12 COVER STORY HCVAC ZONE IT

There are many things to consider when attempting to optimize heating and cooling in different parts of a house, including forced air zoning.

By Ian McTeer60 PLUMBING

HEAT PUMP WATER HEATERS: WHAT YOU NEED TO KNOW!

Steve Goldie re-joins the 30 Mechanical Minutes webinar series to share his insights into the history characteristics and solid market potential for the latest generation of heat pump water heaters.

64 PLUMBING

NEW PLUMBING PRODUCTS

A collection of some of the latest tools, fixtures and fittings to hit the plumbing market and incorporate into your jobs, residential or commerical.

68

REFRIGERATION

SLIME IN THE ICE MACHINE

Regular maintenance and cleaning are the keys to high performing ice production in the food service industry.

By Dave Demma

By Dave Demma

MH6 DESIGN

A COMPLETE SOLUTION

Are you prepared to deliver a total package of heating, cooling, DHW and optimized ventilation?

By John SiegenthalerMH14

PROJECT

NET ZERO IN NUNAVUT

Dealing with supply logistics and lowtemp heating in Canada’s north.

By Doug Picklyk

By Doug Picklyk

MH18

DISTRICT ENERGY

COOLING ON THE CUTTING EDGE

Turning to water from the bottom of Lake Ontario makes The Taylor a cool new build in Toronto’s downtown

By Treena HeinMH24

DISTRICT ENERGY FROM STEAM TO SUSTAINABLE Packaged transfer stations ease the switch at this district energy system.

By Jeff FlanneryMH28

COOL RUNNINGS

Condensation is the radiant cooling killer that can be overcome.

By Curtis BennettMH30

MODERN HYDRONICS SUMMIT PREVIEW

MH34

NEW PRODUCT SHOWCASE

MH36

HEAT PUMP WATER HEATER THE NET EFFECT

Calculating the efficiency of heat pump water heaters.

By John Siegenthaler

Even solo plumbers or HVAC technicians out there rely on the help of other trades, as well as the support of wholesalers and other suppliers to make their operations successful. Everyone works with a team.

The benefit of working with others is the ability to learn and build a better business and improve as a professional and a person. This past June the Canadian Institute of Plumbing and Heating (CIPH) hosted its annual business conference in St. John’s, Newfoundland and Labrador, where the association celebrated its 90th anniversary—a solid achievement for a group that’s built upon the necessity of competing firms getting together and collaborating for the benefit of the entire industry.

At this year’s conference, one of the session speakers was Newfoundland native Brad Gushue, a two-time Olympic medallist (Gold 2006, Bronze 2022) and five-time Brier champion—the winningest curler in Canadian history.

Gushue has done a lot of research into team building and has the experience to back it up. He outlined five pillars to building a successful team which included: assembling players capable of doing the job; having a strong leader; having a defined plan; having a positive attitude; and having clear and direct communication among the team members. His main emphasis was on that final pillar, stressing how clear, concise and constant communication is fundamental to building a strong culture for any team or business.

You can’t impose a culture on a team, it’s developed over time, and Gushue himself explained how he adapted his own leadership style. He went from showing he was the hardest working person and driving the others to excellence by following his example, to becoming more empathetic and vulnerable, showing his teammates that there was trust among team members and that they could all be very open with each other.

He explained that being vulnerable doesn’t mean being weak, it means showing openness and sharing, and the benefit is that by sharing personal and professional thoughts and emotions over time you learn exactly how your teammates are thinking and why. As a leader you gain much better insight into your co-workers’ strengths and areas for improvement.

Another important element to creating a strong culture includes keeping a sense of curiosity among the team. It’s essential to have everyone constantly learning, being adaptable and willing to change to improve themselves and the team or business. Building that culture of ‘vulnerability’ means allowing team members to try, fail and learn from mistakes. Learning and improving is all part of growing stronger and leading to more wins over the long term.

A lot of company leaders I’ve spoken with talk about the importance of having a family-like culture, the challenge is how you define a family dynamic. According to Gushue, it’s all about building trust and keeping those lines of communication open. Take it from a champion.

– Doug Picklyk, EditorReader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Administrator

Tel: (416) 510-5113 Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE PUBLISHER NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

AUDIENCE DEVELOPMENT MANAGER

MEDIA DESIGNER

PUBLISHER

PRESIDENT/COO

Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

David Skene (416) 510-6884 dskene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 510-5180 ugrzyb@annexbusinessmedia.com

Emily Sun esun@annexbusinessmedia.com

Peter Leonard (416) 510-6847 pleonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print)

ISSN 2371-8536 (Online)

Contents Copyright © 2023 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com

Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of: www.hpacmag.com

In the world of potable water protection and backflow prevention, certified specialist testers and inspectors across Canada find cross connections that are controlled, and in many cases also find bad cross connections with no control.

In an effort to raise greater awareness of cross connections and to better educate water industry representatives in the field, the cross connection control (CCC) committee of the Western Canada Section of the American Water Works Association (WCS AWWA) launched its Bad and Ugly cross connections contest in 2014.

The contest has been going strong ever since, as testers and inspectors from across the country are invited to send in photos and explanations of bad cross connections they see.

This year’s winners of the Bad and Ugly contest were Joey Schuster of Edmonton, in the tester category, and a repeat winner in the inspector category was Tayte Southerland of EPCOR, also in Edmonton. (Southerland was also a winner in 2018).

“I went into the mechanical room to test the main line double check valve assembly (DCVA),” explained Schuster. “I immediately spotted the garden hose cross connection between the hot and the boiler. After testing the DCVA (it

Ontario construction sites are now required to have at least one women’s-only washroom. That update to jobsite regulations was one of several new requirements that came into effect on July 1.

The washroom regulations and access to properly fitting equipment such as uniforms, boots and safety harnesses for

passed) I removed the hose and called the building owner.

“I explained to them the dangers of a cross connection and gave them the option to build an auto fill that included a Watts RP [reduced pressure backflow prevention device]. They agreed to the fix on the phone, but I took the hose with me just in case.”

For Tayte Southerland, the bad connection in this building required some reworking.

“To correct this, the double check valve assembly (DCVA) must be relocated downstream of the by-pass and outside

women, were part of several initiatives introduced earlier this year.

One in 10 of the nearly 600,000 construction workers in Ontario are women, and these updated requirements by employers are aimed at making the skilled trades more accessible and more appealing to women.

When the measures were introduced, Andrew Regnerus, Ontario construction

of the meter setting,” says Southerland. “This relocation will provide proper isolation of the water supply.”

The WCS AWWA CCC committee sends a special thank you to Watts Canada for supplying the test kit this year and for many previous years since the contest has run.

The committee also thanks all of the testers and inspectors for submitting pictures into the contest, and to all of those who protect the water systems across the country.

For those interested in participating in next year’s contest, visit: wcsawwa.net

coordinator at CLAC, stated, “We applaud measures that make all job sites more accessible and safer for all, including women.”

Washrooms on sites need to be private and completely enclosed, have adequate lighting and hand sanitizer (where running water is not possible). The number of toilets required has also increased. ontario.ca

Headquartered in Ottawa, the Continental Automated Buildings Association (CABA), an international not-for-profit industry association dedicated to the advancement of the connected home and intelligent building technologies, has changed its name and isl now referred to as the Association for Smarter Homes & Buildings, ASHB (pronounced “ash-bee”).

“Our new name better reflects today’s smart home and intelligent building industries and our vision for the future,” says the association’s Board Chair, Brian Ensign from Superior Essex Communications, in a media release.

“It honours our history while building awareness that we have always represented and will continue to represent the industry and market for intelligent systems in both commercial and residential structures.”

Supporting the smart buildings and homes market since 1988, the association’s mandate remains unchanged: to empower connectivity among people, spaces, and technology to deliver a more livable, sustainable, and efficient connected world.

The group will continue to serve the smart buildings industry through research and collaboration among its over 350 member companies.

“As smart building features move from specialty to necessity, opportunities are opening up across the connected homes and intelligent buildings market,” says ASHB CEO, Greg Walker.

“Our Board and staff have worked hard to boost growth during this exciting time, which has included finding a name that better reflects our pivotal role in growing knowledge and thought leadership across the breadth of the industry.” ashb.com

The CIPHEX West 2023 trade show is taking place this Fall, October 18-19 at the BMO Centre, Stampede Park, in Calgary – and those interested in attending can skip the lines by registering now.

Contractors can register alone or as a group using the secure online registration system.

Those who sign up before September 24 will receive their badge in the mail before the show.

CIPHEX West takes place every two years in Western Canada and provides a one-stop expo for industry professionals looking for new products and technologies in the plumbing, hydronics, HVAC/R and water treatment industries. ciphexwest.ca

On August 1 the federal government announced the first round of categorybased selection within its Express Entry immigration program, placing a focus on skilled trades including plumbers, HVAC mechanics, welders and more.

To be eligible, applicants must have accumulated, within the past three years, at least six months of full-time, continuous work experience (or an equal amount of part-time work experience) in a single occupation within Canada or abroad.

Eligible occupations include: heating, refrigeration and air conditioning mechanics; plumbers; carpenters; welders and related machine operators; elevator constructors and mechanics; machine fitters; construction millwrights and industrial mechanics; electricians (except industrial and power system); contractors and supervisors, other construction trades, installers, repairers and servicers.

Changes to the Express Entry program through category-based selection was first announced by the Minister of Immigration on May 31st. The move to category-based selection was motivated by the need to attract global talent and help meet the need for tradespeople in construction.

“It’s absolutely critical to address the shortage of skilled trades workers in our country, and part of the solution is helping the construction sector find and maintain the workers it needs,” said Marc Miller,

Minister of Immigration, Refugees and Citizenship. “This round of categorybased selection recognizes these skilled trades workers as essential, and I look forward to welcoming more of these talented individuals to Canada.” canada.ca

The Manitoba government has announced that it will adopt the 2020 national model codes for plumbing, building, fire and energy as published by the National Research Council as of Jan. 1, 2024.

In a government news release, it was indicated that public consultations conducted last winter and again in June identified that industry professionals preferred to adopt the 2020 code sooner, bypassing the 2015 edition.

Labour and Immigration Minister Jon Reyes noted: Implementing the codes by Jan. 1, 2024, meets the Manitoba government’s commitment to have new codes in place by March 31, 2024, as per the Regulatory Reconciliation and Cooperation Table agreement under the Canada Free Trade Agreement.

Continued on p10

This summer, Skilled Trades Ontario, the government agency responsible for apprenticeship and skilled trades certification in the province, will begin issuing over 17,500 certificates of qualification and more than 200,000 wallet cards to apprentices and certified skilled trades workers across the province.

“Not only do certificates of qualification and wallet cards serve to validate credentials, they are a testament to the hard work, resilience and unwavering dedication behind every certified skilled trades professional,” said Melissa Young, CEO and registrar, Skilled Trades Ontario, at a media event held on July 24th.

Over the coming months, skilled trades professionals in compulsory and noncompulsory trades who received their certification after January 1, 2022, will begin receiving their certificates of qualification in the mail.

To obtain a certificate of qualification, individuals are required to have passed their certification exam and have met all requirements to practice their trade in Ontario.

Since launching last year, Skilled Trades Ontario has provided online verification of the status and license details of compulsory apprentices and journeypersons on its online public register. This service will continue to be publicly available and updated.

Certificates of qualification issued prior to January 1, 2022, will continue to be valid and recognized by Skilled Trades Ontario. skilledtradesontario.ca

ASHRAE has announced the approval for publication of its airborne infection risk mitigation standard for buildings. The ASHRAE Standard 241, Control of Infectious Aerosols establishes minimum

Canadian Apprenticeship Forum (CAF), a member supported non-profit organization that aims to connect Canada’s apprenticeship community, held its most recent Supporting Women in Trades (SWiT) Conference in Winnipeg, June 10-12, and announced that going forward the group will expand the conference to be more inclusive.

The SWiT initiative, led by CAF, is national in scope and was developed by employers, union groups, educators and equity representatives from multiple trades across the country to create a sustainable and measurable change for women, holding its first SWiT Conference in November 2018 in Halifax.

A stated goal of the initiative includes increasing the percentage of women apprentices and journeypersons among the trades to 15% by 2030, from about 5.3% in 2021. These numbers include trades in construction, manufacturing and transportation.

At the recent 2023 SWiT conference, France Daviault, CEO of CAF, shared news that the organization will expand the mandate of its biennial conference.

In a post-event media release from CAF, Daviault shared: “Differently abled, gender diverse and 2SLGBTQ+ individuals, Indigenous and racialized people who work in the skilled trades, will benefit from a collective voice. I believe that women in the skilled trades can now lend a hand up and create an inclusive community and network for all those who deserve equitable opportunities and better treatment.”

To include more skilled tradespeople in the national conversation around diversity, equity, and inclusion in workplaces, CAF will host its first Supporting Equity in the Trades Conference starting in 2025, with an event being held May 24-26 in Toronto. caf-fca.org

requirements to reduce the risk of disease transmission by exposure to infectious aerosols in new buildings, existing buildings, and major renovations.

The new standard would reduce exposure to SARSCOV-2 virus, which causes COVID-19, influenza viruses and other pathogens that cause major personal and economic damage every year.

Standard 241 provides requirements for many aspects of air system design, installation, operation, and maintenance.

Aspects of the standard include:

Infection Risk Management Mode –Requirements of Standard 241 apply during an infection risk management mode (IRMM) that applies during identified periods of elevated risk of disease

transmission. AHJs (Authorities Having Jurisdiction) can determine when the enhanced protections of Standard 241 will be required, but its use can also be at the discretion of the owner/ operator at other times, for example, during influenza season. This aspect of Standard 241 introduces the concept of resilience – ability to respond to extreme circumstances outside normal conditions – into the realm of indoor air quality control design and operation.

Requirements for Equivalent Clean Airflow Rate – Other indoor air quality standards, including ASHRAE Standards

62.1, 62.2, specify outdoor airflow rate and filtration requirements to control normal indoor air contaminants. Standard 241 sets requirements

for equivalent clean airflow rate, the flow rate of pathogen free air flow into occupied areas of a building that would have the same effect as the total of outdoor air, filtration of indoor air, and air disinfection by technologies such as germicidal ultraviolet light. This approach allows the user of the standard flexibility to select combinations of technologies to comply with the standard that best satisfy their economic constraints and energy use goals.

Requirements for Use of Filtration and Air Cleaning Technology – Dilution of indoor air contaminants by ventilation with outdoor air can be an energy intensive and expensive way to control indoor air quality. Standard 241 provides extensive requirements for use of filtration and air cleaning to effectively and safely achieve equivalent clean airflow requirements efficiently and cost effectively. These include testing requirements to establish performance and to demonstrate that operation does not degrade indoor air quality in other ways, for example by elevating ozone levels.

Planning and Commissioning

Standard 241 provides assessment and planning requirements culminating in the development of a building readiness plan, a concept carried over from the work of the ASHRAE Epidemic Task Force. It also describes procedures for commissioning systems to determine their installed performance.

While not an ANSI standard, the consensus process from project approval, development and final approval of this standard, including a public review, took six months from authorization to completion and only four months of development time dating from the first meeting of the project committee.

The Standard 241 committee will continue and work on improving sections of the standard adding additional requirements, clarifying requirements and developing tools to help the public use the standard. Industry and consumerfriendly resources such as courses, podcasts, factsheets and information events

will be introduced in the future.

Standard 241 is available now for presale in the ASHRAE bookstore. ashrae.org

In a continuing effort to roll up more HVAC service businesses under its banner, the Right Time Group of Companies has acquired Shines Energy Inc. of Dartmouth, Nova Scotia, and Knight Plumbing Heating & Air Conditioning of Calgary, marking the 19th and 20th acquisitions completed by Right Time.

Shines marks Right Time’s first location in Atlantic Canada. Since 2013, Shines has delivered residential heating, cooling and air quality to homeowners in the Halifax Regional Municipality area.

“Sandy Hines has done a fantastic job building a well-respected business in the Halifax area, and Right Time will continue to deliver the Shines brand promise

for years to come,” said Right Time CEO Craig Goettler in a company release.

Operating since 1970, Knight has been a family-owned business with the third generation now involved in the operation.

Knight was started by Tony Hinger as a commercial plumbing service, and over time the business expanded to residential plumbing and HVAC with Tony’s daughter Belinda and son-in-law Bernie Wandler taking active roles.

“Since 1970 we have provided quality customer service to Calgarians and neighbouring communities,” said Bernie Wandler in a media release. “After three generations of our family serving our community, Right Time was a fantastic choice to continue our legacy and take Knight to the next level for our team and customers.”

Right Time is majority-owned by San Francisco-based private equity firm, Gryphon Investors. right-time.ca

Adrian Steel ladder racks are designed to make loading and unloading ladders easier and more ergonomic, but their most important function is helping you make it safely home at the end of each day.

ProLiftTM elevates safety by lifting ladders with unique, patent-pending mechanical advantages and dampers. Ladders can be raised and lowered effortlessly. Requiring up to 50% less effort from you to do the job, ProLiftTM helps reduce back and shoulder injuries. With Adrian Steel, ladders stay put and you stay safe, it’s as simple as that. Learn more about ProLiftTM and our ProfileTM rack system at adriansteel.com

There are many things to consider when attempting to optimize heating and cooling in different parts of a house.

BY IAN McTEERIn the 1989 movie Field of Dreams, the main character decided to build a baseball diamond in a cornfield after an inspiring ethereal voice came into his mind one night and captivated him with the now iconic phrase: “If You Build It, They Will Come.”

And, sure enough, the ghostly greats did come to play. Without completely confusing the point of this award-winning film, my mechanical analogy extends to the popular idea that if you build a duct in front of a fan, the comforting air will emerge in every space, all the time, in all the quantities needed. At least that is what ducts in an HVAC system are supposed to do, right?

Yes, is the right answer. Now, imagine a rectangular bungalow over a basement; the furnace is in the centre of the duct system; all the perimeter runs are straight runs to the floor boots; there is plenty of ducted return air; nearly perfect balance from startup.

If you built that system, we could make a movie called “Ductwork of Dreams,” although I suspect it would be a box office flop. In reality, some duct systems are more like a nightmarish pastiche of ducts, round pipe, elbows and flex pipe all serving to make the homeowner uncomfortable.

Post-war housing construction for the middle class (late 1040s, 1950s) typically involved smaller units, often architecturally unsophisticated square or rectangular bungalows with, as it turns out, reasonably efficient centralized forced warm air heating systems.

But alternative housing designs, attractive to those consumers looking for more room, saw the proliferation of twostorey models often constructed as side splits, back splits, multi-level, many with a room over a garage and oddly-shaped configurations with furnaces hidden under stairs and elsewhere, nowhere close to being the centre of the essential “central heating” system.

In Figure 1, I will not argue that running a duct under a steel beam then back up into an immediate short radius elbow was not designed to conduct a decent volume/velocity of air to designated areas of the house, however, will the conditioned air properly service the inhabitants of those rooms?

That trunk may be serving a north facing and a south facing

space at the same time, so how can comfort and efficiency be served in two such spaces at the same time?

To satisfy heating challenging spaces, some homebuilders in Ontario preferred to install electric baseboard heating systems, and with good reason, as their construction costs were reduced because of having no ductwork to conceal or an extra trade to employ.

And by dumb luck, each independently controlled baseboard offered an unanticipated zoning system allowing for different temperatures throughout the house as desired. Thus, the primary benefit of zoning is to supply customized heating and cooling control in different areas, or zones, of the house leading to better comfort and enhanced energy efficiency.

The majority of tract housing built in post-war Canada to date use a single-zone heating and cooling philosophy that, even professionally designed, installed, commissioned and maintained will keep the desired temperature only in the space that includes a thermostat.

Adjacent spaces often stay comfortable only because they share the conditioned air with the space controlled by the ther-

mostat. It is well known to frustrated homeowners that the desired temperature cannot be maintained in rooms or spaces isolated from the thermostat; you have too often heard the cooling system complaint that the second floor is too hot, the main floor is comfortable, but you can hang meat in the basement.

During the shoulder seasons, one or two rooms may need heat while others could use a bit of cooling. Conventional single-zone systems cannot supply simultaneous heating and cooling. Sometimes continuous blower operation will be able to mitigate room-to-room temperature variations, but continuous blower operation increases operating cost, increases noise level, and may increase room humidity as moisture evaporates from the evaporator coil and drain pain during compressor off cycles.

In most cases, a single-zone system cannot support a desired temperature for all the rooms in a dwelling or allow for differing temperatures when chosen in one room or another.

As shown in Figure 2, the classic baseboard electric heat multi-zone strategy can easily accommodate zoned comfort, as can the incorporation of ductless multi-head indoor sections (Figure 3) consisting of high wall air handlers, ceiling cassettes or floor mounted terminal units that could be connected to a cooling only or a cold climate heat pump outdoors.

Thus, zoning by equipment can be part of a new construction estimate or complete gut renovation project.

Ductless equipment manufacturers include low and high static space-saving air handlers in their catalogues meant to be incorporated in alcoves or other defined spaces providing zoned comfort throughout a building or areas that are hard-toreach with conventional ducting.

Allison Bailes, PhD., posted an informative article on his Energy Vanguard website in June 2020 entitled, “My Duct Systems on Low-Static Mini-Split Air Handlers” providing ad -

vice on how to incorporate a low static air hander into a zoning system, well worth the read.

Other zone-by-equipment products could include throughthe-wall (TTW ) units such as the inverter drive heat pump models from a company like Olimpia Splendid (Figure 4) — an inverter heat pump with 2kw of backup electric heat suitable for cold climate applications.

Zoning kits for add-ons to single-stage HVAC equipment have been around for decades. Too often improperly specified and installed, early adopters paid little attention to the problem of bypassing excess air.

In a 1000 cfm system divided into four zones of 250 cfm each, for example, when one zone calls, the excess 750 cfm was bypassed back into the furnace through a duct connected between the return air duct and the supply plenum with airflow controlled by a barometric damper mechanism.

Sometimes a “dump zone” would distribute some of the excess air into an allegedly innocuous area like the basement or a long hallway. Too often, excess bypass caused furnaces to overheat thus stressing the heat exchanger and evaporator coils to ice sending a ruinous stream of liquid refrigerant flooding back to the unsuspecting compressor.

Manufacturers such as Carrier and Trane offer a modern zoning strategy based on a dedicated duct system with smart thermostats, a controller panel, and powered open and closed zone dampers all communicating with high efficiency units.

Ideally, the indoor unit could be a premium gas furnace (or air handler) featuring capacity control such as two heating stages or heat modulation working in a close relationship with a variable speed blower motor.

The matching outdoor unit necessarily includes capacity controls such as an inverter drive, or two-stage compressor. This modern approach to fully ducted zoning does provide the

Continued on p14

best answer to the classic zoning conundrum of what to do with all the conditioned air produced when only one zone is calling.

When called for by a smart zone thermostat, the heating or cooling side will ramp to a stage most appropriate for the demand of the zone. With the equipment running to provide only the appropriate amount of conditioned air to the zone calling, any small amount of excess air is relieved through the rest of the zoning system.

Known as “relief,” the smart controller will open all the non-calling zone dampers just enough to pass the excess to other zones without affecting their temperature. Such systems can be retrofitted to existing applications when comfort and efficiency are the key system design parameters, not as a method to compensate for fundamental HVAC system or building design flaws.

“Contractors need to know, and be confident, they can zone any existing home that has a duct system,” says Dick Foster of ZoneFirst, a company focused on zoning since the 1950s. “It is only their lack of knowledge of/about zoning that holds them back. When the duct system is accessible, there is no reason not to include zoning.”

While I agree with him, there are important steps a contractor must take to ensure that an add-on zone system will be effective.

In my experience, some forced warm air duct systems are beyond modification and require a well-designed retrofit adding to the cost of a zoning system.

If the existing duct design required 240 cfm in the master bedroom and the current layout can only deliver 150 cfm to the bedroom, it must be determined beforehand how zoning can possibly fix the problem.

• An accurate load calculation is necessary and should not have intentional safety/fudge factors.

• Load calculations are meant to determine HVAC equipment sizing, thus excess capacity must be minimized. The specification of capacity-controlled products with variable speed blowers should be utilized with replacement jobs.

• Note that supply air performance at the floor registers depends on supply air cfm. When specifying variable speed blowers, note that equipment selection and sizing calculations become more complicated when supply airflow can vary.

• A zone system must manage excess air, so be sure to use control strategies that manage the operation of OEM heating and cooling equipment; the zoning system must not interfere with normal operation such as tripping furnace high limit switches or cooling system low pressure controls, for example.

• Each zone should have its own return air path as a large central return could affect the thermostat in an adjoining zone.

• System complexity increases with the number of zones, so be sure the zone design is compatible with the heating and cooling equipment designated for the job.

• Simultaneous heating and cooling are not possible when zoning with a conventional furnace and outdoor unit—typically only multi-split products with refrigerant management systems can do that. However, the zoning controller may be able to signal an independent source of zone heating or cooling such as a baseboard heater or TTW unit in applications where shoulder season comfort discrepancies demand heat in one zone while cooling is needed in another.

• A zoning system may not be compatible with an existing home automation system, be sure to identify any contraindications and agree on a course of action with the homeowner.

• ZoneFirst’s Dick Foster adds, “Once we know the total unit maximum cfm and the size of the ducts for each zone, we look at the smallest zone, and subtract the cfm of the smallest zone and that gives us how much cfm we have to manage for potential bypass.”

• There are several other manufacturers of zoning products available for Canadian contractors such as

Continued on p16

Get more done in less time with RLS press fittings. No torch, gas, solder, burn permits, fire watch or nitrogen purging. Just fast, reliable, CRN-certified, 360˚ mechanical joints every time.

Honeywell, Aprilaire, EWC Controls, Arzel Zoning Technology, and Jackson Systems. These vendors may have proprietary duct sizing rules, be sure to familiarize your team with the appropriate manuals related to specification, installation, commissioning and product maintenance.

• Multiple zone-by-equipment systems may require more indoor space, so access must be provided for maintenance and replacement of indoor parts or equipment when necessary.

• Include a no cost two-year maintenance program into every zoning quotation.

Once an HVAC salesperson has identified a potential client’s frustration with a perpetually underperforming and uncomfortable forced warm air heating system, it makes sense to propose superior comfort combined with the potential for improved system efficiency uniquely afforded by a zoning system.

It is also true that an experienced hand could identify and correct existing problems without going the zoning route, and it should be noted that making claims about energy savings and operating costs ought to take second place to the real value of zoning, that is, improved homeowner comfort.

For more information, be sure to visit the manufacturer’s websites or take local training on zoning systems when available live or online.

The Air Conditioning Contractors of America (ACCA) has published a rather comprehensive Residential Zoning Manual (Manual Zr) that is available for purchase from the association at: acca. org/standards/technical-manuals Happy zoning. <>

Ian McTeer is an HVAC consultant with over 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician and is a regular contributor to HPAC magazine. He can be reached at: imcteer@outlook.com

■ Endure Single Zone Series Features:

• Up to 30 SEER

• Up to 15.2 HSPF

• 100% rated heating capacity at -15ºC and comfortably warm air down to -35ºC.

■ SmartHQ Service and Home Compatibility*

■ Wide range of single and multi-zone options available

For more information visit GEAppliances.com/ductless

“Some forced warm air duct systems are beyond modification and require a well-designed retrofit.”

Air-to-water in sub-zero climate

COOLING CONSIDERATIONS

VENTILATION INTEGRATION

DISTRICT HEATING EFFICIENCY

(Including Aluminum and Solar)

Premier Inhibitors

Higher Temperature Rated Phosphate and Nitrate Free Low Viscosity

For more benefits ask your local wholesaler or visit chemfax.com

Are you prepared to deliver a total package of heating, cooling, DHW and optimized ventilation?

By John SiegenthalerDealing with supply logistics and low-temp heating in Canada’s north.

By Doug PicklykMH18 DISTRICT ENERGY Cooling on the cutting edge

Turning to water from the bottom of Lake Ontario makes The Taylor a cool new build in Toronto’s downtown

By Treena HeinPackaged energy transfer stations ease the transition for Sheridan College’s district energy system.

By Jeff FlanneryCondensation is the radiant cooling killer, but it can be overcome with proper controls.

By Curtis Bennett

Get influenced, as this year’s hydronics-focused event travels to Coquitlam, B.C. September 21.

MH36 HEAT PUMP WATER HEATER

Calculating the efficiency, or inefficiency, of using a heat pump water heater in a heat pump heated home.

By John Siegenthaler

EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

MEDIA DESIGNER

CIRCULATION MANAGER PUBLISHER PRESIDENT/COO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson

use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Business Media, their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities.

Continued on MH8

DESIGN PACKAGES: Complete design, parts list, loop layout, and heat load calculation for your project.

Complete design, parts list, loop layout, and heat load calculation for your project.

Complete design, parts list, loop layout, and heat load calculation for your project.

BOILER ROOM

BOILER ROOM

BOILER ROOM

PRE-BUILDS: We construct boiler rooms according to your designed system.

PRE-BUILDS: We construct boiler rooms according to your designed system.

PRE-BUILDS: We construct boiler rooms according to your designed system.

HIGH-QUALITY PARTS: We provide a catalogue of top-notch parts ensuring optimal performance and longevity.

HIGH-QUALITY PARTS: We provide a catalogue of top-notch parts ensuring optimal performance and longevity.

HIGH-QUALITY PARTS: We provide a catalogue of top-notch parts ensuring optimal performance and longevity.

schuller.solutions

SCHULLERSOLUTIONS.COM

SCHULLERSOLUTIONS.COM

Building codes and energy conservation standards continue to evolve, and today many are requiring proof of high-quality air sealing for buildings, with measurements being done through blower door testing.

BY JOHN SIEGENTHALERTypically, the building envelope is depressurized using a flexible panel with a variable speed fan that’s temporarily in -

stalled in the opening of an exterior door. By measuring the speed of this fan and correlating it to the slight (but measurable) difference in air pressure between the inside and outside of the building, it’s possible to determine the air changes per hour air leakage rate.

A leaky house could test out at 15 to

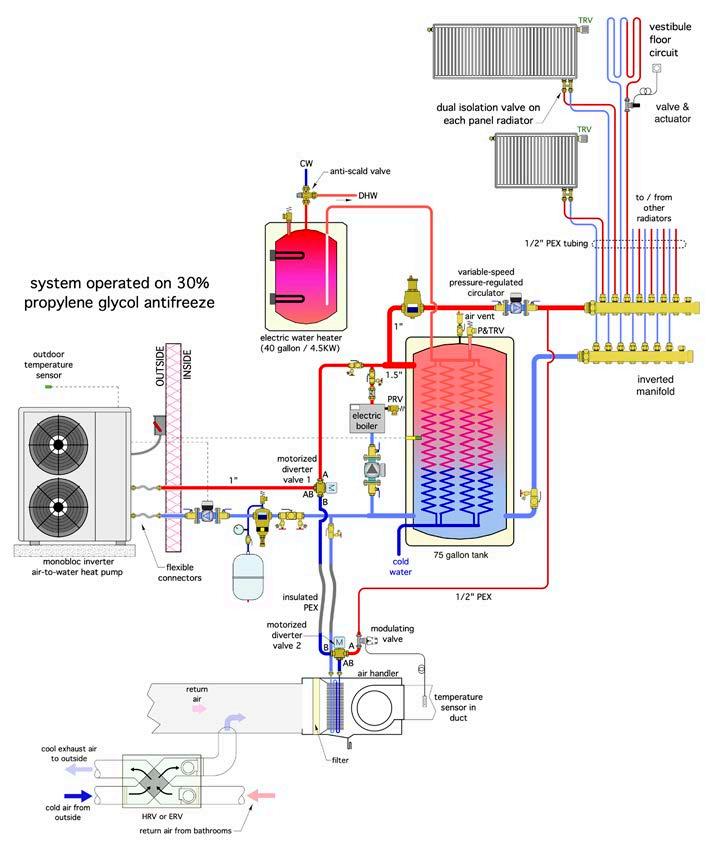

Are you prepared to deliver a total package of heating, cooling, DHW and optimized ventilation?Figure 1. A complete system using an airto-water heat pump for heating, cooling and domestic hot water.

Lochinvar has long been an industry leader in commercial boilers—and now we’re bringing that engineering excellence to residential combi boilers.

The wall mount EPIC® combi boiler you know and trust is now available in floor standing models.

What Makes EPIC a superior choice?

· Easy To Install, Set Up and Service

· Delivers Hot Water Faster

· Display Screen Uses Text, Not Codes

· Better Technical Support and Training

· 10:1 Turndown Ratio

· Floor and Wall mount available

· Advanced Electronic Control -

20 air changes per hour at 50 Pascals (about 0.00725 psi) of air pressure differential. A well-sealed new house could have air leakage in the range of 1 to 4 air changes per hour at 50 Pascals pressure difference (ACH/50).

And a super-tight house, built to current Passive House standards, must not exceed an air leakage rate of 0.7 ACH/50.

Experience has shown that the “natural” air infiltration rates of buildings will be approximately 1/20 th of those established by blower door testing at 50 Pascals differential pressure. Thus, a house with 4 ACH/50 blower door test rating will have a natural air leakage in the range of 0.2 air changes per hour.

You won’t suffocate in such a house, but you’re unlikely to find the air quality provided by air leakage acceptable. Fry up some bacon on Monday, and you’ll still smell it on Wednesday. I could cite more examples of this air quality problem, based on other “facilities” in the house, but I’m confident you get the idea.

The contemporary approach to providing fresh air while at the same time not adding substantially to the home’s heating load, is to install a heat recovery ventilator (HRV), or in some cases an Energy Recovery Ventilator (ERV). Both of devices create two air flows: one brings outside air into the building, and the other exhausts “stale” inside air back outside. Both air streams are generated by small blowers within the ventilator.

During the heating season, the stream of incoming cool (or cold) outside air absorbs heat from the warmer exhaust air stream. This exchange takes place within the heat exchange “core” of the ventilator, through which both air streams simultaneously pass, but never mix.

Typical heat recovery efficiency is in the range of 70%. Thus, the fresh air requirement is met using about 70% less thermal energy that would otherwise be

needed if the air was simply blown into and out of the building with ventilation fans and no heat exchange.

During the cooling season, the outgoing stream of cool (but “stale”) inside air absorbs some heat from the incoming warm (but fresh) outside air. Again, the fresh air requirement of the building is met, but the energy penalty associated with fully cooling and dehumidifying the incoming air to desired indoor temperature and humidity is greatly reduced.

Energy recovery ventilators (ERVs) provide similar functions to heat recovery ventilators (HRVs). The difference is that ERVs can also exchange moisture (in vapour form) between the ingoing and outgoing air streams.

In winter, some of the moisture in the outgoing (higher absolute humidity) air stream is transferred to the incoming (low absolute humidity) air stream. And in summer, some of the moisture in the incoming (higher absolute humidity) air stream is transferred to the (lower absolute humidity) outgoing stream.

This moisture exchange helps maintain a comfortable (and healthy) indoor relative humidity in winter and it also reduces the latent cooling load in summer.

So, what does this have to do with hydronics?

Well, in combination with an air-to-water heat pump, or a geothermal water-towater heat pump, heat recovery ventilation becomes another part of the “total solution” package you can offer. That package includes heating, cooling, domestic hot water and ventilation.

For example, consider a relatively simple system that provides multiple zones of space heating using panel radiators, and “whole house” cooling using a ducted chilled water air handler.

It also provides domestic water heating using energy from both the heat pump and an electric resistance backup

heater. Figure 1 (on the opening page) shows one concept for such a system.

The heat pump maintains the buffer tank between some upper and lower temperature limits. Those limits could be set points or determined using outdoor reset control. Some air-to-water heat pumps have integrated controls that allow either.

The variable-speed pressure-regulated circulator operates continuously during the heating season. Warm water passes through any panel radiator with a partially-open or fully open thermostatic radiator valve. A system that is simple, elegant and even “wireless.”

The motorized diverter valve routes heated fluid from the heat pump to the buffer tank. This flow path is only open when the heat pump is operating.

The path between ports AB and A close as soon as the heat pump turns off, preventing reverse thermosiphoning from the tank.

This valve operation also prevents flow returning from the distribution system from passing through the heat pump when it’s off.

The large coils inside the buffer tank preheat domestic water. The temperature rise of the water depends on the fluid temperature maintained in the tank’s shell, the surface areas of the internal coils, and the rate at which domestic water flows through the coils.

If the tank shell temperature is maintained close to the desired domestic hot water delivery temperature it’s possible that over 90% of the total temperature rise can occur through the coils.

The remaining temperature rise is handled by a tank-type electric water heater, or a tankless electric water heater

If the buffer tank temperature is based on outdoor reset control, the auxiliary water heater will need to contribute more energy for domestic hot water during milder outdoor temperatures.

Continued on MH10

Caleffi’s innovative thermal solution for the control of safe and sanitary domestic hot water combines three main components: LEGIOMIX® digital mixing valve that delivers accurately mixed water temperature and integrates calendar-based thermal disinfection; ThermoSetter™ field adjustable thermal balancing valves that feature a bypass option for disinfection; and SinkMixer™ 4-port anti-scald valves for reliable point-ofuse safety. Approvals include compliance with U.S. and Canadian plumbing codes. CALEFFI GUARANTEED.

In either case, the electric water heater provides a backup source of domestic hot water if the heat pump were down for service.

Cooling is provided by routing chilled water from the heat pump, through the diverter valve, to the coil of an air handler.

The variable speed compressor in the heat pump automatically adjusts to maintain a set chilled water delivery temperature - typically in the range of 45 to 55F (7 to 12C).

The chilled water flows through the coil of an air handler equipped with a condensate drip pan. Cooled and dehumidified air is delivered to the entire building through a ducting system.

The original system shown in Figure 1 cannot simultaneously heat the buffer tank and send chilled fluid to the air handler. One of these loads must take priority over the other.

If maintaining the temperature of the buffer tank is the priority, so as to maximize preheating of domestic water, the system controls would be configured to temporarily stop chilled fluid production and flow to the air handler coil while the temperature of the buffer tank is boosted, which typically only takes 5 to 10 minutes.

If cooling is the priority, heat input to

the buffer tank needs to be temporarily interrupted when the house thermostat calls for cooling. If the cooling call is sustained, the electric water heater can take over the DHW load until the cooling load is satisfied.

Since there’s going to be a ducting system for cooling, why not use it for ventilation?

Doing so would certainly reduce cost compared to installing another air distribution system solely for ventilation.

In fact, why not enhance the system by using the coil in the air handler for “boosting” the temperature of incoming ventilation air during cold winter operation, and thus eliminate possible cool air delivery to the house?

Figure 2 (above) shows one approach for connecting the HRV (or ERV) to the return trunk duct of the air handler, along with hydronic trim to provide that boost function.

The smaller ducts on the “house side” of the HRV connect to the return trunk leading into the air handler. The “stale” air is pulled from one or more bathrooms. The fresh outdoor air, after absorbing heat from the exhaust stream, is injected into the return air side of the air handler.

This configuration can operate in three different modes:

1. Ventilation-only mode

2. Cooling plus ventilation mode

3. Ventilation plus boost mode

For ventilation-only mode the blower in the air handler should provide an air flow rate just above that of the HRV. This ensures that all the incoming fresh air will be entrained in the air flow that’s headed for the diffusers in the house. It also reduces input power to the blower motor in the air handler. Most air handlers have blower motors with multiple speed tap wiring. Check with the air handler manufacturer regarding the best option to bring the air flow rate down to perhaps 100 to 150 cubic feet per minute (CFM). Some air handlers may not be able to reduce their blower speed to such a low value. That’s okay from the standpoint of distributing fresh air. It just means higher electrical power consumption by the blower.

During cooling mode the blower speed would be set to provide 350 to 400 CFM of air flow per ton of cooling capacity. Thus, for an air handler delivering 3 tons (36,000 Btu/h) of cooling, the air flow rate would be about 1050 to 1200 CFM. Again, this will require the system to use the appropriate speed tap on the blower motor.

The ventilation plus boost mode is intended for times when outdoor temperaContinued on MH12

Unmatched heating and DHW performance, all in one compact unit

• Heating up to 150,000 BTU/h and DHW up to 210,000 BTU/h

• Up to 80% smaller than floor standing boiler and tank water heater

• Optimized DHW priority with mixing valve and water adjustment valve to provide consistent DHW temperatures and industry leading flow rates

• Dual stainless steel heat exchangers for heating and separate SS heat exchanger for DHW

• Built-in controls for 3 zone pumps or 3 zone valves

• Heating TDR up to 11:1 and DHW TDR is 15:1

To learn more about the best-selling combi-boilers in North America, visit navieninc.com.

Tear out that wasteful tank and boiler mess...

...and hang up the breakthrough in high capacity combis

tures are cold. The intent is not to heat the house with the ventilation air, it’s to introduce air into living spaces at about the same temperature as those spaces.

For example, assume the outside temperature is -10F (-23C), and the HRV is recovering about 70% of the heat from the exhaust air stream that leaves the occupied space at 70F (21C).

This would make the fresh air temperature delivered from the HRV about 46F (8C). That’s going to feel pretty cool to occupants if it’s not carefully mixed with room air before reaching occupied areas.

If the boost function is used, this air could be introduced in occupied spaces at a neutral temperature and far less concern about creating uncomfortable conditions when it’s frigid outside.

Under these conditions it’s possible to pass heated fluid through the air handler’s coil to boost the temperature of the ventilation air prior to introducing it to occupied space. A modulating two-way valve is used to regulate the flow of warm fluid through the coil. The flow rate is controlled based on maintaining a set supply air temperature on the outlet side of the air handler.

A word of caution is in order. If the system is located where outdoor temperatures are well below freezing much of the winter, the coil in the air handler needs to be protected against freezing. That’s “automatic” with the monobloc air-to-water heat pump system shown in Figure 1 because the entire system operates with a 30% solution of propylene glycol.

If the system operated with water some type of failsafe control would be needed to automatically turn off the HRV if the coil in the air handler approaches a potential freezing condition.

Figure 3 shows the same system as Figure 1, but with the piping needed to supply water to the air handler coil.

The coil is supplied through a threeway diverting valve. When this valve is off, the coil is connected to the piping

path for cooling. When the valve is energized the coil is connected to the warm water circuit.

The pressure differential to drive the latter is supplied by the continuously operating distribution circulator. The modulating two-way valve regulates the flow rate through the coil based on maintaining a set air delivery temperature. This valve should be selected with an equal percentage characteristic.

The longstanding “stigma” that residential hydronic systems can’t provide cooling is slowly waning as air-to-water and geothermal water-to-water heat pumps gain market share against boilers. This

sets the stage for progressive hydronic professionals to offer heating, domestic hot water, and cooling.

Why not extend this even farther to include heat recovery ventilation (HRV)? The market for such total solutions is quickly developing.

Are you prepared to participate and profit? <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit hydronicpros.com).

Sanikiluaq is Nunavut’s southern-most community, located about 150 km off the northwest border of Quebec among the Belcher Islands, an archipelago in the southeast section of Hudson Bay.

Among the newest buildings in Sanikiluaq is a roughly 5,000 sq. ft. multi-purpose research centre owned by the Arctic Eider Society, an Inuit not-forprofit organization dedicated to supporting Inuit-led stewardship and nature conservation in the area.

Positioned on a hill, the main floor brings visitors into the commercial space which includes offices, staff kitchenette, research labs, a large meeting room and a

visitor’s foyer. The second floor provides temporary residence for rotating researchers, with three bedrooms with ensuites, a shared living space and kitchen. The lower level is really a crawl space which accommodates the mechanical room.

This mixed-use complex aims to be the first net zero building in Nunavut.

The project was led by Jeff Armstrong, the managing director at Cold Climate Building, a specialist in designing and building energy efficient structures in Canada’s far north, including a project with Nunavut Housing Corp. where he introduced structural insulated panel (SIP) building systems to create well-insulated air-tight envelopes suited to net-zeroready structures.

The mechanical system in the building was designed by Cameron Haines, P.Eng., of Southface Engineering, who

was brought on board by the building’s design architect, Richard White.

The heating system is driven by three air-to-water heat pumps which are connected to two 70-gallon storage tanks with integrated electric boilers.

“I love this type of system because the buffer tanks act like a battery, and they offer flexibility with being able to tie them into any type of future energy source or backup source that they may need,” says Haines.

The selected air-to-water heat pumps are a split system with separate indoor and outdoor units. The outside section includes the air coil, fan, expansion valve, and outdoor temperature sensor. All other components, including compressor and electronics, are contained in the indoor units.

“The logic is really simple,” says Haines. “All the heat pumps have to do is

Continued on MH16

It is very eco-friendly!

AltSourceTM

The only high-volume electric boiler on the market and the perfect complement to renewable energy. This combination boiler-storage tank for residential use serves as a back-up energy source to the primary system in order to maximize output. Thanks to its T2 UltraSmart® controller, the boiler provides improved comfort through precise temperature control.

Typical installation with standard features

Perfect for optimizing the performance of many types of heating systems.

AltSourceTM with the optional copper coil heat exchanger is shown.

thermo2000.com

keep the buffer tanks at the set point temperature (105F/41C).” Because it’s a really tight building, it allows for a low supply temperature. The heat loss calculation at design temperature of -30C was 128,000 Btu/h (37.5kW) for the building envelope, and Haines says their calculations show they could have gone as low as 95F (35C).

As designed, not all three heat pumps are operating at once, as Haines describes, they are set up so there is one master heat pump and then the other two are slaves, and that process rotates among the three.

The plumbing and mechanical systems were installed by Candor Plumbing and Heating of Ottawa. In operation for over 35 years, the company has a history of working with Armstrong at his previous Nunavut projects. Fortunately, the crew took lessons from that experience when planning for this job.

“We had to load everything in three shipping containers here in Ottawa— that includes every elbow, every valve—and it was all packed in a way that it could be removed in the order of installation,” says Trevor Johnson, who helps run Candor along with his father Kim and brother Cory.

Johnson recalls how this process was better than the last time when they found themselves cutting blocks of snow off of crates in the middle of the dark Arctic winter searching for the parts they needed.

Working on an island in the middle of Hudson Bay presents many challenges. Getting the crew on-site alone required flights connecting through either Winnipeg or Montreal, with the real prospect of cancellations and having to rebook days later.

In total the team took five trips, starting in January of 2022 when they were using a generator for temporary heating (because it was minus 30 inside) and watch-

ing a thermometer waiting for it to rise to where the glue for the ABS would cure.

“We also lost the power to the building where we were staying that January,” recalls Johnson. During a blizzard they needed to crane the generator from the worksite—that was keeping that building warm—to heat up their sleeping quarters, and then start all over again the next day.

“And then we all got COVID,” says Johnson, who adds that things only got better from there.

The primary loop from the heat pumps to the buffer tanks is all in 2-1/2-in. copper that was insulated. The Candor team prefers to use press tools wherever possible. The heating distribution system uses infloor heating on the upper two floors as well as heating coils in the air handling units of two ERV ventilation systems.

There isn’t any type of mechanical cooling the space, but the building is ducted to allow free cooling using outdoor air. “Duct work is not something I do every day, so I was leaning heavily on Jamey Mackenzie of Mack Metal, our subcontractor for installing the duct work,” notes Johnson.

Each room in the building is its own zone. When a thermostat calls, a zone

valve opens and a low-power variable speed ECM circulator near the buffer tanks recognizes the opening and sends heat to that zone. There is a pump for each floor, and a third installed for redundancy. Those tanks are piped in parallel using circuit balancing valves. There are also two totes of glycol in the system. “You take no chances when temperatures can dip to -40C,” says Johnson.

No concrete is used in this cold climate project, so the team used radiant panel flooring, a high-density polystyrene that comes with an aluminum heat transfer sheet on top and pre-set grooves for the PEX piping. The panels were secured on top of an additional layer of insulation board that was placed on top of the subfloor, which was made of a well-insulated SIP panel. “There’s no shortage of insulation,” confirms Johnson.

Vinyl flooring was used on top of the radiant panels. There are also three entry way force flows for heating as well as a unit heater in the mechanical space.

The heat pumps have a double-wall desuperheater which is used for pre-heating the domestic hot water. That system leads to a 50-gallon storage tank with integrated electric boiler that holds the preheated domestic water that runs

through a copper coil at 70F or greater, and then the domestic water goes through a second coil in another 50-gallon tank where it is brought up to a minimum of 140F.

As a back-up for the entire system, there is also an oilfired boiler in the mechanical space that ties into the DHW tank, and it is also piped-up to supply the heating distribution system if necessary.

Mechanically, the building was ready to go and operational last fall and has performed well over one winter. Currently, the electricity for the community is driven by diesel-fuelled generators. To offset some of that carbon-burning power the building has installed solar panels on the roof, and the owners anticipate tapping into a community wind turbine project on the island to get completely carbon free. “Their net zero capabilities are still a work in progress, but they shouldn’t have a problem getting there,” says Johnson.

And Haines agrees: “There’s a lot of wind up there, so that’s why the model was so positive towards net zero.” He adds that when looking to go net zero, everyone seems to be moving towards heat pumps and in-floor heating. “It’s one of the best

systems to use because of the size of the heating area so you need very low temperatures which allows the heat pumps to operate at a very high efficiency.”

Johnson hopes that by sharing this project with the industry others will find inspiration in the simple possibility of achieving net zero in an arctic region. <>

Looking at The Taylor, Tricon Residential’s 37-storey multi-use purpose-built rental building in downtown Toronto, you’d never know it was different from others of its type unless you had a sky-high vantage point to check out its mechanical penthouse, that is.

The penthouse is quite a bit smaller than one would expect for a building of its size, housing only some pumps and air handling equipment, but missing the chiller that would normally be used to provide cool air on hot summer days and nights or gas-fired boilers. That’s because The Taylor is cooled not through normal air conditioning but through the district heating/cooling system from Enwave that uses cold water from nearby Lake Ontario.

As industry efforts across the world aim to bring new buildings closer to carbon neutrality, The Taylor and numerous other buildings in Toronto’s downtown have tapped into the use of lake water and a series of heat exchangers for cooling its residents.

The innovative system involves district-energy operator Enwave sharing infrastructure with the City of Toronto’s water utility, providing comfort to residents while also cutting cooling-related electricity use by as much as 80% – performance that will help the city and its Climate Action Strategy to reduce greenhouse gas emissions.

Like all Tricon’s occupied Canadian

multi-family buildings, The Taylor is built to LEED Gold standards, explains Tricon’s head of development, John English.

“Besides this being a purpose-built multi-use rental building, with groundlevel stores, upper offices and rental suites above, this project stands out in its emphasis on durability, quality and sustainability,” he explains. “The Enwave system is a big part of that. It has been functioning since October 2022 and the commissioning has gone well.”

Enwave calls its system Deep Lake Water Cooling, or DLWC for short. It’s the largest system of its kind, leveraging economies of scale with its connected infrastructure. First completed in 2004, the original DLWC system worked so well that it has been expanded in the years since and currently cools more than 100 downtown buildings, including hospitals, data centres, educational campuses, hotels, a brewery, and government, commercial and residential buildings in Toronto’s core. Notable users include City Hall and Scotiabank Arena, home to the Maple Leafs and Raptors.

Enwave owns and operates the DLWC system but shares infrastructure with the city’s water utility under an energy transfer agreement. As cool water circulates to the connected buildings by way of a series of pipes and heat exchangers, heat from the buildings recirculates back to the John Street Pumping Station

where the thermal energy is transferred to the treated potable water via heat exchangers that keep the two streams of water separated.

The increase in temperature of the drinking water is marginal, while the impact on the electricity use by the buildings is significant.

Moreover, treated water is also saved in the process, since traditional chillerbased HVAC systems would use significant amounts of evaporated water to expel heat, something that can be considerably inefficient on humid days. By using its DLWC system, Enwave e stimates that the Toronto system saves roughly 220 million gallons of water each year; the equivalent of 350 Olympic-sized swimming pools.

The process begins with cold water being drawn from intake pipes in Lake Ontario. The pipes are about five kilometres from shore at a depth of roughly 83 metres. Using relatively little energy, the water travels to the Island Filtration Plant operated by Toronto Water where it is treated to meet drinking water standards.

The water is then conveyed to the John Street pumping station and into the

SEE ALL THESE BRANDS AT THE SUMMIT!

Sept 21, 2023 | Hard Rock Casino Coquitlam

LEARN FROM OUR TOP-NOTCH HYDRONICS EXPERTS

Our hydronic superheroes reunite to discuss the tremendous opportunities for the hydronics industry as we move towards a net zero environment.

LOCAL FOCUS

Join moderator Mark Evans in a lively Panel Discussion on the future of energy in BC and its impact on our trade. Since 2006 Mark has supported the Hydronics Industry as a volunteer member and former Chair of the Canadian Institute of Plumbing and Heating’s Marketing Sub-Committee of the Canadian Hydronics Council.

HAVE A CHANCE TO WIN TOOLS AND VANCOUVER CANUCKS TICKETS!

Curtis Bennett walks us through the future of hydronic system controls operating a hybrid gas & electric system.

Where are we now? Where are we going? Will you be ready when we get there?

ENJOY BREAKFAST, LUNCH AND DAY-LONG REFRESHMENTS

John Siegenthaler

Sit in with John as he discusses the various modern hydronics technologies and their practical installations.

Local Social Media Mechanical Influencers at The Summit!

Speaker: Gary Milligan President Thermal Comfort Association (TECA)

Meet up with Vancouver area’s own Terence Chan, HVAC Jess and their team of Canada’s foremost social influencers, as they live stream on-site system builds to their followers!

Platinum Sponsor

Sponsors

Curtis Bennett HPAC contributor

Curtis Bennett HPAC contributor

DLWC system, which operates via a series of water loops.

One loop moves the lake water, another moves water within the downtown area, and loops in each building interact with the system. Thermal energy is transferred where the loops meet, via heat exchangers, at each customer or building site, as well as where the lake water pipes meet the city pipes.

In the heat exchange system in the basement of The Taylor, water returning from the building’s cooling system transfers heat to cold lake water in other loops, and the cool air is circulated to all building spaces.

After the chilled water has circulated through the buildings, Enwave returns slightly heated water to the pumping station, where the cooler potable water absorbs heat energy, and the process repeats itself.

The model has been so successful in Toronto that the city plans to develop more low-carbon thermal energy networks to support and attract new development.

In 2019, Enwave announced plans for a $100 million system expansion with the federal government providing $10 million in funding from the Ministry of Environment and Climate Change’s Low Carbon Economy Challenge.

It is expected that by 2050, 30% of the city’s “floor space” will be connected to low-carbon heating and cooling systems, including Enwave’s DLWC structures.

The cooling system in The Taylor is not the only way that Tricon has reduced the building’s carbon footprint.

“The apartments have motion sensors to shut off lights when not in use; all the lights are LED; and there’s a master kill switch so that residents can turn off all lights when they leave their units,” says English. “The Taylor also features Enwave’s low-carbon heating system

that uses heat pumps.”

The building uses a four-pipe fan coils in each suite to provide HVAC flexibility.

“With Canada’s unpredictable spring and fall shoulder seasons, it’s critical to have separate systems because the temperature can fluctuate quite a bit,” he says.

Cost savings associated with sustainable heating and cooling systems like the ones deployed at The Taylor are significant but project-specific, says English, adding that his company is in discussions with Enwave about another project where it aims to use another Enwave district system for heating and cooling.

Construction management company Deltera was responsible for the physical construction of The Taylor, including its 37 storeys and 286 apartments, but those units were not the first that it had built to connect to the Enwave system.

“Deltera has been fortunate to have worked with Enwave in the past and completing our first project, The Element, 20 years ago, one of the first residential buildings connected to the Enwave DLWC system,” says the company’s senior vicepresident of construction management, Mario Cimicata. “Now we are working on our largest project yet, consisting of six

mixed-use towers at The Well, where we installed a concrete storage tank to facilitate Enwave’s initiatives to extend the DLWC capabilities west of the city core.”

The tank at The Well, which has a diameter of 50 ft. and a depth of 150 ft., sits at the bottom of the building’s sevenstorey underground garage.

Assessing the project at The Taylor, Cimicata says that the build was made a bit more complicated as a result of the location, site logistics and general conditions the industry faced over the past three years, but the success of the project was a result of the strong continual collaboration among Tricon, Deltera, and their subtrades and suppliers, and the end result will benefit the tenants who started to move into the building last September.

“Tenants are benefiting from the owner’s decisions to incorporate innovative, efficient technologies and equipment, resulting in reduced operating expenses and a reduced carbon footprint,” he says. “Deltera is highly motivated in these areas, and continues to initiate working relationships with innovative organizations, owners, suppliers and technologies like Enwave.” <>

Creating a sustainable energy system to heat, cool and power an entire college campus is no easy feat. In 2013, when Sheridan College in Oakville, Ont. launched its Energy and Climate Master Plan, with the goal of lowering campus energy and greenhouse gas emissions by half, they realized that they would need to transform their heating and cooling system.

The school looked to the Trias Energetica model, first developed in 1979, as a guide to developing a sustainable energy system, integrating heating and cooling functions and recovering energy that might otherwise be wasted.

“We wanted to position Sheridan as a role model on sustainability and follow best practices. This ties into our educational mission as well,” says Herbert Sinnock, Sheridan’s director of sustainability. After an evaluation of the HVAC infrastructure in existing campus buildings, the college realized that the most effective way to make its heating and cooling operations more efficient was to install an entirely new system, using a district energy model, starting with its Trafalgar Campus in Oakville.

Sheridan began constructing its thirdgeneration district energy system in the summer of 2016, burying 3.5 km of preinsulated pipes that carry pressurized hot water across the campus from a central plant to every building.

Sinnock notes that the pipe network is not installed very deep in the ground, which made it quick and easy to install. Modern pre-insulated pipe systems integrate leak detection, helping operations teams quickly identify any problems to ensure the system will continue to operate at peak efficiency.

Reciprocating heat and power engines, installed in 2017 and 2018, generate baseload heating for the system along with a modest amount of electric -

Packaged energy transfer stations ease the transition for Sheridan College’s district energy system.

ity. Supplemental boilers provide additional temperature lift on very cold days.

Centralized delivery uses less energy than a distributed system with separate boilers in each building. In the summer, the engines’ heat can be sent to an absorption chiller that feeds the chilled water network to several campus buildings.

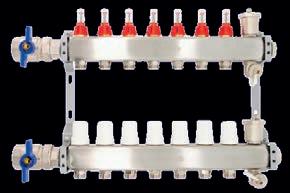

At each building, heat is transferred from the system’s primary loop to each building’s secondary heating system through a Danfoss energy transfer station (ETS). The ETS is an interconnected system of heat exchangers, valves, pumps, programmable controller, metering and piping that draws heat from the primary loop of pipes outside each building to control and feed the building’s secondary heat network.

A pressure-independent control valve on the primary side of the ETS ensures the heat exchanger operates efficiently, using an outdoor temperature sensor to modulate the heat transfer process for each building while allowing each building’s heating system to operate independently.

The ETS is a key component of the district energy system because it contains automated controls which provide continuous digital metering and can monitor and adjust to the demands of the building, controlling temperatures and working to maximize the combined efficiency of the primary loop and the buildings.

“We wanted to acquire the product from a company with an established track record of installing these devices. We were aware that Danfoss had a rich history of selling ETS outside of North America,” said Sinnock. “We liked that the stations could be factory built, customized and programmed to match our facility, then delivered fully-assembled and ready to operate on day one.”

In 2019, Sheridan began a three-year project to decommission a nearly 50-year-old steam plant serving six of its Oakville buildings, replacing it with the new hot water district heating system capable of heating the entire campus.