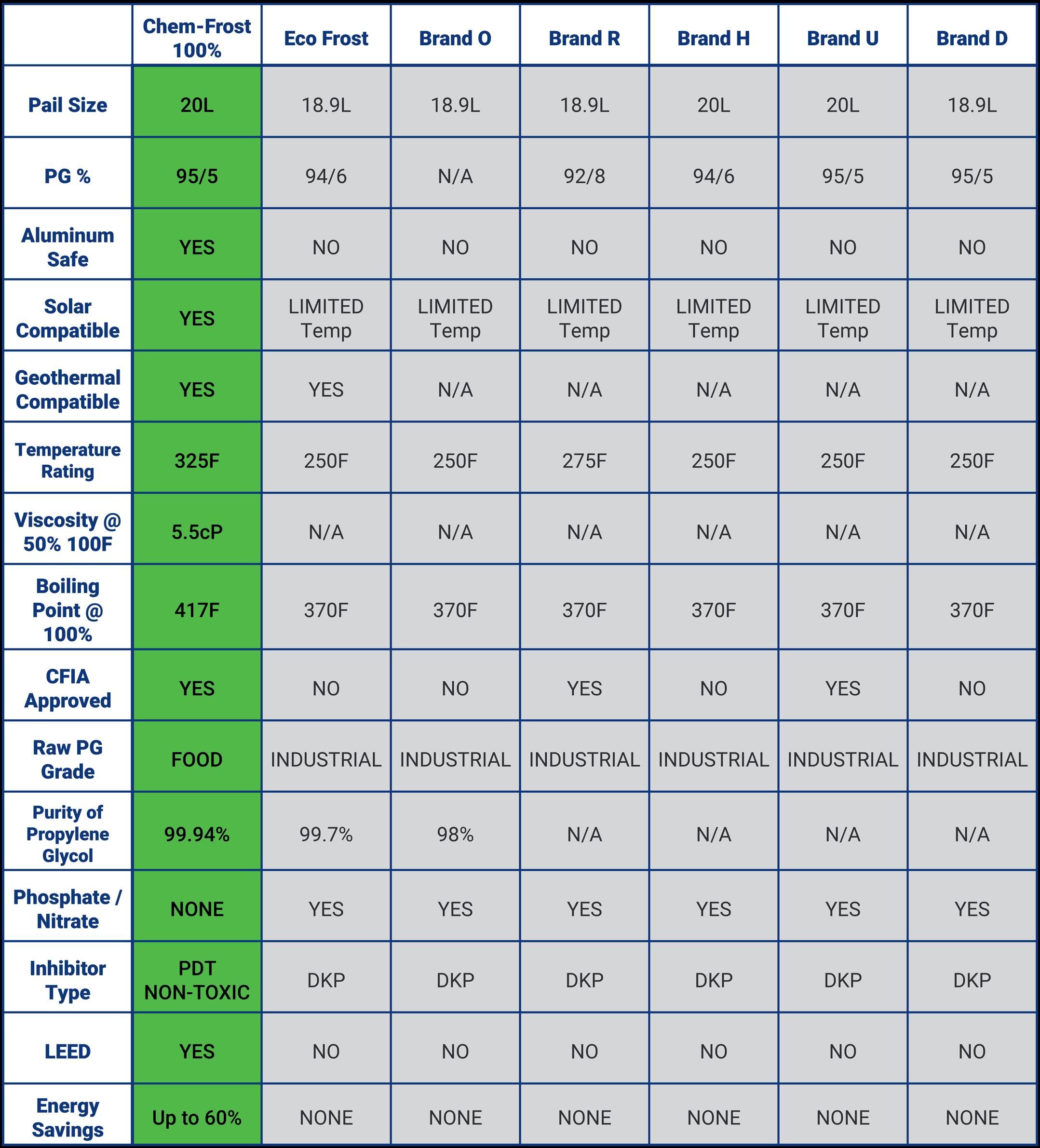

For more benefits, ask your local wholesaler or visit www.chemfax.com or duboischemicals.com Try Chem-Frost

Safe for all systems (including aluminum and solar)

Premier inhibitors

Higher temperature rated

Phosphate and nitrate free

Low viscosity

For more benefits, ask your local wholesaler or visit www.chemfax.com or duboischemicals.com Try Chem-Frost

Safe for all systems (including aluminum and solar)

Premier inhibitors

Higher temperature rated

Phosphate and nitrate free

Low viscosity

Based on information provided on respective manufacturers’ websites*

**Subject to change**

HYDRONICS

ELEVATING THE INDUSTRY

The eighth edition of the Modern Hydronics Summit delivered education and excitement. By HPAC Staff

20 COVER STORY

SWEET HEAT

BRINGING THE HEAT

Three winning projects in the fourth annual HPAC Magazine Sweet Heat Awards reveal variety and ingenuity in hydronic system designs. By Doug Picklyk

29

HYDRONICS

SOLAR EQUALS DHW PLUS MORE

There are still viable applications for solar thermal technology. By John Siegenthaler

34

SOLAR THERMAL SOLAR GAIN

More reasons to reconsider embracing solar thermal for heating the water in our buildings. By Curtis Bennett

X-POD

Now you can inspect drain lines far from a power source. The Gen-Pack battery adapter allows up to 12 hours of remote operation with limited access to power. The Gen-Pack is also sold separately.

But wait, there’s more. You can now record onto a ash drive or send the recording to your customers with the built-in Wi-Fi transmitter. Also, you can track just how far the camera has traveled down the line with the on-screen distance counter.

For more information, visit www.drainbrain.com/XPodPlus, or call the Drain Brains ® at 800-245-6200

36

PIPING DESIGN

COLLABORATION DELIVERS

Piping Canada Post’s newest and greenest parcel sorting facility required coordination and technological efficiencies.

By Brett Lloyd

48 BUSINESS

PREMIUM SERVICES DEMAND

PREMIUM PRICES

Never mix your sales strategy—know your brand and price accordingly.

By Matthew Birch

50

DUCT FREE ZONE

THE UNSUNG HEROES OF HVAC

Appreciating the often underappreciated but indispensable role the humans on the other end of the line.

By Gerry Wagner

52

NET ZERO

PURSUING NET ZERO

Nova Scotia-based Comeau

Refrigeration is leading by example and actively trying to become a net zero operation.

By Dan Vastyan

56

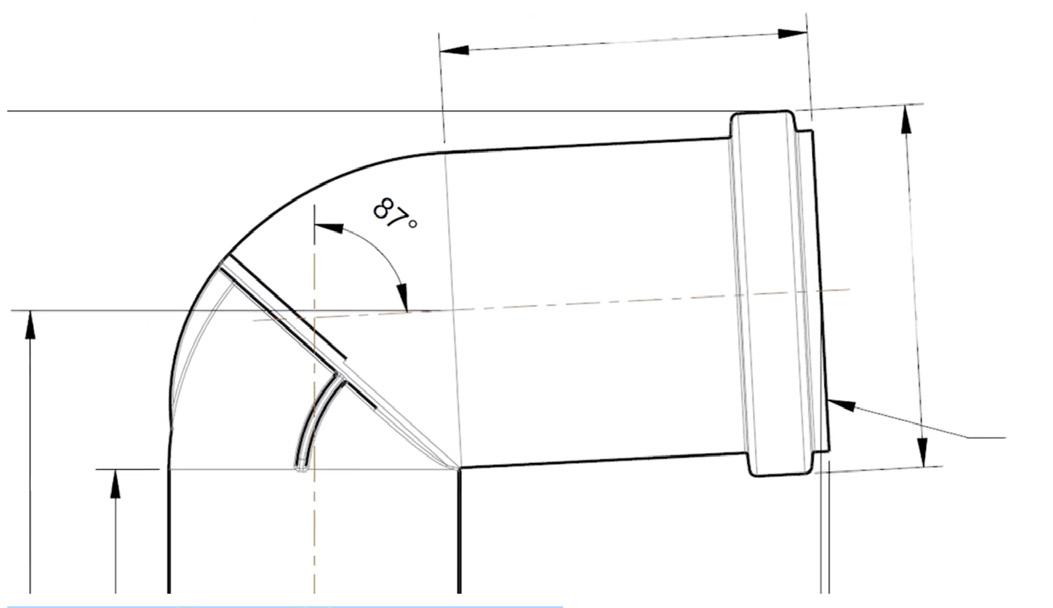

HEATING, VENTING AND INNOVATION

Gas venting systems have evolved over the years with improved solutions for every situation.

By Ian McTeer

64

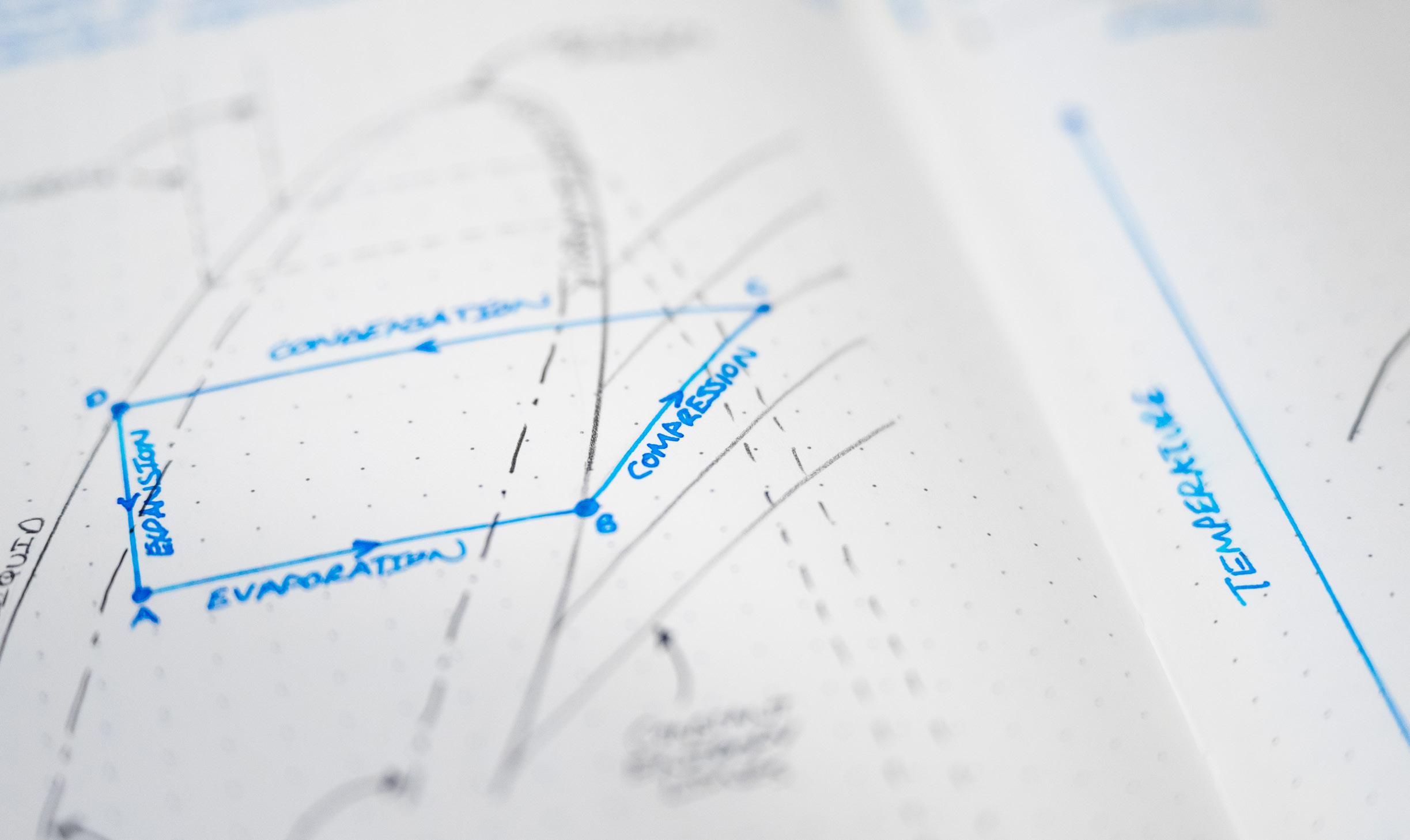

REFRIGERATION

PRESSURE AND TEMPERATURE IN HARMONY

Understanding and appreciating the relationship between these two conditions in the refrigeration cycle is music to this writer’s ears.

By Dave Demma

Trades: HRAI

Setting a new industry standard in hybrid heating products.

Napoleon is recognized as an industry leader in Canada for our cold climate heat pump technology. Our new EQ HUB SMART THERMOSTAT delivers efficiency and lower operating costs through fuel choice and time of use rates*

Our hybrid systems are fully supported and eligible for federal and provincial rebate programs, benefiting homeowners. Count on our nationwide HVAC training and support for these innovative products to support the growth of your business.

*Time of use rates are currently only available in Ontario, Canada.

I HAVE TO COMMEND THE ORGANIZERS OF THE RECENT HRAI CONFERENCE IN VANCOUVER, OR AT LEAST THE BRANDING TEAM. Many conferences propose an event tag line or theme — a concept they hope will inspire and tie everything together — and this year for HRAI it was “The One Thing,” and I think they nailed it.

I’ll admit, going in I didn’t understand the theme, it sounded very Dr. Seuss.

But as the conference began, and the theme was explained, it became clear. And even better than that, the concept carried on throughout the whole event and was actually a useful exercise.

Here’s the gist, every speaker at the conference was asked to share their “One Thing” — their primary take-away message. And even the attendees were invited to share their “One Thing” on a Post-it note and attach it to a communal white board.

With over 20 speakers sharing messages over the course of the conference there were a lot of takeaways. Among the highlights was the session on workforce development, where the idea was put forward that the HVAC industry needs to rebrand itself in the eyes of the public.

We all know that plumbing, heating and even cooling are a necessity. Yet everyone asks, how do we get the next generation interested in this industry? As one person at the HRAI conference said, we need to reframe the industry from a trade to a profession.

Becoming a master technician takes years of classroom and apprenticeship training, like lawyers and doctors, so let’s acknowledge that those in the trades are licensed professionals. It would raise the image of the industry among the youth and more importantly their parents.

For anyone already in this industry who takes the time to attend as many plumbing and HVAC events as possible, it was a busy September. The Modern Hydronics Summit was in Toronto this year, attracting its largest crowd ever. The HRAI conference was followed by the Canadian Hydronics Conference in Edmonton, which featured a packed agenda with the recurring concepts of efficiency and sustainability woven into most presentations.

The month also included a number of events organized by wholesalers and distributors where a cross-section of the industry gathers usually over food, drink and the ability to learn and network (and maybe play road hockey). I even had the chance to chat with Wendel Clark twice in September.

At all of these events I observed a measurable level of excitement and intense dedication that people have for this industry, and a general willingness to share knowledge and best practices with each other.

One recurring theme was the call for even more cooperation. The large associations are always looking to get more contractors involved in both the learning and sharing of information in an effort to lift the overall level of professionalism and profile of the industry.

So, my “One Thing” after attending all these events in September: Be proud, be loud, share your passion and advocate for your industry. <>

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service

Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

DIGITAL EDITOR Jack Burton (416) 510-6809 jburton@hpacmag.com

ASSOCIATE David Skene (416) 510-6884

PUBLISHER dskene@hpacmag.com

NATIONAL Amanda McCracken (647) 628-3610

ACCOUNTS amccracken@hpacmag.com

ACCOUNT Kim Rossiter (416) 510-6794

COORDINATOR krossiter@hpacmag.com

AUDIENCE DEVELOPMENT Urszula Grzyb (416) 510-5180

MANAGER ugrzyb@annexbusinessmedia.com

MEDIA DESIGNER Emily Sun esun@annexbusinessmedia.com

PUBLISHER Peter Leonard (416) 510-6847 pleonard@hpacmag.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2024 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.88 (plus tax) CDN; United States: $114.24 CDN; Elsewhere: $125.46 CDN; Single copy Canada: $8.00 CDN. Heating Plumbing Air Conditioning (establish 1925) is published 6 times per year by Annex Business Media Inc. HPAC Magazine is the leading Canadian business publication for the owner/ manager of mechanical contracting businesses and their supply partners.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-510-5113, Fax: 416-510-6875; E-mail: apotal@ annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

HOW MUCH COULD YOU SAVE BY PRESSING VIEGA FITTINGS AND VALVES?

Let’s start with up to 90% on installation time compared to traditional methods. Our high-quality press fittings and valves mean you can reduce callbacks and labor costs on projects.

See the Viega difference at viega.ca

Recognizing a demand for greater upskilling of existing HVAC technicians across Canada to improve the proficiency of heat pump installations nationwide, the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) applied for and has received over $500,000 in federal funding to support the association’s efforts to identify the skills gap, work with colleges to develop training and initiate a pilot program with a small group of licensed technicians in Ontario.

The funding announcement was made on Tuesday, August 13th, with Julie Dabrusin, MP for Toronto-Danforth (also parliamentary secretary to the minister of environment and climate change), and Tony Van Bynen, MP for Newmarket— Aurora, gathered at Canco ClimateCare in Newmarket, Ont., a local HVAC shop and HRAI member company.

Company owners Nancy and Bob McKeraghan provided a tour of their facility, and two of their installation/service technicians provided an in-house demonstration of a static pressure test on a ducted heat pump installation.

The $500,000 funding for HRAI’s project comes from the federal government’s Low Carbon Economy Fund’s Implementation Readiness Fund stream and the federal Toward Net-Zero Homes and Communities program.

“This program is going to help identify the skills gap and within a year be able to put into effect programming to help people meet that skills gap, so that we’re making sure that these heat pumps are being installed properly, being commissioned properly, and that people feel more comfortable and have more knowledge about these products that are going to become more and more a part of our lives as we move forward,” said Dabrusin.

“I applaud the government for support-

ing the industry, in terms of recognizing that there is a gap, and they are going to help us narrow that gap,” said Nancy McKeraghan, at the event.

“This project will identify specific skills deficiencies and the education the current workforce may need to support today’s (and tomorrow’s) heat pump technologies. It will inform employers and training providers in the industry about needed training development and will help focus apprenticeship efforts for in-the-field experience,” said Martin Luymes, vice president, government and stakeholder relations, HRAI.

HRAI is currently working on the intake of technicians to undergo the analysis to identify the gaps that exist, and from that colleges will work to develop the training required. The association hopes the programs will be in the field in a year from now.

According to a government release, as of 2023, 7% of Canadian homes are using electric heat pumps as their primary heating system, one in four Canadian homeowners is planning to replace their primary heating systems in the next five years, and 300,000 heat pumps were shipped to Canada in 2021, 20% more than gas furnaces.

The Canada Green Buildings Strategy,

launched in July, aims to accelerate retrofits of existing buildings and it also highlights the $800 million Canada Greener Homes Affordability program to assist low- to median-income Canadians, including tenants, by providing home retrofits including heat pump installations at no cost. Complete details of this new program are expected by the end of 2024. hrai.ca

The Zero Emissions Innovation Centre (ZEIC), an independent non-profit organization established to help advance decarbonization in the Metro Vancouver region, has launched the BC Retrofit Accelerator (BCRA), a three-year $20 million program aimed at kick-starting climate and energy upgrades across hundreds of the province’s commercial and residential buildings.

With funding from Natural Resources Canada, the Ronald S. Roadburg Foundation, Metro Vancouver, ZEIC, and others, the BCRA will provide hands-on guidance to the owners and managers of larger commercial and residential properties—including strata-owned, rental, non-market, and off-reserve Indigenous housing.

Over the next three years, the BCRA aims to deliver decarbonization plans for 500 large existing buildings, each showing a path to zero emissions by 2050.

The program will provide coaching for all stages of a retrofit project: such as identifying technology and financing options and support through procurement and implementation.

The BCRA support aligns and connects

The NPF Advantage: The NPF heats water by burning the gas in a sealed combustion heat exchanger, completely isolated from the airstream. The heated water is then pumped through a hydronic heat exchanger that gently transfers the heat into the air.

The fully enclosed Ultra-Low NOx premix burner provides extremely quiet operation, high efficiency of 97% AFUE, and allows for an industry-leading variable capacity that can modulate down to 15% for a next-level comfort experience.

with existing BC Hydro programs and other offers to support multi-family buildings.

By navigating building owners and managers through the upgrade process, the BCRA aims to spark deep energy retrofits— including the installation of heat pumps or distributed renewable energy systems. zeic.ca

The Sustainable Technologies Evaluation Program (STEP) has released a study that examined the impact of cold climate air-source heat pumps (CCASHPs) across six homes in Ontario’s Peel Region during the winter of 2023-24.

The study showed that ASHPs could meet the large majority of home heating needs while maintaining a high efficiency and comfortable indoor temperatures.

Five of the six homes used cold climate ASHPs, with system costs ranging from $4,300 to $8,000. One home used a standard ASHP due to not meeting the criteria for a cold climate device. In most cases, upfront costs were covered by the Enbridge Home Efficiency Rebate Plus (HER+) program.

Over the course of the study, residents saw their whole-home gas consumption reduced by 62 to 91%, with the gas usage of the furnaces typically reduced by more than 80%.

Most homes were close to break-even

on net utility costs when compared to their pre-CCASHP utility consumptions, with the only home seeing an increase being the one that did not meet the criteria for a CCASHP and instead installed an ASHP.

In terms of reception, the study’s homeowners reported being mostly satisfied with their heat pumps, with many expressing they would have made the switch earlier had they known about them.

The benefits experienced include comfortable indoor temperatures, quieter operating noise despite longer run times, and overall utility savings.

The report found all homeowners had a positive installation experience and would recommend heat pumps to others.

STEP is a multi-agency initiative developed to support the implementation of sustainable technologies and practices within a specifically Canadian context. STEP evaluates the impacts of products, practices, site designs and more in creating sustainable and livable communities. sustainabletechnologies.ca

Enwave Energy celebrated the commissioning of the fourth intake to its Deep Lake Water Cooling (DLWC) district cooling system in Toronto during a ceremony on August 29th at the company’s John Street Energy Centre in downtown Toronto.

Construction on the latest expansion began in 2021, and it includes a 3-km pipe into Lake Ontario, which draws in water at 4C and transports it to the John Street Energy Centre through a newly built tunnel that extends under the Toronto harbour.

The expansion has increased the DLWC’s cooling capacity by 60%, with the capability of providing service to an additional 40 buildings.

The DLWC system has been existence for 20 years, now servicing more than 100 buildings in downtown Toronto. It’s

Commissioning ceremony: (l-r) Olivia Chow, Toronto Mayor; William Fernandes, acting deputy general manager, Toronto Water; Lou Di Gironimo, general manager, Toronto Water; Sam Oosterhoff, associate minister, EnergyIntensive Industries; and Carlyle Coutinho, CEO, Enwave Energy Corp.

the world’s largest system of its kind, providing cooling to hospitals, commercial buildings, residential buildings, data centres, and entertainment venues.

With the expansion, it’s estimated the system will save 220 million gallons of water annually and avoids over 60 megawatts of peak electrical demand from Ontario’s grid.

enwave.com

The Plastics Pipe Institute (PPI) has published a revision of its PPI TN-55 Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications standard, with changes made in collaboration the International Ground Source Heat Pump Association (IGSHPA).

tem, PPI TN-55 focuses on piping, fittings and manifold materials,” explains Lance MacNevin. “TN-55 lists the technical requirements for systems using HDPE, PE-RT and PEX piping, plus requirements for PP pipes used as indoor piping, headers, and manifolds.” plasticpipe.org

The new edition updates the original document published in 2018. The standard describes eight different types of installation techniques, including vertical boreholes and horizontal directional drilling (HDD), and discusses various topics related to design such as the effects of borehole depth on static water column pressure.

“Because the piping material is critical to the overall success of the ground heat exchanger (GHX) in a geoexchange sys -

A new report from RBC’s Climate Action Institute, A Smart Heating Solution for Canada’s Fiscally Strained Municipalities focuses on the impact low- to zero-carbon district heating systems can have on lowering the building sector’s emissions across Canada’s largest cities by 36%, based on research from RWDI, the Climate Smart Building Alliance and the Climate Action Institute. thoughtleadership.rbc.com

BY DOUG PICKLYK

The Canadian Hydronics Conference, a two-day tradeshow and educational event organized by the Canadian Hydronics Council (a division of the Canadian Institute of Plumbing and Heating – CIPH), returned to Western Canada with a bang, hosting a series of standing-room-only sessions and a crowded show floor September 25-26 at the River Cree Resort and Casino in the Edmonton area.

This year’s conference marked the first time in over a decade that Edmonton hosted a national hydronics event. For some it was reminiscent of the former Foothills Conferences that used to take place in Western Canada.

With over 300 people registered and 41 exhibitors, the full agenda included presentations on housing demand in Edmonton, hydronics for modular wood construction, and the prospect of hydrogen for heating in Alberta.

There were also a series of technical session for all levels of hydronics professionals covering topics like: hydronics as a career, selling hydronics, building redundancy in commercial applications, outdoor reset, air-to-water heat pumps, ECM circulators, hydraulic separation, project inspection and thermal storage.

Two well-attended panel discussions focused on the country’s track to net zero. Moderated by Jerry Leyte (Viessmann), the final panel of the conference asked: What is the Future of Hydronics in Canada?

Mike Miller (Taco Comfort Solutions) addressed the topic of air-to-water heat

pumps: “In my opinion, although an allelectric solution is where we’re trying to get to, it might not always be the best solution.” Living in Ontario, Miller has operated an air-to-water heat pump for five years, learning lessons about dehumidification along the way. He’s a proponent of using hybrid, dual-fuel, solutions for now.

The only contractor on the panel, Terence Chan, owner of Impetus Plumbing and Heating in Vancouver, emphasized the need for greater training on hybrid solutions. “As a business owner, having to get my team up to speed has been a challenge,” says Chan. “Every manufacturer’s equipment is different.”

Jeremy Young (Pro West Sales) addressed some of the common issues found when integrating air-to-water and gas boiler systems, highlighting different flow characteristics, pipe diameters and circulators, and the importance of addressing the control strategy early in the process.

“Most of the challenges I’ve had with hydronic heat pumps have not been the result of the appliances, but the integration,” says Young. “I think all of us working together to communicate best practices is one of the best ways to deal with that challenge.”

Alan Zanidean (Axiom) also focused on the planning process. “Hydronics is an artform, but with hybrid heat systems it’s very crucial that you have the entirety of the system planned and working consistently together.”

Zanidean, CHC Chair, touched on a planned initiative to improve industry collaboration and promote best practices across the hydronics industry.

Traditionally a biennial event (last held in Saskatoon, September 2022), the CHC Conference will now become an annual affair, with the next edition taking place at the Palais de congrés in Montreal, September 30 - October 1, 2025. <>

The Vitocal 100-AW air to water heat pump is designed for heating, cooling and domestic hot water. Featuring an outdoor unit, an indoor unit and a steel buffer tank (20 gal). The optional domestic indirect tanks come in three sizes (53, 66 or 79 gal), and the buffer tank can be physically mounted on top of the domestic tank to save space.

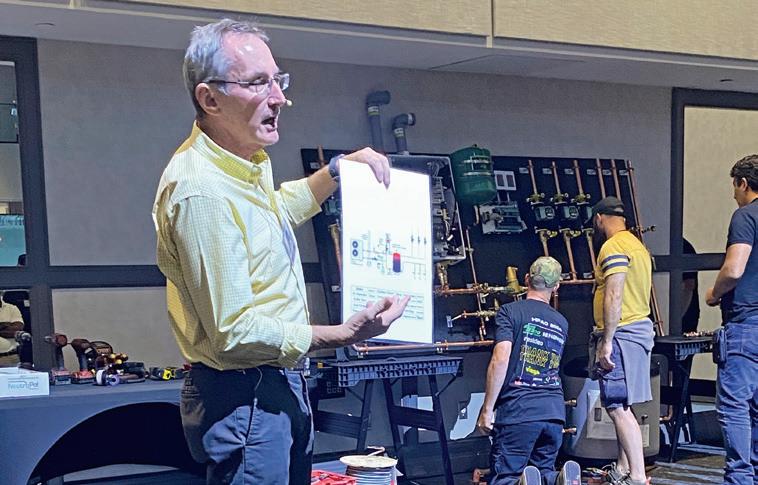

The eighth edition of the Modern Hydronics Summit delivered education and excitement. BY

HPAC STAFF

The hydronics community from the Greater Toronto Area and further afield gathered at the Paramount EventSpace on Thursday, September 12th for the eighth edition of the oneday Modern Hydronics Summit.

Started in 2013, the Modern Hydronics Summit, produced by HPAC Magazine, brings together expert speakers and product manufacturers and distributors to share the latest in technology and know-how with the mechanical contractors who design, install and service hy-

dronic systems in Canada.

The conference and tabletop trade show has been growing larger with every edition in the Toronto area, and once again the exhibit space at this year’s event was sold out. Before the presentations kicked off, and between the sessions, attendees explored the 50-plus booths in the show hall and lobby space.

For the second time in Toronto, the Summit included a special day-long series of Hydronics 101 sessions held off the main floor and hosted by NEXT

on small-scale hydronic cooling.

Supply. This year NEXT coordinated the topics and speakers, and the attendance almost doubled from the first effort in 2022.

Also, for the third time live boiler panel builds were taking place in the lobby during the event. This year’s educational panel build was coordinated by social media promoters Terence Chan of Impetus Plumbing & Heating/Impetus

Media along with Adam Gordon of Orella Group. The builds were generously sup -

ported by manufacturers and distributors, led by Taco Comfort Solutions, working together to support and lift the next generation of hydronics talent. Each of the three builds were led by experienced HVAC social media personalities (Mike Flynn, George De Jesus and Tyler Dynes) who worked along with other influencers and industry newcomers who

Three simultaneous educational panel builds were taking place in the lobby, led by social media regulars Michael Flynn (@flynnstone1), Tyler Dynes (@dyneshvac) and George DeJesus (@georgetheplumber).

signed up to participate and learn.

Like last year, the three panels will be heading to college trade programs, including Mohawk College in Hamilton and Conestoga College in Cambridge, Ont.

Continued on p18

Hello Autumn, May you bring that best feeling of stepping into a warm home, with the smell of freshly baked apple pie in the air. We can help with the warmth, but for the apple pie… the only expert you should call is your grandma!

Scan the QR code below to register and get a chance to win $500 worth of Dettson products. Visit the form for the terms and conditions.

How to participate :

1. Scan the QR Code below 2. Fill out the registration form Thats it ! You’ll be automatically entered for a chance to win.

A lucky winner will be selected at random on December 1st, 2024, and contacted via the email provided in the form.

Scan here to get a chance to win $500 !

Industry expert John Siegenthaler started the day with a presentation on adding an air-to-water heat pump to a legacy hydronic heating system. Siegenthaler addressed the different types of heat pumps on the market, their performance characteristics and how to integrate the system with boiler set ups. Among the many reasons for keeping a boiler include: a backup heat source, avoiding an electrical panel upgrade, resiliency in blackout conditions and possible load shifting. Siegenthaler concluded with sample piping diagrams and reinforced the importance of moving towards low supply temperatures. He was followed by the Controls Panel, a group discussion on integrating controls into modern hydronics systems. Panelists Mike Miller (Taco), Jay Vath (tekmar) and Curtis Bennett (HBX Controls)

“It usually makes sense to keep the existing boiler.” - Siegenthaler

addressed questions from HPAC editor Doug Picklyk. All three stressed the importance of incorporating the control strategy early in the design process, noting it’s easier to use existing control logic built into off-the-shelf products than trying to customize controls once a project has been installed.

During the lunch break one of the panel builds was moved into the main showroom. The design for this panel was a collaboration with John Siegenthaler and incorporated the piping to an air-towater heat pump. With a live feed on the

Sharing best practices and lessons learned from air-to-water heat pump system design and installation experience, panelists (l-r) Benoit Maneckjee (ThermAtlantic), Chris DesRoches (Swegon), and Roger Abdo (Hydro Solar).

overhead video screens, Siegenthaler provided a live walk-thru of the design as the team was working on the finishing touches.

The afternoon included a panel on lessons learned from existing air-to-water heat pump installations in Canada. Three panelists, Benoit Maneckjee (ThermAtlantic), Roger Abdo (Hydro Solar) and Chris DesRoches (Swegon) shared insights from their experience selling, designing and installing systems in Canada.

Then Siegenthaler returned with a presentation on small scale hydronic cooling, addressing cooling options with heat pumps, avoiding condensation, and demonstrating some system design concepts.

The main stage concluded with the announcement of the 2024 Sweet Heat hydronics installation contest, and two

O’Connor of POC Plumbing and

(centre) won a Kane HVAC/R clamp meter, presented by Steve Casalinuovo, Kane Canada (left) and Doug Picklyk (HPAC)

Winners of the Blue Jays tickets courtesy of Aqua-Tech/Lochinvar: (l-r) Ross Koirala, Aqua-Tech; Ryan Theisen, Aqua-Tech; Michael McCallum, McCallum HVAC Design; Ken Carmichael, Bray’s Fuels; and Joe Drago, Aqua-Tech.

of the three winning companies were present to be congratulated by the judges and lead sponsor EMCO.

Once again, the Modern Hydronics Summit was made possible with the support of over 50 exhibitors and key spon-

sors including: IBC and Rheem (Keynote sponsors); Resideo (registration); Roth (refreshments); Taco (bar tickets); Caleffi (dinner); Kane Canada (tool prizes); Lochinvar/Aqua-Tech (ticket giveaway); Grundfos (WiFi); Weil-McLain (show guide); and Next Supply (hydronics 101).

The date and time for the 2025 Modern

Hydronics Summit will be announced in the coming weeks. And an online video replay of John Siegenthaler’s presentations from this year will be streamed during live webinars Thursday, November 21 and Friday, November 22 with John available for questions. Visit hpacmag.com/ siggy-replays for more details. <>

Three winning projects in the fourth annual HPAC Magazine Sweet Heat Awards reveal variety and ingenuity in hydronic system designs. BY

DOUG PICKLYK

For the fourth year running, HPAC Magazine organized the annual Sweet Heat hydronics installation contest, a competition for contractors across Canada to share photos, explain the challenges they encountered and the creative solutions they used on projects completed in the past year.

This year’s competition received 26 entries, and for the first time the projects were divided into three categories: commercial, residential new build and residential retrofit.

Once again, the competition was generously sponsored by nationwide wholesaler EMCO, with the winning entry in each category receiving $2,000 vouchers at their local EMCO branch.

The final evaluations were performed by three judges: hydronics expert John Seigenthaler who brings over 40 years of industry experience to the role; Brian Morgan, a long-time industry veteran and owner of manufacturer’s representative agency The Morgan Group; and Jeff House, a specialized veteran in the

hydronics field providing sales, consulting, training, design, and hands-on jobsite instruction across Canada since 1991, currently with Hydronic Systems.

“All the entries showed excellent craftsmanship - very meticulous component assembly skills,” said Siegenthaler. “If this were a contest based solely on installation skills, pipe fitting in particular, it would be very hard to pick a winner.”

Looking forward to next year, he has a recommendation for those entering the

Continued on p22

The central element of any residential or commercial hydronic heating system. Take advantage of electricity for heating and domestic hot water production. Choose Canadian expertise and know how!

contest: “Most entries focused on the boilers (or in limited cases on the heat pump) as heat sources. Very few discussed the distribution system or heat emitters in any detail. It should not be a contest about who has the fanciest boiler room. It should be about the overall system with better descriptions of the emitters and the overall system.”

With that in mind, following are this year’s winning entries.

The winning project in the commercial category is a roughly 60,000 sq. ft. greenhouse install in Quebec City submitted by BT Energie of St. Joseph-deBeauce, Que.

Hydronics specialists with over 40years combined experience, Frédérick Baronet and Marco Toulouse started BT Energie seven years ago to focus on hydronics and using renewable energy. This project involved the conversion of a greenhouse operation from fuel oil to biomass. The Bedard Blouin Farm greenhouse grows ornamental flowers and plants as well as market garden crops and hosts a consumer market area as well.

BT Energie replaced the fuel boiler with two German-made Heizomat 500kW (1.7 million Btu/h) biomass boilers for built-in redundancy. “It’s very critical for the greenhouses to never be without heating,” notes Toulouse. BT Energie also installed two pumps on the main network for more back-up. And a 52-ton silo was installed on-site to store the wood pellets that feed the boilers.

Toulouse adds that the boiler controls (Siemens) have industrial quality connections, and he notes that Heizomat has its own online portal so the system can be monitored in real time, and alarms will notify both BT Energie and the greenhouse owners of any issues. In addition, tekmar controls were installed for cascading the boilers, and

“All the entries showed excellent craftsmanshipvery meticulous assembly skills.”

those controls also allow them to have eyes on the system, says Toulouse. Together the boilers provide hot water to satisfy a large buffer tank located in the mechanical room.

The project included a complete repiping the entire site, and Toulouse estimates they installed around 900 ft of 4-in. pipe, 600 ft. of 3-in. and different branches of 2-in., 1-1/2-in. and smaller. “I would say close to 2,000 feet of pipe has been installed.”

For heat distribution they installed 36 new fan coils, some help to inflate the greenhouse structure and some are for just heating. There are different set temperatures required throughout the greenhouses depending on the type of plants is being grown. And there is also office space and a market area that require heating in the cold weather.

The temperatures are all controlled by a greenhouse software system that monitors humidity, temperature and the more.

The boilers are also used to heat the irrigation water. “We used a heat exchanger to heat this water,” says Toulouse. A sensor in the irrigation water storage tank will trigger a recirculating pump to keep that water around 18 to 20C.

Greenhouses are unique structures, notes Toulouse, since the walls are basically only a plastic sheet you would think the boilers would be operating at full capacity all winter long, but that’s not the case.

“In fact, you can enter in the greenhouse in February when it’s -10C outside and because of the sun’s radiation you can work in a T-shirt because it’s 10C degrees inside,” he says.

“Once the sun just goes down you need energy, and yes the boiler will work at full power during the night, and as soon as the sun rises and starts to hit the greenhouses, in less than an hour you can completely stop your boiler as there is enough heat. It’s the greenhouse effect.”

The system was installed in the summer of 2023, performing through one winter so far. They kept one boiler running during the fall and early winter as only about 25% of the site is operational. Then in February, as more of greenhouse space opens the boilers become fully operational and keep running until late April or May.

Toulouse notes that because of the Transition Energetique Quebec (TEQ) incentives for fossil fuel to biomass conversion projects the payback of this system is estimated to be less than five years, with the bonus of thousands of greenhouse gas (GHG) emissions removed from the atmosphere.

Whatever your needs may be, you can trust that you're installing a product that is produced to the highest standards.

A 4,000 sq. ft. ranch-style slab on grade bungalow project on the north end of Kingston, Ont. claimed the top spot in the residential new build category in this year’s contest.

Donaldson Plumbing & Heating, located 10 minutes north of Kingston in Inverary, Ont., submitted this entry which included a lot of in-slab piping for heating and the domestic hot water (DHW) supply.

“This customer had high expectations,” says Blair Donaldson. That included radiant heat as primary heat source throughout, an air handler for cooling and shoulder season heating, and a hot water tank sized for all the high-flow fixtures in the house.

A family business, Donaldson was started by Blair’s father in 1982, and Blair grew up around the business and has been involved and working on hydronics jobs for 20 years.

For this project, the homeowner works in the construction trade and knew what he wanted. Because the early building phase was in the winter, and the owner wanted to get the heat on, he insisted on glycol in the whole heating system.

The in-floor has eight zones, including a screened-in covered porch area. Slab sensors and air sensors were installed throughout the house. Because of the high-end hardwood the slabs cannot exceed a maximum temperature or it could void the hardwood warranty.

The system uses tekmar thermostats and a couple different manifold locations with telestats (zone valves) on the manifolds. There is floor warming in the bathrooms and a towel warmer in the ensuite bathroom that runs on a timer. “He added a few things along the way,” notes Donaldson. Fortunately, the owner also wanted a nice-size mechanical room that was off his garage. “And he was the one that actually wanted the checker plate on the walls,” says Donaldson. During the judging, Siegenthaler did ask, “What is it with all

the diamond plate in Canada? Are the customers asking for the diamond plate, or is the installer doing it to enhance the system appearance with the customer picking up the cost?” Well, in this case it was the customer’s call.

The system uses a Navien NFB 175 boiler, and it has a tekmar controlled digital mixing valve with an outdoor reset to monitor the different temperatures required for the air handlers, radiant and the DHW.

The system also incorporates a low loss header for hydraulic separation. “We always try incorporate a low loss header for all our jobs,” says Donaldson. “Everything just seems to work that much better.”

For the DHW they installed an 80-gallon tank, incorporated whole house recirc and large diameter insulated piping to satisfy the high flow fixtures and large bathtub.

“The system has met all the requirements the customer wanted in their hot water and heating system as everything functioned as designed,” notes Donaldson.

The winning entry in the residential retrofit category started as a potential boiler replacement and turned into a complete system overhaul with the design and installation performed by Farr Mechanical of Stouffville, Ont.

The large home, roughly 12,000 sq. ft. complete with indoor pool, is located in Thornhill, just north of Toronto. According to Tyler Dynes, who took the lead on the installation of this project, the original design was poorly organized and required constant servicing, so instead of adding more band aids the owner agreed to revamp the entire system.

“We replaced everything: air conditioners, boilers, furnaces, water heater, and I even went through the pool system with a fine-toothed comb,” says Dynes.

Continued on p26

MECHPRESS Carbon Steel Press Fittings are compatible with Schedule 10 to 40 carbon steel pipe (including seamless steel pipe) in sizes ½” to 2”. MECHPRESS fittings suit various carbon steel systems in residential, commercial, and industrial applications.

Zinc-nickel coating for corrosion resistance

Sealing elements ideally suited for each application:

•EPDM for Mechanical and Fire Protection systems (MECHPRESS)

•HNBR for Gas and Fuel Oil applications (MECHPRESS-G)

Dual visual confirmation ensures fittings are pressed before going into service

Each fitting is marked with colour-coded dots for easy identification:

•Green for MECHPRESS (Mechanical & Fire Protection Systems) and

•Yellow for MECHPRESS-G (Gas & Fuel Oil Systems)

Fittings can be pressed with current industry carbon press tools and jaws

15-Year limited warranty

MECHPRESS

Mechanical & Fire Protection

MECHPRESS-G Gas & Fuel Oil

The mechanical room is about 1,000 sq. ft., and Dynes recommended building a 17-ft. wall in the middle of the room to attach all the controls, piping and boiler set-up in one place. “Once we had a plan in mind, it just flew together,” says Dynes.

The home has five in-floor heating zones including: a slab in the garage; a slab in the basement; second floor bathrooms with a thin slab on the floor; and a lot of staple-up in other areas. “That’s why you see five different mixing valves at the very end of the manifold,” explains Dynes. “It’s because we have different temperatures going to all those different radiant zones.”

And there are also high temperature zones which feed five hydronic furnaces as well as a heat exchanger for the pool and hot tub. The system uses a buffer tank between the two NTI boilers and zone circulators for hydraulic separation and to comfortably handle micro-zones with no fear or short cycling.

The set point for the buffer tank is 160F. “I try to keep temperatures as low as we can,” says Dynes. “I’d rather hear that the fuel bill was great, and that everything else is working great. I am always about trying to lower my boiler

temperature because the lower the temperature the more you stay in your condensing state, which is better.”

The boilers also feed an indirect tank located behind the wall for the domestic hot water (DHW). The NTI boilers with internal pumps are set up with domestic priority, so when there is a call from the indirect tank, a diverter valve in the boiler directs the flow to the DHW instead of the heating system.

Farr Mechanical also installed new air conditioning units outside the house and placed slab air conditioning coils in the furnaces so they can provide heating and cooling in those zones.

The original thermostats in the house used only two wires, making it impossible to install many modern WiFi stats in each zone without rewiring the house. But the company chose the tekmar Invita thermostats which only require two wires along with interface modules that they were able to locate in the mechanical room.

The system is also accessible via an app. “I can diagnose the system without even going there,” says Dynes. He also set up the homeowner with the same access.

One of the Sweet Heat judges, Jeff House, commented: “The install was

neat and simple. With all the exposed copper piping, insulation should have been installed, which may have been done after the installation photo.”

However, Dynes shared that no insulation was installed on this job. “The customer liked seeing the copper so much, he said, ‘I don’t want to cover it.’”

Despite taking the lead on the install, Dynes notes that it was very much a team effort. “It’s a nice team that we have here, and being able to put our heads together we can come up with some great ideas.”

This year two entries tied for the runnerup distinction in the residential new build category. Denrite Mechanical of Edmonton was selected for the installation of the heating and hot water system in a tiny 550 sq. ft. home, fitting the mechanical room into a broom closet.

And Schuller Solutions was recognized for a project on a large house in a remote area around Peterborough, Ont. Reliant on well water and propane, the home’s location necessitated an energy-efficient system with built-in backups and the ability to supply multiple

Continued on p28

temperature options.

The runner-up in the residential retrofit installations went to a high-end 5,500 sq. ft. radiant floor heating installation in Oakfield, Nova Scotia that incorporated a 10-ton air-to-water heat pump system with electric boiler for back up. The system was installed by hyronics contractor S. Robinson Mechanical of Halifax, along

with Glenmar Heating and Air Conditioning of Fall River, NS and CE Fisher Electric of Wellington, NS.

The runner-up in the commercial category went to Boss Plumbing in Saskatoon for an installation in the company’s new shop that includes a 9,600 sq. ft. warehouse and office space with infloor heating. “Design in -

YOUR TRUSTED HOME HEATING AND COOLING PRODUCTS PARTNER

Conforto Panel Radiators offer the perfect blend of radiant heat and sleek design. Trusted in European homes for over 40 years, they

are versatile enough for primary heating, supplementing radiant floors, or working with traditional systems. Virtually silent, they provide both radiant and convective heat for unmatched comfort.

confortohvac.com

contact@confortohvac.com

spiration was drawn from the principles outlined in John Siegenthaler’s Modern Hydronic Heating textbooks,” notes the company. The energy-efficient low-temp system serves not only as a heating system for the shop but also as a showpiece for customers.

Thank you to all the contractors who took the time to enter the 2024 Sweet Heat contest. These entries provide great examples of the exceptional hydronic heating projects being done year after year across Canada.

HPAC Magazine would like to encourage all hydronic system installers in Canada to keep photos of their best work and enter next year’s edition of Sweet Heat. <>

Thank you to all the contractors who entered the fourth annual Sweet Heat hydronics installation contest:

• 4R Mechanical, Wetaskiwin, Alta.;

• A. TECH Mechanical, Welland, Ont.

• Boss Plumbing, Saskatoon, Sask.

• BT Energie, St. Joseph-de-Beauce, Que.

• Canuck Mechanical, Prince George, B.C.

• Capp Mechanical, Coldwater, Ont.

• Chenier Mechanical, Finch, Ont.

• Denrite Mechanical, Edmonton, Alta.

• Donaldson Plumbing & Heating, Inverary, Ont.

• Ed Verboom Plumbing, Simcoe, Ont.

• FARR Mechanical, Stouffville, Ont.

• GTAHeat.ca, Concord, Ont.

• John Sadler Plumbing & Heating, Surrey, B.C.

• Klimatrol, Brampton, Ont.

• Paramount Plumbing, Florence, Ont.

• Pipe Right Plumbing & Heating, Brantford, Ont.

• POC Plumbing & Heating, Coldwater, Ont.

• RNJ Mechanical, Delburne, Alta

• S. Robinson Mechanical, Halifax, N.S.

• Schuller Solutions, Stouffville, Ont.

• TJL Mechanical, Fergus, Ont.

There are still viable applications for solar thermal technology. BY JOHN

These days, the term solar energy is almost always associated with photovoltaic (PV) systems that produce electricity from sunlight. Those systems range from a single small PV module used to maintain charge in a 12-volt battery, to acres upon acres of land used to create a “solar farm” that, by day, generates megawatts of power.

Few would have envisioned such a situation back in the 1970s when I got my first job with a firm that designed and manufactured solar thermal collectors.

Back then PV panels were reserved for mission critical or spacecraft applications, where the $1,000/Watt cost (in 1970s dollars) was acceptable.

Outside of that small niche, solar thermal applications were the norm, with much of the market focused on residential solar space heating.

Houses were constructed as supporting structures for massive solar collector arrays in an attempt to approach 100% solar heating. One example, from 1978, is shown in Figure 1.

Many collector arrays of that vintage were grossly oversized for swing season loads, and they required costly heat dump provisions to “survive” intense summer sunshine.

That first round of interest in solar thermal technology in North America all but died during the latter 1980s and stayed quiet through much of the 1990s and first part of the 21st century.

The solar coals were rekindled around 2008 driven by increasing concerns

SIEGENTHALER

ways interested me is what I call a “solar DHW+” system. The primary load for these systems is domestic water heating, and the “+” implies a small contribution to space heating, mostly during those swing seasons.

This approach keeps the solar array limited to minimize overheating potential in summer, and it also leverages major components of the system, such as the storage tank, for multiple functions.

over global warming and well as some energy price spikes. However, this time around much of the industry recognized that using solar collectors to offset a high percentage of conventional fuel for space heating was not a realistic goal. Domestic water heating became the preferred load to be paired with solar thermal collectors. The primary rationale being that domestic water heating was a year-round load, as such it benefited from abundant solar radiation and higher ambient temperatures for several months every year.

Another benefit was that domestic water heating operated at lower average water temperatures compared to those typically needed for space heating applications.

Although the market for solar thermal systems is a tiny fraction of what it once was, I still believe there are viable applications that could help in decarbonizing modern thermal energy systems.

One system configuration that has al -

The energy collection potential of a solar DHW + system is also better matched with the load in modern energy efficient homes.

One approach to a solar DHW+ system using a dual coil thermal storage tank, is shown in Figure 2 (next page).

The water in the tank’s shell is “system water,” not domestic water. The lower coil provides heat input from the solar collectors. Its position within the tank maximizes the average temperature difference between the outer surface of the coil and the coolest water in the tank.

The tank also provides hydraulic separation of the boiler circulator and variable speed distribution circulator.

The solar collectors are part of a closed circuit operating with an antifreeze (glycol) solution. That circuit is equipped with filling/purging valves, circulator, air separation, expansion tank, pressure relief valve, and high point air vent.

The collector circulator is operated by a differential temperature controller that continually monitors the temperature in the lower portion of the storage tank and the absorber plate in one of the solar

Continued on p30

collectors. The circulator control action could be on/off or variable speed depending on the temperature differential between the absorber plate and the tank.

The upper coil extracts heat from the water in the tank and transfers it to domestic water. The upper coil must be constructed of copper or stainless that’s compatible with domestic water.

This is a “single pass” coil. Cold domestic water enters the lower coil connection and absorbs heat as it flows upward and eventually exits the coil.

Combination isolation/flushing valves have been installed near the inlet and outlet of this coil, allowing it to be periodically isolated from the system and flushed with a mild acid solution to reduce scale build-up.

The temperature of the domestic wa -

ter leaving the upper coil depends on the temperature of the water surrounding the coil, as well as the coil’s surface area and the flow rate through it.

Slower flow rates, and thus more “dwell time” in the coil, may allow the domestic water leaving the coil to approach the temperature at the top of the tank.

The need to provide supplemental heating of the domestic water leaving the coil depends on the upper tank temperature and rate of flow through the coil.

If the coil is generously sized, remains free from scaling, and the water in the tank is maintained at least 10F above the expected DHW outlet temperature by the boiler, there is likely no need for supplemental heating. However, those perquisites are not always met - more on this later.

Given the possibility of some really productive solar days (e.g., sunny and warm) it’s crucially important to include the ASSE 1017 rated anti-scald mixing valve in the DHW assembly to protect against high temperatures entering the building’s plumbing distribution piping.

The thermal mass of the storage tank helps stabilize domestic hot water delivery. The tank also provides buffering for the zoned space heating system, which in Figure 2 consists of several panel radiators and some radiant panel circuits, all regulated by thermostatic radiator valves. A variable-speed pressure-regulated circulator operates 24/7 during heating season to match the system flow needs. A motorized mixing valve, operating

The NEW I-SERIES Plus™ line of Solo and Combi Condensing Gas Boilers offers unmatched value and performance with an expanded product line of 14 models that range from 60-199k Btu.

Now you can Rely on Rinnai for all your Residential Heating projects no matter the size or complexity.

Allows you to connect your smart phone or tablet to the SENSEI® RX Series via Bluetooth®

Use the Rinnai Central™ App for quick, simplified boiler set-up and registration, significantly reducing your install time.

Rinnai’s Adaptive Gas Valve Technology lets you select your fuel type with the touch of a button on the unit controller or your smart phone. Conversion Kits not required. Smart Sense™ is only available on 60-150k BTU units

4 Built-in Zones for better comfort and savings.

on outdoor reset control, ensures an adequate but not excessive supply water temperature to the heat emitters.

Low temperature emitters that can provide design load space heating at supply temperatures at 120F are possibilities. The lower the supply temp., the greater the “solar yield” of the system.

Another variation of the “solar DHW +” system replaces the boiler with an airto-water heat pump (Figure 3).

The heat pump provides supplemental heat input when needed, but its performance is more constrained compared to the boiler. To optimize the heat pump’s performance, the water temperature in the storage tank should be as low as

possible but still able to provide the required heat output at the heat emitters.

Outdoor reset control is ideal in this situation. Based on simulations I’ve done, the seasonal COP of the heat pump improves when this method of control is used in lieu of maintaining the tank temperature based on a setpoint high enough to fully heat domestic water to a temperature of 120F or higher.

Domestic water is “preheated” as it passes through the upper tank coil. A tankless electric water heater provides the final temperature boost.

All domestic hot water passes through the anti-scald valve before entering the distribution system, and the motorized mixing valve is needed if the heat emitters could be damaged or if

Figure 3. A solar DHW+ system incorporating a split system air-to-water heat pump instead of a boiler.

unsafe surface temperatures could be created when the tank is heated by the solar thermal collector.

The “Solar DHW +” concept is a “sweet spot” for solar thermal technology coordinating well with low energy homes.

The all-electric option is well suited for those aiming for “net zero” energy status. It’s worth keeping this concept in your renewable energy portfolio. <>

John Siegenthaler, P.E., is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit hydronicpros.com).

More reasons to consider embracing solar thermal for heating the water in our buildings. BY CURTIS BENNETT

We have all seen movies where the bad guys take the car battery, attach cables to it, and either the floor is wet, or they take wet rags or sponges and attach them to the cables and threaten the hero. I always laugh at this. I laugh because who hasn’t touched both sides of the car battery? It does not do anything. Or does it?

Have you ever stuck your tongue on a 9-volt battery? Don’t lie. I know you have. LOL.

Where am I going with this? Well, you may have guessed it, I shocked myself yet again. This time my son was there to see it and say, “Hey dad, you have another electrocution story.” We both laughed.

I have an electric motor for my small fishing boat. We were done fishing for the day after catching a few fish. I had to filet them, and my hands were still wet. I went into the house and saw that the battery had not been put back on its charger. I needed to unscrew the poles to hook the charger back up. Well, I grabbed both the positive and the negative at the same time. Normally not a big deal, BUT I had wet hands. Needless to say, there was a fairly good squeal that came out of me, and a good laugh from my son.

I have said it before, and I will say it again. Solar is my favorite hot water heating device. It just is. You take this “free” energy, and you can use it to heat water. It’s amazing.

Last year I wrote about the differ-

ences between photovoltaic and solar thermal in my article ‘Here Comes the Sun’ (HPAC, December 2023). If you haven’t read that one yet, you should. It will give you more background for what I am about to get into for this article.

In summary, the basic conclusion of that article was that solar thermal is superior to photovoltaic solutions because the conversion from heat to heat is more efficient that from heat to electrical power. Ok, knowing that, how does that help the HVAC industry? Well, that’s today’s topic.

Because I covered the concept of how heat is captured via solar in that previous article, now I’m going to discuss what we do with that heat energy.

Let’s start with the basics. We know that the heat has been transferred to a fluid from the solar panels, and of course the best way to move fluid is with a pump.

Now, since we are all hydronics’ people, we know that when we have fluid with heat in it, what we really have is usable energy.

Once we have usable energy in our fluid, next we need to transfer it to our heating device(s) (radiators, fan coils, you name it …). In this case we need a heat exchanger, this could be flat plate, coil in a tank, or really whatever option you choose. The easiest one is an indirect coil in a tank.

The hot water from the solar thermal collector then heats up the domestic hot water (DHW) to be easily used by the house or building. Free domestic

hot water, well it’s free during the day, or at least when the sun is out.

Another cool setup for solar thermal is the crazy stratified solar thermal storage tank. I am shaking my head when I say that. I say ‘crazy’ because if you have ever seen one of these— especially on the inside—they have pipes and heat exchangers everywhere.

They work on a stratification principle that you will have different temperatures at different levels in the tank, so you can use these different temperatures to heat different items with the same tank.

You might have some high temperature items like radiators, you can take the heat from the top of the tank. Maybe some DHW that uses the middle of the tank, and then in-floor radiant that would use the coolest section of the tank to heat the floors. These tanks make it easier to do more than one

thing with your heated solar water.

If you want to get into a little bit of physics, as water heats up it has less capacity to hold more heat as it’s less dense and “lighter”. Why is this important? Well, the lower the water temp we are heating with the solar the more heat it can absorb, that’s entropy.

I really hope I got that right; I always mix up enthalpy and entropy. Anyways. I don’t want to go much deeper than that, but just remember that fact.

What that means for us is we will get more out of our solar system if we are “using” the energy during the day. If we heat up a tank to its max, then use that energy we are actually not getting the most out of the system.

So, to get the most efficient system means keeping the system temperature as low as possible so it can absorb the most possible heat when the solar is generating.

“When we have fluid with heat in it, what we really have is usable energy.”

“Is this even possible?” you ask. Yes, the easiest scenario is if we are using solar for DHW. Do the laundry during the day, do the dishes during the day, use the hot water during the day. Sometimes easier said than done, but that will give you the most efficiency. Or, obviously, if there are other things you can use the DHW for during the day, then also do those. The hotter the tank, the more heat loss you will get from the tank itself, so the sooner you can use that energy, the better.

This comes into play as well for using solar thermal for home heat generation. The more efficient the envelope the less heat you need to keep the house warm. It also means you can use lower water temperature to produce the same effect.

Remember BTUs are BTU’s — I love that saying.

Just like in the DHW situation, if the heated water temperature is lower it is more efficient. Efficiency is ALWAYS a good thing.

There are some different ways to get more solar heat at different times of year.

Refraction on the solar panels or tubes plays a big part on the panel’s absorption ability.

Solar gain is at its highest when the panel (or tube) is perpendicular to the sun’s rays, at a 90-degree angle to it. This way you get no refraction.

We can use this to our advantage if we want to heat our house with solar in the winter.

Keep in mind you will still have to make other provisions for cases where you’re making too much heat, but keeping your panels at a high angle will make them more efficient in the winter than in the summer. At least in this case.

Wow, I feel like I gave you 10% of the information on 10 different topics today. So, I apologize. The distribution topic of solar thermal can actually get pretty in depth, but I hope this small overview gives you some interesting food for thought. <>

Curtis Bennett C.E.T is product development manager with HBX Control Systems in Calgary. He formed HBX Control Systems with Tom Hermann in 2002. Its control systems are designed, engineered and manufactured in Canada to accommodate a range of hydronic heating and cooling needs.

Piping Canada Post’s newest and greenest parcel sorting facility required coordination and technological efficiencies. BY BRETT

LLOYD

The new Albert Jackson Processing Centre in Scarborough, in the east end of Toronto, is a $470-million state-of-the-art parcel distribution warehouse and an expansive net-zero facility that can process more than one million packages daily, positioning it to keep pace with the country’s growing ecommerce service demand.

“The Albert Jackson Processing Centre is much more than a building – it is a generational investment in the future of our country,” said Doug Ettinger, president/CEO of Canada Post at the centre’s grand opening, September 21, 2023. “This facility will drive our network nationwide and help support the Canadian

economy for decades to come.”

The project also holds a significant place in Canadian history. It is the largest Zero Carbon Building Standard industrial project to date and it commemorates Albert Jackson, who became Canada’s first Black letter carrier in 1882. Jackson’s colleagues denied him the right to work in the role he was hired for until Toronto’s Black community rallied behind him and the federal government stepped in. Several members of the Jackson family, including one who currently works for Canada Post, attended the grand opening ceremony. The building is not only a technical achievement but represents a legacy as well.

LPI Mechanical, a full-service designbuild, HVAC and plumbing contractor, was awarded the mechanical scope for the 585,000-sq. ft. facility — roughly the size of six CFL football fields.

The company was tasked with piping the heating mechanical room, cooling mechanical room and main penthouse hallway, and installing two 3-in. perimeter heating lines on the processing floor. The facility includes 70,000 sq. ft. of office and administrative space that occupies two-storeys. The operations area, with 40-foot ceilings, occupies the remaining 515,000 sq. ft.

Interior spaces in the processing cen -

tre include a main lobby, a cafeteria, a wellness centre, and training rooms with lockers and showers.

Fitted with 155 high docks, the facility has extensive paved docking as well as parking and truck circulation areas around it. A key element of the plant is its speed of delivery. A package can arrive, be processed and be ready for dispatch in less than four minutes.

The original construction schedule for the site required LPI to complete the work it was doing in under six months, but unanticipated challenges emerged including the coronavirus pandemic causing supply chain delays along with labour shortages.

The project’s success depended on LPI’s ability to offset risk and streamline installation, which they achieved through a collaborative partnership with the virtual design and construction team at pipe joining solutions manufacturer Victaulic.

The processing facility achieved Canada Green Building Council (CaGBC) Zero Carbon Building Design certification in February 2022. Sustainability design requirements included elements like continuous skylights and windows in the processing areas, LED lighting and occupancy sensors.

Photovoltaic (PV) power generation provides a minimum of 5% of the building’s annual energy requirements, thereby rooftop solar panels are able to generate energy onsite and offset the facility’s energy consumption.

The building also features high efficiency mechanical systems and integration into the building automation system.

The mechanical system incorporates a primary variable pumping system, high-efficiency boilers, energy recovery ventilators, and a modern chiller plant to minimize operating costs, which contributed as much to the building’s net-

zero designation as the rooftop solar panels and the plant’s internal electric vehicles for transporting parcels.

LPI Mechanical partnered with the virtual design team at Victaulic to create 3D renderings of the mechanical spaces, including the penthouse boiler and chiller rooms. Throughout the BIM process, they optimized the piping layout to ensure the design met owner requirements and that on-site assembly would be as straightforward as possible to prevent sequencing issues that could impact the installation schedule.

“Spatial constraints with equipment and other disciplines, along with the large quantity of pipe required throughout the building, made this a complex system to map out,” said Chris Buldyke, director of construction at LPI Mechanical. “Frequent communication paired with both of our teams’ technical expertise allowed us to meet the proj -

Continued on p38

ect’s stringent constraints and later led to a seamless installation. It was an incredible collaborative effort.”

The design team provided LPI with final 3D drawings and isometrics that accurately reflected the space and conditions in which the pipefitters would be working.

Buldyke’s team used these resources to inform its logistics and installation strategies, positioning the crew of six pipefitters to perform their work on an aggressive timeline.

The detailed bill of materials generated from the 3D drawings and isometrics allowed LPI to submit early supply orders to mitigate risk even as the global supply chain remained volatile through-

out 2022’s post-pandemic landscape.

Faced with a fast-paced schedule, large scope and crew size restrictions due to remaining pandemic safety protocols, LPI Mechanical attained schedule certainty by leveraging grooved pipe-joining technology.

By avoiding hot works from the installation process, the LPI team also reduced health and safety risks and eliminated additional coordination steps for tasks like hot works permitting and cordoning off work areas.

“We estimated that a welded system would take approximately 20 weeks to complete. With the challenges of the

LPI Mechanical used Victaulic vibration isolation pump drops and outlet fittings to optimize the mechanical room installation and reduce material handling.

current labour market, we set out to find an alternate solution. Instead, we used a combination of Victaulic couplings, valves, headers and pump drops to install the mechanical systems in under

six weeks,” said Buldyke.

Coordinated material deliveries to the project helped maximize crane and labour efficiency. Supplies arrived in accordance with LPI’s installation sequence, ready to be lifted to the building’s rooftop and installed by crews immediately. Materials were organized and labeled according to their designated work areas, which the LPI team could quickly compare with their drawings and isometrics.

“The installation was quick and easy. We had all the materials prepared and delivered exactly on time to hoist onto the roof. Because we paid close attention to the pipe layout during the pre-planning phase, we didn’t have to worry about potential interferences during the actual installation, especially in tight spaces,” said Buldyke. “Altogether, we reduced our total site hours and maintained our project schedule. Everything went above and beyond our expectations.”

“We reduced our total site hours and maintained our project schedule. Everything went above and beyond our expectatations.”

After some pandemic-driven construction delays, Albert Jackson Processing Centre was finally able to hold its grand opening in September 2023. With its many innovative design features, it is revered as Canada Post’s largest and greenest processing facility.

The new site has doubled the organization’s processing capacity in the Greater Toronto Area – where most of the country’s parcels originate – and its impact will be felt from coast to coast. The plant is able to sort more than 60,000 packages per hour – 50% more than Canada Post’s previously largest parcel plant, the Gateway facility in Mississauga.

With ecommerce demands expected to double in Canada over the next decade, it is anticipated that this facility will not only help connect all Canadians with individual person-toperson parcel deliveries but it will also be providing a boost to the national retail economy.

As Canada Post continues to meet community and business needs with its new parcel sorting warehouse, the unique building design and its energy efficient HVAC systems make it a leading example among the efforts to demontrate improved green building standards across the country. And according to LPI, the building operators and owners will also

Continued from p39

find that ease of maintenance was a key consideration throughout the overall mechanical design process.

“We designed these systems with the end-user’s experience in mind,” explained Buldyke. “The grooved pipe components can be quickly and easily removed for regular service inspections, and if the owners decide to replace the air handling units or chillers in the future, whether because of age or to expand capacity.”

As noted by Canada Post, the facility is an important piece of the organization’s transformation plan and will help the company deliver on its purpose: a stronger Canada – delivered. <>

Brett Lloyd is a Greater Toronto Area sales representative for Victaulic. brett.lloyd@victaulic.com.

ALBERT JACKSON PROCESSING FACILITY HIGHLIGHTS

• processes slightly more than half of the volume of parcels in the Greater Toronto Area

• more than 90% of all packages are processed through automated sorters.

• a package can arrive, be processed and be ready for dispatch in less than four minutes

• able to sort more than 60,000 packages per hour

• capacity to process more than one million packages a day

• contains nearly eight kilometres of conveyors

• largest industrial project in Canada with the Zero Carbon Building Standard designation

• infrastructure supports the future electrification of Canada Post’s five-ton truck fleet

• DISTRIBUTORS • WHOLESALERS

The Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) held its 2024 Annual Conference in Vancouver from September 22 thru 24. This year’s theme was “The One Thing,” and the conference successfully carried that concept throughout with every speaker ending their talk with ‘The One Thing’ to take away from their presentation.

This year’s conference agenda consisted of a series of panels covering a range of categories including the energy grid, HVAC in uncommon places, industry consolidation, workforce development, and the refrigerant transition.

This final topic brought some clarity to what is happening with refrigerant phase downs both in Canada and the U.S.

Moderated by Pushpinder Rana (Mitsubishi Electric), the panel included Samantha Slater (AHRI), Martin Rego (Rheem), Michel Gauvin (Environment and Climate Change Canada), and Perry Chao (HRAI).

Rana, chair of CSA B52 mechanical refrigeration code committee, shared some history on the journey towards lower global warming potential (GWP) refrigerants.

The newest evolution in Canada is the introduction of ASHRAE classification A2L refrigerants (included in CSA B52). These mildly flammable refrigerants meet the GWP requirements of government phase down obligations—specifically the U.S. mandate for new residential air conditioning and heat pump units beginning January 1, 2025.

No date has been set in Canada, but Rana is not concerned. “As a cold climate country, if we can handle natural gas or propane inside our homes, A2Ls will be a piece of cake.” He assured the crowd there should be no worries of a “Kaboom” incident.

The two ‘One Things’ from Rana in -

cluded: become familiar the CSA B52 code, and take A2L training.

For her one thing, Slater from AHRI believes it is essential for Canada to align its regulations with the U.S. as soon as possible. Rego from Rheem echoed Slater’s statement, noting the misalignment creates confusion and ambiguity in the market.

Michel Gauvin of the ECCC noted that Canada’s current regulations came into force in 2017 and the review timeline is every 10 years, but because of changes in the U.S. and HVAC industry demand the review has started four years earlier than scheduled.

During a public consultation period this summer the government received over 90 submissions, a high number according to Gauvin, and he acknowledged there was support for an alignment with the U.S. product rules.

He assured the crowd that no new regulation will be forthcoming by January 1, 2025, and it was also made clear that as of January 1, 2025, appliances with

R410A as well those with new A2L refrigerants (R32 and R454B) can be legally sold in the country. The complicating factor could be the building codes in each province.

HRAI director of regulatory affairs, Perry Chao, provided an update of which provinces have adopted CSA B52. B.C., P.E.I., Manitoba and Newfoundland and Labrador are ready for adoption. Ontario, Nova Scotia, New Brunswick and Saskatchewan are almost ready, says Chao. And finally, Quebec and Alberta are on the path.

The new national Chair of the HRAI for 2024-25 is Chris Hann, Wolseley’s director of HVAC/R in Ontario. Hann becomes the 56th Chair of the association, taking the gavel from Tara Smith, owner of Mr. Furnace in Winnipeg.

The association also handed out awards recognizing volunteers and industry veterans.

President’s Recognition Awards were presented to the co-chairs of HRAI’s Skills Competition committee: Brad Mavin, retired from Conestoga Mechanical, and Dick Thomas, retired vice president from AtlasCare.

Recognizing outstanding HRAI Chapter leadership, the Gearld Inch Award went to Andy Gould, of Reliance Home Comfort, long-time chair of the BrantHaldimand-Norfolk Chapter.

The Merit Award, recognizing outstanding contributions to the industry was presented to Bill Davis (formerly with Ecco Supply), who served as national Chair of HRAI 2022-23.

And the Craig McCarty Memorial Award and the Life Member Award were both given to Robert Flipse, recently retired from Ainsworth. Flipse served as Chair of the national board 2020-21.

For the second year in a row, CB Supplies receives the Jacques Deschênes Supplier of the Year award: (l-r) Martin Deschênes (Groupe Deschênes), Eric Finlay (Andrew Sheret), Warren Lowe (CB Supplies) and Rob Dewar (AD Canada)

During the recent AD Plumbing & Heating Supplier of the Year Banquet in Toronto, there was a repeat winner for the first time as CB Supplies was presented with the 2024 Jacques Deschênes Supplier of the Year award. BMI Canada received the 2024 Brian Findlay Supplier of the Year award, while Great Lakes Copper was recognized as the 2024 Most Improved Supplier of the Year. adhq.com

Barclay Sales has added Trevor Hart as technical sales representative in Northern Alberta. After two decades in the plumbing industry, both contracting and on the sales side, Hart brings technical and business expertise to the Barclay team.

Granby Industries has named Ron Vanhevel as Ontario account manager. With over 35 years in the HVAC industry, Vanhevel has previous experience with Condair, Rheem, and Reliance Home Comfort. He will cover the entire province except the Ottawa and Thunder Bay areas.

Congratulations to the group of 10 Next Plumbing and Hydronics Supply athletes who completed Ironman Canada in Penticton BC on Sunday August 25th: (l-r) Jake Storfer, Michael Storfer, Hardeep Chahal, Carolina Lorenz, Randy Walton, Scott Boucher, Jimmy Thuan, Ali Azari Boushehri, Jerrie Keith Manalang, and Johnson Phan.

The Canadian Institute of Plumbing and Heating (CIPH) presented the Joseph K. Seidner award to Tom Gervais, the current director of specification and product development with Bradford White.