COMING CLEAN Heavy-duty automatic bagging machinery gives industrial laundry operator a clear edge in packaging line productivity Story on Page 18

Show Preview Sept. 11-13, 2023 Starts Page 31 CANADIANPACKAGING.COM SEPTEMBER 2023 / $10.00 SERVING CANADA’S PACKAGING COMMUNITY SINCE 1947 PACKAGE DESIGN Page 23 AUTOMATE NOW Page 27 CANNABIS PACKAGING Page 47

FROM LEFT: MARIO FERRON, DIRECTOR OF OPERATIONS, BLANCHELLE ANDRE STRUL, TERRITORY MANAGER, PAXIOM GROUP

Helping you bring your best products to market.

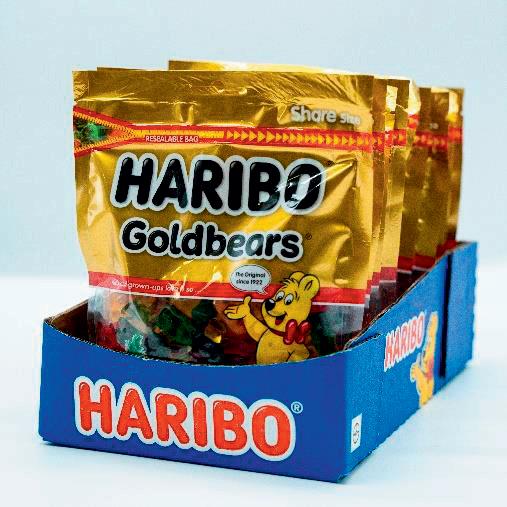

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

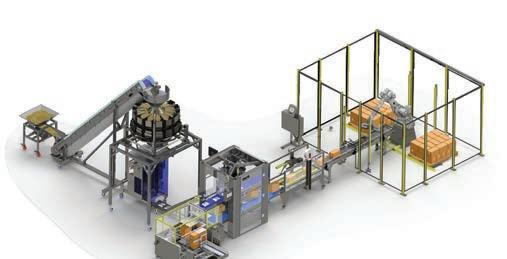

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

98 34

36 41

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

116

Sep. 11-13, 2023 Booth C-1623, Central Hall Las Vegas Convention Center Las Vegas, NV USA

info@heatandcontrol.com | heatandcontrol.com

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

17 20

91 97

107 26

Videojet 1580 C Continuous Inkjet Printer Experience breakthrough soft-pigmented printing technology Discover more at videojet.com/1580C The contrast printer that performs and behaves like a dye-based printer ©2023 Videojet Technologies Inc. All rights reserved. Videojet Technologies Inc.’s policy is one of continued product improvement. We reserve the right to alter design and/or specifications without notice.

2 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM #ReadyToWork • 24 hours per day • No vacations • No workers comp • No insurance • No sick days • No PTO Starting* at: $14 per hour single shift $7 per hour double shift $4.66 per hour triple shift 1.833.4PAXIOM PaxiomGroup PaxiomXperience Learn more at paxiom.com Pre-roll Weighing FillingBaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing USA • CANADA • ITALY PKR-Delta Watch the Full Video Here *Investment adjusted to approximate hourly wage over 5 years Vision Guided Pick & Place Cell

CLEAN SLATE

Industrial laundry operator achieves immediate productivity boost at its new facility with installation of a giant-sized automatic vertical bagging system.

FEATURES

23 Private Matters

Leading Canadian grocery retailer leverages outstanding package design to grow its private brands portfolio.

27 Value Proposition

Packaging machinery manufacturer deploys diverse automation technologies to make its cartoning machinery more flexible.

31 Predictable Outcomes

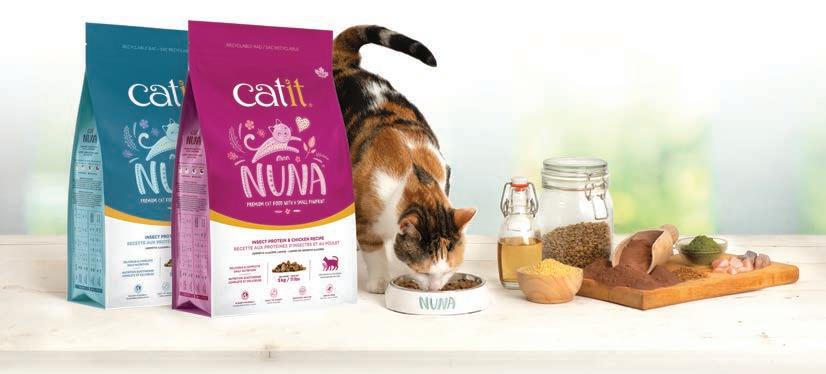

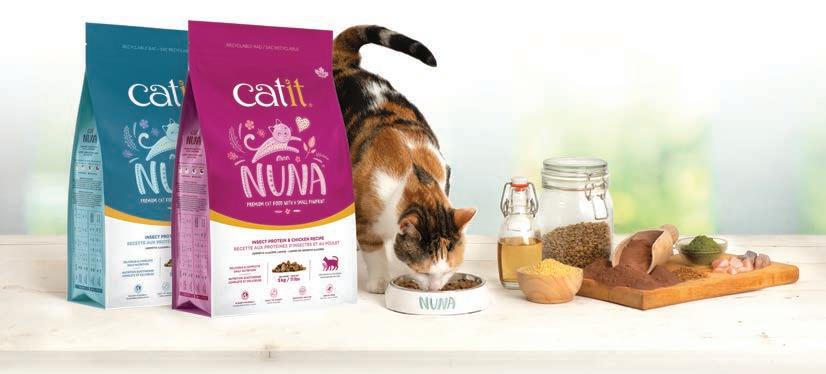

35 Pet Projects

36 Fresh New Ideas

37 Higher Expectations

39 Show & Tell

A sampling of the exciting new technologies to be displayed at the PACK EXPO Las Vegas 2023 exhibition next month.

47 Trusting the Process

A brief preview of the upcoming Process Expo food processing exhibition in Chicago next month.

49 High Stakes

Investigating the current packaging trends in the recreational cannabis business.

September 2023 · CANADIANPACKAGING 3 CANADIANPACKAGING.COM September 2023 Vol. 76, No. 7 canadianpackaging.com ISSN 0008-4654. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2023 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada. DEPARTMENTS NEWSPACK 6-8 Packaging news round-up. NOTES & QUOTES 10-11 Noteworthy industry briefs. FIRST GLANCE 12 New packaging solutions and technologies. ECO-PACK NOW 14 Sustainable packaging innovations. IMPACT 15 A monthly insight from PAC Global EVENTS 53 Upcoming industry functions. PEOPLE 55 Career moves in the packaging world.

COVER STORY 18

COLUMNS FROM THE EDITOR 4 George Guidoni Microplastics pollution a looming crisis. CHECKOUT 56 Sawyer Lewis Joe Public speaks out on packaging hits and misses. 18 37 27 ON THE COVER Blanchelle director of operations Mario Ferron and Paxiom Group’s territory manager Andre Strul share a light moment in front of the toweringVerTek 2400 vertical bagging

at

new Masouche

WeighPack Systems.

machine installed

Blanchelle’s

facility by

Microplastic pollution a looming crisis in search of macro solutions

SEPTEMBER 2023 | VOLUME 76, NO. 7

Reader Service Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: 416-510-5113 apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

3 MILLION

Metric Tonnes

An estimated volume of microplastic ocean pollution by 2040

Sometimes it’s the little things that kill. Typically measuring less than five millimeters, the so-called microplastics are both little and potentially lethal, or at least exceedingly harmful to human health, animal welfare and the plant’s overall well-being.

And according to a new report from leading Chicago-based research intelligence firm PreScouter, the packaging industry must bear a lot of responsibility for its part for creating a global microplastics pollution crisis that is sorely in need of some serious clean-up.

Released earlier this year, the new Microplastics in Industry report clearly identifies packaging as being one of the four major industrial contributors to the microplastics overkill, the other three being cosmetics, textiles and paints.

In 2016, microplastic pollution accounted for 1.3 million metric tonnes, the report notes, representing 11 per cent of total ocean plastic pollution. If left unaddressed, microplastic ocean pollution is predicted to reach three million metric tonnes by 2040.

And while regulatory agencies have expressed concerns about the hazards associated with microplastics, the report’s authors acknowledge, a complete understanding of their impact on human health and the environment is still evolving.

While that may be true, that is hardly an excuse for not taking early remedial action to stave off what could well turn out to be a looming global health catastrophe down the road.

“Microplastics are being talked about as ‘the next forever chemicals’ based on raising health and safety concerns,” says PreScouter’s technical director Marija Jovic. “Although there is more research needed to fully understand these concerns, some regulations in countries across the globe are already in place.

“Therefore, it is important to think about mitigating microplastics in order to keep the company’s reputation and revenue,” Jovic states.

As the PreScouter report points out, “Microplastics are considered an emerging persistent pollutant of diverse shapes, sizes, and chemical compositions and are found from Mount Everest to the deep

sea and within wild animals and humans.

“They are produced because of commercial product development as well as the breakdown of bigger plastics,” the study points out. “Microplastics have been found to accumulate in the bodies of organisms and can cause physical harm, as well as potentially release toxic chemicals into the environment.”

According to the report, about 32 per cent of the 78 million metric tonnes of plastic packaging produced worldwide annually ends up in the oceans, providing huge continuous feedstock for microplastics proliferation

“Many packaging materials degrade overtime into smaller and smaller fragments—producing microplastics that are released into the environment during use, disposal or recycling,” PreScouter notes.

While the sheer volume of packaging plastic-based materials that are produced and used globally makes it difficult to implement large-scale solutions that can effectively reduce microplastic pollution, the PreScouter report suggests that further advances in biodegradable and compostable plastic packaging can help alleviate the problem in the future.

But even without such dramatic technological leaps, there are various measures that companies can take at different points in a package’s life-cycle to minimize its microplastics footprint.

The study cites the example of Nestlé’s new range of Yes! snack bars—packed in paper wrappers coated with a biodegradable polymer—as a noble “upstream” measure for minimizing microplastics waste. Conversely, timely “downstream” measures can be equally effective.

“For example, Filtro produces washing machine filters that can capture up to 90 per cent of microfibers released during the laundry cycle,” the report notes.

While not every measure may be suitable for every particular application, there can be no disagreement that microplastics pollution in an issue we can only continue to ignore at a great peril.

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

President/COO

Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

4 CANADIANPACKAGING · September 2023

FROM THE EDITOR

Many players, one team.

Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time.

www.syntegon.com

Visit us in Las Vegas! PACK EXPO

C-2800

Beloved rice brand serves up a hearty mix of good-for-you medleys

For Canadian rice lovers, nothing beats the convenience and simplicity of the Ben’s Original brand of ready-to-heat seasoned rice mixes, manufactured by Mars Canada in Newmarket, Ont.

And that bond can only get stronger still with last month’s launch of Ben’s Original 10 Medley —a new range of grain and vegetable medleys to supercharge Canada’s favourite instant rice dishes with even

more nutrition, taste and value.

“For more than 70 years, Ben’s Original rice varieties have been the cornerstone of meals around the table,” says Eric Huston, general manager at Mars Food and Nutrition Canada

“The launch of Ben’s Original 10 Medley provides a wholesome selection of vegetables, grains, legumes and herbs in each meal without compromise on taste, nutrition, value or convenience.”

The new Ben’s Original 10 Medley gets its name from the hearty mix of 10 different grains,

vegetables, legumes and herbs that come together with the convenience of Ben’s Original ready to heat products for a nourishing, high-fiber dish.

Each 240-gram, BPA -free pouch has enough flavor and variety to be enjoyed on its own, easily round out a meal, or put a new spin on leftovers to help save on groceries and food waste, according to Mars.

Moreover, every pouch of Ben’s Original 10 Medley has at least 10 grams of fiber from diversified sources and 10 grams of protein to help maintain a

balanced diet while supporting good gut health.

The Ben’s Original 10 Medley is available in Canada in four internationally inspired flavors and combinations:

• Chinese Style Five Spice: A mixture of brown rice, barley, carrots, sweet corn, green peas, French beans, ginger, red bell pepper, onion, garlic and green chili.

• Caribbean Style: A mélange of barley, brown rice, carrots, bell pepper, tomatoes, red kidney beans, black beans, onion, garlic, parsley, thyme and oregano.

• Smoky Southwest: A blend of barley, brown rice, sweet corn, red kidney beans, jalapenos, black beans, tomatoes, red bell pepper, onion, garlic, and coriander.

• Tomato & Herbs: A medley of barley, brown rice, French beans, green peas, tomato, red and green bell peppers, onion, basil, garlic, oregano and chickpeas.

Inspection systems from Fortress Technology are designed to catch contaminants, reduce waste, spot product defects, comply with weight legislation and reduce production downtime - wherever in the world you manufacture or export to. Learn more about our equipment at Pack Expo Las Vegas at BOOTH 4303!

LEARN MORE ABOUT OUR EQUIPMENT ONLINE sales@fortresstechnology.com | (416) 754-2898

NEWSPACK

September 2023 · CANADIANPACKAGING 7 CANADIANPACKAGING.COM www.reiser.com Reiser Canada • Burlington, ON • (905) 631-6611 Reiser • Canton, MA • (781) 821-1290 Reiser UK • Milton Keynes, Bucks • ( 019 08) 585300 2023 Maximize product shelf life with Reiser form/fill/seal packaging n Wide range of versatile machines produce high-quality vacuum, MAP and VSP packages n High-speed production n Superior seals eliminate leakers and returns n Simpler, better, faster packaging n Backed by Reiser’s industry-leading service and support Watch live demonstrations of industry-leading Reiser form/fill/seal packaging machines October 23-25, 2023 | Chicago, IL | Reiser Booth 4451

New state-of-the-art press gives Beneco Packaging renewed competitive edge Manufacturing custom paperboard packaging for the Canadian market, Beneco Packaging strives to provide its customers with the utmost print quality, competitive pricing, and unrivalled turnaround times.

The company’s highly efficient operation boasts an impressive seven die-cutters and six folder-gluers across its two production facilities near Toronto, Ontario.

To further boost its efficiency and print capacity, Beneco recently installed a new Speedmaster CX 104-7+L press, equipped with Prinect Inpress Control 3, from Heidelberg at its new location in Cobourg, Ont.

The new press, together with Beneco’s Speedmaster CX 102 installed in 2018, are amongst Heidelberg’s highest performing presses in their category worldwide.

“We provide a unique solution to the market,” says Carol Jiang, president of Beneco Packaging. “Small companies can’t compete

with us on pricing and delivery dates, and large companies can’t match our run length flexibility.

“Having the right equipment plays a key role in this,” Jiang states.

Previously only equipped with a six-color Speedmaster CX 102 with UV curing at its Scarborough (east Toronto) location, the company could no longer keep up with the increasing demand from its food packaging customers.

Pleased with the speed, value, and versatility of its CX 102 purchased in 2018, Beneco installed a new seven-color CX 104 at the end of 2022—doubling its print capacity.

Thanks to its 15,000-sph (sheets per hour) running speed, the press is very cost-effective for the company’s medium to long runs and, according to Jiang, also gives the company the flexibility for short runs due to its efficient make-readies.

Equipped with Heidelberg’s latest autonomous Push-to-Stop technology, AutoPlate Pro feature, and its new operating philosophy called the Heidelberg User Experience (UX), Beneco’s new CX 104 ensures short make-ready times and the best possible support for press operators throughout the press run

“We’re able to consistently run the press at top speed while maintaining superior print quality,” says Jiang.

The presses’ superior performance, according to Jiang, stem from how Beneco decides to run and schedule the machines.

“It’s our team and Heidelberg’s team working together to reduce downtime and improve productivity,” she states.

Maintaining a high level of efficiency is also key to helping the company reduce costs and enables Beneco to pass these savings onto its customers.

Beneco experiences further efficiency gains thanks to Prinect Inpress Control 3, the industry’s leading inline spectrophotometer that measures and controls color and registers on-the-fly at any speed, delivering the first measurable result in less than 60 sheets.

“We can’t afford downtime,” Jiang says, “so it brings us peace-of-mind knowing they (Heidelberg team) are always making sure that we can keep our machines running.”

OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 OFFSITE INSPECTION bones, stones, glass, aluminum, rubbers, standard foreign bodies services 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 CPK_XrayReclaim_May23_CSA.indd 1 SUSPECT FOREIGN MATERIALS X-RAY INSPECT & RECOVERY 3rd Party Rework Services for Food Products OFFSITE INSPECTION • • metals, bones, stones, glass, aluminum, rubbers, plastic, and standard foreign bodies • mobile services Contact 1-844-XRAY-911 (9729) INSPECTION & RECOVERY PARTNER FOR FOOD PROCESSORS xrayreclaim.com | info@xrayreclaim.com | 5 Loring Drive Bolton, ON L7E 1Y1 Separation bolt

NEWSPACK

Beneco Packaging owner Carol Jiang and the Cobourg plant’s packaging team in front of the new Speeedmaster CX 104 press.

Do you want to eliminate product loss and food waste on your production lines?

Incline conveyors are one of the biggest causes of product loss, food waste and downtime due to cleaning. Whatever your product type, consistency, or temperature the Liftvrac ensures zero product loss.

• Completely smooth belt forms a tubular shape for gentle product handling • The scraper at the discharge eliminates waste and cleans the belt

• Easy access for sanitation and maintenance

you want to eliminate product losses? PACKAGING | INSPECTION | PROCESSING SALES | SERVICE | INTEGRATION E STABLISHED 1990 • QUALITY MACHINES & S E ECIVR • TOLL FREE: (800) 361-5919 ABBEYEQUIPMENT.COM Booth number N-10856

Do

Calgary-headquartered

NOVA Chemicals

Corporation has announced a significant capital investment into its first mechanical recycling facility in Connersville, Ind., for process postconsumer plastic films to produce the company’s SYNDIGO range ofr ecycled polyethylene (rPE) resins at a commercial scale as early as 2025. Expected to create 125 new local jobs, the new plant will be operated by Novolex Holdings, LLC, developer of packaging products for foodservice and industrial markets, with the facility expected to reach its full manufacturing capacity of 100 million pounds of rPE per year by 2026. “NOVA Chemicals continues to show clear leadership in reshaping plastics for a better, more sustainable world,” says NOVA Chemicals president and chief

executive officer Roger Kearns.

Located on 186 acres, the 1.7-millionsquare-foot manufacturing plant has been formerly used for automotive parts manufacturing and cabinet making, and the new recycling facility will occupy approximately 450,000 square feet, according to NOVA Chemicals. “We are committed to helping our customers achieve their recycled content goals through a variety of business models, and we look forward to making more announcements like this as we work to enable a low-carbon, zero plastic waste future,” states Kearns.

Thailand-based plastics group

Indorama Ventures Public Company

Limited says it has completed the expansion of its recycling facility in

Brazil—increasing its annual capacity from 9,000 to 25,000 tonnes of PET (polyethylene terephthalate) plastic made from post-consumer recycled (PET-PCR) material. Located in Juiz de Fora, Minas Gerais, the project is part of Indorama Ventures’ Vision 2030 ambition to continue building a sustainable global company, including spending US$1.5 billion to increase its recycling capacity to 50 billion PET bottles per year by 2025. According to Indorama, the project was made possible with the ‘Blue Loan’ funding program of the International Finance Corporation (IFC), a member of the World Bank, which has committed US$300 million in funding to Indorama Ventures with the objective of increasing recycling capacity and diverting plastic waste from landfills and oceans in Thailand, Indonesia,

Philippines, India and Brazil—countries which are most at risk from plastic waste in the environment. “It is extremely gratifying to leverage the IFC’s generous funding to invest in important projects that build on Indorama Ventures’ industry leadership in sustainability,” says Indorama Ventures deputy group chief executive officer DG Agawal. “We are grateful to IFC for this blue loan reinforcing Brazil’s importance as a leader in sustainability, and which also recognizes the excellence and potential of our recycling operations.”

FUJIFILM North America Corporation, Graphic Communication Division, has announced a distribution partnership with Miamisburg, Ohio-based Kongsberg Precision Cutting Systems (Kongsberg PCS),

10 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications. Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified customers. GavazziOnline.com • 888.575.2275 • Gavazzi@CarloGavazzi.com USA Tel : 8 47 . 46 5. 6 10 0 Canada Tel : 8 88.57 5 .2 27 5 Mexico Tel: 55 53 73.7042 ww w.Gavazz i O nlin e .c om • Info@Ca r loGavazzi.co m twitter.com/CarloGavazziNA facebook.com/CarloGavazziNA Visit our website for downloadable data sheets, brochures and pricing: www.GavazziOnline.com Brazil Tel: 55.11.3052.0832 youtube.com/user/CarloGavazziNA https://www.linkedin.com/company/carlo-gavazzi_2 CARLO GAVAZZI A utomation Components CARLO GAVAZZI A utomation Components CARLO GAVAZZI A utomation Components Innovative Automation Solutions SWITCHES: Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls CPK_CARLO GAVAZZI_future .indd 1 2023-03-23 7:53 AM

NOTES & QUOTES

whereby FUJIFILM will distribute and sell all Kongsberg PCS digital cutting systems across the U.S. and Canada. “Kongsberg PCS is highly regarded as one of the most reliable, innovative finishing/cutter device manufacturers in the wide format market,” say Toyoyuki (Tommy) Katagiri, division president at the Graphic Communication Division in Hanover Park, Ill. By partnering with Kongsberg PCS, Fujifilm customers will have direct access during the purchase process to Kongsberg cutting system solutions for multiple materials, including folding cartons and packaging, labels and decals, POP displays, banners, wall graphics, aluminum signs and flexo plates. Says Katagari: “This partnership demonstrates Fujifilm’s commitment to a ‘whole solution’ approach whereby we are with our customers from start to finish—offering complete printing and finishing solutions in one easy-toimplement package.”

St. Lous, Mo.-headquartered beverage packaging products group TricorBraun has completed the acquisition of CanSource, a leading

provider of can packaging and related services headquartered near Denver, Co. Founded in 2011, CanSource is a leading provider of brite, shrinksleeved, and printed cans to the craft beer, wine, spirits and non-alcoholic beverage markets, operating four locations across the U.S. “Our acquisition of CanSource—a company known for exceptional quality, hands-on service, and reliability— enables us to provide beverage customers across North America with expanded offerings and services, and more sustainable packaging options,” says Brett Binkowski, president of TricorBraun, North America. “We welcome the CanSource team to the TricorBraun family, and we look forward to investing in the company’s continued growth.”

Global packaging products group Amcor has been awarded two AmeriStar awards from the Institute of Packaging Professionals (IoPP) for its McCoy dunnage-free IBC liners for bulk liquid aseptic products, and the Perflex S grab-n-go shrink bags for meat and poultry. “We are honored to be

recognized for Amcor’s innovative applications and design achievements by the IoPP,” said Brian Carvill, vice-president of research and development at Amcor Flexibles North America in Neehan, Wis. “Our capabilities in material science, packaging technologies, and our strong commitment to solving complex performance needs and sustainability challenges creates cost-saving opportunities for brands and more convenience for consumers.” According to Amcor, the company’s 330-gallon McCoy dunnage-free bulk container liner reduces waste and costs, while enhancing sustainability, as the combination of co-polymer blends and decreased materials per ply makes the package less susceptible to pinhole leaks and flex-cracking during transit. For its part, the new Perflex S shrink bags with integrated grab-n-go

handles eliminate the need to use plastic netting with a clipped loop, which previously was the only option to provide a handle to carry heavy products such as turkeys.

Industrial engineering services and products supplier Endress+Hauser Canada of Burlington, Ont., has appointed Contro Valve Equipment Inc. as a full-service channel partner for select sales territories in Ontario, Quebec and the Atlantic provinces. “Contro Valve is recognized throughout the process sector for its wellrespected brand and close ties to customers,” says Anthony Varga, general manager of Endress+Hauser Canada. “It has a strong technical instrumentation background, which is important to us, and a significant presence in key industries that are cornerstones of our business. Contro Valve has the facilities and expertise to serve the needs of our customer base and help it grow.” Headquartered in Brossard, Que., near Montreal, Contro Valve has a network of over 140 employees operating from nine sales offices and five service locations.

September 2023 · CANADIANPACKAGING 11 CANADIANPACKAGING.COM She ran 189K straight. Without a single break. For more information visit us at: sewcan.ca CPK_SEW Eurodrive_April23_CSA.indd 1 2023-03-29 9:33 AM

12 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM

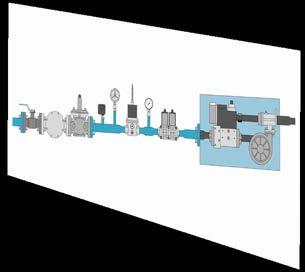

PLENTY OF POWER

Built to power pumps, fans, compressors, hoists, winders and similar equipment in harsh environments, the new severe-duty SIMOTICS SD200 motors from Siemens Digital Industries are now available in frame size 440 to provide high productivity and energy-efficient operation in all torque ranges. With output ranges from 75 HP to 800 HP, the low-voltage motors feature cast-iron frame, end-shields, fan guard and the easy-access oversized terminal box, with zinc-plated hardware, epoxy paint and stainless-steel nameplates also ensuring long life and easy identification in the field, while optional features include IP56 ingress protection, encoders, brakes and blowers. A unique offset rotor bar provides improved efficiency, according to Siemens, while larger bars and end rings reduce resistance. Each die-cast aluminum rotor assembly is dynamically balanced for extended bearing life and includes a high-strength C1045 carbon steel shaft for maximum performance. Premium C5-grade steel laminations and copper magnet wire are standard.

Siemens Digital Industries

THE PAPER TRAIL

Developed in response to growing consumer demand for recycled content in consumer packaging, the new

PaceSetter Rainier coated recycled paperboard (CRB) from Graphic Packaging International offers many of the characteristics of solid bleached sulfate (SBS) in combination with recycled content, while providing improved surface smoothness for enhanced printability and tactile performance for truly stand-out printed packaging. Initially available in 12-pt to 18-pt calipers, PaceSetter Rainier is well-suited for a wide range of packaging applications including healthcare, beauty, confectionery, dry goods and dairy.

Graphic Packaging

Xaar’s TF Technology, High Laydown and Ultra High Viscosity technologies, the Versatex Printbar can handle a wide range of inks and fluids—printing at widths of 410-mm and at up to 720-dpi with eight grey levels at speeds of up to 75 meters per minute. The new Versatex Printbar provides an opacity of 82 per cent at 50 meters per minute to achieve the most brilliant whites and vibrant colors for labels and packaging, while also offering the options of textured and high-build print effects, varnishes, foils, and mass personalization capabilities. For its part, Xaar’s High Laydown technology delivers very high volumes of fluid in a single pass with exact temperature control, enabling the creation of high-build inks and varnishes to deliver an extensive array of tactile effects more efficiently.

Xaar

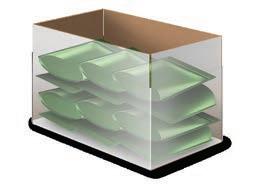

COLD COMFORT

thinner and far more flexible than existing technologies with equal thermal performance—enabling multiple configurations and box size flexibility while maintaining cold temperatures, dramatically reducing food waste, and improving cost and sustainability. In addition, the liner offers an aesthetically attractive solution with positive branding attributes.

Ranpak Holdings Corp.

FIT TO PRINT

The new Versatex Printbar printer from Xaar was developed to enable specialist label and flexible packaging converters to print the highest-opacity whites and colors, according to the company, while adding a wide range of features to their existing presses. Powered by Nitrox printheads with

The new RecyCold climaliner material from Ranpak Holdings Corp. is a highly efficient sustainable thermal liner designed to support ‘cold chain’ shipping needs across a variety of end markets. Designed for one-way transport, the new paper-based thermal liner ensures products stay within their ideal temperature range for up to 48 hours, while simultaneously ensuring recyclability and sustainability. According to Ranpak, climaliner’s thermal liner paper is

REGAL MOTION

Designed for high-speed critical conveying, pressureless combining and decombining, and mass flow conveyor applications in the beverage and food industries, the new 1104 FlushTop MatTop Chain conveyor from Regal Rexnord Corporation combines the container stability benefits of the FlatTop surface with the cleanability of the FlushGrid chain—allowing users to run conveyance lines dry, while saving both water and/ or lubricant with proper cleaning. The 1104 belt features a low coefficient of friction for handling all container types—aluminum cans, glass and PET plastic bottles—while its new sprockets feature a more robust design for improved product engagement and stability.

Regal Rexnord Corp.

September 2023 · CANADIANPACKAGING 13 CANADIANPACKAGING.COM FIRST GLANCE CPK_ESS-technologies_JulyAug23_CSA.indd 1 2023-07-17 8:51 AM

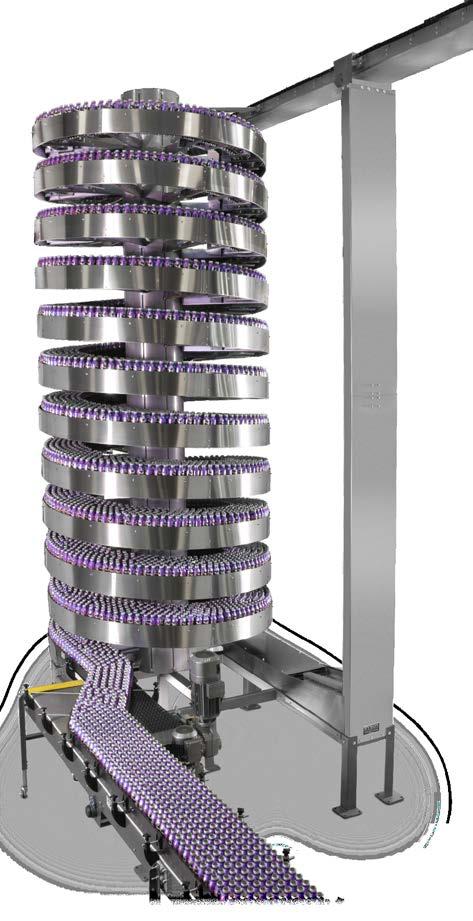

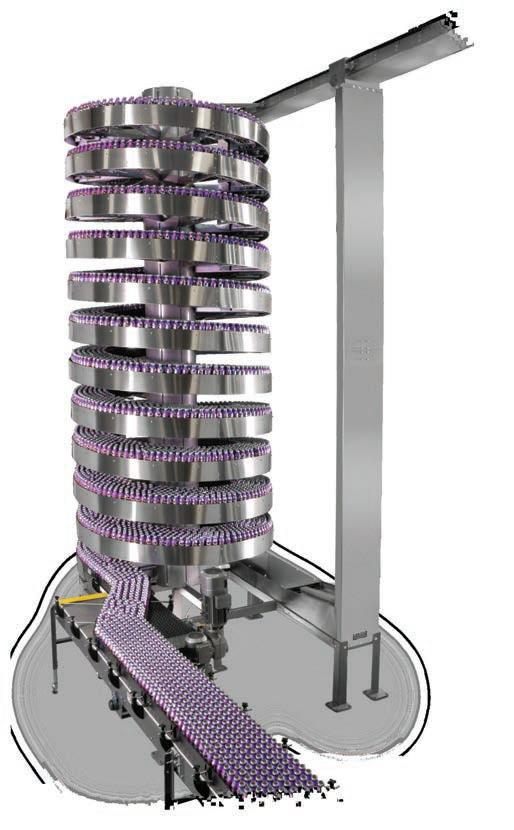

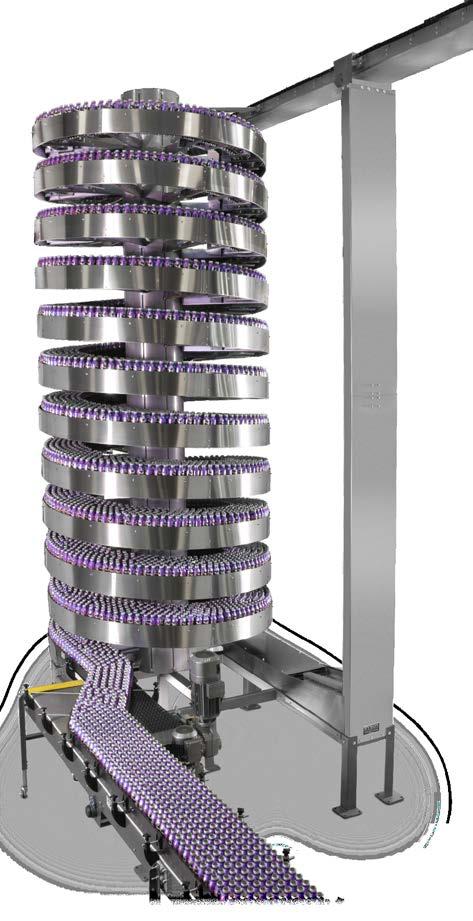

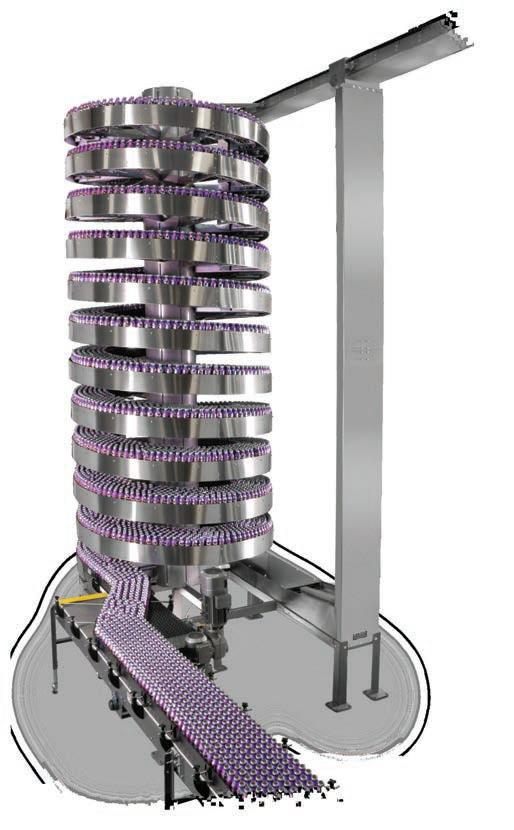

Compact Spiral lifts your line to a new level

The Compact Spiral elevators give you increased access to the production floor and the possiblity to transport goods vertically. The unique spiral-shape is key to its compact construction, offering 40% smaller footprint.

•Small footprint, using less space

•Gentle product handling

•Compact design

•Continuous product flow avoiding stop losses

Husky equipment shows the way to sustainable resins

Leading Canadian blowmolding machinery manufacturer Husky Technologies is playing a key role in the development of a new generation of sustainable hybrid polymer resins for making 100-percent recyclable bottles and other plastic containers in viable commercial quantities.

The company’s joint project with U.S.-based Origin Materials Inc. has recently achieved a major milestone by using Husky equipment to blowmold plastic preforms made from common PET (polyethylene terephthalate) incorporating a bio-based chemical called FDCA (furandicarboxylic acid).

Based in Sacramento, Ca., Origin Materials expects to develop and sell a new family of 100-percent bio-based, low-carbon PET/F polymers offering full recyclability and superior performance compared with traditional 100-percent petroleum-derived PET plastic.

Moreover, Origin anticipates that its PET/F will offer enhanced mechanical performance and superior barrier properties enabling longer shelf-life controlled by adjusting manufacturing conditions and the quantity of FDCA copolymer.

Origin expects to enable the production of FDCA, PEF (polyethylene furanoate) and PET/F at commercial scale using its patented technology platform, which turns the carbon found in sustainable wood residues into useful materials, while capturing carbon in the process.

According to Origin, the successful test run on Husky’s equipment demonstrates a pathway for the drop-in market adoption of FDCA to produce superior polymers cost-effectively from biomass using Origin technology.

“This is a key moment in the commercialization of cost-effective, low-carbon FDCA and PEF and the development of next-generation sustainable polymers generally,” says Origin

Materials co-founder and co-chief executive officer John Bissell.

“We believe these materials have the power to transform plastics and the material economy.

“We are pleased to work with Husky, a trusted leader in injection molding technologies and polymer processing development, to achieve this performance milestone, showing the ready processibility of our innovative hybrid polymers using Husky’s commercial-scale injection molding equipment,” Bissell states.

“This is a major milestone in our effort to help transition the world to sustainable materials,” says Bissell, citing a wide rand of FDCA applications including polyesters, polyamides, polyurethanes, coating resins and plasticizers, as well as being a pre-cursor to the next-generation sustainable polymer PEF (polyethylene furanoate).

As such, Origin’s patented technology platform can help revolutionize the production of a wide range of end products, including packaging, plastics, clothing, textiles, car parts, tires, carpeting, toys, fuels, etc.

“Driving sustainability through innovation is at the core of how Husky has been leading the way in enabling the circular economy of plastics,” says Husky Technologies chief executive officer John Galt. “Preserving and protecting what matters, in even more sustainable ways, is foundational to everything we do at Husky.

“Our collaboration with Origin Materials is an exciting example of combining material innovation with state-of-the-art polymer processing technologies.”

14 CANADIANPACKAGING · September 2023

info.ca@flexlink.com

Read more at Flexlink.com or contact us at

FlexLink is part of Coesia, a group of innovationbased industrial and packaging solution companies operating globally, headquartered in Bologna, Italy. www.coesia.com

CPK_FlexLink_Sept23_CSA.indd 1 2023-08-09 11:11 AM

ECO-PACK NOW

Golden Design Rules Essentials Course – Sept 21

Paper Packaging Plus – Sept 26 - 28

IFS PACsecure Training Course – Oct 3 - 4

Packaging Circularity – Oct 24 - 26

Innofibre Tour, Quebec – Oct 25

PACKEX, Exclusive 25% Member Booth Discount – Nov 7-9

Complete Plastics Packaging – Nov 28 - 30

MembersEnjoySignificantDiscounts JOINPACGLOBALNOW! VISIT WWW.PAC.GLOBAL/EVENTS FOR DETAILS

PAC GLOBAL AWARDS IS OPEN FOR ENTRIES

Deadline: October 13, 2023

Twelve (12) New Categories Added for 2024:

Brand Extension – Food, Beverage, Non-Food Specialty – Beauty, Connected Pack, Customization & Personalization, Fresh, Health & Wellness, Wine & Spirits

Package Innovation Design – Labels

UPCOMING PAC

EDUCATION

Courses

Sustainable Package Design – Carbon Reduction, Package Circularity VISIT WWW.PAC-AWARDS.COM FOR IMPORTANT DETAILS, A LIST OF ALL 23 SUB-CATEGORIES, AND EARLY ENTRY DISCOUNTS

Golden Design Rules Essentials Course – Dec 6

Safely. We make Canada safer. A little bit every day. ™ Find out more: www.pilz.com/we-automate-safely Pilz Automation Safety Canada L.P. - Mississauga, ONWebsite: www.pilz.ca Email: info@pilz.ca Phone: +1 905 821-7459

What You Need to Know About Boosting Productivity and Uptime

By Davor Djukic, National Sales Manager – Product Inspection, METTLER TOLEDO

Manufacturers are under constant pressure to produce more for less.

Excessive downtime can impact productivity, leading to significant revenue loss. Therefore, effective and efficient solutions need to be identified and implemented wherever and whenever possible.

Advanced product inspection systems are now available to help manufacturers overcome a range of challenges that have the potential to limit or stop production, while at the same time ensuring 100% of products coming off the line are inspected and safe to enter the retail supply chain.

Automated Fill Control

Incorrect filling has the potential to cost manufacturers a lot of money. Overfilling leads to costly product giveaway, whereas underfilling can land you in hot water with regulators and customers. Incorrect fill levels coupled with unplanned downtime is a common and costly combination, which is largely avoidable.

If underfill or overfill is detected, then the solution often includes stopping production until the fillers have been recalibrated. This not only has an impact on uptime but can also lead to large amounts of waste if the issue goes undetected for a significant amount of time. Dynamic checkweighing, X-ray, and vision inspection solutions can monitor and adjust fill levels automatically without the need to halt production. They are also

able to identify a trend early, which not only prevents costly waste but also ensures compliance with weights and measures legislation and improves uptime.

Easy Product Changeovers

Many production lines process a variety of products, each with their own requirements in terms of packaging, labelling, and inspection parameters. Traditionally, with every changeover, equipment settings must be manually adjusted according to the requirements of each new product. The more settings that need manually adjusting, the longer downtime becomes between production runs. Moreover, the margin for operator error increases, which can also lead to further downtime and wasted product.

Metal detectors, such as the Profile Advantage from METTLER TOLEDO, feature intuitive clustering technology, which allows products to be grouped together under the same setting. This means that multiple products can be inspected without the need to adjust settings and without having any impact on the availability of the metal detector.

Advanced X-ray inspection systems, such as the X33 Series from METTLER TOLEDO, can store contamination and product integrity settings within the software, enabling product changeover to be completed quickly and easily.

All of these elements simplify the product changeover process, making it faster, more efficient,

and less prone to operator error and unscheduled downtime.

Automated Inspection of every product

Label mix-up or incorrectly placed labels have the potential to ruin an entire production run if undetected. Every mislabeled product must be recalled, and producers face the risk of heavy retailer fines. Brand reputation and consumer confidence can also be rocked by the product recall process.

In this case, vision inspection systems are invaluable as they can detect incorrectly labelled products automatically. The result is dramatic increases in uptime through minimizing product rework, retrieval, and recovery, as well as cost savings where serial faults are detected.

A vision inspection system, such as METTLER TOLEDO’s CV Combination system, is combined with a checkweigher, doubling inspection capabilities, reducing footprint, and further increasing productivity.

This wide range of capabilities

in one solution allows for outstanding efficiency and complete confidence in product and packaging quality. In addition to the automated inspection, advanced warning systems, such as Condition Monitoring, allow you to plan maintenance for when equipment will be offline.

Consider Your Options

The highly competitive nature of modern manufacturing means that the pressure is always on to ensure production lines are optimized for high speeds and healthy profit margins. Product inspection systems that are easily integrated into existing lines can play a major part in achieving these optimization goals by solving the common challenges that lead to downtime – as well as delivering first-class inspection capabilities.

September 2023 · CANADIANPACKAGING 17 CANADIANPACKAGING.COM

FOOD SAFETY

DAVOR DJUKIC is national sales manager for product inspection at METTLER TOLEDO Inc. in Mississauga, Ont.

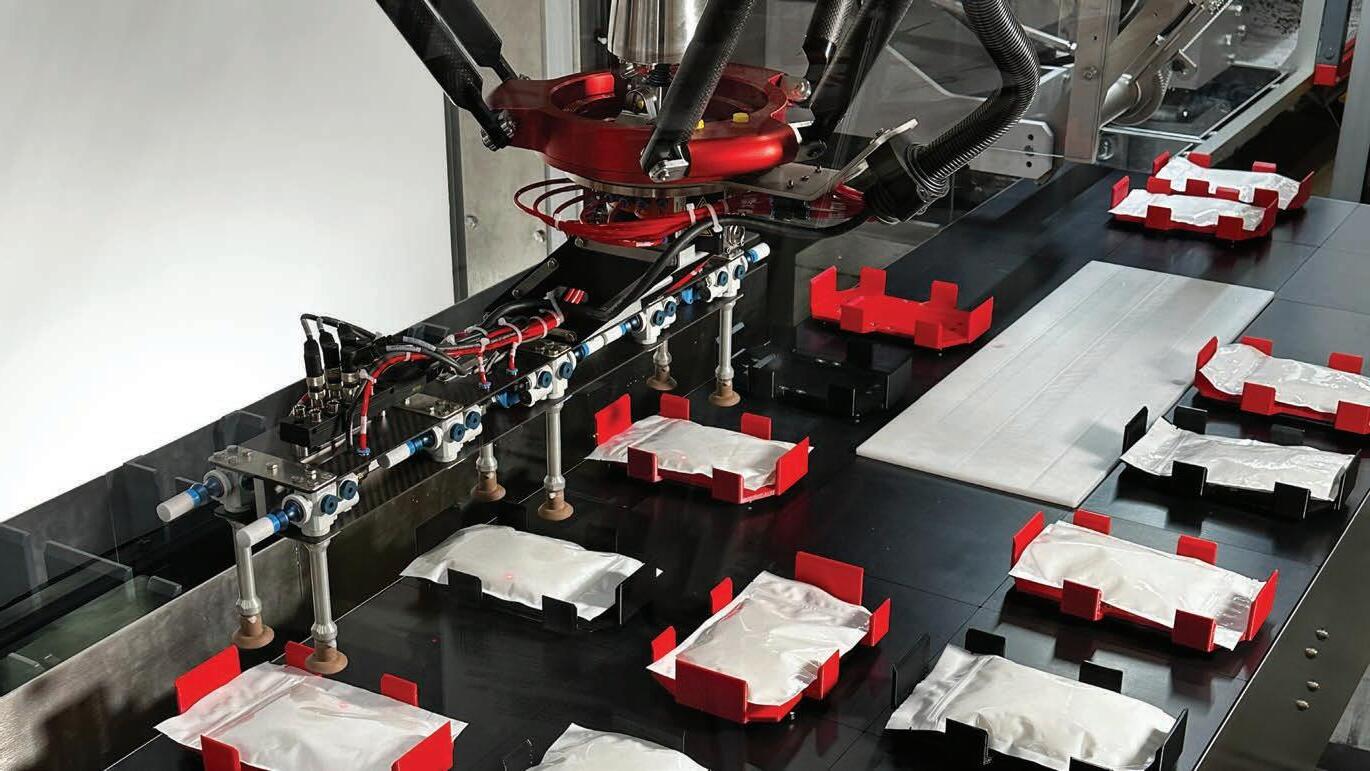

CLEAN SLATE

Leading industrial laundry operator boosts efficiency and reduces manual labor costs in its facecloth packing operation with larger-than-life automatic vertical bagging machine

By George Guidoni, Editor

By George Guidoni, Editor

If cleanliness is indeed the next closest thing to godliness, then doing god’s work is all part of the job for the 300 or so people working at Blanchelle in Montreal.

Founded in 1977, the commercial laundry operator is one of the region’s biggest suppliers of clean linen, bedding, towels, gowns and other essential daily textiles to local hospitals, clinics, laboratories, nursing homes and other healthcare facilities with exceptionally high standards and requirements for hygiene and sanitation on around-the-clock basis.

Operating two Health Canada-certified plants in the Montreal region—including a brand new 60,000-square-foot facility opened up in 2021 in the city’s off-island suburb of Mascouche— Blanchelle provides its comprehensive

turnkey services, including on-site pickup and delivery, to hundreds of healthcare institutions stretching as far south as Vermont in the U.S., as well as to Quebec health providers located up to about 100 kilometers north of Montreal.

“What makes us unique in this business is the fact that we focus exclusively on serving the healthcare community,” says Blanchelle’s director of operations Mario Ferron.

“Many other industrial laundries also service the hospitality and foodservice industry customers,” Ferron says, “but for us focusing on hospital and longterm care facilities was a strategic decision from the start, allowing us to develop a very specialized skillset and to build long-term relationships with our healthcare customers.”

To serve its client base, Blanchelle

18 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM

COVER STORY

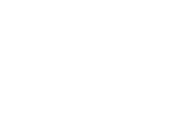

Blanchelle’s director of operations Mario Ferron holds up a 2.7-kilogram bag of freshly washed face-cloths packaged inside a clear plastic film bag by the fully-automatic VerTek 2400 model vertical bagger manufactured and installed by WeighPack Systems in early 2021.

operates both of its plants over a oneshift, six-day-a-week schedule to clean and sanitize close to a million pounds of bedding and linen per day for both locations.

To handle these massive loads, the plants employ towering, high-capacity tunnel washers—manufactured by leading global automated laundry equipment supplier Jensen Group —to completely wash and sanitize individual pieces of fabric in a highly-automated process.

Those tunnel washers each provide around 120 kilograms of clean linen every two minutes.

“These are just about the biggest laundry washers that you can find on the planet,” says Ferron, citing the machine’s 16-compartment design whereby each compartment provides one of the 16 different washing/rinsing/steaming/ chemical treatment and other process stages in perfect repeatable sequence to achieve maximum cleaning and drying.

According to Ferron, having high-capacity machinery is critical to Blanchelle’s operation to make up for any unexpected machine downtime due to power outages of other factors outside the company’s control.

“Because we operate as an essential service, we do not have the luxury of postponing any work until the next shift or next day,” says Ferron, adding that Blanchelle prides itself on self-sufficiency and problem-solving.

“Any lost production we may experience will have to be made up on that same shift: that’s why we have some redundancy built into our process with the two plants.

“We have a huge number of [machine] parts in stock at all times,” he says, “as well as some extra production capacity with the high-volume laundry equipment.

“We need to be able to take care of all our problems ourselves.”

One of the problematic areas that Ferron has been able to address successfully at the new Masouche facility was making the process for bagging freshly-washed face cloths a much more efficient and automated process than it has ever been in the past.

As Ferron relates, the washing and cleaning of face-cloths is by far the least profitable part of the business for a company that charges its customers by weight (kilograms), which makes small, loose and lighweight items like facecloths “a major loss-leader,” according to Ferron.

“Despite losing money on it, it’s an essential product and service that we have to provide as part of our turnkey services,” says Ferron, adding the Masouche plant processes roughly about

Top

An inside view of the busy plant floor at Blanchelle’s new facility in Masouche, where hundreds of mobile carts rotate around the plant to bring incoming dirty linen to the washing machines or to bring clean sheeting and bedding to the plant’s shipment area for delivery to customer.

Bottom

The plant’s upper mezzanine level houses the large HMI (human-machine interface) touchscreen control terminals used to control and monitor operation of the plant’s massive automatic Jensen tunnel washers.

September 2023 · CANADIANPACKAGING 19 CANADIANPACKAGING.COM

“What makes us unique in this business is the fact that we focus exclusively on serving the healthcare community.”

150,000 face and wash cloths per day.

“So the challenge for us was to minimize those losses,” says Ferron, who took it upon himself to scout the market for a suitable solution to automate what was a highly manual labor-intensive process of handling and bagging the facecloths.

During his market research, Ferron says he heard a lot of good things about the high-quality, high-throughput automated bagging systems manufactured by Montreal-based WeighPack Systems Inc., part of the Paxiom Group of companies, which had already completed a couple of successful machinery installations for some large-scale commercial laundry operators in and around Montreal.

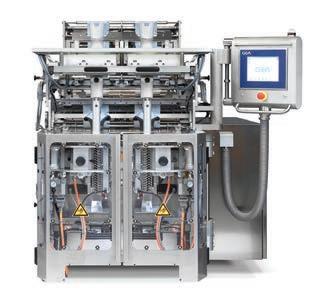

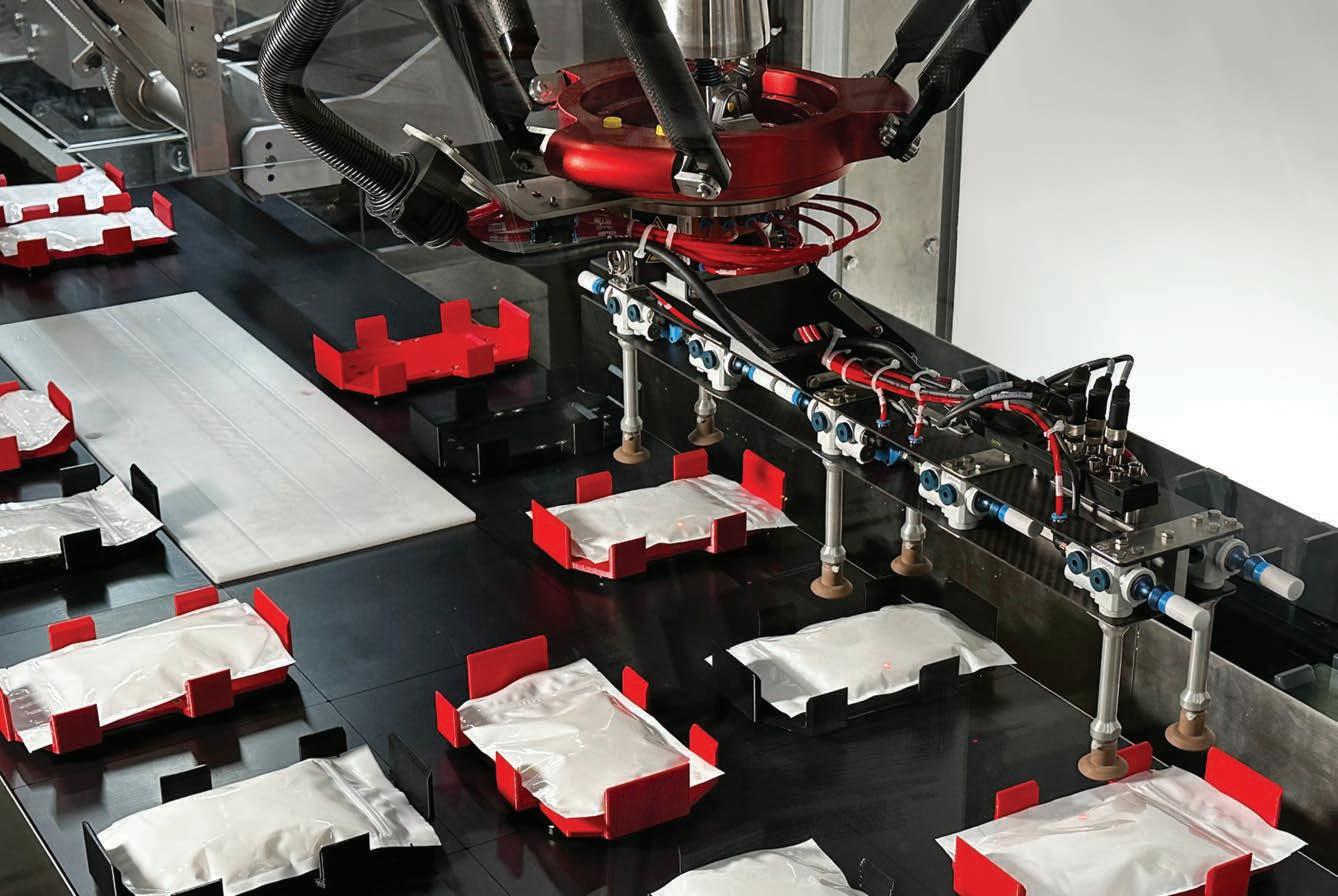

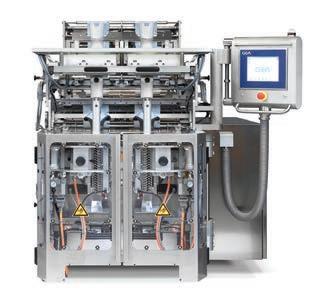

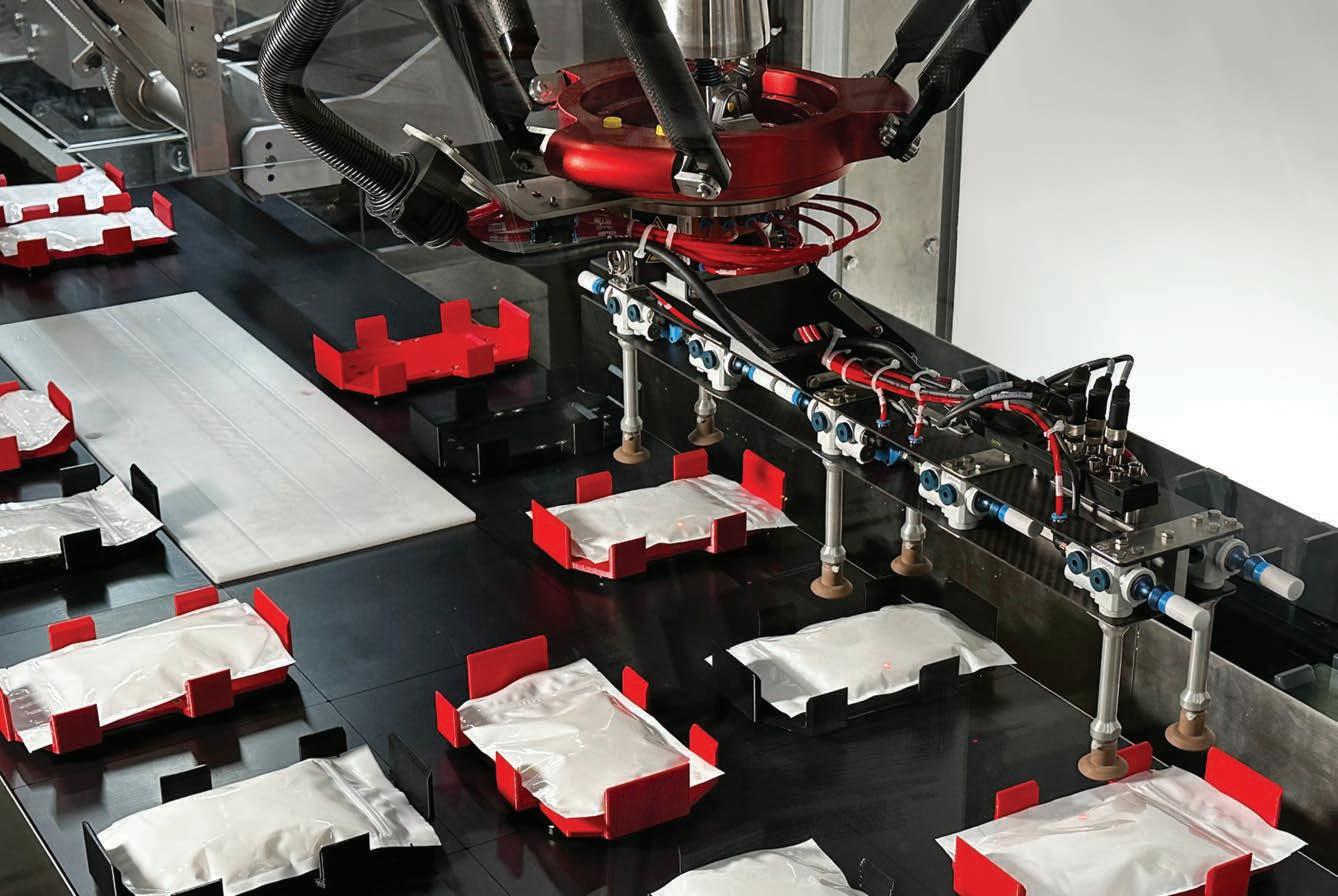

After contacting WeighPack and receiving what seemed like a fair and reasonable proposal, Ferron proceeded to place an order for WeighPack’s VerTek 2400 vertical form/fill/seal (VFFS) bagging machine, which would come online to coincide with the opening of the Masouche plant in early 2021.

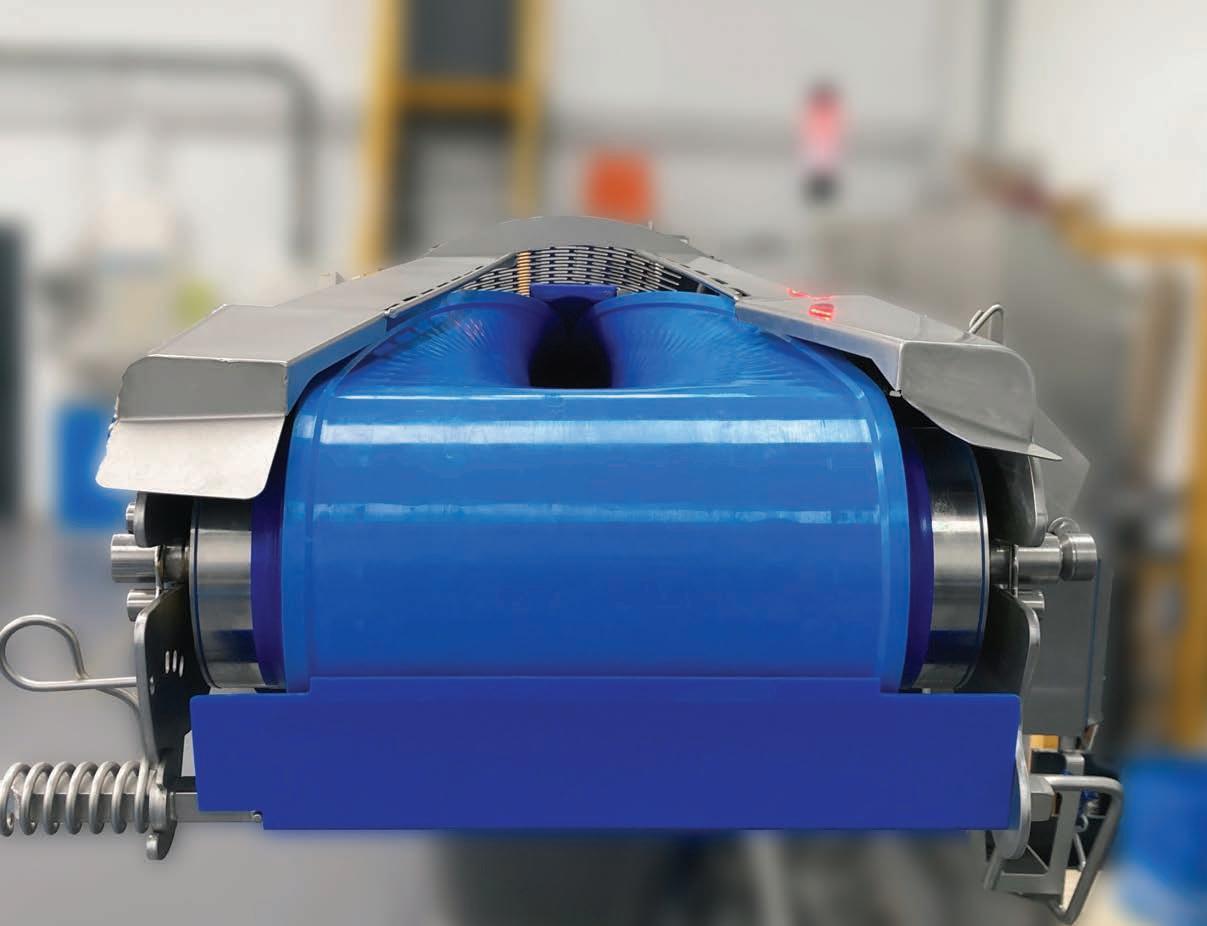

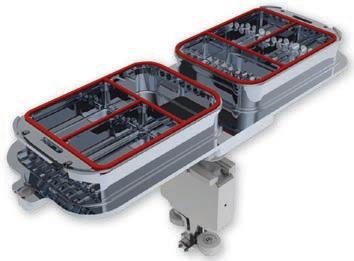

According to WeighPack, the heavy-duty VerTek 2400 VFFS machine is engineered for the toughest and heaviest of filling applications, and it can produce pillow or gusseted pouches up to 600-mm (24 inches) in width.

The machine’s welded tubular steel construction makes it perfect for any bulk packaging application and any tough working environment—having been used for bulk packaging of hop

pellets, confections, pet food, rice, beans, flour, powders and polymers—while ensuring superior sealing on a wide variety of film structures, including laminate, metallized structures and polyethylene.

As with all major machine installations, the commissioning of the VerTek 2400 bagger had a few technical challenges to overcome in the beginning, but they were soon resolved by WeighPack’ technical support team—providing the Masouche plant with a highly reliable and efficient packaging solution for its facecloths.

“It runs pretty much all day long, producing four to six bags per minute,” Ferron relates, using clear plastic film supplied by Gel-Pak

20 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM COVER STORY

From Left

The towering VerTek 2400 model vertical form-fill-seal machine is the largest single piece of equipment ever built by WeighPack Systems; piles of freshly washed face cloths are making their way to the dispensing chute for bagging; each finished bag coming off the VerTek 2400 holds about 100 face cloths.

From left

Close-up of the VerTek 2400 machine’s control cabinet housing all of the machine’s electronic components, along with a built-in touchscreen HMI terminal at the top of the stainless-steel enclosure; the VerTek 2400 bagger sings into action to fill and seal bags of clear plastic film, supplied in rollstock by Gel-Pak, with the freshly washed white face cloths.

“We put roughly 100 cloths inside each 2.7-kilogram bag processed by the VerTek,” says Ferron, adding the machine is capable of much higher throughput speeds if required.

“Compared to what were doing before manually, this purpose-built machine was a great improvement to our operation,” says Ferron, citing a four-fold improvement in labor productivity for this particular task.

As he explains, its used to take up to 12 people to pile the clean washcloths, put them onto a conveyor, bag them and seal them, and move the finished bags on to the awaiting mobile carts.

“With the VerTek machine, the process only requires three people to feed it and direct the finished bags to where they need to go,” says Ferron, adding the line still relies on human visual inspection to ensure optimal final product quality.

“I believe that we’re going to see automated inspection soon to make this technology even more efficient,” Ferron notes, “but for now it is just not as reliable as human inspection for detecting all the little things.

“Nevertheless, we already see future possible applications possible with this

machine for other types of products, or for using different films and bag sizes,” Ferron says, “and we plan to work closely with WeighPack to explore all those possibilities.

“As a company, we are always keen to be the first ones out there with the new technologies and new processes to add value to the services we provide,” Ferron states, adding he has been very satisfied with the VerTek 2400 machine’s reliability and performance so far, as well as WeighPack’s technical and training support.

In fact, Ferron says he is seriously considering installing another VerTek 2400 bagger at the company’s other Montreal location, whose older existing bagging machinery lags behind the VerTek solution in virtually every respect in terms of performance and maintenance requirements.

“It’s a very robust piece of equipment that has proved to be very reliable and consistent in an application for which it was not primarily designed,” he notes. “But it has performed this application very well for us, thanks to all the input, support and advice we got from WeighPack.”

Adds WeighPack’s territory manage

Andre Strul: “The VerTek 2400 is the largest single piece of equipment we manufacture: it’s a real behemoth.

“It’s typically used in a wide range of industries that require bulk packaging into very large bags—installations including fibers, frozen, fresh and pet food, powders, injection-molded pieces and more.

“Blanchelle’s customers are some of the biggest hospitals in the province of Quebec,” Strul points out, “so 24/7 operation is a critical capability for them.

“Thanks to the machine’s integrated film slicing option, there is no need to stop production to accommodate a roll change,” Strul says, “while the machine ‘cruising’ speed of four to six bags per minute, depending on the quantity, is sufficient for their needs right now.

“Manual packing of towels is a very hard job to do all day long, so installing the VerTek 2400 has enabled Blanchelle to significantly alleviate the physical strain on its employees,” he sums up.

Adds Ferron: “We knew from the start that this VerTek machine was not specifically designed to do what we do, so it was very much a judgement call on our part.

“But having made that call, we are very pleased with how things have worked out,” says Ferron, praising WeighPack’s commitment to seeing the project succeed even during the “challenging” circumstances caused by the COVID-19 pandemic.

“It made things somewhat complicated in terms of meeting all our original deadline,” he concludes, “but I give WeighPack full marks for helping us succeed in this project and for being a great partner to work with.”

SUPPLIERS

WeighPack Systems Inc.

Paxiom Group

Gel-Pak

September 2023 · CANADIANPACKAGING 21 CANADIANPACKAGING.COM

Clockwise from top Mario Ferron (left) discussing Blanchelle’s packaging needs with Paxiom Group’s territory manager Andre Strul; a finished bag of face cloths gently tumbles onto a product-transfer conveyor belt immediately after sealing; sets of impeccably washed and folded hospital gowns await pick-up for shipment to customer.

22 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM

PRIVATE MATTERS

Private store brands are no longer the dull-looking, non-distinct products modestly hiding in plain sight on grocers’ retail shelves, with study after study pointing to the relentless rise in the popularity of private brands across the grocery industry landscape, while strongly suggesting that the widespread trend is here to stay.

According to this year’s Food Navigator survey published by FMI – The Food Industry Association, four out of five current private brand consumers intend to purchase more store brands in the future, with a growing number of them saying that store brands influences them as to where they want to do their grocery shopping.

For leading retailers like Metro , along with its banner stores like Metro Plus, Super C, Food Basics, Marché Ami , Les 5 Saisons and Marché Adonis , the trend validates their long-nurtured belief in the power of store brands to differentiate from competition and drive loyalty.

And even though the current inflationary economy is undoubtedly helping private brands to gain momentum, up to 80 per cent of purchase decisions are made outside of the ‘lowest price’ alone, according to another new food industry survey conducted by IMI International

As that survey suggests, it is more about the value equation offered by store brand being perceived as ‘worth it’ by the consumers.

“Metro’s private label team has a very

23 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM

Leading Canadian grocery chain leverages outstanding packaging design to grow its private brands portfolio and drive consumer loyalty and recognition

PACKAGE DESIGN

consumer-centric approach,” says Marie-France Gibson, vice-president of private brands at the Metro Group.

“It is all about delivering the value on those key attributes that consumers want with a portfolio of brands designed to address every moment of consumption, with specific roles to play in the consumers’ lives,” Gibson explains.

And while taste, quality, convenience and price are still the main purchase drivers, Metro and its long-time strategy and design agency Pigeon Brands have also been focusing on some important pillars supporting those drivers, with the environment naturally receiving a great deal of attention.

While people have been talking about it for years, consumers finally seem ready for eco-optimized packaging and are looking for more sustainable options.

And while the so-called ‘green revolution’ many have been waiting for has been slow to materialize, according to

leading consumer intelligence company NeilsonIQ, this is about to change, as more and more consumers want “sustainability” to be the new business baseline.

In doing so, the consumers are rewarding brands who emphasize sustainability by helping them achieve disproportionate growth.

Commitment to the environment is nothing new for Metro’s private brands business.

Well aware of the environmental impact of the approximately 4,000 SKUs (stock-keeping units) in its store brand portfolio, the private brand team has worked relentlessly in recent years to increase the number of Canadian-sources products, which now account for 90 per cent of local suppliers.

Back in 2020, Metro worked alongside Pigeon Brand and other industry leaders such as ÉEQ (Éco Entreprises Québec), Metro created the Better Recycling Blue Book guide to encourage its vendors to improve the recyclability of their packaging, reduce their waste, and eliminate unnecessary packaging.

Some of the key initiatives implemented since then include:

• Recyclable bags for frozen fruit assortments by switching from multilayer to HDPE (high-density polyethylene) film;

• Recyclable cups for 100-gram assorted yogurt four-packs by switching from polystyrene to polypropylene.

• Twenty-percent plastic reduction for the K-Cups coffee pods assortments;

• Carton bread clips for many of Metro’s bread products, replacing polystyrene clips;

• Recyclable tray for the Irresistibles

three-cheese platter, thanks to a switch from polystyrene to PET (polyethylene terephthalate) plastic;

• Removal of a non-recyclable polystyrene tray from the 284-gram Irresistibles Shrimp Torpedo packs;

• Thirty-percent box weight reduction for two SKUs of the Selection brand cereal bars .

Over the past year, seismic shifts in consumer food preferences and eating behaviors have created waves of upheaval across the value chain.

According to a recent Earnst & Young report titled How to Create Long-term Value in a Reimagined Food System, the traditional food system is in the process of reinvention—being shaped with a strong focus on the consumer, the planet, and connections. This is not a foreign concept to the

24 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM PACKAGE DESIGN

Metro team, for whom innovation is a key driver to create and put unique and distinctive products in market, that consumers can only find in the Metro banner stores.

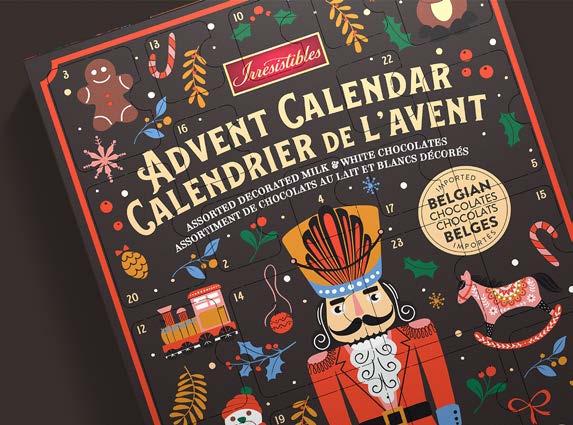

In the last couple of year, Pigeon Brand helped Metro bring many of its store brand to life with exceptional package design, including frozen fruits mixes, seasonal Christmas offerings, limited-edition flavored chip, seafood appetizers, frozen pizzas and snacks, etc.

“These products are not private brands: they are brands, and we treat them as such,” says Pigeon Brands executive creative director Olivier Chevillot.

“From strategy to design, the attention to the visual language and the storytelling is meant to help them win,” Chevillot states, “whatever the category they play in.”

This winning mentality has been

strongly underscored over the last year with multiple prestigious industry awards.

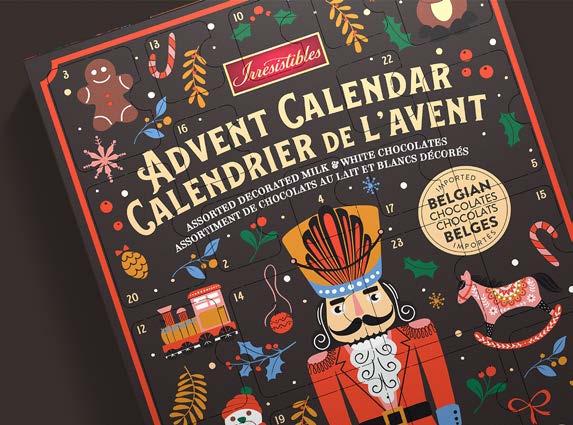

At this year’s 30th annual Grand Prix New Products Awards competition of the Retail Council of Canada (RCC), products from Metro’s brands— including Irresistibles, Selection, Life Smart and Personnelle —stood out with an impressive 26 nominations and 11 awards, making it the highest number of nominations in the private label categories and the highest number of awards overall across all categories.

Among these prestigious awards, Metro received the All-Canadian trophy for its Irresistibles Ice Creams—offering unique flavors such as blueberry and hot chocolate, while highlighting Metro’s commitment to working with local suppliers.

Metro also impressed the judges by

winning the Innovative Packaging Grand Prix award with featuring a playful and clever Advent calendar with design and presentation that communicates value and differentiation.

Since 2018, the Metro Group has received 113 nominations and has won 44 awards from its portfolio.

Metro has also done very well here and abroad over the past few years at the Canadian PAC Awards, the Global PAC Awards and at the Vertex Awards, the latter being an international competition rewarding exceptional private label design.

“This demonstrates the innovative nature and leadership of our brand portfolio,” Gibson concludes, “as well as the exceptional value and quality of our products, while showcasing our commitment to using environmentally responsible packaging and impactful design.”

September 2023 · CANADIANPACKAGING 25 CANADIANPACKAGING.COM

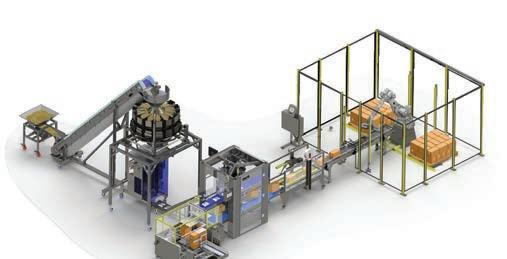

VALUE PROPOSITION

Smart. Flexible. Modular. When it comes to finding automated packaging solutions, these are qualities that many operations value above all else.

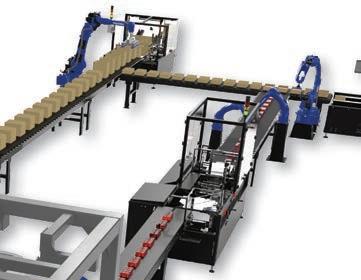

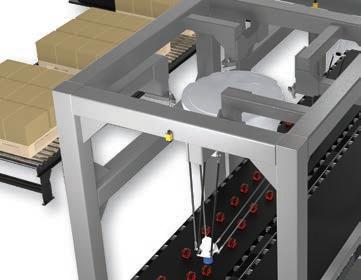

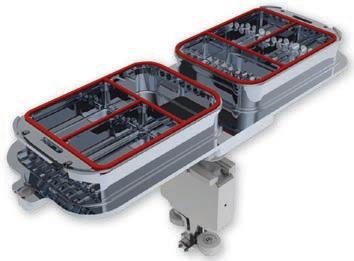

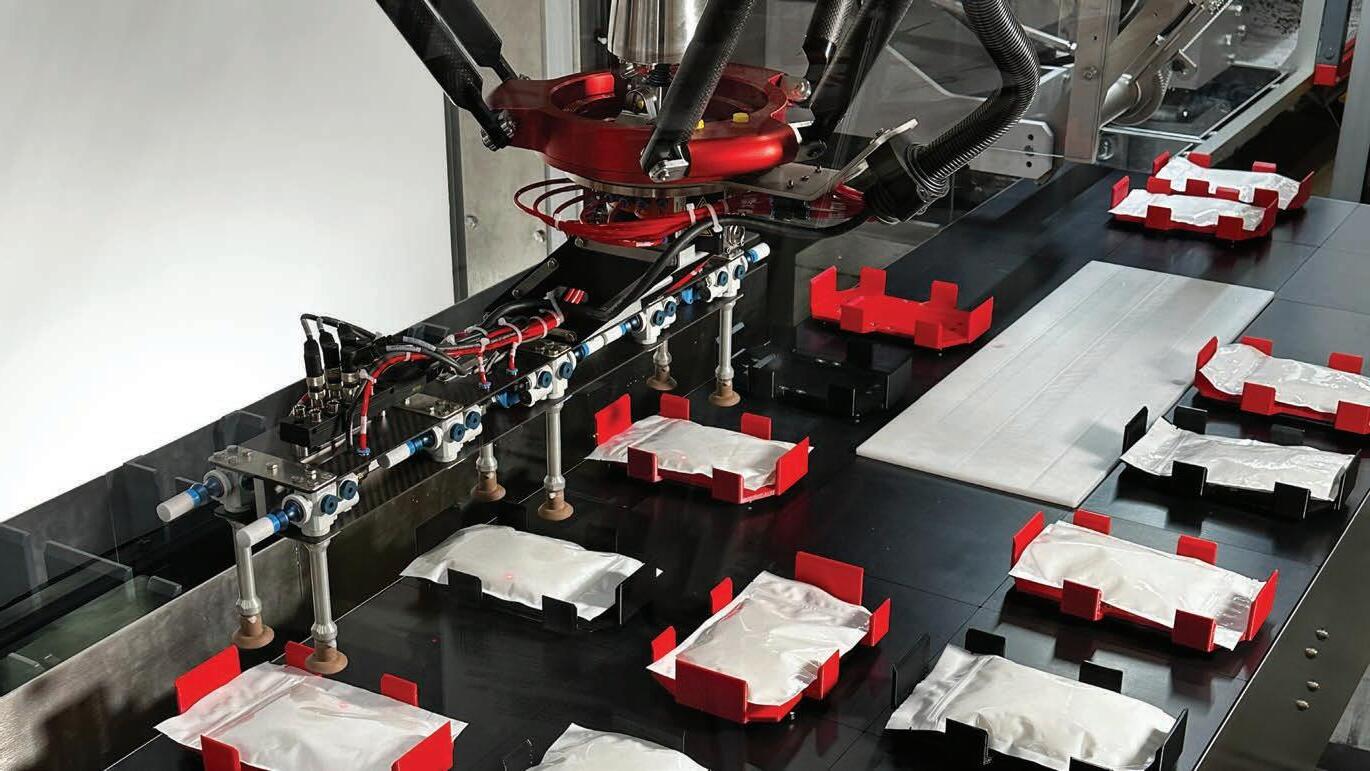

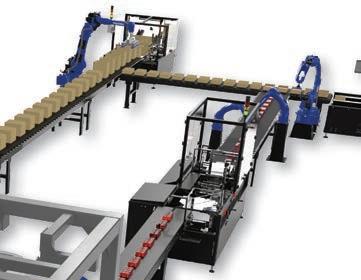

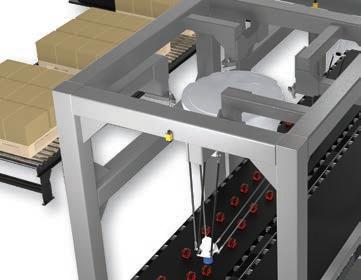

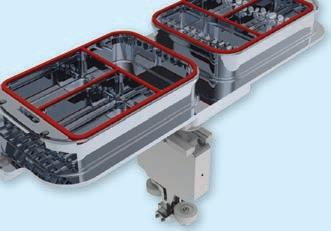

The new iFTS solution for R.A. Jones utilizes 3D-printed red shuttles and magnetic levitation technology to offer virtually unlimited flexibility in pick-and-place cartoning applications.

By Andrew Snook

By Andrew Snook

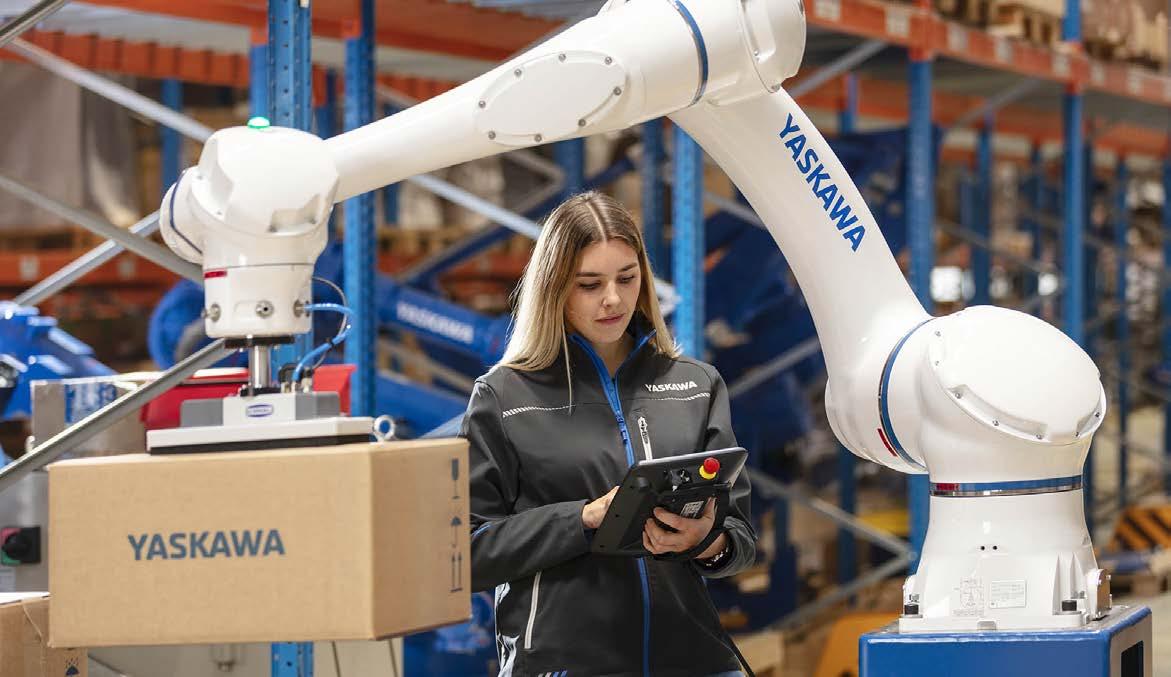

To help clients meet these automated packaging needs, R.A. Jones, a Coesia company, introduced its new-generation iFTS (Intelligent Flexible Transfer System) at the interpack 2023 global packaging exhibition in Düsseldorf, Germany this past May.

Poised to make its North American debut at the upcoming PACK EXPO LasVegas exhbition later this month, the iFTS system was designed to offer solutions for automation challenges—from the simplest to the most complex.

According to R.A. Jones, the company

has married the iFTS with its Criterion CLI-100 model intermittent cartoner to meet customers’ needs for a packaging machine with user-friendly operation and clean-up, as well as quicker and more repeatable changeovers.

The combination of the iFTS and the Criterion CLI-100 stems from over a century of experience.

“We’ve been designing cartoning and automatic product transfers for over 110 years, and we’ve been creating and implementing robotics in packaging along with other flexible automation for 30-plus years.

“This combining of technologies solves some key problems that the customers are facing daily,” explains Bob Burkhardt, product portfolio manager for cartoning, robotics and pouching at R.A. Jones.

“The iFTS we took to interpack, and

Prominent packaging machinery OEM raising operational flexibility to the next level with bold design features and diverse application versatility

AUTOMATE NOW September 2023 · CANADIANPACKAGING 27 CANADIANPACKAGING.COM

that we’re also taking to Pack Expo Las Vegas, is very similar to a solution we made for a customer five years ago, where they were putting pouches of spices in cartons.

“That solution worked,” he says, “but what we realized is that there are ways to do things more simply, particularly using some newer technologies that we’re demonstrating.”

The iFTS to be showcased in Las Vegas that can be integrated into a complete automated packaging solution offered by R.A. Jones in combination with other technologies from their parent company Coesia.

This kind of complete solution is highly sought-after by manufacturers with packaging operations.

“Companies are looking for suppliers that can provide complete solutions,” Burkhardt points out. “They want somebody that can provide the pouch machine, the transfer, the cartoner, conveyance, and the palletizer because they know we are then responsible for making it all work.

“They’re not having to go work with multiple companies where you can have arguments in the boundary areas about who’s responsible if something doesn’t work,” Burkhardt explains. “There’s a really big emphasis on this for us.

“It’s important because it meets the customer’s Operational Equipment Effectiveness (OEE) requirements with

high system efficiencies.”

As Burkhardt relates, the iFTS is designed to offer customers a standard building block platform approach by offering it with a wide range of fixed automation solutions, robot types and sizes, and standard or custom tooling.

In its most typical form, the iFTS receives products from upstream systems that can then be grouped, oriented, and layered for either side-load or top-load cartons or cases.

The unit is built to work alongside other Coesia and R.A. Jones packaging technologies, or be engineered for unique manufacturing applications that can include bags, bottles, bars, cans, cartons, components, medical devices, personal care, pouches, syringes, tubes and vials, and many others.

The automation options on the iFTS include smart conveyance (smart belts, indexing conveyors, two-trains), feeders, and collation, grouping and loading, which includes sweeps, pivot gates, rotary vanes, IndeCarts, and shuttle tables using magnetic levitation.

At interpack, R.A. Jones showcased a completely turnkey Pouch System that integrated the SI 280 Volpak horizontal stand-up pouching machine working alongside the iFTS, the Criterion CLi 100 intermittent cartoner, and the Flexlink RC12 cobot palletizer.

The Volpak SI 280 formed the pouches from rollstock, filled them with product,

and then sealed them.

The iFTS solution then utilized 3D-printed red shuttles that were carried by magnetic levitation technology. The synchronized shuttles on the iFTS magnetic table received the pouch discharged from the Volpak pouch machine, as part of a total integrated solution.

One of the highlights of this solution is the new user-friendly HMI (human-machine interface) touchscreen to help companies manage their labor challenges.

“One thing we’ve seen coming out of COVID-19 and continuing to now is the scarcity of labor,”Burkhardt say .

“Our customers have a hard time getting workers to run these lines at times, “ he says, “and then to keep them after they get them.”

While the company has always trained customers’ employees on any new technologies they are supplying, and will continue to do so, R.A Jones believes the new HMI technology will help less experienced employees get up to speed faster.

“One of the reasons we’re going to newer technologies on our controls for the system is because we want to have the ability to direct the new user,” says Burkhardt.

“We want to train them the first time, but like any of us, users learn through repetition and experience,” Burkhardt points out. “And since the HMI offers more guidance, that is a real benefit.”

28 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM AUTOMATE NOW

The iFTS product transfer system from R.A. Jones integrated with the Criterion CLI-100 intermittent-motion cartoning machine provides a wide range of new manufacturing and packaging applications with bag, bottles, cans, boxes and other types of packaging containers.

“Our parent company, Coesia, is really leading the charge on this because that same interface on the screen will be the same between any Coesia machines,” says Burkhardt.

“And so if you have an operator running the cartoner, the iFTS, or the Volpak, the plan is for everything to have the same look and feel.”

Another innovative feature of the iFTS is the unit’s fault zone lighting option, where LEDs will light up any area experiencing a fault to help operations and maintenance staff save time in keeping the machines up and running.

“The machine will highlight that area to get them to address the issue,” Burkhardt notes. “Most of our customers choose that option these days, because it’s so beneficial,” Burkhardt says.

“And that’s one area where the technology has really advanced,’ he says. “There’s no need to deal with glass light bulbs anymore, and in the world full of LEDs, it’s pretty affordable.”

The push-button changeover (i.e. Acc-U-Change Plus) is another important feature of the iFTS that customers have always wanted but weren’t always able to justify the cost. But with the recent labor shortages, things are changing.

“If your lines are not running because you don’t have trained people to run them, you can quickly see the cost benefit of the push-button changeover,” Burkhardt says.

“We’re actually seeing a trend where customers are more interested in the push-button changeover in general because of this. feature,” he says. “With our machines, we offer different levels of changeover assistance including Standard, Acc-U-Change, or Acc-U-Change Plus.”

Significantly, R.A. Jones has also integrated Coesia’s Performate IIOT (Industrial Internet of Things) platform for real-time machine monitoring into its iFTS and Criterion CLI-100 cartoner.

This portal is designed to allow users to access production data, downtime analysis, real-time data, key production values, machine condition monitoring, technical documentation, remote assistance, and R.A. Jones’ Webshop online parts ordering portal.

Another advantage that packaging operations get when opting for R.A. Jones’ new automated solution is the ability to learn from the company’s depth of engineering experience on the cartoning side, which can offer a wide variety of flexible solutions.

“We call it a flexible transfer system on purpose,” Burkhardt states.

“It’s about bringing the right solution for the customer, and not trying to force them into what you have.

“We have the ability to offer both standard and custom designs with our experience in running production lines, 24-hours-per-day, all-year-long with two

or three shifts, and hitting those OEE efficiencies in the high 90s,” Burkhardt says.

“Some of the customers we’re working with are some of the biggest CPGs (consumer packaged goods) companies in the world, and they have extremely high expectations,” Burkhardt sums up.

“And so whether it’s those companies or medium-sized or small companies, our engineers bring that same experience and intellect to everything we do.

“We are an extremely large company with a great deal of capability.”

September 2023 · CANADIANPACKAGING 29 CANADIANPACKAGING.COM

Spiral Conveyors & Bucket Elevators Vertical Conveying. Simplified.

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2,000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 220 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Our Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. They are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

They can be configured with multiple inlets or outlets that can be controlled individually. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, or stainless-steel for wet environments.

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit www.ryson.com .

Check out our running equipment at Pack Expo | Booth C-4736

30 CANADIANPACKAGING · September 2023 CANADIANPACKAGING.COM www.ryson.com (757) 898-1530

Predictable Outcomes

By Tom Egan

The packaging industry has always been at the forefront of innovation, constantly evolving to meet the demands of consumers and optimize operational efficiency. In recent years, the convergence of predictive maintenance and artificial intelligence (AI) has emerged as a gamechanger, revolutionizing the way packaging and processing operations are conducted.

As stated in the new Challenges and Opportunities for Packaging and Processing Operations report, produced by PMMI, The Association for Packaging and Processing, the integration of these technologies offers immense potential for cost savings, enhanced productivity, and improved overall equipment effectiveness (OEE).

Traditionally, packaging operations have relied on preventive maintenance, following a predetermined schedule of inspections and component replacements.

However, this approach often leads to unnecessary downtime and costs, as maintenance is performed even when equipment may not require it.

Predictive maintenance takes a more proactive stance, harnessing data-driven insights to predict and prevent failures before they occur.

One of the primary advancements in predictive maintenance is the Internet of Things (IoT)

By equipping packaging machinery with sensors, it becomes possible to monitor various parameters in real time.

These sensors collect data on temperature, vibration, pressure, and other vital

Effective predictive maintenance strategies leverage the power of artificial intelligence to help maintenance teams identify machine anomalies and trouble spots before they cause equipment breakdowns and production downtime.

metrics, which are then analyzed using machine learning algorithms.

As a result, maintenance teams can identify patterns and anomalies, enabling them to intervene promptly and prevent equipment breakdowns.

Moreover, the integration of predictive maintenance with AI offers a higher level of accuracy and efficiency.

Machine learning algorithms can analyze vast amounts of historical and real-time data to detect subtle patterns that human operators might miss.

By continuously learning from data, AI-powered predictive maintenance systems become increasingly accurate over time—optimizing equipment performance and minimizing unplanned downtime.

Artificial intelligence is revolutionizing the packaging industry in numerous ways by enabling the automation of complex tasks, enchanting quality control, and streamlining production processes.

Here are some of the most impactful AI applications in packaging to date:

• Quality Control and Inspection.

AI-powered vision systems can inspect packaging materials quickly and accurately, ensuring quality standards are met.

These systems can detect defects such as scratches, dents or printing errors in real time, significantly reducing the risk of faulty products reaching the market.