Around for more than 40 years, Insulating Concrete Forms (ICFs) represent a simple solution to achieve many government- and industry-led climate or environmental goals. Among their benefits are air tightness, labour savings, energy efficiency, resiliency, low carbon intensity, and more.

Most ICF systems can be described as two sections of expanded polystyrene insulation connected by a series of plastic ties. These may arrive on a jobsite in block form, or they may be assembled on site. Blocks have interlocking joints on their edges to connect them together to form the structure. Steel rebar is placed horizontally on the webs and then concrete is cast in the form to create a structural wall.

The plastic webs are embedded in the expanded polystyrene insulation and create flanges that the contractor can use to attach exterior and interior finishes. Many ICF companies have specially designed forms for brick ledges and corners.

The initial introduction of ICF focussed mainly on residential basements. This was due, in part, to engineering restrictions imposed by building codes. Gradually, the market moved to above-grade residential and commercial construction. As concrete pumping has allowed the ICF universe to expand, today’s ICF industry also serves high-rise buildings, schools, commercial buildings and retirement homes.

In the Kitchener-Waterloo region of Ontario, more than 80 eight-storey

buildings have been constructed over the past 20 years. The main driver for many of these builds was time. For example, the use of ICF allowed student housing to be constructed and occupied before the next school year. This advantage allowed the owners considerate improvement in obtaining fully occupied residences in a short amount of time.

Another driver is winter construction. Once the ICF shell is constructed, winter heating is often not necessary as the insulated thermal mass often provides sufficient heat to continue the indoor work to complete the building.

The latest edition of the National Building Code (NBC) 2020 has recognized the national standard for ICFs: “ULC

The use of insulating concrete forms has evolved to address many of today’s construction challenges.

S717.1 Standard for Flat Wall Insulating Concrete Form (ICF) Units - Material Properties.” Other relatively recent changes to the NBC allow for interior and exterior attachment to the plastic webs. Tables have been created to outline the type of fasteners and under which wind and seismic conditions they can be used.

Another significant change is that under Part 9, ICF builds will be allowed up to two storeys without additional engineering. Also revised over the past little while is the allowance for the use of 10M rebar rather than 15M, which is lighter and more manageable to use on site.

To support these changes, the Insulating Concrete Form Manufacturers Association (ICFMA) has created a free document, available on its website, that explains the prescriptive designs for residential buildings, and is stamped for all the provinces. All commercial and industrial ICFs must still be designed to Part 4 of the NBC. These requirements are dictated by the “CAN/CSA A23.3 Design of Concrete Structures.”

Reinforced concrete is one of the strongest structural systems for walls, its used in wall that spans vertically between lateral supports allows for a thinner design. Depending on the project design requirements, some multi-storey buildings up to five storeys have been constructed with a 6” (150 mm) concrete core ICF. Other projects, such as box big stores with walls up to 32-foot (9.75 m) in height have been constructed using an 8” (200 mm) ICF. These ICF walls have load bearing capacities that can support any type of floor or roof system.

For large, multi-storey buildings, ICF walls may be designed as shear walls, elevator shafts and interior load-bearing walls. There is a simplicity with the design and installation of an ICF wall system - the insulating form, the reinforcement, and the concrete working together as one in the structural building envelope. Designs can exceed 20 storeys and beyond.

Concrete contractors should treat ICF construction as typical concrete wall

construction for both commercial and resi dential applications. Vibration, in order to achieve consolidation, is a requirement.

Curing is achieved by the nature of the insulating properties of the ICF form. In cold weather the only concern is the exposed top of the pour, which can be protected by thermal blankets or speciality products recommended by the manufacturer. Since the concrete is never exposed to the weather, it retains a higher moisture content. This slow cure results in a high early strength and longevity. By not being exposed to the weather and having the concrete insulated, the requirement for expansion or control joints is eliminated on most walls.

The responsibility for the concrete mix design should remain with the ready-mix producer. Most producers have a concrete mix design for ICF walls, but they may have to be adjusted due to weather or site conditions. This should always be done in conjunction with your producer.

Concrete specifications for ICFs have two main requirements that are important to the placement and flow of concrete within the forms. The recommended concrete slump for commercial work should be a minimum of 5” to 6” (102 mm to 152 mm), subject to climate and engineering design. This higher slump allows the concrete to flow easily within the forms and prevents damage to the cross-ties during placement. Slump verification by testing upon delivery is recommended. In some instances, higher concentrations of reinforcement may dictate higher slump than this minimum.

Furthermore, a smaller aggregate size is recommended to alleviate congestion in the walls between the reinforcement bars

COURTESY OF ICFMAand the inside face of the ICF. A smaller aggregate also improves the flow rate within the forms. The recommended aggregate size for a 6” (150 mm) ICF core size is either 3/8” to 1/2” (9.5 to 12.5 mm).

For larger ICF forms with 8” (200 mm) and higher core sizes, 1/2” to 3/4” (12.5 to 19 mm) aggregate may be used.

Concrete placement is typically done from a pump truck or line pump with the placement rate controlled and regulated by multiple lift heights, minimizing the hydrostatic pressure within the forms. All ICF wall applications are required to be consolidated by an internal vibrator. Typically, concrete is placed and consolidated in the ICF walls from floor level to floor level as a continuous pour in four-foot (1,220 mm) lifts.

In today’s world, low-carbon concrete and embodied energy have become a major part of design criteria, and ICFs can augment the industry’s efforts toward producing high-performing buildings.

Concrete mix designs have improved the reduction in carbon production by making use of supplemental cement materials such as fly ash and slag – waste materials that provide additional qualities to the long-term performance of the concrete. Chemical admixtures such as water reducers and strengtheners may reduce the need for additional cement, which also lowers the carbon footprint of a project. And cement producers are making use of PLC cements, which lower the carbon footprint of the end product.

ICFs take these performance characteristics and add an airtight building envelope, with higher insulation values and thermal mass performance to create a solid base for the construction of Net Zero buildings going forward. And the sector is not standing still. Exciting developments exist, such as the introduction of fibreglass reinforced rebar and polypropylene fibres as replacement for rebar.

Ross Monsour is the director of ICFMA. For additional information on ICF technology, visit www.icf-ma.org.

Functionality is the main requirement for concrete flooring in industrial and commercial environments. In addition to a very high aesthetic quality, MAPEI products provide excellent flatness and dimensional stability, partially or completely eliminating the need for traditional metal reinforcement and contraction joints.

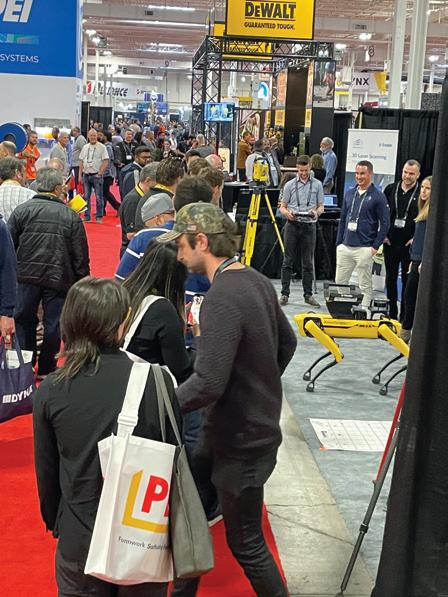

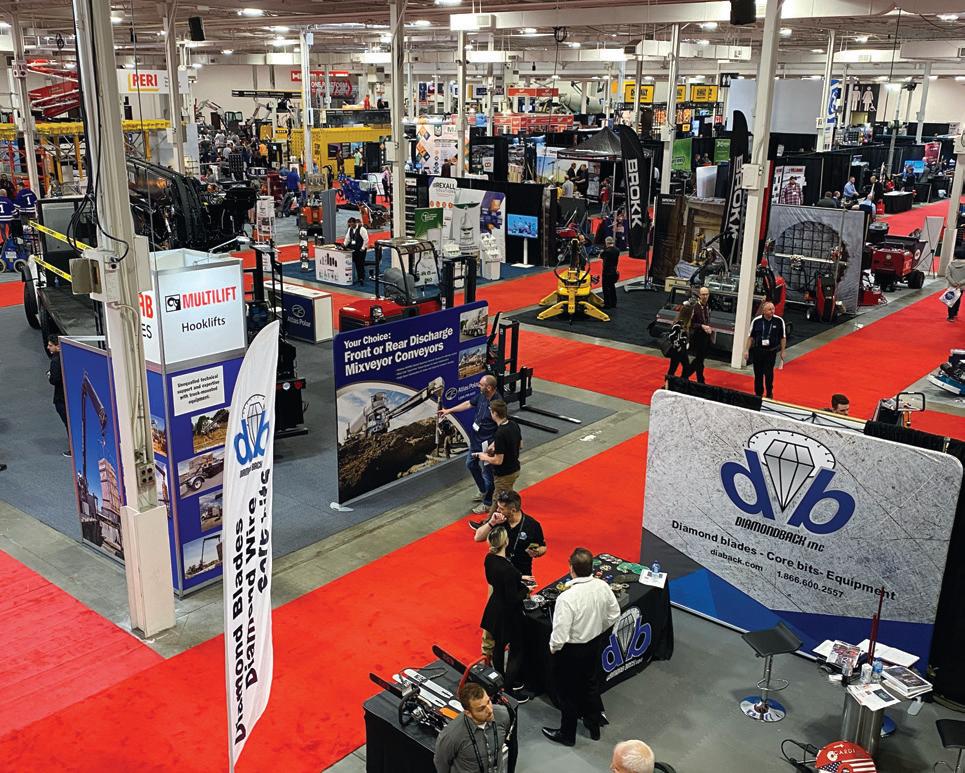

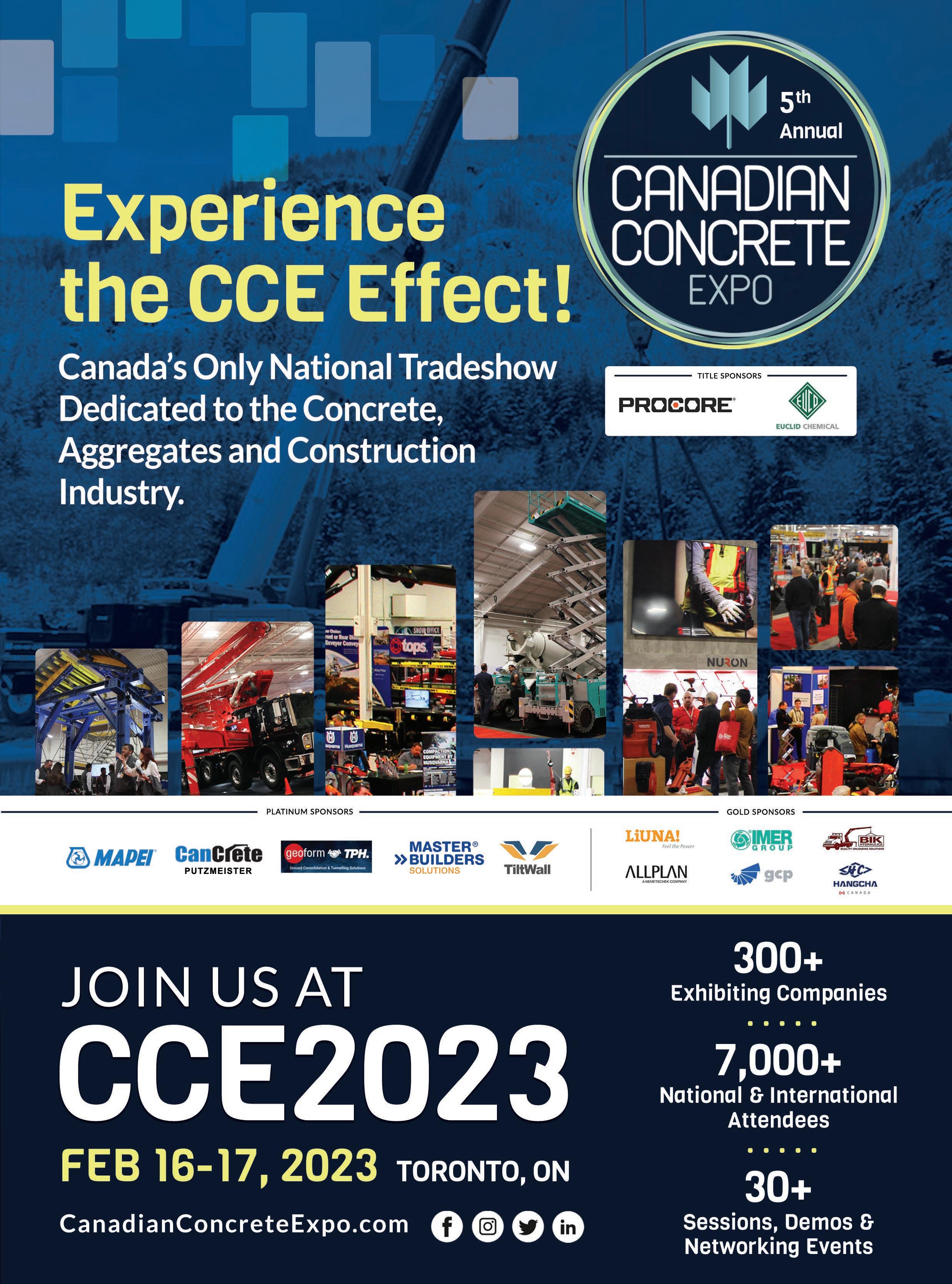

The Canadian Concrete Expo (CCE), Canada’s national trade show for the concrete con struction industry, returns to the International Centre in Mississauga, Ont., this February 16 and 17. More than 7,000 people are expected to attend this fifth edition of this national event, where they will have the opportunity to connect with over 300 exhibitors and participate in the event’s 30-plus conference sessions, presentations and demonstrations.

New technology that’s likely to garner significant attention includes the printing of a full-scale 3-D concrete structure – the first to be printed live and indoors in North America – as Nidus3D will have its system in full operation on both days of the show. And don’t forget to stick around after the close of Day 1, as CCE will host a networking event for all exhibitors and attendees featuring food, entertainment and special guests Georges St. Pierre and P.J. Stock.

Stuart Galloway, president of the Canadian Concrete Expo, describes the event as an ideal environment to connect with suppliers, as well as source new suppliers, find business solutions and build partnerships.

“Nearly 4,000 industry professionals attended CCE 2022 despite being in the height of the construction season and weather that was ideal for construction crews and pouring concrete. Business and sales on the show floor were brisk,” he stated. “After three years, we are pleased to have CCE back into its February time slot and are looking forward to providing the best industry event in Canada for the

construction industry. The trade show floor at CCE 2023 will be the largest to date.”

The 2023 show is set to take place at the International Centre, 6900 Airport Rd. in Mississauga, Ont. Show hours are 9 a.m. to 5 p.m. on Thursday, February 16, and 9 a.m. to 3 p.m. on Friday, February 17.

Pre-registration is now open, and anyone registering prior to February 15 will qualify to save half off the door admission prices. For more information about the show, or to register, visit www.canadianconcreteexpo.com.

concrete and masonry industries,” stated Kevin Archibald, senior show manager.

Work Truck LIVE! aims to highlight innovations in the design and configuration of work trucks, while showcasing some of the most innovative accessories designed to help contractors increase safety and productivity. It will also include a “Ride and Drive” experience with the opportunity to test drive select Class 1 through 7 vehicles.

The North Hall’s autoclaved aerated concrete area will examine all facets of the building material, from production technology through to typical applications of the product in the construction industry.

World of Concrete (WOC) is growing. Informa Markets’ exhibition for the concrete construction and masonry industries is adding features as it prepares for the 49th edition of the show, set for January 17 to 19 at the Las Vegas Convention Center (LVCC). In 2022, WOC drew close to 37,000 registered professionals.

For 2023, organizers are aiming for bigger and better. Along with more than 1,000 exhibitors, over 600,000 square feet of indoor and outdoor exhibit and event space, and its skills chal lenges and demos, organizers have announced the launch of “Work Truck LIVE!,” as well as a new area of the show that will focus on autoclaved aerated concrete. New forums have also been added.

“World of Concrete continues to be the annual inaugural exhibition for the materials, tools, and equipment focused on the

Starting one day earlier than the show floor opening, the education component of the event brings 164 technical, business and safety sessions to attendees of the World of Concrete Education Program. In addition to popular business and project management seminars, industry certifications and interactive workshops, the lineup will also highlight many new technical topics, including petrography, mass concrete, fibre reinforcing, reshoring, superflat floors, repair and restoration, and 3-D printing.

“The 2023 WOC Education Program has scheduled 164 sessions to address the current and anticipated needs of concrete and masonry industry professionals,” said Archibald. “Several technical classes specifically focus on mass concrete placement; pavement design, construction, preservation and repair; commercial/industrial project specifications; 3-D printing in concrete construction; use of high-performance materials; and environmental product declarations.”

Exhibit hall hours for the 2023 edition of WOC are 9:30 a.m. to 5 p.m. from January 17 to 19. For more information, or to register, visit www.worldofconcrete.com.

COURTESY OF WOC/INFORMA MARKETSwww.wirtgen-group.com

Concrete Solutions is a digitized product guide from Brafasco that focusses on key commercial concrete markets. The guide introduces the construction sectors, followed by a streamlined, to-the-point fundamental product listing of products used on all common jobsites. Businesses can realize a range of options likely not considered in the past when planning their next project.

Husqvarna Construction’s recently rebranded Blastrac and Diamatic surface preparation product range, which includes floor scrapers, shavers, scarifiers and floor grinders, is available in Canada and the United States. The company’s walk-behind concrete floor shaver and ride-on milling machines are well suited to jobs where enhanced depths in a controlled pattern are desired. Scarifiers in the lineup allow for the levelling of large surfaces and the removal of thick coatings. They are designed to quickly and cleanly remove concrete to help level slabs, expose large aggregate before concrete polishing, and for coatings removal in demolition applications.

The electric 536-E power cutter from ICS Diamond Tools offers professional-grade cutting capabilities using electric power. Designed to slice through concrete, stone, masonry and ductile iron, the 536-E uses a 4.8 hp motor to deliver industrial cutting capacity while eliminating the need to mix fuel and oil, or maneuver heavy hydraulic hoses. It runs on 220V, making it compatible with most generators.

MAPEI’s Mapecoat Deck T is a high-build, textured, slip-resistant, water-based acrylic deck coating designed for use on new and previously coated concrete. Featuring a light sanded texture and UV-resistance, the coating is suitable for slab-on-grade applications and can handle pedestrian and light vehicular traffic. The company’s custom colour-match capabilities allow for enhanced aesthetics over repairs and irregular substrates to restore the appearance of old and/or damaged concrete.

Designed for heavy-duty demolition, concrete, and masonry work, the Dewalt 60V Max 22 lb. cordless SDS Max Chip ping Hammer is designed to break down dense concrete with up to 19.4 Joules of impact energy. The hammer can be used to tackle horizontal and downward chipping in mid-to-lower wall and flooring tasks, and is also suited to demanding highway jobs. The company also offers a mid-weight 60V Max 15 lb. cordless SDS Max Chipping Hammer capable of delivering up to 10.5 Joules of impact energy. It can be used for horizon tal chipping in upper or lower walls and concrete surface preparation applications.

Takeuchi has added seven sound-suppressed hydraulic hammer models to its attachment program, allowing compact track loader and compact excavator owners to break up asphalt, concrete, rocks and other hard materials. Designed to providing noise and vibration insulation, the sound-suppressed design also protects the hammers from dust and debris. The company offers seven models in its lineup.