Stanford materials engineers have 3D printed tens of thousands p.8

CAD REPORT

Dassault Systèmes unveils long-term plan at 3DExperience World 2024 p.14

CHAOS THEORY

Effective method discovered for creating nanostructured high entropy alloys p.18

ADDITIVE MANUFACTURING Challenges and opportunities in the automotive sector NANOPARTICLES

DESIGN-ENGINEERING.COM MAY/JUNE 2024

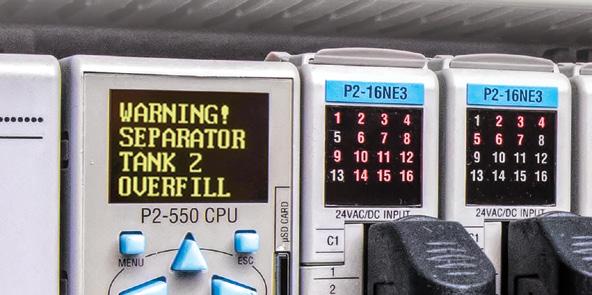

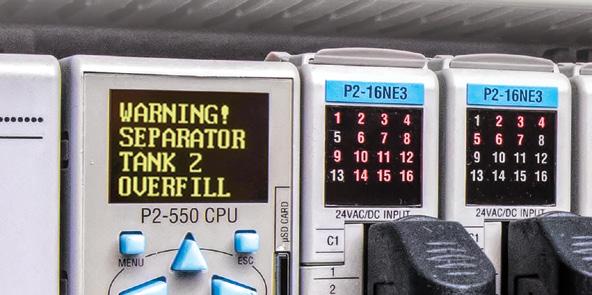

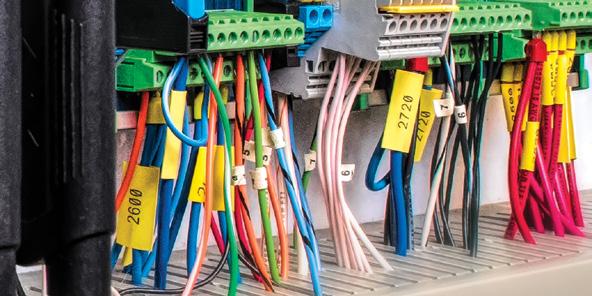

Productivity PLC CPUs start at $237

Whether you are a machine builder, systems integrator, or anyone looking for an advanced, low-cost controls solution, the Productivity family of controllers has what you need. Built to go above and beyond, these controllers offer multiple networking solutions and easy device integration, plus some impressive “WOW!” factors like analog data and CPU status displays. On top of that, the Productivity PLC line also offers:

• CPUs with expansive 50MB memory

• Modular rack-based or stackable footprint with many discrete and analog I/O option modules, scalable up to 59K+ I/O

• FREE advanced tag name programming environment with a convenient project simulator

• 32GB of microSD data logging

• Plus much, much more...

over

policies

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

• Unmatched built-in communications capabilities, including local and remote I/O ports, EtherNet/IP, MQTTS, custom protocols, and more

Affordable and reliable Productivity2000 hardware with a powerful CODESYS engine

• Full IEC 61131-3 compliance

• Modbus RTU/TCP, EtherNet/IP Scanner/Adapter

• WebVisu license included

• IIoT library included with Web Client (http, https), MQTT Client w/ TLS, AWS IoT Core Client, Azure IoT Hub Client, and more

CPU only $529 with free software and over $400 in add-on licenses included!

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2024 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405

Research, price, buy at: www.ProductivityPLCs.com Add more to your systems with advanced low-cost PLCs from AutomationDirect!

direct from the U.S.! 45 4 5dayMoney-BackGuarant e e Lorem ipsum

Orders

$49 get FAST FREE SHIPPING Our shipping

make it easier than ever to order

To see all products and prices, visit www.automationdirect.com All prices shown are U.S. Dollars

INSIDE

8 Elusive 3D printed nanoparticles could lead to new shapeshifting materials

Stanford materials engineers have 3D printed tens of thousands of hard-to-manufacture nanoparticles long predicted to yield promising new materials that change form in an instant

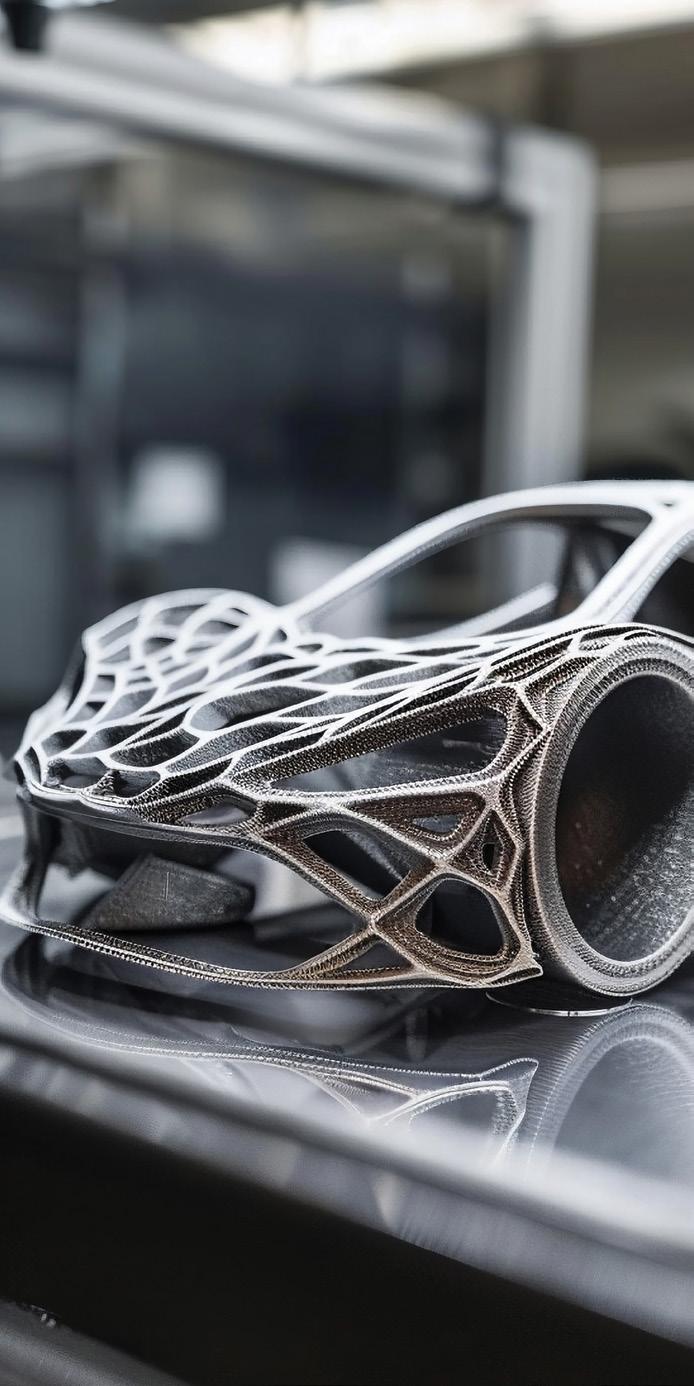

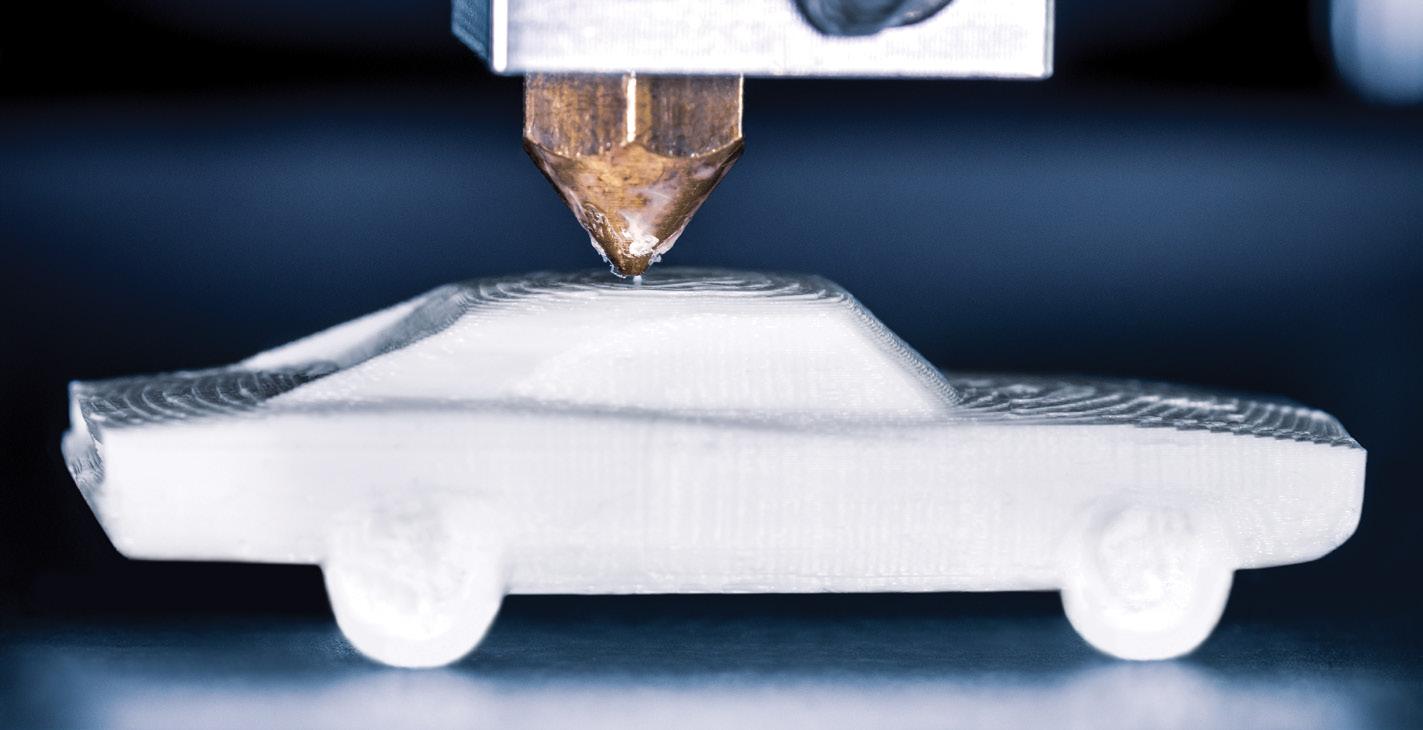

10 Additive manufacturing in automotive Challenges and opportunities for growth in the automotive sector

18 Chaos theory

Effective method discovered for creating nanostructured high entropy alloys

Columns

4 Upfront A new Copper Age

8 Design News

AVL opens Mississauga branch

14 CAD Report

Dassault Systèmes unveils plan to take them through to 2040 at 3DExperience World 2024

21 Idea Generator

The latest industrial products in the marketplace

Cover photo: © Pairat / Adobe Stock

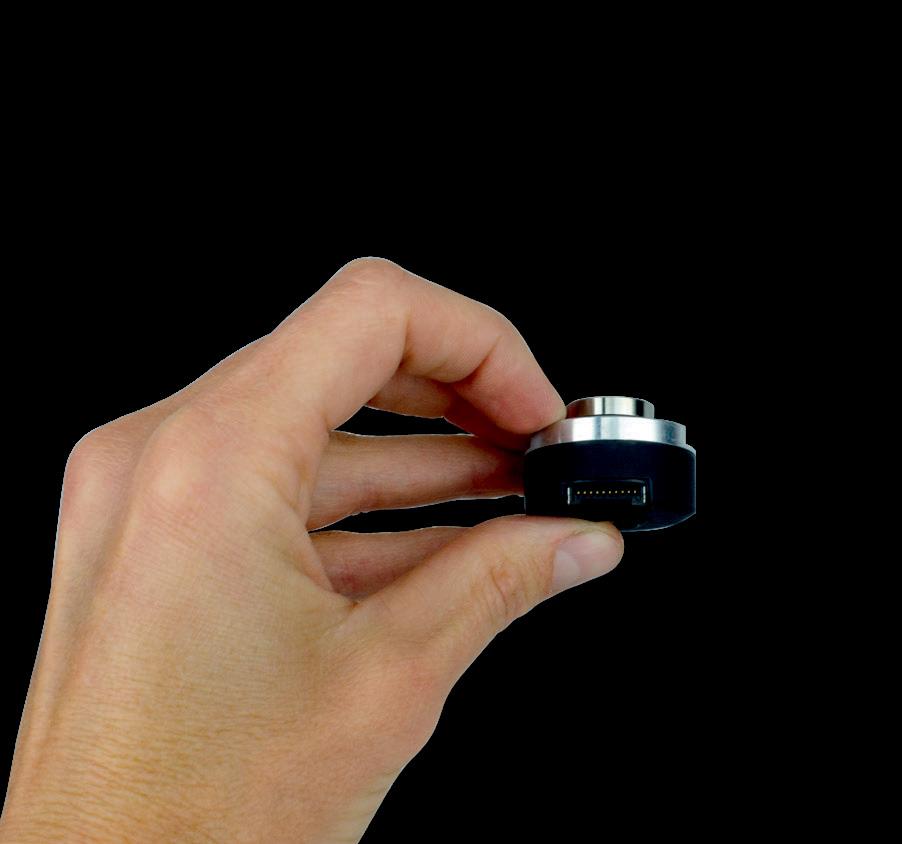

10 14 8 design-engineering.com May/June 2024 Your Responsive Experts IN MOTION CONTROL Encoder Products Company is leveraging new technology to bring you smaller, more accurate, and higher resolution encoders, manufactured and delivered fast from Idaho, USA. 1-800-366-5412 · 208-263-8541 encoder.com MODEL A36R Communication Protocols Compact 36mm Size -40C to +120C Operating Temperature Rating Absolute Thru-Bore Encoder Speak to a live encoder expert in under a minute! 20240503_DES_QuartPage-hor_7.125x2.4375.indd 1 5/3/2024 10:30:11 AM DES_Encoder_MayJune24.indd 1 2024-05-06 1:46 PM @design_eng_mag May/June 2024 DESIGN ENGINEERING 3

A new Copper Age

The Copper Age is seen by many historians as a time of transition.

Taking place between the Stone Age and the Bronze Age, the use of copper became popular with many cultures due to its toughness for improving weaponry and its versatility for creating other items compared to stone.

Fast forward to present day and copper is playing a crucial role in another historical transition: the energy transition.

This metal is in massive demand worldwide, as countries seek to reduce their reliance on traditional fossil fuels, battle global warming, and embrace greater electrification of vehicles and energy infrastructure.

At the Prospectors & Developers Association of Canada’s PDAC 2024 Convention that took place this past March in Toronto, The World Bank’s mining lead, Michael Stanley, presented The World Bank’s Mining Industry Outlook.

One of the key topics discussed during Stanley’s presentation was the global increase in demand for copper. He told attendees that demand for copper is likely to grow by 2.3 times over the next 25 years, a 3- to 3.5-per-cent compound annual growth rate.

Meeting that growing demand for copper will come from a combination of the doubling of mining production globally, and the tripling of recycling operations, he told the crowd.

While there will be many challenges in meeting this spike in demand for copper, if you’re a product designer serving the automotive sector, mining sector, recycling sector, or any other industry embracing a transition to greater electrification, the next few decades may be a time of great opportunity.

Speaking of great opportunity, I wanted to re-introduce myself to the readers of Design Engineering. From 2006 to 2009, I worked as an assistant editor for the publication, and I’m excited to have the opportunity to lead the editorial direction on this brand for years to come.

If you have news on interesting projects, innovative technologies or upcoming events that you would like to share, please do not hesitate to get in touch.

I look forward to speaking with many of you in the future.

ANDRÉ VOSHART

Editor avoshart@annexbusinessmedia.com

Editorial Board

DR. ALAIN AUBERTIN

President & CEO, Canada Consortium for Aerospace Research and Innovation in Canada (CARIC)

DR. MARY WELLS, P.ENG

Dean, Faculty of Engineering / Professor, Mechanical and Mechatronics Engineering; University of Waterloo

AJAY BAJAJ, P.ENG

President and CEO, Rotator Products Limited; Past President and Board Member, Power Transmission Distributors Association (PTDA)

DR. ISHWAR PURI, P.ENG

Vice President of Research; Engineering Professor, University of Southern California

MAY/JUNE 2024

Volume 69, No.3 design-engineering.com

READER SERVICE

Print and digital subsciption inquiries or changes, please contact Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

SENIOR PUBLISHER Paul Burton (416) 510-6756 • pburton@annexbusinessmedia.com

ASSOCIATE PUBLISHER Kathryn Swan (416) 510-6757 • kswan@annexbusinessmedia.com

EDITOR André Voshart (416) 510-5244 • avoshart@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett (416) 829-1221 • ifawcett@annexbusinessmedia.com

ACCOUNT COORDINATOR Cheryl Fisher (416) 510-5194 • cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz (416) 510-5182 • bolechnowicz@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Design Engineering, established in 1955, is published by Annex Business Media, 5 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

Printed in Canada

Publications Mail Agreement #40065710

ISSN: 0011-9342 (Print), 1929-6452 (Online)

Subscriber Services: Canada: $58.65 for 1 year; $94.35 for 2 years;

Outside Canada: USA - $143.31; Overseas - $154.02; $10.00 for single copy.

All prices in CAD funds.

Add applicable taxes to Canadian rates.

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Officer: privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

©2024 Annex Business Media. All rights reserved. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business & Current Affairs Database.

FROM THE EDITOR

4 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

UPFRONT

ADDITIVE

GARY RABINOVITZ RECEIVES LIFETIME ACHIEVEMENT AWARD

The Additive Manufacturing Users Group (AMUG) recently announced Gary Rabinovitz as the recipient of its Lifetime Achievement Award, the second in the organization’s 36-year history. Rabinovitz, AM/3D printing lab manager at Reebok and a member of AMUG’s Board of Directors, was recognized during the group’s 36th annual conference for 24 years of service, hard work and dedication.

Paul Bates, Rabinovitz’s former manager at Reebok and a past AMUG president, presented Rabinovitz with the Lifetime Achievement Award. During the award presentation, Bates recounted his long association with Rabinovitz, having introduced him to Reebok and additive manufacturing as well as facilitated his volunteer work for AMUG.

“Much of what Gary has done is unknown to the AMUG membership. But having worked closely with him for so many years, I witnessed his pivotal role in providing leadership, guidance and counsel as AMUG transitioned over the past 24 years. I have also seen his diligence in doing the work needed to make the changes possible and keep AMUG true to its mission,” Bates said.

Rabinovitz, filled with emotion, could not speak for several moments after accepting the award. When he composed himself, he said that the three priorities in his life are family, wrestling, and AMUG. His wife, Mary, who has been a volunteer at AMUG Conferences for many years, was present to share in celebrating Rabinovitz’s contributions.

“This Lifetime Achievement Award means the world to me. I never imagined being a volunteer in the AM industry for over two decades and then being recognized for it,” Rabinovitz said.

“I am very humbled to receive this prestigious award from AMUG.”

Rabinovitz’s involvement in additive manufacturing user communities began with the Selective Laser Sintering Users Group, which merged with the Stereolithography Users Group to form what is now known as AMUG. In 2001, he became president. From 2002 to 2006, he was president of the Z Corp Users Group (unaffiliated with AMUG). Without interruption, Rabinovitz has served as an AMUG officer or director since 2011. Over those 13 years, he has held the following positions: vice-president, president, past president, advisor to the board, chairman, and director at large. When he took on the role of vice-president in 2011, AMUG’s future was unclear as it transitioned from a group focused on two technologies to one that served all users of all additive manufacturing technologies. With his efforts and those of others central to the restructuring, AMUG has endured, grown and thrived.

Rabinovitz joins Thomas Sorovetz as the most honored AMUG member, having received the three

most prestigious awards that the group bestows: President’s Award [2014], DINO (Distinguished INnovator Operator) Award [2001] and Lifetime Achievement Award [2024]. Source: AMUG.

AUTOMOTIVE

AVL OPENS NEW BRANCH IN MISSISSAUGA FOCUSED ON EV SECTOR

AVL TSI Canada, Inc. (AVL), a global mobility technology company for development, simulation, and testing, announced that it is opening a new branch based in Mississauga, Ont. focused on serving Canada’s emerging battery technology and vehicle electrification sectors.

The company stated it will provide state-of-the-art testing equipment and software to large OEMs, universities, and research facilities in Canada to advance battery technology and EV research and development. The portfolio includes systems that provide customers with advanced capabilities for testing all aspects of vehicle electrification, including batteries, inverters, traction motors, and e-axles.

“AVL’s investment in the Canadian market helps move the industry towards its goal of creating smart, clean, and affordable transportation. These dedicated resources allow us to provide superior service and support as well as enhance responsiveness to suppliers, startups, and OEMs alike,” stated Corey Miller, business director of AVL TSI Canada, Inc.

AVL stated that it would help “strengthen the pipeline of Canadian talent” by investing in North America’s EcoCAR EV Challenge and The Battery Workforce Challenge. AVL will provide participants with simulation tools, testing and engineering support for the development of low-emission and electric vehicles. www.avl.com

DESIGN NEWS UPFRONT

Gary Rabinovitz accepts AMUG award.

Photos: AMUG, AVL. @design_eng_mag May/June 2024 DESIGN ENGINEERING 5

Corey Miller, business director of AVL TSI Canada, Inc.

INDUSTRIAL

GENUINE PARTS COMPANY ANNOUNCES NEW PRESIDENT OF MOTION

The Genuine Parts Company (GPC), a leading global distributor of automotive and industrial replacement parts, has announced that it has appointed James F. Howe as the new president of Motion, the company’s industrial business, effective April 1, 2024.

With almost three decades of dedicated service to the company, Howe will bring “a wealth of experience and expertise to his new role,” the company stated.

Howe’s most recent position held at Motion was executive vice-president and chief commercial and technology officer. He will report directly to Randy Breaux, group president, GPC North America.

“James has an impressive history, having served in numerous executive roles during his long career at Motion,” said Paul Donahue, chairman and CEO. “His extensive experience makes him an excellent choice to lead Motion. We feel confident that under James’s leadership, our talented and experienced Motion team will continue to achieve great results.”

ENERGY

ABB ANNOUNCES STRATEGIC PARTNERSHIP WITH GRIDBEYOND

ABB has announced that has made a minority investment in GridBeyond, a technology provider of energy management solutions based on artificial intelligence and data science. Based in Ireland, GridBeyond’s solutions are designed to allow its customers to optimize distributed energy resources and industrial loads.

ABB stated that this strategic

partnership “will contribute to the continued expansion of ABB’s sustainability advisory services portfolio, and help customers and operators across utilities, industry, infrastructure, and transportation to transition to net zero.”

“Our investment in GridBeyond reflects our commitment to driving technological innovations and creating an ecosystem of partners to enable customers’ energy transition to net zero,” said Stuart Thompson, president of

ABB Electrification Service. “We are helping to transform the way industries generate, distribute and consume energy. We greatly look forward to working with GridBeyond’s team of experts to help drive their next phase of growth.”

GridBeyond works with over 900 clients across four continents to deliver technological solutions to the world’s energy challenges. Through its AI platform, GridBeyond enables its customers to precisely control the energy consumption profiles of their assets, allowing them to unlock new revenue streams, deliver energy and cost savings, optimize production processes and increase resilience by predicting and preventing system failures.

The investment was made through ABB Ventures. ABB joins investors EDP, ESB, TotalEnergies, Act and DublinBIC. Financial terms of the transaction were not disclosed.

AUTOMATION

PILZ AUTOMATION SAFETY CANADA L.P NAMES NEW VP FOR NORTH AND SOUTH AMERICA

Pilz Automation Safety Canada L.P. has announced that its longterm CEO and general manager, Andreas Sobotta, will assume the role of vice-president for North and South America, effective immediately. Sobotta will continue to work from the company’s Canadian office in Mississauga, Ont., and visit all other subsidiaries in North and South America.

Pilz announced that it will take its time to find a successor for the leading position in Canada. The company stated that it is planning to have a proper candidate by Q4 2024 or the beginning of 2025.

“On one hand, it is breaking my heart to leave this wonderful team. On the other hand, I look forward to this thrilling opportunity”, Sobotta says.

James F. Howe has been named the new president of Motion.

DESIGN NEWS UPFRONT

Andreas Sobotta is Pilz’s new vice-president for North and South America.

6 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Photos: Motion, Pilz.

EDUCATION

GINA CODY SCHOOL WELCOMES A NEW MAKERSPACE

Concordia University’s Gina Cody School of Engineering and Computer Science is opening a new makerspace facility. Located on the 10th floor of the Henry F. Hall Building, this space is designed to support a wide range of student projects and initiatives.

“Our staff, all current students, have been thoroughly trained on the equipment,” says Alexis Gosselin, academic facilities coordinator, who also notes the inclusive nature of the makerspace. “This approach ensures that all users, regardless of their prior experience, can safely and effectively engage with the available technology.”

The makerspace is outfitted with equipment for 3D printing, electronics and computer numerically controlled machining, as well as a range of manual tools for woodworking and metalworking. These facilities are available to all Gina Cody School students to work on both academic projects and student society activities.

The space will also offer services such as project consultations and fabrication sessions, which are designed to assist students in developing and completing their projects. During the project consultations, students can presenttheir projects for validation and booking time on the equipment.

The fabrication sessions vary in length depending on the project’s complexity and the availability of equipment and they are always supervised by a staff member.

Mourad Debbabi, dean of the Gina Cody School, highlights the educational significance of the makerspace.

“This facility is an excellent representation of our commitment to experiential learning,” he says. “It provides Gina Cody School students with practical, hands-on experience that is

The makerspace is outfitted with equipment for 3D printing, electronics and computer numerically controlled machining.

crucial in today’s engineering and technology fields.”

Materials for 3D printing projects, including filaments, resins and powders, are provided free of charge. However, students working on machining projects need to supply their own materials.

The makerspace operates across multiple rooms on the 10th floor, with each dedicated to specific activities:

• Room H.1021 for woodworking and basic 3D printing

• Room H.1025 for machining and electronics

• Room H.1020 for advanced 3D printing

“This new facility represents a significant investment in student learning and development, offering a practical space for innovation and creativity,” Debbabi says.

For more information about the makerspace and how it supports student projects, visit the Gina Cody School of Engineering and Computer Science makerspace web page.

This article was republished with permission from Concordia University. To read the original article, visit: https://www.concordia.ca/ cunews/main/stories/2024/03/25/ gina-cody-school-welcomes-a-newmakerspace.html

AEROSPACE

AEROSPACE CONSORTIUM CRIAQ APPOINTS NEW CEO

Guillaume Côté has been appointed as president and CEO

Côté, president and CEO of the Consortium for Research and Innovation in Aerospace in Quebec (CRIAQ).

of the Consortium for Research and Innovation in Aerospace in Quebec (CRIAQ).

Côté has a strong track record in the Quebec and Canadian aerospace ecosystem, including roles within the federal government, key industry bodies like the Aerospace Industries Association of Canada (AIAC), the Canadian Aerospace Consortium for Research and Innovation (CARIC), and his most recent strategic contributions at Collins Aerospace.

“As we look ahead, we anticipate numerous challenges in the horizon,” Côté said. “These include the realization of our ambitious Roadmap 2035, the implementation of the Initiative for Sustainable Aviation Technology (INSAT) by the federal government, and the imminent establishment of the Aerospace Innovation Zone. Working collaboratively with CRIAQ’s team and members, we have the chance to shape future of the aerospace industry”.

He succeeds Alain Aubertin, who has been a member of the CRIAQ management team for the past 12 years, serving as president and CEO from 2019 to 2024. He will continue to contribute as a special advisor until October 2024. |DE

Visit design-engineering.com for the latest new products, news and industry events.

Photos: Concordia University, CRIAQ. @design_eng_mag May/June 2024 DESIGN ENGINEERING 7

Guillaume

ELUSIVE 3D PRINTED NANOPARTICLES COULD LEAD TO NEW SHAPESHIFTING MATERIALS

Stanford materials engineers have 3D printed tens of thousands of hard-to-manufacture nanoparticles long predicted to yield promising new materials that change form in an instant

BY ANDREW MYERS, STANFORD UNIVERSITY

In nanomaterials, shape is destiny. That is, the geometry of the particle in the material defines the physical characteristics of the resulting material.

“A crystal made of nano-ball bearings will arrange themselves differently than a crystal made of nano-dice and these arrangements will produce very different physical properties,” said Wendy Gu, an assistant professor of

mechanical engineering at Stanford University, introducing her latest paper which appears in the journal, Nature Communications. “We’ve used a 3D nanoprinting technique to produce one of the most promising shapes known – Archimedean truncated tetrahedrons. They are micron-scale tetrahedrons with the tips lopped off.”

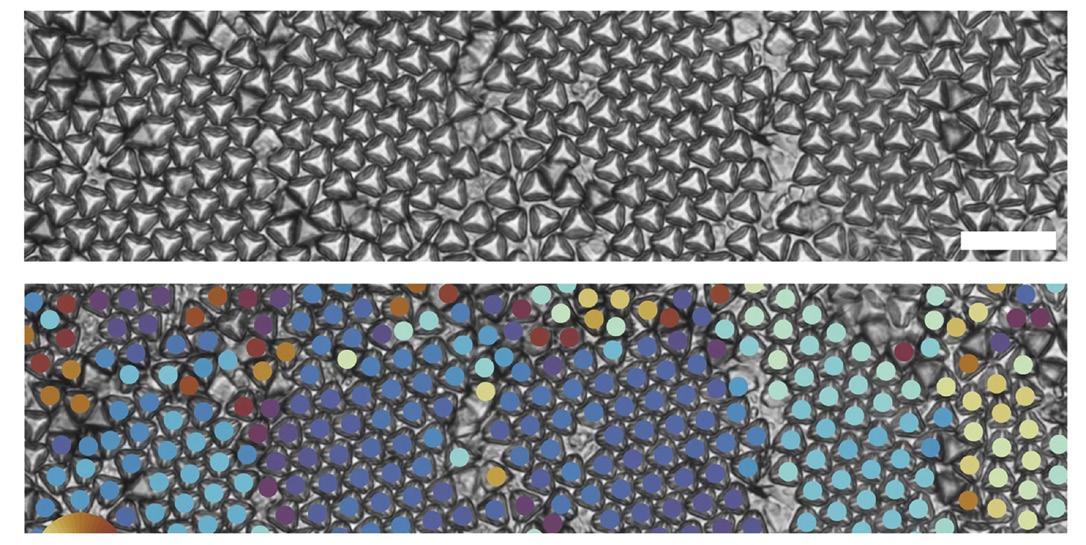

In the paper, Gu and her co-authors describe how they nanoprinted tens of

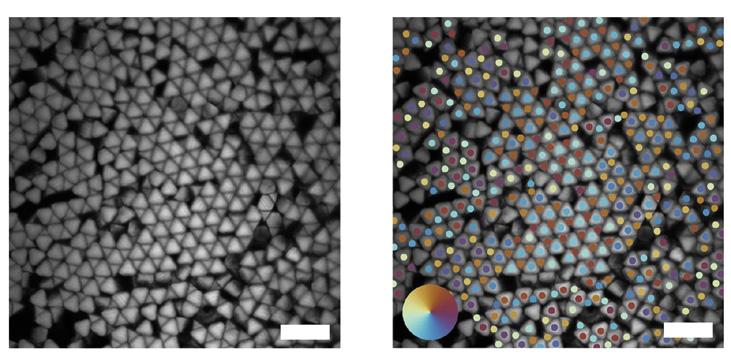

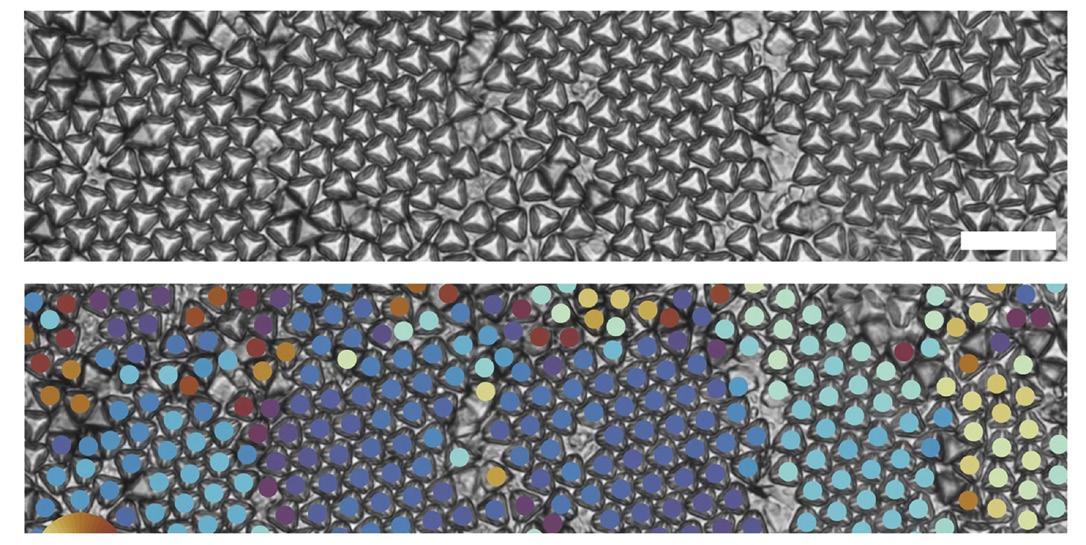

Optical images of truncated tetrahedrons forming multiple hexagonal grains (top). Bond order analysis shows different hexagonal grains through different colors (bottom). Neighboring tetrahedrons that have the same color indicate that they have the same grain orientation. Scale bar is 20 um.

atomic rearrangement that turns iron into tempered steel, or in materials that allow computers to store terabytes of valuable data in digital form.

“If we can learn to control these phase shifts in materials made of these Archimedean truncated tetrahedrons it could lead in many promising engineering directions,” she said.

Elusive prey

Archimedean truncated tetrahedrons (ATTs) have long been theorized to be among the most desirable of geometries for producing materials that can easily change phase, but until recently were challenging to fabricate – predicted in computer simulations yet difficult to reproduce in the real world.

thousands of these challenging nanoparticles, stirred them into a solution, and then watched as they self-assembled into various promising crystal structures. More critically, these materials can shift between states in minutes simply by rearranging the particles into new geometric patterns.

This ability to change “phases,” as materials engineers refer to the shapeshifting quality, is similar to the

Gu is quick to point out that her team is not the first to produce nanoscale Archimedean truncated tetrahedrons in quantity, but they are among the first, if not the first, to use 3D nanoprinting to do it.

“With 3D nanoprinting, we can make almost any shape we want. We can control the particle shape very carefully,” Gu explained. “This particular shape has been predicted by simulations to form very interesting structures. When you can pack them together in various ways they produce valuable physical properties.”

ATTs form at least two highly desirable geometric

ADDITIVE MANUFACTURING FEATURE

8 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Images courtesy of David Doan and John Kulikowski, run with permission of Stanford University.

structures. The first is a hexagonal pattern in which the tetrahedrons rest flat on the substrate with their truncated tips pointing upward like a nanoscale mountain range. The second is perhaps even more promising, Gu said. It is a crystalline quasi-diamond structure in which the tetrahedrons alternate in upward- and downward-facing orientations, like eggs resting in an egg carton. The diamond arrangement is considered a “Holy Grail” in the photonics community and could lead in many new and interesting scientific directions.

Most importantly, however, when properly engineered, future materials made of 3D printed particles can be rearranged rapidly, switching easily back and forth between phases with

Confocal images of truncated tetrahedrons forming several quasi-diamond grains (left). Bond order analysis shows different quasi-diamond grains through alternating colours (right). Neighbouring tetrahedrons that have alternating colours (i.e., blue and red/brown, or dark blue and yellow) indicate that they have the same grain orientation. Scale bars are 20 um.

the application of a magnetic field, electric current, heat, or other engineering method.

Gu said she can imagine coatings for solar panels that change throughout the day to maximize energy efficiency, new-age hydrophobic films for airplane wings and windows that mean they never

fog or ice up, or new types of computer memory. The list goes on and on.

“Right now, we’re working on making these particles magnetic to control how they behave,” Gu said of her latest research already underway using Archimedean truncated tetrahedron nanoparticles

in new ways. “The possibilities are only beginning to be explored.” |DE

Additional co-authors of the work are PhD students David Doan and John Kulikowski. Gu is also a member of Stanford Bio-X. This work was funded by the National Science Foundation, a Stanford Graduate Fellowship. DD, JK, the Hellman Foundation, and the National Science Foundation. Part of this work was performed at the Stanford Nano Shared Facilities, which is supported by the National Science Foundation, and at the Stanford Cell Sciences Imaging Facility. Read the original article published by Stanford University at: https://engineering.stanford.edu/magazine/ elusive-3d-printed-nanoparticles-could-lead-new-shapeshifting-materials.

24_002901_Design_Engineering_MAY_JUN_CN Mod: March 27, 2024 9:55 AM Print: 04/26/24 page 1 v2.5

π SHIPPING SUPPLY SPECIALISTS GET ORGANIZED! SHELVING IN STOCK IN ALL LOCATIONS ORDER BY 6 PM FOR SAME DAY SHIPPING COMPLETE CATALOG 1-800-295-5510 uline.ca DES_Uline_MayJune24.indd 1 2024-04-29 11:14 AM

@design_eng_mag May/June 2024 DESIGN ENGINEERING 9

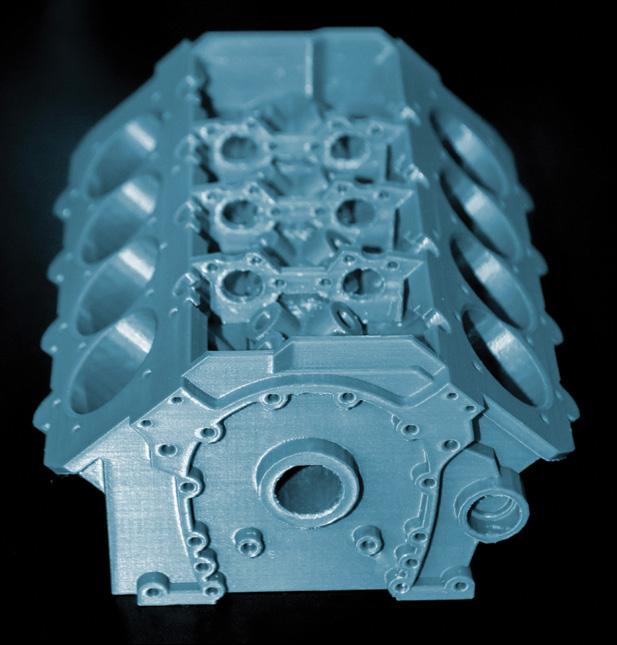

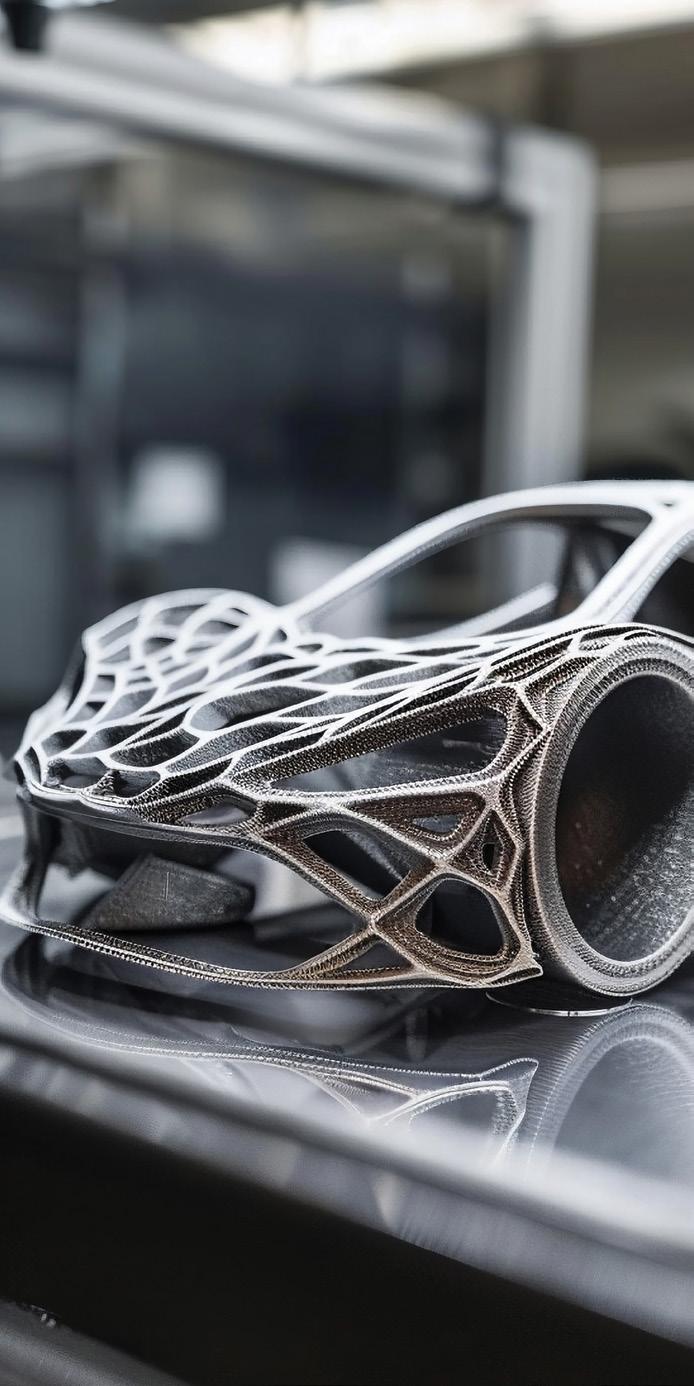

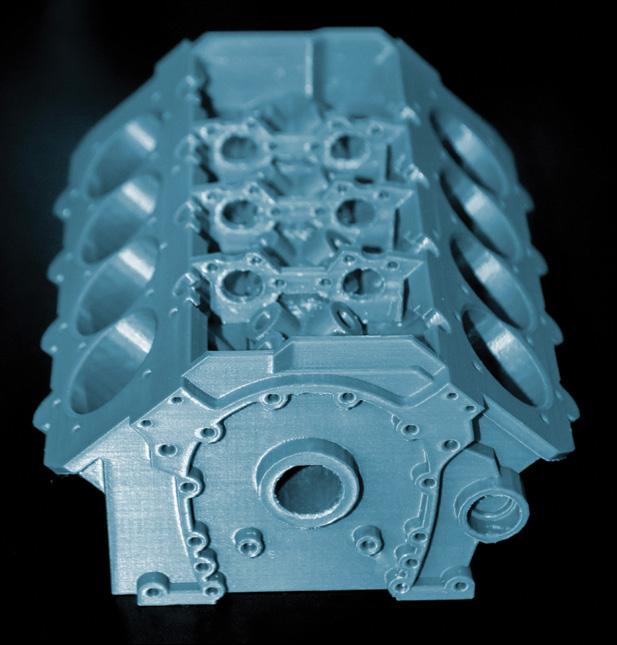

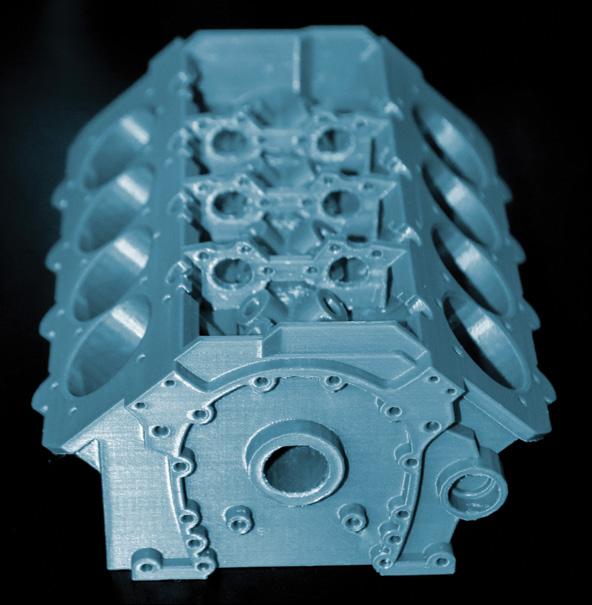

ADDITIVE MANUFACTURING IN AUTOMOTIVE

Challenges and opportunities for growth in the sector

BY ANDREW SNOOK

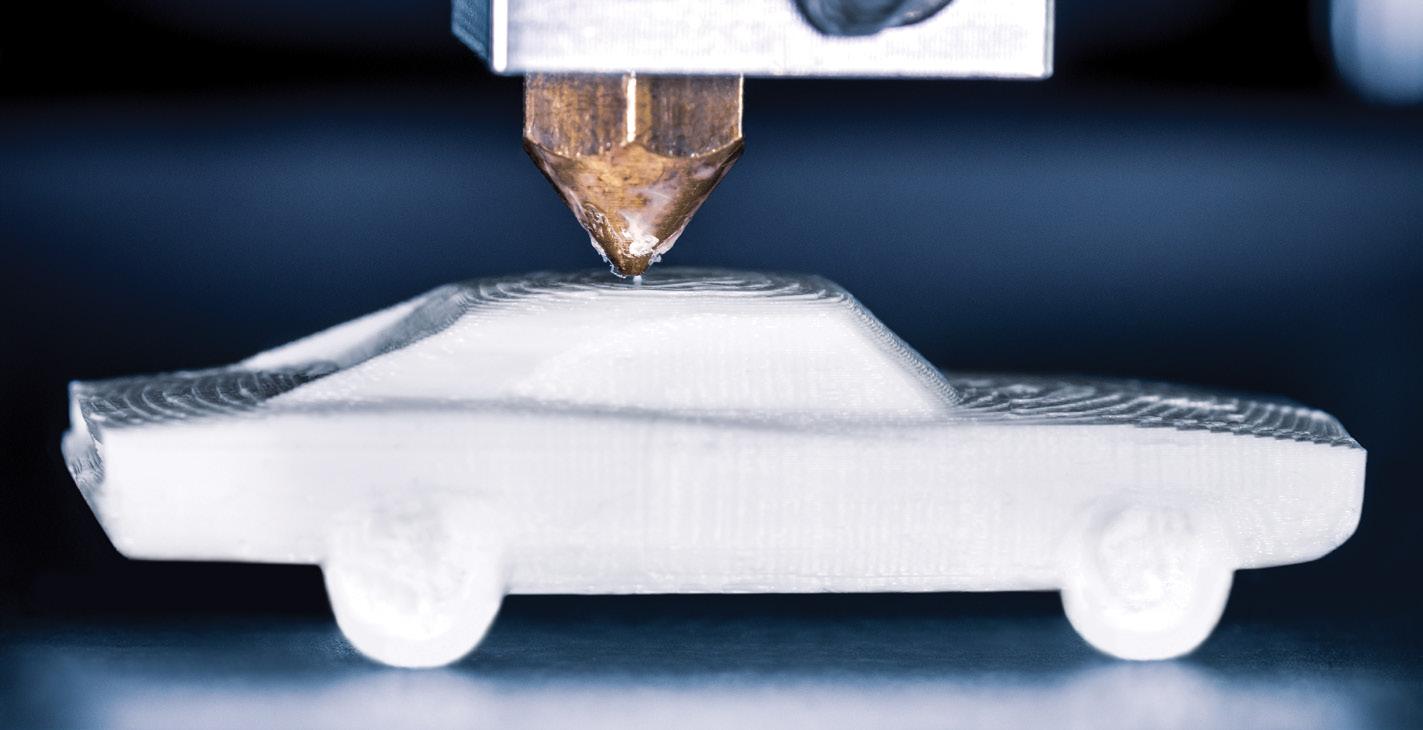

Manufacturers across almost every industry are excited about the rise in popularity of additive manufacturing and all the potential advantages it could offer. In the automotive sector, where every vehicle requires tens of thousands of parts, there are many potential applications for the technology. That said, there are also many barriers.

To learn more about the opportunities and challenges that exist for additive manufacturing in the automotive sector, Design Engineering sat down with Thomas Sorovetz, a director with the Additive Manufacturing Users Group (AMUG).

Sorovetz has been with Stellantis (formerly FCA, LLC) for more than 37 years, including 24 years as supervisor of vehicle engineering development; rapid prototyping development; wood; plastic; CNC; and carbon fiber shops. He has over 37 years of experience in automotive design and engineering and more than 30 years of experience in rapid prototyping/additive manufacturing. Sorovetz was the recipient of the AMUG Distinguished INnovative Operator (DINO) Award; the AMUG President’s Award; and the AMUG Distinguished Service Award for his 25-plus years on the AMUG Executive Board.

Barriers to growth

While additive manufacturing has existed in the automotive sector

since the late 1980s, companies are still adapting to its use.

“To get a vehicle to use your additive plastic parts in the cockpit, which is where everybody sits, there’s several Federal Motor Vehicle Safety Standards (FMVSS) that are required for testing. One of the problems becomes that none of the materials from the build processes are isotropic –they’re not the same,” Sorovetz explains. “If you injection mold, you have that single crystal structure. If you’re doing it with fibre, they’re all fairly directional. With additive, it depends on where it’s at in the build platform, what angle, how it’s rotated, is it standing up; and you get differences of not only build and material properties overall, you also get different test results from those.”

If a company were to require 1,000 pieces of a specific part over the next 12 months, for example, those parts would need to be produced by one specific 3D printing machine with no changes, which can become cumbersome and complicated, Sorovetz explains. Adding to the challenge with this kind of production is that the photopolymer, monofilament line or powdered plastic being used cannot be altered at any point by the supplier.

“You need to sit down with the manufacturer of that material and say, ‘I’m currently using your material ABC XYZ for this product. I want to continue using it and I need to create X parts for

While additive manufacturing has existed in the automotive sector since the late 1980s, companies are still adapting to its use.

over the next X number of years. We need to enter into a contract that says that you are not going to change any piece of the recipe of ABC XYZ. And if you make any modifications, you’ll still be creating the old recipe, because I’ve already tested and certified and standardized this material,’” he says. “If they say they need to switch because their photo initiator company is no longer supplying the photo initiator or decide they could find this material elsewhere as part of the raw materials because it’s less expensive, that could change the entire chemistry. So, now you start from ground zero.”

Photo: © Pairat / Adobe Stock ADDITIVE MANUFACTURING FEATURE 10 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Material costs are also currently a significant barrier for additive manufacturing’s growth in the automotive sector.

“From the metals standpoint, I could buy one kilogram of aluminum A356, for example, at a rough estimate of $10 a kilo for my sand casting. To get a kilo of AlSi10Mg, it might be $60 or $80 a kilogram. So, how do I build parts using that when I can cast the part and it’s going to be a lot less expensive and a lot faster,” Sorovetz says.

Another hurdle that the additive manufacturing sector needs to navigate compared to more traditional options are costly

Material costs are a significant barrier for additive manufacturing’s growth in the automotive sector.

Purchasing metals like aluminum A356 for sand casting is currently a cheaper and faster option for many parts, Sorovetz says.

service contracts that could act as a deterrent to potential customers.

“When you buy a machine tool – I go to Haas and purchase a CNC machine, or I go to LeBlond or Minster for a stamping press – they train you and your skilled workers on how to repair the systems. Only if you have a problem do you need to call up the service guy to have them come out,” Sorovetz says. “In today’s industry with additive, the service contract is a big revenue generator, just like the material. Whereas with machining tools, they don’t care whose collets you’re using as long as they fit the head. They don’t care whose cutting tools, cutting inserts, cutting liquid, that you use, as long as it meets their qualifications and standards and fits their machine, which are pretty standard across the platform. So, because of that the prices are down really low.”

This differs from the additive manufacturing sector, where there are fewer purchasing options for customers for the various

materials required.

“With additive, let’s go with stereolithography, you have three or four companies that manufacture the photo polymer. You’re sort of a contained company now of who you’re going to buy from and what you’re going to purchase, and how much it is. That’s a problem,” Sorovetz says. “When you’re buying an ABS type of pellet material for injection molding, that might be three, maybe even seven cents a pound. By the train loads, it’s still a lot cheaper than one hundred dollars a kilogram for a photo polymer, or a spool of monofilament for any of the additive, or a kilo of the powdered plastic for your sintering systems. So, that is a big thing.”

He believes one solution that would help the industry grow would be for the manufacturers of the 3D printing machines to allow for a wider range of materials to be used in the equipment, as long as those materials meet or exceed the requirements for that machine.

“If it doesn’t meet the

“In today’s industry with additive, the service contract is a big revenue generator, just like the material.”

Photo: © enviromantic / iStock / Getty Images Plus

@design_eng_mag May/June 2024 DESIGN ENGINEERING 11

requirements and you decide to put it in and it clogs the head, or you keep getting build crashes, and now the blades out of alignment and you can’t fix it because it bent the recoder arm, then you’re willing to pay whatever that price is to have everything replaced and repaired,” Sorovetz says. “But that’s part of the reason why when you’re dealing with these million-dollar pieces of equipment, automotive companies – tier 1, tier 2 and OEMs – are a lot slower to react.”

While auto parts have been a difficult space for additive manufacturing to grow, there are certainly opportunities for production line parts, where the same stringent regulatory requirements are not present.

Sorovetz believes one solution that would help the industry grow would be for the manufacturers of the 3D printing machines to allow for a wider range of materials to be used in the equipment, as long as those materials meet or exceed the requirements for that machine.

Additive opportunities

While automotive parts have been a difficult space for additive manufacturing to grow, there are certainly opportunities for production line parts, where the same stringent regulatory requirements are not present.

“For production line stuff –end-of-arm tooling, fixtures, gauges – it’s taking off fairly quickly in the automotive industry,” Sorovetz says. “I can take an FDM (fused deposition modeling) machine and stick it on the shop floor at one of the plants, and all of a sudden there’s been a change of where we want to locate the logo or the brand name of the vehicle… we could go ahead and redesign that, send it over to the machine on the plant floor and they could pull it off the FDM machine and start using it as is, because the ABS (acrylonitrile butadiene styrene) isn’t going to scratch the fresh paint. And you can get it overnight.”

Another big opportunity lies in

the ability to create replacement parts quickly on the plant floor, Sorovetz notes.

“Being on the plant floor where you could hurry up and make changes to end-of-arm robotics if you broke something, you could make a quick part for it overnight, that’s huge,” he says.

One example of a great application of additive manufacturing on the plant floor was Vince Anewenter’s entrance into the AMUG Technical Competition a few years ago, where he showcased a fixture designed for one of his customers.

“He had a split line in it, so if you were to knock it off the table, drop it or mistreat it, it’s going to fracture,” Sorovetz recalls. “People were asking, ‘Why do you want that?’ It’s because with a steel tool, if I accidentally knock it off the table and then it gets twisted and out of shape, I’m putting it back on my table. I’m just going to say, ‘It works, it’s fine.’ You might not figure that out until

ADDITIVE MANUFACTURING FEATURE

© M.Dörr & M.Frommherz, mari1408 / Adobe Stock 12 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Photo:

three shifts from now when something’s not fitting someplace, and no one’s going to own up to dropping it because it’s a $5,000, $15,000 or $30,000 fixture.Whereas if it shatters for $200, the guy could reach into the cabinet, grab a new one, set it down and continue working.”

Where smaller numbers of parts need to be produced, like in niche vehicles, for example, Sorovetz sees room for more adaptation of additive manufacturing technologies.

“With Chrysler we have the SRT brand, which is Street and Racing Technology, like the Dodge Challenger, Hellcat, Demon, and the Hellephant Engine. It’s perfect for those cars because you do 3,500 or 4,000 of those annually, so you can meet those requirements. And it’d be a lot better than having to create hundreds of thousands of dollars of new tooling to do the same thing that we could do with additive.”

To make some of these opportunities for additive manufacturing a reality in the automotive sector, several factors need to be met.

“First and foremost, I think that the materials have to come way down in price. I think that the operators and owners of the equipment need to be trained on how to take care of the machines. And those parts should be common parts that you could call up and get from Grainger, or wherever the case may be,” Sorovetz says.

Another important factor is increasing the build speed of the equipment.

“If you could have a robotic arm set up to grab the part and it puts it on a different platform, and the door gets shut. And then by sequence, it says okay, everything’s there, and starts to build again… then you can run lights out, seven days a week,” he says. “The automotive industry shuts down over Christmas and on holidays. If you know that when you come back on the third of January, you need 700 of these metal parts, as long as you have enough feedstock for it, and you have the robotics all set up to pick and place everything, you can come back to a room full of parts. That is awesome.” |DE

Where smaller numbers of parts need to be produced, like in niche vehicles, for example, Sorovetz sees room for more adaptation of additive manufacturing technologies.

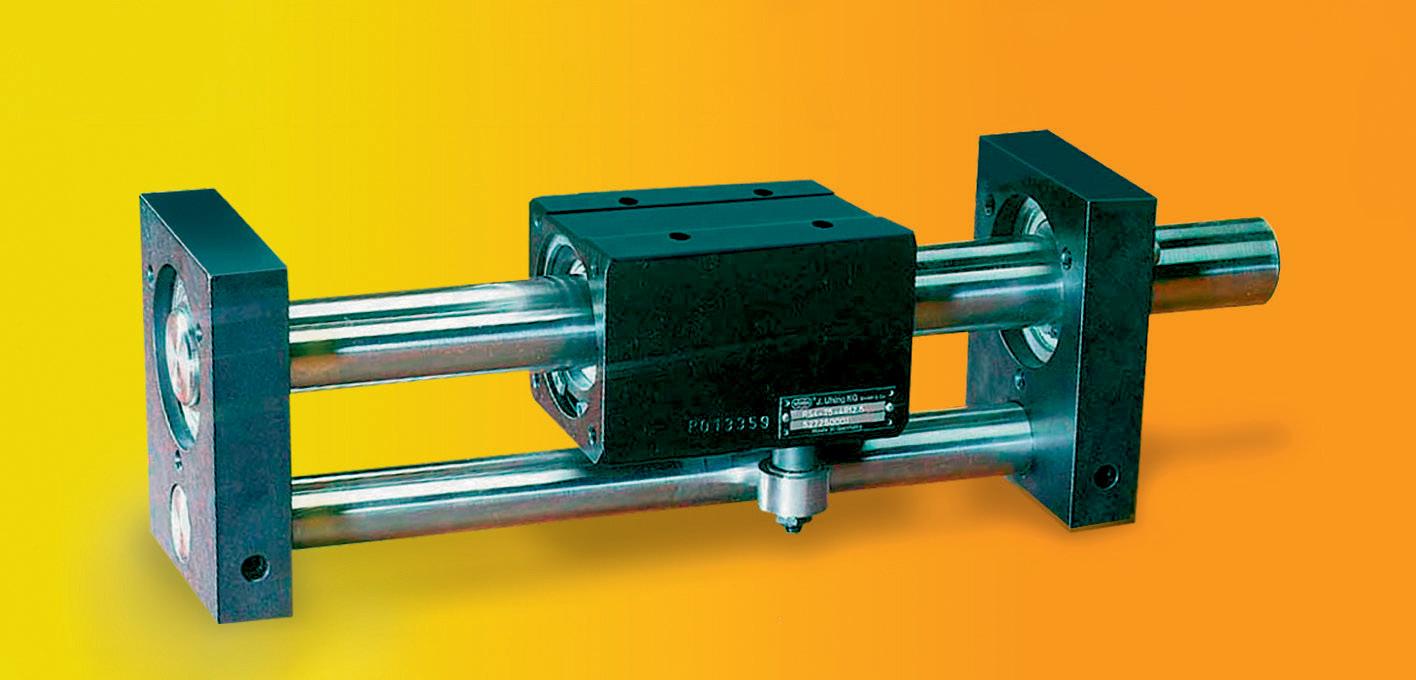

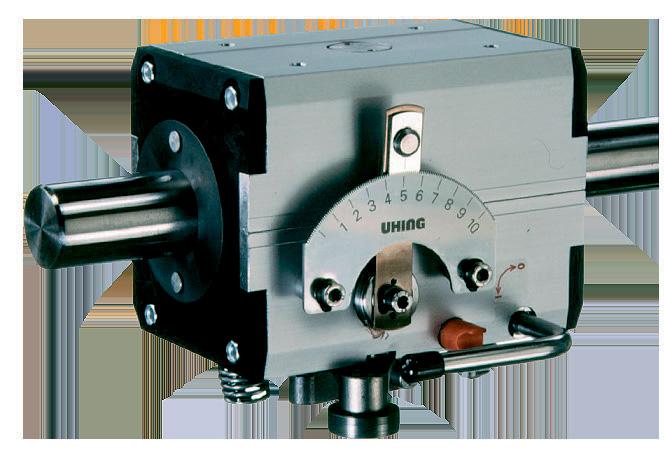

Rolling Ring LINEAR DRIVES

Zero backlash. Jam-proof design.

Example applications: Many different sizes For more information call DES_Amacoil_MarApr23_CSA.indd 1 2023-03-23 9:10 AM

@design_eng_mag May/June 2024 DESIGN ENGINEERING 13

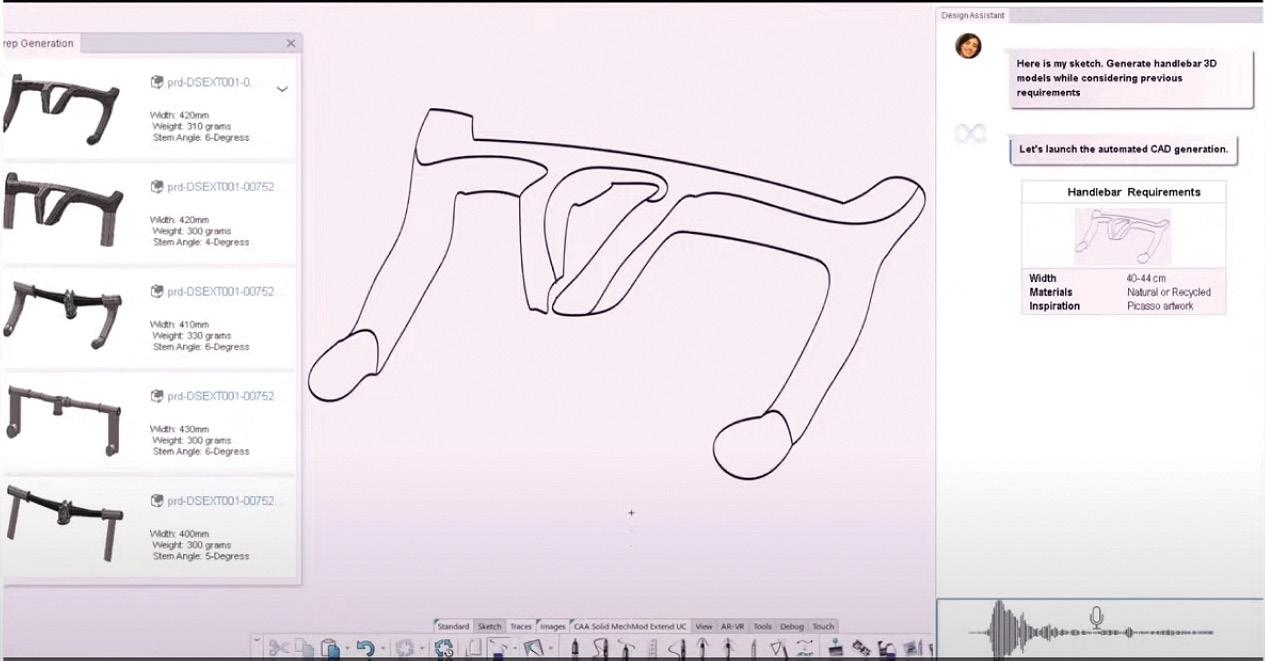

DASSAULT UNVEILS MASTER PLAN

Dassault Systèmes unveils plan to take them through to 2040 at 3DExperience World 2024

BY RALPH GRABOWSKI

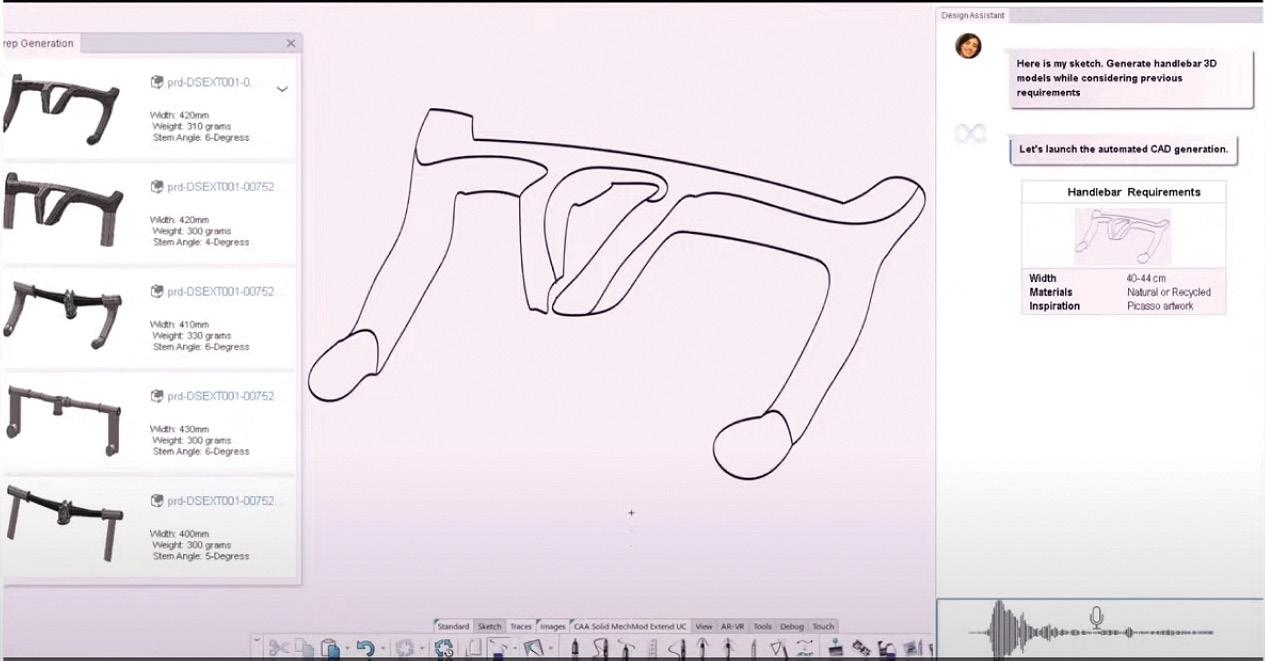

Dassault Systèmes has a master plan to take them through to 2040. It’s to integrate modeling, simulation, and AI to create virtual twins on virtual universes, through data mining of design data that’s stored on the cloud.

During his keynote at the 3DExperience World 2024 conference, Bernard Charlès, executive chairman of Dassault Systèmes, called AI, “the big elephant,” because it reinvents the way design is done. Charlès calls AI the magic of design; indeed, he referred repeatedly to “Magic Solidworks.”

To be clear, when CAD vendors talk about AI, it’s not the currently popular LLM-based AI like ChatGPT. LLM (large-language models) are essentially syntax assemblers. By contrast, the AI in CAD is what we have been calling “rules-based engineering,” a

3D parts (in the left panel) were generated by Magic Solidworks from an AI-generated sketch (centre); conversation with the AI bot is in the right panel.

series of if-then statements that check tables of values to arrive at design suggestions, something that’s been around for a decade and longer.

Here is how Charlès envisions AI

might work in the future of product design. You speak to Magic Solidworks: Show me a handle made of recycled materials... use a style that mimics Picaso’s art... sketch the

Bernard Charlès proposing waste be designed into new products.

CAD SOFTWARE FEATURE

All images sourced from Dassault Systems 14 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

handle... make 3D parts from it. His use of “recycled” is significant, as he sees the reuse of waste a new third stage of 3DExperience, following the modeling and customer experience stages.

The future versions of both Solidworks and 3DExperience will launch every process needed to create 3D objects from sketches, and then generate simulations automatically. Charlès said AI-based functions are expected to become available over the next 12 months.

AI in HomeByMe

Dassault plans that all of its applications have AI interfaces to create, optimize and evaluate design alternatives. As an example, Charlès showed how we could use a phone with his company’s HomeByMe app to scan rooms, after which an AI engine generates the rooms in 3D. (Room scanning works only with the 2020 Pro versions of iPhone 12 and iPad, unfortunately).

Once we have 3D models of the rooms, we can specify a furnishing style and choose the types of furniture we want added to rooms, accessed from the associated https:// home.by.me site. This is a free/for-fee site from which we can access furnishings, store our designs, and see what other users have made.

HomeByMe app populating scanned rooms of a home.

All in the cloud, the cloud in all

Even though HomeByMe is a consumer example, Charlès used it to illustrate his plan for digital-twin universes.

“What some others call metaverse

[Facebook], omniverse [nVidia] is at the core of the future of Dassault Systèmes,” he said.

With so much design content available on the cloud, he foresees these universes merging together. All designs that ever have been made, ideas past and future, can be fully exploited by AI, revealing the intellectual property inside – albeit, Charlès admitted, only when data sharing is authorized.

Executives speaking from the main stage repeatedly reassured us that this will take place amongst the highest level of cybersecurity levels, which, as we follow the news, know to be surprising low for a surprising high number of governments and corporations.

Autodesk has described a similar desire to access all of the information inside files customers have uploaded to its online storage sites. The company

Process improvement is like cycling. Everything runs more efficiently with the right partner.

Energy optimization is the key to sustainable production. As a strong partner for strategic energy management, we help you cope with rising energy costs and tighter environmental targets. We are at your side – uncovering the ways to save and be resourceful while maintaining safety, quality, reliability, and uptime.

Do you want to learn more? www.ca.endress.com

DES_Endress_MayJune24.indd 1 2024-05-02 11:33 AM

@design_eng_mag May/June 2024 DESIGN ENGINEERING 15

claims to have 40 petabytes of user data so far, which it would like to trawl through to train its AI engine – again, given permission by us.

Former Solidworks CEO Gian Paolo shocked me stating that it’s no longer sufficient for 3D digital models to just be accurate.

“We need to bring those models as close as possible to reality, optimizing every ounce of material, and see how they affect all aspects of life, before they are realized,” he said.

He explained that the 3DExperience platform built by Dassault can scale from microstructures in materials to something the size of a city. The platform uses an AI-based backbone for modeling and reuse. Borrowing from statements made by competitors, he proclaimed that the only companies to survive in the future are those that create better products with higher quality, and taking into account resource use.

A 25-year plan takes 25 years to implement, and so all of these things will occur in stages. An initial one, for example, is combining all multi-physics simulations into a single Modsim package.

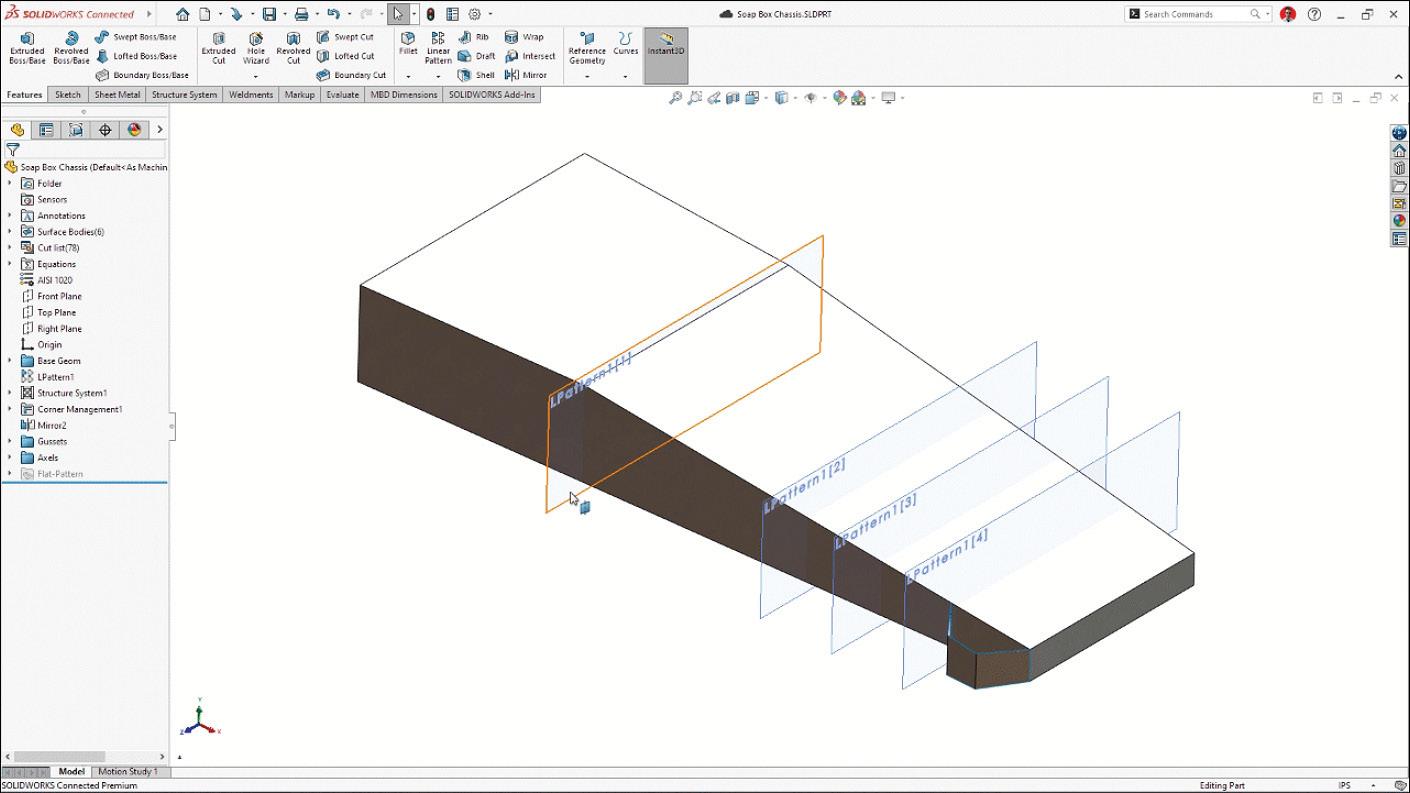

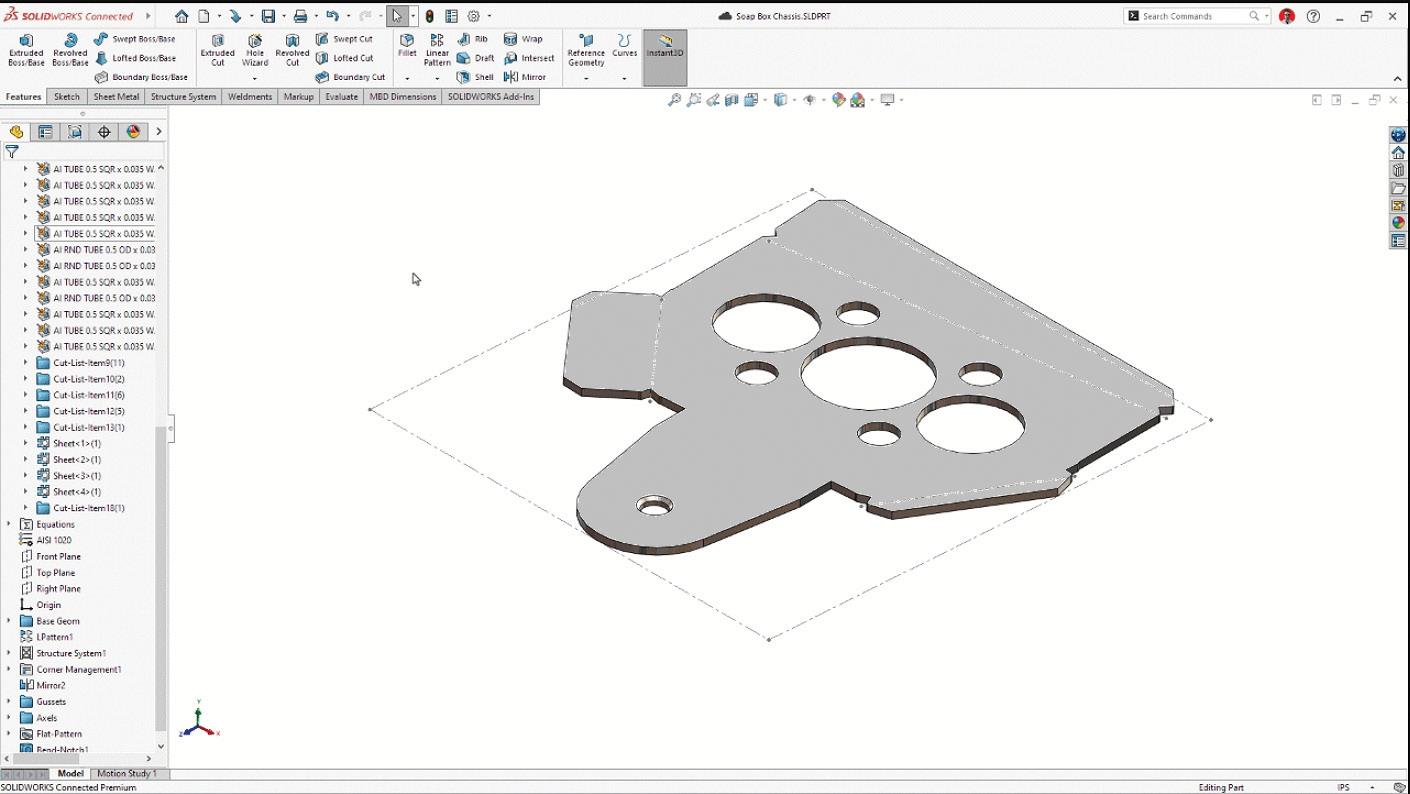

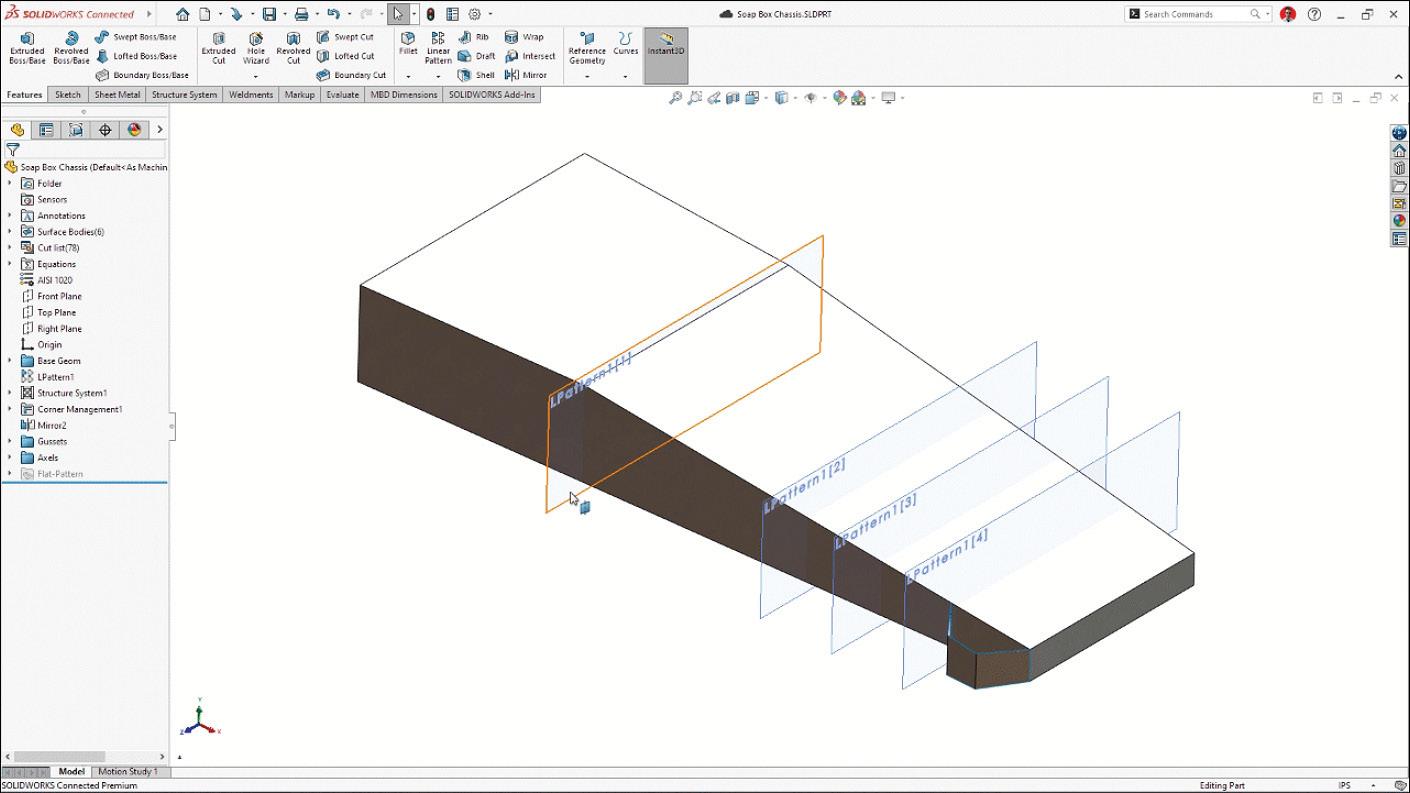

What’s new in Solidworks 2025

A new release of Solidworks ships in November, and so it’s fun to see what’s new months ahead of time. These teases are just a few of the full list, which is usually revealed late summer.

Coming (finally!) for drawings is the ability to reload them (after someone else on the network has edited them), instead of the slower process of closing and re-opening them. Sketches in 2D can be converted to 3D with one click; then by double-clicking splines nodes, the editing triad appears.

Instead of creating similar objects that are different in size one by one, you can now array (pattern) them along a path with dimensions that vary the size of each.

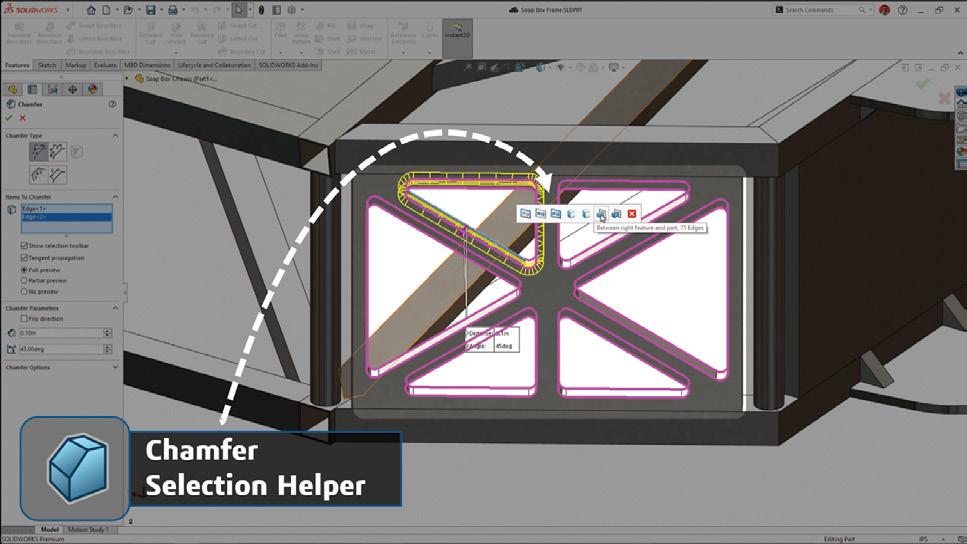

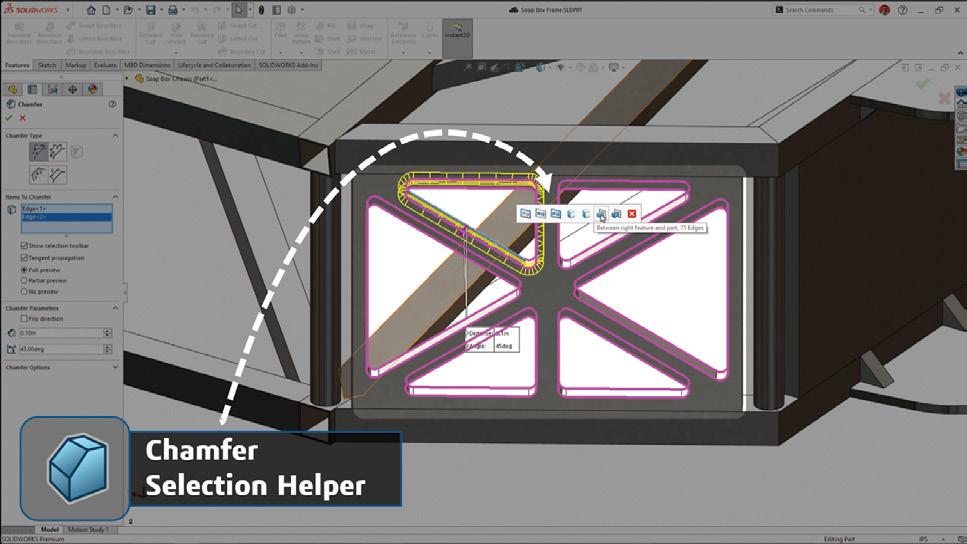

You will be able to chamfer and fillet multiple bodies at once through the use of a selection tool that previews your selection options.

The properties of one weldment can now be copied to other elements

CAD SOFTWARE FEATURE

Patterns with variable sizes.

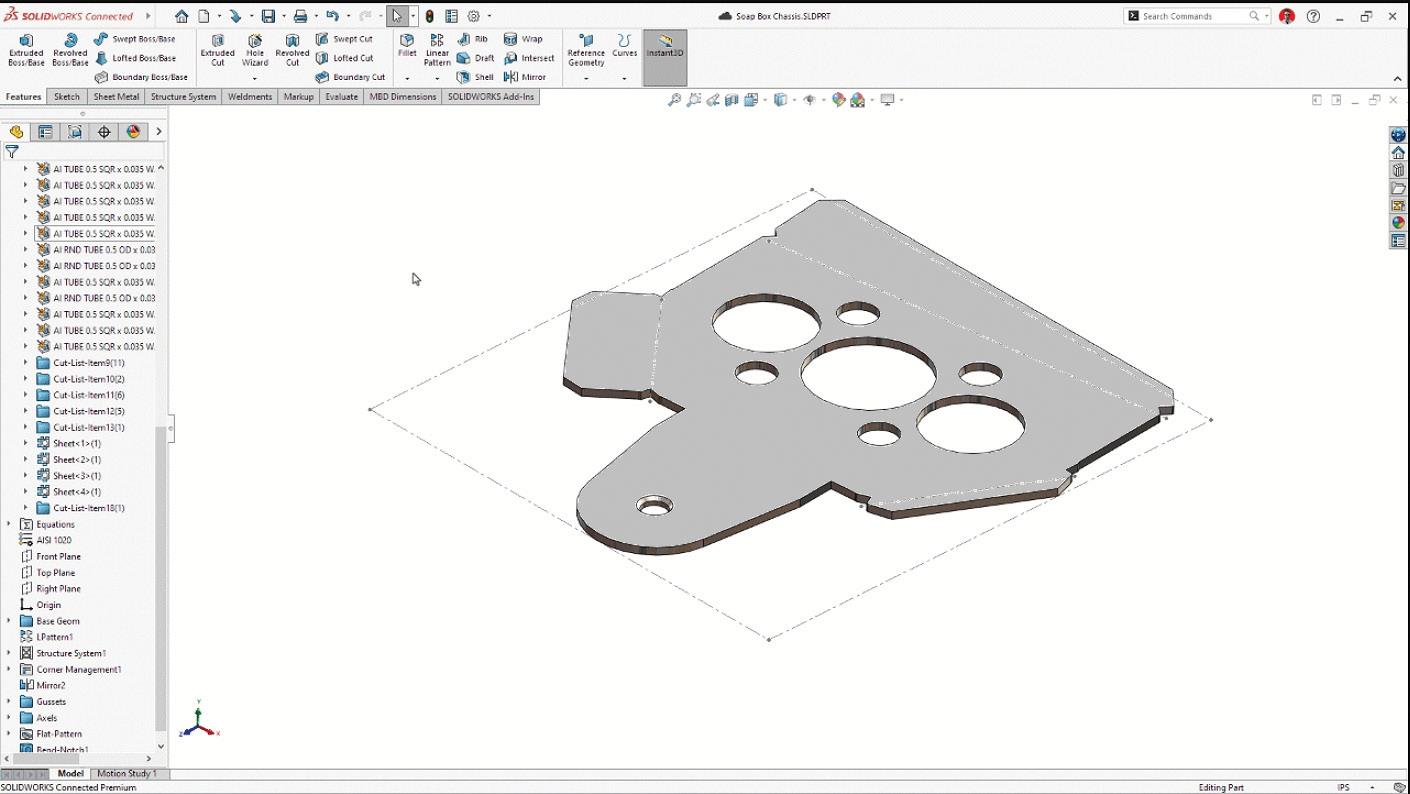

Notches places at bend lines in sheet metal 16 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Multi-body chamfering coming to Solidworks 2025.

of 3D structures. During sheet metal design, you can pick the locations of bend notch points, and Solidworks draws them for you. Notches help sheet metal bend precisely in press brakes.

Large design review mode adds component preview in a second window, so that components can be more easily edited. BoMs can be filtered by display state to reduce their length, useful for projects with very large bills of material.

The team that presented the what’snew session noted it’s usually the small enhancements that get the biggest applause, such as multi-body chamfers.

Conclusion

That Dassault is able to lay out a long-term roadmap like this seems precarious to me, as much can change in even just five years, as was amply illustrated by the last five years.

In an interesting coincidence, executives at both Dassault and Autodesk state that they have been working on AI already for a decade or longer. A closer look seems to indicate to me that what they’ve done is rename an older technology, generative design, as AI. I don’t understand their need to claim, “we’ve been doing AI all along.”

Ever since Dassault executives in 2010 revealed Solidworks “V6,” they have been very keen to get stolid Solidworks users off desktop-bound Solidworks and into the much more lucrative software of cloud-based 3DExperience. At times, executives pleading from the big stage at past Solidworks Worlds became embarrassing for me to watch, as Solidworks users in the audience reacted wanly to their entreaties to switch. Dassault resorted even to changing the name of the event away from Solidworks World.

Dassault kind of failed, because the 3DExperience-based software they wrote initially for Solidworks was incompatible, expensive, and confusing. Dassault seemed to be changing names and product mixes every few years. It appears now, however, that executives have realized a different approach is needed, and so this year they emphasized the cool things that could be done – and will be done – with Solidworks. |DE

Ever since Dassault executives in 2010 revealed Solidworks “V6,” they have been very keen to get stolid Solidworks users off desktop-bound Solidworks and into the software of cloud-based 3DExperience.

DES_RotoPrecision_April23.indd 1 2023-03-17 1:26 PM

@design_eng_mag May/June 2024 DESIGN ENGINEERING 17

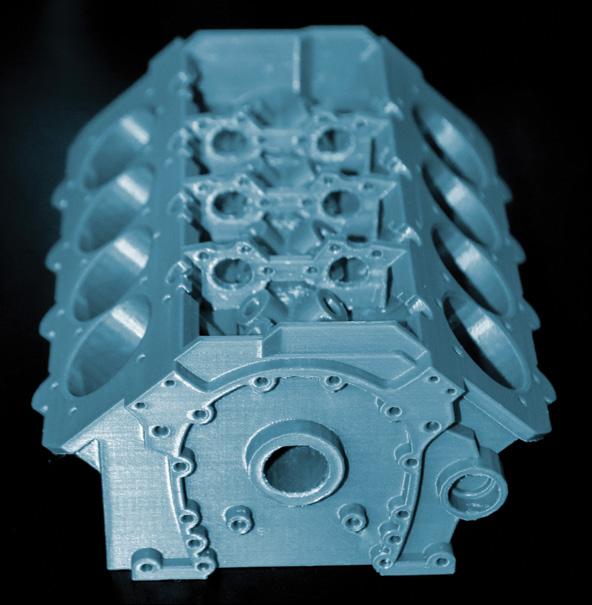

CHAOS THEORY

Effective method discovered for creating nanostructured high entropy alloys

BY ANDREW SNOOK

Nanostructured high entropy alloys have shown a lot of potential for applications in the automotive and aerospace industries. These metals, created from a mix several different elements, have shown impressive strength and stability at high temperatures when compared to regular metals. The challenge with the production of these alloys is that they are energy intensive and expensive to produce. However, researchers from University of Toronto have been working with the Canadian Light Source at the University of Saskatchewan to find less costly methods for the creation of these allows, which could generate opportunities for commercial applications.

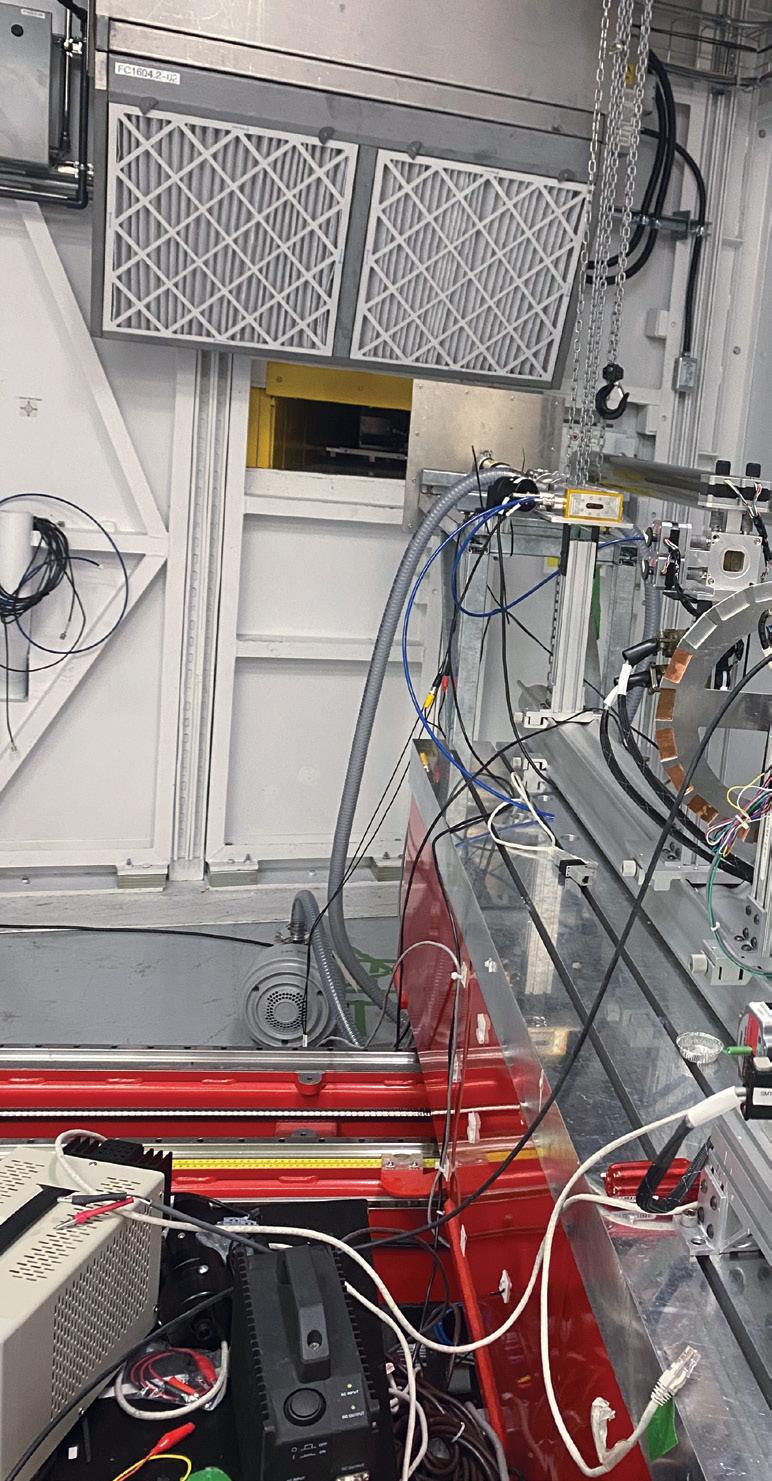

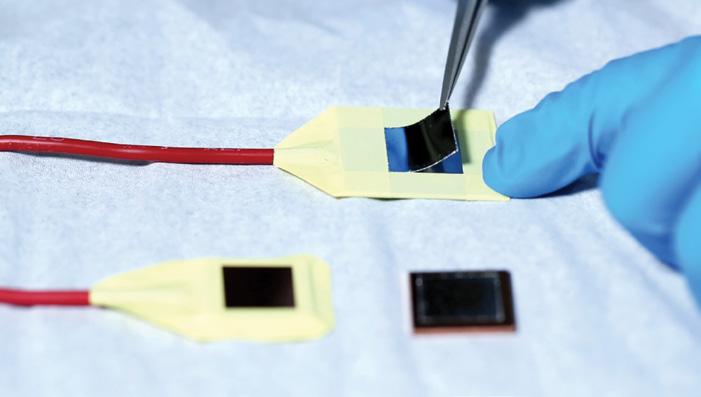

A group of researchers from the University of Toronto have confirmed that these alloys could be created through the use of electrodeposition, the same process used for the production of chrome-plated metal parts. When

comprised of a combination of metals – nickel, iron, cobalt, tung sten, and molybdenum – these al loys could withstand temperatures up to 500C, compared with 270C for pure nickel, and had increased durability.

“We’re using chaos in the ma terial structure to bring out in teresting properties,” says Michel Haché, a materials engineer at the University of Toronto who worked on the research.

The idea for the research orig inated from the collaboration of Haché’s two supervisors at Uni versity of Toronto: Dr.Yu Zou and Dr. Uwe Erb. Zou had done his PhD work on high entropy alloys, while Erb had worked for about 30 years in electrodeposition and en gineering applications, developing materials and processes.

“They kind of merged together on their thoughts and put together the idea of trying to take this new class of materials, which was real ly only introduced around 2004, and we tried to make them using

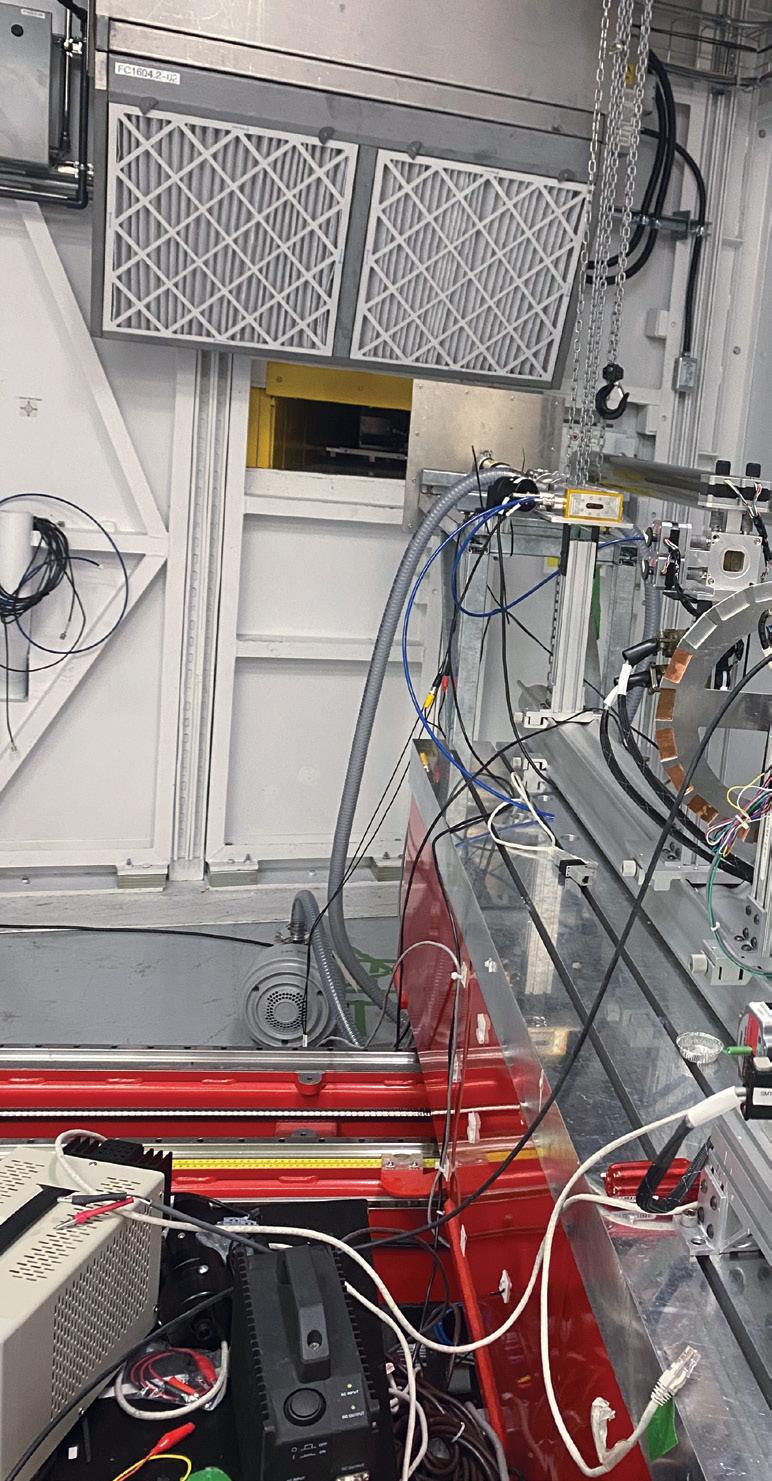

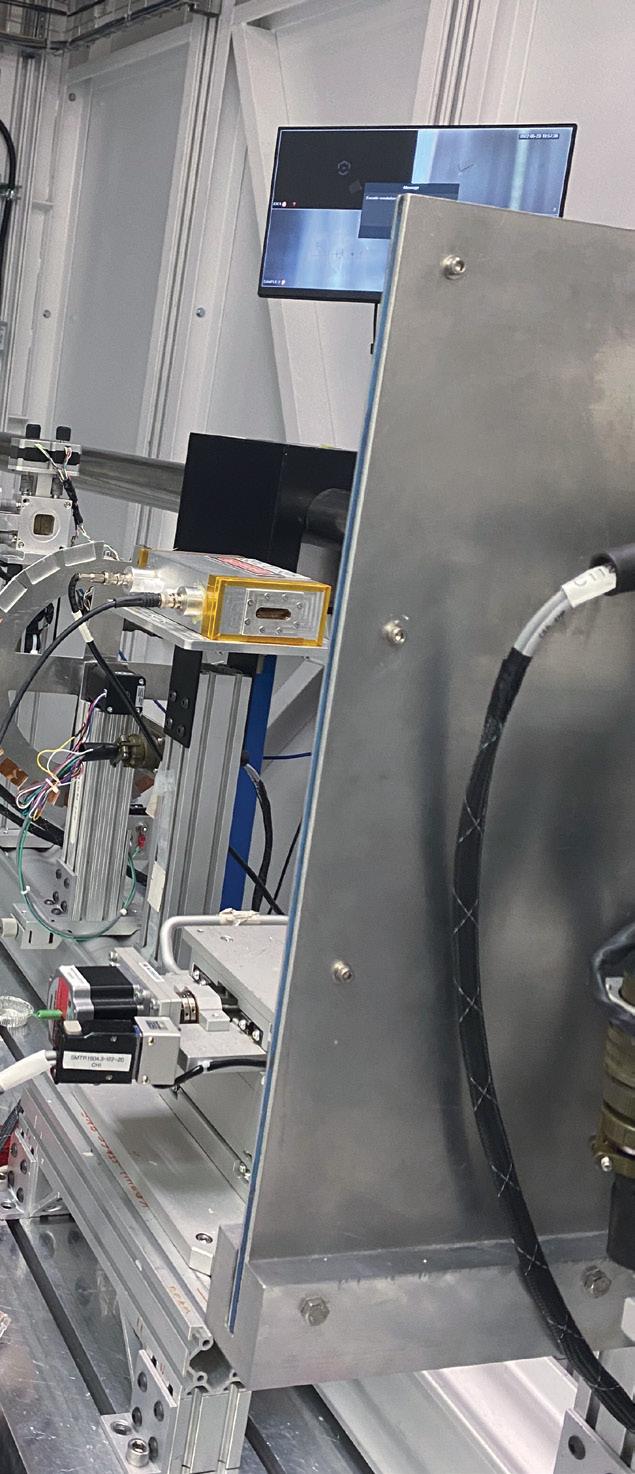

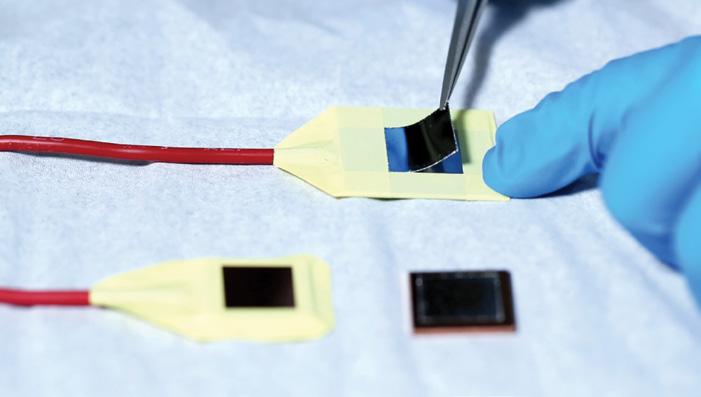

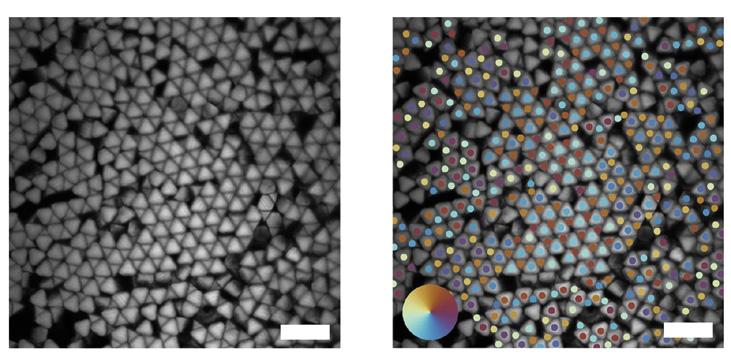

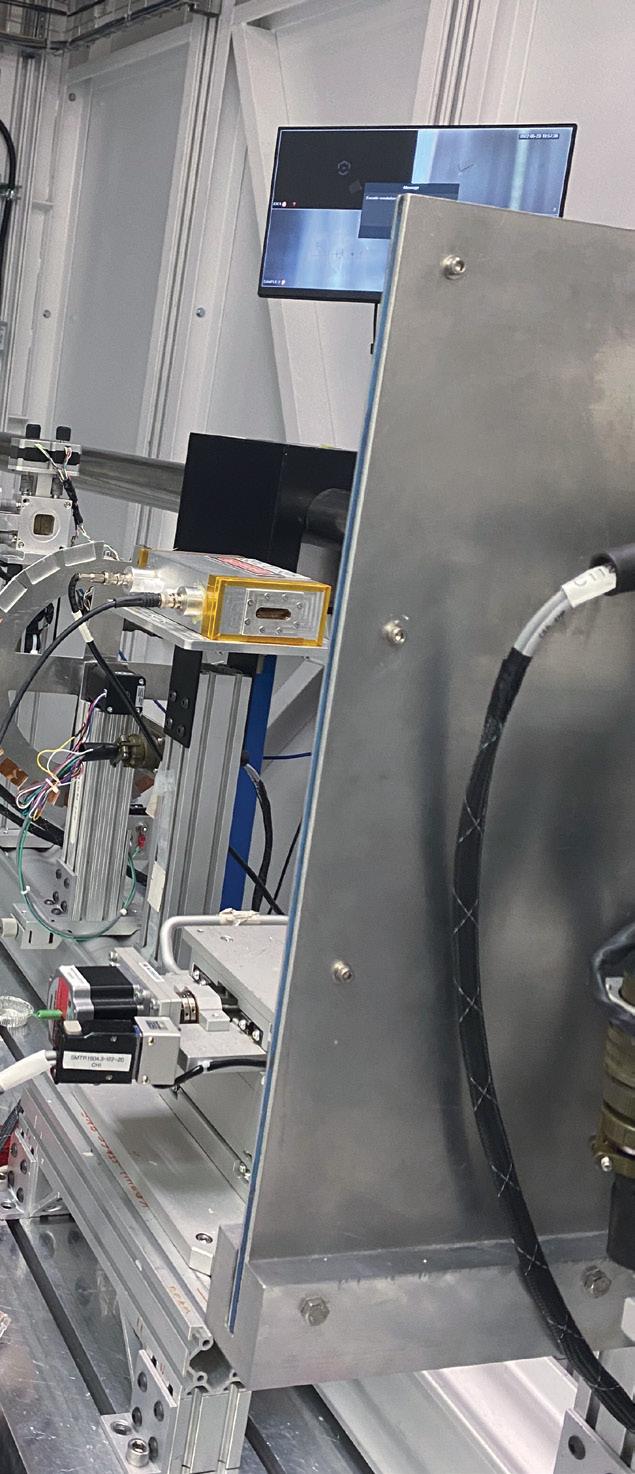

Experimental setup for in situ heating with high-energy X-ray diffraction (left, centre, upper right images).

electrodeposition or electroplating. And in that way, create a very strong material, hopefully, but also one that we could make commercially in a large scale, which is kind of the big limitation right now,” Haché says.

During their research, Haché and his colleagues learned that by adding elements to an alloy they became stronger, to a point. When alloys were created using four different elements, they could withstand temperatures that were 100C higher than those made with three elements. However, they learned that adding a fifth element

MATERIALS RESEARCH FEATURE

18 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Photos courtesy of Michel Haché.

led to no further improvements.

“I started in 2018 and it was a very kind of graduated approach,” Haché says. “We started with simpler systems, three elements, and over the course of five years from 2018 to 2023, we just increased complexity as we went along – three, to four, to five elements.”

One of the biggest challenges was narrowing down the elements that would be most suitable for research on high entropy alloys.

“It’s really like throwing darts at a periodic table. The concept of high entropy alloys is you can mix whatever elements you want together, and just see what happens. So, from that standpoint,

there’s just so much that you can start with and you really have to narrow that down somehow. Part of my research was putting together a way to reasonably narrow things down and find systems that would show the most promise both in applications and in actual feasibility

towards making them,” Haché says.

To test the research, Haché and his colleagues were able to travel to Saskatchewan and conduct experiments at the Canadian Light Source, a national research facility of the University of Saskatchewan located in Saskatoon.

DES_Novotechnik_MayJune24.indd 1 2024-04-15 10:09 AM

@design_eng_mag May/June 2024 DESIGN ENGINEERING 19

One of the biggest challenges was narrowing down the elements that would be most suitable for research on high entropy alloys.

“I was able to travel out there, and with the assistance of some of their staff scientists, we put together those experiments, and then I went through the data afterwards,” Haché says.

He adds that facilities like the Canadian Light Source

are extremely important, not just from the pure research output, but in the training of researchers and the upcoming students coming through.

“It was such a rewarding experience to be able to go to the Canadian Light Source and to just dive deep into the

world of X ray diffraction, in my case, looking at the different applications,” he says. “I took so much away from that in just pure knowledge and thinking of how I can use this in the future to answer some questions. And I pass that on to everybody else within my department.”

The next step in this research will likely prove to be the most challenging aspect: scaling up for commercial application.

“It’s certainly going to need several steps in scaling. The trickiest part is that we’ve never actually electroplated materials like this before. When we talk about electroplated materials, we typically think of pure metals – chrome, nickel, are the very conventional ones. At the very most, binary systems, something like nickel-iron that is commonly

used. When we start talking about three, four, or five elements, we’ve never actually explored that on a large scale. I think that the major hurdle is going to be understanding if we can actually make these at a large scale and keep the bath chemistry in a so-called equilibrium throughout the whole process,” Haché says. “Our limitations are going to be how uniform and how thick can we actually make these materials and, therefore, that’s going to limit what applications we can use them for.”

This research has been published in the journal, Surface and Coatings Technology. To review the published journal article, “Thermal stability of electrodeposited nanostructured high-entropy alloys,” visit: https://www.sciencedirect.com/science/article/abs/ pii/S0257897224003505. |DE

DES_Mocap_JanFeb24.indd 1 2023-12-20 9:54 AM MATERIALS RESEARCH

(Above, top right): Free-standing electroplated NiFeCo foils. During their research, Haché and his colleagues learned that by adding elements to an alloy they became stronger, to a point.

FEATURE 20 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

Electroplating process for NiFeCo samples.

SENSORS

SOFT GRIPPER

AutomationDirect has added machine-mountable barcode scanners, 2D cameras, and 3D vision sensors from ifm efector to their Barcode/RFID/Vision category. Machine-mountable barcode scanners can read popular industrial 1D and 2D codes such as Code 128, Code 39, QR codes, and many more. They are designed for applications requiring machine mounting, conveyor mounting, or process equipment mounting.

2D cameras are simple-to-use yet advanced self-contained vision systems that provide reliable image-based detection. These cameras perform many operations, such as contour detection or BLOB analysis. 3D vision sensors are advanced self-contained vision systems that use time-of-flight technology to measure the distance of numerous points on an object within the sensor’s field of view. They are useful for volume detection and surface dimensioning in many industrial and process applications. ifm efector barcode scanners, cameras, and vision sensors support EtherNet/ IP and TCP/IP communication, and several accessories are available including mounting brackets, mounting rods, and heatsinks. www.automationdirect.com

IAQ SENSORS

Sensaphone offers a range of sensors to assist facility operators and managers in ensuring excellent indoor air quality. These sensors monitor various conditions including temperature, humidity, carbon dioxide, carbon monoxide, airflow and smoke levels. Compatible with most Sensaphone monitoring devices, the sensors provide essential alerting and data logging capabilities. Should a sensor detect readings surpassing or falling below preset thresholds, the monitoring device sends immediate notification to users. The combination temperature, humidity and CO2 sensor uses a highly accurate and reliable dual-channel non-dispersive infrared (NDIR) sensor to monitor CO 2 levels, a precision thermistor to monitor temperature, and a thermoset polymer-based capacitive sensor to measure humidity levels. The carbon monoxide sensor monitors CO levels from 0 to 300 parts per million (PPM) to provide reliable protection against carbon monoxide hazards. It is easy to install, and its 1-inch-by-halfinch LCD displays PPM and menu parameters. The duct mount air flow transmitter measures the

rate of airflow by detecting the presence or absence of cool moving air. It measures relative airflow from 0 to 16 meters per second. The smoke detector, uses a photoelectric sensing method and supports tandem interconnectivity, allowing connection of up to six devices. A 90 dBA audible horn is included. www.sensaphone.com

ADDITITVE

3D PRINTER

The UltiMaker Factor 4 industrial-grade 3D printer is an end-to-end 3D printing solution for light industrial applications. The UltiMaker Factor 4 3D printer is engineered for the development and production of process-critical tools and components. With support for engineering materials, direct drive dual extrusion, onboard

print quality reporting, temperature-controlled build volume, and other innovative features, it delivers high levels of predictability and minimal variance. Built on over a decade of dedication to openness and accessibility, the machine will support one of the widest material portfolios on the market for a variety of applications, including end use parts, functional prototyping, manufacturing tools, and small batch manufacturing of auxiliary components and spares. Factor 4 offers a temperature-controlled

ad-de-qtr-disc-may2024-o.indd 1 5/6/2024 4:06:02 PM DES_Spirol_MayJune24.indd 1 2024-05-07 2:21 PM

IDEA GENERATOR NEW PRODUCTS @design_eng_mag May/June 2024 DESIGN ENGINEERING 21

build volume of 330 x 240 x 300 mm and uniform bed heating, ensuring consistent performance across the entire build plate. Designed for manufacturing and industrial sectors, it launches with a new high-temperature print core that allows engineers to print up to 340°C, enabling a broader range of high-performance, temperature-resistant, and durable materials, such as the new UltiMaker PPS CF, a high-temperature composite material. The machine efficiently uses the heated bed and actively controlled chamber airflow to manage the build volume temperature up to 70°C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located. www.ultimaker.com

ACTUATORS

ELECTRIC ACTUATOR

Festo’s ELGD-TB tooth belt actuators, and ELGD-BS ball screw actuators, are based on an innovative Festo design. The company inlaid the bearings into the aluminum extrusion and extended bearings to the full width of the axis. This design enhancement enables high loads in a compact footprint. Machine builders can pack even more powerful tooth belt or ball screw axes in smaller footprint systems to achieve excellent feed forces and acceleration profiles. The integrated bearing design also enabled Festo to develop the lower profile ELGD-WD (wide actuator) for reduced force applications. This low-profile ELGD is 30% lighter than larger units while its rigidity and guide load capacity are similar. The ELGD-BS ball screw drive offers configurable stroke lengths up to 8.2 ft. The ELGD-TB toothed belt drive provides stroke lengths of

up to 27.9 ft. The ELGD series gives a choice of carriage options, including a long carriage and additional passive carriage. The long carriage integrates a second pair of split ball bearing cartridges, which provides even greater permissible torques to the carriage for the most dynamic applications. The passive second carriage allows the loads on the guidance to be distributed even further, essentially doubling the maximum permissible torques, load capacity, and service life for the mechanics in the application. Suited to most electromechanical handling tasks, ELGD axes deliver exceptional load bearing capacity and torsional rigidity, long service life, and increased reliability in multiple industrial handling situations, from dirty to cleanroom environments.and offer extended cybersecurity and time synchronization IEEE 1588v2 applications. www.festo.com

MOTORIZED ACTUATOR AND SHUTOFF VALVE

Emerson has introduced the new ASCO Series 148/149 safety valve and motorized actuator designed for industrial fuel oil burner recirculation and safety shutoff applications. The new solution provides a reliable, versatile tool for industrial users to prevent overpressure, leaks, and system malfunctions that can lead to health and safety incidents, with one configuration suited to a wide range of combustion system applications. The valve and actuator are designed to be used together in one system for fuel oil recirculation as a safety shutoff. The combination is a compact twoand three-way system with a motorized actuator that achieves rapid, reliable fuel line shutoff from an open to closed position in less than one second. The system features a high-flow and

high-pressure design that enhances heat output and meets approvals from UL (Underwriter Laboratories), FM (Factory Mutual) and CSA (Canadian Standards Association) certifications, improving fuel oil combustion system performance through higher pressure and media temperature tolerance. It is engineered for robust and reliable operation in harsh outside environments, supporting an operating range from -40 degrees to 150 degrees Fahrenheit (-40 degrees to 66 degrees Celsius). The valve’s high-pressure design makes it a versatile option for use across multiple fuel oil burner applications. www.emerson.com

AUTOMATION

CONTROL VALVE

The new Type 2200 Electric-Pneumatic Control Valve from Bellofram Precision Controls is customizable to fit the unique operational needs of specific applications. The Type 2200 is field-tested for unparalleled reliability and proven performance. Designed for many areas of industrial automation, including production, assembly, pharmaceutical, chemical, and packaging systems, the Type 2200 series direct-operated poppet valves are compact in size and provide large flow capacity and low power consumption. The single valve is multi-ported to seamlessly switch between two-way and three-way operations. Options include standard and continuous operation, standalone use or manifold, and flying leads or DIN terminals. The manifold mounted valve can be easily operated through PLC

control in robotics and automation installations. The Type 2200 Electric-Pneumatic Control Valve offers a small size with powerful flow capacity for peak performance and low power consumption for cost savings. Its operational innovation easily integrates into existing systems. www.mb-precisioncontrols.com

MATERIAL HANDLING

Comau’s MI.RA/ OnePicker is designed to autonomously pick miscellaneous objects from the same bin without relying on CAD-based assistance or prior information about their size, shape, colour or characteristics. AI-enabled and adaptable to any brand of commercial robot, customized bin or customized gripper, the smart functionality of Comau’s newest MI.RA solution is ideal for pick and place, kitting, sorting, warehouse, e-commerce and similar applications. Thanks to streamlined virtual simulation tools and predictive algorithms that guarantee optimal path management and collision-free trajectories, Comau’s new MI.RA/ OnePicker ensures unparalleled precision and reliable performance while reducing the need for costly manual and repetitive operations. As an all-in-one-system, MI.RA/OnePicker comes with Comau’s Racer5 COBOT, a 6-axis articulated robot that delivers speed, accuracy, repeatability, and certified collaboration safety without cages. Because the compact COBOT can automatically switch from industrial mode to collaborative mode, working at full speeds when human operators are not in the vicinity, and at collaborative speeds when they are, productivity remains high and cycle times are reduced.

www.comau.com

IDEA GENERATOR

22 DESIGN ENGINEERING May/June 2024 DESIGN-ENGINEERING.com

NEW PRODUCTS

Sign up today for Design Engineering weekly e-newsletter News • Expert Advice Multimedia • Events STAY INFORMED SCAN CODE TO SUBSCRIBE design-engineering.com

OPTIME ™ enables me to keep an eye on hundreds of machines in just a few hours – which makes OPTIME a quick, easy and economical condition monitoring solution. www.schaeffler.us/optime How I optimize equipment availability and maximize plant-wide profitability

pioneer motion

We