MODERN HYDRONICS

NET ZERO IN NUNAVUT

Air-to-water in sub-zero climate

COOLING CONSIDERATIONS

VENTILATION INTEGRATION

DISTRICT HEATING EFFICIENCY

FALL

2023

a publication of

Safe For All Systems

(Including Aluminum and Solar)

Premier Inhibitors

Higher Temperature Rated Phosphate and Nitrate Free Low Viscosity

For more benefits ask your local wholesaler or visit chemfax.com

All Glycols

Created Equal

Not

Are

CHEM-FROST

HEAT TRANSFER FLUID - INHIBITED PROPYLENE GLYCOL COMPARISON CHART

ChemFrost100%BrandRBrandOBrandHBrandUBrandD Pail Size 20L18.9L18.9L20L20L18.9L PG Concentrate Amount 95/592/8N/A94/695/595/5 Aluminum Safe YES LIMITED TO 65C NONONONO Solar Safe YES NO SOME LIMITED NONONO Geothermal Safe YES LIMITED N/AN/AN/AN/A Temperature Rating 325F275F250F250F250F220F Viscosity @ 50% 100F 5.5cP8.5cP10cP10cP10cP10cP Boiling Point @ 100% 417F370F370F370F370F370F CFIA Approved YESYES NONO YES NO Raw PG Grade FOOD INDUSTRIAL GRADE INDUSTRIAL GRADE INDUSTRIAL GRADE INDUSTRIAL GRADE INDUSTRIAL GRADE Purity of Propylene Glycol 99.94%+ N/A98%N/AN/AN/A Phosphate / Nitrate NONE YESYESYESYESYES Inhibitor Type PDT NON-TOXIC DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE DIPOTASSIUM PHOSPHATE LEED YES NONONONONO Based on information provided on respective manufacturers’ websites* **Subject to change**

MH6 DESIGN A Complete Solution

Are you prepared to deliver a total package of heating, cooling, DHW and optimized ventilation?

By John Siegenthaler

MH14 PROJECT Net Zero in Nunavut

Dealing with supply logistics and low-temp heating in Canada’s north.

By Doug Picklyk

MH18 DISTRICT ENERGY Cooling on the cutting edge

Turning to water from the bottom of Lake Ontario makes The Taylor a cool new build in Toronto’s downtown

By Treena Hein

MH24 DISTRICT ENERGY From Steam to Sustainable

Packaged energy transfer stations ease the transition for Sheridan College’s district energy system.

By Jeff Flannery

MH28 Cool Runnings

Condensation is the radiant cooling killer, but it can be overcome with proper controls.

By Curtis Bennett

MH30 MODERN HYDRONICS SUMMIT PREVIEW

Get influenced, as this year’s hydronics-focused event travels to Coquitlam, B.C. September 21.

MH34 NEW PRODUCT SHOWCASE

MH36 HEAT PUMP WATER HEATER

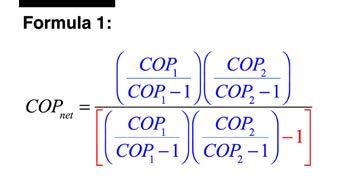

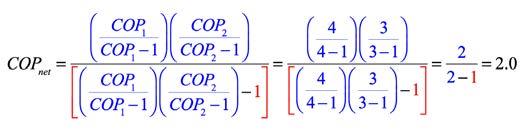

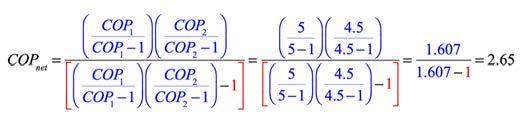

The Net Effect

Calculating the efficiency, or inefficiency, of using a heat pump water heater in a heat pump heated home.

By John Siegenthaler

MODERN HYDRONICS

EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

MEDIA DESIGNER

CIRCULATION MANAGER PUBLISHER PRESIDENT/COO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Amanda McCracken (647) 628-3610 amccracken@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson

use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Business Media, their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities.

Continued on MH8

MODERN HYDRONICS WWW.HPACMAG.COM MH4 FALL 2023

COVER PHOTO: TREVOR JOHNSON

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may

2023

Contents Copyright ©

by Annex Publishing & Printing Inc. may not be reprinted without permission.

Proud member of:

111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1 TEL: 416.442.5600 FAX: 416.510.5140 www.hpacmag.com

of Heating PlumbingAir Conditioning Magazine

a supplement

Modern Hydronics CONTENTS

From conception to construction: WE’RE HERE TO HELP EXPERT HYDRONIC SOLUTIONS FOR PROFESSIONALS

DESIGN PACKAGES: Complete design, parts list, loop layout, and heat load calculation for your project.

Complete design, parts list, loop layout, and heat load calculation for your project.

Complete design, parts list, loop layout, and heat load calculation for your project.

BOILER ROOM

BOILER ROOM

BOILER ROOM

PRE-BUILDS: We construct boiler rooms according to your designed system.

PRE-BUILDS: We construct boiler rooms according to your designed system.

PRE-BUILDS: We construct boiler rooms according to your designed system.

HIGH-QUALITY PARTS: We provide a catalogue of top-notch parts ensuring optimal performance and longevity.

HIGH-QUALITY PARTS: We provide a catalogue of top-notch parts ensuring optimal performance and longevity.

HIGH-QUALITY PARTS: We provide a catalogue of top-notch parts ensuring optimal performance and longevity.

schuller.solutions

SCHULLERSOLUTIONS.COM

SCHULLERSOLUTIONS.COM

TODAY!

CONTACT US

schuller.solutions info@schullersolutions.com

TODAY!

CONTACT US

Solutions & Engineering Inc .

info@schullersolutions.com Schuller

US TODAY!

SCHULLERSOLUTIONS.COM CONTACT

schuller.solutions info@schullersolutions.com

A COMPLETE SOLUTION

Building codes and energy conservation standards continue to evolve, and today many are requiring proof of high-quality air sealing for buildings, with measurements being done through blower door testing.

BY JOHN SIEGENTHALER

Typically, the building envelope is depressurized using a flexible panel with a variable speed fan that’s temporarily in -

stalled in the opening of an exterior door. By measuring the speed of this fan and correlating it to the slight (but measurable) difference in air pressure between the inside and outside of the building, it’s possible to determine the air changes per hour air leakage rate.

A leaky house could test out at 15 to

MODERN HYDRONICS WWW.HPACMAG.COM MH6 FALL 2023

Are you prepared to deliver a total package of heating, cooling, DHW and optimized ventilation?

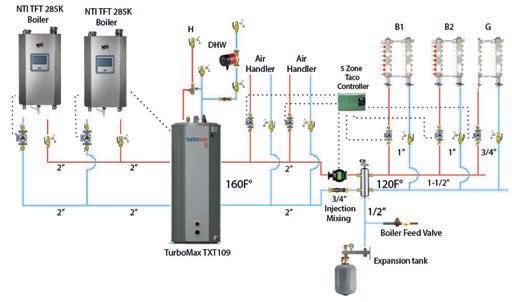

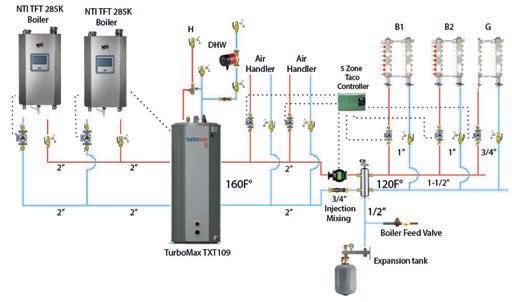

Figure 1. A complete system using an airto-water heat pump for heating, cooling and domestic hot water.

DESIGN

Continued on MH8

Modern Hydronics

A GAME-CHANGER IN COMBI WATER HEATING

Lochinvar has long been an industry leader in commercial boilers—and now we’re bringing that engineering excellence to residential combi boilers.

The wall mount EPIC® combi boiler you know and trust is now available in floor standing models.

What Makes EPIC a superior choice?

· Easy To Install, Set Up and Service

· Delivers Hot Water Faster

· Display Screen Uses Text, Not Codes

· Better Technical Support and Training

· 10:1 Turndown Ratio

· Floor and Wall mount available

· Advanced Electronic Control -

Visit Lochinvar.com to learn more.

20 air changes per hour at 50 Pascals (about 0.00725 psi) of air pressure differential. A well-sealed new house could have air leakage in the range of 1 to 4 air changes per hour at 50 Pascals pressure difference (ACH/50).

And a super-tight house, built to current Passive House standards, must not exceed an air leakage rate of 0.7 ACH/50.

Experience has shown that the “natural” air infiltration rates of buildings will be approximately 1/20 th of those established by blower door testing at 50 Pascals differential pressure. Thus, a house with 4 ACH/50 blower door test rating will have a natural air leakage in the range of 0.2 air changes per hour.

You won’t suffocate in such a house, but you’re unlikely to find the air quality provided by air leakage acceptable. Fry up some bacon on Monday, and you’ll still smell it on Wednesday. I could cite more examples of this air quality problem, based on other “facilities” in the house, but I’m confident you get the idea.

GRAB IT WHILE YOU CAN

The contemporary approach to providing fresh air while at the same time not adding substantially to the home’s heating load, is to install a heat recovery ventilator (HRV), or in some cases an Energy Recovery Ventilator (ERV). Both of devices create two air flows: one brings outside air into the building, and the other exhausts “stale” inside air back outside. Both air streams are generated by small blowers within the ventilator.

During the heating season, the stream of incoming cool (or cold) outside air absorbs heat from the warmer exhaust air stream. This exchange takes place within the heat exchange “core” of the ventilator, through which both air streams simultaneously pass, but never mix.

Typical heat recovery efficiency is in the range of 70%. Thus, the fresh air requirement is met using about 70% less thermal energy that would otherwise be

needed if the air was simply blown into and out of the building with ventilation fans and no heat exchange.

During the cooling season, the outgoing stream of cool (but “stale”) inside air absorbs some heat from the incoming warm (but fresh) outside air. Again, the fresh air requirement of the building is met, but the energy penalty associated with fully cooling and dehumidifying the incoming air to desired indoor temperature and humidity is greatly reduced.

Energy recovery ventilators (ERVs) provide similar functions to heat recovery ventilators (HRVs). The difference is that ERVs can also exchange moisture (in vapour form) between the ingoing and outgoing air streams.

In winter, some of the moisture in the outgoing (higher absolute humidity) air stream is transferred to the incoming (low absolute humidity) air stream. And in summer, some of the moisture in the incoming (higher absolute humidity) air stream is transferred to the (lower absolute humidity) outgoing stream.

This moisture exchange helps maintain a comfortable (and healthy) indoor relative humidity in winter and it also reduces the latent cooling load in summer.

ADD ON

So, what does this have to do with hydronics?

Well, in combination with an air-to-water heat pump, or a geothermal water-towater heat pump, heat recovery ventilation becomes another part of the “total solution” package you can offer. That package includes heating, cooling, domestic hot water and ventilation.

For example, consider a relatively simple system that provides multiple zones of space heating using panel radiators, and “whole house” cooling using a ducted chilled water air handler.

It also provides domestic water heating using energy from both the heat pump and an electric resistance backup

heater. Figure 1 (on the opening page) shows one concept for such a system.

The heat pump maintains the buffer tank between some upper and lower temperature limits. Those limits could be set points or determined using outdoor reset control. Some air-to-water heat pumps have integrated controls that allow either.

The variable-speed pressure-regulated circulator operates continuously during the heating season. Warm water passes through any panel radiator with a partially-open or fully open thermostatic radiator valve. A system that is simple, elegant and even “wireless.”

The motorized diverter valve routes heated fluid from the heat pump to the buffer tank. This flow path is only open when the heat pump is operating.

The path between ports AB and A close as soon as the heat pump turns off, preventing reverse thermosiphoning from the tank.

This valve operation also prevents flow returning from the distribution system from passing through the heat pump when it’s off.

The large coils inside the buffer tank preheat domestic water. The temperature rise of the water depends on the fluid temperature maintained in the tank’s shell, the surface areas of the internal coils, and the rate at which domestic water flows through the coils.

If the tank shell temperature is maintained close to the desired domestic hot water delivery temperature it’s possible that over 90% of the total temperature rise can occur through the coils.

The remaining temperature rise is handled by a tank-type electric water heater, or a tankless electric water heater

If the buffer tank temperature is based on outdoor reset control, the auxiliary water heater will need to contribute more energy for domestic hot water during milder outdoor temperatures.

Continued on MH10

MODERN HYDRONICS WWW.HPACMAG.COM MH8 FALL 2023 DESIGN

Modern Hydronics

AWARD-WINNING

FINALIS

Caleffi’s innovative thermal solution for the control of safe and sanitary domestic hot water combines three main components: LEGIOMIX® digital mixing valve that delivers accurately mixed water temperature and integrates calendar-based thermal disinfection; ThermoSetter™ field adjustable thermal balancing valves that feature a bypass option for disinfection; and SinkMixer™ 4-port anti-scald valves for reliable point-ofuse safety. Approvals include compliance with U.S. and Canadian plumbing codes. CALEFFI GUARANTEED.

www.caleffi.com

LEGIOMIX CONTROL SYSTEM T

2022

In either case, the electric water heater provides a backup source of domestic hot water if the heat pump were down for service.

CHILLED TO PERFECTION

Cooling is provided by routing chilled water from the heat pump, through the diverter valve, to the coil of an air handler.

The variable speed compressor in the heat pump automatically adjusts to maintain a set chilled water delivery temperature - typically in the range of 45 to 55F (7 to 12C).

The chilled water flows through the coil of an air handler equipped with a condensate drip pan. Cooled and dehumidified air is delivered to the entire building through a ducting system.

The original system shown in Figure 1 cannot simultaneously heat the buffer tank and send chilled fluid to the air handler. One of these loads must take priority over the other.

If maintaining the temperature of the buffer tank is the priority, so as to maximize preheating of domestic water, the system controls would be configured to temporarily stop chilled fluid production and flow to the air handler coil while the temperature of the buffer tank is boosted, which typically only takes 5 to 10 minutes.

If cooling is the priority, heat input to

the buffer tank needs to be temporarily interrupted when the house thermostat calls for cooling. If the cooling call is sustained, the electric water heater can take over the DHW load until the cooling load is satisfied.

DUAL PURPOSE DUCTING

Since there’s going to be a ducting system for cooling, why not use it for ventilation?

Doing so would certainly reduce cost compared to installing another air distribution system solely for ventilation.

In fact, why not enhance the system by using the coil in the air handler for “boosting” the temperature of incoming ventilation air during cold winter operation, and thus eliminate possible cool air delivery to the house?

Figure 2 (above) shows one approach for connecting the HRV (or ERV) to the return trunk duct of the air handler, along with hydronic trim to provide that boost function.

The smaller ducts on the “house side” of the HRV connect to the return trunk leading into the air handler. The “stale” air is pulled from one or more bathrooms. The fresh outdoor air, after absorbing heat from the exhaust stream, is injected into the return air side of the air handler.

This configuration can operate in three different modes:

1. Ventilation-only mode

2. Cooling plus ventilation mode

3. Ventilation plus boost mode

For ventilation-only mode the blower in the air handler should provide an air flow rate just above that of the HRV. This ensures that all the incoming fresh air will be entrained in the air flow that’s headed for the diffusers in the house. It also reduces input power to the blower motor in the air handler. Most air handlers have blower motors with multiple speed tap wiring. Check with the air handler manufacturer regarding the best option to bring the air flow rate down to perhaps 100 to 150 cubic feet per minute (CFM). Some air handlers may not be able to reduce their blower speed to such a low value. That’s okay from the standpoint of distributing fresh air. It just means higher electrical power consumption by the blower.

During cooling mode the blower speed would be set to provide 350 to 400 CFM of air flow per ton of cooling capacity. Thus, for an air handler delivering 3 tons (36,000 Btu/h) of cooling, the air flow rate would be about 1050 to 1200 CFM. Again, this will require the system to use the appropriate speed tap on the blower motor.

The ventilation plus boost mode is intended for times when outdoor temperaContinued on MH12

MODERN HYDRONICS WWW.HPACMAG.COM MH10 FALL 2023 DESIGN

Modern Hydronics

Figure 2. An approach for connecting an HRV (or ERV) to the return trunk duct of an air handler, along with hydronic trim to provide a boost function.

Navien NCB-H combi-boilers

Unmatched heating and DHW performance, all in one compact unit

• Heating up to 150,000 BTU/h and DHW up to 210,000 BTU/h

• Up to 80% smaller than floor standing boiler and tank water heater

• Optimized DHW priority with mixing valve and water adjustment valve to provide consistent DHW temperatures and industry leading flow rates

• Dual stainless steel heat exchangers for heating and separate SS heat exchanger for DHW

• Built-in controls for 3 zone pumps or 3 zone valves

• Heating TDR up to 11:1 and DHW TDR is 15:1

To learn more about the best-selling combi-boilers in North America, visit navieninc.com.

THE LEADER IN CONDENSING TECHNOLOGY

Tear out that wasteful tank and boiler mess...

...and hang up the breakthrough in high capacity combis

tures are cold. The intent is not to heat the house with the ventilation air, it’s to introduce air into living spaces at about the same temperature as those spaces.

For example, assume the outside temperature is -10F (-23C), and the HRV is recovering about 70% of the heat from the exhaust air stream that leaves the occupied space at 70F (21C).

This would make the fresh air temperature delivered from the HRV about 46F (8C). That’s going to feel pretty cool to occupants if it’s not carefully mixed with room air before reaching occupied areas.

If the boost function is used, this air could be introduced in occupied spaces at a neutral temperature and far less concern about creating uncomfortable conditions when it’s frigid outside.

Under these conditions it’s possible to pass heated fluid through the air handler’s coil to boost the temperature of the ventilation air prior to introducing it to occupied space. A modulating two-way valve is used to regulate the flow of warm fluid through the coil. The flow rate is controlled based on maintaining a set supply air temperature on the outlet side of the air handler.

A word of caution is in order. If the system is located where outdoor temperatures are well below freezing much of the winter, the coil in the air handler needs to be protected against freezing. That’s “automatic” with the monobloc air-to-water heat pump system shown in Figure 1 because the entire system operates with a 30% solution of propylene glycol.

If the system operated with water some type of failsafe control would be needed to automatically turn off the HRV if the coil in the air handler approaches a potential freezing condition.

Figure 3 shows the same system as Figure 1, but with the piping needed to supply water to the air handler coil.

The coil is supplied through a threeway diverting valve. When this valve is off, the coil is connected to the piping

path for cooling. When the valve is energized the coil is connected to the warm water circuit.

The pressure differential to drive the latter is supplied by the continuously operating distribution circulator. The modulating two-way valve regulates the flow rate through the coil based on maintaining a set air delivery temperature. This valve should be selected with an equal percentage characteristic.

OFFER IT ALL

The longstanding “stigma” that residential hydronic systems can’t provide cooling is slowly waning as air-to-water and geothermal water-to-water heat pumps gain market share against boilers. This

sets the stage for progressive hydronic professionals to offer heating, domestic hot water, and cooling.

Why not extend this even farther to include heat recovery ventilation (HRV)? The market for such total solutions is quickly developing.

Are you prepared to participate and profit? <>

John Siegenthaler, P.E., has over 40 years of experience designing modern hydronic heating systems and is the author of Modern Hydronic Heating (4th edition) and Heating with Renewable Energy (visit hydronicpros.com).

MODERN HYDRONICS WWW.HPACMAG.COM MH12 FALL 2023 DESIGN

Modern Hydronics

Figure 3. An air-to-water heat pump system offering heating, domestic hot water, cooling with integration to ventilation to assist with HRV/ERV delivery.

NET ZERO IN NUNAVUT

Dealing with supply logistics and low-temp heating in Canada’s north.

BY DOUG PICKLYK

Sanikiluaq is Nunavut’s southern-most community, located about 150 km off the northwest border of Quebec among the Belcher Islands, an archipelago in the southeast section of Hudson Bay.

Among the newest buildings in Sanikiluaq is a roughly 5,000 sq. ft. multi-purpose research centre owned by the Arctic Eider Society, an Inuit not-forprofit organization dedicated to supporting Inuit-led stewardship and nature conservation in the area.

Positioned on a hill, the main floor brings visitors into the commercial space which includes offices, staff kitchenette, research labs, a large meeting room and a

visitor’s foyer. The second floor provides temporary residence for rotating researchers, with three bedrooms with ensuites, a shared living space and kitchen. The lower level is really a crawl space which accommodates the mechanical room.

This mixed-use complex aims to be the first net zero building in Nunavut.

AIR-TO-WATER

The project was led by Jeff Armstrong, the managing director at Cold Climate Building, a specialist in designing and building energy efficient structures in Canada’s far north, including a project with Nunavut Housing Corp. where he introduced structural insulated panel (SIP) building systems to create well-insulated air-tight envelopes suited to net-zeroready structures.

The mechanical system in the building was designed by Cameron Haines, P.Eng., of Southface Engineering, who

was brought on board by the building’s design architect, Richard White.

The heating system is driven by three air-to-water heat pumps which are connected to two 70-gallon storage tanks with integrated electric boilers.

“I love this type of system because the buffer tanks act like a battery, and they offer flexibility with being able to tie them into any type of future energy source or backup source that they may need,” says Haines.

The selected air-to-water heat pumps are a split system with separate indoor and outdoor units. The outside section includes the air coil, fan, expansion valve, and outdoor temperature sensor. All other components, including compressor and electronics, are contained in the indoor units.

“The logic is really simple,” says Haines. “All the heat pumps have to do is

Continued on MH16

MODERN HYDRONICS WWW.HPACMAG.COM MH14 FALL 2023

PHOTO: TREVOR JOHNSON

PROJECT

This multi-use resource centre in Sanikiluaq, Nunavut plans to be the area’s first net zero building.

Modern Hydronics

It is very eco-friendly!

AIR WATER HEAT PUMP

AltSourceTM

The only high-volume electric boiler on the market and the perfect complement to renewable energy. This combination boiler-storage tank for residential use serves as a back-up energy source to the primary system in order to maximize output. Thanks to its T2 UltraSmart® controller, the boiler provides improved comfort through precise temperature control.

Typical installation with standard features

Perfect for optimizing the performance of many types of heating systems.

AltSourceTM with the optional copper coil heat exchanger is shown.

thermo2000.com

P

AltSource

keep the buffer tanks at the set point temperature (105F/41C).” Because it’s a really tight building, it allows for a low supply temperature. The heat loss calculation at design temperature of -30C was 128,000 Btu/h (37.5kW) for the building envelope, and Haines says their calculations show they could have gone as low as 95F (35C).

As designed, not all three heat pumps are operating at once, as Haines describes, they are set up so there is one master heat pump and then the other two are slaves, and that process rotates among the three.

COLD CLIMATE LOGISTICS

The plumbing and mechanical systems were installed by Candor Plumbing and Heating of Ottawa. In operation for over 35 years, the company has a history of working with Armstrong at his previous Nunavut projects. Fortunately, the crew took lessons from that experience when planning for this job.

“We had to load everything in three shipping containers here in Ottawa— that includes every elbow, every valve—and it was all packed in a way that it could be removed in the order of installation,” says Trevor Johnson, who helps run Candor along with his father Kim and brother Cory.

Johnson recalls how this process was better than the last time when they found themselves cutting blocks of snow off of crates in the middle of the dark Arctic winter searching for the parts they needed.

Working on an island in the middle of Hudson Bay presents many challenges. Getting the crew on-site alone required flights connecting through either Winnipeg or Montreal, with the real prospect of cancellations and having to rebook days later.

In total the team took five trips, starting in January of 2022 when they were using a generator for temporary heating (because it was minus 30 inside) and watch-

ing a thermometer waiting for it to rise to where the glue for the ABS would cure.

“We also lost the power to the building where we were staying that January,” recalls Johnson. During a blizzard they needed to crane the generator from the worksite—that was keeping that building warm—to heat up their sleeping quarters, and then start all over again the next day.

“And then we all got COVID,” says Johnson, who adds that things only got better from there.

HEAT DISTRIBUTION

The primary loop from the heat pumps to the buffer tanks is all in 2-1/2-in. copper that was insulated. The Candor team prefers to use press tools wherever possible. The heating distribution system uses infloor heating on the upper two floors as well as heating coils in the air handling units of two ERV ventilation systems.

There isn’t any type of mechanical cooling the space, but the building is ducted to allow free cooling using outdoor air. “Duct work is not something I do every day, so I was leaning heavily on Jamey Mackenzie of Mack Metal, our subcontractor for installing the duct work,” notes Johnson.

Each room in the building is its own zone. When a thermostat calls, a zone

valve opens and a low-power variable speed ECM circulator near the buffer tanks recognizes the opening and sends heat to that zone. There is a pump for each floor, and a third installed for redundancy. Those tanks are piped in parallel using circuit balancing valves. There are also two totes of glycol in the system. “You take no chances when temperatures can dip to -40C,” says Johnson.

No concrete is used in this cold climate project, so the team used radiant panel flooring, a high-density polystyrene that comes with an aluminum heat transfer sheet on top and pre-set grooves for the PEX piping. The panels were secured on top of an additional layer of insulation board that was placed on top of the subfloor, which was made of a well-insulated SIP panel. “There’s no shortage of insulation,” confirms Johnson.

Vinyl flooring was used on top of the radiant panels. There are also three entry way force flows for heating as well as a unit heater in the mechanical space.

DOMESTIC HOT WATER

The heat pumps have a double-wall desuperheater which is used for pre-heating the domestic hot water. That system leads to a 50-gallon storage tank with integrated electric boiler that holds the preheated domestic water that runs

MODERN HYDRONICS WWW.HPACMAG.COM MH16 FALL 2023

PROJECT

Three heat pumps staged to operate at peak efficiency provide supply water for heating as well as preheating the DHW through a desuperheater.

PHOTOS: TREVOR JOHNSON

through a copper coil at 70F or greater, and then the domestic water goes through a second coil in another 50-gallon tank where it is brought up to a minimum of 140F.

As a back-up for the entire system, there is also an oilfired boiler in the mechanical space that ties into the DHW tank, and it is also piped-up to supply the heating distribution system if necessary.

NET ZERO

Mechanically, the building was ready to go and operational last fall and has performed well over one winter. Currently, the electricity for the community is driven by diesel-fuelled generators. To offset some of that carbon-burning power the building has installed solar panels on the roof, and the owners anticipate tapping into a community wind turbine project on the island to get completely carbon free. “Their net zero capabilities are still a work in progress, but they shouldn’t have a problem getting there,” says Johnson.

And Haines agrees: “There’s a lot of wind up there, so that’s why the model was so positive towards net zero.” He adds that when looking to go net zero, everyone seems to be moving towards heat pumps and in-floor heating. “It’s one of the best

systems to use because of the size of the heating area so you need very low temperatures which allows the heat pumps to operate at a very high efficiency.”

Johnson hopes that by sharing this project with the industry others will find inspiration in the simple possibility of achieving net zero in an arctic region. <>

Modern Hydronics MODERN HYDRONICS WWW.HPACMAG.COM MH17 FALL 2023

NTIBOILERS.COM With EZ SetUp Wizard control, large colour touchscreen, built-in 3-zone control, Wi-Fi enabled, 11 sizes and more. Residential

Boilers Optional

NTI’s N-Link Control delivers customized comfort for up to six zones in large residential or commercial installations. Improved performance. Increased efficiency. HPAC_NTI_Aug23.indd 1 2023-08-02 10:55 AM

& Light Commercial

Control Available

The two storage/electric boiler tanks staged in parallel provide heating for the building.

COOLING ON THE CUTTING EDGE

Turning to water from the bottom of Lake Ontario makes The Taylor a cool new build in Toronto’s downtown.

BY TREENA HEIN

Looking at The Taylor, Tricon Residential’s 37-storey multi-use purpose-built rental building in downtown Toronto, you’d never know it was different from others of its type unless you had a sky-high vantage point to check out its mechanical penthouse, that is.

The penthouse is quite a bit smaller than one would expect for a building of its size, housing only some pumps and air handling equipment, but missing the chiller that would normally be used to provide cool air on hot summer days and nights or gas-fired boilers. That’s because The Taylor is cooled not through normal air conditioning but through the district heating/cooling system from Enwave that uses cold water from nearby Lake Ontario.

As industry efforts across the world aim to bring new buildings closer to carbon neutrality, The Taylor and numerous other buildings in Toronto’s downtown have tapped into the use of lake water and a series of heat exchangers for cooling its residents.

The innovative system involves district-energy operator Enwave sharing infrastructure with the City of Toronto’s water utility, providing comfort to residents while also cutting cooling-related electricity use by as much as 80% – performance that will help the city and its Climate Action Strategy to reduce greenhouse gas emissions.

Like all Tricon’s occupied Canadian

multi-family buildings, The Taylor is built to LEED Gold standards, explains Tricon’s head of development, John English.

“Besides this being a purpose-built multi-use rental building, with groundlevel stores, upper offices and rental suites above, this project stands out in its emphasis on durability, quality and sustainability,” he explains. “The Enwave system is a big part of that. It has been functioning since October 2022 and the commissioning has gone well.”

THE BIG PICTURE

Enwave calls its system Deep Lake Water Cooling, or DLWC for short. It’s the largest system of its kind, leveraging economies of scale with its connected infrastructure. First completed in 2004, the original DLWC system worked so well that it has been expanded in the years since and currently cools more than 100 downtown buildings, including hospitals, data centres, educational campuses, hotels, a brewery, and government, commercial and residential buildings in Toronto’s core. Notable users include City Hall and Scotiabank Arena, home to the Maple Leafs and Raptors.

Enwave owns and operates the DLWC system but shares infrastructure with the city’s water utility under an energy transfer agreement. As cool water circulates to the connected buildings by way of a series of pipes and heat exchangers, heat from the buildings recirculates back to the John Street Pumping Station

where the thermal energy is transferred to the treated potable water via heat exchangers that keep the two streams of water separated.

The increase in temperature of the drinking water is marginal, while the impact on the electricity use by the buildings is significant.

Moreover, treated water is also saved in the process, since traditional chillerbased HVAC systems would use significant amounts of evaporated water to expel heat, something that can be considerably inefficient on humid days. By using its DLWC system, Enwave e stimates that the Toronto system saves roughly 220 million gallons of water each year; the equivalent of 350 Olympic-sized swimming pools.

COOLING THE TAYLOR

The process begins with cold water being drawn from intake pipes in Lake Ontario. The pipes are about five kilometres from shore at a depth of roughly 83 metres. Using relatively little energy, the water travels to the Island Filtration Plant operated by Toronto Water where it is treated to meet drinking water standards.

The water is then conveyed to the John Street pumping station and into the

MODERN HYDRONICS WWW.HPACMAG.COM MH18 FALL 2023 DISTRICT ENERGY

MH22

Modern Hydronics

Located at the corner of King and Spadina in downtown Toronto, The Taylor connects with Enwave’s district heating/cooling system.

Continued on

PHOTOS COURTESY OF TRICON RESIDENTIAL

Caleffi 548 Series Separator Included (Shown Mounted) PEACE OF MIND WARRANTY PROGRAM A warranty for the whole family. Scan the code now to register your product for the industry leading warranty. BOILER WARRANTY *Boiler Warranty applies to commercial and residential applications. COMMERCIAL TANK WARRANTY RESIDENTIAL TANK WARRANTY

SEE ALL THESE BRANDS AT THE SUMMIT!

Sept 21, 2023 | Hard Rock Casino Coquitlam

LEARN FROM OUR TOP-NOTCH HYDRONICS EXPERTS

SPEAKERS

Siggy and The Bean

Our hydronic superheroes reunite to discuss the tremendous opportunities for the hydronics industry as we move towards a net zero environment.

LOCAL FOCUS

The Future of Fueling Mechanical Systems

Join moderator Mark Evans in a lively Panel Discussion on the future of energy in BC and its impact on our trade. Since 2006 Mark has supported the Hydronics Industry as a volunteer member and former Chair of the Canadian Institute of Plumbing and Heating’s Marketing Sub-Committee of the Canadian Hydronics Council.

HAVE A CHANCE TO WIN TOOLS AND VANCOUVER CANUCKS TICKETS!

Curtis Bennett walks us through the future of hydronic system controls operating a hybrid gas & electric system.

BC’s Regulatory Landscape

Where are we now? Where are we going? Will you be ready when we get there?

ENJOY BREAKFAST, LUNCH AND DAY-LONG REFRESHMENTS

John Siegenthaler

Sit in with John as he discusses the various modern hydronics technologies and their practical installations.

Local Social Media Mechanical Influencers at The Summit!

Speaker: Gary Milligan President Thermal Comfort Association (TECA)

Meet up with Vancouver area’s own Terence Chan, HVAC Jess and their team of Canada’s foremost social influencers, as they live stream on-site system builds to their followers!

Platinum Sponsor

Sponsors

Curtis Bennett HPAC contributor

Curtis Bennett HPAC contributor

Register online at modernhydronicssummit.com

DLWC system, which operates via a series of water loops.

One loop moves the lake water, another moves water within the downtown area, and loops in each building interact with the system. Thermal energy is transferred where the loops meet, via heat exchangers, at each customer or building site, as well as where the lake water pipes meet the city pipes.

In the heat exchange system in the basement of The Taylor, water returning from the building’s cooling system transfers heat to cold lake water in other loops, and the cool air is circulated to all building spaces.

After the chilled water has circulated through the buildings, Enwave returns slightly heated water to the pumping station, where the cooler potable water absorbs heat energy, and the process repeats itself.

The model has been so successful in Toronto that the city plans to develop more low-carbon thermal energy networks to support and attract new development.

In 2019, Enwave announced plans for a $100 million system expansion with the federal government providing $10 million in funding from the Ministry of Environment and Climate Change’s Low Carbon Economy Challenge.

It is expected that by 2050, 30% of the city’s “floor space” will be connected to low-carbon heating and cooling systems, including Enwave’s DLWC structures.

GREEN ELSEWHERE AS WELL

The cooling system in The Taylor is not the only way that Tricon has reduced the building’s carbon footprint.

“The apartments have motion sensors to shut off lights when not in use; all the lights are LED; and there’s a master kill switch so that residents can turn off all lights when they leave their units,” says English. “The Taylor also features Enwave’s low-carbon heating system

that uses heat pumps.”

The building uses a four-pipe fan coils in each suite to provide HVAC flexibility.

“With Canada’s unpredictable spring and fall shoulder seasons, it’s critical to have separate systems because the temperature can fluctuate quite a bit,” he says.

Cost savings associated with sustainable heating and cooling systems like the ones deployed at The Taylor are significant but project-specific, says English, adding that his company is in discussions with Enwave about another project where it aims to use another Enwave district system for heating and cooling.

A DEGREE OF COMFORT

Construction management company Deltera was responsible for the physical construction of The Taylor, including its 37 storeys and 286 apartments, but those units were not the first that it had built to connect to the Enwave system.

“Deltera has been fortunate to have worked with Enwave in the past and completing our first project, The Element, 20 years ago, one of the first residential buildings connected to the Enwave DLWC system,” says the company’s senior vicepresident of construction management, Mario Cimicata. “Now we are working on our largest project yet, consisting of six

mixed-use towers at The Well, where we installed a concrete storage tank to facilitate Enwave’s initiatives to extend the DLWC capabilities west of the city core.”

The tank at The Well, which has a diameter of 50 ft. and a depth of 150 ft., sits at the bottom of the building’s sevenstorey underground garage.

Assessing the project at The Taylor, Cimicata says that the build was made a bit more complicated as a result of the location, site logistics and general conditions the industry faced over the past three years, but the success of the project was a result of the strong continual collaboration among Tricon, Deltera, and their subtrades and suppliers, and the end result will benefit the tenants who started to move into the building last September.

“Tenants are benefiting from the owner’s decisions to incorporate innovative, efficient technologies and equipment, resulting in reduced operating expenses and a reduced carbon footprint,” he says. “Deltera is highly motivated in these areas, and continues to initiate working relationships with innovative organizations, owners, suppliers and technologies like Enwave.” <>

MODERN HYDRONICS WWW.HPACMAG.COM MH22 FALL 2023

DISTRICT ENERGY

Modern Hydronics

Treena Hein is a freelance writer based in the Ottawa area.

The mechanical room at The Taylor.

800.526.0288 | sales@aerco.com Benchmark® Platinum condensing boiler & SmartPlate® EV indirect water heater Maximizes energy efficiency and reduces peak design load Lowers installation costs - less venting and gas connections required Saves space with ultra-compact footprint Streamlines startup and operation with direct two-way communication between units, enhanced diagnostics and configuration capabilities Boost Efficiency and Savings with AERCO’s Combination Plant Learn more at aerco.com/combination

FROM STEAM TO SUSTAINABLE

BY JEFF FLANNERY, BUSINESS DEVELOPMENT MANAGER, DANFOSS

Creating a sustainable energy system to heat, cool and power an entire college campus is no easy feat. In 2013, when Sheridan College in Oakville, Ont. launched its Energy and Climate Master Plan, with the goal of lowering campus energy and greenhouse gas emissions by half, they realized that they would need to transform their heating and cooling system.

The school looked to the Trias Energetica model, first developed in 1979, as a guide to developing a sustainable energy system, integrating heating and cooling functions and recovering energy that might otherwise be wasted.

“We wanted to position Sheridan as a role model on sustainability and follow best practices. This ties into our educational mission as well,” says Herbert Sinnock, Sheridan’s director of sustainability. After an evaluation of the HVAC infrastructure in existing campus buildings, the college realized that the most effective way to make its heating and cooling operations more efficient was to install an entirely new system, using a district energy model, starting with its Trafalgar Campus in Oakville.

IMPLEMENTING DISTRICT ENERGY

Sheridan began constructing its thirdgeneration district energy system in the summer of 2016, burying 3.5 km of preinsulated pipes that carry pressurized hot water across the campus from a central plant to every building.

Sinnock notes that the pipe network is not installed very deep in the ground, which made it quick and easy to install. Modern pre-insulated pipe systems integrate leak detection, helping operations teams quickly identify any problems to ensure the system will continue to operate at peak efficiency.

Reciprocating heat and power engines, installed in 2017 and 2018, generate baseload heating for the system along with a modest amount of electric -

MODERN HYDRONICS WWW.HPACMAG.COM MH24 FALL 2023

Packaged energy transfer stations ease the transition for Sheridan College’s district energy system.

DISTRICT ENERGY

The district energy supply system at Sheridan College in Oakville, Ont.

ity. Supplemental boilers provide additional temperature lift on very cold days.

Centralized delivery uses less energy than a distributed system with separate boilers in each building. In the summer, the engines’ heat can be sent to an absorption chiller that feeds the chilled water network to several campus buildings.

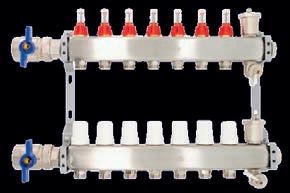

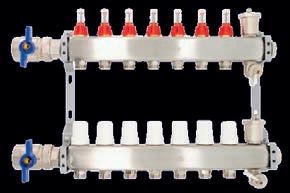

At each building, heat is transferred from the system’s primary loop to each building’s secondary heating system through a Danfoss energy transfer station (ETS). The ETS is an interconnected system of heat exchangers, valves, pumps, programmable controller, metering and piping that draws heat from the primary loop of pipes outside each building to control and feed the building’s secondary heat network.

A pressure-independent control valve on the primary side of the ETS ensures the heat exchanger operates efficiently, using an outdoor temperature sensor to modulate the heat transfer process for each building while allowing each building’s heating system to operate independently.

The ETS is a key component of the district energy system because it contains automated controls which provide continuous digital metering and can monitor and adjust to the demands of the building, controlling temperatures and working to maximize the combined efficiency of the primary loop and the buildings.

A CUSTOMIZED APPROACH

“We wanted to acquire the product from a company with an established track record of installing these devices. We were aware that Danfoss had a rich history of selling ETS outside of North America,” said Sinnock. “We liked that the stations could be factory built, customized and programmed to match our facility, then delivered fully-assembled and ready to operate on day one.”

In 2019, Sheridan began a three-year project to decommission a nearly 50-year-old steam plant serving six of its Oakville buildings, replacing it with the new hot water district heating system capable of heating the entire campus.

A steam-to-hot-water conversion requires replacement of all steam-generating equipment with a completely new system. That means that the campus buildings would potentially be without heat during the installation period. Sinnock noted that while it was a challenge to coordinate both contractor schedules and the school’s academic calendar, the installation went smoothly.

Because each ETS arrives ready for start-up with factoryconfigured and pre-tested controls, they are able to control the heat exchange between the primary loop and the building upon

Continued on MH26

Modern Hydronics MODERN HYDRONICS WWW.HPACMAG.COM MH25 FALL 2023

PHOTOS COURTESY OF DANFOSS

Each ETS includes an interconnected system of heat exchangers, valves, pumps, programmable controller, metering and piping.

The conversion from steam-to-hot-water required replacement of all steam- equipment (left) with a completely new system, often requiring some reconfiguration.

“It only took a couple of hours per unit to start up the system.”

An energy transfer station (ETS) in each building draws heat from the primary loop outside to feed each building’s secondary heating loop.

first start. This meant that the period when buildings would be without heat could be minimized and multiple buildings could make the transition to the new district energy system in quick succession.

The ability to customize the pipe network on each ETS to facilitate connection to the unique conditions in each mechanical room minimized delays in connecting the new equipment. It also enabled quick movement of complete energy transfer stations into the tight spaces of the existing system.

“It only took a couple of hours per unit to start up the system,” said Sinnock. “The pre-programming and pre-testing helped make the transition seamless.”

LEADING THE COMMUNITY

Ultimately, the increased efficiency and decreased system operating temperature will lower the college’s carbon emissions, with the potential to contribute to decarbonization throughout the community.

Sheridan’s district heating system creates an energy network, where heat can not only be recovered and reused within campus buildings but can be recovered and supplied to buildings in the larger surrounding community.

At some point, Sinnock envisions connecting the college’s energy system to a larger municipal district energy network and sharing heat with multiple buildings in the community.

“We are excited to integrate and maximize our district energy architecture,” said Sinnock. For example, a local ice rink would be able to provide excess heat, as can the college’s glass-blowing studio.

“We wanted to be a community leader and educate others about district energy,” said Michelle McCollum, associate vice president of facilities and sustainable infrastructure at Sheridan.

“When people see a district energy

network in action, it becomes real. We are able to help make changes in community energy plans and embed a culture of sustainability. Our district energy system demonstrates that we live the words we are saying.”

She noted that a recent employee survey indicated that 95% of Sheridan employees were aware of the college’s efforts in sustainability and energy efficiency.

ACHIEVING ENERGY REDUCTIONS

Sinnock admitted that reducing carbon emissions in heating is challenging, as is achieving a return on investment in system upgrades.

Fortunately, Sheridan’s leadership and

Board of Governors saw the value and supported the project. Prior to the switch to district energy, the college’s steam plant was losing about 65% of the heat it generated. Following the conversion to the more efficient hot water system, natural gas consumption was reduced by 20%, which equates to an annual carbon reduction of 530 metric tons.

“We expect to see even more reductions in energy use and costs as we attach more buildings to this system,” says Sinnock. <>

MODERN HYDRONICS WWW.HPACMAG.COM MH26 FALL 2023

DISTRICT ENERGY

Modern Hydronics

Jeff Flannery, business development manager, district energy and hydronic solutions, Danfoss.

Each ETS arrived pre-built, factory-configured and pre-tested for deployment, allowing for rapid connections on site.

The pipe network on each ETS was configured to the unique conditions in each mechanical room allowing them to fit into the tight spaces of the existing system.

P-K STORM

• Outdoor Capabilities

• 650-6000 BTU

• 316L Stainless steel coil ensures maximum corrosive resistance and durabiity

• Cabinet and heat exchanger design reduces repair and maintenance costs

• Coming Soon: Storm 8000

We provide the highest quality and most efficient products to our customers.

Demanding conditions call for reliable equipment Patterson-Kelley, LLC www.pattersonkelley.com 877.728.5351

AHRI Certified Up to 97% efficiency

COOL RUNNINGS

BY CURTIS BENNETT

Well, it seems it’s happened again. I electrocuted myself just a little. How can you electrocute yourself a little bit? Well, I needed to put in a new ceiling fan, as the old one had a small tick, tick , tick and it was very annoying trying to fall asleep. Anyways, I purchased a new fan and was going to take out the old one and thought, the fan is off so there is no power going to it. There is no switch for it, it has a wireless control, so that is why I proceeded to start disconnecting it after taking it out of the ceiling.

I think you can see where this is going. Taking the marrettes (wire connectors) off and proceeding to touch the wires— that I thought were not live, of course they were.

Luckily, I have one common practice

when doing electrical work; I don’t grip any wires hard. I know that sounds stupid, but the more pressure you put on the wire the more contact it makes and the bigger the path it has to conduct with your body. So, because of this practice of mine, I just got a little bump. Enough to make me squeal and my family knew exactly what happened. I electrocuted myself … again. Now although I do make light of these situations, they are serious. I hope in my thoughtlessness you can learn a couple things to remember when working with electricity.

Ok so now to the topic at hand: cooling, specifically in-floor or radiant cooling.

I touched on this topic about a year ago in the pages of HPAC, and I just wanted to talk more about the subject. Radiant cooling has been around for a long time. The physics are the same as radiant heating. Have you ever taken something frozen out of the freezer. Dumb question, of course you have, but when you take it out you can “feel” that it is cold even when you are not touching it. Well, that roast or ice cube or whatever it is, is radiating coolness. Sounds like

something I used to say about myself—a different type of ‘cool,’ LOL.

Now, why is there not a lot more radiant cooling used in homes and buildings. I believe the reason is installation. You can radiant cool in the floor, but to get the convection moving a lot the cold needs to “fall” down , the exact opposite of heat rising.

When you use radiant heating in a floor, it does two things, it radiates heat, obviously, but it also starts some convection due to thermodynamics, heat rising.

Not a lot of convection like a furnace blower or fancoil moving air, this is natural convection. The problem with radiant cooling only in the floor is that cold air falls, if it’s already at the floor level the air has nowhere to fall to create convection. To get good cooling convection you need the radiator to be in the ceiling. So, this creates a new set of installation issues.

Now don’t get me wrong, I understand that radiation works and works well in providing comfort in a building. That is the main function of radiant cooling and heating. I am just saying that creating convection helps with the effect.

MODERN HYDRONICS WWW.HPACMAG.COM MH28 FALL 2023

Condensation is the radiant cooling killer, but it can be overcome with proper controls.

PHOTO: BLAKEDAVID TAYLOR/GETTY IMAGES

RADIANT COOLING

Condensation is the enemy of radiant cooling.

CONDENSATION

Back to taking things out of the freezer and feeling them—have you ever taken a pop out of the fridge on a hot day?

What happens to it?

It gets little droplets of water on it. That is the radiant cooling killer: condensation. This is the same thing that can happen in your radiant cooling applications without the proper controls. If you cool the floor or radiator down too much the water in the air will start to condense, and if it condenses enough it can actually cause damage. And it’s not just the emitters, any piping needs to be properly insulated.

Radiant cooling applications can pull a lot of water out of the air in the form of condensation. Remember that when you are using cooling, it’s usually hot outside, that’s the reason we are cooling. It’s that differential in temperature that causes the condensation.

The problem is made worse in areas with high humidity. This is the reason why a lot of radiant cooling applications have dehumidification. This helps to take the moisture out of the air so it will not condense on the floor.

Dehumidification is sometimes stage one in commercial cooling applications. We’ve all heard of humidex levels; it’s the temperature that you “feel” with humidity in the air. For example, if the outdoor temperature is 30C and the relative humidity is 50%, then the temperature actually feels like 36C. The temperature you get in the forecast is called a “dry bulb” temperature—not humidity affected. Anyways I veered off a little there.

The other way to not condense in radiant cooling is to calculate the cooling water temperature based on dew point. This needs to be done room by room, and if you have a central cooling location, the room with the highest dew point sets the temperature.

Dew point is defined as the temperature at which air becomes saturated with water. Now keep in mind there is some

relative pressure involved and some other physics, but basically the point at which air starts to push out its water molecules, and at that point those water molecules form on cold surfaces. This is why radiant cooling has condensation issues. The floor becomes the pop can you just took out of the fridge. It becomes the surface that the air pushes its water molecules onto.

Ok, so now on to some practical stuff. Heat pumps are taking the world by storm. I would say they are now becoming mainstream. Yes, they have been around a long time, but they now get a lot of press with “climate change” initiatives and subsidies for efficiency.

The reason for their popularity is not necessarily just because they are more efficient—and I would agree when installed correctly they are for sure—but they have become popular because they can produce heating and cooling from one device.

I had a friend that moved into a house that had a heat pump, and he was told by the previous utility company that looks after it that he gets “free” cooling because he had a heat pump. He didn’t like it when I laughed out loud.

Now, if the radiant cooling is installed incorrectly, or the proper precautions are not adhered to there can be dire consequences.

I was involved with a house where they had to replace the whole floor because of water damage. The house had radiant cooling in the floor, but they did not control the temperature based on dew point.

They also had wood flooring and it all buckled and shifted because of the water. It’s a slow process, but over time you end up with not only a wrecked floor, but you have the potential for mold build up which is very bad for our health.

Also, heating and cooling wood floors can make the wood expand and contract a lot because of the temperature differential created, just something to think about.

The other issue I have seen with radiant cooling is making sure to only push cold water to the radiant cooling and only hot water to the radiant heating.

Now if they are both in the floor then you don’t have a choice, but if you are designing using two different radiating emitters, then you need to make sure to separate the flows. By this I mean you lose efficiency by pushing warm water to your cooling radiators while waiting for the water to cool down. You are essentially warming them up only to cool them back down.

Now don’t get me wrong, I know it may not be a lot, but over time it does effect efficiency, and this can present an issue when you only have a single storage tank for both hot and cold water.

If the building needs heating and cooling at the same time, make sure there are two tanks. One for heating water and one for cooling water.

I have seen way too many times where the homeowner does not reap the benefits because of installation issues.

Well, I feel like I’ve said just enough to totally confuse you all. My thoughts on this topic get a little scrambled because there is so much that can be done when it comes to radiant cooling.

This I can say. We are getting more and more calls to do radiant cooling applications, not just locally in Canada but North America wide. Its coming, but it needs to be done correctly or watch out, you could make rain inside the house. Don’t guess, call an expert. <>

Curtis Bennett C.E.T is product development manager with HBX Control Systems Inc. in Calgary. He formed HBX Control Systems with Tom Hermann in 2002. Its control systems are designed, engineered and manufactured in Canada to accommodate a range of hydronic heating and cooling needs.

Modern Hydronics MODERN HYDRONICS WWW.HPACMAG.COM MH29 FALL 2023

MODERN HYDRONICS 2023 - THE SUMMIT

The seventh edition of the Summit travels to Vancouver as a one-day in-person event.

BY HPAC STAFF

Since 2013 HPAC Magazine has been hosting a one-day Modern Hydronics Summit every two years in the fall with the event getting bigger and attracting larger crowds every time.

With the worldwide pandemic placing all live events on the sidelines, in 2021 the HPAC Team made a pivot to hold a virtual two-day Modern Hydronics Summit in March of 2021 attracting viewers from across Canada – drawing the largest attendance in the young event’s history.

Following a very successful 2022 Modern Hydronics Summit at the Universal EventSpace located in Vaughan, ON, just north of Toronto, the decision was made to host a Western Canada version of the Modern Hydronics Summit in 2023 – thus, on Thursday, September 21st, the Modern Hydronics Summit will be taking place at the Hard Rock Casino in Coquitlam, B.C.

THE LIVE EXPERIENCE

While the virtual Modern Hydronics Summit in 2021 provided access to industry professionals from coast to coast, there is no replacing the value of personal interactions at our live hydronics events. Meeting up in person with colleagues who share a passion for this industry, whether it’s sharing a laugh with an old friend or meeting up with new contracting pros, making connections and networking is how this segment of me -

Schedule

The 2023 Modern Hydronics Summit includes five educational sessions delivered by industry experts on topics that will set contractors up for success.

Location: Hard Rock Casino Coquitlam (2080 United Blvd., Coquitlam, B.C.)

Thursday, September 21

9:30 am - 10:30 am Registration and Trade Show Floor Open

10:30 am - 11:30 am Siggy and The Bean: Exergy and Hydronics for Net Zero Homes

– John Siegenthaler and Robert Bean (Sponsored by Uponor) 11:30 am -

pm

& Trade Show

The Future of Fueling Mechanical Systems

– Panel moderated by Mark Evans (Sponsored by Fortis BC)

The Big Switch: Preparing for Dual Fuel Controls

– Cur tis Bennett

Regulatory Landscape: Where Are We Now

– Gar y Milligan (Sponsored by TECA)

– John

chanical business continues to grow.

The trade show portion of the Modern Hydronics Summit will feature over 50 exhibiting companies or brands, all specialists in the field featuring technology and services dedicated to this niche segment of the industry.

And of course the line-up of educational sessions will once again set up attendees for success. Our featured keynote speakers feature a reunion of

HPAC writers John Siegenthaler and Robert Bean (Siggy and The Bean). The two will be detailing all aspects of how hydronic heating and cooling are a perfect fit for modern Net Zero buildings.

Other presentations will include: a panel discussion moderated by industry veteran Mark Evans on the topic of what will be fueling hydronic heating systems in the years to come; HPAC contributor

MODERN HYDRONICS WWW.HPACMAG.COM MH30 FALL 2023 SUMMIT PREVIEW

Modern Hydronics

Continued on MH32

1:00

1:00 pm -1:45 pm

Lunch

1:45 pm -2:00 pm Break/Trade Show 2:00 pm 2:45 pm

2:45 pm -3:00 pm Break/Trade Show 3:00 pm -3:45 pm B.C.’s

3:45 pm -4:00 pm Break/Trade Show 4:00 pm -5:00 pm Electrification

Practical Applications for Hydronics

and

Siegenthaler (Sponsored

Caleffi) 5:00 pm -5:15 pm Sweet Heat Contest Results

by

COMBI

COMBI CONDENSING BOILER

CX 150 | CX 199

• New control interface with express setup and intuitive alert system

• Maximum performance: 95% A.F.U.E.

• Full boiler capacity available for both DHW and space heating

• Built-in 4-zone pump control (4 zones + primary pump = 5 pumps)

• Easy to install and service with universal parts for all models

• Long vent lengths up to 170 ft.

• Built-in combi block for easy supply of DHW and easy servicing

• Built-in outdoor reset control of water temperature

• Unmatched safety features - same as a commercial boiler

A Unique Balance of Performance, Efficiency and Value

www.ibcboiler.com | 1-844-HEAT IBC

This product meets a stringent set of our company’s internally defined sustainability standards

Curtis Bennett will walks attendees through the future of hydronic system controls operating a hybrid gas and electric system; and Gary Milligan, president of the Thermal Environmental Comfort Association (TECA) will present on the current regulatory landscape in B.C. and how it will be changing in the years to come; and finally John Siegenthaler will return to share some practical design ideas for incorporating heat pumps into existing or newly-designed hydronic-heated homes.

And courtesy of the event’s tool sponsor, Kane Canada, attendees will be automatically entered into draws for useful tools after each session, and there will also be Vancouver Canucks tickets up for grabs over the course of the day as well courtesy of Lochinvar.

Along with a day filled with educational sessions, catching up with old friends and networking with new contacts, registration to the Summit also includes lunch and regular refreshment breaks throughout the event.

Thank You to Our Sponsors

Platinum sponsor: Resideo.

Lunch sponsor: Fortis BC

Refreshment sponsor: Roth

Tool sponsor: Kane Canada

Ticket Giveaway sponsor: Lochinvar (AquaTech)

Plus over 50 brands on display at the trade show featuring all you need for your hydronics projects.

INFLUENCERS ON BOARD

Last year’s Summit featured a collection of Instagram influencers working hard all day performing a series of boiler panel builds for all attendees to see. This year, HPAC is partnering with well-recognized industry social media influencer Terence Chan (@the__impetus) of Impetus Media who is organizing a hands-on educational program at this year’s event along with a team of other industry personalities including: Jessica Bannister (@hvacjess); George DeJesus (@georgetheplumber); Mike Flynn (@flynnstone1); Adam Gordon (@gordbotplumbing); and HVAC Tactical (@hvactactical).

Taking place in the lobby area, Chan is organizing three worktables where guests including apprentices, wholesaler counter associates and plumbers and contracting company owners looking to learn more about hydronics, will get hands-on guidance from the experts at each station.

This will be the first Summit to do hands-on training and net-

MODERN HYDRONICS WWW.HPACMAG.COM MH32 FALL 2023 SUMMIT PREVIEW

Over 50 brands will be participating in the tradeshow demonstrating hardware and services specific to the hydronics trade.

For the first time at the event, industry influencers will be conducting a hands-on educational event in the lobby for those looking to learn.

working like this during the event. The partnering sponsor for the this hands-on segment is Noble. Also on board to sponsor the educational panel building sessions are: Navien, Heat-flo, Xylem/Bell & Gossett and Webstone, along with Taco,

Centrotherm, Axiom and Viega. A number of other brands will also be supporting this unique interactive learning experience. The space is limited to 42 participants, so if you have interest in being part of this unique experince contact terence@impetus-media.com

SWEET HEAT

In the Fall of 2020 HPAC magazine launched the first ever Sweet Heat contest, inviting hydronic contractors across Canada to get their cameras out and share their creativity, artistry and resourcefulness in delivering “Sweet Heat” to their customers.

The response was great with over 30 entries. In 2022 a generous sponsorship was attached to the contest, with winners (one commercial and one residential project) each be receiving a $3,000 spending spree courtesy of their local

EMCO location. This year the contest continues. The entry deadline was July 31st, and once again the winners will be announced at the close of the Modern Hydronics Summit.

Thanks again to EMCO for sponsoring the two $3,000 shopping spree prizes. And like last year, this year’s winners will be featured in the upcoming October edition of HPAC

REGISTRATION OPEN

The 2023 edition of the Modern Hydronics Summit wouldn’t be possible without the support of our sponsors and exhibitors. So we invite the entire mechanical industry in Western Canada to come visit and see the latest this industry has to offer.

Registration is $125 (plus tax & service charge, $141.72 incl.). For more information and to register today visit: modernhydronicssummit.com <>

Modern Hydronics MODERN HYDRONICS WWW.HPACMAG.COM MH33 FALL 2023

INTRODUCING ECO-KING STAINLESS STEEL ELECTRIC TANKS INTRODUCING ECO - KING STAINLESS STEEL ELECTRIC TANKS ECO-KING INTRODUCING ECO - KING STAINLESS STEEL ELECTRIC TANKS ECO-KING FOR MORE INFORMATION kingheatingproducts.com 50 and 80usg sizes, 3kw or 5kw elements Lifetime warranty Mixing valve for superior performance, T&P and drain valve all included Also featuring our Made in Canada Combi Boilers Products available across Canada

Hydronics industry expert John Siegenthaler will be presenting with Robert Bean.

U.S. Boiler Company introduced new Citadel and Citadel XL condensing boilers and volume water heaters. The Citadel come in five capacities (399 - 1000 MBH) and the Citadel XL in 1250 and 1500 MBH. Rated up to 97% thermal efficiency (98% for water heater), the Citadel is available in natural gas or propane. The boiler includes: 10:1 turndown and 300 GPM max. flow rate, low water cutoff and high and low gas pressure switch, a standard reinforced 3-in-1 vent connector allowing polypropylene, CPVC or stainless steel venting. usboiler.net

REHAU had expanded its Pro-Balance manifold adapter selection with BSPP to copper press adapters for 1 and 1-1/4 in. manifolds. The new adapters connect directly to the manifold supply/return header with a BSPP threaded connection and transition to copper distribution piping using a copper press or solder connection. The adapters are suitable for snow and ice melt applications with an onsite manifold vault separate from the boiler room.

rehau.com

The Uponor commercial stainless-steel manifold handles 48 gpm total flow with up to 4 gpm flow meters, 1½-in. distribution ball valves, and 1-in. loop isolation ball valves that reduce loop pressure drops without impact to pump head pressure. It meets the demands of large commercial hydronic distribution, radiant heating and cooling, snow and ice melting, permafrost prevention (cold storage), and radiant rollout mat systems. It’s available in loop configurations of 3-8, 10, and 12. The manifold features R25 connections for outlet fittings available in ⅝-in. and ¾-in. compression or ⅝-in., ¾-in., and 1-in. ProPEX. uponor.com

Weil-McLain added five sizes to its stainless vertical firetube (SVF) commercial boiler portfolio to now include 500, 600, 725, 850 and 1000 MBH models that join the existing 1500, 2000, 2500 and 3000 Btu configurations. The line-up features up to 98% efficiency, ease of installation and maintenance, and large colour touchscreen control systems. Quick cover-plate or hatch access to the burner and fire tubes allow for simple heat exchanger wash-down and inspection. Other features include: up to 12:1 turn down, 160 psi working pressure, natural gas or propane, Modbus communication with BACnet/Lonworks compatibility, and a full line of venting options. weil-mclain.com

Calefactio’s Cal-X-Tract series now includes a dir t separator, and an air and dirt separator, with magnet. Each product in the line includes a stainless-steel bristle coalescing media to catch micro-bubbles, air and dirt particles. The media allows air and micro-bubbles to fuse and then be evacuated. The dirt particles collide and fall to the bottom of the separator to be drained. Models with a magnet separate ferrous impurities. The units are offered in NPT, sweat or press connections (¾-in. to 2-in.).

calefactio.com

Bell & Gossett has added new high-efficiency “X” plates to enhance its new gasketed plate and frame heat exchanger GPX P45, P55, P86 and P110. The X plate technology increases heat transfer thermal performance up to 20%, reduces surface area up to 20% and reduces materials up to 15%. Standard options include a variety of plate corrugations, material options of 304SS, 316SS or titanium plates, and nitrile or EPDM gaskets. GPX models have higher surface area to volume ratios than conventional shell and tube heat exchangers, and the new plate design generates high turbulence resulting in high heat transfer coefficients.

bellgossett.com

MODERN HYDRONICS WWW.HPACMAG.COM MH34 FALL 2023

PRODUCTS

HYDRONICS

The new Danfoss Aveo line of thermostatic radiator valve (TRV) operators replace the RA2000 series. The new TRVs feature unique energy-saving gas bellow technology, and to help customers adjust room temperature more precisely, the Aveo also features tactile temperature setting, providing a subtle click feeling for every 1F (0.5C) change in temperature. Tamper- and theft-proof versions are available for commercial buildings, and building managers can limit room occupants from changing the thermostat temperature. The click-connection also enables a fast and toolfree installation. danfoss.com

Enertech introduced its hydronic air handler (EAH) and cased coil (EEH), both pairing up with the company’s air-to-water heat pump or its water-to-water heat pumps. The air handler features an 18-gauge sheet metal cabinet, an ECM blower motor, and an all-aluminum air coil. The design includes front-facing water connections, condensate drain openings, and closed cell insulation inside the cabinet. The EAH is available in four sizes, from 2 to 5 tons and is field convertible from the standard up-flow orientation to either down-flow or horizontal.

enertechusa.com

Ironworks Radiators offers Fondital’s Cool series of towel rail radiators in Canada. The towel radiators provide a balance between form and function, providing warmth with a modern design. The towers warm towels and garments while maintaining a safe and comfortable surface temperature. The units also maximize heat distribution and minimize energy consumption. Fondital’s Cool towel radiators are available in three sizes, gloss black and silver gray finishes, and styles to suit various interior designs and preferences.

ironworksradiators.ca

MODERN HYDRONICS WWW.HPACMAG.COM MH35 FALL 2023 Modern Hydronics

HPAC_Velocity Boiler Works_August23_CSA.indd 1 2023-07-26 1:35 PM

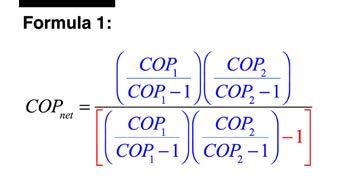

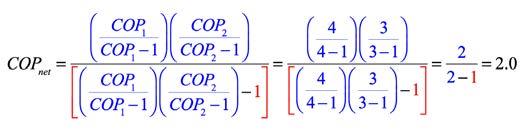

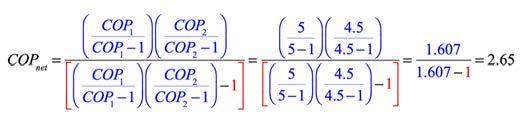

THE NET EFFECT

Calculating the efficiency, or inefficiency, of using a heat pump water heater in a heat pump heated home.

BY JOHN SIEGENTHALER

Heat pumps are incredibly useful devices. They gather what would otherwise be unusable heat from low temperature sources such as outside air, soil, lakes, or water wells and “upgrade” the temperature of that heat to a condition where it can heat buildings, domestic water, swimming pools or other process loads.

As the global taste for fossil fuels continues to “sour,” electrically powered heat pumps will continue to gain market share as heat sources.

One of the areas in which this is already occurring is residential domestic water heating. Federal regulations that went into effect in the U.S. in 2015 require electrically powered storage water heaters having 12 KW or less of power input, and volumes over 55 gallons, to use heat pump technology.

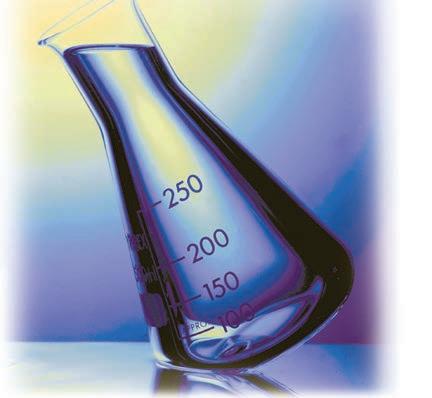

This mandate spawned many products that, in essence, combine a small air to water heat pump assembly with an insulated DHW storage tank. Most commercially available products in this category mount the heat pump components on top of and attached to the thermal storage tank, as illustrated in Figure 1.

The heat pump assembly pulls room air across its evaporator coil, extracting heat from it, and in some cases condensing water vapour in the air. The cooler and drier air discharges into the surrounding space. Refrigerant flows from the evaporator coil to the compressor where its temperature and pressure are

increased. The hot refrigerant gas passes through condenser coils located in the tank or wrapped around the perimeter of the tank under the insulation. Heat moves from the condenser coils into the domestic water.

The refrigerant condenses back to a liquid as it gives up heat. It then flows to an expansion device where its temperature and pressure are lowered to a condition allowing the cycle to continue. This basic non-reversible refrigeration cycle is used in millions of devices like refrigerators, room air conditioners and water coolers.

USE WHERE APPROPRIATE

Heat pump water heaters make a lot of sense when they can be located in areas that have a surplus of heat. Examples would include a garage in a southern climate, or a space filled with equipment that generates heat.

They can also keep a basement cool and drier during humid summer months. Most heat pump water heaters do not have sufficient cooling capacity or a means of air distribution to make them practical for whole house cooling.

One application that I’ve heard pro -

MODERN HYDRONICS WWW.HPACMAG.COM MH36 FALL 2023

HEAT PUMP WATER HEATER

Figure 1. The typical configuration of a heat pump water heater, with heat pump components on top on a thermal storage tank.

posed several times involves locating a heat pump water heater in a house that uses a separate heat pump for heating and possibly for cooling. This concept sets up some interesting thermodynamics.