THE QR CODE RENAISSANCE

KILLS BACTERIA TECHNOLOGY

For more information on Copper DefenseTM technology deltafaucet.ca/copper-defense

Laboratory testing has shown that when cleaned regularly this surface:

• Reduces bacteria contamination, achieving 99.9% reduction within 2 hours of exposure.

• Delivers continuous and ongoing antibacterial action.

• Helps inhibit the buildup and growth of bacteria within 2 hours of exposure between routine cleaning and sanitizing steps.

FLUSH VALVES

Clean and sanitize according to standard practice. Healthcare facilities must maintain the product in accordance with infection control guidelines. The use of this surface is a supplement to and not a substitute for standard infection control practices; users must continue to follow all current infection control practices, including those practices related to cleaning and disinfection of environmental surfaces. This surface has been shown to reduce microbial contamination, but does not necessarily prevent cross contamination.

HVAC

THE INVERTER COMPRESSOR ERA: ARE WE READY?

Compressor technology has been evolving since the earliest days of air conditioning; the time has come to embrace the latest generation.

By Ian McTeer19

30 MECHANICAL MINUTES

HEAT PUMPS: WHAT EXACTLY IS INVERTER TECHNOLOGY?

Ian McTeer and Gerry Wagner sit down with HPAC to discuss the facts behind inverter technology and how it is making heat pumps better.

By HPAC Staff22

DUCT-FREE ZONE

INVERTERS IMPROVE CAPACITY

When considering installation of multizone ductless heating and cooling systems, inverter compressors often allow more indoor capacity than you might think.

By Gerry Wagner24

HYDRONICS

THE RIGHT MIX

Taking a look at many common mixing techniques used to keep closed-loop water temperature at optimal levels for increased comfort and to ensure greater operating efficiency.

By John Siegenthaler30 CONTROLS

HEART OF THE HOME

Advancements in zone controls for hydronic systems are leading in the right direction with more integration opportunities, including forced air.

By Curtis Bennett38 COVER STORY

QR CODES

QR CODES: AT YOUR SERVICE

Digital technology is bringing convenience to the job site and can also help contracting companies attract more business.

By Doug Picklyk40

PLUMBING PUMPED

Guests of SFA Saniflo Canada experience an immersive factory tour in France, as the company looks to grow its reach back home.

By Doug Picklyk42 PROFILE

FROM LEGACY TO EXPANSION

Three brothers step up to lead Norm’s Plumbing and Heating business into the future.

By Doug Picklyk

By Doug Picklyk

46

MANAGEMENT

GET YOUR SERVICE BUSINESS

WORKING FOR YOU

For owner/operators working in the trades, a business manager can help keep the operations on track.

By Mathew Pottins48

REFRIGERATION

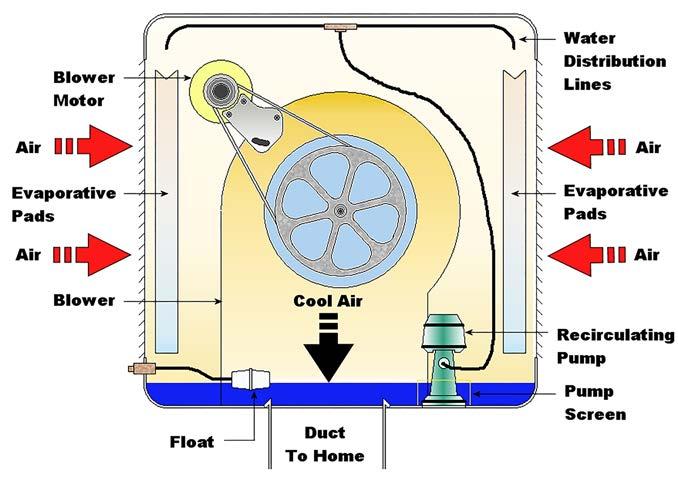

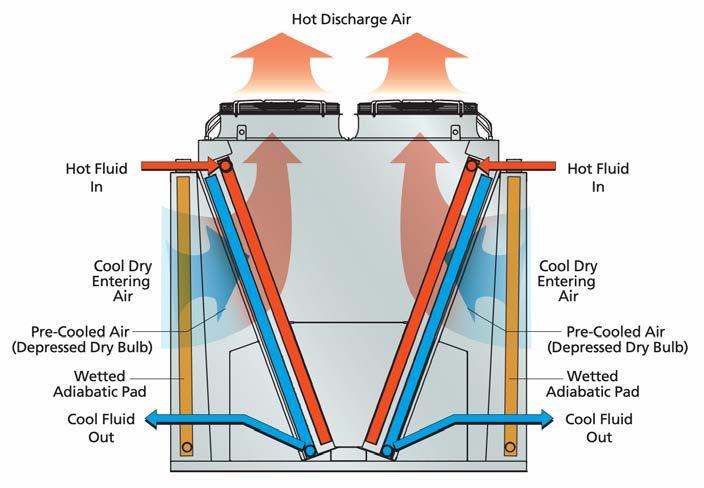

WHAT IS ADIABATIC COOLING?

A form of evaporative cooling, adiabatic condensers can improve the energy efficiency of commercial and industrial refrigeration applications.

By Dave Demma

By Dave Demma

48

General has rethought high-speed, exible shaft machines. The stronger, stiffer shaft lets you clean a wider range of drain lines, up to 75 feet long. It’s exible enough to negotiate 2" lines yet tough enough to clear roots in 4" lines.

General’s unique ClogChopper ® cutter in combination with the carbide tipped chain cutter makes a formidable combination, capable of clearing the toughest stoppage.

The built-in variable speed motor with foot pedal control makes the machine easier to operate. And the shaft is eld repairable. It’s everything a exible shaft machine should be.

To learn more, visit www.drainbrain.com/Flexi-Rooter, or call the Drain Brains ® at 800-245-6200

HVAC and plumbing companies, those who service and replace systems in homes and large buildings, can possibly benefit from the implementation of AI in some of the latest to technologies on the market designed to enhance efficiency and deliver improved services for clients.

One advantage of AI for service companies is the ability to implement predictive maintenance. By analyzing historical data and real-time sensor inputs, AI algorithms can identify potential system failures or malfunctions before they occur. These smart systems enable proactive maintenance, reducing the risk of breakdowns, and minimizing downtime for customers.

Montreal-based BrainBox AI has been developing and deploying its HVAC monitoring technology that leverages AI to make buildings smarter and greener since 2019. Another company in this same space is called 75F, and there are likely many more that will be making their mark on the market.

These companies aren’t replacing HVAC service providers, but their predictive maintenance abilities work to enhance reliability and allow service companies to optimize their schedules and allocate resources more effectively.

These AI-powered systems can be trained to detect and diagnose faults within HVAC systems. By analyzing data, algorithms can identify anomalies, deviations, or patterns that indicate problems. This capability enables technicians to pinpoint and address issues before they occur, reducing troubleshooting time and enhancing efficiency.

This smart fault detection can allow remote troubleshooting, so techs can provide guidance to clients from their offices, potentially minimizing visits.

The technology is also designed for improved energy consumption, lowering utility bills for customers. Endorsing these AI-driven solutions could help service companies demonstrate their commitment to their customers’ environmental responsibility.

These are just a few ways AI technology can assist service companies, not replace them. Plus, if you’re a business owner wondering if ChatGPT, the AIpowered language model that was introduced last year, could help with your business, I would recommend you set up a free account and ask it yourself.

You may be surprised by the response.

For starters, how does this sound: 24/7 customer support through automated chatbots and virtual assistants, basic troubleshooting guidance and intelligent scheduling.

I have a feeling these AI services will be popping up in the most common field service business management software—if it isn’t already.

This is truly emerging technology, so it’s worth making the effort to investigate what it can do to help keep your company from falling behind. <>

– Doug Picklyk, EditorReader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Administrator

Tel: (416) 510-5113 Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE PUBLISHER NATIONAL ACCOUNTS ACCOUNT COORDINATOR

AUDIENCE DEVELOPMENT MANAGER

MEDIA DESIGNER

PUBLISHER

PRESIDENT/COO

Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

David Skene (416) 510-6884 dskene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 510-5180 ugrzyb@annexbusinessmedia.com

Emily Sun esun@annexbusinessmedia.com

Peter Leonard (416) 510-6847 pleonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print)

ISSN 2371-8536 (Online)

Contents Copyright © 2023 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of: www.hpacmag.com

Right Time Group of Companies now has 25 locations across central and western Canada with recent acquisitions of Thomson Industries Ltd. of Port Coquitlam, B.C. and Oosterveld Heating and Air Conditioning of Guelph, Ont.

Both companies provide residential heating, cooling, and air quality services and following the acquisitions both groups’ management and employees joined the Right Time team.

Right Time, majority-owned by San Francisco-based private equity firm Gryphon Investors, has operations in Ontario, Manitoba, Saskatchewan, Alberta, and B.C. right-time.ca

Enwave Energy Corp. has broken ground for a new three-storey low-carbon heating facility using heat pumps at their Pearl Street Energy Centre in downtown Toronto. The new facility is part of an expansion and updating of their existing 60-yearold building at 120 Pearl St. which provides low-carbon heat to Toronto’s district energy grid.

The new facility will include the installation of new assets that recycle district waste heat to produce hot water via electrification using heat pumps, electric feeds, and generators. The technology is optimized due to the scale and magnitude of buildings connected to Enwave’s heating and cooling district.

The company states that when fully utilized, the new heating facility will provide enough low-carbon heating to reduce emissions in Toronto by approximately 11,600 tCO2e, which is the equivalent of converting over 10 million sq. ft. of office space to net zero.

“The addition of a low carbon heating facility to our Pearl Street Energy Centre is a significant milestone for us and Toronto’s district energy grid, because it allows us to provide decarbonization at scale,” said Carlyle Coutinho, CEO of Enwave Energy Corp. in a media release.

Held for the first time at the Palais des congrès de Montréal (Montreal Congress Centre), the 2023 MCEE Expo, held April 19th and 20th, attracted 7,000 visitors.

“It was great after a four-year absence that the MCEE tradeshow is still proof that our industry members can come together for a common cause to create meaningful partnerships that increase the quality of tradeshows for exhibitors, visitors and for the industry associations,” says Ralph Suppa, president of the Canadian Institute of Plumbing and Heating (CIPH).

The biannual show was last held in Spring 2019 (the pandemic forcing the cancellation of the 2021 edition). More

For nearly 20 years, Enwave has provided district energy to Toronto’s downtown hospitals, campuses, and office buildings through its Deep Lake Water Cooling system. Now the organization is building out new district systems that use other technologies and sources, such as wastewater heat recovery and geoexchange, to service communities in the GTA.

Last year the company launched Enwave GeoCommunities, a platform using geoexchange to provide low-carbon energy to buildings.

The new Energy Centre expansion and renewal project is supported financially by a grant from Canada’s Low Carbon Economy Fund and a $600 million loan commitment from the Canada Infrastructure Bank (CIB) to accelerate the scale and build-out.

The new facility is anticipated to be in service by late 2024. enwave.com

than 300 exhibitors occupied 65,000 sq. ft. featuring new products and technologies, and the New Products Showcase, a regular feature of the MCEE Expo, showcased 58 products this year.

The MCEE Expo, organized by the corporation des maîtres mécaniciens en tuyauterie du Québec (CMMTQ), CIPH, the

corporation des maîtres électriciens du Québec (CMEQ), and the corporation des entreprises de traitement de l’air et du froid (CETAF), in collaboration with Électro Fédération Canada (EFC), will return on April 24 and 25, 2025 at the Palais des congrès de Montréal. mcee.ca

HIGH-PERFORMANCE MEETS EASY MAINTENANCE

TOTO’s revolutionary new commercial toilet features its market-leading TORNADO FLUSH® system, which provides a powerful nozzle to create a forceful centrifugal, cyclonic rinsing action that reduces waste buildup and keeps the bowl cleaner.

Available at NEXT has full stock of all TOTO products for residential, institutional and commercial spaces. Contact us and ask to speak to one of our TOTO experts for more information. nextsupply.ca

The Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) in cooperation with the Ontario Geothermal Association (OGA) attracted over 600 people to its inaugural Heat Pump Symposium held April 4 at the International Centre in Toronto.

The sold-out event included some 60 exhibitors and over 25 speakers addressing political will and government policies encouraging heat pump adoption in Canada along with technical sessions addressing both residential and commercial heat pump applications.

The day also included international flavour with a presentation on Sweden’s early adoption of heat pump technology, and also plenty of local insights with heat pump advocates representing contractor, manufacturer and property developer perspectives.

heatpumpsymposium.ca

Eric Ellefsen, refrigeration and air conditioning instructor at New Brunswick Community College (NBCC) St. Andrews, has been selected by the Canadian Council of Directors of Apprenticeship (CCDA) as the recipient of the 2023 Award for Excellence in Apprenticeship Education.

The award honours educators and training instructors who deliver innovative and top-quality instructional programming to apprentices in Red Seal Trades.

ASHRAE has released a new standard to measure zero net carbon and energy goals in buildings.

The new ANSI/ASHRAE Standard 228-2023, Standard Method of Evaluating Zero Net Energy and Zero Net Carbon Building Performance, sets requirements for evaluating whether a building, or group of buildings, meets a definition of “zero net energy” or a definition of “zero net carbon” during building operation.

The standard draws from ASHRAE Standard 105, among others, to address energy and carbon flows across a site boundary, their measurement and their balance.

“Achieving a zero energy building has been viewed by many as a difficult goal to meet, with unforeseeable roadblocks and differing guidance,” said Keith Emerson, P.E., chair of the Standards Project Committee 228.

“Standard 228 provides a consistent method for determining whether new and existing sites have reached zero energy. We hope this standard will become a helpful resource for building professionals in strategic decarbonization planning.” ashrae.org

Ellefsen has been teaching NBCC refrigeration and air conditioning mechanic (RACM) apprentices in St. Andrews for more than 36 years.

He has pioneered various training technologies in course delivery, including 3D virtual training and hybrid in-person/ online classes. And he participates in the refrigeration and air conditioning technician trades exploration program for underrepresented groups, and mentored and inspired the first female Red Seal refrigeration and A/C technician in New Brunswick.

He is an Educational Advisor for the RACM trade on the New Brunswick Provincial Advisory Committee for PostSecondary Education, Training and Labour; a team member of the Atlantic Apprenticeship Harmonization project for the Atlantic Apprenticeship Curriculum Standard; and a regular contributor to the development of Red Seal Occupational Standards (RSOS) and examinations for RACM.

The federal government has launched a $4 billion initiative aimed at helping Canadian municipalities build more housing.

The Housing Accelerator Fund (HAF), first announced in Budget 2022, will launch this summer and run until 202627, and it aims to provide funding for local governments to fast track the creation of 100,000 new homes across Canada.

The fund will help cities, towns, and Indigenous governments unlock new housing supply by speeding up development and approvals, like fixing out-ofdate permitting systems, introducing zoning reforms to build more density, or incentivizing development close to public transit.

The fund will provide upfront funding to support implementation of initiatives that accelerate project timelines, allow for increased housing density, encourage affordable housing units, and more. cmhc-schl.gc.ca

On the right is a 2 inch MJ Cast Iron Pipe manufactured in China supplied to a professional contractor by a plumbing distributor in Canada.

These low price products DO NOT CONFORM to the CSA B70 standard, as the wall thickness is below the minimum requirement of 3mm.

Pipe like this will have a shorter life span and is difficult to cut as can be seen below, resulting in cracks and splinters of iron that will break and pose safety issues for workers and will also significantly increase the cost of installation and possible risk to the owners long term.

Beware of products at a reduced price with appearances of quality equal to those manufactured in CANADA.

Make the smart choice, support Canadian workers and buy Canadian Cast Iron soil pipe.

418-926-3262

bibby-ste-croix.com

It was one spring day in the mid1970’s that I tagged along with an experienced refrigeration technician on a residential service call. My task that day, as a neophyte helper, was to carry tools and equipment in and out of a fabulous mansion located just north of downtown Toronto.

In those days, residential air conditioning consisted mainly of table fans, strategically opened windows and, for some, the emerging window air conditioner market helped to provide relief from Toronto’s notorious summertime heat and humidity.

When I first entered the mechanical room of this home, I stood in awe at the size and complexity of the equipment.

An enormous oil furnace had two slab cooling coils installed in series in the hot air plenum, both on a 45-degree angle with each controlled by an adjustable TXV.

The furnace had a massive two-speed motor running in continuous mode yearround. Part of our job was to lubricate the motor, change the drive pulley and belt, and electrically switch the motor into continuous high speed for the summer cooling airflow requirement.

I really fell in love with the two watercooled serviceable hermetic compressors mounted on springs attached to heavy steel I-beams. Next to them, mounted on the side wall, were two huge motor starters containing a bunch of capacitors and other controls; I couldn’t wait to learn all about it.

An era is often defined as a period of time marked by distinctive character. Never again did I see a serviceable or semi-hermetic compressor in a residential application, because shortly after that fateful day the first residential split

system air conditioning units arrived in my expanding HVAC world.

Several of the earliest splits I encountered used rotary compressors; these are positive displacement compressors using a rolling piston or rotating vane that have the advantage of providing constant flow of suction and discharge gases and are still used today in various applications.

Positive displacement reciprocating compressors, also known as piston compressors, are essentially pumps that provide—as all refrigerant compressors do—a pressure differential allowing refrigerant to flow.

By adding heat during the pumping process vapour pressure is increased to the high side condition. Hermetic compressor manufacturers developed several reciprocating designs for use in residential applications. One such de -

Continued on p14

Unmatched heating and DHW performance, all in one compact unit

• Heating up to 150,000 BTU/h and DHW up to 210,000 BTU/h

• Up to 80% smaller than floor standing boiler and tank water heater

• Optimized DHW priority with mixing valve and water adjustment valve to provide consistent DHW temperatures and industry leading flow rates

• Dual stainless steel heat exchangers for heating and separate SS heat exchanger for DHW

• Built-in controls for 3 zone pumps or 3 zone valves

• Heating TDR up to 11:1 and DHW TDR is 15:1

To learn more about the best-selling combi-boilers in North America, visit navieninc.com.

...and hang up the breakthrough in high capacity combis

Continued from p12

sign had four opposing pistons arranged on a flat plane.

Another design incorporated capacity control by using two pistons. Under low load only one piston pumped, and when greater capacity was required the motor would reverse and engage the second piston thus providing full pumping capacity.

In the 1950’s, General Electric developed a reciprocating compressor meant for cooling and heat pump applications. The compressor had a unique valving system allowing for a minuscule clearance volume: on every discharge stroke of the piston almost all the charge was pushed out of the cylinder thus improving pumping efficiency. The over-sized hermetic shell served as a refrigerant accumulator featuring a loop of discharge tubing running through the bottom of the shell.

The hot discharge line would vaporize any liquid refrigerant finding its way back to the compressor during operation. The all-aluminum frame, motor housing, piston and connecting rod components were designed to reduce thermal stress and to help the compressor to run cooler by dissipating heat away from bearing surfaces. Truly a unique concept, many reciprocating compressors of this type are still in use today.

By 1987, the Trane Company had introduced its 3D Scroll compressor to the commercial marketplace, although Trane was one of the last manufacturers to use scrolls in residential products. While reciprocating compressors continue to enjoy an excellent record of reliability, the improved efficiency, reduced noise levels, and the much lower cost of production inevitably convinced split system manufacturers to fully embrace scroll compressors in most of their product offerings.

Scroll compression volume is formed

by the orbiting relationship between the two involutes that compress the refrigerant gas in a continuous circular motion. As the orbiting scroll moves, it creates a decreasing volume between itself and the stationary scroll. Refrigerant gas is drawn into the pockets between the two scroll involutes, and as the orbiting involute continues to move the pockets become smaller and smaller eventually forcing the compressed gas through the center port and along to the condenser coil.

Without having to worry about a piston colliding with the cylinder head or valve assembly, there is no clearance volume to reduce compression efficiency.

The scroll set incorporates mechanisms that allow for radial and axial conformance: the involutes can move up and down or side to side just enough to allow a small amount of liquid to pass through without damaging the assembly. (Note: small amount!)

In the early 2000’s, scroll compressors with a modulation ring incorporated into the scroll set (Figure 1) were introduced into the premium equipment segment and became known as twostep compressors having pumping capacity reduced by 35% in first step. Two-step scroll outdoor units connected to variable speed air handlers not only

offered some energy savings, but consistent temperatures and better humidity control.

Intense governmental scrutiny of energy using appliances such as gas furnaces, refrigerators, air conditioners and heat pumps (to name just a few) pushed manufacturers to find more substantial ways of reducing watts consumed by these products while delivering the same level or even better performance.

Partial capacity control offered by two-step scrolls was bettered by the introduction of the variable frequency drive, also known as the inverter drive, to residential HVAC over a decade ago.

Inverters control the speed of the compressor by adjusting the frequency of the supplied electrical power rather than using mechanical unloading devices to deliver improved low load efficiency and better humidity control all while using fewer watts while only partially loaded.

An inverter drive takes the incoming AC voltage and converts it to DC using a rectifier. The resulting DC voltage powers the inverter circuit that produces an AC voltage at variable frequency.

The compressor motor speed is controlled by the AC hertz delivered to it

depending upon the heating or cooling load conditions. Inverter drives, combined with the recent introduction of dense vapour injection, or flash injection, of refrigerant directly into the scroll set made the cold climate heat pump a truly revolutionary advancement in our industry.

Early scroll compressors tended to vibrate a bit too much, and some were

even noisier than recips of the day.

I remember reading an article published by one manufacturer in the early days saying that scroll compressors were unsuitable for use in residential applications less than 42K Btu/h. Although those teething problems were eventually satisfactorily attenuated, scrolls have another tendency that some electricity distribution utilities in Canada are very upset about.

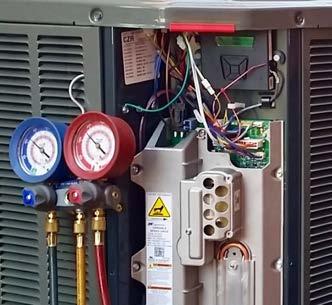

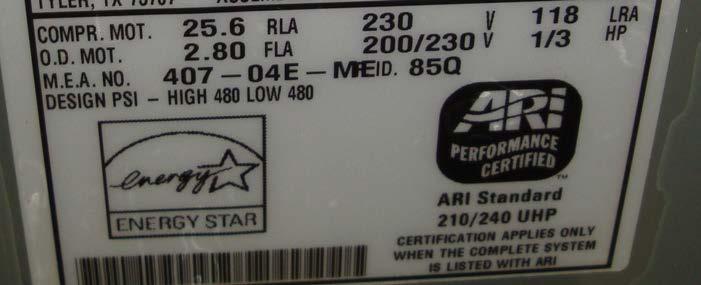

It has to do with rapid voltage changes

caused by high current consumption during the start-up of residential heat pumps having compressors with lock rotor currents capable of drawing more than 100 amps (Figure 2).

Too many large conventional air conditioners or heat pumps starting a cycle at roughly the same time will create a significant voltage drop that can affect the stability of the electrical grid. Homeowners recognize this voltage drop as light flicker, one utility reported that 7% of their customer complaints last year resulted from light flicker.

You often hear comments portraying our electric distribution grid as old and creaky; no doubt, many improvements must be made to support the level of electrification so many of us want.

Utility engineers are working toward fortifying the distribution system by increasing secondary network conductor size, increasing service conductor size,

Continued on p16

Continued from p15

and increasing transformer size among other things.

However, larger transformer installations must be balanced with demand because transformers work most efficiently at ~80% capacity. Thus, utilities are looking for appliance manufacturers to improve the electrical/electronic characteristics of residential and commercial HVAC/R equipment that can potentially pollute the grid with transients, harmonics, voltage sags and surges.

Inverter driven compressors typically require only 30% to 40% lock rotor current at start-up. Inverters often incorporate an automatic function that supplies active power factor correction designed to boost DC output voltage to the compressor when power demand is high.

Such power correction improves the power factor for the local electrical utility by reducing current draw and, at the same time, limiting harmonic distortion that may lead to the utility transformer overheating.

But inverter driven compressors can also be the victims of power quality issues, the very same voltage fluctuations and surges potentially caused by their neighboring conventional compressors creating mayhem on the grid.

Inverter controls can be more susceptible to overheating or heat-driven component failures when poor design or low-quality components such as microprocessors, capacitors and semiconductors fail to properly regulate the compressor speed and control system functions.

Even the best components will generate heat during operation, and without adequate cooling mechanisms such as fans, heat sinks or refrigerant cooled heat sinks (see Figure 3), or, if the inverter is installed in an area with poor ventilation, the heat generated by said components will build up and cause potential premature component failures.

As the inverter compressor era be -

comes better established in the HVAC/R marketplace, there are several outstanding issues making widespread adoption less likely in the near future.

For one thing, the initial cost of cold climate inverter driven compressors featuring dense vapour injection make them less attractive to budget conscious homeowners and builders who continue to prioritize cost over longterm energy savings.

Another potential Achilles Heel is complexity. The process of adjusting compressor speed to maintain consistent indoor temperatures and superior humidity control means more sophisticated sensors and advanced control systems combined with line after line of proprietary software codes making diagnostics and repairs that much more challenging in the event of a malfunction.

Technicians and installers must learn to work with high DC voltage. Line set sizing requires strict adherence to manufacturer specifications related to tubing run and rise maximums, otherwise, oil management systems designed to ensure adequate amounts of oil is returned to the compressor sump will be impaired and will result in disastrous compressor failures.

The potential for considerably higher repair and maintenance costs does exist and cannot be ignored.

Our industry needs no more warnings about the shortage of qualified installers and technicians needed to make the inverter era work as advertised. Only a steady and ample stream of trade school graduates deciding to embrace a career in HVAC/R every year will make a difference in furthering the advance of the inverter era.

Added to the skilled labour challenge, manufacturers intend to introduce residential equipment charged with low global warming potential (GWP) “mildly flammable” A2L refrigerants by early 2025. Another round of training to familiarize the trade with A2L refrigerants coupled with the introduction of new safe handling techniques and new tools approved for use with A2Ls suggests contractors should start early; get your staff up to speed as soon as possible and continue remedial training into the future.

The multiple thorny issues of high initial cost, lack of competent HVAC/R technical staff, linked to an electrical infrastructure not nearly ready for full scale electrification means that the inverter era will, figuratively speaking, stagger into its own rather than take off like the scroll compressor era.

And it’s too bad, because as there are advantages and disadvantages to both inverter driven and conventional compressors, the benefits of comfort, durability, noise reduction, and energy efficiency are surely making inverter driven compressors a better choice for most residential heat pump and air conditioner applications. <>

Ian McTeer is an HVAC consultant with over 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician. Questions? Ian can be contacted via email at: iMcTeer@outlook.com.

Interest in heat pumps is growing rapidly as homeowners are learning more about the technology through government incentive programs and exposure through mainstream media. Being on the front lines, HVAC contractors are doing their part to educate consumers about what heat pumps are and why they make sense for efficient space heating and cooling.

The latest installment of HPAC magazine’s 30 Mechanical Minutes, our free educational webinar series, turned its focus on getting into the specifics of the latest generation of cold climate heat pump technologies. Joining HPAC editor Doug Picklyk in this episode were two regular magazine contributors, Ian McTeer and Gerry Wagner. This edition of 30 Mechanical Minutes was sponsored by Olimpia Splendid.

To begin, McTeer explained how the industry has been trying for years to improve comfort while reducing electrical consumption on air conditioners and heat pumps using mechanical processes, such as two-step compressors, where the unit is only partially loaded to conserve energy when possible. “The mechanical method worked reasonably

well, but an inverter does a much better job,” says McTeer.

As McTeer explained: an inverter drive takes incoming A/C voltage and converts it to DC using a rectifier. The resulting DC voltage powers the inverter circuit that produces an A/C voltage at variable frequency, so the compressor motor speed is controlled by the A/C Hertz delivered to it. A combination of sensors and smart thermostats control the logic and decide what speed the compressor should run at based on the load condition at the time.

“I'd have to say that the inverter drive compressor is probably one of the most significant advances in the HVAC industry, especially residential products,” says McTeer.

And Wagner has stated many times that the inverter compressor is “the greatest invention in the HVAC industry in my lifetime.” He points to heat pump products now having seasonal energy efficiency ratings (SEER) in the high thirties. “I never thought I’d say that in my lifetime. And that’s all a result of the inverter compressor bringing low ambient

heating down to negative 5F (-20C),” says Wagner.

He also credits the inverter compressor for allowing multi-zone mini-split systems, something that wasn’t possible prior to the inverter compressor. And he welcomes the introduction of soft start technology—inverter compressors don’t start at 3,600 rpm and work their way down, they start slowly and work their way up. “Once it finds that sweet spot—the set point temperature—it’ll go into what I call cruise control. It’s a compressor with a gas pedal,” says Wagner.

Ian McTeer and Gerry Wagner sit down with HPAC to discuss the facts behind inverter technology and how its making heat pumps better. BY HPACHPAC editor Doug Picklyk (left) is joined by Ian McTeer (centre) and Gerry Wagner to discuss the technology in cold climate heat pumps. Figure 1. Illustration of two-stage vapour injection compressor.

There are a few different methods manufacturers use to further enhance the capabilities of heat pumps, and one is flash injection technology, sometimes also referred to as enhanced vapour injection. It’s this technology, when combined with inverter compressors, that is allowing heat pumps to perform at much lower temperatures, creating the ‘cold climate’ heat pump category.

As Wagner explains: It's commonly called the two-stage vapour injection compressor. Referring to an image (see Figure 1), he points out the two suction ports and the single discharge. When vapour changes pressure energy is produced, and that’s what is happening here. He explains how that second injection port has a vapour injection valve which, based upon outdoor air temperature and some other criteria, will open and ultimately provide that added heating capacity.

“That’s how we’re getting heat out of outdoor temperatures like -33F (-36C).”

McTeer has connected a cold climate heat pump to the centrally-ducted air handler in his home in the Ottawa area, and he revealed some ‘balance point’ charts to show the difference between a conventional multi-stage system compared with his inverter-driven cold climate technology.

“This chart [see Figure 2, above] is something we used to do in the early days of conventional heat pumps. My outside design temperature is minus -13F (-25C), and the load at design is 34,399 Btu/h.”

So he drew a line from minus -13F (-25C) across and down to 65F (18C), the theoretical point where no heating or cooling is required—that’s the ‘load line.’

Then he created an ‘equipment line’ using data from a conventional twostep heat pump, where at 47F (8.3C) the unit would put out 27,600 Btu/h, and at 2F (-16.6C) its output would be 11,900 Btu/h. The balance point, where the equipment line crosses the load line, is 22F (-5C). That’s the point where second stage is going to call.

Data from his own installed 2.5-ton cold climate heat pump shows that at 47F (8.3C) it’s producing 32,000 Btu/h, and at -13F (-25C) its output is 25,600 Btu/h. Now the balance point, using the same load and the new equipment line is down to 0F (-18C).

“So at -18C I'm going to get a bit of my back up electric resistance heat coming on to supplement, so both units will be running together,” says McTeer. “We’ve been through two winters now and it’s just been absolutely delightful.”

Among other benefits, Wagner explained how inverter technology actually improves the capacity of multi-zone mini-split systems. Since the inverter compressor matches the load, whichever zones are calling, or not calling, the output of the compressor matches the load at that moment in time.

Also, when looking at different multizone possibilities, he insists that contractors don’t just look at model number of Continued on p20

the outdoor unit and assume that is the highest output capacity. For example, an 18,000 Btu/h outdoor inverter multi-zone compressor can, in many cases, give you as much as 22,000 or 23,000 Btu/h of cooling and heating. “So it’s always best to look at the capacity chart, not the model number,” he says.

Today’s cold climate heat pumps are premium products, so cost could be a barrier to acceptance, and McTeer shared other concerns regarding market adoption of the technology.

Following the live webinar, here are a few of the questions posed by the attendees:

Where is the flash injection line taken from in the refrigerant circuit? And how is the quantity taken?

Wagner: There is a vapour injection valve, which is really, quite frankly, nothing more than a motorized bypass valve, coming off the suction. And again, only activating when the outdoor air temperature drops below where vapour injection is required.

McTeer: Some manufacturers divert a little bit of liquid coming back from the condenser and run it through a plate heat exchanger. And then they have a solenoid valve that allows them to inject that dense vapour as needed. It looks like they’re injecting it into the scroll set or into the suction line just upstream of the compressor. Others use a system where they dump a little bit of a hot gas into a flash tank where it immediately becomes a dense vapour that’s injected into the compressor. The manufacturer could use a solenoid valve controlled by the inverter board in conjunction with an engineered metering device that will create and thus control the flow of dense vapour to the compressor as the conditions demand.

Why do heat pumps take longer than fossil fuel equipment to get set point?

Wagner: I would disagree with that statement in general. In fact, I may even suggest just the opposite, at least up against a hydronic system. I think that question suggests there is a trade-off for efficiency and comfort, and there absolutely is not.

“If everyone on my street converted to a heat pump like mine tomorrow, there’s not enough electricity on the street to run all those heat pumps and the required electric furnace back up on the coldest days.”

For Wagner, who has been traveling across Canada educating wholesalers and others about heat pump technology, the future looks bright.

“We have gone through a number of winters with the inverter technology, and even with the vapour injection technology, and we are just thrilled to be getting reports from coast to coast, and in northern Canada as well, where systems were performing as designed. The technology is working. It’s tried and true, and it’s nothing to be afraid of at this point.” <>

To view this entire episode of 30 Mechanical Minutes and to re-visit past editions of the series visit our website hpacmag.com/tech-pulse or go to our YouTube channel (@hpacmag).

McTeer: Well, in the early days of conventional heat pumps, there was a lot of truth to that. We used to advise people to never set back in the winter time, because the heat of a conventional heat pump coming out of setback would take hours to bring the temperature up. But the newer heat pumps have changed that. I set mine back 2C at night, and there's absolutely no problem in the morning coming out of setback.

How do you size an inverter unit? Do you size for heating or cooling load?

Wagner: Start with a proper heat gain/heat loss calculation. It’s 2023, and we have to apply science to this. There are no more excuses for guess work.

McTeer: I sized for the heating load. I got the manufacturers specifications, and I saw the heating output. And then I looked at my load calculation and saw my cooling load, and of course there’s quite a difference there. I wanted the Btus on the heating side. In the old days they used to say, size for the cooling load and add half a ton. Which was probably the worst advice I have ever heard, because cooling equipment was often oversized, and then adding half a ton to it to try to take advantage on the heating side just left systems working very poorly, in my in my opinion. And quite often the air handling side wasn’t adequate either. So, in the case of a of a cold climate heat pump, you want to look at the heating output.

Are the inverter heat pumps quieter starting?

Wagner: Absolutely. I think that goes without saying, and I can actually throw some numbers at you. A typical 4-ton system outdoor unit is about 58 decibels. In comparison, a normal conversation between two people standing next to each other is somewhere between 60 to 70 decibels. So it’s quieter than a normal conversation.

The questions and answers have been edited for clarity. To view the entire webinar visit hpacmag.com/tech-pulse or @hpacmag on YouTube.

“The technology is working ... and it's nothing to be afraid of at this point.”

“The inverter compressor is the greatest invention in the HVAC industry in my lifetime.”

Ihave made that statement many times in this column as well in my mini-split and central-ducted training events. I remain committed to it and offer the following as further evidence to support it.

There is a feature of the multi-zone mini split system I represent that I had been apprehensive to use myself in a residential application when I was still contracting, and it’s one that as a trainer I had a difficult time describing objectively.

The feature is the ability to install more indoor capacity than outdoor capacity.

In my training events I almost have a hard time completing that sentence because on the surface, it seems so wrong.

However, like most features and components of the inverter mini split, we need to scratch below the surface a little bit to uncover the true advantage.

If you look at the chart of approved standard multi-zone combinations I’ve included above (Figure 1, outdoor unit models in the top bar and capacity of the multiple indoor units below), you will notice that 73 of the 123 approved combinations actually add up to more indoor capacity than outdoor capacity.

Well, clearly you are always limited to the capacity of the outdoor unit, but when you look closely at the capacities of these standard multi-zone outdoor units (Figure 2), you see that the 18K, 24K and 30K outdoor unit capacity range in brackets exceeds their capacity stated in their model number for both cooling and heating.

You will also notice that the 36K and 42K exceeds their capacity stated in their model number for heating.

So, when we look at the approved combination of 9+9+9 for the 24K unit, at first glance it appears we have 3K more indoor capacity than the 24K out-

door unit. However, a closer examination reveals that the 24K unit has a capacity in cooling to 33K and in heating to 28K, more than enough to handle the 27K of indoor units!

Please note that not all of the approved combinations work out this way. Many still represent more indoor capacity than outdoor, and in these instances, should all indoor units call simultane -

ously the system is limited to the overall capacity of the outdoor unit and may result in the indoor units de-rating.

My example of the 9+9+9 with the 24K exemplifies how instead of moving up to the 34K outdoor unit, you can keep your equipment cost down yet still maintain necessary capacity.

Note this also applies to enhanced multi-zone units as well (Figure 3).

I love that even after all my years with these products, I still find revelations like this to excite me and cause me to rethink previous concerns. <>

Gerry Wagner is vice president business development for Bathica, and he can be contacted at gerrywagner@bathica.com

Taking a look at common mixing techniques to keep closed-loop water temperature at optimal levels.

BY JOHN SIEGENTHALERThere are many hydronic heating systems where the temperature of water from the heat source is (or might be) well above the temperature required by the heat emitters. Radiant floor heating supplied from a “conventional” boiler is probably the most common example. Although some installers might assume the solution is to turn down the high limit temperature setting of the boiler, that’s not the answer.

The North American hydronics industry learned this lesson the hard way when radiant floor heating began its “resurrection” in the early 1980s. Many boilers along with their venting systems were trashed due to sustained flue gas condensation caused by operation at low water temperatures. Turning down the heat source temperature also doesn’t apply to “wild” heat sources such as thermal storage tanks heated by solar collectors, pellet boilers or cordwood gasification boilers.

Fortunately, there are many proven methods of interceding between higher temperature hydronic heat sources and low temperature distribution systems. They are all based on mixing hot water from the heat source with cooler water returning from the heat emitters.

The proportions of that blend can range from 0 to 100% of the hot water. In most cases the blended supply water temperature is between these two extremes.

The “primary” objective of mixing is to create a suitable supply water temperature for the heat emitters. However, when any type of conventional boiler (e.g., one not intended to operate with sustained flue gas condensation), serves as the heat source, the mixing assembly must also protect that boiler against conditions that would cause that condensation.

The only consistent way to prevent sustained flue gas condensation is to sense and react to the temperature of water entering the boiler.

The sensing part of this requirement is easy - just add a sensor to the pipe leading into the boiler.

The “reaction” part of the requirement is a bit more involved. It requires piping design that allows the boiler to be thermally “uncoupled” from the load when necessary. I like to describe this function as a “thermal clutch.” To understand the clutch analogy, think about the function of a clutch in a vehicle. It al -

lows the engine to be mechanically uncoupled (fully or partially) from the drivetrain when necessary.

When fully uncoupled, the engine can quickly increase its power output, and not be “lugged down” by a significant mechanical load, such as starting to move a five-ton truck up an inclined road. Once the engine’s power level has increased, the vehicle’s clutch is slowly actuated to begin transferring the engine’s power to the drivetrain. Those who drive vehicles with clutches quickly learn how to control the clutch pedal so as not to overload the engine.

Mixing assemblies that act as a thermal clutch must have the “intelligence” to allow heat to move from the boiler to the load, but not at a rate that would thermally overload the boiler, causing its temperature to drop and creating conditions that cause sustained flue gas condensation.

The best way to understand different approaches to mixing is to consider a generalized piping design that’s adaptable to several mixing hardware configurations. Figure 1 shows this “mixing assembly” concept that creates a bridge between a boiler (or other heat source) and the distribution system.

Grow your business with Viessmann future-proof solutions. Our smart generation of high-efficiency gas condensing boilers and digital applications are designed to work for you. Save time and energy on and off the job.

+ Flexible installation with dual position display

+ Fast commissioning with preconfigured start-up guide

+ Easy remote monitoring and servicing with Vitoguide

+ Optimize maintenance with interchangeable spare parts and accessories

+ Fits any home with residential boiler sizes from 85 to 199 MBH, all with WiFi inside

Scan

100 Series

200 Series

100 Combi Series NEW 199 MBH

100 Series

200 Series

100 Combi Series NEW 199 MBH

viessmann.ca

smart heating solutions made easy

The mixing assembly is the only path for heat to move from the heat source to the load. As such it can prevent heat flow, allow heat to cross at the maximum output, or regulate heat transfer between those two limiting conditions.

The mixing assembly is “informed” by two temperature sensors. One on the supply side of the system and the other near the boiler inlet.

Figure 2 shows several hardware configurations that would fit into the conceptual box called the mixing assembly. Each configuration connects to the boiler loop at two points (labelled A and B), and also to the distribution system at two points (labelled C and D).

There are several hardware groupings that can be used as the mixing assembly (also shown in Figure 2).

All of these mixing assemblies can

provide supply temperature control as well as anti-condensation protection for a conventional boiler. However, some are more “practical” than others.

Of the six mixing assemblies shown we’ll discuss 2-way, 3-way- and 4-way motorized valves, and variable speed injection mixing.

A two-way motorized valve, piped as shown in assembly #5, allows for injection mixing. The motorized valve meters hot water from the boiler loop into the distribution system. Mixing occurs in the tee downstream of the valve.

The amount of flow passing through the valve is regulated by an electronic controller that monitors both the supply water to the distribution system and the water returning to the boiler.

When the latter is low enough to allow sustained flue gas condensation (typically below 130F), the controller operates the motorized valve to limit the amount of hot water passing into the distribution system.

This monitoring and adjustment continues as long as the distribution system is active. It keeps the boiler inlet temperature at or slightly above some minimum temperature setting on the controller whenever possible.

The globe valve shown between the tees near points C and D is adjusted so that the 2-way motorized valve is fully open while yielding the required supply water at design load conditions.

Notice that the supply temperature sensor for the mixing assembly is located downstream of the tee where the hot and cool fluids mix.

That sensor should be at least four feet downstream of the tee. This is an important detail that ensures the hot and cool water streams are fully mixed by the time the flow passes the sensor.

Although not shown in Figure 2, locating the supply temperature sensor downstream of several fittings, or the distribution circulator when possible, further ensures complete mixing before temperature sensing.

Most controllers that operate a twoway motorized mixing valve output either a “3-wire floating” signal, or a 2-10 VDC modulating signal, depending on the type of actuator used on the valve.

These controllers would also be able to adjust the valve to supply the distribution system with either a fixed setpoint supply temperature, or a temperature based on outdoor reset.

One of the most common and long-es -

tablished mixing methods used in lower temperature hydronic systems is based on a three-way motorized valve.

These valves combine hot water from the heat source with cooler water returning from the heat emitters to create a supply water temperature based on either setpoint or outdoor reset control.

The controller operating the valve could be identical to that used for a twoway motorized valve. That controller would also monitor boiler inlet temperature and reduce the hot water entering the valve, when necessary, to prevent sustained flue gas condensation.

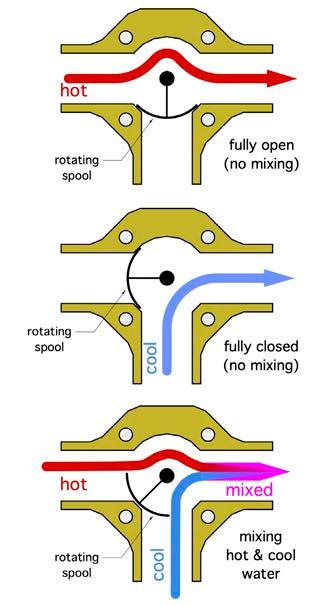

Figure 3 (next page) shows an example of the rotary type valve used for three-way mixing. The valve is shown with a manually adjustable knob which would be replaced with a motorized actuator for automatic control.

The valve has an internal spool that rotates with the shaft. The spool’s position determines the proportions of hot

water and cooler return water that enter the valve and mix together.

One extreme position allows no return water into the mix, and the other extreme position allows no heat source water into the valve.

The full range of rotation between the two extreme positions is 90 degrees. Most actuators used to rotate the valve shaft require from 1.5 to three minutes to move the shaft through its full range of travel. Although this probably seems slow, it allows for smooth, stable, and accurate control of the supply water temperature.

Assembly #2 shows how a three-way motorized valve would be combined with other fittings and a purging valve to form a mixing assembly.

These valves are specifically designed to create two mixing points within a single

Continued on p28

ent, eliminating the boiler circulator saves first cost and life cycle cost.

Figure 4 shows a four-way mixing valve with attached motor actuator.

The concept of using a circulator to inject hot water from a heat source into a circulating lower temperature distribution system goes back into the 1960s. The use of a variable speed injection circulator is a contemporary variation on the concept, and it’s been used with conventional hydronic circulators (those with permanent split capacitor or shaded pole motors) for about 30 years.

Variable speed injection mixing often has a cost advantage over mixing with three-way or four-way valves in larger systems that would require mixing valve bodies of 3-in. pipe sizes or larger.

When applied as shown in Figure 2 (assembly #6), variable speed injection mixing can provide setpoint or outdoor reset control functions as well as anticondensation protection.

valve body. One mixing point regulates the supply water, the other boosts the water temp. entering the boiler.

Figure 2 (assembly #3) shows how a four-way mixing valve is piped. In many ways a four-way motorized valve is functionally equivalent to a three-way motorized valve. However, there’s one important distinction. If the four-way valve is used with a low flow resistance boiler (such as one made of cast iron sections), AND if the valve is mounted close to the boiler, AND if the boiler is operated at a relatively high temperature (such as 170-200F), it’s possible to eliminate the heat source circulator.

The momentum of the flow returning from the load circuit is sufficient to carry the necessary flow through the boiler. When these unique conditions are pres -

The path ahead for variable speed injection mixing is unclear because most currently available controllers for this mixing method are designed for use with permanent split capacitor or shaded pole motors, whereas the circulator world is quickly transitioning to ECM-based motor technology.

This article provides an overview of common mixing techniques. Readers are encouraged to dig into the details and create systems that provide the “right mix” for years to come. <>

John Siegenthaler, P.E., has designed hydronic systems for over 40 years and has written Modern Hydronic Heating (4th Edition). Visit hydronicpros.com.

The Central-Moov NEEP and AHRI listed add-on heat pump system consists of a Moovair M20 condenser and matched Moovair A-coil meets the NRCan ccASHP and Canada Greener Homes Grant requirements.

No one has ever told me that I am a quiet person. Literally no one. Ever.

It’s actually one of my goals in life to try to be quieter. Be a good listener— slow to speak and quick to listen. Unfortunately, I have not quite made it there yet. So just to warn you, I have an opinion in this article that may seem counter intuitive. You might agree, or you might disagree, but just remember we can still be friends.

Zoning and zone controls are a big part of the hydronics industry. The good old “relay box” as it used to be called has been transforming over the decades. I can say that because I have been here for over two.

Zone controls came out of a need to clean up some wiring. You know what I’m talking about—we’ve all seen the jobs where someone thought they could get away with a couple relays to do the job. That was probably true, but they forgot about how many wires it would take

to get everything working properly.

Then just as they were finishing, the homeowner told them they would also like to control the hot water tank. We can laugh about this because we’ve seen it happen, probably firsthand. This is exactly why zone controls have found a niche in our world.

Zone controls, in my opinion, are the heart of the home. No, this is not the opinion I was talking about earlier; you will know it when you see it.

Zone controls are designed to take inputs from thermostats (mainly) and decide where to push some heat. Generally, when a thermostat ‘calls’ the controller will maybe turn on a “system pump” in that zone, or for that zone it could be a valve or a pump. The original “relay boxes” did only this much.

Now I am simplifying this somewhat but stay with me. This was a big step, as the wiring that these “relay boxes” cleaned up was remarkable. Inputs in one side, outputs on the other. Even the

high voltage for pumps was taken care of. They had big relays; they even went as far as to be replaceable relays. This was just the start of a long relationship with zone controls.

The next evolution brought in more inputs. I think the reason for some of the changes was that boilers started to offer more options. To clean up even more wiring it was “easy” to add some more features to these boxes. DHW priority with a timer was available when a small CPU was added to the boards. It was no longer a “relay box” but it had morphed into a zone control at this point.

Thermostats in our industry have also gotten smarter so they can make more relevant decisions. But at the end of the day, the movement of water is controlled by the zone control. The addition of a CPU to zone controls was a good step. It allows designers to add features that you just can’t add in the hardware— decision-type additions. I do however

Continued on p32

Continued from p30

think the biggest change has been the onset of Wi-Fi in zone controls.

Wi-Fi on zone controls is a blessing and a curse. It is great to be able to program and monitor the zone control, like the thermostats, from your phone. It really is. Now keep in mind this type of functionality is not available on all zone controls. Insert shameless plug here. :)

Adding Wi-Fi also allows contractors to see what’s happening and trouble shoot remotely, which is a bigger deal than it seems. The reason I say that is, when the homeowner has access to the temperature, settings, and everything the controls are doing, it creates its own set of issues.

I am all for the adage, information is power. It really is, but it can also create issues. I have found that homeowners monitor their system way more when they have the information on their phone. Way more!

They should be able to; they paid for it. But sometimes it does create questions about the system, about the inner workings, that can become a bit of a pain for contractors.

I see it all the time. It can create a new set of headaches.

Most of the technology for our industry originates in Europe. When it comes to zoning in Europe, radiators are king. They are a different animal than heated floors. They are a set it and forget it approach. Zone controls do not really exist in Europe, well at least until recently with the onset of wireless valves for radiators, but that is not our topic today.

The reason I bring this up is because there are a lot of “zones” in a European system, but you wouldn’t know it. Each zone does not have a thermostat and a possible associated pump or valve. If it did it would seem to get a bit chaotic. At least in my opinion. Now here it comes. Keep in mind I love zone controls. We

make a lot of them and sell them for all sorts of different applications. But I think we may have an over zoning problem.

There, I said it. You can stop reading if you like.

Why the heck would I say that. Well, I was told a long time ago that other hydronic heating companies were not my competitors. It was a Robert Bean quote that took me by surprise and stuck with me forever. His next statement: “The forced air guys are the competitors. They have all the heating system market share.”

cost, more pumps, more valves. The homeowner begins to be uncomfortable because his or her wallet is getting too light. We sell comfort, but with that should not come a bunch of complexity.

Back on topic. Sorry about the “rant”.

The newest generation of zone controls have added even more features, including the control of forced air. Air systems are a part of our industry, they are not going away, so why have they always been treated separate.

The radiant system had no idea what the air was doing and vice versa. Now, by adding the air controls to the radiant zone systems we have full control over everything. Bwahahahaha (my ominous laugh).

This is a good thing. The more we know about the whole system improves the decisions the control is able to make. Taking control of the air system does not make more complications, it makes less in the end.

I had never thought about it like that. I was young at the time, but the perspective shift that gave me was huge. The goal became not competing with the other companies in our space, but how can we all gain market share from the air guys.

Putting 60 zones in a house is not the way to do that.

If we are to ever compete with a furnace, we need to bring the cost of radiant heating down. The way to do that is not to add more zones. I am actually very passionate about this topic.

I see it all the time. We often get asked for help on a system that is just too complicated.

When did we throw K.I.S.S. (keep it simple, stupid) out the window.

Each zone we add to a system not only adds cost in controls, thermostats, and wiring but in distribution cost, pipe

I have been seeing over the last few years more and more fan coils built into hydronics systems. Yes, I know they have been around for a long time, I’m just seeing more built in, and I like it.

So how do I wrap up this zoning mess. I’ll do it by leaving you with some math.

If the air industry has 93% of all installations in North America and the “wet guys” have 7%, how much can we gain by just ticking our number up to 8%?

We are all in this together, and I am a high tide rises all ships kind of guy. <>

Curtis Bennett C.E.T is product development manager with HBX Control Systems Inc. in Calgary.

He formed HBX Control Systems with Tom Hermann in 2002. Its control systems are designed, engineered and manufactured in Canada to accommodate a range of hydronic heating and cooling needs.

“The newest generation of zone controls have added even more features, including the control of forced air.”

SILVER SPONSORS

BRONZE SPONSORS

THANK YOU TO OUR GENEROUS SPONSORS FOR THEIR SUPPORT OF WOMEN IN CONSTRUCTION

THANK YOU TO THIS YEAR’S KEYNOTE SPEAKER, MODERATORS AND PANELISTS

SPECIAL THANK YOU TO ALL OF YOU WHO ATTENDED. ALL SESSION RECORDINGS ARE NOW LIVE ON THE WOMEN IN CONSTRUCTION WEBSITE

Women in Construction is jointly presented by the Construction Magazine family at Annex Business Media. GLASS

I wish that this had been in place when I started in Construction in the late 1980s.

“ ”

In late April, Carrier Global announced a proposed acquisition of Viessmann Climate Solutions, the largest segment of Viessmann Group, in transaction valued at 12 billion Euro ($18B).

“The acquisition of Viessmann Climate Solutions is a game-changing opportunity,” said Carrier Chairman/CEO David Gitlin in a company release.

“Climate change, sustainability requirements and geopolitical factors are driving an unprecedented energy transition in Europe. Viessmann Climate Solutions is uniquely positioned to capitalize on this opportunity with its premier brand, highly differentiated distribution channel and innovative product offerings,” said Gitlin. “We look forward to welcoming its 11,000 team members to the Carrier family and Max Viessmann, CEO of Viessmann to the Carrier Board of Directors at closing, which is expected around the end of 2023.”

Within the announcement, the company notes that Viessmann’s sales and EBITDA have grown over 15% on a compounded annual growth rate basis since 2020, with double-digit growth expected to continue through 2030.

“Following the closing of the transaction, the Viessmann Group will remain committed as a significant, long-term shareowner of Carrier, reflecting our family’s high confidence in the superior value to be created by this combination,” said Max Viessmann.

Viessmann Climate Solutions will continue to be led by current CEO Thomas Heim, and its headquarters will remain in Allendorf, Germany. Both parties also agreed on long-term guarantees which

>> Bartle & Gibson has established a new regional partnership to distribute Bradford White’s full line of residential, commercial and industrial products across Western Canada. bartlegibson.com

>> Visionary Sales, a Toronto-based manufacturer’s representative, has partnered with Ecoer North America heat pump systems for Eastern Canada and is introducing AquiSense Technologies’ PearlAqua line of UV-C LED water disinfection products to the Canadian market. visionarysales.ca

>> Wolseley Canada has opened a new 21,000-sq. ft. store and showroom at 377 Fairall St. in Ajax, Ont. wolseleyexpress.com

>> Master Group has expanded to Sudbury, opening a new Northern Ontario branch at 180 National St. master.ca

include: refraining from terminations for operational reasons (three years), site guarantees for all main manufacturing and R&D locations (five years) as well as the headquarters in Allendorf (10 years). corporate.carrier.com viessmann.family

ELECTED TO AD BOARD

AD, the member-owned organization of independent distributors across North America, has announced that François Deschênes, president/ CEO of Montreal-based Deschênes Group has been elected to the AD board. One of three Canadian-based representatives on the 11-member board.

Martin Deschênes, vice chairman, Deschênes Group Inc., is departing his post after serving since 2016.

François Deschênes has been chairman of AD Plumbing & Heating – Canada, and of the buying group Canaplus LP. He is also on the national board of directors of the Canadian Institute of Plumbing and Heating (CIPH). adhq.com

Bosch Thermotechnology has been renamed to Bosch Home Comfort Group.

As a manufacturer of heating, cooling, and hot water systems, in a media release the company indicated that the new name embraces the global megatrend toward electrification. And earlier this year, Bosch announced an investment of $737.6 million in electrification to further accelerate its heat pump ramp up. bosch-homecomfort.com

Biomass boiler manufacturer Hargassner has celebrated its 20th anniversary in North America with the establishment of Hargassner North America Inc. and the opening a North American headquarters in Toronto.

The company has also invested in local warehousing as part of its commitment to meet the needs of Canadian and U.S. customers and distribution partners. hargassner-northamerica.com

>> Next Plumbing and Hydronics Supply has opened its first location outside the GTA with a warehouse and counter at 136 Ottawa St. S. in Kitchener, Ont. nextsupply.ca Continued

Noble, the wholesaler serving the plumbing and heating trade for over 30 years in Ontario, officially launched its AutoStore, a fully automated warehouse system operated by autonomous robots.

Now fully operational at Noble’s Jane Street branch, the picking and fulfillment system is designed to maximize warehouse space and minimize inefficiencies through automated robots programmed to collect orders from thousands of storage bins.

Noble is the first in the industry to implement such a solution.

“AutoStore is faster, more accurate and will help us offer a wider range of products to the trades,” said Jim Anderson, general manager at Noble, in a media release. “The volume of products you can stock in a small footprint with AutoStore far exceeds anything else on the market. In our case, we can fit 21,000 SKUs in less than 5,000 sq. ft., dramatically impacting the amount of inventory our teammates can quickly supply to our clients.”

The company will also be launching a new e-commerce platform later this year, so the new automated warehouse will deliver greater efficiencies to that platform as well. And the AutoStore grid is scalable and can grow as demand increases. noble.ca

Rheem Canada has announced that Martin Rego, P.Eng., is now the director of product management for the company. Rego has held multiple leadership roles within the industry and has participated in the development of codes and standards with the Canadian Standards Association and technical committees with the TSSA.

Mestek has promoted Kevin O’Rourke to vice president of sales – wholesale products. O’Rourke, with the organization since 1998, was serving as the national sales manager, North America, for residential comfort group products. In his new position, he will work with sales representatives, wholesale distributor partners and contractors in North America, and in Canada he will also be responsible for the Slant/Fin Baseboard brand.

NTI Boilers has named Rohit Nair as technical trainer supporting Ontario contractors. Nair has spent three years working with NTI’s technical support team, and now he will provide installation, maintenance and troubleshooting training on the company’s full line of boilers and water heating equipment.

Desco celebrated the return of its annual Parade of Products on May 4th at the Bingemans Conference Centre in Kitchener. It was the first opportunity for the group to host local contractors and its manufacturer partners since the pandemic. desco.ca

Uponor North America has named Anna Picchetti as the new vice president of marketing and strategy. Picchetti brings 20 years of experience to the role, having worked across industrial, technology, and medical device industries. The company has also announced Jon Sillerud, vice president, operations, is now also leading the supply chain function for the company. Having led operations since 2017, Sillerud took on the supply chain role on an interim basis and will now add that to his portfolio. His new title is vice president, integrated supply chain.

John Doughty has joined Armstrong Fluid Technology as director, global sales enablement. Based in the UK, Doughty will work with sales teams worldwide. Previously he was a global director of sales excellence with Honeywell, where he spent 23 years.

After 40 years working in the heating industry Rob Brennan has announced he will be retiring. Brennan has spent the last 20 years with Flexmaster Canada, most recently serving as Ontario regional sales manager.

EMCO and Bathica have announced a cooperative sponsorship of the RGC Sports #59 Dodge Challenger NASCAR Pinty’s Series race car participating in the WeatherTech 200 at Canadian Tire Motorsports Park in Bowmanville, Ont. on Sunday, September 3, 2023.

The car will be driven by Gary Klutt, a past race winner on the track and the holder of a lap record there as well.

As sponsors, EMCO and Bathica will have VIP opportunities on race day for its guests.

“We had guests at the F1 event in Montreal … and our customers really appreciate high performance cars, and I think to be able to sponsor a car is taking that to another level,” says Guillaume Caillé, CEO Bathica.

“We’re in a mechanical industry and we’re partnered with some great customers that for the most part are ‘gear heads’, and having seen the car at Gary’s shop and … knowing the experience our customers are going to get, it’s just going to be an unforgettable day for everybody,” says Bruce Passmore, eastern regional manager for HVAC/R with EMCO. emco.ca

The formal investiture ceremony is scheduled to be held on Thursday, July 20.

Price Industries was founded in 1946 as a sales company by Gerry’s father and began as a manufacturer’s agent for Hart & Cooley, Farr, and Maid-o-Mist, as well as its own line of fill and vent caps for oil furnaces.

Gerry Price has become an accomplished business executive and philanthropist, as he and his family support charities and capital campaigns in Manitoba across many areas including children and families, youth mentorships, education and scholarships, health care and other community-led initiatives. priceindustries.com

The first of five scheduled Wolseley Expo tradeshows in 2023 kicked off in Edmonton on April 4th, inviting plumbing and HVAC/R professionals to join the national wholesaler and manufacturer part-

ners to view the latest technologies and participate in technical training sessions. Formerly called the Wolseley One Tradeshow, the nationwide tour also made a stop in Toronto on May 11th at the Toronto Congress Centre (photo above). Due to wildfires, the Halifax Expo scheduled to take place June 1 has been postponed to the fall. And the other remaining dates include Vancouver’s Cloverdale Agriplex (Sept. 12), and Montreal at the Sheraton Laval (Nov. 7). wolseleyexpress.com

Gerry Price, the chair and CEO of Winnipegbased Price Industries, manufacturer of air distribution equipment and noise control products for the commercial HVAC industry, will be one of 12 Manitobans to receive the Order of Manitoba, the province’s highest honour.

The quick response (QR) code has become ubiquitous in modern society. The square black-and-white pattern, resembling a maze or puzzle, has replaced restaurant menus and business cards, and can be found on airline tickets, event tickets and many other places, including plumbing and heating products.

What is a QR Code? In simple terms, a QR code is simply a link that can provide information or lead users to a website. QR Codes were invented in Japan in 1994 as an improvement on the bar code. Made publicly available in 2002, adoption began in Japan, and it wasn’t until 2011 that they gained more mainstream attraction worldwide. But adoption was slow, as us-

ers needed to download and launch spe cific apps to scan the codes.

Things changed in 2017 when Apple iPhones and the Android operating system both added native QR code reading to smart phone cameras. It’s a feature that not everyone was aware of, and applications were still slow to jump onboard. (If you’ve never tried it, scan the codes on this magazine’s cover and see where they take you, and remember digital files are instantly shareable.)

The COVID-19 pandemic helped drive adoption as the demand for contactless interactions was elevated, and QR codes allow a fast and touchless way to access information, perform transactions and even make payments.

The codes have become popular in advertising campaigns, as a quick snap with a smart phone brings the user immediately online with a brand. The printed codes bridge the gap between the physical and digital worlds where companies can provide interactive experiences, discounts, or even offer users exclusive content.

QR codes are being integrated into various platforms, such as magazine advertising (take a look through the pages of this issue), posters, flyers, packaging and outdoor advertising.

For manufacturers in the plumbing and heating industry, the QR codes are proving attractive for marketing to con -

tractors as well providing a true utility.