CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vol. 52 No.2

out front:

At M.C. Smith Enterprise in Burkeville, Texas, Mike Smith (pictured left) and his wife Andrea (right) are keeping things steady. Their single crew operation has persevered as others around them fold. The couple credits their work ethic and dedication to the job as the major reasons for their success. Story begins on Page 8.

February 2023

A Hatton-Brown Publication

Phone: 334-834-1170

Fax: 334-834-4525

www.southernloggintimes.com

Publisher David H. Ramsey

Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Senior Editor Dan Shell

Managing Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director Cindy Segrest

Ad Production Coordinator Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING CONTACTS

DISPLAY SALES

Eastern U.S. Kathy Sternenberg

Tel: 251-928-4962 • Fax: 334-834-4525 219 Royal Lane Fairhope, AL 36532

E-mail: ksternenberg@bellsouth.net

Midwest USA, Eastern Canada

John Simmons Tel: 905-666-0258

29 Bugelli Dr.

Whitby, Ontario, Canada L1R 3B7

E-mail: jsimmons@idirect.com

Western Canada, Western USA Tim Shaddick

Tel: 604-910-1826 • Fax: 604-264-1367 4056 West 10th Ave. Vancouver, BC V6L 1Z1

E-mail: twshaddick@gmail.com

Kevin Cook

Tel: 604-619-1777

E-mail: lordkevincook@gmail.com

International Murray Brett

Tel: +34 96 640 4165 +34 96 640 4048

58 Aldea de las Cuevas • Buzon 60 03759 Benidoleig (Alicante), Spain

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane

Tel: 1-800-669-5613 • Tel: 334-699-7837

Email: bdevane7@hotmail.com

Southern Loggin’ Times (ISSN 0744-2106) is published monthly by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—SLT is sent free to logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel in the U.S. South. See form elsewhere in this issue. All non-qualified U.S. subscriptions are $65 annually; $75 in Canada; $120 (Airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.southernloggintimes.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Southern Loggin’ Times magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Southern Loggin’ Times. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or in part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed In USA. POSTMASTER: Send address changes to: Southern Loggin’ Times, P.O. Box 2419, Montgomery, AL 36102-2419

(Founded in 1972—Our 605th Consecutive Issue)

FEATURES 4 ● FEBRUARY 2023 ● Southern Loggin’ Times Other Hatton-Brown publications: ★ Timber Processing ★ Timber Harvesting ★ Panel World ★ Power Equipment Trade ★ Wood Bioenergy

14 Steep Terrain

Southern Stumpin’. . . . . . . . . . . . . . . 6 Bulletin Board. . . . . . . . . . . . . . . . . . 20 From The Backwoods Pew. . . . . . . 22 Industry News Roundup. . . . . . . . . 24 Machines-Supplies-Technology. . . 30 Iron Works. . . . . . . . . . . . . . . . . . . . . 33 Trucking Safety Focus. . . . . . . . . . . 37 Coming Events/Ad Index. . . . . . . . . 38 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

(Photo by Jessica Johnson)

Harvesting

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Happiest, Deadliest SOUTHERN STUMPIN’

By David

driving a big blue ox. Or maybe I hear it used in a trendy way, such as by hipster dudes from a big city who’ve never really been in the woods, guys who wear big beards and unmuddy boots ironically, with skinny jeans. To me, lumberjacks compete in shows to entertain, like rodeo cowboys, displaying skills that are impressive but largely obsolete in modern practical use. When you’re talking about people who work in the woods cutting timber, I think you mean loggers. But hey, what do I know?

In any case, it’s not fair to fault people for not knowing what they don’t know, so sure, we can let the “lumberjack” label slide. No big deal. Besides, it’s nice to see you guys get some positive attention in mainstream mass media.

The article’s author, one Andrew Van Dam, advises the reader to “Envy the lumberjacks, for they perform the happiest, most meaningful work on earth. Or at least they think they do. Farmers, too. Agriculture, logging and forestry have the highest levels of self-reported happiness— and lowest levels of self-reported stress—of any major industry category, according to our analysis of… the Bureau of Labor Statistics’ American Time Use Survey.”

Basically, the government surveyed a bunch of people over the last decade or so and asked them how happy or sad, stressed, frustrated or fulfilled, their various activities made them feel.

Van Dam (presumably no relation to Jean Claude?) goes on to say that “Additional reporting sharpened our focus on lumberjacks and foresters, but almost everyone who works on farms or in forests stands out.” Well hey Andy, I could have told you that. Loggers, farmers and foresters have always been standouts in my book.

No Surprise

On one hand, this really shouldn’t come as any surprise to me or any of you. Of course working in

agriculture and/or forestry makes people happy. They sure don’t do it for the money! But you’re in the great outdoors, growing and harvesting renewable natural resources that we all need. Working in the woods, or in the fields, breathing fresh air, absorbing the smells and the sounds unique to a logging job or a cattle ranch or a farm…you fall in

Van Dam seems to get it, writing: “Researchers across the social and medical sciences have found a strong link between mental health and…being outdoors. Even seeing a tree out your window can help you recover from illness faster. So imagine the boost you get from being right next to said tree— even if, like our friend the lumberjack, you’re in the process of chopping it down.”

Chopping it down, I should point out, generally, to plant more, in a never-ending cycle of renewability. But his point remains valid. Most loggers like being in the woods. How many people get the same vibe from an assembly line or office?

Logging is hard work, yes, but it’s fun, and it’s fulfilling (if not always financially viable). It’s not just a job; it becomes an identity. It’s in your blood; it’s your family, your community, your culture, your lifestyle.

And moreover, you know that what you’re doing matters; it’s meaningful. You know you’re part of a tradition, leaving a legacy that will outlive you. You plant trees you’ll never harvest, and harvest trees planted by others before you, hauling logs that will become lumber in some family’s home, where someone you’ll never meet will live and love, raise their kids and grow old, in a house that may stand for generations after we’re all gone.

True, yours is different from the important work done by healthcare workers, teachers, police officers, fire fighters, and those brave souls who serve in the military. But it’s just as vital. Those in the rural professions provide goods and services that are not only essential to society but fundamental to survival. The basics are food and shelter, right? Farmers provide food, and loggers provide the materials needed to build shelter, among other things, including comforts like toilet paper and diapers. Arguably those are not “essential,” strictly speaking, but think back three years ago to the pandemic-panicked shortages in the TP aisle and ask how many folks are real enthusiastic to do without some Charmin or Angel Soft.

Then Again...

Still, on the other hand, I was very surprised when my friend in Washington forwarded me this article. Logging ranks as the happiest job? Really? Loggers love logging, sure, no surprise there, and it’s great to be outside in the sunshine with the smell of pinesap and fresh sawdust. But there are just so many difficulties that go with the job. And

this is where Van Dam kind of loses me. He writes, “…our friends the lumberjacks and farmers do the least-stressful work…”

Do what now?

I’ve never actually been a logger, but I seem to recall Abbott Logging Co. having my parents pretty well stressed out a lot in the ’80s and ’90s. I heard from a logging family just this very evening who told me rain has kept them from working for the last seven weeks straight. Seven weeks! That’s seven weeks with no income. If you can’t produce, or you can’t haul, then you don’t get paid. But the bills...the equipment payments, the insurance, not to mention your house note, your utilities, your groceries…yeah, those bills just keep on piling up; they don’t take a break just because the ground is wet or the mill’s on quota. That ain’t stressful?

See, you gotta remember this is based on what people self-reported. White collar jobs report more stress than blue collar jobs, according to the article. Lawyer ranks as the most stressful profession. In other words, lawyers think they’re more stressed than others. So maybe it’s just that loggers and farmers don’t whine about their stress as much.

Read the article if you can (www.washingtonpost.com/business/2023/01/06/happiest-jobs-onearth/). Van Dam talks to and about some pretty interesting folks in there, like timber sports world champion Alissa Wetherbee of the Axe Women Loggers of Maine and Dana Chandler of South Carolina’s Family Tree Forestry.

Van Dam briefly notes that logging is a “particularly perilous” profession. This is supported by an article that ran on the Fox Business web site on 1222-22 (www.foxbusiness.com/economy/deadliestjobs-america-revealed-industries-dangerous-difficult). Greg Norman writes, “The U.S. Bureau of Labor Statistics’ national census of fatal occupation injuries revealed that the logging industry has a fatal work injury rate of 82 per 100,000 full-time equivalent workers in 2021.”

You should check this one out too. Norman quotes American Loggers Council’s Scott Dane, who points out that while the risk is a badge of honor for some loggers, most take professional pride in focusing on safety.

Bottom line: survey says that farming and forestry, despite being difficult, dangerous, and not generally among the highest paying professions, produce the happiest lifestyles overall. Sure, it’s not for everyone…not everyone can do it, not everyone wants to do it, not everyone really has what it takes to do it…but those who do choose to do it are generally happier than those who don’t.

What about you? Does this reflect your experience? Do you love what you do? Do you feel like you’re the happiest people you know? I hope you can answer yes to all. Till next time…Excelsior! SLT

6 l FEBRUARY 2023 l Southern Loggin’ Times

• Fax: 334-834-4525 • E-mail:

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Abbott • Managing Editor • Ph. 334-834-1170

david@hattonbrown.com

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

All Week Long

FSmith, both 46, their fate was decided when Mike was just five years old. See, Mr. Smith was a pulpwood mechanic and young Mike would often follow him around to the logging woods to work. There, Mike was exposed to logging and quickly found his path in life. Fast-forward to high school, and Mike was still obsessed with logging. He started his own company in 1994. He worked small private tracts on the weekends with a chain saw, a tractor and his dad’s winch truck.

Andrea was also exposed to logging at a young age, as her father worked on a crew in the woods. But the logging bug didn’t bite her until she fell in love with the senior class valedictorian, Mike Smith. “When I met Mike I was so head over heels in love with him I found out real

time, I fell in love with it, too.”

She went into the woods each weekend alongside Mike when they first got M.C. Smith Enterprise started. “We started out with just junk,” she says. “We took baby steps. It took years to build us up to what we are now.” The business has survived crashes, vandalism and mill closures and still hung on.

Logging became even more important in the Smiths’ lives when they lost Mike’s father to pancreatic cancer over five years ago. As he passed, Andrea says he told them, “Whatever you do, don’t stop what we started.” After that Mike really threw himself even more into making the logging venture a success.

That humble beginning and the tenacity required to make it through by the Smiths has not gone unnoticed by others in the industry. In 2021, Texas Forestry Assn. named

could have been anything he chose to be and he chose logging,” she says with pride.

Making A Home

From 1994 to 2003, the Smiths lived a fairly “typical” logging lifestyle. They worked for various companies, cutting tracts, working on equipment and traveling home each night from wherever they were working. As with many, the Smiths bounced around a little as mills sold their landholdings in east Texas. At one point, they were working up to 200 miles from their house, traveling back and forth from Louisiana to their Texas home. Then the equipment started getting vandalized. And the Smiths noticed some thefts.

So, in 2003, while working in Louisiana, the Smiths made a choice.

of further vandalism.

Moreover, it allows Andrea to see more of her husband, who often puts in 14-plus hour days. “Mike works 24/7,” she laughs, noting with pride that their crew (just Mike with two employees) is able to move the same production as many larger operations do. That’s only possible, she adds, because of the hours he puts in.

Thanks to a combination of Mike’s never-quit work ethic, his “no stick left behind” mentality and their ability to be nimble, M.C. Smith has the edge on certain specialty tracts. Currently, the crew works exclusively for WestRock, and therefore spends 99% of their time in pine plantations on first thinnings. “We are often appointed to designated tracts because of the way we work,” Mike says. “We make sure everything is gone before

8 ● FEBRUARY 2023 ● Southern Loggin’ Times

★ CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Logging is truly a full-time lifestyle for Mike andAndrea Smith,who live on the job site. Their company,M.C.Smith Enterprise,was namedTexas Logger of theYear for 2021.

we go on to our next set—even if that means paying a contract driver to haul a full load when the trailer only has a half load—everything gets to the mill. We merchandize it plumb up to the stem. All you see is a little bit of trash, no cut offs.”

The crew averages 1,000 tons per week of pulpwood, with an average of 40-50 miles haul distance, typically on 50-100 acre thins. While Mike will sort out everything possible, cutting for WestRock means getting all the pulpwood possible for them.

Manpower

The three-man operation is like a family, Mike says, while Andrea acknowledges that they all spend more time together as a unit than with anyone else. The crew has always been small, with very little turnover. That tightness is evidenced by the company’s untarnished 28year safety record. Marcel Riley was the employee who had been with M. C. Smith the longest, working here 17 years before retiring at age 76. His own son James stepped into his spot in 2016. While the hands are like family, they do travel back and forth from the job site to their own homes, not electing to stay out here full-time as the Smiths do.

While the crew has always been small, there were times when it was not just three men in the woods, plus Andrea hauling set out trucks and running parts. The Great Recession hit M. C. Smith hard, slashing production from 65-70 weekly loads to a quota of 30-something, with the crew only consistently getting 20something of those 30-something. “We almost starved to death,” Andrea says. In addition to what she does in the woods, she also handles all bookkeeping for the enterprise.

In 2010, the Smiths were working in Louisiana and according to Andrea had to liquidate old, paid for equipment in order to get the needed cash flow to stay in business.

“Everybody is jumping up and down about how bad it is now,” she waves. “If you lived through that, you’re prepped as to what we’re going through now. Logging is not easy by any means.”

Mike’s key takeaways from that time were efficiency-based. More machines and more employees is not always necessary to keep wood flowing to the mill for their operation. Instead, they run one skidder, one feller-buncher and two loaders that Mike rotates depending on what wood he has decked, mill needs, driver availability and other factors.

“When we are in good enough wood and close to the mill, we can move a good amount instead of having all that excess overhead,” he says.

M.C. Smith Enterprise uses three

The M.C.Smith crew—from left,William“Buster”Moye,Smith and James Riley—is like a family.

Smith cuts with a 2021 724G fromTejas Equipment.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

The Smiths work primarily forWestRock.

contract haulers to handle production. Though the company does own its own trucks, they don’t run full-time because of the cost liability associated with them. Andrea describes Mike as acting like Mickey Mouse, hopping between both log trucks to haul a load after work-

ing the day in the woods. “He’ll hop in one of them, go to the mill and then come back and hop in the other to go to the mill, and loads them back up for the next day,” she explains. “Depending on how big the wood pile is, he might end up hauling all day long. Mike’s pet

peeve is he wants lots of wood in the set. We’re always shorthanded and in case of a breakdown the wood is still there.”

Mike hears this explanation and laughs, agreeing with his bride. “I’m a little bit of a stickler for how my job operates,” he adds.

Moving Wood

Aside from a few things here and there over the last few years, Smith hasn’t acquired much new logging equipment recently, citing the rising cost of insurance as one of the variables he factors into equipment purchases. That cost is made even worse by the rising cost of equipment. When he is in the market, Texas Timberjack, Tejas Equipment and Suttle Equipment all take good care of his equipment sales and service needs.

The complete equipment list for M.C. Smith includes a 2017 Prentice 2484C loader, ’14 Prentice 2384C, 2020 Tigercat 620E skidder, ’13 Caterpillar 525C skidder, ’21 Tigercat 724G cutting machine, ’96 Cat D5H dozer, ’78 Galion dozer, ’98 Mack RD 688S log truck, ’20 Mack Pinnacle log truck, and a 1978 Chancey Equipment lowboy.

“We’ve got some of the best equipment made,” Mike says. “All the manufacturers make good equipment. It is 100 times easier than when I started running choker skidders pulling pulpwood. Everything is so much better.”

He explains that his view on equipment is simple enough—take care of it well and it will work

10 ● FEBRUARY 2023 ● Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

if they weren’t living on the job, with Mike able to do all his own mechanic work and working in the “off” hours, the couple wouldn’t be able to make it. All profits are returned to the business.

As with many of his peers, Mike is cognizant that rates have really never increased in a number of decades, and lots of loggers in his area are going out of business. He says that things have changed so much from what it used to be, he’s not sure what the future holds. “I honestly don’t know what is going to happen,” he admits. “If something doesn’t change, there’s going to be a lot more going out of business. If we didn’t do things the way we do them, it would be time to mash ‘flush’ and shut it down.”

The couple remembers when you could overcome a bad day or a bad week with hard work and determination. Obviously that is not the way the game is played today. Andrea says now if you get behind the eight ball you will never catch up. “When the hands decide to retire, I don’t know what we’re going to do,” she confesses. “We’ve been blessed with a good crew; we have always been blessed with a good crew since we started. Those guys are getting harder and harder to find, daily. And it takes a team to be successful at what we do.”

Her husband shares similar sentiments: “You can’t bring someone out, and because everything moves at such a fast pace now, you really don’t have time to be teaching. And it is sad. I don’t know what the answer and solution is going to be in another five years about help and trucks.”

One thing is certain: If Mike and Andrea Smith can find a way, they are sure to keep on logging. SLT

12 ● FEBRUARY 2023 ●

Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Contract drivers and company trucks combine to haul 1,000 tons weekly.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

High Country

By David Abbott UNICOI, Tenn.

As teenagers, many people don’t know what they want to do in life or in their career. Even when we finish high school, even if we go to college, even after graduating college, finding one’s life calling can be difficult for a lot of us. Some people go their whole lives and never really figure it out.

Most of those who come up or end up in the forest products industry don’t have that problem, and 5th generation logger Jerry Byrd was no exception. Byrd recalls an incident from his senior year of high school in 1994. He was assigned a project in his economics class to make a class presentation on what kind of career he wanted as an adult. Settling on a vocation was no problem; he already knew he wanted to get into logging. “This is a logging area,” Byrd says of his part of Tennessee.

Byrd made his presentation in front of the class, using spreadsheets

14 l FEBRUARY 2023 l Southern Loggin’ Times

MeadeTractor in Kingsport is Byrd's John Deere supplier.

★ CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Workingonsteepslopes,ByrdusesaRyan'sdangleheadformostfelling;however,aboutathirdofthetimechainsawsarerequiredfortimbereventhismachinecan'treach.

a copy of Southern Loggin’ Times His teacher noticed the Pitts Trailers ad on the back cover, which at that time still featured the “Pitts Girls” promotion (“You’re ahead with a Pitts behind”). She asked him what that had to do with his future in logging. “Well, see,” he replied jokingly, “The one on the right there, that’s the one I’m gonna marry.”

Now 47, he owns Jerry Byrd Logging, a one-crew operation that focuses on steep ground in east Tennessee. He went into business right after finishing high school in 1994, partnering with his dad. Jerry bought his first truck that year, a 1989 Mack that he still runs today.

Crew, Family

His dad, Eddie Lee Byrd, had already been in logging more than 20 years when his son joined him in the woods. “We were a two-man operation at first, and grew from there,” the younger Byrd recalls. “We got pretty big for a while,” Byrd says of the years he spent with his dad. They had two crews for a while. They remained partners until a trucking accident forced Eddie Lee into retirement 17 years ago, at which point Jerry bought his dad out and started his own solo operation.

“Now with the labor market where it is, well, I am fortunate to have the men I have,” Bryd says. “I know everyone says that, but I really am.” The crew includes Tim Laws, who has worked in logging for 35 years; Byrd’s brother-in-law Carl Bullen, who has been on the crew nine years;

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

days they’re into hay and sheep.

“We run several head of sheep and we also put up hay on our own farm in addition to several other farms in the community, for our own use and to sell to other farmers,” Byrd says.

“Sheep are more laid back than goats or cattle, easier to handle and there’s more money in it than any of the others for us; it does really well in this area.” Sara is most heavily

active in the farming side of the family business, and hopes to become more involved in the farmto-table movement. Also, Millie really enjoys working with chickens and started selling eggs at the local farmers market this past summer and to others in the community. With the price of eggs, the little girl could do quite well. “We have our plate full,” Byrd admits.

Equipment DS28 dangle head for felling, a 2010 John Deere 648H dual arch skidder, ’17 Barko 295 ML loader with CSI buck saw and ’12 John Deere 700J dozer with winch for road work. He also has an

“We probably cut 30% by hand,” Byrd figures, using Stihl 500 and Husqvarna 562 chain saws with 24 in. bars. “I am a Husqvarna fan but these boys are Stihl guys.”

Jerry Byrd Logging buys fuel in

16 l FEBRUARY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

The Komatsu is a versatile machine; Byrd uses it to fell and shovel,and sometimes as an excavator for road work.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

bulk from Volunteer Oil Co. in Johnson City. They fill fuel tanks at Byrd’s 40x40 shop, where the crew handles roughly 75% of equipment repairs, the owner estimates; they do 90% of routine maintenance in the woods. “It seems like skidders need the most maintenance, because they take the most beating,” Byrd figures. He and his team tackle undercarriage work, packing cylinders, replacing pins and bushings and the like. “We have stuff at the shop to fabricate a lot of what we need. The only thing we don’t do is

engines and transmissions.”

For that, they turn to Meade Tractor for John Deere and Power Equipment for Komatsu and Barko; both dealers are located in Kingsport. He bought the Ryan’s dangle head from Randy Bowlin at The Logger Shop Equipment Sales & Service in Wilkesboro, NC.

Byrd bases his operations in northeastern Tennessee, not too far from Virginia, and the North Carolina line was only about three miles from his job site last summer, visible through the mountains. In these

hills, Byrd harvests 60% poplar/ pine and 40% oak. He saves jobs near Knoxville and Green County to work in the winter.

“We have to build roads to 90% of what we cut because it is so steep,” the logger says. “We couldn’t make it without the dozers. It takes a week ahead to build the landing, and the roads, before you can get started on a job. And that’s one reason I went with the dangle head; I can put my bucket on when we need it. It’s a versatile machine, so we can still use it as an excavator when needed. It is a

perfect machine to shovel with and has cut my worker’s comp by a third, without men on the ground as much. That makes the payment on it.”

Byrd gets workers’ comp insurance through Forestry Mutual, while Elizabethton Insurance covers equipment and Progressive insures log trucks and trailers. He emphasizes safety, with high visibility vests, saw chaps and hardhats in the woods.

Markets

Production from Jerry Byrd Logging hauls on two trucks: the ’89 Mack he started with in ’94 and a ’94 Western Star. He pulls two Pitts pup trailers when he can get it to the job site. “We can’t get tractor trailers into this terrain sometimes,” he explains; they often work in steep elevations with rough roads. The latest addition on the trucking side is an Army GI truck fitted with a log bed to handle short hauling in rough terrain. They also use a Volvo day cab road tractor with a lowboy to move equipment.

In December, Byrd and his cousin Adam Byrd (another logger) cleaned up the ’89 Mack and Adam’s Ford LTL log truck, and drove them in a Christmas parade in the town of Erwin.

Byrd himself is the primary log truck driver; his father-in-law, Wayne Bullen, and Jerry King, father of loader man Jon King, help fill in part time. Eddie Lee Byrd, though retired after that wreck 17 years ago, still runs parts for his son and helps set up timber tracts to look at when he’s able.

The crew sends five loads a day. When they surpass a minimum number of loads in a week, Byrd pays his operators a bonus. The tract Byrd was working when SLT visited last August was 90% grade poplar, bound for Parton Lumber Co. in Rutherfordton, NC. Pulpwood went to Unaka Forest Products in Jonesborough, Tenn. They buy all Byrd’s pulpwood, while Parton takes the majority of what his crew cuts, including gate logs. Byrd buys the bulk of his own stumpage (75%). The remaining balance comes from contract logging jobs for Parton Lumber.

“I’ll be honest: we have been blessed,” Byrd attests, thinking about all the upheaval of the last few years. “I have come through it good. Parton has been good to pay a fuel surcharge. My fuel in the last year doubled or tripled. But Parton has really been good to us and we have had some good quality tracts of timber to cut, some good white oak jobs and we have had some good markets. I would be lying if I said I hadn’t done pretty good because I have.”

SLT 18 l FEBRUARY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Aircraft Complaints, Solutions

After every flight, UPS pilots fill out a form, called a ‘gripe sheet,’ which tells mechanics about problems with the aircraft. Mechanics correct the problems, document their repairs on the form, and pilots review the gripe sheets before the next flight.

Never let it be said that ground crews lack a sense of humor. Here are some actual aircraft complaints submitted by UPS pilots (marked with a P) and the solutions recorded (marked with an S) by maintenance crews.

P: Left inside main tire almost needs replacement.

S: Almost replaced left inside main tire.

P: Test flight OK, except auto-land very rough.

S: Auto-land not installed on this aircraft.

P: Something loose in cockpit.

S: Something tightened in cockpit.

P: Dead bugs on windshield.

S: Live bugs on back order.

P: Autopilot in altitude-hold mode produces a 200 feet per minute descent.

S: Cannot reproduce problem on ground.

P: Evidence of leak on right main landing gear.

S: Evidence removed.

P: DME volume unbelievably loud.

S: DME volume set to more believable level.

P: Friction locks cause throttle levers to stick.

S: That’s what friction locks are for.

P: IFF inoperative in OFF mode.

S: IFF always inoperative in OFF mode.

P: Suspected crack in windshield.

S: Suspect you’re right.

P: Number 3 engine missing.

S: Engine found on right wing after brief search.

P: Aircraft handles funny.

S: Aircraft warned to straighten up, fly right and be serious.

P: Target radar hums.

S: Reprogrammed target radar with lyrics.

P: Mouse in cockpit.

S: Cat installed.

P: Noise coming from under instrument panel. Sounds like a midget pounding on something with a hammer.

S: Took hammer away from midget.

Golfer Statistics

Recent studies found that the average golfer walks 900 miles a year. Another study found that the average golfer drinks 22 gallons of alcohol a year. This means, on average, that golfers get 41 miles to the gallon!

Conservatives, Liberals

If conservatives don’t like guns, they don’t buy one. If liberals don’t like guns, they want all guns outlawed.

If conservatives are vegetarian, they don’t eat meat. If liberals are vegetarian, they want all meat products banned for everyone.

If conservatives are down-and-out, they think about how to better their situation. Liberals wonder who is going to take care of them.

If conservatives don’t like a talk show host, they switch channels. Liberals demand that those they don’t like be shut down.

If conservatives are non-believers, they don’t worship. Liberal

non-believers want any mention of God and Jesus silenced.

If conservatives decide they need health care, they shop for it or choose a job that provides it. Liberals demand that the rest of us pay for theirs.

Mass Media Spin On D-Day

Here is how the D-Day Invasion might be reported by today’s liberal media:

NORMANDY, FRANCE (June 6, 1944) Three hundred French civilians were killed and thousands more were wounded today in the first hours of America’s invasion of continental Europe. Casualties were heaviest among women and children. Most of the French casualties were the result of artillery fire from American ships attempting to knock out German fortifications prior to the landing of hundreds of thousands of U.S. troops.

Reports from a makeshift hospital in the French town of St. Mere Eglise said the carnage was far worse than the French had anticipated, and that reaction against the American invasion was running high. “We are dying for no reason,” said a Frenchman speaking on condition of anonymity. “Americans can’t even shoot straight. I never thought I’d say this, but life was better under Adolph Hitler.”

The invasion also caused severe environmental damage. American troops, tanks, trucks and machinery destroyed miles of pristine shoreline and thousands of acres of ecologically sensitive wetlands. It was believed that the habitat of the spineless French crab was completely wiped out, thus threatening the species with extinction. A representative of Greenpeace said his organization, which had tried to stall the invasion for over a year, was appalled at the destruction, but not surprised. “This is just another example of how the military destroys the environment without a second thought,” said Christine Moanmore. “And it’s all about corporate greed.”

Contacted at his Manhattan condo, a member of the French governmentin-exile who abandoned Paris when Hitler invaded, said the invasion was based solely on American financial interests. “Everyone knows that President Roosevelt has ties to ‘big beer’,” said Pierre Le Wimp. “Once the German beer industry is conquered, Roosevelt’s beer cronies will control the world market and make a fortune.”

Administration supporters said America’s aggressive actions were based in part on the assertions of controversial scientist Albert Einstein, who sent a letter to Roosevelt speculating that the Germans were developing a secret weapon—a so-called ‘atomic bomb.’ Such a weapon could produce casualties on a scale never seen before, and cause environmental damage that could last for thousands of years.

Hitler has denied having such a weapon and international inspectors were unable to locate such weapons even after spending two long weekends in Germany. Shortly after the invasion began, reports surfaced that German prisoners had been abused by American soldiers. Mistreatment of Jews by Germans at their so-called ‘concentration camps’ has been rumored, but so far this remains unproven.

Several thousand Americans died during the first hours of the invasion, and French officials are concerned that the uncollected corpses will pose a public-health risk. “The Americans should have planned for this in advance,” they said. “It’s their mess, and we don’t intend to help clean it up.”

Actions Speak Louder Than Bumper Stickers

The invasion is blamed on Roosevelt’s hawkish military advisers and the influence of British Prime Minister Churchill, who have repeatedly ignored calls for a negotiated settlement to end the war and who have reportedly rejected peace overtures from Germany through several neutral parties. Instead, the Roosevelt administration and its allies have chosen to insist on maintaining their extreme policy of demanding unconditional surrender.

There have been notable voices of opposition from sports figures and celebrities decrying the horrific violence and saying that this is not who we are.

20 l FEBRUARY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FROM THE BACKWOODS PEW The Bog

Scattered throughout the woodlands of the South, and other regions as well, is an occasional mixing of water and soil to the extent that the weight of a passing forester cannot be supported. Like the eager young groom who sweeps his bride from her feet to carry her across the threshold, only to find that each step brings his love closer to the floor, so the forester finds himself walking across a bog, only to find himself slowly sinking. The miry mixture of soil and water begins to give way to the weight of the forester, and while he accelerates in order to “walk on top of the soil” in such a manner as to get to something solid fast, it is usually without success. He is sinking. He is stuck.

If he is fortunate, he may only “bog down” to mid-calf level, but that is usually the case only if he skipped lunch that day. The depth of any bog is directly proportional to the weight of the forester in question. It is one thing to have water in your boots because the swamp was deeper than expected, but it is another issue altogether where a bog is concerned.

The bog desires to devour.

The forester must find a means to break the suction created by the bog, if he desires to again see his family. Unlike quicksand, the bog is made up of dirt, debris, peat, small living and dead animals, and of course, water (or some form of semi-liquid, black, odiferous substance). All of these ingredients mix together, creating suction, a grip on whatever is suspended in the bog.

Now would be a good time for prayer, prayer that the flies and mosquitoes who are calling their friends to the feast, would be blown away by a strong breeze. A prayer that the cottonmouth moccasin you just spotted on a root a few feet away will continue to snooze; a prayer that your new boots are still attached to your feet when you eventually extract yourself from this mess. A prayer that the circling turkey buzzard doesn’t know something you need to know.

Save me, O God! For the waters have come up to my neck. I sink in deep mire, where there is no standing; I have come into deep waters, where the floods overflow me. I am weary with my crying; my throat is dry; my eyes fail while I wait for my God. ~ Psalms 69:1-3

Maybe you have found yourself in a bog; confined to a hospital bed, stuck in a house, or perhaps chained to a system of treatments that seems to be draining away more life than it is restoring. It was hidden from you, you didn’t purposely choose this path, and suddenly, you aren’t moving anymore. Progress has stopped, and in its place is instant fear. Will I survive this bog? What the forester has learned about the bog is that it does not discriminate. It will take whatever or whomever, and pull them into its suffocating ooze. The results are the same: you are stuck.

Logging equipment, large and expensive, designed to leave the lightest footprint in the woods, will hit these bogs, and like the forester on foot, they will begin to sink. With no bottom, the machine will sink until it finds buoyancy, and there it will stop. It will take another machine to get them out. I have seen entire bulldozers, skidders, excavators, and cutters all buried so far down in the bog that only their antenna was sticking out. One skidder stuck in southern North Carolina tried to wench itself out of a bog by running a cable to a nearby tree, a 90-foot-tall tree, only to pull the entire tree down on itself, roots

and all, and still be stuck in the bog.

The muddy side of life is no respecter of persons. The bog will pull on the wealthy, the poor, the healthy, and the weak. It is the curse of sin in this world; it is not part of the original plan, yet as we travel through life, we will step into the bog at some point. Like the forester or the heavy equipment operator, we must cry out, we must seek help.

But as for me, my prayer is to You, O LORD, in the acceptable time; O God, in the multitude of Your mercy, hear me in the truth of Your salvation. Deliver me out of the mire, and let me not sink; let me be delivered from those who hate me, and out of the deep waters. Let not the floodwater overflow me, nor let the deep swallow me up; and let not the pit shut its mouth on me. ~ Psalms 69: 13-15

What a resource the children of God have, to call out in prayer to their Father.

Hear me, O LORD, for Your loving kindness is good; turn to me according to the multitude of Your tender mercies. And do not hide Your face from Your servant, for I am in trouble; hear me speedily. ~ Psalms 69:16-17

22 l FEBRUARY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

There is good news, even when the bog is all around you. When you feel like you’re about to suffocate because of the grip of the bog upon you, when you think no one is hearing you; know that the Father hears the cries of his children. He will respond to you in your hour of need.

When the forester has finally extracted himself from the bog, there is a certain spring in his step. Sure, he lost a boot, and he is covered with slime, but the snake never moved, and a breeze did blow away the bugs. God is in the swamp with us, he is aware of our pain, our fear. Yet he desires to use us, to show others in the bog that there is hope. If you claim God as your Father, then he wants you to be a clanging cymbal of God’s mercy, to show those who are not, that they are missing the love of a lifetime.

But I am poor and sorrowful; let Your salvation, O God, set me up on high. I will praise the name of God with a song, and will magnify Him with thanksgiving. ~ Psalms

69:29, 30

Bradley Antill is a forester and an author. Excerpted from Pine, Prayers, and Pelts. For more see www.onatree forestry.com

Southern Loggin’ Times l FEBRUARY 2023 l 23

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Clutter Was Leading Forestlands Expert

Dr. Michael Lee Clutter, who served as Dean of the University of Georgia Warnell School of Forestry and Natural Resources from 2007-2015, and was a noted expert in his field, died on December 24. He was 63.

Born in Durham, NC, Clutter

grew up in Athens and attended Clarke Central High School, where he graduated with honors in 1977, was captain of the soccer team, and lead trumpeter for the school’s band. He pursued his undergraduate education at Ohio University, playing collegiate soccer, and later at

Mississippi State University, where he earned a bachelor’s degree in forestry resources in 1981. Returning to his hometown, Clutter received a master’s degree in 1982 and a doctoral degree in 1991, both from Warnell.

Clutter was considered an authority on the eco-

nomics of the forestry industry, including finance, budgeting, timberland management and timber supply and sizing trends. Early in his career he held various management positions with Georgia-Pacific Corp. and Union Camp Corp. in Savannah.

Joining Warnell’s faculty in 2001, he was later named the Hargreaves Distinguished Professor of Forest Finance and received the Warnell School’s Faculty Award for Outstanding Teaching.

Assuming the role of Dean on August 15, 2007, Clutter was determined to keep students at the forefront of his scholarship and research, continuing to teach forestry courses until his departure in January 2015. Along with his Warnell classes, he also was an adjunct professor at the Terry College of Business, where he taught corporate finance. One of his proudest accomplishments was his lifetime affiliation with Warnell as a dean, professor, student, and the son of a professor at the school.

Desiring to return to the private sector, Clutter became an executive with Forest Investment Associates Timber Partners, a timber and timberland investment fund. He worked there until 2021, when he was named Chief Analytics Officer at F & W Forestry, a position he held until his death.

Along with his academic and professional accomplishments, Clutter was the co-editor of a book on timberland investment, author of numerous articles and other publications, a recipient of several research grants, an editorial board member of the professional journal Forest Science, a member and past chair of the American Forest and Paper Assn.’s forest inventory committee, and a member of the U.S. Forest Service’s forest inventory and analysis review committee. He was an inductee of the Georgia Foresters Hall of Fame.

He is survived by his wife of 38 years, Catherine (Cathy) Nemetz, and their three children, Matthew, Emily, and Maggie. Clutter was predeceased by his father, Dr. Jerome Clutter, also a leading professor at Warnell for 20 years.

Visitation was held January 6 in Watkinsville, and a funeral mass was January 7 at The Catholic Center at the University of Georgia. Interment was at Oconee Hill Cemetery.

In lieu of flowers, the family kindly requests that donations be made to: The Dr. Michael L. Clutter Fellowship, University of Georgia Warnell School of Forestry and Natural Resources, attention: Bridget Harden (bharden@uga.edu). In

24 l FEBRUARY 2023 l Southern Loggin’ Times INDUSTRY NEWS ROUNDUP CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

addition, donations may be made to Trout Unlimited, at gifts.tu.org.

Waratah Forestry Celebrates 50 Years

Waratah Forestry Equipment is celebrating 50 years of innovation in the forestry industry in 2023.

Established in 1973 in Tokoroa, New Zealand, the company manufactured a delimber-feller-buncher with a four-roller fixed head to meet local loggers’ heavy-duty delimbing needs. Following that innovation, a red grapple processor manufactured for the Canadian markets marked the start of the 600 Series line.

Today, Waratah’s full line of harvesting, processing and felling heads are used in a variety of logging applications from cut-to-length hardwood harvesting at the stump, to processing on a landing, felling on steep slopes or debarking on plantations.

“Waratah heads are designed well, tested well and built well,” comments Pasi Volotinen, managing director of Waratah OM, Finland. “We are always aiming for best-in-class. We are happy when our customers are feeling good in the forest.” Visit Waratah.com

Doosan Changes Name To DEVELON

Doosan will now be called DEVELON throughout the world and will continue providing innovative products and solutions in construction and other heavy equipment industries.

Work began to identify a new brand name to replace Doosan following the August 2021 sale of Doosan Infracore to HD Hyundai, formerly Hyundai Heavy Industries Holdings Co. The name DEVELON was chosen to convey the company’s drive to develop onward to bring innovative solutions through technological transformation and the development of exceptional equipment and services.

“We believe the new DEVELON brand will help us build on the success we’ve had in North America over the past 30 years and throughout the world for more than 80 years,” says Todd Roecker, Vice President of growth initiatives.

DEVELON products and services will help customers and partners become industry leaders in construction, logging, recycling, mining, rental and agriculture. Efforts will also be placed on advancing sustainable

development through alternative energy sources of power for construction equipment.

In North America, DEVELON will continue supporting its more than 180 dealer locations while

DEVELON North American operations will remain headquartered near Atlanta, in Suwanee, Ga., where the company continues to offer a training center for dealership service technicians. The company

Southern Loggin’ Times l FEBRUARY 2023 l 25

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

will maintain parts availability through its two regional parts distribution centers: one in Atlanta and a second in the Pacific Northwest. A customization plant in Savannah, Ga. will still play a key role in supplying machines to DEVELON dealers and customers.

DEVELON will continue as a subsidiary in the Hyundai Genuine group alongside Hyundai Construction Equipment (HCE). These two subsidiaries will remain independent

construction equipment companies under HD Hyundai.

Long-Running SAF Project Has Life

LanzaJet, a sustainable fuels technology company and producer, joined government officials, industry leaders, and investors in mid-December to celebrate a major construction milestone at the LanzaJet Freedom

Pines Fuels facility in Soperton, Ga.

LanzaJet Freedom Pines Fuels is building an ethanol-based alcohol-tojet sustainable aviation fuel (SAF) production plant. Construction will be completed in 2023, according to the company. The plant will produce 10 million gallons of SAF and renewable diesel per year from ethanol, using a range of sustainable, low carbon intensity ethanol, including from waste-based feedstocks. LanzaJet Freedom Pines Fuels reports it will

approximately double the amount of current SAF production in the United States.

LanzaJet was joined at the event by its shareholders International Airlines Group (IAG), LanzaTech, Mitsui & Co., Shell, and Suncor Energy, investors including Microsoft Climate Innovation Fund, Breakthrough Energy, and All Nippon Airways (ANA), and government representatives from the Federal Aviation Administration (FAA), the U.S. Department of Energy (DOE), and the U.S. Dept. of Agriculture (USDA) as well as representatives from the State of Georgia and local and county officials.

In 2012 LanzaTech purchased the bankrupt Range Fuels facility in Soperton at auction for $5.1 million. Range built the biomass gasification plant with the intention of making ethanol from wood chips, but the firm was unable to produce the biofuel.

Arkansas Group Receives Grant

Dr. Homer Wilkes, Under Secretary for Natural Resources and Environment at the U.S. Dept. of Agriculture (USDA), met with faculty from the University of Arkansas at Monticello (UAM) and the Arkansas Forest Resources Center (AFRC) of the University of Arkansas System Div. of Agriculture housed at UAM to award them a grant for $3.7 million. The meeting took place at Five Oaks Ag Research and Education Center in Humphrey, Ark., where part of the work for the project will be conducted.

The grant provides funding for USDA Partnerships for Climate-

26 l FEBRUARY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Smart Commodities projects, which are aimed at supporting sustainability in agriculture. AFRC at UAM is the lead on the project and will partner with the University of Arkansas at Pine Bluff (UAPB) and Texas A&M University (TAMU), as well as with recruited landowners. Dr. Nana Tian, assistant professor of natural resources economics and policy at UAM, developed the proposal for the grant and will serve as the project director.

The project will support small and underserved landowners in the riverinfluenced forest regions of Arkansas to develop and harness climate-smart commodities from restoration of the region’s hardwood forests. Bottomland hardwood forests have shown high potential for producing climatesmart commodities including carbon sequestration and storage, wood products, wildlife and other ecosystem services. Despite their importance, 70% of bottomland hardwood forest areas have been lost in the past 100 years.

The project aims to plant 500 to 600 acres of oak forests in the agriculturally dominant floodplain of the Red River Valley of southwestern Arkansas, the Ouachita River Valley of southcentral Arkansas and the Bayou Meto Watershed in eastern Arkansas. The project will also quan-

tify and demonstrate the ecological and economic benefits of bottomland hardwood forest restoration on working lands and help landowners manage the plantations and market climate-smart commodities.

West Fraser Timber Idles Florida Sawmill

West Fraser Timber Co. announced in January it will indefinitely curtail its sawmill in Perry, Fla., citing high fiber costs and softening lumber markets.

The indefinite curtailment will impact 126 employees and reduce West Fraser’s U.S. lumber production by 100MMBF. West Fraser expects to mitigate the impact on effected employees by providing work opportunities at other West Fraser operations.

Drax Announces Aliceville Expansion

Drax has announced a $50 million expansion at its wood pellet plant in Aliceville, Ala., which will increase production capacity by nearly 50% from 250,000 tons to 380,000 tons.

Aliceville is well-positioned as a growing hub for sustainable forestry

and the biomass industry, according to Drax. “The region boasts of a high concentration of existing sawmills that produce the residuals necessary to support sustainable wood pellet production.”

The expansion will include upgrades to existing systems as well as new truck dumps and pelletizer units, which will allow for an increase in the amount of sawmill residuals processed. The additional capacity is expected to begin commissioning in 2024.

Drax also operates a wood pellet plant in Demopolis, Ala. and has 19 operational pellet plants and developments with nameplate production capacity of around 5 million tons a year in North America. Drax is targeting 8 million tons of production capacity by 2030.

Timber Companies Will Combat CWD

Seven timber companies and four conservation organizations are joining together to fight the spread of chronic wasting disease (CWD) among deer, elk and other species of the deer family (known as “cervids”). The new CWD coalition will promote practices that help discover, manage, and mitigate the negative

impacts of CWD. The Coalition includes the Forest Investment Associates, Molpus Woodlands Group, PotlatchDeltic, Rayonier, Resource Management Service, The Westervelt Company, Weyerhaeuser, Alabama Wildlife Federation, Boone and Crockett Club, Georgia Wildlife Federation and National Deer Assn. This footprint spans to well over 20 million acres across the nation.

“We are pleased to join with so many other private landowners and other stakeholders in addressing this critical problem,” comments Brian Luoma, The Westervelt Company President and CEO. “Federal and state agencies, the U.S. Congress, state legislatures, researchers and sportsmen conservationists are all doing their part in educating the public about this critical issue. We are fully supportive of all efforts to prevent further spread and are grateful to everyone who is participating in the coalition.”

The group has developed a list of voluntary best management practices to help monitor, manage and prevent the spread of CWD.

Chronic wasting disease is transmitted animal-to-animal and from contact with infectious material. No treatments or vaccines are currently available, and CWD is 100% fatal to cervids.

Southern Loggin’ Times l FEBRUARY 2023 l 27

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

MACHINES-SUPPLIES-TECHNOLOGY

Komatsu Tracked Harvester

With Komatsu’s XT-5 tracked harvesters, operators can harvest closer to the carrier and maneuver confidently thanks to a lower center of gravity and off-set boom. Made to perform in demanding conditions, Komatsu’s XT-5 closed loop tracked harvesters enable operators to simultaneously travel, cut, delimb, harvest and swing timber. Engineered with hydraulic lines for each function, operators can use tracks, boom, arm and tools concurrently.

The short-tail swing of Komatsu’s 331 HP harvesters lets operators work through dense forests and clear-cutting environments. The set-back boom allows cutting close to the undercarriage and tracks, while the powerful swing torque excels in demanding applications.

Designed to significantly increase lift capacity, handling trees with the arm fully extended is made easier. With an excellent balance between boom lift and arm holding capacity, the XT-5 harvesters can be equipped with a wide selection of harvesting sawheads.

The harvesters can be adapted to the job with two different working ranges. Use the short reach and larger-scaled head to harvest larger trees or switch to a longer reach and more compact

designed head to grab trees further from the carrier. Even on sloped terrains operators can work with confidence. The XT455L-5 is equipped with a heavy-duty, four-way leveling system that promotes front/rear/side leveling for exceptional stability. The fuel tank placement lowers the center of gravity for enhanced stability.

With the XT-5 harvesters, you can save on maintenance costs because the innovative hydraulic tank system design requires 55% less hydraulic oil. Pumps are equipped with hydronucleation to help prevent pump cavitation and are 17% larger to help extend component life by operating 500 rpms slower. The engine gull-wing and wide swing-out doors on the XT-5 harvesters offer quick and easy access to all engine service points and all key components. Visit komatsu.com

Vermeer Upgraded Grinder

Vermeer offers its redesigned Vermeer HG4000 horizontal grinder. This new generation delivers powerful performance in various wood waste recycling applications and landscaping material production. It’s equipped with a 536 HP (399.7-kW) CAT C13B T4F/Stage V diesel engine, a Series III duplex drum, an aggressive infeed to accommodate a variety of materials, and many

performance and durability features.

According to Vermeer product manager for environmental equipment Jeff Bradley, the Vermeer HG4000 horizontal grinder is ideal for professionals looking to expand their service as well as for bulk landscaping material producers.

The HG4000 has a feed table capacity of 4.6 cubic yards (3.5 m3). It features the proven cutting performance of the Vermeer patented Series III duplex drum with reversible hammers and tips for extended wear life compared to singlesided designs while offering bolt in replacement parts. The hard-faced anvil on the HG4000 delivers impressive cutting action with the drum, and a redesigned robust anvil-mount structure helps ease the hard-faced wear edge replacement process.

The HG4000 benefits from an updated feed roller with aggressive teeth and down pressure to maintain control of the fed material. A fully enclosed feed roller drive planetary helps provide protection and a tight clearance between the roller and mill housing to optimize material feeding while minimizing material catch points.

A wireless remote control comes standard with the HG4000, allowing operators to run most machine functions from up to 300' (91.4 m) away.

The HG4000 has a transport width of 8.2' (2.5 m), a height of 13' (4 m), a fifth-wheel hitch trailer length of 32' (9.7 m), and a weight of 52,910 lbs. (24,000 kg), or a pintle hitch trailer length of 37' (11.3 m) and weight of 55,155 lbs (25,000 kg). Visit Vermeer.com/HG4000.

30 ● FEBRUARY 2023 ● Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vermeer HG4000 horizontal grinder

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

IRONWORKS

TOLL

FREE: 1-800-669-5613

CLASSIFIED AD RATES: Classified advertising rates are $55 per inch. Space is available by column inch only, one inch minimum.

DEADLINES: Ad reservation must be received by 10th of month prior to month of publication. Material must be received no later than 12th of month prior to month of publication.

CONTACT: Call Bridget DeVane at 334-699-7837, 800-669-5613, email bdevane7@hotmail.com or visit www.southernloggintimes.com

Southern Loggin’ Times ● FEBRUARY 2023 ● 33

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

6209 4433

34 ● FEBRUARY 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 5078 6288 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Southern Loggin’ Times ● FEBRUARY 2023 ● 35 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2891 2687 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

36 ● FEBRUARY 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 13189 7393 2687 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

WANTED FOR SALE

Bent or Repairable

John Deere FD-45 SAW DISK

(Uses the smaller 1" shank tooth)

Straightening and balancing or other repairs on Saw Disks IS MY SPECIALTY

CARVER SAWDISK REPAIR

252-945-2358 566

HYD trailer, CTR delimber, 10K hrs, just coming in...............................POR Maplesville, AL Call or Text Zane 334-518-9937 3939

RECONDITIONED DELIMBINATORS!!

In addition to new machines, CHAMBERS DELIMBINATOR,

INC. now has factory reconditioned DeLimbinators. These units have been inspected, repaired, and updated as needed. Call us and we will help you select a DeLimbinator for your needs. WE ALSO BUY USED DELIMBINATORS

Call: 662-285-2777

Email: chambersdelimbinator@gmail.com

1123

30.5 x 32 Ring Tire Chains

LIKE NEW, NEVER USED Call Bryan (256) 366-6769

Log Truck Driver Injured During Crash While Not Wearing a Seatbelt TRUCKING SAFETY

Background:

On a fall morning in the Southeastern U.S., a truck driver hauling an empty log trailer was traveling eastbound on a state highway. The logging crew was in the process of moving to a new tract. The driver was driving the posted speed limit which ranged from 55 to 65 mph. Conditions were clear and dry, so weather was not a contributing factor to the accident.

Personal Characteristics:

The driver had worked for the business owner for approximately three years and was considered a great employee. The driver did have over 20 years of experience hauling a wide variety of loads while owning his own trucking company. The driver and logging business owner had known each other for over 30 years.

Accident:

A witness traveling behind the truck driver observed the truck leave the road, travel into a ditch, then strike a raised driveway bank. The truck came to a stop on the other side of the driveway. The witness contacted authorities to report the accident, then called the business owner to notify him that one of his trucks was involved in an accident. The accident occurred approximately eight miles away form the logging job site.

Injury:

County rescue workers found the driver lying in the passenger floorboard of the cab. He had sustained injuries to his right leg in addition to head lacerations. The driver was extracted from the cab around the time additional EMS personnel arrived on the scene. The driver was transported

to a local medical center for further evaluation and treatment. While shaken from the accident, the driver did not sustain any serious injuries.

The driver was not able to communicate with first responders and did not indicate a cause for the accident. He later claimed that he ran off the road to avoid hitting a deer and lost control of the truck and trailer. A post-accident inspection revealed that the driver was not wearing his seatbelt. The cab did not have a dash camera system installed.

Unsafe Acts/Conditions:

● The driver was not wearing a seatbelt

● The driver drove his truck off the road to avoid hitting a deer

● The driver failed to maintain control of his truck and trailer while driving

13862

Recommendations:

● Always wear a seatbelt while traveling in a moving vehicle

● Keep tires on the pavement at all times to maintain proper control

● Always stay alert and focused on driving

● Consider requiring all employees to sign a “safety rules document” to ensure understanding of company safety policies and rules compliance

● Be vigilant when deer are active, especially at night and during hunting seasons

● Consider dash camera installation on all trucks

Supplied by Forest Resources Assn.

Southern Loggin’ Times ● FEBRUARY 2023 ● 37 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM EUREKA! EUREKA! EUREKA! OWNERS HAVE OVER 30 YEARS COMBINED EXPERIENCE! We can save you money on Saw Teeth. Hundreds of satisfied customers. Rebuilt Exchange or New. We specialize in rebuilding Koehring 2000, Hurricana, Hydro Ax split teeth and all other brands. Call Jimmy or Niel Mitchell. Quantity Discounts! EUREKA SAW TOOTH CO., INC. 4275 Moores Ferry Rd. • Skippers, Virginia 23879 PH./FAX (day) 1-434-634-9836 or Night/Weekends • 1-434-634-9185 NOW ACCEPTING CREDIT CARDS 7180 VISIT US ONLINE southernloggintimes.com ANYTIME

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

COMING EVENTS

February

22-26—Appalachian Hardwood Manufacturers annual meeting, Ponte Vedra Inn & Club, Ponte Vedra, Fla. Call 336-885-8315; visit appalachianhardwood.org.

24-26—South Carolina Timber Producers Assn. annual meeting, DoubleTree Resort by Hilton, Myrtle Beach, SC. Call 800-371-2240; visit scloggers.com.

March

8-10—2023 SLMA & SFPA Spring Meeting & Expo, Hyatt Regency Savannah, Savannah, Ga. Call 504443-4464; visit slma.org.

28-30— Kentucky Forest Industries Assn. annual meeting, Embassy Suites, Lexington, Ky. Call 502-695-3979; visit kfia.org.

30-April 1—Southeastern Wood Producers Assn. annual meeting, The Okefenokee Fairgrounds, Waycross, Ga. Call 904-845-7133; visit swpa.ag.

April

26-28—Virginia Forestry Summit, Williamsburg Lodge, Williamsburg, Va. Call 804-278-8733; visit vaforestry.org.

August

11-12—Southwest Forest Products Expo, Hot Springs Convention Center, Hot Springs, Ark. Call 501-2242232; visit arkloggers.com.

17-20—Virginia Loggers Assn. annual meeting, Hotel Roanoke, Roanoke, Va. Call 804-677-4290; visit valoggers.org.

23-25—Forest Products Machinery & Equipment Expo, Music City Center, Nashville, Tenn. Call 504443-4464; visit sfpaexpo.com.

September

5-8—Tennessee Forestry Assn. annual meeting, Marriott Cool Springs, Franklin, Tenn. Call 615-883-3832; visit tnforestry.com.

7-9—Great Lakes Logging & Heavy Equipment Expo, UP State Fairground, Escanaba, Mich. Call 715-282-5828; visit gltpa.org.

15-16—Kentucky Wood Expo, Masterson Station Park, Lexington, Ky. Call 502-695-3979; visit kfia.org.

22-23—Mid-South Forestry Equipment Show, Starkville, Miss. Call 800-669-5613; visit midsouthforestry.org.

26-28—Arkansas Forestry Assn. annual meeting, Oaklawn Hotel & Spa, Hot Springs, Ark. Call 501374-2441; visit arkforests.org.

27-29—North Carolina Forestry Assn. annual meeting, Biltmore Estate, Asheville, NC. Call 800231-7723; visit ncforestry.org.

October

3-6—American Loggers Council

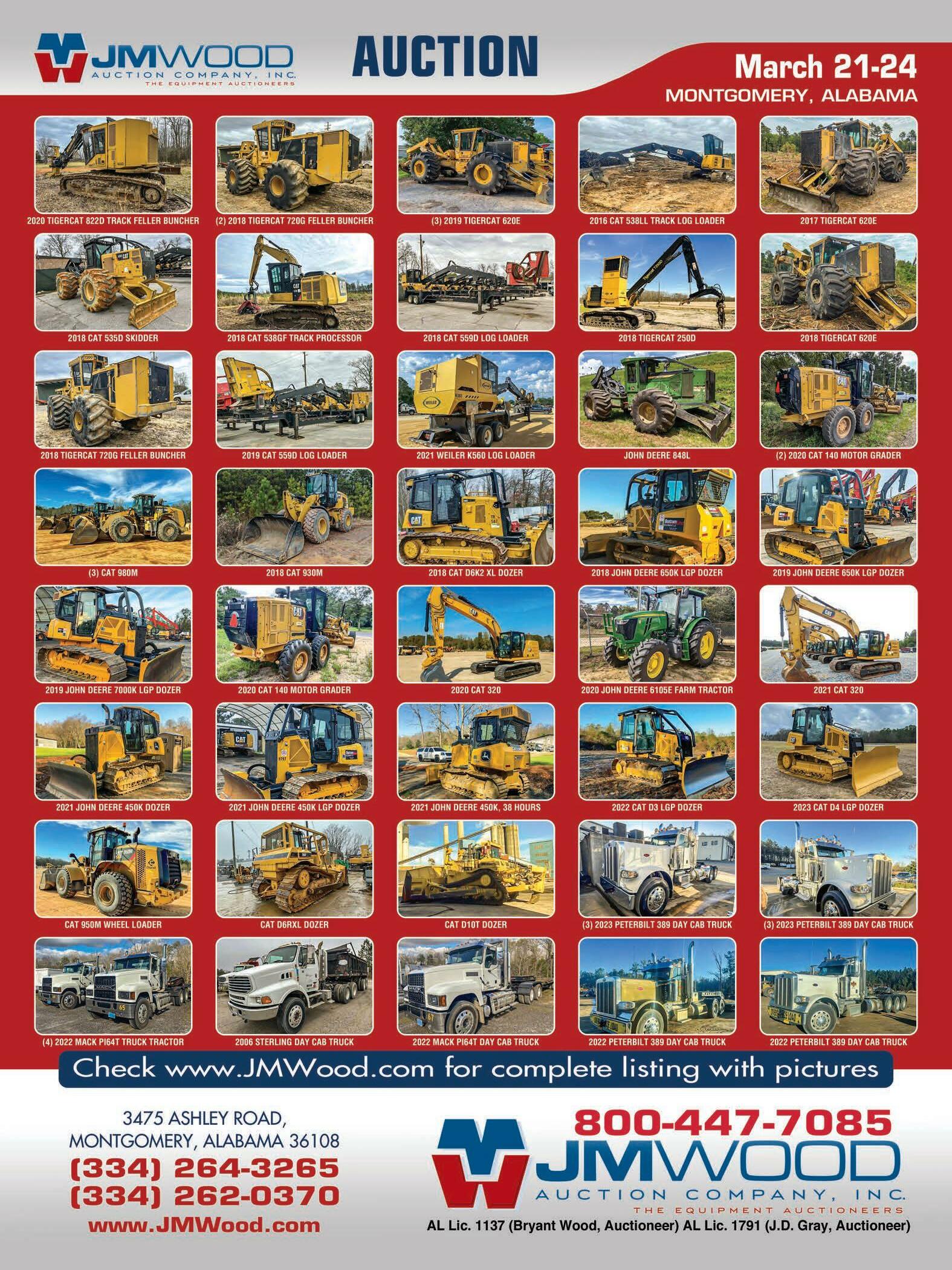

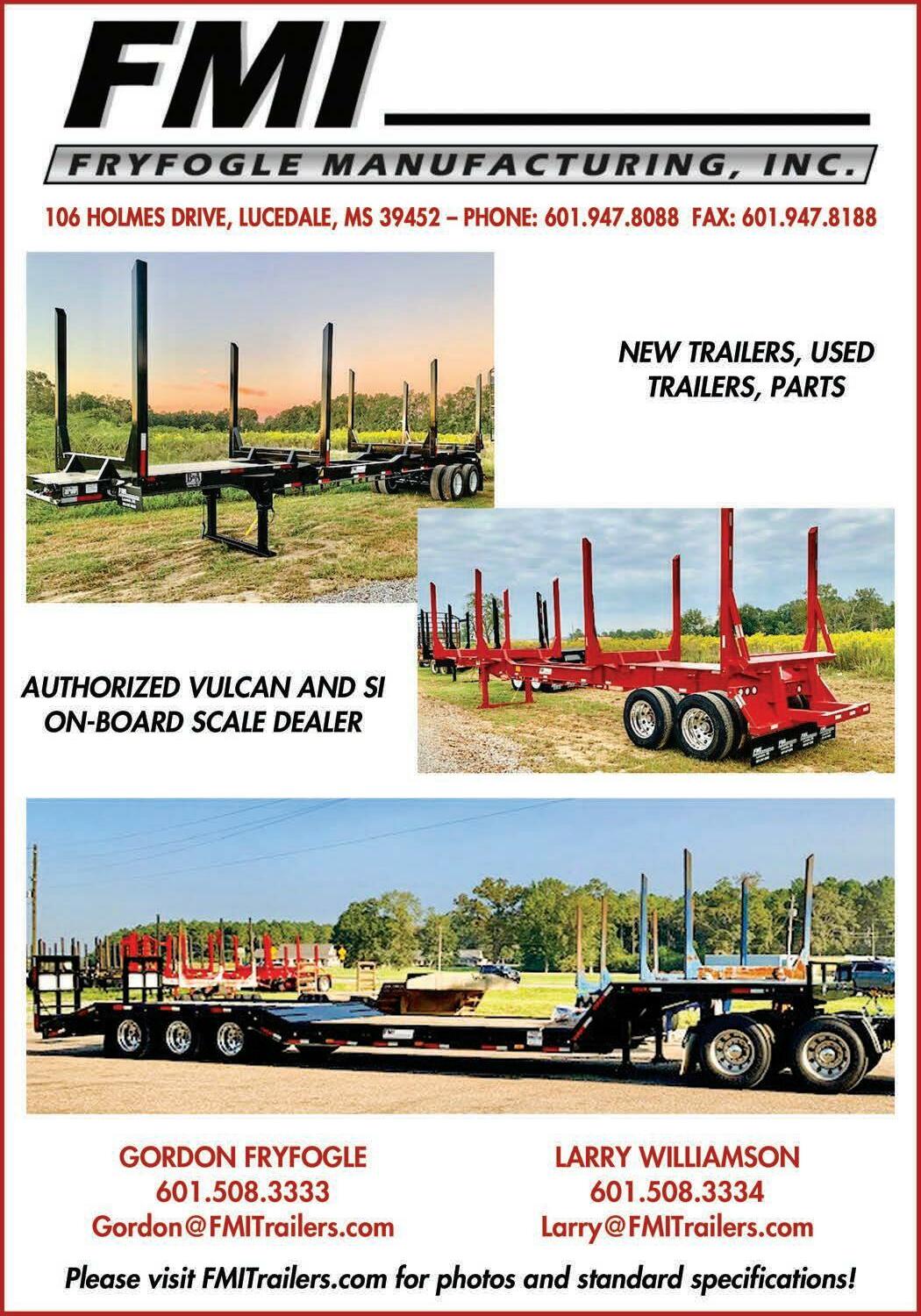

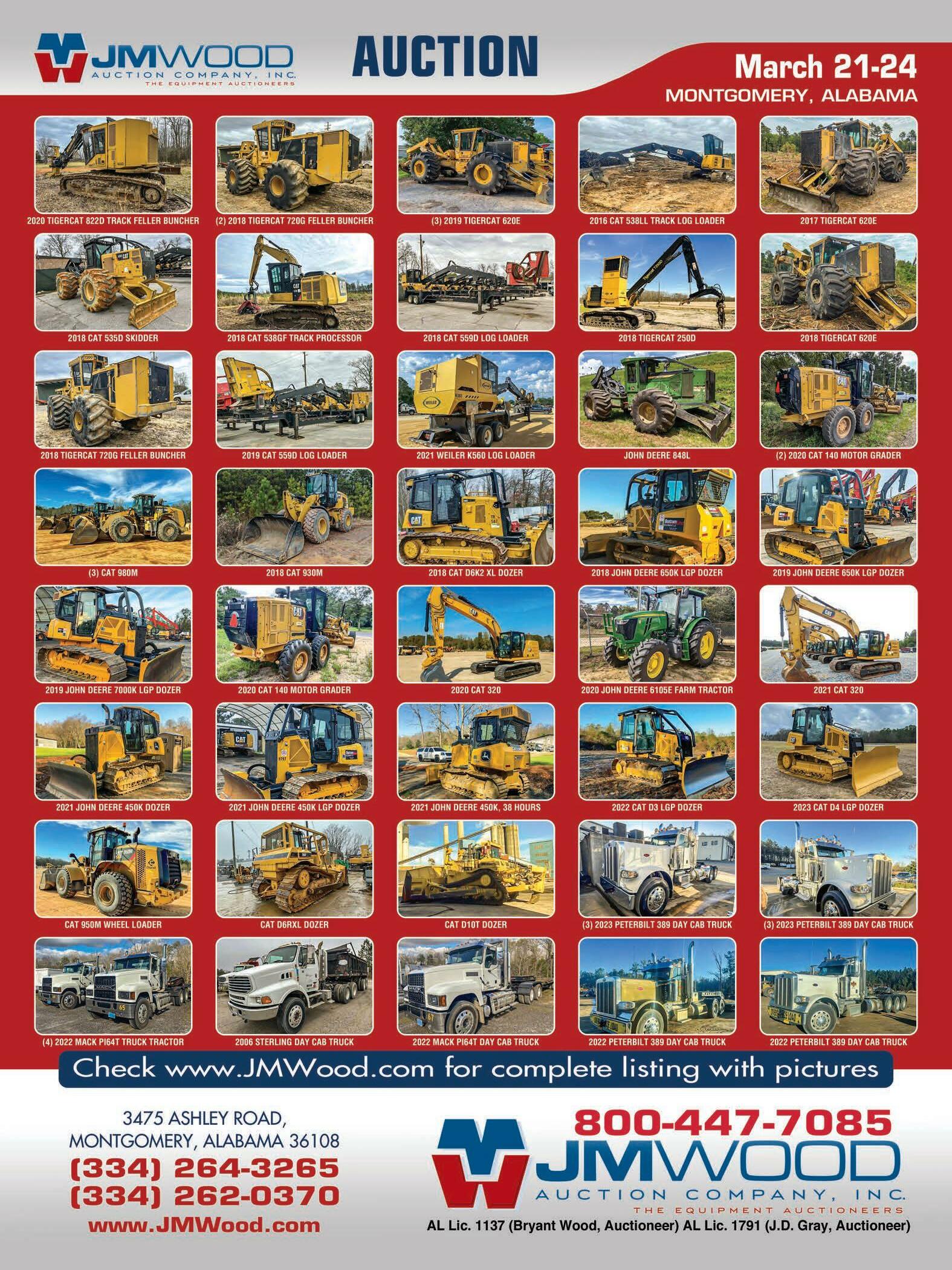

American Truck Parts 26 888.383.8884 Around The World Salvage 34 936.634.7210 Big John Trailers 5 800.771.4140 BITCO Insurance 30 800.475.4477 Caterpillar Dealer Promotion 13 919.550.1201 Cleanfix North America 38 855.738.3267 John Deere Forestry 17 800.503.3373 Dobbs Equipment 2 844.469.3622 Eastern Surplus 25 855.332.0500 FMI Trailers 24 601.508.3333 Forest Chain 25 800.288.0887 Forestry First 34 803.708.0624 Forestry Mutual Insurance 3 800.849.7788 G & W Equipment 23 800.284.9032 Hawkins & Rawlinson 12 888.822.1173 Interstate Tire Service 36 864.947.9208 Kaufman Trailers 19 336.790.6807 Mike Ledkins Insurance Agency 22 800.766.8349 LMI-Tennessee 29 800.467.0944 Loadrite Southern Star 26 256.270.8775 Logger Associations 25 Magnolia Trailers 31 800.738.2123 Maxi-Load Scale Systems 18 877.265.1486 Midsouth Forestry Equipment 10 870.226.0000 Moore Logging Supply 26 888.754.5613 Morbark 1,11 800.831.0042 Pitts Trailers 40 800.321.8073 Ponsse North America 39 715.369.4833 Prolenc Manufacturing 10 877.563.8899 Quadco Equipment 16 800.668.3340 Quality Equipment & Parts 33 386.487.3896 Southern Loggers Cooperative 23 318.445.0750 Stribling Equipment 35 855.781.9408 Tidewater Equipment 35,36 912.638.7726 Tigercat Industries 7 519.753.2000 TraxPlus 27 601.635.5543 W & W Truck & Tractor 32 843.761.8220 Waters International Trucks 36 601.693.4807 Watts Auction Realty Appraisal 21 434.821.5263 J M Wood Auction 28 334.264.3265 Yancey Brothers 23 800.282.1562 38 ● FEBRUARY 2023 ● Southern Loggin’ Times

ADLINK is a free service for advertisers and readers. The publisher assumes no liability for errors or omissions. A ● D ● L ● I ● N ● K ADVERTISER PG. NO. PHONE NO.

are submitted months in advance. CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

southernloggintimes.com Listings

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!