COLD COMFORTS CANADIANPACKAGING.COM MAY 2023 / $10.00 SERVING CANADA’S PACKAGING COMMUNITY SINCE 1947 EcoPack Now Page 12 Meat Industry Overview Page 21 Folding Cartons Page 27 East Coast deli meats processor using cutting-edge technology to carve out a bigger slice of the market

HIGGINS, V-P OPERATIONS, BONTÉ FOODS LTD. Connecting you to what's new & innovative in packaging 2023 June 6, 2023Barrett Centre for Technology Innovation Special Report After page 31 Page 21

ROBERT

Helping you bring your best products to market.

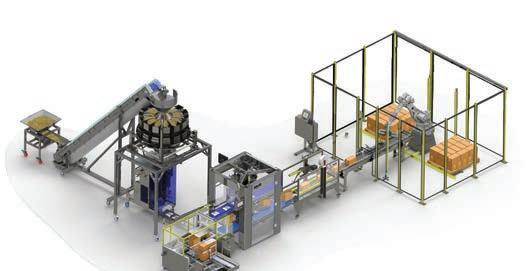

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

98 34 116

36 41

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Sep. 11-13, 2023 Booth C-1623, Central Hall Las Vegas Convention Center Las Vegas, NV USA

info@heatandcontrol.com | heatandcontrol.com

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

17 20

91 97

107 26

Videojet 1580 C Continuous Inkjet Printer Experience breakthrough soft-pigmented printing technology Discover more at videojet.com/1580C The contrast printer that performs and behaves like a dye-based printer ©2023 Videojet Technologies Inc. All rights reserved. Videojet Technologies Inc.’s policy is one of continued product improvement. We reserve the right to alter design and/or specifications without notice.

Vision Guided Pick & Place Cell

2 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM

• Up to 24 hours per day • No vacations • No workers comp • No insurance • No sick days • No attitude

PKR-Delta #ReadyToWork

Starting* at: $14 per hour single shift $7 per hour double shift $4.66 per hour triple shift *Investment adjusted to approximate hourly wage over 5 years 1.833.4PAXIOM PaxiomGroup PaxiomXperience Watch video at paxiom.com Pre-roll Weighing FillingBaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing LAS VEGAS • MILWAUK EE • MIAMI • TORONTO • MONTREAL • SCHIO, ITALY

DEPARTMENTS

NEWSPACK

7-8 Packaging news round-up.

NOTES & QUOTES

10 Noteworthy industry briefs.

FIRST GLANCE

11 New packaging solutions and technologies.

ECO-PACK NOW

12 Sustainable packaging innovations.

PEOPLE

43 Career moves in the packaging world. EVENTS

43 Upcoming industry functions.

COLUMNS FROM THE EDITOR

4 George Guidoni

More women industry leaders is a refreshing and long overdue development.

CHECKOUT

44 Jaan Koel

Joe Public speaks out on packaging hits and misses.

COVER STORY

15 CUT TO SIZE

Atlantic Canada’s biggest deli meats processor boosts its retail product output capacity with swift and seamless installation of a new high-performance thermoform packaging machine that has already exceeded all expectations for line efficiency and productivity.

FEATURES

21 Meat on the Table

As the Canadian Meat Council (CMC) celebrates its Centennial anniversary next month, top CMC executives reveal the marketplace and regulatory challenges facing the country’s red meat producers both domestically and abroad.

27 Maximum Impact

U.S.-headquartered specialty packaging producer makes a bold entry into the Canadian market for folding cartons with a game-changing acquisition set to transform the competitive landscape and shake up the industry’s status quo.

AFTER PAGE 31: SPECIAL REPORT

PAC CONNECTED 2023

Celebrating this year’s PAC Global Awards competition winners and promoting plastics circularity through cross-industry collaboration.

ISSN 0008-4654. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2023 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

ON THE COVER

Bonté Foods Limited vice-president of operations Rob Higgins strikes a cheerful pose next to the company’s new Reiser RE25 thermoform packaging system recently installed at the company’s production plant in Dieppe, N.B.

Cover photography by Dale Preston.

May 2023 · CANADIANPACKAGING 3 CANADIANPACKAGING.COM May 2023 Vol. 76, No. 4

canadianpackaging.com

15 35 21

More women industry leaders will benefit all packaging stakeholders

4%

Packaging industry

CEO jobs held by women in 2020

There is something exciting and refreshing going on in the top echelons of the global packaging industry, where glass ceiling are being smashed on many levels to give women industry leaders unprecedented levels of recognition and influence to breathe new life into an industry that had essentially remained an old boys network for far too long .

Earlier this month, the World Packaging Organisation (WPO) had elected Luciano Pellegrino, managing director of the Brazilian Packaging Association (ABRA) as WPO president, marking the first time that WPO will be headed by a woman in the group’s 50year history.

A few months ago, the venerable PMMI-The Association for Packaging and Processing Technologies had elected Patty Andersen, vice-president of human resources at prominent end-of-line machinery manufacturer Delkor Systems, as PMMI’s chairman of the board—again, for the first time in the group’s history.

Over at the Canadian Meat Council (CMC), which is celebrating its Centennial anniversary this year, Sofina Foods vice-president of industry and government relations Kerry Towles was elected as chair of the board in yet another significant “first” in CMC’s illustrious history.

Happy coincidences or an emerging megatrend? We would like to believe it’s the latter, and long overdue at that.

The lack of women in senior leadership roles is not something that has historically been restricted to packaging industry circles, far from it, but it’s about time that imbalance is being rectified, with women professionals finally getting their due as a largely untapped vast pool of visionary leadership excellence to disrupt the industry outdated sexist status quo to the dustbin of history.

As president of the Toronto-based rigid plastic packaging products manufacturer Polytainers, Susan Dalgleish is an inspired choice to lead the privately-owned company forward after the eventual pending retirement of its founder and current chief executive offi-

cer Robert Barrett.

For all the remarkable success that Polytainers has achieved over the years, the strengthening anti-plastic backlash will be a serious challenge for Polytainers and other companies like it to navigate in coming years. Happily for Polytainers, Dalgleish seems exceptionally well prepared and confident in taking on the enormous task of changing the narrative about the role of plastic packaging in the modern consumer society.

“A lot of our customers as grappling with how to explain a very complex topic to their consumers the right way, to ensure their brands remain strong and healthy,” Dalgleish told the Canadian Packaging magazine in a recent interview. “We have a big job our hands to educate people that plastic is a wonderful material.

“Any time you look at a proper lifecycle assessment, you will find that plastic is often a better material than any other out there in terms of putting more product on a pallet, taking more trucks off the road, and generating real savings in greenhouse gas emissions.

“There is no doubt that there are big changes coming,” Dalgleish says, “but it’s still difficult to predict exactly what those will be.

“What worries me is that when science and data don’t drive the conclusions, virtually any type of packaging can be banned for political reasons.

“That’s why we are committed to working with all our partners in the industry to try to inform the public about the many sustainability advantages of plastic by getting the right information out there.

Says Dalgleish: “I think our customers are going through a major education process that we are a part big part of.

“And as everyone in the value chain becomes more versed in the subject (plastics sustainability), we will be able to agree on promising new options that provide a more pragmatic approach to plastics circularity than we had so far.”

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

MAY 2023 | VOLUME 76, NO. 4

Reader Service Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

President/COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

4 CANADIANPACKAGING · May 2023

FROM THE EDITOR

Reiser Form/Fill/Seal Packaging Machines n Wide range of flexible machines produce high-quality vacuum, MAP and VSP packages n High-speed production n Superior seals eliminate leakers and returns n Backed by Reiser’s industry-leading service and support Watch video 2023 www.reiser.com Reiser Canada • Burlington, ON • (905) 631-6611 Reiser • Canton, MA • (781) 821-1290 Reiser UK • Milton Keynes, Bucks • ( 019 08) 585300 Take your business to the next level with Reiser packaging Extend product shelf life with superior packaging technology from Reiser

A CONFECTIONERY JUNGLE PACKAGED AUTOMATICALLY. BROUGHT TO LIFE WITH SCHUBERT.

How can you package confectionery and baked goods flexibly in a wide variety of pack formats? With pick & place robots that accurately position each product and systems that effortlessly switch between different packaging materials. Saving precious resources –with virtually no waste. This is our Mission Blue. A true benefit for the climate and the many FMCG manufacturers who have been relying on us since 1966. And for you too. www.schubert.group/en/confectionery-snacks.html

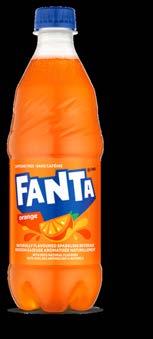

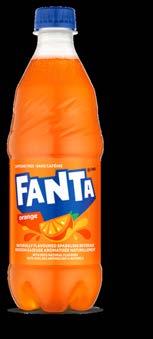

New Fanta Orange flavor a bold fruity treat for all senses

As the second-oldest soda brand owned by The Coca-Cola Company, Fanta Orange has had an illustrious history since its introduction to consumers in the 1940s—literally conquering the word with a unique bold flavor that many people says tastes more orange than the orange fruit itself. While that may be a feat of a lifetime in its own right, the universally beloved soda brand is aiming for even greater glory in Canada with the national rollout

of an all-new Fanta Orange said to be even bolder, fruitier and more refreshing than the original recipe.

Made and packaged in Canada by Coca-Cola Canada Bottling Limited, the new Fanta Orange comes in five sizes—sold individually and in multipacks—including 300-ml mini bottles (eightpacks); 200-ml mini cans (six-packs); 355-ml cans (12-can Fridge Pack cartons); and

500-ml and two-liter plastic bottles.

Each packaging format features splashy orange graphics created by The Coca-Cola Company’s global design team in collaboration with Jones Knowles Ritchie (brand identity and packaging), Relative (packaging guidelines and imagery) and Colophon (typography).

“We’re excited to introduce a new bolder Fanta, which is reflected on the packaging,” says Coca-Cola Canada’s senior marketing manager Jacques Blanchet.

“With a new look and feel, which includes a new visual identity and logo, Fanta still has the orange flavor you know and love, but is now fruitier and bolder than before—just in time for the summer.”

In addition to the new colourful look and feel, Fanta is celebrating the new flavor through an

integrated marketing campaign designed to immerse the senses, Blanchet relates, with the mission to inspire and infuse more fun and moments of everyday indulgence.

This includes the rollout of the Fanta Digital Ride n Sip, a new interactive mobile game that simulates the unique Fanta Orange flavor and offers fun rewards for the players.

In. addition, Canadian consumers can even experience the Fanta Orange flavor in-person at the experiential activations across Canada, which includes an out-of-home scented mural located at Queen St. West and Ryerson Avenue in downtown Toronto, where they can smell the bold, bright Fanta Orange scent.

CANADIANPACKAGING 7 CANADIANPACKAGING.COM NEWSPACK

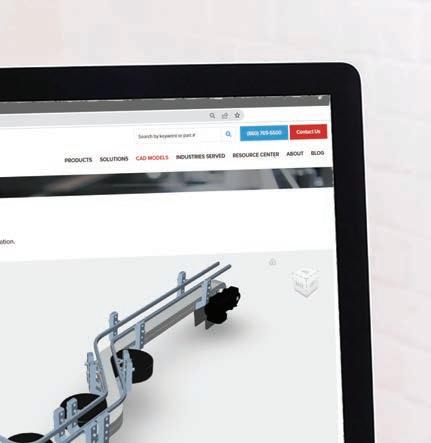

Conveyor Models at Your Fingertips Customize and download conveyor models in minutes with mk’s CAD360. Belt Conveyor Roller Conveyors Timing Belt Conveyors Flat Top Chain Conveyors Individual conveyors and entire conveyor systems. Registration is FAST and FREE!

New Natrel dairy beverage offers a perfect daily boost of tasty quality protein

While most modern consumers are nowadays week aware of the need to consume sufficient amount of protein over the course of the day, not all of them are aware that not all proteins are created equally.

According to Canada’s leading dairy products manufacturer Natrel, which has just added the new Natrel Plus Vanilla milk beverage to its popular Natrel Plus brand family, dairy protein offers a number of significant benefits compared to other types of protein.

For one, it contains all the essential amino acids, i.e. the protein building blocks that have to come from the diet because human body cannot produce them on its own.

In addition, the body can absorb and use dairy protein more easily than other proteins.

And with the launch of Natrel Plus Vanilla, getting the proper amount of protein has never been as delicious as when using the new protein shake concoction, made from 100-percent Canadian milk, to make fruit smoothies, lattes or matchas, as well as simply enjoy it on its own.

Containing 18 grams of protein per 250-ml single serving, the lactose-free beverage is also a good source of 11 essential nutrients.

According to Natrel, a glass of Natrel Plus Vanilla provides as much quality protein as consuming three large boiled eggs; 10 tablespoons of chia seeds; five tablespoons of peanut butter; four-and-an-half 100-ml yogurt cups; or 4.5 liter of almond-based milk substitute.

According to Natrel, a subsidiary of leading Canadian dairy processor Agropur, both the Natrel Plus Vanilla and the Natrel Plus Chocolate contain 50 per cent less sugar than regular chocolate

milk, with no artificial flavors or sweeteners.

Sold in two-liter gabletop cartons with built-in resealable caps for easy pouring, the Kosher-certified beverage is made form ultrafiltered lactose-free milk to make it safe and accessible to lactose-intolerant consumers.

Cascades to shut down underperforming plants in its tissue paper division

Leading Canadian paper products manufacturer Cascades Inc. has announced a sweeping restructuring of the company’s tissue business that will see it shut down its “underperforming” tissue plants in Barnwell, S.C., and Scappoose, Ore., as well as the virgin paper tissue machine at its St. Helen’s plant, also in Oregon.

Although the equipment slated for closure has total annual rated capacity of 92,000 short tons of tissue paper and 10 million cases of converted product, according to the Kingsey Falls, Que.-headquartered Cascades, it has recently been

operating well below capacity— producing 56,000 short tons of tissue paper and five million cases of converted product in 2022.

“A portion of this production will be absorbed by open capacity at our other facilities and by the increase in productivity at our sites, particularly in the U.S.” says Cascades, adding it has the option to evaluate the possibility of redeploying the seven conversion lines impacted by this decision to other sites at a later date.

While the company expects the closure costs, including severances, to total between $20 million and $25 million, it has pledged to work closely with the 300 affected employees to mitigate the impact of this decision.

“This will include, among other things, offering to relocate as many employees as possible to its other business units in the U.S.,” Cascades states.

“Employees who cannot or do not wish to relocate to other plants will receive support in their search for other employment.”

8 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM

NEWSPACK 23_002265_CN_Pckg_MAY_CN Mod: March 22, 2023 10:28 AM Print: 04/12/23 1:34:52 PM page 1 v2.5

COMPLETE CATALOG 1-800-295-5510 uline.ca π SHIPPING SUPPLY SPECIALISTS CPK_Uline_May23_CSA.indd 1 2023-04-17 9:02 AM

HUGE SELECTION OF POLY BAGS IN STOCK

Preparation & Processing

Portioning & Slicing

Packaging Equipment

Packaging Materials

Automation & Integration

Inspection & Verification

Labelling & Coding

Dough Processing

May 2023 · CANADIANPACKAGING 9 CANADIANPACKAGING.COM

MULTIVAC Canada Inc. 1-877-264-1170 ca.multivac.com sales@ca.multivac.com

Meat and Poultry Ontario (MPO) has officially opened up the new Centre for Meat Innovation and Technology (CMIT) at the University of Guelph campus to help Canadian meat processors collaborate, find and adopt new technology and innovation and make it easier for their employees to learn and advance their skills. “This center will ultimately help both processors and meat and poultry producers,” says CMIT director Luis Garcia. “We did our research, and both processors and farmers told us there was significant room for them to grow if some of the key barriers holding them back could be addressed.” Founded and supported by MPO, CMIT is planning to become a self-sufficient innovation, training and research hub within five years by building fees for its

services, starting with the launch of a fundraising campaign aiming to raise $1 million to cover initial operating costs.

industries. Under the agreement, Krones has an option to buy the remaining 10 per cent of the shares in Ampco—which remains operating under current management—at some point in the future. “The acquisition of Ampco is a major step in enhancing the Krones Processing Group portfolio and will provide a broader distribution network to offer customers a wider range of processing technology and components,” says Krones Inc. president and chief executive officer Holger Beckmann. “In addition, the businesses of the two companies complement each other perfectly in regional terms.”

From

Beverage processing and packaging equipment supplier Krones Inc. of Franklin, Wis., has reached an agreement to acquire a 90-percent ownership stake in Ampco Pumps Company, Glendale, Wis.-based manufacturer of sanitary pumps, mixing, and blending equipment for the food, beverage, dairy, personal care and pharmaceutical

Leading Japanese manufacturer of advanced packaging and life science materials Toppan has announced plans to open up a new production facility in the Czech Republic to manufacture transparent barrier plastic films for a broad range of packaging applications. To be located in Most, the new plant is expected to commence mass production by the end of 2024, according to the Tokyoheadquartered Toppan. “By taking advantage of the new plant’s location, Toppan will bolster its capacity to supply transparent barrier films to packaging manufacturers in Europe, where we see some of the world’s most environmentally-friendly countries, and accelerate our sustainable business transformation globally by strengthening relationships with top-rated companies in the areas of ESG (environment, social and governance) and the SDGs (sustainable development goals),” says Masahiko Tatewaki, managing executive officer of Toppan’s global packaging business. “This plant will also employ the most environmentally-friendly technologies, such as heat reuse systems, with an emphasis on maximum energy efficiency

Stahl, a globally operating supplier of coating technologies headquartered in Waalwijk, The Netherlands, has completed the acquisition of ICP Industrial Solutions Group (ISG), Andover, Ma.-based manufacturer of high-performance coatings for packaging and labeling applications. With annual revenues of about US$140 million, the ISG acquisition reinforces Stahl’s position as the global leader in the field of specialty coatings for flexible substrates, according to the company.

“Completing this important strategic acquisition is an important milestone for our organization,” says Stahl’s chief executive office Maarten Heijbroek, “as it will enhance our growth profile, diversify our target markets, and broaden our technology base. Moreover, integrating ISG’s expertise and range of innovative low-impact solutions into our portfolio will add further value to our stakeholders, as we work to create a more sustainable coatings value chain.”

10 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM

NOTES & QUOTES 10 CANADIANPACKAGING · May 2023

From Left: MPO president Kevin Schinkel, MPO executive director Franco Naccarato, Ontario minister of agriculture, food and rural affairs Lisa Thompson, and CMIT Director Luis Garcia.

The new UX2 InkJet Printer-Developed for Tomorrow’s production line Call us today for more details or to book a demonstration 1-877-427-5863 sales@harlund.com www.harlund.com QUICK CHANGE CONNECTORS ON BOARD VIDEO GUIDANCE CLEARER CODES & FASTER SPEEDS LONGER PRINTING CYCLES FIRST IN INDUSTRY SAFE PRINTHEAD CLEAN STATION CPK_HARLUND_SQ_MAY23_MLD.indd 1 2023-04-24 10:52 AM

Left: Krones Inc. CEO Holger Beckmann; Krones AG chief financial officer Uta Anders; Krones AG director of M&A Sebastian Schaefer; Ampco executive vice-president Lori Neisner; Ampco president Michael Nicholson; Krones AG head of process technology Buelent Bayraktar; Krones AG chief executive officer Christoph Klenk.

HYBRID SOLUTION

The new model 9750+ continuous inkjet (CIJ) printer from MarkemImaje is a hybrid coder designed to provide the flexibility to print standard dark codes or color-contrasted codes by using dyes or pigmented inks, while delivering premium legibility and permanence. Whereas producing both code types traditionally required two types of machines and many different spare parts, the 9750+ hybrid solution enables manufactures to achieve both with one printer model—streamlining maintenance and spare parts needs, while also providing operational flexibility and lower costs. Incorporating an innovative polyvalent ink circuit, said to be the first of its kind for coding, the 9750+ can generate text messages up to five lines, logos, and high-resolution linear and 2D codes on a vast array of packaging substrates using its patented unique Intelli’Inks system to ensure optimal performance when coding different materials, while its Jet Speed Control technology automatically adjusts ink and printer variables to provide perfect drop placement, print quality and code consistency to minimize scrap and rework.

Markem-Imaje

accommodate future changes in capacity requirements.

Regal Rexnord Corporation

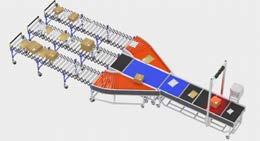

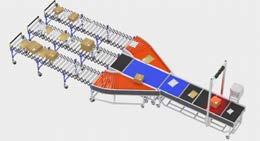

SORTING THINGS OUT

The ModSort sortation system from Regal Rexnord Corporation is a fully-automatic sortation solution capable of handling a diverse range of products—from small polybags to boxes up to 30-kg—at rates up to 3,000 pieces per hour. Powered by a safe and energy-efficient 120V AC power supply, and operating at only 72 dB—about the same amount of sound generated by a household washing machine—ModSort uses the company’s patented System Plast belts, which utilize rotating spheres to provide a high degree of motion control and the ability to convey packages in any direction. Intended for use as a ‘Last Mile” sorter, the plug-and-play system’s divert and transfer module can be easily enhanced and expanded with the addition of new sort zones to

THINK ABOUT INK

INX International Ink Co. has launched two new printing formulations offering significant sustainability advantages to help brand-owners achieve their environmental objectives. Designed as a solvent ink for flexographic outdoor bag printing, DuraINX HRC is formulated with high-performance pigments to offer excellent high speed printability and superior long-lasting properties with robust product, fade, and rub/scuff resistance that stands up to environmental exposure. The highly durable inks are free of nanomaterials, fluorochemicals, fanal pigments, heavy metals or PTF (platinum fluoride) particles. For its part, the mew Ecostage GB-XA is an oxygen barrier coating that addresses food safety and preservation issues, while improving sustainability and recyclability by allowing for mono material packaging to replace multilayer packaging for specific food applications—thereby making it easier to recycle the package. Developed specifically to improve the oxygen transmission rate of flexible packaging materials, the transparent, chlorine- and metal-free coating offers a cost-effective alternative expensive barrier films, according to the company.

INX International Ink Co.

FAST AND EASY

Leveraging touchscreen operation to automate powder induction and dispersion processing, the Fastfeed PLC system from Admix, Inc. offers many attributes for quick and ergonomic incorporation of powder ingredients into mix tanks at high efficiency levels, including rapid incorporation and wetting out of powder ingredients; touchscreen operation, recipe storage and job status monitoring, and one-touch CIP (clean-in-place) mode.

Admix, Inc.

May 2023 · CANADIANPACKAGING CANADIANPACKAGING.COM

FIRST GLANCE FOR FRYER, BREADING, AND BATTER CONVEYING KleanTop® PacTitan™ Pro Proven to last more than 6 times longer than the average metal conveyor belt. Regal Rexnord, KleanTop, PacTitan and Rexnord are trademarks of Regal Rexnord Corporation or one of its affiliated companies. © 2022, 2023 Regal Rexnord Corporation, All Rights Reserved. MCAD22025E • Form# 10491E Scan the QR Code to speak to a Rexnord Specialist and learn how PacTitan Pro can help improve production and employee safety. For more information, visit Rexnord.com or call 866-739-6673 within the U.S., or +31 174 445 111 outside the U.S.

Standing Up for Recyclability

Making the ever-popular stand-up pouches and other flexible packaging products truly sustainable and circular is a massive industry challenge that will require material producers and machinery manufacturers to be on the same page throughout the next-generation packaging’s life-cycle.

And while not everyone in the industry may have gotten the memo just yet, some progressive companies—including German-based film manufacturer SÜDPACK and packaging machine-builder SN Maschinenbau—are already setting a benchmark for collaborative excellence in fast-tracking the sustainability of flexible packaging.

Earlier this month, the two companies teamed up at the recently held interpack 2024 global packaging showcase in Düsseldorf, Germany, for a joint demonstration of the Pure-Line zippered stand-up pouches from SÜDPACK running at speeds of up to 270 pouches per minute on SN’s new FMH 300 pouch packaging machine.

Developed to address the ongoing trend in pouch packaging to use more material-efficient and more recyclable alternatives, the high-performance films in the Pure-Line product family are based on the PE (polyethylene) polymer compounds lauded for their widespread recyclability and material efficiency, according to SÜDPACK.

The PE monomaterial can be equipped with different features and barrier properties to ensure that products are aroma-proof, airtight, and

have a longer shelf-life when packaged, with easy-to-integrate zipper systems making it convenient to open and close the pouches.

These PE-based systems are already available on the market, which means these stand-up pouches can be assessed as a true single-material solution and introduced into the appropriate recyclable material cycles.

As SÜDPACK explains, “Customers will greatly benefit from the minimal use of resources while enjoying optimal pouch stability and reduced packaging weight, which leads to an improved carbon footprint along the entire process chain.

“The recyclability of the packaging can be verified with a certificate from independent external institutes,” says SÜDPACK, adding the PE monomaterial is particularly suitable for primary packaging for grated cheese, sausages, snacks and other food product requiring superior shelf-life properties.

For its part, the high-speed FMH 300 pouch packaging machine is a horizontally operating pouch packaging machine that features a special hygienic design with a rotary table to form, fill and seal flat stand-up pouches from rollstock.

While it is fully capable of processing conventional multimaterial structures, it really stands out for its ability to work with the new sustainable and recyclable monomaterial films, like SÜDPACK’s PurePE films.

Boasting a wide array of innovative technologies—such as continuous web draw-off, the option of adding continuous ultrasonic zipper sealing, or the fully-automatic block adjustment of the sealing frames—it offers considerable cost-saving potential due to the use of even thinner and more recyclable films to limit the environmental impact.

Moreover, the hygienic design of the FMH machine range makes it particularly suitable for packaging products such as grated cheese or air-dried sausages, which are extremely demanding applicationa when it comes to the cleanability of the packaging machine.

The hygienic structure of the range keeps surfaces, corners and crevices to a minimum to avoid possible product build-up, which reduces potential contamination as well as the amount of effort needed to clean the machine.

Last but not least, the impressive FMH 300 triplex model offers high speed operation and maximum flexibility thanks to its extremely broad format range.

Depending on the product properties and the size of the pouch, it is possible to achieve an output quantity of up to 270 pouches per minute, with the nearly fully-automatic changeovers performed almost entirely on the machine’s HIM (human-machine interface) operating panel.

The One & Only Green Choice

Leading Danish skincare brand NUORI has combined eight hero skincare ingredients in a single formula for its new launch of The One.

The simple, yet highly functional, all-natural cream benefits from the powerful protection of Quadpack’s Regula Airless packaging, which shields the hard-working formula from external contamination without the need for synthetic preservatives.

As a responsible skincare brand, NUORI selected recyclable materials for its packaging, including 100-percent rPET (recycled polyethylene terephthalate) for the outer bottle and cap, retaining their sea-green shade, aesthetically blended with the brand logo.

“We wanted the most sustainable pack with the highest protection,” says NUORI brand manager Ann-

Marie Rønlund Jensen.

“As our expert partner, Quadpack always takes us on a journey to navigate the options in terms of innovation and sustainability,” Jensen explains. “With The One, our research and discussions led us to embrace recycled material, complete with its imperfections and color variations.

“Airless was a given,” she sates, “and the finished pack perfectly fits

our mindset of high performance, simple aesthetics and low waste.”

As Jensen explains, The One is formulated to be an all-inclusive product for everyone— simplifying complicated skincare routines into an easy, yet effective one-step ritual.

Like all NUORI brand products, it contains no synthetic preservatives, stabilizers and other additives often used to prolong shelf life.

Instead, it relies on Airless technology and small-batch production for the freshness of the ingredients.

“The One carries an expiry date that applies from the moment it was made,” Jensen points out.

Made entirely in Europe, The One is bended in Denmark, while its packaging is manufactured and decorated at Quadpack’s production facilities in Kierspe, Germany.

“Quadpack’s experience in PET injection enabled a flawless mix of PP and rPET,” Jensen relates.

“The inner bottle and metal-free pump—the parts in contact with the ‘bulk’ conents—are made of PP for product compatibility.

“A rigorous three-month testing process ensured perfect affinity between formula and packaging,” she adds.

As Jensen relates, the outer bottle and cap, both rPET, were left uncolored and visibly recycled, with branding applied in two-color silk-screen.

The inner bottle, adapter and dispenser were color-injected for a harmonious match with the sea-green of the outer surface—resulting in attractive and sustainable packaging solution that perfectly encapsulates Scandinavian minimalism.

12 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM

ECO-PACK NOW

May 2023 · CANADIANPACKAGING 13 CANADIANPACKAGING.COM STAND UP & OUT GETTING INTO STAND-UP POUCHES? 647-323-4797 929-800-4912 1-866-339-3407 planitpackaging.com Weighing | Bagging | Flow Wrapping GET INTO PLAN IT PACKAGING We offer a complete range of horizontal and vertical pouch packaging machines. Buy entry level or something with all the bells and whistles and with all the re-sealable options. We supply weighing, bagging wrapping and end of line packaging systems. Our machinery solutions incorporate all leading sustainability measures: reduced energy consumption; minimal waste of materials; machine compatibility with recycled materials. Let us tailor-make a stand-up, re-sealable pouch packaging solution that fits your exact needs.

14 CANADIANPACKAGING · May 2023 SUSPECT FOREIGN MATERIALS X-RAY INSPECT & RECOVERY 3rd Party Rework Services for Food Products OFFSITE INSPECTION • x-ray inspection of finished food products • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 Separation identification of bolt Identified foreign body: Single 1 inch long Stainless-Steel Bolt Identified foreign body: Steel Shaving from Auger Failure Identified foreign body: Calcified hollow chicken bone Chicken Bone: 22 x 7 x 2.4mm

CUT TO THE CHASE

Enterprising New Brunswick deli meats processor doubles down on thermoform packaging to drive future market growth

By George Guidoni, Editor

Photos by Dale Preston

By George Guidoni, Editor

Photos by Dale Preston

As the most popular topping on one of the world’s most popular dishes, sliced pepperoni is a genuine contender for being one of the most enduring and beloved cured sausage meats ever invented.

Made from ground beef and pork— and seasoned with salt, paprika, garlic and other flavorful seasonings—the tasty, zesty and tangy can be found on many of the estimated five billion pizzas consumed around the world each year.

Coupled with its mainstream popularity as an enjoyable stand-alone snack

or as an integral part of fancy charcuterie spreads, cheese boards and antipasto platters, this chewy Italian-American invention has become a perennial crowd-pleaser across North America over the decades.

With an estimated 250 million pounds of pepperoni consumed each year in the U.S. alone, its remarkable mass appeal is even celebrated with a dedicated National Pepperoni Day on every September 20 south of the border.

Here in Canada, pepperoni is also a must-have item in the product portfolio of just about every meat processor specializing in the production of deli meats and cold-cuts, including Bonté Foods Limited of Dieppe, N.B.

May 2023 · CANADIANPACKAGING 15 CANADIANPACKAGING.COM

COVER STORY

Bonté Foods vice-president of operations Rob Higgins holds up a pepperoni and cheese combination snackpack packaged in airtight high-barrier film on the plant’s Reiser RE20 rollstock thermoform packaging machine directly to his left.

Top One of two high-performance Seydelmann AG160 grinders located in the Dieppe plant’s processing area.

Middle & Bottom

Neat rows of sliced pepperoni, salami and ham placed onto the film-lined cavities of the Reiser RE25 rollstock thermoform packaging machine prior to being packed into thermoformed Pizza Variety Valu Pak retail packages.

Operating out of the same 66,000-square-foot facility for the last 46 years, albeit comninously expanded and retrofitted ove the years, Atlantic Canada’s largest deli meats manufacturer produces over 150 food products for the foodservice, grocer retail and institutional markets, including pepperoni, salami, ham, bologna, pastrami, donairs, gyro meat, pizza sauces, and many other popular food items.

Nowadays producing and packing about 85,000 kilograms of product per week, the company’s varied product portfolio comprises more than 150 SKUs (stock-keeping units), according to vice-president of operations Rob Higgins.

In addition, Bonté Foods markets a comprehensive line of high-quality sauces, condiments and RTE (readyto-eat) meals that are co-packed for it offsite under the company’s brand labels and distributed throughout Canada.

“Being centrally located in the Maritimes makes it easy to ship our products within Atlantic Canada, Higgins says, “and it’s also a perfect location for exporting to the U.S.”

Having joined Bonté Foods 20 years ago, Higgins has been actively involved in numerous facility and equipment upgrades and capital investments that have enabled the one-time niche food manufacturer to evolve into a highly diversified and well-respected player in the Canadian meat processing industry.

“In 2005 Bonté acquired Chris Brothers, who operated a federal plant in Nova Scotia and was well-known for their snack pepperoni,” Higgins relates.

“This purchase started Bonté down a more focused business approach on meat production with decision to discontinue sauce and bakery production in-house and securing co-packers for these items,” Higgins continues.

16 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM COVER STORY

Above Equipped with touchscreen graphic HMI (human-machine interface) display terminal, the Reiser thermoform packaging machine features one-touch pushbutton cycle activation.

Left Vacuum-packed in clear high-barrier transparent plastic film supplied by Winpak, the air-tight Pizza Variety Valu Paks feature easy-open peel-off lidding for enhanced consumer convenience.

“The focused approach has been a successful,” he asserts, “with Bonté now enjoying a very strong retail deli presence in Atlantic Canada, complemented by national foodservice sales across Canada.

“In 2020 Bonté was acquired by ADP Direct Poultry in a move intended to diversify their existing chicken processing facilities in Ontario,” says Higgins, noting that it also allowed Bonté Foods to expand its offering of poultry-based meat products.

“Our raw products, including some packaging, are sourced locally when possible,” Higgins points out. “If something is not available locally, we source it from within Canada whenever possible.

“Our raw processing side runs five days per week,” says Higgins, “and our RTE operations runs seven days per week.

“Our busiest time of the year is from November through January,” he relates, “as this is when consumers tend to entertain and eat more.

“We know this going into this period, so we ramp up production in September and October to help out with this production increase.”

As Higgins relates, some of the more popular foodservice industry products produced at the Dieppe plant include bulk-sized Donair and Gyro cones (made in 10-, 15- and 20-pound versions); cooked beef toppings (in 2.5and five-kilogram portions); and a variety of cooked sliced pepperoni and salami shipped in five-kilogram packs.

On retail side of the business—comprising the company’s flagship Chris Brothers and Bonté brand labels—the plant makes a broad variety of sliced deli meats and donair slices in portions ranging from 150 to 375 grams.

“Our two highest-selling branded SKUs are our Pizza Variety Valu Pak and our 1.5-kilogram Wax Style Bol -

May 2023 · CANADIANPACKAGING 17 CANADIANPACKAGING.COM

ogna,” Higgins reveals.

“Our Pizza Variety Valu Pak is a 175gram vacuum pack containing pepperoni, salami and ham,” Higgins states. “It has been a key retail product for us for several years.”

Two of the plant’s three slicing lines are primarily used to make retail products, Higgins explains, with the third slicer dedicated to foodservice production.

“We also have a bulk pack-off area where we pack our beef toppings and any whole pepperoni, salami and bologna sticks,” he relates.

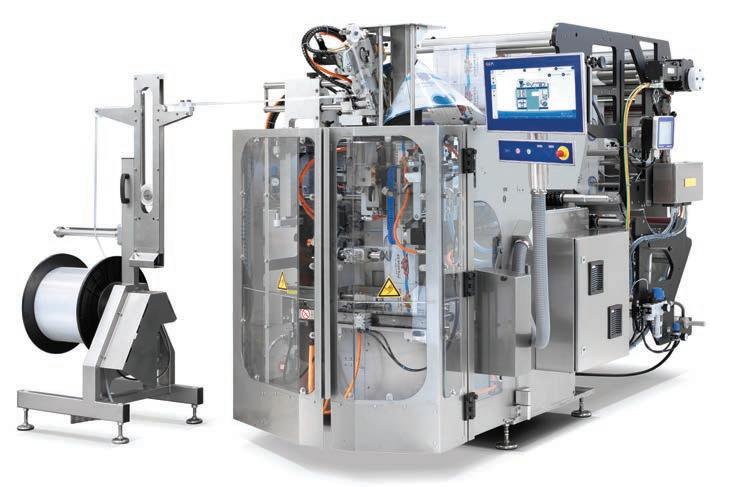

“In the raw meat department we have an automatic linking and hanging line, an automatic pan oiler, and an automated label applicator in the RTE area on the new RE 25 thermoform packaging machine we recently bought from Reiser,” adds Higgins, hailing the recent

arrival of the spanking new Reiser RE 25 horizontal form/fill/seal thermoform packaging machine onto the factory floor.

Commissioned and started up earlier this year with the assistance of local Reiser Canada sales rep Jean Collette, the new state-of-the-art Reiser RE25 is actually the second Reiser thermoformer at the Dieppe facility, which installed the earlier-generation Reiser RE20 rollstock machine supplied to the plant by Reiser back in 2011.

While that machine is still performing admirably, the new Reiser RE25 has been a real game-changer for the plant, according to Higgins.

“We have several pieces of equipment from Reiser, but I have to say the one that has made the fastest impact has been the most recent purchase of the

RE25,” he states.

“The new RE25 purchase replaced an aging rollstock machine,” he says, “and it has exceeded our expectations.

“This (RE25) line is by far our busiest line,” Higgins states.

“It packages about 85 per cent of our retail sliced deli meats, and we have seen an overnight increase in output of almost 20 per cent coming off this line, with packages that look better and have great seals and consistent vacuum.

“This has been huge for us, as it gives us plenty of room to grow,” says Higgins, while lauding the excellent service and support provided by Reiser throughout and following the installation.

“We had a tight installation time-line on this, so we actually went to test the RE25 at Reiser’s headquarters facility

18 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM COVER STORY

Above left The Reiser RE20 rollstock thermoform packaging machine originally installed at the Dieppe facility in 2011.

Above right The popular pepperoni and cheese snackpacks, produced on Reiser RE20, contain side-byside pepperoni and cheese sticks in one convenient package.

in Canton, Ma., and their team was exceptionally professional and knowledgeable.”

Such endorsement is naturally music to the ears of Collette, who points out that Reiser was also the key supplier and integrator for the two high-performance Seydelmann grinders for Dieppe plant’s processing area.

“We have always had a good long-standing relationship with Bonté and Rob Higgins,” Collette says. “We have always worked to support them when called upon, and we are happy to do this as a good partner.

“The equipment was installed within a tight-time frame,” Collette points out, “so we relied on good communication and planning on both sides.

“We worked together with Bonté and had our people on-site for the duration of the project to make sure everything

went as planned,” Collette relates.

“It was important that we listened to what Bonté needed and that we provided the correct solution and start-up.

“Our service department made sure we delivered on this, providing Bonté with a high-quality solution to update their packaging.”

Higgins agrees: “The installation was on schedule and without any issues— thanks to our maintenance team and Reiser’s personnel.

“We are proud to be a BRCGS AA+ (Retail British Consortium Global Standards)-rated plant,” Higgins points out. “We made the decision to start with unannounced audits three years ago as we felt it would challenge us to be better,” he explains, “and we have held on to the AA+ rating every year since.

“We have also been Halal-certified since 2017,” Higgins adds.

Such attention to product quality and consumer trends have certainly served Bonté Foods well in its journey to become ‘Atlantic Canada’s Deli,’ as the company’s logo tagline proclaims.

“Although we have a few national listings, our retail presence is most predominant in Atlantic Canada, where you can find our deli meats and donair packaged under Chris Brothers and Bonté brands,” Higgins relates.

“On the foodservice side we sell sliced cooked pepperoni and salami, donair cones and cooked beef topping to dis -

tributors across Canada,” says Higgins, adding that retail products account for about 60 per cent of the plant’s production volumes.

“Brand recognition is one of our biggest strengths,” Higgins says, “and being smaller than most of our key competitors allows us to be flexible and responsive to our customers’ and consumers’ needs.”

According to Higgins, the high-quality vacuum-packing and MAP (modified atmosphere packaging) capabilities enabled by the Reiser-supplied equipment will play key role in the company’s further growth in the marketplace.

“Obviously, from a marketing and presentation perspective the packaging is the customers’ first impression of your product,” he says, “and that will help drive out sales going forward.

“But beyond that, and perhaps more importantly, it plays an important role in shelf-life and food safety, and you need the right packing materials and the right equipment for your products.”

According to Higgins, Bonté Foods has those angles well covered through long-standing partnerships with leading materials and machinery suppliers such as Reiser, Poly-Clip , Winpak and Master Packaging, among others.

As he sums up, “We view all our key suppliers as true partners, and we strongly believe in utilizing their expertise to grow our business.”

May 2023 · CANADIANPACKAGING 19 CANADIANPACKAGING.COM

Left Bonté Foods production manager Dean Young (left), Rob Higgins and Reiser Canada’s sales representative Jean Collette inspect the sealing quality of the combo pepperoni-and-cheese snack packs coming off the Reiser RE20 rollstock machine.

Right Finished packs of Pizza Variety Valu Paks being manually placed inside corrugated shipping containers supplied to the Dieppe facility by Master Packaging.

“Being smaller than most

of our key competitors allows us to be flexible and responsive to our customers’ and consumers’ needs.”

Please see a video of the Reiser RE25 thermoform packaging machine from Reiser in action at the Bonté Foods plant on Canadian Packaging TV at www.canadianpackaging.com

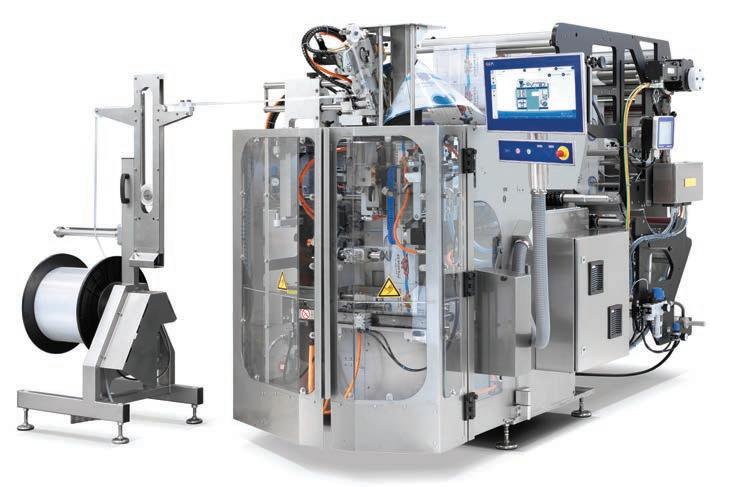

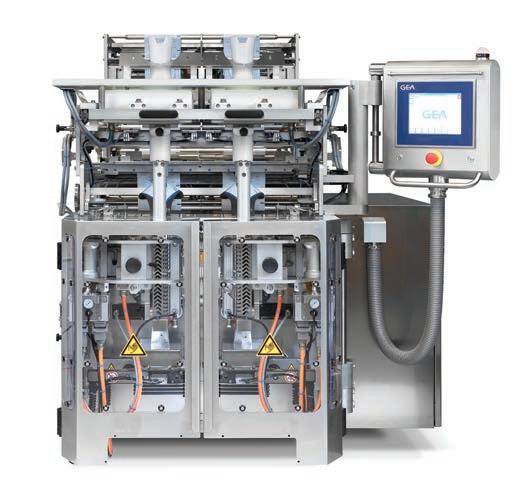

GEA

The GEA SmartPacker vertical packaging solution offers more than 10 different bag styles directly from the reel, from flat pillow bags to stand-up zipper bags for a wide variety of products. You can switch bag styles quickly and easily, without the need for special tools. Most importantly, changeover time takes only minutes.

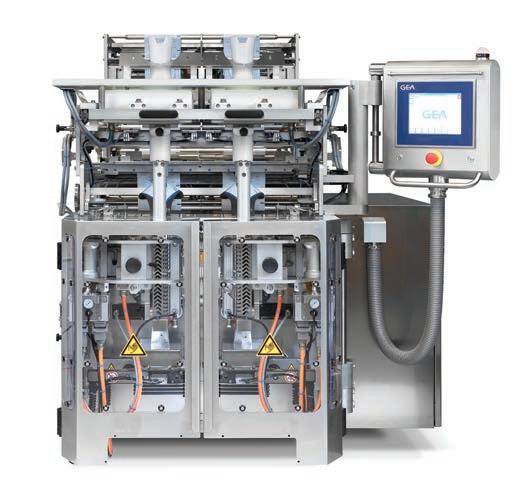

GEA

With a combined production output of up to 500 bags per minute and a new reinforced modular design, the GEA SmartPacker TwinTube high-speed packing system brings big productivity benefits, more flexibility and operational efficiency.

20 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM Looking for flexibility, speed, and efficiency in a bagger? PACKAGING | INSPECTION | PROCESSING SALES | SERVICE | INTEGRATION

SMARTPACKER CX400 D-ZIP

SMARTPACKER TWINTUBE

E STABLISHED 1990 • QUALITY MACHINES & S E ECIVR • TOLL FREE: (800) 361-5919 ABBEYEQUIPMENT.COM

SMARTPACKER TWINTUBE SMARTPACKER CX400 D-ZIP

Canadian Meat Council’s vice-chair of the board Russ Mallard is president of Atlantic Beef Products in Albany, P.E.I., where the company operates a 55,000-square-foot facility that is actually the only federally-inspected beef-processing establishment in the Maritimes region, primarily supplying local grocery retailers, specialty meat shops, foodservice distributors and value-added meat processors.

CHEERS TO 1OO YEARS!

Canadian Meat Council marking its centennial anniversary with a keen eye on future industry trials and tribulations in new uncharted global trade headwinds

Turning 100 is a once-in-alifetime feat that very few people or organizations manage to achieve, but if anyone really deserves high praise for a century of work well done, the Canadian Meat Council (CMC) certainly merits all the accolades it genuinely deserves.

And as the venerable industry group prepares to formally toast the occasion with due aplomb at its upcoming annual CMC Conference and AGM (Annual

General Meeting) next month (June 5-7, 2023) at the landmark Omni Hotel Mont-Royal in downtown Montreal, the Canadian Packaging magazine caught up with its top two executives to assess the current state of the country’s critically vital red meat processing industry, which is facing some serious new economic and trade challenges that can only be resolved through concerted efforts of all of the industry’s stakeholders to make sure it remains a robust engine of economic growth and product innovation.

Here is the two-part interview recently conducted by the magazine’s editor

May 2023 · CANADIANPACKAGING 21 CANADIANPACKAGING.COM

MEAT REPORT

KERRY TOWLE Q&A

QLastyear marked CMC’s 100th anniversary and you were named CMC’s first woman as Chair of the Board of Directors. As you reflect on one year in the position, which of the major milestones/initiatives that the Canadian Meat Council has carried out are you most proud of? How have they benefited the industry and the Canadian consumers?

AAs Chair, I am most proud of the hard work and information our dedicated staff provides to both industry and government.

Our staff works diligently to engage with membership to understand their opportunities and challenges. Using fact-based data and best practices ensures our members have the information they need.

This allows for industry and government to work collaboratively and provide resolutions rather than barriers. This has benefited industry and regulators.

CMC has long been the voice for the meat industry, and it continually strives to provide solutions to address the challenges facing our members.

The regained access for pork into China has been critical for our pork

Top right China’s ambassador to Canada Peiwu Cong (third in left row) meeting with the CMC board of directors ast month at the Maple Leaf Foods offices in Mississauga, Ont., to discuss trade and market access issues between the two nations.

members.

We have more work to do on access for beef, but I am confident in the collaboration between CMC and international trade offices that this will be resolved.

QPleaseexplain CMC’s success in longevity, staying power, relevance, and healthy membership base. What would you like to see the Council initiate, address, and accomplish going forward?

AThe longevity is based on our approach to and with government.The tone the Board and staff have in all their interactions with government is to be constructive and solutions-based. Government wants to work with us because they see us as a credible partner.

In terms of going forward, I want to see more cohesion amongst the various trade associations in the industry.

We work well together, but there are at times to much light separating our positions, and that affords government the chance to do what is easier, as opposed to what we need, because we are not fully aligned.

Alignment and approaching challenges and opportunities aligned is critical to the success of our industry as a whole.

QPlease provide a macroeconomic snapshot of the state of the Canadian meat processing industry now – revenues, employment, GOP contribution, R&D activity, trade and exports, and spin-off economic activity.

AOur members directly employ over 64,000 people in rural and urban

locations nationwide and additionally support 300,000 jobs along the supply chain.

Our sector offers highly-skilled, well-paying jobs that support all Canadians. The meat processing sector strengthens communities where it operates, while significantly contributing to the GDP (Gross Domestic Product).

Canada is the world’s 5th largest exporter of agricultural and agri-food products, and Canada’s consumption of red meat was estimated at $13.8 billion in 2019, accounting for all the fresh, frozen and processed red meat products purchased from stores and restaurants.

Trade enables an economic and environmentally sustainable sector. Different markets demand different products; cuts that may not be popular in Canada are sought-after elsewhere in the world. This permits our members to obtain a higher value for our product overall and reduce waste.

QWhat would CMC like to see the Canadian governments do to help ensure a healthy and viable meat processing industry in Canada – regulations, guidance, new market development, investment funding, tax breaks, other incentives, etc.? What are the specific industry challenges and concerns that the Council is addressing/advocating on their behalf?

AThe key factor for us is communication. When government is looking at new regulations/standards we need them to bring us into the conversation at the beginning of the process, rather than

22 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM MEAT REPORT

George Guidoni with Kerry Towle, CMC Board Chair and Vice President, Industry and Government Relations, Sofina Foods Inc., and Russ Mallard, Vice Chair, CMC Board, and President, Atlantic Beef Products Inc.

Top left Kerry Towle, CMC Board Chair, Vice-President, Industry & Government Relations, Sofina Foods Inc.

Russ Mallard, CMC Vice-Chair, President,

mid-way through or at the tail end, when it becomes very difficult to undo what they have decided to do.

The biggest issues right now are market access and equitable trade agreements stemming from the government’s trade program.

Naturally, access into China is always top-of-mind and, increasingly, the issue of ESG (environmental social governance) for the members-companies.

QPlease describe the significance/ intent/impact of the upcoming CMC Conference & AGM in Montreal on June 5, 2023, and why the meat companies in Canada should try to attend the event.What are some of the most important industry trends and issues to be highlighted at the event?

AHaving the new president of the Canadian Food Inspection Agency (CFIA) speaking at our event allows for insight and feedback into this agency’s critical role for our industry, so hearing it all directly is a fantastic learning opportunity.

Companies who attend will have the opportunity to engage with a variety of industry partners, government officials and vendors. Bringing these groups together in one environment provides an exceptionally cohesive and efficient option for engagement.

This is a key factor in the value of CMC’s AGMs and our organization.

Of course, there will be many additional topics of interest to our members and others.

These include issues such as the en-

vironment, AI and market access—all the critical issues that permeate the dayto-day activities of all our members.

RUSS MULLARD Q&A

QWhatare biggest challenges and hot-button issues and talking points for the beef industry at the moment?

AThe biggest challenge and the hot-button issue is the Specified Risk Material (SRM) removal policy, and the need to harmonize it with the United States.

While Canada and the U.S. have both been recognized as having “negligible risk status” for BSE (bovine spongiform encephalopathy) , the costs associated with the different policies put Canada at a competitive disadvantage.

Canadian abattoirs must remove an average of 57 kilograms of SRM material, whereas their U.S. counterparts must only remove three kilograms from animals over 30 months of age.

For animals under 30 months of age, Canada must remove 7.2-kilograms, compared to three kilograms in the U.S. As a result, the disposal cost to Canada averages $167 per metric tonne, and the cost to the industry is about $31 million per year.

To put it in perspective: if you look at 500,000 head of cattle in both countries, disposal costs in Canada are $6.5 million, whereas for the same number in the U.S. it is only $514,000.

It should be noted that about one million head of Canadian cattle that are exported to the US for slaughter are subject to the U.S. policy.

Our Industry is working with the government to address this issue, and a comprehensive risk assessment is being performed to justify the change to harmonize with U.S. policy.

Regarding market access issues, now that Canada has received negligible risk status, there are still some countries that have not removed the BSE restrictions that were put in place after the first case

of BSE was discovered in Canada in 2003.

The Canadian Government Market Access team—consisting of Agriculture and Agri-Food Canada, Global Affairs and the Canadian Food Inspection Agency —is working with international counterparts to negotiate the removal of these outstanding restrictions, which include such things as only access for animals under 30 months of age, limits for bone-in beef and offal, and meat and bone meal.

Moreover, there are other important issues that affect the beef industry, such as the challenges we face in the European Union.

The Canada-EU Trade Agreement (CETA) has had a very unbalanced effect on beef and pork trade to date. While exports of beef and pork from the EU to Canada have risen significantly, Canadian exports to the EU have been very limited.

The strict measures we must face, such as hormone-free beef and various restriction on processing methods, will be further complicated by more new barriers coming in connection with the New Green Deal, which will further limit our access.

Moreover, China remains a very challenging market for our industry. We are working with our Embassy in China, we met recently with the Chinese Ambassador to Canada, and we have CMC staff back meeting on the issue in China.

We are very focused on finding a solution, not just for the short term but a longer term. We want and need stable and reliable access.

QHow does Canada’s beef industry rank on the world stage and in the context of global economy? Are there any particular areas of strength or weakness that stand out?

ACanada is the fifth-largest exporter of agricultural and agri-food products, and meat processing is the largest component of Canada’s food processing industry. It represents about 12 per cent

May 2023 · CANADIANPACKAGING 23 CANADIANPACKAGING.COM

Atlantic Beef Products Inc.

“Our members directly employ over 64,000 people in rural and urban locations nationwide and additionally support 300,000 jobs along the supply chain.”

of Canada’s agri-food exports, and it employs more than 68,500 Canadians.

On average 46 per cent of Canada’s beef production and 69 per cent of pork production is exported, excluding the live animals exported to the U.S. for feeding and slaughter.

Canada is an efficient producer of high-quality beef, and we export it to 80 countries around the world.

Our biggest trading partner is the U.S., accounting for 70 per cent of our exports, followed by Japan, Mexico and South Korea.

Until recently, China was our second most important market.

Canadian consumption of beef is growing. We consume an average of 18 kilograms of beef per person annually, but, since our population is relatively small, we export almost 50 per cent of total beef and cattle produced in Canada.

Beef exports were valued at $4.7 billion in 2022, as our export numbers have doubled in the past five years.

Notably, 95 per cent of Canada’s cattle and hogs are processed in a federally-inspected facility.

QWhatare the companies in your sector doing to lower their environmental and packaging footprint?

AAt the plant level, many CMC members have up-to-date sustainability plans that address the primary environmental impacts of meat processing: water usage, energy consumption and waste reduction.

Activities such as metering incoming and outflowing water, and using the data to evaluate progress towards conservation targets and planning for upgrades, as well as retrofitting existing facilities to incorporate solar and thermal power sources, are clear examples of concerted efforts being made to minimize our

plants’ overall environmental footprint.

Individual companies do seek ways to reduce plastics usage. However, it is only one piece of the environmental puzzle, and we must always keep food safety considerations in mind as we explore ways to minimize our packaging use.

Positively, innovation and research has introduced cost-effective alternatives, which some of our members have incorporated.

In terms of future improvements, there are discussions underway to explore an industry-wide target-setting initiative. It would be useful to define some useful benchmarks for the industry, against which individual companies can measure themselves.

QWhatare some of the most significant meat packaging/labeling trends that you have witnessed in your industry in recent years?

AThe use of plastic packaging is important to preserve the meat products’ safety, as Canada’s federal government is looking to reduce plastic waste and promote sustainable procurement in all sectors.

A regulatory framework has been

created to achieve the plastic reduction objectives, but the government understands the role of plastics to comply with the high food safety standards of meat products manufactured in Canada.

The meat industry keeps searching for innovating packaging which is more friendly for the environment, and it is conscious about the plastic pollution.

The Canadian meat industry is monitoring these development closely, and we will continue to underscore the importance of the ongoing engagement of Canada in an ambitious global treaty on plastic.

On the labeling initiatives, on July 20, 2022, Health Canada published the Regulations Amending the Food and Drug Regulations to add a new requirement for front-of-package (FOP) nutrition symbol labelling for most pre-packaged products containing nutrients of public health concern—including saturated fat, sugars and/or sodium—at or above specified thresholds. The FOP nutrition symbol will help Canadians to more easily identify foods high in these nutrients.

On May 1st, 2023, the guide for stakeholders in the Canadian food industry was released. This guide should be followed by Canadian manufacturers, retailers and importers of foods for sale in Canada. Prepackaged raw single-ingredient meat, meat by-products, poultry meat or poultry meat by-products that are not ground products are conditionally exempt from the symbol requirements.

Likewise, raw single ingredient meat, meat by-products, poultry meat or poultry meat by-products that are ground are conditionally exempt from the FOP requirement.

However, they are required to carry the Nutrition Facts table.

Regulated parties must comply with the requirements for all components of these amendments as of January 1, 2026, so there is still a lot of work to be done in the months and years ahead.

24 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM MEAT REPORT

“The strict measures we must face, such as hormone-free beef and various restriction on processing methods, will be further complicated by more new barriers coming in connection with the New Green Deal, which will further limit our access.”

CANADIANPACKAGING.COM Discover Solutions Up Close Step onto the PACK EXPO Las Vegas show floor and immerse yourself in the largest display of innovative packaging and processing machinery and materials on the continent. packexpolasvegas.com Everything you need to move projects forward and prepare for the future. REGISTER NOW at the $30 Early Bird Rate! 2,000 exhibitors 40+ vertical markets 100+ free show floor sessions Endless networking opportunities expectinnovation

26 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM With the innovative Speedmaster CX 104 offset press, combined with the new Mastermatrix 106 CSB die-cutter and Diana X-2 115 folder gluer, discover easy job changeovers and a high level of productivity that can take your path into packaging to the next level. heidelberg.com/cx104 Heidelberg Canada Graphic Equipment Limited 5900 Keaton Crescent, Mississauga, Ontario L5R 3K2 Phone +1 (800) 363-4800, ca.customerservice@heidelberg.com

MAXIMUM IMPACT

New Canadian folding carton industry stalwart looking to make instant impact as turnkey packaging solutions provider

By George Guidoni, Editor

Photos by Naomi Hiltz

Reaching for the stars is not just wishful thinking when the stars are as perfectly aligned as they are for MAX Solutions in the company’s bold quest to be a leading player in Canada’s highly competitive folding carton industry.

With its recent acquisition of the family-owned Ellis Group of companies last fall, the U.S.-headquartered specialty packaging producer has many good reasons to feel confident about its big strategic move north of the Canada-U.S. border, having inherited a vast wealth of leading-edge production equipment and machinery, a highly trained and dedicated workforce, and an impressive client base of blue-chip

CPG (consumer packaged goods) customers built up under the Ellis family’s 40-year-long ownership.

With three Ontario-based state-ofthe-art operating plants in Pickering, Mississauga and Guelph, the newly-acquired assets provide a robust launching pad for the privately-owned MAX Solutions—founded in 2021 by longtime paper industry veterans Mark Shore (chief executive officer) and Dennis Kaltman (president and chief operating officer)—to accelerate its rise to the elite ranks of North America’s speciality packaging industry segment.

With over 75 years of industry experience and leadership between them, the two life-long entrepreneurs are certainly no strangers to recognizing a good opportunity when one comes along, as vividly illustrated by their

May 2023 · CANADIANPACKAGING 27 CANADIANPACKAGING.COM

FOLDING CARTONS

MAX Solutions president Dennis Kaltman (left) and Pickering plant manager Don Smart discussing the quality of the final print on a sheet of paperboard printed on the plant’s Komori Lithrone GL40 eight-color offset press.

Clockwise from top:

A selection of high-end folding cartons printed for top CPG brands by MAX Solutions; a side view of the eight-station

Komori Lithrone GL40 printing press; the Optima-K 106 40-inch die-cutter manufactured in Barcelona, Spain, by Iberica, part of the Koeing & Bauer (KBA) group of companies.

amicable Ellis Group acquisition.

“The company founder Bill Ellis had a lot of success building up his company over the years along with his children, Cathy and Dave, over the last 40 years, so when we heard that the business was up for sale, we were very interested,” Kaltman told the Canadian Packaging magazine in a recent interview.

“When we first decided to start up MAX Solutions, the Canadian market was something we thought about a lot,” Kaltman says, adding the new assets perfectly fit into MAX Solutions’ strategic plan to become a leading supplier of value-added folding cartons, labels and specialty rigid packaging.

According to Kaltman, the landmark deal provides plenty of synergies and opportunities for MAX Solutions to become the one-stop packaging solutions provider it wanted to be right from the outset.

With that in mind, Kaltman says the new owners will be actively pursuing the idea of adding new label manufacturing capabilities to its Canadian locations, which is something MAX Solutions already has in place at its two original greenfield manufacturing facilities near Philadelphia, Pa., and Charlotte, N.C.

“There is a reason why we have the word ‘Solutions’ in our company name,” Kaltman points out. “We’re not here just to provide a product: we want to be able to provide customers, particularly those in the healthcare industry, with a complete packaging solution,” he states.

“Customers like dealing with less

suppliers, not more,” Kaltman reasons, “so if you are only good at doing one thing, you are not as valuable as someone who can make all the things they need across the board.

“The quality requirements for cartons and labels are the same,” he asserts, “so if you put in the quality system for both, it adds value to the customers, as well as for the salespeople selling our products and services to them.

“It creates more opportunities for us going forward,” says Kaltman, citing the company’s commitment to making positive “multidimensional” impact on four key stakeholder groups:

• Customers , by investing in

next-generation technology to support their growth by always putting forth the best solution regardless of format, material or process.

• Teammates (employees), by creating a great environment to work in and empowering them to learn, take on new opportunities and reach new heights.

• Communities where the company operates, by supporting the local “home” economies through employment opportunities and training programs.

• Environment , by creating the most efficient production flows;

28 CANADIANPACKAGING · May 2023 CANADIANPACKAGING.COM FOLDING CARTONS

innovating ways to simplify the supply chain; designing solutions that are recyclable and minimize waste; and investing in technology and materials that reduce the company’s carbon footprint.

As Kaltman relates, MAX Solutions prides itself on executing complete and highly customized packaging concepts with its talented and creative in-house design team, top-notch project managers, and long-standing vendor relationships to live up to its corporate mission.

According to Max Solutions, the company’s primary core competencies include:

• Speed to Market. From designing production floors for optimizing manufacturing flow and efficiencies to investing in hybrid presses that run multiple imaging concurrently, the entire process is designed reduce downtime and provide quick turnaround. According to the company, this includes utilizing highly integrated software for a seamless integration of upfront prepress workflows.

• Contingency Planning . The company’s strategically selected plant locations are outfitted with with duplicate technologies to reduce the risk inherent in produc-

tion planning. According to MAX Solutions, its Cloud-based software systems make it easy to adjust production plans quickly, while mitigating any security issues.

• Zero Defect Quality. The company’s massive investment in new-generation technologies enables it to deliver Six Sigma product quality levels on everyday basis. All of its printing presses feature built-in color control and inline inspection and power registration, while its high-performance folder-gluers feature the most advanced reject detection and ejection capabilities in the market.

• Sustainability. The company’s carbon-neutral presses are designed to the highest levels of energy efficiency to minimize emissions, scrap and process waste, coupled with the “leanest” manufacturing standards to shorten the supply chain and reduce fuel consumption, including the use of electric-powered forklifts for internal operations.

As one would expect, the company is no slouch when it comes to product innovation, with the patented PaperFoam material—supplied via a joint-venture with Dutch producer PaperFoam BV—providing an effective biodegradable and compostable alternative to plastic packaging inserts, thereby ensuring full product protection and integrity for with minimal environmental impact.

Combined with expert in-house

Top There are a total of six Iberica die-cutters installed a the three former Ellis Group production facilities in Ontario over the years.

Left The BOBST Cartonpack II is a fully automated packing station that can pack up to 150,000 sheets of printed cartonboard per hour inside shipping boxes in various stack patterns.

May 2023 · CANADIANPACKAGING 29 CANADIANPACKAGING.COM

30 CANADIANPACKAGING · May 2023

die-cutting and tooling capabilities, the company’s repertoire covers the entire gamut of high-impact finishing processes, including specialty embossing, inline Braille embossing, specialty coatings, inline cold-foil application, hot-foil stamping, cello windowing, holographic primography, and security tag labeling, among others.

According to Kaltman, such versatility and diversification made the Ellis Group an especially attractive proposition for connecting with top brand names in the high-end market segments for beauty and personal-care, food-and beverage, confectionery, healthcare and pharmaceutical, consumer electronics and, more recently, medical and recreational cannabis markets.

As Kaltman relates, “We were very impressed by the wonderful job they (Ellis) did in maintaining the service levels to their customers during and coming out of the COVID-19 pandemic.

“And that’s a testament to the people working there,” he states, “as well as to being such a service-oriented company.”

Despite the often-cited industry M&A trend whereby companies often buy out their competitors primarily to reduce competition, Kaltman insists that MAX Solutions is totally committed to growing its new Canadian assets in a way that generates new employment opportunities at all three former Ellis locations—both on the production floor and within management ranks.

Says Kaltman: “Ellis has built up a lot of brand equity in the marketplace, and it is our intention to build on that brand equity by not only continuing to

do what they have already done so well, but by being able to offer even more value to the market.”

Similarly, Kaltman says that MAX Solutions is fully committed to retaining strong bonds with the existing supplier base that includes household industry names such as Metsä Board , Heidelberg , Sun Chemical and BOBST, among others.

According to Kaltman, the Canadian market for folding cartons has a lot of good things going for it at the moment—especially with the ever-growing emphasis on sustainability and related plastics substitution—to provide MAX Solutions with a unique opportunity for significant growth in market share and reach.

“It’s a great market to be in,” he states, “and we look forward to expanding our presence in it.

“While the shortage of labor is the one thing many people are talking about nowadays, in my experience Canada is in better position in this respect than the U.S.,” Kaltman says.