PM40065710 Recladding for Renewal Façade upgrades are not merely esthetic. P. 12 Decarbonizing Remote Communities p. 8 Hydrogen Faces Roadblocks p. 18 Mass Timber Reaches New Heights p. 22 May/June 2024 ccemag.com

XTR-aordinary Performance ALL-NEW NEOTHERM® XTR BOILER AND VOLUME WATER HEATER

May/June 2024

COLUMNS

04 | Comment

Bamboo may be the building material of the future.

16 | Legal

In construction, who is considered an employer?

22 | Conversation

Mass-timber construction is changing building codes.

DEPARTMENTS

05 | ACEC Review

Taking pride in the industry. Consulting engineering in numbers.

11 | Letter to the Editor

Unifying regulation of professional engineers.

FEATURES

8

Decarbonizing Remote Communities

The federal government is incentivizing communities to switch away from hydrocarbons to emissions-free and/or renewable energy sources.

12

COVER STORY Recladding for Renewal

Recladding existing towers with new building envelopes can make them more energy-efficient, comfortable for tenants and visually appealing.

15

Breaking Down Barriers to DEI

Inclusion for the next generation of engineers begins with increasing awareness of engineering and its prerequisites at the high school level.

18 Why Hydrogen Has Been a Non-Starter

Hydrogen is touted as a tool against climate change, but faces scientific, engineering, environmental and economic roadblocks, particularly with regard to access and delivery.

20

Fire Protection for EV Plants

Special measures are needed to engineer new facilities to contain any fire scenario and protect occupants from what could be a large and intense hazard.

CANADIAN CONSULTING ENGINEER 3 ccemag.com

22 18 ON THE COVER Exp helped WZMH Architects renovate this Toronto tower to improve insulation, airtightness and water resistance. See story on p. 12. PHOTO C OURTESY W ZMH AR CHITECTS.

8

CONTENTS

Volume 65 | ISSUE 3 ccemag.com

Comment

by Peter Saunders

Can Canada Do Bamboo?

Efforts to make construction more sustainable have turned, in part, to unconventional building materials. One example that may seem particularly unlikely in Canada is giant bamboo. The federal government is helping Amir Mofidi, P.Eng., an associate professor of engineering at Brock University in St. Catharines, Ont., research options to (a) grow new types of bamboo locally and (b) engineer them as composite materials.

“Bamboo has the potential to become the construction material of the future.”

– Amir Mofidi, P.Eng.

While bamboo is already popular in floors and decking, structural applications are still being explored. The motivation for Mofidi’s research—funded by a Natural Sciences and Engineering Research Council (NSERC) Discovery Grant—is the construction industry’s current reliance on concrete and steel, which are associated with high carbon emissions, and softwood timber, which takes decades to grow. By way of comparison, some species of giant bamboo grow up to 1 m a day and can be harvested after just five years.

“The realization that giant bamboo has the potential to become the construction material of the future came to me a few years ago, in discussion with two undergraduate students,” says Mofidi, who is better-known for rehabilitating concrete structures. “It’s renewable, it can grow quite fast, it can reduce the risks of deforestation and carbon emissions and the fibr e in some species is so strong, it is comparable to steel.”

The backgrounds of the students in question were in Asian and African regions already well-known for using bamboo in construction. Modern, engineered, struc-

tural bamboo buildings are now rising up to six storeys in China, for example.

If much of the potential for bamboo construction remains in warmer climes, Mofidi’s hope is to develop a non-invasive species that could survive Canadian winters, down to -40 C, so it could eventually be grown outdoors, not just in his lab.

“We want to develop partnerships with the Niagara Region’s farming community and work toward providing an economically justifiable crop,” he says. “If our coldhardy bamboo grows big and strong enough, we could produce laminated bamboo lumber (LBL).”

“Bamboo can grow viably anywhere in the tropics, but it also has great potential as a local material in Canada,” adds Mofidi’s colleague, Kent Harries, P.Eng., a Canadian professor of structural engineering and mechanics at the University of Pittsburgh, who has been glad to see consulting engineering firms like Arup engage with the bamboo growing community. “When we look at sustainability in the construction industry, a local option is a good option. If you’re shipping it around the world, I’m not sure you’re addressing sustainability! We have to make sure we’re specifying something that’s appropriate.”

And Mofidi’s work is building on a foundation of existing research where Canada has punched above its weight, even though bamboo has so far only been grown far from its borders.

“Research has been ongoing in North America for almost two decades,” he says. “Brock Engineering is rather new and we want to make sure our work with bamboo is aligned with the progress made so far and correlates to the future goals of the global construction community.”

Peter Saunders •

psaunders@ccemag.com

READER SERVICE

Print and digital subscription inquiries or changes, please contact: Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Peter Saunders (416) 510-5119 psaunders@ccemag.com

SENIOR PUBLISHER

Maureen Levy (416) 510-5111 mlevy@ccemag.com

MEDIA DESIGNER

Lisa Zambri

EDITORIAL ADVISORS

Darryl Boyce, Todd Busch, Guy Bruce, Andrew Macklin, Sadaf Parvaiz

ACCOUNT CO-ORDINATOR Cheryl Fisher (416) 510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER

Beata Olechnowicz (416) 510-5182 bolechnowicz@annexbusinessmedia.com

GROUP PUBLISHER

Paul Grossinger (416) 510-5240 pgrossinger@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CANADIAN CONSULTING ENGINEER is published 6 times per year by Annex Business Media 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 Tel: (416) 442-5600 Fax: (416) 510-6875 or (416) 442-2191

EDITORIAL PURPOSE: Canadian Consulting Engineer magazine covers innovative engineering projects, news and business information for professional engineers engaged in private consulting practice. The editors assume no liability for the accuracy of the text or its fitness for any particular purpose.

SUBSCRIPTIONS: Canada, 1 year $67.32, 2 years $108.12. Single copy $8.50 Cdn + taxes. (HST 86717 2652 RT0001). United States $153.00 (CAD). Foreign $175.44 (CAD).

PRINTED IN CANADA. Title registered at Trademarks Office, Ottawa. Copyright 1964. All rights reserved. The contents of this publication may not be reproduced either in part or in full without the consent of the copyright owner(s). Annex Privacy Officer: Privacy@annexbusinessmedia.com Tel: 800-668-2374. ISSN: 0712-4996 (print), ISSN: 1923-3337 (digital)

POSTAL INFORMATION: Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to Circulation Dept., Canadian Consulting Engineer, 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1.

PRIVACY: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us. Tel: 1-800-668-2374, fax: 416-5106875 or 416-442-2191, e-mail: vmoore@annexbusinessmedia.com, mail to: Privacy Officer, 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1.

Member of the Audit Bureau of Circulations.

Member of Magazines Canada

SCAN CODE TO VISIT CCE’S WEBSITE: Find the latest engineer-related news, stories, blogs and analysis from across Canada

4 CANADIAN CONSULTING ENGINEER May/June 2024

TAKING PRIDE IN OUR INDUSTRY

Over the past year in my role as Chair of ACEC-Canada, I have been lucky to travel to cities big and small across Canada to meet with our incredible member firms. It has truly reaffirmed my pride in the important work our industry does to improve the lives of Canadians in every corner of the country.

Every time I connect with our members and learn about their projects, I can’t help but think of all the spin-off benefits their work provides to the broader community. The projects create local jobs for numerous related industries, including suppliers, contractors, inspectors and operators. Not to mention that consulting engineering firms are leaders in core infrastructure and climate-friendly initiatives that the community can depend on for generations. The work you do has long-term positive impacts on people’s everyday lives.

This research will support our ongoing advocacy work to push the government to implement good policies

The value our industry brings to this country is unmistakable

And this isn’t just my opinion—the data backs it up. Over the past few months, we have been hard at work putting ACEC’s new Strategic Plan into practice, including our objective of becoming a resource centre for industry trends, data, and best practices for our members. That’s why we commissioned a study with the ACEC Research Institute on the consulting engineering industry’s impact on the Canadian economy. From contributing over $61 billion to Canada’s GDP to supporting 389,000 jobs, the value our industry brings to Canada is unmistakable. While the Institute’s final report will be released in a few weeks, you can read more about their preliminary findings in the pages that follow.

In addition to this report, the Institute is conducting “Engineering Business Sentiment” surveys on behalf of ACEC. These surveys will be conducted twice a year to track perspectives from firm executives and business leaders like yourselves; they will serve as a complement to the economic data to create a more detailed picture of our industry and its future. I know many of you have already participated in the first survey and I’d like to thank you for offering your thoughts and opinions for this important collection of data. We look forward to releasing the results of this survey in the coming weeks.

All of this research will support our ongoing advocacy work to push the government to implement good policies that benefit our members and all Canadians. As well, we hope that it will prove useful in your roles as community leaders and advocates as you promote our industry.

Consulting engineering companies have so much to be proud of. It’s been an honour to serve you all in my role as Chair over the past year, and I’ll be sure to share everything that I’ve learned from our members as I continue to champion your vital, nation-building work in the years ahead.

Allyson

Desgroseilliers, P.Eng. Chair, Board of Directors ACEC-Canada

CANADIAN CONSULTING ENGINEER 5 ccemag.com

HAVE YOU HEARD?

All provinces and territories enjoy a significant boost to their economies thanks to the A/E industry.

CANADIAN ENGINEERING AND DESIGN SERVICES REVENUE BY PROVINCE IN 2022 ($CAD)

THE CONSULTING ENGINEERING INDUSTRY IN NUMBERS

Last year, ACEC-Canada adopted a new Strategic Plan that outlines our objectives of championing our industry, strengthening consulting engineering firms, and supporting our members. Becoming a resource centre for industry trends, data, and best practices for our members is a key aspect of achieving these goals.

That’s why ACEC recently partnered with the ACEC Research Institute (the research arm of American Council of Engineering Companies) to commission a study of our industry’s impact on the Canadian economy. The Institute has captured data of our sector’s contribution to Canada’s GDP, wages, jobs, taxes, and more, and they will be releasing their final report in June. In the meantime, ACEC is pleased to share the following high-level preliminary findings, which clearly demonstrate just how important our industry is to the Canadian economy.

This will certainly support ACEC’s advocacy work with the federal government, and we encourage you to use this research to showcase the positive role of consulting engineering companies in people’s everyday lives in communities across the country.

6 CANADIAN CONSULTING ENGINEER

NL $773M PEI $53M NS $681M NB $538M QC $8.9B ON $15.7B AB $9.7B BC $8.0B YT, NT & NU $155M MB $959M

SK $979M May/June 2024

ARE YOU AWARE?

In 2022, our industry contributed $61 billion to the economy and supported 389,000 jobs across the country.

Over the past decade, engineering services have accounted for the vast majority – between

0 $10 $20 $30 $40 $50 2022 2021 2020 2019 2018 2017 2016 2015 2014 2013 32.27 3.78 3.82 4.10 4.36 4.90 5.26 5.44 5.42 6.28 6.77 33.10 30.81 29.30 28.14 29.00 33.15 33.64 35.15 39.64 0 $10 $20 $30 $40 $50 2022 2021 2020 2019 2018 2017 2016 2015 2014 2013 10.6% 2.4% 3.7% -1.8% -3.6% -5.5% 12.7% 1.2% 6.0% 12.1% 36.92 34.90 33.65 33.04 34.25 38.59 39.06 41.42 46.42 36.05

ANNUAL CANADIAN ENGINEERING & DESIGN SERVICES OPERATING REVENUE (2013 - 2022) Total Revenue ($ Billions CAD) Total A/E Annual Growth

KEY FACT

84-90%

total A/E

Canada. ANNUAL CANADIAN ENGINEERING & DESIGN SERVICES REVENUE: ENGINEERING SERVICES AND ARCHITECTURAL SERVICES Total Revenue ($ Billions CAD) Architectural Services Engineering Services (vs. 2022) CANADA’S ENGINEERING & DESIGN SERVICES INDUSTRY TOP-LINE ECONOMIC CONTRIBUTION Industry revenues and associated tax contributions both grew at double-digit rates in 2022 INDUSTRY GROWTH & PUBLIC IMPACT A/E INDUSTRY REVENUE VALUE TO FEDERAL, PROVINCIAL & LOCAL GOVERNMENTS AGGREGATE ECONOMIC & BUSINESS IMPACT A/E CONTRIBUTION TO THE CANADIAN ECONOMY BUSINESSES ccemag.com CANADIAN CONSULTING ENGINEER 7

– of

revenue in

Decarbonizing Remote Communities

The potential in Canada is significant.

By Peter Saunders

Through a combination of tax credits, infrastructure funding and carbon pricing, the federal government is incentivizing communities across the country to switch away from traditional hydrocarbons to emissions-free and/or renewable energy sources. This switch, which can help wean residential, commercial and industrial facilities off of increasingly costly diesel and natural gas, is also intended to help meet goals relating to First Nations prosperity, equity and business development.

In April, Canadian Consulting Engineer gathered industry experts to speak to the scale of such opportunities, the progress made so far and the current reality on the ground. The resulting virtual summit was sponsored by Rheem, CIMA+ and Reliable Controls.

Starting with the end in mind

Michael Wrinch, president and CEO of Vancouver-headquartered Hedgehog Technologies, an electromechanical engineering firm with offices in Burnaby, B.C., and Calgary, started the event off with his keynote presentation on past, cur-

rent and future efforts to decarbonize remote communities.

Pulling from his 20-plus years’ experience working in remote communities and with renewable energy, he emphasized the need for engineers to start such projects with the end in mind, collaborate with locals on logistics (which can be particularly challenging in isolated regions), consider all uses of energy (including heating, transportation and electrical utilities) and ensure the process of consultation and engagement is continual.

“If you want your project to still be in operation 50 years from now, you need to work back to today to determine what types of training, support, operations and maintenance (O&M) need to take place in the community for that outcome,” he said.

Wrinch cited input from the Haida Nation with regard to project priorities and requirements:

• Renewable resources must be used.

• The technology must be mature.

• The generating capacity must be significant.

• The system must be environmentally sustainable.

• The project life must be more than 20 years.

• The project must integrate into existing systems.

• The costs must be funded or achieve quick payback.

• Operations, ownership and employment must be local.

• Leadership and community must ‘buy in’ and accept the technology.

• The timeline must be less than three years.

“Simple is better,” he added.

Setting the stage for a panel discussion to come, Wrinch outlined renewable options from the most mature (hydroelectricity, solar and wind) to those less commonly accessible (biomass, geothermal and tidal).

“The problem is the most popular of these, including run-of-the-river hydro, are intermittent,” he said. “It’s not always sunny or windy and Canada’s experiencing a three-year drought that’s affecting hydro. So, you need battery storage and/or backup diesel generators.”

A multifaceted challenge and opportunity

Next, I moderated the panel discussion, which not only touched on a variety of subtopics, but also represented different perspectives.

Kevin Brown, for example, is the energy department manager and climate action co-ordinator for Old Massett Village Council on the north end of Haida Gwaii, B.C., which has relied heavily on diesel consumption. He spoke from an energy management perspective about his community’s decarbonization journey.

“It was a difficult learning curve at the beginning to learn what’s out there,” he said. “The best way to get

“Simple is better.” – Michael Wrinch

8 CANADIAN CONSULTING ENGINEER May/June 2024 PHOTO C OURTESY HEDGEH OG TE CHNOLOGIES.

SUSTAINABILITY

to net-zero is to partner with those in the know and build capacity and self-reliance in our own communities.”

Having helped create a local utility to oversee decarbonization projects, Brown also cited the significance of provincial and federal funding and programs.

“Those have never been as available as they are today,” he said. “It’s amazing. The electrification of cars and fishing vessels is in the queue, as we work on demand-side management of buildings, homes and primary energy sources. We are installing a 2-MW solar field at our northern airport, followed by another at our southern airport, and we will look at wind turbines.”

Another panelist, Mark Heyck, brought a unique perspective as the former mayor of Yellowknife and current executive director of Arctic Energy Alliance, a not-for-profit society mandated to help reduce the costs and environmental impacts of energy and utility services in the Northwest Territories through efficiency and renewables.

“One of the first questions I asked when I was elected to city council," he recalled, "was why didn’t Yellowknife have a community energy plan?”

Heyck chaired the committee to develop just such a plan. Along the way, a failed geothermal heating initiative taught him the importance of a holistic view of local realities.

“Yellowknife sits on solid bedrock, which is not a great conductor of thermal energy,” he said, “so even at 6,000 ft down, we were only finding temperatures of 30 to 35 C. If

you went down that far in Europe, you’d reach 90 C!”

Fortunately, Yellowknife’s community energy plan did achieve stronger success, with biomass, as it led to the widespread adoption of wood pellet-based heating for city facilities.

On that note, the next speaker was Jean Blair, director of planning and outreach for Torchlight Bioresources, based in Newburgh, Ont. She too emphasized how biomass is well-suited for heating buildings in the North.

“Biomass boilers are a proven technology,

We support our clients to meet the needs of their communities, optimize long-term performance and achieve sustainable development goals.

Based in more than 30 o ices across Canada, our engineers combine world-class skills with an intimate understanding of local communities to deliver innovative and adapted solutions.

cima.ca

CCE_CIMA_MayJune24.indd 1 2024-05-28 11:49 AM

with readily available parts for replacement when needed,” she explained. “Biomass heating companies can work with the community to make sure there are people in place to install, operate and maintain those boilers and there is a fuel supply chain.”

In some communities, the local forestry sector can provide a steady supply of wood chips. For others, including those in the Northwest Territories, wood pellet supply companies have emerged to meet demand.

“A few communities have tried combined heat and power (CHP), but it’s been a really big challenge so far and the technology is not as proven,” said Blair. “Most of the projects that have been successful are heat-only.”

Torchlight maintains a database of biomass heating systems across Canada. During the virtual summit, Blair used it to show there are 647 systems in place, representing an installed capacity of 481 MWh.

While biomass has proven better at heating buildings in the North than solar power, that’s not to say there isn’t an important role for photovoltaic (PV) panels in remote communities. Brian Walmark, decarbonization advisor for Ontario’s Fort Severn First Nation community,

worked with Wrinch’s Hedgehog Technologies to develop a solar array in response to a local risk.

“There are polar bear denning sites along the Severn River,” he explained. “If there were even a small diesel spill, it could wipe out the polar bears, which are important to the community. So, they decided to displace diesel-generated power with an alternative, which led to commissioning Hedgehog to help make that transition.”

Community members were trained in solar power, so a few would become the project’s champions and leaders. As a result, they have been able to take one of their diesel generator sets off-line and are now looking at scaling up their solar energy system.

“ Their intention is to displace as much diesel as possible,” Walmark said.

While Fort Severn looks to scale up solar, another type of energy is being scaled down for future applications—nuclear, in the form of small modular reactors (SMRs), which are currently in development to output anywhere from 1 to 300 MWe per unit. Nathan Tedford, Hatch’s director of nuclear technologies in Port Hope, Ont., addressed this concept as the virtual summit’s final panelist. “Diesel generators were deployed

as a primary power source in remote areas because they’re very flexible,” he pointed out. “Nuclear emulates a lot of the same characteristics. It can provide baseload power, you can put it just about anywhere and it can supply both heat and electricity. And unlike a diesel generator, an SMR will only need to be refuelled every three to five years.”

While Tedford predicted SMRs will be cost-competitive with diesel for remote sites, he noted they will require high usage and won’t be cost-effective for backup generation. With this in mind, a hybrid energy system could, for example, see an SMR complemented by wind and hydrogen for backup and redundancy purposes.

Remote and off-grid applications for SMRs are now being explored in Ontario and Saskatchewan. The implications for the future are yet to be seen, but the potential to bring non-emitting baseload power to areas where it was previously not possible is certainly worthy of engineers’ notice.

To view full video recordings of the virtual summit, including Q&A with those who viewed it live, visit www. canadianconsultingengineer.com/ virtual-events/decarbonizingremote-communities-virtualsummit.

“The intention is to displace as much diesel as possible.”

– Brian Walmark

“SMRs emulate a lot of the same characteristics as diesel generators.” – Nathan Tedford

10 CANADIAN CONSULTING ENGINEER May/June 2024

SUSTAINABILITY PHOTOS C OURTESY RES PECTIVE S PEAKERS.

The virtual summit’s speakers included (top left to right) Michael Wrinch, Jean Blair, Kevin Brown, (bottom left to right) Mark Heyck, Brian Walmark and Nathan Tedford.

Unifying regulation of Canadian engineers

As an engineer who is registered across Canada, I want to raise an issue most of us take for granted. Simply put, the separate regulation of engineers in each province is needless, bureaucratic and unhelpful, despite the efforts of various organizations to make transitions between jurisdictions as simple as possible

While it’s true labour regulation has traditionally been the jurisdiction of the provinces, following an unconvincing decision by the Judicial Committee of the Privy Council (the British based predecessor of the Supreme Court of Canada) in 1925, I would argue that c an be worked through— though I’m sure lawyers will have wildly diverging views on the practicality.

First, examine the why. Today, schools are accredited by a single national organization that sets the standard for an engineering education across the country. In every jurisdiction, this education is the core requirement for becoming an accredited engineer.

Next, each jurisdiction acknowledges its peers perform an equivalent role. When moving between provinces, in most instances, simply demonstrating equivalent accreditation in another jurisdiction is sufficient. To my kno wledge, only the Northwest Territories and Nunavut Association of P rofessional

Engineers and Geoscientists (NAPEG) asks for applicants to additionally demonstrate a basic understanding of the unique engineering limitations of the north.

Further, the differentiation of jurisdictions applies more stringently to some disciplines than others. A car, train, plane or boat can be engineered by a team of professionals registered in a single jurisdiction. In contrast, the corresponding roadways, railways, airports and docking facilities for those vehicles are regulated by each province where they are constructed.

The multiplication of the regulatory process simply adds barriers to interprovincial commerce and, frankly, discourages new engineering firms from

starting up in Canada. While I’m all for effectively acknowledging engineering experience from abroad, I think our first focus should be on maximizing the use of engineers already in Canada.

If we accept that a single organization can and should effectively regulate Canadian engineers, how can that come to pass? I would suggest we do not need to remove the provincial organizations immediately. Instead, two paths are possible.

One we can focus on is creating a Canadian certification process that would allow engineers, within their scope of practice, to work anywhere in the country. I think this would have obvious benefits to many engineers. Over time, it would simply become the preferred

licensing process and the provincial organizations could be allowed to close.

Alternatively, the provincial organizations can agree to a free exchange of practice and equal regulation between bodies, perhaps restricting their membership to place of address to protect funding for smaller jurisdictions.

Would this take some political will? Definitely, yes, but unless we make this an issue, we will continue to function under an archaic and cumbersome regulatory process that fundamentally multiplies the regulation burden on engineers without any substantive additional benefit for permit holders.

Sasha Harpe, P.Eng. Owner and principal engineer, Straight Tracks, Petawawa, Ont.

CANADIAN CONSULTING ENGINEER 11 ccemag.com PHOTO: © RZ OCKY2803 / ADO BE S TOCK.

letter to the editor

Recladding for Renewal

Upgrades are not merely esthetic, but can also help decarbonize buildings.

By Jennifer Davis

Afew decades after its construction, a tall office building begins to lose its lustre. Its exterior may look a little behind the times, which can negatively affect tenant retention. Capital repair also be comes a pressing concern when certain components of the building envelope are approaching end of life.

Recladding is key to renewing such buildings. Experience has borne out that close collaboration between architects and engineers is essential to the success of these projects.

A shift in motivation

Recladding modernizes and upgrades the building envelope either through the tactical replacement of one or more components, such as glazing or spandrels, or by replacing entire façades. This can address capital repair issues, improve tenant comfort and update a tower’s appearance—but in recent years, there has been a major shift in clients’ motivation for undertaking such projects. In an era of net-zero targets, decarbonization and environmental, social and governance (ESG) issues, recladding can help them reach their sustainability goals.

Instead of demolishing an aging office tower and replacing it with new construction, recladding can revitalize a building while retaining the structural materials that constitute the bulk of its embodied carbon footprint.

“When you’re replacing a component that’s at the end of its service life, whatever you put in there is likely to be there for the next 50 years,” says David De Rose, managing principal at Toronto-based consulting engin-

eering firm Synergy Partners. “So, make sure it’s tied to an overall decarbonization plan for the entire building.”

Approaches to recladding range in cost and complexity.

On any recladding project, the first steps will be to gain a clear understanding of the client’s objectives and to thoroughly examine the existing building envelope's condition. Engineers’ detailed building investigations, which involve destructive testing and verification of as-built conditions, are a prerequisite in ensuring new design solutions can be included or excluded with confidence.

If the recladding is part of a comprehensive retrofit with a net-zero target, then the consulting engineering team and owner will develop an emissions reduction plan to be progressively implemented over time. Which cladding system components are approaching their end of useful life and which could be retained for longer-term use? The answers will help determine the best approach to the project.

In one recent recladding by WZMH Architects, building science engineers used <i>in situ<i> smoke tests to identify where air and water leakage was occurring. They proposed a detail to establish air barrier continuity and improve wall assembly resistance to water penetration.

Choosing a method

There are many approaches to recladding, ranging in cost and complexity, that can be used alone or in combination on the same project.

12 CANADIAN CONSULTING ENGINEER May/June 2024

BUILDINGS

PHOTOS C OURTESY W ZMH AR CHITECTS.

At the lower-cost end of the scale, windows can be replaced with new insulated glazing units (IGUs).

‘Non-window’ exterior wall surfaces can also be renewed. Removing spandrel cladding panels allows access to fasteners that may need repairs and provides an opportunity to replace insulation and air water barrier (AWB) systems in the wall cavity to improve thermal performance, before installing new spandrel cladding panels. The existing spandrel cladding panels can either be repaired and reinstalled or discarded and replaced with new. As all of these cases involve retaining and reusing the back section of the existing mullions, the proportion of glass to solid wall remains unchanged.

Another option is to retain a portion of the existing mullions while attaching new cassettes, i.e. panelized units integrating new

glazing and spandrels. This approach can streamline construction and makes it possible to alter the window-to-wall ratio, if desired.

When existing masonry wall assemblies are too onerous to remove, overcladding offers a solution. The masonry is retained and may be repaired, with a new envelope installed outside the existing one.

The aforementioned options are all suitable for buildings that will remain occupied during construction, as the bulk of the renovations are undertaken from the exterior by workers on height-adjustable ‘mast climber’ platforms, while any work that does need to be done inside can be scheduled outside of business hours.

It is not always feasible, however, to retain and reuse a building envelope’s components. With a technical understanding of how recladdings

are constructed, architects and engineers propose design solutions that can be implemented practically on-site. In some cases, this will mean ‘reskinning’ a building with a complete curtain wall replacement. Looking ahead, new technological developments that are becoming increasingly relevant for recladding projects include building-integrated solar photovoltaic systems and vacuum insulating glazing (VIG).

Case studies

One example of a building that needed recladding is 95 Wellington Street West in downtown Toronto. This 23-storey tower, measuring 330,000 sf, is part of the TD Centre office complex, owned and managed by Cadillac Fairview (CF).

Decades after its completion, the stone façade’s fasteners were corroding, due to overtightening during

Exp helped WZMH renovate 95 Wellington Street West to improve insulation, airtightness and water resistance in the roof and envelope.

downtown Toronto, at 76 Adelaide Street West, is a 16-storey, 432,000sf tower with above-average ceiling heights.

By 2020, more than 50 years’ exposure to the elements had caused several components in the main façade’s integrated cladding system to deteriorate severely. Based on the findings of a destructive investigation, Bell opted for a complete reskin.

Prior to the removal of the building’s existing skin, a temporary wall was constructed in behind it, both to protect the interior and to create a zone for construction activities.

“On this project, we had an open canvas,” says Harrison Chan, principal at WZMH, which consulted on the project.

The team specified large-format glass panels with concave curvature on their exterior surface. Integrating double-glazed vision and spandrel glass, the panels spanned floor to floor. The slab edge detail included curved anchors and fire stopping to resolve the geometry between new and existing elements.

“Make sure it’s tied to an overall decarbonization plan for the entire building.” – David De Rose

their installation. Air and water leakage became problematic.

Building science engineers at Exp helped WZMH Architects lead a renovation project that combined insulation, airtightness and water-resistance improvements in the roof and envelope, replacing the reddish-pink granite on the exterior with new Bethel White granite. A new, self-adhered membrane installed in the cavity reduced water infiltration and increased airtight-

ness to significantly enhance energy performance, while the upgraded insulation improved the building’s thermal performance.

“With the recladding completed, all of the building's tenants are much happier with their workplace,” says Carlo Guido, CF’s senior director of project management and development.

Another example is a building owned by Bell Canada since its completion in 1965. Also located in

The project illustrated how recladding system types can be combined to address different conditions in different parts of a building, as a non-insulated overcladding has been completed on its mechanical penthouse. In the future, new insulation and cladding installed overtop the blank side walls could further improve building performance.

Today, WZMH is part of a multidisciplinary team conducting a study commissioned by Desjardins for recladding and decarbonizing an office tower at 95 St. Clair Avenue West in Toronto. As it happens, the architecture firm will be directly affected by the study’s outcome—since its head office is in the building.

Jennifer Davis is a licensed architect and the s trategic b usiness d evelopment l ead for WZMH Architects, which recently launched Remake It B etter: The WZMH Recladding Guide. For more information, visit www.wzmh. com/news/recladding.

14 CANADIAN CONSULTING ENGINEER May/June 2024

BUILDINGS

Breaking Down Barriers to DEI

Engineering can only serve the public interest if it becomes more inclusive.

By Michelle Liu, P.Eng.

The engineering discipline lags in diversity, equity and inclusion (DEI). In 2019, for example, only 13% of licensed engineers in Canada were female, compared to 41.6% of legal professionals and 42% of medical professionals.

Early-stage barriers

Ensuring a more inclusive next generation of engineers in Canada begins with critically examining who is—and who is not—aware of engineering at the high school level. A significant early-stage barrier is that female students (along with other students belonging to groups currently underrepresented in engineering) are not being empowered to take Grade 12 physics, a prerequisite for all accredited undergraduate engineering programs in Canada.

A 2018 Ontario Network of Women in Engineering (ONWiE) study found only 15% of female students who completed Grade 10 academic science enrolled in Grade 12 physics, compared to 30% of male students. As a result, many girls were not leaving high school ‘engineering-ready.’

Protecting the public interest

Statutes and policies clearly require engineers to serve and protect the public interest. Professional Engineers Ontario (PEO), for example, has a statutory duty to regulate itself in the public interest, under

section 2(3) of the Professional Engineers Act. Section 5 of the PEO’s guideline on professional practice goes a step further, stating members of the profession—and not just the regulatory body itself—have a duty to the public.

Engineers must serve and protect the interest of all members of the public, not just those who align with the dominant identities in the profession. The lack of female individuals in automotive engineering, for instance, has contributed to vehicle safety features poorly suited to the female anatomy, while the absence of people with physical disabilities in civil engineering has led to some of the country’s most important buildings being inaccessible to many. Such examples form the basis of an argument that the engineering profession does not currently fulfil its statutor y mandate.

Empowering leaders

In 2012, the University of Waterloo’s Faculty of Engineering—Canada’s largest engineering school—saw its first woman dean, Pearl Sullivan (since deceased). At that time, only 18.5% of the faculty’s undergraduate students were women. By the e nd of Sullivan’s term in 2019, that in-

creased to 29%. It rose again to 39% in 2022 under the leadership of a second woman dean, Mary Wells.

This trend suggests the system needs to make space for girls and women not only to study engineering, but also to go on to become deans, heads of engineering firms and leaders of regulatory bodies, among other prominent roles.

Seeking equity

More equity-seeking leaders in engineering spaces will foster more opportunities to implement policies and practices that improve access to the profession for equity-seeking people. As such, this is one of the ways to ensure engineers can work in the public’s best interest.

Michelle Liu (they/them), P.Eng., is an Ottawa-based Queer, racialized and non-binary engineer who worked in construction and design for consulting engineering firms after studying civil engineering at University of Waterloo. Their experience of racist, homophobic and gender-based violence in engineering empowered them to pursue a law degree and engineering PhD at University of Ottawa. Liu has served as a councillor for Professional Engineers Ontario (PEO), mentored with the Ontario Network for Women in Engineering (ONWIE), co-chaired a task force for the Ontario Society of P rofessional E ngineers (OSPE) and co-created and co-funded the Liu-Kennington Award for the 2SLGBTQ+ Engineering Community.

CANADIAN CONSULTING ENGINEER 15 ccemag.com

INCLUSION P HOTO C OURTESY UNIVERS ITY O F W ATERLOO.

By Victor Kim and Patrick Pinho

By Victor Kim and Patrick Pinho

Victor Kim is a partner and Patrick Pinho is an associate at McMillan LLP, based in Toronto. For more information, contact them at victor.kim@mcmillan.ca and patrick.pinho@mcmillan.ca, respectively.

Health and Safety Obligations and Liabilities

Many professionals in the construction industry have heard about the recent Supreme Court of Canada (SCC) decision in R. v. Greater Sudbury. When the city of Sudbury retained a contractor to repair a watermain, it sent employees to perform inspections, while the contractor assumed control over the project and the health and safety obligations of the “constructor” under Ontario’s Occupational Health and Safety Act (OSHA). Tragically, a road grading machine operated by an employee of the contractor struck and killed a pedestrian. There was no fencing between the roadway and the project and no flag person, which are required by OSHA. Ontario’s ministry of labour charged both the contractor and the city in their capacity as “employers” under OSHA. (Notably, before the accident occurred, the city had raised safety concerns relating to the site with the contractor.)

The decision

A trial court initially ruled the city was not the employer, as it did not have direct control over the employees and site—and even if the city had been an employer, it had satisfied its due diligence obligations by raising its concerns about site safety.

This decision was appealed to the Ontario Superior Court of Justice (SCJ) and then to the Court of Appeal for Ontario (ONCA), which concluded the city was an employer because it had its own employees on-site and breached its corresponding duties. The ONCA did not discuss due diligence, but directed the SCJ to revisit this issue.

The city appealed this conclusion to the SCC, which issued a 4-4 split decision, ultimately dismissing the appeal. The first decision upheld the ONCA findings relating to the city as an employer, divorcing them from the city’s actual degree over control. The remaining judges agreed with the trial judge, stating the city lacked requisite con-

trol to be considered an employer.

Since the SCC was split, the ONCA decision—stating control is not determinative—stands, with persuasive commentary on what can come into the determination of due diligence. The issue of whether or not the city met its due diligence obligations was remitted to the SCJ. While this decision does not set precedent outside Ontario, stakeholders in other provinces will want to keep up-to-date on the determination of due diligence.

Addressing uncertainty

Thrust into a new level of uncertainty, owners, contractors and consultants alike must assume they are all “employers” under OSHA by virtue of having employees onsite, including self-proprietors.

Not much has changed for contractors assuming the role of constructor, as the obligations remain the same. As owners are often not experts on construction safety, a primary consideration will be to ensure a properly qualified constructor is retained, which may require additional health and safety pre-qualifications.

Owners will also need to ensure they are

familiar with their constructor’s health and safety plan and understand their obligations to indicate identifiable hazards to the constructor and follow the plan.

Consultants with employees on-site also have an obligation to ensure they are properly trained and the health and safety plan is adhered to. As with owners, it is important for consultants to report visible hazards to the constructor immediately, as simply doing so can help consultants establish they have met their due diligence obligations.

A consultant’s regulatory responsibilities may be a helpful way to introduce health and safety concerns while maintaining its relationship with the contractor.

Impact on operations

Consultants and contractors are both likely to see changes in their contracts with owner-clients and between themselves.

Owners may seek further clarity on safety obligations, as well as additional indemnities relating to safety incidences, particularly when engaging a contractor as the constructor. Owners may also include more contractual requirements for the provision of information upon request re-

16 CANADIAN CONSULTING ENGINEER May/June 2024 PHOTO: © SURIY O / ADO BE S TOCK.

Legal

garding compliance with the health and safety plan and training records.

Contractors, in turn, may attempt to ‘flow through’ these requirements in their contracts with consultants and subcontractors, who will need to diligently review to ensure such responsibilities and liabilities are appropriate for their respective scopes.

Owners are likely to introduce additional pre-qualifications for contractors bidding on work, to ensure they have appropriate certification. Once a project is underway, they may also call the ministry of labour to ensure they are engaging in safe practices and sufficient due diligence.

Consultants should adequately review construction contracts and identify any language that will need to be qualified in bids or where further clarity is required. In their own contracts with contractor-clients, they will also need to ensure expectations relating to health and safety and the scope of their review are clearly identified.

Beyond contract terms, consultants

A

Choose from top-rated products that:

Reduce energy use

Enhance your space

Boost your bottom line

Find a participating distributor today! Visit saveonenergy.ca/ instantdiscounts

should also implement more robust documentation procedures to ensure they have adequate records in the event they need to bring forward a due diligence defence.

Where consultants are relied upon in a project advisory role, they need to ensure they do not overstep their expertise. While they may be involved in reviewing contractor pre-qualifications, certifications and safety records, consultants should avoid recommending the award of a bid, advising if a bid is compliant or doing anything else that could expose them to uninsurable risk.

See something, say something

It is important for all stakeholders to report any identifiable hazards and carefully document them, even those outside their direct work area. Before R. v. Greater Sudbury, such parties took comfort in clearly defining their work areas and who was responsible for site safety. Today, however, the broad application of “employer” means even consultants working in a clearly defined

area should take care to document and report any potential hazards or incidences outside that area for due diligence purposes. It is still important for all stakeholders not to overstep their areas of expertise. Parties should take care to identify and report a hazard, but stop short of providing suggestions on how to address it, as this may be beyond their expertise and expose them to additional liability.

The road forward

This case’s uncertainty affects stakeholders at all levels. While some, including the City of Sudbury itself, have made formal submissions to the provincial government requesting legislative amendments to clarify the rules and responsibilities relating to owners and employers, no formal guidance has followed yet.

For the time being, the emphasis remains on ensuring all stakeholders focus on documenting their safety practices as due diligence.

your business No paperwork. No

hassle-free way to get instant savings on lighting for

waiting. Just savings.

Subject to additional terms and conditions found at SaveOnEnergy.ca ™ Trade Mark adopted and used by the Independent Electricity System Operator. Used under licence. IESO 138 04/2024

INSTANT DISCOUNTS PROGRAM

Why Hydrogen Has Been a Non-Starter

Roadblocks remain in place.

By Stan Ridley

Hydrogen has widely been touted as a ‘wonder element,’ expected to help bring humanity to a green energy future. Many governments and agencies position it as part of the solution to global warming and the climate crisis.

Those rosy expectations, however, ended for many experts in the early 2000s, for very sound scientific, engineering, environmental and economic reasons. Roadblocks were identified—and those roadblocks effectively remain in place today.

When one is only considering hydrogen’s reconversion to a usable form of energy, it certainly offers the benefit of zero greenhouse gas (GHG) emissions. When considering the full life cycle (LC) of hydrogen systems, however, from pr oduction and compression to transport, storage and distribution, it turns out to be one of the least attractive forms of energy in terms of efficiency and GHG emissions.

Even though hydrogen is very abundant on our planet, it is invariably tied up with other elements, such as with oxygen in water. So, hydrogen can only be ‘produced’ by

breaking up those compounds, using energy. Today, more than 95% of all hydrogen used globally is produced using fossil fuels, releasing enormous quantities of GHGs. We need technological breakthroughs in energy if we are to win the battle against global warming and climate change. While these breakthroughs may include nuclear reactors, carbon capture systems and the storage of energy from intermittent renewables (e.g. wind and solar), there seem to be very few valid technical justifications for the present ‘push’ on hydrogen.

Carrier of energy

Hydrogen is not a primary energy source, but rather an inefficient carrier of energy. Complete LC hydrogen processes are only 45% efficient or less, regardless of energy inputs. By way of comparison, modern electricity transmission lines are typically 95% to 98% efficient.

Grey hydrogen

At present, more than 95% of all the hydrogen used globally is ‘grey hydrogen’ produced using fossil fuels, mainly natural gas. Grey hydrogen’s LC processes lose 55% to 75% of the input energy and emit enormous amounts of GHGs.

Blue hydrogen

Grey hydrogen is considered ‘blue hydrogen’ if carbon capture, utiliza-

tion and storage (CCUS) systems address its associated GHG emissions. In present LC analyses, however, there do not seem to be any viably scalable CCUS processes to meet such requirements.

Green hydrogen Humanity is not going to significantly reduce GHG emissions by burning more fossil fuels to drive hydrogen. Faced with this stark reality, many proponents of hydrogen are now focused on using relatively clean energy from renewable sources (e.g. wind, solar and hydroelectric) and/or nuclear reactors to drive hydrogen processes. Hence, ‘green hydrogen’ is produced with very little carbon content.

Globally, humans consume about 600 exajoules (EJ) of primary energy every year. More than 80% is from fossil fuels, including coal, oil and natural gas. Wind, solar, hydroelectric and nuclear energy consumption represent about 3%, 2%, 7% and 4%, respectively. As these non-fossil fuel sources are very limited, they must continue to be allocated and committed prudently to the most efficient systems while w e seek to increase their generation and availability widely. And indeed, our present processes for using limited, relatively clean, renewable energy to directly displace and/or replace GHG-heavy energy are already at almost 100% efficiency (i.e. 1 MWh clean for 1 MWh dirty).

There are some applications where we will continue to need hydrogen.

18 CANADIAN CONSULTING ENGINEER May/June 2024

ENERGY

While nearly all green hydrogen proposals seem to be scientific and environmental non-starters, there may be an exception in proposals to harness massive amounts of solar energy from the world’s major deserts, to fuel international hydrogen storage, transport and distribution systems.

Recent geopolitical developments, however, including the bombing of major inter-country undersea pipelines that were once economic lifelines, must raise grave concerns about energy dependence and self-sufficiency of major industrial nations.

Natural hydrogen

In the last few years, there has been much discussion about the possibility of mining naturally occurring hydrogen in enormous quantities. While relatively minute quantities of natural hydrogen have been mined, such sources are not well-understood.

As yet, is not clear whether sig-

nificant quantities of natural hydrogen are available and can be mined, with what form or energy, at what overall efficiency and at what commercial price. There is still a paucity of scientific, mining and commercial expertise in this area. While some small players are exploring such horizons, major energy companies are still maintaining a watching brief.

Niche applications

There are some applications where we will continue to need hydrogen.

A substantial portion of the hydrogen produced and consumed today is used by industr y while producing metals, refining petroleum, processing food and producing fertilizers and other chemical products.

Fatal flaws

Without major technological breakthroughs to significantly improve the overall efficiency of hydrogen processes or the discovery of enormous quantities of natural hydrogen

that we could access and deliver competitively, there would seem to be no technological or environmental justification for increasing the production and consumption of hydrogen using fossil fuels, renewables or nuclear sources.

Nearly any increase in the production and use of hydrogen would increase overall emissions of GHGs much faster than current processes for directly displacing and/or replacing dirty energy with clean.

Further, the notion of using non-dispatchable intermittent renewable energy—some of which is indeed available—to produce and store hydrogen until it can be reconverted to a usable form when needed seems highly questionable. Such a suggestion ignores the reality of many other existing energy storage systems that are already much more efficient than a hydrogen LC process.

CANADIAN CONSULTING ENGINEER 19 ccemag.com PHOTO © AD DMESHCUBE / ADO BE S TOCK.

Stan Ridley is president of West 2012 Energy Management, based in Vancouver.

Fire Protection for EV Plants

New facilities need to be engineered for safety.

By Chris Reynolds

As the electric vehicle (EV) revolution continues both its organic and its planned growth trajectories, safety protection considerations have come to the fore, especially given the complexities around batteries in a fire scenario. With open dialogue with engineers, fire protection systems can play a leading role in moving new battery manufacturing facilities forward.

Given the increased risk found in EV battery plants, it is important for special measures to be taken to contain any fire scenario and thus protect occupants from what could be a large and intense hazard.

“Fires can break out in EV plants as regularly as in other manufacturing facilities,” says Dave Groen, vice-president (VP) of construction at Classic Fire + Safety. “However, the key difference lies in the significantly higher risk in an EV plant, due to the type of product being stored, necessitating a deep understanding of the product’s heat release rate and how to control that specific type of fire if it does occur.”

A growing need

The number of both EV manufacturing and EV battery manufacturing plants has surged in Canada—particularly in Ontario—and the U.S.

These projects are typically estimated to span two to three years, in terms of their opportunities for engineers, designers, project managers, safety specialists, sprinkler fitters and fire alarm technicians. By

“The significantly higher risk in an EV plant is due to the type of product being stored.” – Dave Groen

collaborating with the manufacturers’ own engineering teams, they can oversee system design, fabrication, installation and testing, ensure seamless integration of safety measures, address potential issues and plan for long-term system maintenance and servicing throughout a building’s useful life.

Indeed, fire protection calls for engineers to work on every stage of a project, to address its full intent and scope. Consulting mechanical engineers typically work with the owner and fire protection specialists to create guidelines for design and installation. All parties play key roles in the approval process, through to the insurance provider and the authority having jurisdiction (AHJ).

A stage-specific approach

EV battery plants are very large buildings. Batteries are stored at different stages of

their life cycles throughout a facility. By understanding how these sections of the building are configured, engineers can work effectively to keep the entire facility up to code by protecting against the specific hazards at each stage of the EV battery manufacturing process.

While there have been many advances in protection systems, water suppression remains the predominant choice for fire containment in EV battery facilities. This is because a lithium-ion battery fire is driven by a thermal runaway condition and cooling the fire is the most effective containment method.

Water’s effectiveness at reducing a high heat release rate, its wide availability and its cost-effectiveness make it a reliable suppression agent. With a lithium-ion battery, however, the amount of water required to contain the fire is much more significant

20 CANADIAN CONSULTING ENGINEER May/June 2024 SAFETY

PHOTO C OURTESY CLASS IC FIRE + LIFE S AFETY.

than for a standard industrial fire. Also, it will burn for an extended period and require the fire suppression system to operate throughout the entire burn cycle. Challenges can arise in applying water directly to the fire hazard in various storage scenarios. For rack storage arrangements, for example, in-rack sprinkler systems are used to deliver water to each storage section of the racking assembly.

Literature review

In addition to suppression, there are systems designed for early detection of offgas events, before a fire scenario occurs. If the facility can eliminate the affected battery cell prior to a fire scenario beginning, it may be able to mitigate the issue before a suppression system activates.

A comprehensive approach

As the industry continues its expansion,

a comprehensive approach to fire protection will help ensure a secure future for th ese burgeoning facilities. The support and expertise of engineers with a keen eye on evolving industry standards will continue to play an integral role in the EV revolution.

Chris Reynolds, based in London, Ont., is director of marketing for Classic Fire + Life Safety. For more information, visit www.classicfls.com.

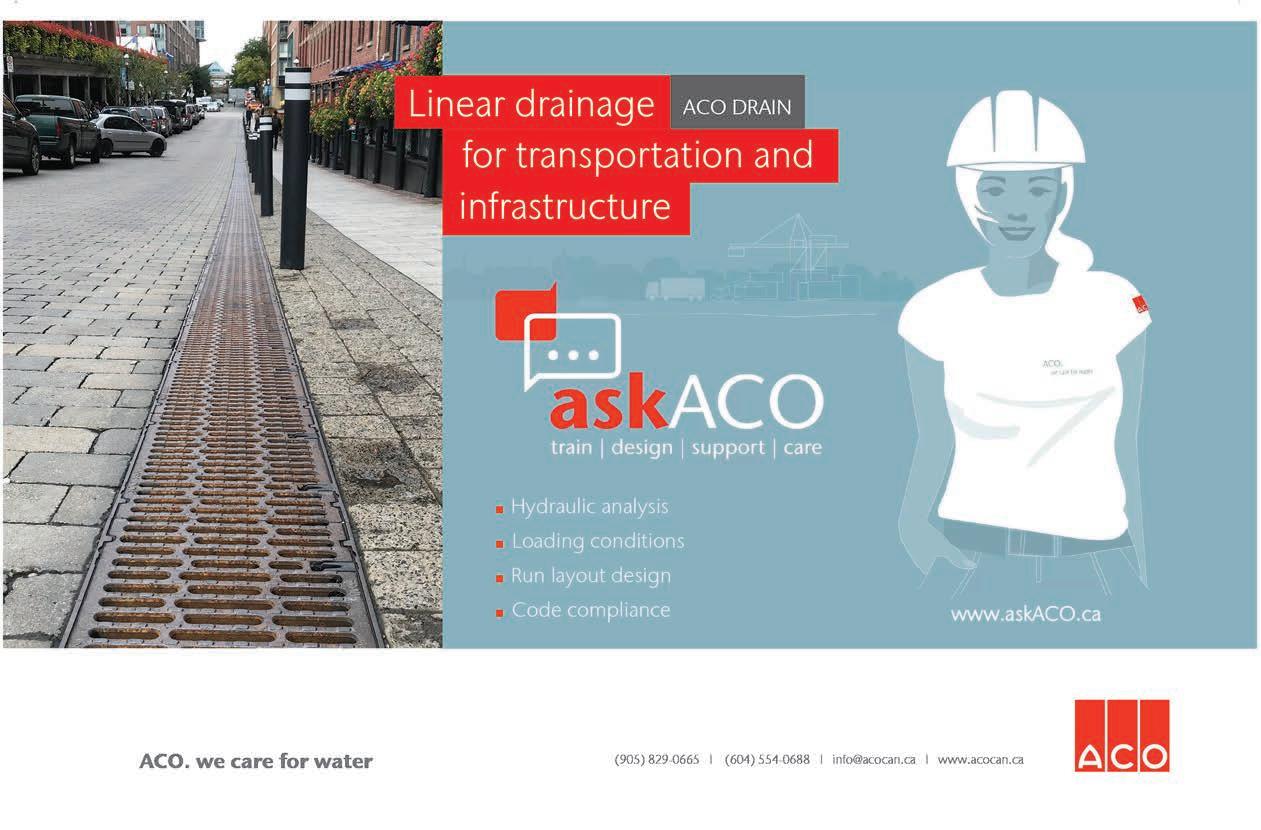

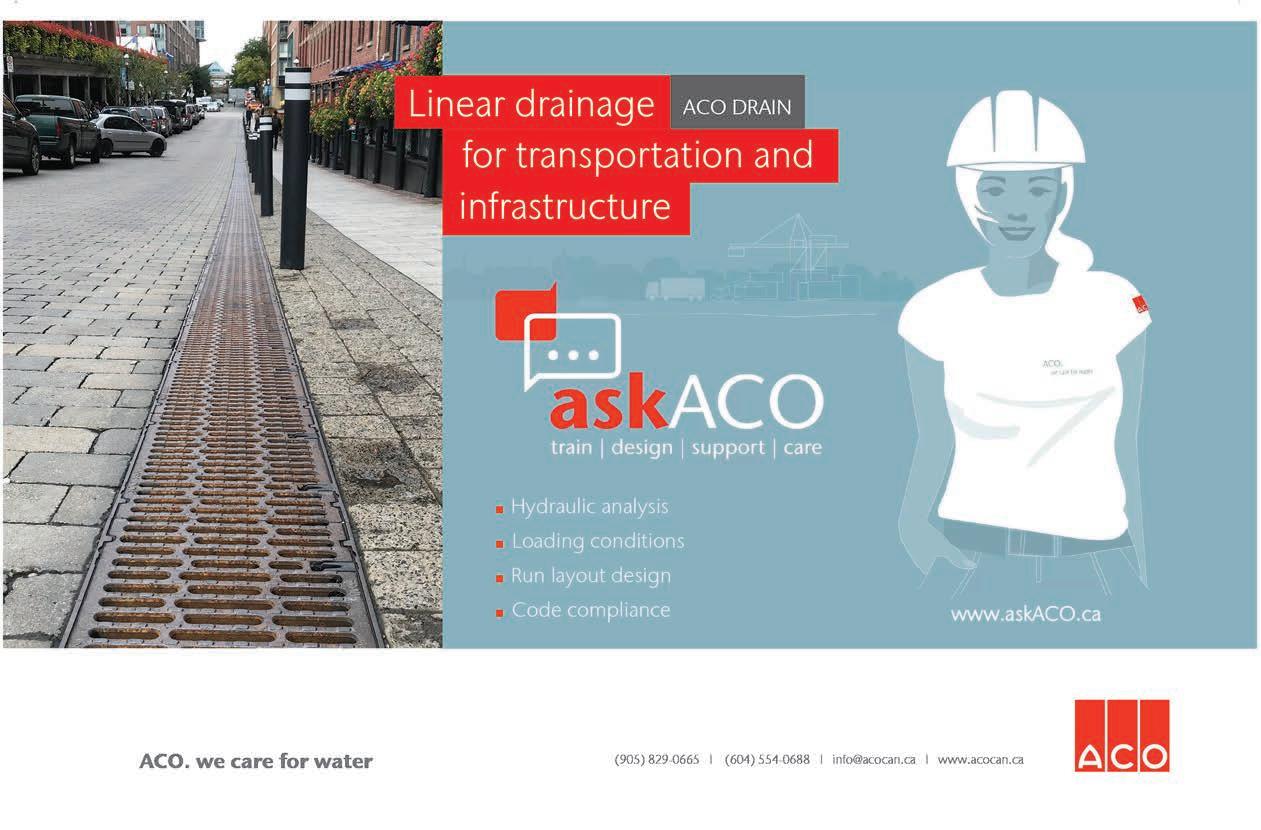

ACO Qmax - High capacity slot drainage system

ACO Qmax has been developed to satisfy the demand for a versatile, high capacity slot drainage system for a wide range of applications to any load class. The system is specifically designed to form an integral part of modern, sustainable surface water management solution requiring effective collection, storage, or attenuation. ACO Qmax is also economical compared with traditional drainage methods. Email: info@acocan.ca

Whatever the Commercial Need, Spec Bradford White®

Whether it’s a hotel, restaurant or office building, spec a solution that delivers:

• PERFORMANCE: Infiniti® GR Tankless Water Heaters offer a built-in recirculation pump

• EFFICIENCY: Up to 97% with eF Series® Gas Water Heaters

• FLEXIBILITY: ElectriFLEX Series™ Electric Water Heaters are field-convertible so a single model solves multiple installation requirements

• INNOVATION: Microban® antimicrobial product protection built into every tank lining Visit forthepro.bradfordwhite.com/our-products

CHAMPION FIBERGLASS®

pion Duct® elbows offer light weight, low coefficient of friction and no burn-through. Champion Fiberglass® helps contractors and engineers reach successful project outcomes with speedy installation and low material and installation costs. Championfiberglass.com/281.655.8900

CANADIAN CONSULTING ENGINEER 21 ccemag.com

Professional directory

www.hgcengineering.com Experts in Measurement, Analysis & Control

905-826-4546 answers@hgcengineering.com

Performance Elbows for Renewable Energy

DOWNLOAD GUIDE

Building Code Updates for Mass Timber

With British Columbia’s upcoming decarbonization targets in mind, RJC Engineers principal Grant Newfield, P.Eng., is focusing on making buildings more sustainable. In March, updates to the B.C. Building and Fire Codes came into effect that allow for taller mass-timber buildings, up to 18 storeys. We spoke with Newfield about the significance of these changes.

How are code updates reflecting the increased use of mass timber?

For a long time, there was a high level of public awareness of fires involving dimensional lumber in stick-frame buildings up to four or six storeys. Most of these fires occurred during construction, not a fter drywalling, but they gave wood a negative connotation.

“One of mass timber’s properties is it takes a long time to get ignited.”

When we started developing provisions for encapsulated mass timber, which came over from Europe in 2009 and 2010, we made sure to differentiate it from dimensional lumber because it performed very differently in a fire.

One of mass timber’s intrinsic properties is it takes a long time to get ignited. It’s like when you put a big log into a fireplace with nothing else to start a fire. You can hold a torch to it, but you can’t get that big log going!

As mass-timber construction started to be demonstrated in Canada in buildings that met the same fire-safety requirements as for steel

and concrete, people started to become more comfortable with it and the public per ception gradually changed.

Around 2019, the B.C. government mandated provisions to allow mass-timber construction up to 12 storeys, as part of a push to get more wood into buildings, both for sustainability reasons and to support the local forestry industry.

Meanwhile, national codes were starting to move in the same direction to limit carbon emissions. The 2 020 National Building Code (NBC) adopted B.C.’s provisions for encapsulated mass-timber construction up to 12 storeys. And now the 2023 B.C. Building Code, which has just been adopted, is in turn based in part on the 2020 NBC.

How does mass timber help meet sustainability targets?

Wood is a low-embodied carbon material. While concrete and steel require energy-intensive processes for their production, wood is harvested at low energy intensity. It’s a lighter material and it sequesters carbon.

The first wooden buildings were post-and-beam structures. Crosslaminated timber (CLT) can span in two directions like plywood, so for a straightforward residential building, you can work with the architect on a grid layout and specify point-supported CLT with no beams. That’s a very efficient approach, reducing both the amount of materials in the building and the cost of constructing it.

What needs to change for mass-timber buildings to become taller?

The provisions for 12 storeys required 15 minutes of encapsulation,

which meant you needed two layers of drywall. You could either drywall even further to provide full fire protection or you could allow some charring of the timber, as long as you came up with a two-hour burn fire assembly.

In 2023, a joint provincial group between B.C. and Quebec wrote a proposed change form for the NBC to allow mass timber up to 18 storeys. That change was reviewed by the Canadian Board for Harmonized Construction Codes (CBHCC) and went out for public comment. It could go on to become part of the 2025 NBC, but the provinces might not wait that long—they could go ahead and implement similar changes ahead of time.

The new provisions for 18 storeys require more encapsulation, getting us up from 15 minutes to 70 minutes. You add more drywall the higher you go. It’s a logical approach that follows provisions that have already been adopted in the U.S., in the International Building Code (IBC).

22 CANADIAN CONSULTING ENGINEER May/June 2024

Conversation PHOTO C OURTESY RJ C.

Grant Newfield.

The awards are co-sponsored by acec.ca/events/engineering_excellence_2024/ccea.html CANADIAN CONSULTING ENGINEERING 2024 SEPTEMBER/OCTOBER ISSUE CLOSING September 22, 2024 FOR ADVERTISING CONTACT Maureen Levy mlevy@ccemag.com Tel: 416.510.5111 OCTOBER 24, 2024 IT’S TIME TO CELEBRATE ALL THE AWARD WINNERS AND PARTNERS FOR THEIR PROJECT EXPERTISE SCAN HERE FOR UPDATES ON THE AWARDS GALA

NO BURN-THROUGH

CHAMPION DUCT®

SOLVES RENEWABLES PROJECT CHALLENGES

Low coefficient of friction allows for smooth pulls

No burn-through eliminates elbow repairs

DOWNLOAD GUIDE

Fault resistance makes repairing cables easy

Mechanical strength protects cables

©2016 Champion Fiberglass, Inc. BIM/REVIT

Champion Fiberglass® Elbows

By Victor Kim and Patrick Pinho

By Victor Kim and Patrick Pinho