In this issue:

WHEAT MILLING INNOVATION:

Well-established systems and technologies in pasta production

- Wheat, bread, gluten and health: Where do we stand in 2024?

- Efficient dough testing with the Brabender FarinoGraph

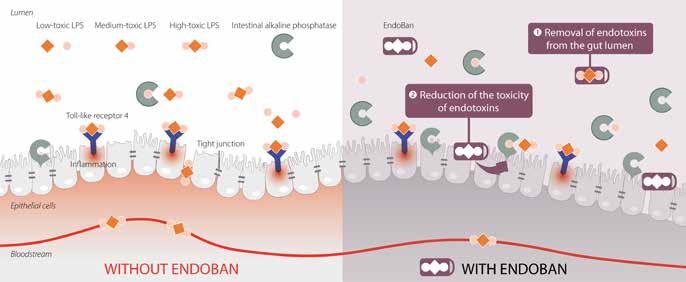

- Endotoxins and heat stress - not your cows’ best friends

- Moving Beyond Break/Fix to Prevent Downtime of Critical Animal Feed Conveyors

Milling and Grain . Volume 135 . Issue 6 . June 2024 millingandgrain.com June 2024 Proud supporter of Download the Milling and Grain app to your smart phone

GLOBAL

Volume 135 Issue 6

YOUR

PARTNER

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 1242303792 darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286

dantef@perendale.com

Latin America Marketing Team

Cristina María Roldán Otero

Tel: +44 1242 267700

cristinaot@perendale.co.uk

44 Wheat, bread, gluten and health: Where do we stand in 2024? 52 Wheat milling innovation 58 Efficient dough testing with the Brabender FarinoGraph 62 Endotoxins and heat stressnot your cows’ best friends

Moving Beyond Break/Fix to Prevent Downtime of Critical Animal Feed Conveyors

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Social Media Journalist’

David Harvey davidh@perendale.com

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager James Taylor jamest@perendale.co.uk

Circulation & Events Tuti Tan tutit@perendale.co.uk

Development Manager Antoine Tanguy antoinet@perendale.co.uk

millingandgrain.com ISSN No: 2058-5101

©Copyright 2024 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com

Perendale Publishers Ltd also publish ‘The

and ‘The Global

8 10 24 37 38 41 76 78 84 102 108 111 112 114

International Milling

Miller’ news service Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 MAXIMISED FLOUR MILLING

Directory’

STORAGE

MAXIMISED

THE PUBLISHER Milling News Gems from the Mills Archive Mill TRAINING FOCUS Product FOCUS Special CASE STUDY Commodities INDUSTRY EVENTS PEOPLE 20 Mildred Cookson, Mills Archive Trust, UK 27 Dr Mahmoud Riyad 10 www.millingandgrain.com Find out more at: YOUR GLOBAL PARTNER VOLUME 135 ISSUE 6 June 2024 Industry Profile CHARITIES DIRECTORY the interview Regular items Feature content

& HANDLING

70

THE PUBLISHER

Sometimes you have to go that extra mile to find something really special.

So far this year I’ve spend time, effort and of course resources to report on milling sector events and expositions across the world in order to bring readers the latest information on developments and innovations that they need to be aware of in addition to simply reporting on those events themselves.

Roger Gilbert

Rallying both myself and our team to organise themselves to fly to Istanbul to attend the Turkish premier milling event IDMA 2024 which is that country’s first combined expo under new management aimed to get back it back on course following the pandemic years, and to deliver what it was building in the year’s prior to the emergence of Covid-19 was a challenge - or as we say in English, it was likely to be ‘A bridge too far.’ Just for background, that saying comes from the title of a 1977 film directed by Richard Attenborough which depicts an Allied operation in Nazi-occupied Netherlands during World War II, which failed.

Was this ‘A bridge too far’ in terms of milling events? Not at all.

If we are talking of man and machines, then this was event was a huge success.

While numbers of visitors might not have reached expectations nor representative of earlier years, the magnitude of what was on offer, nevertheless was a triumph for the Turkish milling industry

Exhibitors showed off their amazing innovations and their overall commitment to the milling industry globally. This was a showcase of what one nation can do for an industry and this was clearly reflected in the huge range of roller mills, pellet presses, optical sorters and laboratory equipment along with almost every other aspect of the milling process that you are likely to see in one place – or rather over three halls under one roof.

What show was this? It was the IDMA expo of course and it was celebrating its tenth outing.

The roll call of roller mills was second to none. I took photographs of everyone and there were over 25 separate company roller mills on display - and they were almost exclusively Turkish.

Of course there were numerous non-Turkish companies exhibiting, but this year’s event was dominantly a domestic affair and the competition among roller mill manufacturers was clear to see.

Every company was able to point to aspects of their mill that made them unique and advantageous to the visitor

In this issue we report on the show itself with our highly respected Turkish representative, Mehmet Ugur Gürkaynak, providing the basics of the show along with a range of photos of exhibitors and others that we were fortunate to meet with.

However, for our summer edition next month – that is our July edition - I plan to present a photo round up of what must shortly be a unique gathering of roller mills. There must be a collective word for this - how about: ‘An amassment of mills?’

In walking the corridors, I was invited by the Turkish company

MILLING AND GRAIN | JuNe 2024

Tanis to be interviewed and was asked what I thought of this year’s event - you can see that interview and that of my colleague Darren Parris, who was also interviewed by Tanis, in our MAGTv which has links on the next page.

In brief I took the opportunity to congratulate the Turkish manufacturers of milling equipment for their dedication and commitment and added that all millers should be aware of the quality and range of milling machinery this country has to offer.

Handing over the sculpture

It was a great pleasure to be able to visit New York in mid-May (on my way to Mexico for yet another event) to be joint host in a luncheon to present the 2023 Milling Hall of Fame sculpture to John Coumantaros of the Flour Mills of Nigeria.

We were fortunate to find a stunning venue for this occasion, which was the New York Yacht Club in Manhattan.

This was a private lunch with members of Mr Coumantaros family present and both myself and Torsten Wuywiol of Mühlenchemie, who supports the FlourWorld Museum in Wittenburg, Germany.

This was a special day and one I’d like to revisit as Mr Coumantaros and his family’s development of the milling sector within Nigeria has done much for food security in that country. He tells me more is to come as Nigeria’s population growth and the subsequent demand for foodstuffs, such as bread from wheat flour, is unrelenting.

I hope you enjoy this edition and I look forward to providing the July edition in due course!

VIDEO: Our Publisher Roger Gilbert and Group President Darren Parris were interviewed by Tanis Milling Technologies at IDMA. Please check out the videos here:

Roger Gilbert talks to Mr Robert Cau mymag.info/xWmP

Darren Parris talks to Mr Robert Cau mymag.info/rFOv

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information www.millingandgrain.com http://gfmt.blogspot.co.uk

Milling and Grain has a cooperative partnership with COFCOET

8 | June 2024 - Milling and Grain

Flour Milling Maximised

The Presentations from our Flour Milling Maximised Conference, Co organised by VICTAM, which took place at VICTAM Asia and Health and Nutrition Asia 2024 in Bangkok, Thailand, are out now!

The theme of the conference was how equipment and technology can be used in modern day flour milling to improve efficiencies whilst maximising output.

Hear from leaders and key players in the flour Milling Sectors here:

mymag.info/QNhh

Raymond Ma – Wudeli

Raymond Ma, General Manager of Handan Company of WuDeLi Flour Mill Group, introduces Wudeli and their revolution of equipment and tech. Established in 1989, WuDeLi is the biggest flour mill group in the world, and also China, with a capacity of 80000t/d. Raymond Ma discussed the companies past and present, and their most important evolutionary innovations.

Adi Witono – Bogasari

Adi Witono, from Bogasari, speaks on ‘The Sustainability Journey

Within Our Bogasari Group’. Currently the Operation Vice President for Bogasari Division of PT. Indofood Sukses Makmur Tbk, Adi Witono talks about Bogasari’s (the biggest flour mills in Indonesia) is commitment to sustainability, by taking preventive measures against covering water, air and soil pollution through continuous assessment and improvement of environmental practices.

Welcome! It is the June edition of Global Miller and the sixth edition of Milling and Grain this year. We have made it through half of the year and Summer has officially begun now, or will do on June 20, so that officially means it’s time to stock up on suncream and buy yourself a hat to protect yourself from the sun, especially with all the outdoor farming that you’ll be doing. Protecting the skin is important.

Summer is the perfect season to begin growing those crops that need hotter vegetation and longer days such as corn, okra, tomatoes and more. If you haven’t done so already, now is also the time to be either transporting your pumpkin plants outside if you’ve been growing them indoors or sow them as early as you can this month outdoors. Those pumpkins will be popular later this year and if you want to carve them in time for Halloween then you better get sowing. For a handy tip for a successful pumpkin this autumn, line the floor beneath the pumpkin with a protective sheet. It’ll keep those pumpkins better than if they were directly on the ground.

For some local news in the UK, Parliament have announced that the general elections have been scheduled for July 4, 2024. For those who aren’t aware, this is the once in a five-year election that decides which political party will end up in charge of Parliament and will decide who will be the new Prime Minister. This next month is going to be a busy one with everyone in the UK needing to brush up on their political manifestos and deciding who they want to become the next Prime Minister. Enough of future events though, as for a recent event in the UK that is currently happening, the Farming Union have been urging major retailers to support their local farmers. The US Department of Agriculture plan to offer millions of dollars to support their local farmers through a new program. This is an incredible help to the farming community.

Rogers Foods Ltd, a Japanese owned company, have commissioned an expansion of its hard wheat milling plant in Fraser Valley. This was a lovely, large expansion for the plant that was assigned to Ocrim to perform reconfirmed their partnership. Definitely some interesting bits of information to look into with this news piece.

As for our adventures around the world, you’ll be receiving the Build My Feedmill conference report that we held back in March at Health and Nutrition Asia. We will also be providing all the latest news from our trip to IDMA in Instanbul, Turkiye. It was an amazing trip that we’re so grateful to have gone to.

10 | June 2024 - Milling and Grain Milling News

NFU secures win for seasonal worker’s scheme

Following several years of campaigning by the NFU, the UK Government has announced a five-year extension to the Seasonal Workers Scheme which will help give many farming and growing businesses the vital certainty needed to boost our national food security.

The announcement was made as part of a package of measures in response to the Shropshire Independent Review into Labour Shortages. It provides much needed confidence for businesses and applicants, while also addressing concerns about the recruitment and upskilling of domestic staff.

NFU President Tom Bradshaw said: “This will be a huge relief for the horticulture and poultry sectors that rely on seasonal workers and is a brilliant win for the NFU, which has been campaigning for a long-term plan for seasonal workers for some time.

“We have seen in the past how damaging shortages of workers has been, with approximately £60 million worth of crops lost in 2022 due to a shortfall of workers. We know that with the correct trading conditions there are significant opportunities for growth and the commitment to a five-year scheme is very positive. Moving forward, it is vital to have assurance that the number of visas and the costs associated with accessing them will continue to meet the needs of our food producers.

“Funding announced for further automation of packhouses is also welcome, along with the commitment to accelerate the development of robotic crop harvesters. It is important that these positive announcements are reinforced by the Government at its forthcoming Farm to Fork Summit, and that the industry and government can work together to drive growth for UK food and farming.”

12 | June 2024 - Milling and Grain Milling News

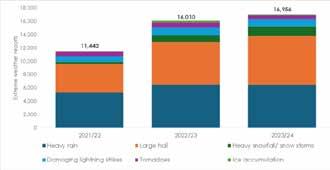

Farming Unions urge major retailers to back British farming

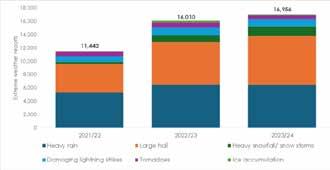

UK farming Unions are calling on major retailers’ commitment to support the industry during this difficult time in response to extremely challenging and disruptive weather this spring.

Exceptional rainfall and a succession of damaging storms have impacted livestock, arable and horticultural sectors and disrupted individual farm businesses the length and breadth of the country. No area of the UK has escaped with lambing, calving, planting and field work all proving very difficult and bringing additional cost to the business.

In a joint letter on behalf of the NFU, NFU Scotland, NFU Cymru and Ulster Farmers’ Union, it seeks major retailer commitment to support the industry during this difficult time. The letter states “These challenges come at a time when many of our members are already struggling to remain viable due to the perfect storm of sustained and spiralling production costs, low market returns and increasing levels of regulation. This latest challenge, whilst not new, is more acute than ever, and is compounding the pressure on our members.

“Farmers and growers continue to bear the lion’s share of the risk within their supply chains, and this is unsustainable. We are in discussions with our respective Governments on further support to assist the industry in navigating these short-term challenges, but we also recognise the important role which retailers have to play in helping the industry to withstand this latest crisis.”

Rogers Foods set for expansion

Rogers Foods Ltd, owned by the Japanese company Nisshin Flour Milling, has recently commissioned the expansion of its 300 T/24h “B-unit” hard wheat milling plant in Fraser Valley. This is a facility built in 2017 in a new building adjacent and communicating with the existing one, which is at the forefront of technology. It presents, in fact, a futuristic vision in terms of food safety, with the use of stainless steel as the predominant material for the entire grinding section, including the roller mills with automatic gap adjustment.

The project, which was completed in June 2023, consisted of the inclusion of the SHE high-efficiency peeler in the cleaning section to increase efficiency and food safety by lowering contamination, reducing bacteria and ash content through gentle dehulling of hard wheat. In the grinding section, on the other hand, the automatic roller mills. In addition, the existing pneumatic plant was upgraded, increasing its capacity to ensure more efficient and continuous production.

The expansion, assigned to Ocrim, reconfirms the partnership between the two groups that dated back in 2004 with the construction of the first 250 T/24h “A-unit” milling plant, later expanded to 300 T/24h. “We were pleased with the first project, and since then, we have been relying on the Italian company’s expertise to continue to achieve new goals and consolidate the success of our initiatives,” said Kelly O’Brien, Vice President Operations at Rogers Foods Limited.

Get insights in the quality of the steam process

With the IVS Smart Steam Dosing Unit

Anticipating data facilitates predictive maintenance

Recommendations for optimisation

Increases user expertise of steam dosing

Insight into the quality of the steam network

www.ivsdosingtechnology.com info@ivs.nl +31(0)413 29 19 76 Milling and Grain - June 2024 | 15 Milling News

USDA announces millions to support farmers

The US Department of Agriculture (USDA) announced approximately US$22.3 million available to community-based and non-profit organisations, institutions of higher education and tribal entities that help underserved and veteran farmers and ranchers own and operate successful farms. Funding is made through USDA’s 2501 Program.

“2501 Program partners are based in local communities and rural areas where they serve a critical role in maximising USDA’s outreach efforts to underserve communities,” said OPPE Director Lisa Ramírez. “They provide training and technical assistance to help these agricultural producers succeed and also connect them to USDA programs and services.”

For more than 30 years, and in partnership with organisations nationwide, the 2501 Program has helped reach underserved farmers and ranchers. The 2014 Farm Bill expanded the program to include assistance to veteran farmers and ranchers. The 2018 Farm Bill increased mandatory fund-

ing for the program through fiscal year 2024. With 2501 funding, organisations conduct education, training, farming demonstrations and conferences on farming and agribusiness.

Since 2010, the 2501 Program has continued to increase access to USDA’s programs and services and awarded 615 grants totalling more than $194 million. For example, FY 2023 grantee Farm to Table Guam is helping farmers in Guam with business training, financial planning and technical assistance in crop production and distribution. Quivira Coalition is reaching rural producers in New Mexico with radio spots in English, Spanish and Diné Bizaad (Navajo) about arid land stewardship practices and conservation.

Eligible applicants include not-for-profit organisations, community-based organisations and a range of higher education institutions.

Applications must be submitted through grants.gov and received by Friday, July 5, 2024.

At PCE, precision engineering meets custom design to produce dies that fit all pellet press models. Our dedication to quality ensures your operations are seamless, efficient, and high-quality. Our dies are essential for top-notch performance in feed, biomass, or any material pelleting.

Reduce costs and prevent risks Optimize your entire production chain Guarantee higher quality products BESTMIX® Feed Formulation, Quality Control, Ration Calculation and ERP solution. Scan to learn more: www.bestmix.com The most advanced software solutions for feed production: MAXIMIZE YOUR PELLET PRESS’S POTENTIAL WITH TAILOR-MADE DIES.

Elevate your pellet production now. Visit www.pce.eu

16 | June 2024 - Milling and Grain Milling News

www.pce.eu

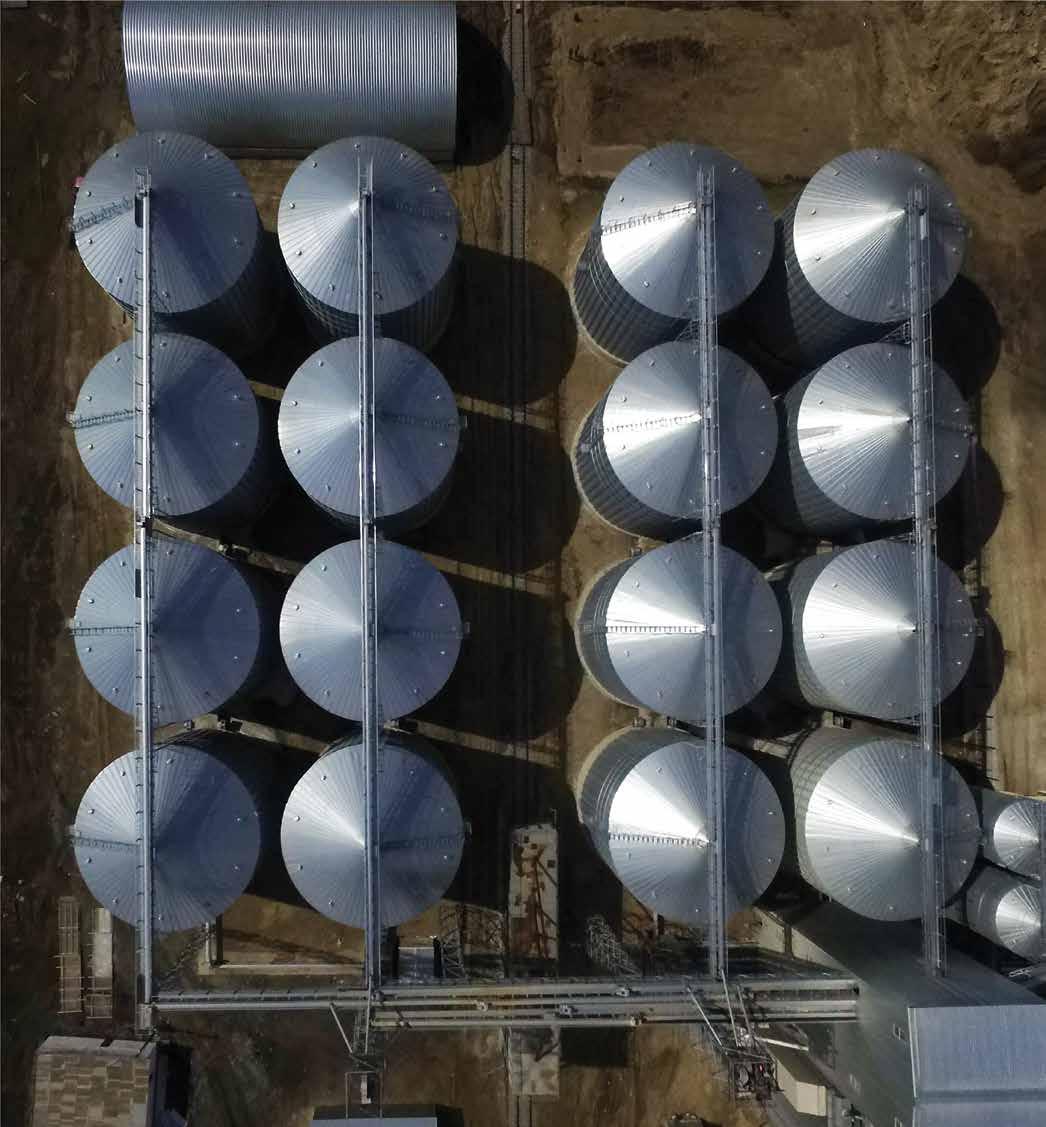

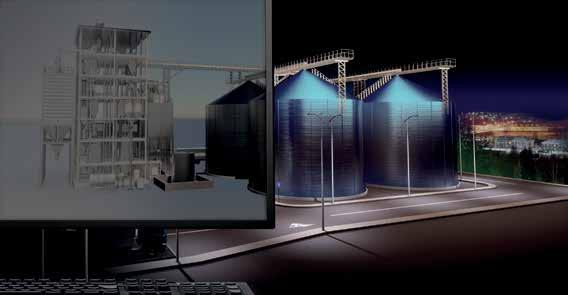

Cesco launches new project in Saudi Arabia

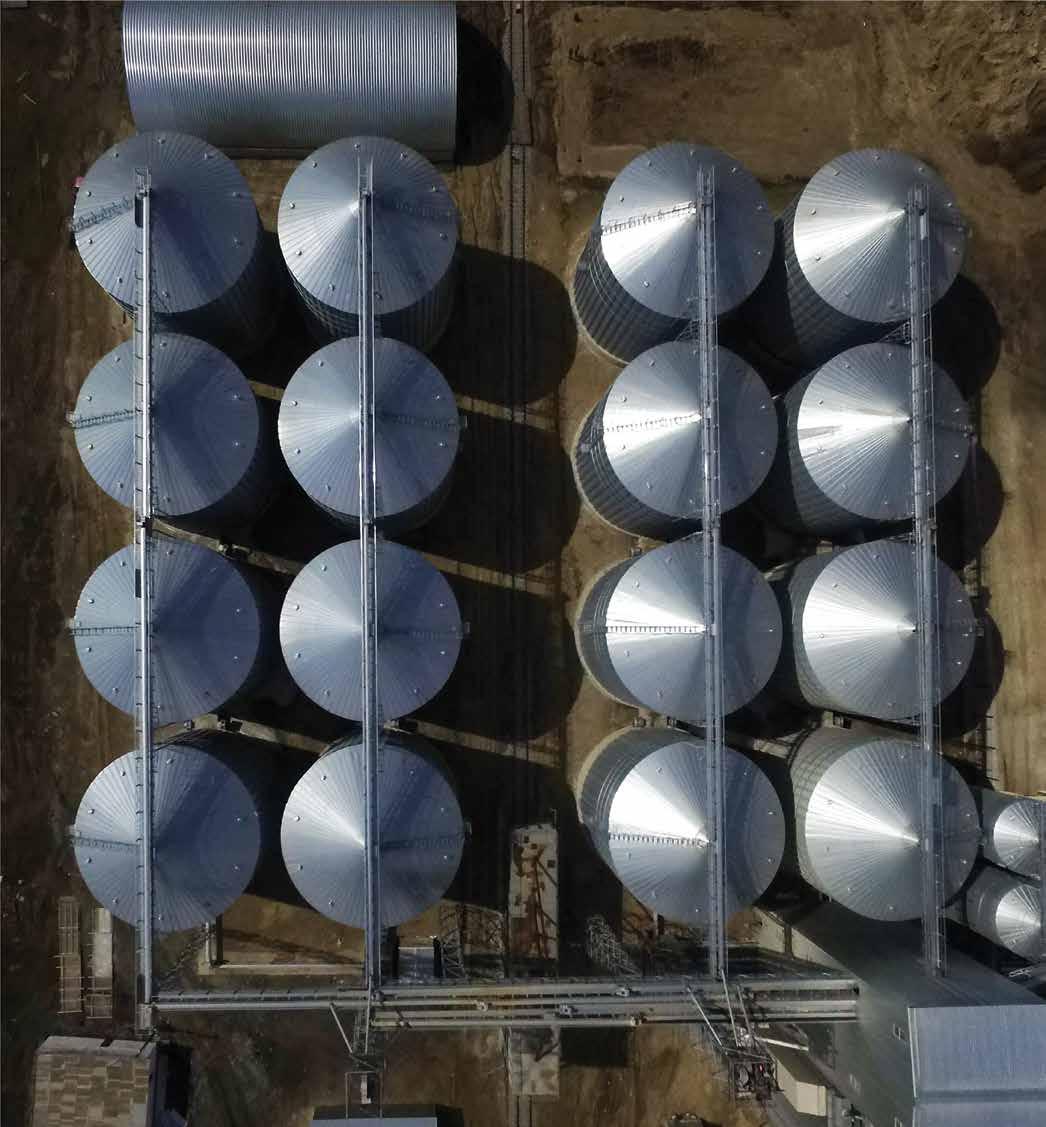

Cesco EPC, a leading German company specialising in grain storage and processing plants, is pleased to announce its new project in collaboration with United Feed Company (UFC) in Saudi Arabia. This project exemplifies Cesco’s commitment to innovation and adaptability to meet the unique challenges of the region.

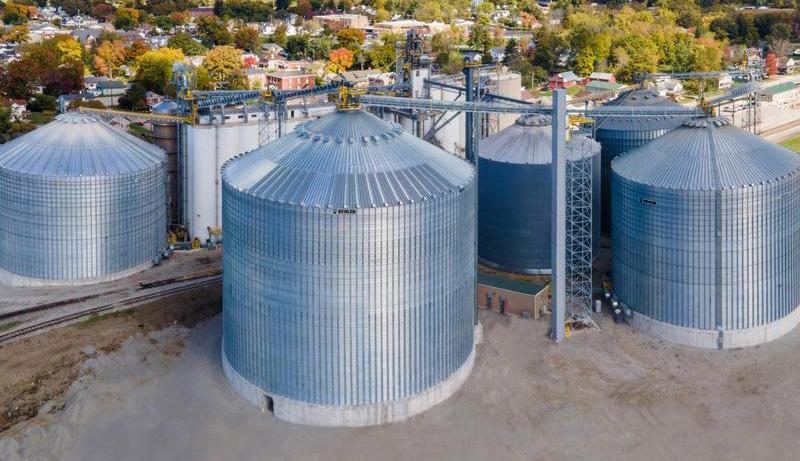

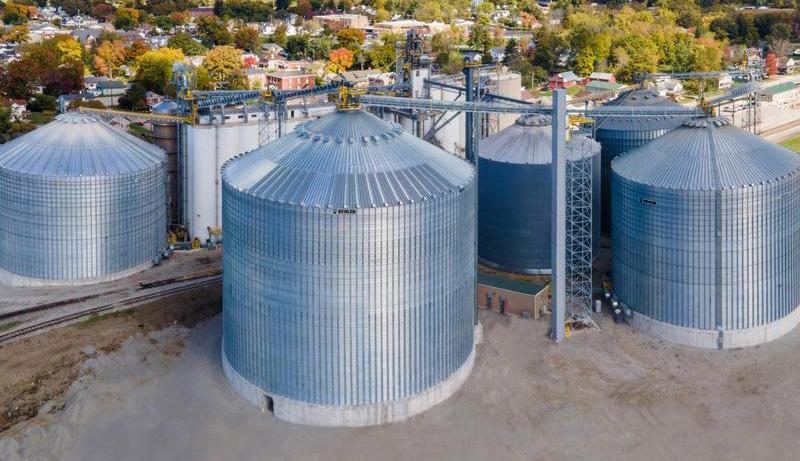

The project includes 15 corrugated steel flat-bottom storage silos with a total capacity of over 20,512 tonnes. Additionally, Cesco will provide conveying equipment for a flat storage warehouse for soy meal, covering a total surface area of 3800m². This substantial storage capacity allows UFC to maintain a strategic reserve of essential feedstock materials, mitigating the impact of potential supply chain disruptions.

The plant is designed to receive, transport and store free-flowing materials like grains, cereals and oilseeds. With dedicated high capacity 2x400t/h receiving lines for grains and 2x125t/h for soy meal, the facility can handle a significant daily intake, ensuring a consistent supply of raw

Grains undergo a thorough pre-cleaning process using advanced rotary cleaners and magnet pipes to remove impurities. Flow scales integrated into the system ensure accurate weighing of incoming materials, optimising production efficiency and cost control.

The plant features a versatile reclaiming and recycling system that allows for efficient distribution of stored materials. Grain can be directed to bulk truck out-loading silos, bagging lines, or back to storage based on production requirements.

Cesco’s innovative chain conveyors, belt bucket elevators and roller belt conveyors are incorporated throughout the facility. These conveyors offer several advantages, including improved cleanability, reduced maintenance needs, and a modular design for easier transport and installation.

The design of the plant enables simultaneous operation of various processes. For example, grain and soy meal receiving/loading can occur concurrently, maximising overall efficiency and throughput.

The design accommodates future expansion with an additional nine corrugated steel flat-bottom storage silos, increasing the total capacity by over 123,091 tonnes to reach a combined capacity of 328, 243 tonnes. Additionally, the sot meal storage capacity will be doubled to a total of

Milling and Grain - June 2024 | 19 Milling News

MA Complete New Mill at Bishop’s Stortford

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

ILLING, the earlier title for Milling and Grain, in its issue for June 19th, 1937, told the story of the fall and rise of this Hertfordshire mill. It began in 1882 when Sylvester Edwards ran a windmill at Great Wilbraham in Cambridgeshire. This was followed by a one sack water mill at Little Hallingbury in Essex, and then in 1901 he built the original flour mills at Bishop’s Stortford, installing a roller plant of his own design. When Sylvester died in 1933 the control of the firm passed to his son, Charles, who was joined by

his brother John. They used nothing but English wheat, and a large proportion of their output was used for biscuit making.

In 1935 a disastrous fire destroyed the two top floors along with the roof, and with the exception of some of the roller mills and wheat cleaning plant, the machinery was so badly damaged that it was beyond repair. It was decided to install an entirely new up to date five sack plant, together with a new silo, screen room, and provender plant. All of this was designed, built and equipped by Henry Simon Ltd.

The purifier floor

The purifier floor

20 | June 2024 - Milling and

Simon roller mills Centrifugals on the top floor

Grain

The walls of the old mill had been left standing after the fire, but reconstruction of the building to its original height would not provide enough space to accommodate the proposed new plant. Mr Edwards decided to erect a completely new building on the ample space available adjacent to the old mill. Constructed by Joseph Parks & Son of Northwich in Cheshire, it was a steel framed structure, filled with brick and surmounted by a flat asphalted roof with a three-foot coping.

The local yellow brick was used to harmonise with the old mill and surrounding properties. The name of the firm and of the mill was prominently displayed on all sides of the building by large signs which were painted in bright red, and the silo carried an advertisement of the firm’s activities which could be seen from a considerable distance. The mill building comprised of eleven

bays, three occupied by the wheat cleaning plant, six by the mill and the remaining two by the flour packing and storage section.

The mill and screen room comprised four lofty floors, giving plenty of headroom and reducing the cross conveyers to a minimum. In the flour storage section an extra floor was added making it five floors at this end. A verandah provided at the flour warehouse end of the building protected vehicles from the weather while loading.

The old mill building was reconstructed and a new provender milling plant installed in it. It was also used for the storage of provender and wheat feed. The screen room was arranged on the latest Simon all-metal system, machines, conveyers, elevators and spouts. Wheat from the silo was passed through an Exact measurer to a fan-less type millerator, which extracted dust, sand

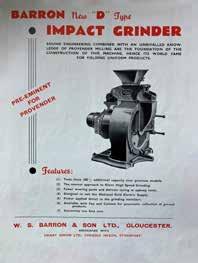

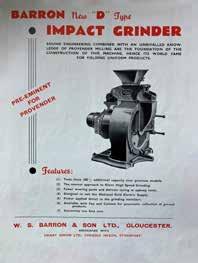

Barron’s D type impact grinder

Mr Edward’s new mill

Barron’s D type impact grinder

Mr Edward’s new mill

Milling and Grain - June 2024 | 21

Little Hallingbury watermill in Essex

pubblicità italiana_MOD.pdf 1 27/01/22 10:59

C M Y CM MY CY CMY K

22 | June 2024 - Milling and Grain

and larger impurities. Following this the wheat went through a Carter separator that removed barley and oats, the grain then passed to a washer and whizzer and finally a hot air dryer.

The mill had four breaks and a capacity of five sacks an hour. It had been designed so that by the addition of two or three roller mills the capacity could be increased to seven sacks per hour. The most outstanding feature of the mill was the generous roll and dressing surfaces provided, extremely desirable in a mill working continuously on native wheat, which for many years might be excessively damp.

The mill was arranged with reels and centrifugals for scaling and grading. The scalping of the first two breaks was carried out on reels; the remaining break and reduction stocks were dealt with on centrifugals. The purifier stocks were divided into six classes. Interestingly the third break semolina was dealt with separately and the middlings were re-purified. The purification of all stocks was done on Simon fan-less purifiers that were exhausted by high speed metal trunking to fan and cyclone.

The flours, after being treated on a double feed centrifugal, were collected in three worms and conveyed to a flour dividing board arranged in a convenient position on the purifier floor so that any desired variety of flours could be made. The flour then passed to a double feed centrifugal for re-dressing. There was a system for the grading of wheat feed, and a bran roll, with a bypass spout, so that either rolled or straight run bran could be made at will.

The provender mill had the latest types of machines for grinding barley, maize and oats, and for the production of rolled oats. Maize meal was done on a Barron No. 2 type D impact grinder and after being ground was collected by means of a fan and cyclone system. Barley meal was also dealt with on the impact grinder. However, when a softer meal is required, the barley was

treated on a Barron 36-inch Dreadnought grinder. Corn cutting was done on a Barron No.1 size Diamond corn cutter capable of producing three grades simultaneously, combined with an aspirator. Rolled oats were produced on a Barron oat crushing roll.

Power from a Ruston & Hornsby four-cylinder horizontal, crude oil engine of approximately 200hp drove the main shaft by means of Dick Balata ropes whilst high test belting was used within the mill itself. The engine also drove a 30kw generator for lighting and power.

As might be expected after the destruction of the old mill, every precaution against fire had been taken. Fireproof doors at various points and a system of automatic sprinklers were installed throughout the mill, screen room and warehouse.

We train the workforce of tomorrow. Expand your knowledge, exchange ideas and gain experience in our academies around the world. Let’s shape the future together. Scan the QR code for more information. millingacademy@buhlergroup.com Innovations for a better world. Milling and Grain - June 2024 | 23

The Ruston and Hornsby oil engine

Gems from the Mills Archive

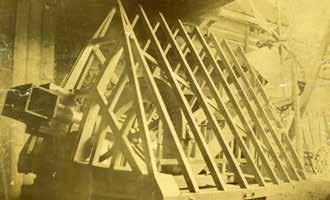

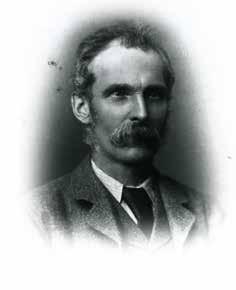

A photograph on iron

by Nathanael Hodge, Mills Archive, UK

Measuring approximately 6 x 9 cm, this photograph is not on paper or film but on an iron sheet. It is a tintype, a method of photography developed in the mid 19th century. Much cheaper than the earlier daguerreotype which used a sheet of silver-plated copper, tintypes were often used by itinerant and fairground photographers, as the photograph could be taken, developed and given to the customer within only a few minutes, similar to later polaroid film. Because the photograph is not a copy, like a print made from a negative, it retains a high level of detail, as can be seen from the much higher resolution version shown here.

This photo shows the Canterbury millwright T R Holman, with his staff. The two young men immediately to his right and left are his sons, Harry Branford and William John Holman. The Holman firm was founded by T R Holman’s father John in 1816 and built smock windmills in Kent as well as repairing other wind and water mills. The wooden smock mills were often constructed of Baltic pine, imported through the ports of Dover and Folkestone – it was slow growing and had a high resin content which helped it withstand the elements. Much of the work in building a mill would be carried out in the works by a number of men, before the mill was finally erected with poles, shear legs and blocks and tackle – cranes did not yet exist. The carriage of tackle to the site would have been done with wagons drawn by horses.

Hours were long, 6 am to 5.30 pm with half an hour for breakfast and an hour for lunch. When working on complex repairs to mills which took several days or weeks, it was usual for the millwrights to lodge with the miller. Harry Branford was doing this on 18 January 1881 when there was a snowstorm which left him snowbound and isolated for more than a week. The Holmans’ records show work done to more than 120 mills within 20 miles of Canterbury.

In 1857 T R Holman was hired by the banker and philanthropist Sir Moses Montefiore to construct a windmill in Jerusalem. The Holmans were later commissioned to provide machinery for a mill

in Haifa, Syria (now in Israel). Unfortunately, on this occasion an important part of the machinery was lost in the sea while being unloaded at Jaffa.

After their father’s death in 1897, the brothers Harry and William took on the business which became ‘Holman Bros, engineers and millwrights’. The character of the firm was gradually changing as wind power fell out of use, and they began placing more emphasis on their agricultural machinery business, as well as hiring steam ploughs and threshing machines to local farmers.

The firm finally closed down in 1975 due to the compulsory purchase of the Old Dover Road yard by the City Council. The final auction sale of fixtures, fittings and stock took place on the 3 April 1975, marking the end of over 150 years of continuous trading.

www.millsarchive.org 24 | June 2024 - Milling and Grain

If you can think it, we can pack it!

With over 150 years of combined experience, we help you find your individual packaging solution. Over the years, we have developed machines that cover a range of weights from 50 grams to 25 kg for flour based products. In addition, we help you meet global environmental challenges without compromising on performance.

Let’s create your perfect flour packaging solution!

The Packaging Group GmbH · Germany · www.tpg-packaging.com

Visit us online at www.perryofoakley.co.uk sales@perryofoakley.co.uk +44 (0)1404 890300 Perry of Oakley Ltd. The UK’s Most Experienced Manufacturer of Bulk Drying, Handling & Storage Equipment Twin Trace Conveyors | Belt Conveyors | Screw Conveyors Flat Bottom & Hopper Bottom Silos | Square Bins A SQUARE APPROACH FOR A WORLD WITHOUT FOOD WASTE. DISCOVER OUR TAILORED SOLUTIONS ON OUR WEBSITE SCE.BE 26 | June 2024 - Milling and Grain Milling News

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

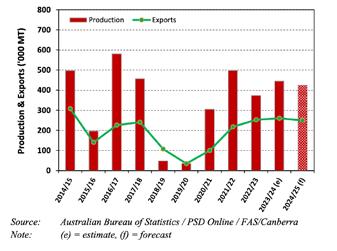

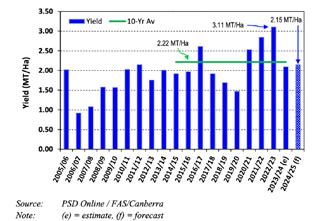

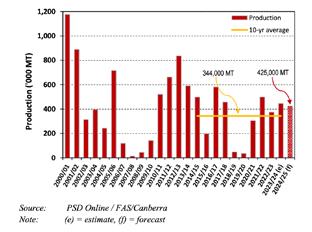

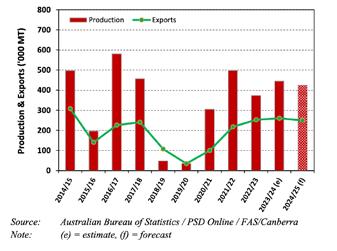

USDA: Egypt’s Wheat Imports Expected to Rise

Egypt’s wheat imports are forecast to climb in the 2024/25 marketing year as the country’s economy stabilizes and access to foreign currency improves, according to a report by the Foreign Agricultural Service of the US Department of Agriculture (USDA) released on Tuesday, April 23.

The report cites several factors contributing to the anticipated increase, including a recent influx of foreign currency from deals with the International Monetary Fund (IMF) and the United Arab Emirates, and the Egyptian government’s decision to float the Egyptian pound. These measures are expected to alleviate the severe foreign currency shortages that have hampered Egypt’s ability to import essential commodities in recent years.

“Due to the recent changes within the Egyptian economy, [FAS/ Cairo] forecasts Egyptian imports for grains (such as wheat, corn, and rice) to increase in MY 2023/24, on account of more access to U.S. dollars and the stabilization of the market,” the USDA report states.

Despite the positive outlook, the report acknowledges that full market normalization may take time, with some industry experts predicting it could extend into 2025 or even 2026.

Egypt, with a population exceeding 106 million and heavily reliant on subsidized bread, is one of the world’s largest wheat importers. The country’s domestic wheat production, while increasing slightly, remains insufficient to meet the population’s needs.

Since 2022, Egypt has suffered from severe shortages in foreign currency, which inadvertently interrupted commodity supply chains and produced high inflation rates. As a result, many traders began using the parallel market exchange rate which stifled economic growth as many importers did not have enough U.S. dollars (USD) for imports. Coinciding with this, the lingering impacts on the economy from COVID-19, the Russian invasion in Ukraine, the war in Sudan, the Israel-Hamas conflict, and the Houthi attacks on shipments in the Red Sea have also affected grain trade. However, in March 2024, Egyptian banks received a large influx of foreign currency from a deal with the International Monetary Fund (IMF) for $5 billion and a $35 billion investment deal with the United Arab Emirates for projects in Ras El-Hikma. As a result of the increased availability of foreign currency, some traders have reported Egyptian banks resolving outstanding

payments for grains stuck at the port. As the GOE announced the floating of the Egyptian pound, it hopes that Egypt’s domestic economy will better adjust to external shocks and support the ability of Egyptian businesses and industries to import the necessary raw materials needed for their industries. The GOE also hopes that the changes in the economy will encourage greater investment and enhance Egyptian exports. Due to the recent changes within the Egyptian economy, Post forecasts Egyptian imports for grains (such as wheat, corn, and rice) to increase in MY 2023/24, on account of more access to U.S. dollars and the stabilization of the market. However, many traders report that the market may not normalize until 2025, with some from industry reporting as late as 2026.

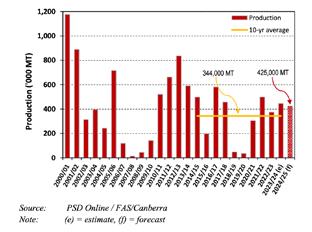

The USDA report forecasts Egypt’s wheat imports to reach 11.2 million metric tons in the 2024/25 marketing year, a two percent increase from the previous year. Russia, Romania, and Ukraine remain the primary wheat suppliers to Egypt, with the report noting that Egypt is a “price-sensitive market” that relies heavily on these countries due to competitive prices and lower freight costs.

With its wheat reserves continuing to decline, Egypt’s wheat imports in the marketing year 2024-25 are forecast to increase by two percent over the previous year due to population growth and the availability of more foreign currency in Egyptian banks, according to a report from the Foreign Agricultural Service (FAS) of the US Department of Agriculture.

The report, released April 23, noted that Egyptian banks in March received a large influx of foreign currency from a deal with the International Monetary Fund for $5 billion and a US$35 billion investment deal with the United Arab Emirates for projects in Ras El-Hikma.

“As a result of the increased availability of foreign currency, some traders have reported Egyptian banks resolving outstanding payments for grain stuck in ports,” the FAS said.

The FAS forecasts wheat imports in 2024-25 reaching 11.2 million tonnes in Egypt, which always has relied heavily on imports to help supply its considerable subsidy program that provides low-cost bread to consumers.

The country’s wheat ending stocks for 2024-25 are expected to slide to 2.48 million tonnes, about half the amount that was in reserve in 2022-23 and the lowest level since 1.85 million tonnes in 2002-03.

With Egypt’s population surging higher — it now stands at 106 million but is expected to reach 124 million by 2030 — increasing production and imports is a top priority of the Egyptian government. Perennially among the world’s top consumers of wheat products per capita, Egypt’s total consumption in 2024-25 is forecast at an eightyear high of 20.65 million tonnes, the FAS said.

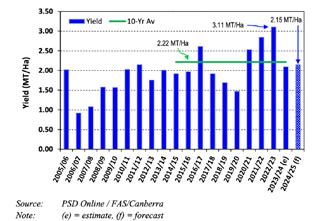

The FAS projects 2024-25 wheat production at 9 million tonnes, up slightly from the previous year.

“Wheat production in Egypt has improved through the development of new breeding and cultivation practices which have led to the spread of new high-yielding varieties,” the FAS said.

“Moreover, the use of the raised bed planting method, instead of the old method of planting in basins, has made the largest contribution to an increase in yield.”

Milling and Grain - June 2024 | 27

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

John G. Coumantaros inducted into the Milling Hall of Fame

The FlourWorld Museum of Wittenburg, Germany, has passed the sculpture recognising the induction of John G. Coumantaros, chairman of The FMN Group, into the Milling Hall of Fame.

This prestigious accolade, awarded by the museum on behalf of the Milling Hall of Fame, celebrates individuals whose lifetime contributions have significantly shaped the milling industry.

Torsten Wywiol, CEO of the Stern-Wywiol Gruppe and Roger D Gilbert, publisher of Milling and Grain magazine, which founded the Milling Hall of Fame, personally honoured John G. Coumantaros for his outstanding achievements at the award ceremony on May 22nd in New York.

Together they presented him with a bronze millstone sculpture by renowned artist Sibylle Waldhausen. John G. Coumantaros is the 2023 inductee.

At the award ceremony Mr Wywiol said, “It is a great privilege for me to pay tribute today to a man who has had a lasting impact on the milling and food industry in Nigeria as a true pioneer. John G. Coumantaros perfectly embodies the values we uphold in the Milling Hall of Fame: Dedication, passion and innovation. He is a shining example of how the visionary actions of one person can change the world for the better.”

Volkmar Wywiol, founder of the FlourWorld Museum, added, “Flour.Power.Life, our museum’s motto, underscores flour’s essential role in human nutrition, health and societal development. John G. Coumantaros embodies these principles through his transformative work in Nigeria’s food supply.”

The FlourWorld Museum is dedicated to the rich history of flour and its essential role in human civilisation.

Being inducted into the Milling Hall of Fame is the highest honour in the milling industry, recognising leaders who have made remarkable impacts through their visionary work.

The independent jury commends John G. Coumantaros for his successful implementation of a sustainable and innovative approach to food production. His leadership and dedication to advancing the industry have truly set him apart.

Our congratulations go to John G. Coumantaros on this welldeserved recognition -Roger Gilbert, publisher..

30 | June 2024 - Milling and Grain Milling News

Preparing for a more sustainable future demands a proactive partner with insights, innovative solutions, and precision services. One who can help you save costs and get the most value from locally sourced raw materials while reducing environmental emissions — all without ever compromising on performance. Our specialists on the ground work closely together with you to help shape a strong future for you and your business. Reduce waste, optimize pig performance, and step up to the circular economy — because sustainable farms are more efficient farms.

EMISS

RAWMATERIALS SUSTAI

COST SAVINGS

$ Learn

IONS CONTROL

NABLE

$

more at dsm-firmenich.com/anh

Is your herd

ready for tomorrow?

Starting signal for the expansion of the Bauck Oat Mill

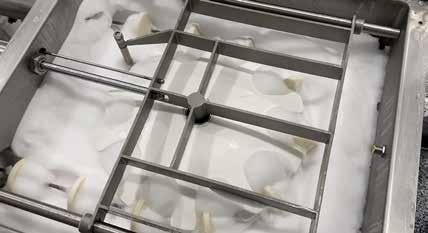

Bauck GmbH is expanding the largest and most advanced organic oat mill in Europe commissioned in 2021. Thanks to successful cooperation with the internationally renowned machine and plant manufacturer F H Schule Mühlenbau GmbH, the output of all sections of the mill will be doubled in the future. This is the response of Bauck GmbH to the strongly increasing demand for gluten-free products and organic products from sustainable production.

There is hardly any other topic that concerns people as much as nutrition. There is a philosophy for literally every aspect of nutrition, including fitness trends, culinary health risks and food intolerances. For anyone who values the organic cultivation of cereals, Bauck GmbH is the ideal choice. The family and employee run medium-sized company based in Rosche, Lower Saxony, is renowned for the high quality of its Demeter and organic products. Under the brand name ‘Bauck Mühle’, it produces a range of products including flours, mueslis and baking mixes. Three years ago, Bauck launched the largest production facility for gluten-free cereal products in Europe in Rosche – with high-performance machines and plants from Schule. And Bauck relies on the experienced specialist for oat processing from Reinbek also for the expansion of the mill. Currently, up to 20,000 tonnes of grain a year can be converted into flour or flakes in the eight-storey building in the district of Uelzen, which has a total height of 48 metres. This expansion of the mill will double the capacity in all sections, from fine cleaning, hulling and sorting to flaking and pelleting. For the market leader in gluten-free organic products, this is not just a response to the rising demand. By providing additional capacity for organic and Demeter raw materials, Bauck is also pursuing the goal of further expanding organic farming in the region. The expansion of the mill will take place while the mill is in operation and is expected to be completed by the beginning of 2025.

“The quality of the plants and the sound technical advice we receive from Schule have won us over,” explains

Jan-Peter Bauck, Managing Director of Bauck. “Above all, the enormous commitment of the Schule team, starting from the first meeting, through the entire construction phase and commissioning of the mill, including the subsequent customer service, was the decisive factor in our decision to implement also the expansion of our mill with Schule. When working with Schule, we always get the feeling that it is not just about providing a service, but about working together on a joint project.” Friedemann Wecker, who has also been a member of the Bauck GmbH Management since 2023, adds: “The plant’s performance speaks for itself – from the first commissioning until today. We also appreciate the fact that the plant technology is constantly being advanced due to Schule’s outstanding expertise. That is reason enough to continue our joint success story with the project ‘Good Flake 2.0’.”

Especially in the currently difficult market situation, it cannot be expected that consumers spend money on premium products, explains Marius Hermes, Managing Director of Schule Mühlenbau. “Of course, we are also very pleased about the success of Bauck GmbH. The significant increase in our plant output after just four years of operation is testimony to the high quality of the products and their popularity with consumers. The fact that Bauck has once again chosen Schule for the mill expansion is of course the greatest compliment for us as a plant manufacturer and a confirmation of our long-standing and good partnership.”

Use the Promo Code ATLANTA24 Would you like a complimentary digital subscription to Milling and Grain magazine? YOUR GLOBAL PARTNER Simply visit: https://store.magstand.com/millingandgrain Milling and Grain - June 2024 | 33 Milling News

New agri-tech initiative enhances farm resilience with

seaweed innovation

In a significant boost to sustainable agriculture, the UK Agri-Tech Centre, in collaboration with Rothamsted Research, Algapelago Ltd, and Harper Adams University, backed by Innovate UK, has announced the launch of the groundbreaking ‘low energy kelp’ project.

The 24-month project ‘optimising low energy extraction of kelp for soil and livestock nutrition’ is set to receive a research grant to develop a novel two-stage extraction process that will produce consistent, high-quality liquid bio stimulant and an animal feed supplement from cultivated kelp.

These products are intended to enhance soil and animal health while reducing reliance on chemical inputs.

Ross Robertson, UK Agri-Tech Centre farming technol-

ogy specialist explains: “Cultivated kelp is a sustainable and rich source of nutrients and bioactive compounds that benefit microbial communities, leading to healthier soil and livestock systems.”

He explains that the project will conduct kilo-scale laboratory trials, prototype systems development, and controlled field trials to test the efficacy of the products under environmental stresses.

In-vitro livestock trials conducted by Harper Adams University will focus on the impact of seaweed supplements on rumen function and performance.

Rothamsted Research will lead plant trials focusing on how Algapelago’s seaweed biostimulant influences plantsoil interactions, under abiotic stresses of heat and drought.

Luke Ansell, head of operations at Algapelago, says: “This project is a pivotal step towards unlocking the potential of seaweed in agriculture.

“We’re eager to lead the way in demonstrating how low-energy, sustainable practices can significantly benefit agriculture while adhering to environmental standards.”

Dr Martin Blackwell, soil scientist at Rothamsted Research, adds: “We’re excited to work with Algapelago Ltd and the UK Agri-Tech Centre on this initiative.

“Algapelago’s novel approach to seaweed processing now only supports sustainable farming but also addresses the pressing challenges of modern agricultural practices in our changing climate.”

The ‘low energy kelp’ project is ambitious in its long-term goal and promises to be a cornerstone for future agricultural practices, driving forward the integration of sustainable resources like seaweed into mainstream farming.

This initiative not only supports the health of the environment but also ensures the resilience and productivity of the agriculture sector in the UK and beyond.

34 | June 2024 - Milling and Grain Milling News

Introduction to Manual Turning and Milling

The Introduction to manual turning and milling course, from Seta, is a combination of elements from their popular manual turning and manual milling courses. It’s an excellent introduction to practical turning and milling, providing instruction in safety, use of drawings and measuring equipment, feeds and speeds, work-holding, tool setting and a range of turning and milling operations.

Instruction takes place both in the classroom and in Seta’s state-of-the-art workshop facilities. This course is ideally suited to those with little or no previous turning or milling experience.

Content

Among the topics in this course includes:

• Safety relevant to turning and milling

• Interpretation of engineering drawings and symbols

• Measuring instruments relevant to turning and milling: - types, care and use

• The centre lathe and its controls

• The milling machine and its controls

• Cutting tools: terminology, selection and mounting

• Feeds and speeds: guidance on calculations; setting feeds and speeds

• Coolants: types and uses

• Turning operations: A selection from: facing; turning diameters; centre drilling; taper turning (using compound slide method); producing threads. Use of 3 and 4-jaw chucks

• Milling operations: A selection from: milling faces; milling step faces; open and closed slots; vees and angles

• Faults recognition: guidance on turning and milling faults and means of avoiding them

The Dates for this four-day course begin on July 15 – July 18 and takes place from 8:30am to 4:00pm. Seta provides accredited, industry-recognised training to an advanced level, delivered by highly experienced staff with vast industry knowledge.

https://seta.co.uk

Milling and Grain - June 2024 | 37 Mill TRAINING

FOCUS Product June 2024

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

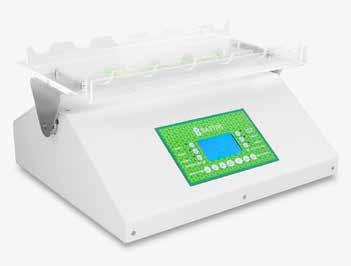

Batch Mixer by

Avlan Blanch

The Alvan Blanch Mixer is ideal for blending a wide range of dry products of varying densities, including meal, rolled grain, cake, pellets, dried beet pulp, vitamin/mineral premix and proportions of moist product like brewer’s grain. Liquid molasses can be evenly applied in ratios of up to 10 percent. The Mixer is also suitable for industrial applications, able to handle granular or powdered plastics. Mixers can be fully adapted to suit a range of needs.

The Mixer has a gentle, but rapid action. The conveyor draws the material up the inclined base, towards a segmented agitator. Having passed through the agitator, the material tumbles backwards. Additives are introduced via the low-level intake hopper. The mixed product is discharged from the slide operated spouts.

www.alvanblanchgroup.com mymag.info/mqcR

Sortex H SpectraVision by Bühler

Sortex H SpectraVision has been developed using the best of Swiss and British engineering know-how. As the culmination of our 75 years of extensive experience in optical sorting, SpectraVision offers three key benefits for our customers. SpectraVision has been designed to supply maximum yields. The newly designed in-house full-color cameras provide the best color differentiation for the sublest of color defects, while new InGaAs cameras take foreign matter (FM) detection to new levels. Innovative ejection algorithms significantly minimise false rejects and new calibration, and tracking algorithms improve machine consistency, reducing false rejects. With machine setup changes logged and saved on Bühler Insights and real-time tracking of sorting performance and emergency warnings with SORTEX Monitoring System. Default modes and recipes for each product are pre-set and tested by SORTEX experts for optimum machine set up right out of the box. A simple user interface design and individual sensitivity control over each defect makes it easy for operators to maintain the optimum machine performance.

www.buhlergroup.com

mymag.info/dIpw

NHP200 by TekPro

The full Holmen range of Pellet Durability Testers are exclusively Made in Britain by Tekpro, and offer a fast and reliable method of testing PDI or Mechanical Durability. From feed pellets to wood pellets, either manual or automatic testing, TEKPRO provides the solution whatever the size of your mill!

The NHP200 is preferred by quality focused feed mills due to its ease of use and repeatable accuracy of the test process, its other benefits include:

• Suitable for Animal Feed & Wood Pellets between 3mm and 12mm

• Semi-Automatic – less need for human input

• Quicker than alternative methods

• Ideal for laboratories in busy testing environments

• Reproducible accuracy of ± 0.1%

• PDI results are stored and displayed on Colour LCD touch-screen, and can be printed or sent to other software by Ethernet socket

• Daily test results can be sent by email to staff, even if working remotely

• Digital Self Calibration built in

• Now includes dedicated Fines Calculation feature

• 1PH 110V-115V or 1PH 220V-240V

www.tekpro.com

mymag.info/pZkv

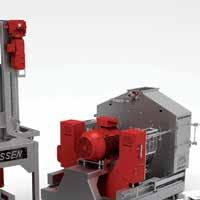

Platinum Series PT1200 Gear Driven Pellet Mill by Yemmak Yemmak Platinum Series PT1200 Gear Driven Pellet Mill has a high production capacity and impressive pelleting performance of up to 45 metric tonnes/hour. With three rollers with a diameter of 454 mm, the capacity increases proportionately to the higher active pelleting area. The engine is paired with a specially designed two-stage gear set that helps transmit its power to the machine efficiently.The most important advantage of the new Platinum Series Gear-Driven Pellet Mills is the 12–15 percent (up to 20 percent in some cases) capacity increase for higher energy efficiency and the same amount of consumption. The gearbox technology allows the Platinum series pellet mills to increase their power transmission efficiency to 97–98 percent. They enjoy enhanced capacities compared to their equivalents with belt-pulley power transmission systems. The two-stage precision gear set guarantees the highest efficiency and capacity.

www.yemmak.com mymag.info/lLLU

Maize Grinder by Pingle

The maize grinder is developed on the basis of a hammer mill. For the integral maize kernels that have been moisture conditioned, this machine is able to finish dehulling, degerming and grinding operations in one step, and the processing efficiency is improved. Technically speaking, the power consumption for producing one tonnage of maize grit is reduced by 20-30 percent when compared with traditional machines, thereby significantly enhancing the economic returns. With the help of this machine, a complete granule of maize is shattered into 4-6 fragments with a tidy appearance. The embryo breakage rate is less than 10 percent, and the hull is kept whole. This brings great convenience for the following separation of embryo, hull and grit. So, this maize grinder is highly recommended.

www.plflourmill.com mymag.info/eoKS

38 | June 2024 - Milling and Grain

Arrakis by Bühler Reinventing an icon

Have you ever met someone for the first time, but felt as if you’ve known them forever? Meet Arrakis.

Viewed from the front, Arrakis tells the story of the past, but at the same time, also offers a glimpse of the future. It offers features centered around performance, robustness and simplicity, all brought together in a timeless and contemporary design.

The latest addition to Bühler’s state-of-the-art grinding portfolio

- Arrakis is the successor of the Airtronic, considered an icon in the history of milling for its durability and straightforwardness in operation. The new solution, Arrakis, takes these qualities to the next level: increases efficiency, reliability, and simplicity of operation.

At the heart of Arrakis is the grinding unit – a true pillar that millers can rely on thanks to its stable grinding performance. The patented grinding gap adjustment ensures rigidity and stability over time to maximise grinding performance. Sturdy casted frame with load-carrying structure provides high vibration absorption, ensuring robustness for long periods of continuous operation. Load cell sensors control the feeding gap to provide a stable product flow across the grinding rolls for maximum efficiency. In addition,

FOCUS Special

the foreign object protection prevents damage, increasing security and longevity of the roller mill.

Another highlight of Arrakis is its ease of operation. Its intuitive interface makes controlling and monitoring simple and straightforward. Thanks to its secure remote access function, the grinding can be operated through various devices and from anywhere.

The need to retrofit existing plants has been thoughtfully addressed, aiming to minimise potential risks associated with transitioning while enhancing productivity, effectiveness, reliability, and lowering maintenance costs. As Arrakis is built on the same footprint as its predecessor, Airtronic, one-to-one replacements can be made, simplifying the installation process. Connecting the fixed speed feeding roll to the main roll’s drive guarantees a more streamlined system that is easy to install and maintain.

The feeding unit is equipped with a cleaning flap, which ensures the complete discharge of the remaining product and easy cleaning of the feed module. Brushless synthetic scrapers eliminate productaccumulating dead spots, increasing food safety, while selfadjusting knife scrapers align to the surface of rolls, eliminating the need for manual adjustments, and ensuring clean rolls at all times.

For more information, go to mymag.info/EaSD

Milling and Grain - June 2024 | 41

ai-lati.com

simaimpianti.net

BEYOND MAKES US SEE KNOWLEDGE THE HORIZON paglierani.com ocrim.com

Where do we stand in 2024? Wheat, bread, gluten and health:

by Em Prof Fred Brouns, Maastricht University, Netherlands; Prof Peter Shewry, Rothamsted Research, Harpenden, UK & Prof Daisy Jonkers, Maastricht

University Medical Center, Netherlands

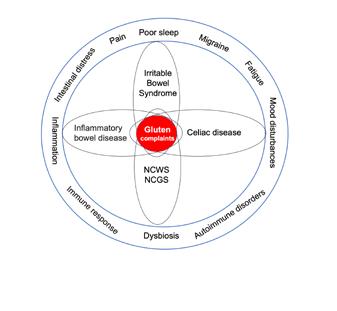

During the past decade an increasing number of consumers have reduced their consumption of wheat products, due to concerns about adverse effects of wheat, bread and gluten on health. This has been driven by social media posts, articles in the press and popular books claiming that consumption of wheat causes gastrointestinal complaints, obesity, diabetes, cardiovascular and immune diseases. As a result, the number of people reporting health complaints after consumption of bread and other foods that contain wheat and gluten has increased sharply in a relatively short period of time.

Interestingly, many consumers who report adverse reactions after eating modern factory-produced bread but not after eating pasta or after eating bread made using traditional processes or from modern spelt bread, although all these products contain gluten. An important point here is that the symptoms perceived are real but that there is in most cases no clear organic explanation.

The lack of plausible explanations (and mechanisms) for these reactions led to the establishment of the international research consortium ‘Well on Wheat?’ in 2016. The aim of the research program was to determine whether differences in types of wheat and bread-making processes, and the naturally occurring compounds present in the grains and breads, could play a causal role in the gastrointestinal complaints experienced.

All steps in the grain processing chain that influence the composition of the bread, and thereby may impact on health and / or the perception of gastrointestinal complaints, were evaluated, namely: grain cultivation, milling, mixing, baking and consuming bread.

In the “WellonWheat?” research program Maastricht University, Wageningen University Research, Rothamsted Research (UK) and the Dutch Bakery Center, worked together with other Universities and crop research centres. “Well on Wheat?” was financed by a grant of the Dutch Government “TKI- Top Knowledge Institute” and by a wide range of additional partners* from the AgriFood chain who donated unrestricted research grants. *These

partners are: AB-Mauri bakery Ingredients, , Made, Netherlands; Borgesius Holding BV-Albert Heijn, Stadskanaal Netherlands; CSM innovation Bakery Center, Bingen, Germany; CYMMIT, Texcoco, Mexico; DSM Food Specialties, Delft, Netherlands; Fazer Bakeries Oy, Helsinki, Finland; Health Grain Forum, Vienna, Austria; ICC- Intl. Vienna, Austria; IWGA, Kansas 66210, USA; Lantm¨annen EK , Stockholm, Sweden; Mondelez , Saclay, France; Nederlands Bakkerij Centrum, Wageningen, Netherlands; Baking Industry Research Trust, Wellington, New Zealand; Nutrition et Sante, Revel, France; Puratos BV, Groot Bijgaarden, Belgium; Rademaker BV-Bakery equipments, Culemborg, Netherlands; Sonneveld Group BV, Papendrecht, Netherlands; Zeelandia- HJ Doeleman BV, Zierikzee, Netherlands.

Causes and prevention of health problems related to grain consumption

Gastrointestinal complaints due to eating grains that contain gluten can be divided into three types: celiac disease, gluten sensitivity in the absence of celiac disease and wheat allergy.

What is gluten?

Gluten is a protein fraction that is present in all types of wheat: bread wheat, spelt, emmer, durum, einkorn, triticale (a man-made cross between wheat and rye) and tritordeum (cross between durum and wild barley). These include types of wheat are marketed under trade names, such as Kamut™ and Khorasan™ wheat. Semolina, farro, farina, bulgur and couscous are all products made from wheat and all contain gluten.

Gluten is a mixture of related proteins that are stored in the grain to support germination. They constitute 70 to 75 percent of the total proteins in wheat grain and are classified into two types, gliadins and glutenin’s. The amount and composition of the glutenin fraction is an important factor determining dough strength, and hence breadmaking quality, with the gliadins contributing to dough viscosity and extensibility.

Barley and rye grains contain related proteins, called hordeins and secalins, and are also considered as ‘gluten sources’ in ‘gluten-free recommendations’.

In addition to gluten, wheat also contains other components

44 | June 2024 - Milling and Grain F MAXIMISED FLOUR MILLING

World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT-FS Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT-EX Mixers, conveyors, Ducting System, High Temperature Non Food-Safe available Non EX available Non EX available enquiries@hydronix.com Contact us for more details hydronix.com Hydronix-Milling and Grain-Advert Mar 2023 215x140mm.indd 1 28/02/2023 13:55 Milling and Grain - June 2024 | 45 F

Agribusiness facilities

Silos Córdoba provides engineering services for product quality control, storage and handling equipment, ensuring convenience, reliability, efficiency and profitability in plant management.

Silos Cordoba mainly operates in the post-harvest sector where it offers comprehensive solutions for your grain storage, handling and conditioning needs.

FROM CONCEPTION OF THE PROJECT TO MANAGEMENT

Turn-key projects

SCG Silos Grupo S.L. Glorieta de las Tres Culturas Nr. 1, 4º A 14011 Córdoba. Spain T +34 857 835 623 info@siloscordoba.com www.siloscordoba.com

• GRAIN STORAGE INSTALLATIONS • GRAIN PORT TERMINALS • GRAIN DRYING FACILITIES • INDUSTRIAL PROCESSES • DESIGN

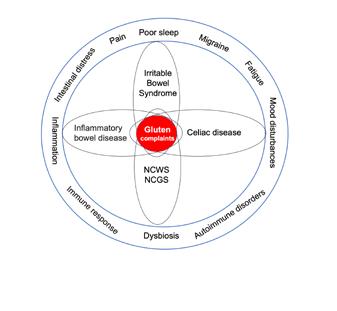

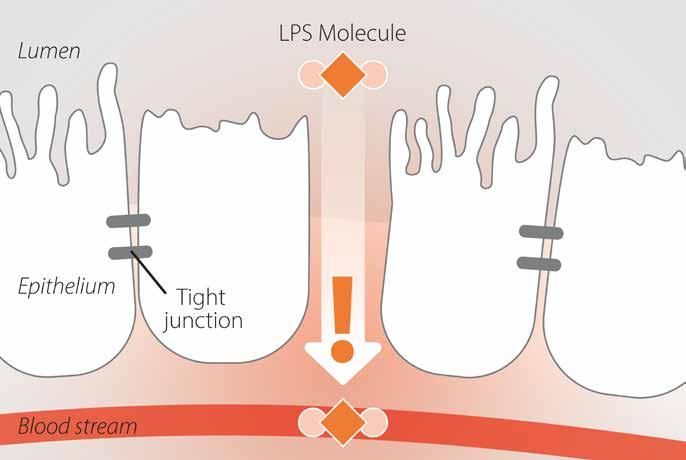

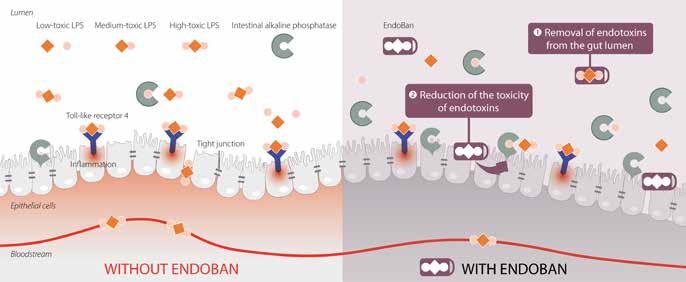

that may lead to intestinal complaints in some people, including amylase-trypsin inhibitors (ATIs) and rapidly fermentable oligosaccharides, disaccharides, monosaccharides and polyols (FODMAPs), the most important being fructo-oligosaccharides (fructans). The fermentation of FODMAPs may result in rapid gas formation causing sensations of bloating in the large intestine and an urge to defecate (figure 1).

Gluten and Celiac Disease (CD)

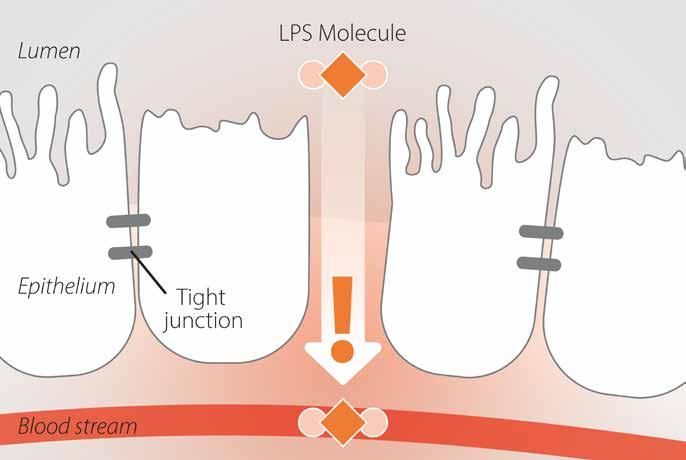

Celiac disease is caused by exposure of the intestinal epithelium to peptides released by the partial digestion of gluten.

Gluten, like most other plant proteins, is easily digestible (>94 percent). However, this digestion may release fragments (peptides containing the amino acids proline and glutamine) that cannot be further broken down into individual amino acids by our digestive enzymes. In certain circumstances, these peptides can pass through the intestinal wall, after which in a series of steps, they are detected by our immune system as a foreign, unwanted protein. This can then lead to inflammatory reactions and cause damage to the intestinal wall, which reduces the absorption surface of the intestine and can lead to nutritional deficiencies.

Many celiac-active peptides (often called epitopes) have been identified which are particularly abundant in (but not restricted to) gliadins. Research has shown that CD can only develop in individuals who have a specific hereditary predisposition to it. Depending on the region of the world, this genetic predisposition is present in approximately 25-40 percent of the total population. However, only approximately 4 percent of these individuals develop the disease, which results in an overall CD-prevalence of about 1 percent of the global population.

Complexity of the complaint pattern

The abdominal and health complaints frequently reported to be associated with wheat and gluten consumption overlap with the patterns of symptoms of other diseases, such as intestinal inflammatory diseases and irritable bowel syndrome (IBS). As a result, CD may fail to be diagnosed and the CD may be higher than the commonly quoted 1 percent of the population. CD is more common in women than in men (ratio 60-40 percent), the reason for this is unclear. CD-related intestinal damage and other symptoms are greatly reduced or almost completely disappear after following a strict (lifelong) gluten-free diet.

Wheat allergy

Food allergy usually results from reactions to specific proteins in consumed foods (e.g. nuts, fish, crustaceans and shellfish, milk protein, soy) and occurs in approximately six percent of children

Hammer mills

Feeding devices

Grinding systems ` Dust explosion protection

*The protein content of wheat may vary significantly due to environmental, and fertilizer use circumstances.

and three percent of adults. Figures for wheat allergy in children vary depending on age and country between <0.1% and 1 percent but then 80 percent of these children ‘outgrow’ the allergy before reaching the age of eight and 96 percent before the age of 16. The percentage of adults suffering from wheat allergy is therefore low, approximately 0.25 percent.

Based on protein analysis wheat grains contains over 1000 different proteins, several of which are classified as potential allergenic. Wheat allergy occurs as respiratory allergy (bakers’ asthma), contact urticaria (hives), and as food allergy.

The incidence of asthma (1-10 percent) and hay fever (18-29 percent) is high in professional bakers due to exposure to flour dust, which can enter the lungs during breathing. The allergic symptoms are usually reduced or disappear completely after avoiding exposure to wheat and other grains that contain gluten.

Gluten or wheat sensitivity?

There have been numerous suggestions in the media and popular press, including the popular books ‘Wheat Belly’ and ‘The Food Hourglass’, that gluten/bread consumption leads to health problems in many people due to ‘being sensitive to gluten. This has greatly stimulated consumer demand for ‘gluten-free’. However, important questions remain, on the true nature of the condition, how it can be diagnosed, the true prevalence in the population and how (and by what) the reaction is triggered.

Originally, the term ‘non-celiac gluten sensitivity’ (NCGS) was used because gluten was considered to be the causative agent. However, because other components from wheat may also play a role, the term

Figure 1: Schematic overview of bread wheat composition and components that may be involved in health complaints.

Figure 1: Schematic overview of bread wheat composition and components that may be involved in health complaints.

Solutions

tietjen-original.com/en Tietjen Verfahrenstechnik GmbH | Germany

`

Milling and Grain - June 2024 | 47 F

It All Depends on the Grinding

for Feed Mills and Milling Companies

`

`

‘non-celiac wheat sensitivity’ (NCWS) is increasingly used. Table 1 provides a brief overview of the main characteristics of the wheatrelated diseases.

Do non-gluten components trigger adverse reactions?

Amylase-trypsin inhibitors (ATIs) are natural plant proteins that inhibit the digestion of the starch (by amylase) and protein (by trypsin) in the wheat grain by harmful insects and thereby contribute to protection of the plant. In this respect they may be considered as ‘natural plant pesticides’. However, ATIs, particularly in bakers’ asthma, may play a role in the development of CD.

Gluten and ATIs occur together in the grain and flour and are therefore both present in wheat products. They are also difficult to separate which makes it difficult to separate their effects in glutenrelated disorders.

In many studies, vital gluten (which is prepared by industrial separation from starch) has been added to a gluten-free meal (which itself serves as a control), assuming that it is 100 percent pure. However, this gluten-isolate also contains a significant quantity of ATIs, as well as other proteins. Consequently, differences in responses to consumption of ‘gluten-free’ and ‘with gluten’ foods could be caused by gluten, ATIs or both components. In addition, ATIs exist in multiple forms (at least 19 ATI isoforms in wheat) which may differ in their biological activity. Because ATIs are very difficult to purify, the effects of individual isoforms have not been determined. As a result, it is not known which isoforms and in what amounts may cause adverse health reactions in humans.

Furthermore, wheat products also contain indigestible dietary fibres, which pass into to the colon, where they are subject to fermentation by the microbiota. Some of the non-digested/non-

Figure 2: The strong similarities between symptoms that patients report when self-diagnosing and symptoms of other gastrointestinal disorders makes it difficult to make a rapid and correct diagnosis. Dysbiosis = abnormal intestinal flora (microbiota). NCWS: Sensitivity to wheat in the absence of CD, NCGS: Sensitivity to gluten in the absence of CD

absorbed carbohydrates are called FODMAPs (Fermentable Oligo-, Di- and Monosaccharides and Polyols). These can lead to osmosis-induced water retention in the intestine while fermentation may result in gas formation, which may result in unpleasant bloating, flatulence, abdominal pain and loose stools/ diarrhoea. There is increasing evidence that FODMAP (not gluten) are the cause of many of the complaints reported as gluten sensitivity.

When does non-celiac wheat/gluten sensitivity occur?

There is uncertainty about the occurrence of NCWS/NCGS. The available figures are self-reported and differ worldwide, with a

SETS THE STANDARD IN SQUARE SILOS

Bauck Mühle, Germany

“The biggest challenge during installation was working simultaneously with the concrete builder. This required good cooperation and planning. The installation went smoothly, with a great result. And so we contributed to one of the most modern bio-mills in Europe.”

Dennis Haman, Project leader

Location: Application: Rosche, Germany Bio grainhandling and flour

www.tsc-silos.com Scan for references!

Capacity 5.700 m³ Project details Bins 51 Width 11 m Length 35 m

48 | June 2024 - Milling and Grain F

Fane Valley, Ireland

Looking for a total feed mill solution? We’re listening

As industry experts, we understand the unique challenges you face in the animal feed industry. That’s why we are committed to assist you throughout the entire journey, from concept to complete installation. We are fully equipped to bring your vision to life!

Let’s talk partnership »

range reported for European countries of 6.2 percent to 13 percent. It is striking that the reported gastrointestinal complaints are usually present within a very short time after consumption (minutes to hours). The precise cause of the complaints is often unknown and this makes it difficult to provide specific advice to patients. Because the experience of symptoms can be strongly influenced by ‘expectations created by hearsay’, the possible role of psychological effects is very relevant. A reliable diagnosis of NCWS is at present problematic because no reliable biomarkers are available and many of the symptoms reported during ‘self-diagnosis’ overlap with other conditions such as IBS and chronic intestinal inflammation (IBD)

To better understand NCWS/NCGS, a study was carried out in Italy on patients who were referred to a university gastrointestinal clinic for a period of two years because of their complaints. 292 patients who reported that they were certain that their symptoms occurred immediately after eating gluten, were selected for further study. These individuals were required to follow a gluten-free diet

Table 1: overview of the most important

for six months and the occurrence of symptoms was recorded. After this gluten-free period, gluten was added to the diet for 1 month and symptoms were recorded.

This showed that that 86 percent of people with self-reported wheat/gluten sensitivity did not experience any effects when gluten was reintroduced into the diet. In addition, 6 percent of those selected were shown to suffer from celiac disease. It is therefore important to rule out celiac disease in case of persistent gastrointestinal complaints (which can be done by a blood test).

A small group of patients (6.88 percent) experienced symptoms after ingesting gluten (which would also contain ATIs) without celiac disease. The observation of immune reactions, changes in intestinal permeability (which allows unwanted substances and bacteria to enter the body) and increased numbers of white blood cells in the intestines in some of these patients shows that further research into the possible causes is urgently needed.

(References available upon request)

gluten-free eating followed by a gluten challenge test, the true figure is estimated to be lower (5-7 percent).

Celiac disease (CD)

Wheat allergy (WA)

NCWS/NCGS

Prevalence 0.6-2%, mean~1%, more in women than in men (ratio 2:1 - 3:1). Ca. 0.25% 6.2% to 13%*.

Time to complaints

Gut surface damage

Weeks to years

Almost always

Minutes to hours

Not observed

Symptoms Complaints pattern not different between CD, WA en NCWS.

Hours to 2 days

Not observed

Intestinal bloating, pain, diarrhea, nausea, irregular defecation/ consistency, gut microflora disturbances, inflammation. Other complaits: general malaise, tiredness, headache, anxiety, foggy mind, impaired quality of life.

characteristics of the wheat-related disorders. CD-celiac disease, WA-wheat allergy, NCWS/NCGS-self-reported wheat/ gluten sensitivity in the absence of celiac disease. In a Dutch study this figure was 6.2 percent. *Based on testing after a period of

characteristics of the wheat-related disorders. CD-celiac disease, WA-wheat allergy, NCWS/NCGS-self-reported wheat/ gluten sensitivity in the absence of celiac disease. In a Dutch study this figure was 6.2 percent. *Based on testing after a period of

Are you ready for substantial reduction in batch time ? alfraequipment.com/en/Intro-ADA

in dosing & weighing systems and smart automation software for the nutrition and solids industry. Milling and Grain - June 2024 | 51 F

KSE Group specializes

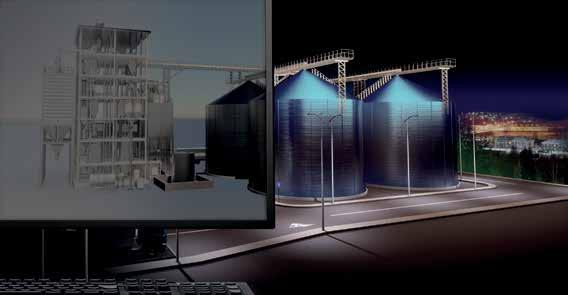

WHEAT MILLING INNOVATION

Well-established systems and technologies in pasta production

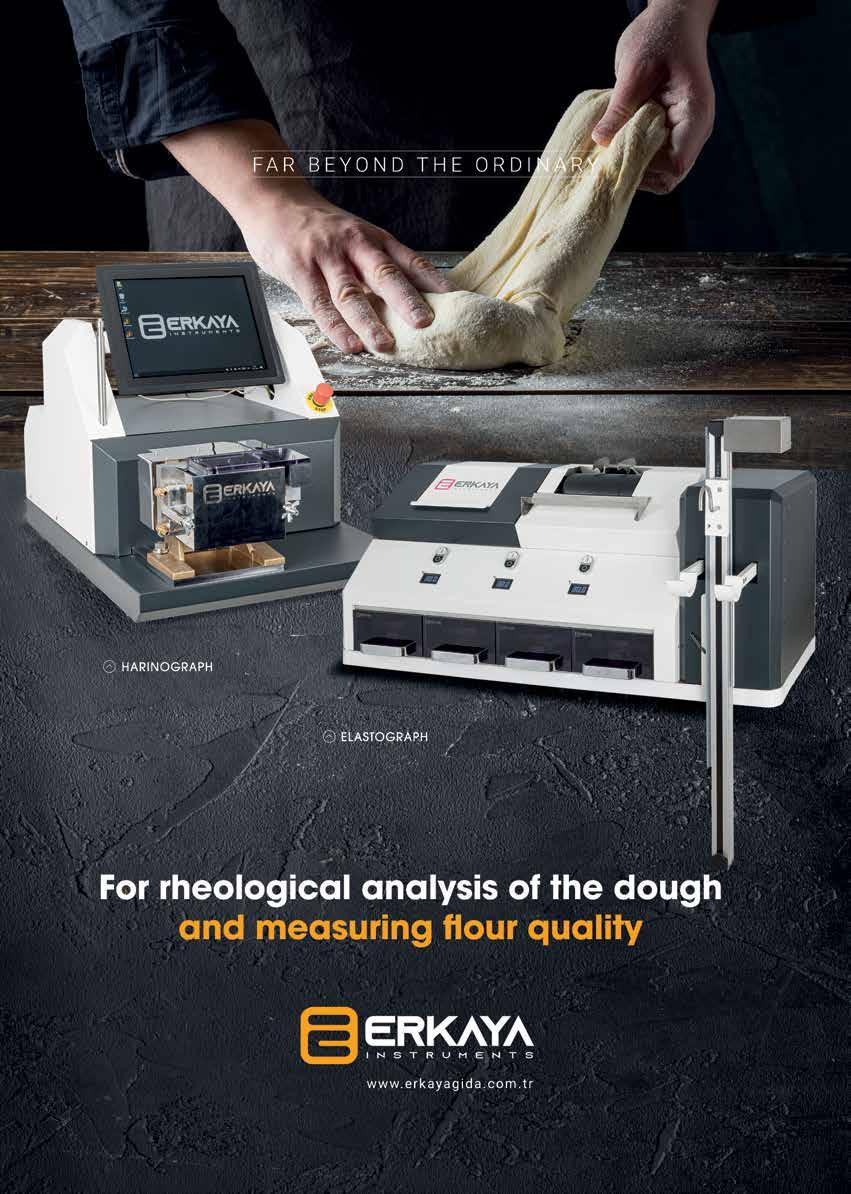

by Luigi De Lisio, Quality manager, Colavita S.P.A, Italy

The operations involved in milling wheat are the same, whether it is durum or soft wheat. Basically, they include the following steps: grain reception, precleaning in silos, cleaning, conditioning at appropriate humidity, milling, storing, mixing, transfer to means of transportation or packaging. The flow chart of a durum wheat mill differs from a soft wheat mill in that the goal is to obtain a final product with a sharp edge, i.e. semolina (passing through a sieve with a mesh size of 0.180 mm, maximum 25 percent; presidential decree no. 187 of 09/02/2001), while in the soft wheat mill the aim is to obtain a finished product with a reduced grain size, i.e. flour. Consequently, in the durum wheat mill there is a greater number of crushing mills than in the soft wheat mill where regrind mills are preferred. As it is well known, the characteristic machine of the durum wheat mill is the purifier.

Debranning