3 minute read

mood board

Learning about mordants

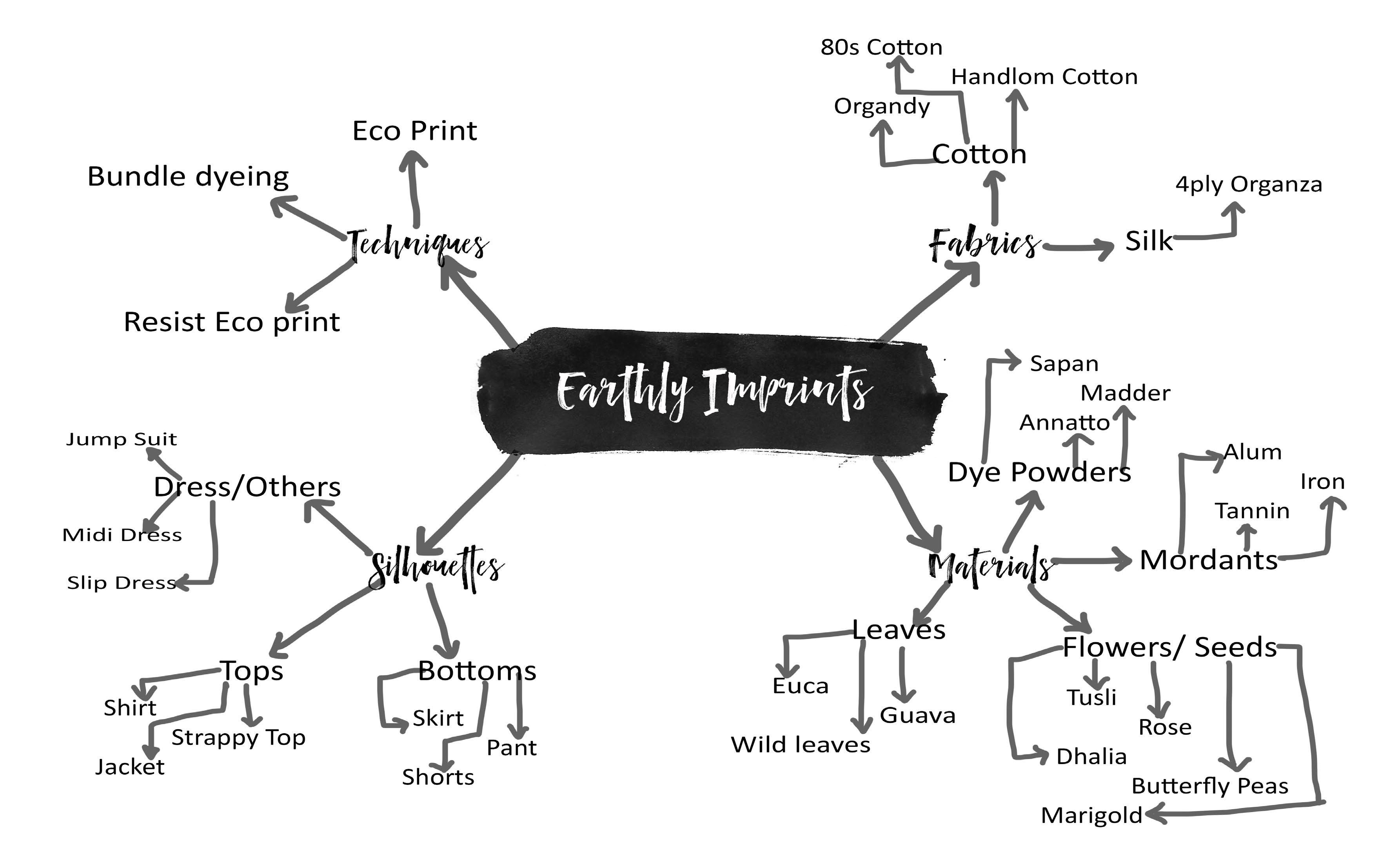

Some of the natural dyes can form metal-complexes with metal salts of iron, aluminium, copper, tin and chromium. Mordants can impart fastness properties and widen colour gamut depending on the type of the mordant. Dramatic colour changes are achieved by using the same natural dyestuff only by changing the mordant type. A wide range of colours with very different shades, darkness and fastness values can be obtained depending on the kind and concentration of natural dye and mordant and mordanting method. • Conventional Metallic mordants: Most mordanting agents are metallic salts of chromium, tin, iron, copper and aluminum. Copper and chromium containing compounds were widely used as mordants, but their usage has declined because of toxicity concerns. Likewise, iron and tin mordantscan affect the color and tactile qualities of the dyed textile. Aluminum mordanting agents are commonly used and considered among the safest in the application of natural dyes. • Oil mordants: These are mainly used in dyeing Turkey Red colour from madder. The main function of the oil mordant is to form a complex with alum used as the main mordant. • Bio mordants: These are tanin, tannic acid, tartaric acid and metal containing plants. Myrabolan, pomegranate rinds, tannin, tannic acid, tartaric acid, guava, banana leaves ash, valex, rosemary, and thuja are reported as bio and eco-friendly mordants providing satisfactory dyeing and fastness properties. Commonly used mordants include aluminum potassium sulfate, iron sulfate, copper sulfate, stannous chloride, and potassium dichromate Mordant and mordanting method choice directly affects colour shades and fastness properties obtained. It is not possible to present strict rules and instructions for mordanting method because results vary depending on plant and mordant type. Pre and post mordanting method may produce darker shades depending on on the same. Mordant concentration is also essential factor on darkness.

Advertisement

Fig 15: Mordanting Materials Fig 16: Marigold Dyed fabric samples 1) no mordant, 2) Alum, 3) Copper, 4) Iron

the Process

Scouring:

Each type of fibre needs to be readied for taking the colour from the leaves. To make sure you are starting with the cleanest possible fibres you should scour your fabric. Most fabrics have some coatings, starches and buildup of oils. Scouring is a strong cleaning to get of these impurities.

Mordanting

Mordanting is the most important process of preparing fibers to accept color. This is not an optional step but there are many mordant variations. Using a mordant helps to ensure the most durable and long-lasting colors.

FIBER RECOMMENDED MORDANT OTHER MORDANT OPTION

• Wool, alpaca, and other animal fibers

• Cotton, linen, Tencel, bamboo and other plant fibers • Aluminum Potassium Sulfate with optional Cream of Tartar • Aluminum Sulfate

• Aluminum Potassium Sulfate • Aluminum Sulfate

• Aluminum Acetate with wheat bran or with calcium carbonate afterbath • Symplocos

• Aluminum Acetate with wheat bran afterbath • Symplocos

• Tannin andAluminum Sulfate • Symplocos

Prepare your leaves

Depending on the time of year, you may have fresh or dried/ pressed leaves to dampen. Let them soak in the iron water or just water for at least 30 minutes

Place the leaves

The fabric is streched out on a plastic sheet to protect gainst the tsians. The dipped leaves are placed on the fabric seeing if there is a good coverage. Some are facing up and some down.

Tie the Bundle

To keep the fabric tight to the leaves, wrap at regular intervals quite tightly. As an extra measure you may wrap the entire roll in a foil or plastic. This will keep the moisture in and not let more in. Each slight variation may effect the result slightly as well.

Steaming (or boiling)

Depending on the type of leaves you have used they may give off odd smells/vapour when they are steamed/boiled. You can add metals to the water as extra mordant but I feel that they don’t really get into the bundle when steaming. You can steam them from 3omints to several hours.

Preparing Leaves

PLacing Leaves on the Fbaric

Tying the fabric

Steaming the Rolls