WHAT IS PFAS?

‘FOREVER CHEMICAL’ CONCERNS

FEBRUARY 2024 HPACMAG.COM Follow Us On @hpacmag GRINDER PUMPS REFRIGERANT EVACUATION DUCTLESS ACCESSORIES

MODERN HYDRONICS SPRING 2024 ALSO INSIDE

Setting a new industry standard in hybrid heating products.

Napoleon is recognized as an industry leader in Canada for our cold climate heat pump technology. Our new EQHUB SMART THERMOSTAT delivers efficiency and lower operating costs through fuel choice and time of use rates*

Our hybrid systems are fully supported and eligible for federal and provincial rebate programs, benefiting homeowners. Count on our nationwide HVAC training and support for these innovative products to support the growth of your business.

*Time of use rates is currently only available in Ontario, Canada.

Napoleon is a trademark of Wolf Steel Group Inc. and is used under license. HEATINGCOOLINGHYBRID NAPOLEON.COM

LEARN MORE

15

FEATURES

10 COVER STORY

HVAC

NAVIGATING THE PFAS LANDSCAPE

Understanding the evolution and potential challenges of forever chemicals in the HVAC/R industry.

By Ian McTeer

15

DUCT FREE ZONE

NECESSARY ACCESSORIES

Take advantage of the new mini split installation and service aids available on the market.

By Gerry Wagner

52 PLUMBING PUMP AND GRIND

Taking care of the unflushables and reducing call backs.

By Doug Picklyk

58 REFRIGERATION

EVACUATION PLAN

Mastering the vacuum pump, the technician’s key to efficient system charging.

By Dave Demma

COVER PHOTO: TYLIM/GETTY IMAGES

CONTENTS

10 52

P4 FEBRUARY 2024 / VOL. 98 NO. 1

CONTINUED ON

HPACMAG.COM FEBRUARY 2024 | HPAC 3

CONTENTS

MH6

HEAT PUMPS

WHEN ONE ISN’T ENOUGH

Details for piping multiple hydronic heat pumps together in one design.

By John Siegenthaler

MH14

PROJECT

OPERATIONAL NET ZERO

Carmichael Engineering’s new branch office in Belleville, Ontario provides a template for the company’s future net zero projects.

By Doug Picklyk

MH18

BUSINESS

THE MAINTENANCE PLAN

Ensure long-term customer satisfaction by removing the confusion and offering service plans and more with every installation.

By Mathew Pottins

MH20

30 MECHANICAL MINUTES

ELECTRIC BOILERS:

WHEN AND WHERE?

John Seigenthaler joins HPAC to talk about how electric boilers work and where they make sense.

MH24

DUAL FUEL

THE BIG SWITCH

Modern controls can optimize hybrid gas/electric hydronic heating solutions, here’s why it matters.

By Curtis Bennett

MH26

HYDRONICS PRODUCTS

MH28

DESIGN

MATHEMATICS VS. REALITY

Exploring the non-proportional relationship between heat output and flow rate.

By John Siegenthaler

4 HPAC | FEBRUARY 2024 HPACMAG.COM DEPARTMENTS 6 UPFRONT 8 NEWS FEATURE Report supports geothermal and thermal storage to offset Ontario grid loads. 8-9 INDUSTRY NEWS 49 MECHANICAL SUPPLY NEWS 50 PEOPLE 61 THE SOURCE 62 CALENDAR

FEBRUARY 2024 / VOL. 98 NO. 1 MODERN HYDRONICS SPRING 2024 BUILDING TO OPERATIONAL NET ZERO New construction in Belleville DUAL FUEL MULTIPLE HEAT PUMPS FLOW RATE AND BTUS a publication of MH 26 MH 18

BREAKTHROUGH TECHNOLOGY

“ Flexi-Rooter’s ClogChopper rips open a hole for the chain knocker to work. It’s a great product.”

Flexi-Rooter ® featuring ClogChopper ® Cutters

Flexi-Rooter uses ClogChopper six-bladed cutters along with carbide-tipped chain cutters to break through the toughest clogs, scale and roots. The cutters then grind up the stubborn stoppages and scour the pipe walls clean.

The rotating shaft is 10 times faster than traditional shafts, yet easy to handle. It’s extremely exible for clearing 2" lines, yet strong enough to cut roots in 4" lines up to 75 feet long. Plus, the foot pedal leaves both hands free to guide it into the drain.

To learn more, visit www.drainbrain.com/Flexi-Rooter, or call the Drain Brains ® at 800-245-6200.

Visit us at CMPX Booth #1702

© 2024 General Wire Spring

Flexi-Rooter ®

Seth Mikulin • SureFlo Sewer & Drain

ClogChopper with carbide tip cutter

< UPFRONT

GAME TIME

THERE IS NOTHING QUITE LIKE THE FEELING YOU EXPERIENCE IN A PACKED

STADIUM OR ARENA WHEN THE HOME TEAM IS PLAYING AN IMPORTANT GAME. The crowd energy is palpable, you can feel it in your bones, there is real excitement in the air. Well, when walking the halls at the AHR Expo in Chicago on the first two days of the show this year, that's what I was reminded of. It wasn't quite playoff game energy, but it was definitely a very important regular season game and the attendees were excited and happy to be there.

Despite near zero temperatures outside on day one, crowded hallways and packed booths were a welcome sight for the exhibitors and the show organizers. The annual expo for the HVAC/R industry hadn’t been in Chicago since 2018, and the strong attendance was a great sign, revealing great interest from the contractor community to see the latest products available and gain insights on industry trends.

It's an interesting time in the industry with such a strong global push on environmental issues and reductions in carbon emissions. The HVAC/R sector is facing significant change from technology applications to refrigerant phase downs and restrictions that are coming on board soon.

It was no surprise to see a strong heat pump presence across the major heating equipment manufacturers, and this was a significant show for hydronics as air-to-water heat pumps begin gaining more traction based on the number of products revealed, some serving as previews of what’s to come.

Yes, electrification and decarbonization continue to be popular themes at exhibitor presentations, and although the concept of artificial intelligence (AI) was being thrown around and attracting interest, it’s still a challenging subject to communicate in terms that make sense, so it wasn’t a main topic of discussion for most of the presentations I saw.

During an engaging State of the Industry panel discussion on Tuesday, the key messaging for contractors centered around the need to encourage ongoing training among HVAC techs and the ever-important role of contractors as the conduits of educating homeowners and building owners on the new technologies coming out and how these new solutions can best provide comfort while meeting efficiency or environmental goals.

The upcoming refrigerant phase downs was also a hot topic, and keeping up to date on what is happening with refrigerants is very important for contractors. One panelist, Talbot Gee from HARDI insisted that the transition to A2L (mildly flammable) refrigerants is going to be unlike any other transition the industry has experienced before.

Steve Yurek of AHRI stressed the need for more industry training around that topic, and he emphasized the growing importance of R410a recovery and reclamation going forward to support the large existing installation base.

Like I said, this year's trade show energy was high, and I expect the Canadian crowds will bring that playoff level excitement to CMPX next month in Toronto. I look forward to seeing you there.

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

AUDIENCE DEVELOPMENT MANAGER MEDIA DESIGNER

PUBLISHER PRESIDENT/COO

Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

David Skene (416) 510-6884 dskene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 510-5180 ugrzyb@annexbusinessmedia.com

Emily Sun esun@annexbusinessmedia.com

Peter Leonard (416) 510-6847 pleonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print)

ISSN 2371-8536 (Online)

Contents Copyright © 2024 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.88 (plus tax) CDN; United States: $114.24 CDN; Elsewhere: $125.46 CDN; Single copy Canada: $8.00 CDN. Heating Plumbing Air Conditioning is published 6 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com

Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

6 HPAC | FEBRUARY 2024 HPACMAG.COM

*E&OE, some conditions apply. See website for details. NEED APPRENTICES? Up to $20,000* in help is available right now! Eligible small and medium-sized businesses can apply for support from the Canadian Apprenticeship Service. In addition to the grant, build your future workforce with:

free access to employer-apprentice matching services;

free access to mentorship programs; and

free access to diversity and inclusion training. Apply for your grant at ApprenticeSearch.com/CAS

•

•

•

REPORT SUPPORTS GEOTHERMAL AND THERMAL STORAGE TO OFFSET GRID LOADS IN ONTARIO

A new report commissioned by the Ontario Clean Air Alliance recommends incentives to boost the installation of more ground source heat pumps, thermal storage solutions, electric batteries and two-way electric vehicle chargers to help offset the demand on the province’s power grid.

Prepared by McDiarmid Climate Consulting, the study, An Analysis of the Impacts of All-Electric Heat Pumps and Peak Mitigation Technologies on Peak Power Demand in Ontario, did the research to determine how the shift to using heat pumps to heat and cool homes in Ontario will affect peak period electricity demand.

It’s widely acknowledged that Ontario and other provinces will need to increase grid capacity as more sectors of the economy electrify, and this report analyzes specific solutions for reducing peak power draws from single family homes that adopt all-electric heat pumps.

The conclusions reveal that solutions such as thermal storage, batteries and pairing with electric vehicles can reduce demand more cost effectively than building additional electricity generation.

It shows how installation of ground source heat pumps (GSHP) instead of air source heat pumps (ASHP) can reduce the power demand from all-electric heat pumps on winter peak hours.

Therefore, it recommends that utilities and governments incentivize the adoption of all of these solutions for single family homes.

The entire report can be viewed at the Clean Air Alliance website. cleanairalliance.org

NEXT PHASE OF DEPARTMENT OF ENERGY COLD CLIMATE HEAT PUMP TECHNOLOGY CHALLENGE UNDERWAY

The U.S. Department of Energy (DOE) has announced that four additional heat pump manufacturers (Bosch, Daikin, Midea, and Johnson Controls) have successfully produced heat pump prototypes as part of the DOE’s Residential Cold Climate Heat Pump (CCHP) Technology Challenge, and their prototypes will join products from Lennox, Carrier, Trane, and Rheem in the next phase of the Challenge, which is to involve the installation and monitoring of more than 23 prototypes in various cold-climate locations throughout the U.S. and Canada over the next year.

First announced in May 2021, the Challenge — launched in partnership with Natural Resources Canada (NRCan) and the U.S. Environmental Protection Agency (EPA) — was enlisting manufacturers of residential, centrally ducted, electric-only heat pumps, and the Challenge had two segments: one for a CCHP optimized for 5F (-15C) operation (“the 5F challenge”) and the another for a CCHP optimized for -15F (-26C) operation (“the -15F challenge”).

In the Challenge Specifications, published in September 2021, manufacturers could choose to participate in either one or both segments of the Challenge.

The first six industry partners announced in Fall 2021 included: Carrier, Daikin, Johnson Controls, Lennox, Mitsubishi Electric and Trane. In February 2022 three more companies joined the Challenge: Midea, Rheem and LG. And subsequently Bosch also joined the Challenge.

In June 2022 it was announced that Lennox had developed the first prototype that achieved the Technology Challenge’s lab testing standards, delivering 100% heating at 5F (-15C) at double the efficiency, and 70% to 80% heating at -5F (-20C) and -10F (-23C).

Now there are eight companies (Bosch, Carrier, Daikin, Johnson Controls, Lennox, Midea, Rheem and Trane) participating in the field testing phase of the 5F challenge. It’s still to be determined if product commercialization can be achieved in 2024. energy.gov

FEDERAL PROMPT PAYMENT LEGISLATION NOW IN EFFECT

To ensure all construction workers on projects contracted by the Government of Canada are paid in a timely manner, the government has announced that federal prompt payment legislation has come into force as of December 9, 2023

The Federal Prompt Payment for Construction Work Act states that the federal government will have 28 calen -

dar days to pay after the contractor submits a proper invoice.

The contractor will then have seven days to pay its subcontractors; subcontractors will have another seven days to pay their sub-subcontractors; and so on down the contracting payment chain.

The federal prompt payment legislation aims to ensure that payment for the construction is predictable and timely.

Any existing construction contracts will

8 HPAC | FEBRUARY 2024 HPACMAG.COM SEE THE LATEST NEWS @ HPACMAG.COM INDUSTRY NEWS

CCHP technology challenge timeline.

have one year, as of December 9, 2023, to comply with the new Act.

Also, any federal construction work being done in provinces or territories that have already enacted a similar prompt payment and adjudication regime (which currently includes only Ontario, Saskatchewan and Alberta), in those designated provinces contracts will by default be under the prompt payment regime of the province. canada.ca

COLD CLIMATE HEAT PUMP PROTOTYPE BEING DEVELOPED IN TORONTO

Terravis Energy, a subsidiary of New York-based Worksport Ltd., is testing a working prototype of a cold climate air source residential heat pump in a specialized climate chamber in Toronto.

“We are engaged in this rigorous and severe testing protocol because Terravis’s mission is to offer a zero-emission residential heat pump that sets new standards in cold-weather performance,” commented Terravis Energy’s CEO, Lorenzo Rossi in a company press release. “Our heat pump’s goal is to provide heat to homes in as low -31F (-35C), which we believe will make us the most effective heat pump technology in the market.”

The testing chamber conducts cold weather trials across a range of temperature points from 14F (-10C) to -31F (-35C). These tests include checking four refrigerant pressure zones, airflow, and the energy consumption of each component with an aim of optimizing the heat pump’s efficiency and performance at various temperatures.

The Terravis heat pump is being designed to offer an easy-to-install modular design permitting different ways of mounting depending on the space.

MECHCAN EXPANDS INTO B.C.

MechCan Inc., the Canadian company that has been partnering with and rolling up mechanical services companies, has expanded beyond Ontario with its acquisition of Pro Ace Heating & Air Conditioning of Vancouver.

This marks MechCan’s seventh transaction since the business launched in January 2022. Its other acquisitions have all been in southern Ontario and the Ottawa area.

“Since its inception in 2005, Pro Ace’s success has been driven by our commitment to customer satisfaction,” said Ali Soroush, Pro Ace’s owner-operator.

Pro Ace will continue to operate under its brand and retain its team. mechcan.ca

ASHRAE ENHANCES PERFORMANCE STANDARD FOR EXISTING BUILDINGS

ASHRAE has released the latest version of its energy efficiency standard for existing buildings, with an expanded focus to incorporate building decarbonization.

Standard 100-2024, Energy and Emissions Building Performance Standard for Existing Buildings is a codeready building performance standard that provides processes and procedures for reducing energy consumption and carbon emissions through improved energy efficiency of all types of existing buildings, including residential, commercial, institutional, and industrial.

The latest edition of the standard includes carbon emissions performance requirements for existing buildings, as well as emissions targets for dozens of building types. ashrae.org

ProLiftTM elevates safety by lifting ladders with unique, patent-pending mechanical advantages and dampers. Ladders can be raised and lowered effortlessly. Requiring up to 50% less effort from you to do the job, ProLiftTM helps reduce back and shoulder injuries. With Adrian Steel, ladders stay put and you stay safe, it’s as simple as that. Learn more about ProLiftTM and our ProfileTM rack system at adriansteel.com

HPACMAG.COM FEBRUARY 2024 | HPAC 9 INDUSTRY NEWS >

Adrian Steel ladder racks are designed to make loading and unloading ladders easier and more ergonomic, but their most important function is helping you make it safely home at the end of each day.

HPAC_AdrianSteel_Oct23.indd 1 2023-09-18 8:58 AM

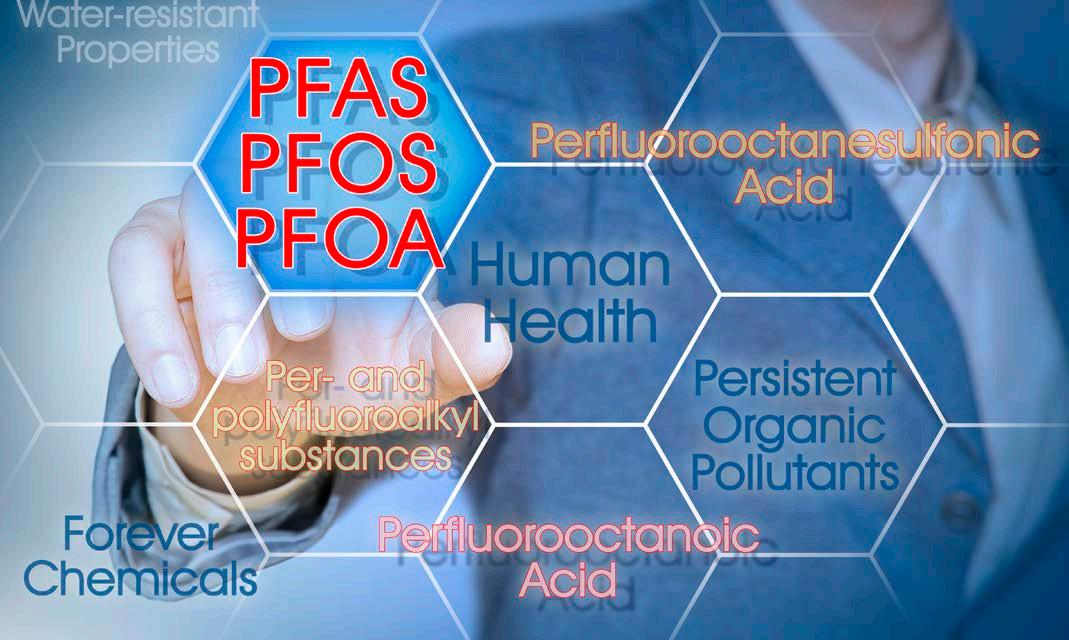

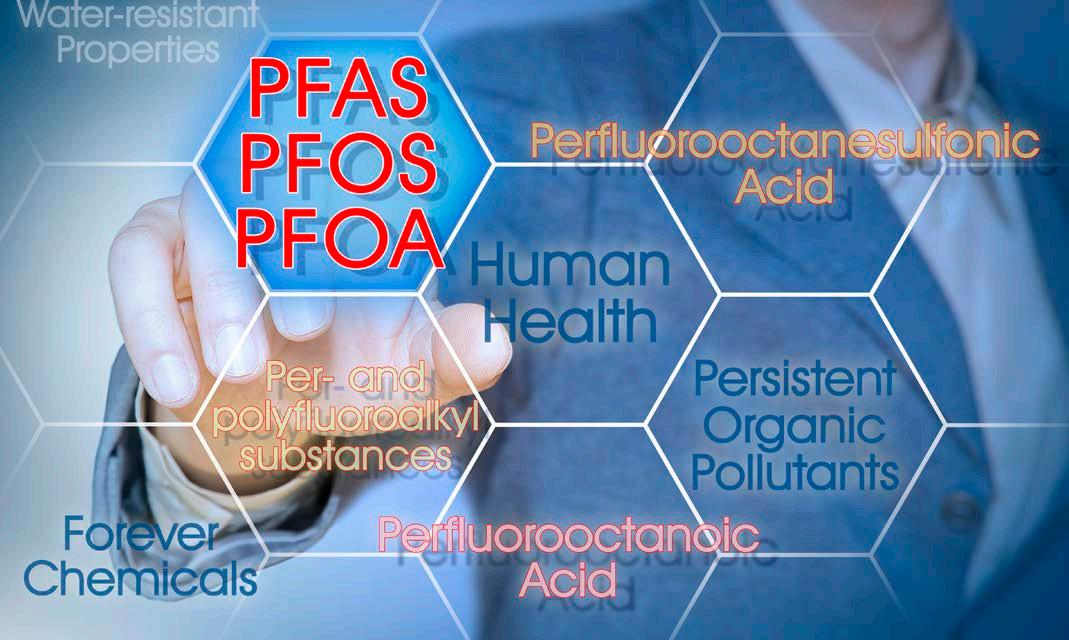

NAVIGATING THE PFAS LANDSCAPE

Understanding the evolution and potential challenges of forever chemicals in the HVAC/R industry.

BY IAN McTEER

You may not hear much about this topic during your average workday, but in the grand domain of HVAC/R systems, the pervasive and ubiquitous presence of per- and polyfluoroalkyl substances (PFAS) has become a topic of increasing concern and scrutiny.

This family of synthetic chemicals, which some refer to as forever chemicals, was developed by several companies, 3M being a major pioneer starting production of the compounds back in the 1940’s.

The first major product was perfluorooctanoic acid (PFOA) widely used in non-stick coatings such as Teflon, introduced into the market by DuPont in 1945. Highly desirable for their waterand grease-resistant properties, PFAS compounds have been instrumental in a variety of industrial applications, including firefighting foams, non-stick cookware, and, notably, as key components in certain HVAC systems.

While their initial incorporation into these systems brought about unparalleled advantages in terms of performance and efficiency, the dark side of PFAS has gradually surfaced. Some members of this chemical family, known for their persistent nature and resistance to degradation, have been identi -

fied as posing potential risks to human health and the environment, leading to regulatory actions that have banned or restricted their usage in certain regions.

In 2016, the government of Canada banned the manufacture, use, sale, and import of PFOA, its salts and precursors throughout our country.

As we try to reconcile the complexities surrounding PFAS, it becomes imperative for the HVAC industry to examine these challenges carefully, striking a delicate balance between maintaining the beneficial aspects of these chemicals and safeguarding the well-being of our customers and the ecosystems in which HVAC systems operate.

10 HPAC | FEBRUARY 2024 HPACMAG.COM TYLIM/GETTY IMAGES < HVAC Continued on p12

Teflon and plumber’s tape are known products using PFAS chemicals.

Replaces conventional top discharge heat pumps APPLY TO BECOME A DEALER HERE : HEAT PUMPS DESIGNED FOR CANADIANS Stock now available in BRAMPTON, Ontario Join the GREE Canada team ! Contact us to become a certified dealer. BENEFITS Local sales and after-sales support Frequent sales and technical training Largest inventory of GREE products and parts in Canada OFFICIAL DISTRIBUTOR IN CANADA Up to 15.2 SEER2 and 8.5 HSPF2 Up to 80 % Heating Capacity at Outdoor Ambient Temperature of -30 °C Integrated 24 V Control Logic for Easy Installation Heat pump combination AHRI Certified for installation with ANY 3rd party furnace. Eligible to financial incentives in certain provinces, contact us for more detail. UNIX SERIES HIGH-EFFICIENCY CENTRAL HEAT PUMPS WITH CASED COILS

PFAS compounds are now regarded worldwide as “emerging contaminants” as more information about their toxicity and environmental impact becomes known. Fluorination makes PFAS compounds exceptionally durable and slow to break down and thus are persistent in the environment.

PROPOSED TOXIC LABEL

PFAS, or forever chemicals, meet two criteria for being listed as toxic under the Canadian Environmental Protection Act, according to a draft assessment from Environment and Climate Change Canada (ECCC) and Health Canada. Those criteria include their potential long-term effects on human health and environmental biological diversity.

“To reduce the immediate and longterm harmful effects on human health and the environment, important measures are needed to control the use of PFAS,” Canada's Health Minister JeanYves Duclos said in a statement in May of 2023.

This past spring ECCC published a Risk Management Scope for Per – and Polyfluoroalkyl Substances (PFAS) for a 60-day public comment period. The Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) assembled a panel of experts to address the government’s Risk Management Scope and submitted a lengthy and comprehensive document detailing Canada’s HVAC/R industry’s desire to base any regulatory outcomes on a weight of the evidence approach using the best available science.

Other groups such as the Chemistry Industry Association of Canada took exception to the proposal in which all PFAS would be treated as an entire class, noting: “It is neither scientifically accurate nor appropriate to regulate as one class,” and, “Canada will not be able to meet climate goals without fluorinated chemistries,” said the associa -

tion’s policy manager Danielle Morrison.

To date there has not been any indication as to the regulatory route ECCC and HC intend to take, however, ECCC has, no doubt, received numerous and complex briefs from other industries that will be affected as well.

“PFAS compounds are now regarded worldwide as “emerging contaminants”

REFRIGERANTS & COMPONENTS

It should be noted that PFAS compounds represent a diverse and wideranging group of synthetic compounds valued for their strength, versatility, and durability.

We are learning about the need to limit or to even prohibit certain PFAS compounds from certain applications, however, many other PFAS composites have well-known properties that do not pose unreasonable risks to human health or the environment when used properly.

The U.S. Environmental Protection Agency (EPA) has developed a working definition of PFAS in which chemicals must have at least two adjacent carbon atoms that are fluorinated, and at least one of those must be fully fluorinated. The EPA characterization means approximately 6,500 chemicals used throughout North America would fall under their definition.

Even so, the EPA’s definition makes it difficult to determine which substances might fall under any new regulation. The HVAC/R industry depends upon fluorinated gases such as Hydrofluorocarbons (HFC) and Hydrofluoroolefins (HFO) to provide heating, cooling, and refrigeration to meet societal needs that include

preserving agricultural produce and dairy products, pharmaceutical cold chains, and human comfort.

Potential PFAS restrictions could include a comprehensive list of currently used pure refrigerants, such as: R-125, R-134a, R-1234ze and R-1234yf, and many others.

Blends such as R-410A, R454B, R-513A, R-448A also fall under the EPA’s definition of PFAS.

R-32, also an HFO, is not on the list as it is outside of the proposed EPA definition, at least for now.

A U.S. industry group, known as the Sustainable PFAS Action Network (SPAN) is a “non-profit organization representing stakeholders that responsibly produce and utilize PFAS compounds in a wide range of commercial products,” according to their website.

SPAN membership includes: Arkema, Daikin, Honeywell, AHRI, and the Aerospace Industries Association (AIA), among others.

SPAN argues that HFO’s do not show any of several characteristics frequently cited as most concerning when related to PFAS compounds; they are not persistent, bioaccumulative, nor toxic. In fact, SPAN noted EPA’s proposed Toxic Substances Control Act does not include HFO’s.

SPAN advocates for a science-based management policy noting how a blanket restriction that treats all PFAS compounds the same would have devastating economic and safety consequences for our and many other industries.

As there are currently no alternatives to HFO’s, an all-out PFAS ban leaves only the “natural refrigerants” such as CO2, ammonia, and the A3’s left to work with.

The European HVAC/R industry association, EUROVENT, has expressed similar concerns about banning PFAS and fluoropolymer refrigerants, noting, “For

Continued on p14

12 HPAC | FEBRUARY 2024 HPACMAG.COM < HVAC Continued from p10

SETTING A NEW INDUSTRY STANDARD IN HYBRID HEATING PRODUCTS.

Continental is recognized as an industry leader in Canada for our cold climate heat pump technology. Our new EQHUB SMART THERMOSTAT delivers efficiency and lower operating costs through fuel choice and time of use rates*. Our hybrid systems are fully supported and eligible for federal and provincial rebate programs, benefiting homeowners. Count on our nationwide HVAC training and support for these innovative products to support the growth of your business.

*Time of use rates is currently only available in Ontario, Canada.

continentalcomfort.com SCAN HERE TO VIEW PRODUCTS

Continental is a trademark of Wolf Steel Group Inc. and is used under license.

Continued from p12

those components a time unlimited derogation for both fluoropolymers and non-fluoropolymers should be developed that also reflects the availability of spare parts for repair in the sense of Ecodesign (e.g. is not acceptable to scrap a compressor due to unavailability of an PFAS free O-ring with interchangeable design).”

Fluoropolymers are used in many devices because of their chemical inertness and durability—these are the same characteristics that also make them undesirable.

You are going to find PFAS in a wide variety of components and tools used every day by about everyone, everywhere in our industry. Here is a small sampling: compressor oils and components; air filters: anti-drip additive in flame retardant plastics; coax cables; electronic components – diodes, capacitors, sensors, motors and switches; exterior cabinet paints and coatings; foam cleaning and firefighting agents; heat exchanger tubes –hydrophilic coating (potential); high temperature and/or chemically resistant O-rings/seals/gaskets; lithium-ion batteries – electrode substrate and in the electrolyte; plumber’s tape (PTFE / Teflon); printed circuit board coatings (potential and likely); and pumps (using PFAS O-rings, seals, gaskets).

EUROVENT describes the fundamental importance of PFAS on the properties of air filters, namely the ability to remain durable in high humidity applications along with providing superior dust holding capacity.

Air filters typically contain a PFAS compound known as C6 (PFHxA) providing water and oil repellency. C6 is added to the filter during manufacturing preventing the media from absorbing bonding adhesives that would otherwise plug the air passages and reduce the filter efficacy. There is no alternative to C6 at this time.

In a pathogen-anxious world, the po -

tential loss of air filtration media could leave many people feeling vulnerable, although I would be just as worried about our unfiltered HVAC equipment suffering damage from accumulated contaminants.

WHAT IS THE PROBLEM?

Scientists, citing the precautionary principle, are studying the effects of PFAS compounds, especially those that might contribute to developmental defects in fetuses and infants.

Some are suggesting a potential link between certain PFAS compounds and an increased risk of cancer.

PFAS has been shown to accumulate in the liver over time, potentially leading to liver damage, and exposure to PFAS compounds may suppress the immune system; metabolic issues might be caused by PFAS induced thyroid damage; some PFAS exposures are potentially linked to reproductive problems including decreased fertility and hormonal imbalances.

Some scientists, like Professor Miriam Diamond of the University of Toronto Department of Earth Sciences said in a recent interview by CBC’s Marketplace program, “we can’t afford to wait for more studies.”

Governments are studying proposed legislation to ban PFAS chemicals, for example, the European Chemical Agency (ECHA) suggests chemicals and mixtures along with articles (complex goods) having 25 parts per billion (ppb) or more of any particular PFAS compound, or 250 ppb of a combination of PFAS ought to trigger a potential ban. If finalized, the ECHA proposal would be one of the most all-encompassing chemical bans ever enacted.

This kind of proposal puts all PFAS chemicals in the same class despite a hierarchy of significant differences. Certainly, expect a ban on the low hanging fruit such as any PFAS compounds

that have immediate alternatives combined with toxic labelling of complex goods and chemical preparations.

There is also no question about restricting manufacturing, use and marketing of products potentially contaminating food or drinking water.

In late November 2023, the 6th U.S. Circuit Court of Appeals dismissed a class action lawsuit against PFAS manufacturers 3M and DuPont. The judge decided the suit filed by the lead plaintiff was too broad and failed to show how the PFAS detected within his body could be linked to the manufacturers.

Such a finding does not mean we can rest on our laurels, certainly more studies are needed so that a solid database of credible facts about any harmful effects to humans and to the environment caused by PFAS can be compiled.

As if the coming transition to A2Ls will not be stressful enough, there is little doubt that every industry could be affected by the PFAS regulatory process.

Businesses may well have to reexamine the composition of their products and potentially institute redesigns free of PFAS fluoropolymer compounds costing untold billions of dollars.

In the meantime, learn more by visiting the SPAN website (span.org) and monitor the Environment Canada and Climate Change website (canada.ca/ en/environment-climate-change). And of course, continue to use personal protective equipment (PPE) when appropriate and dispose of chemicals according to the manufacturer’s instructions and local regulations. <>

Ian McTeer is an HVAC consultant with over 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician. Reach Ian at imcteer@outlook.com.

14 HPAC | FEBRUARY 2024 HPACMAG.COM

< HVAC

NECESSARY ACCESSORIES

Take advantage of the new mini split installation and service aids available on the market.

BY GERRY WAGNER

Mini splits have become so popular that their sales and installations increase annually by double digits, and as a result an onslaught of mini split installation/service aids and accessories have hit the market—some good, some not so much. But there are a few I now consider necessities for anyone in the trade.

The first essential product has to be a surge protection device. I’m always shocked (pun intended) when I’m conducting a mini split training class and find out many installers and technicians have never considered surge protection or even heard of it as it relates to HVAC equipment.

A surge protection device will protect equipment and the control boards within equipment from damaging voltage surges, whether man-made in the form of something internal to the grid or an act of God like a lightning strike.

In a home my wife, Patricia, and I owned in New York state, we had an older inverter mini split that heated a four-season room (a glass enclosed deck if you will). The compressor fried on its own, but because I had a surge protector on the system it did not take out the board along with it.

How do I know the surge protector saved the board? Easy, the surge protector has a little green LED light that illuminates as long as the surge protector is not spent (most are one and done). In my case, the surge protector was spent, clearly sacrificing itself to save the board when the compressor fried—impressive!

Those of you who know me, or read my articles regularly, know that I preach to small business owners that we must always do everything we can to limit our liability. Do all we can to isolate and insulate ourselves and our businesses from liability. A surge protector, a component that in most cases nets out to less than $125, can save you thousands of dollars in lost equipment and liability expenses.

We all put little stickers on equipment that we have installed that say, “When you need service, call ACME Heating & Air.” It’s how we get repeat business, and it’s something all contractors have done since time immemorial. But that sticker has the potential to take you from being the installer to the defendant when that equipment is destroyed by a power surge.

We need to protect ourselves from that potential, and a surge protector does just that!

I have used the Intermatic AG3000 for many years, and recently I used the Rectorseal RSH-50. I see where my friends at Diversitech have introduced the Surge-Trap surge protector. Any one of these products should be included in every mini split installation no matter where that installation is taking place.

FLAIR FOR FLARING

My second item would be a proper flaring tool. Because today’s mini split systems use R410A refrigerant and run at higher pressures than R22, the diameter of the flare needs to be larger to compensate for the higher pressures the connection will experience.

That said, we need to use a flaring tool specifically designed to create the

Continued on p16

HPACMAG.COM FEBRUARY 2024 | HPAC 15

PHOTO CREDIT: WITSAWAT/ADOBE STOCK

DUCT-FREE ZONE >

Mini split evaporator cleaning could be new revenue potential.

Continued from p15

R410A flare. I like the Yellow Jacket Deluxe 45-degree flaring tool.

The key to this tool is that it has a tubing stop; if used properly it won’t allow you to over or under flare the tubing. Now, I won’t say the tool is idiot-proof, because idiots try real hard, but if the tubing stop feature is used as designed the flare diameter and depth will be perfect each and every time.

Now, I’m an old guy so I tend to do things “old school,” but my friend Jeremy Torra of Centric Sales, the NAVAC tool representative, has turned me onto their battery powered flaring tool, the NEF6LM. Besides being “state of the art” technology it also has a tubing stop—brilliant!

Now, a flaring tool alone does not guarantee a perfect, non-leaking flare, but one more element will.

Nylog by Refrigeration Technologies

UL 60335-2-40 RECERTIFICATION

The HVAC industry is making a momentous transition to alternative refrigerants to meet Global Warming Potential Requirements. Manufacturers will need to meet the latest safety requirements to UL 60335-2-40 for certification.

Contact our experts today to learn more.

+1 800 WORLDLAB (967 5352)

icenter@intertek.com

Intertek.com/HVACR

will assist in creating a seal between the two mechanical components of the flare. I’m a huge believer in Nylog and preach its value in every training event I conduct.

“The exponential growth of the mini split market in Canada provides an opportunity to find new revenue streams.”

CLEAN CLEANING

The last item I want to address is a service-related item. It’s a product that makes cleaning the mini split evaporator coil and blower wheel relatively simple and easy.

The SpeedClean Mini Split Bib Kit, the Rectorseal Desolv Cleaning Kit and the Nu-Calgon Complete Care Mini Split Kit all allow for the cleaning of an indoor unit coil and blower wheel without extensive disassembly of the indoor unit and without any damage to finished walls and floors.

The three products are very similar in that they provide what I call a mini split diaper. The diaper essentially creates a basketball hoop effect around the bottom of the indoor unit.

The bottom of the diaper is then directed into a five-gallon bucket in which the kit was packaged, and then the cleaning process begins. The three products are a bit different in how the diaper attaches, but they all provide a watertight seal that allows power washing of the coil and blower wheel with all fluids being directed into the bucket— Ingenious!

I have heard horror stories from service techs of how they essentially completely disassembled a mini split indoor unit in order to clean it. “No more,” I say. These products are inexpensive, and a single kit allows for multiple uses.

TOOL YOU CAN USE

The exponential growth of the mini split market here in Canada provides an opportunity for service companies to find new revenue streams like mini split evaporator cleaning. All the companies I mentioned and others are producing low-cost service products to help us reap some of the benefits of this extraordinary growth. <>

Gerry Wagner is the vice president of business development for Bathica in Canada. He has 43 years in the HVAC/R industry working in manufacturing, contracting and training. You can contact Gerry by email: GerryWagner@Bathica.com

16 HPAC | FEBRUARY 2024 HPACMAG.COM

<

DUCT-FREE ZONE

HPAC_Intertek_Feb24.indd 1 2024-01-17 2:44 PM

FOR MORE INFORMATION

MODERN HYDRONICS

SPRING 2024

BUILDING TO OPERATIONAL NET ZERO

FUEL

HEAT PUMPS FLOW RATE AND BTUS a publication of

New construction in Belleville DUAL

MULTIPLE

Not All Glycols Are Created Equal CHEM-FROST For more benefits ask your local wholesaler or visit chemfax.com Safe For All Systems (Including Aluminum and Solar) Premier Inhibitors Higher Temperature Rated Phosphate and Nitrate Free Low Viscosity

HEAT TRANSFER FLUID - INHIBITED PROPYLENE GLYCOL COMPARISON CHART HEAT TRANSFER FLUID – INHIBITED PROPYLENE GLYCOL COMPARISON CHART ***Based on information provided on respective manufacturers’ websites* **Subject to change Brand Chem Frost 100% Eco Frost Brand O Brand R Brand H Brand U Brand D Pail Size 20L 18.9L 18.9L 18.9L 20L 20L 18.9L PG % 95/5 94/6 N/A 92/8 94/6 95/5 95/5 Aluminum Safe YES NO NO NO NO NO NO Solar Compatible YES LIMITED Temp LIMITED Temp NO NO NO NO Geothermal Compatible YES YES N/A N/A N/A N/A N/A Temperature Rating 325F 250F 250F 275F 250F 250F 220F Viscosity @ 50% 100F 5.5cP N/A N/A N/A N/A N/A N/A Boiling Point @ 100% 417F 370F 370F 370F 370F 370F 370F CFIA Approved YES NO NO YES NO YES NO Raw PG Grade FOOD INDUSTRIAL INDUSTRIAL INDUSTRIAL INDUSTRIAL INDUSTRIAL INDUSTRIAL Purity of Propylene Glycol 99.94% 99.7% 98% N/A N/A N/A N/A Phosphate / Nitrate NONE YES YES YES YES YES YES Inhibitor Type PDT NON-TOXIC DKP DKP DKP DKP DKP DKP LEED YES NO NO NO NO NO NO Energy Savings Up to 60% None None None None None None Based on information provided on respective manufacturers’ websites* **Subject to change**

MH6 HEAT PUMPS When One Isn’t Enough

Details for piping multiple hydronic heat pumps.

By John Siegenthaler

MH14 PROJECT Operational Net Zero

Carmichael Engineering’s new branch office in Belleville, Ontario provides a template for future projects.

By Doug Picklyk

MH18 BUSINESS

The Maintenance Plan

Ensure long-term customer satisfaction by offering service plans with every installation.

By Mathew Pottins

MH20 30 MECHANICAL MINUTES Electric Boilers: When and Where?

John Seigenthaler joins HPAC to talk about how electric boilers work and where they make sense.

MH24 DUAL FUEL The Big Switch

Modern controls can optimize hybrid gas/electric hydronic heating solutions.

By Curtis Bennett

MH26 HYDRONICS PRODUCTS

MH28 DESIGN Mathematics vs. Reality

Exploring the non-proportional relationship between heat output and flow rate.

By John Siegenthaler

MODERN HYDRONICS WWW.HPACMAG.COM MH4 SPRING 2024 CONTENTS COVER PHOTO COURTESY CARMICHAEL ENGINEERING

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. NOTICE: HPAC Magazine, Annex Business Media, their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements. Contents Copyright © 2024 by Annex Publishing & Printing Inc. may not be reprinted without permission. Proud member of: We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities. 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 TEL: 416.442.5600 FAX: 416.510.5140 www.hpacmag.com MODERN HYDRONICS a supplement of Heating PlumbingAir Conditioning Magazine Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com David Skene (416) 510-6884 DSkene@hpacmag.com Amanda McCracken (647) 628-3610 amccracken@hpacmag.com Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com Emily Sun esun@annexbusinessmedia.com Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com Peter Leonard (416) 510-6847 PLeonard@hpacmag.com Scott Jamieson EDITOR ASSOCIATE PUBLISHER NATIONAL ACCOUNTS ACCOUNT COORDINATOR MEDIA DESIGNER CIRCULATION MANAGER PUBLISHER PRESIDENT/COO Modern Hydronics

HPX 3 | HPX 5

• Renewable air energy with zero C02 emissions

• No refrigeration licenses required to install and service

• Advanced modulating temperature control

• Outdoor reset functionality

• Enhanced Vapor Injection (EVI) increases efficiency, lowers ambient temperature operating range to as low as -22°F / -30°C, and increases maximum supply water temperature

• Extremely quiet: 38-53 dB operational sound level

• 24V AC interface for easy thermostat connection

• Increased reliability with few moving parts

• Flow-proving and high limit safeties built-in

Easy-To-Install Decarb Solution For Year-Round Comfort

www.ibcboiler.ca | 1-844-HEAT IBC

PUMP This product meets a stringent set of our company’s internally defined sustainability standards

AIR-TO-WATER MONOBLOC HEAT PUMP HEAT

WHEN ONE ISN’T ENOUGH

Details for piping multiple hydronic heat pumps.

BY JOHN SIEGENTHALER

Multiple boiler systems have been used for decades.

They allow full heating capacity to be delivered when necessary, while also retaining high efficiency under partial load conditions compared to a single large boiler.

They also increase the resiliency of the overall heating plant. If one boiler is down for service at least one other boiler is likely ready to supply at least partial capacity.

All the benefits of multiple boiler systems also apply to multiple heat pump systems. If the set up is configured to supply heating-only, or cooling-only, the generic system piping is identical to that of boilers, as shown in Figure 1.

Each “source device”, be it a boiler or heat pump, is piped in parallel with the others. Each has its own circulator that operates only when that source device is on. Each source device branch contains a check valve, purging valve and at least

one means of isolating the source device from the remainder of the system if it has to be removed or replaced.

The headers that supply and collect flow from the source devices should be short and generously sized (e.g., max flow velocity of two feet per second).

They lead back to a hydraulic separator that isolates the pressure dynamics of the source device circulators from that of the load circulator. The hydraulic separator also provides air and dirt separation.

It’s also possible to pipe a multiple boiler, or multiple heat pump system, using a single variable- speed pressure-regulated circulator along with motorized ball valves on each source, as shown in Figure 2 (page MH 8)

The variable-speed pressure-regulated circulator is set for constant differential pressure mode. It automatically adjusts speed up or down as one or more of the motorized ball valves opens or closes.

In theory, the number of source devices could vary from two up to whatever is needed to meet the design load capacity. However, there are diminishing returns on incremental gains in plant efficiency versus the added cost for piping, as well as space in a mechanical room tends to lead to a “practical” limit of four source devices.

Several manufactures now offer “modular” heat pump products that reduce the external piping requirements. In some cases the header segments are built into each heat pump.

SIMULTANEITY

Many commercial buildings, as well as some large custom homes, can require simultaneous heating and cooling. A common scenario is when the perimeter areas require heating while the “core” areas (e.g., those without exposed exterior

MODERN HYDRONICS WWW.HPACMAG.COM MH6 SPRING 2024

HEAT PUMPS

IMAGES: JOHN SIEGENTHALER

Continued on

Figure 1. Piping plan for multiple energy sources.

MH8

Modern Hydronics

surfaces) require cooling due to internal heat gains. Another scenario is when the building contains large glass areas that receive solar gains on sunny winter days.

There are several ways to design HVAC systems that provide simultaneous heating and cooling. They include variable refrigerant flow (VRF), variable air volume (VAV), four-pipe hydronic systems supplying air handlers or fan-coils, and water loop heat pumps.

Monobloc air-to-water and water-to-water heat pumps are another option for applications requiring simultaneous heating and cooling. Systems can be designed that allow any heat pump to operate independently in either heating or cooling mode.

In addition to space heating and cooling, such systems can be configured to heat (or pre-heat) domestic water or add heat to a pool through a heat exchanger. The piping configuration for such a system, based on monobloc air-to-water heat pumps, is shown in Figure 3 (page MH10)

This design use four risers, two for heated water supply and return, and two for chilled water supply and return. Although shown vertical in Figure 3, these risers can be in any orientation that suits placement of the heat pumps.

Flow in the risers is handled by a single variable-speed circulator set for con -

stant or proportional differential pressure regulation, depending on the length and size of the risers.

If the risers are relatively short and generously sized for a maximum flow velocity of 2 ft/sec., the circulator can be set for constant differential pressure control.

If the risers are long, and represent a significant part of the head loss through the heat pump assembly, proportional differential pressure control can be used.

In either case, the circulator automatically adjusts speed and flow rate as individual heat pumps turn on and off.

Each heat pump uses a pair of threeway diverter valves and a single two-way ball valve. The latter only opens when its associated heat pump is running. It ensures that there is no possible “short-circuiting” through inactive heat pumps.

Without this two-way valve the flow path through the heat pump remains open to either the heating or cooling risers when the heat pump shuts off. This creates a flow path, but with no heating or cooling input.

For example, if the heat pump shuts off in heating mode, the two three-way diverter valves remain in the heating position, which allows cooler heating water to flow through an inactive heat pump and then on to the hot water riser. This

“thermally dilutes” the temperature in the hot water riser.

Each set of risers leads to a buffer tank, one for heated water and the other for chilled water. For the system shown in Figure 3, heated water from the buffer tank is routed to multiple radiant panel manifold stations, and chilled water is routed to multiple fan-coil units.

These emitters are only examples. The heated water could also go to panel radiators, chilled beams, or even satellite air handlers.

Flow on the load side of the buffer tanks is also handled by variable-speed circulators set for proportional differential pressure mode. Each crossover between the distribution supply and return pipes has a zone valve that opens when that crossover is active and closes at all other times.

In addition to thermal buffering, each buffer tank provides hydraulic separation between the circulator supplying the heat pumps, and the load circulator.

The two three-way diverter valves and single two-way valve shown for each heat pump in Figure 3 could be replaced by four two-way valves. However, this likely adds to piping cost and also creates more points of potential failure.

The controls for this system would

Continued on MH10

MODERN HYDRONICS WWW.HPACMAG.COM MH8 SPRING 2024

PUMPS

HEAT

Modern Hydronics

Figure 2. Multiple heat sources using a single variable-speed pressure-regulated circulator and motorized ball valves.

The More You Install, The More You Earn

Triangle Tube is proud to introduce an industry leading loyalty program providing you with rewards for installing our best-in-class products. Join Connect and begin earning amazing rewards today!

Visit our website to learn more.

Caleffi 548 Series Separator Included (Shown Mounted) AVAILABLE NOW

LOYALTY PROGRAM

monitor the temperature of both buffer tanks. Since there is a limit to both heating and cooling capacity, and since any heat pump can only operate in one mode at a time, the control logic must prioritize heating over cooling, or vice versa.

In winter it’s likely that the priority would be heating, and thus operating the heat pumps to maintain the temperature in the heated buffer tank based on some

setpoint or outdoor reset schedule.

Cooling operation might only be allowed when the temperature in the heated buffer tank is within some differential of the target temperature.

During summer the priority would likely switch to cooling. The only heating load might be domestic water heating (if present), or early morning warming of select spaces using low mass heat emitters.

VARIATIONS

Air-to-water heat pumps with variable speed “inverter” compressors are becoming more common. It’s possible to leverage their modulating capacity control with staging to improve the load tracking ability of a plant. Doing so is analogous to how modulation and staging are now commonly combined with boilers.

Continued on MH12

MODERN HYDRONICS WWW.HPACMAG.COM MH10 SPRING 2024

buffer tank temperature sensor (S2)

Chilled

buffer tank

entire system filled with antifreeze solution All piping and components conveying chilled water must be insulated and vapor sealed VS ∆P circulator VS ∆P circulator VS ∆P circulator Air separator Air/dirt magnetic particle separator

Heated

Fan-coil

Zone

Balancing valve

valve

Purge valve

Balancing

Purge valve

Zone valve

valve

isolation valves PRV PRV Heat pump 1

VS ∆P circulator Dirt & magnetic separator

feeder diverter valves

motorized ball valve Heat pump 2 Heat pump 3

feeder

Balancing valves Purging/

Fan-coil

Fluid

2-way

Fluid

HEAT PUMPS

Modern Hydronics

Figure 3. A multiple heat pump set up for simultaneous space heating and cooling.

Ampex Insulated Radiant Floor Heating Panel ®

alleguard.com1 877-470-9991

Amvic Insulat ed PE X panel is designed to pr ovide the most cost -effec tive installation and per formance for hydronic radiant floor heating syst ems for new cons truction and r enovat ions. Ideal for basement s, car ga rages, slab-on- grade areas and exterior use for snow and ice melt applicat ions on driveways and walk ways.

fast er installation & optimum per formance design

Easier,

Save time, labour and money

ties

Walk in installation No st aples or

required

Superior tube insulation

multiple PEX

diameters

Integrated vapor barrier Available for residential and commercial Suitable for

tube

30 & 45 PSI

R12, R14 & R16 R10

Easyto assemble

Also available in

A heat pump with a variable speed compressor can reduce its capacity to about one-third of its rated output. If two were combined the overall turn-down ratio would be approximately 6:1.

This range of capacity modulation can eliminate the need for buffer tanks. Hydraulic separators would take their place, as shown above in Figure 4 System controls would monitor the supply on both the heating and cooling distribution system and operate the heat pumps based on load priority of the desired “target” supply water temp.

Another option is based on two threeway diverter valves at each heat pump,

but those valves must have three position settings: one to connect to the heating risers; another for connecting to the cooling risers; and a third that blocks flow through the heat pump when it’s off. This approach eliminates the need for a two-way motorized ball valve to block flow through a heat pump that is off.

Most three-way ball valves could provide the necessary positions. What’s missing (at least from my inquiries) is a three-position actuator. If anyone knows of a source I’m all ears.

The piping concepts shown can also be applied to water-to-water heat pumps sourced from a common earth loop. It

would also be possible to combine heat pumps with one or more boilers.

The market for heat pumps as alternatives to fossil fuel boilers is growing rapidly. Designers need to have concepts for deploying multiple heat pumps ready to roll. <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit hydronicpros.com).

MODERN HYDRONICS WWW.HPACMAG.COM MH12 SPRING 2024

HEAT PUMPS

system filled with antifreeze solution

piping and components conveying chilled water must be insulated and vapor sealed

∆P circulator hydraulic separator PRV

VS ∆P circulator entire

All

VS

Balancing valves

Purging/

isolation valves Heat pump 1 diverter valves

∆P

2-way motorized ball valve

Heat pump 2 VS

circulator

temperature

VS ∆P circulator supply temperature sensor supply

sensor hydraulic separator

Fluid feeder

Modern Hydronics

Figure 4. Heat pumps with inverter compressors could eliminate the need for buffer tanks.

P-K SOLIS

P-K SOLIS™ Capabilities

-1500-3000 MBTU

-Up to 96% Thermal Eiciency

-10:1 Mechanical Turndown

-Zero Clearance Capable for Side-by-Side Installation

-Narrow Footprint Fits Through Standard 36” Doorway

Our proprietary NURO® Touchscreen Control System is equipped standard on all SOLIS boilers. Designed to maximize boiler efficiency, the NURO utilizes the most advanced technology available.

Patterson-Kelley, LLC

877.728.5351

www.pattersonkelley.com

OPERATIONAL NET ZERO

Carmichael Engineering’s new branch office provides a template for future projects.

BY DOUG PICKLYK

From modest beginnings as a Montreal-based plumbing and heating business, over the past 100 years the family-owned Carmichael Engineering company has embraced an adventurous entrepreneurial spirit and developed into a nationwide commercial, industrial and institutional HVAC service, maintenance and designbuild contracting organization.

Founded by Ray Carmichael Sr. in 1922, today the company is led by Carmichaels’ grandson, Ray Jr., and has 23 branches and over 700 employees across the country.

In 2022 the business celebrated its centennial, while at the same time it was undertaking an ambitious project—designing and overseeing a ‘smart’ operational net zero building to serve as the new branch office for its Belleville, Ontario location.

WALK THEIR TALK

Carmichael made its name in service and maintenance and added Building Automation, Energy Services and DesignBuild divisions over the years. Although the company performed energy projects for clients, designing the new branch was their opportunity to walk the talk.

“We’ve been preaching this is the way to go,” says Carmichael’s Eric Rockarts, “Now we had to put our money where our mouth is by developing a building for our own team.” Rockarts, a 30-year employee with the company, launched the Belleville location in 1998 and served as branch manager for 24 years. He formally retired in June 2022, and then re -

MODERN HYDRONICS WWW.HPACMAG.COM MH14 SPRING 2024

PHOTO: DOUG PICKLYK

PROJECT

PHOTO COURTESY CARMICHAEL ENGINEERING

The two 20-ton heat pump air-cooled chillers provide heating and cooling.

The new Carmichael Engineering branch in Belleville, Ont. has been designed to generate as much energy as it consumes in a calendar year.

PHOTO: SEAN HAMMOND

The building has enough solar to generate 125 kW of energy.

joined as part of the Engineering and Project Management group.

The goal for the new office was an energy efficient building that would produce as much energy using solar panels as it would consume in a calendar year with almost no reliance on carbon-burning fuels. And through its own building automation team it will be able to monitor and optimize the building’s operations. The project was a true team effort.

MECHANICAL SYSTEM

The new branch is around 22,000 sq. ft. in total, with Carmichael occupying 4,000 sq. ft. of office space in the front along with 6,000 sq. ft. of warehouse, and the building has two additional tenant spaces available for lease.

The warehouse and tenant section of the building is made up of pre-formed, pre-insulated, wall panels, and a double roof with about nine inches of insulation

and materials. The south facing office space has well-insulated walls, a lower roof surface and tinted high-efficiency double paned windows, all providing a tight building envelope.

Rockarts explains how the project’s mechanical design evolved over time.

“We wanted to add solar panels, so the energy group ran the models, balancing cost versus achieving the goal of operational net zero.”

The solar installer was able to accommodate all the panels on the building’s high roof, with the ability to generate 125 Kw of electrical energy. All the modeling is based on that capability.

Initial design options included using geothermal or VRF, but ultimately the team selected LG air-cooled inverter scroll heat pump chillers for an air-to-water system, the first installation of these units in Canada.

They installed two 20-ton chillers on the lower roof to provide heating and cooling. Using a glycol/water mix to prevent freezing, four pipes lead from the chillers into the building to satisfy either the hot water or chilled water buffer tank. The hot water tank is maintained at

Continued on MH16

MODERN HYDRONICS WWW.HPACMAG.COM MH15 SPRING 2024 Modern Hydronics

A DIFFERENCE MAKER Learn more at Lochinvar.com Raising the bar on energy efficiency and simplifying installation and operation, the Veritus Heat Pump Water Heater (HPWH) serves as a sustainable option providing energy savings and reliable domestic hot water for a wide variety of commercial applications. HPAC_AquaTech_Feb24.indd 1 2024-02-07 1:38 PM

Glycol loop from heat pumps to buffer tanks.

and the

When there are calls for heating or cooling in the building, the system draws from the tanks to a heat exchanger, where the distribution system for the occupied spaces is then fed a water-only supply of hot or cool water.

As Rockarts explains, “In January both chiller units would be in heating mode, and then come the shoulder seasons we can have chilled water and hot water working simultaneously. And, of course, cool water in the summer.”

A back-up gas-fired Lochinvar boiler is in place for supplemental heating if required, and it will only kick in below -15C.

HEATING/COOLING DISTRIBUTION

The system is designed using low temperature in floor radiant as the primary heating and hot water fan coils for zone tempering. The fan coils are also equipped with chilled water coils for water-based cooling.

Using all ECM-driven fan coils, it is designed with heating coils downstream from cooling coils, so they can provide dedicated dehumidification.

“We’re controlling plus or minus 0.1F of set point in all spaces,” says Rockarts. The systems are all controlled by Belimo electronic valves, and the building’s mechanical system is fully automated courtesy of Carmichael’s building automation system design using ABB-based controls.

“We also have Belimo Btu meters on everything,” notes Rockarts. “We know exactly where all of our energy is at, at all times.” As the generator of solar electrical power, plus heating and cooling energy, they can monitor all the energy heading to the tenant spaces to charge for consumption.

Because it’s an industrial site the demand for domestic hot water is very low, so instead of incorporating DHW off the heating water loop the team is using a 40-gallon domestic hot water electric heater to manage demand.

VENTILATION

The building operates a dedicated outdoor air system with ERV. “We wanted to precondition the outside air before it hit the fan coils, so it’s got an SCR controlled electric pre-heater on the incoming air to take the chill off, but then it has post heating or cooling from the heat pump chillers,” explains Rockarts.

The system design provides preconditioned constant ventilation with CO2 reset, whereby for all zones it calculates average CO2 and decides if it needs to increase fresh air or decrease to a minimum rate. “When there is no one in the office it will go down to a minimum ventilation rate to bring fresh air in, so the building starts fresh every day,” says Rockarts.

GRAND OPENING

The basic build was completed in June 2023 followed by commissioning. The BAS system operations are monitored by the company’s secure cloud-based Performance Analyzer platform. It was the joint forces of the Carmichael Divisions [DesignBuild, Engineering & Project Management, Building Automation and the Energy Group] that brought the project to life.

The Belleville team moved into the building in mid-October and celebrated a grand opening on November 21 st with the Mayor participating in the ribbon cutting along with Maddie Carmichael, the Vancouver branch manager and the fourth generation of the family to continue the legacy.

“As part of the new generation of Carmichael, we’re aiming to pioneer solutions that not only elevate the operation, efficiency and comfort of indoor spaces, but to pave the future for a greener world for generations to come,” said Carmichael, adding, “This building, in itself, represents the importance of, and our commitment to, sustainability.”

The Belleville branch is creating a template for future Carmichael facilities, and its Ottawa division is already working on a new space. <>

MODERN HYDRONICS WWW.HPACMAG.COM MH16 SPRING 2024

114F (45.6C)

chilled water at 44F (6.7C).

PROJECT

The entire building has in floor heating.

Buffer tanks in the mechanical room, one for hot one for cold.

PHOTO: DOUG PICKLYK

Modern Hydronics

PHOTO COURTESY CARMICHAEL ENGINEERING

CANADA’S HYDRONIC INSTALLATION CONTEST

WIN ONE OF THREE $2000 BUYING SPREES FROM EMCO!

Get your cameras ready. Be a part of Canada’s hydronic installation contest. Proud of your work? Better than the rest? It’s time to bring it on!

THERE WILL BE A WINNER IN EACH CATEGORY: COMMERICAL, RESIDENTIAL NEW-BUILD & RESIDENTIAL RETROFIT

ENTRY IS SIMPLE - send us pics of your installation. Include a brief description of the particular challenges that you faced with this installation and how you overcame the obstacles. Submissions are limited to one per contractor. Deadline to enter is July 31, 2024. All submissions will be shown at the Modern Hydronics Summit 2024. The three winners will also be announced by John Siegenthaler at the Summit. In addition to having your winning entry shared across our social media channels you’ll also be interviewed by HPAC’s editor and featured on the cover of the October edition of HPAC –

SEND ENTRIES OR QUESTIONS TO DPICKLYK@HPACMAG.COM WITH THE SUBJECT LINE “SWEET HEAT CONTEST”

BY...

SPONSORED

THE MAINTENANCE PLAN

Ensure long-term customer satisfaction by offering service plans with every installation.

BY MATHEW POTTINS

Hydronic systems are often praised for their efficiency and comfort. As we all know, these systems are an intricate network of components piped together to create a seamless heating experience in homes and commercial buildings.

However, their complexity can pose challenges for homeowners and contractors when it comes to maintenance and upkeep. A new system installation shouldn’t be a one and done with that customer.

In the world of HVAC services, unlike some other industries, contractors face a unique opportunity to not only retain customers but also expand their business. They can do this by offering comprehensive maintenance and service plans tailored specifically for the hydronic systems they install.

It’s understood, but it’s also important

to reflect on the many key components of a hydronic system and to educate your customer on the different parts and their proper servicing requirments:

Boilers or heat pumps: these are the heart of the system, responsible for heating the water or fluid before circulation and a source requiring regular inspection.

Pumps and valves: these components facilitate the movement of the heated liquid throughout the system, ensuring even distribution to the radiators, underfloor heating or other heat exchange points. Are they doing their job? (Let’s not get into the zoning with pumps or valves argument right now)

Radiators or heat emitters: these are the key devices that release heat into the occupied spaces. You might think radiators are as easy as install and walk away, but once you’ve introduced thermostatic radiator valves and auto air bleeders things start to change, homeowner education is always welcome. Or maybe you’re installing air handlers or fan coils which now have electronics involved.

Expansion tanks, makeup water

feeds and pressure regulators: these essentials are vital for maintaining proper pressure levels within the system and preventing damage.

Piping and insulation: the network of pipes through which the heated water travels, often concealed within walls or floors, require periodic checks for leaks, corrosion, or insulation integrity.

Condensate kits: providing a condensate neutralization kit and keeping the neutralizer fresh to ensure there is no corrosion in the plumbing and following local codes.

These are six major elements of a hydronics system that need to be maintained, and the average homeowner doesn’t want that servicing burden. So, let’s dig into how to make more money in hydronics while keeping your customer happy for the next 20-plus years.

CUSTOM PLANS

Every hydronic system can be a little unique, and this can be overwhelming to the common homeowner, which also means service plans can be specifically tailored to the heating system installed

ISTOCK/GETTY IMAGES PLUS MODERN HYDRONICS WWW.HPACMAG.COM MH18 SPRING 2024 BUSINESS

in each and every location.

Regular maintenance not only keeps your company fresh in the face of the homeowner. but it allows you to keep that system running smoothly for the long haul.

I recently installed a boiler with an air handler and in-floor heating in my house, and the first thing my wife said was: “This looks pretty complicated, what if something goes wrong?”

I replied: “I know a guy.”

OPPORTUNITY

There is no question that maintenance and service plans will benefit your customers, likely extending the life of their systems. And of course providing service plans offers benefits to your business as well:

Predictable revenue stream: service plans provide a consistent source of income, ensuring a steady cash flow.

Customer loyalty: by offering regular

service, you build trust and loyalty with end users, increasing the likelihood of repeat business and referrals.

Reduced emergency calls: regular maintenance helps identify and address potential issues before they escalate, reducing the number of emergency service calls for your team (how about we sleep on the weekends).

Extended system lifespan: proactive maintenance leads to a longer lifespan for system components, reducing the constant replacement of parts.

Market differentiation: contractors offering comprehensive service plans stand out in the market, attracting homeowners who prioritize the long-term health of their hydronic systems.

Upselling opportunities: during routine service visits, contractors can iden tify opportunities for system upgrades or improvements based on customer feed back, leading to additional sales (I know

we are a humble trade, but you have permission to do this).

BUSINESS VALUE

The addition of a comprehensive service plan with scheduled visits that you initiate by reaching out to customers annually, will not only keep your customer happy, safe, and lower their stress levels, but it will give you (the contractor) the opportunity to hold on to that customer.

And that’s what really increases the value of your company.

Mathew Pottins has worked with HVAC manufacturers and suppliers for over a decade, and his passion is in growing the industry. He runs Laylan Hydronics and HVAC Sales

MODERN HYDRONICS MH19 SPRING 2024 Modern Hydronics

<>

• 5,000 TIES PER CHARGE • HALF A SECOND PER TIE SAVE TIME SAVE MONEY WITH A ® OnSite_MaxUSA_Dec23.indd 1 2023-11-28 10:08 AM

ELECTRIC BOILERS: WHEN AND WHERE?

John Seigenthaler joins HPAC to talk about how electric boilers work and where they make sense.

BY HPAC STAFF

The latest installment of HPAC magazine’s 30 Mechanical Minutes, the free webinar series, took place January 31st and focused on electric boilers. In this episode, HPAC editor Doug Picklyk was joined by regular contributor and hydronics expert John Siegenthaler to discuss how electric boilers work, their advantages and drawbacks and some installation considerations.

This edition of 30 Mechanical Minutes was sponsored by Conforto, a division of Granby Industries.

ELECTRIFICATION

To begin, the discussion opened with comments about the recent AHR Expo that had taken place in Chicago just one week prior. The trend towards decarbonization and electrification was very evident on the trade show floor, with both

the host and Siegenthaler noting the large presence of new air-to-water heat pump demonstrations. But they both also commented on the growing number of electric boilers being shown, particularly products for the commercial segment of the industry. “Electric boilers were a hot topic at AHR Expo this year, and thus a great time for us to be talking about them here on 30 Mechanical Minutes,” said Picklyk.

In explaining just exactly how the technology works, Siegenthaler began by describing the electric boiler is a “relatively simple device.”

The units convert electricity through some type of a resistance element, similar to the elements in an electric water heater. “Typically, a residential electric boiler has a small pressure vessel, and there could be anywhere from one to as many as four heating elements,” says Siegenthaler. “While some of the large commercial electric boilers have more—I actually looked at one at the show that had, I believe, 15 different elements.”

All of these elements are controlled, and he acknowledged that in the past they were just turned on and off with con -

tactors, but today most of the electric boilers control the current that goes through the element, and they do that with solid state devices.

“So an electric boiler, unlike a fossil fuel boiler, can basically regulate heat output anywhere from 0 all the way to 100%,” says Siegenthaler.

He also explained how the controls within these boilers have progressed, some can not only maintain a pre-set boiler outlet temperature, even though the inlet temperature varies, they can also control based on outdoor reset, so as it gets warmer outside the supply temperature is reduced.

The devices can also be relatively small compared to fossil fuel boilers because they don’t need to accommodate the combustion chamber and gas assemblies.

PANEL CONSIDERATION

Something to beware of with electric boilers is the wattage that is being converted to heat. Siegenthaler provided a simple equation to convert kilowatts (kW) to Btu/h: just multiply kW by 3,413. For example, a 15-kW boiler is just over 51,000 Btu/h.

MODERN HYDRONICS WWW.HPACMAG.COM MH20 SPRING 2024

30 MECHANICAL MINUTES

Doug Picklyk (left) editor of HPAC and hydronics expert John Siegenthaler discussed what applications are a great fit for electric boilers. The complete video is available at youtube.com/@hpacmag.

“That would be high enough capacity to heat a house, and it’ll be served by a single phase, 240-volt circuit, and that would require almost 63 amps,” he says.

This is why the circuit panel is one of the very first things a contractor will want to check, especially in a retrofit situation where some older houses, especially those already using fossil fuel heating systems, might have 100- or 150-amp services.

“I don’t want to say that you can’t install an electric boiler with 100-amp service, but if that panel is pretty much filled up with breakers, you’d probably reach the limit.”

For new construction, using an electric boiler with enough capacity to heat a 2,500 sq. ft. modern house will require at least a 200-amp service, and that’s especially true if an electric vehicle charger is being added to the home.

TYPICAL USES

Electric boilers can be used for any hydronic distribution system that you would supply with a gas-fired or oil-fired boiler including radiant floors, panel rads, hydronic baseboard, etc. And an advantage of the electric boiler is no combustion, so there’s no issues with fuel supply or venting, and it doesn’t generate carbon monoxide (CO), so that’s one safety concern that’s eliminated.

In addition, Siegenthaler says that short cycling is really is not an issue at all with an electric boiler, plus they make very little sound. “You may hear a very small amount of sound coming from it, but that might be just the water moving through it.”

One of the unique potential advantages of an electric boiler over a fossil fuel boiler is the ability to coordinate their operation with time-of-use utility rates.

“You could easily set up controls that would allow an electric boiler to operate under the lowest-cost electricity,” suggest Siegenthaler.

Also, an electric boiler can take advan-