motion

bucket

Delivering Results.

Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

23-26, 2022 Booth N-4706, McCormick Place Chicago, IL USA

FROM THE EDITOR

George Guidoni

not throw the baby out with the bath water

cannabis legalization review.

Myles Shane

Public speaks out on packaging hits and misses.

Independent Toronto brewery completes a massive new Krones canning line installation to quadruple its output capacity, improve its production flexibility, and further expand its product portfolio.

A Top Tier Canadian cannabis producer automates its pre-rolls production with a unique made-in-Canada automation solution.

A high-performance automatic thermoform packaging solution enables British Columbia producer of raw pet food products to improve production efficiencies and develop more consumerfriendly packaging formats.

A preview of the advanced packaging technologies and solutions to be displayed at the upcoming PACK EXPO International 2022 packaging extravaganza in Chicago.

PAGE 20: SPECIAL REPORT

Celebrating this year’s PAC Global Awards competition winners.

Brunswick Bierworks president Sean Fleming and chief operating officer Christoph Von der Heide strike a cheerful pose from top of the stairs leading to the mezzanine level of the company’s newly built production facility housing a turnkey state-of-theart Krones canning line.

Cover photography by Naomi Hiltz.

Since legalizing cannabis for rec reational use in October of 2018, Canada has become the world’s testing ground and research lab for cannabis legislation and regulation, with governments around the world keeping a close eye on how the country’s fledgling cannabis sector evolves into a bona fide consumer packaged goods (CPG) sector making s meaningful eco nomic and social contribution to the Canadian society.

According to the federal government’s own figures, Ottawa will be spending, or mostly has spent, some $108.5 billion over six years (2017-2023) on various public education and awareness initiatives that include national advertising and social media awareness campaigns, along with various unspecified “collaboration projects” with provincial governments.

The amount spent by Ottawa on cannabis education and awareness efforts since 2017

With many of the world’s leading “rich” countries having already declared their intentions to liberalize their own existing prohibitive laws on cannabis possession and consumption in coming years, the last thing Canada needs is some kind of a regulatory rollback of the considerable progress many of Canada’s LP (licensed producer) companies have made to date in providing Canadians with safe and in novative cannabis products.

No more sketchy nickel and dime baggies filled with sticky skunkweed of dubious quality and efficacy being hustled by even sketchier street dealers hawking their wares at dark street corners or underground grow-ops.

No more fear, anxiety and paranoia of falling afoul of the law for slight transgres sions involving a little marijuana enjoy ment after a stressful day, with punishment usually exceeding the nature of the of fence—a victimless crime if there ever was one—with disproportionately harsh punitive measures.

It’s worth noting that well more than half of Canadian cannabis users who used to get their marijuana from the black market have turned to legal cannabis producers for their needs, which is a highly encouraging trend insofar as driv ing the black market out of existence.

So while a federal review of the Canna bis Act’s impact on the Canadian society is not in itself a step backwards, there is a risk it could well become one if it draws the wrong conclusions or falls for the same old traditional prohibitionist rhetor ic advocating a dramatic policy turn around.

For an industry that was supposed to replenish the governments’ coffers with a whole new tax revenue stream, the amount of money spent by Ottawa to bombard consumers with cautionary advice and information about cannabis is staggering.

In addition, the government has author ized Health Canada to spend yet another $62.5 million over the same time period through its Substance Use and Abuse Pro gram to provide educational resources to vulnerable groups that include youth and young people, indigenous populations, pregnant and breastfeeding women and older adults, along with healthcare profes sionals and Canadians in general.

It’s anyone’s guess how much the new legislative review process, led by the socalled independent Expert Panel, will cost, but another eight-number figure is definite ly not out of the question by any stretch.

For an infant industry that is still trying to reach anything resembling reliable prof itability and return on investment, such fiscal largess would seem a tad inappropri ate at the very least.

Be that as it may, the government is adamant that its review of the Cannabis Act, specifically the seven key objectives speci fied in Section 7, are necessary to help:

• protect the health of youth by restricting their access to cannabis;

• protect youth and others from induce ments to use cannabis;

• provide for the licit production of can nabis to reduce illegal activities in rela tion to cannabis;

• deter illegal activities through appropri ate sanctions and enforcement meas ures;

• reduce the burden on the criminal jus tice system in relation to cannabis;

• provide access to a quality-controlled supply of cannabis;

• enhance public awareness of the health risks associated with cannabis use.

All noble goals, no doubt, but only time, and money, will tell how it all turns out in the end for the industry, the public and the government itself.

OCTOBER

Reader Service

|

Print and digital subscription inquires or changes, please contact

Angelita Potal, Customer Service

Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher

Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor

George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator

Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager

Barbara Adelt | (416) 510-5184

Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer

Alison Keba | (519) 429-5181 akeba@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR

(INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2022 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

For Canadian consumers concerned about their sugar intake, a new innovative product from organic chocolate producer Theo broma Chocolat will provide plenty of cheer in coming months following the launch of the company’s new Yummy Zero Sugar brand of plant-based, zero-sugar, organic chocolate.

Said to be two years in development, the nutritious, delicious-tasting chocolate is made with an organic and natural sweetener derived from cassava fibers, making it is rich in vegetable fibers.

According to the company, these fibers significantly differ from the current sug ar-free or sugar-controlled confectionery

products available on the Canadian market, which use synthetic sweeteners that are hard on the digestive system, and also mask the creamy taste of chocolate.

Founded in 2008 by Josée Vigneault and Jean-René Lemire in Saint-Augustin-deDesmaures, Que., the company plans to begin exporting the new product to U.S. markets following its well-received launch last month at the Canadian Health Food Association Natural Organic Wellness (CHFA NOW) exposition in Toronto.

“Yummy Zero Sugar is an indulgent healthy alternative which provides consumers with low to zero-sugar options,” says company co-founder and vice-president Lemire.

“Our delicious alternatives complement our current collections and align with our

quest to be a delicious force for change,” says Lemire, citing “social manufacturing” as the cornerstone of the company’s innovation and product development efforts.

“We don’t say no to sugar,” she states, “but we focus our energy on creating healthier indulgences that are fun and care about you, the planet, and your eating habits.”

Available in Coconut and Special Dark flavors, the new treats are individually wrapped in Mini format size inside resealable 90-gram stand-up pouches manufactured by TC Transcontinental Packaging, headquartered in Montreal, and feature high-impact decorative graphic design created by Theobroma’s Vigneault Chocolatier Ltée in-house design team.

According to 2010 market research conducted by Sugarwise, an international certification authority that assesses sugar content in foods and beverages, and branding consultants Strategy, 39 per cent of Canadian consumers cite sugar content was an important criterion when selecting their foods .

By 2017, that number had jumped to 69 per cent, and in 2020 about 72 per cent Canadians said that low sugar content was a priority, with nearly 80 per cent of surveyed participants saying they wanted to reduce their sugar intake.

According to many nutritionists, Canadian consumers are currently taking in 10 times the daily amount of sugar recommended by the World Health Organization (WHO)

“Our Yummy Zero Sugar products won’t fix everything, but they will help consumers meet World Health Organization recommendations,” says company co-founder Josée Vigneault.

“The carefully chosen ingredients have been certified organic, and they deliver on the same promise as all Theobroma products: pleasure first, enjoy!

“Yummy Zero Sugar has a rare flavor profile that matches that of dark chocolate with sugar, while surpassing the traditional ‘no sugar added’ choco late experience,” Vigneault states.

“Theobroma Chocolat has achieved this goal with its range of premium certified organic products.”

Originally starting out as a part-time sales gig for young business student Eric Frechette, who sold fresh strawberries door-to-door to fund his education, Taste of the North has come a long way in 25 years to become a widely respected distributor of local fresh produce within a 250-mile radius of the company’s fields in Quebec’s famed St. Lawrence Valley.

With the company’s reputation for the freshness of its products and minimal transpor tation carbon footprint starting to take hold in new key U.S. markets within its geographic reach, Taste of the North recently decided to upgrade the look of its products through a comprehensive packaging redesign to com municate the taste, quality and sustainability attributes of its strawberries and other Que bec-grown produce.

To make it happen, Taste of the North teamed up with leading Canadian package design services provider Pigeon Brands, tasking its designers to make its brand position, identity and package design align better with its identity as a punchy, youthful brand looking for the best ways to offer American clients fresh and tasty produce from Québec.

“We developed the brand strategy around the Taste of the North’s brand promise that delivers regionally-sourced produce grown the

right way—resulting in exceptional taste,” explains Pigeon Brands creative director Jean Francois Beliveau.

“This translated into the consumer truth of

experiencing delicious flavorful produce, which was the driving point of differentiation and insight leading us to develop the tagline ‘Joy in every bite.’

“With a stronger emphasis on ‘taste’ in the logo, a more contemporary wordmark, and a saturation of a fresher green on pack, the new look and feel truly speaks to the brand’s delicious offerings and sustainable values,” Beliveau.

Featuring on both the quart-sized paper board punnets and the six-pack corrugated cases used to ship them to market, the new strawberry packaging is expected to help Taste of the North solidify its market share growth south of the border, according to company founder and chief executive officer Eric Frechette.

“We work with specialized local partners in Québec to supply the northeastern region of the U.S. to offer quality food filled with taste and freshness—all thanks to our short-circuit transportation policy.

“As environmental values weigh more and more in consumers’ purchase decisions, our business model enhances the sustainable practices of our Québec partners, with whom

Do you want

you want SUPERIOR production?

love the speed.

you want SUPERIOR package seals?

love not worrying about

Two of The Coca-Cola Company’s biggest brands in North America are taking major steps to support a circular economy for plastic packaging, with DASANI bottled water rolling out bottles made from 100-percent recycled PET (polyethylene terephthalate) plastic—ex cluding caps and labels—and Sprite transi tioning from green to clear plastic to increase the material’s likelihood of being remade into new beverage bottles.

A majority of DASANI bottles in the U.S— from 20-ounce and 1.5-liter singles to 10- and 12-ounce multipacks—have been gradually replaced with 100-percent recycled plastic since mid-summer. In Canada, this innovation spans all DASANI bottles.

The shift supports both DASANI’s pledge to remove the equivalent of two billion virgin plastic bottles from production by 2027, compared to 2021 levels, and its World Without Waste initiative’s goal to use at least 50-percent recycled material in its bottles and cans by 2030.

The brand’s transition to 100-percent recycled plastic is projected to save more than 20 million pounds of new plastic, compared to 2019, and cut more than 25,000 metric tons of GHG (greenhouse gas) emissions in 2023 alone.

“Demand for rPET currently exceeds supply, so the first step to scaling up use of 100-percent rPET across our portfolio is building a sustainable pipeline of high-quality material,” says Chris Vallette, senior vice-president of technical innovation and stewardship at Coca-Cola North America

“We do this by working with communities to boost PET recycling and collection; collaborat ing with recycling partners; and, finally, securing rPET to help ensure the material for our bottles is used again and again,” says Vallette, adding the DASANI brand will continue to drive consumer awareness through the bold, on-pack “100% Recycled Bottle” and “Recycle Me Again” calls-to-action also used on retail signage and other communications.

“We saw how much the 100-percent recycled PET message truly resonates with our custom ers and consumers, particularly DASANI fans whose sustainability expectations are especially high,” says Vallette, noting that DASANI has long been at the forefront of sustainable

innovation.

Over the last decade, America’s leading bottled water brand has unveiled a steady stream of footprint-reducing packaging breakthroughs, including PlantBottle; HybridBottle fusing rPET and virgin PET; aluminum cans and bottles; DASANI PureFill package-less water dispensers; and indus try-first bottle caps made from recycled high-density polyethylene (HDPE) plastic.

For its part, the Sprite soft-drink brand began transitioning all of plastic PET packaging from the original signature green color to clear in early August. Although green PET is recyclable, the recycled material is more often converted into single-use items like clothing and carpeting that cannot be recycled into new PET bottles. Moreover, green and other colored PET must be separated from clear material during the sorting process to avoid discoloration when making new PET bottles.

“Taking colors out of bottles improves the quality of the recycled material,” says Julian Ochoa, chief executive of R3CYCLE, which is working with Coca-Cola Consolidated to enable bottle-to-bottle recycling across the largest U.S. bottler’s 14 state-territory.

“This transition will help increase availability of food-grade rPET,” Ochoa states. ”When recycled, clear PET Sprite bottles can be remade into bottles, helping drive a Circular Economy for plastic.”

When expanding your canning or bottling operations, there is much to consider. It can take many months to plan and procure new equipment prior to installation. Plus, it can take several months to get to producing saleable cans after you’ve installed new equipment. You know beer, we know conveyors – we can assist with design, consultation, installation, service and support during and after run-in. From conveying components, guide rail, speed reduces and bearings to Perceptiv™ diagnostic services, we can help you get new conveyors running smoothly and make the complex simple.

Based in Hamilton, Ont., profes sional cleaning products manufac turer Project Clean provides customers with superior industrial and commercial cleaning products designed for people and the environment. But during the recent COVID-19 pandemic, Project Clean president and chief executive officer Normand Frechette recalls the company encountered a supply chain issue with an existing line and needed an immediate packaging solution.

Acting on advice of one of his industry peers, Frechette emailed Court Carruthers, chief executive officer of St. Louis, Mo.-headquar tered rigid plastic products manufacturer TricorBraun, to see if he could help out.

Highly impressed with Tricor Braun’s swift response and turnaround, Frechette felt compelled to contact TricorBraun again earlier this year to help Project Clean carry out a compre hensive packaging redesign.

Specifically, Project Clean wanted to align its product range with the company’s 30-year mission of to providing more effective and safer environmentally-friendly solutions with a sustainable custom design solution.

“The industrial and commercial cleaning industry is renowned for very little innovation,” Frechette states. “For as long as I can remember, the typical industrial cleaning bottle has always been a round shape.

Says Frechette: “It constantly irritated me to open a shipping case with round bottles and see all the extra space.

“Not utilizing that space means using more cardboard boxes to ship a specific number of bottles,” Frechette points out.

“There had to be a better way.

As Frechette recalls, Project Clean also required a sustainable packaging solution that would reduce its plastic impact at the source and minimize waste leakage by creating a product that was not just single use—ultimately selecting 100-percent PCR (post-consumer recycled) content resin.

“We knew we couldn’t divert from plastic because it is the best option for our industry to protect goods from damage during shipment from point A to point B,” says Siriya Couturier, sustainabil ity, innovation, and marketing director for Project Clean.

“Therefore, we chose 100-per

cent PCR resin as it has the same functionality as regular plastic but reduces our overall environmental footprint.”

After engaging a series of focus groups to obtain consumer insights on the most impactful ergonomic handle placement, the Tricor Braun Design & Engineering team recommended a rectangular gallon bottle with an angled handle for a more comfortable pour.

TricorBraun also recommended an ergonomically-friendly, squaredoff one-liter bottle that would not only maximize the space inside the sipping boxes during transit, but would also make the brand stand out from all the round bottles used in the industrial market.

“We had a pretty tight launch time-frame,” says Frechette, “which was a challenge in itself.

“Yet TricorBraun worked tirelessly to manage our time-line and design a solution that would move our company towards better packaging and a superior user experience,” added Frechette.

And while Project Clean swiftly approved the bottle design, both teams had to immediately address a pandemic-driven obstacle before the design could be produced.

Trigger sprayers often come with cleaning products because they are easy to use and conven iently dispense liquids. However, with the pandemic disrupting the supply chain, it was nearly impossible to source a trigger sprayer supplier.

“TricorBraun quickly pivoted to address this supply chain disrup tion by recommending its Halo Multi-Stream push-pull closure that provides an optimal user experience,” says Rachel Murphy, director of category and consumer insights for TricorBraun Design & Engineering. “Because our team constantly prioritizes product innovation and development, we had this commercially-available solution ready when Project Clean needed it.”

Unlike typical push-pull closures have four different holes that spray outward into a stream that merges into one, the new Halo Multi-Stream closure from TricorBraun provides unique ability to dispense a wider spray pattern.

Designed as a durable solution for daily indoor and outdoor applications, the new IRC40 inductive proximity sensors from CARLO GAVAZZI enable accurate detection of actuating parts, such as skid conveyor positioning, step detection on escalators, and material positioning on conveyor systems. Resistant to extreme operating conditions such as exposure to a wide range of temperatures, frequent high pressure, and washdown cycles, the IRC40 series sensors offer flexible adjust ment and adaptability for any application with their the five-position sensing face, and they can be quickly installed without any tools with the mounting bracket’s push-lock mechanism. Well-suited for a wide range of conveyor system applications on production lines and escalators requiring optimal reliability and flexibility, the IRC40 series inductive proximity sensors are loaded with value-add features such as:

• Four-corner visible LEDs with diagnostic functions;

• Extended sensing distance range from 22-mm to 40-mm;

• Operating temperature range of -25˚C to +80˚C (-13˚F to +176˚F);

• IP68 and IP69K protection against high pressure and high-temperature washing cycles;

• 40x40x66-mm plastic housing with M12-plug;

• Flush or non-flush mounting with antivalent output.

CARLO GAVAZZI (Canada) Inc.

The new ThicknessPen measuring device from Agr International Inc. is a highly innovative new portable thickness gauge featuring patent-pending, dual measurement mode technology that makes it ideal for measuring applications in the laboratory or on the plant floor. Developed to address the multiple and diverse thickness measure applica tions of the production environment, the Thickness Pen’s small size, light weight and robust design enable its use just about anywhere to obtain easy, non-destructive and highly accurate thickness measurement of all types of non-ferrous products, regardless of their size, shape or material. Accord ing to the company, the user-friendly ThicknessPen differs from other measurement devices with its patent-pending, dual-mode operation that offers users the option to measure using either a magnetic or capacitance mode, whichever is most appropriate for the application.

To suit rugged material handling and product transfer applications that require frequent cycling (lifting and lowering) of heavy-duty lift tables, Southworth Company now offers high-duty cycle packages that increase recommended maintenance intervals from 50,000 cycles to 200,000 cycles by incorporating more rugged and durable wear parts to provide longer service life and better performance in applications that involve oversized or non-uniform loads, which can cause uneven wear in standard lifts, requiring premature replacement and resulting in unplanned production downtime . Often specified for integration with other material handling systems like conveyors and sortation systems, all of the compa ny’s LS Series lifts—including 2,000-, 4,000-, 6,000- and 8,000-pound capacity units—can be configured for high-duty cycles.

Southworth Company

Designed to automate reliable product transfer conveying of powders, granules and other small particles, the new piFLOW range of batch volume optimization vacuum conveyors from Piab operate by taking bulk solid particles from a pick-up point and releasing them into a receiving vessel or a piece of equipment in pre-determined batches, using an integrated level sensor to ensure optimal wight and volume accuracy. Once the conveyor is filled up by each cycle, the sensor automatically triggers the release process. This way, operators can set the conveyor up quickly and the automatic level sensing adds an extra layer of safety, according to the company, which protects the equipment from unplanned maintenance.

Piab

Making honey for a liv ing has been a sweet and joyful ride for Texas-based Nature Nate’s Honey Co., which has grown into the Number One branded honey company in the U.S. only 10 years after launching its flagship Nature Nate’s brand into the retail markets.

Originally started up in 1972 under the North Dallas Honey moniker, the company was acquired by recent college graduate Nathan Sheets in 1997, who started out by filling pure, raw and unfiltered hon ey inside glass containers in his home garage.

By 2013, the fledgling start-up secured enough capital backing to move to a new production facility company in McKinney, Tex., and to acquire 12 acres of prime farmland for beekeeping and harvesting.

Dedicated to offering honey as nature intended—100-percent pure, raw and unfiltered—the Nature Nate’s brand honey arrives in its most natural form—the closest to its original provision from the hive.

Adhering to strict quality-control standards, sourcing honey from trusted beekeepers, and minimally processing it to ensure the honey retains its natural benefits, the com pany is keenly aware of the need to make its packaging as sustainable as

possible.

To achieve this, Nature Nate re cently worked with Glenroy Inc., a leading sustainable flexible pack aging company headquartered in Menomee Falls,Wis., to develop the innovative, squeezable STANDCAP Pouch package offering a wide range of sustainable benefits.

Developed as an alternative to the traditional rigid plastic bottles dom inating the honey category, the pre made STANDCAP Pouch pack

aging provides a gravity-fed, no-drip solution that uses far less materials and energy to produce.

According to a comprehensive LCS (life-cycle analysis) study con ducted by Glenroy, the new STANDCAP Pouch packaging’s sustainability benefits include:

• Using approximately 60 per cent less plastic to make;

• Consuming 71 per cent less water during production;

• Generating 50 per cent less GHG

(greenhouse gas) emissions in the production process;

• Requiring approximately 44 per cent less fossil fuel during trans portation;

As Nature Nate’s founder and chief executive officer Nathan Sheets proclaims, “It’s our role to bring innovation to the honey shelf and kitchens across the country— whether that’s in taste, purity, testing, or packaging.

“Our inverted pouches are unique to the market and allow our custom ers to enjoy our honey with every easy squeeze,” says Sheets, citing a steady increase in online pouch sales on the Amazon network.

According to Sheets, the success of STANDCAP Pouch on amazon has caught the attention of some of the nation’s leading grocery retailers, gaining additional shelf-space at Kroger and Walmart stores nation wide.

As Says Nature’s Nate senior vice-president of marketing Becca May explains,“The pre-made STANDCAP Pouch creates new usage across generations, as people of all ages can interact with the pouch because it is easy to use.

“It’s exciting to see our customers migrate to the new pouch format and introduce our high-quality products to new customers in our more sustainable packaging.”

Toronto beverage processor completes milestone capital investment project with expert turnkey canning line installation and advanced inline processing capabilities

By George Guidoni, Editor Photos by Naomi Hiltzhile most people will agree with the endur ing notion that quality is always preferable to quantity, there is really nothing better than having both. And although chasing the best of both worlds can often be a frustratingly elusive pursuit for many, falling short on either count was never an option for hardworking folks at Toronto-based brewer Brunswick Bierworks Inc.

Founded in 2016 and already ranking as one of the country’s leading privately owned brewers, the company has enjoyed stellar growth and success by operating as a partner manufacturing business focused on providing turnkey beverage production and packaging services for a diverse range of alcoholic and non-alcoholic beverage brands including beer, cider, pre-mixed

Wcocktails, coolers, seltzers and many other popular and trendy RTD (ready-to-drink) beverages.

“Our sole focus is on our customers,” says company founder and president Sean Fleming, noting that beer produc tion currently accounts for half of its total output.

However, that output is all set to in crease significantly the double in coming weeks and months as the company finetunes a newly commissioned, state-ofthe-art turnkey canning line, along with some processing equipment, supplied to the east-end Toronto brewery earlier this year by leading global beverage process ing and packaging systems manufacturer Krones AG.

Housed inside a newly refurbished 30,000-square-foot building adjacent to Brunswick’s original 47,000-square-foot brewhouse and storefront facility, the new turnkey line has enabled the com pany to ramp up its throughput speeds up to 1,100 cans per minute, according to

Fleming, boosting its annual capacity to about one million hectoliters per year.

“The state-of-the-art functionality and additional extra capacity will certain ly go s long way towards serving our customers’ ambitions and ensuring product integrity,” Fleming told Can adian Packaging on a recent visit to the new building, equipped primarily with high-quality, leading-edge Krones equip ment throughout all stages of the produc tion process—from blending and depal letizing to end-of-line packaging and labeling.

For Fleming, the $30-million expan sion of the company’s manufacturing capacity represents a milestone leap into the elite ranks of the Canadian beverage processing industry—opening up lucra tive new exporting opportunities in the nearby U.S. markets.

“We are looking to expand, not just here in Canada but across North Amer ica,” says Fleming, complimenting the company’s dedicated project team, con tractors and Krones for enabling a rela tively smooth and on-schedule line in stallation and commissioning despite the logistical and other challenges encoun tered during the COVID-19 pandemic.

“It was a great team effort all around to get everything in place on time and run ning up to the speeds we wanted,” says Fleming, clearly delighted with the new line’s “solid performance” so far.

“We wanted to get the best equipment possible for this line,” Fleming says, “and that’s why we selected to work with Krones, who are renowned for the high quality of their equipment.

“We also wanted to deal with just one partner instead of multiple suppliers, so that any equipment issues can be readily addressed and resolved quickly and dir ectly,” he continues.

“Krones gives us the ‘one-stop’ solu tion we were looking for with best-inclass equipment and top-notch profes sional service,” Fleming states. “They were absolutely fantastic to work with from Day One.”

While installing high-speed, high-per formance canning lines is nothing new for Krones, one of the world’s elite manufacturers of beverage production machinery and equipment, the Bruns wick Bierworks project carries extra significance because it also involved in stallation of important new processing machinery also made by Krones— namely a state-of-the-art multipurpose blender and a powder dissolving station.

“The integrated powder dissolving station will enable them to produce beverages with almost every possible composition and formulation,” says Mathias Gorlitt, managing director and head of Canadian sales at Krones Machinery Co. Ltd. in Mississauga, Ont.

“For its part, the blender is able to de-aerate the product in up to three

(From Top)

A partial view of the new Krones canning line from the plant’s mezzanine level.

Filled can being transported en masse inside the high-volume Krones Linaflex tunnel pasteurizer.

Filled cans exiting the Krones Linaflex pasteurizer to pass through the Linadry 890 can dryers to remove all moisture off the surface prior to labeling.

The new Krones canning line at Brunswick Bierworks has been optimized to run at speeds of up to 1,100 cans per hour.

(From top)

An overhead view of the Krones Variopac Pro TFS 6 packer, whic is a fully-automatic system that can produce a broad range of secondary packaging formats.

One of many SEW-Eurodrive motors deployed to power various conveyor lines throughout the new Brunswick Bierworks facility.

A close-up view of the Krones Modulpal 2A fully-automatic palletizer building layers of boxed beverages on top of a wooden skid.

Close-up of the Krones Robobox TG-S tripod robot inside the Modulpal 2A palletizer swinging into action.

stages for the highest product quality possible, carbonate it, and mix up to four different components into the main product stream inline,” says Gorlitt, cit ing the line’s flexibility as one of its key attributes.

“It is possibly one of the highest flexible lines in Canada when it comes to the product range which can be produced inline,” says Gorlitt, noting the new pro cessing equipment is perfectly suitable for both batch and inline processing.

According to Brunswick’s chief oper ating officer Christian Von der Heide, the new processing equipment has enabled the brewery to achieve processing speeds of up to 400 hectoliters per hour—a tenfold increase from a year ago—while significantly expanding its product reper toire and portfolio.

“We can now use all kinds of innovative ingredients—powder formats, sugars, non-nutritive sweeteners, flavorings or dry ingredients, and blend them all into stable liquid components is required to produce the exact beverage recipe that our customer partners want,” says Von der Heide, lauding the benefits of having fully integrated processing and packaging capabilities.

“Inline instrumentation enables us to control and adjust all the product speci fications in terms of carbonation, calories, alcohol content, and sugar levels in real time,” he says, “and have the whole pro cess data-logged for later analysis.

“It’s a real leap forward for us in terms of delivering optimal product integrity,” Von der Heide asserts. “We have become the transparent plant for our partner breweries, like their virtual own produc tion facility.”

Adds Gorlitt: “We also integrated our Line Diagnostic System (LDS) technol ogy, which enables Brunswick to monitor and analyze filling line performance in real time and long-term.

“Moreover, our integrated Line Manage ment System (LMS) helps to guide and support the Brunswick equipment oper ators in parameterization during the oper ation of the line, especially during change overs, and makes sure the line efficiency is kept on the highest possible level,” Gorlitt states.

“Brunswick has recognized that digi talization is the way forward and key to securing their success in the market,” says Gorlitt, “and our embedded IT/ digitalization solution will undoubtedly play a role in helping them achieve their ambitious goals going into the future.”

Expertly installed and integrated by Krones technicians and Brunswick’s inhouse technical team, the new Krones canning line comprises:

• Krones Pressant Universal 1A de palletizer. Capable of depalletizing up to 400 layers of cans per minute, the modular seep-off machine is designed to ensure reliable and gentle container

handling at high speeds.

Incorporating high-precision ser vo-controlled drive technology, the flexible system can process pallets with inverted trays, pallets with layer pads and inverted trays, or pallets with layer pads and top frames.

Using sensor for determining each top layer, the fully-automatic depallet izer centers the layers from all four sides before safely transporting them to the container discharge table.

• Krones Cantronic 709 empty can in spection system. Capable of inspecting up to 130,000 cans per hour, the Can tronic 709 features a high-resolution camera to detect and reject damaged, deformed, and dirty cans before they proceed to the filling stages.

• Krones VODM-C volumetric can filler and Krones Modulseam MS8 can seamer for high-speed filling and cap ping of the different-sized cans with carbonated beverages, assisted with integrated Mini Multifeeder-2 auto matic closures dispenser—manufac tured by CSW Machinery B.V. in Holland—automatically feeding the seamer horizontally with the aluminum closures from sleeved stacks.

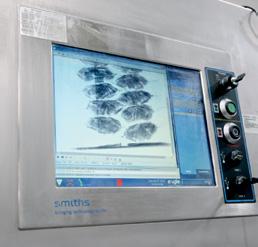

• Krones Checkmat 707 inspection system for filled cans, used for inline fill level and cap inspection using ad vanced X-Ray inspection technology.

• Krones Linaflex tunnel pasteurizer. Designed to ensure optimal product safety and shelf-life, the high-volume

LinaFlex pasteurizer can process up to 180,000 containers per hour in a double-deck configuration, with its modular design ensuring the most economical use of resources like water and energy.

The tunnel pasteurizer is made up of eight tunnel modules divided into tem perature zones, which allow gentle heat ing and cooling of the containers before and after pasteurization, as specified by their product-specific programs stored in the system’s HMI (human-machine interface) control panel.

The machine’s patented CHESS heating system incorporates an energy-ef ficient method of operation whereby only one heat exchanger is required to supply

the individual zones of the pasteurizer with hot water.

The system’s tank collects the overflow and returns it to the pasteurization zones via the heat exchanger to close the water cycle— thereby slashing the heating-up times for the individual zones and saving vast amounts on energy and water con sumption, according to Krones.

• Krones VarioClean clean-in-place (CIP) system.

• Krones Linadry 890 can dryers for blowing water droplets off the cans, at speed of up to 72,000 cans per hour, to ensure a dry surface for label application.

• Krones Variopac Pro TFS 6 packer. Designed for maximum operational flexibility, the fully-automatic Variopac

“We have become the transparent plant for our partner breweries, like their virtual own production facility.”

Pro packer combines the main machine, blanks magazine, feeder, the pack for mation unit, the film wrapping module and a shrinking tunnel to produce a broad variety of secondary packaging formats—including trays, shrink wrapped packs, shrinkwrapped packs with pad, shrink-wrapped packs with tray, and wraparound packs—at from 30 to 150 cycles per minute, depending on pack format and dimensions.

The fully-automatic Variopac Pro pack er easily adapts to all packaging trends. Packaging with pads, in trays, or wraparound cartons—with, without or exclu sively in a shrink-wrapped film—the dif ferent models of the Variopac Pro cover a wide range of packaging variations.

• Krones Modulpal 2A fully-automatic

palletizer. Incorporating a high-per formance Robobox T-GS tripod robot, the two-axes system picks up the finished multipacks at the grouping station and places them down again on the pallet position at up to 500 layers per hour, depending on the gripper system, with 700-kilogram load capacity.

As Gorlitt relates, Krones also sup plied container, pack and pallet convey ors used to link all the different Krones machines in the line, which reaches its end at the fully-automatic Lantech ro tary-arm stretchwrapping station to prepare the palletized loads for storage and/or shipment.

Says Gorlitt: “Brunswick’s goal was to not only have world-leading, first-class filling equipment in place, but also a

unique processing solution that flawless ly integrates into their production and packaging process.

“It was a great project on many levels,” he says, “and the fact that it has been done practically in front of our company’s front door makes it extra special.

“We are proud to have been chosen a key supplier to make sure they are per fectly positioned for their ambitious goals,” Gorlitt concludes. “This line provides Brunswick with a highly flexible operation that will enable them to pro vide innovative co-packing solutions in the biggest variety of products and pack aging formats possible.”

Krones Machinery Co. Ltd.

All Krones equipment in the new canning line is controlled by user-friendly Krones iPanel CD HMI terminals to ensure optimal real time process monitoring and on-the-fly adjust ments.

Two of the high-volume stainless-steel blending and holding tanks housed inside the new Brunswick Bierworks facility.

Close-up of the Moduseal MSB seamer applying lids to the filled cans coming out of the VODM-C volumetric can filler.

We’ve learned so much during the pandemic. We’ve learned that Plastic Pacts, Golden Design Rules, global communication, and purpose-centered enterprises are all key stepstones on the global path toward reducing plastic waste. Runaway inflation and broken supply chains are some of the obstacles on that path.

These new learnings and challenges enabled us to charter a new course post-pandemic, as PAC Global. We wish to bring the packaging world to our members’ doorstep.

The future demands that our industry stay at the cutting edge of opportunity and will allow brands and retailers to showcase their ability to innovate and inspire through package design. The packages of today must be designed by all, for all. Sustainable, accessible, and inclusive packaging is no longer optional. It is the cost of entry.

PAC Global has endeavoured to meet the moment for our members through new initiatives and an international and diverse board of directors. We recently welcomed several global members into our family:

• Anheuser Busch | Belgium Innovation Center

• Indorama, Thailand | The world’s largest PET producer

• Kellogg’s, P&G, Unilever | Three of the U.K.’s largest brands and leaders of the accessible packaging movement

• Pulpac and Paboco | Scandinavia’s Fibre Packaging Leaders

• Aire Global and Pearlfisher |U.K. brand design agencies.

Jim Downham, PAC Global President & CEO with Rebecca Casey, Senior VP Marketing & Strategy at TC Transcontinental.

In March 2021, we launched PAC IOU (Inclusive Opportunities and Universal Design) program—at no cost to our members—that champions inclusivity, equality and accessibility in packaging brand design and innovation. Since launch, we have seen tremendous growth and we are excited about what this group will accomplish for the future of packaging. Sign the PAC IOU charter today at pac.global/charter

In April 2022, we launched the PAC MART, a global packaging marketplace designed to offer members a curated, digital shopping mall experience. We recently made the decision to broaden the reach and power of this program and move the platform to our public website. We seek to offer our members an opportunity to showcase themselves to the entire PAC Global worldwide network. The PAC MARTVersion 2.0 is set to launch in the coming months.

In May 2022, Rebecca Casey was appointed as Chair of the PAC Global Board of Directors. Rebecca is the third female chair in history and is the Senior Vice President of Marketing & Strategy at TC Transcontinental Packaging. Her long history of leadership, coupled with her experience in strategy makes her an ideal person for this role.

Thank you to outgoing Chair Brent Heist of Procter & Gamble for all his leadership and support. Brent recently stepped down but will remain on the Board of Directors after serving as our Chair for the last four years.

In this PAC Connected edition, you will find a round-up of 2022 PAC Global Awards winners. This global competition features the best of brand design and packaging innovation.

We’d like to thank our members for their continued support. If you are not yet a member, we hope you’ll join the growing PAC Global network. Our future growth and our ability to create valuable programs and initiatives for you like PAC IOU and PAC MART depend on your support.

Our PAC Global guiding principles remain: Champion. Collaborate. Innovate. Educate. Celebrate.

CHAIR

Rebecca Casey, Senior VP Marketing & Strategy

TC Transcontinental

FIRST VICE-CHAIR

Priya Roberts, Global DirectorInnovation & Technology Maple Leaf Foods Inc.

Paul Yang, Director - Global Innovation Tim Horton’s

Brent Heist, Global Packaging Sustainability Procter & Gamble

DIRECTORS AT LARGE

Stephen Beauchamp, Regional General Manager: Merchandising Displays, WestRock

Ben Blaber, Senior Vice President, Account Director, Davis

Phillip Crowder, Director, Corporate Sustainability, Winpak Ltd

James D. Downham, President & CEO PAC Global

Emilio Filice, Sr. Sales Manager

National Beer & Wine Accounts O-I Canada Corp.

Nicole Fischer, Head of Sustainability Kraft Heinz Canada

David Gnadt DirectorPackaging and Dispense R&D & Innovation, Molson Coors Brewing

Louis Lemaire, Director of Sales Foodservice Graphic Packaging International Canada

Luc Lortie

Sustainability & Environment Director Costco Wholesale Canada

Pete Matthews

Director, Brand Design & Operations Kelloggs

Paul McCarthy, Country Manager HP Indigo

Rob McCarthy, President, Marks

Stephen Miranda

Vice President, Recycling - Canada GFL Environmental Inc.

Richard Pileski, Senior Vice President, Business Development Jones Healthcare Group

John Shorthouse STELLAMike Richmond, Principal, PTIS

John Wilson, Sustainability Director

Amcor Flexibles North America

What do a single serve cof fee cup, a bag of chips, and a bread tag have in common? At the end of their life-cycle, these plastic items will either be thrown away in a landfill, incinerated, or lost to the environment—contributing to the mil lions of tonnes of plastic pollution gen erated in Canada each year.

Poor packaging design, problematic materials, and excess packaging are disrupting the plastics recycling indus try, but it doesn’t have to be this way.

On a global scale, we’ve identified design interventions and innovative ap proaches that are more in line with Circular Economy principles and evolv ing recycling systems.

The Golden Design Rules (GDR) for Plastics Packaging , launched by the Consumer Goods Forum Coalition of Action on Plastic Waste , were developed collaboratively with 41 global companies in response to the New Plastics Economy Global Commit ment led by the Ellen MacArthur Foundation and the UN Environment Programme

Since April 2022, the Canada Plas tics Pact (CPP) with the support of its Redesign Working Group has been leading the consultation and implemen tation of these nine packaging rules in Canada.

Vlad Rebellon, Director of Strategic Initiatives at Loblaw Companies Lim ited , and Jim Downham, CEO at PAC Global , serve as Co-chairs on the Re design Working Group, driving GDR review and acceptance. Dan Lantz, PAC NEXT Director, serves as the committee technical director.

Key actors across the plastics value chain are working collaboratively to drive innovation and scale action to create this visionary new business mod el, in which problematic or unnecessary plastics are eliminated by 2025.

Now those single-serve coffee cups and bag closures are among many types of plastic packaging for which CPP Partners are innovating new, closedloop options.

Canadian Tire Corporation , Club Coffee, and Bimbo Canada are among 20 CPP Partners and 10 consumer goods companies that have adopted the packaging rules in Canada and commit ted to taking effective action for the benefit of consumers and the environ ment.

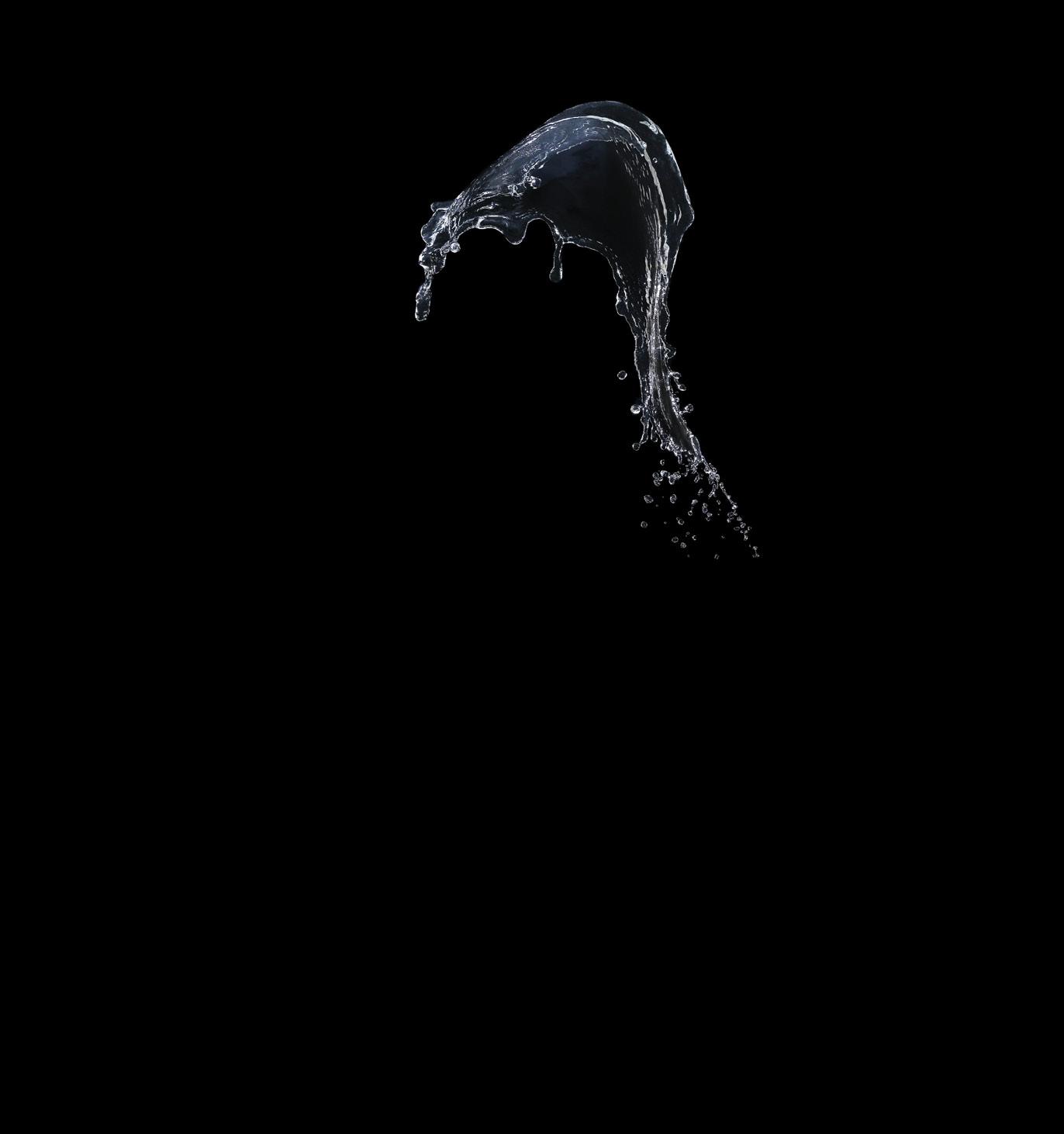

Club Coffee, one of the largest coffee roasters and sustainable packaging in novators in North America, has set new benchmarks for coffee packaging by implementing a vast majority of the GDRs. Club Coffee’s revolutionary AromaPak system has reduced the weight of its packaging, transitioned from plastic coffee bags to recyclable, paper-based packaging, and innovated its single-serve coffee pod to become fully compostable.

These design changes to its R&G coffee packaging have reduced plastic use by 48 per cent compared to a similar foil quad seal bag, and by 83 per cent compared to a similar plastic canister,

2022 PAC Global Awards winning package, President’s Choice store brand of roast coffee, developed by Club Coffee using the recyclable and renewable Aroma Pak Boardio paperboard packaging de veloped by AR Packaging in Sweden.

while reducing carbon emissions by 78 per cent compared to canisters.

“We’re looking for solutions to cus tomers’ problems and using the Golden Design Rules as guardrails along that journey to make sure we are making the right decisions,” says Claudio Gemmiti, Chief Innovation Officer, Club Coffee.

What many companies have learned from the GDRs is that a small change can have a big impact. Bimbo Canada, the nation’s leading bakery, has transi tioned to compostable cardboard clips on its bread bags to reduce its use of single-use plastic by approximately 200 metric tonnes annually.

Canadian Tire Corporation is also taking effective action to scale change. Last year, the giant retailer completed a pilot with its top 38 vendors to collect more accurate packaging data to meas ure compliance with the GDRs, and introduced new sustainable product packaging standards for its branded products.

This year, Canadian Tire is advancing process change across the enterprise, developing vendor education, scaling successful pilot programs, and gather ing detailed packaging data for its new products.

“This common set of guidelines will not only reduce waste and our impact on the environment, but also make it easier for our customers to recycle and for municipalities to collect and pro

cess,” says Kim Saunders, Vice Presi dent, ESG Strategy & Community Im pact, Canadian Tire Corporation.

“Working with partners like CPP to consider how our business decisions of today will impact our world tomorrow is one of the many ways we are helping to make life in Canada better.”

Choices about materials, colors, labels and adhesives, shape, and size of packaging all affect the circularity of packaging.

They impact whether packaging will be rejected and end up in a landfill, or if it will contaminate recycling systems, hindering the recyclability of even well-designed packaging.

The Golden Design Rules are timely— enabling businesses to take immediate action to address some of the most pressing concerns.

While we still have a long road ahead to address all challenges around pack aging design, such as creating end markets that give value to recycled plastics, the GDRs serve as a tool to

enable innovation and evolution of plastic packaging, while providing com mon design guidelines to simplify and align the market.

As countries around the world imple ment policies and measures to reduce or eliminate plastic waste, the GDRs will be reviewed and iterated to incorporate learning and respond to a changing context.

There is no doubt that plastics serve many practical purposes in our daily lives, but with an unprecedented amount of plastic pollution flowing into our natural environment, the scale of the challenge to ensure plastics are re used, recycled or composted will not only require new ways of thinking, but also require businesses to unite and take bold risks to transform a broken system into one that is able to scale impact.

The Canada Plastics Pact supports member and non-member companies to address and/or amplify their progress in tackling any number of the GDRs.

The CPP encourages companies

adjust their packaging design

more or

on to the Golden Design Rules at any point in time by reaching out to info@plasticspact.ca

Managing Director

Disruptive package design methodology yields bold new look and feel for the universally beloved global beer brand

First brewed in 1926 by Brouwerij Artois in Leuven, Belgium, the Stella Artois pilsner is a well-traveled and much beloved global beer brand that never seems out of place at any social occasion.

Leveraging illustrious history and a classy, universally recognized brand logo design framed in an oblong car touche shape, the Stella Artois brand is a key strategic asset in the broad product portfolio of AB InBev

Available in 90 countries around the world and generating annual revenues of over US$1.7 billion, the iconic brand enjoys exceptional popularity in North America, U.K, Australia and many other international markets.

“We have a rich history of brewing that goes back 600 years,” says Brad Weaver, Global Vice-President Of Com mercial Innovation for the supply side of Anheuser-Busch InBev business.

As part of his job responsibilities, Weaver serves as the Line Manager, bridging innovations with the needs and requirements of the business through the Commercial Marketing team work ing at the company’s AB InBev Global Innovation & Technology Center in Leuven, Belgium.

Their latest commercialized collabor ation involved a comprehensive package design project for the multipack cartons of the new Stella Artois Unfiltered beer for the U.K market.

As a first major Stella Artois brand expansion in 15 years, the new beer re quired highly effective packaging to mark its arrival to British markets, re sulting in a highly creative and unortho dox package design process unfolding at the Leuven facility.

Earlier this year, key members of that design team shared their experience of

developing the new packaging during the highly informative virtual PAC Global Packaging Disruptors Sum mit , a one-day event broadcast to a worldwide audience from Toronto, where PAC Global is headquartered.

“Instead of classic design thinking, where we try to identify a new need or a new pain-point in the market, we were doing exactly the opposite,” said Benedikt Pröll, Managing Director of IC3 GmbH, a creative collective of “innovation insti gators” and practitioners of the com pany’s ADT (accelerated design thinking) methodology that played a critical part in the successful development of new Stella Artois packaging.

“We’re using existing expert know ledge to help those experts avoid those patterns of thought that can prevent us from getting to new ideas and solutions,” Pröll said, describing the team’s ap proach to the task as creative “decon struction.”

“As a first step, this team made a huge effort trying to deconstruct the entire world of packaging—literally look at each element available for solution de velopment in order to create a really new and innovative solution, “ Pröll related.

“The second step was take all the

The new 12-bottle pack of Stella Artois Unfiltered beer developed for the U.K. market.

knowledge that we gathered during the deconstruction phase, and then look at each individual element of a pack and relate that knowledge to specific ele ments and components of the package,” he said.

By focusing on each function of the package, such as carrying the product or opening the case, the team proceeded to develop the required packaging element best-suited for the specific function, such as a built-in carrying handle and wraparound perforated tear strip around the box for opening the carton to reveal the glass bottles inside the pack.

“We are basically using a function transfer approach to develop new pack aging ideas, which eventually really helped to add more value for our con sumer at the other end,” said Pröll.

“We would look at an external func tion like a carrying strap on a woman’s handbag and try to translate that into the world of packaging,” Pröll elaborated.

“We systematically looked at the capabilities of a pack and then trans ferred new or external functions into that product or into that pack.”

For Marina Buzaglo, Global Pack aging Innovation Specialist at the Leu ven innovation center, the disruptive approach to packaging design brought to the table by IC3 clearly paid off with stellar execution of the final package boasting innovative features thoughtful ly incorporated throughout the entire carton structure.

As Buzaglo told the summit audience,

“The role of packaging in the beverage industry is sometimes more important than in other industries.

“The packaging is not only about looking good on the shelf,” she said. “It is also about how we grab the pack from the shelf, how we take it home, how we store it, and how we ac cess the bottles from the packs,” Buzaglo said, stressing the need to consider all the key “interaction points along the consumer jour ney” when developing new packaging concepts.

For Stella Artois , those interaction points include:

• Being easy to navigate and memorable during the shopping stage;

• Communicating value to the consumers;

• Being easy to carry/transport;

• Being easy to open and to carry after opening;

• Being easy to dispose of and to recycle.

“In the case of Stella Artois, it very import ant to make sure that we’re delivering pre miumness when handling, opening and storing the product,” said Buzaglo, drawing to atten tion to innovative features such as rounded and smooth corners of the box; a super sturdy built-in carrying handle on top of the box; and a 360-degree tear-off strip that allows the user to simply lift the top of the box to reveal 12 branded glass bottles of Stella Artois Unfiltered perfectly positioned inside to project the icon ic brand label right into the line of sight in all

directions.

“This level of differentiation wouldn’t be possible with a little bit of disruption to the supply chain and the way we pack the product,” Buzaglo concluded, crediting the AB InBev engineering team for bringing the designers’ wish-list to life in the production environment.

For AB InBev’s global Director of Supply Transformation Wim Dekocker, meeting all of the design team’s requests with the brewery’s existing three continuous lines would also turn out to be a highly disruptive experience that prompted him to look far and wide for the right equipment solutions—not just for this particular 12-pack but for 30 different pack styles to accom modate an expansive new packaging rage.

With help from technology partners Schu bert Consulting and leading German equip ment beverage line equipment manufacturer Krones AG , AB InBev’s engineering team was able to develop a flexible medium-throughput solution to meet the challenge.

“One big element in the disruptive engineer ing solution is the fact that we developed a modular machine with five big modules that allowed us to produce all pack styles we were briefed for,” Dekocker recalled.

“The other big element is robotics, which provide the flexibility we needed,” he said.“We have a total of 19 robots inside that machine doing all kinds of things,” he said, including

Entrance to the AB InBev Global Innovation Technology Center in Leuven, Belgium.

applying the aforementioned carrying handle.

“The machine enables very precise forming of the box around the bottles,” Dekocker noted, “as well as orientation of the bottles inside the box in whatever position we choose.

“We have an amazing platform that we de veloped together with Krones, which gives us infinite possibilities for developing brands with distinctive looks that can really differentiate them on the shelf for consumers,” Dekocker concluded.

“In the end, it’s all about the consumers.”

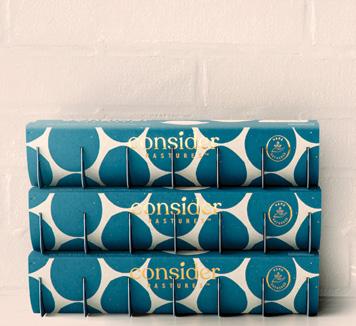

Brand: Consider Pastures

Owner: Consider Pastures

Entering Company Name: Pearlfisher

Brand Agency/Graphic Designer: Pearlfisher

A revival of the classic egg carton, and a great example of breakthrough disruptive design that is wonderful looking, simple and soothing. This design raises the bar in a historically conservative category. The stunning navy blue boxes are unlike any other egg cartons you’ll find in stores, and the box itself allows each egg to sit in its own flawlessly imperfect little pocket. With packaging that creates a wallpaper impression when stacked on the shelves and the mindset of giving the product outstanding value on the farms and in the kitchen, this brand brings a whole new meaning to golden egg.

Brand: Tim Hortons

Owner: Tim Hortons

Entering Company Name: Tim Hortons

Package Converter/Printer/Raw Materials: Circular&Co (cup) + Tupperware (Food Container)

Sustainability without compromise. The iconic red cup has been transformed, maintaining a premium package and product experience, with much less waste than the traditional single use solution. The integration of technology with materials that are both reusable and recyclable, along with the reverse supply chain to support collection is impressive. This design blends sustainability and creativity in harmony – from consumer appeal and consideration, to smart technology infrastructure.

In 2022 we introduced a new category, PAC IOU, focusing on Inclusive Opportunities for Universal Design. This category champions inclusivity, equality and accessibility in packaging brand design and innovation. For more information on the PAC IOU initiative, visit www.pac.global/iou

Congratulations to the four winners in this new category!

Brand: Bud Light Pride

Owner: Bud Light

Entering Company Name: Marks Brand Agency/Graphic Designer: Marks

Pre-press/Structural Designer: SGS&Co Package Converter/Printer/Raw Materials:Westrock Ajax (boxboard cartons), CCS and MCC (aluminum cans), and Bemis (shrink-wrap)

Brand: Shot of Gold

Owner: Shot of Gold Tumeric

Entering Company Name: Jump Branding & Design Inc. Brand Agency/Graphic Designer: Jump Branding & Design Inc.

Brand: Victorialand Beauty

Owner: Victorialand Beauty LLC

Entering Company Name: Victorialand Beauty LLC

Brand Agency/Graphic Designer: Victoria Watts – Symbol Design, Base Beauty Creative Agency – Packaging Design Package Converter/Printer/Raw Materials:Toly, USA

Brand: Olay

Owner: Procter & Gamble

Entering Company Name: Procter & Gamble

Brand Agency/Graphic Designer: Alexis Schrimpf & Kate Patterson, Olay, Procter & Gamble

Pre-press/Structural Designer: Andrew Dapore, Olay, Procter & Gamble

Brand

Brand:

Brand:

Get Inspired - See how we bring brand purpose to life through sustainable and personalized packaging and other digital print solutions.

www.reinventing-creativity.com

With the expertise of retailers, manufacturers, and other experts, IFS develops globally recognised product quality and safety standards and development programs.

www.ifs-certification.com

TC Transcontinental Packaging blends art, science and technology to create the perfect flexible packaging hat accentuates our customers’ brand, protects their products, inspires consumers, and, is sustainable.

tctranscontinental.com Winpak manufactures and distributes high-quality packaging materials and innovative packaging machines, primarily used for the protection of perishable foods, beverages, pharmaceuticals, medical and personal care.

www.winpak.com

Sustainable plastic packaging manufacturer. PET film extrusion and PET or PP trays thermoforming. Recycled and recyclable sustainable food-grade packaging. Customized products; tailor made production.

www.roboplast.com

The PAC MART is currently available through a secure portal to PAC Global members exclusively.

In Fall 2022, the PAC MART will launch to the public at www.pac.global. If you are looking to showcase your available products and innovation to the PAC Global audience, please contact Jim Downham at jdd@leaderlinx.com for details on the opportunity.

Western Canadian cannabis producer hits the productivity sweet-spot with automatic preroll system to boost throughput and product quality to new heights of manufacturing excellence

By George Guidoni, Editor Photos by David BuzzardFor a legal industry barely four years in the making, Canadian producers of rec reational cannabis products are quickly finding out that simply getting a license was never going to be a license to print money without lift ing a finger.

And with the industry’s early growing pains further exacerbated by the pro longed outbreak of the COVID-19 pan demic, it’s safe to say that many of the early high expectations of Canada’s can nabis sector becoming an overnight jug gernaut with endless financial windfalls were based on a lot of wishful thinking.

That said, there is no doubt that the industry is now entering a critical stage of its accelerated evolutionary process—re warding serious players committed to helping the market grow to its full poten tial and weeding out wannabe charlatans and opportunists hoping for a quick and easy payday.

Headquartered in the heart of the famed Okanagan Valley in Kelowna, B.C., The Valens Company certainly falls into the ranks of true industry leaders, not only in terms of sales and market share growth, but also in the science and technology of cannabis production—with packaging very much included.

Founded in 2012 , Valens has quickly emerged as an industry leader under the leadership of its founding chief executive officer Tyler Robson. Blessed with a unique skill set and valuable contacts with other industry professionals, Robson has worked tirelessly to assemble a seasoned management team with extensive experi ence in cannabis production.

Operating as a cannabis LP (licensed producer), Valens currently ranks as one of Canada’s top 10 producers of recrea tional cannabis products, with about a 3.5-percent share of the Canadian market.

“The Valens Company is a leading manufacturer of cannabis products with a mission to bring the benefits of cannabis

to the world,” says Valens director of technical development and innovation Anastasia Reyes.

“We provide proprietary cannabis pro cessing services, in addition to best-inclass product development, manufactur ing, and commercialization of cannabis consumer packaged goods,” says Reyes, an Alberta native who moved to Kelowna to join Valens in 2021 after supporting the construction and license submission of an LP in her home province to complete a personal move “from oil-and-gas to oiland-grass,” she quips.

“Like anything new, the cannabis mar ket has seen its challenges,” Reyes says, “but it’s still exciting to be a part of what future generations will call “The Great Green Rush.’

“We are all pioneers of the industry, finding new ways to focus on our execu tive teams’ drive to be ‘fewer, bigger and better’.”

The lion’s share of the company’s flower processing and production takes place at its modern, spanking-clean 100,000-square-foot Agritech manufac turing compound in Kelowna, which employs over 125 people on a three-shift production schedule to manufacture cannabis products for the company’s own brands and for its many “white label” customers, according to Reyes.

“Our state-of-the art facility has al lowed us to master diverse extraction methods, and develop in all categories of the Canadian market, including flower, vapes, extracts, edibles, beverages and topicals,” Reyes explains.

“We can fully support the progression of product from flower to retail shelves,” says Reyes, adding that all of the com pany’s branded products are available across Canada.

According to Reyes, the opening of the Agritech plant in Kelowna has been wel comed with open arms by the local busi ness community and municipal polit icians for its positive local economic impact and job creation in Kelowna, where Valens also has a purpose-built edibles facility, along with Valens Labs Centre of Excellence in Plant-Based Science to offer third-party testing services as re quired by Health Canada

“Rooted in the Okanagan, we pull from the local history of agriculture in the in dustrial era to the modern-day end of prohibition to create cannabis with pur pose, backed by science,” Reyes states.

Also operating a newly commissioned, purpose-built plant to produce canna bis-infused beverages in Bolton, Ont., Valens clearly has its eye on the future with its comprehensive and wide-ranging port folio of high-quality cannabis products spanning most common product types, consumption methods and potency levels.

“Formulated for the recreational, health-and-wellness and medical con sumer segments, our high-quality prod

ucts are offered across all cannabis prod uct categories— with a focus on quality and innovation,” Reyes states.

“Working in partnership with brand houses, CPG (consumer packaged goods) companies and licensed cannabis produ cers around the globe, The Valens Com pany is continuing to grow its diverse product portfolio in alignment with evolving cannabis consumer preferences in key markets,” she relates.

“We hit the market as one the first and best in class extraction facilities and continue to do so in CO2, ethanol, and hydrocarbon facets,” she adds.

“Our portfolio has expanded to allow our facility to house cutting edge-equip

ment to produce consumer package goods in all categories of the market.”

Despite the growth in extraction cat egories, dry flower cannabis remains the dominant product in the Canadian rec reational cannabis markets with about an 86-percent share of all sales, according to Reyes, with sales of pre-rolled cones (joints) accounting for a large majority of that total.

As Reyes relates, Valens has achieved significant success in this market segment with its four core flagship brands that in clude Contraband, Versus, Citizen Stash, Vacay, and the newly launched Bon Jak label for the Quebec market.

“Our Versus God Bud ranked as the

(Above) The 100,000-squarefoot Agritech production facility in Kelowna produces the lion’s share of The Valens Company’s flower cannabis products.

(Left) Machine operator loading up the eight-channel magazine feeder with stacks of pre-rolled filtered cones to feed the pre-roll making process inside the JuanaRoll machine manufactured by WeighPack Systems.

(Above)

A close-up of the JuanaRoll machine placing eight filtered paper cones into their places prior to the filling, compacting and trimming steps.

Number One bestselling SKU (stock-keep ing unit) for four consecutive months in 2022 amongst all product categories in Ontario, Alberta, British Columbia and Saskatchewan,” Reyes confides.

“We also have the ability to support our partners in all formats—providing prod ucts in bulk to complete ‘white label’ solutions.”

As many recreational cannabis startups in Canada have struggled to turn a profit on a regular basis, Reyes says that many industry newcomers had failed to realize the extent to which they would have to automate their existing manual-intensive processes to achieve profitability.

This is especially true in the market for pre-rolls, where many companies still rely on outdated manual techniques or using rudimentary tabletop technologies to produce their pre-rolls.

“One of the main challenges this indus try presents is that the security and quality control of producing compliant products comes with a price,” says Reyes.

“Not only are we subject to excise duty

of approximately $1 per gram of dried flower, but a manufacturer has significant overhead in security equipment and addi tional personnel needs.

“So even as we are actively striving to lower manufacturing costs, we have addi tional fixed levies and labor costs on cannabis products that other CPG (con sumer packaged goods) industries are not constrained with,” says Reyes.

Hence profitability is directly linked to how well manufacturers manage to slash their operating costs, she says, with labor being one of the main culprits.

As Reyes relates, that has not been problem with the Agritech plant’s preroll production ever since the company installed and started up a fully-automatic JuanaRoll pre-roll system in December of 2021—essentially automating the en tire pre-roll production process and vastly expanding its manufacturing throughput, capacity and productivity levels.

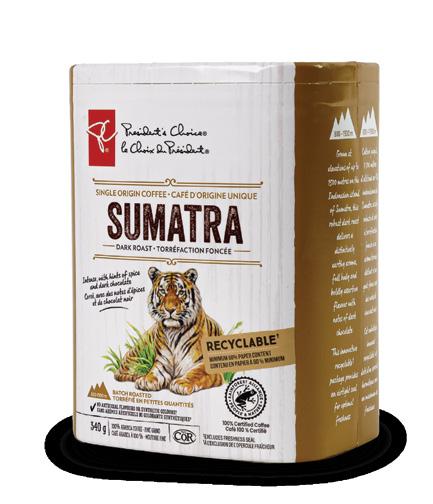

Manufactured by renowned Canadian packaging machinery manufacturer

WeighPack Systems in Montreal, the highly innovative JuanaRoll automatic pre-roll machine was developed as an automated solution to replace manual hand-rolling of pre-rolls with a fully-auto matic process delivering high-precision weighing accuracy and consistent prod uct quality and uniformity at breath taking speeds.

Available in four-, six- and eight-chan nel configurations, the high-speed Juan aRoll machine features an easy-to-load cone magazine, an integrated PreCheQ checkweigher, and special stations for compacting, tamping and twisting/trim ming, along with value-added standard features such as no-cone/no-fill detection, cone-open camera vision system, and free online technical support.

Installed in an eight-channel version at the Agritech plant, the JuanaRoll has performed with remarkable reliability and flexibility, according to Reyes, pro ducing up to 65 perfectly made cones per minute—ranging from 0.35-gram to two grams—in continuous operation.

Says Reyes: “I had the privilege of previously working with the WeighPack group before moving to Valens, so when I began facing the challenges of a rapidly growing and evolving industry, I knew exactly who to call on.

“Their knowledge of manufacturing equipment, and focus on manufacturing efficiencies, helps to create specifications

“As the legal cannabis industry has evolved, it is clear that key success criteria in this business is based on being a good CPG manufacturer.”

for not just equipment but for supporting an entire process,” says Reyes, compli menting the JuanaRoll machine’s linear modular design that allows it to make pre-rolls simultaneously in up to eight lanes, rather than the one-at-a-time preroll production offered by standard ro tary-design pre-roll systems.

“WeighPack offered us full support throughout the project: from the equip ment specification phase straight through to pre-arrival room requirements, instal lation qualifications, and performance verifications, with onsite support for training and real-time troubleshooting,” Reyes recalls.

“They also provided detailed vendor manuals, checklists and an access portal help to ensure we have support while we’re running through all three shifts: days, nights and weekends.

“It’s been a fantastic investment from Day One,” Reyes extols. “It hasn’t even been a year, but it feels like it’s been here forever. It has taken our pre-roll produc tivity to a whole new level of excellence.

“It’s not just the impressive speed,” Reyes points out, “but also the product weight consistency and quality, which we have to maintain within Health Canada’s strict tolerances.

“So it has been a real game-changer for us.”

Says Reyes: “Since legalization the Canadian consumer has become more discerning—giving LP’s the chance to bring even better products to the market, but still needing to compete with the di versity and pricing of the legacy [black] market.

“As the legal cannabis industry has evolved in Canada, it has become clear

Considered to be the fastest pre-roll system in the world thanks to its linear design and multi-channel configurations, the JuanaRoll system is equipped with leading-edge drives, controls, pneumatics and other automation components to enable it to perform all the key measur ing, filling, compacting and trimming steps inline within a blink of an eye across all channels simultaneously.