millingandgrain.com December 2022 In this issue: Milling and Grain . Volume 133 . Issue 12 . December 2022 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 133 Issue 12 THE OCRIM MILLING HUB “Not just a mill” - The power of additives in feed cutting emissions and boosting business - Effect of protein, starch, fat and fiber in extrusion - Post-harvest grain handling: How careful & efficient processing can help you to maximise profitability

Behlen bins range

silos

wall panel design. COMMERCIAL GRAIN BINS Behlen hoppers are designed to ensure strength, ease of assembly, and trouble-free operation. COMMERCIAL HOPPER TANKS Behlen Steel BUILT TO LAST Behlen Grain Systems... Standing the test of time with competitive prices and Customer Service second to none. CONTACT US TODAY TO DISCUSS YOUR PROJECT! Call 1-402-564-3111 or Visit www.behlengrainsystems.com Bigger and Better than Ever!

in size from 85 to 66,000 cubic meters. These

feature a unique trapezoidal

Pneumatic and mechanical ship (un)loaders Up to 2500 tph for loaders and up to 1200 tph for unloaders. Low noise & no dust emission Turnkey solutions for cereals, soy flour, fertilizer, pellets and more... Handle bulk with efficiency and reliability

PINGLE. PROFESSIONAL MANUFACTURER OF GRAIN MACHINERY ★ INTEGRATED MILLING SOLUTION PROVIDER ★ ISO 9001:2015 CERTIFIED Аdd: Zhengding, Shijiazhuang,Hebei,China Tel: +86-311-88268111 Fax: +86-311-88268777 E-mail:pingle@pingle.cn / www.pinglemachine.com

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

International Marketing Team Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant Shannon Parsons shannonp@perendale.co.uk Niamh Cassidy niamhc@perendale.co.uk

Digital community manager Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com Professor Wenbin Wu wenbinw@perendale.com Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk 0

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager Antoine Tanguy antoinet@perendale.co.uk

millingandgrain.com ISSN No: 2058-5101

VOLUME 133 ISSUE 12 NEWS 10-30 44 The Ocrim Milling Hub 48 The power of additives in feed cutting emissions and boosting business 52 Selecting Performance Analysers to Reduce Waste and Streamline Product Development 56 Pioneering in Postbiotics 60 Effect of protein, starch, fat and fiber in extrusion 66 Can agricultural robots reverse the trends of water resource shortage and climate change? STORAGE 70 Post-harvest grain handling: How careful & efficient processing can help you to maximise profitability 8 PUBLISHER Roger Gilbert 104 INTERVIEW Alberto and Sergio Antolini ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 84 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 22 Mildred Cookson 26 Dr Mahmoud Riyad 30 The Rex Wailes collection FACES 106 People news from the global milling industry TRAINING 35 Industry training news PRODUCT FOCUS 38 CASE STUDY 84 INDUSTRY PROFILE 82 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 December 2022 COVER IMAGE: The Ocrim Milling Hub - see more on page 44 FEATURES

Post-harvest grain handling See more on page 70

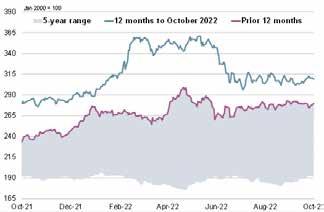

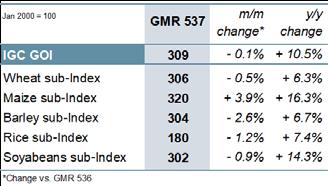

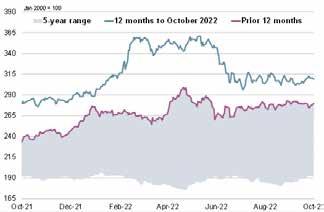

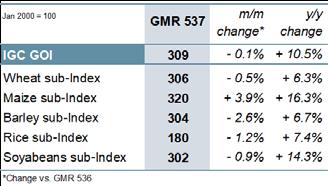

74 MARKETS

Reflecting on what really matters

This is our last edition for the year - December 2022 has come quickly upon us in our busy schedule lives and I’m sure it’s the same for everyone in the milling sector.

The end of year should reflect the past and look forward to a new beginning in a new year of busy and productive times for all of us involved in food production.

During 2022 we have had to cope with the transition from a restricted lock-down scenario to a more unrestricted and normal lifestyle with the challenge of complex travel arrangements and meeting with people, that prior to the pandemic we took so much for granted.

Some of us quickly lost our natural ability to engage with family, friends and strangers as circumstances isolated us while others were desperate to get back into circulation with the view that the virus posed little if any risk to them.

This combination of extremes has gradually moderated over the past 12 months until now, with the end of the year in sight, we feel more equipped to face the challenges of 2023 that includes among other things coping with high energy prices, disrupted logistics, the impact of a war that is shocking supplies of raw materials and an increased requirement to address global climatic changes that threaten many societies if left unchecked.

We have learnt that we should not take anything for granted.

Do we want to work as hard as we did prior to the pandemic? Some do not and would rather not return to the jobs they were doing. Many have sought a change of lifestyle or ‘retirement’ or simply are less motivated than before.

Life is not like it was and it might not return to the ‘normality’ we once knew and trusted and perceived in 2019.

But our industry’s products are still in great demand – flour and the products it produces will never go out of fashion and demand continues to climb.

However, for many on this planet food is not a fashionable item at all and nor is it seen to entertain or be an enjoyable thing to do.

For many it is a necessity where limited income restrict the amount of bread available to feed a community or a family adequately.

It occurred to me on my visit last month to Zanzibar, Tanzania, to attend the 32nd IAOM Middle East-Africa Convention that we have convinced many countries to not only consider wheat flour as a staple in the diets of their populations, but to construct their own flour milling industries. And using all the modern technologies available they have done just that and delivered high-quality, safe and life sustaining food through a wide variety of flour to bakeries at prices that has put this staple at the centre of a country’s meal tables.

It seems poignant that we are now unable to supply wheat to these new country mills, - in a growing number of countries - at prices their ultimate consumer can afford to pay for the breads produced.

In the west we may complain about our fuel and energy prices increasing, but our bread prices are still affordable and still offer us a nutritious staple.

What we must not overlook while enjoying our daily bread is the role and responsibility our industry has in helping to correct the imbalance that has occurred in a way that allows all bread providers, their customers and their family members, to continue to receive what they have come to depend upon.

This is why, in many countries, governments have taken a direct interest in the functioning of our milling industries.

We have already seen in Africa, Middle East and other regions millers who have gone to extraordinary lengths to provide flour to consumers. Long may we hold dear the idea that we support the production of safe, high-quality and affordable foodstuffs that is available to all.

As we are entering the season of goodwill we should expect our industry to be among the first to assist when mills need wheat and food is needed.

In this edition

From the comments I’ve received from meeting millers and suppliers to the trade events around the world, 2021 was a successful business year for most however 2022 did not live up to expectations.

We’ve covered many of the reasons in this edition and previously. While we close the year with a full and diverse edition of Milling and Grain we want to wish all our advertisers, supporters, writers and readers a most enjoyable festive season when it comes and we look forward to serving you in 2023. From our base in the UK we wish you all a Merry Christmas and a Happy New Year.

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information

and Grain has a cooperative partnership with COFCOET

www.millingandgrain.com http://gfmt.blogspot.co.uk Milling

and use the Promo Code ZANZIBAR22 This offer entitles you to a 12 month digital subscription to Milling and Grain magazine on our app and desktop versions. This offer is on a first come first served basis and will run until 01/12/2022 Would you like a complimentary digital subscription to Milling and Grain magazine? Simply visit: https://store.magstand.com/millingandgrain

Roger Gilbert

The Commercial Director of OMAS of Italy, Pietro Barbalarga, was interviewed by Roger Gilbert, the publisher of Milling and Grain magazine as part of the review of the exhibition area associated with this year’s 32nd International Association of Operative Millers for Middle East and Africa (IAOM MEA) 2022 in Zanzibar, Tanzania in late October.

There were some 150 companies and 80 exhibition stands in the heat of this coastal city on the island of Zanzibar where temperatures were in the low to mid 30s. That did not stop companies such as OMAS promoting its ‘second version’ Leonardo milling unit to an audience that was receptive to newer technologies entering the East African market in particular.

The interface for the machine, for example, is being evaluated by an independent international committee of software technology as it demonstrates several advanced features that are not just applicable for the milling industry but for all software development. Not only saving on energy but also gaining more that 15kg of yield from wheat processed through a scrubbing process that removes the ‘raincoat’ protecting grains.

Listen to the full interview on our website at MAGTV or via our YouTube channel: www.youtube.com/@ MillingandGrain

Welcome to the December edition of Milling and Grain magazine, along with the twelfth and final edition of the Global Miller column for the year! I hope that all of you readers are happy and well prepared for the New Year and entering 2023.

Temperatures are dropping in the Northern hemisphere and costs are rising in the UK, so people here are having to choose between whether they want a fancier Christmas or a warmer house this season. For me, as long as I can stay warm with a nice cup of tea, I’ll be as happy as ever this holiday season.

This is also the season for farmers in the colder regions to begin preparing and reassessing their plans for the year. Checking for equipment repairs and maintenance, soil management, ensuring the livestock is prepared for the cold temperatures and more. Plans for farming in 2023 will be well underway, so the use of crop covers and ploughing in preparation will be the key activities for farmers for the next few weeks.

The Southern hemisphere will be heading right into summer though, unlike us Brits. They’ll be working hard to cover any of the shortfalls created in the grain industry caused by the Northern hemisphere due to the seasonal changes.

Back in the UK though, we have officially fallen into a recession due to higher energy prices, the conflict in Ukraine, Brexit, and inflation. The mini budget set up by former PM Liz Truss did not help the country much, so now it is the autumn statement's turn to rescue Britons from the financial crisis. At least we don’t have to worry about the Christmas presents because Santa Claus provides them for us – oh wait…

As for a sneak peek into the news around the world though, COP27 was held in Egypt last month which we’ll cover more on, along with New Zealand’s lamb farming carbon footprint and two Malaysian millers being recognised for their outstanding results in the UK Flour Millers course, earning them both medals for their work. All of this exciting news and more can be found in our news section of this magazine or on our website.

Discussing the world a little more, this month there aren’t many events to report on with people preferring to spend the holidays with their families. This doesn’t stop Milling and Grain though, as we have a report ready to read from our team who attended IAOM 2022 in Zanzibar, Tanzania. We have also prepared some information about the events in January next year, so now you can rest assured that you’ll be starting the year off well informed.

With the New Year coming in and resolutions being made, why not start something new and get your company’s name and products in our magazine. Your company could be shared around the world and in multiple languages, both online and in print. We offer amazing flexibility and value with our packages, plus free editorial, so don’t be afraid to get in touch.

If you have any interest, email editorial@perendale.co.uk

gfmt.blogspot.com

more videos from all aspects of the industry at millingandgrain.com/videos

NewsMilling

See

10 | December 2022 - Milling and Grain

www.balaguer-rolls.com Facebook Youtube Linkedin

TO BOOST YOUR PROFIT

LATEST TECHNOLOGY

Mühlenchemie improves baking with composite flour

Flour treatment specialist Mühlenchemie has developed a new series of enzyme-based products that improve baking results with composite flours. These solutions allow replacement of up to 20 percent of the wheat with alternative raw materials, without losses in quality. This enables the use of locally available grains and reduces dependence on global raw materials markets. The 'Compozym' toolbox is available for numerous applications and flours and is being extended for further uses.

Rising grain prices and varying market availability have hit the milling and baking industry hard. In particular, import of the wheat used for many baked goods increases the cost pressure on companies. So mills are looking for ways to make their raw materials sourcing less dependent on the global wheat market. One way to achieve this is to use composite flours made of wheat and other crops, such as maize, cassava or sorghum, which are grown and available locally in many parts of the world. With Compozym from Mühlenchemie, these crops can replace up to 20 percent of the wheat without impairing quality. The use of regionally grown grains or other crops makes it possible to efficiently manage raw materials fluctuations and shorten supply chains. Reverting to local suppliers not only supplements wheat imports, but also opens up the possibility of marketing innovative and more sustainable products made of composite flour.

Solutions for optimum baking results with composite flour

Reducing the proportion of wheat flour and adding other flours changes the properties of the flour, dough and final baked goods. This can result in reduced volume, lower stability and shorter fresh keeping, as well as differences in the colour and/or surface structure of the final products. With the Compozym enzyme series, bakers can compensate for these effects and get the same results as

with pure wheat flour. The toolbox consists of intelligent, state-of-the-art product solutions, including complete solutions for tin loaves like sandwich bread, freestanding breads like baguettes and fino, and flatbreads like parotha and chapati. The toolbox also offers products to address the special requirements of composite flour, regardless of the application. Among these are solutions that provide better water absorption during dough production, improved stability during fermentation, and longer freshness and softness. All the solutions can be used in a variety of composite flours.

The new Compozym product line was developed based on extensive analyses in Rheology and subsequently in the baking laboratory and has been tested and refined with a wide variety of flours and applications. “Our development work continues, and we have further MC product solutions in the pipeline,” says Mühlenchemie Product Manager Greta Reers. “We're expanding the Compozym line to address additional applications and are continually adapting it to market conditions."

Long experience, innovation and local knowledge

Mühlenchemie is in close dialogue with over 2000 mills in more than 150 countries. In recent years Mühlenchemie has steadily expanded its capacities for applications research in local markets. Today, experts in Germany, Mexico, Singapore, India, China, Russia, Kazakhstan, Turkey, Kenya and Nigeria assist mills locally with their own laboratories. Thus, Mühlenchemie technicians are familiar with the latest requirements of the mills, what raw materials are on the market, and how to process them for which results. This knowledge is bundled at the central 'Futuremaker' Stern-Technology Center in Ahrensburg, Germany, where over 100 scientists and applications technologists work on tailormade solutions to meet the requirements of the worldwide milling industry.

12 | December 2022 - Milling and Grain Milling News

Global animal agriculture faces a ‘barrage’ of crises

The global agricultural industry faces “a barrage of multinational crises,” says EuroTier Chief Executive, Dr Lothar Hövelmann

Speaking at an opening press conference on the eve of the opening day. He expressed the view that events such as EuroTier were essential now that the pandemic is receding, saying there is no substitute for direct-dialogue and meeting face-to-face.

Dr Hövelmann’s ‘barrage of crises,’ includes international trade challenges, feed price increases, the outcome of the pandemic and the interruption to supply chains all directly impacting global livestock production. But he remaines positive that energy prices for example and animal feed prices will return to more normal levels in the medium term.

He also added that changes to climatic conditions is adversely impacting the industry, in addition to world agriculture being “overshadowed by the war in Ukraine.”

The issue of climate change is ongoing, and Dr Hövelmann states it “has to be managed through international agreements” although the need for an international platform, such as Eurotier, to provide a key catalyst for tackling these issues is essential.

In food production, animal husbandry is an integral part of agriculture and these two areas cannot be separated from each other. Meat, milk and eggs are fundamental, and will remain so for a very long time, he added. He went on to say that animal agriculture needed to transform itself as it struggles to find solutions to current challenges.

African Swine Fever and Avian Influenza present familiar

problems, and the industry needs to find solutions to minimise their impact, he says.

Innovation has always been a key aspect of the EuroTier event and in preparation for this year’s event, it carried out a survey of 2000 industry experts from farmers to equipment suppliers to consultants to identify trends in agriculture.

In Dairy farming for example, the survey revealed trends towards greater automation in the provision of feeds, milking equipment and floor cleaning in addition to the use of sensors to monitor herd management, animal welfare and health. Monitoring individual animal behaviour can no longer be done by farmers using their eyes only, he says.

In Pig farming, the survey shows that trends pointed to improvements in biosecurity and hygiene, pigsty conditions, climate, welfare and data management which is important in supporting decision making. The issue of reducing the use of antibiotics was also noted, as there is a growing importance to look at ways of reducing their use.

The survey also showed a clear trend in labour shortages on farms globally.

While farmers have experienced their businesses under pressure, the majority are still willing to make future investments to improve in areas such as buildings and renewable energy.

In summary, Dr Hövelmann says the key points arising from the survey show that: diary farmers want to adopt more digital solutions; pig farmers are more focused on equipment, welfare and hygiene and the poultry industry is currently looking to build and adopt more renewable energy sources.

Milling and Grain - December 2022 | 13 Milling News

£1.5M crop research centre opens at University of Warwick

Afacility using gene-editing technology to improve quality, resilience and sustainability of vegetable crops has opened at the University of Warwick.

The Elizabeth Creak Horticultural Technology Centre (ECHTC), which also contains The Jim Brewster Laboratory, is a UK£1.5 million facility which will use cutting edge techniques such as gene-editing to improve vegetable crops. Addressing issues relating to disease resistance, crop yield, adaptability to climate change and nutritional value in horticultural plants, the research will help with the key global challenges of climate change and feeding the world's growing population.

The new Centre, funded by philanthropic donations from the Elizabeth Creak Charitable Trust and the estate of Jim Brewster, who was a research scientist at the former National Vegetable Research Station in Wellesbourne, adds to Warwick's world leading expertise in crops and plant breeding.

The ECHTC is part of a suite of facilities for research and technology in horticulture at the University of Warwick. Warwick already has responsibility for conserving genetic

diversity of vegetable crops through world-leading collections of carrot, lettuce and onion seed, and joint responsibility for brassica collections hosted by the UK Vegetable Gene Bank (UKVGB) at the University's Wellesbourne Campus. The creation of the ECHTC will help further plant scientists' understanding of a range of questions about plant growth and continue to harness the rich resources of the UKVGB.

The Centre will also train future research scientists in vegetable tissue culture and gene editing techniques, with Jim Brewster Scholarships awarded to PhD students working in the area of crop science.

Murray Grant, the Elizabeth Creak Chair in Food Security at the University of Warwick, comments, “With food one of the top issues on a global agenda, and in the year that the Genetic Technology Bill is going through the UK Parliament and opening up our ability to use gene editing technology, we have a pressing need to grow and harness skills and expertise to help us improve food systems, adapt to changing environments and help solve growing global problems.

“Researchers at the Elizabeth Creak Horticultural Technology Centre will be applying precision genetic editing approaches to key UK horticulture crops to improve disease resistance, enhance nutritional value and increase resilience to climate change. Aside from increased yields, there are significant environmental benefits to be gained by growing crops with reduced needs for pesticides and water.”

Miriam Gifford, Head of the School of Life Sciences at the University of Warwick, adds, “We are delighted that these generous gifts have been used to establish a new research centre and student scholarships here at Warwick.

… because that’s what we do, too. On every single FILIP cleaner, we monitor every detail throughout the entire manufacturing process. We know that our proven quality will guarantee effective sieve cleaning within your plansifters. And that, in turn, will ensure a high yield from your passages.

Efficient. Quality. Cleaning.

The impact of the Elizabeth Creak Horticultural Technology Centre will be far reaching. It will accelerate the translation of mankind's understanding of plant productivity and responses to stress into resilient and more sustainable crop varieties. The Jim Brewster Scholarships will provide a PhD student with a muchneeded annual top up award that will help fund expenses such as travel to conferences.”

FILIP

Telephone: +49 (0)5241 29330 • Telefax: +49 (0)5241 20321

info@filip-gmbh.com

Paul May, a trustee for the Elizabeth Creak Charitable Trust and Elizabeth Creak's nephew, says, 'Innovations in farming and horticulture were so important to Elizabeth, who was Warwickshire's first female High Sheriff and ran a 2000 acre dairy farm in the county. I'm proud the centre established in her name will continue her legacy and address the important global challenge of food security.'

GmbH • Müllereibürsten • Anemonenweg 4 • D-33335 Gütersloh

E-mail:

• www.filip-gmbh.com SIEVE CLEANERS

14 | December 2022 - Milling and Grain Milling News

Growing Into Performance.

Better than the human eye, Cimbria sorting technology is the most advanced and reliable solution to meet the high quality standard of the grain and seed processing industry. The use of the ultimate Full-Color and infrared high-resolution cameras ensures the total removal of any foreign body like stones, wood and glass, as well as the best separation of non-conforming or unwanted grains. Great purity, optimized yield and food safety are so granted by Cimbria optical sorters. Growing into performance is easy and effective, thanks to the extraordinary technology signed by Cimbria.

Cimbria.com Cimbria Srl Imola, Italy Tel +39 0542 361423 seainfo@agcocorp.com INNOVATIVE OPTICAL SORTING SOLUTIONS. Intuitive and Fast Program Setting Full-Color & Multispectrum

Research confirms the carbon footprint of New Zealand beef and lamb is amongst the lowest in the world

The comprehensive study by AgResearch has found that a kilo of New Zealand sheepmeat has a carbon footprint of just under 15 kilograms (kgs) of CO2 equivalent emissions per kilo.

Meanwhile, the carbon footprint of New Zealand beef is just under 22kgs– making the country's red meat among the most efficient in the world.

The researchers, which compared New Zealand's on-farm emissions to a range of countries' footprints across the globe, concluded that when New Zealand beef or sheepmeat is exported, the total carbon footprint is lower or very similar to domestically produced red meat in those nations. This is because New Zealand is so efficient at the farm level, which represents about 90-95 percent of the total carbon footprint. New Zealand's on-farm footprint was about half the average of the other countries compared in the study.

Based on the research, an analysis by B+LNZ and MIA shows eating red meat 2-3 times a week over the course of an entire year is just under the carbon footprint of a single passenger's return flight from Auckland to Christchurch.

The Life Cycle Assessment (LCA) study was commissioned by Beef + Lamb New Zealand and the Meat Industry Association of New Zealand (MIA). As the world's second biggest exporter of lamb and one of the largest beef exporters, sustainable farming is a critical part of the country's red meat sector strategy. The LCA was calculated using the standard GWP100 approach for converting methane to carbon dioxide equivalent to enable valid international comparisons.

AgResearch scientists also measured the carbon footprint of New Zealand beef and sheepmeat using an emerging approach known as GWP, which determines a carbon footprint based on a product's actual contribution to the warming of the planet over a period of time rather than total emissions.

The Intergovernmental Panel on Climate Change (IPCC) has found that the traditional GWP100 method overstates the impact of methane when this gas is not increasing, as is the case in New Zealand. The calculation using GWP for the period 1998 to 2018 showed that when taking into account sequestration-trees and other vegetation on farms absorbing emissions-New Zealand's sheep meat is arguably 'climate neutral' and New Zealand beef is also well on the way towards that.

That means over the last 20 years, New Zealand sheep meat has not added any additional warming. Absolute greenhouse emissions from New Zealand sheep and beef farming have decreased by 30 percent since 1990.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic millingandgrain.com

Milling and Grain - December 2022 | 17 Milling News

Infarm successfully demonstrates the potential of indoor-grown wheat

Leading vertical farming company Infarm and co-host of the Food Systems Pavilion at COP 27 has successfully produced wheat in an indoor farm, using no soil, no chemical pesticides and much less water compared to open field farming. Infarm is the first vertical farming company to tackle staple crop production in a controlled environment. The first trials demonstrated exceptional results, allowing a projection of 11.7 Kg per m2 yield per year. Further projected at scale, this is the equivalent of 117 tonnes per hectare per year - 26 times that of open-field farming yields. This production is independent of external climatic conditions and is thus genuinely climate resilient. This is an important milestone, as climate impacts worsen, in providing staple food in a controlled environment.

Guy Galonska, CTO and co-founder of Infarm says, “To continue to feed the world's growing population, we need to achieve higher crop yields which we have now proven to be possible for wheat through indoor, controlled environment agriculture. Our results are significant when compared to the average yield of outdoor wheat production, which is about 4.5 tonnes per hectare per year and heavily dependent on weather and seasons. We are confident that wheat can be grown successfully at scale indoors as a climateresilient alternative. Our record yield could potentially be increased by a further 50 percent in the coming years using a combination of improved genetics, hardware, and optimised growth environments.”

Erez Galonska, CEO and co-founder of Infarm says, “Being able to grow wheat indoors is a milestone for Infarm and of significant importance for global food security, as wheat is a calorie-dense but resource-intense crop that is a core component of diets worldwide. We started Infarm to find new ways of producing food to feed the world's growing population and the results show that we are a big step closer to achieving this goal.”

Wheat provides much of the global population with its daily energy requirements and is a significant source of protein, accounting for almost 40 percent of daily protein intake in some regions. Wheat is grown over a larger area than any other crop and due to a destabilised environment, the yield per hectare is expected to decline. To continue to feed the world's growing population it is necessary that we need to increase wheat yields which is now possible through indoor, controlled environment agriculture.

Milling and Grain - December 2022 | 19 Milling News

Double medal success for Malaysian students in UKFM distance learning course

Two Malaysian millers have been recognised for their outstanding results after completing the worldwide distance learning programme run by UK Flour Millers. Senior production engineers Yasmin Sholikhin, 29, and 28-year-old Cheang Jia Man were awarded silver and bronze medals respectively.

The pair, who work at the Malayan Flour Mills (MFM) plant in Johor State, successfully completed all seven modules over the course of five years and were presented with their medals by the firm's managing director Teh Wee Chye earlier this month. And both said the programme – which covers all aspects of the milling industry – will stand them in good stead for long and successful careers.

“Even though we are thousands of miles away, UK Flour Millers' distance learning programme has allowed us to learn about sectors of the industry we don't come across in our current roles,”says Ms Sholikhin, who has been with MFM for seven years.

And Mr Jia Man says, “It is hard work, but the programme is very informative and tutors are very helpful. I am planning to travel to work in our plants in Indonesia and Vietnam, and this will help me a great deal.”

MFM is regarded as a pioneer in the flour milling industry in Malaysia. When the Perak plant was opened in 1966, the country's prime minister described it as the 'pride of the nation'. Designed and fitted by English company Henry Simon Ltd, the plant is located on a natural deepwater harbour, allowing deliveries of wheat from all over the world.

Plant manager Jimmy Okristian says, “We are all extremely proud of what Yasmin and Cheang have achieved through their hard work. They are a wonderful advertisement for the flour milling industry in Malaysia.”

UK Flour Millers' courses are studied by hundreds of students around the world and lead to the Advanced Certificate in Flour Milling. The modules cover every aspect of flour milling, and students are not required to have any previous qualifications.

For each module, students are allocated a tutor experienced in the operation and management of flour mills, providing them with expert assistance in their training. They also have access to the Virtual Mill, an online resource which enables students to engage with scenarios in 'virtual' milling environments.

UK Flour Millers director Alex Waugh says, “Yasmin and Cheang are to be congratulated on their achievements, and for their hard work in successfully completing the course.Their success is an indication of the reach and effectiveness of the distance learning course, and I hope they prove to be an inspiration for all of our students, wherever they happen to be in the world.”

Milling and Grain - December 2022 | 21 Milling News

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

Aprevious article in “The Milling World” formed the basis for a description in “The Miller” of 1 August 1881 of the Deseronto roller mills, and I thought it of sufficient interest to summarise here.

The mill was in the then littleknown village of Mill Point in Ontario on the site of a comparatively small sawmill. The sawmill, originally erected and operated by H B Rathburn and his son, had grown significantly, supplemented by machine shops, planning mills, cedar mills, and stave mills. Shipyards, extensive warehouses, substantially constructed docks, lines of sailing and steam vessels were also necessary for the expanding business which father and son were developing.

The flour mill, rebuilt and remodelled in 1880 by Mr Rathburn, was supplied with Manitoban wheat by an iron screw conveyor which passed into the mill on the third floor. About 65 feet west of the mill was a bran and flour warehouse, 40ft x 60ft, and 45ft high. The upper portion was used for the storage of bran, and had a capacity of 400 tons, whilst the lower portion was intended for a flour warehouse, with a capacity of 1,800 - 2,000 barrels.

The mill was a substantial stone structure 45ft by 70ft., four storeys in height, each ranging from 12 to 16 ft high. The engine house, also of stone, was 40ft x 40ft and situated at the north end

of the building. To the south or rear of the mill, on the waterfront, was the elevator entirely sheeted with iron 50 x 60ft and 45ft high. This was surmounted by a cupola 22 ft high.

On the first floor, which was level with the dock, a large room featured immense timbers supporting the heavy machinery above, and the main line shaft. This ran from the engine room with counter shafts extending and driving the twelve sets of corrugated and smooth rollers on the second floor as well as other machinery There were two smut machines and two flour packers, the packing chest extended from the first to the fourth floor having a capacity of 120 barrels.

In the grinding room an elevated platform held twelve sets of rolls and three pairs of stones. Eight sets of rolls were of the ‘Stevens’ corrugated type, the remainder were smooth rolls. The first three sets of rolls had little wire scalping reels for removing what little flour was produced during these three breaks. These effected a perfect splitting of the berry lengthwise, through the crease. This liberated the germ whilst not cutting the bran; the second break reduced these halved portions of the berry in size, producing little flour but a considerable quantity of middlings. This product, like the first passed to a scalping reel, and the tailings passed on for further reduction to the third roller mill, the product of which was also scalped. The products from this were wholly bran, which was sent to the bran rolls where every particle of flour was loosened and could be readily bolted or scalped out. The middlings produced by the first three reductions

by Mildred Cookson, The Mills Archive, UK

The Deseronto Flour Mills, Canada

Engraving showing the front view of the mill

22 | December 2022 - Milling and Grain

after purification went to the two pair of 4ft millstones for final reduction. A third run used a 3ft Munson mill for grinding corn. The mill at the time of the article had the capacity for turning out 250 barrels of flour every 24 hours.

A series of elevators passed up through various parts of the building and the main drive belt, 13 inches wide, enclosed in a neat box on each floor, extended through the various floors to a

counter shaft on the fourth and drove three lines of shafting which ran the whole length of the mill.

On the third floor there were three bolting chests running from the third up through the fourth floor. The three chests contained 24 reels. On this floor were also two large middling purifiers. The wheat was received into bins on this floor by means of an iron conveyor from the elevator. On the fourth floor were four

Section of the mill

Detail of the Stevens patent

IF YOU THINK YOUR FEEDMILL COULD RUN FASTER... >YOU’RE PROBABLY RIGHT Here at Anderson Feed Technology, we believe that building a successful feed milling operation is about more than just a building. With a combined 200 years-plus milling experience, we help you build efficiency into your entire process – unlocking more from your existing assets. In fact, our popular Feed Milling Health Check is proven to realize improvements of 10-20% for customers. So why not contact us to arrange one or visit our website to learn more. >www.andersonfeedtech.com/healthcheck Milling and Grain - December 2022 | 23

illhead from Munson Bros, manufacturers of portable mills

SEFAR NYTAL ® . The name you can trust. Since 1830, Sefar is the single-source supplier to millers for all products for sieving, grading, and dust filtration as well as connector sleeves, sieve cleaners and tensioning equipment. FOOD SAFETY FDA COMPLIANT Headquarters Sefar AG Hinterbissaustrasse 12 9410 Heiden – Switzerland Phone +41 898 57 00 filtration@sefar.com www.sefar.com As your trusted supplier of precision woven fabrics, Sefar is proud to introduce our newest complimentary innovation: SEFAR NYTAL® Sieve Cleaners

middlings purifiers, the bolting chests and two Sturtevant fans. The fans blew the fine and coarse bran through a five-inch iron pipe into the bran house. On the top of the mill was a dust room 33ft x16ft. into which the dust from the mill was gathered, brought back into the reels and the flour separated from the bran. The walls throughout the whole mill were plastered and calcimined. (a wash of white or pale blue suitable for walls and ceilings). All spouts and woodwork were painted a pure white

with blue relief lines, whist all the iron work was well painted or polished.

As everything depended upon the reliability of the motive power, the engine room was well described. Its polished and burnished fittings and clean appearance indicated that the person in charge had a pride in his work and surroundings. The steam was generated in two steel boilers, 14ft long by 5ft diameter. The engine was of the ordinary slide valve type, with an 18 x 30 inches cylinder, and could develop 175 horse power. The fly wheel was 12ft diameter, making 96 revolutions per minute and transmitted its motion to an 8ft wheel on the main shaft by means of a 24inch belt. Steadiness of motion was essential for a uniform product and the main shaft was fitted with a motion indicator which at once notified the engineer if an increase or decrease in speed was needed.

Direct communication by rail with the outer world was assured by means of a 3-mile branch line, which made direct connection with the operators of the Grand Trunk Railway. The article credited Messrs. Jno. T. Noye & Sons and Mr. Ira Westcott, their superintending millwright for this successful mill using the Stevens system. John Stevens was born in Wales in 1840 before moving to Canada at an early age. In 1859 he began work in flour mills. In 1874 he developed the roller mill process on which his patent was issued in 1880.

www.millsarchive.org

Milling and Grain - December 2022 | 25

The Stevens Roller Mill

Anthony F. Raimondo, Chairman Emeritus, Behlen Mfg. Co, passes away

Anthony F. Raimondo, 83, of Columbus, Nebraska, and Lakewood Ranch, Florida, died Wednesday, November 9, in Lakewood Ranch, Florida.

Anthony F. Raimondo 'TR' was born on July 24, 1939, in Buffalo, New York, as an only child to Carmela (Turchiarelli) and Felix 'Phil' Raimondo. TR graduated from South Park High School in 1957, where he met the love of his life, Jeanne English. TR and Jeanne dated until their wedding on August 27, 1960.

TR attended Michigan Technology University, receiving his BSME in 1962, while Jeanne worked as an AT&T switchboard operator. After completing college, TR took a job with General Motors and moved back to Buffalo, New York. In 1969, TR left GM and started at Moog, an aerospace company. TR received his MBA degree from the University of Rochester in 1972.

In 1976, the Raimondo family moved to Omaha, Nebraska, when TR took a job with the Sperry Corporation as General Manager of Vickers. They eventually found their way to Behlen Mfg. Co. in Columbus, Nebraska in 1982, when TR started as a General Manager for Wickes Corporation. In 1984 TR led a management buyout with Richard Casey, Stephen McGill, and Bob Theilen, as Behlen experienced major losses due to market changes, and Wickes emerged from Chapter 11. TR went on to lead a successful turnaround of the company. Behlen currently has six manufacturing facilities across the United States and more than 1080 Partners in Progress (employees). Today, the Raimondo family owns Behlen Mfg. Co., and they are committed to growing the company and supporting the Columbus community.

TR and Jeanne had four wonderful children: Philip, Tony Jr., Linda, and Diana. TR and his family are proponents of lifelong learning as all four children, and TR hold Master's degrees, and Jeanne even earned a Bachelor's degree at age 60! TR had uncompromising core values, extraordinary leadership skills, a strong spiritual foundation, and enjoyed travelling around the globe

for business and fun. Family, faith, and love were of utmost importance to TR and Jeanne.

TR was the beloved husband to the late Jeanne for nearly 59 years; devoted father of the late Philip M. Raimondo (Mary), Anthony F. Raimondo, Jr. (Sharon), and Linda C. Bock (Tom), all of Columbus; and Diana J. Raimondo of Chicago, Illinois; loving grandfather of Rachel Hays (Brandon), Matthew Raimondo (Kayla), Nicholas Raimondo (Katy), Patrick Raimondo (Kayla), Natalie Raimondo, Kellen Raimondo, Leo Raimondo, Cody Myers (Robyn), Paxton Myers, Tanner Bock (Lily), Tayler Bock (Amanda), Nahom 'Enzo' Montalto, as well as the late Luca and late Santino Luca Montalto. TR was the proud great-grandfather of Henry, Emma, Colin, Emersyn, Madeline, Sophia, Lennon, Lyla, Tucker and Turner.

TR joins his wife, Marion 'Jeanne' English, his mother, Carmela Turchiarelli, his father, Felix 'Phil' Raimondo, as well as his eldest son, Philip Raimondo, in heaven.

TR's Legacy

During TR's tenure at Behlen Mfg. Co., retiring as Chairman Emeritus in 2019, TR held Government, National, State, and Community Board positions, earning several distinguished awards. Not to mention competing on the national circuit in his favorite sport, handball - winning his last doubles tournament at the age of 81, with his handball partner, Lyle Burbach.

Of TR's many accomplishments and awards, notable Awards include National winner of the Inc. Magazine, Turnaround Entrepreneur of the Year (1994), Nebraska Business Hall of Fame (1999), Nebraska Workforce Development, Distinguished Leadership Award (2001), Top 100 Training Award - Behlen Ranked #74 in Training Magazine (2002), Aksarben Court of Honor – Business and Industry (2003), Grand Marshal Aksarben River City Roundup (2009), Hall of Fame – Harvard Cup Football, City of Buffalo (2011), Columbus Region Business Hall of Fame (2012).

TR's numerous Board Positions included: Chairman – Nebraska Advanced Manufacturing Coalition,

NAMC (2006-2022), Steering Committee – Blueprint Nebraska (2018-2020), Director NAM (National Association of Manufacturers) (19982018 | Chairman Small Medium Manufacturers 2003), Trustee of the Manufacturing Institute (20062019), Director Nebraska Chamber of Commerce (past Chairman) (19902019), Director Federal Reserve Board, Omaha Branch, Kansas City District (past Chairman) (1997 –2004), Board of Policy for Peter Kiewit Institute (PKI) (1996-2015), Director MBMA – Metal Building Manufacturers Association, Chairman (1996) -- Member UNMC Board of Counsellors (2006-2012), Teammates State Advisory Board (1996-2003) TR held several Political Appointments, including a run for U.S. Senate in 2008. In 2004, under President Bush, TR was selected as first ever Manufacturing Czar –Assistant Secretary of Commerce for Manufacturing and Services (but withdrew due to Presidential politics).

Governor Appointments included: NE Department of Labor Unemployment Insurance Advisory (1996-2006), Department of Labor Worker Training Board (1996-2006), Chairman Nebraska Economic Development Commission (1994-2003), Director, Nebraska Industrial Competitive Alliance (1996-2003)

Besides Handball, TR enjoyed golfing with friends, business partners, and Jeanne, watching Yankees baseball, travelling, and having a glass of wine by the pool watching the sun set in Florida with friends.

TR's favourite quote was as follows: "People do not care what you know, until they know that you care!' He made each and every one of us better. And for that, we are grateful.

26 | December 2022 - Milling and Grain Milling News

MILLING MORE

COMPLETE

R O L L E R M I L L We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

YEARS IN

THAN 400

PROJECT PERFECTLY RUNNING AROUND THE WORLD

Ukraine Agri export crosses quarter of a billion tonnes

Ukraine has exported more than 26 million tonnes of agricultural products since the beginning of the war. These are cereals, legumes and oil crops. Of these, over 5.5 million tonnes of wheat, over 10 million tonnes of corn, 2.4 million tonnes of rapeseed, two million tonnes each of oil and sunflower seeds.

How farmers finish this season and what support programs for agricultural producers is implemented by the Government – says the First Deputy Minister of Agrarian Policy and Food of Ukraine on the air of the informational marathon on UA First.

According to him, during the eight months of the war, it was possible to achieve good export figures.

“The least number of exports occurred in the first months of the war, then exports gradually increased. But during this period, the potential of approximately 15 million tonnes was lost. That is, during this period in peacetime, we could export about 40 million tonnes in total,” says Taras Vysotskyi.

Despite all the difficulties, farmers continue to work on their front. To support them, a number of programs have been introduced that allow agricultural producers to work,

at least covering the cost of work.

“This is the 5-7-9 affordable lending program, which has been extended for another year. These are loans in hryvnia, almost at zero percent, when the cost of the loan is compensated by the state. A program is also being implemented to pay the smallest agricultural producers per hectare of cultivated land. Within the framework of grant support, 900 million hryvnias have already been paid to farmers who cultivate up to 120 hectares or keep up to 100 cows. Grants for the development of horticulture and greenhouse farming have also been launched – 70 percent of the funds are covered by the state. So far, 50 applications for gardens and four for greenhouses have been approved. In total, more than UAH 250 million have been allocated for this,” says the Deputy Minister.

The problem of grain storage is also being solved, including thanks to humanitarian aid from FAO and other international partners. Thanks to this assistance, six million tonnes of bags for temporary grain storage were purchased.

“Now these sleeves are actively distributed, 30 percent of farmers have already received the means. The situation with grain storage is not critical, there is no shortage of containers for storing the crop,” Mr Vysotsky emphasises.

Precise weighing and clean filling of valve bags – up to 2000 bags/h each 25 kg.

Contact: Phone: +49 251 9796 252 E-mail: sales@behnbates.com www.behnbates.com

A HAVER & BOECKER Company

OUR ROTO-PACKER®

28 | December 2022 - Milling and Grain Milling News

Windmills of Finland

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

Rex Wailes’ love of windmills led him to travel extensively through many countries, recording the varieties of mill he found. His journeys across Finland led to him amassing over 1200 photographs of Finnish windmills. The main types of windmills common in Finland were similar to those in other countries but with a few variations.

Varvasmylly – ‘toe mill’

The varvasmylly or ‘toe mill’ is the Finnish name for what in England was called the ‘post mill’. This is the oldest form of windmill in Europe and was very common in Finland. It consists of a mill body containing the mill stones, which rotates around an upright wooden post to face the wind. A tailpole is used to turn the mill. Finnish ‘toe mills’ were characterised by vertical timber panels with four equal sides and usually contained two pairs of heavy millstones.

Harakkamylly – ‘magpie mill’

The harakkamylly or ‘magpie mill’ was similar to the ‘toe mill’, but with a hollow central post through which the power of the sails was transmitted into the base. This meant that the machinery and stones could be housed in the base instead of in the upper part that was turned to the wind. A long tailpole which could be moved into a horizontal or sloping position was thought to resemble the tail of a magpie, hence the name. A variant in South Bothnia was named after the kanahaukka, the northern goshawk.

Mamsellimylly – ‘mademoiselle mill’

The mamsellimylly is the type of mill known in English as a ‘smock mill’ from its resemblance to someone wearing a smock – the Finnish mamselli is from French mademoiselle, indicating a resemblance to a woman in a dress. This mill has a fixed body almost exclusively constructed of weather-boarded timber, and a moveable cap. The caps came in many shapes and sizes but usually had a manual tailpole to turn it to the wind.

Shingle mills

Shingle mills drove saws or other woodworking machinery and were in widespread use in the 19th century when roofs were made from thin chips of wood. They could be powered by wind or water, and shingle machines could be attached to mills with millstones. Commonly they were skeleton mills, constructed without any weather-boarding on the framework.

The Rex Wailes Collection

Mamsellimylly

Varvasmylly

Shingle mills

30 | December 2022 - Milling and Grain

Harakkamylly

CONTINENTS more COUNTRIES than 5 80’ APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Buhler-KSU Expert Milling Course

The Buhler-KSU Expert Milling course is set to begin February 27 - March 3, 2023. With in-depth discussions about flow sheet diagrams and milling processes, as well as optimum machine adjustment and mill handling, the course covers a variety of topics.

Other topics include a comparison of special cleaning systems which offer the possibility to improve milling performance further than a regular cleaning section; tempering of wheat (systems, bin designs, possible traps, various tempering philosophies and their application, pre-tempering systems, flow sheet options for optimum sanitation in and around the tempering bins); bacteria count reduction by scouring, peeling, light peeling and pearling; in-depth flow sheet technology (comparison of international flow sheets with milling systems

in the U.S., discussion of differences and possible application of system parts in U.S. milling; practical exercises in the Hal Ross Mill (the perfect break release, optimum purifier set-up, judging sifting performance – finding the ideal area between poor dressing and bare dressing), starch damage (what is it, its effects on water absorption, attrition flour – production and usage; flour quality: general quality control and assurance, flour ageing, etc.); and mill pneumatic systems (in-depth pneumatics with practical measurements and adjustments in the Hal Ross Mill).

The course is aimed at those who have a theoretical milling background (milling school or university, prior advanced milling course - IAOM or Bühler training centre), KSU Milling science graduate with two years practical experience or five years of shift milling experience. Ideally Production managers, head millers, and shift managers, will be attending this course.

The course fees are $1,900 for IAOM members, and $2,100 for nonmembers. The registration deadline is February 1, 2023.

Learn more – Learn onsite Enroll in the 12-week Course

provides a

12-week remote learning experience covering

of feed milling,

raw material

packaging

dispatch. Your industry training platform Milling and Grain - December 2022 | 35 TRAINING

The Online Milling School

comprehensive

all aspects

from

handling through to final

and

Mill

The African milling school (AMS) offers comprehensive and intensive training in the food industry, focusing on theoretical and practical elements, which is aimed at expanding the knowledge base from experienced millers to the next generation for millers. The courses they offer inform attendees on technology and equipment used to process grain into high value products and hopes to develop and share food-processing knowledge to a range of industry workers, such as maintenance staff, quality control and operation management.

The Head Millers program is located in Nairobi, Kenya, and would require in-person attendance. The dual milling

credential program is an apprenticeship that spans two years, with three modules each year. Each module is four weeks and contains regular examinations. The modules contain practical work in a flour mill and theoretical schooling at the AMS.

The requirements for those attending state they must be a current employee of a flour milling company, be aged 20+, have a basic education and good knowledge in English, and have at least one year of milling experience. The current employer of the trainee will bear all costs and expenses of the course, and during the program, trainees will be placed with a mentor.

The course requires trainees to gain work experience in all plant sections, including intake and storage, cleaning, milling, finished product section, packing and quality control.

After completing the two-year apprenticeship, successful candidates will become a miller’s graduate. The AMS apprenticeship is a well-recognised professional development and will enhance the skills and status of those attending in a challenging and highly developed industry.

The first module for the ‘Head

Program’ at the

Milling school starts in January, running from January 10 to 28 mymag.info/e/1706 Back in January 2017, Darren Parris from the Milling and Grain team reported on trip to Nairobi, Kenya for the inaugral class graduation at the African Milling School. From our archive TRAINING Mill 36 | December 2022 - Milling and Grain

millers

African

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less

£12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME We will be seeking enrolments from June ... . . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

than

FOCUS Product December 2022

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process. Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

VIB-CHECKPOINT© by Vibronet

VIB-CHECKPOINT© is a precise continuous control system for hectolitre weight (specific weight/ test weight/ volume weight/ bulk density), temperature, moisture and protein (option) of all free flowing granulated materials such as cereals, pellets, etc. at raw material intake and for blending in the production process. The system works fully automated and guarantees laboratory results at online operating conditions.

Sensors measure the temperature and initial moisture content of the product. The hectolitre weight is measured batchwise within a fixed time interval.

SmartFil M1by GEA

The GEA SmartFil M1 features configurable product metering options, including vertical auger and horizontal vibratory feeder, that can be selected based on the product to be packed. An optional deaeration probe may be added for improved consolidation of the product if required. The sealed filling head is designed to prevent product contamination whilst ensuring the safety of the machine operator. A bag preparation station enables the operator to safely close the top of the bag before presenting to the closing system. Closing is configurable dependent on packaging type. Continuous heat sealing with glue reactivation or with sewing is available for open-mouth bags, whilst impulse sealing is offered for hermetic sealing of plastic packaging. A simple operator interface is easily configured to adjust the key filling parameters and closing functions. The stainlesssteel design is durable and low maintenance.

OptoSelector OS t901 roeber by Petkus

The OptoSelector 901 is a full colour sorter for achieving products of the highest quality level. The advanced software processes individual kernel images and includes size and shape recognition technology as a standard feature. Defects having the same colour as the good material can now be removed by recognising different shape characteristics. Similarly, broken or deformed pieces of otherwise good material can also be rejected. A new individually available option serves to inspect seeds based on translucent effects. High power LEDs which are additionally focused are combined with excellent optical components with high light transmission. They allow for detection of defects in the inner part of translucent seeds which are not visible from the outside. Examples of this are the detection of red rice vs. rice or durum vs. wheat.

Soya Extruder by Yemtar

There is a conditioner, feeding spiral and vertical spiral on the extruder. Broken soybean, which is taken into the conditioner with the feeding spiral, is heated by feeding steam. It is sent into the shell by pressure through a vertical spiral. Soy is cooked by producing heat by friction inside the hive. Extruder capacity 6-8 t / h (steam) is driven by 250 Kw main engine, the sleeve and helix groups are made of alloy steel and hardened by heat treatment. 160°C temperature is reached at the barrel exit, and the extruder can be made in different sizes. It has a high cooking rate in a short amount of time and eliminates the negative effects of antibacterial factors.

The microprocessor determines the current hectolitre value, as well as its average accumulated value based on this measurement and on the data from the temperature and moisture sensors. The system consists of a control panel with colour touch screen with easy menu guidance, as well as a stainless steel measuring section. www.yemtar.com

Roller Mill Device 4500 by Bastak

This device is a laboratory type double passaged mill. It is used to determine the quality of the wheat which will be used for flour production. The Roller Mill Device is used for both dampened and undampened wheat grinding. It is the mixing laboratory mill that enables necessary modifications and amendments by predetermining the values of the flour to be ground in the factory.

The device consists of two parts: crushing and liso. The wheat is milled and divided into three parts as flour, bran(sharp) and semolina by passing through three fluted rollers at the crushing section. Flour and semolina are collected into different drawers by two 160 µ and 800 µ sieves and bran(sharp) taken from the front side of the device. The company gets informed about the capacity of semolina of wheat right after crushing. Semolina which passes through between two flat rollers gets divided as flour and bran by 160 µ sieve.

38 | December 2022 - Milling and Grain

mymag.info/e/1707

mymag.info/e/1708 https://vibronet.com

www.gea.com www.bastak.com mymag.info/e/1709 www.petkus.com

Pegasus® Vacuum Coating The vacuum coating revolution

Vacuum coating is a processing technique that can be used to add value to your product. It allows producers in the feed, aqua feed and petfood industry to drastically improve the quality and characteristics of their products. Dennissen process technology has been involved with vacuum coating technology for many years. The Pegasus Vacuum Coater enabled feed producers to apply liquid additives to and into pellets and extruded products, by creating a vacuum environment within the production process.

For the first time, feed producers were able to improve the quality and characteristics of their products drastically, without influencing the main processes, by adding functional additives like enzymes, vitamins, and drugs, end of line. By using vacuum coating technology, the additives penetrated homogeneously into the entire pellet. This resulted in better, more nutritious feed and food, healthier animals, and less emissions. The process starts with creating a vacuum inside the vacuum coater, where after multiple layers of additives can be applied to the product. The Pegasus Vacuum Coater gently suspends ingredients homogeneously in the air while the vacuum unit creates a vacuum environment. The spraying functionality makes it possible to spray a precisely predetermined quantity of liquid onto the powders, pellets or granules. When air is then allowed to enter the mixing unit, the liquids are evenly distributed deeply into each particle. The ingredients being sucked deep into the particles through the vacuum, also has the effect of protecting them against crumbling. After this step, additional layers of top coatings or aromas are applied to each particle, which results in a highquality extruded product. Often a thin layer of fat is applied to the granular feed material. This extra protective layer makes the material more elastic so that it breaks or crumbs less quickly. All this is done very fast, the entire batch process takes just a couple of minutes. The process starts with creating a vacuum inside the vacuum coater, were after multiple layers of additives can be applied to the product. The Pegasus Vacuum Coater gently

suspends ingredients homogeneously in the air while the vacuum unit creates a vacuum environment. The spraying functionality makes it possible to spray a precisely predetermined quantity of liquid onto the powders, pellets or granules. When air is then allowed to enter the mixing unit, the liquids are evenly distributed deeply into each particle. The ingredients being sucked deep into the particles through the vacuum, also has the effect of protecting them against crumbling. After this step, additional layers of top coatings or aromas are applied to each particle, which results in a high-quality extruded product. Often a thin layer of fat is applied to the granular feed material. This extra protective layer makes the material more elastic so that it breaks or crumbs less quickly. All this is done very fast, the entire batch process takes just a couple of minutes.

Vacuum coaters are used primarily for adding essential ingredients such as aromas, oils, vitamins, minerals and enzymes to granules and extruded products. The Pegasus Vacuum Coater makes it possible to add precisely the right amount of powder or liquid to each granule, after which the additive penetrates deeply into the granule. With the same technology, batches of solid as well as liquid ingredients can be mixed quickly and very homogeneously. The Pegasus Vacuum Coater is capable of adding much larger quantities of additives to powders, granules and granulates, than traditional production methods. Additionally, it’s possible to quickly add several coatings (one after another) on granules and extruded products and to vary the effect of the vacuum process. For example, switching the vacuum on and off controls the depth to which the liquid additives penetrate into the granule. The sophisticated control program makes it easy for producers to vary the vacuum settings and with it the injection of powders and liquids. As a result, the vacuum coater is suitable for producing a wide range of products on a single production line. Varying with ingredients and switching between recipes is fast and convenient. This also applies to the production of small quantities.

Milling and Grain - December 2022 | 41 FOCUS

www.dinnissen.eu mymag.info/e/1705 Special

www.ai-lati.eu

Let

www.paglierani.com www.ocrim.com

’ s w a l k t o g e th e r i nto a n e w E r a

The Ocrim Milling Hub

“Not just a mill”

Constructing and operating a flour mill is an unusual, although not unique development for a flour milling equipment company to make.

Named the Milling Hub, Ocrim SpA of Cremona, Italy commissioned its new joint-venture mill with the publicly listed Italian company BF SpA in the second year of the pandemic in July 2021.

And its a revolutionary concept for a milling company to adopt says Alberto Antolini the CEO of Ocrim, at the time of the opening of the mill.

“The industrial part of the mill is currently and solely aimed at sub-supplying. This revolutionary project was created to bring together the agricultural side of the industry - represented by the BF driver - and the industrial side, represented by Ocrim. The current module is the first of 10 for the Milling Hub project with a view to shortening the procedures of the supply chain.”

The project - the Milling Hub SpA, is a start-up with 51 percent owned by BF, a listed company, and 49 percent owned by Ocrim, a privately-owned company with 100 percent owned by the Antolini family – has come to fruition and lending more value to Italian-made products by combining the know-how, technology,

innovation and research of the two companies.

The strength lies in the pooling skills. Ocrim has an international track record in the production of milling plants while BF SpA is the first Italian agro-industrial group to focuses on managing the entire production cycle.

The new complex represents a unique and exclusive opportunity which, as Sergio Antolini, the chairman of Ocrim points out, “allows the customer to use his own grain in a mill of his own design. It will not involve any investment, staff, maintenance or operating costs and will ensure total safety and traceability of the final product.“

BF SpA’s CEO Federico Vecchioni adds “It’s not just a mill, it’s also a competitive and winning way of promoting the value of food products on the international market … it is a new way to forge future alliances.

“The partnership with Ocrim is not just a corporate one, it is also a partnership of skills, vertical integration, monitoring of every step of the supply chain and very high specialisation,” said Mr Vecchioni.

“No single player will be able to be sufficiently competitive in the coming years.

“Platforms, strategic alliances and size are required to win. And it is within this perspective that Ocrim and BF have agreed that their roles complement one another.”

F 44 | December 2022 - Milling and Grain

Location

The large Milling Hub is strategically located in Cremona near the Agricultural Consortium, the main grain storage centre in the area, next to the factories of Ocrim and near the railway network and canal port.

The building is designed for two durum wheat milling lines with a capacity of 150 tonnes in a 24-hour period per line.

The project is one of a kind, created with the most advanced technologies to ensure the highest standards of quality, efficiency and food hygiene.

It is a fully automated system, capable of self-regulating with a series of sensors that constantly communicate with the control management system. 4.0 technologies are used to also control and track the progress of each batch of product.

Mr Marco Galli, Director of the Ocrim’s Technology Department, says that with this evolution in mill management, “The figure of the miller will have to adapt and collaborate in the development of these technologies, offering his experience to help improve the flow of information. There will always be a need for the miller to

Milling and Grain - December 2022 | 45 F

operate the mill and create the products.”

Other significant changes were made in the name of saving energy and sustainability, the guiding values of the project and principles on which the corporate culture of Ocrim and BF is based.

The mill is equipped with an innovative air handling unit capable of regulating the temperature and humidity inside the building, maximising the yield and quality of the final product. The air handling unit also recirculates the hot air produced by the mill itself through special filters, thereby allowing considerable energy savings.

In the interview, Mr Alberto Antolini also mentioned a number of important projects that Milling Hub has in the pipeline, such as offering the possibility of further dividing the quantity of the processed product to also serve market niches. Or the logistics relating to the receipt, transport and storage of materials, which the new complex will be able to carry out by rail, road and water thanks to its structure and geographical location.

Deadlines and the pandemic

It was not easy to meet the deadlines for delivery of the first mill.

The restrictions due to the spread of the Covid-19 pandemic required significant reorganisation of the work to ensure distancing between the various companies operating on site at the same time.

To speed up the work and reduce set-up times, the machines were assembled even before construction of the building was completed. This bold choice required a new organisational plan to ensure the safety of the personnel and machinery.

The work was successfully completed with the full cooperation of all the companies involved. The new complex will be put at the service of the Ghigi pasta factory. The pasta factory in Emilia Romagna will be one of few in Italy to have full control of its entire supply chain.

F 46 | December 2022 - Milling and Grain

Visitors from the Ocrim 'Open Days 2022' visit the Hub

www.tsc-silos.com Check out our references: “By building some of the cells one above the other, the maximum flexibility has been raised to an even higher level.” STORE SMART STORE SQUARE Location: Moudon, Switzerland Product: Grains and seeds Capacity 2.600 m³ Bins 51 Height 32 m Width 7,5 m Length 19,9 m C M Y CM MY CY CMY K pubblicità italiana_MOD.pdf 1 27/01/22 10:59 F

The power of additives in feed cutting emissions and boosting business

by Virginie Blanvillain Rivera, Global Services Manager, AB Vista, UK

Pressure on farmers to reduce emissions is growing at a time when they already face a host of other challenges. It’s become a daily battle to survive in an industry threatened by economic uncertainty, changing consumer habits and geopolitical and environmental concerns.

The fight against emissions begins before the animals have even left the farm gate. Research shows that animal feed highly contributes to carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O) of meat, milk and egg. Indeed, animal feed contributes to more than 50 percent of carbon emissions of processors and retailers. Hence the pressing need for the industry as a whole to reduce its carbon footprint.

Depending on the region, there has been a 50-100 percent increase in diet cost globally since 2020. With the price volatility and high emissions of animal feed, farmers might think they are facing a losing battle. But, as the saying goes, knowledge is power.

Data might not seem like an obvious friend of the farmer but bringing decades of AB Vista scientific research and experience to the farm table has proven not only to cut emissions but to increase productivity, the outcome being getting more from less. Technologists from our Emissions Reporting Service identify, quantify and mitigate feed-related emissions, searching for the right formula to free up farmers to concentrate on their business. We help them achieve the right balance between cost, productivity and performance, while reducing emissions.

Improving performance

Whatever the animal – ruminant, swine or poultry – the ingredients that go into feed, and their quantity, can have a significant impact on cost and emissions. So, the first step in our feed strategy is to define a list of ingredients, taking into account cost, location and availability. Sourcing alternative ingredients and making the best use of them without compromising on performance, comes back to costs of production – with price remaining the primary driving force for farmers.

Ingredients are the main contributor to emissions when it comes to feed, usually accounting for more than 70 percent of the carbon footprint at farm gate. Other elements of feed production –transportation, fuel, energy and water use from manufacturing –are responsible for a comparatively minor level of emissions.

Revisiting formulations and assessing feed additive combinations both help farmers maintain performance and remain competitive. By looking at feed additives and the different roles they can play, carbon footprint can be reduced by ensuring the best use of nutrient utilisation, thereby reducing waste and excretion.

As well as providing a nutritional value to feed formulation, the great advantage of enzymes is that, at specific target levels, they can improve general animal health, resilience, and welfare, therefore improving sustainability and overall herd performance consistency.

For example, in recent years the rising cost of non-organic phosphorous has reinforced the need to use a phytase feed additive to break down the phytate found in ingredients such as soybean meal, corn and wheat, making more phosphorus available to the animal. Additionally, high levels of phytase are being widely adopted to optimise feed formulation to a greater

48 | December 2022 - Milling and Grain F

extent by maximising amino acids and energy utilisation, therefore reducing CO2 emissions and N2O excretion in the environment.

The science bit

Let us invite you into our offices and laboratories for a moment, where our teams of experts work to build a picture of a farm’s individual emissions and how to reduce them.

It’s not a one-size-fits-all approach; we do the groundwork, analysing and benchmarking data to identify areas within the

live animal production system with a high emissions rate, to tailor specific solutions aligned with the medium- to long-term farmer objectives – thus enabling the farmer to apply sustainable solutions while running their business efficiently and profitably.

Our Emissions Reporting Service (ERS) allows farmers to calculate the carbon footprint, and the nitrogen and phosphorus excretion at farm gate. Our experts then recommend mitigation strategies in line with farmer objectives. These recommendations are based on ‘what-if’ scenarios which explore the benefits technologies and management strategies can deliver to an individual farm.