaper than travelling down by train. I will be at the show from lunchtime onwards on Thursday and Friday until about 3pm so make sure you come and say hello if you see me wandering about.

Stay Safe everyone.

Get a regular dose of forestry on our Facebook page. Share your photos and experiences. Stay in the loop with the latest news from the forest industry. We love to see your photos too!

Subscribe to our YouTube channel to enjoy our dedicated forestry videos.

#homeoflogging

September 2023 Issue 42

ISSN 2398-8568

YES! I would like to subscribe to Forest Machine Magazine

Online

www.forestmachinemagazine.com

A quick, easy and secure way to subscribe

BY POSTName:

Address:

Editor and Publisher

Robert Easton

Advertising

Rab Easton

Social Media Manager

Rab Easton

Layout and Design

Wendy Easton

Subscriptions

Wendy Easton

Photography

Wendy Easton

Postcode:

Email Address:

Tel No:

GIFT?

If you are taking out this subscription as a gift for someone else. Please complete the gift recipient’s details.

Name:

Address:

forestmachinemagazine@mail.com

+44

(0)7582055748 / +44 (0) 7951 473 846

Website: www.forestmachinemagazine.com

Address: 33 Holm Gardens, Bellshill, ML4 2PB. UK

Forest Machine Magazine assumes no liability or responsibility for any inaccurate information, errors or omissions. Forest Machine Magazine considers its sources reliable and verifies as much data as possible. However, reporting inaccuracies can occur and consequently readers using this information do so at their own risk. The opinions expressed in each article are those of its author and do not necessarily reflect the opinions of Forest Machine Magazine. Therefore, Forest Machine Magazine carries no responsibility for the opinions expressed thereon. Through the magazines you are able to link to other websites which are not under the control of Forest Machine Magazine. We have no control over the nature, content and availability of those sites.

The inclusion of any links does not necessarily imply a recommendation or endorse the views expressed within them. No part of this publication and/or website may be reproduced, stored in a retrieval system or transmitted in any form without prior written permission of the Publisher.

© 2023 Forest Machine Magazine. All rights reserved.

Postcode:

Email Address:

Tel No:

UK only - I wish to pay £15 p&p for 6 issues of Forest Machine Magazine

Europe - I wish to pay £35 p&p for 6 issues of Forest Machine Magazine

Rest Of World - I wish to pay £45 for 6 issues of Forest Machine Magazine

Please make cheques payable to: Robert Easton Ltd

Please return your completed form to: Forest Machine Magazine, 33 Holm Gardens, Bellshill, ML4 2PB.

Split Ends: We take a look at the world’s first battery operated portable log splitter from Ryobi.

Well Oiled: GB Lubricants give readers a step by step guide on how to correctly store, handle and dispose of their lubricants.

FEATURES FIND

Readers Gallery: A selection of the fantastic runner up photos that were sent in to our Facebook page for our front cover competition.

Confor Woodland Show: A preview of the event taking place at Bath and West Showground on September 21/22

Swedish Forestry Expo: Highlights from the premier event which took place in Stockholm. Fire

Nice and Warm : How firewood processors are vital in the supply chain of the 1.8 million tonne of logs that were cut, split and sold in the UK last year.

Getting Rid of Deadwood: Sennebogen’s 718E Tree Care Handler is designed specifically for forestry use.

18 NEXT ISSUE AVAILABLE From 28th October 2023 SUBSCRIBE ON PAGE 4

fire-fighting trailer commences with deliveries expected early next year 6 52 8 16 33 20 49 23 14 NEWS EQUIPMENT CONTENTS 36 30 10 www.forestmachinemagazine.com Page 5 September 2023

The RYOBI 40V HP Technology delivers 12 tons of splitting force with more power than an 80cc gas log splitter, making this a true gas replacement. 40V HP technology combines a brushless motor, advanced electronics, and high performance lithium technology to provide more power, longer runtime, and greater durability. This log splitter has the power to split hardwoods like white oak, red oak, and hickory.

Save time with the kinetic design, which yields a fast, 2 second cycle time and 10X faster splitting. With 150 splits per charge, this kinetic log splitter is perfect for splitting chopped down or fallen trees into smaller pieces of firewood.

Easily transport the kinetic log splitter around your yard with the comfortable hand grips & all-terrain wheels. The heavyduty steel frame can handle even the toughest terrain, and the stores vertically when the job is done. Best of all, it is part of the RYOBI 40V system where any 40V battery works with any 40V product. This RYOBI 40V HP Brushless Kinetic Log Splitter Kit is backed by the RYOBI 5-Year Manufacturer’s Tool Warranty, Lithium Battery, OP404 40V Charger, Wedge, Scabbard/ Cover, Wheels, Hardware, and Operator’s Manuals. 3-Year Manufacturer’s Battery

Warranty, and includes RY40740 40V HP Brushless Kinetic Log Splitter, OP40404 40V 4Ah Charger, Wedge, Scabbard/ Cover, Wheels, Hardware, and Operator’s Manuals.

www.espanol.ryobitools.com

pewag bluetracks feature unique case hardened links and c-links

Special case-hardening of the bluetrack links and c-links, maximises wear resistance, leading to longer intervals between tensioning and adjustments.

Try them for yourself.

GB Lubricants take great care in the manufacture, filling, packaging selection and transportation of our products to ensure they are free from contaminants and arrive at their destination in top quality condition. Of course, once the lubricants leave the care of GB, or its logistics partners, the continuing quality and integrity depends on the subsequent handling and storage protocol at the end user’s site.

All lubricants should be stored and disposed of in accordance with the local laws and environmental measures with respect to containment / bunding within the end user country. We would always recommend the customer to check what the legal requirements and additional guidelines for their own country as it is their legal reasonability and duty of care to do this.

These guidelines offer some simple tips to keep GB lubricants products and packaging in good condition which is essential in ensuring effective product performance.

Ideally lubricants should be stored inside, or at least under cover, at moderate temperature, and without a wide variation in upper and lower temperature range. The risk rainwater ingress

to the lubricant is drastically reduced with an internal store. In many real-world scenarios this may not always be possible, and the lubricants store may have to be at least partly outdoors. Regardless of if it is outdoors or under cover, it is good practice that the store should be sited to provide:

• Adequate access for vehicles to pass and unload.

• Sufficient and appropriate handling equipment on site and staff trained to use it properly.

• There should be an area that offers clean, dust free, sheltered conditions for the unsealing of the lubricant container and its subsequent dispensing.

• If the lubricant store is not immediately adjacent to all points of usage, then where possible consider the safest simplest method / route to transfer the lubricant to the point(s) of use.

• Consider stock/inventory control, measures to ensure

• the usage of older batches first and a routine periodic check on the conditions of containers.

• Also think about segregated areas in which to store empty packaging/returnable containers and packaging waste once the lubricant is used.

The majority of lubricants will be unaffected by the climate if protected from extremes of temperature and water ingress. For these cases they may be stored outdoors for short periods without concern and assuming normal containment measures are adhered to. However, if temperatures below Zero Celsius / 32 Fahrenheit are anticipated, protection should be given to products which are sensitive to the effects of frost such as oil / water emulsions and a general guideline metal working products etc… One thing that may not be

immediately obvious is the risk from condensation or water ingress increases when a barrel is only part-full. Lubricant packaging, especially metal barrels and packs, stored outside may suffer variations in temperature and corresponding changes in the internal pressure. This leads to “breathing” where there is a leaking closure, with moisture able to be drawn in. This is a particular risk if a barrel is standing up-right with the closure on the top. In this scenario the rim of the barrel forms a rain trap and therefore standing water is held immediately above the container closure. This can also lead to corrosion of the barrel surface and damage to labelling. For these reasons, ideally barrels stored outside should be stored horizontally and ensure they are safely racked and in a contained / bunded area in case

of spillage.

Another tip is to ensure the closures of horizontal barrels are at the 3 o’clock and 9 o’clock positions. This helps to ensure the seals are kept in contact with the oil in the barrel where possible. Regular inspections should be made for signs of rust, label damage and for evidence of any leaks. If barrels must be stored outside and upright, then as a last resort the purchase of barrel lid covers should be made, and a protocol in designed to ensure they are used, and staff trained in the proper fitting of these items.

Special care should also be taken with the storage of smaller packages such as 25/20 litre “polys” and pails. These are not designed to withstand extreme weather and prolonged storage outside. UV damage can also be a factor for plastic in

extreme cases and labels can easily be damaged by the climate. If outdoor storage is unavoidable, they should be placed under cover and ideally protected from rain by tarpaulins while ensuring the free circulation of air.

As may be obvious, the risk of contamination is greatly increased when lubricants are decanted or dispensed outdoors. Contamination from rainwater, dust and particulates are all factors to consider. Regardless of whether dispensing inside or outside, then also be mindful of the receptacle used to transfer the oil. It’s very easy to introduce contamination via a nondedicated dirty measuring jug.

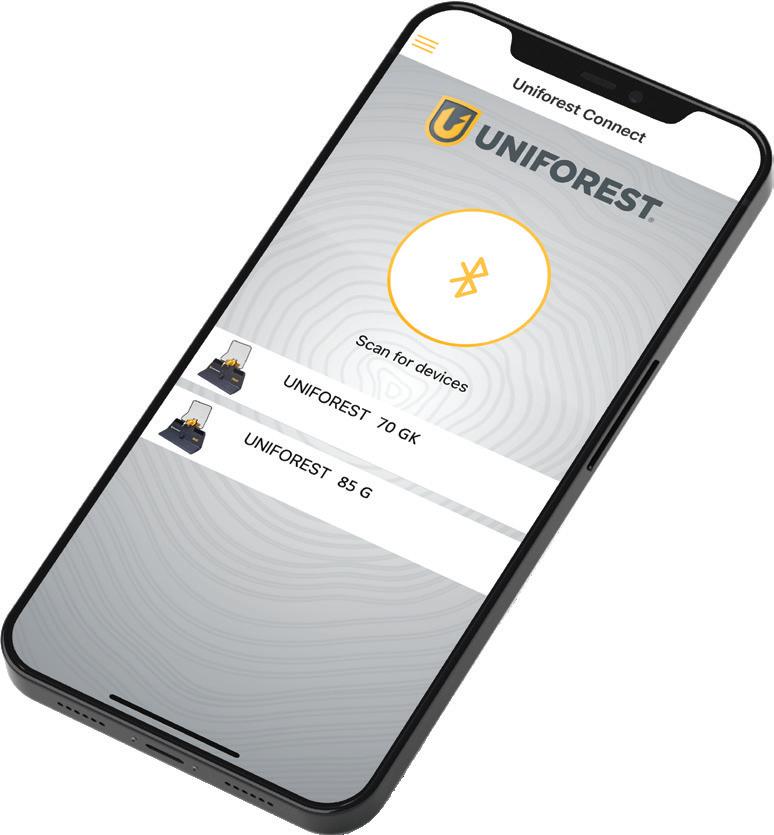

Kieran Anders is a forestry contractor working in the lake district. His work involves hand cutting and extracting timber using a skidder and tractor-trailer forwarder. He has recently upgraded his equipment with the purchase of a new Farma 10 tonne trailer complete with a C7.2 crane, a Valtra T121 tractor and a new Uniforest 8.5 tonne winch.

I arranged to meet Kieran at the thinning site he was working at, near Grange over Sands, not far from Newby Bridge. The mature stand of timber, with a mix of Corsican pine, Alder, and Birch,

was a private woodland belonging to the Halker estate and managed by Tilhill. Kieran and his team were carrying out selective thinning which would improve the overall health of the stand, as some of the Pine had beetle damage. It was a narrow, twisty single-track road to get to the job, but articulated timber lorries were managing to get in and out okay.

Walking through the area that had already been thinned, the forest felt light and airy compared to the area yet to be thinned. Looking up there were no large gaps in the canopy and

I could see they had done an excellent job of selecting the trees to cut.

When we caught up with Kieran, he was halfway through loading the new trailer. The distinctive noise of chainsaws snedding out trees could be heard not too far away. The new Valmet tractor and Farma trailer looked a perfect match together, each complimenting the other in both size and style. The tractor has a powerful six-cylinder 133hp engine and guards had been added to the areas that were vulnerable in the forest. Offcuts and branches are incredibly

clever at finding their way into places and disabling equipment unless protection is added.

The Farma T10 G2 Trailer is of a good solid design with a strongly mounted crane and robust stabilising legs. The widest and strongest side of the Kingpost is facing the load, the other side, which is narrower, gives an uncluttered view from the tractors rear window.

Kieran was loading some substantial 3m lumps of pine, the lift on the C7.2 crane was impressive, and the stabilising legs did a fine job of keeping the trailer solid when loading from the side. He is delighted with the performance of his new forwarding outfit and decided against the option of drive wheels on the trailer, any awkward areas are skidded out

and crosscut to where the trailer can access them. Kieran and his team pride themselves on doing a good tidy job. Keeping the weight of the equipment they use as light as possible, helps minimize their impact on the forest floor.

Kieran opted for the stronger trailer to deal with the aftermath of the recent storms. His last trailer was a Farma T9 with a C6 crane and it served him well, but he needed a longer reach crane with a bit more lift to deal with the mature timber. The T10 has bigger wheels and a lighter impact than the T9 and has better clearance for traversing over rough ground. The unparallel frame steering is excellent for manoeuvring when in tight spaces or narrow entrances.

Kieran has another Valtra Tractor, a 6800, which is used with the new Uniforest 85 professional three-point linkage winch for skidding out wood. This winch was a like for like replacement on his previous one, has a pulling force of 8.5

It is good to see a securely mounted crane while travelling.tonne and can be operated by a hand-held remote control which also feeds out the cable. The battery on the remote lasts about a week between charges.

Kieran can’t praise Fuelwood Warwick enough for the service and back up they offer; he pointed out that they always have the parts you need and once ordered they arrive the next day.

His two chainsaw operators joined us, Theo Kewan, and Cody Cavendish. Cody has been felling with Kieran for about a year now, while Theo has been with him for many years. As well as felling, Theo also operates the skidder when required. The last time I saw Theo he was felling alongside his partner Ailidh Camp, they have since had a child and share the childcare and work between them. Theo works for three days and Aildh covers the other two. Kieran has other trusted chainsaw operators who he can call on to help with the felling

work as and when required. Kieran started out in forestry in 2003 and decided to break out on his own in March 2020, “My timing couldn’t have been better” laughs Kieran “It was the very first day of Covid lockdown”. Despite this, he has done well, and in the short time he has been contracting he has built up an impressive resume of equipment and an even better reputation. There is still quite a lot of storm damaged trees that require clearing up and the Forestry Commission, Tilhill and Halker Estates all call on his services.

Kieran is an affable young man with a good work ethic and an astute business head on his shoulders. He can carry out large volume jobs, storm damage, as well as being perfectly placed for smaller volume parcels. All his extraction equipment is road legal and can be moved from site to site, under its own steam, saving the transport costs that come with larger equipment.

I’m sure this won’t be our last visit to see Kieran as he is a forward-thinking, reliable, young contractor who deserves every success that comes his way.

K. Anders Forestry: 07964 332 179

Kieran’s extra helpers taking five minutes after a busy morning. ↑ Cody in the process of felling a Pine tree. Theo ↓ alternates between felling and operating the skidder.

ENGINE 245 SPEED KM/H 40

WHEEL DRIVE 4

For operators who need multi-purpose and high-performance machines that are easy to use but are not afraid of demanding work, the TreEmme MM250X is the machine for you. This versatile machine is intended for use with a wide range of attachments. A key application is that of high output mulching in conjunction with a heavy duty mulcher, shredding post-harvest debris, tree stumps, soil reconditioning and more. Find your local Merlo Dealer at merlo.co.uk to find out more.

Finnish company Kesla

Oyj is well known for its forestry machinery, timber loading and city cranes, as well as tractor attachments including forestry trailers and loader cranes. Tractor equipment has become more and more versatile in recent years and now Kesla has introduced a multi-purpose concept with a tow-able fire-extinguishing unit for use in Germany. Sales in Germany will take place from the third quarter of 2023 via their Kesla sales partners.

THE TRAILER WITH FIREFIGHTING EQUIPMENT CAN BE USED WITH LARGE AGRICULTURAL TRACTORS

The fire-extinguishing tractor trailer consists of a KESLA multipurpose trailer, a KESLA loading crane and a modern water tank made of special plastic which has a capacity of 10.5 m³ along with space for other fire-extinguishing equipment. The fire-extinguishing trailer is equipped with its own hydraulic unit and can therefore be used

with any larger agricultural tractors without any problems.

The fire-extinguishing trailer consists of a KESLA trailer with a multi-purpose structure and the attached fire-extinguishing unit can be driven to the fire site, since the KESLA 144 trailer can be used in a variety of ways as no special chassis is required. When the water tank is full, the transport speed is still fast, and this keeps the travel time between the filling point and the point of use as short as possible. The concept is based on a KESLA 144 series trailer with drive, either HD (Robson drive) or ND (nave drive). This is pulled by the tractor and the trailer mounted KESLA hydraulic unit is driven via the PTO shaft. As a result, the system is extremely efficient off-road, for example in forest or field fires, and has excellent traction.

The combination of good performance on and off-road gives the fire-fighting trailer flexibility and economy. It can also be used for other purposes like irrigation.

The KESLA fire-extinguishing system has two water cannons with jet nozzles - one at the rear of the fire-extinguishing superstructure which is hydraulically adjustable and a second on the boom of the loader crane. Both can be manually adjusted from either a water jet or the spray jet and have a maximum range of up to 30 m with the water jet. Both can be easily and precisely directed to the fire. The water cannon / hollow jet pipe on the loader crane boom can also be used to extinguish fires, which are then scattered with the grapple.

The water tank of the fireextinguishing equipment can be filled via hydrants or water pipes and also via natural water sources such as ponds, lakes, rivers or even larger ditches. It is filled with the hydraulically driven filling pump, which can be used with the loader crane thanks to its reach. This is a good solution when working away from water hydrants. The fire-extinguishing unit is controlled via a separate joystick and the control element is hydraulically driven via the trailer’s hydraulic unit.

As already mentioned, the KESLA trailer fire-extinguishing unit uses a multi-purpose structure, and the semimounted fire extinguishing unit can be easily removed from the trailer. After unhitching the fire extinguishing unit and the KESLA multi-purpose body frame, the bolsters can be put back on the trailer and the trailer can load timber again.

Kesla is currently working on additional equipment for the KESLA multi-purpose body frame.

The concept was presented back in mid-September 2021 with the release of a video of the prototype of the KESLA Fireextinguishing Unit with trailer KESLA 144 on YouTube. The video and the unit attracted a lot of attention and Kesla Oyj received many enquiries for the system globally. After extensive tests and operations, the fireextinguishing tractor trailer has performed well and is ready for customers in Germany. Sales will start in Q3 2023 with deliveries expected in early 2024.

www.kesla.com

Davie Green

Jimmy Riddle

Eifion Glyn Davies

Elaine Warfield

Mark Richardson

Aaron Ferguson

Davie Green

Jimmy Riddle

Eifion Glyn Davies

Elaine Warfield

Mark Richardson

Aaron Ferguson

Thank you all for taking the time to send your photos in, I was overwhelmed with the response. The quality of your photos was outstanding and it was a very difficult decision choosing one for the front cover.

Jock McKie of John Deere Forestry UK, kindly donated a hundred pound voucher for the winner and runner up prizes of fifty pound vouchers for the other two finalists.

Our winner this month is Jack Osborne who is from a small village in mid Wales, ten miles from Builth Wells. Builth Wells is known to many as the home of the Royal Welsh Show.

“I am currently 22” said Jack, “I decided I wanted to get into the industry from a very young age

due to my dad being a timber hauler. He packed the lorries in when I was seven to operate a forwarder for one of his mates who was starting out. He later progressed to a harvester and I spent many weekends and school holidays going up to his workplace to watch them working. It didn’t take long for me to realise that is was what I

wanted to do.

“I’ve been operating a forwarder for six years now, I started after leaving school and two weeks before my 17th birthday. I was offered a position with MV & JM Davies & Son, my dad had been driving a harvester for them for about a year at this point. I started as banks man for a while

Peri Dunford

Jonny Porteus

Miguel Duarte

Samuel St-Amaud

Peri Dunford

Jonny Porteus

Miguel Duarte

Samuel St-Amaud

helping the winch boys on the bank and assisting them setting up the skyline between racks. It was a good experience to get a taste of the different roles this job has, but I was eager to get on one of the machines, for sure.

“I haven’t had any experience operating a harvester apart from simulators, I do find the harvesting very interesting but also very stressful and I feel the level of concentration needs to be doubled, especially when working in mature timber. I find it easier on the forwarder as you just follow where the harvester goes, maintaining the site is probably the most difficult part of forwarding especially if it’s a very wet site.

“I thoroughly enjoy operating the forwarder, it is good being able to sit back and relax a little with some music or a podcast playing in the background. I usually work for around 10 hours, but I can work longer or shorter hours if I wanted to. Fortunately, our work-sites are not too far from home, so I travel each day but there have been occasions where we have had to stay away. Most of our work is in mid or south Wales and the size of the jobs can be anything from 8000m³ to 30,000m³ and range from flat sites with a short haul to steep banks with a long haul.

“My current forwarder is a 2020 John Deere 1910G, I didn’t get it new. I was operating a new John Deere 1210G roughly for two months after the 1910 arrived but due to driver changes, I was offered the opportunity to drive the big beast last year. I have previously operated a 2011

840tx, which I started my forestry career on, I then drove a 2015 Ponsse elk for just over two years before I got the 1210G brand new. I’ve driven a few different forwarders so far but in my opinion the John Deere 1910G is my favourite by a long shot! The drive power it has is incredible, it appears to go anywhere you want it to and gets out with minimal effort, even when fully loaded. The swivel cab with the IBC crane is a huge game changer, it makes loading and unloading much faster and far more efficient. The only thing I’ve struggled with is the single extension crane. Although it’s far more powerful, all my previous machines had longer reach with double extensions.

“The site I was on when I took the winning photo was a 7000-tonne skyline/harvesting site. We had spruce to skyline to the road with a steep larch bank we managed to harvest. I’m fortunate to be following my dad 90% of the time he’s currently driving a 2021 John Deere 1270G 8-wheel harvester.

We are lucky with our product sizes, most of our jobs tend to have three to five different sizes. The sizes depend on the size tree and company you’re cutting it for.

“As for the future, I don’t have any plans on leaving the industry anytime soon. I think if I was to stop operating a forwarder, I’d look at going to the management side of the industry. I don’t think I’d want to leave the industry fully as it’s always been a big part of my life with both my dad and grandad being in the forestry. Even my hobbies away from work are forestry related, I like to go on walks in the forest and exploring the trails on my mountain bike. I love my cars but it’s a costly hobby, so I quickly sold mine and now enjoy looking at other people’s instead. Any other free time is spent with my family and close friends”.

Join leaders from the forestry and timber industry for a two-day event focused on the key issues facing the sector, new innovations in machinery and research, and exploring opportunities for future growth.

The Confor Woodland Show is a place for anyone interested in trees and wood to hear about the latest products and services, receive practical advice, network with peers, and enjoy the demos and seminars on offer.

names and influencers to discuss topics like agroforestry, bioplastics, trends in the forest marketplace, and modern management techniques. This year’s speaker line-up includes representatives from DEFRA, Forest Research, FSC UK, Rainbow Professional, CSX Carbon and more!

Held this year at the Bath & West Showground on 21-22 September, the Show promises a valuable snapshot of the current state of the industry, whether you’re a part of it already or are looking to find out more.

conforwoodlandshow.org.uk

Confor is the voice for forestry and wood-using businesses in the UK, and our tent is set to be the central hub of the Show, bringing together big

Richard Hunter, Technical and Industry Support Manager at Confor, said: “After a four-year break, it’s great to have the Confor Woodland Show retaking its place in the sector’s calendar. With a move to the Bath & West Showground, we hope that our members and colleagues from across the industry will agree the Show has returned bigger and better than before. Everyone at Confor is excited to welcome old and new faces back in September. We are immensely grateful to our sponsors and exhibitors for making our excellent programme of discussions, panels and demonstrations possible.

“This is an extremely important time for forestry in the UK. The benefits that woodlands, forestry and timber can provide for the economy, for rural communities, and for the mitigation of climate change present unique challenges opportunities for the sector. Bringing leaders in the industry together to share knowledge and ideas is now more important than ever.”

Exhibitors will include manufacturers and distributors of forestry machinery like Fuelwood, Jas P Wilson Approved Hydraulics, Lister Wilder, DJB Machinery and Wood-Mizer UK among others. Forest advisory and management services, nurseries, wildlife and conservation bodies, suppliers of wood heating systems and woodland craft workers will also be attending, ensuring there will always be something to draw your attention.

Visitors can expect to view machine demonstrations, see the new innovative technologies being developed in the sector, enjoy live chainsaw carving and archery showcases, and get involved in the conversations around the future of forestry. Additionally, the Forest Workers Zone will be a key feature of the Confor Woodland Show this year, acting as a ‘one stop’ hive of activity for people working in the practical

side of the industry to come for information, advice and networking. Experts will be holding practical demonstrations on skills such as chainsaw maintenance and tips for safe use, as well as being on hand to answer your questions or discuss any issues you are facing.

Organisations attending include Perennial, Land Workers Alliance, Forestry Contracting Association, Small Woods Association, Mid Wales and Marches Assessment Centre, The National Coppice Federation, and others campaigning on behalf of forest workers.

Single and two-day tickets for the Confor Woodland Show can now be purchased online. Bookings made before the event will cost less than tickets purchased at the gate and special discounts for students and Confor Members apply.

The last few exhibitor spaces are also up for grabs with various pitch sizes and promotional opportunities included. Availability is extremely limited so if you’d like to be a part of the Show, please get in touch as soon as possible. To find out more about what’s on at the Confor Woodland Show and stay up-to -date with announcements, visit www.conforwoodlandshow.org.uk

WITH THANKS TO OUR SPONSORS

GOLD: B.PRICE MUS-MAX SPECIALIST LTD

RAINBOW PROFESSIONAL

SILVER: CUMBERLAND PLATFORMS, EUROFOREST LTD

FTA, CABCARE, GEOSYNTHETHICS LTD, APPROVED HYDRAULICS LTD, FORESTRY COMMISSION, SYLVAGEN, AGROVISTA

BRONZE & SEMINAR: ANGLO AMERICAN OIL COMPANY, CSX CARBON, JOHN CLEGG & CO. LLP, KOMATSU

Book in advance online and get exclusive discounts on your tickets

Iwas looking forward to visiting this Expo as the list of exhibitors was certainly impressive. The large forestry harvesting machinery manufacturers had all got together and decided to organise their own event aimed directly at forest professionals.

Although held at a horseracing track in the centre of Stockholm, it was easy to get to by taxi - a tip though for anyone visiting Stockholm, make sure you have the UBER app set up on your phone as you will save a small fortune on taxi fares. The more sceptical might say that you should not have a Forestry Expo in the middle of a city, but there are advantages.

There are plenty of hotels and B&B’s close by to suit all budgets, easy to get to by taxi, car, bus (free parking) or train, a good, firm, level walking circuit around the exhibitors for young, old and wheelchairs/pushchairs, good clean washrooms and excellent and reasonably priced catering facilities.

I travelled over on the first day and visited on the Friday and Saturday. It was very well organised with hardly any queuing to enter. Although entry was free you had to preregister and receive a QR code for your phone or to download, this would allow the organisers to get an accurate analysis of numbers and geographical

location of visitors. John Deere, Ponsse, Eco Log, Komatsu Forest, Rottne and Maskin Leverantorerna sponsored the fair and there were 150 exhibitors. As soon as you entered there was a vibrant buzz and I could hear music, people on loudspeakers and engine noises. Around 13,000 visitors attended over the three days, as a visitor this was perfect as you could see what was going on without the pushing and jostling you find at other events. My highlight of visiting big events like this is finding out about the latest technology integrated into the machines. As equipment capabilities improve, increased operator comfort and safety is paramount.

PONSSE displayed the company’s new EVI 15 tonne capacity Electric Forwarder and held demonstrations throughout each day of the expo. It is strange to hear how quiet this machine really is, and the acceleration from a standstill to top speed is incredible. This is a concept idea developed between Ponsse and the company Epec Oy. I spoke to one of the testing operators regarding this concept and the biggest difference he found was the speed of the functions.

When using the crane for example, the instant you touch the lever the crane is in motion. He explained that when using a conventional crane, you do not realise that there is a slight delay until you operate the EV1, which is instant. The PONSSE EV1 features Epec Flow, Epec’s electromobility system solution. The solution is based on the Epec Flow Power Distribution Unit (PDU), to which electric motors, batteries and various devices connect. The PDU’s integrated safety solutions enable effective manufacturing and maintenance of the machines, as well as their operations in demanding conditions. The Epec Flow Hybrid Control Unit (HCU) controls the electric powertrain and includes software developed through simulations, enabling optimal energy consumption, productivity, and usability. www.ponsse.com

Centre stage on the Komatsu Forest stand was the Centipede minimal impact forwarder project. This is a collaboration between eight forest companies and Komatsu Forest. The rubber tracked forwarder offers greater operator comfort as it absorbs smaller obstacles and reduces whole-body vibration by 50%. The 855 forwarder is a size reference, but the Centipede can carry a heavier load and traverse the ground much quicker. This low ground pressure forwarder causes minimal impact to the forest floor and is suited to extracting timber from wet boggy areas. The Centipede is currently undergoing evaluation to determine whether serial production is viable.

www.komatsuforest.com

Kasi-Glas were a short walk from the entrance. The German company manufacture impact resistant and chain-shot proof glazing. Their booth featured a Logset cabin with a Kasi-Glas front window on display and Jochen Lanio, Kasi’s Global Key Account Manager was excited to show us the new concept window that Kasi-Gals have developed. The window gradually changes from clear to visionless at the push of a button. This is a great solution as it can be in installed in separate stages down the window with each section independently controlled. The amount of light progressively or completely blacked out depending on the strength of sunlight, perfect for reducing eye strain when working towards the low winter sun.

Kasi Glas has been at the forefront of safety windows for years and are the first choice of the emergency services. They offer excellent operator protection from chain shot and have heated and tinted options. www.kasiglas.de www.forestrypartsdirect.com

Iggesund Forest had a broad selection of products on display including their latest urea spray bars. The spray bars are reversible which means that both sides of the bar can be used to spray on the stump. The spread of urea fluid is adjusted by drilling in the punched holes in the harvester bar.

We will be able to offer a comprehensive report on these in our next issue as we are conducting field trials.

www.iggesundforest.se

Flotation

Grip Climate

Terrain Machine

Durable and hard wearing, even on rocky terrain

One of John Deere’s key features was the latest Intelligent Boom Control System, a giant step forward in aiding new operators get up to speed in a shorter timescale as it improves productivity and ease of operation.

The harvesters and forwarders on the stand attracted a good crowd. There was a 1510G forwarder available for visitors to try with the new IBC crane technology, I wanted to try it, but it was proving extremely popular with long queues waiting every time I went past.

The company’s new Intelligent Harvester Head Control (IHC) makes logging easier and improves delimbing quality. The force control of the delimbing knives gives the harvester head the right compression and excellent measuring accuracy in all conditions. www.johndeereforestry.com

Guerra had travelled to the Expo from their base in Galicia in Northern Spain and had interesting equipment to look around. Although their harvesting heads and tree shears are not a common sight in UK forestry, they are a popular choice in other European countries. Their largest harvesting head looks a strong robust structure, designed for use on excavator carriers in the 20-35 tonne class. The head is capable of felling and processing trees of up to 60cm.

Guerra’s largest TC700 tree shear has double cut blades and can shear up to 70 cm diameter trees, it stands at almost 2.8m tall and has two claws for log accumulation.

Jos Dodd, a timber haulier, was impressed with the timber cranes on Guerra’s stand. The 257AN model crane is strong and will lift almost three tonnes at 8.1m and almost six tonne at 4m. Jos enquired as to the crane prices and was pleasantly surprised as he thought they would have been more expensive.

www.iguerra.com

www.forestmachineservices.com

↑ Gary, Brogan and the team at Clark Tracks.Dasa is an electronic company who specialise in intelligent systems for machines, attachment controls and information management and communications. Dasa work within three primary technology areas: Forestry Operations, Machine Control and Fleet Management solutions.

Mikael Frimodig, the key account manager at Dasa, was able to offer an insight into the advancements they had made. In June 2022 they premièred a world-first wireless system for advanced bucking, the Dasa Wireless 1. This is a hassle-free system where you never have to worry about broken data cables, resulting in an increase in the harvester’s uptime. Another advancement is the Dasa insight, this is a cloud service for production and operational monitoring. Dasa Insight can manage StanForDfiles from different machine brands. There are several ways to transfer files from a machine to the Dasa Insight cloud, either directly via a cellular or satellite connection, or via the Dasa Sync App installed on a smartphone. There is also the Dasa H50 which will collaborate with excavator-based harvesters, this offers a remote solution where you can connect your smartphone and get support from anywhere in the world. www.dasa.se

PALFINGER EPSILON never fail to impress with their stands at any forestry show and the Expo was no exception. Visitors are always welcome to try out their latest technology and many got to grips with the OFFROAD cranes, which included the intelligent assistance system SMART CONTROL, and were impressed with the efficiency and ease of operation.

PALFINGER EPSILON also had their latest GENERATION 3 for ONROAD use cranes on display. www.palfinger.com

↑ There was a good selection of machines, equipment, accessories and tools on display

↑ Who let this lot out, Harold Taylor, George Dunlop and Bobby Melvyn enjoying the day.

↑ Compact tractor based harvester from Kesla

↑ There was a good selection of machines, equipment, accessories and tools on display

↑ Who let this lot out, Harold Taylor, George Dunlop and Bobby Melvyn enjoying the day.

↑ Compact tractor based harvester from Kesla

↑ Merlo showcasing a range of telehandlers. With good stability and incredible reach they are the perfect base unit for tree shears.

↑ Ponsse’s huge 25 tonne capacity Mammoth forwarder with CVT stepless transmission.

↑ Scarifying arms for preparing clear felled sites ready for planting from Bracke Forest

↑ Rottne had the opportunity to introduce their new e-cabin.

↑ The all black Logset colour scheme makes their machines stand out in a crowd.

↑ Konrad Forstechnik’s KDH40-1 levelling tracked thinning harvester.

↑ Michael Keller from HSM with the 208F forwarder.

↑ Liebherr Grapple Loader.

↑ Ponsse’s huge 25 tonne capacity Mammoth forwarder with CVT stepless transmission.

↑ Scarifying arms for preparing clear felled sites ready for planting from Bracke Forest

↑ Rottne had the opportunity to introduce their new e-cabin.

↑ The all black Logset colour scheme makes their machines stand out in a crowd.

↑ Konrad Forstechnik’s KDH40-1 levelling tracked thinning harvester.

↑ Michael Keller from HSM with the 208F forwarder.

↑ Liebherr Grapple Loader.

This is just a small selection of what was at the EXPO. It was great catching up with Garry Henderson, Brogan and the rest of the team at Clark Tracks who had a great display and excellent hospitality, Michael Keller from HSM who was over from Germany with a stunning 208F Forwarder, Konrad Forsttechnik with their Woody harvesting heads and KDH40-1 tracked levelling thinning harvester and all the others which are too many to mention on here.

I enjoyed the Expo and all it had to offer, it had a good friendly atmosphere, and the two days were sufficient to feel I had not missed anything. The manufacturers did the Expo proud with an amazing selection of equipment on display and superb hospitality.

I will be visiting the Confor Woodland Show in September and that will be my last event for this year. For anyone interested, the Confor Woodland Show will be at the Bath & West showground on the 21st and 22nd of September. www.confor.org.uk

Next year will bring another broad selection of events for us widtinks but the one highlighted in my diary is the KWF Tagung in Schwartzenborn/Hessen, Germany from the 19th to the 22nd of June. This forestry demo fair is central Europe’s largest exhibition of its kind and is not to missed as it offers a huge static display of all types of forestry equipment along with working demonstrations. For more information on this show visit www.kwf-tagung.net

The Treeline Open Days are an event that I look forward to each year. Nick Marshall and the team at Treeline Woodlands and Fuelwood Scotland make every effort to impress while hosting this event.

Treeline, based at Baddingsgill near West Linton, are the Scottish distributors - Fuelwood Scotland - for Fuelwood Warwick’s extensive range of equipment for forestry, biomass, and firewood production. The open days are a good opportunity for potential customers to get handson with equipment before deciding if it is suitable for their requirements.

Treeline was established by Nick’s parents, Gavin and Elaine,

in 1991 after Gavin left the Economic Forestry Group. The couple wanted to offer clients a personal forestry service by applying for grants, fencing, planting, spraying, weed control, brush cutting and tree surgery. Nick joined the business in 2011 and increased the range of services the company offered by introducing a bespoke first and second thinning service using low impact thinning machinery. Nick purchased a Small Hyundai 145 excavator with a Kesla 25RHS harvesting head and a Malwa 560F forwarder, this was ideal for the work Nick acquired in the Lothians and Border districts.

Treeline’s thinning services continue to this day, and the company can offer their clients the full management package

from applying for felling licenses to harvesting and marketing timber. They are also the UK distributors for Malwa forwarders and harvesters.

Two large kilns have been added to their yard, which allows them to have a large stock of ready to burn firewood available for pick up or local delivery.

A recent addition is timber and fencing products and the extensive stocks of materials, tools and equipment required for all types of fencing can be collected from the yard or available to order for delivery. These open days allow Treeline to highlight the full range of equipment they offer through Malwa and their partnerships with Fuelwood Warwick and Kilworth Machinery. The equipment was spread over a

large area with plenty of room to walk around, this is one advantage of open days over exhibitions as equipment isn’t crammed into an allocated area. Most of the equipment can be seen working and tried out personally by potential customers and there were plenty of experienced personnel on hand who could give advice and answer any questions put to them.

There was an excellent selection of Moheda FTG forwarding trailers and cranes, Heizohack chippers, Uniforest grapples, firewood processors and winches, AVR firewood processors and splitters, Japa firewood processors, grapple saws, and Fuelwood’s own Woodcutta and Splitta 400 log/ kindling processor, Fuelwood Kindlet and a Kilworth compact 4wd tractor and Kilworth

mowing equipment.

One of my highlights of attending this event is sampling one of the delicious burgers hot off the wood fired BBQ and for those not driving, bottles of Fuelwood’s own Jolly Logger beer. This is an interesting day out that never fails to put a smile on your face and it’s always such a pleasure to catch up with the Marshall family.

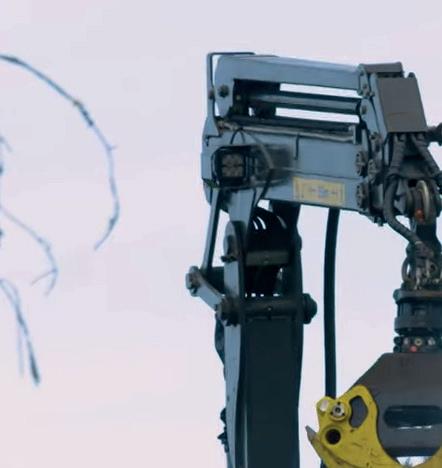

Bald spots to dead roots: ash dieback is causing numerous, challenging operations in the field of tree felling and traffic safety. The use of SENNEBOGEN tree care handlers is proving to be a particularly environmentally friendly and efficient option for the removal of rotten deadwood at the company Messingschlager from Franconia in Germany.

In Asia, a harmless leaf fungus - in Europe, a major plague for nature. Especially in summer, the leaves of the ash tree are infected first, before the pathogen leads to the death of the shoots. So far, no practical measures are known to contain the fungal infestation. Ash trees in which the crowns are visibly heavily infested or the base of the trunk shows necroses must be removed quickly along traffic routes for safety reasons.

The ash dieback is also having a strong impact in Upper Franconia. Managing director Sven Messingschlager has therefore decided to expand his fleet with a SENNEBOGEN tree care handler 718 E from SENNEBOGEN Vertriebsgesellschaft in order to implement, among other things, complex tree felling operations in the future as part of the deadwood removal caused by

the ash dieback. In addition to his original focus, the timber trade as well as forestry services, Messingschlager can now take on an even broader range of services in the area of traffic safety, tree care and hazardous tree felling.

“I have many customers where I previously had to use aerial lifts and harvesters for hazardous tree felling due to the complexity of the operation. With the 718 E, I can handle such operations in a much more cost-efficient, safe and pleasant way for the customer. Time savings also play a major role for my customers, especially when roads have to be closed,” says Messingschlager.

Messingschlager completed one of the first jobs with its new 718 E in the area of the “Lillachtal” natural monument in Franconia. In the spring, a fatal accident occurred along a hiking trail due to a falling branch. A large number of dead ash trees had to be removed as quickly as possible. The operation was complicated by challenges, such as a narrow hiking trail that made it impossible to use other machines, such as harvesters. “Especially here in this area, we had to choose the most naturefriendly option for felling the trees. With a machine width of just under 3.5 m inclusive the

outriggers, the 718 E just barely fit on the narrow hiking trail. Anything else would have been impossible for us,” Sven Messingschlager points out.

Bald spots to dead roots: ash dieback is causing numerous, challenging operations in the field of tree felling and traffic safety. The use of SENNEBOGEN tree care handlers is proving to be a particularly environmentally friendly and efficient option for the removal of rotten deadwood at the company Messingschlager from Franconia in Germany.

In Asia, a harmless leaf fungus - in Europe, a major plague for nature. Especially in summer, the leaves of the ash tree are infected first, before the pathogen leads to the death of the shoots. So far, no practical measures are known to contain the fungal infestation. Ash trees in which the crowns are visibly heavily infested or the base of the trunk shows necroses must be removed quickly along traffic routes for safety reasons.

Next to the hiking trail stretches the Lillach limestone tufa stream, a millennia-old watercourse that is home to many rare and endangered animal and plant species. To protect the natural monument, a felling method had to be chosen that avoided all contact with or alteration of the watercourse. Messingschlager explains that the use of rope technique would have been a possible, but more inefficient alternative: “With rope technique, we would never have been able to leave the stream course without any impairments. In addition, the operation would have been more expensive and also more dangerous for our employees. The 718 E has the necessary reach that we could cut the trees from the trail and deposit them across the creek to the other side.” sennebogen.com

The ash dieback is also having a strong impact in Upper Franconia. Managing director Sven Messingschlager has therefore decided to expand his fleet with a SENNEBOGEN tree care handler 718 E from SENNEBOGEN Vertriebsgesellschaft in order to implement, among other things, complex tree felling operations in the future as part of the deadwood removal caused by

the ash dieback. In addition to his original focus, the timber trade as well as forestry services, Messingschlager can now take on an even broader range of services in the area of traffic safety, tree care and hazardous tree felling.

“I have many customers where I previously had to use aerial lifts and harvesters for hazardous tree felling due to the complexity of the operation. With the 718 E, I can handle such operations in a much more cost-efficient, safe and pleasant way for the customer. Time savings also play a major role for my customers, especially when roads have to be closed,” says Messingschlager.

Messingschlager completed one of the first jobs with its new 718 E in the area of the “Lillachtal” natural monument in Franconia. In the spring, a fatal accident occurred along a hiking trail due to a falling branch. A large number of dead ash trees had to be removed as quickly as possible. The operation was complicated by challenges, such as a narrow hiking trail that made it impossible to use other machines, such as harvesters. “Especially here in this area, we had to choose the most naturefriendly option for felling the trees. With a machine width of just under 3.5 m inclusive the

Limited space: the 718 E can also be used on narrow terrain due to its minimal width.

Limited space: the 718 E can also be used on narrow terrain due to its minimal width.

On a recent trip to North Wales, I drove past Glasfryn Fencing and Sawmill which is situated just outside Llanaelhaearn on the edge of the Llyn Peninsula. I remembered, from my time living in Wales, that this sawmill and forest had an interesting history behind it.

In 1952, aged just 25 and being the oldest son, Roger WilliamsEllis took over the running of the Glasfryn family estate

following the death of his father Rupert.

Prior to this Roger was commissioned into the Royal Engineers during WWII and spent his first three months aboard a troop ship bound for India. Once there he joined the Sapper Minors and rose rapidly to the rank of major, he was one of the youngest in the British Army at the time to hold that rank. When he was demobilised from the army he trained as a

land surveyor in Denbigh until returning to Glasfryn.

Roger never drank or smoked and had always been careful with his money, so when poorer quality land became available on the north side of the river of the Glasfryn estate, he began to purchase it for himself to establish a forest. He was also a keen barterer; he had purchased 20 acres of good farmland which he swapped with a local farmer for 40 acres of poorer-quality,

which was ideally suited for growing spruce trees. The land was quite acidic as it had a thick layer of peat on top of a clay subsoil. Getting the right crop was pivotal to his plans, as he believed that 40 years was a long time to live with a mistake if you planted the wrong species.

All the Sitka Spruce on the estate originate from seeds from the Queen Charlotte Islands (QCI) in British Columbia. Sitka is grown along the west coast of North America from California to Alaska. It is found up to about 80km from the coast as it thrives on a damp maritime climate. This specific area has a similar climate to the west coast of Wales. Roger tried some experimental planting with other tree species, but none faired quite as well as the Sitka.

I arranged to meet sawmill manager Arwel Roberts who had kindly offered to show us around the mill and explain a bit

more about the history of the Glasfryn estate.

Arwel and Roger had been lifelong friends and when asked if he would establish and manage a sawmill on the estate,he jumped at the opportunity. Right at the start boundaries were set between the two, “In the mill, you’re the boss and in the forest, I’m the boss” stated Roger. Arwel smiles when he explained that it was a strange feeling telling your employer what to do whenever he was working in the mill.

We started our tour with the first tree that was planted on the estate in 1948, this involved a short journey by car to the heart of the forest. The tree is a magnificent specimen in amongst a beautiful stand of Sitka spruce and was more than 10m³. When Roger handed over the managing of the forest to Arwel his hope was that this tree would remain untouched. Arwel

has certainly kept his word and all the trees surrounding this noble giant have all been given a protected status.

“Roger lived and breathed forestry” explained Arwel “his knowledge of trees was a pleasure to behold. He knew their common names, Latin names, soil types needed for each tree to grow properly and how to nurture and care for them.”

Whilst establishing the new commercial forest Roger also built up a very successful nursery which sold two to three million trees to private and investment foresters annually. When the tax relief on tree planting ended in 1973, it unfortunately spelled the beginning of the end for the nursery, and it closed almost overnight. Roger was devastated at having to lay off his staff, he managed to keep on one employee who worked well past his retirement age and into his

Arwel Roberts, Manager of Glasfryn Sawmill.

Arwel Roberts, Manager of Glasfryn Sawmill.

eighties helping to look after the young trees that were growing.

By this point, many of the trees were now ready for thinning and North Wales had two good markets for small roundwood.

Anglesey Aluminium, located on the outskirts of Holyhead, was a joint venture between Rio Tinto (a global mining group that finds and processes the Earths mineral resources) and Kaiser Aluminium. They produced 142,000 tonnes of Aluminium each year which was distributed all over the world from the port at Holyhead. The local firm took in thousands of round timber pokers; these were generally cut from spindly trees roughly 1-3” in diameter and around 12’ long. I remember cutting hundreds of these and hand balling them out of the forest. The first couple of feet were inserted into the furnace which helped to burn off any impurities when the Aluminium

was being made. Roger approached Anglesey Aluminium regarding tendering as a supplier but he was turned down as he was considered too small a company. The Forestry Commission was the Aluminium company’s’ main supplier, so Roger sold his pokers to Anglesey Aluminium, but through the Forestry Commission.

One Saturday, the Aluminium firm were in desperate need of pokers and there was no one available at the Forestry Commission. The company contacted Roger and he agreed to help them out if they would allow him to tender for future contracts, this was agreed and the rest as they say is history. This benefited other small forest estates who were in the same boat as Roger had been in and they began to sell their pokers to him to supply to Anglesey Aluminium.

Glasfryn became one of the main suppliers of pokers for Anglesey Aluminium. Roger was also approached by another Aluminium producer who were on a visit from the middle east. They also wanted a continual supply of pokers and were happy to take thicker diameter timber which was easier to locate.

A good source of pokers came from the now obsolete nursery, being grown close together had created a good crop of spindly tall trees.

The pokers can also be attributed to the start of the fencing business. Some of

the trees were a bit too big in diameter for pokers so Glasfryn cut a piece off the bottom. The mill acquired a Cundy Peelerwhich is still at the sawmill and is the oldest working Cundy peeler in existence. Cundy confirmed this themselves who in recognition, completely overhauled the peeler free of charge - a Massey Ferguson tractor and PTO driven McConnel saw bench and started peeling and pointing the posts. They were treated by being immersed in a Creosote bath once seasoned.

The other good market at that time was the Bowater pulp mill at Ellesmere Port which had opened in 1931. The large North American paper manufacturer took small roundwood in 1m lengths and produced almost 60% of British newsprint until its closure in 1980 when it went into administration. Timber loading cranes were in their infancy and most lorries were loaded by hand and double stacked lengthways. Unfortunately, the cost of hauling timber from the Llyn Peninsula to Bowater’s pulp mill meant timber would be sold at a loss so this was immediately discounted.

In the meantime, Roger had increased his foothold and now owned an impressive 800 acre forest. He also restored buildings on the estate. If he hadn’t chosen forestry, he would probably have forged a career as a rural architect as he collected multiple awards for his heritage work.

The poker market dried up

During

Please

when Anglesey Aluminium closed and there was no longer any demand from the Aluminium plants in the middle east.

It wasn’t all doom and gloom though for Glasfryn as the fencing market slowly increased. Roger approached Arwel regarding establishing the sawmill which was financed with the income from the pokers. Arwel smiled again when he recalled this “There had been several sawmills spread around the Llyn Peninsula, but they had all now closed due to cheap imported timber. Roger was undeterred by this and insisted that what the local farming community wanted was top quality fencing materials that would outlast any of the poorer quality imports that were currently available.”

Roger bought a second-hand treatment plant, but to achieve the quality they both required took time and resulted in a more expensive product. At the beginning, the farmers didn’t get the bigger picture and only saw a more expensive product. Hindsight has proven that Roger and Arwel were right to insist on such a high quality product.

Access was a big problem that the duo had to overcome. A local farmer owned the land where the sawmill sits today and he was reluctant to sell. Roger asked the farmer to give him first refusal if he ever changed his mind and that he would outbid any other offers he received. Fortunately, the farmer did have a change of heart and Roger acquired the land.

On our way back to the mill I noticed quite a lot of timber stacked at roadside which was next to a recently clear-felled area.

“We have a forestry contractor, Dylan Taylor, who comes in and does our forestry work for us.” said Arwel “We are fortunate that we always have a good stock of timber seasoning so we can be flexible time wise when it comes to our felling programmes. We are pleased with the work that Dylan does for us, he not only does an excellent job of the harvesting, but he understands the importance of the quality of the wood we are looking for.”

I asked about Glasfryn’s harvesting system “We don’t thin out our trees but instead carry out clear-felling when the timber is around 35 years old. This is an ideal size for us as we get plenty of fencing material and some wood for milling. Fencing is our biggest market, so this suits us best. The type of

ground we have here is quite boggy and soft so we would end up with a lot more premature windblown trees if we started a thinning regime.”

As we approached the sawmill, I saw a lot of poorer quality softwood and hardwood stacked up “Seasoned firewood has become a large part of the business now,” said Arwel, “there are so many people using wood for central heating in their stoves. We had a customer almost in tears a while ago, he had spent a fortune lining his chimney and installing a wood burner and central heating and had bought firewood from a local merchant. He couldn’t get any heat as the fire was just sizzling and kept going out. I asked him if he was using seasoned wood and the look of bewilderment on his face told me everything I needed to know. I gave him a bag of our seasoned wood to try, and he was back the following day beaming from ear to ear. He has

been a regular firewood customer of ours ever since.”

Once back in the sawmill Arwel proudly showed us around. The first thing that struck me was just how tidy everywhere was. I had only given him a days’ notice of my visit, so it certainly hadn’t been done just for me. �� The yard is immaculate, the whole area has been concreted and is kept clean. All the round timber once peeled and pointed is stacked under shelters with open sides to help speed up the seasoning process prior to treatment. No matter where you looked everything was tidy and in its place.

Arwel takes great pride in the fact that the mill has no waste whatsoever, “the peelings are used for children’s playgrounds, gardens and for farm animals in barns in the winter and the sawdust has multiple uses in gardens and farms as well. The pointings from making posts are sold as firewood along with the outside edges when we are sawing boards or square posts,

and rails and rejected timber is recycled to the forestry stack where it will be processed into logs.”

I asked Arwel about staff as I thought being in a rural location getting skilled workers wouldn’t be that easy. “We have been fortunate as we have no turnover of workers, all nine of our staff have been here for years. They get a lot of variation in their work which keeps the job interesting; there are so many different things to do, they never get bored. Most of our staff are from agricultural backgrounds and have been brought up with a can-do attitude. They always find a solution to problems and are hard workers with a good positive attitude.

“During Covid we had to shut down completely” explained Arwel “and we had to put our staff on furlough. We decided the sawmill would make up any shortfall in their wages between furlough and what they usually got.”

With that kind of approach, it’s

no wonder they have a loyal and hard-working workforce!

Although production at the sawmill ceased during Covid, Arwel was still able to assist local farmers with any materials they had in stock. “During the pandemic we only supplied essential materials to regular customers, and we were able to adhere to Government guidelines. Customers phoned the sawmill office, which my wife Olwen manages, to place an order and I would put it together. I would then load it onto their trailers at the entrance with the forklift or drop it there for collection. They paid over the phone with their bank cards.

“It was after Covid we felt the impact, our stock was depleted and we had to start again from scratch. Our reputation is built on supplying quality timber, so we had to delay orders as we waited for our timber to season properly.”

While I was there the peeler

was being used and this wasn’t just one pass through and off for pointing, the timber was being checked for quality, straightness, stress as well as being peeled. If the quality of the bark removal wasn’t satisfactory it was put through again until the operator was satisfied. Once peeled the timber was passed through a band saw and ripped in half or quarters before being pointed. At each of these stages the timber was further checked for stress.

I asked Arwel why they were constantly looking for stress in the wood and he replied “Stressed wood doesn’t take the pressure treatment very well so won’t last as long. What’s the point of doing the job if you are not going to do it right.” he exclaimed.

All the timber is seasoned to around a 28% moisture content prior to pressure treatment, this can take anything from two to five months depending on the climate. Glasfryn have two treatment plants and can have two cycles in each tank each day if required.

Posts ready to be seasoned.

Storage area for seasoning.

Posts ready to be seasoned.

Storage area for seasoning.

Next to the treatment plant is a large, fully equipped joiners’ workshop. A local joiner utilises this space on a part time basis and manufactures finished products which are for sale at the mill, these include stiles, gates, troughs, and garden furniture.

Two classic County tractors with roof mounted Botex Cranes, three Valtra’s one with a roof mounted Botex and trailer, one with a Botex trailer and crane and one with a timber trailer along with an ex-military Valmet with a front forklift loader are used for moving timber and loading the log decks. Just like everything else in the sawmill, the tractors were in excellent condition and very well maintained.

Another area of the sawmill was busy on firewood production, one of the county’s was loading poor quality hardwood timber onto the deck from the Valtra with the timber trailer. It was being cut and split with the large Dalen Firewood processor and then loaded into large

Large, fully equipped joiners workshop.

Valtra with Botex trailer and crane.

Tannalising plant.

Large, fully equipped joiners workshop.

Valtra with Botex trailer and crane.

Tannalising plant.

wooden crates and then stored undercover.

When Arwel isn’t around, his wife Olwen is next in command. Olwen started working on the paperwork when the mill was in its infancy. Roger was delighted with this and soon talked Olwen into joining the team but they agreed that work had to revolve around her and Arwel’s young daughter, who came first every time.

When unsure of anything, it is Olwen the staff go to for advice or reassurance. Again, Arwel laughs “Olwen is completely indispensable, she isn’t just the office manager, you will find her doing almost anything that’s needed in the yard apart from driving the County forwarder.”

Back in 2001 when the foot and mouth disease hit the UK the mill caught the attention of local Welsh TV station S4C. The broadcasting company came to see them about doing a programme on the sawmill for a weekly farming programme as they were not allowed near

farms due to the risk of cross contamination.

Arwel agreed but only if the programme told the full story from the forest to the sawmill and reported the care and attention, that Glasfryn took in manufacturing fencing posts. Filming took a few days and it was aired the following Friday evening. The next morning the phone rang constantly and the office was inundated with orders. The programme had done a brilliant job of highlighting what was involved in growing a tree, right through to producing a seasoned fencing post. Farmers finally understood that buying the cheap posts cost more in the long run, as they rotted after a few years, whereas Glasfryn’s posts exceeded all expectations.

The mill was so busy that it took up to six months to complete some orders. The local farmers were undeterred and happy to wait for such a quality product. The mill eventually got back into a steady rhythm and although they are still very busy the

waiting times from ordering to delivery are nowhere near as long. Fencing is Glasfryn’s biggest market followed by firewood and then sawn timber.

Christmas trees are another good source of income for the mill, people came from far and wide to buy their trees and it is a fun day out for all the family. The fresh-cut to order trees, ensure quality and longevity over the Christmas period, and importantly, are harvested in a way that ensures zero-waste. By not cutting in bulk, Glasfryn doesn’t create an excess of unsold trees – meaning smaller trees that might have been cut down, continue to grow into larger Christmas trees for the following year. Some of the older growth trees that were sold reached as high as 30ft.

Today the complete estate stands at 1,000 acres. Roger Williams Ellis served as chairman of the Welsh Timber Growers Association and was awarded the OBE for his services to forestry. The Royal Welsh Agricultural Society

Valtra with front loader.awarded him the Sir Bryner Jones Award in a ceremony at the Royal Welsh Show in Builth Wells for reaching the highest level of achievement in their chosen sector.

Sadly, Roger died in 2018 aged 94. Since then Arwel and Olwen have done a magnificent job of keeping his legacy alive.

Arwel exudes passion for the sawmill and rightly so as he is the person responsible for making it the successful business it is today. He is also quick to point out how lucky Olwen is, “This has to be one of the best office views in the world” as he points over to Yr Eifl, the mountain range

towering over them. “Not many office managers can boast a view like that from their desk” and I must admit it was hard to disagree.

Arwel has a wry smile when he explained that at one time some people criticised them for their monoculture forestry system. However, a visit from the RSPB soon quashed that. Bird species have been found in Glasfryn forest that the RSPB haven’t seen in a very long, time. The estate is not only a haven for wildlife but is also home to beehives which are beneficial to everyone.

No place was out of bounds on this trip and Arwel was very open and honest about everything to do with the mill. It was a privilege to be given such an insight into the day to day running, the history of the mill and the sense of achievement and pride Arwel has for what they manufacture.

I often hear the saying teamwork makes the dream work, but I’ve never quite seen it implemented as well as in this sawmill. It is a very successful mill, and it has taken hard graft, dedication, and close attention to detail by Roger, Arwel, Olwen and the rest of the team to achieve what they have today.

I grew up in north Wales and have many friends who are farmers. When it comes to purchasing fencing materials there is no one that I know that would go anywhere except Glasfryn Sawmill.

01758 750 623

www.glasfrynfencing.co.uk

Firewood production.on a crane, excavator, timber trailer or telescope stage Woodcracker max. 54 cm max. 127 cm

• Powerful 3-finger-gripper retains the cut material safely.

• Large cutting diameter despite low deadweight

• automatic chain tensioner

The working process is not interrupted by a jumped off chain.

• Sophisticated hydraulic control enables to withdraw parts the tree vertically from its setting.

• Suitable for any standard crane thanks to refined technical features. Only one double-acting hydraulic connection needed.

• Optional: Walking foot for excavators For movement in rough terrain.

Sales of firewood are expected to surge once again this year as more households continue to install wood burning stoves. When I first started out in forestry, firewood was a sideline of contracting and useful for generating extra beer money. There was no market for deadwood and companies were happy for the contractors to remove it and sell it for firewood. Each night before leaving work we would cut the wood with chainsaws and split it with axes, filling both my pickups to deliver on our way home from work.

In the 80’s, council estates and private households had open fires for their source of heating, very few had central heating. Coal was the main source of fuel for the fires and although it gave off good heat, people still liked the flames of a log fire.

Sitka Spruce wasn’t the best wood for an open fire, it burnt well enough but some of the knottier wood sounded like a machine gun going off. Embers would shoot out the fire in all directions burning big holes in carpets and hearth rugs unless you licked your fingers and threw them back into the fire straight away. I missed a great business opportunity as I should have been selling a fireguard with every load. ��

With a loyal and regular customer base we managed to make a few quid in the winter.

This escalated in 1984/85 when the miners went on strike, the UK suffered power cuts and a coal shortage, and we found ourselves suddenly inundated with firewood orders.

Once the country got back to normal, we saw a momentous change, gas central heating was the next big thing and was being installed on council estates. For more rural locations, oil central heating was installed. Although clean air acts were introduced by parliament in 1956 and updated in 1968 it wasn’t until 1993 when a new act was passed that consolidated the previous two acts that prohibited dark smoke from chimneys and industrial or trade premises in urban areas. Our softwood firewood market almost dried up, wood burners became popular, but customers preferred using seasoned

hardwood as it had much better burn properties. The tide shifted from forestry contractors who rarely worked in hardwoods, to tree surgeons who had plenty.

Since the late 90’s firewood has become a colossal market with wood burners gaining a huge foothold in the market, last year alone 1.8 million tonnes of firewood were sold. The days of chainsaws and axes for firewood production have all but passed and been superseded by log decks and processors that load, cut, split, and convey the logs into large bags, trailers, pickups, or lorries.

Processors are available in a multitude of sizes to suit every requirement, from small hand fed units for occasional users to large industrial machines that dispose of large diameter timber with ease. The output

of processors varies according to their size and cost, but small units are capable of around two tonne per hour up to industrial machines producing well over 10 tonne per hour. Most processors offer different log length options and splitting blades for a selection of sizes. There are also options for power sources with either PTO or electric motor options. These can be attached to a tractor’s three-point linkage, on wheels for towing or secured in a yard or building as a static unit. I think if you have good access to wood supplies firewood production is an avenue I would pursue. The initial outlay and the returns make this a lucrative business.

The rules regarding selling

firewood changed in 2021 to help reduce pollution. Anyone selling more than 600m³ of firewood annually must make sure it is ready to burn with a moisture content of no more than 20%. To me this isn’t really an issue as most customers require seasoned timber, so felling in advance and stacking it to air dry is something we would normally do.

Firewood equipment is reliable if used within its limitations and maintained properly. When eventually something does go wrong - with the best will in the world no machine is infallible - the availability of spare parts and technical backup from distributors and mobile engineers gets you up and running in no time.

Once you know what your requirements are it is well worth contacting one of the larger firewood processor distributors with local service centres near you for advice.

Uniforest Titan 43-20 from Fuelwood at a recent open day. This processor is easily capable of producing over 6m³ of firewood per hour.

Uniforest Titan 43-20 from Fuelwood at a recent open day. This processor is easily capable of producing over 6m³ of firewood per hour.

Hiab, part of Cargotec, announces the launch of HiSkill, a cost-efficient training simulator to improve safe and efficient knuckle boom crane operations.

HiSkill uses virtual reality (VR) technology to create a safe and realistic learning environment for operators of HIAB knuckle boom cranes. Operators can learn the basics of crane operation without the risk of personal injury or damage to equipment or the surrounding environment. HiSkill also tracks and analyses operator movements to provide actionable improvement suggestions.

“HiSkill is a game-changer for crane operator training, providing the safest, most efficient and cost-effective learning system on the market. The new training simulator from Hiab is a great tool for any company that wants to improve the safety and efficiency of its crane operations,” says Maria

Lindroos, Director, Digital Services Transformation, Hiab.