THE NOW GENERATION CANADIANPACKAGING.COM MARCH 2023 / $10.00 CPMA Q&A Page 15 Packaging for Freshness Page 33 Foil Stamping Page 38 Greenhouse operator aims to grow in leaps and bounds by riding the health-and-wellness wave Story on Page 18 FRANCIS TERRAULT, OPERATIONS MANAGER - LETTUCE, LES SERRES LEFORT SHOW PREVIEW April 25-27, 2023 Page 30

Mar. 19-21, 2023

Booth 818

Orlando, Florida USA

CANADIANPACKAGING.COM

Videojet 1880 Continuous Inkjet Printer Enabling Industry 4.0 productivity pioneers Discover more at videojet.com/1880 The Videojet 1880 CIJ printer builds upon comprehensive insights gained from the fleet of cloud-connected Videojet printers, the largest in the industry, to help in your journey towards Industry 4.0. Not only does the 1880 enable exceptional uptime, it is expressly designed to help your team improve productivity and drive lower costs over the lifetime of the printer. Harness the collective intelligence of 10,000 cloud-connected Videojet printers to help keep your lines ©2023 Videojet Technologies Inc. All rights reserved. Videojet Technologies Inc.’s policy is one of continued product improvement. We reserve the right to alter design and/or specifications without notice.

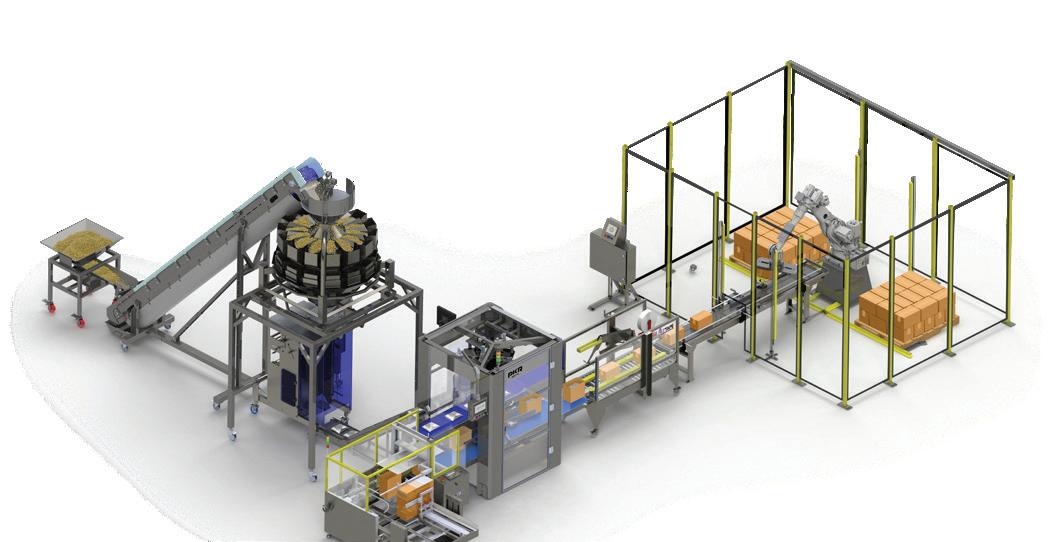

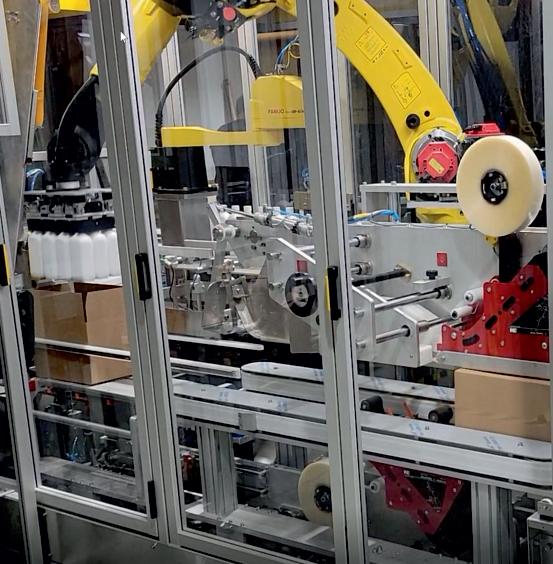

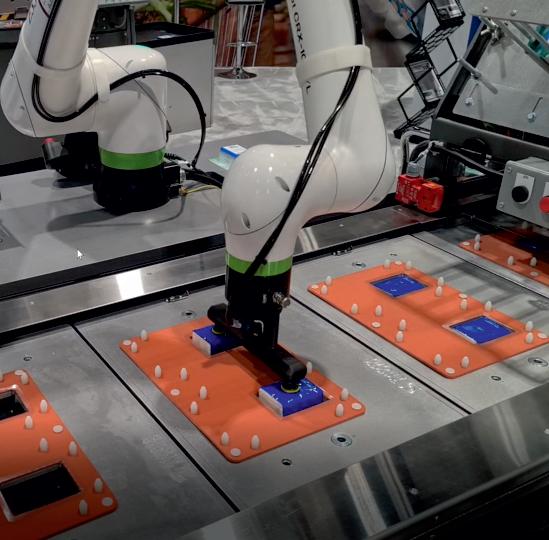

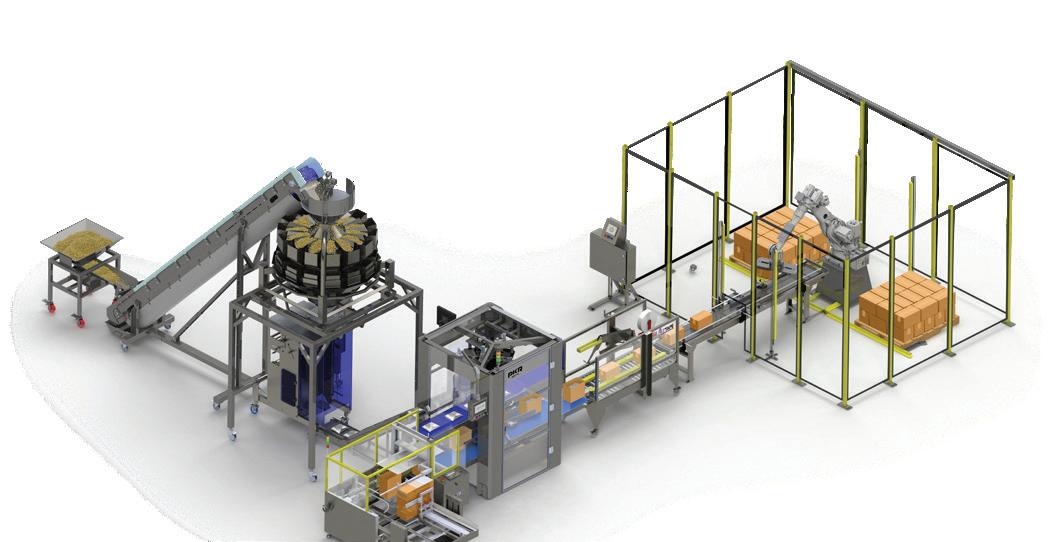

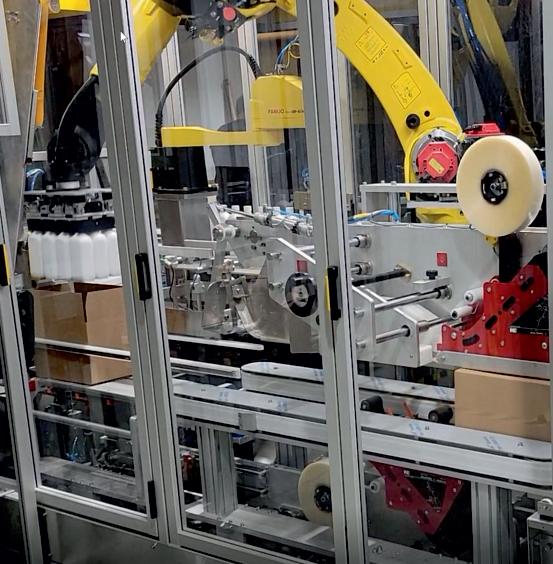

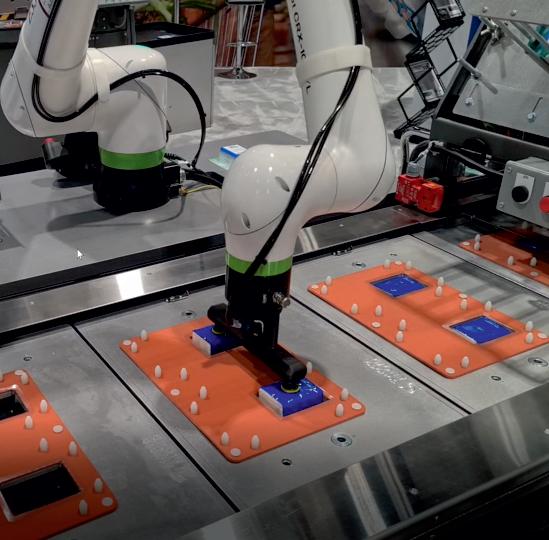

Vision Guided Pick & Place Cell

2 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM

Up to 24 hours per day

No vacations

No workers comp

No insurance

No sick days

No attitude

PKR-Delta #ReadyToWork •

•

•

•

•

•

at: $14 per hour single shift $7 per hour double shift $4.66 per hour triple shift *Investment adjusted to approximate hourly wage over 5 years 1.833.4PAXIOM PaxiomGroup PaxiomXperience Watch video at paxiom.com Pre-roll Weighing FillingBaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing LAS VEGAS • MILWAUK EE • MIAMI • TORONTO • MONTREAL • SCHIO, ITALY

Starting*

DEPARTMENTS

NEWSPACK

6-9 Packaging news round-up. NOTES & QUOTES

10 Noteworthy industry briefs.

FIRST GLANCE

11 New packaging solutions and technologies. ECO-PACK NOW

12 Sustainable packaging innovations. IMPACT

13 A monthly insight from PAC Global. EVENTS

46 Upcoming industry functions.

ISSN 0008-4654. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2023 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

COVER STORY

18 HIP TO BE GREEN

Enterprising Quebec greenhouse operator setting its sights on younger consumer demographics to keep the family-owned business on firm upward growth trajectory with updated brand messaging and increasingly vogue local producer credentials.

FEATURES

15 Grow Forward

CPMA president Ron Lemaire shares his thoughts about the currrent state of the Canadian fresh produce industry and its upcoming challenges.

30 Growing Gains

Your preview to the annual CPMA Convention and Trade Show in Toronto next month.

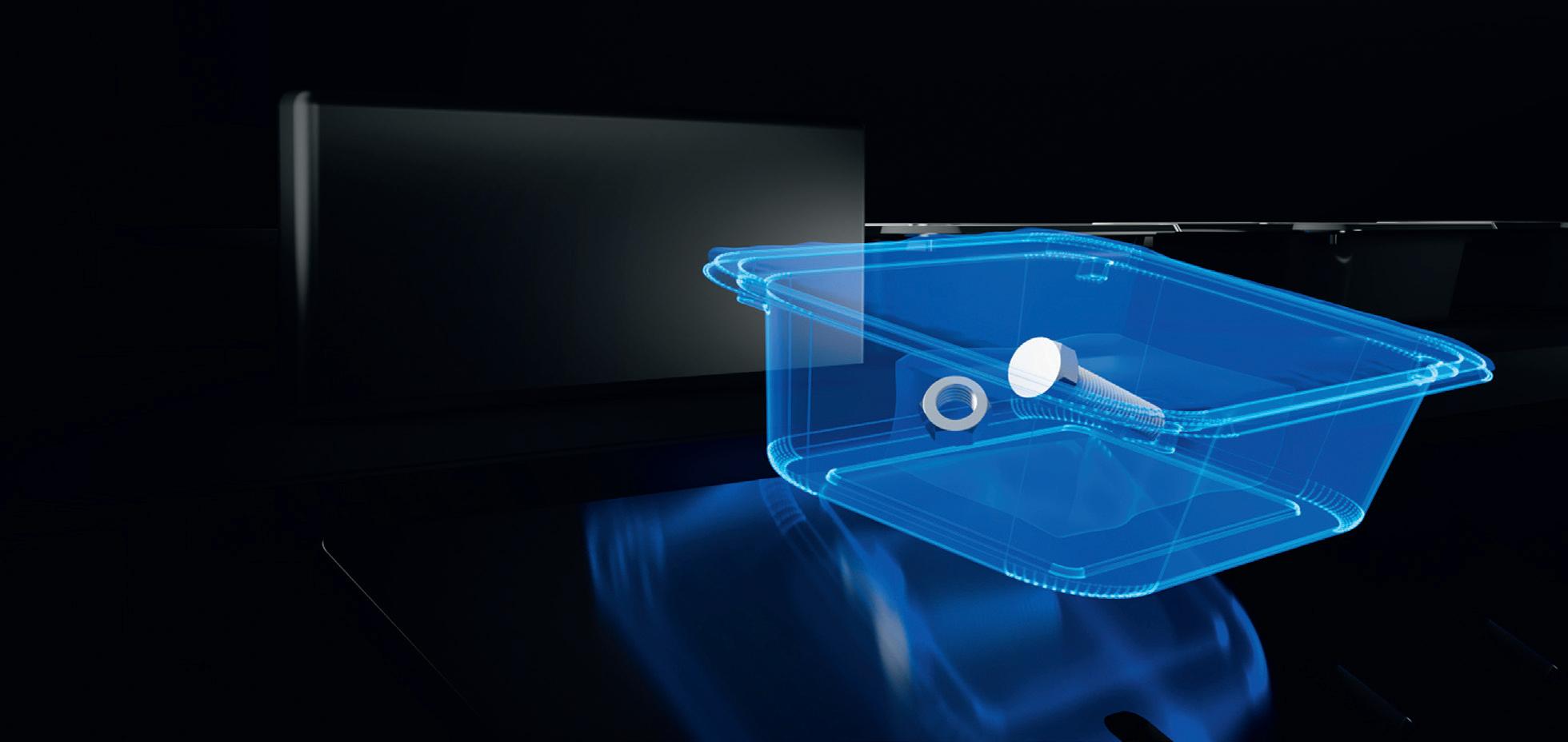

33 Making Dough

Timely investment in thermoform packaging technology helping pizza dough manufacturer make assertive entry into the retail marketplace.

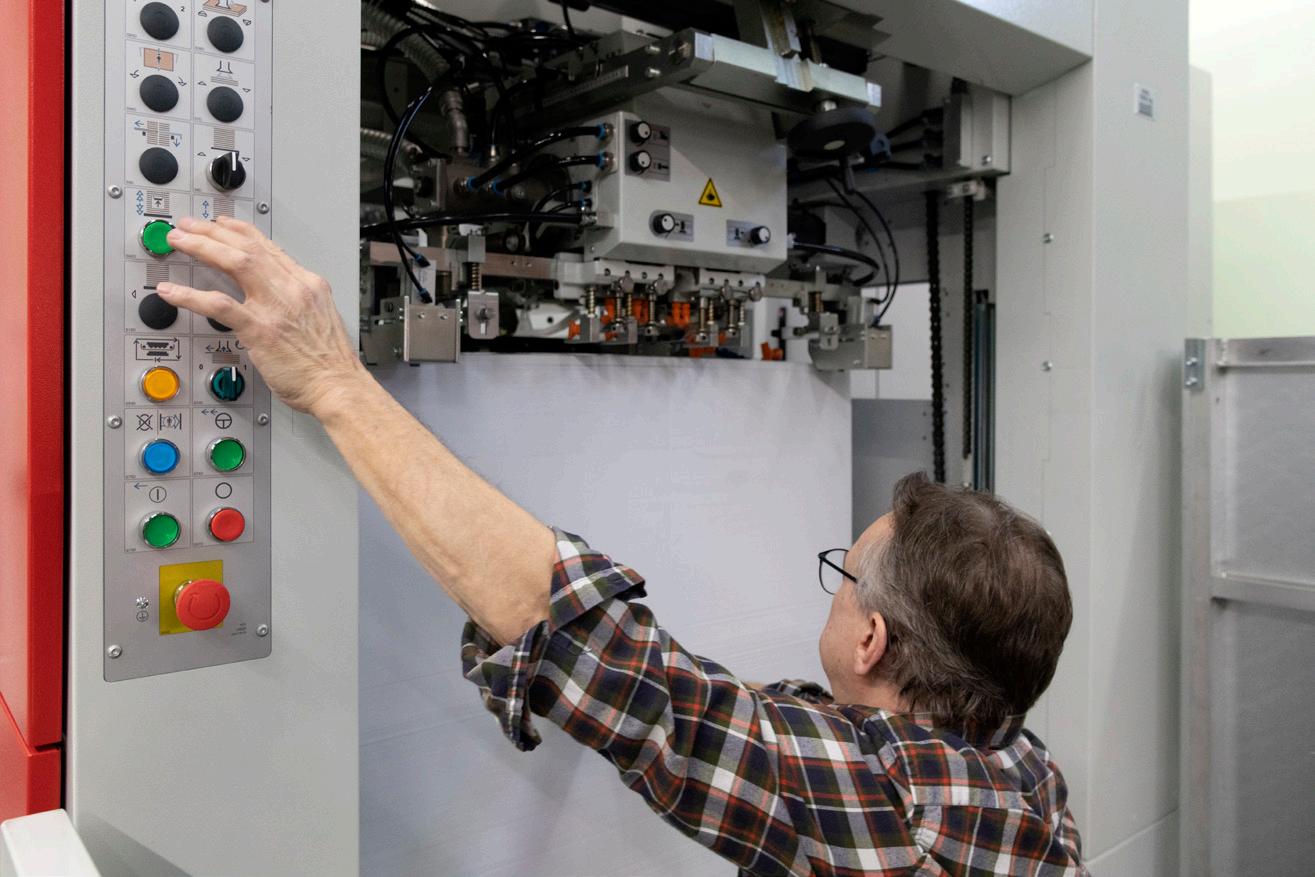

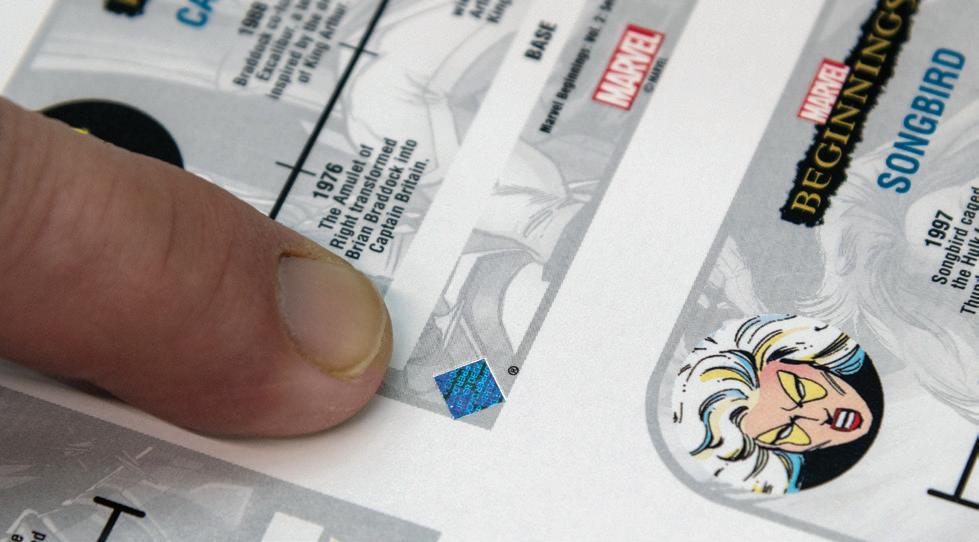

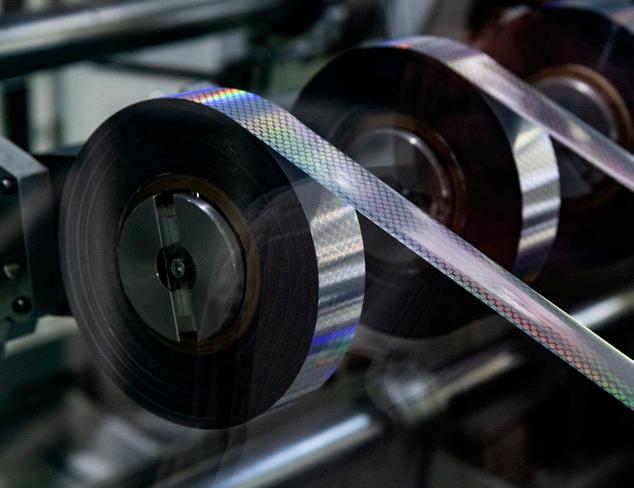

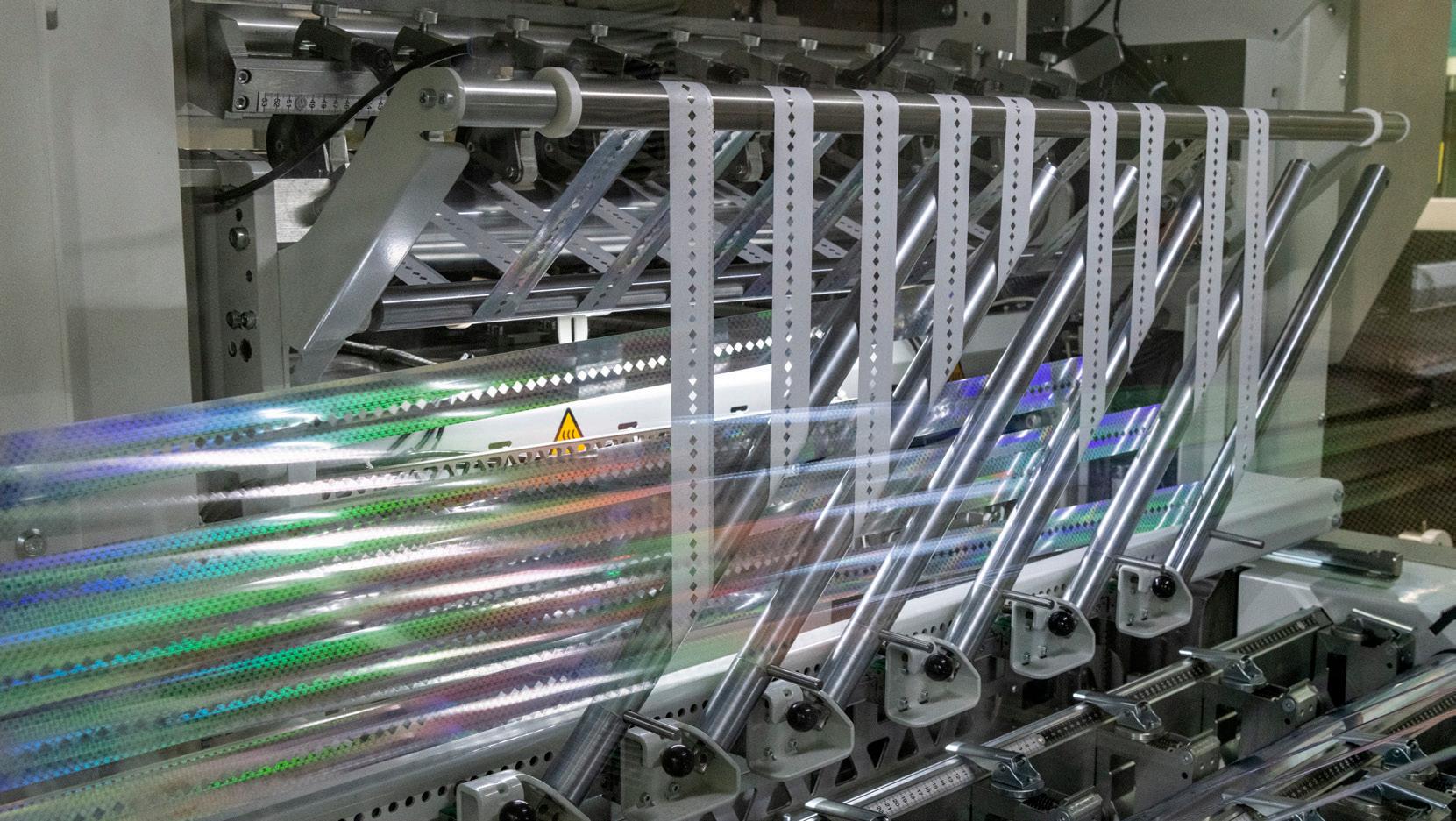

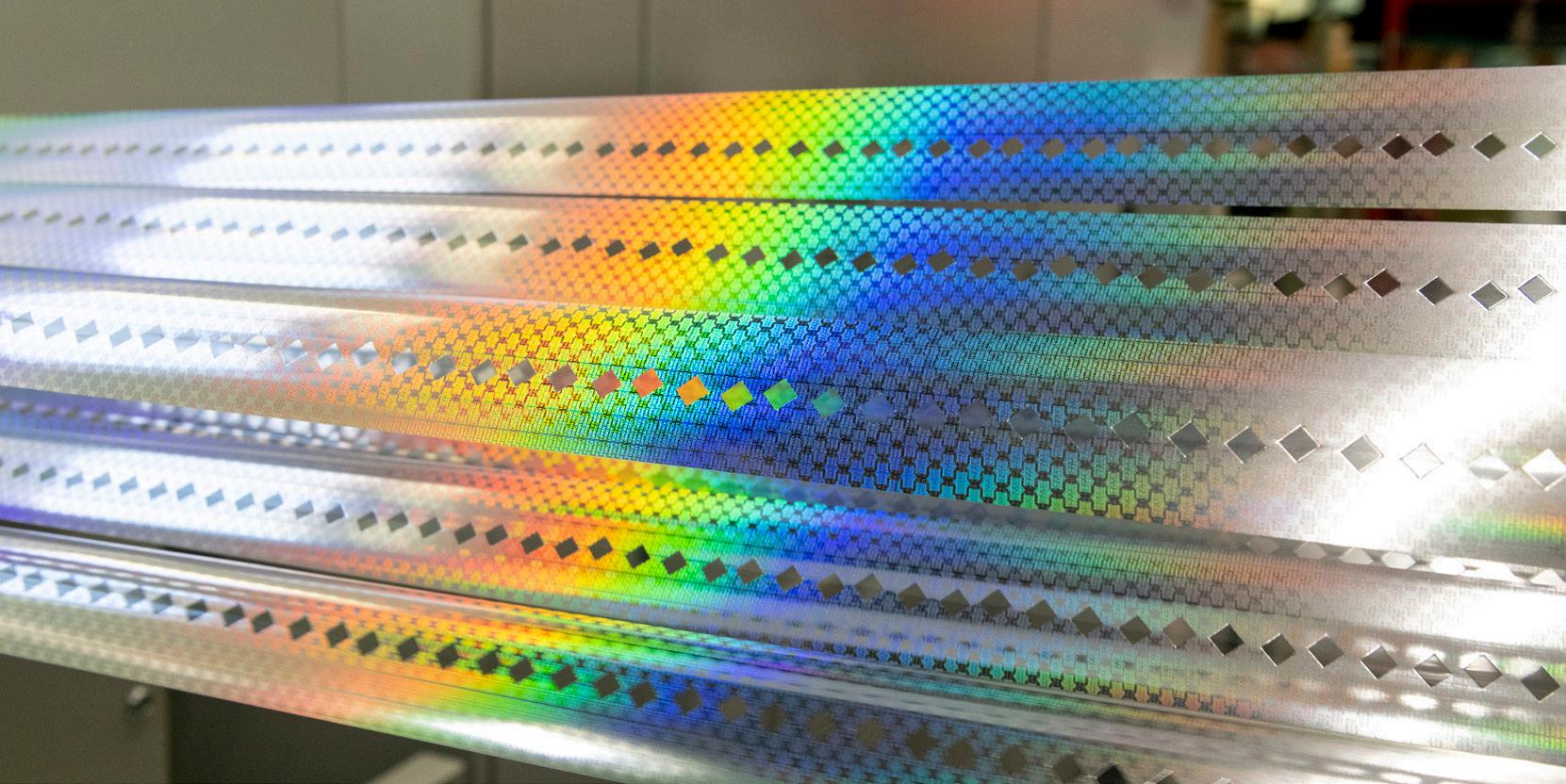

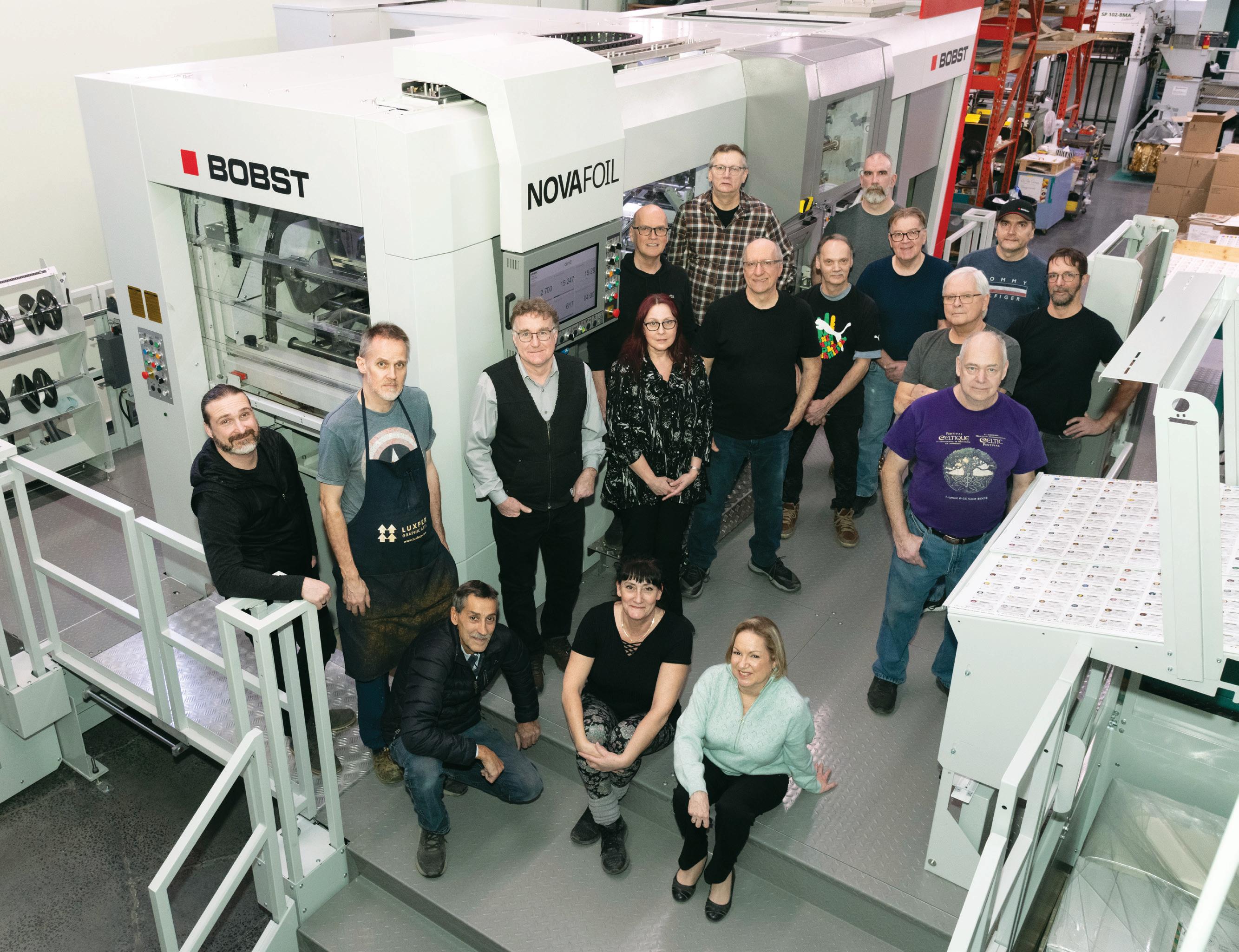

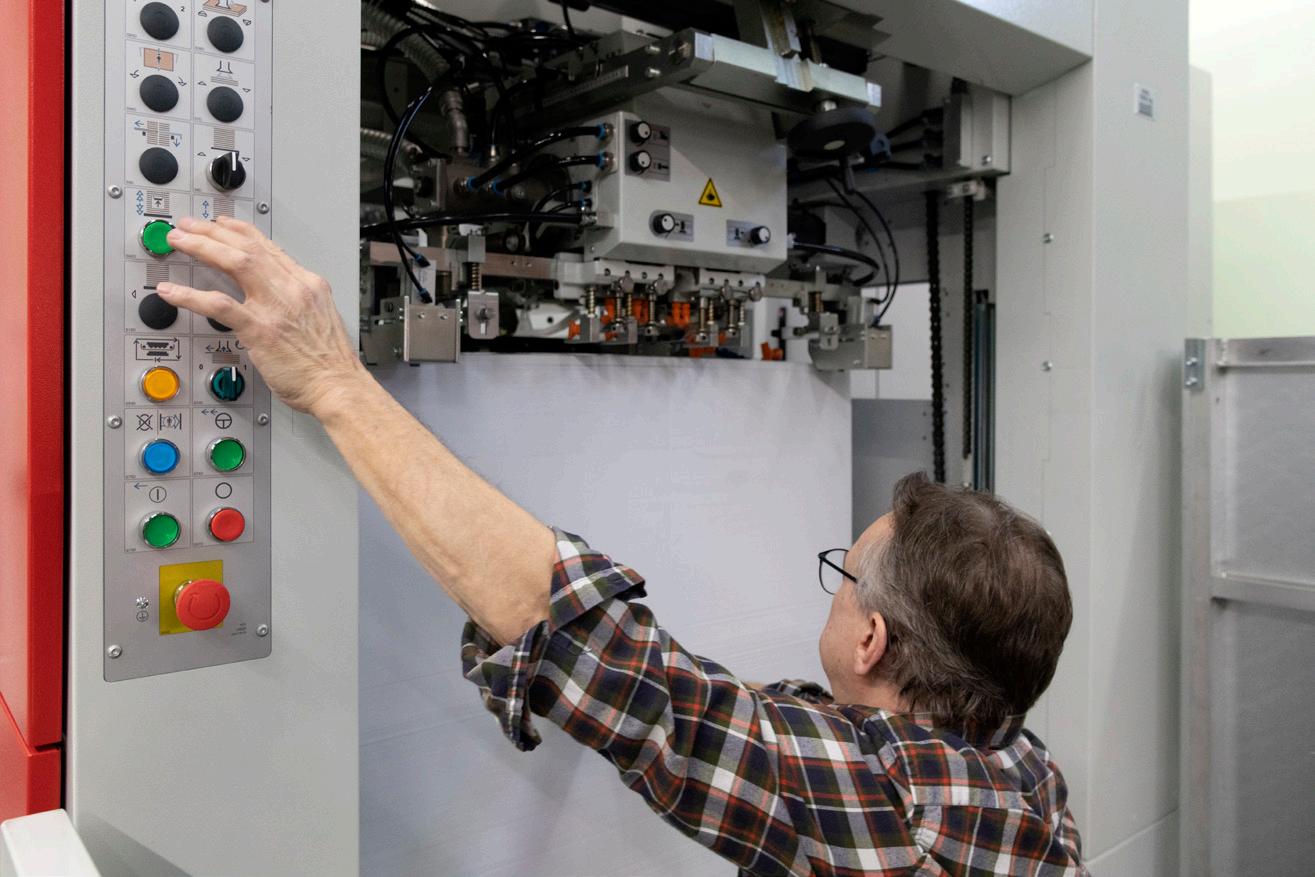

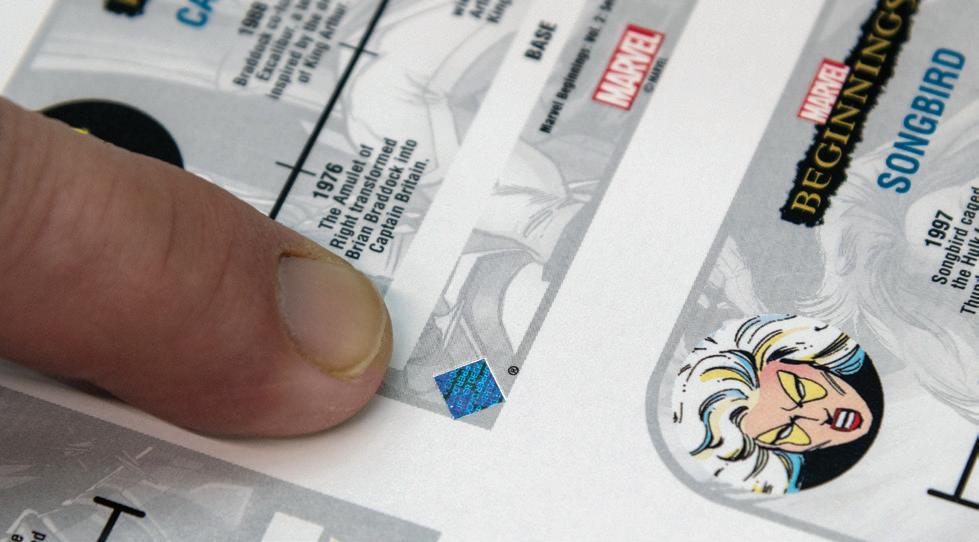

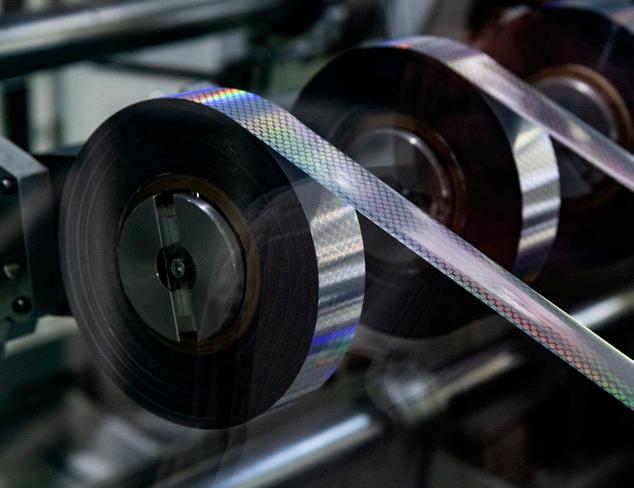

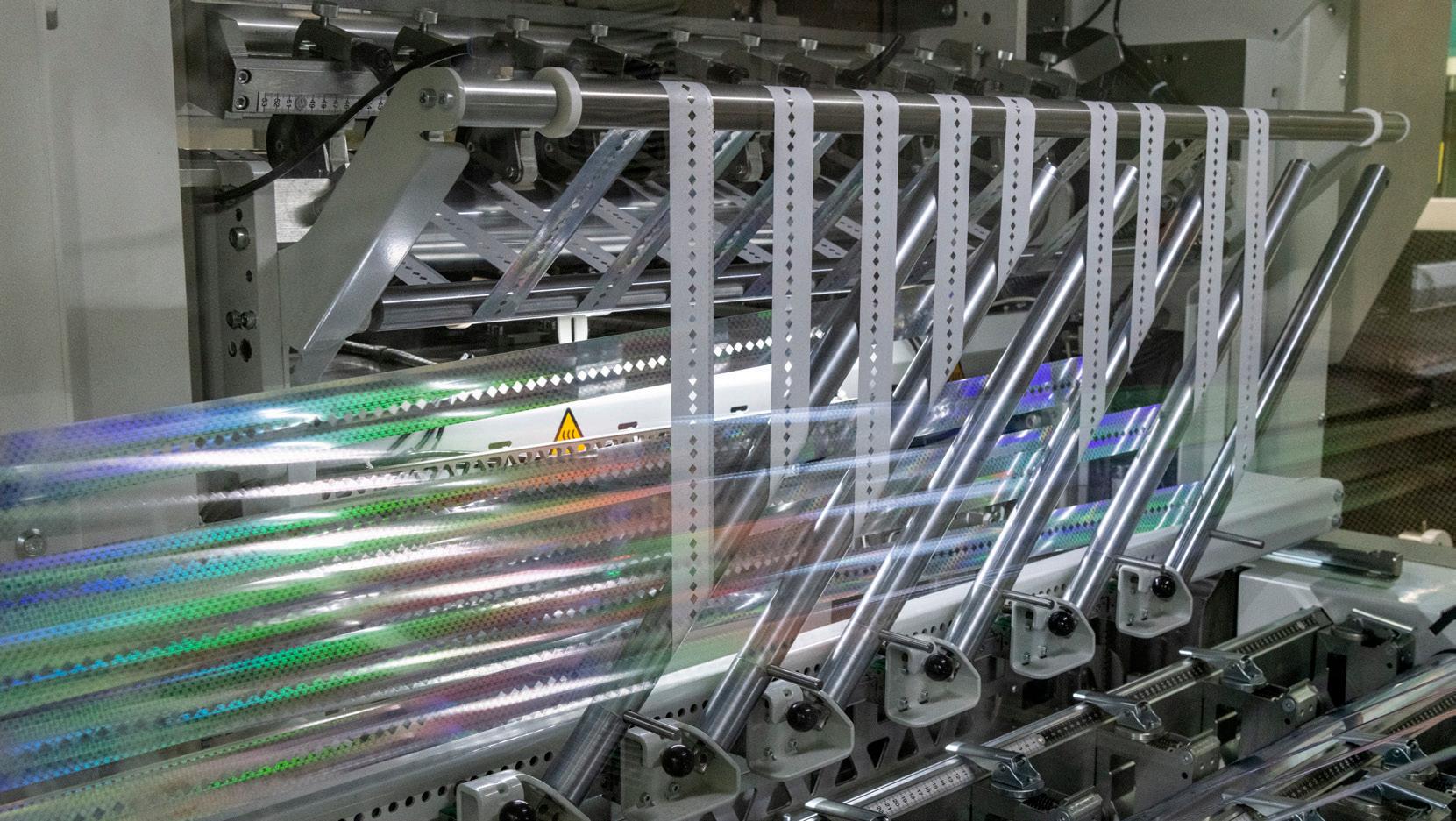

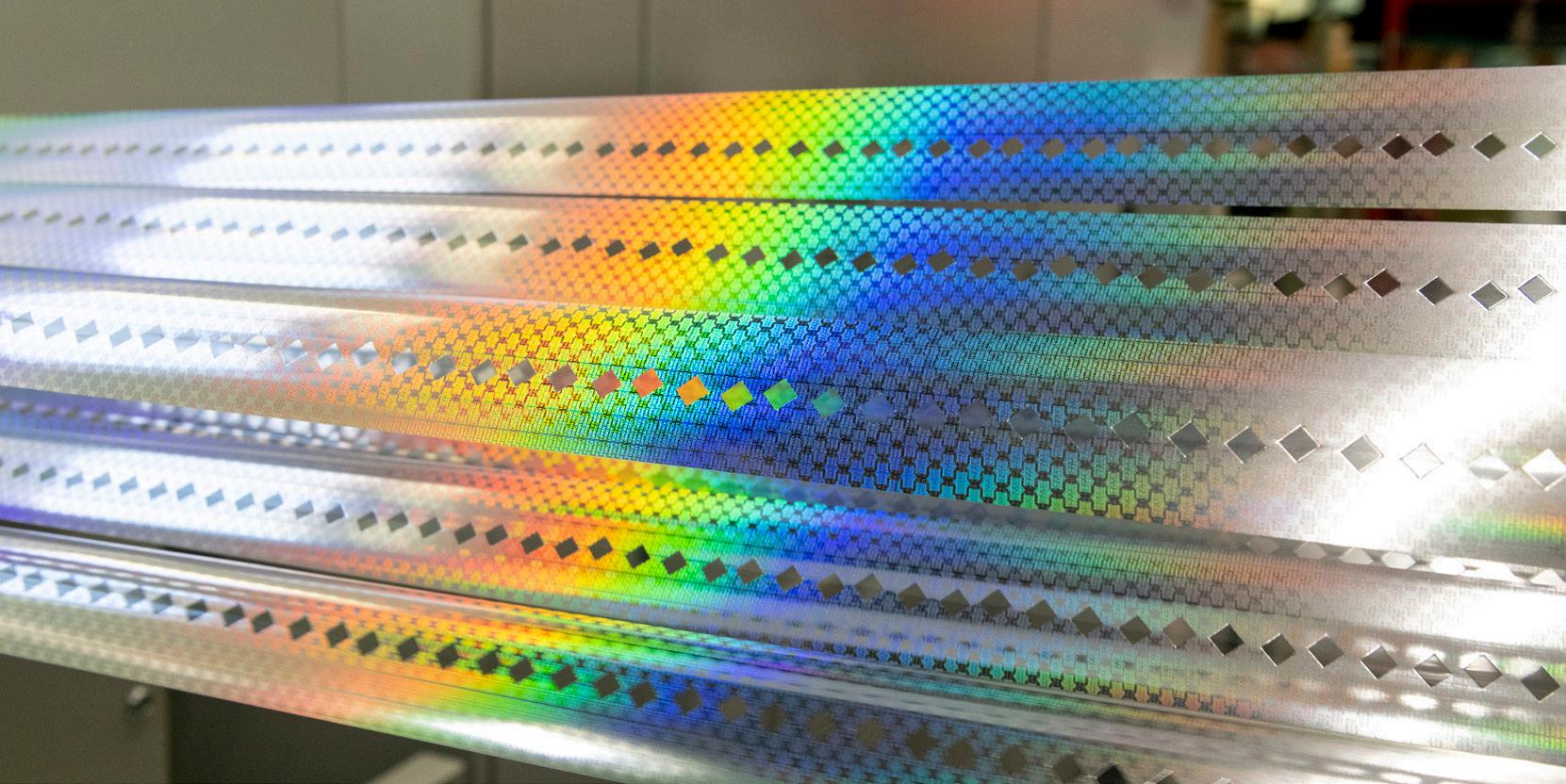

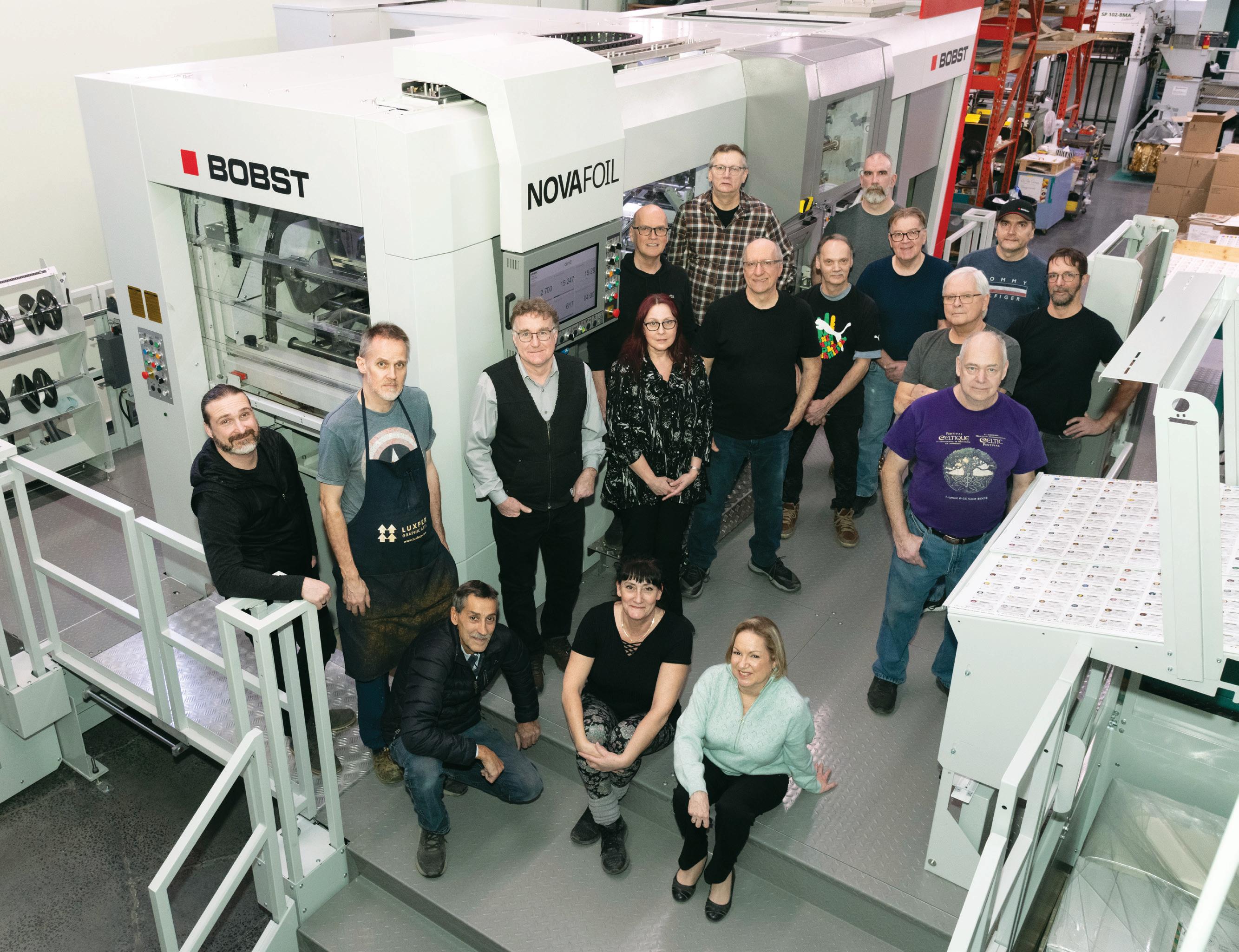

38 Hot off the Press

Quebec package converting stalwart leverages state-of-the-art hot foil stamping technology to turn ordinary product packaging into elegant high-end eye candy.

Les Serres Lefort operations manager Francis Terrault holding up a twin-pack of fresh Boston lettuce grown indoors at the company’s state-of-the-art greenhouse farming operations in Ste-Clodilte, Que.

Cover photo by Pierre Longtin.

March 2023 · CANADIANPACKAGING 3 CANADIANPACKAGING.COM March 2023 Vol. 76, No. 2

canadianpackaging.com

COLUMNS FROM THE EDITOR 4 George Guidoni Finding the right people to fill the right jobs in the food and beverage manufacturing industry. CHECKOUT 48 Rhea Gordon Joe Public speaks out on packaging hits and misses. 18 38 33

THE COVER

ON

Finding the right people to fill the right jobs

MARCH 2023 | VOLUME 76, NO. 2

Reader Service Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher

$110 BILLION

Annual contribution of Canada’s food and beverage manufacturing industry to the country’s GDP

In some ways, the acute and chronic labor shortage across many critical manufacturing sectors is tempting to dismiss as a case of economic karma at work—a payback for decades of stubbornly high unemployment in the very same industries who had heartlessly laid off thousands of Canadian workers over the years under the ruse of global competitiveness and shareholder value.

But while finding some sort of a new and just equilibrium in the job markets is not going to be a quick fix, just hoping that the markets will sort things out eventually is wishful thinking. Like it or not, the old self-correcting supply and demand dynamics have been disrupted in a bad way since the outbreak of COVID-19 and all the related supply chain disruptions left in its wake.

And with food security increasingly a top-of-mind issue facing a growing number of Canadian consumers, there is an urgent need for the country’s food and beverage processors to get their houses in order by addressing their current and future labor requirements with inclusive, mutually agreeable and collaborative problem-solving.

With that in mind, we have high hopes that the newly-unveiled Achieving Our Workforce Destination: Qualified People, Successful Careers & Competitive Business program of the non-profit Food Processing Skills Canada (FPSC) workforce development organization succeeds in its noble goals of creating a skilled workforce and more effective employer recruiting and retention strategies. Funded with a $7.7-million grant from the federal Sectoral Workplace Solutions Program (SWSP), the new initiative aims to elevate the food and beverage manufacturing industry’s workforce development expectations and ambitions with real, practical activities and resources.

According to FPSC’s executive director Jennefer Griffith, the program is designed to enhance the skills and employability of Canadian job-seekers, while improving employers’ capacity to fill positions through better recruitment, on-boarding and retention best practices.

“Ensuring a highly competitive Canadian food and beverage manufacturing industry demands skilled individuals and exceptional workplaces,” Griffith states, adding the industry offers many “exciting career and business opportunities for

Canadians and recent immigrants.”

As the country’s largest manufacturing employer—providing employment for about 290,000 Canadians and contributing $110 billion to our GDP (Gross Domestic Product)—the sector’s critical importance to the nation’s economic well-being cannot be overstated.

As Griffith explains, the program has secured the services of management consulting experts Rapid Results Consulting to create a new national panel representative of the entire Canadian food and beverage processing industry, with the mandate to collect real-time data on key areas such as recruitment and retention, supply chains and rising costs. The panel’s results would then be shared across Canada to provide critical information that will guide labour and employment solutions for the industry.

For its part, Skills Training Across Canada (STAC) will provide online micro-credential training for supervisors to drive new industry leaders and attract the next generation of talent through a blended learning approach that includes on-boarding, goal-driven content, coaching, gamification, and self-directed technical and social emotional learning known as Acahkos (Star in Cree)—to ensure the industry is at the forefront of leadership that values personal growth as much as professional development.

Moreover, the industry’s first Learning and Recognition Framework will provide occupation details and accreditation to support post-secondary schools, employers and private trainers in aligning skill requirements, competencies and recognition for careers in the industry.

As the federal minister of agriculture Marie-Claude Bibeau points out, “The future of Canada’s agriculture and agrifood sectors depends heavily on having a skilled and reliable workforce.

“Recently, these vital sectors have faced significant challenges in maintaining stability and ensuring social and economic benefits for farmers, their families, and Canadians.This new program reflects our collaborative commitment to strengthen this vital sector that contributes to Canada’s growth and overall well-being.”

Well said, and here’s hoping that action will match the well-meaning words to everyone’s benefit.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor

George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

President/COO

Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

4 CANADIANPACKAGING · March 2023

FROM THE

EDITOR

n Uses stretch film to overwrap fresh food products in preformed trays.

n Produces tight, over-the-flange, wrinkle-free packages with securely sealed bottoms.

n Handles a wide range of tray sizes with no changeovers to reduce downtime and increase production.

n Up to 75 packs per minute.

March 2023 · CANADIANPACKAGING 5 CANADIANPACKAGING.COM www.reiser.com Reiser Canada • Burlington, ON • (905) 631-6611 Reiser • Canton, MA • (781) 821-1290 Reiser UK • Milton Keynes, Bucks • ( 019 08) 585300 2023 Fabbri Automatic Stretch Wrappers produce low-cost, highly attractive packages that make your products look fresh and “just packed”. Nothing says fresh like Fabbri packaging

Coca-Cola launches new offbeat flavor to highlight mega pop star Soft-drink giant Coca-Cola is on the move again with what it calls the “boldest and edgiest limited-edition Coca-Cola Creations flavor yet” in a striking multimedia collaboration with emerging musical powerhouse and Grammy-award winning artist Rosalía.

Launched across Canada and the U.S. last month, the new Coca-Cola Move—available in full-sugar and zero-sugar versions—follows up on the success of Coke’s previous fan-

tasy-flavored limited-edition drops under the Coca-Cola Creations platform, including Coca-Cola Starlight, Coca-Cola Byte, Marshmello’s Limited Edition Coca-Cola and Coca-Cola Dreamworld.

According to the Atlanta, Ga.-headquartered beverage producer, Coca-Cola Move aims to bring the transformational power of music to life by working with Rosalía—a trailblazing artist credited for breaking boundaries across musical genres, industries and identities—to push the limits of the company’s core Coke

products into a whole new taste experience.

“As fans sip the new drink, the familiar Coke taste they know and love will evolve in a surprising way,” says Oana Vlad, senior director of global strategy at The CocaCola Company.

“Transformation as a means of self-expression is powerful and resonant for today’s generation, and music is the universal language for transformation,” Vlad explains.

“Partnering with the inspirational and genre-defying Rosalía to bring to life our latest drop under Coca-Cola Creations has been a blast and has broken new ground for Coca-Cola Creations,” Vlad adds. “We hope our collective fans will love this drink!”

The new Creation comes in a beautifully contrasting packaging design intended to display Rosalía’s personality through vibrant colors; candid doodles that Rosalía handdrew while sampling Coca-Cola Move for the first time, and the iconic patented Spencerian script that transforms into a sketch to capture a moment of metamorphosis.

The collaborative project is in fact credited for inspiring Rosalía to write an exclusive, new single titled LLYLM, debuting just ahead of the product launch.

Not only is it the first time Rosalía has released a song that features multiple languages, including a full section in English, it also is the first time a song has been created for Coca-Cola Creations.

“I’m so excited for this co-created drink launch with Coca-Cola,” says Rosalía. “I hope everybody enjoys this journey of music, flavors and creation as much as I did.”

To further bring the product to life, fans can scan a QR code on the collectible Coca-Cola Move can or bottle to access the company’s digital Creations Hub, which features behind-the-scenes content of Rosalía’s making of the single, along with a live personality quiz that uses people’s answers to customize their own 3D avatar in the Metaverse environment, a play-list based on their mood, and a video starring Rosalía.

Fans will also have a rare opportunity to bid on autographed items —including a helmet, tour outfit, posters and other memorabilia—through an online auction, with proceeds going to the Antonio Gala Foundation. Based in Spain, the foundation provides residency scholarships to young creators, and it was chosen by the Barcelona native to continue its mission of inspiring youth to explore their transformative journey.

6 CANADIANPACKAGING · March 2023

NEWSPACK LIMITED EDITION FLAVOR Move

Kellogg planning to launch multiple exciting product variations in coming year

Canadian consumers expect a lot from their food products these days: convenience without sacrificing taste; nutrition without ignoring natural cravings for an occasional indulgence; and fresh new ideas without abandoning the familiar comfort zone.

It’s a tall order, but breakfast foods stalwart Kellogg Canada Inc. is heeding the call by delivering an extensive line-up of new product offerings that will make mouths water and households happy throughout the year.

“We want to add a little brightness to the lives of Canadians with innovative new

products that meet household needs throughout the day,” says Emma Eriksson, vice-president of marketing and well-being at Kellogg Canada Inc. in Mississauga, Ont. “Consumers are at the heart of everything we do and we know that household habits are constantly evolving.

“Our innovation experts have been working overtime to create these new products to provide Canadians what they need, when they need it,” she states. “We can’t wait for everyone to try them.”

Scheduled for multiphase rollouts throughout the year, Kellogg Canada’s upcoming new product innovations include:

• Vector Apple Cinnamon Crunch cereal. High-protein cereal featuring the slightly sweet, homey goodness of apples and cinnamon, while packing 10 grams of protein, 14 grams of whole grains and 11 vitamins and minerals to provide a delicious way to help Canadians power their day.

• K Cinnamon Pecan cereal. The new addition to the flagship Special K brand family features

crunchy whole grain flakes with real pecan pieces and warm cinnamon for a delicious, nutty experience.

• Maple Cinnamon Frosted Flakes cereal. A good source of vitamins and minerals, this new combo flavor combo is as good in a bowl with milk or as a sweet snack straight from the box.

• Krave Brownie Flavour cereal. Featuring the decadent chocolaty flavor of fresh-cooked brownies, the new cereal is made with whole grains and is a source of seven vitamins and minerals.

• Kellogg’s Cinnabon cereal. Featuring a cinnamon roll swirl shape that delivers a crunchy texture bursting with warm cinnamon bakery notes, specks of real cinnamon and delicious, sweet icing flavor, the multigrain cereal is a source of seven vitamins and minerals.

• Kashi Maple Waffle Crisp cereal. A new spin on a Can-

adian classic, this bite-sized, light and crispy waffle cereal features the taste of Canadian maple syrup and notes of warm cinnamon. Made with minimally processed natural ingredients, it contains no artificial flavors or colors.

• Eggo Thick & Fluffy waffles are getting a mouth-watering makeover with the addition of three new flavors that include Cinnamon Brown Sugar, Strawberry Delight and Blueberry

• Pringles Scorchin’ Potato Chips. Famous for edgy flavor creations, the new Pringles family is dialing the heat by adding a spicy kick to some of its most beloved ‘flavorites’ that include BBQ, Cheddar, Sour Cream & Onion and Ranch flavors.

• Rice Krispies Squares Homestyle bars. Delicious protein bars packed with pockets of melted marshmallows throughout the square to craft a thick and gooey home-style recipe.

March 2023 · CANADIANPACKAGING 7 CANADIANPACKAGING.COM

Improve the detection of ultra-thin metal contaminants often encountered in the bakery and snack industries. The Interceptor DF metal detector uses Divergent Field Technology to enhance food safety and brand protection. sales@fortresstechnology.com | (416) 754-2898 LEARN MORE ABOUT OUR EQUIPMENT ONLINE METAL DETECTOR VISIT BOOTH 516

EVOLUTION LEADS TO REVOLUTION MEET THE R-SERIES! Let VC999 help you create the perfect packaging solution! - www.VC999.com The R-Series runs Flexible, Rigid, Skin, Shrink, & Easy Peel Films ALL ON ONE MACHINE! www.vc999.com · 877-435-4555 · Sales.Canada@VC999.com • Durable • Customizable • Increased Speed Certifications Pending

Iconic global gin brand taking creative license for stunning new collectible glass bottles

Based on a 1761 recipe, the Bombay Sapphire gin is one of the world’s oldest global brands of distilled spirits—created by perfectly balancing a unique combination of 10 hand-selected exotic botanicals from around the world.

Nowadays an integral part of Bacardi Limited’s extensive product portfolio, the premium-quality gin is no stranger to the world of art, with the brand’s self-styled Stir Creativity campaign—launched in 2018— acting as a call to arms for artists of all types to engage with their creativity and unlock their creative potential.

As part of that mission, the iconic brand has launched a new special-edition bottle— created in collaboration with the Artestar global licensing agency and creative consultancy—paying homage to cultural icon and prolific artist Jean-Michel Basquiat.

Rolled out across parts of Canada last month, the beautiful new collectable shines a light on Basquiat’s fearless creativity and the brand’s quest to make the art world more accessible to all who have a passion for self-expression, a part of the brand’s ongoing ‘Stir Creativity’ platform.

The special-edition 750-ml glass bottle features one of Basquiat’s earliest works, his Untitled (L.A Painting). Never before licensed and only displayed to the public once, it is a masterpiece influenced by the surrounding remote environment of Venice Beach, Ca., where Basquiat found security and solitude away from the hustle and bustle of New York City in 1982.

Exhibited as part of Basquiat’s second ever show, the piece features many of the key motifs that are associated with his work: the crown, the bird, the coin and the skul, which are all beautifully collaged over soft hues of blue.

“We’re thrilled to be launching the special edition bottle in Canada to honor Basquiat’s dynamic creativity and offer an entirely new way to experience art,” says James Fisher, senior brand manager for Bombay Sapphire.

“This collaboration was born from a shared mission to shine a light on the arts and inspire creative self-expression within everyone,” says Fisher, adding the brand worked closely with the Basquiat Estate to highlight the late painter’s fearless creativity and meaningful artistic expression that transcends generations.

Like Basquiat and his sisters, Jeanine Heriveaux and Lisane Basquiat, Bombay Sapphire strives to foster creative self-expression and open alternative pathways to champion equal representation in the arts, according to Fischer.

“We are excited to collaborate with Bombay Sapphire to share Jean-Michel’s work with those passionate about his art, life and journey,” say the Basquiat sisters, who are formal administrators of the Basquiat Estate.

In addition to supporting the arts, Bombay

Sapphire is also on a mission to become the world’s most sustainable global gin, with all 10 botanicals being certified sustainably sourced as per the For Life certification from Ecocert S.A. In addition, the design of the brand’s home distillery at Laverstoke Mill in England has recently won a BREEAM award of the BRE Group (Building Research Establishment) for sustainability of its unique Vapour Infusion process, which skillfully captures the natural flavors of the botanicals to create fresh and vibrant taste synonymous with the brand.

NEWSPACK March 2023 · CANADIANPACKAGING 9 CPK_SHAWPAK_FP_March23_MLD.indd 1 2023-02-24 8:46 AM

Leading Canadian containerboard producer Cascades Inc. of Kingsey Falls, Que., has announced a US$9million capital investment at the company’s corrugated packaging converting facility in Piscataway, N.J., including installation of a brand new printing press, the plant’s sixth, expected to be commissioned by the end of April. Started up in 2018, the Piscataway plant is already one of the company’s most modern production sites, according to Cascades, primarily serviung the distribution and food processing markets. The addition of the new EVOL press from Mitsubishi

to increase the plant’s production capacity by 17 per cent, the equivalent of 480 million square feet, while creating 20 new jobs at the 175-employee facility. “The purchase of an EVOL press, one of the fastest technologies in the world, will allow us to continue our growth in the U.S. northeast and increase our ability to serve our current and future customers,” says Cascades president and chief executive officer Mario Plourde. “This investment is part of our 2022-2024 strategic plan aimed at increasing our integration rate by adding additional converting capacity in the United States.”

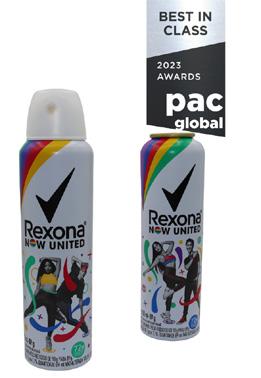

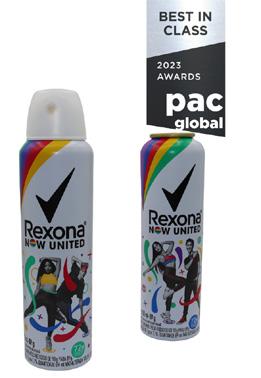

Leading global metal packaging product group Trivium Packaging has been honored with three Pack Global Awards in the recent international awards competition of Toronto-based industry group PAC Global, including the Best-in-Class in the Package

Innovation Technical Design category, and two awards of distinction in the Package Innovation Sustainable Design category. The Best-in-Class award in this year’s competition acknowledges the high-quality printing and technical competence of Trivium’s aluminum aerosol cans used for the Rexona Now United aerosol antiperspirant brand, featuring members of the Los Angeles-based pop-music group Now United. Featuring bright colors and engaging brand imaging, the cans were printed with eight-color dry-offset technology to ensure life-like reproduction of the Now United bandmates’ faces, while maintaining Rexona’s brand imaging, group approval and technical feasibility. “We always strive to make products that are visually engaging for both our clients and the consumer, while also keeping the production process in mind,” says Marcelo Nery, head of R&D at Trivium’s Brazil business. “We’re committed to pushing technical design forward while reducing plastic packaging waste,” he says, noting this is the third straight year that Trivium topped the Package Innovation Technical Design category.

Universal Robotics (UR), leading manufacturer of collaborative robots (cobots) based in Odense, Denmark, has signed an agreement to supply cobot arms to San Francisco, Ca.-based robotics integrators Rapid Robotics for widespread deployment of cobot workcells across North America. “As the number of unfilled, critical manufacturing roles increases and global economic uncertainty continues to impact supply chains, more and more North American manufacturers are turning to automation,” says Rapid Robotics chief executive officer Jordan Kretchmer. “This collaboration with UR helps us deploy more cobots, with a wider variety of capabilities and at a faster rate—ultimately helping manufacturers of all shapes and sizes to manage and even thrive through the adversity they are facing.”

Kretchmer adds Rapid Robotics can deploy UR cobot model to suit many high-payload palletizing, box-building and packaging applications.

NOTES & QUOTES

23-03 Canadian Packaging (8.875x5.75).v1.1.pdf 1 2023-03-01 3:39 PM

Mario Plourde, President and CEO, Cascades Inc.

SANITARY FOCUS

The VF-1200 continuous-motion vertical bagger from WeighPack Systems is now available in a sanitary version for high-pressure washdown applications. Engineered for wet, cold and harsh environments where traditional vertical form-fillseal machines may fail, the VF-1200 ensures optimal reliability with its stainless-steel construction, along with the highest IP protection standards for motors, heating elements, thermocouples, electronics, touch screens and cabinets. “We feel strongly that our industry requires more solutions for high sanitary washdown to help mitigate any risks of cross-contamination or bacterial growth as a result of poor cleaning to ensure that the consumer remains safe,” says WeighPack Systems vice-president Nicholas Taraborelli. Designed for high-speed handling of multiple package formats and sizes, the VF 1200 provides exceptional flexibility for both retail and Club-size packaging for industries ranging from snack foods, confectionery and frozen foods to cheese, seafood, meat and poultry. Engineered with an open-frame design for easy operator access, the VF 1200 is fullyequipped with vacuum pull belts, a second film roll support, a film splice table, Omron motion controller and servos, a 15-inch color touchscreen HMI (human-machine interface) panel, a tool-free removable vertical seal bar, horizontal jaws and a forming shoulder.

WeighPack Systems

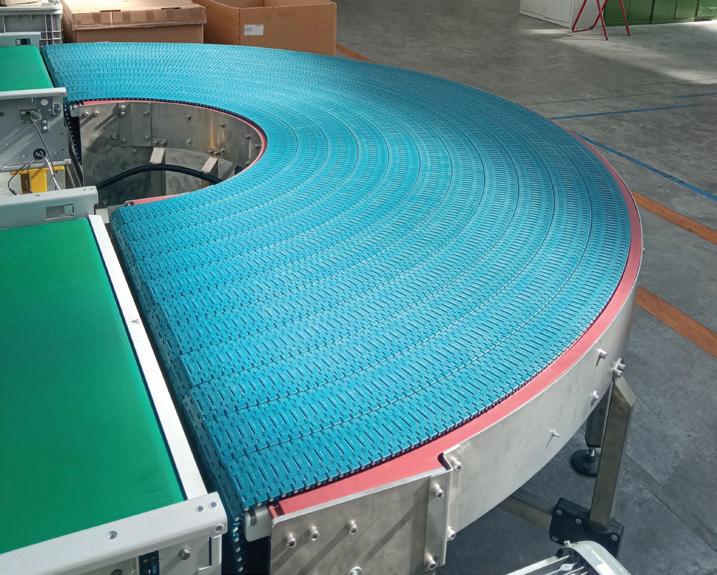

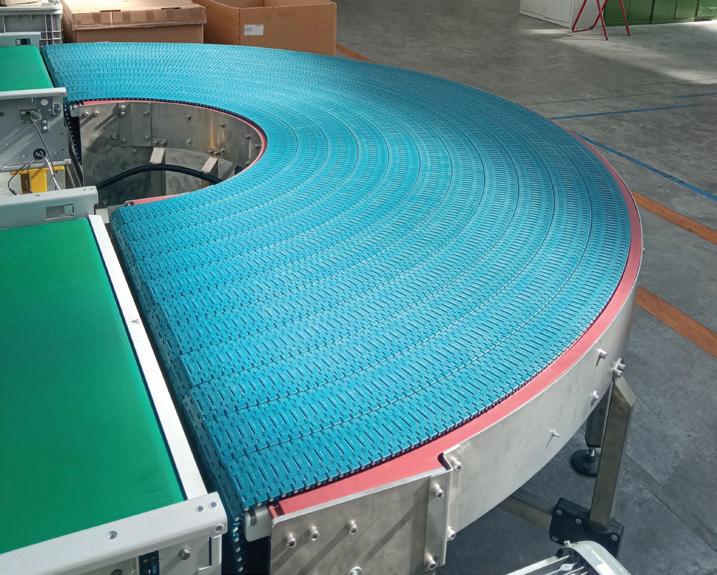

and lightest cases without the need for micro pitch conveyors, transfer modules or plates. A consistent small nose radius across the width of the conveyor, coupled with smallest transfer available in the industry, results in a safe small gap between the Curve System and the adjacent conveyor—eliminating the need for roller transfer bars while providing more flexibility in container types when changing lines.

Regal Rexnord Corporation

part, the new fruit suction cup FCX50 is designed specifically for handling items with challenging and permeable surfaces and varying shapes and sizes at remrkably low vacuum levels—grips the fruits firmly and gently to ensure no marks or bruising.

Piab

WELL AHEAD OF THE CURVE

Designed for conveyor line requiring a zero-tangent 180° and/ or 90° curve, the new Rexnord Curve System with 1540 Series mat top chain from Regal Rexnord Corporation offers exceptionally tight inner radius (420-mm) and small transfer (15-mm) for greatly improved space utilization and package handling. Offering an economical drop-in solution that can be easily integrated into existing conveyance systems, the Rexnord Curve System enables head-to-tail transfer of even the smallest

COMING TO GRIPS

Robotic end-of-arm-tooling experts Piab has introduced two new innovative suction cups designed for optimal handling of specific food products. The new ECX36 egg suction cup features a stable design with multi-stage actuation to provide easy control over the product release—greatly reducing the risk of damaging eggs in high-speed egg handling. For its

GEARED UP FOR HARSH DUTY

JW Winco has expanded its range of polyamide gears and racks for applications that must transmit high torque at low speeds to convert rotational movements into linear movements, or vice versa. Well-suited for packaging machines, as well as food production and chemical manufacturing, the EN 7802 spur gears and EN 7822 gear racks are made from strong long-lasting polyamide, with their low friction coefficients eliminating the need for lubrication. Available in gray or blue doe better visual detectability, the FDA-compliant, glass fiber-reinforced plastic is suitable for most food processing applications up to 120°C, fully withstanding contact with acids, acids, gases and saltwater.

JW Winco

March 2023 · CANADIANPACKAGING 11

FIRST GLANCE Proudly Introducing the Hitachi UX2 Ink Jet Coder Move into the future of Ink Jet Coding Call us today for more details or to book a demonstration 1-877-427-5863 sales@harlund.com www.harlund.com QUICK CHANGE CONNECTORS ON BOARD VIDEO GUIDANCE CLEARER CODES & FASTER SPEEDS LONGER PRINTING CYCLES FIRST IN INDUSTRY SAFE PRINTHEAD CLEAN STATION CPK_HARLUND_SQ_MAR23_ASK.indd 1 2023-03-01 10:46 AM

Putting the lid on plastic pollution one cup at a time

With the days of single-use plastic packaging and food containers nearing the end in many countries around the world, restaurant operators are scrambling to find practical commercial-scale alternatives to the everyday products they have relied on for decades.

And while the humble coffee lid is hardly the biggest source of global plastic pollution crisis in itself, the sheer quantity of plastic coffee lids discarded by consumers each day is nothing less than staggering.

According to credible market research, there are more than 300 billion plastic lids produced each year, an equivalent of 1.5 million tons of plastic, with many of them ending up as litter in the world’s oceans.

Happily, a promising new technology developed by Swedish-based fiber forming pioneers PulPac just may provide the permanent solution for eliminating, or greatly reducing, this problematic global waste stream.

Invented and patented by PulPac, the Dry Molded Fiber manufacturing technology has recently been embraced by leading Swedish burger chain MAX Burgers AB to offer customers “a better, safer and more natural way to drink on the go.”

Founded in 1968, MAX Burgers has long been recognized as one of the foodservice industry’s most proactive advocates for environmental sustainability, and the switch to the new fiber-based Liplid lids—developed by local lidding manufacturer Liplid AB and the Research Institute of Sweden (RISE)—will enable the chain to eliminate two million plastic lids from the waste stream annually.

“The world needs smart and functional alternatives to single-use plastic,” states Liplid’s chief executive officer Jesper Berthold. “Using PulPac’s innovative approach, we produced a fully recyclable, plastic-free and biodegradable cup lid with a new and unique design, bringing a new drinking experience to the market.”

A recipient of the 2022 World Star Packaging Award of the World Packaging Organisation (WPO), the innovative lid is placed inside the cup, rather than around the top, to prevent leakage and improve the stability and drinking experience of on-the-go beverages.

In addition to using 25 per cent less

From top

The innovative plastic-free Liplid cup lid design has enabled MAX Burgers to replace plastic coffee lids at the company’s 141 franchise locations across Sweden.

A sampling of foodservice single-use cutlery and utensils manufactured with PulPac’s breakthrough Dry Molded Fiber technology.

material with this innovative and climate-smart design, the Dry Molded Fiber process used to make the lids also saves significant amounts of valuable water resources and energy—resulting in up to 80-percent lower carbon footprint compared to traditional plastic lids.

According to PulPac, the Dry Molded Fiber also offers many other performance benefits such as structural strength, undercuts, de-nesting, advanced geometries and virtually unlimited control of material thickness—making it possible to produce very thin fiber products.

Said to be up to 10 times more efficient than the original fiber molding process invented over 100 years ago, PulPac’s Dry Molded Fiber technology also offers competitive unit economics , according to the company, making it possible to replace single-use plastics on a global scale.

“This has been a fantastic project, where we have adapted Liplid’s brilliant

product to our technology to manufacture the first series of two million lids for Liplid,” says PulPac’s chief commercial officer Sanna Fager.

“For us at MAX, this collaboration was a perfect solution,” says Malin Laurén, global head of purchasing at MAX Burgers.

“We work continuously to develop our business and our menu to reduce our climate footprint,” Laurén says, “and we always strive to improve the experience for our guests.

“We’ve analyzed the coffee lids on the market and focused in on Liplid as the best out there,” says Lauren, adding the rollout of the new lidding is currently being implemented at all 141 locations that MAX operates across Sweden.

Adds Liplid’s Berthold: “Sustainability is not just an empty word at MAX Burgers: it’s fully integrated into their values and actions.

“They are also very focused on combining sustainability with a positive customer experience.”

Headquartered in Gothenburg in southwestern Sweden, PulPac operates a fast-growing global network of licensees— including brand-owners and converters— using Dry Molded Fiber manufacturing technology to make sustainable products and packaging for the unfolding Circular Economy.

Once of its most recent new licensees—U.K.-based company ThermoFibre—has just placed an order for a fully automated Dry Molded Fiber production line, to be installed at the company’s production facility in Lincolnshire this year.

According to PulPac, the newly-developed PulPac Modula is a standardized machine platform that will initially be used to make high-volume products such as food trays, lids, cutlery, etc., for ThermoFibre’s U.K. customers.

“At ThermoFibre, we are taking on the challenge each day to make a positive difference on the environment with the products we make,” says ThermoFibre’s president Fuad Khan.

“Providing sustainable packaging and products is critical in today’s climate,” Khan says, “and we are driven by assisting companies shifting to packaging that is better for our planet.

“By extending our offerings with Dry Molded Fiber, we aim to continue to lead the charge.”

12 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM

ECO-PACK NOW

June 6, 2023 | Toronto Barrett Centre for Technology Innovation All-Day Event Innovators Showcase & Tabletop Gallery FOR UP-TO-DATE INFORMATION VISIT WWW.PAC.GLOBAL P A C K A G I N G I N N O V A T I O N D I S R U P T O R S S U M M I T Innovators contact Jim Downham at jdd@leaderlinx.com

GROWING FORWARD

While the fear of COVID-19 pandemic may be receding into the past, its long-lasting impacts continue to hamper many key Canadian industries scrambling to regain the lost revenues and market share.

By all early indications, alas, the return to normalcy will be a challenging journey for the Canadian fresh produce industry, whose emergence from COVID-19 misery has been accompanied by the highest inflation growth in decades, with the prices for fresh fruits and vegetables in soaring beyond many households’ budgets.

This could have profound implications for one of the country’s most important food industries, which is also struggling to cope with the sector’s long-term labor shortage and growing regulatory and public pressure for more sustainable packaging and manufacturing practices.

With so much on the industry’s plate, Canadian Packaging recently reached out to Ron Lemaire, president of the Ottawa-based industry group CPMA (Canadian Produce Marketing Association), to assess the industry’s economic prospects and its chances for a reasonably quick recovery.

QPlease provide a current macroeconomic snap-shot of the state of the Canadian fresh produce industry.

AThe fruit and vegetable industry continues to demonstrate resiliency as we navigate the lingering effects of the pandemic. That said, in Canada and around the world, all parts of the fruit and vegetable value chain continue to face higher operating expenses, mostly due to increased costs of fertilizer, fuel, packaging and logistics.

For example, the cost of fertilizer increased by 29.3 per cent in 2021 to $7.3 billion, according to Agriculture and Agri-Food Canada, and continued to rise throughout 2022.

The big challenge our industry’s value chain faces today is the inability to pass

the true cost of food onto the Canadian consumer. Although we are seeing inflation numbers drop as we begin 2023, food inflation still remains high, as evidenced by the price increases for fresh vegetables (10.4 per cent) and fresh fruits (8.3 per cent) on a year-over-year basis in 2022.

The goal for 2023 will be to address the challenge of high production and supply chain costs, which the system can no longer absorb without creating additional burden on the consumer.

And while labor shortage continues to be an issue across the supply chain, the industry supported approximately 249,000 jobs across Canada last year.

QHow does this position Canada’s produce industry in terms of overall global competitiveness?

ACanada continues to be a significant importer of fresh produce from around the world. In 2021, Canada imported two-thirds of consumed fresh produce, worth over $10 billion. This is partly influenced by our weather and our multicultural population.

While a high volume of fresh produce in Canada is imported, greenhouse-grown produce is an area that has been expanding, as it continues to grow in key regions like Ontario and British Columbia.

According to Statistics Canada , total greenhouse acreage continues to

grow across Canada. Notably, most new acreage is being built under glass—representing 87 per cent of all new acreage in 2021—with poly film accounting for the remainder.

Produce export is also another sector that is experiencing growth, with the demand for Canadian produce increasing in countries such as the U.S., Indonesia and Israel. Naturally, the U.S. accounts for lion’s share of Canadian produce exports with a 97-percent share, or $3.2 billion in revenues, which is the highest share in the last 10 years. This is driven in part by a great interest in Canadian-grown peppers, tomatoes, cucumbers, mushrooms and potatoes.

QNow that COVID-19 no longer dominates the news cycle, could you reflect on how well the industry weathered the storm?

ADuring COVID-19 , our industry showed remarkable resilience and capacity to adapt and innovate to meet Canadian consumers’ needs.

Our sector is one that requires the consumer to, see, touch and smell the product before they purchase it, and the pandemic totally flipped this relationship upside down.

As consumers were locked in their homes, they focused more on personal health and wellness, which benefited our sector. At the same time, our industry had to adjust to new services such as curbside

March 2023 · CANADIANPACKAGING 15 CANADIANPACKAGING.COM

PepsiCo bottler, the

PRE-SHOW REPORT

and exporting some

CPMA

president Ron Lemaire says the Canadian

fresh produce industry has displayed commendable resilience during the two years of pandemic lockdowns, albeit full recovery to pre-pandemic levels is still very much a work in progress.

CPMA president provides thoughtful update on the fresh produce industry’s post-pandemic reality

16 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM

pick-up, e-commerce and grab-and-go purchases at restaurants.

This drove our need for more packaging and for many more home meal preparations, which was a new and exciting journey for many companies.

On the downside, preparing meals at home had positive impacts on our retail sector and negative impacts on restaurants in Canada.

According to a recent report released by Restaurants Canada, sales in the foodservice sector remain below the pre-pandemic levels. Additionally, more than 10,000 foodservice establishments have closed permanently.

Employment across the supply chain is also a challenge. A 2021 CPMA survey found many members reporting gaps in their labor pool and increased labor costs, while also citing lower performance, innovation and production levels due to the labor issues.

While the federal subsidies supported many companies from immediate failure and financial collapse during the pandemic, we are now starting to experience the collateral effects of the pandemic’s supply chain impacts on our sector.

While the burden of dramatic cost increases has forced some businesses to close, this negative market shift seems to be addressed, with the gaps filled by other businesses in the supply chain.

QWhat has been the impact of COVID-19 on consumers’ eating patterns insofar as their consumption of fresh fruits and vegetables during and following the lockdowns and supply chain disruptions?

ADuring lockdowns, produce with short shelf life was impacted the hardest as consumers rushed to buy produce with longer shelf life such as potatoes and onions in bulks.

During COVID-19, Canadians looked at ways to improve their health and well-being and produce played a key role in their diets and their purchasing behaviours. Many worked from home and ate at home-prepared meals and tried new products.

In a study by CPMA’s data partner Execulytics, nearly half of Canadians, especially the younger generation, tried a new fruit or vegetable product for the first time in 2022.

Dragon fruit currently is the most popular new produce item, followed by exotic tropical fruits such as star fruits, guavas and passion fruits.

QPlease explain the extraordinary price inflation for fresh produce sector and its impact on consumers and the industry.

AThe produce industry has experienced several challenges these past three years, which have had significant impacts on the cost of running businesses

and the flow of goods around the world. This has led to an increase in the costs of growing, harvesting, transporting and selling produce in the country.

Many of these are trickling down to consumers. For instance, at the beginning of 2022 the industry experienced logistical challenges with truck blockades impacting the transportation of fresh produce across the border. This led to Canadians noticing empty shelves, especially in the fresh produce sections, although for a relatively short period of time.

To accelerate the return to normalcy, CPMA has been advocating on behalf of the industry for government support in prioritizing access to food, and we are working both domestically and globally to frame key policy requirements to make fruit and vegetable essential.

This includes ensuring priority lanes for our produces when entering or exiting the country.

QWhat are some of the major global market trends and geopolitical events impacting the produce sector right now?

AOur country is one of the largest produce importers in the world, and as mentioned earlier, there is a high demand for Canadian produce from countries such as the USA, Indonesia,and Israel.

Unfortunately, the war in Ukraine has also led to a disruption of the flow of goods around the world, including fertilizers needed by the agriculture sector in Canada.

Ongoing supply chain challenges continue to impact our sector, and while logistics costs are gradually falling, they still remain well above pre-pandemic levels.

QPlease provide an update on what’s happening in the fresh produce sector in terms of packaging sustainability, especially in light of federal ban on single-use plastics?

ACPMA continues to support the industry in its efforts to build a path towards removing unnecessary and problematic plastics from our supply chain.

I sit on the board of the Canada Plastic Pact (CPP) supporting efforts to navigate the complexity of problematic plastics. As an association, we are developing tools such as the Fresh Produce Plastic Packaging Design Guide, which builds on the consumer good forum Golden Design Rules and support our industry in working towards 2025 targets of less plastic packaging and increase recycled content.

Additionally, CPMA will be launching a new online tool (April 2023) for the food industry, which will provide packaging guidelines and resources to make the most

sustainable packaging choices , given the current and emerging packaging technologies and the state of waste management and recycling systems in Canada.

The CPMA is also providing its input to the federal government on the development of a federal plastics registry, which would address the challenges for the food sector related to food-grade recycled content, and the potential negative consequences of a shortage or lack of supply, as we work towards the government target dates and metrics.

QWhat are some of the major notable initiatives and programs that CPMA has carried out in the last couple of years?

AThe CPMA continued to advocate on behalf of the produce industry for government support in several priority areas, including addressing supply chain disruptions; prioritizing access to food; supporting a sustainable fresh produce sector and establishing financial protection for produce growers and sellers through legislation (Bill C-280), which anticipated to be debated in the House of Commons in the coming months.

Produce consumption: Through Half Your Plate program, CPMA has also continued to educate Canadians of all ages about the importance of fresh produce consumption through our Half Your Plate program by encouraging them to fill half their plates with fruits and vegetables to improve their health. We have been working to address food inflation, showing Canadians what they can buy for $20 to ensure that fresh fruits and vegetables remain a healthy part of their plates.

Reuniting the produce industry: through the 2022 CPMA Annual Convention and Trade Show in Montreal was also a key highlight. Keeping the industry connected is part of CPMA’s mandate that has, in part, contributed to its longevity. Our annual convention and trade show is a massive platform that brings the entire produce industry together to build and strengthen business relationships. All these things were put on hiatus when COVID-19 struck in early 2020—forcing us to cancel in-person events for two consecutive years.

To address the impacts of the pandemic and supply chain issues, CPMA has been engaged both domestically and internationally with industry and governments to find solutions to supply chain disruptions, labor issues and business continuity. Over the past two years CPMA was part of the Surplus Food Rescue Program, which diverted over 11 million tonnes of food to at-risk Canadians. Finally, we continue to work tirelessly worked to lower the many trade barriers still impeding the free flow of fresh produce across the national borders.

March 2023 · CANADIANPACKAGING 17 CANADIANPACKAGING.COM PRE-SHOW REPORT

a pack of Gen V brand of organic cucumbers grown and harvested at the company’s greenhouse

HIP TO BE GREEN

Greenhouse farming pioneer launches major rebranding to connect with the next generation of Canadian consumers on pressing health and sustainability issues

By George Guidoni, Editor

Photos by Pierre Longtin

By George Guidoni, Editor

Photos by Pierre Longtin

For an industry that didn’t really get serious traction and attention until the mid-1980s, the growth of the Canadian greenhouse produce farming industry has been a stunning, if often overlooked, success story celebrated by millions of grateful consumers on daily basis both in Canada and abroad.

An acknowledged leader in greenhouse vegetable production, with over 2,000 hectares (5,000 acres) under cultivation, the sector ensures year-round supply of tomatoes, bell peppers, lettuce, cucumbers, cabbage, cauliflower and many other popular crops to grocers and foodservice operators across the country, while also enjoying steady growth in ex-

port sales to the U.S. and other markets with high demand for organic products.

According to Statistics Canada , “Canada has a technologically advanced indoor agriculture sector with long-standing success in the global marketplace.

“Canada’s greenhouse vegetable and mushroom sectors are an important part of Canadian agriculture and a source of significant economic activity within Canada,” says StatsCan, “contributing $2.7 billion in farm gate sales and approximately $1.7 billion in exports in 2021.”

With an estimated 838 commercial greenhouses currently operating across Canada, the indoor farming industry also meets many of the goals and objectives driving the concerted global efforts to make farming a more sustainable industry worldwide.

18 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM

COVER STORY

Les Serres Lefort operations manager Francis Terrault proudly dispays

produce farming operations in Ste-Clotilde, Que.

For one thing, it allows farmers to produce plants year-round without the need for cold storage or refrigerated shipping , both very energy-intensive activities.

In addition, greenhouse farming also reduces soil degradation and supports biodiversity by using a variety of climates and light levels to grow different vegetables.

By relying on renewable energy sources such as solar and wind power, it also offers a more environmentally-friendly method of production that eliminates the need for pesticides or other chemical inputs to facilitate organic farming.

And being highly resilient to weather conditions, greenhouses make ideal locations for producing healthy food during prolonged droughts or other serious weather disturbances.

Above all, greenhouse produce farming fits perfectly into today’s fastchanging food consumption patterns in Canada, with Millennials, Generation Z and other younger consumers increasing-

ly departing from the traditional meat-and-potato fare of their parents for fresh fruits and vegetables in pursuit of their health-and-wellness goals.

Naturally, this demographic-driven youthquake is having a profound impact on the marketing strategies of leading Canadian greenhouse operators, including Les Serres Lefort of Sainte-Clotilde, Que.

Founded in 1987, the family-owned company is currently in the process of rebranding its well-known flagship Mirabel brand of lettuce to the new Gen V brand label that, according to oper-

ations manager Francis Terrault, will resonate better with the younger, socially aware Canadian consumers prioritizing healthy living and the health of the planets as their prime top-of-mind issues.

“The Generation V is all about brining consumers vibrant new ways to eat fresh,” Terrault explains. “We are the vision of a new generation, serving up vitality in every crunchy vegetable and verdant green.

“Responsible production is at the heart of our promise, honoring sustainability for our planet and respect for our community.

“Our products are alive and thriving, just like our values,” he says, “and so the Gan V brand name is all about being true to those values.”

Founded in 1987, the family-owned company has grown continuously since its inception for 35 straight years,Terrault points out, but with more companies entering the industry each year, the competition is getting more intense all the time—prompting brand-owners to raise

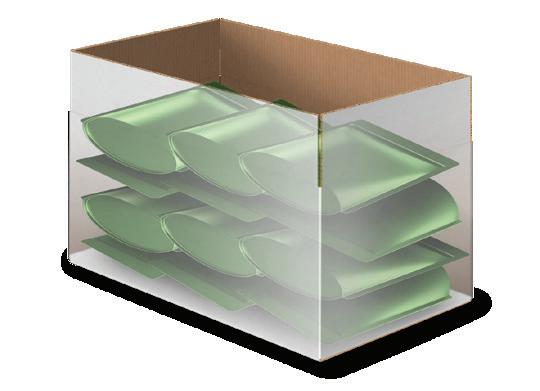

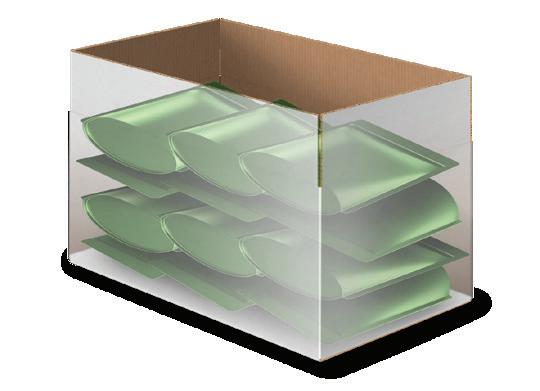

The Lefort greenhouse operations use fully-recyclable corrugated boxes from leading Canadian packaging suppliers like Cascades and Mitchel-Lincoln to ship the finished multipacks of its Gen V brand produce to its customers in eastern Canada and the U.S. northeast markets.

March 2023 · CANADIANPACKAGING 19 CANADIANPACKAGING.COM

“We are the vision of a new generation, serving up vitality in every crunchy vegetable and verdant green.”

their marking game.

“There’s much more competition out there than before and we wanted be more aggressive on our marketing and branding end of things,” Terrault notes.

“That said, this rebranding was a carefully thought-out decision,” Terrault asserts, “considering that the Mirabel brand has been around for 36 years.

“We called on the experts, we did consumer research with a research firm, we analyzed the competition, we conducted management interviews … so that in the end it was a purely rational decision,” he relates. “It took us three years to accomplish.”

Nowadays operating four production sites across Quebec with combined acreage of 20 hectares (300,000 square meters), the company employs roughly 350 people throughout the year to produce 9,000 tonnes of vegetables—including several lettuce varieties and organic cucumbers and bell peppers.

In addition, the company annually produces an estimated 250 million transplants (seedlings) that are used by field growers for outdoor farming.

According to Terrault, about 75 per cent of the lettuce and organic cucumbers produced in Sainte-Clotilde under the Gen V label is distributed to leading

retailers throughout Eastern Canada, including Ontario, and in selected major markets in northeastern U.S, including New York, New Jersey and around Boston.

All in all, the facility produces a total of 22 different SKUs (stock-keeping units), with half of them for retail customers and the other half for wholesalers the serving restaurant, hospitality and institutional sectors.

Terrault says he is proud of the company’s Number One ranking for the production of hydroponic “living” (roots attached) lettuce in Quebec.

“Because we grow lettuce hydroponic-

Above

A close-up of the stacked corrugated shipping trays from Cascades used to transport the film-wrapped trays of Gen V brand organic cucumbers to the company’s retail and foodservice customers.

Left The Sleekwrapper horizontal flow wrapping machine from Paxiom Group used for overwrapping trays of cucumbers in clear plastic film at high speeds.

20 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM COVER STORY

ally, for some of our SKUs we make sure to the root of the head of lettuce, so it stays fresher longer because the product is still ‘alive,’” he explains.

“Our hydroponic production uses 80 per cent less water than harvesting in a field,” he points out, “while our yields are eight times higher.”

Using minimal space and up to 90 per cent less water than traditional agriculture for some crops, hydroponic vegetables, herbs and flowers are planted in inert growing media and supplied with nutrient-rich solutions, oxygen, and water in a controlled process that fosters rapid growth, stronger yields and superior quality.

Because the plant’s root system is exposed directly to water and nutrition, the plant does not have to exert any energy to sustain itself like it must when planted in soil, where its roots are perpetually searching for the necessary nutrition to sustain itself.

As a result, hydroponic produce can be harvested in half the times as their soil-grown cousins, depending on the product.

“Our system of cultivation on mobile floats ensures a constant transition and movement to be uniform and continuous at every step,” says Terrault. “We operate a manual line, which means everything that is harvested by our employees is checked and cleaned by our quality control staff at the end of the line.

“We like this connection to nature,” says Terrault, citing an impressive list of authoritative product quality certifications that include Canada Bio, USDA, Canada Gap and SQF, among others.

For packaging the lettuce, the Lefort primarily uses clear plastic clamshell packaging—in double- and triple-pack sizes—to provide consumers a good unobstructed view of the contents, while also providing the product with decent shelf-life.

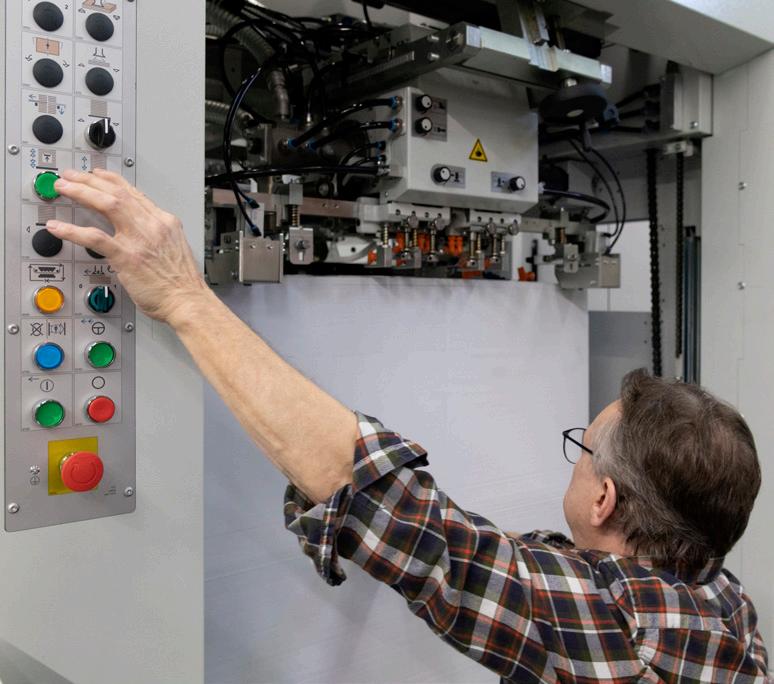

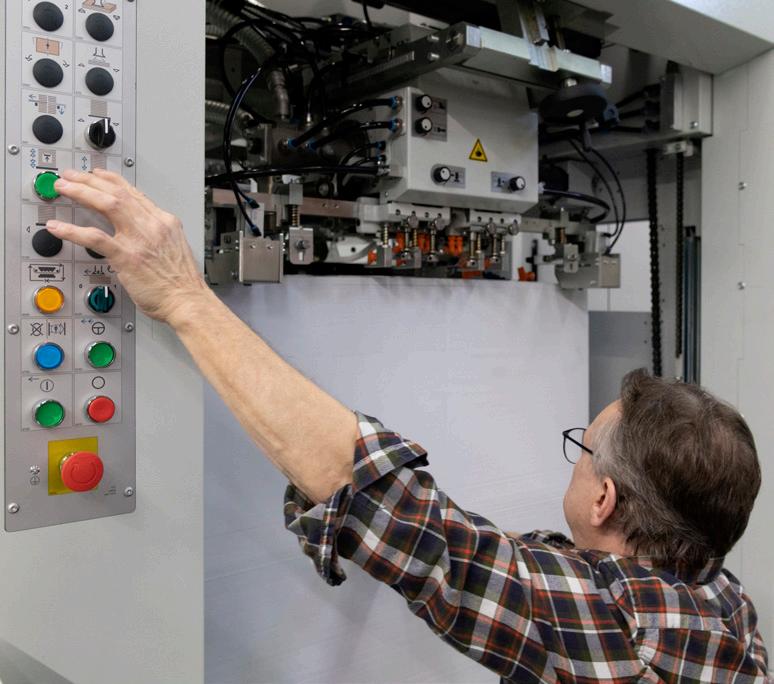

Above The Lefort lettuce greenhouse uses Schneider Electric controls (above) for ensuring the proper climatic conditions for ultimate yields for the hydroponically-grown lettuce, which is packed in two- and threepack clamshells (right) for retail sales.

Below Individually wrapped large cucumbers exiting the Aweta Vision machine that uses an external camera to scan sort cucumbers by length, width, curvature and diameter prior to being place inside corrugated carriers for shipment to customers.

March 2023 · CANADIANPACKAGING 21 CANADIANPACKAGING.COM

“Our current packaging was designed to extend shelf life from two days to 14 days or more,” Terrault states.

“This packaging has been conceptualized by recognized expert in eco-design,” he says, noting the widespread recylability of the PET (polyethylene terephthalate) #1 plastic used by the Gen V brand.

“We are really attentive to innovation,” he says, “and are always open to try a solution that could be less impactful than PET #1.”

Says Terrault: “We want our packaging to be perceived as a way to extend the

shelf-life of the product and not to be perceived as over-packaging.

“It’s a big task to educate our consumers on this: why there is a reason for us to utilize the packaging that we use.

“If we have the opportunity to make an eco-friendlier p[packaging choice we will do it, says Terrault, citing a recent switch from Plastic #6 clamshells once used to package mini-cucumbers to compostable and recyclable trays at a reasonable cost.

“There’s some innovation going on in the plastic industry,” he says, “but it’s still really expensive.

GrowPack NET TRAYS GrowPack NET TRAYS

“I hope that I hope one day the demand will be so high that we can all start using [recycled] rPET #1, for example, but right now it’s still too expensive,”Terrault says.

“There is a limit to how much more the consumers are ready to pay for ‘greener’ packaging,” he adds, “with price still being the Number One purchasing decision.

“We also wants be careful with greenwashing,” Terrault cautions.

“Sometimes the packaging that is considered ‘compostable’ is totally not, depending on the local municipality.

Made with 50% less plastic than traditional trays, the mesh design allows for reduced waste, easy washing, and cushion to your product. GrowPack net trays provide great savings and reduced carbon footprint. info@crawfordpackaging.com

crawfordpackaging.com The total solution! The total solution! Produce Packaging Films Top Seal Machines Flow Wrap Machines Come see us at Come see us at BOOTH 131 at BOOTH 131 at CCPMA! PMA! COVER STORY

1-800-265-4783

Close-up views of the beatiful Boston lettuce and organic cucumbers grown year-round at the Les Serres Lefort greenhouse complex in Ste-Cotilde.

March 2023 · CANADIANPACKAGING 23 CANADIANPACKAGING.COM Optimize your production output with DIGI Canada. At DIGI, we have extended our ingenuity and world-leading name in food packaging to create high productivity industrial machines. Ideal solutions for meat & poultry factories, central processing facilities, as well as agri-business entities seeking flexible, versatile solutions to increase speed and efficiency to meet the changing needs in today’s food retail. www.digisystem.com SCAN TO LEARN MORE

REVOLUTION sales@ca.digi-group.com |

JOIN THE DIGI

Systems

High-speed In-line Stretch Wrapping System Labelling

“It’s a big puzzle, and there’s a lot of advancement that needs to happen in the packaging world in this area,” he states.

“At the end of the day we are growers— not packaging specialists.

“That said, we want to do what’s right for the next generation,” says Terrault, arguing greenhouse farming is by definition a more sustainable farming method for growing many types of produce.

“We always favorize green energies like biomass and renewable electricity at our installations,” he points out.

“Climate change is a hot topic,” he acknowledges, “and we are seeing more and more difficulties with harvesting in field due to viruses, e-coli, water shortages, heat waves, frost and much more.

“We need to figure out new ways of cultivating so that we are not always at the mercy of Mother Nature,” he says, “and we think that greenhouses offer a

great way of doing this.

“We’ve been cultivating vegetables at -30° temperatures here in Quebec for 36 years,” Terrault points out. “Without this innovation, we would probably still be eating imported vegetables.”

As Terrault reasons, product and process innovation are integral components of the greenhouse farming industry.

“We are equally growers and entrepreneurs: one can’t go without the other,” he asserts. “We know that our core business is production and we put a lot of energies in that aspect.

“One of our biggest strengths is that we always ship on time,” he says, “and our client really like this consistency and reliability.

“We are looking at introducing some process innovation in the next few years,” Terrault reveals.

“We our doing some tests right now

with robotic arm for our cucumber harvesting,” he relates, “and we are working to launch more niche produce.

“The organic trend is getting bigger each year,”Terrault notes, “and we would like to launch an organic lettuce soon.”

In the meantime, Terrault is focused on seeing the company’s Gen V rebranding initiative succeed in the competitive marketplace.

“Our positioning is rooted in the agriculture of new values that match the value of cultivating fresh, tasty and healthy vegetables at a green house near you cultivated with respect for people and respect for the planet.

“This is what the next generations will not only want, but demand,” Terrault asserts. “Being a commodity product, what will set us apart is the choice we offer consumers: the choice to buy a fairtrade product that pays its employees a decent wage; the choice of a greenhouse that uses renewable energy; and the choice of a local vegetable produced by a local family.

“To do that, we want to disrupt this category with our positioning by focusing on our storytelling on all out platforms,”Terrault sums up. “We are a fresh, modern and vibrant brand with the added appeal of letting consumers choose a product that reflects their values.

“The next generation of consumers, people under 35 years of age, is ready to take over in the next few years, and it’s great to be able to offer them such a successful family business story.”

SUPPLIERS

Paxiom Group

Mitchel-Lincoln Packaging Ltd.

Cascades Canada Inc.

The high-speed Aweta GS model cucumber sorting machine is equipped with patented sorting cups to ensure accurate and stable weighing at high speeds and capacity.

March 2023 · CANADIANPACKAGING 25 CANADIANPACKAGING.COM CPK_ESS Technologies_march23_CSA.indd 1 2023-02-27 10:24 AM COVER STORY

Superior turnkey produce lines with Abbey Equipment Solutions.

ABBEY EQUIPMENT

SOLUTIONS is a Canadian company with the expertise and experience to deliver highly flexible equipment to automate your production line from the incoming raw materials to final packaging. With their diverse line-up of equipment options, they provide their customers with fully integrated solutions all supported by their local service team.

Abbey Equipment Solutions objective when embarking on a new project is to ensure that they are providing innovative, flexible, and cost-effective options from full lines to single machines.

PROCESSING

different types of cuts (cubes, sticks or slices) for a wide variety of vegetables and fruits (carrots, potatoes, cucumbers, melon, etc.). The three cutting heads allow flexibility in size and shape.

Main features:

• High cut quality and uniformity

• Wide selection of cutting thicknesses

• Continuous operation

• Blades and components durable/ high quality

Main features:

• It carries out the draining with beaters, extraction of the water under vacuum and blown air

• Maximum flexibility for a wide variety of products and applications

• Ideal for very fragile and delicate products

• Designed and manufactured in compliance with sanitation principles

VORTEX Automatic Electric Spin Dryer.

Main features:

• Shortening the cooling time

• Excellent control of the product temperature

For all your processing needs, TURATTI has Prep Tables, Grading/Sorting, Cutting/Dicing/Spiralizing, Peeling, Weighing/Mixing, Infusion, Blanching, Cooling,Washing/ Sanitizing and Drying.

K Series Transversal Slicer. The family of transverse cutters are suitable for cutting lettuce and different types of vegetables into slices or strips, changing the thickness of the cut with a simple speed adjustment or replacement of the cutting wheel.

Main features:

• High flexibility and possibility to adjust the speed of the conveyor belt

• Large selection of cutting thicknesses with continuous operation

HERA Universal Multi-Cutting Slicer. This versatile solution is designed for

VENEZIA Blowing Washer. This washing machine adapts to different production volumes and takes advantage of the gentle action of air bubbles to ensure an excellent result while preserving the integrity of the product. Suitable for baby leaves, lettuce, fruit, vegetables, and mushrooms, etc.

Main features:

• Suitable for floating and non-floating products

• Adjustable intensity of water jets and aeration

• Self-cleaning water filter

• Monofilament extraction belt

• PLC controlled with “touch screen”

• Available with insect drum

• Customizable

• Sanitizing and/or rinsing

Dewatering, Drying Solutions. These systems continuously remove water from the surface of fresh fruits and vegetables, limiting the mechanical stresses on the product. They are often used upstream of the drying tunnel and are offered in different solutions based on the customer’s needs.

This centrifuge is one of Turatti’s iconic models because of its innovative technology. It is designed to remove water quickly and effectively from the surface of the product after washing while respecting the most delicate of products. Its effectiveness, compact design, and the different capabilities available, makes this machine very flexible.

• Reduces cooling costs

• Easy access for sanitation and maintenance

INSPECTION OF RAW MATERIAL

RAYTEC VISION optical sorting machines remove foreign bodies, mold, and poor-quality product from the line.

Main features:

• Drying of very delicate and fragile products, whether in leaf or not

• High quality drying level

• Sanitary design for quick cleaning

• Fully automatic operation with recipe control of machine parameters

ARCTIC-WIND Hybrid Cooling Tunnel

Ideal for greenhouse operations this Hybrid Cooling Tunnel is specially designed to insure maximum product temperature (1/2°C) at the exit with minimum running costs. The main advantage of the ArcticWind model is it can operate with cold air, with nitrogen or with both. It consists of one cooling section installed in the tunnel frame and is powered with glycol.

The CURIOSITY is the first optical sorting machine born to achieve the totally hygienic compliance according to the EHEDG guidelines. This sorting machine combines innovation, essential design, and latest vision technology, it perfectly meets the needs of safety and quality control, hygienic operation, easy and quick sanitation.

Main features:

• Double-Chlorophyl technology

• Pulsed LED technology for optimum performance, flexibility, and low cost of ownership

26 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM

• Up to ten frequencies including red, green, blue, yellow, near infrared and chlorophyll can be combined to inspect any product for greater flexibility

• Automatic capture of images and production data for post-production analysis

CONVEYING

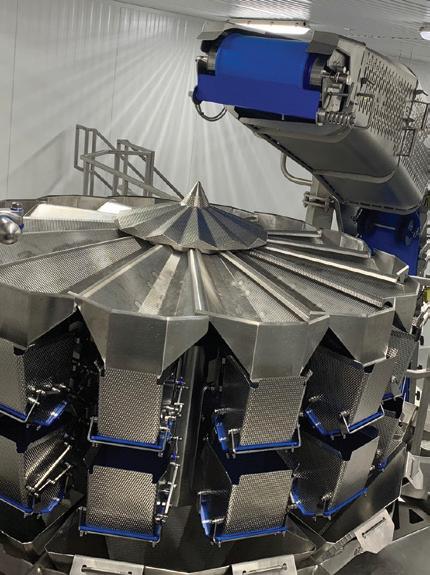

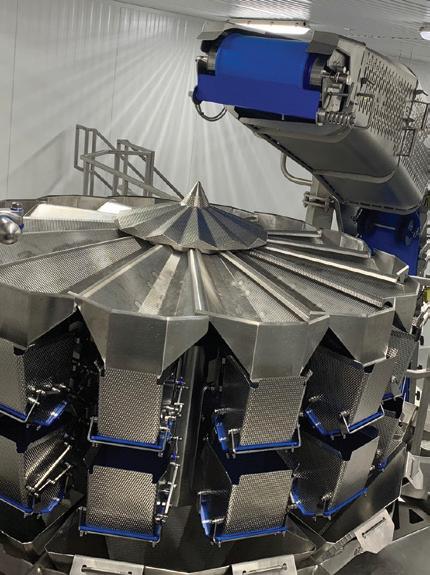

Main features:

• ARGUS 3D Camera for precise infeed control from the LIFTVRAC conveyor to the Multipond weigher

• Motorized rotary distribution cone is programmable and spins to feed the product where it’s needed on the weigher

Main features:

• Fast changeover of bag formats and film types in less than 5 minutes

• Reproducible settings using recipe management

• Easy-access design allows fast film changeover

• Low maintenance costs & limited wear parts

• Gas flushing capabilities

• Hygienic solution

INSPECTION OF FINAL PRODUCT

MECHANICAL SOLUTIONS, LINE INTEGRATION & SERVICE

Mechanical Solutions range from platforms, conveyors with a variety of styles/capacities, vertical tippers, wash racks and walls, plus a wide range of custom fabrication options. All of which are coupled with an additional understanding of clean design, ease of maintenance, sanitation, and methodology of working with different raw materials, which flow seamlessly into your HACCP programs.

The LIFTVRAC conveyor is a great alternative solution replacing other existing lifting systems on the market such as cleat belts, screws, vacuum sytems, and bucket elevators.

• Patented surfaces such as “stepped profile” aid the product flow in a way that dimpled surfaces simply cannot

• Standard IP69K construction

• Automatic calibration and feed control

BOWL & CLAM SHELL FILLING

The MULTIPOND transfer system allows for simulaneous filling of 1, 2 or 4 trays depending on the required speed.

Main features:

• Adaptable for different tray/bowl sizes

• Tool-less format change

ANRITSU’s SSV checkweigher, XR75 X-Ray and\or Metal Detector can be combined providing outstanding weighing accuracy and product inspection.

Setting the standard in X-Ray performance

Abbey Equipment Solutions Canadian based service team provides ongoing accessible technical support throughout the whole process from, testing, training, and installation to ensure customer satisfaction. With our various programs and a focus on service & support we can guarantee a heightened level of performance and up-time throughout the life of the equipment.

Main features:

• Gentle product handling

• Elevates product without flights

• Scraper at the discharge eliminating waste

• Modulates product and provides a controlled product flow to a Multihead weigher

• Easy access for sanitation and maintenance

WEIGHING & FILLING

MULTIPOND’s industry leading performance, accuracy, and reliability characterizes their weighing systems.

MULTIPOND’s J-Series combination weigher for leafy products include motorized rotary cone, patented stepped profile feed trays and ARGUS 3D camera providing hands-off consistent distribution of the product into the cone resulting in optimum speed and weight accuracy.

• Servo motor controlled with integrated product tamping

• Integrated controls with the Multipond weigher

• Easy access for sanitation and maintenance

BAGGING

Main features:

• Industry leading performance

• Low TCO – Advanced Long Life (A.L.L) technology up to 300% longer tube & detector life

• Diverse product line for packaged, bulk, and cased product

Combination, Checkweigher and Metal Detector coupled with an integrated reject system to inspect the final product.

GEA’s Vertical Flow Packaging

Solutions set the standards for reliability and performance with proven uptime of greater than 98%

The GEA SmartPacker CX400 handles a wide range of packaging types featuring its advanced sealing technologies - SmartSeal and UltraSonic Sealing.

Main features:

• Smallest footprint in the industry

• Detection of the smallest contaminants

• Various combinations of units to meet your requirements

For more information visit us at the CPMA Trade Show April 26th – 27th, BOOTH #440 or contact us at sales@abbeyequipment.com or 1-800-361-5919.

You can also visit our website www.abbeyequipment.com

28 CANADIANPACKAGING · March 2023 CANADIANPACKAGING.COM

E STABLISHED 1990 • QUALITY MACHINES & S E ECIVR •

Innovative turnkey solutions for the produce industry.

Abbey Equipment has machine solutions to deliver highly flexible produce lines.

Turatti – Grading/Sorting, Cutting/Spiralizing, Peeling, Weighing/Mixing, Infusion, Blanching, Washing/Sanitizing/Drying and Cooling

Multipond – Weighing, Transfer Distribution Systems, Filling, Clam Shell Packaging

GEA – Bagging, UltraSonic Sealing System

Anritsu – X-Ray Inspection, Metal Detection, Checkweighing, Combination Systems

Raytec Vision – Optical Sorting Solutions

Consolidated Technologies – Cartoners, Case Packing, Palletizing

With our diverse line-up of equipment options, we can provide our customers with full turnkey integrated solutions all supported by our local service team. Work with our skilled and knowledgeable team on your next project.

March 2023 · CANADIANPACKAGING 29 CANADIANPACKAGING.COM

| INSPECTION | PACKAGING SALES | SERVICE | INTEGRATION Visit us at the CPMA Trade Show at the Metro Convention Centre, April 26th to 27th. BOOTH #440 E STABLISHED 1990 • QUALITY MACHINES & S E ECIVR • TOLL FREE: (800) 361-5919 ABBEYEQUIPMENT.COM

PROCESSING

GROWING GAINS

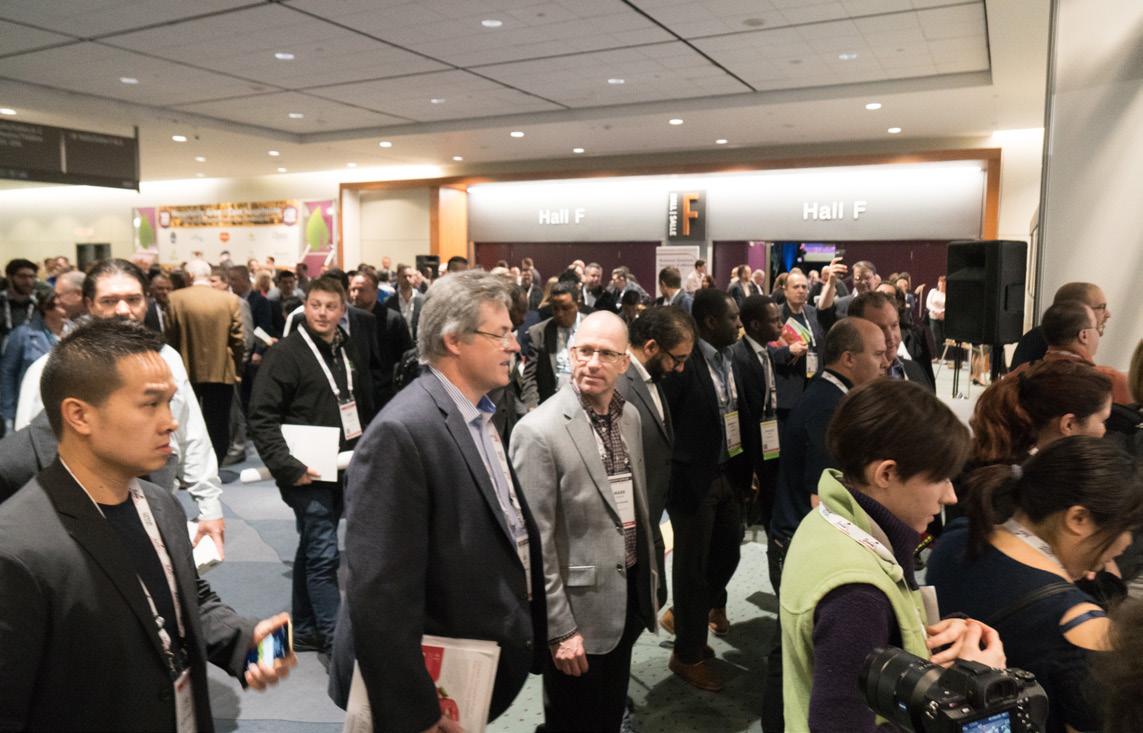

The annual CPMA Convention and Trade Show is Canada’s largest event entirely dedicated to the fresh fruits and vegetable industry. Each year, the show attracts thousands of participants representing the entire fresh produce supply chain.

This year, the 98th annual convention and trade show of the Canadian Produce Marketing Association (CPMA) will take place at downtown Toronto’s state-of-the-art Metro Toronto Convention Centre, which will house over 600 exhibit booths representing more than 270 companies from around the world.

As always, the CPMA Trade Show will enable visitors to discover new fruit and vegetable products like air-fryer veggie kits, veggie-based pastas and living lettuce, while providing live demonstrations and keen insights in how greenhouses, fieldgrown farms and packaging facilities operate across Canada and around the world.

All show participants will be offered an introductory guided tour, while sampling an array of tasty fruits and veggies throughout the show floor, to meet and greet the hardworking people who help provide Canadians with fresh fruits and veggies throughout the year to match their nutritional needs and increasingly healthy lifestyles.

Attendees who purchase full delegate registration will have access to all that the vibrant event has to offer, according to CPMA, including the Chair’s Welcome Reception, all meal functions and keynote speaker addresses, business sessions, social events, award presentations, and the grand Annual Banquet.

“We are thrilled to welcome Canadian and international produce industry professionals back to Toronto,” says Steve Bamford, chair of the CPMA 2023 Organizing Committee.

“In addition to showcasing products and services of the produce supply chain,

this year’s event is designed to offer exceptional opportunities for business development, education, networking, and socializing,” Bamford states

One of the CPMA Convention’s main attractions this year will be the so-called Learning Lounges, where industry experts will share their knowledge on various hot-button industry topics, including:

WEDNESDAY, APRIL 27, 2023

2:00 pm – 2:30 pm

Wholesalers - Solution Providers in an Evolving Marketplace