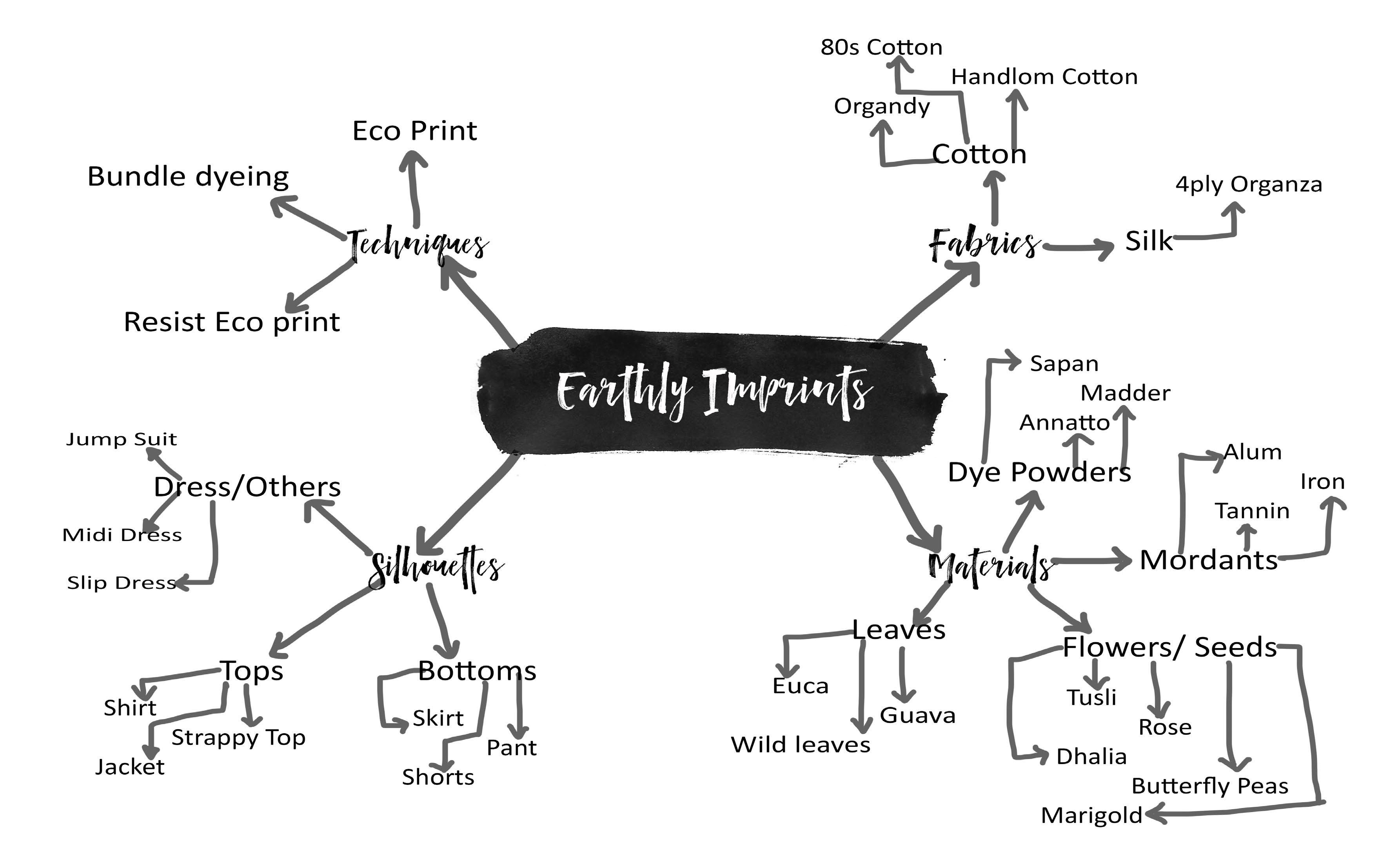

Mordant and mordanting method choice directly affects colour shades and fastness properties obtained. It is not possible to present strict rules and instructions for mordanting method because results vary depending on plant and mordant type. Pre and post mordanting method may produce darker shades depending on on the same. Mordant concentration is also essential factor on darkness.

Learning about mordants Some of the natural dyes can form metal-complexes with metal salts of iron, aluminium, copper, tin and chromium. Mordants can impart fastness properties and widen colour gamut depending on the type of the mordant. Dramatic colour changes are achieved by using the same natural dyestuff only by changing the mordant type. A wide range of colours with very different shades, darkness and fastness values can be obtained depending on the kind and concentration of natural dye and mordant and mordanting method. • Conventional Metallic mordants: Most mordanting agents are metallic salts of chromium, tin, iron, copper and aluminum. Copper and chromium containing compounds were widely used as mordants, but their usage has declined because of toxicity concerns. Likewise, iron and tin mordantscan affect the color and tactile qualities of the dyed textile. Aluminum mordanting agents are commonly used and considered among the safest in the application of natural dyes.

Fig 16: Marigold Dyed fabric samples 1) no mordant, 2) Alum, 3) Copper, 4) Iron

• Oil mordants: These are mainly used in dyeing Turkey Red colour from madder. The main function of the oil mordant is to form a complex with alum used as the main mordant. • Bio mordants: These are tanin, tannic acid, tartaric acid and metal containing plants. Myrabolan, pomegranate rinds, tannin, tannic acid, tartaric acid, guava, banana leaves ash, valex, rosemary, and thuja are reported as bio and eco-friendly mordants providing satisfactory dyeing and fastness properties. Commonly used mordants include aluminum potassium sulfate, iron sulfate, copper sulfate, stannous chloride, and potassium dichromate 27

Fig 15: Mordanting Materials

28