Proven Reliability

Superior Efficiency

Zero Ozone Depletion Potential (ODP)

At Napoleon®, our systems are optimized for R410A refrigerant, ensuring outstanding performance in every season —whether cooling in summer or staying warm during the harshest Canadian winters. With unmatched reliability and e ciency, Napoleon keeps your home comfortable while supporting sustainability.

DISCOVER THE POWER OF R410A WITH NAPOLEON ®

12

HVAC

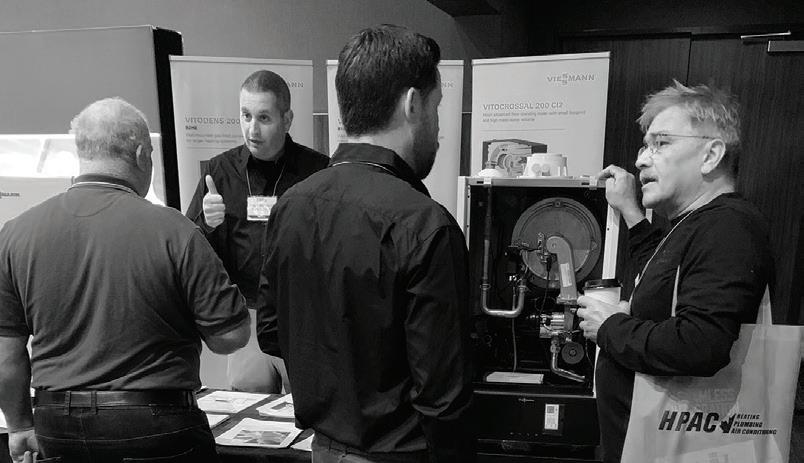

NEW REFRIGERANTS, NEW TOOLS, NEW TECHNIQUES

The introduction of A2L refrigerants will require some modifications to how HVAC techs get the job done.

By Ian McTeer

43 COVER STORY

HPAC MAGAZINE

100 YEARS OF REPORTING

Although the name has changed over the years, the role of following the news and being a source of information on new trends and technology in the Canadian plumbing, HVAC and refrigeration industy remains a constant.

By Doug Picklyk

45

PIPING

INSULATED PEX SPEEDS INSTALL

Two new Victoria-area schools in B.C. are being fed by a geothermal plant.

By Ali Sajjadi

48

BUSINESS

REPUTATION ISN'T ENOUGH

How to position your business for sale. By Matthew Birch

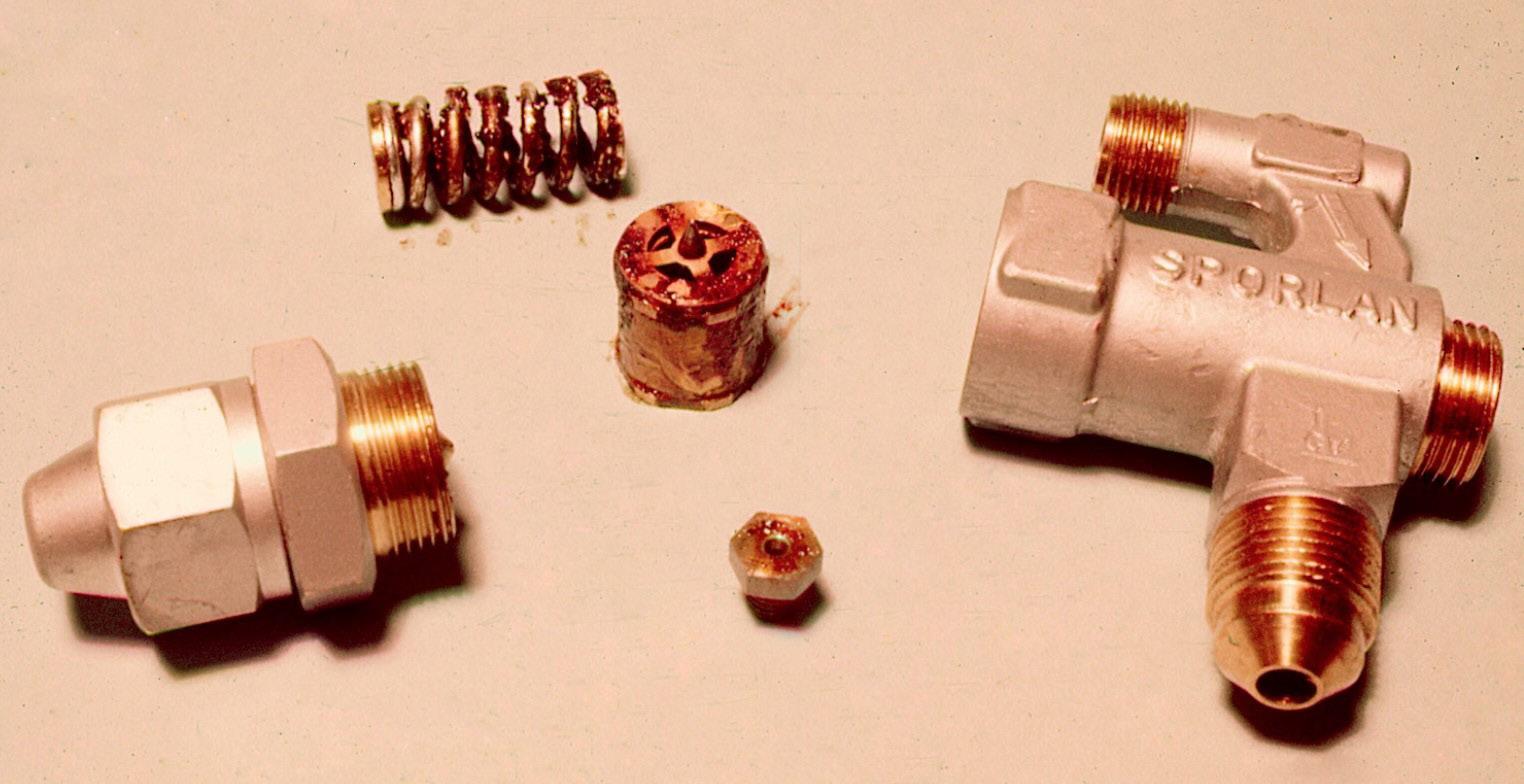

50 REFRIGERATION

OIL, THE COMPRESSOR'S LIFEBLOOD Monitor a compressor inside and out. By Dave

Demma

MH4

GLYCOL

WHAT'S THE DIFFERENCE

Exploring the changes that occur when antifreeze is added to the water in hydronic circuits

By John Siegenthaler

30 MECHANICAL MINUTES

GLYCOL AND HYDRONICS

Webinar highlights with John Siegenthaler sharing how antifreeze affects performance.

By Doug Picklyk

SNOWMELT

FROSTY THE SNOWMAN

Melting snow can be a delicate situation.

By Curtis Bennett

HAUNTED THEATRE RECEIVES MODERN UPGRADE

Historic site in downtown Vernon, B.C. retains its old-world charm while its steam heating systems gets a boost with networked controls.

By Dan Vastyan

HYBRID SOLUTION

A MIX OF OLD AND NEW

Making the case that new air-to-water heat pump systems can still work effectively and cost efficiently with older fuel-fired boiler systems that have remaining service life—even older cast-iron boilers.

By John Siegenthaler

“ Flexi-Rooter’s ClogChopper rips open a hole for the chain knocker to work. It’s a great product.”

Seth Mikulin • SureFlo Sewer & Drain

Flexi-Rooter ® featuring ClogChopper ® Cutters

Flexi-Rooter uses ClogChopper six-bladed cutters along with carbide and non-carbide-tipped chain cutters to break through the toughest clogs, scale and roots. The cutters then grind up the stubborn stoppages and scour the pipe walls clean.

The rotating shaft is 10 times faster than traditional shafts, yet easy to handle. It’s extremely exible for clearing 2" lines, yet strong enough to cut roots in 4" lines up to 75 feet long. Plus, the foot pedal leaves both hands free to guide it into the drain.

To learn more, visit www.drainbrain.com/Flexi-Rooter, or call the Drain Brains ® at 800-245-6200.

Visit us at MCEE Booth #2305

I HAVE A CHUCKLE EVERY TIME I'M SCROLLING THROUGH INSTAGRAM AND SEE MECHANICAL CONTRACTORS POKING FUN AT SPARKIES, those electricians who walk around construction sites like they own the place. But of course it's all in good humour, those aren't trade wars, those are just the trades having some fun.

Obviously, the latest version of trade wars to hit the news in early 2025 revolve around the tariffs being proposed by our neighbours to the south. The new American administration has proposed 25% across the board tariffs for goods and services crossing the border from Canada into the U.S. So what does that even mean for our plumbing, HVAC and refrigeration industries?

For companies who manufacture products in Canada and export to the U.S., these tariffs will have an immediate impact - making their products more expensive and possibly less competitive.

The greater fear for Canadians is the threat of retaliatory tariffs proposed by our own federal government, making the importing of plumbing and HVAC/R products more expensive.

Our industry associations have stepped up to raise awareness that plumbing and HVAC/R products and services are essential and should not be used as leverage in some form of trade war.

Martin Luymes, vice president of government and stakeholder relations at the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) made an appearance on Parliament Hill on January 31 to speak about the impact of these tariffs.

“While we understand the government may need to consider retaliatory measures, the HVAC/R industry’s products and services are too essential to be caught in the crossfire of trade disputes,” said Luymes. “At a time when Canadians are already struggling with the cost of living, adding tariffs to heating and cooling equipment would increase costs for Canadians on goods and services that are essential for Canadian families.”

Remember the supply chain challenges of only a few years ago when the pandemic, along with clogged shipping channels overseas, led to worldwide shortages of products? A trade battle could once again lead to companies having to scramble to source supplies from new locations.

The CEO of the Canadian Institute of Plumbing and Heating (CIPH), Satinder Chera, wrote to the government reminding them of these recent issues: “As an industry association that represents nearly 250 companies, many of whom operate on both sides of the border, we are concerned by the real possibility that escalation will challenge supply chains, not to mention inflationary pressures – two issues that had finally started to subside, after the global events of the last several years.”

As I write this, the U.S. has agreed to hold off on its 25% tariffs for 30 days, while Canada takes action on border security, steps that were already underway. Unlike plumbers poking fun at sparkies, this trade spat is not funny, and the best solution is keep aware and be prepared for any bizarre actions carried out by the guy down south who's acting like he own's the place.

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

DIGITAL Jack Burton (416) 510-6809

EDITOR jburton@hpacmag.com

ASSOCIATE David Skene (416) 510-6884

PUBLISHER dskene@hpacmag.com

NATIONAL Amanda McCracken (647) 628-3610

ACCOUNTS amccracken@hpacmag.com

ACCOUNT Kim Rossiter (416) 510-6794

COORDINATOR krossiter@hpacmag.com

AUDIENCE DEVELOPMENT Urszula Grzyb (416) 510-5180

MANAGER ugrzyb@annexbusinessmedia.com

MEDIA Emily Sun DESIGNER esun@annexbusinessmedia.com

PUBLISHER Peter Leonard (416) 510-6847 pleonard@hpacmag.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 6 times per year by Annex Business Media. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2025 by Annex Business Media may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.88 (plus tax) CDN; United States: $114.24 CDN; Elsewhere: $125.46 CDN; Single copy Canada: $8.00 CDN. Heating Plumbing Air Conditioning (establish 1925) is published 6 times per year by Annex Business Media. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-510-5113, Fax: 416-510-6875; E-mail: apotal@ annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Business Media, their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

To raise greater awareness of cross connections and to educate water industry representatives in the field, the Western Canada Section of the American Water Works Association (WCS AWWA) Cross Connection Control (CCC) committee first launched its Bad and Ugly cross connections contest in 2014.

The contest encourages cross connection testers and inspectors from across the country to send in photos and explanations of the bad and ugly cross connections they witness.

The winners of the 2024 Bad and Ugly contest are Logan Skagen, back flow prevention tester with A+E Air Plumbing and Heating in Medicine Hat, AB (Tester Award) and Dylan Gerlack, manager CCC - EPCOR Water Services in Edmonton (Inspector Award).

As Gerlack explains in his contest submission, part of EPCOR Edmonton’s Cross Connection Control Program (CCCP) requires customers who need to access water in hydrants to apply for a hydrant permit and include pictures of the air gap (AG) that is permanently fixed to the water hauler or the vessel they intend to fill up.

An AG is the most effective and reliable form of preventing water from reversing flow and creating a potentially hazardous condition in the water distribution system that is feeding water to the hydrant. “The risk associated with using an AG to prevent backflow is that they are vulnerable to bypass arrangements that can nullify its effectiveness, as was the case with the picture submitted in 2024 for approval.” (photo above)

“What had previously been an approved AG of six inches the previous year had a section of rubber hose clamped to the pipe, negating the air separation between the fill pipe and the tank.”

“After a discussion with this customer, they removed the rubber section of pipe along with the clear garden hose that was submerged in the tank and re-submitted pictures for approval.”

Skagen won his award for noticing a potential cross connection on a potable water line while upgrading water lines in a mechanical room. “On one half-inch branch line there was an eyewash station and just a few feet away, on the same half-inch line, were multiple fill lines for chemical tanks.”

He noticed that one of the chemicals was hydrochloric acid. “Upon closer inspection I found that there were hoses attached, presumably to stop spillage, to the tank fill lines. Not only were these hoses too long to provide a sufficient air gap between each outlet and tank, but the hoses were long enough to go directly into the tanks and potentially become submerged in the chemicals.”

Skagen noted that if one of the hoses became submerged in a chemical tank and the eyewash station, immediately downstream from the chemical tanks, was turned on, a Venturi effect could be created from the sudden pressure drop and the chemical would be drawn into the eyewash station.

“To correct this potential cross connection, I separated the water lines, removed the hoses and installed both an RP [reduced pressure] and DCVA [double check valve assembly] device to isolate the tank fill.”

Both winners were recognized for their entries, and a new test kit was provided courtesy of Zurn Canada. wcsawwa.net

A new collaborative report, entitled Decarbonizing Canada’s Commercial Buildings: The Owner & Investor Perspective has been produced by the Canada Green Building Council, REALPAC and the PLACE Centre at the Smart Prosperity Institute. The report focuses on the barriers to decarbonization across Canada’s commercial buildings and is aimed at increasing collaboration among the utilities, real estate owners/developers, financial institutions and all levels of government. Ten actionable recommendations:

• Increase incentives and knowledge sharing around decarbonization technologies.

• Provide long-term low fixed-rate debt financing options for low carbon construction and retrofits.

• Recognize decarbonization investments in property valuations.

• Provide tax relief and incentives for low and net zero carbon buildings.

• Grow capacity and conservation across electricity systems and continue to decarbonize existing electricity generation infrastructure.

• Provide electricity users with choice for electricity procurement.

• Increase decarbonization leadership, knowledge and skills across the industry.

• Ensure building owners and investors have access to whole building data.

• Harmonize standards across Canada.

• Create stronger incentives for decarbonization.

The report identifies the barriers of technology, capital, valuation, energy, people and data standards and disclosure as current obstacles that require urgent action from all stakeholders to meet decarbonization goals. decarbonizebuildings.ca

short-term business boost these programs provide.”

Efficiency Canada's new report: What Canada Can do to Support Residential Decarbonization — Policy Perspectives from Contractors, places its focus on three areas: incentives and financing; consumer awareness; and workforce development. The authors interviewed contractors from different sectors and geographies. On the topic of government incentives: “Nearly every HVAC participant pointed out that start-stop programs disrupt their business models, complicate operations, and leave them with stranded inventory when programs end abruptly, despite the

One potential remedy is to shift incentives to contractors, not homeowners, or upstream to distributors and manufacturers, coupled with performance standards.

Raising consumer awareness to drive demand is recommended, encouraging consumer education campaigns and policies like energy labelling for homes.

The report also notes support for programs that require manufacturer-specified installation and commissioning standards for every install. Respondents encourage accessible training resources and policies that promote employersponsored on-the-job training programs for continuous learning. efficiencycanada.org

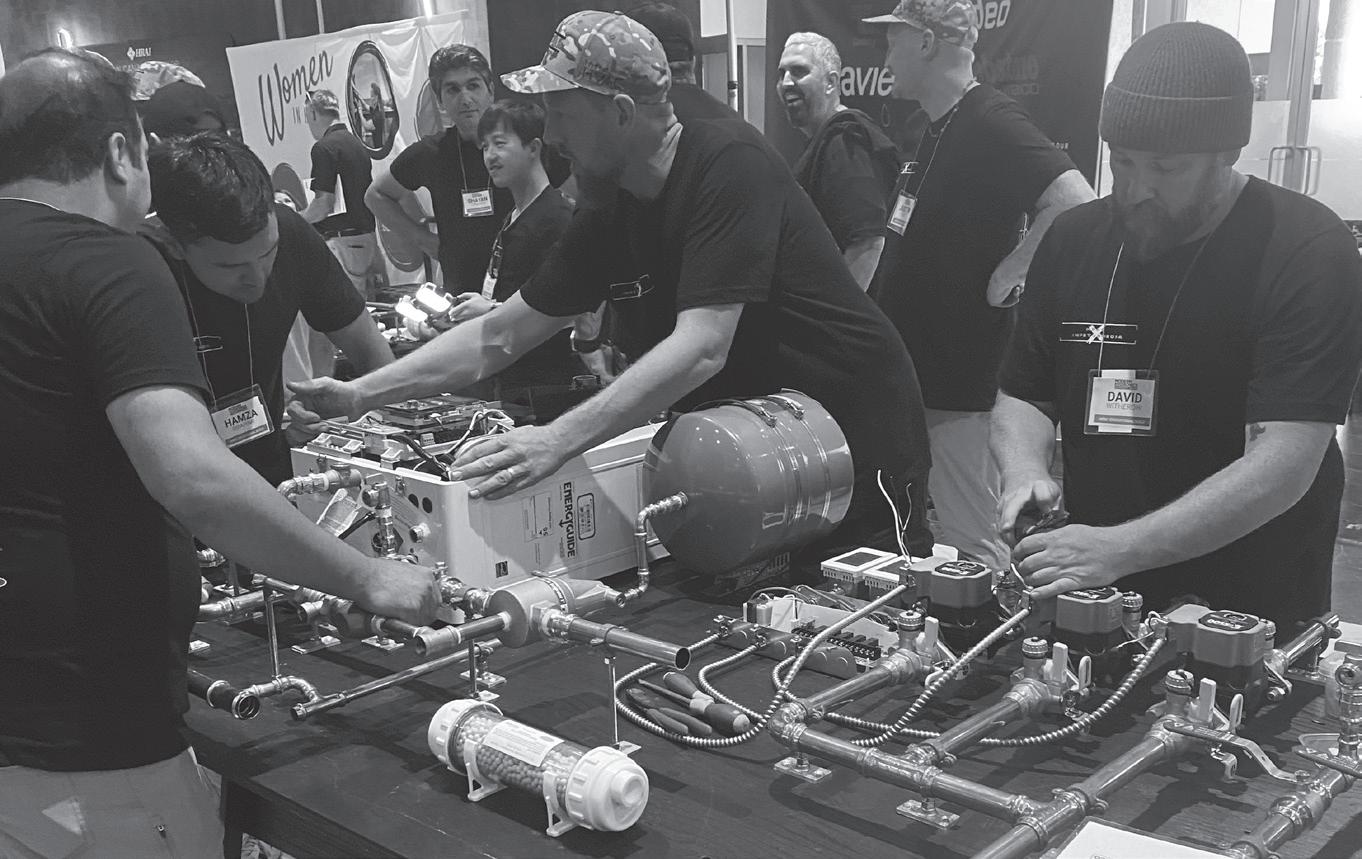

The introduction of A2L refrigerants into the market will require some modifications to how HVAC techs get the job done. BY

IAN McTEER

As the clock struck midnight on January 1, 2025, a significant transformation took place in the residential air conditioning and heat pump industry in the U.S. Manufacturers must now adopt lower global warming potential (GWP) A2L refrigerants to align with stringent environmental regulations and sustainability goals.

To date, large volume residential manufacturers such as Lennox, Trane and Carrier have opted to use R-454B, while Daiken/Amana/Goodman will utilize R-32. These new refrigerants, characterized by their reduced impact on global warming, will undoubtedly reshape the universe of HVAC systems. However, this transition is not merely about substituting old refrigerants with new ones. It necessitates an evolution in tools, techniques and safety protocols, prompting technicians and industry professionals to adapt to the changing dynamics.

This article delves into the implications of this shift, exploring the benefits and challenges posed by the introduction of A2L refrigerants and what it means for the future of residential cooling and heating solutions.

Yes, it is true, the latest lower GWP refrigerants are mildly flammable. At the same time, it is important to consider the lower flammability limit (LFL) of these A2L refrigerants. LFL is the minimum concentration of any refrigerant that is capable of propagating a flame

under specific test criteria. Since every flammable gas requires oxygen to burn, too little gas or too much gas (upper flammability limit), although mixed with oxygen, will not burn.

For example, R-32 has an LFL of at least 14% in air, any less gas and the lean mixture will not ignite. The upper limit is 31% in air, any additional gas (rich mixture) will not ignite. Only mixtures between 14% and 31% can ignite. The LFL of R-454B is 11.3% by volume in air, its UFL is 23.6%. By contrast, natural gas (a hydrocarbon) burns between 5% LFL and 15% UFL.

Thus, a higher LFL means a higher concentration is necessary to create a flammable situation. Another important related flammability metric is the Minimum Ignition Energy (MIE). These values indicate the minimum energy required to ignite a flammable mixture of

refrigerant with air under specific conditions.

For example, R-32 has an MIE of approximately 8.0 millijoules (mJ) whereas R-454B is approximately 10 mJ. By comparison, natural gas MIE is about 0.25 mJ, even gasoline is about 0.24 mJ.

Both R-32 and R-454B have higher MIE values compared to A2 and A3 refrigerants. Remember, A2Ls do not contain hydrocarbons. R-32 is a pure HFC while R-454B is a zeotropic blend of two refrigerants: 68.9% R-32 and 31.1% of R-1234yf.

The lower flammability limits of A2Ls are roughly 10 times higher than that of an A2 such as R-152a or any A3 such as R-290 or R-600a. Thus, something like 10 times the amount of liquefied gas would have to leak from a cylinder in order to create a flammable mixture in air.

Continued on p14

Compresseur Inverter et moteur à vitesse variable

Capacité de chauffage/refroidissement jusqu’à 11 600 Btu/h

Polyvalence d’installation : dans le haut ou le bas du mur

Facilité d’installation et d’entretien

Télécommande (de série) et thermostat mural (facultatif)

Moteurs 115 V et 230 V monophasés en stock

Minimum Ignition Energy values are in the order of 100 to 1,000 times higher than A2 and A3 gases. Isobutane and other A3s can be ignited by a static discharge, whereas A2Ls typically will ignite only in the presence of an open flame or active fire. And a lower burning velocity (BV less than 10 cm/sec) means the potential for an explosion or flash fire is much less likely.

Installation processes related to equipment containing A2Ls are nearly identical to industry standards in use today. However, A2L refrigerants and their unique, but not necessarily burdensome, characteristics will require contractors and individual technicians to invest in several new tools and to implement some upgraded techniques into daily routines.

Figure 1 (right) is a chart comparing tools, equipment and practices used with an A1 refrigerant (R-410A) to those needed with an A2L (R-32 or R-454B).

There are many tool manufacturers ready to supply dependable A2L products today. While I am not recommending any particular brand, it is worth it to purchase high quality equipment thus ensuring reliable performance over the long run. A NAVAC recovery machine, for example (Figure 2), is A2L compliant by virtue of its inherent protection features: sparkless design; DC brushless motor; soft contact power switches; covered connections for all electrical terminations; and internal fan included.

The Yellow Jacket A2L complaint vacuum pump (Figure 3) also has important features allowing for the unit to operate in close proximity to the A2L installation: high torque, brushless DC motor; lighter than AC motor pumps; non sparking switch; oil reservoir port doubles as a pump exhaust – threaded to attach garden hose exhausting to a remote location; locking power cord connection

Requirement R410A A2L Comments

Properly remove refrigerant following applicable codes

Purge system with nitrogen

Cut out defective part(s)

Torch out defective part(s)

Required Required For A2L, recovery machine must be A2L certified

Best Practice Required Typically, at 15 Cu Ft/hr for 2 minutes ... refer to manufacturer charts

Best Practice Best Practice Refer to equipment manufacturers instructions

Customary

Hand Tools Customary

Customary Recover to O psig then A2L system must be purged at 15 Cu Ft/hr + time factor from manufacturer charts.

Customary

LH Tank Adaptor Not Required Required Hoses with LH thread are available

Fire Extinguisher

Recommended Required Chemical compatible Dry Powder/CO2

Vacuum Pump Customary

Leak Detector Customary

Customary Switch located away from work zone: vented away from work zone Recommend A2L compliant pump, vent away from work zone

Required Must be A2L Certified

Recovery Machine Customary Required Must be A2L Certified

Recovery Cylinder Customary Required Flammable marking, LH thread

Figure 1

to prevent arcing due to accidental disconnection.

While it is not required to use an A2L compliant pump if the unshielded switch and vent are away from the work area (10 feet is suggested), a compliant pump allows the use of a short vacuum hose that should help to uncomplicate the dehydration and evacuation procedure. Leak detectors must also be A2L compliant, many updated units are already on the market.

Electronic gauge manifolds available

from a variety of manufacturers may or may not be upgradable to deal with A2L refrigerant data. Be sure to check with your manufacturer for A2L updates.

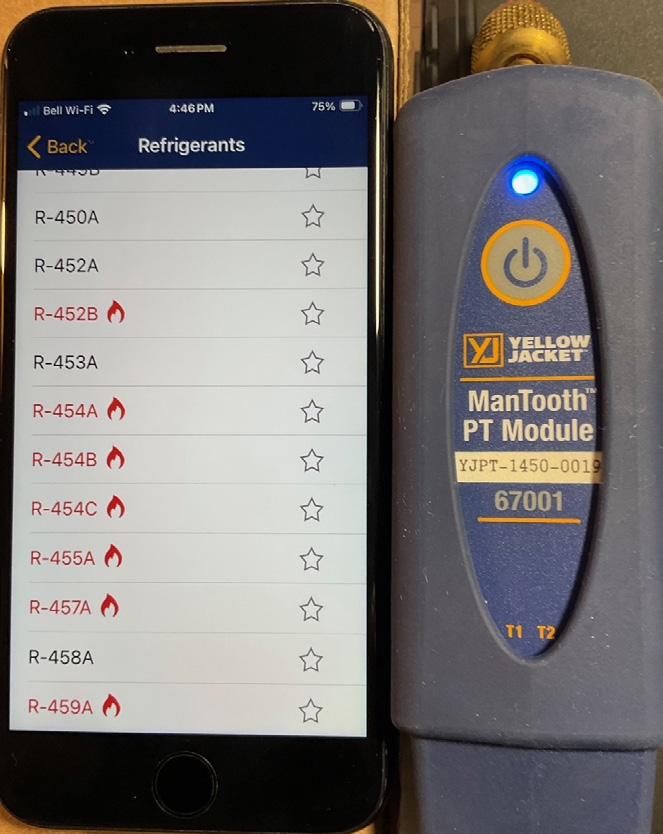

I checked my Mantooth gauge purchased 10 years ago and discovered the supporting app has been updated with data for a variety of A2L refrigerants. (Figure 4, page 16).

While not essentially new, as industry professionals have been working with sealed systems all along, A2L practices will require a heighted attention to detail. Technicians will be faced with servicing equipment containing R-22 with mineral oil to R-410A and A2L systems containing POE oil.

While traditional gauge sets will still be useful at initial system commissioning and after a system repair, with today’s technological alternatives, a bulky gauge set may not always be the best

choice for accurate charging results.

Many experts are advising against connecting a gauge set every time a low system refrigerant charge is suspected.

Gary McCreadie, owner of the HVAC Know It All website, posted a podcast interview with engineer Jim Bergmann about how to verify system charge without using the traditional invasive method of first “slapping on the gauges.”

When parameters such as superheat/subcool and discharge line temperature ring true, then the technician may decide to avoid invasive testing thus avoiding some loss of charge and potential system contamination from the residue of “stuff” leftover in hoses.

Should an evaluation of the system charge be necessary, consider using low loss wireless probes now widely available (Figure 5, page 16).

Yes, I know, working with an app can be problematic, especially outdoors in the bright sunshine. Some systems,

equipped with pressure transducers, allow technicians to read system pressures using a DC voltmeter directly from a control board. Other units might include a communicating display within the unit or permit remote reporting that send data directly to the servicer.

Using digital data collection means the refrigeration system will remain unaffected unless absolutely necessary.

As always, due diligence according to manufacturer’s installation instructions and industry standards are paramount to achieving successful A2L equipment installations and efficient servicing.

While I am all in for safety, that includes protection of the public and HVAC/R personnel, I should note that many residential applications have an extremely flammable A3 quasi refrigerant (namely natural gas/methane [R50] or propane [R-290]) already flowing to appliances for decades using a simple chemical odorant as a mitigation strategy. Nevertheless, companies will be required to ensure the conditioned space is large enough and contains enough air to maintain the indoor atmosphere below the lower flammability limit (LFL) should the entire system charge leak into the conditioned space. Thus, exhibiting an abundance of

Continued on p16

Combining the reliability of elastomeric insulation and the durability of a polymeric coating to provide the only coated line set available in Canada that meets the current CAN/ULC S102.2 requirement for smoke and flame and backed with an industry-leading 5-year UV warranty.

Approaching our 7th decade in Canada, our products are a part of everyday life and our company is proud to support communities nation-wide. From hospitals that heal us to schools that enlighten us, generations of Canadians continue to rely on their domestic partner for quality, integrity and a service that is distinctly Canadian.

caution, manufacturer’s instructions will identify the maximum allowable charge for every AHRI matched system installation. These charge values are not universal and will vary by application. One HVAC industry standard, the updated version of UL60335-2-40, provides the safety requirements for household and similar A2L charged appliances, including air conditioners, heat pumps, and dehumidifiers. This standard specifies the necessary ventilation measures to ensure safety in the event of a refrigerant leak. The standard places charge limitations on indoor spaces and manufacturers will have distilled the standards into appropriate charts in their literature.

• For unventilated spaces (m1 charge) is the amount of refrigerant that can be used without additional ventilation measures.

• For ventilated spaces (m2 charge for residential applications) requires systems to include ventilation measures to ensure any leaked refrigerant is dispersed and diluted. Manufacturers will supply an evaporator coil leak sensor and control board. Should the sensor detect a significant leak and report it to the control board (diffusion control), gas/electric heating will stop, and the furnace fan will operate at an appropriate diffusion speed.

• For larger applications (m3 charges) such systems will require more extensive ventilation and other mitigation measures including additional sensors, alarms and control systems to manage refrigerant leaks.

• Accessories such as electronic air purifiers may require an airflow sensing kit; HRV/ERV equipment should be checked ensure the unit will not recirculate air meant for proper diffusion.

• Auxiliary devices must not be a potential ignition source.

I read one manufacturer’s chart in which an AHRI matched 3-ton split system had the A2L charge limit related to space size and necessary mitigation airflow: 3-ton A2L heat pump unit; max. total system charge—205.70 ounces (5.83 kg); min. conditioned space size— 185.87 sq. ft. (17.27 sq. m.); min. mitigation airflow: 335.40 cfm.

Since a 3-ton unit is likely to be installed in a space much larger than 185 sq. ft., I believe most regular AC or heat pump installations with simple line sets will be within range of m2 requirements.

Ensure all refrigerant has been removed from the system or isolated by shut off valves before opening for repair or replacement of parts. Manufacturer requirements are universal in this regard:

• Recommended to have a 10-foot work perimeter with no ignition sources (e.g., gas water heater in service), no other flammable vapours, and where an exit point cannot be readily utilized. Wear proper PPE.

• Be sure the area is adequately ventilated prior to opening the system.

• Have a CO2 or dry powder fire extinguisher nearby.

• Recover the charge down to atmosphere (0 psig) and weigh the A2L refrigerant into an appropriately marked recovery cylinder. Keep the CCH on, run the air handler fan, use a heating banket to be sure liquid A2L trapped in the system is vaporized and removed.

• A dry nitrogen purge is required, see manufacturer chart for purge times.

• Brazing-in new components (flow nitrogen at 3 – 5 CuFt/hr) is typically required, check with manufacturer for approval to use press fit connections.

• Pressure/leak testing followed by deep evacuation to less than 500 microns is required. The deep vacuum decay test should indicate no vacuum to creep above manufacturer’s minimum standard within mandated time limit.

It must be stressed that long-standing HVAC/R practices and procedures still predominate.

Improve your knowledge and sharpen your skills by taking advantage of all available A2L training. HRAI is offering on-line training programs.

An ancient idiom sums up A2Ls nicely: “Things are the same, only different.” All you need to do is to learn the different parts. <>

Ian McTeer is an HVAC consultant with over 35 years of experience in the industry. He was a field rep for Trane Canada. McTeer is a refrigeration mechanic and Class 1 Gas technician. He can be reached at imcteer@outlook.com.

Exploring the changes that occur when antifreeze is added to the water in hydronic circuits.

By John Siegenthaler

30

Glycol and Hydronics

HPAC speaks with John Siegenthaler about how the addition of antifreeze affects performance, and he shares tips on system design and maintenance.

By Doug Picklyk

Frosty the Snowman

Melting snow can be a delicate situation.

By Curtis Bennett

Historic site in downtown Vernon, B.C. retains its old-world charm while its steam heating system gets a boost with networked controls.

By Dan Vastyan

A Mix of Old and New

Making the case that new air-to-water heat pumps can still work effectively with older boiler systems.

By John Siegenthaler

EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

MEDIA DESIGNER

CIRCULATION MANAGER

PUBLISHER

CEO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson

Exploring the changes that occur when antifreeze is added to the water in hydronic circuits.

BY JOHN SIEGENTHALER

I’ve been known to throw out a rather sarcastic comment when the subject turns to using antifreeze in hydronic systems: “The only good thing about antifreeze is that it doesn’t freeze.”

That quip was based on the facts that using antifreeze in a hydronic system: a.) adds to the cost of the system; b.) increases the pumping power required to achieve the given rate of heat transfer, relative to water alone; c.) decreases the heat storage ability of the system fluid;

and d.) needs to be periodically checked for chemical stability.

Still, when it comes to worst case conditions (e.g., subfreezing air temperatures for hours or days, no electric power, and no one available to open drain valves in the system), an antifreeze solution in the system is the only way to prevent freezing.

One concept that’s getting increasing attention among HVAC engineers is “resilient design.” It refers to approaches that “ideally” allow systems to remain operational under very abnormal conditions or minimize effects that could cause major damage to systems when and if they are rendered inoperative.

The methods used by designers to

achieve resilient design vary. For example, one might think including an automaticstart emergency generator for a building with a hydronic system provides sufficient protection against freezing during a utility power outage. It would, if the generator starts when it’s supposed to and has enough fuel to keep running for the duration of the outage. A more conservative designer might specify antifreeze in the entire hydronic system to ensure that freezing would not occur, regardless of the duration of a power outage.

Over the last several decades there are several fluids that have been mixed with water to produce antifreeze solutions. They include inhibited ethylene glycol, in -

hibited propylene glycol, methanol, ethanol, calcium chloride and other salts.

All these solutions have pros and cons. For example, methanol solutions, which have some acceptance in the geothermal heat pump industry, have lower viscosity and better specific heat that glycol solutions. But methanol is both toxic and highly flammable.

Ethanol (the alcohol used in “booze”) is a controlled chemical. It typically requires a license to purchase. There are also government restrictions on how these flammable materials can be legally transported. You can’t just put a 55-gallon drum of methanol in your pickup, throw on a couple of straps and legally head down the highway.

Salts such as calcium chloride can depress the freezing point of water, but their “Achilles Heel” is corrosion, especially on ferrous metals.

The most used antifreeze fluids used in HVAC systems are ethylene glycol and propylene glycol. Ethylene glycol, although having more desirable fluid and thermal properties compared to propylene glycol, is toxic in relatively small amounts.

My preference for antifreeze is inhibited propylene glycol. I would wager that everyone reading this article has, at times, ingested some amount of “food grade” propylene glycol. It’s used in eye drops, candy, soft drink, acetaminophen, aspirin, and the list goes on.

However, “food grade” propylene glycol is not an ideal antifreeze fluid for hydronic systems. It can degrade at elevated temperatures, support microbes, and eventually become acidic with age and elevated temperatures.

That’s where the word “inhibited” comes in. Inhibited propylene glycol contains chemical additives to better stabilize the fluid and reduce corrosion potential between the fluid and specific metals in the system (copper, iron, aluminum etc.).

The rate at which any single-phase fluid conveys thermal energy can be determined by formula 1 illustrated below.

Formula 1:

q = 8.01 Dc (f )(∆T )

Where:

q= rate of heat transport (Btu/h)

D = density of the fluid (lb/ft3), which depends on the fluid’s temperature.

c = specific heat of the fluid (Btu/lb/F), which also depends on the fluid’s temperature.

f = flow rate of fluid (US gallons per minute)

∆T = temperature change of the fluid as it absorbs or releases heat though some device. (F)

8.01 = a constant needed to make the units work out correctly.

Today we are proud to announce the merger of KOSTChill and RECOFREEZE brands into a single global brand, S OLUTHERM™ . As the global industry leader in vehicle antifreeze+coolants with our iconic brand Prestone® and as the top manufacturer of fully formulated INHIBITED GLYCOL-BASED HEAT TRANSFER FLUIDS; we offer a range of aluminum safe, food grade and LEED certified formulations specifically developed for optimal thermal management in HVAC applications.

S OLUTHERM™ Services is an array of services that we offer to our customers to meet their needs.

• Formulation selection specifically developed for your application In-use testing and remediation

• Industry specific technical guidance

• Tailored trainings & sessions

• Education material (webinars, newsletters, video capsules, whitepapers, etc.)

Formulations specifically developed to be environmentally safe and ensure an excellent performance.

The higher the fluid’s density, and the higher its specific heat, the greater the rate of heat transfer for a given flow rate and given temperature change. The graph in Figure 1 shows the density of water, along with that of 30% and 50% solutions of one commercially available inhibited propylene glycol (PG).

Figure 2 shows the specific heat of these same fluids. The density of all the fluids decreases as temperatures rise, while the specific heat of the two glycol solutions increases with increasing temperature. The specific heat of water varies insignificantly over the temperature range shown in Figure 2

The multiplication of density (D) times specific heat (c) represents the “net effect” of how different fluids effect heat transfer. The chart in Figure 3 shows a relative comparison of this multiplication at three different temperatures 50F,100F, and 150F. In each case the multiplication (D x c) for the glycol solutions is given as a percentage of that for water. This allows for a comparison of the heat storage ability of antifreeze relative to that of water.

These numbers show that the heat storage ability of glycol

solutions is not as good as that of water. This is especially true at lower fluid temperatures and higher glycol concentrations. Still, at reasonably “hot” temperatures such as 150F, the heat storage ability of a 30% solution of propylene glycol is only about 3% lower than that of water. This would imply that a storage tank would need to hold about 3% more 30% PG solution compared to water to store the same amount of heat and while undergoing the same temperature change.

Another characteristic of glycol solutions is they have higher viscosity than water at the same temperature. This property, in combination with higher density compared to water, results in more head loss (and associated pressure drop) through any hydronic circuit, and at any given flow rate. Higher head loss implies that more pumping power is needed to achieve and maintain a given flow rate through a circuit compared to operating the same circuit with water alone.

The table in Figure 4 shows another relative comparison of

Backed by industry leading technology, The HPX™ Air-to-Water Heat Pump is the perfect solution to year round comfort. Pair it with the SKy-35 control to optimize your comfort, operating costs and energy consumption.

160 ºF supply temp.

Taco 007 circulator

3/4" copper x 200 ft equivalent length circuit

70 ºF surrounding air temp.

100 total ft. of residential baseboard

the head loss of 30% and 50% solutions of propylene glycol at the same three temperatures used in Figure 3

For example, the head loss of a 30% solution of propylene glycol at 100F is 1.24 times higher than for water at 100F in the same circuit and at the same flow rate.

The head loss of a high percentage glycol solution relative to water is very significant at lower fluid temperatures. A good example is the use of a 30% solution of propylene glycol in an earth loop for a geothermal heat pump system. At a fluid temperature of 32F, the head loss of a 30% PG solution is approximately 40% higher than that caused by water. Some earth loops can operate at temperatures down to around 25F, which would push viscosity and resulting head loss even higher. This must be considered when sizing earth loop circulator(s).

The combined effects of lower specific heat and higher viscosity imply both higher flow rates and higher head loss to create the same heat transfer ability of a given circuit operating with an antifreeze solution compared to that circuit operating with water. The combined effects are easily evaluated using software such as the Hydronics Design Studio.

To demonstrate the “net effect” of using propylene glycol solutions I created a simple circuit consisting of 100-ft. of residential fin-tube baseboard, a total circuit equivalent length of 200 feet of ¾-in. type M copper, a Taco 007 circulator, and a supply fluid temperature of 160F. Figure 5 shows the simple circuit.

Figure 6 shows the flow rate and heat output of the circuit when the fluid is changed, with all other operating conditions remaining identical. The red numbers in parentheses indicate the percentage change in flow and heat output relative to using water in the circuit.

The drop in heat transport rate using a 30% PG solution isn’t

too bad - down just over 3%. However, the drop in heat transport rate using a 50% solution is almost 10%. That’s certainly significant.

That loss of heat transport capacity could be compensated for by 1) using a more powerful circulator or a higher speed on a multi-speed circulator, 2) increasing pipe size to reduce head loss, 3) looking for any component substitutions that could reduce head loss.

The changes in density of propylene glycol solutions with temperature is greater than that of water. This means that expansion tanks used in systems with glycol solutions may need to be larger to operate with the same pressure limits.

I used the Expansion Tank Sizer module in the Hydronics Design Studio software to calculate the minimum expansion tank volume for a system containing 50 gallons of fluid, with a temperature cycling range from 60F at cold fill, to 180F at maximum temperature.

The top of the system was assumed to be 10 feet above the expansion tank connection, and a 30 psi relief valve was assumed. The calculated minimum expansion tank (shell) volumes for this scenario are listed in Figure 7

In this case the expansion tank volume requirement for a 30% solution of PG is about 25% greater than that required if the system operated with water alone.

I support the idea that reasonable oversized expansion tanks are useful in hydronic systems, especially those operating with antifreeze. One benefit of oversizing is that the tank can store a “reserve volume” of fluid that can flow into the system as air is captured and eliminated following initial startup.

In a typical space heating system the temperature of the fluid is unlikely to drop below the temperature at which the sys -

The Summit will host: • a full slate of excellent speakers • 40+ exhibitors demonstrating the latest technologies • and unparalleled networking with hydronics professionals.

Hydronics 101 sessions are sponsored by – perfect for newer technicians! For experienced pros, Master-Class sessions sponsored by, featuring John Siegenthaler and friends.

Lots of prizes including test instruments and Calgary Flames tickets will be won!

SPONSORS INCLUDE

tem was filled and commissioned. However, in systems such as geothermal earth loops, solar thermal systems, hydronic cooling, and snowmelt systems, the fluid temperature will often drop below that at which the system was filled and commissioned.

In such situations it’s undesirable for the diaphragm inside the expansion tank to be fully expanded against the tank shell. If this occurs there’s no way the expansion tank can release more fluid back into the system as the temperature continues to drop and the fluid continues to shrink.

This might lead to sub-atmospheric pressure at some locations in the system. Devices such as automatic air vents or air separators at such locations will act as vacuum breakers allowing air into the system.

Although there are ways to calculate the extra fluid volume needed to avoid this situation, oversizing the expansion tank by 20-25%, and pumping up the system pressure an extra 5 psi at commissioning is generally sufficient to ensure that some residual fluid volume is available when temperatures drop below the cold file temperature.

Glycol-based antifreeze should not simply be mixed with whatever water is available on the site. Ideally, solutions should be combined with demineralized water to minimize any chemical interaction with chlorine, minerals, microbes or other contaminants in the site water. Several companies now offer equipment to create demineralized water on site.

Don’t assume this mixture can then be pumped into a newly constructed system or an existing system that has been drained. New systems often contain residuals amounts of soldering flux, oils from manufacturing processes or other debris. Existing systems may contain iron oxides, or residual amounts of older antifreeze solutions.

Best practice is to use a “hydronic detergent”, which is available from several suppliers in North America, to internally wash the system prior to adding the antifreeze solution. Doing so prolongs the service life of the antifreeze and reduces the possibly of chemical interactions.

Companies that supply glycol-based antifreeze often list two temperatures that apply to a given percentage concentration of their antifreeze. The “freeze point temperature” is the lowest temperature that prevents the formation of ice crystals in the solution. The solution can operate at or above the freeze point temperature, indefinitely, without ice crystal formation.

The “burst point temperatures” is the lowest temperature at which expansion of the solution as it changes from liquid to solid will not cause pipes or other components to fracture. The

burst point temperature is significantly lower than the freeze point temperature.

Figure 8 (above) shows how the freeze point temperature and burst point temperature of one commercially available propylene-glycol antifreeze vary with temperature.

Antifreeze solutions are the only way to protect unassisted hydronic systems from freezing. They are essential in geothermal earth loops, solar thermal systems, and snowmelting systems. Most manufacturers of monobloc air-to-water heat pumps also require that antifreeze be used with their units. It protects them from freezing in winter, as well as against the formation of ice crystals in the heat pump’s evaporator during cooling mode operating under lower outdoor temperatures.

Adjust your designs to compensate for the differences in head loss and heat transfer capacity of antifreeze solutions and upsize expansion tanks when necessary.

Don’t use concentrations that are significantly higher than required. Check water quality against the specifications given by the antifreeze manufacturer, and be sure to test the solution periodically for both freeze point and inhibitor reserve levels. Finally, sleep well on cold winter nights knowing that chemistry is at work to protect your systems. <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit hydronicpros.com).

The NEW I-SERIES Plus™ line of Solo and Combi Condensing Gas Boilers offers unmatched value and performance with an expanded product line of 14 models that range from 60-199k Btu.

Now you can Rely on Rinnai for all your Residential Heating projects no matter the size or complexity.

Allows you to connect your smart phone or tablet to the SENSEI® RX Series via Bluetooth®

Use the Rinnai Central™ App for quick, simplified boiler set-up and registration, significantly reducing your install time.

Rinnai’s Adaptive Gas Valve Technology lets you select your fuel type with the touch of a button on the unit controller or your smart phone. Conversion Kits not required. Smart Sense™ is only available on 60-150k BTU units

4 Built-in Zones for better comfort and savings.

John Siegenthaler shares lessons learned when designing systems where glycol is used. BY DOUG PICKLYK

In January, HPAC magazine hosted a free 30 Mechanical Minutes webinar with John Siegenthaler covering the use of antifreeze in hydronics systems. Siegenthaler shared how the addition of inhibited propylene glycol affects the heat transfer and density of the fluid (see previous article). When designing a system, he strongly recommends compensating upfront for these changes.

He outlined the typical applications that use glycol: snow melt, garage addi -

tions, monobloc air-to-water heat pumps, and whole house systems in climates where the temperature often gets below freezing and power outages are frequent.

He shared an example of a highway garage project in upstate New York, a 10,000 sq. ft. slab on grade building with floor heating. “If we had a long-term power outage, the antifreeze in the circuit would keep that system from freezing. But we also found out the garage had an automatic-start emergency generator. With

the generator, we could maintain circulation through the slab, which would buy several days’ worth of freeze protection, as long as that water was moving.”

“So, there’s an application where we didn’t necessarily need the antifreeze protection.”

He noted that most modern monobloc air-to-water heat pumps will automatically start their circulators if they sense that water in the outdoor unit is approaching freezing to scavenge heat from inside the building.

For the safety of both property and occupants proper venting of condensing gas-fired appliances is critical

Over time, scaling, poor combustion, elevated temperatures, and lack of maintenance can cause appliance fl ue gas temperatures to rise above safe operating temperatures of plastic vent material

For an added safety margin and peace of mind install Z-VentBLU®

Visit us at Booth 427

Z-VentBLU® a stainless steel vent independently listed by Underwriters Laboratories to UL1738 & ULC-S636 vent standards is rated for a maximum flue gas temperature of 550°F where similarly listed PVC is only rated to 149°F

During a power outage that doesn’t work. “The ultimate freeze protection in hydronics is antifreeze. It’s going to work when everything else fails,” he says.

The amount of glycol used in a system will be climate dependent. If you’re up in Northwest Territories, you’re probably going to be using a minimum of 50% possibly a 60% solution, says Siegenthaler. In milder climates you can still use a higher percentage to be on the safe side,

but remember that adding more will require more pumping power.

“It’s a trade-off. You don’t want to be excessive, but obviously you want to have enough to protect the system.”

Setting up the glycol mix, manufacturers have the option of premixed solutions. If the contractor is mixing, the initial water quality is very important. Ideally, use demineralized or deionized water.

Degradation of the glycol over time can be a function of temperature, notes Siegenthaler. “Generally speaking, high temp. applications (i.e. solar thermal) can cause glycol to break down faster.”

It was pointed out by one attendee that not all types of inhibited propylene glycols have the same specifications, there are differences in viscosity for example.

One attendee asked about the consequences of mixing glycol with non-

treated water. Not being a biologist, Siegenthaler deferred to following manufacturer instructions. But propylene glycol can react to organic materials in water, so start with demineralized water. It was suggested that concentrations above 25% propylene glycol should not experience bacteria issues in the fluid.

Another attendee asked if there was any difference in removing air from a hydronic system that is using a glycol mixture.

“It might take a little bit longer, but a micro bubble air separator and a good force will do it. It may take a little bit longer with glycol because of the viscosity, but I don’t know of any specialized equipment specific to de-aerating a glycol fluid versus water,” says Siegenthaler. <>

To see the entire webinar video, or any past episode of 30 Mechanical Minutes, visit hpacmag.com/webinars, or visit our YouTube channel, @hpacmag.

Flange to Flange ZV-Clamp™ outer connection

Factory installed Double Fail-Safe™ self-sealing FKM gasket connection

Precision factory formed pipe and fittings, with fusion welded seams

Melting snow can be a delicate situation. BY CURTIS BENNETT

Iam a sucker for ingenuity. I’m that guy that goes on Facebook (not a regular) to watch 5-axis CNC machines work. I love how people problem solve. My favourite shows are about mining, especially Outback Opal Hunters, basically 60 minutes of pure problem solving. I don’t even care about the opal, I care about how they fix things in the middleof-no-where Australia. The ingenuity is OUTSTANDING. One of my favorite characters is 73 years old and he can fix anything, and fix thing fast. Time is money. I am amazed at things like that.

How does this tie into today’s topic. Well, I am sure the first snow melt system ever was just a guy that was like, “man, I hate shoveling,” and so he came up with this ingenious way of how not to shovel. “I’m going to just melt this snow off my driveway somehow!”

Snow melt, as I have said before, is my least favourite control. Not only is it the most problematic system out there, but our industry builds products for efficiency, and snow melt by all definitions is 0% efficient.

The by-product of heating the outside world is you melt the snow off the concrete. I know we need it for ramp heating and safety, but it’s the driveways that “drive” me nuts. But I digress, let’s talk snow melt.

Snow melt controls are kind of just glorified mixing controls. Yes, it’s true. Albeit they have way more inputs than a run-ofthe-mill mixing control, the basis of what they do is the same. The snow sensor tells the control that there is snow, this is our

demand to the control to start doing things.

We have a high temperature device, usually a boiler, and we mix that higher temperature down and push it to the slab. As important mixing can be in a house, it becomes ultra important in a snowmelt control. Why? Good question. What happens to that extra-large ice cube that you throw into your room temperature old fashioned? [Jeopardy music] …. It cracks.

With the ice cube it’s cool when it happens, with a slab of concreate, not so much. Controlling the temperature going out the slab is not based on a reset curve or a setpoint, it’s based on a Delta T. The reason we base it on a Delta T is so we don’t crack the slab.

Let’s go back to our ice cube demo. If you were to put that drink in the freezer for a bit, cool down the liquid to just above freezing, when you drop the ice cube in it won’t crack. There is no thermal shock to the ice cube.

The same applies to our slab. If we keep the supply water “fairly” close to the return water temperature, usually 20F to 25F, then like the second example of the old fashioned, the slab won’t get shocked.

Controlling this mixing can be done a couple of ways. The first is 3 or 4 way mixing valves. The main reason these systems are used is volume. In snowmelt systems “we” usually run about 50% glycol. What does glycol do to water? It makes it thicker. So, we need bigger pumps to push it around, that is also on top of the fact that we need way more

Btus per square foot for snowmelt. Remember these systems are outside. Both of those requirements equate to big pumps. This also means big heat exchangers. In snow melt systems we always keep the two portions separated with a heat exchanger. This way we don’t run 50% glycol through the portion of the system inside the building. We mix off the secondary side of the heat exchanger in this case carefully mixing the water temperature to achieve the consistent Delta T for the slab.

The signal to the mixing valve is the portion that gets “mixed” up the most. Everybody calls them both modulating valves. This is true, but to a controls guy like me they are very different. There are two types of mixing valves: floating action and 1-10VDC. Now both valves modulate up and down, and I think that is where the hangup usually is.

A floating action valve takes two 24VAC signals and one common. You hit one side with 24VAC “R”, and the valve opens, hit the other and it closes. It also stops if you take off both signals. This is how it “modulates” (see how I put that in quotes).

When it finds just the right mixing point to achieve the temperature output it can stop there. The second type is the

1-10VDC mixing signal. This valve is powered with 24VAC and a +1-10VDC signal to modulate the valve. As the signal goes up the valve opens more, to stop the valve where it’s at, the signal just stays where it was at and the valve won’t open or close any more.

The second type of mixing is injection. Good ole primary secondary injection! Taking a “hydraulically” separated fluid (I’m sure you already know this) and pumping it into a main system loop using closely spaced t’s. In this scenario you can get away with some smaller equipment.

By using higher Delta T’s on the boiler side you can use lower flow rates. This article is about controls, not mechanics. LOL. Back on track. There are a lot of pumps out there now that take a 1-10VDC signal to use as injection. These are a good choice to do the job right. ECM pumps are kind of everywhere now, and all manufacturers have them. This way you can have good and tight control of the Delta T.

Remember we talked about shocking the slab, so control of your Delta T is important. The setpoint for the system temperature on a snow melt control is determined by the return temperature coming back from the slab. We add our desired Delta T on top of that to give us the target for the system temperature. This temperature is moving, as is the boiler temperature on the other side of the heat exchanger, so we need to have accurate mixing to hit it properly.

One other aspect of mixing out to the slab is that we can protect the boiler as well. Protecting the boiler doesn’t seem to make sense most of the time, but it is possible to freeze the boiler in a snowmelt system. It freezes the condensate inside the boiler. I think we all know that’s a bad thing!

The return water can be below freezing—remember that the slab (using a glycol mixed fluid) is usually kept well below freez-

ing until snow is sensed. If you don’t keep the slab temp low when there is no snow, the slab won’t be the only thing that can get shocked!

So, by using a mixing device you can shut off the temperature going out to the system, which in turn stops the possible freezing return water temperature coming back to the boiler. You can essentially give it bumps of hot water into the system until the return water temperature is above the freezing point.

“Controlling” your Delta T is so important. The last thing you want is to damage the slab; by using some tried and true mixing techniques we can ensure a smooth temperature and Delta T.

Nobody likes shoveling snow. Don’t lie to yourself, no you don’t. As for the safety aspect we also need good control to make sure no one slides into the garage door of a down ramp to a condo or industrial building. Smashed doors are also no fun for anyone. <>

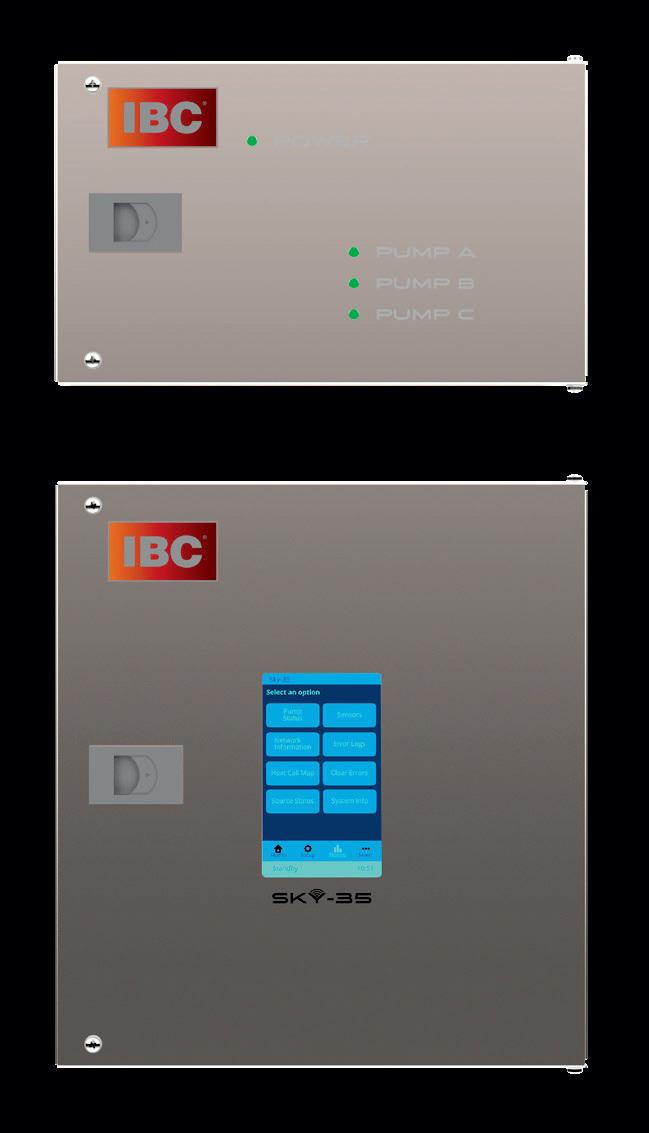

Curtis Bennett C.E.T is product development manager with HBX Control Systems in Calgary. He formed HBX Control Systems with Tom Hermann in 2002. Its control systems are designed, engineered and manufactured in Canada to accommodate a range of hydronic heating and cooling needs.

Historic site in Vernon, B.C. retains its old-world charm while its steam heating system gets a boost with networked controls.

BY DAN VASTYAN

Known for its vintage charm and intimate atmosphere, the Vernon Towne Theatre, located on the main street in Vernon, B.C., offers a unique experience for moviegoers and event attendees.

With its classic marquee and art decoinspired interiors, the theatre maintains

an old-fashioned ambiance while showcasing both first-run movies and independent films, as well as hosting concerts and community events.

Rumors circulate that the old building is haunted. Some visitors are skeptical, but most of the staff believe the stories.

“The rumours go back many decades and have continued to current day with employees experiencing unexplainable phenomenon,” says Scott John, theatre manager. “It’s been featured in books and paranormal TV shows as one of the most haunted locations in Canada. There are documented cases of deaths in the theatre, that may have added to the legend.”

Strange, intermittent noises come from inside the walls. Troy Lehr, general manager at Brown Mechanical Services, the local contractor with the maintenance contract for the theatre, has his own theory.

“The noise is largely due to an old steam piping system, coupled with a wood structure that was built in 1929,” he explains. “The creaks that are heard when the heat is on are part of the building’s character that will likely be with it for life.”

Creaking, as Lehr describes it, is likely caused by the expansion and contraction of steam pipes, which rub on the wall studs. Steam hammer can also be

heard, which occurs when condensate water collects in the sagging return pipes. Steam pressure then throws the water down the pipe until it hits an elbow, creating a ghastly ring.

There are no plans to fix these issues, simply because and entire retrofit would be too costly and invasive. Plus, evicting the ghosts would detract from the build -

ing’s historical panache.

Phantom noises aren’t the only oddity at the cherished cultural venue. Originally a dance hall called The Capitol, the building was converted into a cinema in 1938, and the Vernon Towne Theatre is one of the few theatres in North America that still has its old 35mm film projector hooked up and useable—though a new

digital system is the workhorse of the venue. In the boiler room, the original Viking coal-fired steam boiler is also still in place, though it has long been abandoned.

Brown Mechanical Services is a nine-person 40-year-old company based in Vernon, and the team has worked at the theatre for years, though they entered a service contract with theatre management only recently in the summer of 2024.

Since then, they’ve been improving the health of the two-pipe steam and plumbing systems. Steam traps and vents have been replaced and the two 299-MBH Carrier cast iron boilers have been cleaned and calibrated.

To combat winter conditions, which can drop as low as -35C in Vernon, the theatre has cast-iron radiators providing heat in the projection room, baseboard

commercial and

residential space and water heating solutions that engineers, specifiers, builders and contractors can depend on. Turn to AQUATECH for heating and hot

heaters installed along the lobby, and an air handling unit with a steam coil conditions the auditorium.

Until the summer of 2024, the dualboiler steam system at the theatre has been “dumb.” There’s no building automation system, and both boilers fired when there was a call for heat.

To bring some modern touches to the system, before the 2024-2025 heating season began a tekmar Smart Steam Control 289 was installed to improve the efficiency and longevity of the system. It also helps to simplify maintenance for the Brown Mechanical team.

The new system is a web-enabled boiler control designed to operate up to two steam boilers on either one or two pipe steam applications. The control system can provide up to 20% energy savings through outdoor reset technology, indoor temperature feedback, and warm weather shutdown.

“Through the Watts OnSite mobile and web app, we can remotely monitor the heating system at the theatre,” says Lehr.

“The control notifies us of anomalies to ensure the system is operating efficiently and comfortably in the building. It also provides runtimes across the boilers so we can balance the system to ensure maximum life of equipment is achieved.”

With these new remote insights and a better understanding of what’s going on in the steam system, many issues can be identified and addressed before a noheat scenario arises. It also reduces the number of staff hours needed onsite.

The outdoor reset technology built into the control provides progressively longer boiler runtimes as the outdoor air temperature drops. And conversely, runtimes are shorter when the outdoor temperature rises.

“The control stages the two boilers based on pressure, using a pressure sensor,” explains Lehr. “It also rotates the two boilers to provide equal run time and helps point our techs to areas that may require attention. We can see all of

this and make many changes within the system through the app, without ever leaving the office.”

The new control has helped Brown Mechanical’s technicians care for the theatre heating system, but it’s also simplified the system for theatre staff, too.

“The ability to remotely control our system with the tekmar dashboard has been great,” says John, the theatre manager. “We can log on and see the status of the boilers and receive error or warning notifications. Our hours can be variable, so the ability to change the temperature and start the system via the dashboard and start warming up the theatre has been helpful.”

“We haven’t determined the exact energy savings from the addition of the new control, but we know our energy costs are lower. We have yet to account for variables like heating degree days and occupancy hours.”

This year’s heating season will provide a better picture of the energy savings provided by the new control, so long as a supernatural presence doesn’t take up residence in the boiler room.

“It’s exciting to see our Smart Steam

Control 289 bringing both efficiency and modernization to a historic landmark like the Vernon Towne Theatre,” said Mercedeh Fallahkhair, senior product manager at tekmar Control Systems, which also happens to be located in Vernon. “This project showcases how innovative solutions can enhance energy efficiency while respecting the building’s vintage charm. Our technology simplifies maintenance for service providers and delivers meaningful benefits to building owners and operators alike.”

The Vernon Towne Theatre demonstrates how thoughtful upgrades can breathe new life into historic spaces while preserving their unique character. <>

Dan Vastyan is president of Common Ground, specializing in marketing communications and serving the North American construction industry with a focus on plumbing, mechanical and HVAC markets. danv@seekcg.com

Making the case that new air-to-water heat pumps can still work effectively with older boiler systems.

BY JOHN SIEGENTHALER

There’s a lot of interest in adding an air-to-water heat pumps to existing hydronic heating systems supplied by fossil-fuel boilers. I get inquiries on that subject almost every day.

An air-to-water heat pump is a state-ofthe-art device for producing heat. By comparison, a cast-iron boiler might be considered (by some) to be outdated technology. I’ve even been asked: “John, why do you still talk about cast iron boilers, they’re the ‘dinosaurs’ of our industry.”

That’s not my take. Although I strongly support the use of air-to-water heat pumps in applications where they can perform well, I don’t support doing so by

first ripping out a perfectly good cast-iron boiler that has remaining service life.

I’ve specified many cast iron boilers over the years and have had excellent results in terms of reliability, minimal service requirements and stable performance.

I have an oil-fired cast iron boiler in my home that’s 26 years old and still going strong. There’s another identical one in my office that’s 25 years old, and it still looks like the day it was installed. I fully expect to get another 10+ years of service from both boilers (assuming it’s still legal and affordable to purchase fuel oil).

Can you name an appliance in your home that has lasted 25 years or more? Refrigerator? Washing Machine? Dishwasher? Microwave? Mod/con boiler?

I’ll stop short of saying that cast iron boilers are “bullet proof,” but when properly applied and maintained they’re likely to outlast any alternative hydronic heat source.

When they do reach the end of their service life the cast iron is highly recyclable. About 90% of the cast iron used in a new boiler is recycled iron from scrap such as old fire hydrants, railroad car wheels, bathtubs, or recycled old boilers. Today, over half the boilers used in new North American hydronic systems are capable of operating with sustained flue gas condensation. When properly applied they can attain efficiencies in the mid-90% range.

This leads to a question that’s likely to come up when a client wants to add an air-to-water heat pump to their existing hydronic system, and they want to use a boiler as the backup to the heat pump: “Is it be better to remove the existing conventional boiler operating at an AFUE of say 85%, and replace it with a mod/ con boiler operating at an assumed AFUE of 95%?”

To help answer this question, consider the following scenario:

– Building: 2,500 sq. ft. house with design load of 20 Btu/h/ ft2.

– Building design load: 50,000 Btu/h at outdoor temp.= 0F, and indoor temp. = 70F.

– Average internal heat gain: (1 kW) or 3,413 Btu/h.

– Location: Syracuse, NY, 6,720 heating degree days.

– Heat Pump: 4-ton rated, low-ambient air-to-water.

– Distribution system: fin-tube baseboard requiring 170F water at design load.

– Existing boiler : 60,000 Btu/h oil-fired cast-iron, with AFUE = 85%.

– Alternate boiler : 60,000 Btu/h condensing boiler, with AFUE =95%.

– DHW load: 60 gallons per day, heated from 50-120F.

– Cost of fuel oil: $US 3.36/gallon*.

– Cost of propane: $US 2.70/gallon*.

– Supply water for space heating: based on outdoor reset.

– Defrost correction on heat pump performance in effect.

– Upper temperature limit allowed for heat pump: 130F, all heat required at higher supply water temperatures is provided by the boiler. (*prices from Fall 2024, upstate New York)

The existing system has an oil-fired cast-iron boiler. There are

no mod/con boilers that operate on fuel oil (at least at present in North America), so a decision to convert an oil-fired boiler system in a rural location to a mod/con boiler would force a fuel change to propane.

Using simulation software the estimated heating energy use for the above system is as follows:

– Seasonal space heating energy required by house: 110.6 MMBtu

– Yearly domestic water heating energy : 12.7 MMBtu

– Total heating energy required = 110.6+12.7 = 123.3 MMBtu (1 MMBtu = 1,000,000 Btu)

The delivered cost of heat from the existing oil-fired boiler operating at AFUE = 85%, and with the above fuel oil pricing (US$3.36/gallon) is US$28.22/MMBtu.

The delivered cost of heat from a mod/con boiler operating at 95% AFUE with the propane pricing (US$2.70/gallon) is: US$30.98/MMBtu.

Using the above assumptions the simulation software indicates that the nominal 4-ton low-ambient air-to-water heat pump would provide 114.1 MMBtu of the total heat, and the boiler would provide the remaining 9.3 MMBtu.

All New Commercial Boilers and Volume Water Heaters

Whatever your needs may be, you can trust that you’re installing a product that is produced to the highest standards. Both models offer our Peace of Mind Warranty Program. Choose Triangle Tube for efficient and reliable solutions for your heating and hot water needs.

That 9.3 MMBtu is only about 7.5% of the total annual heating energy, and as you’ll see, this informs the decision about upgrading the exiting boiler.

The simulation software estimated the seasonal average COP of the heat pump to be 2.78.

If the existing oil-fired boiler remained in place the cost of the 9.3 MMBtu auxiliary heat would be: 9.3 MMBtu x US$28.22/MMbBtu = US$263 per year.

If a new mod/con boiler produced this heat it would cost: 9.3 MMBtu x US$30.98/MMBtu = US$288 per year.

Based on these numbers the cost of operating the 95% efficient mod/con boiler on propane (at the fall 2024 local price) would be about US$ 25 more than the existing cast iron boiler operating at 85% efficiency on fuel oil (at the fall 2024 local price).

These two costs are obviously very close, and different fuel pricing or thermal efficiency assumptions could make the mod/con boiler the lower cost option. The take away is that the installation cost of new boiler is definitely NOT justified based on fuel cost savings.

I also ran a comparison based on installing an electric boiler as a replacement to the oil-fired boiler. The cost of electricity in the same area was US$ 0.25 per kWhr. The 9.3 MMBtu of auxiliary heat would cost US$ 681 if supplied by an electric boiler (or other resistance heating elements). That’s US$ 418 per year more than if the heat was supplied by the existing oil-fired boiler, and US$ 393 more per year than if that heat came from the mod/con boiler.

Suppose the existing conventional boiler was fueled by natural gas. The most recent data for pricing of natural gas in this region is US$ 2.32 / therm (1 therm = 100,000 Btu).

If an existing gas-fired conventional

boiler remained in place, and operated at an AFUE of 85%, the cost of the 9.3 MMBtu auxiliary heat would be 9.3 MMBtu x US$27.29/MMbBtu = US$ 254 per year.

If the existing gas-fired conventional boiler was replaced with mod/con boiler operating with an AFUE of 95%, this heat it would cost 9.3 MMBtu x US$24.42/ MMBtu = US$227 per year.

The annual savings would be US$254US$227 = US$ 27 per year. True, it’s a savings based on the assumptions, but hardly one that justifies removal of the existing boiler and replacing it with the mod/con boiler at an estimated cost of US$ 9,000.

The take aways from this example:

1. A properly sized and controlled air-towater heat pump is capable of providing just over 90% of the total heating energy required for the typical house, even in a relatively cold climate, and even with heat emitters that require 170F supply water temperature at design load.

2. The use of outdoor reset allows the “high temperature” heat emitters to be supplied reasonably well by the air-to-water heat pump on a seasonal basis, especially considering the simulation limited the supply water temperature from the heat pump to 130F. Any heating energy required above this would come from the boiler.

3. The underlying reason for these results, which probably weren’t intuitive, is that whatever auxiliary boiler is used in the system, it’s only supplying a small percentage of the seasonal heating energy. That’s going to produce economics that are far different from the more common scenario of replacing a conventional 85% efficient boiler with a 95% efficient boiler, where either boiler would provide all heating energy. It’s not just about efficiency; it’s about how much fuel gets processed though the boilers at those efficiencies.

4. The cost of removing the existing oilfired boiler and its fuel tank, and replacing it with a mod/con boiler could easily be US$9,000 or more in today’s market. With little if any savings generated by a scrapping the exiting boiler and replacing it with a mod/con boiler there’s very little, if any, economic justification. Still, different clients have different goals. Some just want to rid themselves of anything that operates on fossil fuel. You may not agree with that goal, but you can make it happen, and profit from it.

Government (and global) manipulation of energy prices, or increases in carbon taxes, could significantly skew these comparisons. Still, for the recent prices used in this comparison it appears there’s merit in designing air-to-water heat pumps systems that retain existing boilers that have remaining service life— even those older cast-iron boilers. They’re not necessarily the “dinosaurs” that many claim them to be. <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit hydronicpros.com).

Proud of your work? Better than the rest? It’s time to bring it on!

THERE WILL BE A WINNER IN EACH CATEGORY: COMMERCIAL, RESIDENTIAL NEW-BUILD & RESIDENTIAL RETROFIT

ENTRY IS SIMPLE - send us pics of your installation. Include a brief description of the particular challenges that you faced with this installation and how you overcame the obstacles. Submissions are limited to one per contractor. Deadline to enter is July 31, 2025. The three winners will also be announced by John Siegenthaler at the Modern Hydronics Summit 2025. In addition to having your winning entry shared across our social media channels you’ll also be interviewed by HPAC’s editor and featured on the cover of the October edition of HPAC –

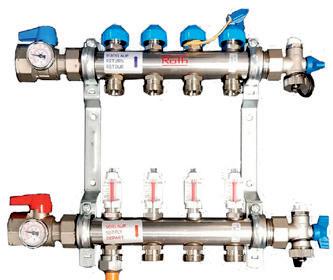

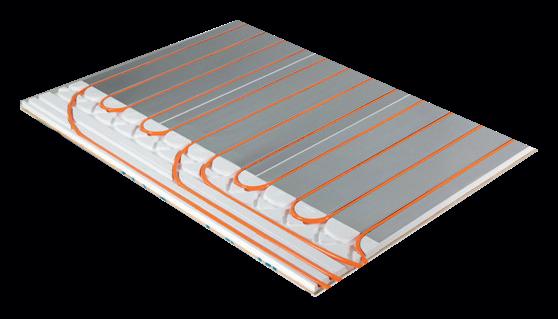

Thanks to our ideal set-up for installers using our unique flow meters on each manifold loop, IVAR stainless-steel manifolds guarantee perfect system balancing, optimizing energy use, while providing premium thermal comfort.

Every manifold set is supplied with all components included in the box, ensuring a smooth commissioning process for radiant system installers.

Pair the IVAR Manifolds with our premium VIPERT™ (PE-RT) Oxygen Barrier Tubing, manufactured specifically for radiant systems, and you have a winning solution every time.

Take advantage of our in-house hydronic expertise, including LoopCAD design and layouts customized for each of your residential and commercial projects.

MANUFACTURERS • DISTRIBUTORS • WHOLESALERS

Early in the New Year, Trane Technologies closed its acquisition of Montreal’s BrainBox AI, an autonomous HVAC controls and generative AI technology platform for buildings.

Using deep learning algorithms, BrainBox AI predicts building energy needs, automates HVAC systems and can reduce both energy consumption and GHG emissions for real estate clients over a portfolio of building types. This acquisition follows numerous collaborations between BrainBox AI and Trane over the last two years. BrainBox AI’s team of more than 190 employees will join Trane Technologies. tranetechnologies.com brainboxai.com