GATHERING STEAM CANADIANPACKAGING.COM JUNE 2023 / $10.00 SERVING CANADA’S PACKAGING COMMUNITY SINCE 1947 Package Design Page 22 Conveying Page 27 Automate Now Page 36 Innovative standout packaging an integral part of Big City brewer’s production repertoire Story on Page 17

Helping you bring your best products to market.

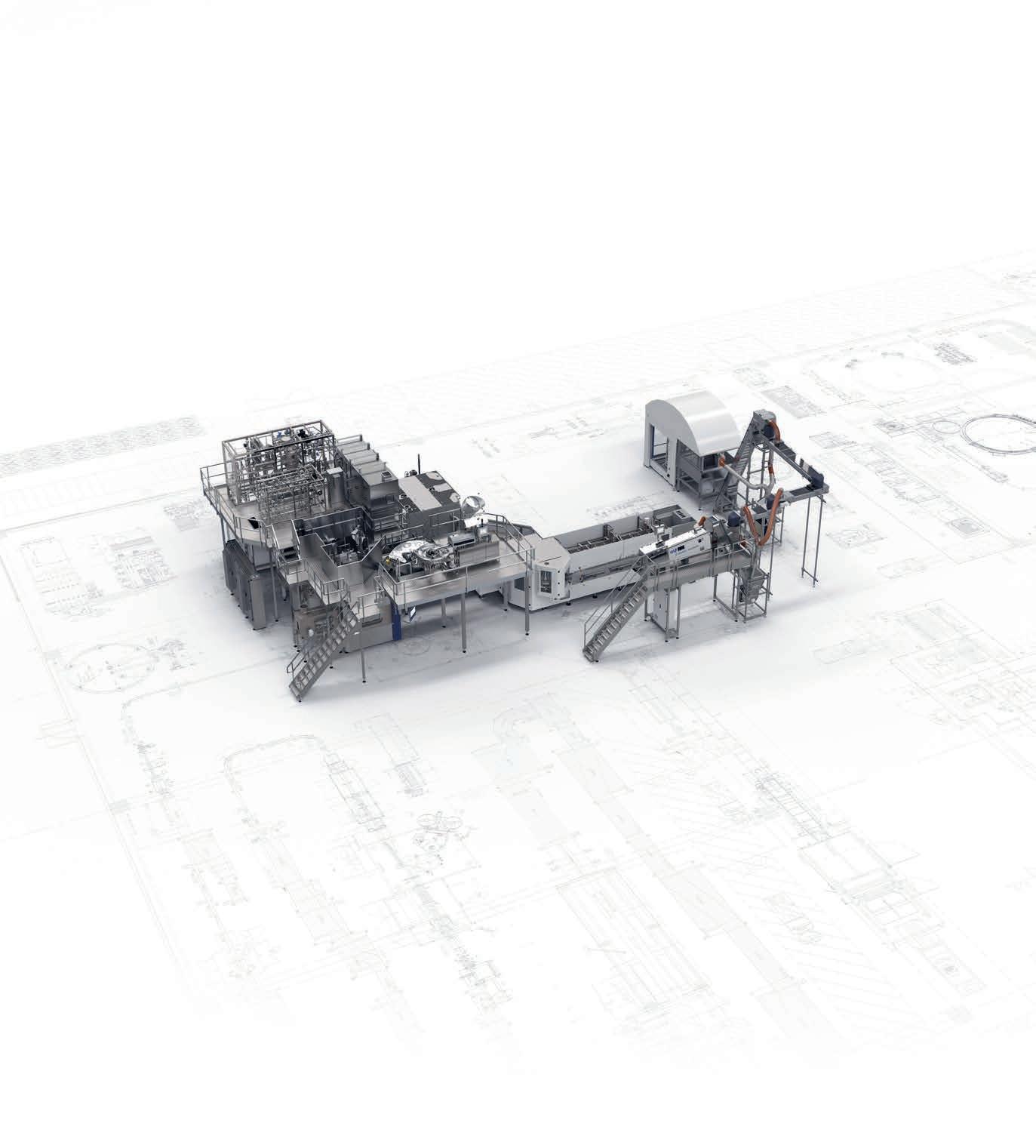

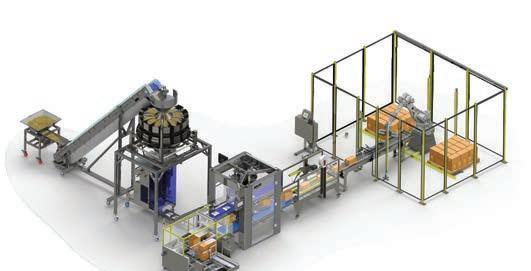

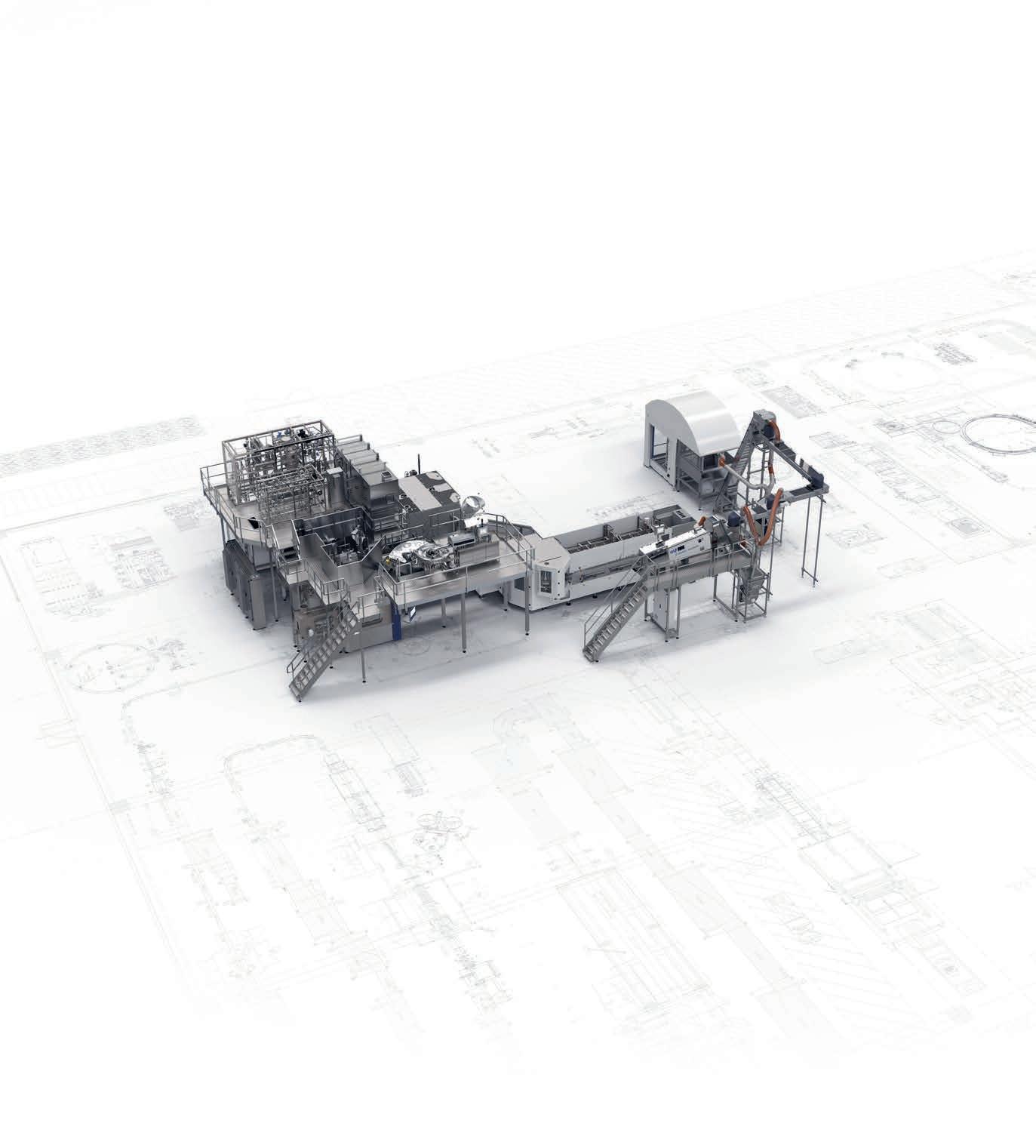

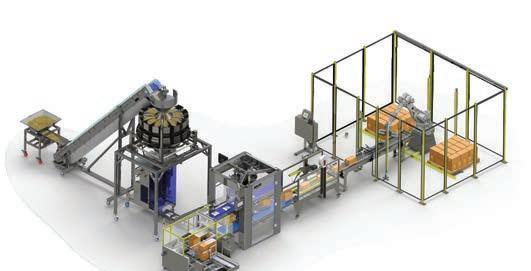

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

36 41

98 34 116

Sep. 11-13, 2023 Booth C-1623, Central Hall Las Vegas Convention Center Las Vegas, NV USA

info@heatandcontrol.com | heatandcontrol.com

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

17 20

91 97

107 26

Videojet 1580 C Continuous Inkjet Printer Experience breakthrough soft-pigmented printing technology Discover more at videojet.com/1580C The contrast printer that performs and behaves like a dye-based printer ©2023 Videojet Technologies Inc. All rights reserved. Videojet Technologies Inc.’s policy is one of continued product improvement. We reserve the right to alter design and/or specifications without notice.

Vision Guided Pick & Place Cell

2 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM

Up to 24 hours per day

No vacations

No workers comp

No insurance

No sick days

No attitude

PKR-Delta #ReadyToWork •

•

•

•

•

•

at: $14 per hour single shift $7 per hour double shift $4.66 per hour triple shift *Investment adjusted to approximate hourly wage over 5 years 1.833.4PAXIOM PaxiomGroup PaxiomXperience Watch video at paxiom.com Pre-roll Weighing FillingBaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing LAS VEGAS • MILWAUK EE • MIAMI • TORONTO • MONTREAL • SCHIO, ITALY

Starting*

DEPARTMENTS

NEWSPACK

6-8 Packaging news round-up.

NOTES & QUOTES

10-11 Noteworthy industry briefs.

FIRST GLANCE

13 New packaging solutions and technologies.

ECO-PACK NOW

14 Sustainable packaging innovations.

IMPACT

15 A monthly insight from PAC Global PEOPLE

39 Career moves in the packaging world.

EVENTS

39 Upcoming industry functions.

ISSN 0008-4654. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2023 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

COVER STORY

17 PICKING UP STEAM

Leading Canadian independent brewer get back to the basics with single-minded focus on its original brand of European-style pilsner, using updated innovative packaging formats for optimal shelf impact.

FEATURES

22 Breaking Bread

Vibrant new packed eigne earns Ontario baker prestigious industry award and accolades, while unifying tis brand identity across its flaghip retail product offerings.

2 7 Upwardly Mobile

Ontario automation systems integrator completes a major warehouse automation upgrade with the help of leading vertical conveyor systems manufacturer.

3 1 Friends for Life

Young Ontario entrepreneurs shaking the packaging status quo in the foodservice market with an innovation return-deposit service aimed at eliminating single-use plastic packaging.

36 Happy Middle

Packaging machinery manufacturers assess the need for rapid AI (artificial intelligence) deployment across their entire equipment range.

June 2023 · CANADIANPACKAGING 3 CANADIANPACKAGING.COM June 2023 Vol. 76, No. 5

canadianpackaging.com

FROM

CHECKOUT

17 31 22

COLUMNS

THE EDITOR 4 George Guidoni Consumers right to rage at food inflation.

40 Paul Pethick Joe Public speaks out on packaging hits and misses.

Consumers have every right to be angry about the rising food inflation

10.8%

Year-over-year rise in the cost of fresh vegetables in March 2023

It is a troubling sign of the times when economists and politicians cheer a muted slowdown in overall rate of rising inflation for all sorts of everyday consumer products rather than an outright drop in the inflation rate, but its seems that any silver lining will do these days.

While the rise in global energy prices, particularly oil and other fuel, often makes a convenient scapegoat in explaining the prolonged sticker shock at grocery stores charging unprecedented high process for fresh fruits and vegetables, among other essential foodstuffs.

But global oil prices still nowhere near their all-time highs, there must be many other factors at play behind the soaring food inflation that is giving Canadian consumers real fits about their ability to afford essential products that form the basis of sound daily nutrition, fresh fruits and vegetables notably among them.

Even with the overall inflation rate slowing to 4.3 per cent last month, according to Statistics Canada, the cost of fresh fruit was still 7.1 per cent higher in March on year-over-year basis, while fresh vegetables rose by 10.8 per cent.

For some everyday staples like apples (up 15.8 per cent), tomatoes (10.9 per cent) and lettuce (eight per cent), the cumulative effects of consecutive monthly rises ever since the outset of COVID-19 are transforming these products into outright luxury items, for heaven’s sake!

No one ever said that getting back to post-COVID normal was going to be a walk in the park, but pricing consumers out of reach across such a large population segment is not a happy recipe for rebuilding consumer confidence.

Coming at a time of record profits for leading Canadian grocery retailers, the accusations of greed-driven price-gouging are a valid reflection of the consumers’ exasperation with their monthly food bills, and who can blame them?

As our elected policy makers are often painfully reminded at election time, hell hath no fury as an angry electorate, and a hungry electorate is as angry as it gets.

In this context, it may be a good idea for the feds to review a timely new report from Global Coalition of Fresh Produce (GCFP), the umbrella organiza-

tion for leading national fresh produce industry groups such as the CPMA (Canadian Produce Marketing Association)

Titled Global Value Chains for Fresh Produce: An Urgent call for Policy Measures, the report predictably decries the alarming drift towards unaffordability as a sure a precursor to serious healthcare system repercussions.

“First and foremost, governments and international bodies across the globe should recognize fruits and vegetables as essential goods,” says GCFP’s chief public policy officer Robert Guenther. “By establishing that fruits and vegetables are fundamental to the health of populations and an essential element in the shift towards more sustainable food systems, other measures can be unlocked to ensure their consistent supply.”

According to the report, available from CPMA, those measures must include:

• Helping fresh produce operators shoulder the burden of increased energy bills;

• Promoting the creation of safe and good-paying jobs in the fresh produce industry and in transportation;

• Ensuring undisrupted and priority access for fresh fruit and vegetables to all transportation networks;

• Creating priority lanes for imported fresh produce to ensure quick offloading at all points of arrival;

• Improve operational practices to ensure the seamless movement of fresh produce;

• Working towards the harmonization and mutual recognition of sanitary, phytosanitary and other market entry requirements;

• Promoting the consumption of fruits and vegetables by exempting fresh produce from value-added taxation,

• Offering more fruits and vegetables through school feeding programs. While it’s just a sampling of things regulators could do to improve the status quo, it’s a good starting point for moving in the right direction.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

JUNE 2023 | VOLUME 76, NO. 5

Reader Service Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

President/COO

Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

4 CANADIANPACKAGING · June 2023

FROM THE EDITOR

Kellogg’s goes back in time with limited-edition retro boxes for Fab Four brands

Cereal giant Kellogg Canada Inc. has tastefully turned backthe time last time with a sensational launch of limited-edition retro packaging of the company’s Fab Four brand favorites adorned with playful throwback graphics and iconic brand mascots bringing bodacious cereal boxes from the ‘70s, ‘80s and ‘90s to life on store-shelves from coast to coast.

Offering a generous serving of fun cereal facts gathered over the 100-plus years of the Kellogg Company’s prominent and prosperous presence in the Canadian market, the retro-designed boxes of the company’s

perennial bestsellers Frosted Flakes, Froot Loops, Rice Krispies and Corn Flakes—created by Equator Design (part of SGK))—tap into a rich vein of nostalgia of millions of Canadians who fondly recall growing up with the crunchy bites of their beloved breakfast staples.

“Our collective memories flash back to those familiar Kellogg’s cereal boxes that sat on our breakfast table every morning while we were growing up,” says Emma Eriksson, vice-president of marketing and well-being at Kellogg Canada.

“Whether it was Toucan Sam, Tony the Tiger, Cornelius (the Corn Flakes rooster) or Snap! Crackle! and Pop!, these images are

remembered fondly in the hearts of Canadians, who can now share them with their own families with our Kellogg’s Retro Series.

“The nostalgic designs will take Canadians back in time,” she says, “while the cereal provides the easy, convenient nutrition that today’s consumers demand.”

As part of its Retro Series Cereal Box release, Kellogg Canada is offering a special promotion featuring four Frisbee-like flying discs—each showcasing a different lovable mascot.

A purchase of two boxes automatically qualifies every shopper to claim a disc of their choice online by simply scanning their receipts and registering on www.kelloggs.ca/RetroPromo

“Kellogg is about bringing families together, enjoying special moments, and creating memories to last a lifetime,” says Eriksson.

“With the advent of warmer weather right around the corner, a flying disc premium is a fun, yet nostalgic way to celebrate getting back outside after a long, cold winter.”

As Eriksson point out, each of the Fab Four brand mascots has a unique story line that has withstood the test of time over generations.

For Kellogg’s Frost Flakes, Tony the Tiger has been a “Gr-r-reat” brand ambassador since the product’s 1952 launch, including being voted into the Advertising Hall of Fame in 2004.

Also originally launched in Canada in 1964, the Froot Loops’ Toucan Sam has never looked better, with the new retro pack showing the bird mascot sporting his original beak with three color stripes (red, orange and yellow) to match the colors of the cereal.

For their part, the Snap! Crackle! And Pop! elves synonymous with the Rice Krispies brand have been featured together on the crispy-textured cereal puffs since 1933. As for Cornelius “Corny” Rooster, introduced in 1957, being the face of the original Kellogg’s Corn Flakes is a unique honor for a product that has remained basically unchanged since it was first introduced back in 1906.

6 CANADIANPACKAGING · June 2023 23_003270_CN_Pckg_JUN_CN Mod: May 8, 2023 3:10 PM Print: 05/10/23 page 1 v2.5 PRODUCTS THAT SHINE 1-800-295-5510 uline.ca ORDER BY 6 PM FOR SAME DAY SHIPPING π CPK_Uline_June23_CSA.indd 1 2023-05-11 10:15 AM

NEWSPACK

June 2023 · CANADIANPACKAGING 7 CANADIANPACKAGING.COM Reiser Form/Fill/Seal Packaging Machines n Wide range of flexible machines produce high-quality vacuum, MAP and VSP packages n High-speed production n Superior seals eliminate leakers and returns n Backed by Reiser’s industry-leading service and support Watch video 2023 www.reiser.com Reiser Canada • Burlington, ON • (905) 631-6611 Reiser • Canton, MA • (781) 821-1290 Reiser UK • Milton Keynes, Bucks • ( 019 08) 585300 Take your business to the next level with Reiser packaging Extend product shelf life with superior packaging technology from Reiser

project took two years of collaborative planning and designing by the Arterra team and ita agency partner to bring the fresh new

Leading off with the brand’s Pinot Grigio, Sauvignon Blanc and varietals, the new packaging has a fresh but familiar look to show that Jackhas the same rich bouquet Can-

“Through a bold use of color, dynamic lines and special finishes, we designed a new Jackson-Triggs Proprietor Selection that has a high impact on the shelf, but is still rooted in the DNA of Jackson-Triggs,” says Kim Norwich, creative director at Toronto-based

“The new design is familiar to their current audience but invites a new audience to engage,” Norwich says. “A refreshed logo and emblem kept the iconic elements of the Jackson-Triggs brand but modernized the

As Norwich points out, the high-end bottle labels now feature bold, geometric patterns and vibrant, eye-catching colors, while retaining the gold accents to show consumers this is the same award-winning wine they’ve grown to love over the last 30 years, albeit with a more modern and sleeker

In addition, the brand’s four-liter cask of wine was also updated to reflect the label more closely, while sporting a similar look to

Furthermore, the Jackson-Triggs wordmark was updated and refined using a new

NEWSPACK OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 OFFSITE INSPECTION bones, stones, glass, aluminum, rubbers, standard foreign bodies services 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 CPK_XrayReclaim_May23_CSA.indd 1 SUSPECT FOREIGN MATERIALS X-RAY INSPECT & RECOVERY 3rd Party Rework Services for Food Products OFFSITE INSPECTION • • metals,

bodies • mobile services Contact 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 Separation bolt

bones, stones, glass, aluminum, rubbers, plastic, and standard foreign

In developing efforts to create a more sustainable package, we can eliminate up to 60% of the additional contents that go along with your standard ground meat packaging. Formost Fuji has manufactured an innovative packaging solution for ground meat to give grocers, consumers, and processors the best quality package for product freshness and shelf life while reducing waste, space, and overall greenhouse emissions.

PROCESSING SALES | SERVICE | INTEGRATION

INSPECTION

Innovative trayless meat system reduces waste. PACKAGING |

|

E STABLISHED 1990 • QUALITY MACHINES & S E ECIVR • TOLL FREE: (800) 361-5919 ABBEYEQUIPMENT.COM

London, Ont.-based packaging equipment and materials supplier Crawford Packaging has been named as one of Canada’s Best Managed Companies in the annual business awards program of leading management consulting services provider Deloitte Private for the third year in a row in recognition of the company’s leadership credentials in the areas of strategy, culture and commitment, capabilities and innovation, governance and financial performance. “This award is a testament to the dedication and hard work of our team, who consistently strive to provide innovative packaging solutions and exceptional service to our customers,” says Crawford Packaging president John Ashby. “As we look towards the future, we remain committed to our core values of integrity, collaboration and continuous

improvement, and we will continue to invest in our people, technology, and processes to drive growth and success for our business and our customers.”

Leading Canadian paper packaging products group Cascades Inc. of Kingsey Falls, Que., has officially commenced production at the company’s new recycled containerboard mill in Bear Island Va. With annual production capacity of 465,000 short tons of lightweight, high-quality, 100-percent recycled containerboard, the state-of-the-art mill is equipped to perform within the top quartile of its industry segment, according to the company, while significantly strengthening the operational flexibility, geographic footprint and competitiveness of the Cascades Containerboard business unit. “After the commissioning of the Greenpac mill nearly 10 years ago, the start-up of Bear Island marks another historic milestone in the strategic modernization of our mill network,” says Cascades president and chief executive officer Mario Plourde. “More

than ever, Cascades has modern and competitive assets that will allow us to pursue long term-growth in packaging, on a North American scale.”

Leading industrial robotics manufacturer Yaskawa Motoman has announced plans for a major 185,000-square-foot expansion of its headquarters facility in Miamisburg, Ohio, starting this summer. According to the company, a division of Yaskawa America Inc., the expansion will nearly double the size of its current production space, while adding about 70 new jobs to its current workforce of 400 people, with the expected completion date of June 2024. “When we built our current 305,000-squarefoot headquarters and manufacturing facility in 2011, we purchased additional land to support our expectation of continued growth,” says Yaskawa Motoman president and chief operating officer Steve Barhorst. “This expansion is the fulfilment of that vision, and is the next step in Yaskawa’s growth plan for the Americas.”

Trimco Group, a leading global supplier of brand identity products for international fashion and sports brands, has reached a definitive agreement to acquire Wah Lung Labels, Toronto-based supplier of labels, tags, and product authentication and traceability solutions for apparel industry. “We are excited to partner with the Wah Lung team to continue serving our Canadian customers with an even broader set of products and designs, production locations, and industryleading supply chain sustainability digital solutions,” says Trimco Group’ chief executive officer Amy Wan. “Today we are one of the leading supply chain partners for over 800 brands globally, and we are still early in our growth journey in North America, where we see huge growth potential for our brand and services.”

10 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications. Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified customers. GavazziOnline.com • 888.575.2275 • Gavazzi@CarloGavazzi.com USA Tel : 8 47 46 5. 6 10 0 Canada Tel : 8 88.57 5 .2 27 5 Mexico Tel: 55 53 73.7042 ww w.Gavazz i O nlin e .c om • Info@Ca r loGavazzi.co m twitter.com/CarloGavazziNA facebook.com/CarloGavazziNA Visit our website for downloadable data sheets, brochures and pricing: www.GavazziOnline.com Brazil Tel: 55.11.3052.0832 youtube.com/user/CarloGavazziNA https://www.linkedin.com/company/carlo-gavazzi_2 CARLO GAVAZZI A utomation Components CARLO GAVAZZI A utomation Components CARLO GAVAZZI A utomation Components Innovative Automation Solutions SWITCHES: Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls CPK_CARLO GAVAZZI_future .indd 1 2023-03-23 7:53 AM

CARLO

NOTES & QUOTES

Wilmington, Del.-headquartered specialty chemicals manufacturing group Solenis has formally unveiled the company’s newest designated Center of Excellence facility in Mönchengladbach, Germany, to help drive more sustainable solutions for waterintensive industries and consumer paper packaging. The state-ofthe-art 3,100-square-meter R&D facility—housing dynamic sheet formers, a lotion paper coater, different types of refiners, and repulping and recycling capabilities—can provide more than 70 different tests for paper packaging and food-and-beverage packaging characteristics across a broad range of categories, including strength, sizing, transport phenomena, sustainability and barrier coating performance. According to Solenis, the facility’s labs are equipped with leading-edge instrument-based capabilities for water analysis, microbiology, wastewater treatment, compound analysis, deposit identification, product determination and other research and testing applications.

U.K.-headquartered specialty films manufacturer Innovia Films has commenced expansion of its business unit near Leipzig, Germany, to house a new 8.8-meter-wide multilayer coextrusion line to produce highly engineered thin-gauge label films to support the growing, sustainability-driven demand for lower-resin content materials.

According to the company, the new line will feature best-in-class energy efficiency and annual capacity of 36,000 tonnes, with production scheduled to begin in the second half or 2024. “The

Vertical Conveying Solutions

intended introduction of the BOPP (biaxially-oriented polypropylene ) film on a production scale represents a big innovation for the labeling applications with the unique uncoated and printable label film that does not exist yet,” says Simon Huber, managing director at Innovia Films Europe “Polypropylene is a widely recycled material that has an established recycling stream and that supports a ‘Circular Economy’ for plastics.”

Charlotte, N.C.-headquartered Sealed Air Corporation has announced the change of its corporate brand name to SEE as part of the company’s transformation from a productdriven manufacturer to a marketdriven solutions company. As brand-owner of iconic packaging products like CRYOVAC food packaging, LIQUIBOX fluids and liquids systems, and SEALED AIR and BUBBLE WRAP protective packaging, among others, the company says its corporate rebranding was prompted by the need to better reflect the full extent of its brands and solutions that include equipment, services and materials—proving packaging for over 30 billion products a year.

“We are relentlessly reinventing SEE from a product-driven supplier to a world-class, market-led company powered by automation, digital and sustainable packaging solutions,” says SEE president and chief executive officer Ted Doheny. “We are solving our customers’ critical packaging challenges to make our world better than we find it.”

Ryson has the Right Vertical Conveying Solutions for the Packaging Industry.

Whether you are handling cases, trays or packs, or bottles and cans in mass – or single file, we can help.

Ryson Spirals need less floor space than conventional incline conveyors and are faster and more reliable than any elevator or lift. Central to our modular design is our proprietary slat-type belts. They provide rolling friction and can start and stop fully loaded.

Quality and service come first at Ryson. We are the number one spiral manufacturer in the USA. We offer sales, service and support worldwide. For application assistance or more information, give us a call or visit www.ryson.com

898-1530

June 2023 · CANADIANPACKAGING 11

From left: Solenis chief sustainability officer Lotta Kanto Öqvist and chief executive officer John Panichella join the mayor of Mönchengladbach Felix Heinrichs at the official opening of the company’s newest Center of Excellence facility.

Innovia Films Europe managing director Simon Huber (third from left) joins colleagues and business partners at the official groundbreaking ceremony.

www.ryson.com (757)

50% L SS P CK G NG

IS STILL 50% TOO MUCH.

The KHS solution for more sustainability: New avenues in packaging technology.

We are continuously improving our packaging. By applying innovative technologies and switching over to mono-material packaging we have halved our packing materials over the last five years. And we are soon to take another big step forward in using new, thinner types of film. khs.com/packing-systems

CARRY THE LOAD

Designed as a semi-automatic solution for the filling of the film pouches and then loading them into the chamber belt packaging machines, the new MULTIVAC Pouch Loader (MPL) from MULTIVAC Group can accommodate a broad range of pouch lengths in a range of 200-mm to 800-mm, as well as pouch widths between 150-mm and 600-mm, with maximum flexibility in terms of products and pack formats. The system is based on a simple principle, whereby one operator positions the products on the infeed conveyor of the machine, with two other staff loading the products by pulling the film pouches over the loading conveyor, so that the product can be conveyed automatically from the conveyor into the film pouch. Designed for minimal human contact with the product, so that the operators no longer need to lift the products and place them awkwardly inside the pouches, the MLR facilitates a simple and effortless packaging process with a high degree of efficiency, reliability, operating convenience and cost-effectiveness, according to MULTIVAC. The MLR can be easily outfitted with the compact MULTIVAC Pouch Rack (MPR), which can accommodate up 10 different stacks of various pouch sizes and features special pouch opening aids so that the individual film pouches can be easily separated from the stack and removed from the rack.

MULTIVAC Group

detection, container back-up and stalled container detection, along with an optional automatic rejection system to remove faulty containers from the production line.

Enercon Industries Corp.

reaching into the press.

Maxcess

SEAL THE DEAL

Designed to deliver superior sealing performance, the new Super Seal Pro induction cap sealer from Enercon Industries Corporation features the company’s advanced induction cap sealing technology with powerful new features for easier set-up, operation and troubleshooting. The new system features a user-friendly seven-inch touchscreen interface to provide operators with an intuitive experience, with the larger screed enabling advanced controls supporting remote, recipe and local operating modes, along with the addition of maintenance reminders. Compatible with a broad range of inspection and detection options for seamless mechanical and electrical integration, the Industry 4.0-ready system offers many powerful capabilities such as foil detection, high cap

MAXCESS ACCESS

Designed for automated tag-and-label and material web converting applications, the new Tidland RD AutoScore system from Maxcess offers automatic and repeatable trim width and cut depth positioning for score (kiss-cut) blades—optimizing job set-ups to improve safety, reduce downtime, and enable faster running performance with more types of material. According to Maxcess, the RD AutoScore provides quick and precise set-up of score blades, reducing set-up time, and allowing for consistent scoring of all liner materials, including film liners like PET plastic. Moreover, it also improves safety by eliminating the need for operators to make regular adjustments while

BOTTLE-READY

Designed for highly efficient handling of complex-shaped and unstable bottles, the new-generation Cermex ProSelex flexible collating system from Sidel is a gentle, streamlined grouping device compatible with any type of case-packe. Designed as an as an integrated module of a case-packer that is receiving products upstream from one lane, the new Cermex ProSelex continuously pitches, collates and prepares the container batches before they are transferred and case-packed at speeds of up to 300 products per minute. Designed to facilitate quick and easy changeovers, the module is perfectly adapted to cater to the secured handling of complex unstable shaped bottles and asymmetric containers common in the food, home and personal care industries.

Sidel

June 2023 · CANADIANPACKAGING 13

FIRST GLANCE The new UX2 InkJet Printer-Developed for Tomorrow’s production line Call us today for more details or to book a demonstration 1-877-427-5863 sales@harlund.com www.harlund.com QUICK CHANGE CONNECTORS ON BOARD VIDEO GUIDANCE CLEARER CODES & FASTER SPEEDS LONGER PRINTING CYCLES FIRST IN INDUSTRY SAFE PRINTHEAD CLEAN STATION CPK_HARLUND_SQ_MAY23_MLD.indd 1 2023-04-24 10:52 AM

Open Innovation a Path to Sustainability

By Lee Metters

By Lee Metters

As a society, we face a unique challenge that cannot be solved in isolation.The path to sustainable development involves addressing many economic, social, and environmental challenges.

This is no more evident than in the development of sustainable packaging solutions, which requires collaboration from the whole value chain including manufacturers, packaging providers, coding and marking suppliers, retailers, end users, and waste and recycling companies.

There is also a need for broader understanding and agreement on the definition of sustainability. As Dominic Oughton, principal industrial fellow, at the Institute for Manufacturing of University of Cambridge and leader of the Open Innovation Forum, comments: “Retailers have been

on a crusade to reduce the use of plastic packaging, which is of course a laudable initiative, but it needs to be balanced against the potential impact on food waste, and the carbon cost of volatile organic compounds (VOCs) in food, which is largely invisible.

“The overall sustainability effort is compromised when a decision to save 10 grams of packaging might well write off a kilogram of fruit,”

says Oughton, citing key factors such as:

• Scale. The packaging industry is vast and global, and achieving sustainable packaging at scale is a significant challenge that requires collaboration between different regions and stakeholders.

• Consumer behavior. Playing a critical role in the success of sustainable packaging, consumers need to be aware of its importance, understand how to recycle and dispose of it, and be willing to pay for sustainable packaging.

The concept of open innovation may run contrary to traditional business practices, whereby internal knowledge and expertise are typically held as a competitive differentiator or intellectual property, and innovation kept secret and closely guarded.

However, open innovation is crucial when developing for sustainability, whereby solutions are developed within the context of the entire value chain to make significant change and move in a way that benefits everyone.

The Open Innovation Forum is a consortium of food and beverage companies that includes major manufacturers and organizations across the food and beverage industry, including ingredients and materials suppliers, technology providers, brand-owners, retailers, and waste and recycling companies.

For Domino, working with the Open Innovation Forum provides a broader perspective and a series of contacts up and down the supply chain with which to develop solutions to the sustainability challenge.

Sustainability cannot be achieved in isolation. To address this system-level problem and make a substantial difference, we must look outside our businesses and collaborate and network with actors from the entire supply chain.

14 CANADIANPACKAGING · June 2023 ECO-PACK NOW

CPK_Tempo Flexible_June23_CSA.indd 1 2023-06-05 9:19 AM

LEE METTERS is the director of group business Development at Domino Printing Sciences in Cambridge, U.K.

Safely. We make Canada safer. A little bit every day. ™ Find out more: www.pilz.com/we-automate-safely Pilz Automation Safety Canada L.P. - Mississauga, ONWebsite: www.pilz.ca Email: info@pilz.ca Phone: +1 905 821-7459

PICKING UP STEAM

Being a one-brand company my seems like an outdated business strategy in these days of relentless new product launches and brand extensions, but for Toronto-based Steam Whistle Brewing, staying true to its roots is an idea that has recently come full circle.

By George Guidoni, Editor

By George Guidoni, Editor

Founded in 1998 at the outset of the game-changing craft beer revolution sweeping through Ontario and across North America, the company’s original Steam Whistle Pilsner has enjoyed fabulous market growth over the years,

enabling the company to outgrow its humble microbrewer origins to evolve into a highly competent and reputed Canadian beer industry stalwart with national market presence and resounding brand loyalty for its premium European-style pilsner product.

And while the flagship pilsner remained the company’s one and only brand for just over 20 years, the opening of a new production facility in Toronto’s west end five years ago provided an irresistible opportunity for Steam Whistle to diversify its product portfolio, as well as to launch a complementary co-packing business at the new site.

June 2023 · CANADIANPACKAGING 17 CANADIANPACKAGING.COM

Toronto brewer gets back to its founding basics with single-minded product focus and renewed passion for packaging excellence and innovation

COVER STORY

Steam Whistle Brewing plant manager Euen Miller displays some of the new innovative packaging created by the Toronto brewer in time for the busy coming summer season.

However, after launching several new beer brands into the market—including Steam Whistle Pale Ale , Session Lager, Lemon Shandy and Harvest Lager, among others—the company’s management found that this brand proliferation was beginning to dilute the brewer’s original focus on making the best possible pilsner product.

This realization prompted a recent decision by management to reverse course by “discontinuing our brand extensions and renewing our commitment ‘to do one thing really, really well’.”

As the company’s brewmaster Erica McOustra points out, “Making only one style of beer means you can possibly come close to perfection, because you’ve given yourself the time and opportunity to do so.

“The practice of doing one thing allows you to pick out subtleties of flavor and aroma, McOustra says. “You can explore the depth and elegance of each ingredient until you arrive at the ‘true expression’ of the Pilsner style.

“This is the difference between good beer and truly world-class beer.”

Because making a world-class beer typically requires world-class facility and equipment to brew and package it,” Steam Whistle has poured millions of dollars into equipping its new 35,000-square-foot plant with some of the best brewhouse and production machinery available in the market. On the brewing side of the plant, the facility’s tank-farm comprises:

• Wort production: A three-vessel 110-hectolliter brewhouse manufactured by Esau & Hueber;

• Beer fermentation: A total of 21

18 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM COVER STORY

Steam Whistle president Bromlyn Bethune says the company places a high premium on packaging innovation to draw attention by virtue of being a one-brand brewer.

Left Empty cans (background) entering the Krones filler in a single row for filling. Right Filled cans of beer coming out of the Ferrum seamer after being crowned with aluminum pull-tab lids.

The Krones Volumetric VOC can filler at the Steam Whistle Brewing’s plant typically fills about 1,500 cans per minute.

tanks—in 400-, 300- and 260-hectoliter capacities—manufactured by Highland Equipment Inc., Falcon Brewing Company and MacDonald Steel – HDP

• Beer ageing/maturation: A total of 13 ageing tanks—in 400- and 425-hectoliter sizes–supplied by Highland and Falcon.

• Beer filtration: A DE (diatomaceous earth) filter with 50- to 60- hl/hr capacity from Krones AG, along with a trap filter and a lenticular filter manufactured by Pall Corporation.

• Filtered beer storage: Three 600-hectoliter bright beer tanks from Highland.

On the packaging side of the plant, configured to accommodate three production lines—cans, bottles and kegs— the Steam Whistle facility employs:

• A Krones can filler for 355-ml and 473-ml cans.

• A fully-automatic bulk depalletizer, manufactured by Alliance Industrial Corporation, processing arriving empty cans at speeds of up to 1,500 cans per minute.

• A high-speed Quickflex cartoning system from Graphic Packaging International (GPI), for packing cans of beer into four-, six-, 12- and 24-pack cases.

• A fully-automatic Columbia Machine model HL2000 palletizer.

On the bottling line, the plant deploys a Krones bottle washer and a Krones filler—both handling 300 bottles per minute—and a Standard Knapp case-packer.

Employing 35 full-time and 20-parttime people on the production floor, the

Multi-sided views of the leading-edge Quikflex cartoning system from GPI, which can pack beverage and food cans, as well as glass and PET bottles, in a wide range of product sizes, pack configurations and package styles.

plant produces about 550 hectoliters per day over a three-shift, five-day-week schedule, with working Saturdays added during the peak summer season.

About 60 percent of the output is reserved exclusively for the production of Steam Whistle Pilsner, with co-packing accounting for the rest of output.

Cans account for 60 per cent of the total Steam Whistle Pilsner brand output, with signature-green 341-ml glass bottles for 20 per cent and kegs—available in five-, 20-, 30- and 50-liter sizes—for the remaining 20 per cent.

Available across most of Canada, Steam Whistle Pilsner is sold at various landmark entertainment venues, liquor board outlets, retail chains, grocers, local bars and restaurants in bottles, cans and as draught in most provinces.

According to the brewer, the GTA (Greater Toronto Area) accounts for about 70 per cent of the brand’s total sales, with rural Ontario for another 10 per cent, and the remaining 20 per cent split between British Columbia, Alberta and Quebec.

Primarily targeting younger men in the 25 to 55 age range bracket and women in the 25 to 35 demographic, the brand appeals primarily to urban, social-

June 2023 · CANADIANPACKAGING 19 CANADIANPACKAGING.COM

A view from above inside the newly-installed Quikflex cartoning machine form Graphic Packaging International that enabled the plant to eliminate single-use plastic wraps.

The ionized air line from R.E. Morrison used to clean the cans instead of water has enabled major reduction in water usage.

ly-conscious professionals with balanced lifestyles, healthy eating habits and a preference for stylish setting for their beer consumption outings.

“We strive to be the choice of beer for drinkers looking for an approachable, high-quality beer in the premium segment,” says Steam Whistle Brewing president Bromlyn Bethune. “We are the only true Canadian brand that can stake a claim as ‘Canada’s Beer.’

“Since the company was founded in 1998, we have been committed to our original vision of becoming the most respected premium beer in Canada,” Bethune states.

“Steam Whistle is uniquely positioned to compete against of the leading import and premium brands available in Canada,” she adds. “We have all of the aspirational qualities of leading European beers, while at the same time being authentically Canadian.”

Says Bethune: “The beer industry continues to be a competitive landscape: consumers have more choice than ever before, brewers continue to launch new innovations weekly, and RTD (ready-todrink) beverages continue to take space from the beer category as a whole in retail.

“Our brand really flexes between various categories of drinkers, from those looking for a great Euro-style Pilsner, import, premium and craft drinks alike.”

As Steam Whistle plant manager Euan Miller points out, quality control is a paramount priority for the brewer, both for its own brand and its co-pack customers.

“Our on-site QA (quality assurance) lab conducts hourly quality checks,” says Miller, “using statistical analysis to help us identify ways in which we can improve.

“We do all the required tests to ensure packaged product targets are met, including dissolved oxygen, carbonation, pH, fill volume, fill level, etc.

“We continuously track all the inci -

dents, hazards and near-misses,” Miller says, “and we have a joint health-andsafety committee performing monthly inspections and team meetings.”

Energy efficiency is another area where the Steam Whistle plant keeps making continuous improvements, according to Miller.

“We introduced an ionized air line from R.E. Morrison for cleaning empty cans before filling,” he says. “This replaced rinsing the cans with water, significantly reducing our water usage.”

“Moreover, the recent installation of the GPI Quickflex case-packer enabled

20 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM

COVER STORY

A single row of filled cans of Steam Whistle Pilsner moving by the Nordson hot-melt adhesive applicator integrated into the Quikflex cartoner to glue the carton flaps shut.

An angled view of the Steam Whistle-branded beer cases being formed and positioned for loading inside the Quikflex cartoner.

Steam Whistle Brewing brewmaster Erica McOustra keeping a watchful eye on the brewing process.

the canning line to switch from single-use plastic wraps to fully-recyclable cartonboard, Miller says, resulting in “less waste and increased packaging efficiency.”

As Miller elaborates, “Our brewhouse captures heat from outgoing brews to heat the water for the next brew.

“Our green bottle can be refilled more than 45 times, due to its thicker glass that doesn’t break, and because of the painted label on our bottles we save paper, color inks and glue from going into wastewater or landfill.

“We also have a cardboard baler a plastic baler for recycling,” Miller says, adding the company uses the services of Wasteco to recycle waste bottles, and Attar Metals for recycling empty cans.

Adds Steam Whistle’s marketing communications lead, Sybil Taylor: “In the last year, we got out ahead of coming government regulations that outlaw single-use plastics by removing our plastic-wrap machine and converting to cardboard packaging again for all our canned beer.

“The was a very significant project for us, from the equipment purchase and installation to the retooling of conveyors and the introduction of a new carton design.

“In fact, we have redesigned our cardboard boxes, trays and even our cans, making our Steam Whistle trademark front-and-center on all our packaging,” says Taylor, stressing the critical importance of packaging innovation for the company’s marketing strategy.

“When you don’t have new products to share,” she says, “one way to attract attention is by launching new packaging and gift packaging.

“We made a big splash this spring with our five-liter Mini Party Keg for Steam Whistle Pilsner,” she says, “which is the only domestic craft brew on offer in this 14-beer equivalent package.”

The brewer also partnered up with houseware product manufacturer Igloo Product Corp. to create Steam Whistle-branded IGLOO Playmate Cooler, which will be used in upcoming limited-time promotional campaign at the LCBO (Liquor Control Board of

Ontario) this summer.

And to mark last year’s acquisition of Beau’s All Natural Brewing, Steam Whistle will soon launch a special commemorative three-pack carton of Beau’s Lug Light brand containing a branded collectible beer glass.

As Bethune points out, “Consumers demand a lot from their brands, and it goes far beyond beer.

“So we are always looking for new ways to bring consumers in,” she says, “and format innovation can do that when you have a single-brand focus like Steam Whistle in a category known for never-ending choices.

“After two years of consuming cans or bottles at home, post-COVID is all about the experience we have been missing, enjoying that brewery-fresh draught beer at your neighborhood bar or favorite local restaurant,” Bethune remarks.

“Cold and convenience is where it’s at for Gen Z these days,” she states, “so we expect the can format, both 473-ml and 355-ml, continue to grow.

“We have also found that beer drinkers are also really looking for their tried, true and trusted brand, something they can count on, like their favorite pair of jeans,” Bethune adds.

“That continues to be a big branding and CPG (consumer packaged goods) trend,” she concludes, “and being a onebrand brewer fits into that perfectly.”

June 2023 · CANADIANPACKAGING 21 CANADIANPACKAGING.COM

Loaded cartons of Stem Whistle Pilsner cans exiting the Quikflex cartoning systems to make their way to the plant’s end-of-line packaging area.

A Ryson vertical spiral conveyor is used to move the loaded beer cases up to the plant’s mezzanine level for palletizing.

One of many SEW-Eurodrvie heavy-duty motors deployed throughout the Steam Whistle Brewing plant to ensure optimal power distribution to the facility’s conveyor lines and other production machinery.

Furlani Foods’ Head of Marketing, Jackie Brenkel, proudly displays the new award-winning packaging design. These new graphics were created for the company’s Furlani brand of ovenable bread products and were designed by leading Canadian branding and packaging design agency Davis.

BREAKING BREAD

Stunning new package design earns family-owned Canadian bakery industry accolades and instant market share gains

By Myles Shane

Headquartered in Mississauga, Ont., Furlani Foods is a remarkably successful family-owned bakery that specializes in specialty bread products such as garlic bread, garlic Texas toast, and various flavors of bread knots and breadsticks.

Operating three production facilities—one in Mississauga and two in Oak Creek, Wis.—the company enjoys a healthy market share and shelf presence at major retailers and foodservice operators across North America, which it has recently reasserted with a stunning new package design that may well be new golden standard for this highly competitive product category.

Launched in April 2022, the Furlani

brand’s new packaging—developed by leading Canadian product branding and design agency Davis—picked up the prestigious Best-in-Class Brand Marketing Revitalization Award in the 2023 PAC Global Awards competition in recognition of its new brand identity and packaging design.

Featuring cheerful food-forward photography, an updated wordmark, and a warm orange-and-gold color scheme that accurately projects the brand’s optimism, comfort and family friendliness, the new packaging was also updated to include a new QR (quick response) code that instantly connects consumers to helpful serving suggestions and recipe ideas.

According to Furlani Foods’ head of marketing Jackie Brenkel, the award-winning packaging design was created to better connect consumers

22 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM

PACKAGE DESIGN

with the brand’s mission “to transform everyday meals and take them to a whole new level.”

The new packaging design integrates key information such as product flavor, preparation time and nutritional claims on the principal display panel.

In addition, the new packaging also integrates different packaging materials and substrates from a diverse group of reputed packaging suppliers that includes Accord Carton (folding cartons), Graphic Packaging International , Interflex Group

(bake-in-bag foil), Precision Colors, Pentaflex (bake-in-bags) and Tempo Flexible Packaging (polybags).

For South African-born Brenkel, who collaborated with Davis vice-president and creative director Mark Roberts on the new design, the PAC Global Award is aresoundingvalidationofthecompany’s appreciation of packaging as a highly effective marketing competence.

“We were delighted to receive this PAC Global packaging award, the second ever to be bestowed on Furlani Foods,” said Brenkel in a recent inter-

view.

“The award recognized the impact of our new family-friendly packaging design and its ability to transform the garlic bread category,” says Brenkel, who moved to Canada over 30 years ago.

Describing herself as an experienced award-winning CPG (consumer packaged goods) marketer, Brenkel has built up an impressive professional track record working at well-known Tier One CPG companies like ConAgra, Henkel, Kraft Foods, Nestlé, Corby Distilleries and

June 2023 · CANADIANPACKAGING 23 CANADIANPACKAGING.COM

Seagram Spirits and Wines.

Clockwise: The vibrant new package design for Furlani Foods’ flagship Furlani brand earned the company a 2023 PAC Global Award in the Brand Marketing Revitalization category; close-up of the Woodman Appache Bagger machine used to package some Furlani brand products inside flexible packaging; finished bags of product await pick-up at the accumulation table; neat rows of freshly topped Furlani Garlic Texas Toast entering the oven at the company’s production facility in Mississauga, Ont.

“I have led projects in various highly competitive categories,” she says, “including frozen meals, desserts, pantry items, snacks, beauty, and beverage alcohol.”

For his part, growing up as a son of a mechanic provided Mark Roberts with a keen appreciation of all things design-related early on in his working life.

“I joined Davis almost 30 years ago as an intermediate designer,” Roberts says.

“I grew with the company as it evolved from a Canadian-centric packaging design company to a North American and global integrated agency, working with a far-reaching breadth of clients from start-ups to the world’s leading brands,” he says, citing an impressive list of clients that include Arterra, Canadian Tire, McCormick, ConAgra, Kraft, Heinz, Corby and, of course, Furlani.

As Roberts explains, being a part of Davis’ continuous growth and evolution into a formidable player in the package design world—along with its sister

Above

Furlani knots are carefully crafted to provide the perfect combination of crispiness and softness in a fun knot shape, for a perfect pairing with saucy entrees, dips or soups.

agency Bridgemark—has been a highly rewarding and gratifying professional experience.

“Davis was the original company, built by Glenn Davis starting in 1971,” he relates. “Over the years of growth, we found ourselves in scenarios where we had to turn work away due to mergers and acquisitions of brands and other companies.

“Our solution was to form a completely separate agency, in 2007, that was staffed with some of the people from Davis,” he explains.

“This ensured consistent quality control, a similar product output and the ability to service more clients,” says Roberts, adding that both Davis and Bridgemark operate as separate but related agencies under the Glenn Davis Group corporate umbrella.

According to Brenkel, one of the prime reasons why Furlani decided to undertake a major packaging redesign was to unify and streamline its various individual brands under one distinct, re-energized Masterbrand with the same look and feel across North America.

As Brenkel explains, “The need for revitalized creative stemmed from the

updated brand positioning and key consumer insights.

“We did a lot of research that informed our new packaging design,” Brenkel states.

“The evolved branding communicates what makes Furlani special—bringing consumers delicious products of the highest quality, while speaking to meal makers through fun and joyful visual language.

“So we repositioned the brand to promote the fact that it’s good mood food,” Brenkel elaborates.

“This is an important step in the branding process, as it ensures that the new look resonates with the target audience and effectively communicates the brand’s values and key messaging.”

According to Brenkel, any new design had to succeed in effectively projecting Furlani Foods’ commitment to delivering high-quality products by using visual language that would create and reinforce a positive association with the brand.

For his part, Roberts was also convinced that Furlani Foods’ retail products were also due for some special

24 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM PACKAGE DESIGN

Furlani Foods head of marketing Jackie Brenkel cheerfully holds up the 2023 PAC Global Award alongside Mark Roberts, creative director at branding agency Davis.

branding upgrades.

“My thought with any successful brand is that over time, decisions are made with hasty speed, which can create disparity amongst all the offerings,” he says.

“At some point, companies need to take a step back and unify the overarching look of the brand,” he says, “so that it can be seen more as a leader than a commodity.”

From early on, Davis and Furlani Foods worked closely to establish clear goals and objectives for the redesign of the brand—starting with basic sketches and theories in the early stages and moving on to refine and improve the evolving design collaboratively.

Throughout the process, they tested their theories with consumers and shared the design with internal stakeholders at Furlani.

Says Roberts: “The team followed simple rules of communication, ensuring that the brand clearly communicated who they are (Furlani), what they offer (garlic toast), and why they are a unique choice (flavor and convenience).”

As he explains, the new brand identity and packaging identity of the Furlani brand were a major part of brand restage.

“It breaks away from the mundane and static food photography that is so common in the category,” he reflects.

Brenkel concurs, noting that the bright color scheme is unique to this Furlani brand, while creates an unmistakable beacon across both the fresh bakery and frozen aisles inside the grocery stores.

Roberts agrees that the standout imagery used in the new design aptly captures the brand’s belief in “setting the mood before you set the table.”

As he reiterates, the new Furlani packaging design emphasizes the

Vibrant comforting colors and striking product imagery provide instant shelf impact and strong strong differentiation for the entire Furlani portfolio, both in Canada and the U.S.

brand’s uniqueness, captures the brand’s core values, and sets it apart from category competitors by using technology to bring consumers ever closer to the brand-owner.

Strategically located on the packaging’s backside, the QR code instantly connects consumers to an extensive collection of Furlani recipes on the company’s website, which has seen a big increase in traffic since its introduction, according to Brenkel.

Just as important, the product information on the front panel has also been expanded to include preparation time, nutritional information, and whether the product contains any artificial colors or flavors.

In addition to being visually engaging and informative, the new design has also done a masterful job of having all the different substrates used to make it seamlessly work together in one highly functional structure that also addresses consumers’ growing concerns about packaging sustainability.

According to Brenkel, all the folding cartons used to pack Furlani products are made from 100-recycled fiber with 60-percent PCR (post-consumer recycled) content, while fully meeting the Recycled Paperboard Association (RPA) and the Forest Stewardship Council (FSC) certification standards for responsible forestry management.

With the whole package redesign

product taking about six months to complete, the early market reception to the new packaging suggests it was time very well spent.

As Brenkel confides, the sales of Furlani Garlic Texas Toast have increased by a healthy 5.3 per cent since the launch of new packaging, while the sales of Furlani Garlic Bread have soared by a remarkable 25.2 per cent.

With growing sales and volumes across the entire brand range, Brenkel says the Furlani brand is starting to reach unprecedented popularity and brand loyalty levels with consumers across both Canada and the U.S.

“The new packaging has a confidence that exudes the pride of the people who make it—it really stands out,” she states.

“It is now unified across North America, and the newly-created assets provide us with the breadth to grow our communication beyond packaging for years to come.

“The highlight of our work solved not only the immediate need of unification and greater shelf impact,” she asserts, “but it also future-proofs the brand by being so uniquely distinct from our competitors.”

“Importantly, it sends a clear message to consumers that Furlani products bring joy to everyone at the table,” Brenkel concludes. “The new Furlani packaging design makes the brand even more relevant to its audience.”

June 2023 · CANADIANPACKAGING 25 CANADIANPACKAGING.COM

Reducing Total Delivered Cost for Food Manufacturers with Product Inspection Equipment

With profit margins being squeezed, operations managers in food manufacturing need to make a robust business case to secure additional capital expenditure for processing and packing equipment. To support this, Total Delivered Cost (TDC) is among the latest metrics utilized for the measurement of business performance.

This eGuide illustrates how technological advancements in product inspection equipment, notably metal detection and X-ray inspection, can provide support in reducing TDC.

This can be achieved through:

• Reducing the frequency of equipment testing

• Automating the physical test procedures

• Minimizing instances of false rejects

• Utilizing advanced software to optimize power usage and equipment set-up times

Download the eGuide to learn more about how you can reduce TDC by increasing process efficiency and improving product quality www.mt.com/ca-reduce-TDC-eGuide

26 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM

Systems marketing specialist Matthew Pereira strikes a pose at the foot of a towering Ryson vertical spiral conveyor installed as part of a comprehensive warehouse automation systems upgrade at the Carquest Auto Parts distribution center in Bolton, Ont.

UPWARDLY MOBILE

By George Guidoni, Editor

As the growth in e-commerce continues its relentless transformation of everyday life in many consumer and manufacturing industries, the need for warehousing and logistics automation has never been more urgent for countless commercial enterprises dependent on reliable, responsive and smooth-running supply chains to deliver their products to market.

And as the recent global COVID-19 pandemic painfully demonstrated, taking supply chains for granted is often an invitation to chaos and catastrophic disruptions to normal economic activities in business and consumer sectors alike.

But for companies like Mainway Handling Systems, a family-owned conveyor systems integrator and manufacturer based in Burlington, Ont., helping to keep the wheels of commerce spinning despite the current supply chain challenges and overhauls is the proverbial opportunity of a lifetime to establish itself as an elite Canadian warehousing and logistics expert par excellence

Founded in 1988, the family company started out as provider of systems design, installations and integration services for several key logistics industries, including:

• Warehouse and Distribution (e-commerce, order fulfillment);

• 3PL (third-party logistics) and logistics (middle mile, final mile);

• Freight and Parcel (courier, cargo);

June 2023 · CANADIANPACKAGING 27 CANADIANPACKAGING.COM

Ontario conveying systems specialist reaches new heights of customer service excellence with in-house expertise and proactive peer collaboration

CONVEYING

Mainway Handling

• Food and Beverage (packaging, post-manufacturing);

• Automotive and Manufacturing (assembly lines and OEMs).

Building up a solid industry-wide reputation for providing effective leading-edge customized solutions for businesses across these key sectors, the company has grown from strength to strength over the years—recently moving its operations to a bigger new facility, including a 10,000-square-foot warehouse, to accommodate its growing staff of 25 full-time employees and a fairly extensive product inventory.

“The new building houses our sales, project management, estimating, design, marketing, engineering, and the manufacturing and assembly of our automated conveyors,” says Mainway Handling’s marketing specialist Matthew Pereira.

“We do have an in-house service team comprising electricians and technicians, but they mostly work on-site along with our project managers.”

According to Pereira, that fact that a company of such relatively small size is consistently called upon to execute complex logistics projects for some of the biggest names in the distribution business—including Decathlon ,

Book Depot , Loomis , Canpar , Ikea and Yusen Logistics speaks volumes about the level of its in-house expertise and customer service excellence.

As Pereira relates, “From start to finish, Mainway excels at providing complete turnkey integrated systems.

“We take pride in our ability to design an efficient system utilizing several key partners and innovative technologies in warehouse automation, being able to provide customer-specific solutions.”

To complement its extensive service capabilities, Pereira notes, “In the last three years we have designed and started manufacturing or one line of motor-drive roller (MDR) conveyors, with a lead time of 10 to 12 weeks.

According to Pereira, Mainway is particularly proud of this accomplishment, as the company

found it difficult to acquire reliable delivery times for these types of conveyor in Canada.

Moreover, the majority of automated conveyors sold within Canada are exported from the U.S. “By producing our own conveyors, we are able to ensure product availability in the event of future supply chain disruptions,” he says.

Moreover, being able to carry the ‘Ontario Made’ seal on its conveyor, indicting that Mainway sources the majority of its materials within the province, is a strong selling point.

“Now Canadian organizations can look to Mainway as their ‘goto’ supplier for turnkey warehouse solutions,” Pereira states.

According to Mainway, the company’s flagship Mainway MDR (motorized drive roller) run-on-demand, zone-controlled conveyors have already proven to

be highly efficient, reliable and flexible conveying solutions at multiple customer sites.

“With current lead times reaching up to a year in some cases, and shipping costs doubling or tripling in some cases, it made sense for us to have our own conveying manufacturing on-site, enabling us to have more control over the quality and delivery of our product,” Pereira explains.

“We see tremendous growth opportunities in both the Canadian and U.S. markets,” he adds, “as out goal is to expand our MDR conveyor offering to become a leading Canadian conveyor supplier.”

In addition to bringing its own expertise and know-how to the table, Mainway has also benefited from collaborating with leading material handling systems manufacturers, such as Ryson Inter-

28 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM CONVEYING

Anchored to the four-level pick tower installed by Mainway Handling, the heavy-duty Ryson vertical spiral at the Carquest Auto Parts facility reaches upwards a staggering 38 feet in height.

The Ryson vertical spiral is outfitted with proprietary rolling friction belt technology to ensure that the transferred products remain safe and stable at all stages of the conveying process.

“By producing our own conveyors, we are able to ensure product availability in the event of future supply chain disruptions.”

national Inc. , to provide full turnkey material handling solutions for its clients.

Operating out of a 50,000-square-foot facility in Yorktown, Va., Ryson specializes in manufacturing heavy-duty vertical conveyance systems—primarily spiral conveyors and bucket elevators—and ancillary equipment, producing an average of 500 machines per year.

As part of the globally operating Royal Apollo Group , headquartered in The Netherlands,

Ryson primarily serves customers in North and South America, with CPG (consumer packaged goods) companies—particularly in the food-and-beverage sectors—and logistics providers accounting for most of its installations.

Available in a broad assortment of application-specific configurations—including unit load, mass flow, high-capacity, wide-track, narrow-track, dual-track and multiple exit/entry versions— Ryson spirals are a common sight at many fast-paced North Amer-

ican manufacturing, warehousing and distribution facilities with limited floorspace availability.

With their compact footprint and far greater speeds compared to traditional elevators or lifts, Ryson spirals offer a highly-efficient and reliable means of transferring mass quantities of product wherever it’s needed in the manufacturing process or on the packaging line.

Outfitted with proprietary slattype belts with rolling friction and without any sliding movements or

wear-strips, the modular Ryson spirals can be tailored to fit virtually any space or application requirement, according to the company’s technical account manager Taoufik Haddadi.

“Our modular design allows the equipment to be reconfigured at a fraction of the cost of a new spiral when layouts change,” Haddadi says, “while benefiting OEMs and integrators because it allows flexibility in layouts.

“Another key element to our spirals’ uniqueness is the fact that

June 2023 · CANADIANPACKAGING 29 CANADIANPACKAGING.COM

A close-up view of the Ryson vertical spiral conveyor from the top level of the four-level pick tower installed by Mainway Handling.

A Mainway MDR (motorized drive roller) conveyor manufactured by Mainway Handling is used to transport heavy loads onto the Ryson spiral.

As part of the automation upgrade project, Mainway Handling deployed several types of signature-yellow Cognex scanning equipment for quality control and process verification functions.

Mainway Handling has installed hundreds of feet of its heavy-duty MDR conveyor belts in a tightly synchronized conveying network linking the entire 500,000-square-foot Carquest Auto Parts facility.

the conveying surface relies on rolling friction rather than sliding,” he adds. “This allows the Ryson spirals to handle heavy loads, to start and stop even when fully loaded, and to have a very low noise level.

“All of our spirals are custom-configured with standard components to match layout needs,” Haddadi points out. “Because all our company functions are co-located at our facility, we have access to everything needed to provide technical support and service to customers—be they integrators, OEMs or end-users.”

All these factors came into play in a big way during Mainway Handling’s recent major project involving installation of a towering 38-feethigh Ryson spiral as part of a sweeping warehouse automation upgrade at the vast Carquest Auto Parts distribution center in Bolton, Ont.

Carrying a massive fast-moving inventory of automotive parts, fluids and countless related accessories, the 597,000-square-foot warehouse provided plenty of opportunity for Mainway and its partners to showcase their competencies and skillsets.

“There is a high level of custom-

ized components, units and systems that go into every project, as no two warehouses are alike,” notes Pereira.

“For the Carquest project, we built a four-level pick tower integrating several partners and systems, including a multi-belt sorter, the 38-foot Ryson spiral, our own Mainway MDR conveyor, and a multi-sided scan tunnel,” Pereira reveals.

“To make optimal use of all the available warehouse space, we incorporated hundreds of feet of our conveyor around the facility, which was mounted to the floor along with the ceiling, connecting the entire warehouse.”

Says Pereira: “We have had a great relationship with Ryson for many years due to their quality and consistent work.

“We always look to them when we need a condensed system that is robust enough to convey high volumes and heavier products, like the one anchored at the back of the four-level pick tower,” Pereira elaborates.

“We found that installing a pick tower with automated conveyor and a Ryson spiral enabled us to handle the majority of their product count while keeping a fairly small footprint, in addition to handling a wide

range of product weights—from wiper blades to disk rotors,” Pereira extols.

“As a complete systems integrator, Mainway relies on suppliers like Ryson to provide equipment for systems such as the one at Carquest.

“Being able to integrate the spiral as one piece to the puzzle at Carquest, along with various other types of conveyors, steel structures and the scanning system, has allowed Carquest to not only meet their demands today, but also to grow with them in the future.”

As Pereira relates, all of the projects commissioned by Mainway Handling are strongly supported by value-added follow-up services that include emergency repairs, preventative maintenance, and parts supply.

“We have a highly competent inhouse service team comprised of electricians and mechanical technicians, which allows us to provide preventative maintenance and emergency repair services.”

Says Pereira: “We are continuing to see more adoption of automated systems in our markets, as continued growth in e-commerce and speed of shipping/delivery demands have made automation a necessity in many cases.

“Given the recent challenges of soaring real estate costs, many companies are now looking for ways to pivot and best utilize the resources they have now.”

As Pereira concludes, “We want to ensure that Mainway Handling is always looked upon as a trusted partner to tackle any warehouse challenge, while allowing companies to focus on their core business and customer satisfaction.

“We believe that being able to provide that appropriate solution for our customer is the key to our own prosperous future.”

SUPPLIERS

Mainway Handling Systems

Ryson International, Inc.

30 CANADIANPACKAGING · June 2023 CANADIANPACKAGING.COM CONVEYING

One of a series of high-performance SEW-Eurodrive motors deployed to provide precise power distribution for energy-efficient operation of the Ryson vertical spiral conveyor.

The sleek Ryson vertical spiral conveyor was custom-tailored to meet the exacting specs and requirements of the Carquest Auto Parts distribution center in Bolton, Ont.

From left A Friendlier Company co-founders Kayli Dale and Jacquie Hutchings at their company’s head office in Guelph, Ont., which also serves as the innovative start-up‘s central hub for sales and marketing, R&D, product testing, and planning.

FRIENDS FOR LIFE

Young Ontario entrepreneurs on a mission to eliminate single-use plastic packaging in Canadian foodservice with reusabe takeout containers

By George Guidoni, Editor

You can never have too many friends in the sustainability business, and the sheer pace and success with which A Friendlier Company (AFC) is making friends in all the right places is a truly exceptional tale of how Canada’s younger generation plans to address the world’s plastic pollution crisis with entrepreneurial zeal and purity of purpose.

Launched in October of 2020 by University of Waterloo graduates Jacquie Hutchings and Kayli Dale, the Guelph, Ont.-based company is on a mission to make single-use food takeout containers a thing of the past through a unique service that provides restaurants and foodservice operators with high-quality, durable reusable containers through an app-driven deposit-return program designed to encourage reuse of the company’s distinct takeout containers by 100 times.

Partly inspired by the federal government’s ban on many single-use plastic

products, AFC has quickly attracted numerous local foodservice operators to sign up for the service, which not only saves them money—compared to other ostensibly sustainable takeout options—but also fosters strong consumer loyalty among their customers by making them willing participants in the ongoing war on plastic waste.

“The initial response to our reuse system has been incredible and demand has been increasing rapidly,” says AFC co-founder and chief executive officer Hutchings, who met Dale while studying chemical engineering in university.

During the third year of their studies, the two schoolmates traveled to Sweden on a four-month co-op posting, where they learned a great deal about the Circular Economy, minimalism and sustainable design.

While in Europe, the two familiarized themselves with some long-cherished circular concepts—such as reusable mugs for mulled wine at outdoor Christmas festivals and reusable beer cups at rugby matches—

June 2023 · CANADIANPACKAGING 31 CANADIANPACKAGING.COM

SUSTAINABILITY

deciding to introduce similar principles to the North American marketplace upon their return.

“We knew that North American consumers were more convenience-driven than those in Europe,” Hutchings says, “so we came up with the Friendlier concept to make reuse convenient.”