TREATING CRACKS IN CONCRETE

APRIL 2024 34 Canadian Concrete Expo | 36 World of Concrete | 40 Concrete Paving IN THIS ISSUE:

GAM1983 / ISTOCK / GETTY IMAGES PLUS

Since 1953 we’ve believed in keeping things simple. The Power Curber 5700-D, the world’s #1 selling curb machine, is a reliable, simple, and versatile solution for curb and gutter, safety barrier, bridge parapet, sidewalk, and more. We stand behind our equipment with world-class support and unmatched commitment.

PIONEERS THEN. EXPERTS NOW.

Our Commitment Shows www.powercurbers.com | 704-636-5871 Ontario Dealer 905.670.3440

From the Inventors of Rebar Tying Technology DISCOVER THE FUTURE OF REBAR TYING maxusacorp.com RB441T RB611T SCAN TO VISIT OUR WEBSITE OS_MAX USA_April24_CSA.indd 1 2024-03-15 7:30 AM QUALIFICATION FORM NAME _______________________________________________ COMPANY NAME ______________________________________ JOB TITLE ___________________________________________ ADDRESS ___________________________________________ UNIT/SUITE: _________________ PO BOX: ________________ CITY _______________________________________________ PROV. ______________________________________________ POSTAL CODE _______________________________________ PHONE _____________________________________________ FAX ________________________________________________ ARE YOU A CURRENT SUBSCRIBER? YES______________________ NO_____________________ On-Site Magazine 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 TEL. 416-510-5113 FAX 416-510-6875 E-MAIL apotal@annexbusinessmedia.com WEB www.on-sitemag.com TO SUBSCRIBE ONLINE – ON-SITEMAG.COM THANK YOU FOR SUBSCRIBING Signature ______________________________________________________ Date ____________________ TO QUALIFY FOR A FREE SUBSCRIPTION, WE REQUIRE THE FOLLOWING INFORMATION Yes! I wish to receive On-Site Magazine FREE! Choose your edition Digital Print Both What best describes your primary business (select one) Contractor engaged in Highway & Heavy Construction Contractor engaged in Building Construction Distributors & Rental Houses Government Other Allied to the Field (please specify) Do you use rental equipment Yes No Are you a contractor who works with concrete related products and services Yes No FREE! Subscription Do you purchase and/or approve the purchase of construction products or services If Yes, please indicate those products Number of Employees at this location 1-4 5-9 10-19 20-49 50-99 100-199 200-499 500-999 1000-2499 2500+ Unknown E-Mail ___________________________________________________________________________________ I also would like to receive the On-Site E-newsletters SCAN HERE TO SUBSCRIBE Earth Moving Equipment Compact Equipment Safety Equipment Paving Equipment Used Equipment Dump Trucks Pick-Up Trucks Trailers Generators Attachments Hand Tools Compressors Lifting Equipment Power Tools Welding Tools SO, YOU SAY YOU’RE INTO CONCRETE OS_CIRCSUBFORM_HALFPG_APRIL24_CWM.indd 1 2024-03-21 8:08 AM

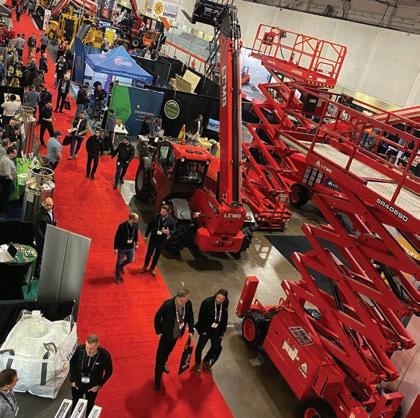

BUSY AISLES AND

HAPPY CUSTOMERS

Canada’s concrete event continues to grow.

BY ADAM FREILL

Not even a bit of snow could dampen the spirts of attendees and exhibitors at the 2024 edition of Canada’s national concrete show, the Canadian Concrete Expo (CCE), which returned to the International Centre in Mississauga, Ont., this past February.

The sixth edition of the event, which attracted more than 7,000 members of the concrete, aggregates and construction industries, was the largest yet, growing by some 20 per cent over last year with an expanded show floor, some new attractions, and the return of a fan favourite, all of which garnered positive responses from visitors, exhibitors, and show organizers alike.

“We were 20 per cent bigger this year, and it looks like our attendance has grown in the same capacity,” said Stuart Galloway, president of the Canadian concrete Expo from the show floor on Day 2. “The feedback we’re getting from attendees and exhibitors is excellent.”

In addition to offering more than 40 conference sessions, as well as live demonstrations and stage presentations, organizers brought back a large equipment demonstration area and introduced the 2024 CCE Pump Rodeo, sponsored by CanCrete.

“Everybody seems to kind of embrace this event, and it shows with the increased attendance that we get and with increasing the size of the show each year,” said Galloway. “We brought back the large equipment demonstration area. We haven’t had it since 2020. And the pump rodeo had about 300 people attend it.”

Pitting a pair of experienced pump operators against each other in a test of

speed and precision, the deft touch of Hugo Lacroix of Pompage Industriel saw him navigate his pump through the obstacle course in the fastest time, earning him the title of Pump Truck Rodeo Champion.

Galloway says that the use of the large spaces at the trade centre is something that the show plans to take advantage of going forward. “They have 42-foot ceilings in a couple areas so they can get their booms out there,” he explained. “We’re going to expand in that area for 2025.”

The main attraction for the exhibitors were the attendees, of course, and the show delivered on that front as well.

“I was happy with the attendance over previous years,” said Dave Watson, concrete specialist for Canada at Sunbelt Rentals. His company, which he says will be back for more in 2025, specializes in the rental of machinery like concrete grinders, scarifiers, shavers and shot blasters. He usually expects to see a bit of a lull on the final day of a show, but that was not the case this year. “We seem to have had some traction.”

“The attendance seems like it’s up, and the show seems much bigger than it was last year,” added Troy Steele, regional sales manager at Brokk Sales Canada. He too expects to see his company back again next year. “For us, it’s a perfect show because it’s focused on what we focus on, concrete.”

With the more than 350 booths on the show floor now including over 50 American-based exhibitors, and visitors coming in from all over the globe, Galloway is focused on continuing the event’s growth curve.

“Our goal is to make this a truly national show, and we keep growing

every year in attendance from outside of Ontario,” he said.

Next year’s dates have been set for February 12 to 13, with the event returning to the International Centre for its seventh edition.

“For next year, we’ll probably be expanding again,” said Galloway, who says his team is aiming to hit, or exceed, the 400-exhibitor plateau. “We’re trying to expand the interactiveness of the show with the large equipment demos, and more demonstration-stage presentations and conference sessions to create more value for those that are attending.”

Watch for more information about the 2025 event to be posted on the show’s website, canadianconcreteexpo.com.

4 / APRIL 2024

PHOTOS BY ADAM

CCE 2024

FREILL

Pump Truck Rodeo Champion Hugo Lacroix of Pompage Industriel.

CCE 2024 featured an expanded show floor.

New sustainable solutions for your next project

FULLY OFFSET IN THE ENTIRE LIFE CYCLE

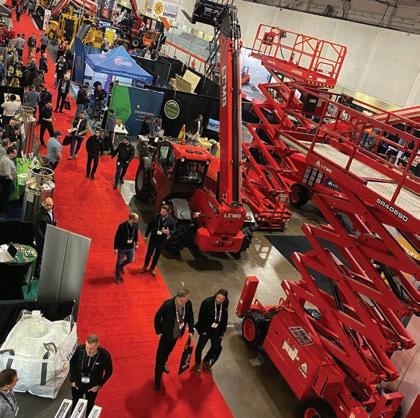

CONCRETE INDUSTRY FLOCKS TO VEGAS

50 th anniversary show attracts almost 60,000 construction professionals.

BY ADAM FREILL

Texhibitors also made the trek to showcase the tools, resources and tricks fuelling the future of the trade. Regardless of where they were from, exhibitors appeared to be happy with both the quality and quantity of visitors this year.

“Rather than having to push the concepts of enhanced efficiency, data utilization and collaboration across workflows through software, we saw a lot of energetic, inquisitive contractors at World of Concrete who were already aware of, and actively looking for, these opportunities,” said Greg Norris, marketing communications director at B2W Software. “Traffic was steady, and we met with more large concrete contractors focused on civil-type work than at past World of Concrete shows. This was a valuable show.”

he 50th anniversary edition of World of Concrete (WOC) did not disappoint. The largest event dedicated to the concrete construction and masonry industries in North America attracted nearly 60,000 registered professionals from all segments of the industry to Las Vegas for three days of exhibitions and four days of education.

The event, which saw a 23 per cent increase in traffic from its 2023 edition, presented products and services from more than 1,400 companies, along with a record-high 185 education sessions, as it covered more than 700,000 square feet of indoor and outdoor space. Large crowds kept the exhibit halls bustling and training sessions at capacity.

Along with well-known brand names like Caterpillar, Hilti, Husqvarna, John Deere, Makita and Stihl, the event welcomed 325 new, first-time exhibitors, and more than 450 international

In addition to the seasoned and experienced veterans of the industry, event organizers say that new audiences and the incoming next generation of concrete professionals continue to be a focus for increasing visibility in the sector.

“Every year, World of Concrete serves as the cornerstone where concrete and masonry professionals exchange knowledge and hone skills that propel businesses forward,” said Jackie James, vice-president of the show. “We emphasize creating real-world scenarios, hands-on situations to try and test products and share expertise, which is what makes WOC so unique and our community so special. We look forward to continuing to share the latest and greatest in concrete and masonry for another 50 years to come.”

In honour of its 50th anniversary, World of Concrete donated 50 trees to the Las Vegas Tree Initiative. The ongoing program aims to lower the urban heat island effect that currently makes Las Vegas the fastest-warming city in the United States.

World of Concrete will return to the Las Vegas Convention Center again in January, with the trade show running from January 21 to 23, and the education program starting one day earlier. Visit www.worldofconcrete.com for more information on the upcoming exposition.

6 / APRIL 2024 WOC 2024

PHOTOS COURTESY OF WORLD OF CONCRETE

POWER CURBERS CURB MACHINE

The 5700-D curb and gutter machine from Power Curbers is a slipform unit designed for such applications as curbing, sidewalks, barrier, ditches, paving, and tunnels. The compact-sized machine can be used with the SlipSmart Control System to interface with 3D, stringless systems. It is equipped with auto-calibration for the radius steer sensor, a vibrator master scaling knob, and a single switch that raises or lowers all crawler posts simultaneously. A canopy with an overhead lamp is also available, in addition to Bimini and umbrella choices.

GOMACO HYBRID CURB AND GUTTER

Gomaco’s Xtreme GT-3600 is available as a hybrid machine powered by a 74-hp engine, a 48-volt generator/motor and between four and six 7-kWh capacity lithium-ion batteries, which provide supplemental power when needed. Features include rotary-sensored slew drives on each of its three tracks, independent hydraulic control to each track, and the ability to slipform a 24-inch radius. The hybrid model is the same size as the non-hybrid version, and is available with Gomaco Remote Diagnostics.

WIRTGEN SLIPFORM PAVER

Wirtgen’s SP 15/SP 15i is engineered for paving large poured-inplace concrete profiles at heights of up to 1.3 m or widths of up to 1.8 m. The machine can produce a wide variety of different profile geometries, including curbs and gutters, among others. Changing moulds or switching them from one side of the paver to the other can be accomplished quickly and easily right on site. The company’s AutoPilot 2.0 can be used to assist with the automated paving of offset and inset concrete profiles, such as curbs for traffic islands.

MINIMIZE THE RISK OF RANDOM CRACKS

Husqvarna Soff-Cut® is an ideal system for Ultra Early Entry™ sawing of contraction joints one to two hours after pouring a concrete slab. The system is designed to minimize the risk of random cracks - one of the most costly and aggravating problems for contractors. Appreciate high production rates, the ability to pour and cut concrete on the same day, and the tidy end result achieved by only cutting shallow depths. To learn more visit our website.

www.husqvarnaconstruction.com

on-sitemag.com / 7

OS_Husqvarna_April24_CSA.indd 1 2024-03-01 9:20 AM

CONCRETE PRODUCTS

TREATING CRACKS IN CONCRETE

There are a variety of current methods for treating and healing narrow cracks.

BY JENNIFER MIZER

Today’s concrete technology provides several ways to limit the size of cracks, and to prevent them.

Despite available preventative measures, such as a sound subgrade, designs for low-shrinkage concrete that incorporate shrinkage-reducing or shrinkage-compensating admixtures, using concrete with lower water-to-cementitious ratios, adding macro or microfibres, proper curing, using evaporation retarders, and performing joint cutting operations as soon as possible, concrete can still maintain its tendency to crack.

Narrow cracks in concrete slabs, typically in the 0.01 to 0.06-inch width range, are especially troubling when they occur on bridge and parking decks, elevated floor slabs and similar high-use horizontal slab surfaces. Cracking can allow for the penetration of water, sulfates, chlorides and other harmful agents, accelerating surface spalling and the corrosion of steel reinforcement.

This cycle of deterioration can shorten the life of a concrete deck, requiring expensive repairs or full replacement of in the future. There are several common methods for treating cracks, however.

PROTECTIVE COATINGS

One way to treat narrow cracks in concrete is to use film-forming acrylic waterproofing coatings. Many of these coatings are quite flexible and have crack bridging properties.

Traffic deck coatings based on epoxy or urethane polymers are commonly installed on bridge decks, parking decks, factory floors and loading docks. Many of these systems incorporate an aggregate broadcast to provide skid resistance and have the added benefit of waterproofing the concrete.

Since protective coatings are applied to the concrete surface, exposure to weather, abrasion or other damage will eventually lead to the deterioration of these materials. As such, many acrylic coatings, for example, are primarily used on vertical surfaces and horizontal decks for decorative purposes or exposure to lighter pedestrian traffic.

WATER REPELLENTS

Penetrating water repellent sealers containing silane, siloxane or a silane/siloxane blend penetrate the crack and coat its sides to provide the substrate with a water-repellent barrier, but do not fill the cracks entirely or fully seal the concrete surface.

Penetrating silane or siloxane sealers soak into the surface of the concrete where they chemically react to form a hydrophobic barrier within the pores that causes water and other liquids to bead off the surface, reducing the absorption of water.

These sealers will not change the appearance or colour of the concrete, and do not leave behind a visible surface film. When properly applied, silane and siloxane sealers can last for up to 10 years before resealing.

HEALER/SEALERS

Another treatment for narrow cracks is to use a thin, chemically curing polymeric resin to fill the cracks. Penetrating by gravity alone, the resin fills the crack and seals out water, salts and other damaging elements. This method of crack repair is intended to seal cracks that are “static” or “non-moving,” such as shrinkage and settlement cracks that have stabilized.

This method can also be used to protect the entire concrete deck by applying a flood coat of the polymeric resin on the entire surface. This essentially seals the deck while sealing or “healing” the cracks. The term healer/sealer is often used to describe the polymeric resin applied in this process.

Although concrete healer/sealers have been around for decades, their ability to fully fill, seal and heal cracks often yielded mixed results. When healer/sealers were first developed, it was easy to look at the viscosity of the resin as the reason for these mixed outcomes. If the viscosity was too low, it could flow into the crack and out the bottom of the slab. If the viscosity was too high, it didn’t penetrate far enough to fill the crack.

When a new generation of healer/sealers were developed, other factors were considered, including the method used to achieve the desired viscosity, modulus of elasticity and surface tension.

Through laboratory testing and field trials, the best results were found when the crack healer/sealer material was found to be low viscosity. In formulating chemically curing polymeric sealers and coatings, the simplest way to lower the viscosity of a product is to increase solvent content, however increased solvent typically means a higher

8 / APRIL 2024

CONCRETE REPAIR

PHOTOS COURTESY OF EUCLID CHEMICAL

Penetrating concrete sealers repel water.

volatile organic compound (VOC) content, increased hazards in mixing and handling, and an impact on physical properties.

Formulators can adjust the molecular weight and molecular weight distribution of the healer/sealer, which can have a profound effect on the viscosity of the finished product. Generally, the higher the molecular weight, the higher the viscosity. This is often not desirable for a crack healer/ sealer. Higher molecular weight also results in higher strength and durability of the final product though.

To solve this conundrum, the molecular weight distribution of the healer/sealer is adjusted, resulting in lower viscosity, without affecting the strength properties of the material.

A wide distribution of different sized polymer chains results in a healer/sealer with higher viscosity and therefore less ability to flow and penetrate cracks. Newer generation healer/sealers are formulated with a narrower distribution of polymer sizes, which produces a more flowable material.

MODULUS OF ELASTICITY

Modulus of elasticity is a measure of stiffness, with higher-modulus materials exhibiting less deformation under load compared to low-modulus materials. A low-modulus crack healer/sealer can provide better resistance to mechanical or thermal movement of the concrete deck.

Since many treated cracks found on bridge and parking decks are often subjected to this type of movement, a low modulus of elasticity product is optimal in many instances, as it will withstand a certain amount of movement and help prevent re-cracking. In addition, low surface tension is an important factor in allowing the healer/ sealer to penetrate the crack. Healer/sealer products are formulated using specially designed agents to reduce surface tension, which allows the resin to penetrate the concrete cracks more readily.

A liquid with high surface tension contains molecules that are more attracted to each other than they are to the surface upon which they are applied. Also, the molecules at the surface of a high surface tension liquid have no molecules attracting them

from above, so these surface molecules can only be attracted down and in. This attraction to itself coupled with strong surface tension causes the liquid to bead up instead of spreading out on the surface.

Concrete healer/sealer formulators incorporate surface tension reducing additives called surfactants to ensure the healer/ sealer spreads out onto the concrete surface instead of beading up.

HEALER/SEALER APPLICATION

Application of a healer/sealer begins with proper surface preparation. The concrete surface must be structurally sound and free of grease, oil, curing compounds, soil, dust and other contaminants. New concrete and masonry must be at least 28 days old. Surface laitance must be removed. Concrete surfaces must be roughened and made absorptive, preferably by mechanical means, and thoroughly cleaned of dust and debris.

If the surface was prepared by chemical means (acid etching), a water/baking soda or water/ammonia mixture, followed by a clean water rinse, must be used for cleaning to neutralize the substrate. The Concrete Surface Profile (CSP) should be CSP 2-5 in accordance with Guideline 310.2R from the International Concrete Repair Institute.

Following surface preparation, the strength of the surface can be tested if quantitative results are required by project

specifications. A tensile pull-off tester may be used in accordance with ASTM C1583, with a required tensile pull-off strength commonly specified to be at least 250 psi.

The application of the materials includes pretreating large cracks, if necessary, flood coating with the low-viscosity, low-modulus epoxy, distributing the epoxy onto the substrate, removing excess epoxy, broadcasting fine sand onto the wet epoxy, removing the excess sand when the resin has cured, and opening the deck to traffic.

After properly mixing the material, cracks may be pre-treated by gravity feeding the healer/sealer by hand directly on top of the crack or by ponding the material over cracks, permitting it to sink in and seal the crack onto the properly prepared surface in a wave form, and spread uniformly with a squeegee or a short nap roller.

If necessary, allow the epoxy to penetrate the surface, re-applying to cracks and porous areas as needed. Excess epoxy can be removed with a squeegee before it becomes tacky. Broadcast clean, oven-dried silica sand (recommended 16/30 or 20/40 mesh) into the wet epoxy to provide a skid-resistant surface, or where subsequent toppings or coatings will be applied. Before opening to traffic, and when the healer/sealer has cured, remove any loose aggregate.

Despite current concrete technology’s aim to avoid cracks in concrete, and to limit the size of any such cracks, they still happen. Cracking in concrete slabs is especially troubling when it occurs in bridges and parking decks, elevated floor slabs and similar high-use horizontal slab surfaces.

There are methods for treating and healing narrow cracks, however including film-forming coatings, penetrating water repellent sealers, and chemically cured polymeric resin.

Jennifer Mizer is the director of marketing services at Euclid Chemical, a manufacturer of specialty concrete and masonry construction solutions that includes admixtures, fibre reinforcement, concrete repair products, flooring materials and decorative concrete systems.

on-sitemag.com / 9

Pretreating cracks.

Spreading material over deck slab.

CONCRETE DISCUSSIONS ABOUT INDUSTRY INNOVATIONS

Second annual Concrete Pavement Seminar was an opportunity to share practical advice about emerging materials and best practices.

BY ADAM FREILL

More than 60 industry professionals hit Mississauga, Ont., in February for the second annual Concrete Pavement Seminar, presented by Concrete Ontario and the Cement Association of Canada. The day-long event featured several sessions, ranging from updates on key projects and advances in concrete mixes, to technical applications of concrete as a paving medium.

In his discussion about the next generation of pavement, the Cement Association of Canada’s Tim Smith discussed how an examination of project timelines can impact both the strength and the carbon footprint of the concrete being poured. He said, for example, where the project can provide for a longer curing time, it becomes possible to select a concrete mix that will deliver the prescribed strength, while reducing the carbon impact.

“If we start thinking about the carbon footprint of the material, then we can possibly reduce the amount of cementitious material. We can actually go with a later date on the strength, so that we can minimize that cement content and minimize the carbon footprint of the pavement,” he explained. “Something that we need to start thinking about is when is the project going to be open to traffic… if you don’t need that for a while, then maybe we should start thinking, from a global warming potential, of the 56-day or the 92-day strengths instead of 28 days.”

Also leading a technical discussion during the event was Mark Popik of Thurber Engineering Ltd. He shared insights into the use of lightweight cellular concrete applications, outlining a few projects where the material has made it possible to solve some unique problems, such as those that can be created by trying to build a road foundation on soft organic substrates.

Brian Killingsworth of the National Ready Mixed Concrete Association kicked off the afternoon sessions with a look at his organization’s Pave Ahead program.

“We try to partner with other technical groups with representation from contractors, users, cement suppliers, stone suppliers; we all try to work together to be able to promote a product that we fully believe in,” he explained. His organization has created

a website containing information that the industry can access without fees, to help with their concrete projects.

“Where we want to help is to be able to step in and say here’s some of the best practices; here’s how you can improve your specifications; here’s some of the tools that you may need, and provide those tools,” he said. “We do that through our design assistance program.”

In addition to outlining some of his organization’s activities, Peter Taylor of the National Concrete Pavement Technology Center talked about water and cement ratios, and provided advice about how admixtures are changing the rules of thumb as the constituents of concrete mixes are changing.

“Do your homework. Do your trial batches,” he advised. “You will get the performance you need, but don’t just flip one [mix] out and put another one in and hope it’s all going to go well.”

After a quick look at some research projects conducted over the past few years at the University of Waterloo’s Centre for Pavement and Transportation Technology, the day wrapped up with a networking social.

The dates have been set for next year’s event. The third annual Concrete Pavement Seminar will take place on February 19, 2025. Keep an eye on the Concrete Ontario website for more details.

10 / APRIL 2024

CONCRETE PAVING

Thurber Engineering Ltd.’s Mark Popik discusses lightweight cellular concrete applications during the second annual Concrete Pavement Seminar, presented by Concrete Ontario and the Cement Association of Canada.

PHOTO BY ADAM FREILL

The Worldwide Leader in Concrete Paving Technology

CONCRETE STREETS AND HIGHWAYS | AIRPORT RUNWAYS | CURB AND GUTTER | SIDEWALKS RECREATIONAL TRAILS | SAFETY BARRIER | BRIDGE PARAPET | BRIDGE DECKS | IRRIGATION CANALS GOMACO CORPORATION IN IDA GROVE, IOWA, USA | 712-364-3347 www.gomaco.com | info@gomaco.com GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/

and

GOMACO

features

exclusive and

G+®

cure machines

bridge/canal finishing equipment.

equipment

our

proprietary

control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.