MODERN HYDRONICS

SPRING 2023

AIR-TO-SLAB LOW TEMPERATURE RECIRCULATION FORECASTING FOR SNOWMELT

HEAT PUMP DROP-IN

Toronto

condo replaces chiller with heat pumps.

condo replaces chiller with heat pumps.

a publication of

Not All Glycols Are Created Equal CHEM-FROST Safe For All Systems Including Aluminum and Solar Premier Inhibitors Higher Temperature Rated Low Viscosity your local wholesaler or visit chemfax.com CHEMFAX Manufacturer of Specialty Chemicals Low Viscosity your local wholesaler or visit chemfax.com TM

Not All Glycols Are Created E CHEM-FROST Safe For All Systems Including Aluminum and Solar Premier Inhibitors Higher Temperature Rated Low Viscosity your local wholesaler or visit chemfax.com Not All Glycols Are Created Equal CHEM-FROST Safe For All Systems Including Aluminum and Solar Premier Inhibitors Higher Temperature Rated Low Viscosity your local wholesaler or visit chemfax.com Chem Frost 100% Brand R Brand O Brand H Brand U Brand D Pail Size 20L 18.9L 18.9L 20L 20L 18.9L PG Concentrate Amount 95/5 92/8 N/A 94/6 95/5 95/5 Aluminum Safe YES LIMITED TO 65C NO NO NO NO Solar Safe YES NO SOME LIMITED NO NO NO Geothermal Safe YES LIMITED N/A N/A N/A N/A Temperature Rating 325F 275F 250F 250F 250F 220F Viscosity @ 35% 60C 5.5cP N/A N/A N/A N/A N/A Boiling Point @ 100% 417F 370F 370F 370F 370F 370F CFIA Approved YES YES NO NO YES NO Raw PG Grade FOOD INDUSTRIAL GRADE INDUSTRIAL GRADE INDUSTRIAL GRADE INDUSTRIAL GRADE INDUSTRIAL GRADE Purity of Propylene Glycol 99.94%+ N/A 98% N/A N/A N/A Phosphate / Nitrate NONE YES YES YES YES YES Inhibitor Type PDT NON-TOXIC DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE LEED YES NO NO NO NO NO *Based on information provided on respective manufacturers’ websites * **Subject tochange** HEAT TRANSFER FLUID - INHIBITED PROPYLENE GLYCOL COMPARISON CHART Based on information provided on respective manufacturers’ websites* **Subject to change**

MH6 INDUSTRIAL Air-to-Slab

Combining an air-to-water heat pumps with a heated floor slab in suitable industrial spaces, no buffer tank required.

By John Siegenthaler

By John Siegenthaler

MH12 PROJECT Condo Retrofit

Toronto condo buildings replace air-cooled chiller with heat pumps to provide cooling and offset heating load.

By Doug Picklyk

By Doug Picklyk

MH18 SNOW MELT Weather or Not?

Connecting to the internet to improve snow melt efficiency.

By Curtis Bennett

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

MEDIA DESIGNER

CIRCULATION MANAGER

PUBLISHER

PRESIDENT/COO

MH20 WOOD STOVE Hydronic Adventures in Rural Ontario

Combining open-loop and closedloop systems to provide efficient heat distribution.

By Paul O’Connor

By Paul O’Connor

MH26 NEW PRODUCT SHOWCASE

MH27 MODERN HYDRONICS SUMMIT 2023

Don’t miss the return of Siggy & The Bean (John Siegenthaler and Robert Bean) on stage in Coquitlam September 21.

MH28 RENEWABLE ENERGY Low Temperature Recirculation

Strategies for incorporating renewable energy thermal storage with DHW.

By John Siegenthaler

By John Siegenthaler

MODERN HYDRONICS

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

Logan Caswell (416) 728-6209 LCaswell@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson

NOTICE:

as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Contents Copyright © 2023 by Annex Publishing & Printing Inc. may not be reprinted without permission.

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities.

Proud member of:

CONTENTS

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

HPAC Magazine, Annex Business Media, their staff, officers, directors and shareholders (hence known

111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 TEL: 416.442.5600 FAX: 416.510.5140 www.hpacmag.com

supplement of Heating PlumbingAir Conditioning Magazine

a

MODERN HYDRONICS WWW.HPACMAG.COM MH4 SPRING 2023 Modern Hydronics COVER PHOTO: TECZR MEDIA/SEAN HARRISON (COURTESY PRESTIGE MECHANICAL)

AIR-TO-SLAB: AN INDUSTRIAL SOLUTION

Combining an air-to-water heat pump with a heated floor slab in suitable industrial spaces, and no buffer tank is required.

BY JOHN SIEGENTHALER

Over the last few years I have written several HPAC columns describing how air-to-water heat pumps can provide heating, cooling, and domestic hot water for homes. Many of the systems involve buffer tanks to help stabilize heat transfer from the heat pump to a zoned distribution system.

Those tanks are especially important with a single speed heat pump that supplies a highly-zoned distribution system. Without the thermal mass provided by the buffer tanks, the single speed heat pump would undergo frequent on/off cycles that ultimately leads to premature failure of components such as compressor contactors or start capacitors. Short cycling also lowers the overall efficiency of the heat pump.

The emergence of air-to-water heat pumps with inverter driven variable speed compressors allows heat output to be reduced down to about 30% of the heat pump’s rated capacity. This can reduce the size of the buffer tank—perhaps into the range of 25 to 40 gallons in typical residential systems— depending on the extent of independent zoning.

In this article I want to look at potential applications for air-towater heat pumps that could eliminate the need for a buffer tank all together.

MASSIVE ADVANTAGES

Consider all the non-residential buildings that could be served by a one- or two-zone heated floor slab. Examples include highway garages, farm shops, automobile service facilities, small aircraft hangers or RV showrooms. Workshops used for woodworking or metal fabrication often have similar heating needs. So do light manufacturing or assembly facilities with open floor plans, and warehouse areas where materials are stored on racks (rather than directly on floors) would also fall into a similar category.

The common thread here is a heated floor slab that adds lots of thermal mass to the system, combined with minimal zoning, which would keep most, if not all, of that thermal mass

“online” whenever the system is operating.

For example: a farm shop building has a 40-ft. x 80-ft. footprint. Due to the heavy equipment it’s designed to handle, the concrete slab is six inches thick, and rests on two inches of high compression strength extruded polystyrene. The thermal mass of that slab equals its volume multiplied by the heat capacity of concrete:

That’s equivalent to 5,646 gallons of water storage. Imagine a buffer tank of that volume. All that thermal storage is already in the system, as concrete rather than water.

The best way to keep that mass “online” is constant circulation through the floor circuits. Doing so also helps even out slab temperatures because it moves heat stored in the core area of the slab to the cooler areas near perimeters and just inside overhead doors.

SIMPLEST SYSTEMS

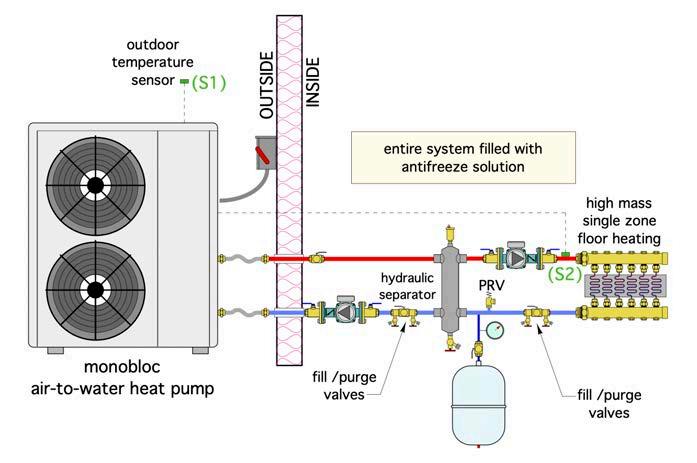

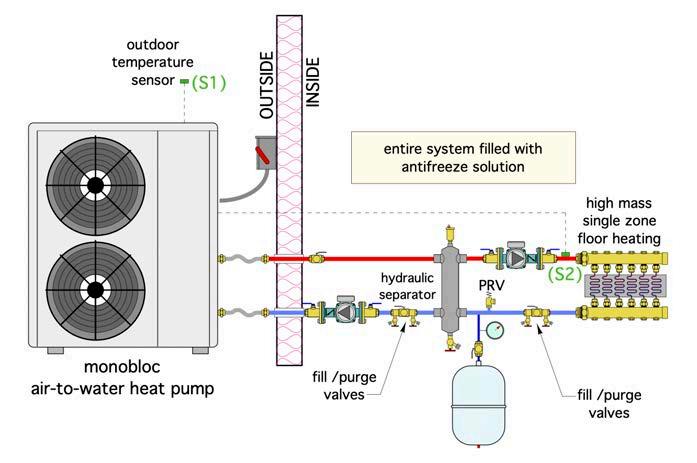

The system layout shown in Figure 1 (next page) is about as simple as it gets. A hydraulic separator connects the heat pump circuit to a manifold station supplying the floor heating circuits. Constant circulation is maintained between the hydraulic separator and the floor circuits. The heat pump and its associated circulator are turned on and off based on the supply water temperature to the manifold station.

The preferred method for determining the required “target” supply water temperature at sensor (S2) is outdoor reset control. An inexpensive controller (or perhaps the controller built into the heat pump) continually calculates the target supply water temperature based on current outdoor temperature.

When the measured supply water temperature drops 3F or 4F below the target temperature the heat pump and its circulator are turned on. They continue to run until the measured supply water temperature is 3F to 4F above the target value.

The on/off differential of 6F to 8F should allow for relatively long heat pump on-times, and off-times, while still keeping the average water temperature relatively close to the target value.

The heat pump on/off cycle times can be lengthened by widening the on/off differential setting of the reset controller.

MODERN HYDRONICS WWW.HPACMAG.COM MH6 SPRING 2023

INDUSTRIAL Continued on MH8 Modern Hydronics

Navien NCB-H combi-boilers

Unmatched heating and DHW performance, all in one compact unit

• Heating up to 150,000 BTU/h and DHW up to 210,000 BTU/h

• Up to 80% smaller than floor standing boiler and tank water heater

• Optimized DHW priority with mixing valve and water adjustment valve to provide consistent DHW temperatures and industry leading flow rates

• Dual stainless steel heat exchangers for heating and separate SS heat exchanger for DHW

• Built-in controls for 3 zone pumps or 3 zone valves

• Heating TDR up to 11:1 and DHW TDR is 15:1

To learn more about the best-selling combi-boilers in North America, visit navieninc.com.

THE LEADER IN CONDENSING TECHNOLOGY

Tear out that wasteful tank and boiler mess...

...and hang up the breakthrough in high capacity combis

However, wider differential settings also increase the chances of “feeling” differences in comfort. A little experimentation with the differential settings will find the “happy spot” for each individual building and its hydronic distribution system.

Air-to-water heat pumps equipped with variable speed compressors are likely to have built-in outdoor reset capability. The compressor modulates its speed in an attempt to hold a specific outlet water temperature.

The temperature is most likely measured by a factory-installed sensor near the outlet of the heat pump. This is not ideal when the heat pump is coupled to the distribution system using any type of hydraulic separation technique.

The potential problem is differences in flow rates between the heat pump circuit and the distribution circuit. Any difference in these two flow rates sets up mixing inside the hydraulic separator.

When the load side flow rate is higher than the heat pump side flow rate, the water temperature supplied to the manifold will be less than the temperature leaving the heat pump. These two temperatures will only be the same when the two flow rates are the same.

The best solution, assuming that the outdoor reset control action is being done by the heat pump’s internal controller, is the ability for the heat pump to monitor an external temperature sensor that’s mounted downstream of the hydraulic separation point.

Sensor (S2) in Figure 1 is an example. That sensor measures the true supply temperature to the manifold, after any mixing has taken place in the hydraulic separator.

LINE THEM UP

Current generation air-to-water heat pumps designed to operate on single phase 240 VAC power, are limited to about 5 tons (60,000 Btu/h) rated heating capacity. When the design load of the building increases beyond the out-

put of such a heat pump a couple of options are possible.

One is to look at higher capacity three-phase air-to-water heat pumps. They’re available in several heating capacity ranges, some of which top out at over 200 tons. Their use is obviously dependent on the availability of three-

phase power and sufficient service entrance capacity.

The other option is to use two or more single phase heat pumps in a staged arrangement as shown in Figure 2

Some of the newest air-to-water heat pumps may have internal firmware

MODERN HYDRONICS WWW.HPACMAG.COM MH8 SPRING 2023 INDUSTRIAL

Figure 2. The option of using two or more single-phase heat pumps.

Modern Hydronics

Continued on MH10

Figure 1

SEPARATION WITH NO COMPROMISE THE GOLD STANDARD

GOLD

S

T

ANDARD

Separation with NOCompromise

Make a smart choice by selecting The Gold Standard Kit for clean hydronic systems to ensure maximum protection and efficiency. The Kit includes two product favorites that effectively eliminate three problems:

The DISCAL® high efficiency air separator is dedicated to removing the system culprit: excessive oxygen resulting in the formation of corrosion. The DIRTMAG® PRO dirt separator with magnetic technology and particle mesh captures troublesome ferrous and non-ferrous debris. CALEFFI GUARANTEED.

www.caleffi.com

allowing them to coordinate multiple heat pumps. If not, there are several off-the-shelf multiple boiler controllers that could be used.

As is the case with multiple boiler systems, multiple heat pumps provide better load matching, and partial capacity if one heat pump is down for servicing.

ADDED FUNCTIONALITY

Although the primary application we’re focusing on is floor heating, these heat pumps have reversing valves allowing them to supply chilled water cooling. That’s a very sellable upgrade in many of these buildings, where equipment, lighting, tools and people all generate heat, and it’s also relatively easy to accomplish using one or more chilled water air handlers. Figure 3 shows one approach.

A motorized diverter valve is shown downstream of the hydraulic separator. It routes the output stream from the heat pump to the floor slab during heating mode, or to the chilled water air handler in cooling mode.

It’s also possible to use a manually operated three-way diverter valve rather than the motorized diverter valve. That would reduce cost, but don’t forget to change the valve setting whenever switching between heating and cooling mode.

The system in Figure 3 also assumes that the same circulator that supplies the floor heating system has the flow and head capacity to supply the chilled water subsystem.

Be sure to verify this during design. If there are significant differences in the flow and head requirements it’s better to use two circulators, each sized for its specific subsystem. Doing so also eliminates the need for a diverter valve, but be sure to include check valves in each subsystem.

The air handler has much less thermal mass than the heated floor slab. Since there’s no buffer tank in the system, it’s critically important to match the cooling capacity of the air handler

with the cooling capacity of the heat pump. Match these capacities for chilled water temperatures in the range of 45F to 55F.

If the heat pump has a variable speed compressor it should be able to adjust speed as necessary to hold a target chilled water outlet temperature. This allows the cooling capacity of the air handler to be lower than the rated cooling capacity of the heat pump.

However, make sure that the air handler’s cooling capacity is not less than the cooling capacity of the heat pump when it’s operating at minimum compressor speed.

Finally, if you’re going to be doing cooling be sure that all the piping and components that convey chilled water are insulated and vapour sealed.

Domestic water heating is also a possibility, but before going in that direction be sure that the load justifies the added cost and complexity.

In many garage or shop-type buildings

the DHW load might only be one or two sinks. No showers, kitchen, washing machine, or other significant needs for hot water are present.

These light loads can be handled by small electric tankless water heaters. The small amount of electric energy they require doesn’t justify the use of an indirect tank or controls that switch the heat pump between space conditioning and DHW loads.

Garage and shop buildings may not have the “glamour” of custom residential design, but their suitability for conditioning using an air-to-water heat pump combined with slab heating is none-theless compelling.

The system design is simple, especially in comparison to what some custom residential projects might require. Keep these simple approaches in mind as electrification efforts for all types of buildings continue to present new opportunities.

John Siegenthaler, P.E., has more than 40 years of experience in designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition available now) and Heating With Renewable Energy (visit hydronicpros. com).

MODERN HYDRONICS WWW.HPACMAG.COM MH10 SPRING 2023 INDUSTRIAL

<>

Figure 3. Incorporating cooling through a chilled water air handler.

Modern Hydronics

“Chilled water cooling is a very sellable upgrade in many of these buildings ”

CONDO RETROFIT

Toronto condo buildings replace air-cooled chiller with hydronic heat pumps to provide cooling and offset heating load.

BY DOUG PICKLYK

The downtown Toronto skyline is littered with cranes popping out of high-rise towers in various stages of completion. In the third quarter of 2022 Toronto had 230 active cranes, by far the most of any city in North America (almost as many as the next 13 cities combined).

Toronto has set a goal of achieving net zero by 2040, so incentives and building code requirements are in place to minimize the greenhouse gas emissions of new towers. Yet the city is faced with retrofitting a large inventory of existing building stock, a process that’s just beginning to be addressed.

Built in 2003, a 10-storey condo located at 120 Lombard St. in the heart of

the city, is a short walk from all the bigcity attractions: shopping, dining and entertainment. “I like it, and I can’t leave because everything else is getting so expensive,” says Karima Dharssi, P.Eng., a senior electrical engineer and a resident of the building since 2010.

Dharssi is a member of the condo board and has been instrumental in spearheading energy efficiency initiatives including LED lighting retrofits and more recently the installation of new airto-water heat pumps.

CHILLER REPLACEMENT

The penthouse mechanical room on the building distributes the hydronic heating and cooling to in-suite fan coil units at

120 Lombard as well as its sister building, a separate structure at 115 Richmond St. which is connected by a shared underground parking garage.

“We had two (large atmospheric) boilers functioning as our heating system,” explains Dharssi. “A couple years ago we decided to replace one of them (with a more efficient boiler) with the intention that it would become the primary boiler and the other would only kick in during colder temperatures.”

For cooling, the buildings’ two-pipe system switched in the summer months to be fed by a 110-ton air-cooled chiller. In the fall of 2021 the condo board, faced with replacing its nearly 20-year-old chiller, approved the purchase of air-to-

MODERN HYDRONICS WWW.HPACMAG.COM MH12 SPRING 2023

PROJECT

This 110-ton air-cooled chiller was replaced with 55-ton air-to-water heat pump

water heat pumps to provide the cooling requirements of the buildings while also offsetting some heating capacity away from the remaining gas-fired boiler.

A FIRST IN CANADA

The condo committee selected Italianmanufactured air-to-water heat pumps from Climaveneta, a brand of Mitsubishi Electric. They represent the first field installation of this technology in Canada.

To meet the cooling capacity, two heat pump units were required, a 55-ton unit that fits in the space previously occupied by the chiller and an additional 65ton heat pump unit is being located on the rooftop.

According to Chris DesRoches, P. Eng., applied product manager – HVAC division with Mitsubishi Electric Sales Canada, applications like this will become more common going forward. “Air-

to-water heat pumps make sense in this class of building as a retrofit product –it’s like a chiller-plus,” says DesRoches. “Instead of replacing a chiller like-forlike when it’s at end of life, we’re going to see more people upgrading to the heat pump and put it to work in the winter months, when you would normally be shutting down the chiller.”

After the condo board accepted the heat pump solution, the engineering design revealed necessary additional costs including upgrades to the electrical connections (a larger breaker to protect the system and a transformer to convert the voltage) and new structural supports on the rooftop for the larger unit. Fortunately, the unique aspects of this project appealed to a Toronto-based environmental agency who were able to lend some financial support.

TAF COMES ON BOARD

The Atmospheric Fund (TAF) is a nonprofit climate agency seeking scalable low-carbon solutions for broad implementation across the Greater Toronto and Hamilton Area (GTHA).

Keith Burrows, senior manager low carbon buildings at TAF, was contacted about the 120 Lombard project. “Our mandate is emissions reduction, and as part of that work we’ve been doing retrofits of multi-unit residential buildings for over a decade,” says Burrows. His team takes the lessons they’ve learned and offer retrofit services through what they call the Retrofit Accelerator.

Their services include funding support, project management, measurement and verification (m&v), and follow up. The services are offered for free to multi-unit residential building owners

Continued on MH14

MODERN HYDRONICS WWW.HPACMAG.COM MH13 SPRING 2023

23_000095_HPAC_FEB_CN Mod: January 10, 2023 4:19 PM Print: 01/18/23 page 1 v2.5 TAPE FOR EVERY TASK π SHIPPING SUPPLY SPECIALISTS ORDER BY 6 PM FOR SAME DAY SHIPPING 1-800-295-5510 uline.ca HPAC_Uline_Feb23_CSA.indd 1 2023-01-23 11:22 AM Modern Hydronics

who are looking at retrofits targeting emissions reduction of 40% or more.

The 120 Lombard project fit their criteria, and TAF partnered with the condo board, providing a financial contribution to keep the endeavour on track. The agency is also supplying project delivery support, resident engagement, and m&v services.

“We are keen to see this technology implemented and determine how effective it can be,” says Burrows. TAF is partnering with the Toronto and Region Conservation Authority's Sustainable Technologies Evaluation Program (STEP) energy team who will perform the detailed monitoring.

“We’re confident the system will perform, but we’re going to verify this with hard data and we’re going to report on our findings as part of a case study,” says Burrows.

Part of the measurements include monitoring temperature and relative humidity in 22 suites across the two buildings. The team also conducted pre-retrofit surveys with residents to get a qualitative assessment of how they experience their indoor space and comfort, and they will follow-up with another survey in about a year to assess how the change is affecting the residents.

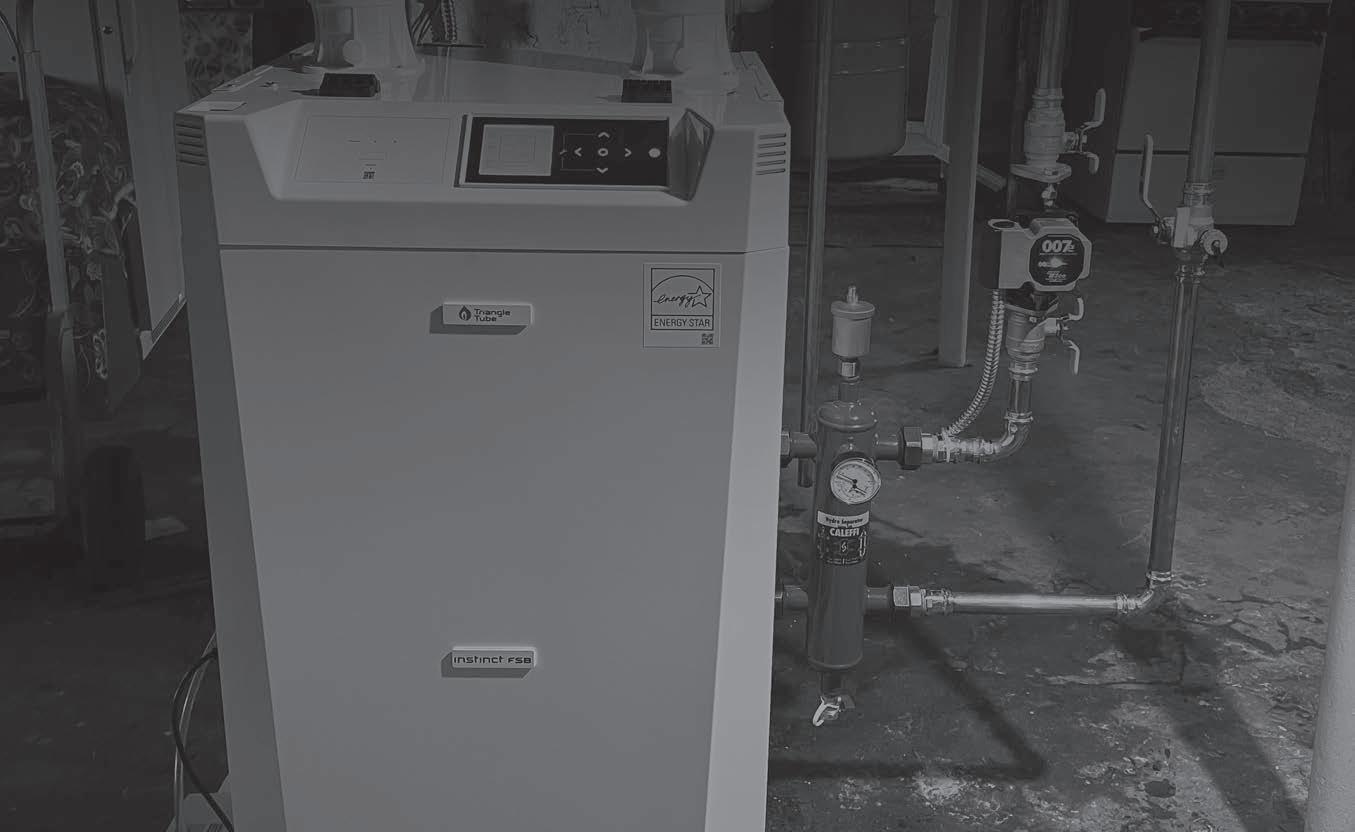

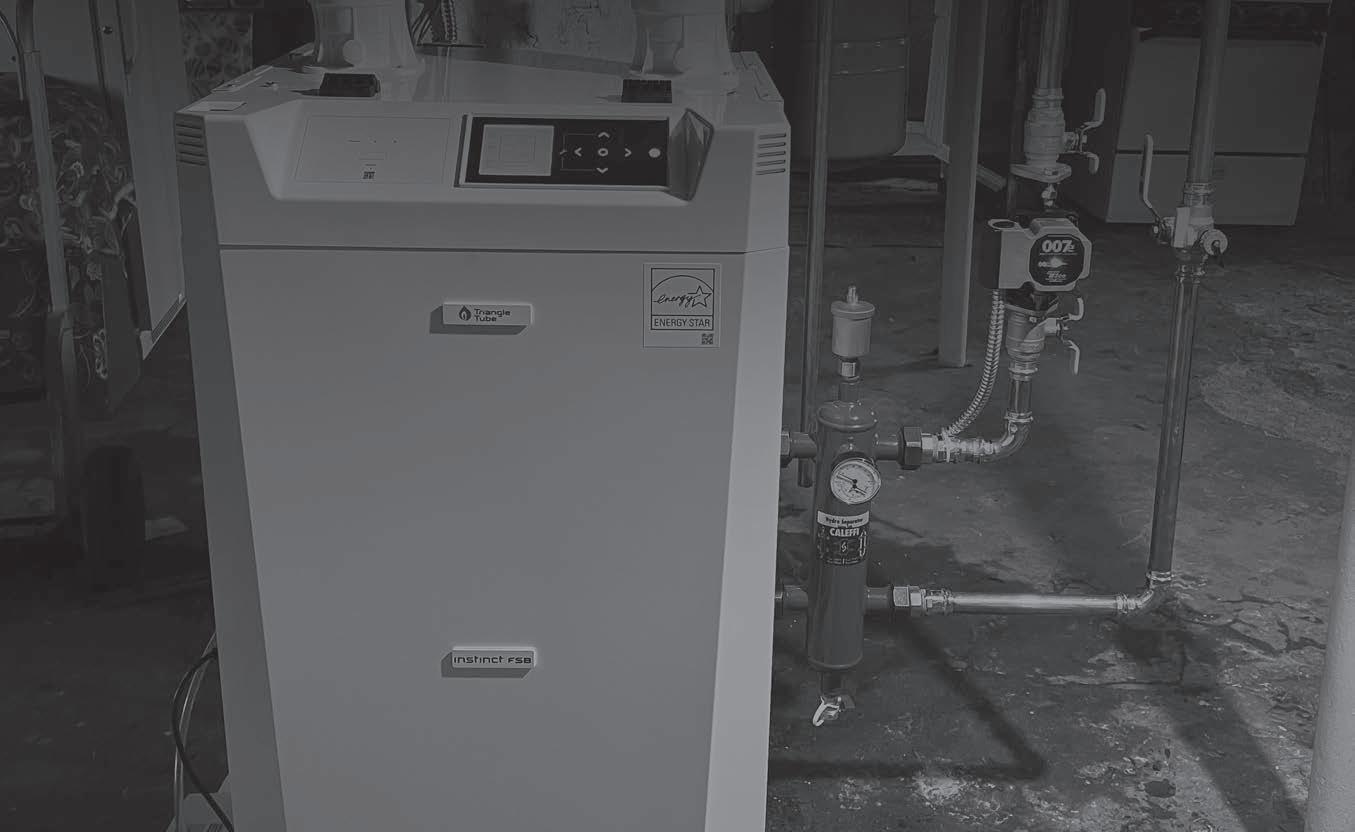

MECHANICAL ROOM REDESIGN

Before the heat pumps arrived the team at Prestige Mechanical, specialists in the Toronto high-rise residential market, was brought in to prepare for the installation.

“If it would have been a like-for-like install with a replacement chiller, it would have been simply cut the pipes and reconnect,” says Bradley Welch, estimator with Prestige. Instead, the team had to rework the entire mechanical room and create new piping loops and connections to suit the new heat pump system.

“The biggest challenge with this project was actually the logistics—it was a very small mechanical room in the penthouse,” says Welch. “A lot of thought

and planning went into different ways to support and mount equipment and piping while keeping floor space for walkways and paths for serviceability.”

First, the team demolished the old atmospheric boiler along with all the piping to and from the retired chiller. Each heat pump requires its own closed-loop circuit with a buffer tank, expansion tank and circulating pump. The heat pump loops are filled with a 40% glycol solution which runs outside to the heat pumps and ultimately supplies heating (or cooling) via brazed plate heat exchangers to a primary water-filled loop in the mechanical room, which isolates the glycol from the building distribution.

The primary circuit then transfers heat to the secondary distribution loop which supplies the heating/cooling water to the fan coils in the buildings.

The remaining gas-fired boiler in the mechanical room is on an injection loop that feeds the secondary circuit when it

kicks in. If the heating boiler ever breaks down, an additional heat exchanger between the domestic hot water (DHW) boiler and the heating distribution system is in place for emergency back up.

A new building automation system (BAS) controls the staging of the two heat pump units, and based on outside temperatures the BAS also controls when the boiler will kick in.

“Retrofits in older buildings like this can be really challenging,” says DesRoches. “What’s encouraging and unique about this project, is that the engineers are taking more of a qualitative approach, rather than quantitative. If we looked for hydronic heat pumps in the conventional sense, the numbers don't seem all that attractive compared with other technology choices for retrofits (like VRF), but they are a much more invasive retrofit. In this case they know the heat pumps will provide heat to the building, but at what point they’re going to be effective is subjective relative to the characteristics of the building itself.”

The initial target was to have the heat pumps supplying 45C (113F) water to the building down to -10C (14F), any colder and the gas boiler would kick in. Both DesRoches and Burrows acknowledge

Continued on MH16

MODERN HYDRONICS WWW.HPACMAG.COM MH14 SPRING 2023

PROJECT Modern Hydronics

The rooftop mechanical room was reworked to create new piping loops and connections for the heat pump system.

“We’re confident the system will perform, but we’re going to verify this with hard data.”

CANADA’S HYDRONIC INSTALLATION CONTEST

WIN ONE OF TWO $3000 BUYING SPREES FROM EMCO!

Get your cameras ready. Be a part of Canada’s hydronic installation contest. Proud of your work? Better than the rest? It’s time to bring it on!

THERE WILL BE A WINNER IN EACH CATEGORY: COMMERICAL AND RESIDENTIAL. ENTRY IS SIMPLE- send us pics of your installation. Include a brief description of the particular challenges that you faced with this installation and how you overcame the obstacles. This can be a new installation or a retrofit. Submissions are limited to one per contractor. Deadline to enter is July 31, 2023. All submissions will be shown at the Modern Hydronics Summit 2023. The two winners will also be announced by John Siegenthaler at the Summit. In addition to having your winning entry shared across our social media channels you’ll also be interviewed by HPAC’s editor and featured on the cover of the October edition of HPAC –

CREDIT: TECZR MEDIA/SEAN HARRISON (COURTESY PRESTIGE MECHANICAL)

SEND ENTRIES OR QUESTIONS TO DPICKLYK@HPACMAG.COM WITH THE SUBJECT LINE “SWEET HEAT CONTEST”

SPONSORED BY...

that getting the controls set perfectly for the system will be an iterative process.

TAF, together with the STEP team, will be involved with a real-time assessment of performance to help optimize the system.

“We want to learn from this project,” says Burrows. “How much gas can be offset? What can we do to improve the next installation of the same technology? And how can others benefit from the work that we’ve done?”

CRANE DAY

Initially the condo board was hoping to have the project complete in spring 2022, but due to supply chain issues and other delays preparations for the heat pumps were finished in the fall and the units arrived in mid-December.

DesRoches was on-site for crane day, an experience he describes as nerve wracking. “After the long lead times, the last thing you want is to have something go wrong when these units are hanging, suspended, hundreds of feet up in the air.”

Ahead of crane day Prestige had to pre-fabricate the structural steel that was placed on the roof to support the larger 65-ton heat pump unit. That steel was the first to get hoisted up, positioned and bolted together. The next steps were to remove the outgoing chiller and then lift and set the heat pump units in place.

“We worked with Prestige closely leading up to the project, making sure vibration mounts were installed in the right location and the orientation of the unit was installed correctly,” says DesRoches.

In the end he was impressed with how smoothly the day went: “The team at Prestige had it down pat.”

FUTURE PROSPECTS

The units were connected in the days after installation and commissioning of the system began in late January. “We’ve been involved with a lot of mini-split renovations and some VRF retrofits as well, but this is the first large central air-to-water system that we’ve installed, which is part of the reason we’re really excited about it,” says Burrows, who adds that he’s already received calls from social housing providers and municipalities asking about the technology.

Electrification retrofits in buildings like this—with hydronics systems and fan coils—are challenging, and the ability to provide a potential drop-in solution onto the roof to at least offset greenhouse gas emissions seems promising.

TAF projects a reduction in space heating emissions by 60% or more along with a reduction of over $200,000 in carbon taxes over 20 years.

“Once we do the case study on this project, we’ll have data and recommendations for improvements, and this will become a blueprint for broader decarbonization at scale for similar buildings,” says Burrows.

For Karima Dharssi and the other residents at both 120 Lombard and 115 Richmond, their pioneering efforts to switch to heat pumps places them well on their way towards net zero carbon living in the heart of Toronto, while also allowing them to benefit from lower costs in the long term.<>

MODERN HYDRONICS WWW.HPACMAG.COM MH16 SPRING 2023

Modern Hydronics PROJECT

“This will become a blueprint for broader decarbonization at scale for similar buildings.”

Crane Day, the heat pumps were hoisted to the rooftop of 120 Lombard in Toronto in midDecember.

PHOTO: TECZR MEDIA/SEAN HARRISON (COURTESY PRESTIGE MECHANICAL)

THE PERFECT FIT FOR YOU AND YOUR CUSTOMERS.

From easy install to long-lasting reliability, it’s the trusted boiler. THE ORIGINAL INNOVATORS *Caleffi 548 Series Separator (Shown Mounted)

WEATHER OR NOT?

Connecting online to improve snow melt efficiency.

BY CURTIS BENNETT

Ihave never claimed to be a great parent. Ok, that’s not true, I actually make that claim all the time, and I have always said that hard work is a valuable trait—something I try to instill into my kids. I have also said that I had children so I wouldn’t have to work outside anymore, and shovel snow.

This all leads me to the topic of the day: snowmelt controls. I want to take things in a slightly different direction this time.

For those of us in the hydronics business, we have all heard the infamous stories about snowmelt systems costing homeowners $2,000 per month to operate over the winter. Why not just pay some kids to shovel for $100 per month? Well, I am not sure that’s the answer, but I do think there is a better solution.

Connected controls for snow melt are not new, but controls gleaning information from websites to drive control algorithms is fairly new. And when it comes to snow melt, what information is most useful? Well, it’s weather forecasting.

I’m going to go out on a limb and say that weather forecasting on snowmelt controls is the largest control advance in snow melting in a long time—the last major advance since optical sensing technology.

It’s the idling of snowmelt systems that use the most energy. If a snowmelt control is set to idle, it will remain in this mode for 90% of the time.

Let me back up slightly, there are three states in a snowmelt control: off, idle and melt. If I was going to make a snowmelt control as basic as possible, it’s a two-stage setpoint control. The

first setpoint for the slab target (idle) is used when there is no snow present on the sensor. We idle the slab to react quicker when we do finally detect snow. The melt demand happens when snow hits the sensor. At this point we change the slab target from idle up to a target that will melt the snow on the slab.

Usually, these targets are between 3C to 10C for melt with the idle target between -10C to -2C. Now that being said the control spends most time in idle, so it makes the most sense if we try to keep idling time to a minimum.

There are really only two ways to do this. The first is the end user is responsible for turning the snowmelt control from off and into idle. This can be with a manual demand at the control, or now with a smartphone app. Using an app does help, but the end user still needs to know when the snow is coming. Wouldn’t it be nice if the control could know that?

Well … they can. Weather data is becoming very sophisticated, not only are there accredited weather stations, but there are thousands of data points they can gather from in any given area, even

home-based weather stations. This allows for very accurate forecasting.

But what if the forecast is wrong? The amount of potential savings far surpasses the amount of false starts. If you can set the target percentage of precipitation (POP), the end user can mitigate false starts by keeping this number higher. As well as the POP, the user can also set how far out they would like to look into the forecast.

This is truly where the value of forecasting comes in. By setting the POP to 70% and for forecast two days ahead, if the forecast coming to the control meets these criteria, the system will come out of off mode and into idle.

On the flip side, if the forecast falls below the set point values then the control will go back to off mode.

As we all know, forecasts can change, so this is a far better way to control the idle stat than manual mode, or even worse idling all the time.

Let’s put this into a perspective. In Calgary, we fall below 0C at around midOctober, but for this example, let’s say November 1. We stay cold until about March 1. Yes these are round numbers,

MODERN HYDRONICS WWW.HPACMAG.COM MH18 SPRING 2023

CONTROLS

but work with me here. So, let’s call that four months, or 120 days more or less.

If your control is set to idle all the time, you are constantly injecting heat into that slab. During this 120-day period we might get 10 snowfalls, at least good ones, and maybe 10 smaller ones. We will call this 20 snowfalls in total.

I will also conjecture that those snowfalls last one day. So, we have a season of 120 days where 20 of them we have to get rid of snow.

Please , don’t lambaste me here with not taking into consideration how long the slab takes to heat up, I get that, we don’t want to crack a slab so we need to control DeltaT so it takes time to heat up the slab.

So, 20 snow days out of 120, that’s 17% of the time in melting mode, and the other 83% is spent idling and the energy being put into the slab is wasted.

Even small snowmelt controls take a lot of energy, but for this quick calculation I’ll use 250,000 Btu/h. If we are injecting 250,000 Btu/h into the slab even for only six hours per day, while idling that’s 1,500,000 Btu’s per day. That's around 1.6Gj, which right now is about $3.50. That’s $5.60 per day for 100 extra days. That’s $560 dollars.

So how can forecasting save money?

We know we won’t save all $560. We want to set up the control so that we go into idle one day before the snow comes. Since we know there will be 20 snow days, we will take off 20 days’ worth of idling money because the forecast will turn the control to idle one day before the forecasted snowfall. That $5.60 per day for 20 extra days. That’s $560 minus $112 = total “potential” savings of $448. That’s a significant saving potential per snow melting season.

For those who don’t idle their slab, well, forecasting will save you time. And at the end of the day, energy will be saved. On a control where every single Btu evaporates into thin air, literally, I think that’s a good thing.

Our industry does not always see eye to eye, but this is one of those things where we all know that if we can do better, we should.<>

Curtis Bennett, C.E.T, is the product development manager with HBX Control Systems in Calgary. He formed HBX Control Systems with Tom Hermann in 2002. Its systems are designed, engineered and manufactured in Canada to accommodate hydronic heating and cooling needs in residential, commercial and industrial design applications.

MODERN HYDRONICS WWW.HPACMAG.COM MH19 SPRING 2023

Grow Your Business With AQUATECH™ AQUATECH™ offers innovative Lochinvar® commercial and residential building heating and hot water solutions that are easy to install, service and engineered to perform. Turn to one of your best resources for heating and hot water solutions that are perfect for your customer. Aqua-Tech Sales and Marketing Inc. Burlington, ON 905.631.5815 Port Coquitlam, BC 778.285.9596 aquatech-canada.com HPAC_AQUATECH_HP_FEB23_ASK.indd 1 2023-01-24 1:25 PM Modern Hydronics

HYDRONIC ADVENTURES IN RURAL ONTARIO

BY PAUL O’CONNOR

BY PAUL O’CONNOR

In mid-November 2022, Paul O’Connor, owner of POC Plumbing and Heating, reached out to share his progress on an interesting project that involved the integration of an outdoor woodstove open-loop hydronic system with an indoor propane-fired boiler closed-loop system in a home in rural Ontario. Following is an edited version of Paul’s correspondence.

This project is in Coldwater, Ont. on a 25-acre bush lot. Initially I was brought in to try and find out why the customer was burning twice as much firewood as everyone was telling him would be necessary. The customer’s outdoor woodstove hydronic system (an open system) was being used to heat the family home and a garage with a workshop.

The hydronic heating in the house uses rads, and the supply and return lines are run up into the attic, and the system had no air elimination devices. I don't know how it even worked without them.

But as I asked questions, I found out they could hear the air and water gurgling around constantly, and therefore they always had to run the outdoor woodstove really hot to heat the rads due to low water flow—the flow sucked.

Ultimately, a heat exchanger was incorporated to separate the open outdoor system from a newer closed-loop indoor system that was run from an oilburning boiler.

My job was to swap out the oil boiler for a “newer” propane-fired Navien

boiler that was reclaimed from a barn, and then also make the entire system work better and more efficiently.

The goal was to use less firewood and use the propane boiler only as a back-up to heat the home.

WOOD-BURNING CENTRAL HEATING

The system is designed to heat primarily with firewood, which by some is perceived as better than burning carbon from fossil fuels.

If you believe in the philosophy that if a tree blows down and decomposes over 30 years and emits pollution very

slowly—but eventually releases 100% of the carbon that tree was holding—then by cutting up and burning that tree in the outdoor woodstove, we’re releasing the same 100% of carbon simply over a much faster period, and you’re also using that same tree to heat your house for a couple of weeks instead of using fossil fuel, so it’s an environmental win.

The outdoor woodstove boiler superheats hot water outside and transports that heat via underground supply and return lines into the buildings.

In Figure 1 you can see a big chimney and a smaller pipe coming through the

MODERN HYDRONICS WWW.HPACMAG.COM MH20 SPRING 2023

OUTDOOR WOOD STOVE Modern Hydronics

PHOTOS: PAUL O’CONNOR

Continued on MH22

Figure 1. Woodstove chimney and smaller open pipe for the water vessel.

Session 1 – Attracting Women to your Construction Business

Moderated by Melissa Young, CEO and registrar, Skilled Trades Ontario

Session 2 – Tackling Harassment in the Workplace

Moderated by MJ MacDonald, CEO, Construction Safety

Nova Scotia

Session 3 – Retaining Women in your Construction Business

Moderated by Rebecca Kragnes, director, Indigenous Relations and Community Engagement, Bird Construction

Attend

MARCH 8, 2023 International Women’s Day FOR SPONSORSHIP INFORMATION, CONTACT DAVID dskene@hpacmag.com • 416-510-6884

Women in Construction on March 8 to learn successful strategies from our expert panelists for both recruiting women and

them in your construction business.

www.women-in-construction.ca AND CLICK Virtual Event

REGISTER NOW

retaining

VISIT

3RD ANNUAL EVENT

SILVER SPONSORED BY BRONZE

roof. The big chimney is obviously for the firewood exhaust, but the little pipe is for the water vessel. If the water were to get too hot, it can vent out this pipe. The homeowner can also fill the vessel through this pipe, something that gets done every week or so depending on the usage (see Figure 2, below).

The wood stove boiler is an open system because it is open to the atmosphere, and therefore the system doesn’t require an expansion tank, or 15 psi of water pressure. But it also has to be separated from the closed-loop system in the house and connected via a heat exchanger.

These types of jobs are quite common around farms and rural properties. The advantage is that the woodstove can be a central heating system for two or three buildings on the property at once, and heating is free if you are able to cut your own firewood.

The disadvantage is that you have to be around it to feed the outdoor woodstove all winter. Or the customer must rely on family and friends to keep it burning.

It makes it hard to go on any vacations or hockey tournaments. So, this where I come in.

OPEN-CLOSED INTEGRATION

In the house, they have a radiator distribution system with three zones—a system I rebuilt to integrate the propane-fired boiler (Figure 3).

I initially had the boiler turn on with a set point controller set to 140F of the incoming supply water from the outdoor woodstove. When the woodstove is burning, there was enough heat to satisfy the home to a comfortable 72F. Unfortunately, as it got colder, the outdoor woodstove couldn’t keep up.

I had 180 – 190F water coming through the heat exchanger from the outdoor woodstove, but only 140F coming out of the supply end of the heat exchanger on the closed system.

I had to attain a higher supply temp coming out of the heat exchanger to get the existing rads hotter, so the answer was to add a second heat exchanger.

CUSTOM HEAT EXCHANGERS

Plate heat exchangers don’t work well here because the little passages sometimes get plugged up with sediment, especially on the open-loop outdoor woodstove side.

When I started this project I knew very little about the operations of the outdoor woodstove (the open loop side).

Fortunately, local outdoor woodstove specialists taught me everything I know about it, and it defied a lot of things I had learned on the closed-loop systems I am more accustomed to.

First is, these specialists tend to make their own copper pipe heat exchangers. I had never seen anything like it.

In Figure 4 (next page) you can see how we made the copper heat exchangers. You need a length of 1-½-in. copper pipe, one length ¾-in. copper pipe, and two 1-½ x ¾ x ¾-in. copper tees.

Then somebody hammers the ¾-in. copper pipe right through the tee. Then connect the 1-½-in. copper pipe from the other side and hammer the last tee on from the other side.

The outdoor woodstove loop runs through the ¾-in. copper pipe in the which is encased by the larger 1-½-in. pipe. It runs constantly all winter. Therefore, a heat exchanger like this won’t clog up or wash out because it is totally laminar flow.

The closed-loop side is tied into the branch sides of the tee and runs intermittently when there is a call for heat. The water runs inside the 1-½-in. copper pipe and contacts the ¾-in. copper pipe and exchanges heat that way.

Continued on MH25

MODERN HYDRONICS WWW.HPACMAG.COM MH22 SPRING 2023

PHOTOS: PAUL

OUTDOOR WOOD STOVE

O’CONNOR

Modern Hydronics

Figure 3. The propane-fired boiler and closed-loop system in the house.

Figure 2. Outdoor wood stove panel: You fill the tank until the water in the clear plastic tube in the centre is half way full. The woodstove will blow air on the fire in order to attain the temp required by the aquastat in the top left corner.

Offering the Best of Both Worlds

Whether you need the power of a storm or the intensity of the solis, we have you covered.

Between the PK-STORM® and the PK-SOLIS™ Patterson-Kelley has built up a highly versatile line of heating solutions that can fit any application necessary. The STORM® is a highly efficient watertube boiler that ranges in sizes 1250 to 4000 that operates at 97% efficiency. The SOLIS™ is a firetube boiler ranging in size 1500 to 3000 and operates at 96% efficiency. Both models utilize 10:1 mechanical turndown with ultra-low NOx emissions. As with all Patterson-Kelley equipment, the NURO Touchscreen controller is a standard feature on both units. Whatever the heating needs your building calls for, Patteson-Kelley has the right solution.

Patterson-Kelley, LLC www.pattersonkelley.com • 877.728.5351

MODERN HYDRONICS SPRING 2022 MONTREAL HEALTH NETWORK ADDS HEAT PUMPS Part of an $18.8 million energy efficiency project CONTROLLING ATW HEAT PUMPS SNOW MELT OPTIMIZATION PELLET BOILERS & FORCED AIR a publication of MODERN HYDRONICS FALL 2022 DISTRICT ENERGY IN NWT Pellet boiler fires up heating system in Yellowknife. OPTIMIZING BRAZED PLATE HEAT EXCHANGERS CIRCULATORS: TEMPERATURE OR PRESSURE CONTROL TROUBLESHOOTING TIPS & LARGE PUMPS a publication of FREE to qualified subscribers! Please fill in the following and fax today to 416-442-2230 or visit our website and click on subscribe www.hpacmag.com YES! I wish to receive/continue to receive HPAC Magazine absolutely FREE! No Name Title Company Address City Province Postal Code Business Phone # ( ) Business Fax # ( ) Your FREE subscription also includes our FREE e-newsletter, please provide your e-mail address below: E-mail: Signature Date / / (Must be signed and dated to be valid) D M Y Publisher reserves the right to determine qualification & limit distribution. FAX: 416-442-2230 February 2023 IS CANADA’S #1 SOURCE FOR HYDRONIC COVERAGE: products, applications, events, news and more. MODERN HYDRONICS SPRING 2023 HEAT PUMP DROP-IN Toronto condo replaces chiller with heat pumps. AIR-TO-SLAB LOW TEMPERATURE RECIRCULATION FORECASTING FOR SNOWMELT a publication of I SEE YOU’RE INTO HYDRONICS… DON’T MISS A SINGLE COPY OF HPAC. 1. Company Business Activity? (Check ONE only) Mechanical Contractor Refrigeration Service Engineer/Contractor Fuel Oil Dealer/ Contractor Wholesaler/Distributor/Agent Consulting Engineers/Specifying Writer Plumbing Inspector Government Hospitals and Related Institutions Utilities General Building Construction Others Allied to the Field (please specify) 2. Do you specify, purchase and/or approve the purchase of mechanical products or services? Yes No 3. Company Job Sector? (Check ALL that apply) Commercial Residential Industrial Institutional 4. Number of employees at this location? 1 - 4 20 - 49 200 - 499 2500 + 5 - 9 50 - 99 500 - 999 Unknown 10 - 19 100 - 199 1000 - 2499 5. Company Job Activities? (Check ALL that apply) Plumbing (i.e DHW, Piping etc.) Ventilation Hydronic Heating Refrigeration Forced Air Heating Fire Protection Electric Heating Air Conditioning Other (please specify) HPAC Magazine 111 Gordon Baker Rd. Suite 400, North York, ON M2H 3R1

We initially made a copper tube heat exchanger that’s about six feet long, but it wasn’t able to exchange enough heat for the closed system, so I added a second 10-ft. heat exchanger.

I connected the two heat exchangers in series, so that return water would run through the little heat exchanger first, then come out and enter the second heat exchanger which super heats it. Now I am getting 165F water to send to the rads, and the house is attaining room temperature easily.

BACK UP

If the wood fire burns out, the set point controller has a thermal well sensor, and it will command the propane boiler to turn on and heat the rads in the house directly, and this will also provide heat to the outdoor woodstove and the outside building as the heat exchanger basically works in reverse.

The system has three pumps. The outdoor woodstove pump must run 24/7 during heating season. The pump beside the heat exchanger only runs when either of the zone valves are calling for heat or if the boiler is running.

One of the home’s three zones is protected by a WiFi thermostat in case a pump or zone valve breaks, or if the customer runs out of propane while he is on vacation. If that

happens, the thermostat will send a notification so the customer can address the issue and prevent a potential freeze. This past fall the system started up on just propane for the first month until the wood was delivered. It took about a day to iron out the bugs, but the system is working flawlessly now.

The customers are very happy, and the only thing left to do next year is tie the electric hot water tank into this system so the wood stove can heat that as well. <>

MODERN HYDRONICS WWW.HPACMAG.COM MH25 SPRING 2023

PHOTOS: PAUL O'CONNOR Grow Your Business With AQUATECH™ AQUATECH™ offers innovative Lochinvar® commercial and residential building heating and hot water solutions that are easy to install, service and engineered to perform. Turn to one of your best resources for heating and hot water solutions that are perfect for your customer. Burlington, ON 905.631.5815 Port Coquitlam, BC 778.285.9596 aquatech-canada.com Aqua-Tech Sales and Marketing Inc. HPAC_AQUATECH2_HP_FEB23_TD.indd 1 2023-02-08 10:34 AM OUTDOOR WOOD STOVE

Paul O’Connor, POC Plumbing and Heating.

Modern Hydronics

Figure 4. The custom fabricated heat exchangers connecting the open woodstove system and the closed in-house system.

NTI Boilers has announced the evolution of its TFT line with the introduction of the TFTN series featuring onboard touchscreen controls for improved precision and set-up efficiency. The new TFTN series delivers the same performance for residential and light commercial hydronic applications, while introducing a seven-inch colour touchscreen and onboard WiFi capability to provide contractors with more functionality and diagnostic ability from anywhere. The TFTN lineup is currently available in sizes 85, 110, 150 and 199 MBH. Larger sizes from 285 to 850 MBH will be available in early 2023. ntiboilers.com.

The Hercules Sludgehammer System Restorer and Noise Reducer provides system cleaning and reduced kettling while restoring heating system efficiency. From Oatey, it is suitable for all metals, including aluminum, cast iron, and stainless steel. The restorer effectively removes sludge and corrosion while reducing boiler noise. It also pairs well with Hercules Sludgehammer Universal Corrosion Inhibitor as part of an annual heating system maintenance program. The new product also helps restore efficiency to all hydronic systems. The system cleaner can be used in older boiler systems or when a new boiler is fitted into an existing system with sludge and scale build-up. oatey.ca

Weil-McLain has updated its ProTools App with features to provide contractors and service technicians with the support to streamline customer visits. Available for iOS and Android devices, the app now allows heating professionals to work virtually with Weil-McLain’s tech support team to problem-solve issues as they occur on the job. Service technicians who run into complications while on the job can contact WeilMcLain tech support for site-call video and receive immediate real-time assistance.

weil-mclain.com

REHAU has announced the addition of R-20 manifold connectors to the EVERLOC+ compression-sleeve fitting line. The new R-20 connectors are designed for use with RAUPEXcrosslinked polyethylene (PEXa) pipes and PRO-BALANCE manifolds. The manifold outlets are available in ⅜-, ½-, ⅝- and ¾-in. sizes. The design features reconfigured bushings for increased accessibility when using larger hydronic circuits. The EVERLOC+ R-20 fitting is a single piece that pairs with existing REHAU EVERLOC+ compression sleeves used in the company’s PEXa plumbing systems rehau.com

Aquatherm has released of the Aquatherm FieldPro App. The new app is for anyone installing Aquatherm piping systems, putting all the essential tools at installers’ fingertips, making installation faster and easier. Additional features include: a fusion timer that incorporates multiple timers, pressure times, and logging capabilities and a hanger spacing calculator that provides in-field access to all hanger spacing information. The free FieldPro App can be downloaded from the App Store or Google Play.

aquatherm.com

A new addition has been announced to the SpacePak line of Solstice heat pumps, the Solstice Inverter Extreme, an inverter-driven cold climate air-to-water heat pump that provides hydronic heating, cooling, and DHW, without the use of fossil fuels. Features including an inverter-driven compressor, inverter-driven fans, and fan motors, and enhanced vapour injection technology allowing for high-performance heating operation in outdoor temperatures as low as -22F (-30C), while delivering reliable water temperatures as high as 130F (54C).

spacepak.com

MODERN HYDRONICS WWW.HPACMAG.COM MH26 SPRING 2023 Modern Hydronics HYDRONICS PRODUCTS

Presented

SUMMIT 2023

SEPTEMBER 21ST AT HARD ROCK CASINO IN COQUITLAM, BC!

By popular demand we are moving our Modern Hydronics Summit across the country to share the knowledge and excitement. First up: British Columbia. Be there for the triumphant return of Hydronics Super Heroes - Siggy and The Bean.

AT THIS YEAR’S SUMMIT,YOU WILL:

• Learn from our top-notch hydronics experts; featuring John Siegenthaler (with a few surprise guest speakers!!)

• Enjoy refreshments, lunch, dinner and trip to the bar

• Have a chance to win tools and Vancouver Canucks tickets!

SEE THESE BRANDS: AND MORE TO COME!

•

•

•

EARLY BIRD PRICING OF $99 ENDS AUGUST 21ST

KEYNOTE

REGISTRATION IS OPEN NOW! MODERNHYDRONICSSUMMIT.COM

by

SPONSOR

Belimo

Caleffi

Centrotherm • Chemfax • Eco-King • Grundfos

HBX Controls

Hargassner • IBC

Lochinvar • MacDuffco • Navien

NTI

Resideo

Small Planet

Spacepak

Tamas

tekmar

•

•

•

•

•

•

•

•

•

•

•

•

Thermo

Viessmann

2000 •

Weil McLain

Wilo

LOW TEMPERATURE RECIRCULATION

Strategies for incorporating renewable energy thermal storage with DHW.

BY JOHN SIEGENTHALER

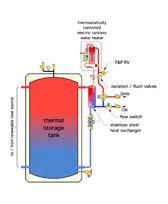

Given their intermittent heat generation characteristics, many hydronic-based renewable energy systems require thermal storage. Examples include solar thermal systems and biomass boilers. Thermal storage is also used in heating systems supplied by off-peak electricity and micro combined heat and power (MCHP) systems.

The temperature of the thermal storage tank can vary over a wide range. If supplied by a solar thermal collector array, and following two or three sunny days with minimal loading the tank temperature could be upwards of 180F.

These temperatures are also possible at the end of tank “charging” cycle from a biomass boiler, as well as in off-peak electric thermal storage and MCHP systems.

At other times, when there’s little if any heat input from the renewable energy heat source, the thermal storage tank could cool down, even down to the surrounding air temperature.

This wide temperature variation implies there will be times when thermal storage could supply all the energy needed to heat domestic hot water (DHW) to a typical maximum delivery temperature of 120F.

Heat would be passed from the “system water” in the thermal storage tank to DHW through a stainless steel heat exchanger. There will also be times when thermal storage could only preheat DHW, and another heat source would “top off” the water to the required delivery temperature.

LEVERAGING LOW TEMPERATURES

Even though preheating doesn’t bring DHW all the way to the final temperature, it’s importance shouldn’t be underestimated. It takes as much energy to bring a quantity of water from 50F to 60F, as it does to bring it from 150F to 160F.

Thermal storage tanks, even at reduced temperatures, can “leverage” the low end of the temperature rise. Because of this, domestic water heating, where it’s needed, is an enticing load to combine with renewable energy heat sources.

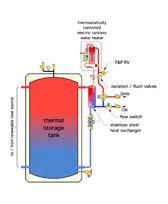

Figure 1 shows heat from thermal storage transferred to DHW using a single pass stainless steel heat exchanger.

A flow switch closes its contacts when it detects a specific minimum flow rate of domestic water, typically around 0.5 to 0.7 gpm. This turns on a circulator that routes water from the upper portion of the thermal storage tank through the primary side of the brazed plate stainless steel heat exchanger. Heat is transferred to “cold” domestic water entering the secondary side of the heat exchanger.

Brazed plate heat exchangers have a high ratio of internal surface area to fluid volume and respond very quickly to temperature changes. With the heat exchanger and circulator located as close as possible to the tank to minimize piping length, the response time from when the flow switch closes, to when heated domestic water emerges from the secondary side of the heat exchanger, should be about 3 to 5 seconds.

A thermal storage tank at 95F could potentially heat domestic water from 45F to 90F. That’s 60% of the temperature rise, and 60% of the energy required to fully heat the water from 50F to 120F.

A thermostatically-controlled electric tankless water heater provides the final temperature rise, when required. If the DHW

MODERN HYDRONICS WWW.HPACMAG.COM MH28 SPRING 2023

RENEWABLE ENERGY

Figure 1. Heat transfer from thermal storage to domestic water using a single pass stainless steel heat exchanger.

enters this heater at or above the required delivery temperature, the elements in the heater do not turn on.

An American Society of Inspectors of Plumbing and Sanitary Engineers “ASSE 1017” listed thermostatic mixing valve provides protection against high DHW delivery temperature in situations where the thermal storage tank is at an elevated temperature.

ADD A LOOP

The system in Figure 1 doesn’t ensure that DHW, at the required temperature, is instantly available at every fixture. That requires a recirculation piping system. The system in Figure 2 adds a recirculation loop, along with several point-of-use electric tankless water heaters to the heat exchanger/circulator subassembly shown in Figure 1

Each point-of-use tankless heater draws heated water from the recirculation loop. A typical system would use one tankless heater for each bathroom group (shower/tub and lavatory), and it would use separate tankless heaters for the kitchen, laundry or other areas where DHW is required.

Each tankless heater would be sized to the flow and delivery temperature requirements of its fixture group. Each would be controlled by its internal thermostat so only the energy necessary is added to the preheated water.

If the entering water is already at or above the required temperature the elements within these heaters remain off. An ASSE 1070 listed thermostatic mixing valve ensures that the water delivered to the fixtures doesn’t exceed a safe delivery temperature.

A small stainless steel recirculation circulator moves water around the loop whenever DHW may be required in the building. This is not necessarily 24/7. Another small high-efficiency circulator maintains flow between the storage tank and stainless steel heat exchanger.

Assuming an upper tank temperature of 120F, a high efficiency circulator between the tank and a 5-in. x 12-in. x 50 plate heat exchanger could yield an output of 4 gpm of domestic water heated from 50F to 115F with a power input of about 30 watts.

A small recirculation circulator would add another 12 watts of power input. If

both circulators ran continuously in a location where electricity costs $0.15 per kWh, the operating cost would be about $0.15 per day. This could be reduced by turning off the recirculation system during times with little or no expected demand for DHW.

Even when the recirculation system is off, each tankless heater can provide some hot water to its associated fixture(s) with energy being supplied solely by electricity. The flow rate and delivery temperature would depend on the power rating of that heater.

The check valve downstream of the recirculation circulator forces domestic cold water through the heat exchanger whenever hot water is drawn from any fixture. This approach has several advantages.

First, the power requirement of each tankless heater is only for the fixture group it serves. For example, a 7 kW tankless heater would provide up to 1.9 gpm flow rate with a corresponding temperature change from a “preheat” temperature of 95F, to a delivery temperature of 120F. A 7 kW tankless

MODERN HYDRONICS WWW.HPACMAG.COM MH29 SPRING 2023

Continued on MH30 Modern Hydronics

Figure 2. The addition of a recirculation loop, and electric tankless water heaters, to the subassembly shown in Figure 1.

heater could be supplied from a 240 VAC/30 amp circuit. Higher capacity tankless heaters could be used where higher flow rates are needed.

Second, multiple tankless units provide redundancy relative to a single higher capacity heater.

Third, when water in the recirculation loop is at a lower temperature, heat loss from the loop is reduced. Still, the recirc loop should always be insulated.

KILL THE BUGS

Any DHW system operating at temperatures in the range of 68F to 122F has the potential for legionella bacteria growth. Tempered water between 77F and 113F provides an optimum growth environment.

To address this, the system from Figure 2 has been further detailed with a dedicated thermal sterilization tankless heater, as shown in Figure 3

The purpose of the sterilization heater is to periodically elevate the water temperature in all portions of the recirculation loop high enough—and maintain that temperature long enough—to kill Legionella bacteria. In the absence of specific codes that require otherwise,

typical daily thermal sterilization temperature/cycle durations are as follows:

• 158ºF (70ºC) for 10 minutes

• 149ºF (65ºC) for 15 minutes

• 140ºF (60ºC) for 30 minutes

Some electric tankless water heaters can heat water as hot as 180F, while others have internal safety switches that prevent temperatures above 140F.

The sterilization cycle could be programmed to occur at times of no DHW use, such as early morning hours. If one assumes no DHW draws during this relatively short sterilization cycle the power output of the sterilization heater is only that required to match the heat loss of the recirculation loop.

Here’s an example: assume a DHW loop is 100 feet of 1-in. insulated copper tubing on the supply side, and 100 feet of ½-in. insulated copper tubing for the recirculation piping. Also assume an average water temp in the loop of 155F during the sterilization cycle.

The total heat loss of the piping under these conditions is about 2,700 Btu/hr. Add 20% to account for heat loss from riser piping to fixtures, heat loss from the insulated heat exchanger, and from the recirculation circulator, valves, etc.

The total estimated 3,240 Btu/hr heat loss is just under 1 kW (3413 Btu/ hr). One of the smallest available electric tankless heaters (about 3kW) has more than enough capacity to achieve the sterilization requirements.

The ASSE 1070 mixing valves on each fixture prevent scalding temperatures from reaching the fixtures if water is drawn during the sterilization period.

LEVERAGING LOW TEMPERATURES

Due to its low starting temperature, domestic water heating is a very “attractive” load to be supplied by renewable energy heat sources.

This concept takes advantage of the low starting temperature and ensures consistent, safe, and immediate DHW delivery at all fixtures, and minimizes the potential for harmful levels of bacteria to reach any fixture. <>

John Siegenthaler, P.E., has more than 40 years of experience in designing modern hydronic heating systems. To learn more visit hydronicpros.com

MODERN HYDRONICS WWW.HPACMAG.COM MH30 SPRING 2023 RENEWABLE ENERGY

Modern Hydronics

Figure 3. Adding a thermal sterilization tankless heater to address Legionella bacteria.

COMFORT at its best Distributed by directairhvac@powrmatic.ca * • Up to 20 SEER and 12 HSPF • Dual-fuel capable when matched with a gas furnace and evaporator. • Superior low ambient heat output, 100% output at -15°C with a COP up to 2.0, 75% output at -25°C. *On certain models. Contact your representative for complete details. Montréal : 1 800 667-7697 • Québec : 1 800 666-2708 • Ottawa: 1 800 461-3722 Halifax : 1 800 994-3287 • Toronto: 1 800 215-9150 • London: 1 800 667-7697 program Eligible to the

THE LATEST IN CONDENSING TECHNOLOGY

SIMPLE

Mount > Connect > Plug In > Enjoy Endless Heat and/or Hot Water

• Up to 5 moving parts - Unparalleled in the industry

• Illuminated touchscreen control display panel

• Built-in bypass valve to prevent temperature fluctuations

• SFT Tankless features superior performance in hard water areas

• Contractor friendly: 2” venting up to 65 ft. with 2” vent adapter

• Extended pipe fittings for easier installation

• Universal internal parts

• Factory installed domestic water strainer on all DHW models

RELIABLE

• 30-year track record with more than 2 million installations worldwide

• Innovative state-of-the-art electronic control

• Proven patented Labyrinth heat exchanger with fully integrated copper waterways

• No flow reduction in hard water conditions (SFT Tankless)

EFFICIENT

• Fully condensing one-piece heat exchanger

• Qualifies for top-tier energy rebates. Check your local utility for rebate opportunities.

• Wireless cascade of up to 8 units. Multiple cascade configurations available.

• DHW recirculation pump control eliminates the need for an external timer.

• Ultra low NOx / low greenhouse gases

• Up to 5.2 GPM continuous at a 70˚F rise

• Advanced temperature control

SUPERFLOW

SFC 99-1 | SFC 125-1 | SFC 199-1 SFT 199-1 SFB 99-1 | SFB 120-1

www.ibcboiler.com | 1-844-HEAT IBC

condo replaces chiller with heat pumps.

condo replaces chiller with heat pumps.

By John Siegenthaler

By John Siegenthaler

By Doug Picklyk

By Doug Picklyk

By Paul O’Connor

By Paul O’Connor

By John Siegenthaler

By John Siegenthaler