1 minute read

Colour Board

Product manufacturing

Fig 49: Washed resist-eco printed fabrics, Both the tannin and iron blankets

Advertisement

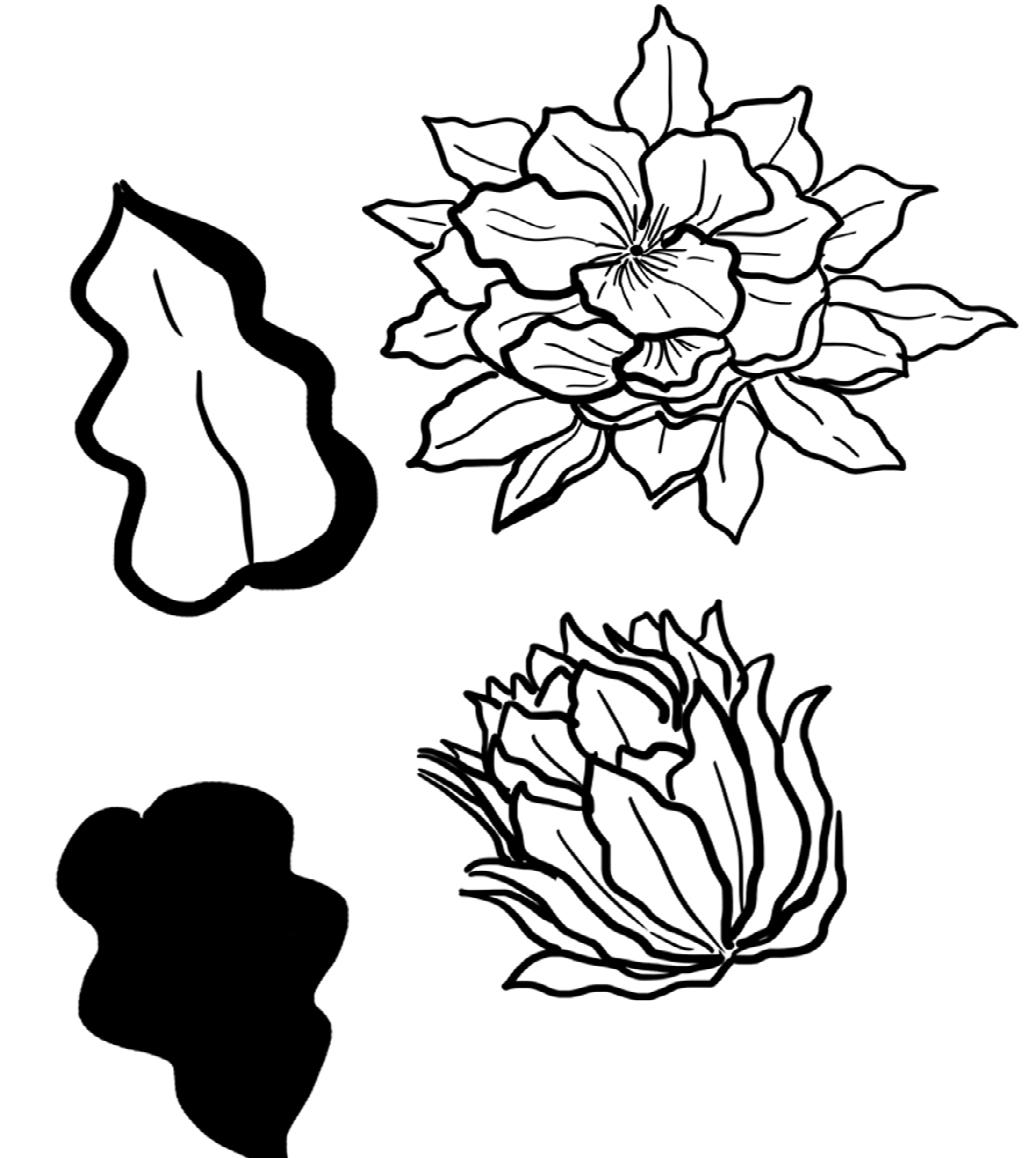

Once the fabric is printed, rinsed and washed. they are iorned for the next stage of production. If this includes addition surface work the fabric is first gievn to the artsist for fiishing and defining the forms. for emobroidery and aari work first the threads are selected and then given for processing, For the final product other than just simply printing the fabrics with leaves and flowers, to excentuate the prints and to give the forms some defenition, several finishing processes were done on them. This imcluded mostly embroidery,aari work, foil printing and other surface finishes.

Fig 50: 1 Thread selection, 2 Aari work, 3 Embroidering printed fabrics Fig 51: Marking and cutting the fabric The emroidered or finised fabric is later steam iorned and the pattern for the product is drawn over checking the placement of the prints. But for many of the peices the marking and cutting were already done before the printing process to make the fabeic handeling easier. The fabric is later if not cut then cut accoridng to the pattern, sewn and finsihed with seams and hems.

Fig 52: Stitching and finishing the products