SEAL THE DEAL

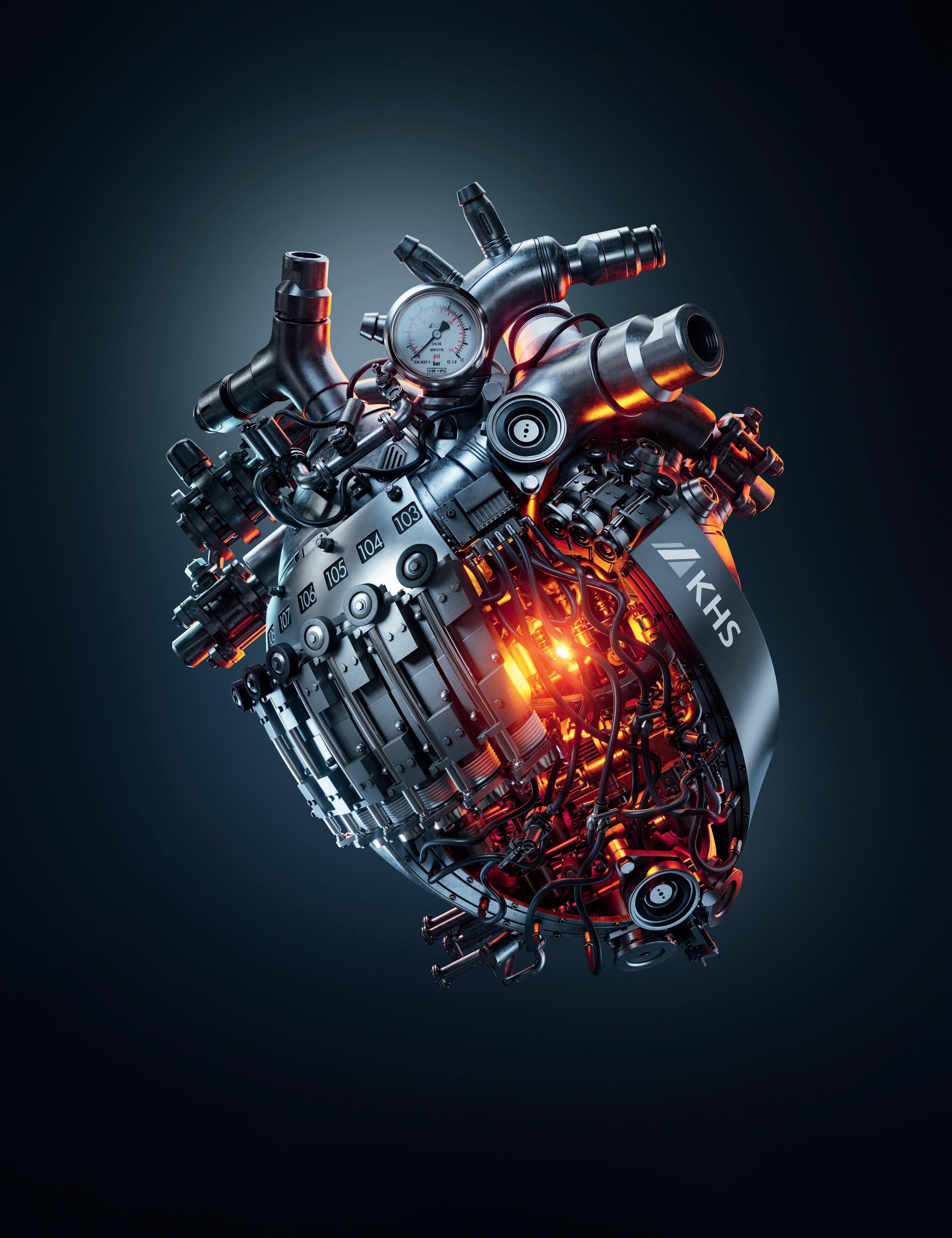

Precision vacuum sealing technology provides Quebec meat processor with vital cutting edge to serve up retail packaging masterclass

Story on Page 16

TERRY TOUNTAS, GENERAL MANAGER, ALPHA MEAT PACKERS LTD. Page 30 Ice Cream Packaging Page 23 Meat Sector 2024 Outlook Page 30

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Nov. 3-6, 2024 Booth N-6106 McCormick Place Chicago, IL, USA

info@heatandcontrol.com | heatandcontrol.com

91 97 98 34 17 20 107 36 41 ~2~ 26 LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

Helping

bring your best products to market.

you

Videojet 1880 + continuous inkjet printer Unlock high-speed performance and precision Discover more at videojet.com/1880+ Featuring an enhanced design and comprehensive connectivity options ©2024 Videojet Technologies Inc. All rights reserved. Videojet Technologies Inc.’s policy is one of continued product improvement. We reserve the right to alter design and/or specifications without notice. 102

16 Seal and Sizzle

Quebec meat processor beefs up its production arsenal with leading-edge vacuum packaging technologies to grow its flagship brand in the retail markets with value-added, case-ready portion packs.

23 Sticking around

Canadian ice-cream stalwart leverages product innovation and packaging excellence to solidify its industry leadership credentials.

30 Cuts and Glory

Canada’s meat industry continues no navigate through tough economic, competitive and regulatory challenges to ensure a healthy future for one of Canada’s most important economic growth drivers.

36 Acing the Test

Globally operating third-party certification and consulting services provider unlocks promising business opportunities in the Canadian market for industrial equipment safety validation and accreditation.

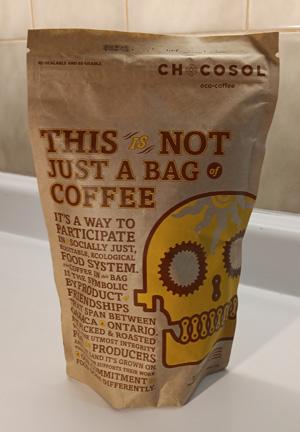

40 Bagging to Differ

Exploring the many surprising sustainability and flexibility advantages of liquid pouch filling technology.

of plastic packging.

44 By Jaan Koel

Joe Public speaks out on packaging hits and misses.

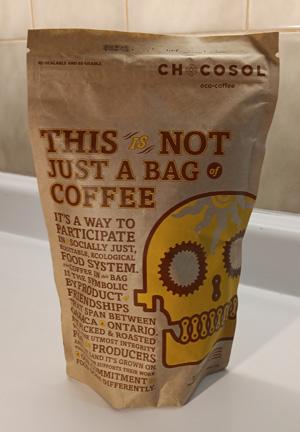

Alpha Meat Packers general manager Terry Tountas cheerfully displays a growing assortment of the company’s premium-quality branded meat products produced on the high-performance MULTIVAC vacuum and skin packing machinery. Cover photography by Pierre Longtin

Gordon Baker

Suite

Return

ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2024 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada. ON THE COVER

Canadian addresses to: Circulation Department,

May 2024 · CANADIANPACKAGING 3 CANADIANPACKAGING.COM May 2024 Vol. 77, No. 4 canadianpackaging.com DEPARTMENTS NEWSPACK 6-8 Packaging news round-up. NOTES & QUOTES 11 Noteworthy industry briefs. FIRST GLANCE 13 New packaging solutions and technologies. ECO-PACK NOW 14 Sustainable packaging innovations. IMPACT 15 A monthly insight from PAC Global. PEOPLE 39 Career moves in the packaging world. EVENTS 39 Upcoming industry functions. COVER STORY

FEATURES

COLUMNS FROM THE EDITOR

CHECKOUT

4 By George Guidoni The Dirty Dozen

16 23 30 ISSN 0008-4654. Canadian

is published 10 times per year

Annex Business Media. Canada Post Publications

40065710.

Packaging

by

Mail Agreement No.

undeliverable

111

Rd.,

400, Toronto,

Calling out the Dirty Dozen of problematic plastic packaging

Ever since checkout plastic bags have been banned from the vast majority of Canadian grocery stores and many other retail outlets, the movement for banning all packaging plastics altogether has been getting a lot of traction among consumers and governments alike.

978,00

tonnes of plastic packging waste generated through residential recycling systems and waste management initiatives in 2022

While seemingly noble in principle and on the surface, the anti-plastic crusade overlooks many of the positive benefits that certain plastic packaging products provide in terms of product protection, shelf-life extension and food waste reduction, where the downside of outright plastic elimination can have huge negative implications for consumer welfare, economic prosperity and food security on an epic global scale.

Being labeled as the world’s chief environmental culprit this century is undoubtedly a very heavy cross to bear, and it takes a lot of courage and self-belief these days to suggest that plastics still have an important role to play in the global packaging industry of today and tomorrow.

Regrettably, such arguments and opinion get remarkably little air play of media coverage compared to the doomand-gloom anti-plastic hysteria dominating the current narrative.

So for the sake of a little balance and fairness, we applaud the efforts by groups like the Canada Plastics Pact (CPP) and the National Zero Waste Council (NZWC) to identify a list of so-called problematic and/or unnecessary plastic packaging products that could be removed from everyday use without long-lasting negative consequences.

Released last month, the new guidance document—titled Supporting the Elimination of Unnecessary & Problematic Plastics—uses a five-step criteria to determine which plastics should be the first to go, including:

• The item or material can be avoided or replaced;

• The item or material contains hazardous chemicals;

• The item or material hinders or disrupts recycling or composting systems;

• The item or material has a high likelihood of being littered.

• The item or material is non-recyclable,

compostable or reusable, and is not likely to be so by 2025.

“Research has shown that single-use items are the most common items found in clean-up efforts in Canada and worldwide,” says CPP’s managing director Cher Mereweather.

“Our latest CPP data reveals that an estimated 978,000 tonnes of plastic packaging waste was produced in 2022 through residential recycling systems and waste management initiatives, with only 20 percent of it being recycled.

“Today’s reality is that many products that are technically recyclable are not collected or processed, and may contaminate other recycling streams.

“It’s clear that the first step we need to take is to eliminate the plastics we don’t need.”

The Unnecessary & Problematic Plastics list includes various items such as checkout bags, cutlery, straws, oxo-degradables, and materials containing intentionally added Per- and Polyfluoroalkyl Substances (PFAS), aka the dreaded ‘Forever Chemicals.’

Other items on the list include stir sticks, beverage six-pack rings, undetectable carbon black, PVC (Polyvinyl Chloride) and|PVDC (Polyvinylidene Chloride), PETG (Polyethylene Terephthalate Glycol), EPS (Expanded Polystyrene), PS (Polystyrene) and multi-material flexibles.

According to CPP, relying solely on recycling systems will not solve Canada’s plastic packaging waste challenges, and that even if industry were to meet all recycling targets it would not be sufficient to eliminate plastic waste entirely.

As Cher points out, “Immediate action is imperative to tackle the challenges posed by plastic waste [and] this document gives industry clarity and direction.

“Keeping plastics in our economy and out of people, animals, and nature is a complex challenge that requires collaboration and innovation at all levels, from all sectors.”

We could not say so better ourselves.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

MAY 2024 | VOLUME 77, NO. 4

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

CEO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $80.07 per year,USA $183.09 (CDN) per year, Outside Canada $207.57 (CDN) per year, Single Copy Canada $10.00.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

4 CANADIANPACKAGING · May 2024

FROM THE EDITOR

Reiser Form/Fill/Seal Packaging Machines

Wide range of flexible machines produce high-quality VSP, MAP, and vacuum packages

High-speed production

Superior seals eliminate leakers and returns

Backed by Reiser’s industry-leading service and support Take your business to the next level with Reiser packaging Extend product shelf life with superior packaging technology from Reiser Watch video 2023 www.reiser.com Reiser Canada • Burlington, ON • (905) 631- 6 611 Reiser • Canton, MA • (781) 821-1290 Reiser UK • Milton Keynes, Bucks • ( 019 08) 585300

n

n

n

n

New Sprite flavor offers cool thirst relief to beat the coming summer heat

With scorching summer heat now just around the corner, The Coca-Cola Company is betting that its new limited-time edition version of the company’s iconic brand Sprite has exactly what it takes to help Canadians chill out in perfectly good taste.

Launched across Canada last month, the new Sprite Chill and Sprite Chill Zero Sugar add a deliciously refreshing twist of cherry-lime to the brand’s signature lemon-lime taste, accentuated by a proprietary blend of

cooling agents to deliver a uniquely elevated sensory experience.

“Sprite understands that people’s lifestyles and tastes are ever-changing, and the introduction of Sprite Chill is just one way that the brand is innovating to keep pace with its consumers and deliver on a unique beverage experience,” says Jacques Blanchet, director of integrated marketing at The Coca-Cola Company.

“This limited-time-only beverage amplifies the refreshing flavour Sprite fans love with a cooling sensation that intensifies with every sip. Prepare to get chills!”

As Blanchet relates, The Coca-Cola Company’s R&D team went through several rounds of development and testing before landing on the optimal ratio of cherry-lime flavour and cooling intensity—making sure the beverage deliver waves of refreshment, with the cooling sensation building from the first sip to the last.

While similar technology is used in confectionery and baking, Sprite Chill is the first-ever sparkling soft-drink to deliver a cooling sensation without an accompanying mint flavor.

“Consumers today are looking for multisensorial beverage experiences, so we saw a unique opportunity to elevate the crisp, refreshing taste Sprite fans expect with a first-of-itskind cooling sensation,” said Felicity Boucetla, Coca-Cola’s senior director of product development for sparkling flavors.

Available in individual 500-ml bottles, as well as 12-packs of 355- m l cans and six-packs of 222-ml cans— and also in 12-packs of 355-ml cans for Sprite Chill Zero Sugar—the brand’s eye-catching packaging combines an icy blue and frosted cherry color palette with jagged iceberg-inspired graphics.

“The packaging for Sprite Chill was designed by our North American team who localized it for the Canadian market, following all local rules and regulations,” Blanchet relates.

“The design is intended evoke the feeling of the intensified cooling sensation and flavor that Sprite Chill delivers,” he adds.

“The details are reflective of jagged ice to graphically represent the icy chill, flavor change and cut-

through refreshment that Sprite Chill brings forward,” Blanchet states.

“This was a fun creative brief to work on because Sprite Chill is an intrinsic-led innovation platform,” adds A.P. Chaney, senior creative director for sparkling flavors.

“The cooling sensation technology inspired us to lean in to the ‘ice-cold’ colloquialism, a cultural double-entendre for Gen Z consumers that implies being at the top of your game.”

Made and packaged by Coca-Cola Canada Bottling Limited , an independent, family-owned business operating five bottling facilities across Canada, the new soda is a follow-up to recent successful limited-time launch es of Sprite Lymonade Legacy and Sprite Winter Spiced Cranberry

“We’re aware that people’s taste preferences and lifestyles are changing, so we’re evolving our brand to meet those needs,” Blanchet says.

“Cherry-lime adds a refreshing taste to the brand’s signature lemon-lime flavor and it marks a first for Sprite Chill: a soft-drink that delivers a cooling sensation that isn’t accompanied by a mint flavor. “

Conveyor Models

NEWSPACK

at Your Fingertips Customize and download conveyor models in minutes with mk’s CAD360. Belt Conveyor Roller Conveyors Timing Belt Conveyors Flat Top Chain Conveyors Individual conveyors and entire conveyor systems. Registration is FAST and FREE!

Canadian print stalwart keeps raising the bar with automation investments

Calling Cober Solutions a jack of all trades would be missing the point for a venerable Canadian print services provider that’s still growing from strength to strength after more than 100 years in the print business.

Headquartered in Kitchener, Ont., the family-owned print specialist is more like a Swiss army

knife, boasting extensive industry experience and a vast production arsenal enabling it to turn out high-quality products ranging from packaging and retail displays to commercial print and large-format signage.

Built on the foundation of innovation and print, Cober has continuously embraced change and technology to serve its clients, with recent investment in state-ofthe-art equipment from renowned

press manufacturer Heidelberger Druckmaschinen underscoring the company’s growth-driven investment philosophy.

Aiming to boost productivity for smaller-volume print runs, Cober has recently commissioned two Canadian ‘firsts,’ including the Speedmaster XL 106-8P press with a patented Plate-toUnit system and a new robotic P-Stacker for its Stahlfolder TH 82 automatic folding machine with a PFX feeder.

Installed to eliminate bottlenecks in Cober’s plate-making process, Heidelberg’s Plate-to-Unit is a fully-automatic printing plate logistics solution designed to reduce operator workload and ensure higher process reliability, whereby the printing plates are automatically placed in and removed from the correct platechanging shaft without operator intervention.

“After using Plate-to-Unit for a couple of months, I couldn’t imagine buying a press without this functionality,” he states. “It has become a game-changer.”

For its part, the new Stahlfolder TH 82 folding machine with PFX Feeder and new P-Stacker has replaced two older buckle folders, and it is used exclusively for folding the company’s 16-page signatures.

As Cober explains, the PFX Feeder is designed to feed sheets like the feeder of a printing press, whereby the sheets are shingled and underlapped in the first folding unit.

The underlapping of sheets (shingling sheets) on the infeed register table nearly doubles the number of sheets that can be processed compared to conventional sheet-gap feeding at the same running speed.

“With our older stream-fed folders, we would have three people running two folders,” Cober points out.

The system has enabled Cober to consistently achieve two-minute make-readies “without burning out its crew,” according to company president Todd Cober. 24_002896_CN_Pckg_MAY_CN Mod: March 29, 2024 3:45 PM Print: 04/12/24 page 1 v2.5

“Now it’s one person on one folder—at twice the speed.”

8 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM NEWSPACK

ORDER BY 6 PM FOR SAME DAY SHIPPING π

SUPPLY SPECIALISTS COMPLETE CATALOG 1-800-295-5510 uline.ca SAFETY PRODUCTS ALWAYS IN STOCK IN ALL LOCATIONS CPK_Uline_May24_CSA.indd 1 2024-04-17 9:49 AM

SHIPPING

From left: Cober Solutions press operator Jonathan Walsh, lead hand Joe Bain, and director of operations Sam Mueller in front of the Stahlfolder TH 82 and P-Stacker from Heildelberg.

SUSPECT FOREIGN MATERIALS X-RAY INSPECT & RECOVERY 3rd Party Rework Services for Food Products OFFSITE INSPECTION • x-ray inspection of finished food products • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 Separation identification of bolt Identified foreign body: Single 1 inch long Stainless-Steel Bolt

foreign body: Steel

Failure Identified foreign body: Calcified hollow chicken bone Chicken Bone: 22 x 7 x 2.4mm

Identified

Shaving from Auger

From Left: MG Tech general director Xavier Lucas; Premier Tech Systems and Automation president and CEO André Noreau; MG Tech president Eric Gautier; Simon Roy, president and chief operating officer at Premier Tech Systems and Automation; Jean Bélanger, president and chief executive officer at Premier Tech.

Premier Tech , Rivière-du-Loup, Que-headquartered manufacturer of automated machinery for agricultural and horticultural industry applications, has entered into a strategic partnership with MG Tech Group of Les Achards, France, for joint marketing and distribution of the two companies’ respective packaging technologies for manufacturing applications in the nutritional, industrial, fast-moving consumer goods and parapharmacy industries. According to MG Tech, the addition of Premier Tech to MG Tech’s portfolio will allow the French group to fully leverage the global ecosystem of Premier Tech Systems and Automation and access an extensive network of products, services and technologies to support its growth in North American and international markets. “With the integration of Premier Tech Systems and Automation to the MG Tech ecosystem, we will expand our footprint and further open ourselves to the world,” says MG Tech president Gautier. “The establishment of our subsidiary in Canada confirmed that our end-of-line packaging equipment is perfectly designed for the North American market,” Gautier adds. “We will come up, alongside Premier Tech, with new services and continue our international expansion.” According to Simon Roy, president and chief operating officer of Premier Tech Systems and Automation, “This partnership opens the door to the global expansion of our secondary packaging operations, previously centred in North America, by setting the development of market segments with a broader range of products such as leading-edge case erectors and robotic case-packers. Joining forces allows us to harness complementary strategic skills, delivering more value to our clients.”

Headquartered in Washington, D.C., the former North American Meat Institute has announced the official change of the venerable association’s name to Meat Institute, while also unveiling a new logo and brand identity to better reflect its dynamic, forward-looking approach to ensuring that meat remains at the heart of nourishing the present and sustaining the future generations. Evoking the shape of a plate and featuring an open frame indicating transparency and inclu-

siveness, the new logo intends to project a sense of movement—signaling constant evolution and pursuit of continuous improvement—while the new dark blue primary logo colors also include an energetic pastel blue and a modern orange accent that serves as an updated nod to the association’s previous maroon brand. “Sustaining meat’s future is central to the Meat Institutes’s mission and vision, building on our 120 years of leadership and meat’s centuries of contributions to healthy diets and strong communities,” says Meat Institute’s president and chief executive officer Julie Anna Potts. “Our updated logo is fresh, open, and keeps meat at the very center of nourishing today and sustaining tomorrow.”

Winnipeg-headquartered flexible packaging product group Winpak Ltd. has received an A- score in the company’s recently concluded the 2023 Carbon Disclosure Project (CDP) assessment, a globally recognized initiative that evaluates and scores companies based on their efforts to mitigate climate change, manage environmental risks, and operate sustainably. “Our A- score places us in the CDP leadership category and in the top 18 per cent of disclosers for plastic product manufacturing,” says Phillip Crowder, Winpak’s director of corporate sustainability. “This leadership level is a testament to the hard work of every member of our organization and our collective efforts to make a positive impact on the planet.”

Leading global packaging products group Amcor has announced plans for a major expansion of its North American printing and converting capabilities for the dairy market to support customers’ demand for flexible packaging solutions. According to Amcor, the installation of new state-of-the art equipment over the next 18 months—primarily in Wisconsin—will expand and optimize local manufacturing capacity, while also support the planned conversion to more sustainable packaging. “Amcor is committed to deliver innovation, service flexibility and agility that will ultimately enhance our customers’ experience,” says Derrick Sytsma, vice-president and general manager for dairy business at the Amcor Flexibles North America headquarters in Oshkosh, Wis. “This strategic investment represents the largest of its kind in Amcor Flexible North America’s extensive history within the cheese business, which solidifies our commitment to the dairy industry, as well as our continued support of our customers’ growth.”

May 2024 · CANADIANPACKAGING 11

NOTES & QUOTES The new Hitachi UX2 InkJet Printer-Developed for Tomorrow’s production line Call us today for more details or to book a demonstration 1-877-427-5863 sales@harlund.com www.harlund.com QUICK CHANGE CONNECTORS ON BOARD VIDEO GUIDANCE CLEARER CODES & FASTER SPEEDS LONGER PRINTING CYCLES FIRST IN INDUSTRY SAFE PRINTHEAD CLEAN STATION CPK_HARLUND_SQ_OCT23_MLD.indd 1 2023-09-26 1:50 PM

www.vc999.com · 877-435-4555 · Sales.Canada@VC999.com SMALL BUT MIGHTY OUR NEW COMPACT ROLLSTOCK THERMOFORMER Let VC999 help you create the perfect packaging solution! - www.VC999.com WE’VE PACKED THE FUNCTIONALITY OF A MUCH LARGER THERMOFORMING MACHINE INTO A COMPACT MACHINE ONLY 12 FOOT LONG. • Durable • Efficient • Small Footprint

FASTER WITH FESTO

The new heavy-duty Cartesian gantry robot for palletizing applications from Festo features robust lift capacity of up to 200 kilograms, along with Z-axis stroke lengths exceeding eight feet and speeds of up to five feet per second. With free online design tools, off-the-shelf servo drives, motors, and other components, and quick-assembly kits, this palletizing solution shortens project time and reduces engineering and assembly costs, according to Festo. The new palletizing solution incorporates robust, high-rigidity electric actuators at the core of the system, including the tough cantilevered Z-axis EHMH rack and pinion actuator for loads up to 200-kg; the ELCC toothed belt actuator with ball bearing guides for loads up to 100-kg; and the Festo EGC-HD heavy-duty toothed belt or ball screw actuator for the X-axis. Offering a lower-cost alternative to six-axis robotic palletizers, along with superior accuracy and speeds whether handling a small load over a long reach or a heavy load over short distances, this Cartesian robot is claimed to be the ideal solution for most heavy-duty applications. Unlike six-axis robots that lose accuracy and lift capacity at the periphery, the gantries cover the entire workspace with equal accuracy, speed and performance at each point on the X/Y axes, while also providing a smaller footprint to fit into today’s smaller and more compact operations. Festo Inc.

PERFECT SENSE

The three new series of M12 capacitive sensors with IO-Link communications from Carlo Gavazzi are designed to provide an ideal solution for industrial automation equipment in applications where sensing performance must be continuously and accurately monitored and logged, such as semiconductor

and printing applications requiring high-precision detection of different-sized objects, shapes, and dielectric values. Based on the company’s fourth-generation TRIPLESHIELD brand sensors, these sensors have been designed to flexibly adapt to industrial applications with a choice of housing options, including: PBT for less challenging environments;l AISI316L stainless steel for strength; and PEEK polymer, offering a smooth surface to reduce accumulation of dust or liquids. In addition to the full range of technical features provided by this capacitive sensor upgrade, the IO-Link communication allows additional advanced data such as: QoR (Quality of Run), QoT (Quality of Teach), temperature and dust alarms, and diagnostic parameters—facilitating timely scheduling of predictive maintenance procedures for maximum equipment uptime.

CARLO GAVAZZI

(Canada) Inc.

THE LONG THROW

The new CoPilot Max LT long throw printing system from Squid Ink Manufacturing features 2.8-inch print height per printhead, print speed of up to 440 feet per minute, up to a half-inch throw distance, and the capability to run two printheads from one controller. Offering a highly versatile and cost-effective solution for a broad range or product marking and coding applications, CoPilot Max LT’s increased throw distance makes the printing system a very efficient solution for users to make their mark on overfilled cases, angled or recessed surfaces, irregular-shaped products, or product lines with inconsistent handling. In addition, the CoPilot Max LT printing system is designed to print superior-quality, high-resolution characters on porous or non-porous surfaces, along with the capability to run UV LED curable inks for applications that require instant dry times on non-porous surfaces. Moreover, CoPilot Max LT utilizes Squid Ink’s innovative active ink system to enable users to tilt or rotate the printhead in any direction without making height adjustments to the system’s 500-ml ink cartridge.

Squid Ink Manufacturing

NATURAL FLOW

With an eye on packaging sustainability, Theegarten-Pactec has recently re-engineered its FPC5 high-speed packaging machine for chocolate bars to enable it to process paper-based flow-packs using the conventional cold-sealing process, as well as in the more complex heat-sealing process. Now capable of producing flow-pack packaging with integrated heat-seal capability and a pure paper content of at least 95 per cent, the FPC5 can achieve high processing speeds of 100 meters per minute for paperbased packaging—thanks to reduced sealing time achieved by pre-heating the seal area during the wrapping material unwinding process. According to the company, this significantly reduces the required duration of heat application by the sealing tools to the packaging—thereby avoiding damage to the packaging and the product as they glide smoothly through the machine.

Theegarten-Pactec

FIRING ALL CANONS

The new Flexi 22 software suite from SA International (Sai) is an all-in-one design, print and cut software for sign and print providers now offers compatibility with Canon’s entire UVgel roll-to-roll printer range, including both the both the Colorado 1600 series and the newly introduced Colorado M-series printers. Incorporating new drivers and supporting both white and multilayer printing, the Flexi 22 software drivers also includes Canon’s FLXfinish+ technology, which enables customers to print matte, gloss or mixed matte and gloss on the same print, without the need for additional varnish. Capable of driving up to five printers simultaneously and any number of cutters, Flexi 22 offers a complete solution for designing, printing, cutting and print-and-cut, lever-

aging built-in 64-bit RIP architecture to ensure optimal performance and precision in advanced color management, spot color mapping, Pantone matching, true-shape nesting, and banner finishing.

SA International

OPEN & SHUT CASE

The new LDX-RTB Premier semi-automatic random case sealer from Signode is designed to provide superior flexibility in processing a large range of case sizes and fill levels at high speeds, while minimizing downtime. With belt speeds of up to 155 feet per minute, the LDX-RTB Premier case sealer is especially well-suited for fast-paced environments like e-commerce and retail with value-added features that include: correlating CaseLocker series tape cartridges, each featuring a patented locking knife guard system for pinch point prevention; pneumatic assist for highspeed operation; and a simplified threading path for quick and easy tape loading.

Signode

CUT TO THE CHASE

Developed for industrial applications demanding utmost accuracy and precision, the new Kongsberg C68 Exact larger-format digital drawing and light cutting machine from Kongsberg PCS delivers high-quality drawing and plotting with fiber or ball point pen tools on paper and other smooth surfaces. With a special vacuum drilling pattern and smooth surface treatment, the tabletop facilitates extra-precise drawing and light cutting. Based on the powerful market-leading Kongsberg C platform of cutting tables, the Kongsberg C68 Exact is capable of precisely cutting paperbased materials, plastics, or other flexible materials—including masking films, polyester sheets, PVC films and flexible foils—over surface area measuring 3,210 x 6,400-mm. Kongsberg PCS

May 2024 · CANADIANPACKAGING 13 CANADIANPACKAGING.COM

FIRST GLANCE

Moving Beyond Plastic

Unwrapping the multiple benefits of paperboard packaging for fresh produce

By Louis Lemaire

The fresh produce sector has always been a hotbed of innovation. One only needs to look at the advent of canning in the 19th Century, the adoption of refrigerated trucks and train carriages in the 1920s and ’30s, and the way the industry has embraced e-commerce and digitalization to facilitate the omnichannel market we rely on today.

This legacy of innovation is something we are very proud to carry forward at Graphic Packaging, as we continually strive to develop the next generation of paperboard packaging innovations.

Today the fresh produce sector faces a new set of challenges, as it becomes increasingly clear that heavy reliance on plastic packaging cannot continue.

Paperboard packaging is well-placed to provide a solution to this challenge, combining the barrier performance of traditional plastic solutions alongside improved recyclability and being made from renewable raw materials.

By now most Canadians are well aware of the federal government’s ‘Zero Plastic Waste Agenda,’ a series of measures aimed at banning or disincentivizing many categories of plastics, while promoting the use of recycled or recyclable materials.

While the legislative landscape remains uncertain, the minds of Canadian consumers are anything but.

A 2021 study found that over 93 percent of Canadians were personally motivated to reduce their consumption of single-use plastic food packaging, while many retailers were also exploring ways they can minimize or eliminate plastic packaging in their fresh produce aisles .

By any measure, paperboard packaging is more closely aligned with the vision of Canadian consumers, retailers and regulators, with the vast difference between paper and plastic recycling rates emphasizing this point further.

Almost 70 per cent of all paper and paper-based packaging is recycled to-

Graphic Packaging manufactures a broad range of highly attractive and practical paperboard packaging solutions for many types of fresh produce, helping to reduce the industry’s reliance on plastic packaging without compromising product protection and shelf-life properties.

day—positioning Canada as one of the world leaders in its recovery—whereas only nine per cent of plastic waste is recycled .

While there is a strong focus on plastic reduction, this trend must be balanced with robust product protection and shelf-life preservation.

This is particularly important in Canada, where the short growing season means that much of its fresh produce has to be imported.

Any business looking to reduce the overall carbon footprint of its operations should view limiting food waste as a mission-critical imperative.

Globally, food waste has a much greater emissions profile than plastic waste, so eliminating plastic can be counter-productive if it results in pack aging that delivers compromised performance.

For some applications, it is now possible to develop paperboard packaging solutions that do not contain any plastic, without negatively impacting product preservation.

Our recent collaboration with BelleHarvest, a major U.S.-based apple grower, provide powerful evidence to this capability.

We worked with the grower to create a recyclable paperboard carton to replace a flexible plastic pack that led to a

15-percent reduction in apple defects due to bruising.

We acknowledge that there is no onesize-fits-all solution for fresh produce, and that a 100-percent paperboard solution may not be viable for some applications that have more complex barrier needs, such as berries.

However, plastic content can still be minimized, for example, by moving from a flow-wrapped to a top-sealed tray.

For applications requiring modified atmosphere, such as prepared fruit, trays that combine a paperboard base with a barrier liner can be readily adopted—offering up to a 90-percent reduction in plastic, but still offering an equivalent shelf-life.

Functional performance is not the only area that growers and packers must consider, as operational efficiency should ideally match that offered by plastic solutions.

Paperboard solutions can be tailored for both hand- or machine-packing, and businesses can often transition from plastic to paperboard packaging with minimal, or even no new machinery investment.

Even when dealing with chilled packing environments, paperboard-based solutions like the ProducePack punnet trays show that it is possible to augment paperboard materials with water-based barrier coatings that offer protection against moisture in high-humidity environments.

Because a pack’s aesthetic design will continue to play a role in a consumer’s purchasing decisions, paperboard offers many unique many structural and graphic design possibilities—unlocking new opportunities for creating great onshelf differentiation.

Transitioning to paperboard packaging offers growers and fresh produce companies many benefits.

Canadian consumers strongly support its use, the federal government is strongly committed to reducing plastic packaging, and operational efficiency and product shelf-life no longer need to be compromised.

So what better time to make the switch than now?

LOUIS LEMAIRE is the director of sales at Graphic Packaging Canada, the Canadian subsidiary of globally-operating consumer packaging producer Graphic Packaging Holding Company, headquartered in Atlanta, Ga.

14 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM

ECO-PACK NOW

SUMMIT2024

Get inspired by Futures Edge sustainable innovations for the packaging value chain: flexible packaging disruptors and coatings in response to the call for the Golden Design Rules, sustainable digital workflow, printing and connected processes, RFID and end-to-end automation, reusable/refillable landscape, and fibre-based packaging alternatives. Keynote Disruptors Keynote Disruptors

Disruptor Lineup

Disruptor Lineup

Vlad Rebellon Sr. Director, Loblaw Brands

Vlad Rebellon Sr. Director, Loblaw Brands

Tom Szaky Founder & CEO, Terracycle & Loop

Tom Szaky Founder & CEO, Terracycle & Loop

Kent Wootton Manager of Circular Materials Innovations Canadian Tire Corporation

Kent Wootton Manager of Circular Materials Innovations Canadian Tire Corporation

2024

REGISTER NOW FOR DISRUPTORS SUMMIT AT BARRETT CENTRE FOR TECHNOLOGY INNOVATION, TORONTO, CANADA ON JUNE 11, 2024 @ PAC.GLOBAL/DISRUPTORS-SUMMIT-2024/

2024

SEAL TO SIZZLE

Montreal meat processor puts itself on fast track for growth in retail space with state-of-the-art vacuum and skin packaging technologies

By Andrew Snook

Photos by Pierre Longtin

Alpha Meat Packers started out with humble beginnings in 1970 as a small butcher shop in old Montreal

Fast-forward to today, and the company operates a 28,000-square-foot facility servicing major retailers and foodservice companies as a secondary processor and packer of a wide variety of meat products.

The company acquires raw meats and processes them into finished goods, specializing in portion cutting, generic packaging, and in-house or private label packaging.

“There was a growing need at the retail level and at the foodservice levels to

provide portions and portion control,” explains Terry Tountas, general manager of Alpha Meat Packers, whose father founded the company 54 years ago.

“Major retailers are depending upon secondary processors like ourselves to provide value-added, which to them is case-ready packaging.”

The company’s business is split roughly 25/75 between the hospitality and retail segments, with its customer base including restaurants, hotels, cafeterias, convenience stores, smaller grocery stores, and large conventional supermarkets operating under all the major banners.

“Our Alpha brand is strong, especially in foodservice, and it has been strong for a long time,” says Alpha’s director of

16 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM

COVER STORY

sales and marketing Peter Koukos.

“Our short-, medium- and long-term plan is to build and develop a stronger presence for our brand in major retail outlets,” he adds.

“What’s most important to our customers today is the attention to detail, quality, collaboration, and the after-sales service.”

Running on year-round basis, the company’s Montreal plant operates one 12-hour shift, five-days-a-week, as well as weekends and overtime when necessary.

Depending on the time of year, Alpha Meat Packers can have upwards of 150 employees in peak season during the summer months, with about 130 staff on average over the course of a year.

In addition to the globally recognized SQF (Safe Quality Food) and the all-important HACCP (Hazard Analysis and Critical Control Points) certifications, Alpha also boasts the Halal certification from ISNA Canada, validating the company’s credentials for producing meat products in accordance with Islamic dietary guidelines.

“What’s most important to our customers today is the attention to detail, quality, collaboration, and the after-sales service.”

Says Koukos: “We have a robust food safety improvement program to analyze and control critical points to ensure that our product is prepared under hygienic conditions, is safe for consumption, and generates minimal waste.

“Moreover, we are currently working on and pursuing an extended producer responsibility program (EPR) for our packaging, which we hope to have fully operational by 2028,” Koukos says.

As Koukos relates, the demand for Alpha Meat Packers’ products has grown exponentially in recent years, with its most popular offerings comprising a wide assortment of chicken, beef and pork products.

According to Koukos, the company’s beef burgers are undoubtedly its most popular product line, as evidenced by the approximately 5,000 pounds of ground beef processed at the plant on a daily basis.

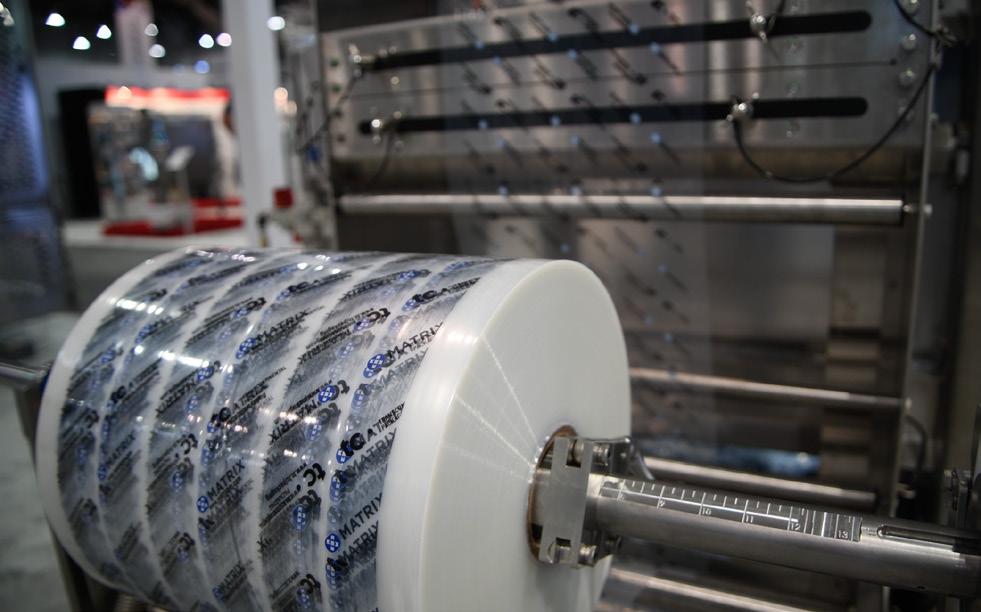

To keep up with the growing demand while optimizing its production process, Alpha has recently made a major capital investment in technologically advanced packaging machinery manufactured by MULTIVAC, namely the model R126 thermoforming packaging machine and the model R275 MultiFresh vacuum skin packaging system.

“These latest additions have significantly enhanced our production efficiency, leading to a notable reduction in costs,” says Alpha’s director of maintenance Éric Boivin.

“Furthermore, they have played a pivotal role in addressing personnel challenges, streamlining our workflow, and enabling us to offer premium products to our customers, thereby elevating their satisfaction and loyalty.”

As Boivin relates, the company was quickly impressed with the flexibility and throughput speed of R126 thermo-

May 2024 · CANADIANPACKAGING 17 CANADIANPACKAGING.COM

Below Alpha Meat Packers sales and marketing manager Peter Koukos (left) and maintenance manager Éric Boivin inspecting seal and label quality on a package of pork chops processed on the MULTIVAC R275 skin-packer.

forming packaging system.

“We are consistently achieving 10 cycles per minute with products that are ready to be packed directly after exiting the machine—significantly enhancing our efficiencies and allowing us to reduce our staffing requirements,” Boivin relates.

“This achievement not only streamlines our production process, but it also optimizes our operational costs—contributing to an overall increase in productivity and resource allocation.”

Adds Tountas: “That machine alone has been a real growth driver for us.

“I’d say we’ve had maybe 40-per-cent growth on that line right now, which has us thinking of purchasing a second one.”

According to Tountas, the R126 thermoforming packaging system has also enhanced the quality and popularity

of the company’s line of marinated beef products.

As he explains, “The aging process is still taking affect, along with the tenderizing process, through the marinade [after packaging].

“The longer we keep these products entirely vacuum-sealed, the more we’re actually increasing its quality over time,” Tountas states.

This new investment was not the first time that Alpha has made a major purchase from MULTIVAC, says Boivin, recalling a much earlier installation of a MULTIVAC R120 thermoforming packaging machine and a C500 vacuum sealer that have both delivered outstanding service and reliability.

“We began working with MULTIVAC in 2010,” Boivin relates, “choosing them for their competitive prices and value.

18 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM COVER STORY

From Left: Alpha’s maintenance manager Éric Boivin, MULTIVAC Canada’s senior account manager Denis Poulin, and Alpha’s sales and marketing manager Peter Koukos.

Machine operator placing portioned cuts of marinated beef inside the film-line cavities of the MULTIVAC R126 thermoforming packaging machine prior to the next run.

Close-up of the user-friendly HMI panel used to control and monitor operations of the R126 thermoforming packaging machine.

Close-up of marinated beef cuts placed inside the film-lined cavities of the MULTIVAC R126 thermoforming packaging machine.

“Their excellent customer service and the ability to provide equipment tailored to our needs have further confirmed our choice.”

“More recently, their excellent customer service and the ability to provide equipment tailored to our needs have further confirmed our choice,” Boivin says.

As Koukos points out, investing in automation for the packaging line has been vital for enabling Alpha to manage its operational costs and remaining competitive.

“We understand the efficiencies that come with automation and the impact it has, like speeding up production, re-

ducing operational costs, and having the agility to meet customers’ varied demands,” Koukos states. “This is undeniable.

“Despite its advantages, it also comes with its challenges, such as integration, adaptation, compliance, and employee training.

“But all and all, Alpha Meat has really embraced this technology,” Koukos asserts, citing the plethora of value-added performance features provided by MULTIVAC machinery, epsecially the

R275 MultiFresh (MF) skin-packer.

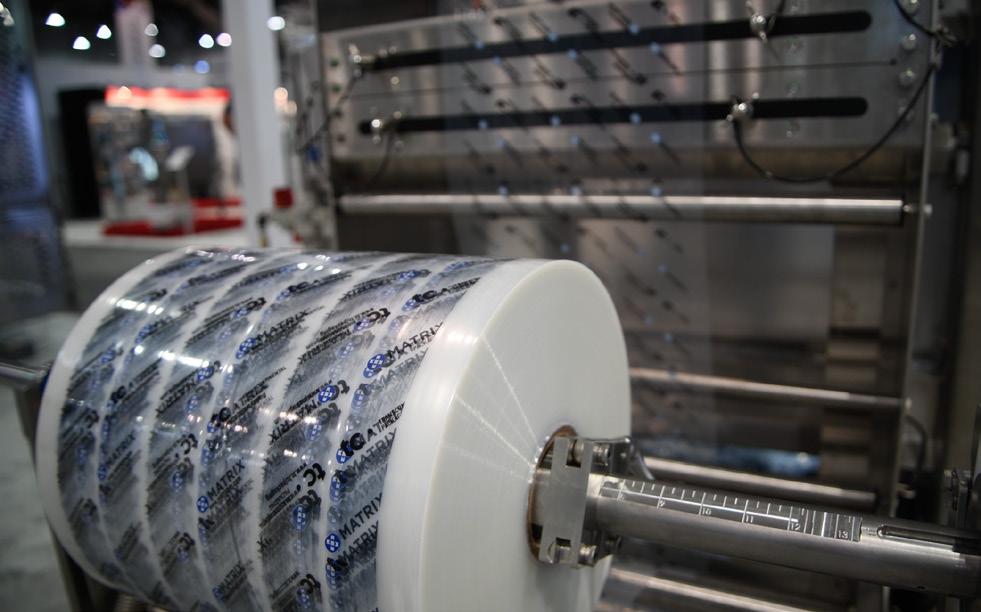

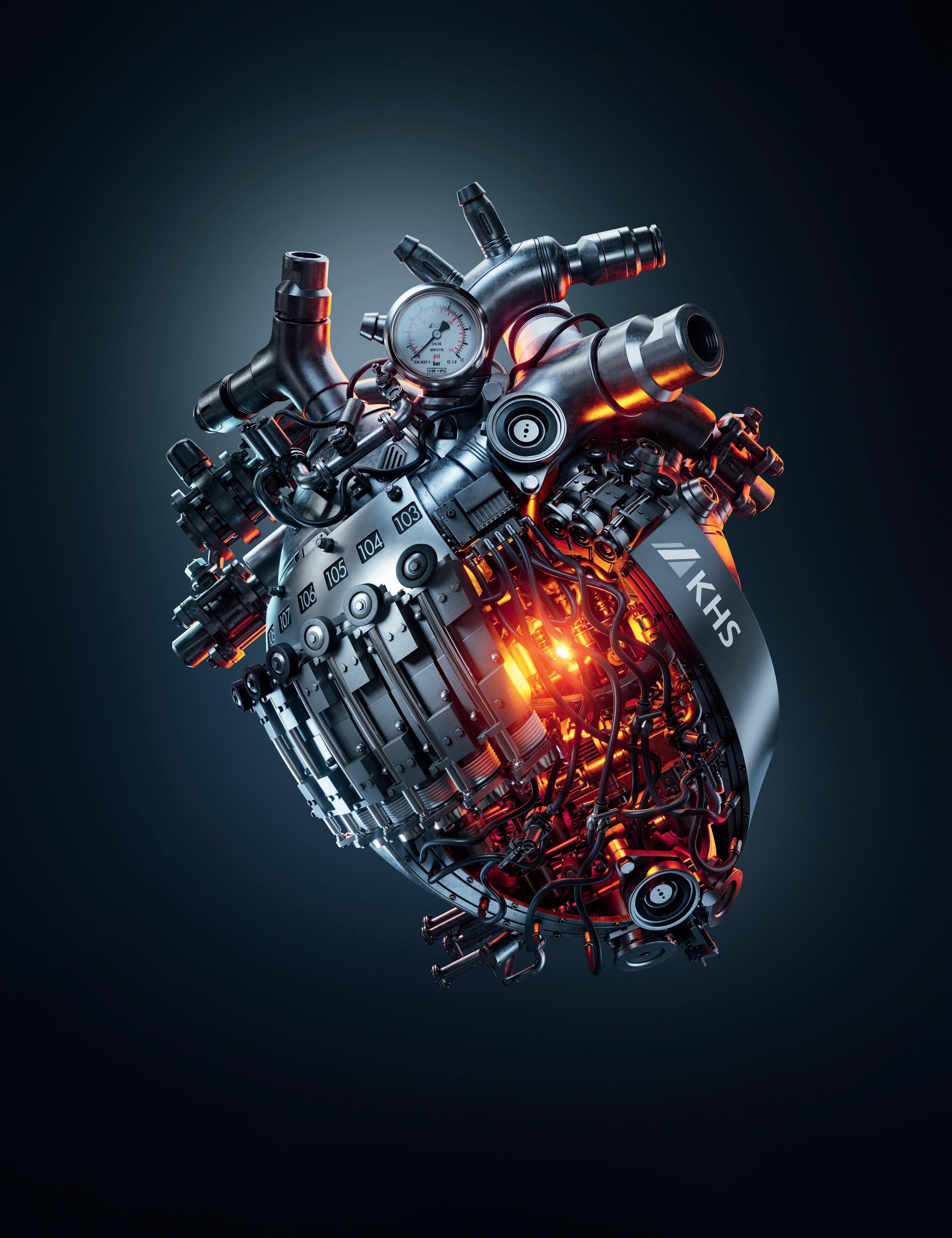

Made in Germany, the R275 MF thermoforming packaging machine enables the production of MultiFresh vacuum skin packaging in large batches. With maximum depth of draw of 150mm, it offers a great degree of variability with regard to MultiFresh applications— including MAP (modified atmosphere packaging)—producing attractive, consumer-friendly packages with extended shelf-life properties and optimal product protection.

Full view of the high-performance MULTIVAC R126 thermoforming packaging machine.

Close-up of the roll of Alpha brand labels inserted onto the R126 machine’s on-board labelling system.

The Alpha brand bavette steak packaged on the MULTIVAC R126 thermoforming packer.

May 2024 · CANADIANPACKAGING 19 CANADIANPACKAGING.COM

Clockwise from left

Full view of the MULTIVAC R275

MF

A high-efficieny Busch vacuum pump generating suction for the

As Boivin further points out, “The Busch R5 RA 0630 C pump that connects to the MULTIVAC R275 MF skin packaging machine and is a real workhorse.

“It’s a very powerful pump that enables proper performance of the machine due to its size.”

One of the key advantages that the MULTIVAC R126 and R275 MultiFresh vacuum skin packaging machine have provided for the Alpha Meat Packers packaging department is the complete automation of its labeling operations.

“We installed a top and bottom labeler and printer on the two machines, so now they don’t need anybody putting labels on by hand on any packs at all,” says Denis Poulin, senior account manager with MULTIVAC Canada

“They don’t have anybody with a hand applicator putting dates on it: it’s all done automatically on the package coming

out of the line.

“And it’s a great looking package,” he extols, recalling how the Alpha Meat Packers team was impressed by the commissioning process of both machines.

“The delivery and installation process were seamless, marked by excellent communication with our maintenance department,” Boivin says. “The training provided was thorough and well-executed, enabling our staff to achieve automation relatively quickly,” he points out.

“This efficient approach ensured a smooth transition and integration of the new systems into our operations—significantly enhancing our team’s capability and confidence in managing the new equipment.”

Boivin notes that training the plant’s staff on the two new machines was made significantly simpler through MULTI-

20 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM

From left

Close-up of the user-friendly HMI panel controlling the R275 system’s operation.

R275 skin-packer.

COVER STORY

vacuum skin-packing machine recently installed at the Alpha Meat Packers production facility in Montreal.

VAC’s human-machine interface (HMI) terminals.

“Their human-machine interface is remarkably intuitive,” he enthuses, “simplifying the navigation through menus and significantly enhancing the user experience.

“This ease-of-use not only streamlines our production process, but also reduces training time and increases operational efficiency,” Boivin says.

Another advantage of the two new machines is their ability to seamlessly transition between different products throughout the day.

“The R126’s changeover is less than 10 minutes because of the side-ejection tooling we have on it,” says Poulin. “That is significant to them.”

To ensure the equipment continues to run efficiently, Alpha also invested in a maintenance support program.

“We opted for a bi-yearly maintenance program with MULTIVAC, a decision that best aligns with our needs when considering the size of our maintenance department and the critical nature of these machines, due to their unique capabilities and lack of redundancy,” Boivin says.

“This tailored maintenance schedule ensures that our equipment remains in optimal condition—minimizing downtime and supporting our operational efficiency despite our department’s constraints.”

Boivin adds that MULTIVAC’s responsiveness and support play a crucial role in keeping Alpha Meat Packers’ operations running smoothly.

“I can attest to the swift and efficient service we receive from MULTIVAC across the board: from parts and service to the packaging film and, of course, sales,” he says.

Having enjoyed significant growth in recent years, Alpha Meat Packers plans on maintaining controlled and sustainable organic growth in the years ahead as the economy continues to change and evolve.

Machine operator placing fresh pork chops onto the meat trays to be packed and sealed inside the MULTIVAC R275 MultiFresh skin packaging machine.

Below A pefectly sealed and labeled retail skin-pack of Alpha brand pork chops ready for display on a grocery store shelf.

“We want to progressively expand our offering to produce case-ready products regionally and nationally,” Koukos says. “Part of our business model is to always think ahead strategically.

“Our key objective is to invest heavily into our retail brand,” Koukos sums up. “This is the one Alpha focus which is very important to us. We have set some exciting goals and a course of action, and we are ready to execute.”

SUPPLIERS

MULTIVAC Canada

May 2024 · CANADIANPACKAGING 21 CANADIANPACKAGING.COM

Right

Both MULTIVAC machines incorporate on-board labeling systems for fully-automatic label placement.

Please see a video of the MULTIVAC vacuum and skin packaging machinery in action at the Alpha Meat Packers plant in Montreal on Canadian Packaging TV at www.canadianpackaging.com

* Sanitizers

* Entry Control

* Hygiene Stations

* Handwash Stations

* Sole & Boot Cleaning

* Knife Cleaners

* Mesh Glove Cleaners

* Locker Room Storage

* CSA/ESA Approved

* Demo Facilities

* Full Layout Design

HYGIENE EQUIPMENT SOLUTIONS Handwashing Sole & Boot Knife & Glove Cleaning www.shawpak.com FOOD SAFETY REVOLVES AROUND SHAWPAK YOUR TRUSTED ADVISOR Hygiene Station Oakville 905.847.0122 Hygiene Equipment . Product Inspection . Packaging Equipment Consulting Services . Training & Demonstration Facility Essential tools to minimize the risk of pathogen transmission / cross-contact in production areas. Ensures employee health and personal hygiene compliance

largest

standardized

For more information info@Shawpak.com WWW.SHAWPAK.COM Montreal 514.566.7093 Edmonton 780.224.0776 Hygiene

Hand

Contact Shawpak to find out why some of the

Food manufacturers have

on Shawpak Hygiene Solutions across North America

Equipment

Sanitizers

Chapman’s chief operating officer Ashley Chapman flashes a welcoming smile at the company’s boardroom in Markdale, Ont., where the family-owned business celebrated it 50th anniversary last year.

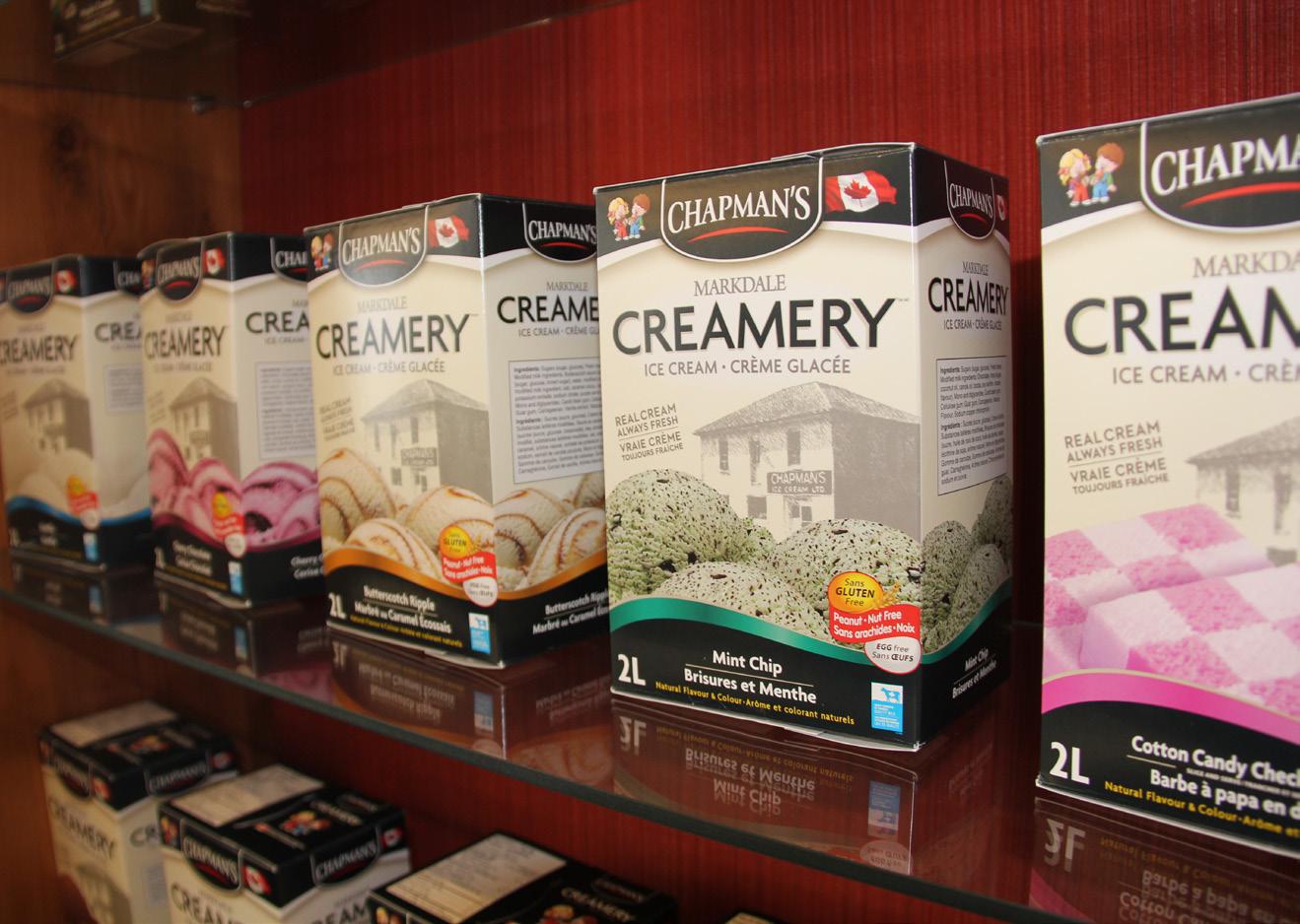

STICKING AROUND

Canadian ice-cream stalwart leverages product innovation and packaging excellence to solidify its industry leadership credentials.

By Andrew Snook

If there’s any one company that has been synonymous with ice cream and other frozen treats beloved by Canadians across multiple generations, it’s Chapman’s

Originally established in 1973 by David and Penny Chapman, the Markdale, Ont.-based producer has grown to become the country’s largest family-owned, independent ice cream manufacturer.

Nowadays operating under the leadership of the founders’ son, Ashley Chapman, the company produces more than 280 frozen treats ranging from premium ice creams to frozen yogurt, sorbet, water ice Lolly treats, and a wide variety of single-serve novelties.

Always striving to be at the forefront of innovation, Chapman’s has been recognized by several health organizations and

has been the recipient of numerous national and international awards.

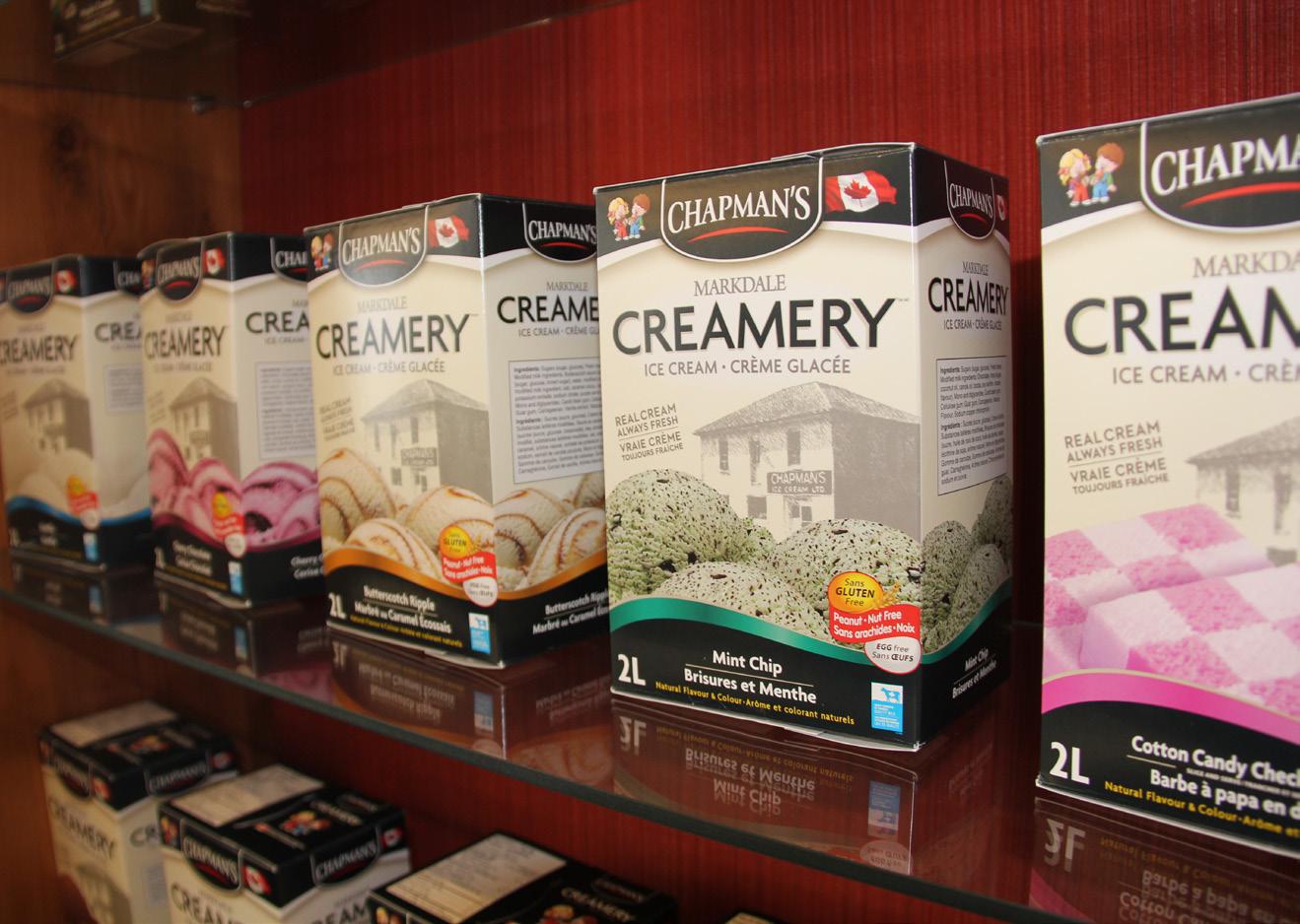

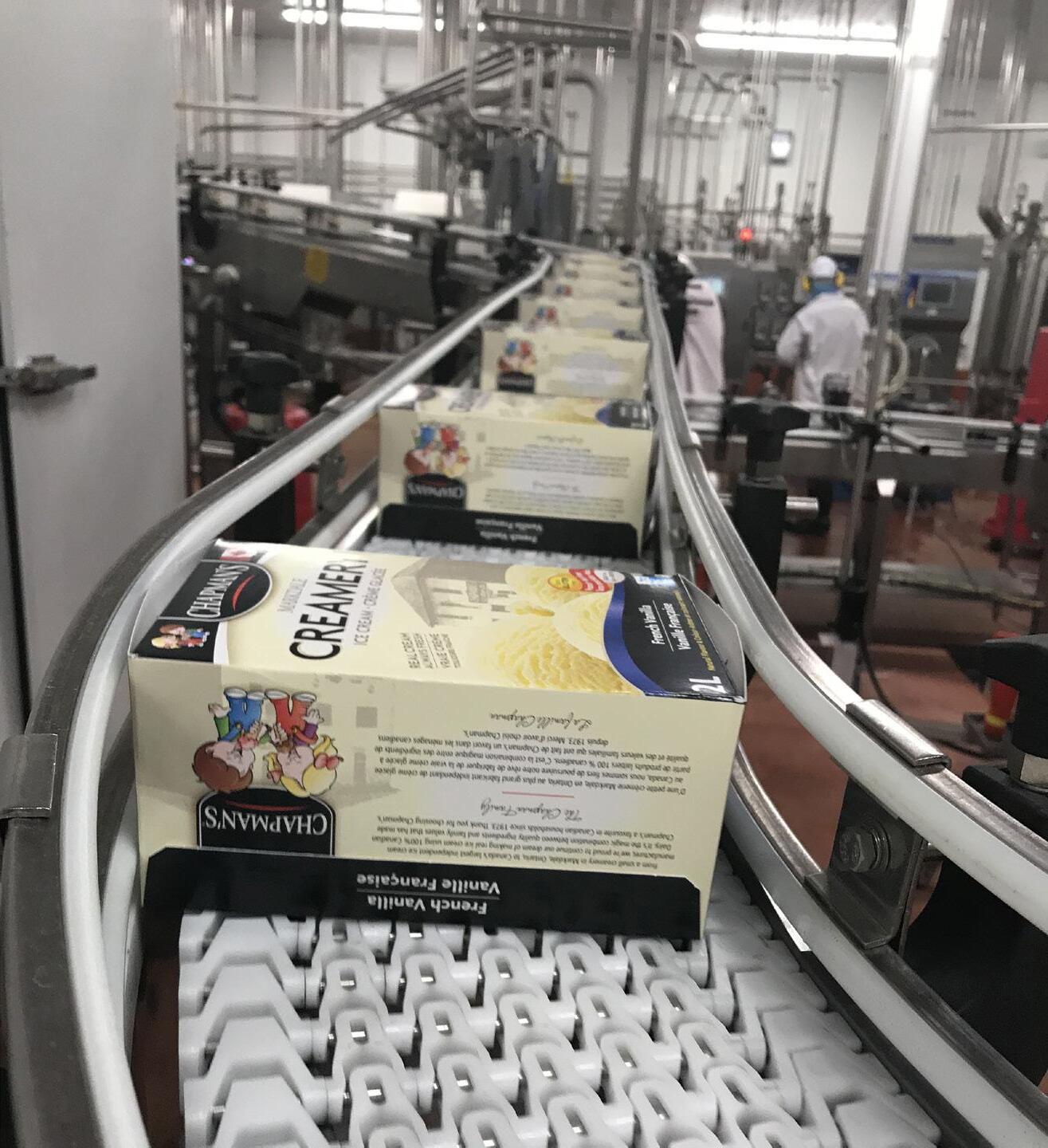

Celebrating its 50th anniversary last year, the company continues to be an acknowledged trail-blazer in the world of ice cream, shaking up the market last year with rebranded Markdale Creamery ice cream range— packaged in signature two-liter boxes— and also moving into the luxury segment of the market with the new Super Premium Plus allergy-friendly product offerings packaged in 500-ml round tubs.

But product innovation is only a part of the Chapman’s story: so is the continuous process improvement.

One of the company’s more recent projects involved automating its largest packaging line for their popular water ice Lolly brand treats that have been keeping kids cool on hot days for many

May 2024 · CANADIANPACKAGING 23 CANADIANPACKAGING.COM

ICE CREAM PACKAGING

A METTLER TOLEDO Safeline metal detector and and Hi-Speed checkweigher combination installed at the Markdale plant by Shawpak Systems.

years.

According to chief operating officer Ashley Chapman, the company sells approximately four million Lolly ice treats per year.

To automate the line, Chapman’s reached out to Gram Equipment, experts in ice cream and other frozen treats production equipment based in Denmark.

Gram Equipment supplied the Chapman’s plant with a custom-built packaging line complete with a robot that gently picks up the pre-packaged Lolly bars, indexes them .and places them into the bright 28-piece cardboard packages that retailed at the grocery store freezer aisles across the country.

This process is still performed manually on a smaller production line at the plant nearby, but Chapman notes that the automated Gram Equipment line offers significant advantages.

Filled and sealed two-liter ice cream tubs, supplied to the Chapman’s plant by Stanpac, pass through the METTLER TOLEDO combination metal detectorcheckweigher station for a final quality assurance test before heading towards the secondary packaging area.

“The machine runs about 30 per cent more output than the smaller manual line with the same amount of people on the line,” he says, “except for the packing station.”

Not only does the line’s robot reduce labor requirements for packing the Lolly treats, Chapman notes, but it does it faster and more reliably.

“We have two people on the line right now, because we just commissioned it,” he relates, “but we’re going to take one of these people off in the very near future.” Chapman says investing in automation for these types of jobs is highly beneficial for the company and its employees.

“It’s all about the jobs that people aren’t really suited for anymore,” he ex-

24 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM ICE CREAM PACKAGING

Markdale plant employees using the high-end sanitation and hygienic stations installed at the Markdale production facility by Shawpak Systems.

“If we can switch robots into that stream to do a better, faster and cleaner job, then everybody wins.”

plains. “It addresses ergonomic problems, carpal tunnel, and all those wrist issues that people get from repetitive motions.

“Humans will always be the ones that are directing the filling of the tanks, the filling of the machines—all of these things where I don’t see machines ever performing like a human,” Chapman points out.

“But for this type of stuff, if we can switch robots into that stream to do a better, faster, cleaner job, then everybody wins both the company and the employees,” Chapman states. “Especially when we’ve been having historic labor [availability] issues.”

Ashely stresses that as the company continues to automate certain aspects of production, it is not reducing its labor force.

“We’re not putting robots or automation in and firing people,” he sates. “That’s not something that we would do, regardless, but it’s also not something that the current labor market would allow.

“We just divert them to a different line,

so instead of packing products, they’re putting containers into a machine or putting chocolate chunks into a fruit feeder to get into the ice cream,” Chapman relates.

“It’s the same type of work, just a little bit more interesting.”

While the Gram Equipment line was only installed a short while ago, Ashley is very impressed with the results to date.

“It has been amazing, and commissioning was not a problem,” he recalls.

One of Ashley’s favorite features about the packaging line is that the robot’s maintenance and repair is fairly simple and straightforward.

“The beautiful thing about their system is that if I was to ever have a problem with my robot, I can pull it out, and my people can get in and pack directly in the pocket,” he says.

“It will slow down the line, but I don’t have to stop production if there was a serious issue with the robot,” Chapman explains.

“And there’s nothing to the robot: you open up the control interface and there’s

One of many SEW-Eurodrive motors deployed throughout the Markdale facility to regulate conveyor speeds.

just a couple of servos and a few wires in there,” he reveals.

“These kinds of robots have been used in automotive manufacturing and all sorts of different things for decades.”

According to Chapman, the key to keeping the line moving smoothly is the programming.

“With programming food production machines, it is pretty basic,” he says. “If you have good programming, you’re not going to have any issues.

“That’s what Gram Equipment is doing:

May 2024 · CANADIANPACKAGING 25 CANADIANPACKAGING.COM

A high-speed Videojet product coding system used to apply lot numbers and all other pertinent variable product information onto the ice-cream tubs.

hiring more programmers, and better programmers with better pay,” he states.

“At the end of the day, they know that if they can get the mechanical simple and the programming done perfectly, then the amount of service calls that they have to deal with will be next to none.”

Getting the programming right is also critical for the entire plant’s operations, Chapman points out, as all the key production equipment at the facility uses the Allen-Bradley range of controls, drives and other industrial automation devices manufactured by the leading global industrial automation powerhouse Rockwell Automation

“We are strictly Allen-Bradley,” Chapman says. “Our maintenance guys know Allen-Bradley; our engineers know Allen-Bradley.

“They are the most user-friendly [controls] for us.”

The signature two-liter ice cream boxes used for the Markdale Creamery brand are produced at Beneco Packaging’s new state-of-the art folding-carton manufacturing facility in Cobourg, Ont.

“If they can get the mechanical simple and the programming done perfectly, then the amount of service calls that they have to deal with will be next to none.”

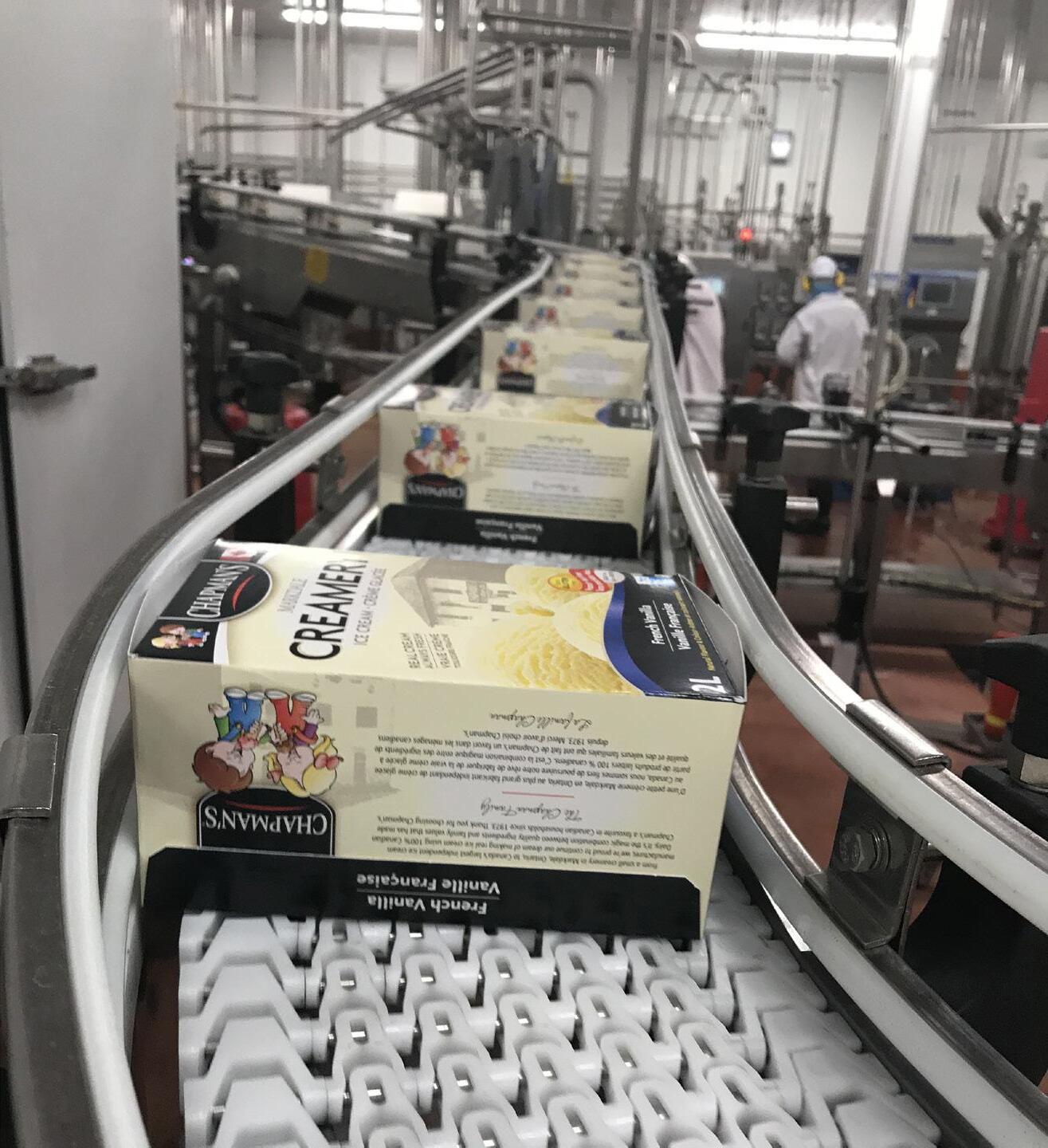

The filled signature two-liter ice cream cartons, manufactured for Chapman’s by Beneco Packaging, riding the product transfer conveyor from the WCB Ice Cream filler towards the secondary packaging part of the production line.

Once the Lolly brand products are packaged, they go through the METTLER TOLEDO Safeline X-Ray inspection system and the Hi-Speed checkweigher scales for a final thorough quality check, before traveling towards the labeling station equipped with a Videojet 1860 continuous inkjet coder manufactured by Videojet Technologies of Wood Dale, Ill.

“Videojet are great: we’ve been doing businesses with them forever,” Chapman extols.

“Their stuff is simple, and their service agreements are awesome.”

The coded retail boxes are then sent to the end-of-packaging line to be manually placed inside the corrugated shipping cases.

With four million ice Lollys heading out the production doors every year, the company needs a regular supply of wooden sticks.

Because these day such sticks must be made from sustainably-sourced wood, Ashley says that securing a reliable uninterrupted supply is becoming trickier, with suppliers beginning to feel the impact of climate change.

“Climate change is changing the growth patterns of beech and birch trees to the point where they’re having to move to other locations to source their

26 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM

ICE CREAM PACKAGING

wood,” he explains.

As Chapman points out, keeping the Markdale production plant running smoothly at all times is very much dependent on finding and keeping reliable suppliers for the facility’s packaging operations.

A close-up of the boxforming system in action as it turns carboard blanks into the finished erected boxes ready to be filled with the Lolly brand ice-treats in different 28-pack product varieties.

To that end, the ice cream producer has recently formed a solid business relationship with fast-growing, Toronto-headquartered folding-carton manufacturer Beneco Packaging , which now supplies approximately 60 per cent of the folding cartons used by Chapman’s, including those used for the Lolly brand products.

“They (Beneco) do an excellent job,” Chapman states. “They have quality issues like everybody does, but they listen to us.

“We compile the data, and we hand it off to them,” he continues. “They give us a corrective action and they stick to their guns.

“And if they don’t do what’s been promised, they come back to the table and figure out a different way.

“So, they’re a great company to deal with,” he says.

Another company that Chapman’s has built a solid relationship with is Technical Adhesives of Mississauga, Ont.

“They’re the only company in the last four years that has actually given us a slight price reduction,” Ashley relates.

One package format for which Chapman’s is having difficulty sourcing a sustainable alternative is for the single-serve sundaes, which are currently packed in Styrofoam cups.

“Styrofoam is being banned soon,” he notes, “but these are used primarily for foodservice, like hospitals and long-term care and nursing homes,” he says.

As Chapman explains, the company is actively looking for an effective replacement, but hasn’t been able to find one with the same thermal properties offered by Styrofoam

The Chapman’s plant makes extensive use of food-grade hot-melt adhesives supplied by Technical Adhesives of Mississauga, Ont., for its carton erecting and closing applications.

“You can take these sundaes out of the freezer and they can travel 30 minutes on a tray, get to the end-line consumer, and it’s still solid ice cream,” he explains.

“You take a paper cup and that melts down in about 10 to 11 minutes,” he says.

“And for hospitals and long-term care homes, it’s really difficult for them to get it to their patients,” he relates.

“So, we’re trying to figure out something sustainable.”

While Chapman’s was able to find one possible alternative, he relates, it proved to be extremely cost-prohibitive.

“We have tried one option, but unfortunately the cost was about 10 times that of Styrofoam,” he confides.

“We did a trial on it and that raised the time to 16 or 17 minutes, which is re-

28 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM ICE CREAM PACKAGING

spectable, but the cost of doing it was just exorbitant.”

With 280 different product offerings, going out into the market, Chapman’s uses a wide variety of different package sizes and shapes.

That said, the company does try to simplify packaging operations whenever possible and practical, as illustrated by 28-packs of ice Lolly treats.

“That 28-pack is all we run now,” Chapman says. “We run the fruit products in there, our triple-treat products, banana, chocolate, all in the same box— same shape, different mix.”

“That (Gram) machine runs 48, 49 weeks out of the year, and it just keeps on going.

Says Chapman: “As soon as you get to a situation on a machine where you’ve got to switch between different formats, it can be a nightmare.”

While the quality of packaging performance is naturally a top priority for Chapman’s, sustainability is also important.

For Chapman’s, taking a holistic approach to sustainability that encompasses all aspects of the operations is the right path to follow.

“It’s a big deal for us,” Chapman states. “We’ve really improved our systems over the years to make sure that if we need 10,000 packages, we don’t run 15,000 packages to get those 10,000 packs.

“But we also look at sustainability more in a holistic sense,” Chapman expands. “So it’s not just the machines, it’s not just the packaging: it’s the whole process.

“Even all of our wastage ice cream goes to the local pig farms.”

As Chapman emphasizes, , the company is always trying to position itself as a leader when it comes to staying on top of sustainability regulations.

“We’ve always done more than was required by the government,” Chapman states.

“Our conversions to paperboard from plastic was a big deal in 2011, as it did a lot of good for the environment.”

However, Chapman says the company is starting to hit a wall when it comes to finding more ways to be sustainable, and that the packaging industry needs to find ways step up their innovation in this regard.

“The packaging industry is falling behind in some of the most important areas, which are single-use plastics,” he comments.

“We need a compostable and recyclable wrap, so it doesn’t matter where you are—northern Ontario or the GTA (Greater Toronto Area) region—people can put it into a waste-stream that can deal with in a responsible manner.

“There are certain types of packaging right now that are technically recyclable,” he acknowledges, “but there are only a few places in the entire country that can properly break those things down.

“We need more oversight from the federal government, and more guidelines on what people should be using,” Chapman states.

To address the issue, Chapman suggests that Canada should follow in the

Markdale plant machine operator making sure there is always an uninterrupted flow of the two-liter ice cream cartons being fed inside the WCB Ice Cream filler during production runs of the company’s flagship Markdale Creamery ice cream products.

footsteps of other countries, like Italy, which are making real progress in moving towards a Circular Economy model for food production.

“Look at a place like Italy,” he states. “Italy has an entire infrastructure built around one set of standards for composting.

“They’ve been doing it for around 150 years and now they’re starting to have a ‘good’ problem of having too much soil,” he points out. “That’s the direction in which we should be moving as well.”

SUPPLIERS

Beneco Packaging

Technical Adhesives

Shawpak Systems

Gram Equipment

Videojet Technologies

Rockwell Automation

Stanpac

May 2024 · CANADIANPACKAGING 29 CANADIANPACKAGING.COM

A

Production line workers making sure the Lolly ice treats are conveyed inside the Gram Equipment packaging system in proper order and orientation.

Paperboard tubs supplied by Stanpac being filled with ice cream product.

CUTS AND GLORY

Canadian meat industry emerges from post-pandemic uncertainty to begin recapturing lost ground in the global export markets

As one of the world’s largest producers and exporters of beef, pork and other red meat products, the Canadian meat sector is one of the country’s most important generators of revenues, employment and trade— contributing well over $24 billion to the nation’s GDP (Gross Domestic Product) each year.

And while the industry has endured a lot of pain and uncertainty during the prolonged COVID-19 global epidemic and the resulting supply chain disruptions, the sector’s long-nurtured resiliency and grace under pressure have enabled it to bounce back from those dark days relatively quickly—to the collective benefit of Canadian consumers and the country’s meat product manufacturers and their suppliers.

With the Canadian Meat Council (CMC) preparing to highlight and

celebrate the Canadian meat industry’s accomplishments at the group’s upcoming 2024 Conference and Annual General Meeting next month in Ottawa, June 10, 2024, the Canadian Packaging magazine recently reached out to CMC chair Kerry Towle, vice-president of industry and government relations at Sofina Foods Canada , and vice-chair Russ Mallard, president of P.E.I.-based Atlantic Beef Products, to discuss the challenges and opportunities facing the nation’s top meat producers in coming years.

QPlease provide a macroeconomic snapshot of the state of the Canadian meat processing industry at the moment.

Canada’s meat industry is a big part of the country’s economy and generates significant revenue and employment each year.

In 2022, the meat processing industry shipped products worth $24.72 billion, showcasing its substantial economic

30 CANADIANPACKAGING · May 2024 CANADIANPACKAGING.COM

MEAT SECTOR OUTLOOK 2024

impact and contribution to Canada’s overall economy. The red meat processing industry—comprising beef, veal, pork, lamb and horse-meat—is the largest sector of the food manufacturing industry in Canada, with annual revenues valued at over $16.3 billion and total employment of over 64,000 people.

In 2022, the volume of beef produced in Canada amounted to 1.38 million metric tons. Canada’s meat processing companies manufacture a wide variety of meat products ranging from fresh and frozen meat to processed, smoked, canned, cooked, and sausage and deli meats.

Canada is a significant exporter of meat products—exporting over half of total production. The Canadian meat industry is domestically and globally recognized for well-established safety standards of the highest quality, as overseen by the Canadian Food Inspection Agency (CFIA).

Led by pork and beef, meat is one of Canada’s highest valued agri-food exports. The meat industry is the largest part of Canada’s food processing sector with annual sales surpassing $31 billion in 2023, and red meat exports valued at $9.7 billion in 2023.

Canada’s consumption of red meat was estimated at $13.4 billion in 2018 and 13.9 billion in 2019.

The number of direct jobs in the Canadian red meat sector in 2021 was 40,131, accounting for the workers employed in employment of production workers for animal slaughtering (poultry excepted), and for carcass rendering and meat processing.

In 2021, the total number of people employed within the Canadian red meat sector was 48,156, representing seven-percent growth in the total number of direct and indirect jobs in 2020.

QWhere does Canada’s meat industry rank on the world stage in the context of global economy?

The sector takes pride in feeding families in Canada and around the world.

Canada stands out as the fifth-largest exporter of agricultural and agri-food products globally. The meat processing industry is the largest component of Canada’s food processing sector, accounting for about 12 per cent of the country’s agri-food exports and employing over 64,000 Canadians.

In 2022, Canadian farmers and food processors exported $9.5 billion dollars in red meat products, which includes pork, beef, lamb,and horse.

As the global per capita consumption of meat is expected to rise in the next 10 years, Canada’s opportunity to export red meat products will continue to grow.

On average, 50 per cent of Canada’s

beef production and 70 per cent of its pork production is exported, excluding live animals sent to the U.S. for feeding and slaughter.

All in all, Canada is a highly efficient producer of high-quality beef and pork products—exporting to over 90 countries worldwide.

For its part, the overall trend for meat consumption in Canada appears to be relatively stable. According to the OECD data, Canada’s projected per capita consumption of beef and veal, pork, and sheep meat in 2029 will be relatively flat compared to current levels.

Founded more than a century ago, Canadian Meat Council represents Canada’s federally licensed meat packers, meat processors and suppliers of goods and services to the meat industry.

This research indicates a growing trend among younger Canadians, particularly Millennials and Gen Z, to consume less meat and shift towards other alternatives.

According to Statistics Canada , total beef consumption in Canada declined by 6.6 per cent in 2021 to 919,720 tonnes, even as domestic production rose by 4.3 per cent.

The decline in beef consumption was predominantly due to strong global meat demand for Canadian beef exports and for fewer beef imports—resulting in less beef available for the domestic market.

In addition, supply chain pressures and food inflation resulted in higher beef prices and declining consumer purchases. As a result, per capita beef consumption in Canada fell by 7.2 per cent in 2021 to 16.9-kg retail weight.

Despite its relatively small population, Canada exports almost 50 percent of its total beef and cattle production. In 2022, beef exports were valued at $4.7 billion, doubling in the past 5 years reaching 511,000 tonnes, the second largest year for export volume on record.

Work in international markets continues to create opportunities for the Canadian beef industry to realize greater value for the carcass than could be realized in the domestic market alone.

About 95 percent of Canada’s cattle

and hogs are processed in federally inspected facilities, ensuring high standards of quality and safety.

QPlease describe the impact of the post-COVID inflation in terms of the cost of production inputs and the retail-level cost to consumers.

Meat price inflation can be traced directly to the energy prices, which surged in early 2022 due partly to the Russian invasion of Ukraine and reduced oil output from oil-producing nations. In August 2022, meat prices in Canada were up 7.6 per cent year-over-year, lagging the overall food price inflation rate. Fresh beef prices rose by 6.7 per cent, while beef steaks were up 10.7 per cent in January of 2024 compared to a year earlier. In contrast, pork prices increased by only 0.2% year-over-year in August 2022, the slowest among fresh meats. However, processed products like lunch-meat (up 24.2 per cent), sausages (up 15 per cent) and frankfurters (11.3 per cent) experienced the fastest price growth.

But while meat prices have increased, the rate of inflation has generally been more moderate compared to other major food categories. Our industry is aware of this challenge for consumers by and striving to process our products in the most efficient manner possible.

QMany Canadian food industry sectors are concerned about the speed and scope of the federal ban(s) on single-use plastic packaging. How big of a deal is this in the meat industry, and how is the meat industry responding to it?

The use of plastic packaging is crucial for preserving the safety of meat products in the meat processing sector.

While the Canadian government is working to reduce plastic waste and promote sustainable procurement across all sectors, it recognizes the important role of plastics in meeting the high food safety standards for meat products manufactured in Canada.

The government has created a regulatory framework to achieve its plastic reduction objectives,, and the meat industry is advocating for solutions that allow industry time to adopt the technology that will serve the dual purposes of environmental sustainability and food safety.