FOCUS ON: Predictive maintenance in oil and gas ALSO: What is a hot bearing? Effective lubricant filtration

ARE YOU SAFE?

Concussions, enclosures, and safety checks.

MROMAGAZINE.COM / SUMMER 2023 VOLUME 39 / ISSUE 2

10 12 14 20 SUMMER 2023

IMPORTANT IMPLICATIONS AND BENEFITS OF PREDICTIVE MAINTENANCE IN THE OIL AND GAS INDUSTRY

Oil and gas industries are volatile and complex, subject to strict regulatory and environmental controls and wildly fluctuating prices.

PREVENTING CONCUSSIONS IN THE WORKPLACE

Concussions tend to receive significant media attention when they occur in professional sports, but they can happen almost anywhere, including in manufacturing facilities.

TAKE CONTROL: PLAY IT SAFE WITH THE HELP OF ENCLOSURES

How an enclosure manufacturer integrates safety, efficiency, and automation protocols.

EVERYONE WINS WITH GOOD TRAINING

@MROmagazine Summer 2023 / MRO 3 Cover photo: Thanakorn Piadaeng/iStock / Getty Images Plus/Getty Images Columns 4 EDITORIAL Never neglect safety. 16 WHAT’S UP DOUG What is a hot bearing? 18 MAINTENANCE 101 Contractor safety systems. 22 MRO QUIZ Oil Filters, types, ratings, and applications. In every issue 6 NEWSWATCH 8 EVENTS CTMA holds navigating economic uncertainty seminar. 24 NEW PRODUCTS 26 IN CONVERSATION WITH MRO 10 20 14 12 INSIDE

Inaugural Machinery Alignment Specialist certified training program took place at the CMVA Technical conference. FEATURES

Never neglect safety

The Association of Workers’ Compensation Boards of Canada (AWCBC) publishes lost time, injury, and f atality reports through its National Work Injury/Disease Statistics Program (NWISP).

Doing a deep dive into the statistics for 2021 (the most recent available), we found that of the approximately 20 Canadian industries covered, manufacturing had the second most fatalities, with construction being the only industry to have more.

In all, 1,081 total fatalities were reported. With trades, transport and equipment operators and related occupations accounting for nearly half (537), and occupations in manufacturing and utilities next at 120. The vast majority of injuries were exposure to harmful substances or environments with 728 f atalities. Other causes were contact with objects and equipment (80), falls (60), and transportation accidents (137). As exposure to harmful substances is the main reason for fatalities, it is no surprise that the majority of fatalities are caused by neoplasms, tumors, and cancer (401), and systemic diseases and disorders (329); with what we would term to be ‘accidents’ or traumatic injuries and disorders accounting got the major ity of the rest (322).

Fatalities are not as common, but they do happen, and in many cases are the reason for change within a company. However, lost time claims, which do not garner the same headlines, but are just as important to safety, are much more common.

According to the NWISP data, 277,217 lost time claims were recorded in 2021. With manufacturing once again placing second (37,655), this time behind the heath care and social assistance industry (67,685).

This is significant, as contact with objects and equipment (55,575) is the second leading cause of lost time claims. While the data does not specifically break down how many of these claims

were related to maintenance work on machines, it is safe to say that incidents while doing maintenance work contr ibute to the number. Additionally, unlike fatalities, lost time claims were led by traumatic injuries and disorders (210,990).

What does this all mean for the manufacturing industry, and more specially, maintenance and reliability?

Putting it in perspective, when MRO asked its readers how important do you believe safety is at your company? Zero per cent said not important. With 60 per cent saying it is of utmost importance, 23 per cent saying it is important, and 10 per cent saying it somewhat important. Eight per cent said other.

What this shows is that everyone believes safety is important, with many going above and beyond to make sure their company is as safe as possible, while others may only do what they are required to do through legislations or standards. The latter group fail to see that this may be a short sighted vie. As not spending money on safety may help your bottom line in the short term, if an accident or fatality happen, and your company is found to be negligent and at-fault, the bottom line will be much worse off.

Keep in mind that safety spans many different aspects, with each needing to be thoroughly examined, and in turn turned into a safety program at your company. However, the key is to make sure that the procedures outlined in the program are followed, and any infractions are documented. The key for many companies is training, to make sure that their employees (and contractors) know what the policies and procedures are while on the premises.

Be sure to read our safety articles within this issue to help you be the safest you can be.

MARIO CYWINSKI Editor mcywinski@mro.ca

ESTABLISHED 1985

SUMMER 2023 Volume 39, Number 2

READER SERVICE

Print and digital subscription inquiries or changes, please contact Customer Service Angelita Potal, Customer Service Administrator Tel: 416-510-5113 email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR Mario Cywinski 226-931-4194 mcywinski@annexbusinessmedia.com

SENIOR PUBLISHER Paul Burton 416-510-6756 pburton@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett 416-829-1221 ifawcett@annexbusinessmedia.com

BRAND SALES MANAGER Chander Verma 437-218-0941 cverma@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

MEDIA DESIGNER Svetlana Avrutin

ACCOUNT CO-ORDINATOR Trish Ramsay 416.510.6760 tramsay@annexbusinessmedia.com

PRESIDENT/COO Scott Jamieson sjamieson@annexbusinessmedia.com

Machinery and Equipment MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

Subscription rates. Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

4 MRO / Summer 2023

MAINTENANCE NOTEBOOK

Connect with MRO magazine @mro_maintenance @MROMagazine /company/mro-magazine @mromagazine info@mromagazine.com mromagazine.com @mrocanada

ACROW’S MODULAR STEEL TRUSS SYSTEM SUPPORTS REHABILITATION OF BRIDGE IN QUÉBEC

Acrow, an international bridge engineering and supply company, noted a steel truss system it designed was used to provide support to Pont Perrault during the project to rehabilitate the historic covered bridge in Québec. Although it had been many years since the bridge carried vehicular traffic, it was closed to pedestrians and cyclists in 2018 after damage to timber components was discovered.

Pont Perrault opened to traffic in 1929 and spans the Chaudiere River in the parish municipality of NotreDame-des-Pins. At 150.9 metres long, it is the longest covered bridge in the province.

After delays due to sharp increases in the cost of building materials during the pandemic, the project began in May 2022 and was completed in November

Your Resource for Precision Bearings

enables us to respond rapidly to your requests. Our manufacturing can handle any size order. Our quality control procedures ensure consistent tolerances and our engineering expertise give you a deep knowledge base to draw on.

EQUIPMENT

CASCADES ANNOUNCES THE CLOSING OF A PAPER MACHINE AT ITS NIAGARA FALLS, N.Y. FACILITY

Cascades is announcing the permanent shutdown of paper machine number two at its Niagara Falls, New York mill, which had been temporarily

shut down since November 2022. The machine, amongst the oldest in the Container board platform, has a production capacity of 90,000 short tons per year, and would require investments for it to remain competitive. The permanent closure of this machine will impact approximately 40 positions. Most of these positions are currently vacant or will be subject to attrition in order to minimize the impact on the employees.

Cascades inc., a manufacturer of green packaging and hygiene products and also announces that it has produced its fir st roll of 100 per cent recycled container board at its Bear Island, Virginia mill.

The project created 700 jobs in the region during the construction phase, and 180 permanent jobs with the onset of commercial production.

The Bear Island mill is now entering the ramp-up phase of the machine and will gradually increase its production to reach full capacity. An official inauguration will be held in the coming months.

6 MRO / Summer 2023 MROMAGAZINE.COM TRANSPORTATION

NEWSWATCH

Bearings and Power Transmission... XtendaTM Stainless

Cam

Followers Hi-RollerTM Bearings

The World of

Steel

and Cam Yoke

• Standard Needle Bearing Cam and Cam Yoke Followers • Eccentric Stud Cam Followers • Heavy Stud Cam Followers • Neverlube ™ Cam and Cam Yoke Followers

BALL BEARING UNITS

For Special Environments try Ceraball Hybrid Bearing Units good for up to 450° C (842° F) MONTREAL TORONTO WINNIPEG EDMONTON VANCOUVER (514) 685-6006 (905) 826-1100 (204) 694-1455 (780) 465-3311 (604) 294-3461 Fax (514) 685-6007 Fax (905) 826-9691 Fax (204) 633-7230 Fax (780) 490-4664 Fax (604) 294-4680 montreal@ringball.com toronto@ringball.com winnipeg@ringball.com edmonton@ringball.com vancouver@ringball.com MRO_RingballLeft_Spring23.indd 1 2023-02-28 11:19 AM

One of the world’s oldest mounted bearing manufacturer, they are available in wide array of sizes and styles.

2022. The repair work enabled the reopening of Pont Perrault for yearround use by pedestrians and cyclists.

Photo: Acrow Bridge

BUSINESS OPERATIONS

HITACHI GLOBAL AIR POWER ESTABLISHED

Hitachi Industrial Equipment Systems Co., Ltd., a wholly owned subsidiary of Hitachi, Ltd. announced the establishment of Hitachi Global Air Power, a new company bringing together its global compressed air business. Sullair will now operate under Hitachi Global Air Power.

“We are the same organization, ownership, leadership, and staff, but now we have a name that more clearly demonstrates Hitachi’s breadth of compressed air solutions, product lines and innovation that both Sullair and Hitachi bring to the market,” saidYasuhiro (Charlie) Takeuchi, president and CEO of HIES.

“In today’s relentlessly transforming society, Hitachi Global Air Power is uniquely positioned to raise the bar on the value we deliver to customers through our

comprehensive portfolio of compressed air products and solutions such as Air as a Service.”

Sullair was founded in 1965, and became a wholly owned subsidiary of Hitachi, Ltd. in 2017.

Hitachi Global Air Power will continue to offer a full range of integrated compressed air solutions, including portable air compressors, industrial air compressors, aftermarket OEM parts, and fluids.

While Sullair will change its corporate name, the branding will remain intact on its products, including Sullair, Champion and Air-One. By maintaining m arket appearance, customers and distributors will continue to recognize the familiarity of the Sullair.

“The company name change from Sullair to Hitachi Global Air Power is only the latest move in a growing list of Hitachi’s commitments to our business and brand,” said John Randall, president and

CEO, Sullair. “Since our acquisition, Hitachi has invested more than $45 million in our company, and Hitachi has been instrumental in allowing us to expand our caliber and capabilities. We are excited about the opportunities ahead of us—for our business, employees, customers, channel partners and communities.”

ENERGY

PYRO GREEN-GAS COMPLETES INTEGRATED COLD TEST FOR A CLIENT

PyroGenesis Canada Inc., a hightech company that manufactures and commercializes advanced plasma processes and sustainable solutions to reduce greenhouse gases, announced that its subsidiary, Pyro Green-Gas has successfully completed the Integrated ColdTest (ICT) under a previously announced $9.3M project with a client, a diversified steel producer.

Under the terms of this project, Pyro Green-Gas has been mandated to (i) supply coke oven gas pur ification solutions and (ii) hydrogen production processes that have combined the potential to allow for the extracting of hydrogen with a 99.999 per cent purity level and improve the client’s environmental outcome. The successful demonstration of Pyro Green-Gas coke oven gas purification and hydrogen extraction processes during the ICT confirms that all systems, equipment, and their components meet and exceed the required operation and safety standards. The ICT achievement triggers an aggregate milestone payment of $460,000, which is expected to be received in the coming weeks. The balance for this project (approximately $920,000) would be ear ned upon the completion of two final milestones, namely obtaining the PAC and completing the post-performance bond.

@MROmagazine Summer 2023 / MRO 7

DISTRIBUTED IN CANADA BY Linear Rail Systems SBC Linear Rail System Ball Screw Support Units Linear Bushings Cross Roller Guide Robot Carrier Guide Linear Actuator Great Products. Great Reputation. Quality bearings are only one aspect of RBL’s product line. We take pride in our products that encompass bearings, rod ends, bushings, sprockets, roller and leaf chains along with a range of power transmission products. To assure product availability and the best possible service for our customers, we have extensive inventories at our five regional warehouses. Ball Bearings Cylindrical Bearings Spherical Roller Bearings Split Pillow Blocks Adapter

Locknut

Slewing Rings Rod

Sleeves

& Lockwashers

End Bearings

www.ringball.com MRO_RingballRight_Spring23.indd 1 2023-02-28 11:28 AM

Ball Bearing Units Stainless Steel Units Spherical Plain Bearings Bronze Bushings

CTMA holds navigating economic uncertainty seminar

The Canadian Tooling and Machining Association (CTMA) held the Economic Uncer tainty: Helping You Navigate info session at the EDC Export Growth Hub in Kitchener, Ontario. The seminar looked at various facets of tooling and machining industry that are being affected by the current economic uncertainty.

“It was great to see a large turnout for the first of two CTMA breakfast speaker events,” said Robert Cattle, executive director, CTMA. “You always know that there is a lot of interest in the presentations when all the participants engage in pertinent discussions, and stay until the very end, which was the case here. It was interesting to hear the comments from our members concerning everything from current work status, economic forecasts, to cyber security issues.”

The seminar kicked off with a presentation on Preparing your business for an economic slowdown by Celso Oliveira, Manager, Business Centre, BDC. His presentation focused on where the economy is headed, how

are your customers doing, and getting your company’s finances ready for a slowdown. He spoke about inflation, global growth, economies, consumption, unemployment, price pressures, and interest rates.

Oliveira also looked at the four proven strategies to address the labour shortage. Which were invest in technology and automation; use a formal hiring process, provide a competitive salary and benefits, and expand your hiring pool. He

also looked at strategies to improve your cash flow management, that included know your cash burn; identify and defer non-essential expenditures; and keep talking with your lenders.

Next was Jason Roberts, commercial account executive, Cowen, who looked at How Cowan can support your organization during times of economic uncertainty , and how this impacts commercial property, liability, and trade credit insurance. His colleague, AJ Feltis, group benefits consultant, Cowen, spoke about how mental health in the workplace is being affected by a changing economy.

The next presentation was by Glen Millard, regional vice-president Ontario, EDC, who outlined how Connecting the Dots to Drive your International Growth. He spoke about how EDC can help, and how to navigate challenges and opportunities for inter national growth by planning, research and intelligence, having a network, and using capital.

Each session was followed by a question-and-answer session. Another session was also held in Windsor, Ont.

8 MRO / Summer 2023 MROMAGAZINE.COM

Photo: Mario Cywinski

EVENTS

Photo:

FEATURE

Speaker: Celso Oliveira, Manager, Business Centre, BDC.

NEWSWATCH

AUTOMOTIVE

MAGNA AWARDED NEW HIGH-VOLTAGE EDRIVE BUSINESS WITH GLOBAL OEM

Magna announces it has been awarded a high-volume contract with a Europe-based Global Premium OEM to supply its new eDrive system (eDS Mid). The eDrive is planned for 2027 model SUVs/sedans, with production expected to begin in 2026.

Magna’s eDS Mid is a compact, high-speed e-motor that offers a scalable power range from 100 kW to 140 kW, optimized for 800V. As a high-voltage eDrive system for electric AWD applications, it enables reconnecting through a new decoupling system and delivers am efficient inverter with Silicon Carbide (SiC) technology which contributes to efficiency, drivability and safety.

Production of the eDrive system will be at the company’s powertrain facilities in Kechnec, Slovakia, and Lannach, Austria, both of which are carbon neutral facilities.

ENERGY

HOPA EXPLORES GREEN HYDROGEN WITH ATURA POWER

The Hamilton-Oshawa Port Authority (HOPA) entered a Memorandum of Understanding (MOU) with Atura Power to provide them with green hydrogen.

As one of 17 Canadian port authorities and the largest on the Great Lakes, HOPA operates facilities in Hamilton, Oshawa, and Niagara. HOPA is investigating the use of green hydrogen from Atura Power to decarbonize both its operations and that of its customers. The hydrogen will be produced at the Niagara Hydrogen Centre on the Niagara River.

Once complete, Atura Power’s Niagara Hydrogen Centre will have a 20-megawatt electrolyzer system, making it Ontario’s largest green hydrogen facility. It is expected to be operational by the second half of 2024.

AUTOMATION

ATS ACQUIRES TRIAD UNLIMITED

ATS Corporation has acquired Triad Unlimited LLC, a U.S-based reliability engineering service provider.

“Adding the Triad team and their differentiated offerings will further our unique value proposition and enable us to support customers throughout their equipment’s lifecycle,” said Simon Roberts, Senior vice-president, after sales and services. “Triad’s experience and leadership in life sciences, food and beverage, and other key industries offers synergies with both our current and targeted portfolio of customers.”

Triad will support ATS’ after sales and service initiatives that focus on delivering customer value. With Triad’s interconnected asset management framework and propr ietary Relialytics software, it is expected to enhance ATS’ connected-asset value chain and predictive maintenance abilities, in addition to strengthening their reliability engineering capabilities. Financial terms were not disclosed.

@MROmagazine Summer 2023 / MRO 9 MRO_Benchmark_Spring23.indd 1 2023-02-21 11:22 AM

Photo credit: Magna International Inc.

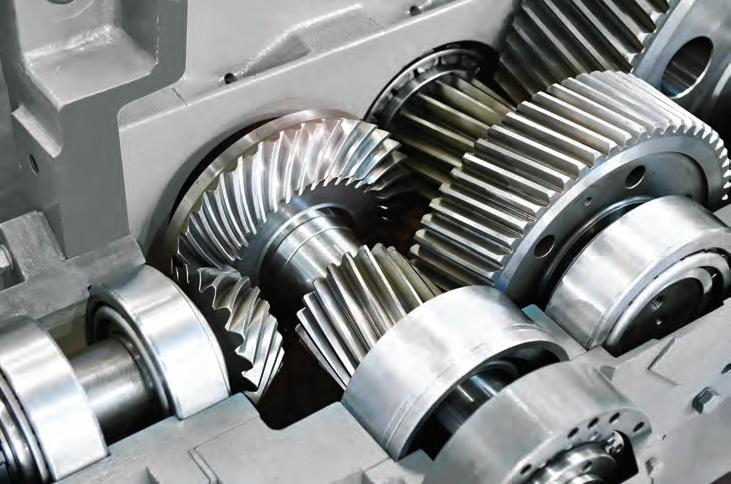

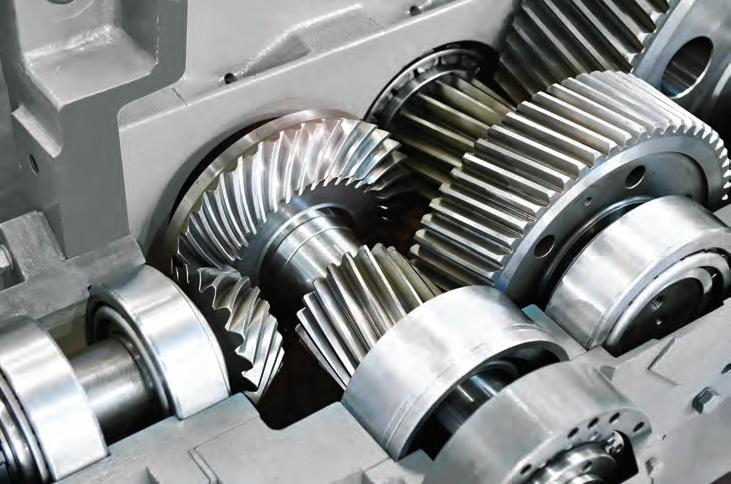

Important implications and benefits of predictive maintenance in the oil and gas industry

Oil and gas industries are volatile and complex, subject to strict regulatory and environmental controls and wildly fluctuating prices. Additionally, recent surges in viable renewable energy sources and investor emphasis on sustainability has added greater pressure to an already competitive industry.

BY BRYAN CHRISTIANSEN

With oil and gas being asset and capital-intensive, the industry relies heavily on the performance of complex process equipment for production efficiency; as competitive pressures mount, companies are seeking help from technology.With regulatory, environmental, and competitive pressures set only to grow, increased industry investment in predictive maintenance will be inevitable.

Implications of that investment and some benefits to be achieved by early adopters.

Implications

Increased investment in PdM technology will create a virtuous circle of technology development. Here are two areas where growth will occur:

Increased virtual monitoring

Artificial intelligence and machine learning have accelerated in maturity with increased focus and investment,

allowing companies to automate field operations and processes. This automation has several drivers, not least the labour shortages we’re experiencing now, which will only worsen over time.

Another catalyst to automate is the cost and difficulty of using operators to collect data and adjust operating criteria. Transferring data to a centralized database is cumbersome, does not occur in real-time, and there is potential for human error. While PdM will still operate on the data, such manual systems do not realize the full potential of predictive maintenance.

When Petroleum Development Oman introduced asset management software to automate its operations, it saw benefits beyond maintenance. Yes, processes were faster with automated workflow triggers, and the resolution of issues and routine tasks was more rapid. However, the added benefits were seen in ordering spares, where the previous 46 steps were reduced to 14, saving one full-time equivalent.

Also, visibility into the facility’s management increased with integrated perfor mance dashboards.

Increased use of PdM and Physics-based modeling

Companies have been reticent to automate because of the cost, complexity, and time to generate a meaningful retur n on investment (ROI).Technology adoption leads to a greater number of products being introduced to the market, and their prices continue to drop, accelerating growth further. With the cost issue receding, companies will now point to complexity and ROI as the next barriers to adoption.

Typical PdM solutions require extensive time from data scientists to gather and clean maintenance data before training the machine learning models. However, an emerging solution is using physics-based modeling to speed up PdM implementation. Physics-based, digital simulations help predict how the equipment will fail, providing greater certainty, speed of implementation, and advance notice of failure when compared to purely data-driven PdM.

Benefits

There are two main tactical and operational benefits for oil and gas companies using PdM:

Improved equipment availability

Kimberlite, a market research firm that specializes in collecting market data for the oil and gas industry, claim that less than four days of unplanned downtime costs an oil and gas company over $5 million, with most companies averaging 27 days of annual unscheduled downtime.

10 MRO / Summer 2023 MROMAGAZINE.COM

PREDICTIVE MAINTENANCE FEATURE

Photo: LeoWolfert/iStock/Getty Images Plus/Getty Images

Meanwhile, McKinsey has carried out numerous studies into oil and gas operations. Their findings suggest that operators using PdM achieve a five to 10 per cent improvement in production efficiency, and a 20 to 30 per cent decrease in maintenance costs compared to contemporaries using time-driven maintenance philosophies. Additionally, they claim a 30 to 50 per cent reduction in downtime on critical machines.

Findings from the US Department of Energy support McKinsey’s figures, with PdM implementation in oil and gas providing a 25 to 30 per cent reduction in maintenance costs, a 70 to 75 per cent reduction in breakdowns, and a 35 to 45 per cent reduction in downtime. They also show production increases between 20 to 25 per cent, and a 10 times ROI.

Enhanced environmental and safety performance

As both the investors and the public demand increased performance from oil and gas companies in matters of the environment and sustainability,

predictive maintenance offers an opportunity for serious improvements. Unplanned shutdowns can cause product release through leaks or purging, poorly functioning equipment can consume g reater energy, and equipment failure can lead to safety issues and environmental contamination.

PdM gives advance notice of operating parameters trending away from in-ser vice norms, despite these characteristics being unnoticeable by human senses. Alerts allow the planning and procurement for a planned maintenance inter vention, and — where possible — changes to the operating process to militate failure until repairs take place.

One oil and gas operator discovered almost three-quarters of all flaring emissions occurred due to poor equipment reliability. By implementing PdM, the company reduced its emissions significantly and increased production. Another operator created algorithms to predict gas compressor train failures, achieving 70 per cent accuracy and increasing production by almost 0.5 per cent.

OVER 1,000 GLOVES ALWAYS IN STOCK

The take-up of PdM in the oil and gas industry has been surprisingly slow, with predominantly larger companies investing. However, this reluctance will change as technology costs continue to reduce, and the numbers of available PdM solutions increases. Oil and gas companies face strong headwinds with increased competition from renewables, regulatory oversight, and societal demands for greater accountability, environmental performance, and sustainability.

Advanced analytics is something the oil and gas industry can use to cope with the varied demands, investing in machine learning, Ai, and p redictive algorithms, to improve operating asset monitoring, management, and control. The return on investment experienced by those who have taken the plunge, has been good due to improved production, reduced maintenance costs, and fewer breakdowns.

@MROmagazine Summer 2023 / MRO 11

Bryan Christiansen is the Founder and CEO at Limble CMMS (a mobile CMMS software company). He can be reached at bryan@limblecmms.com.

23_003267_MRO_SMR_CN Mod: April 25, 2023 12:16 PM Print: 05/10/23 page 1 v2.5

ORDER BY 6 PM FOR SAME DAY SHIPPING 1-800-295-5510 uline.ca π MRO_Uline_Summer23.indd 1 2023-05-11 9:23 AM

Preventing concussions in the workplace

BY CANADIAN

According to theWorkplace Safety and Insurance Board, the number of lost time claims for work-related concussions increased by approximately 340 per cent in Ontar io from 2012 to 2022. Despite this rise, research shows there is still a general lack of awareness of this type of brain injury, particularly in the workplace, which means they often go underreported.

In Canada, the highest rates of workplace concussions are in the transportation, storage, government, and primary industries (forestr y, fishing, and mining). The most common cause of workplace brain injuries overall are falls, being struck by or against an object, and motor vehicle collisions. However, the main causes of work-related concussions vary by industry and occupation.

How concussions occur

A concussion is the most common form of traumatic brain injury. It is caused by a bump, blow, or jolt to the head, or by a hit to the body that causes the head and brain to

move back and forth rapidly. It may or may not involve a loss of consciousness; you do not have to black out or be knocked out to experience a concussion.

However, if it results in a loss of consciousness, it is considered a critical injury – one that could be life-threatening. Concussions may lead to an altered mental status that affects cognitive (thinking, memory, learning) and physical performance. Although symptoms usually resolve within weeks, they can persist.

Concussions can result from whiplash, rapid rotation, getting struck by or against an object, shaking or jerking of the head or even the body. In a manufacturing facility, hazards that may cause falls, slips, and trips, and vehicle collisions can lead to concussions.

Signs and symptoms

Signs and symptoms of a concussion usually include a new onset of one or more symptoms, which may include headaches or a pressure sensation in the head, dizziness, a loss of consciousness, seeing stars, or blurred/double

vision. Slurred speech, nausea or vomiting, and balance problems are also symptoms. If a worker experiences sensitivity to light and/or noise, difficulty concentrating or remembering, confusion, drowsiness, and an incoherent thought process –these are all warning signs that they may have a concussion.

Some symptoms may not be present immediately after an injury but may emerge in the subsequent hours or days. It is therefore necessary to monitor for symptoms several days following a head injury.

Managing a concussion

Workers who experience any of the above symptoms after an injury should alert a supervisor and seek immediate medical attention. It is important to consult with a medical professional on how best to manage a concussion. Someone with a suspected concussion should not be left alone or allowed to drive.

With proper diagnosis and treatment, most people with concussions recover fully within a short period of time. However, in some cases, symptoms linger for weeks or months, making it challenging to resume normal activities or return to work. An individual’s ability to return to work can be influenced by co-existing medical conditions and their concussion history.

Strive for prevention

There are several ways to help prevent concussions in the workplace. Start by identifying and removing tripping and fall hazards, and hazards that could

lead to a worker getting struck by or against an object. Make sure walkways and workspaces are free of clutter, cords, puddles of water, or anything else that can cause a slip, trip, or fall. Use proper signage to alert employees of wet surfaces and ensure the proper type of safety footwear is worn to prevent falls.

To prevent objects from falling, keep shelves and storage areas and your workspace clean and organized. In a maintenance facility, place the heaviest objects on the floor or the lowest possible shelving. Do not stand on chairs, desks or tables when reaching for higher-up items, but rather use an appropriate step stool, access platform, or ladder to avoid falls. Appropriate control measures and procedures need to be in place when working from heights. Know when and how to use fall protection and fall restraint equipment. Encourage workers to report all unsafe conditions immediately to their supervisor.

If a job requires wearing a hard hat, make sure it’s appropriate for the job, properly fitted, and in good condition. Implement measures to safely manage traffic flow on site, promote good driving practices, and make sure company vehicles are properly maintained to reduce the risk of a collision.

Given the prevalence of head injuries in the workplace, it’s important to train workers on the safety protocols to prevent falling objects, vehicle collisions, and trips, slips and falls in your facility. Ensure workers are outfitted with the proper personal protective equipment. Highlight the importance of reporting all head injuries as soon as possible and implement a system where no worker is left alone with even the slightest potential for a concussion.

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial, and mental health — of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips.

12 MRO / Summer 2023 MROMAGAZINE.COM

Photo: PeopleImages/iStock/Getty Images Plus/Getty Images

SAFETY FEATURE

Concussions tend to receive significant media attention when they occur in professional sports, but they can happen almost anywhere, including in manufacturing facilities.

CENTRE FOR OCCUPATIONAL HEALTH AND SAFETY (CCOHS)

Take control: Play it safe with the help of enclosures

How an enclosure manufacturer integrates safety, efficiency, and automation protocols.

BY MRO STAFF

On the surface, the structure of an electrical enclosure seems basic. Get involved in selecting one, however, and the power, place, and parts of this humble component takes on new dimensions.

The sheer volume of heat-generating electronics in the market has made industr ial control panels and enclosures integral to electrical engineering. These specially fabricated and machined cabinets are a conduit for distributing voltages between circuits, ensure critical equipment provide a lifetime of service, protect auxiliary components from damage and, emphatically, keep personnel out of harm’s way.

What’s the code?

The starting point for specifying electrical enclosures in industr ial applications is to have

knowledge of the protection system or the codes and standards applicable to the geographic location of the industrial user. These standards ensure high quality and reliability.

In general, electrical enclosures in North America require UL approval, with an emphasis on the type of rating, as shown on the rating plate. In Canada, enclosures and cabinets that house electrical equipment are listed with NEMA ( National Electrical Manufacturers Association), UL (Underwriters Laboratories) and/ or CSA (Canadian Standards Association) ratings.

NEMA enclosure type ratings set standards for electrical enclosure safety and reliability by specifying the performance criteria for enclosures based on the environment the enclosure is intended for. The ratings cover

such criteria as the degree of protection against water and dirt, mechanical impact, or oil and corrosion resistance.

Keep in mind that NEMA does not test products. Both UL and CSA use NEMA guidance for the investigation and listing of their electrical enclosures. Only once tested can enclosures carry a NEMA, UL or CSA label. Differences amongst these ratings may depend on whether the equipment was third party tested or whether standards were left in the hands of the manufacturer.

Form factors

Enclosure manufacturers take great care to define precise requirements with respect to materials (stainless steel, aluminum, zinc, galvanized steel, or polycarbonate), positioning and mounting (free-standing

or wall-mounted) options, distance from other assemblies and climate control. These instructions must be observed, along with regular quality inspections, otherwise the warranty may be voided in the event of a malfunction or damage.

For insights into selecting an electrical enclosure that has as its objective a solution for both protecting equipment and guarding against arc flash conditions, André Bousette, president, Rittal Limited, Canada, suggested we look at the company’s isolation enclosure solution, which helps engineers design the ideal system for their application with arc flash prevention in mind. The Flange Mount Disconnect Enclosure, for example, meets Requirement 66.1.3 from the UL508A Standard for industr ial control panel construction.

14 MRO / Summer 2023 MROMAGAZINE.COM

Photo: Mories602/iStock/Getty Images Plus/Getty Images

SAFETY FEATURE

A simple mechanical interlock solution with robust safety considerations can function to prevent an operator from opening a power enclosure while the system is energ ized. The logic behind a simple principle that all doors must be closed to power the system on, is as follows:

• The connecting door interlocking kit provides the means to lock the connecting door while the main door is closed and the power is on. It also prevents the main door from closing while the connecting door is open and unsecure.

• The interlock activator allows the activator kit to work properly by latching and unlatching connecting doors when required.

• The adapter plates ensure compatibility with most commercially available operator handles and allow upgrades and modifications without performing additional cut outs in the field, all while maintaining Type 12 rating. (A type 12 NEMA rating is intended for indoor enclosures without knockouts. They provide a degree of protection to personnel against access to hazardous parts, and protects the enclosed equipment inside against ingress of dirt, dust, and fibres).

• The defeater lever provides safety locking between most common operator handles, enclosure and door. Assembly is simple with just two sc rews while the door is open. The activator bracket synchronizes the enclosure door latch with the operator handle. This allows the enclosure to be powered on only when the door is latched, and lock the internal doors in the event the main door is unlatched. (This lever is factory installed.)

• The connecting rod connects the defeater lever to the activator bracket and provides s imple adjustments for the adapter plate and operator handle selected. This allows quick and easy installation with the flange door open.

Future-proofing power management

At Hannover Fair 2023, Markus Asch, CEO, Rittal International and Rittal Software Systems touted at a high level the benefits of smart production in the context of efficient processes that can be adapted to individual customer needs.

“ Innovation that goes beyond products and solutions is needed,” said Asch. “We need to understand the various processes surrounding our customers’ v alue chains, consider new ecosystems and develop overarching solutions.”

To understand the full impact of how hardware and software work to streamline complex engineering processes and integrate safety, “we have to look at the global ecosystem around manufacturers like Rittal,” said Roland Younk, president, Eplan Canada. “These manufacturers provide hardware—components that all must work together in any given automation and control system. Their daily business relies on the precision of the customer’s BOM (bill of materials). This BOM must be 100 per cent before manufacturing starts to insure a proper workflow.”

Younk explained that during the early days of engineering, customers must be aware of all technical details of all parts involved in the design.

“Eplan’s design and engineering software provides over 1.4 million par ts and provides access to more than 245 manufacturers via the data portal,”

said Younk. “Here, not only commercial data is handled for the BOM, but also technical data as well as 3D connection data is carried along. I said carried along because once the BOM is forwarded for the sourcing of the parts, the game continues. Manufacturing and operations still require more smart data. The software will be using the rest of the carried data to calculate the precise length of all wiring required. The fact that the length is now known means extra wire pre-fabrication machines can be used, such as the WT Terminal from Rittal.”

The software is what allows manufacturers to use initial data along the process chain. All users—including the engineer, designer, purchasing, mechanics, and electricians—have visibility on the initial data provided and continue adding value. “At Rittal and Eplan we like to call it the added value chain,” said Younk. “It means engineering,

sourcing, manufacturing, and operations are all served through data coming from the same and unique engineering software.”

Robust safety assessments

In today’s industrial environment, where safety is closely tied to precision and error-free performance, manufacturers are increasingly reliant on complementary areas of expertise.

Plants may link technology and data to process design and operational assets to derive insights from a single source of truth and drive improved performance through risk assessments and standard operating procedures based on the operating environment.

In some cases, a low-tech enclosure is all it takes to do the job. In others, future-proofing will require secure and protected equipment and controls through edge solutions. Either way, developing integrated safety training programs can save an arm and a leg.

@MROmagazine Summer 2023 / MRO 15 Photot: Rittal North America, Inc. MRO_Davely_Summer23.indd 1 2023-05-23 2:52 PM

Example of an enclosure.

What is a hot bearing?

BY DOUG MARTIN

Recently, a customer said that their bearing was running hot, at about 80C. Although this seems high, it is not excessively hot. We discussed some of the conditions such as speed, lubricant type, and load, and bearing type. It was reported as a medium load, so calculations suggested that grease was not the best choice for a lubricant (based on the combination of bearing type, speed, and degree of load).

However, if the load was classed as low, it would have been acceptable with grease as a lubricant. The bearing is getting to the upper limit as to whether grease or oil should be used, and would be expected to run at the observed temperature. There is classification of operating temperature ranges when calculating a grease life/re-lubrication interval. That range is: low - 47 to 63 C, moderate - 63 to 78 C, high -78 to 93 C, and very high - 93 to 107C.

Grease operating temperature classifications

As a rule, there are three operating zones of a grease lubricant.These zones are: reliable performance,

unreliable performance (OK for short term), and too high a temperature for the grease. Typical lithium/mineral oil g reases (often refer red to as ‘EP2’) can provide predictable performance up to about 110C. Lithium complex greases, whether mineral or synthetic are in the 140C range as is polyurea/ mineral oil greases. For short periods, lithium complex, calcium complex, and polyurea g reases can operate for short periods up to about 240C, but in that range 140C to 240C, the grease performance is not predicable. Not all grease manufacturers publish data, they may only say that the grease is good to 240C (without the caveat that in these upper temperatures the performance of the grease may not be predicable (behave as expected)).

Of interest, SKF temperature classifications for greases are:

• “Low”Temp Grease as typically used for operating temperatures under 50C.

• “Medium” temperature greases are typically used for operating temperatures 50C to 100C.

• “High” Temperatures Grease is used for Temperatures over 100C and under 210C.

Changes in temperature?

There are cases where an 80C operating temperature may not be acceptable. Such as when the operating temperature is normally at 30C and then you find it at 80C. Or the last assembly ran at 30C and after an overhaul or repair, it is now operating at 80C.

Factors that can contribute to high bearing temperatures include excessive load, inadequate lubrication, and improper installation. Monitoring the bearing temperature regularly and ensuring proper maintenance can help prevent overheating and extend the life of the bearing.

Bearing temperature

There are several steps that can be taken to reduce the temperature of a bearing.

Proper lubrication: Ensuring that the bearing is adequately lubricated with the correct type and amount of lubricant is critical to reduce friction and heat buildup.

Proper installation: Ensure that the bearing is properly fitted to the shaft and housing and that the bearing seats are concentric. Ensure that machine components are in alignment (i.e., coupling).

Monitor ing load: Excessive loads can cause bearings to overheat, so be aware of how process changes affect the bearing operating conditions.

Heat sinks: Heat sinks can be installed to draw heat away from the bearing and dissipate it into the surrounding environment. An example of a heat sink is a heat flinger on a fan shaft assembly.

Using circulating oil lubrication: The use of oil circulation allows for the removal of heat by the lubricant as it flows through the bearing. A cooling radiator could be used or simply the volume of oil in the reservoir may be sufficient for temperature control.

High temperature bearing What are the temperature limiting factors with standard industrial bearings? The lubricant used; seal material (if the bearing is sealed) is typically Nitrile which is limited to 100C; cage material, metallic cages (brass and steel) do not limit bearing operating temperatures, however, polyamide, phenolic and PEEK cages do have temperature limits that are usually below the material limits of the bearing steel; and bearing steel - depending on the bearing size and type, the heat stabilization temperatures range from 120C to 200C.

Often, the question “can I get a high temperature bearing without every stating what that temperature is” is asked. Some believe that 80C to 120C are “high temperatures”, but standard industrial bearings can have operating temperatures up to 200C (given that you can find an appropriate lubricant), and are within the possible operating temperatures of normal industrial bearings.

There are high temperature bearings that are typically made from materials which can withstand the elevated temperatures, such as high-temperature steel, ceramic, or special polymers. These bearings can operate at temperatures of 250C to 350C. They incorporate specialized lubrication systems and seals that can operate at high temperatures without breaking down or degrading; however, the ability to run at high temperatures comes at a cost, they are limited in their speed ability.

For industrial bearings, the limiting temperature is based on the lubricant used and/ or the sealing system than the bearing itself.

16 MRO / Summer 2023 MROMAGAZINE.COM

Photo: Petrovich9/Getty Images Plus/Getty Images

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him at mro.whats.up. doug@gmail.com.

WHAT’S UP DOUG FEATURE

Contractor safety systems

refresher course to maintain a valid certificate. Are companies hiring contractors reviewing the training records of the people coming to their site to work?

• Are the safety courses generic or are they specific to the work site? When a contractor comes on-site are they educated about the specific hazards they may face while performing their work? Most companies hiring a contractor provide the workers with a safety or ientation program that covers worksite hazards. Depending on the job the contractor will perform, they may need specific training on job procedures and safety risks in and around the equipment or structure where the work will take place.

Risk identification system

BY PETER PHILLIPS

Association of Workers’ Compensation Boards of Canada (AWCBC) reports an average of 945 workers have died each year from work-related reasons since 2009. In Nova Scotia, there were 24 deaths in 2022, 20 in 2021 and 32 in 2020. These AWCBC statistics do not single out contractor fatalities. While statistics about contractor safety aren’t readily available in Canada, experts say as a group, contractors are disproportionately likely to be hurt or killed on the job

Companies are seeking to improve safety records after a high-profile string of workplace deaths in Canada. Contractor work force safety is one of the biggest challenges for companies when it comes to workplace safety. Although a separation between contractor and company employee death and serious injury is not easily available, companies that have contractors working at their facility are just as responsible for their safety as the

contractor employer.

Safety on the job site is a joint responsibility of both the facility owner and the contractor. Some provincial legislation dictate that the facility owner is responsible for the contractor employee’s safety while they are working on their worksite, and when injury claims go through litigation, the role of who is responsible for workplace safety generally resides with the group or person in most control of the work environment. This responsibility often lies with the facility ownership.

According to safety publications there has been a significant increase in contractor f atalities and serious injury in recent years. The question is why is this happening and what can be done about it? Incident investigation, as it searches for the root causes of a death or injury, must look at the systems in place or not in place that failed and caused the incident to take place. An important statistic shows that 80

to 90 per cent of serious injuries and deaths are caused by human error. We think of human error as what the person did to cause the incident, and if they hadn’t done the unsafe act the incident would not have occurred. Human error; however, should also include other systems within an organization that may have failed to protect the worker and caused the incident. Remember that contractor and facility systems are developed, implemented, and enforced by people, thus the human error link. There are multiple systems that play an important part in workplace safety.

Employee training system

Safety training is one of the first things given to any employee. When it comes to safety training there is more to it than one and done. Questions about training should include:

• Is the employee training up-todate, many safety certification courses have an expiry date, and the person must take a

Risks and hazards that are present or could become present as the work is performed need to be identified before the work commences. A risk/hazard analysis should always be done regardless of the size of the job. The analysis may take a few minutes or several hours depending on the complexity of the tasks. Contractors need to be fully informed and educated on the hazards they may encounter and how to mitigate them and work safely.

PPE system

Although employee training and a risk analysis will identify the PPE that well be needed, the condition of the PPE is a critical component and often overlooked. PPE needs to have an inspection program in place where safety equipment is inspected by a trained person to ensure the equipment is in good repair. Workers need to be trained to know when to take a piece of PPE out of service and when they do not comply with the safety standards.

Facility maintenance system

A poorly maintained facility or equipment can contribute to contractor injuries. A contract employee would not necessarily know how a company maintains their facility and equipment.

18 MRO / Summer 2023 MROMAGAZINE.COM

FEATURE MAINTENANCE 101

Photo: © whyframeshot / Adobe Stock

Every year families in Canada are changed by workplace tragedy. Worker fatalities and serious injury, both contractor and company employees, remain high even with though focus on safety is viewed as the most important program for any company.

Deficiencies in the building and asset maintenance system can cause injury and fatalities due to unexpected safety hazards encountered by the contractor. For example, does the owner of the facility have a robust lock and tag program and are lock and tag procedures tested on a regular basis. A faulty lockout procedure can cause contractors to inadvertently work on equipment that does not have zero state energy.

Due diligence system

Workers need to be supervised and given support to work safely. Supervisors often have many other duties and as a result their time is stretched very thin. They often do not supervise contractor adequately. There are many instances where workers have worked outside of safety perimeters to get a job completed. Had proper super vision been in place many of these incidents would not have occurred. If an incident does

occur, one of the many things an investigation team will review is the supervision given to the people involved in the incident. Companies and supervisors must prove their due diligence to authorities.

Safety support system

Contractor companies, depending on the number of employees, will have their own safety coordinator. They manage the safety prog rams of their company. It should not be solely a desk job, but should take on a hands-on approach, and visit the job sites where their people are working. They should evaluate the work being performed and that their employees are following all safety rules. The safety coordinators’ presence on the work site, while the work is in progress, will show their commitment and support of their safety programs.

Companies that hire contractors will want the training certifications of people that will be on their site. The same should apply

for the contractors asking about the company’s safety systems like the lock and tag program.The goal is to understand the environment their employees are stepping into and if that workplace has good safety systems in place.

Communication and reporting system

It is also important that company employees are aware of the contractor s on-site, where they are working, and the nature of the work they are performing.

A best practice is to have a contractor work location board. This is a simple drawing of the facility with magnetic markers that show the contractor’s work location.

Communicating with all employees and contractors is important. Sometimes, work overlaps between company and contractor employees and it’s important everyone knows what’s going on. At the end of the job, it is also imperative the job is inspected to ensure all the safeties are back

in place, and equipment is commissioned and working properly before it goes back into ser vice.

Many companies use checklists that are reviewed by company officials and the contractor to make sure the work has been completed and it is safe to release the equipment into operation.

Contract employees need to have a procedure to follow to report safety issues, and they need feedback on previously submitted safety concerns. They need to know the steps to take when an incident occurs whether it’s a near miss or injury.They need to know who to contact and who to call in case of an emergency.

@MROmagazine Summer 2023 / MRO 19 MRO_TROSolutions_Summer23.indd 1 2023-05-26 11:22 AM MRO_Fluke_Summer23.indd 1 2023-05-26 8:46 AM

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or peter@trailwalk.ca.

Everyone wins with good training

Inaugural Machinery Alignment Specialist certified training program took place at the CMVA Technical

conference.

BY JOHN LAMBERT

The Machinery Alignment Specialist Level One certified training program was limited to 10 participants, with two instructors at the Canadian Machiner y Vibration Association (CMVA) Technical conference. The group included millwrights, engineers, vibration analysts, technicians, and maintenance supervision. Participants came from manufacturing, power generation, natural resources plants and some even owned their own businesses that provide condition monitoring and machine installation.

Machinery Alignment SpecialistLevel One

Emphasis at this level was on alignment and pre-alignment principles, what we measure and why. Understanding tolerances and what makes them change, making sure we know the consequences of not following the standard given is the key is to understand the terminology. The core of the training is understanding that machine installation is a process, and shaft alignment is one element of that process. Four stages of the process are: preparation – to quote a common saying “failing to plan is planning to fail;” inspection – what do we have and can we work with it; measurement/analysis – it’s a process, we measure in a sequence

and analyze as we go; correction – if we get the sequence wrong, the correction is wrong.

The critical element is finding and removing machine stress.

Machinery Alignment SpecialistLevel Two

This level includes all you see in level one. However, the focus is on shaft alignment of coupled, un-coupled and non-rotating fixed shafts using different methods of measurement tools. Mathematical calculations are used, and graphical modeling to help troubleshoot and overcome issues such as being bolt bound and base bound. This is done using the results from laser/detectors and dial work. Dynamic stress (thermal growth) including calculations and targets is used for training purposes.

The level one that was conducted at the CMVA conference had a hands-on component to it. The participants all did laser/ detector alignment and rim and face dial indicator alignment.

Rim and face are still the most recommended method from the coupling manufacturers. Usually, a straightedge is being used to take a rim reading, which is an offset value, and a caliper or feeler gauge taking a face reading, which is an angular value. However, the

ANSI standard says quantifiable tools (dial indicators or laser/detector systems) be used to do shaft/coupling alignment. Straightedges, calipers, and feeler gauges are not quantifiable tools, they are subject to human interpretation.

In the Benchmark PDM program, we measure the same thing by using correct tools. Coupling manufacturers do not promote the concept of precision alignment. Using straightedges, calipers, and feeler gauges is a trial-and-error method, and although it is not required for level one, a simple mathematical calculation is added to demonstrate that it does not have to be a hit or miss process. Shaft misalignment is one of the major contributors to machine casing stress, leading to premature machine failure.

Changing the paradigm

All machines are manufactured and machined to exacting geometric dimensioning and tolerancing standards. The foot pads will be machined flat, and if this is a split casing pump, the flat plane of the foot pads will be parallel to the split in the casing. The two pump flanges will also be parallel. There are six bores in a standard split casing pump. That’s two wearing ring bores, two stuffing box or mechanical seal bores and two bearing bores or journals. All these bores are machined so that they are concentric with each other. Flatness, concentricity, perpendicular and parallel are important measurements that are taken when a machine is made.

A machinery alignment specialist knows they must maintain these tolerances for that reason. Machine casing stress is the result of an applied force, which is the result of shaft misalignment, distorted bases, or foot pads, from pipe strain or soft foot.

For example, a large split casing pump, it looks very robust and can support piping; however, they are not designed to support piping. If you pull out the shaft and impeller, it is strong, but it is a hollow casing. A base is recommended to be at least four times the weight of the pump, but here, it is double.

Remember these are not large amounts of movement. A typical ball bearing will have 0.003 thou of clearance for lubrication. If you pull on a casing and change the ovality of the bore by 0.0015 thou. You have halved the lubrication of that bearing, which may be the difference between getting two years of life expectancy or 10. We must look at these machines for what they are, precision-made machines that must be installed so they maintain their geometric dimensions and tolerancing, and for this you need to install using precision.

20 MRO / Summer 2023 MROMAGAZINE.COM

Photo Credit: Colette Keith, CMVA

FEATURE TRAINING

John Lambert is the President of Benchmark PDM. He can be reached at john@benchmarkpdm.com.

Reliable. Innovative. Trusted.

Empowering facilities management teams with powerful maintenance management

For more than 30 years TMA Systems has provided configurable software solutions that help facility executives deliver value by reducing downtime, increasing maintenance productivity, improving equipment reliability, and saving money.

solutions. Schedule a demo to learn more about how TMA Systems can transform your maintenance operations. Contact us today!

sales@tmasystems.com tmasystems.com

Oil Filters, types, ratings, and applications

graphite, and the particle sizes are in the size range which may prevent them from moving through the filter.

Lubrication related failures dramatically increase downtime, cause unnecessary high operating costs, and reduce overall equipment life. Oil contamination in recirculating systems like turbines and hydraulics contributes to 70 per cent of lubrication related failures. Unresolved friction and wear problems cost Canadian industry over six billion dollars annually.

Q | Does the maintenance group understand how contaminants enter a lubricated system?

LOGIC: contamination of lubricated systems occurs in four ways, generated by the system itself (by normal wear, poor system or component design, surface fatigue and temperature related chemical reactions), implanted (by welding slag), induced (by careless maintenance practises), and escaped contamination (that enters a lubricated system through poor quality filters or poor filtration system design).

Q | Is the maintenance group familiar with oil filter types and their standards

of quality as they apply to the equipment they maintain?

LOGIC: there are two basic types of oil filter elements. Surface elements in which the oil passes through one layer of filter media constructed of pleated paper or fibreglass with a specific pore size that determines the micron size rating, usually a range of 10 to 40 micrometres. Surface type filters are mounted in full flow applications, where all the lubricant in the circuit passes through the filter, but not necessarily through the media if the pressure regulating valve opens during cold start-ups or pressure surges.

The second filter type is depth filters whose elements are constructed of one of two groups of materials. One group of materials is referred to as absorbent and these consist of inactive materials such as cotton waste, waste or wound paper, cloth, and wood pulp. These filters depend upon the absorption of contaminants as the oil flows through the media in tortuous paths. Depth type absorbent filters will not remove oil additives unless the additive is a solid lubricant, such a

Another group of materials used in depth type filters are referred to as adsorbent and consist of chemically active materials such as Fullers earth, active clays, charcoal, or chemically treated paper.These filters remove contaminants through a chemical reaction with the lubricant, and as a result, may remove some oil additives.

Q | Does the maintenance group understand when and where depth type filters should be considered?

LOGIC: depth type filters should be considered for use when oil must be kept extremely clean, and the full flow surface filter may not satisfy this need. Depth type absorbent filters are often installed in parallel to the surface filter, referred to as a side stream system and will remove contamination in the one to 10 micrometre range. They are particularly effective in hydraulic systems and turbines using control valves susceptible to valve sticking and binding due to contaminants in the three to five micrometre size. These combined circuits permit approximately 10 to 15 per cent of the system’s oil to flow through the depth filter.

Poorly constructed absorbent depth filters are susceptible to channelling, a condition

22 MRO / Summer 2023 MROMAGAZINE.COM

Photo: surasak petchang/Getty Images Plus/Getty Images

Effective lubricant filtration is one of the misunderstood and misapplied of maintenance practices.

BY L. (TEX) LEUGNER

FEATURE MRO QUIZ

whereby the oil flow through the media creates a path of least resistance. Once channelling occurs, effective depth filtration ceases. The best depth type absorbent filters contain finely wound paper and are particularly effective in removing contaminants including water. Some equipment manuf acturers provide secondary side stream filtration circuits using depth type filters as original equipment.

Q | Does the maintenance group understand oil filter cleanliness ratings?

LOGIC: to understand the size relationship of a contamination particle of one micrometre, visualize a forty (40) micron particle. It is the largest particle that can be seen with the naked eye and is 0.0016 of an inch in size. A one micrometre particle on the other hand, is one millionth of a metre or approximately 0.0000394 of an inch in size.

Nominal filter ratings refer to a filter that will remove 96 per cent by weight of contamination of a specified size.Tests have shown that particles as large as 200 micrometres can pass through a nominally rated 10 micrometre filter. An absolute rating indicates the size above which no par ticles of any size will pass. It does not specify the size of the smallest opening in the media, so that a filter rated at 10 micrometres absolute will do little to reduce silt particles measuring less than 10 micrometres. These filters will be ineffective every time the pressure regulating valve opens (regardless of their absolute rating) when they are used in full flow applications.

Q | Does the maintenance group understand the factors that affect oil filtration?

LOGIC: these factors include temperature changes, pressure drops resulting when the pressure regulating valve opens, and flow rate changes when cold starts and pressure surges occur. Any differential pressure across the element can cause deformation or separation of the filter media pleats, if the pleats are not properly designed and supported resulting in ineffective filtration.

Hydraulic systems are subjected to high pressure and compression of the oil occurs at the rate of about two per cent per 1000 PSI. If the oil volume in the connecting line is 100 cubic inches and the pressure is 1,000 PSI, the liquid compression can reach .005 X 100 or .5 cubic inch. When an operational valve is opened downstream under these pressures, the sudden increased flow rate can be dramatic. This shock flow can be several times pump output, when

large bore or long stroke cylinders operating at high pressure decompress quickly. When pressure line filters are located some distance from the pump outlet or mounted in the return line, these shock flows can cause filter media bunching or total collapse, particularly in poorly constructed filters. Pump pulsations and mechanical vibrations can dislodge fine abrasive particles from the filter media and contamination may re-enter the fluid stream.

L. (Tex) Leugner, author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

@MROmagazine Summer 2023 / MRO 23 30-34 Rue du Chemin Vert 75011 Paris +33 (0)1 85 56 97 00 www.carrenoir.com TONS RECOMMANDÉS TOTAL TOT_21_00008_TotalEnergies_Logo_CMYK JFB Date 26/05/2021 Choose Nevastane for food industry applications Offering improved performance for every food industry application, Nevastane products protect your equipment and extend its working life. totalenergies.ca EN_MRO Publication 5.1875x8.indd 1 2023-05-26 14:14:53 MRO_TotalEnergies_Summer23.indd 1 2023-05-29 8:58 AM

WHAT’S NEW IN PRODUCTS

ATLAS COPCO E-PUMP

Atlas Copco range of electric self-priming dewatering pumps, E-Pumps, manage demanding flows and large solids.

E-Pump range offers PAC High Head and High Flow models. The E-Pumps help reduce energy consumption and noise generation under normal operating conditions.

A patented hinge door allows access to the pump internals; and the electric motor does not need oil changes or shutdowns for engine services. www.atlascopco.com/e-pump

ABB STAINLESS STEEL MOTORS

ABB Baldor-Reliance Food Safe motors has made enhancements in performance and protection to its Food Safe stainless steel motor line. Baldor-Reliance Food Safe motors exceed IP69 ingress protection ratings for washdown conditions. It covers single to three-phase ratings, with TEFC or TENV enclosures, in foot-mounted and footless configurations. Features are: bearing protection ring; 360-degree rotatable conduit box; plugged drain holes; all stainless-steel construction, IP69 laser marked nameplate; hardened epoxy resin encapsulation; two-barrier mechanical shaft seals; and high-temperature Class H insulation with low-temperature (Class B) rise.

www.abb.com

EXOR WIRELESS HMI: X5

Exor X5 wireless HMI features a durable design, with a five-inch colour display and a user-friendly interface. It utilizes wireless technology, includes a built-in Webserver, enabling remote access and monitoring from any web-enabled device. Features include real-time data acquisition and visualization, customizable alarms and notifications, advanced reporting and data analysis tools, compatibility with a wide range of industrial protocols, Bottom of Form Linux-based open platform, system settings by web browser, two Ethernet ports for network separation WAN/LAN, dual-band Wi-Fi for safety communication to handheld devices, ready for Corvina Cloud secure remote connectivity, and supports JMobile protocols including OPC UA server and client.

www.electromate.com

EMERSON ALUMINUM FILTER REGULATORS

Emerson ASCO Series 641, 642 and 643 aluminum filter regulators can handle the high flow rates of any regulators in their class and provides pressure regulation to downstream instruments. Highest flow rate capabilities of up to 10,500 liters per minute. Higher flow rates provide more air to the valve actuator, which increases the opening and closing speed of process valves. Specialized powder coating ensures operation in harsh, corrosive process environments. This three-tiered regulator line provides quarter inch to one-inch coverage and is customizable. Features such as quick relief, which enhances safety and operational certainty by exhausting downstream pressure if supply air pressure is lost, and low-temperature and low-copper variants, manual and automatic draining, global certifications.

www.emerson.com

CYLINDRICAL PLOW BLENDER

Munson Machinery Company, Inc. Cylindrical Plow Blender with feed hopper and intensifiers handles dry, fibrous, dense, interlocking, or moist/oily bulk materials in batches up to 1.13 m3.

A high-strength agitator shaft with radial arms rotates wedge blades at high speed within tight tolerance of a heavy-gauge vessel. Two independently powered, high speed tulip-shaped intensifiers produce any shear necessary to assist with dispersion.

The unit achieves batch uniformity in ratios to one part per thousand. It is constructed of #304 or #316 stainless steel and finished to sanitary standards.

It is equipped as standard with dual access doors on the side, a bottom discharge port, and air purge packing shaft seals. Optional are heating or cooling jackets, injection ports for liquid additions and various discharge and inlet configurations.

www.munsonmachinery.com

KBC TOOLS AND MACHINERY RELIABLE UBERLIGHT

KBC Tools & Machinery Reliable Uberlight lights up work area with up to 600 lumens, nine settings, (2700k, 4000k, 5000k, with three colour settings: warm white, natural white, or ultra-bright).

Reliable Uberlight comes in black or white with three styles: with a clamp mount, with a 7.75” base, or a direct table mount, (black only). It has a 26.5” silicone gooseneck and 270-degree rotational head.

The 4.75” LED panel does not create glare or flickering and provides up to 60,000 hours of use. All are provided with a six-foot USB cord and adapter.

www.kbctools.com

24 MRO / Summer 2023 MROMAGAZINE.COM

SafeTBrake’s control package includes a manual on/off switch with permissive start and stop logic. The logic is set so that the brake will not engage if the motor is energized, and the motor cannot be energized if the calipers on the brake are engaged or locked. processbarron.com

New motors come with a TEFC or TENV IP55 enclosure and offer speeds of 1,200, 1,800, or 3,600 RPM (depending on model). Brake motors come with a spring set, solenoid actuated AC brake with a manual brake release lever. All new WEG rolled steel motors come with an 18-month warranty.

www.automationdirect.com/ac-motor

MILLER ADDS FILTAIR 215 SYSTEM

Miller Electric Mfg. LLC, fume extraction solution, FILTAIR 215 fume extraction system provides an industrial, high-vacuum fume extraction unit that can handle multiple fume guns. The system features a self-cleaning filter mechanism and an optional auto start/stop function that extends filter life and minimizes maintenance-related downtime.

FILTAIR 215 system maximizes flow capacity for multiple operators to use extraction attachments, such as nozzles and fume guns, for multi-weld fume capture at the source. The system was designed for durability and convenience, with storage handles that allow operators to store a dual wire feeder and fume extraction guns/hoses. www.millerwelds.com

SEALMASTER STAINLESS STEEL GOLD BEARINGS

Regal Rexnord Corporation Sealmaster stainless steel (SS) gold bearings feature a triple lip contact seal with an integrated flinger for multi-directional sealing.

FKM seal lip material is chemical resistant and capable of withstanding high temperatures.

Sealmaster SS Gold bearings are IP69K certified. The bearing housings are constructed from 316 passivated stainless steel. The 440C stainless steel inner and outer rings provide great load capacity and corrosion resistance. www.regalrexnord.com/SS-Gold

PROCESSBARRON SAFETBRAKE FOR FAN SYSTEMS

ProcessBarron Canada SafeTBrake, a rotor-locking device provides an integrated lock on a fan.

SafeTBrake is a fully-assembled system consisting of dual air-applied calipers, air-ventilated discs, and a positive holding and lock. The brake system stops the rotor in under a minute. A pinning feature allows for physical lockout at fan.

WEG ROLLED STEEL MOTORS

WEG brand motors add several general-purpose one- and three-phase motors from ¼ to three horsepower; certain high-performance inverter duty motors from ½ to one hp; motors certified for hazardous locations (Class I, Div 2, Groups A,B,C,D) up to three hp; and three-phase brake motors from ¼ to two hp.

EXPANDED RANGE OF SHORT RIGID COUPLINGS

Ruland expands range of short rigid couplings to include keyways and step bore sizes. Short rigid couplings are available in steel, stainless steel, and aluminum. Ruland manufactures short rigid couplings in one- and two-piece clamping styles. Available in straight or step bore combinations, with or without keyways, in bore sizes ranging from 1/8 inch to two inches or six millimetres to 25 mm.

www.ruland.com

@MROmagazine She ran 147K straight. Without a single break. For more information visit us at: sewcan.ca MRO_EuroDrive_Summer23.indd 1 2023-05-16 5:37 PM

MRO Pro Tip 1 Clean to Inspect

BY RICHARD KUNST

Many years ago, while being trained on the Toyota Production System, I was dispatched to a local CNC machine shop to observe methodologies in action.

I walked into a pristine factory where there was no debris, metal chips, dust, clutter, or oil mist, everything was clean. All the machines looked brand new, like they had never been used. Sitting on top of one of the machines was a team member cleaning. Pretty profound I thought, these folks in general were much shorter than the height of the machines, therefore I asked the plant manager What? and Why?

His response has stayed with me since that day.

“We clean to inspect – the touch of the human hand while cleaning is the world’s most sensitive instrument and is the best detector of abnormalities that can be immediately corrected while you are cleaning.”

He explain that although he appreciated having a clean shop, that was only the by-product of making sure team members with their hands touched every square inch of surface on the machine once per week, as they cleaned while inspecting.

Indeed, as you support your 5S program (sort, set in order, sanitize, standardize, sustain) and you get to “sanitize”, change your paradigm to invoke a “clean to inspect” mentality.

Your machines will look much better, your environment will look more professional, and it will improve the moral of your employees. Finally, should something break, your mechanics will appreciate working on a clean machine rather than digger through reams of grease and dirt to find the problem.

Combine the mantra of “If you have time to lean you have time to clean” to now include clean to inspect.

WITH

MRO Pro Tip 2

Preparing for Industrial 4.0

BY STAN SHANTZ