CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Vol.

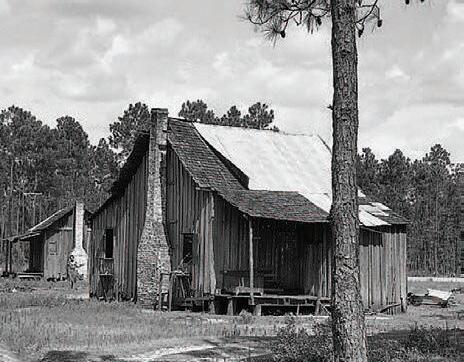

Steven Coatney found his life’s passion while working in the woods for his future father-in-law during college. He quit school and started his own logging business. Now he's expanded into land development as well under a separate-but-related company, Oso Pardo Investments. Story begins on Page 8. (David Abbott photo)

May 2023

A Hatton-Brown Publication

Phone: 334-834-1170

Fax: 334-834-4525

www.southernloggintimes.com

Publisher David H. Ramsey

Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Senior Editor Dan Shell

Managing Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director Cindy Segrest

Ad Production Coordinator Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING CONTACTS

DISPLAY SALES

Eastern U.S. Kathy Sternenberg

Tel: 251-928-4962 • Fax: 334-834-4525 219 Royal Lane Fairhope, AL 36532

E-mail: ksternenberg@bellsouth.net

Midwest USA, Eastern Canada

John Simmons Tel: 905-666-0258

29 Bugelli Dr. Whitby, Ontario, Canada L1R 3B7

E-mail: jsimmons@idirect.com

Western Canada, Western USA Tim Shaddick

Tel: 604-910-1826 • Fax: 604-264-1367 4056 West 10th Ave. Vancouver, BC V6L 1Z1

E-mail: twshaddick@gmail.com

Kevin Cook

Tel: 604-619-1777

E-mail: lordkevincook@gmail.com

International Murray Brett

Tel: +34 96 640 4165 +34 96 640 4048

58 Aldea de las Cuevas • Buzon 60 03759 Benidoleig (Alicante), Spain

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane

Tel: 1-800-669-5613 • Tel: 334-699-7837

Email: bdevane7@hotmail.com

Southern Loggin’ Times (ISSN 0744-2106) is published monthly by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—SLT is sent free to logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel in the U.S. South. See form elsewhere in this issue. All non-qualified U.S. subscriptions are $65 annually; $75 in Canada; $120 (Airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.southernloggintimes.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Southern Loggin’ Times magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Southern Loggin’ Times. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or in part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed In USA.

52 No.5

(Founded in 1972—Our 608th Consecutive Issue)

POSTMASTER:

, P.O. Box

FEATURES 4 ● MAY 2023 ● Southern Loggin’ Times Other Hatton-Brown publications: ★ Timber Processing ★ Timber Harvesting ★ Panel World ★ Power Equipment Trade ★ Wood Bioenergy 16 Turpentine History Part 3 of 3 Southern Stumpin’. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Bulletin Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 From The Backwoods Pew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Industry News Roundup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Safety Focus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 IronWorks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Coming Events/Ad Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Send address changes to: Southern Loggin’ Times

2419, Montgomery, AL 36102-2419

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

‘Let The Sawdust Fly’ SOUTHERN STUMPIN’

By David Abbott

segment, Peter Wood has developed a platform in a public forum where he can deliver the message to people outside the industry.

And that’s what Wood was going for in the first place. “Many people don’t realize that biomass is more renewable than solar power or wind mills,” he points out. “Forestry is number one when it comes to renewability, but we get a bad rap because society doesn’t know the truth. And that’s where the radio show came in.”

It was something he had thought about for years before “Let The Sawdust Fly” first aired in 2016. “I thought we needed someone to tell John Q. Public on a regular basis about our industry, where they can learn about timber while they go about their life, driving around,” Wood explains. “And when they go to the store for groceries or building supplies, they start to realize that all that stuff has to come from somewhere. And slowly they start to get it.”

AM talk radio is well known as a domain largely for politics, but Wood strives to keep his segment strictly focused on the timber industry. He realized his approach was finding an audience when a listener to the talk show called in one day to ask, “When is that logger coming back? I am so sick of listening to all this other stuff all the time.”

Woods Roots

We always say loggers have the woods in their blood, but it’s even more true in Peter Wood’s case. “I didn’t have much of a choice in it, did I?” he laughs. Last name aside, Wood was born into a timber family; he’s a third generation Minnesota lumberjack. “My granddad settled here in 1917 and I live in the old place that he settled back then; it has been in the family ever since.” The family lives in Canyon, a little town in northeastern Minnesota about 20 miles out of the

Duluth city limits. “It’s a great way of life.”

The family company, Wood Forest Products, Inc., is a conventional operation with a chipper. “We cut a lot of areas where cut-to-length wouldn’t work very well, a lot of sales nobody else cuts with a lot of chips and biomass,” he says.

As a child, Wood was severely injured, and nearly killed, in an accident. At 13 a machine he was running tipped over and cut his leg almost entirely off just above the knee; it was barely holding on by a thin strand of flesh. “I should have bled to death right there,” he admits. “My dad was nearby. He was a World War II vet, a DDay Normandy vet, a just-keep-going kind of guy. We didn’t have any money and during that time our family car had no battery. So he had to get a battery out of a farm tractor, put in the car, and got me to the hospital; they reattached my leg, but it was touch and go for a while.”

Wood sometimes uses this personal story to illustrate a point about not giving up even when things are bad. He admits these are tough times in the woods. “But tell me: when was logging easy? It never has been. It’s always been a tough, uphill battle. We believe it should get easier, but it’s not going to.”

Despite that, he advises an optimistic perspective. “Logging is great, until you look at the money. But it is the quality of life we have that is so precious. Look at how you live and where you live compared to other people. Even on our toughest days, we still have a pretty good life.”

The Show

“Let The Sawdust Fly” airs on KDAL 610 AM, a local talk radio station in Duluth (one of several stations owned by Midwest Communications out of Green Bay). Brad Bennett, called the “Commandant of Common Sense,” is a U.S. Marine and Vietnam War vet who hosts “SoundOff with Brad Bennett.” The talk show airs on KDAL daily in the 11-2 slot, covering local, national and international news and politics.

Wood had gotten to know Bennett a little bit after Bennett served as keynote speaker at a Minnesota logging conference years ago. After 10 years of thinking that someone should get the loggers’ story to the general public, Wood decided in 2016 that it

might as well be him since no one else was doing it. He called Bennett, not expecting a positive response. After a short chat, he asked, “Would it be possible for me to come on your show to talk about the timber industry?” To his surprise, Bennett answered, “It’s about time you asked.”

The first time he went on the air, Scott Dane, who was then still Executive Director of the Associated Contract Loggers and Truckers of Minnesota, went with him, “In case I blew it totally,” Wood laughs. “That first show I talked fast, trying to get in as much information as possible, because I thought I’d never get another shot.” But Bennett and producer Kenny Kalligher asked him to come back, and the original 22minute segment grew to a half hour and finally a full hour, and added theme music.

“I always thank Brad that he allows me the opportunity to come on and co-host that segment once a month on his show,” Wood says.

The lifelong logger wasn’t sure how to approach radio at first; he looked to hosts like Rush Limbaugh as a reference, and he was open to learning from his mistakes. “I thought my first show was ok, but I got critiqued by my family where I messed up, and I tried to pay attention to what works and what doesn’t.”

Wood says each show takes close to 40 hours of advance prep and he always loses a half a day of work when he goes to the studio. The segment airs live the last Wednesday of every month; recordings are available as a podcast online, usually posted a few hours after the live show.

Wood records in-studio with Bennett, but has guests phone in if they are too far away to come in person. Among the many he’s had on the show in the last seven years are Texas equipment guru Tom Hirt, Southern Loggers Co-op’s Bill Jones from Alabama, South Carolina Timber Producers Assn.’s Crad Jaynes and HattonBrown’s DK Knight.

Besides interviewing guests, he’s done multiepisode series on specific topics, such as the history of how the Native American population managed their forest resources in the pre-European times.

Wood thought the show would reach only a local or regional audience, but thanks to the podcast, it has found listeners in far away places. Wood makes no money from it, but he’s happy it’s allowed him to reach a wide audience. “I want everyone who tunes in to be glad they did,” Wood says.

To listen for yourself, search for “Let The Sawdust Fly” on Google or on various podcast hosting services like Apple, Spotify and Audible. SLT

Editor • Ph. 334-834-1170 • Fax: 334-834-4525 • E-mail: david@hattonbrown.com

• Managing

6 ● MAY 2023 ● Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

PeterWood,left,withAlabama's Joel Moon at ALC last fall

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

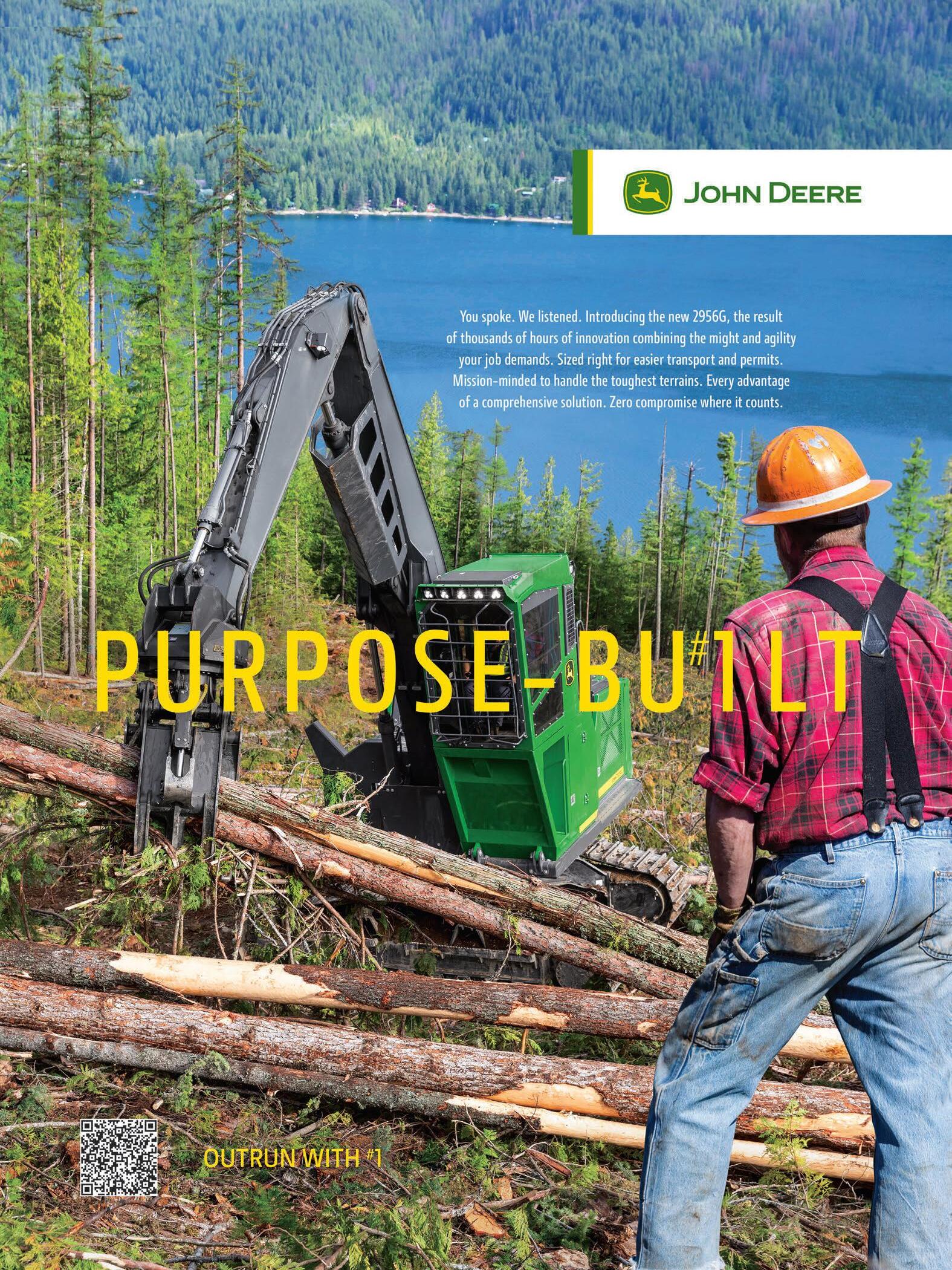

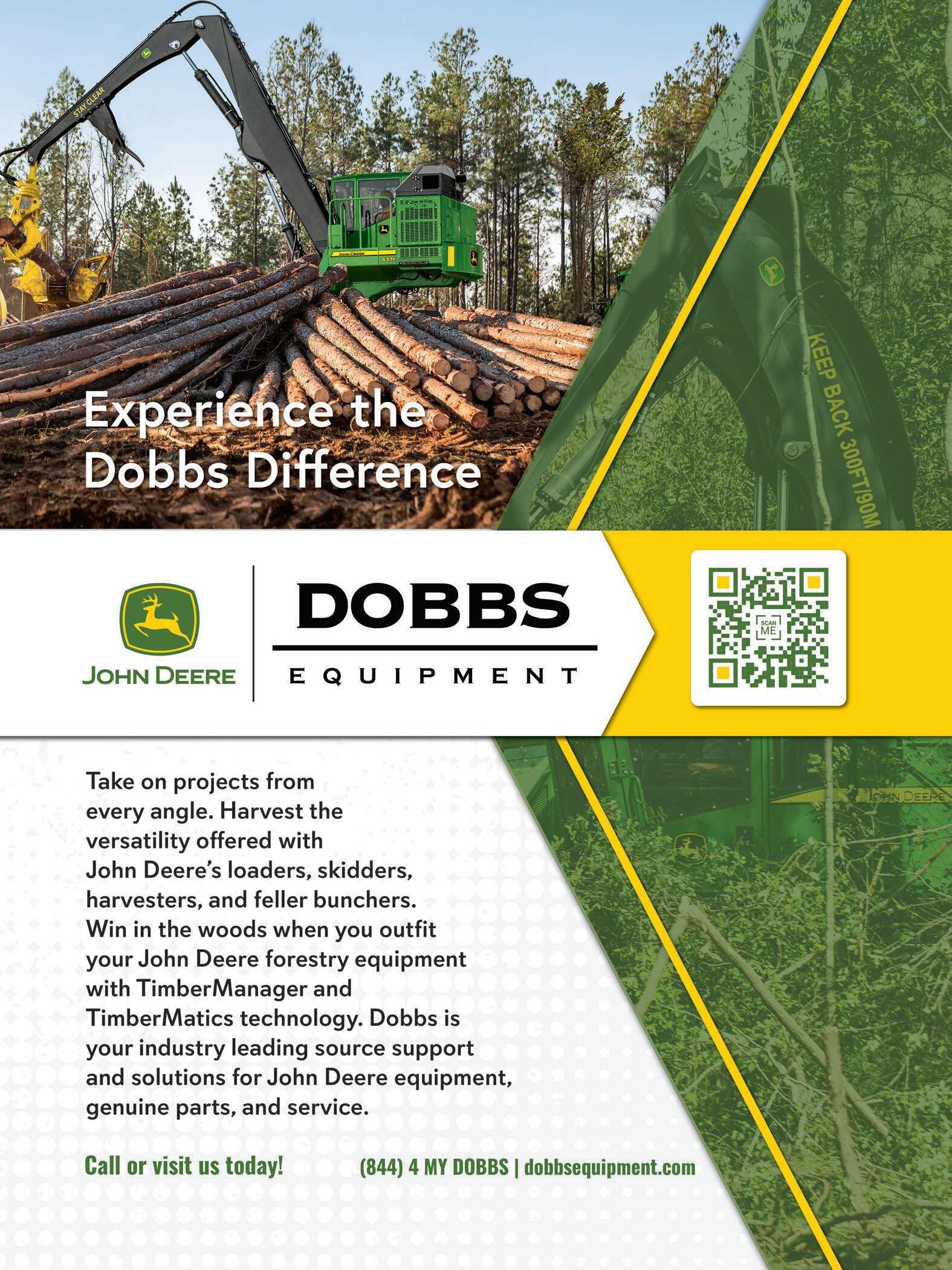

Going Big

By David Abbott LIVINGSTON, Tex.

Steven Coatney didn’t grow up with a family background in forestry. He attended Blinn College before transferring to Sam Houston State University to study agriculture business. While he was a student, Coatney worked part-time in the woods for his future father-in-law Roland Hickman (Coatney married Hickman’s daughter in 2007). “I fell in love with the woods during college,” Coatney says. He didn’t finish the degree, leaving after his junior year to start his own logging business when he was 21, in 2004. “Not that I don’t regret not finishing, but I think it worked out. I was ready and it was a good time to get

into the logging woods.”

The fledgling logger started small, with a skidder and loader, still felling with chain saws back then, but the young man kept growing his company till he could buy new equipment, including a feller-buncher. He eventually expanded into three crews. Since then, Steven Coatney Logging, LLC has flourished.

More recently Coatney has become involved in land development. He and his good friend, James Edward Harrison the Third (known as “Tres”), partnered to form Oso Pardo Investments. As with Harrison’s nickname, the company name derives from their local cultural heritage; it’s Spanish for “Grizzly Bear.” The partners chose it as a reference to an expression Harrison has been fond of: “If

you’re gonna be a bear, be a grizzly.” It’s his way of saying, “Go big or go home,” essentially. “When we did anything, he’d say that to mean we gotta do it big or not do it at all,” Coatney explains. It certainly seems like an appropriate attitude in the Lone Star State, where everything is, of course, bigger.

When Southern Loggin’ Times visited in early March, one of Coatney’s crews was working on a 170acre tract in development by Oso Pardo. They were doing a real estate cut, leaving trees spaced every 50 feet or so, trees people would want in their yard once people move in. Logging the land would take about four weeks, with subsequent cleanup lasting at least two months.

“Once we get it logged, we have our dozers and excavators grubbing, raking and burning and mulchers

going behind them,” Coatney says. That process had already begun, in fact, on cleared sections while logging was still in progress on the rest of the property. “When we get done it will be ready to build on. We will put in the road infrastructures, the drainage systems, the power, water, Wi-Fi; we do everything from start to finish short of building the houses.”

Once finished, the neighborhood will be called Grand Oaks. Coatney expects it be ready within a year or so; they’re certainly aiming for it not to take any longer than necessary to do the job right. “When we hit something, we hit it hard,” he explains. “You have so much invested that you have to start seeing something come back from it.”

The biggest hold up, he explains, is the engineering plat (professional land survey). During the prelimi-

8 l MAY 2023 l Southern Loggin’ Times ★

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

■ Steven Coatney Logging and Oso Pardo Investments don’t settle for small goals.

nary survey, Coatney and Harrison work with a civil engineer to determine the best layout for roads, drainage and such, making adjustments based on what crews see on the ground. Once a plan is ready, it goes before the county for subdivision approval. “Once that’s done we can legally start selling the property off.” Oso Pardo has a realtor to sell the properties. “This is our first big project; we’ve done a lot of smaller stuff, but this is our first time tackling one of this size.”

When he started logging, Coatney was more hands-on, personally operating machines in the woods every day. Only in the last seven years or so has he taken a step or two back from that to focus on other areas, such as buying and developing properties. “Logging is a good business, but with the cost of

Southern Loggin’ Times l MAY 2023 l 9 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

10 l MAY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

least 2,500 acres of solid timberland and harvest so much of it every year on a cycle,” he explains. “I love all this stuff but longleaf was native here and I would really like to bring back some longleaf to my properties. I know as far as generating income it’s a lot slower but I’d love to have some established longleaf tracts, mainly just for personal enjoyment and maybe my kids one day will benefit from it.”

Steven Coatney Logging has contracted for Woodville-based North American Procurement Co. (NAPCO) for 17 years. Other than development projects for Oso Pardo, Coatney’s crews work primarily on NAPCO-purchased timber.

“We don’t cut a lot of hardwood, this tract aside,” Coatney says. “Our crews are set up to do it all: first thin, second thin and clear-cut.” They haul to Woodville Pellets (where NAPCO has a supply contract), West Fraser in Lufkin, Georgia-Pacific in Camden, Corrigan

and Dibol, and Steely Lumber Co. in Huntsville. “Steely is to me one of the best private owned mills that I know of,” Coatney says. “When you pull up to this mill it blows my mind how clean it is, how well organized and how up to date it is.”

When SLT visited the one Oso Pardo crew in March, Coatney’s other two crews were combined on a NAPCO tract near Kountz where they were pumping out 20+ loads a day. The three Coatney crews, taken together, average around 50 loads a day total, and shoot for at least 200 loads a week with all crews combined.

Equipment

Over the past 20 years, Coatney says he has tried different setups with different size machines. “To me my best set up is a crew with one cutter, say a 843 size, two 648 skidders and two loaders. If I have a skidder go down I still have one

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Land clearing equipment includes Deere dozers,Volvo and Cat excavators and Raptor (above) and Barko mulchers.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

capable of dragging to both loaders, or if a loader goes down you can still load with the other. If the cutter goes down, it should be ahead so you should be ok for a day or so. With the single machine set up, one of each, if one machine is down your whole job is down.”

The only problem with running this setup on his crews, he says, is that tracts these days have gotten smaller and smaller. “Instead of having a 200 or 300 acre clear-cut we may be down to a 40-50 acre

clear-cut. It’s hard to move a crew of that size onto a tract that small. Right now we can still maximize with that size.”

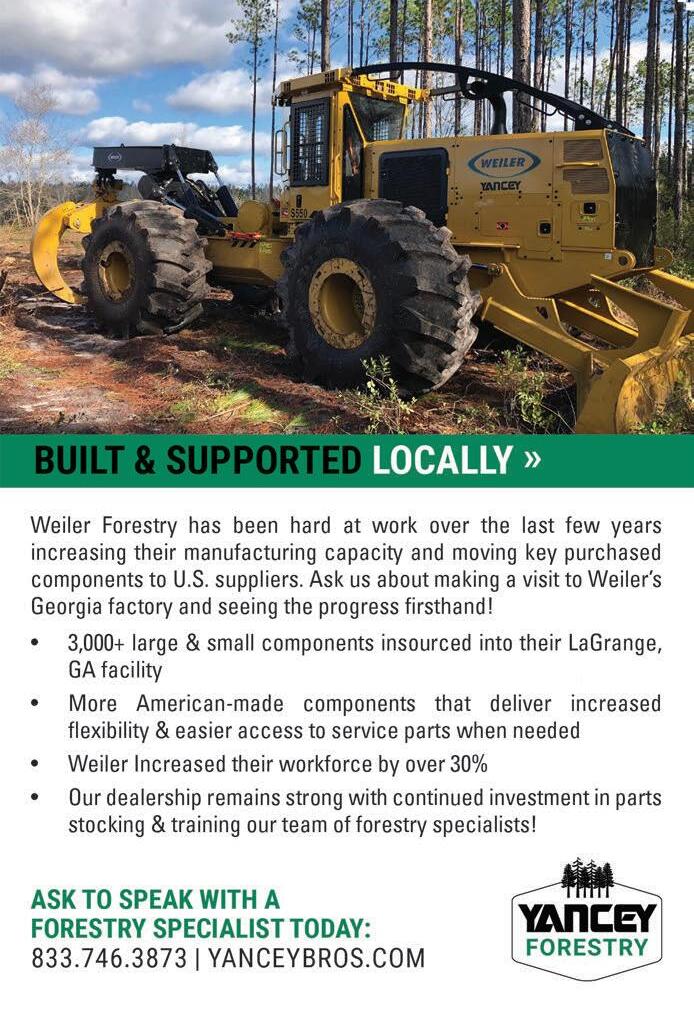

Among its three crews Steven Coatney Logging runs John Deere 648 and 748 skidders, Deere 813LII and Tigercat 718E cutters, a Deere 437 and two Barko 595 loaders, with CSI pullthrough delimber/slasher deck combos. Doggett Machinery in Lufkin supplies all John Deere machines, while Tejas Equipment in Hillister is the Tiger-

cat dealer for the territory, and FTR Equipment in Lufkin sells Barko machines.

Coatney owns six trucks and with contractors runs a total of 12 trucks among the three crews, pulling all pole trailers from a variety of brands, mostly Fontaine. Performance Trucks in Lufkin is Coatney’s truck dealer. He owns five Macks and a Kenworth. “When the KW is ready to trade in we will be running all Macks,” he says. They run M drive automatics in all the trucks

now. “It has really saved us because a lot of the new drivers now can’t drive standards. It’s not knocking them; they learn on an automatic. Drivers are hard to find, and in the logging business you get punished for hiring anybody under 25 years old. Since we switched to the M drive, I haven’t replaced a clutch in I couldn’t tell you how many years, and they just seem to be working really well.”

For insurance Coatney uses H&H Risk Partners in San Antonio, and he tries to have safety meetings every week.

Steven Coatney Logging is a member of the Texas Logging Council, and Coatney says he tries to make it to as many meetings as he can. Several of his men take the Pro Logger certification classes, and he’d like to get more of them involved. “You only have to have one person on each crew, but there are a lot of new things being implemented, like with creek crossings,” he says. “We want to enhance our knowledge on things like stream crossings. If you take away the cover of the creek, it raises the temperature of the water, no doubt, and you have to think about soil runoff and contamination in the water.”

Moreover, in our increasingly litigious society, a logger can get himself in trouble without knowing it. Coatney figures it would be beneficial to have as many operators as possible certified and trained in those areas. “It’s just protecting us; everyone is suehappy these days, and it is very easy to mess up in this business. Take something as simple as a pipeline. I met with a pipe guy when we came out here. A lot of these lines are old, they’re from the ’50s. When he tested to see how low the pipe is, it’s two feet. Well, if we didn’t have crossings like we’ve built to cross that, it’s very easy to erupt a diesel line or oil crude line and then you’re talking about millions of dollars of cleanup. It’d put me out of business. I’d be done.”

Coatney thinks of his employees like members of his family. “They work well together and have a lot of respect for what they do, and that means a lot to me because you’re only as good as your crew,” he says.

He and his wife Veronica Hickman Coatney dated in junior high and then got back together when they were in college, and it was working for her dad that led him to his career. They have been married for 16 years and have two daughters, Camryn and Katelyn, ages 10 and 12. SLT

14 l MAY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

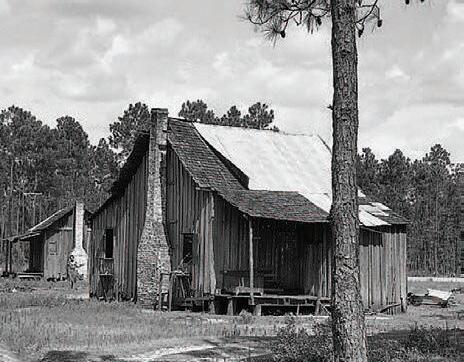

TAR-nished Industry

■ The birth, development and demise of the South’s important Naval Stores sector

By DK Knight

Third Of Three Parts

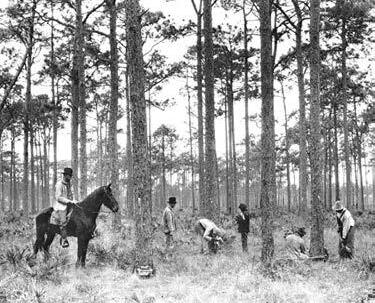

At its very best, logging work was tough, exhausting and dangerous in early America and through the first half of the 20th century, but by most historical accounts, conditions were tougher, in some instances downright cruel, for those who toiled in the gum turpentine woods.

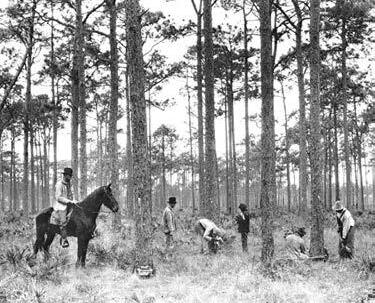

The dirty, sticky, ‘can to can’t’ work regimen was a grueling treadmill, given its tree-to-tree walking requirement, at times through thick brush, mud, or standing water. While heavy, the tools used for tree chipping were light compared with gum buckets, which could weigh 50 lbs. when full. Throw in searing heat, stifling humidity, hordes of mosquitoes and other insects, and the always there snake threat. Add high quotas imposed by demanding camp bosses and enforced by mounted woods riders, who could be ruthless.

No job in the woods paid very much in these decades, but at pennies a day, even up to World War II, wages for turpentiners were as thin as their occasional breakfast gravy.

It is not likely that most tree boxers, gum dippers, wagon drivers, barrel makers, and distillery attendants wanted to be turpentiners, but it is likely that a majority of them did not know anything else, or simply could not find anything better. So, they stuck with it, some for decades or a lifetime, some by choice or circumstance. As a group, turpentine troops were often intimidated by management to be submissive and generally were looked down upon as social outcasts, even though the turpentine industry was a mainstay in the Southern economy.

Early on, turpentine tasks were carried out by slaves, although some

poor whites did join in, often working trees of their own. When longleaf pine gave out in North Carolina around 1860 and turpentine operators relocated to South Carolina or elsewhere to the south and west, they generally moved their slaves with them. Some whites, and even a few Native Americans, joined them, creating a phenomenon known as the Turpentine Trail, which eventually extended to east Texas.

After the Civil War, many former slaves stayed the turpentine course, following who they knew and what they knew. Most post-war workers were black, and a majority had roots in North Carolina. They were assigned to work in crops of 10,000 faces—some trees had up to three— and were expected to meet production quotas as tall as the trees themselves. Within a crop, hackers and dippers typically were in charge of 2,000 faces. Each time they worked a face, or a boxer made a new tree cavity, they yelled out their code name to a mounted rider, who recorded it in a tally book and otherwise coordinated the work of a specific squad or two. Boxers were expected to chop 80 to 100 cavities a day.

Few women and children worked in the trade, and those who did dipped gum or kept weeds and debris cleared from the base of chipped trees.

Life Of Isolation

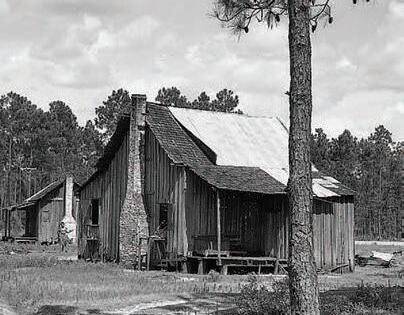

Turpentine camps were typically located deep within the worked timber, isolated from other communities, houses, or towns. One important benefit of this isolation was the control it provided camp owners over workers and their families.

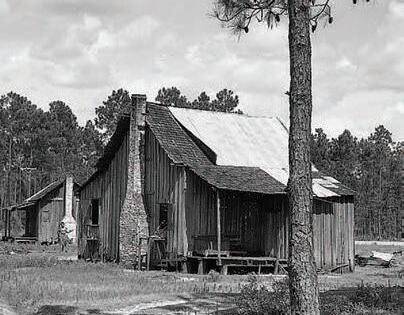

For the most part, only a token effort went into developing worker housing. Given a camp’s short life, housing for workers usually consisted of shacks or lean-tos, some with a wood stove and fireplace and a small plot for a vegetable garden. Houses in some camps were mounted on skids, facilitating movement from one place to another. Some had a school and church; most had a ‘juke joint’ where weekend drinking, dancing and gambling took place.

Many camps separated married households from unmarried ones, as this helped dampen, but failed to eliminate, confrontations between single and married workers. The number of workers in a typical camp ranged from 50 to 200.

Immigrants, Convicts

Ironically, even though naval stores operations were heavily labor dependent, many of their managers, bosses and foremen treated workers with contempt and in some instances abused them verbally and physically. On the other hand, a good number treated them with a degree of respect. Some never condoned abuse and a few permitted those unable to work due to age or physical impairments to continue living, rent-free, in camp housing.

The labor requirement led some turpentine, logging, and lumbering concerns to pay fees to agents in Northeastern cities to recruit European immigrants, who often were fed misleading information concerning the work, pay, and living conditions. Numerous migrants were sent South and reported for work, only to later learn that their transportation expenses were charged against their wages. They were already in debt to their employer when they arrived. If they lasted, foreigners typically had difficulty fitting in with the established social order.

In keeping with the practice of many logging and lumber interests of the period, wages were paid in the form of script, specie or token, and pay was usually based on production. Workers used this ‘currency’ to buy goods at the operation’s on-site commissary, which usually charged higher prices than stores in

distant settlements or towns. Even if a worker could get to an outside store, his company pay was no good there. Workers at times drew advances against wages and otherwise more often than not remained in debt to the commissary, the manager of which could easily conduct ‘creative’ bookkeeping.

If workers left to go elsewhere and were indebted to the commissary, they were routinely hunted down, sometimes with the aid of dogs, and forced to resume work. Technically, this was considered debt peonage (forced labor), and a violation of federal law, but several states had adopted laws that to some extent circumvented the federal statute. In the early 1900s federal authorities apparently had little or no enthusiasm for investigating alleged peonage incidents, and even when they did bring charges, few of the accused were convicted. The few convictions that did occur were often struck down by state courts. Prevailing racial attitudes of the period were a primary means of shaping and sustaining the elusive peonage system.

The labor scarcity led some logging, lumbering, mining, farming and turpentining concerns in Florida and Alabama, and perhaps other states, to lease state and county convicts. At times these operations paid an under-the-table fee to government officials for this arrangement.

Extremes Examined

Jerrell Shofner, in an article titled “Forced Labor in the Florida Forests 1880-1950” and appearing in the January 1981 issue of the Journal of Forest History, described two telling incidents, the

Georgia turpentine camp houses,early 1900s

A chipper takes a rare break.

16 ● MAY 2023 ● Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

A woods rider coordinated the work and kept a tally of each worker’s daily performance.

first apparently in a non-convict camp:

“In 1921 Fred Cubberly (U.S. Commissioner for the Northern District of Florida) found evidence that peonage in all its vicious forms had continued throughout the war years at the Putnam Lumber Company’s Shamrock turpentine camp. The camp boss was ‘Captain’ Austin Brown, who operated the camp according to his own set of laws and had the assistance of the judge of Dixie County.

“Rosa Whitlock described what she had seen while a resident of the camp. Men were beaten regularly for various infractions. They were not allowed to discuss their punishment or they would be beaten again.

“Brown enforced his rules by keeping workers inside a fenced enclosure guarded at the gates. He had several black informers who kept him apprised of all that happened. Whitlock knew people who had lived in the camp for 15 years, having never seen anyone, including relatives, from outside. She alleged that Brown’s operation differed from a chain gang only in that he paid workers once a month, but even that was small consolation. He operated a gambling house at which all blacks were encouraged under threats of

violence if necessary, to gamble. Brown interpreted the rules of the games and usually won…..

“Commissioner Cubberly prosecuted Brown (three counts of peonage) in 1923, but the trials were eclipsed by a sensational exposure that finally ended the county convict lease arrangement. Young Martin Tabert, a member of a prosperous, white farming family in South Dakota, set out to see the country in 1921. Arrested for vagrancy by a corrupt Leon County sheriff at Tallahassee, he was sent to the Putnam Lumber’s camp in Madison County. When his family finally located him weeks later, they found that he had died, allegedly from malaria. They later learned that he had literally been beaten to death by T.W. Higginbotham, the camp’s notorious boss.”

Shofner wrote that the state legislature investigated and found revolting conditions that existed throughout Florida’s turpentine belt, to one of which the local sheriff had a private arrangement to provide Putnam Lumber with convicts for a fee. The legislature passed a law that forbade the leasing of county convicts to private employers. Higginbotham was later sentenced to 20 years for manslaughter.

Shofner continued the story:

“The shocking revelations and the emphatic legislation changed nothing. Even Higginbotham had his conviction overturned by the Florida Supreme Court. While on bond awaiting retrial, he was transferred by Putnam Lumber to its Shamrock camp, where Austin Brown had but recently been in charge. There, Higginbotham allegedly killed another man. He was later acquitted in the Tabert case and charges were dropped in the latter one.”

Shofner reported that two turpentine camp operators in Calhoun County, Fla. at times would force an out-of-line worker to spend hours at a time in a small, coffin-like wooden ‘sweatbox.’ Short of the traumatic sweatbox punishment or whipping, authorities in some camps often goaded workers into making work-related mistakes, or falsely accused them of stealing tools or trying to influence coworkers in a negative way.

Conditions improved somewhat during World War II, given the growing scarcity of gum turpentine

workers, additional employment opportunities, and more intense competition from wood and sulfate turpentine manufacturers and petroleum companies.

veteran of 50 years in the turpentine business, R.W. Wishart in

R.W. Wishart’s View

A

R.W. Wishart’s View

A

Southern Loggin’ Times ● MAY 2023 ● 17 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

A dipper pours gum into a bucket.

1939 offered his illuminating perspective on the industry and the worker subculture that accompanied it in the first four decades of the 1900s. He was interviewed by Lindsay Bryan of the Federal Writers Project. Wishart had worked at various camps owned by different companies in Georgia and Florida, the largest being a group of eight camps with 120 tree crops and 400 workers.

Wishart described turpentine workers as being in a “class by themselves,” saying their behavior

differed from that of farm workers or town people. He said most workers he had known were born in a camp, never lived elsewhere, and seldom went to town.

According to Wishart, except for crimes such as murder, local sheriffs tended to let the camp foreman enforce the law. Called “Cap’m” to his face and “the man” in his absence, the foreman was viewed as “the law, judge, jury and executioner,” Wishart recalled, saying it was important that he never show weakness. “If he ever

stands for any back talk or shows a streak of yellow, he’s through, and might as well quit,” he said.

Wishart pointed out that fair but firm treatment of workers was an important aspect of handling workers, as was understanding their nature and tendencies. He said workers liked him and would follow him, if asked, when he quit one job and went to another.

He recalled an instance in Polk County, Fla. that depicted how turpentine operators habitually competed for labor in a manner that

was always serious and at times dangerous. On a Saturday night, some 40 of his hands were playing a favorite card game called ‘skin.’ An owner of the company happened to show up and took note of the illegal gambling, which he frowned on, and demanded that the county sheriff arrest them. The owner did not inform the camp foreman of his action. The men were jailed, pending payment of a $35 fine for each. Wishart’s boss refused to pay the fines.

While the men remained in jail, word got to another turpentine company rep that 40 solid workers could be had by paying their fines, which he did. The man sent the men toward his camp but remained behind. Wishart headed off the men and talked them into returning to his camp, promising they could gamble without fear.

Several days later Wishart said he encountered the man who had paid the fines, and he complained that “some SOB stole” 40 good workers from him after he had paid their fines to get them. “I sympathized with him and it was weeks afterward before he found out it was me got his hands,” said Wishart, who later learned that meanwhile the man had “stolen” another turpentine operator’s workers.

Indeed, turpentine operators used whatever edge they could find to lure workers away from competitors. In the book Judge Harley & His Boys, Billy Langdale, son of Judge Harley Langdale, Sr., a largescale operator based in Valdosta, Ga., recalled going on recruiting trips to Florida with a generous supply of moonshine whiskey in hand to “soften up” potential recruits as he told them about advantages of working at the camp he managed at Mayday, Ga.

It seems fitting that this series should conclude with the way it began (March 2023 issue):

It was dirty, demanding, and destructive, a remarkable forestbased industry that endured for most of three centuries and even today is survived by a distant remnant. It was a major component of the South’s economy, but it wiped out untold volumes of longleaf and slash pine timber and scarred the lives of many who toiled at the tasks it entailed. And, in some instances, it left a shameful wake of social wrongdoing. SLT

Note: Some information and illustrations in this article appeared in Naval Stores—A History of an Early Industry Created from the South’s Forests, James P. Barnett, U.S. Forest Service, June 2019.)

18 ● MAY 2023 ● Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

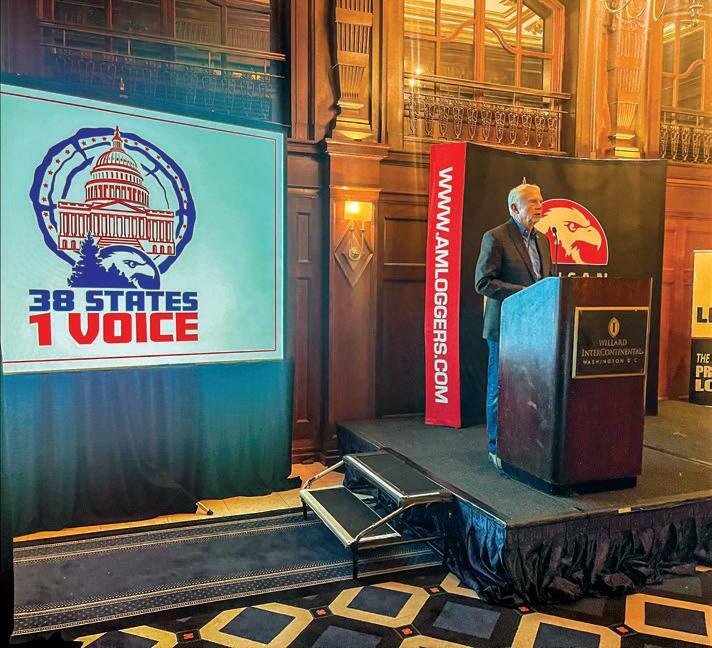

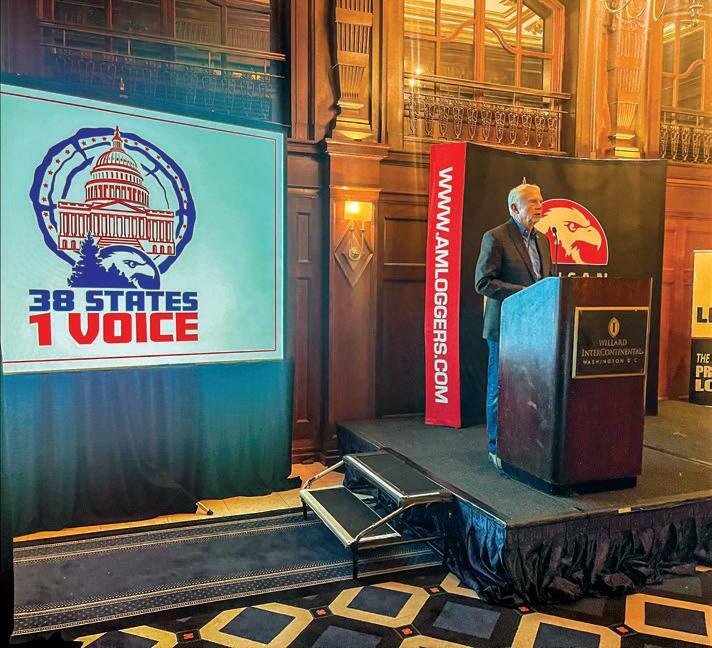

‘Swamp’ Loggers

■ The ALC is back in DC to resume Congressional meetings after a three-year hiatus.

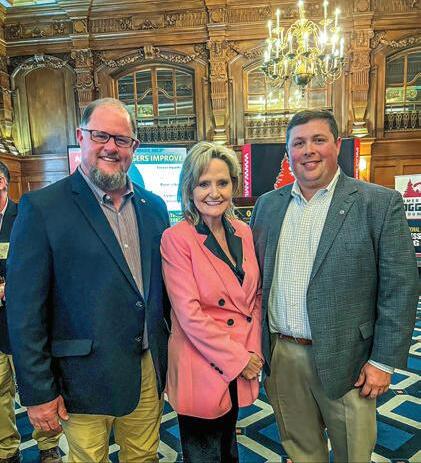

Golden (ME)—and two Senators— Baldwin (WI) and Hyde-Smith (MS)—attended. Congressmen Golden and Westerman were presented the inaugural ALC Congressional Leadership Award for the House of Representatives and Senators Collins (ME) and Baldwin (WI) were the recipients for the Senate. Timber is not a partisan issue, and the American Loggers Council has received strong bipartisan support on our federal legislative agenda.

Additional Congressional staff from other offices attended the reception along with representatives of the United States Forest Service, John Deere, and the Biomass Power Assn. The Reception was sponsored by ALC Gold and Platinum Members (Tigercat, International Truck, John Deere, CAT, Southern Loggers Coop-

A Memorable Gift

In conjunction with the legislative agenda and meetings, representatives of the American Loggers Council had the opportunity to make a special presentation to the Speaker of the House, Kevin McCarthy. Two months ago, a logger from the east coast called the ALC and suggested that a gavel made from wood from across the country be made and presented to newly elected Speaker of the House McCarthy. Having worked with acclaimed Montana wood artist Ron Kelley, the ALC contacted him and asked if he would craft a custom-made gavel with wood species from across the country. Montana ALC Board Member Ken Swanstrom worked with Ron, and he produced the perfect Speaker’s gavel. Considering that the Speaker’s home state is California, the Associated California Loggers secured a meeting with Speaker McCarthy where their delegation (Eric Carleson, Mike Albrecht, and Jeff Holland), ALC President Andy Irish (ME), and ALC Executive Director Scott Dane made the presentation to the Speaker of the House. Following the presentation, a meeting was held with Speaker McCarthy’s staff to discuss the ALC legislative agenda.

The following was included with the presentation of the gavel to Speaker McCarthy:

On behalf of loggers across the country, the American Loggers Council presents this gavel in recognition and honor of your selection as the Speaker of the House of Representatives. This gavel was crafted by acclaimed Montana wood artist Ron Kelley with wood from across the country to reflect the national role of the American Loggers Council.

l Black Walnut – Found across a wide swath of the U.S., it is one of the rarest and most valuable hardwood species in North America.

l Holly – The state tree of Delaware, Holly is often associated with Christmas because of its use in making Christmas wreaths.

l Alder – Primarily a western states tree, found in California, Oregon, Washington, Idaho, and Montana, alder symbolizes strength, protection, determination, and confidence.

l Maple – One of America’s best-loved trees, claimed as the state tree more than any other single species, including by New York, Vermont, West Virginia, Rhode Island, and Wisconsin

l Gum Wood – The Gums are an important part of the Eastern hardwood

forests, used in veneer, plywood, cabinets, and furniture.

l Poplar – The state tree of Tennessee and Kentucky, these trees are fast growing and key to paper making.

l Cedar – Cedar wood is rot-resistant and often used for fence posts, shingles, and outdoor furniture. It’s Latin name, arborvitae, means tree of life, symbolizing strength, long life, and everlasting friendship.

l Ash – Known in Scandinavian mythology as the tree of rebirth and healing. Ash tree wood is hard, heavy, tough, and is used in making bats for America’s pastime, baseball.

l Mesquite – Prevalent in Texas but native to the Southwest, their deep roots enable them to thrive in harsh environments and provide resources ranging from construction materials to medicinal uses.

So, like the wood from the trees represented in this gavel, the American logger represents different regions, provides different benefits, have different characteristics, but all contribute to the culture and society of America from coast to coast. As you govern, may this gavel serve as a reminder of the complex and integral component of the country and guide your consideration and efforts to preserve not only the timber industry but the country as a whole.

ALC presented Congressional LeadershipAwards to Senators Susan Collins (top left) and Tammy Baldwin (top right) and Representatives Jared Golden (bottom left) and Bruce

20 l MAY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

erative, Fuel & Resources, Morbark, Bitco Insurance Companies, Bandit, and Ponsse) with specific portions also sponsored by International Truck, International Union of Operating Engineers, the Louisiana Loggers Assn., the Louisiana Logging Council, Southern Loggers Cooperative, Walsh Timber, the Great Lakes Timber Professionals Assn., the Associated California Loggers, and the Professional Logging Contractors of Maine.

The day on the Hill saw timber

industry representatives from Louisiana, Maine, New York, Pennsylvania, Rhode Island, Vermont, Connecticut, New Hampshire, South Carolina, Florida, Georgia, Virginia, Alabama, Mississippi, California, Michigan, Wisconsin, Minnesota, Idaho, Oregon, and Maryland meet directly with their respective state Congressional Representatives and their staffs. These industry representatives left their logging operations in the woods, traveled from across the country, and waded into the “swamp”

of Washington, DC, not for personal gain, but to bring all the U.S. timber industry’s voice to be heard through the halls of Congress and to the doors of the White House.

In Congress

The bank robber Willie Sutton, when he was caught, was asked why he robbed banks. He replied, “Because that is where the money is.” Why do we go to Washington, DC? Because that is where the policy and legislation (money) are made that affect the logging industry.

The ALC prepared a comprehensive 24-page Congressional Briefing Package that provided background on the legislative priorities and served as information literature to share with the Congressional Offices. The issues advocated for include:

l Biomass inclusion in the Renewable Fuel Standard

l Future Logging Careers

l Interstate Access

l Truck Driver Incentive

l Elimination of the Federal Excise

l National Loggers Day

l Increased Federal Forest Management

Capping off the Fly-In was a White House tour for 45 ALC members, including Ponsse President of North America Pekka Ruuskanen.

The consensus from all state logger representatives was that their meetings and interactions with Congressional officers were met favorably, and that the Congressional Representatives and staff were more engaged and supportive than in some prior meetings. Those that attended and participated opened doors that the ALC will continue to take advantage of in our follow-up and push to pass our legislative priorities.

The ALC representatives provided Congress and the Administration with the information and opportunity to address some of the threats and challenges to the timber industry. Some of these bills have been introduced with bipartisan support in both the Senate and the House.

ALC’s legislative agenda discussed in meetings included the following:

Future Logging Careers Act

Introduced in the Senate and House on March 7, 2023, by Senator Risch (ID), Senator King (ME), Congressman Thompson (PA), and Congressman Golden (ME). Additional cosponsors include Senator Crapo (ID), Senator Collins (ME), Senator Scott (SC), Senator Cornyn (TX), Congressman Fulcher (ID), and Congressman Pingree (ME).

22 l MAY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Mississippi Senator Cindy Hyde-Smith,center,serves on several Committees:Appropriations;Agriculture,NutritionandForestry; Energy and Natural Resources; and Rules andAdministration.

This bipartisan, bicameral legislation will allow logging families the same opportunity to pass on experience as farming families can as they prepare for the succession of these multigenerational family businesses.

Safe Routes Act

Bipartisan support (Congressman Gallagher (WI) and Congressman Golden (ME)) for the Safe Routes Act was demonstrated with the recent introduction in the House of Representatives.

This is a safety bill, first and foremost. It would simply allow (as has been established by precedent in numerous states) for current state weight limits for logging trucks operating on non-federal roadways to be extended to the interstate system. Representative Gallagher drove in a logging truck transiting the current non-interstate route through communities, rural roads, school zones, intersections, and single-lane routes and then the alternative interstate route this legislation would allow “It’s crazy how inefficient it is,” Gallagher said. “It’s bad for the truck, it’s bad for the trucker, it’s bad for the road, it’s bad for the environment, it’s less safe, so it absolutely makes no sense.”

Safe, Modern Trucks Act

With bipartisan Congressional support from Congressman LaMalfa (CA) and Congressman Pappas (NH), the Safe, Modern Trucks Act was introduced. This legislation rec-

ognizes that the 100-year-old 12% federal excise tax on new trucks and trailers de-incentivizes investment in new trucks by adding $30,000 to the price. The excise tax on heavy trucks is the highest excise tax levied on any

product in the country. Half of America’s trucking fleet is over 10 years old, is less fuel efficient, and emits greater emissions. “On one hand, regulators want operators out of older trucks, but on the other hand, this tax

Southern Loggin’ Times l MAY 2023 l 23 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

penalizes them for trying to update their equipment,” Congressman LaMalfa said. Co-sponsoring the Bill are Congressman LaHood (IL) and Congressman Blumenauer (OR). “If Congress is serious about creating jobs, reducing emissions, and improving highway safety, then repealing the Federal Excise Tax should be a priority,” according to Chris Spear, American Trucker Associations, President and CEO.

Strengthening Supply Chains Through Truck Driver Incentives Act

Introduced by U.S. Representatives Spanberger (VA) and Gallagher (WI), the Strengthening Supply Chains Through Truck Driver

Incentives Act would provide a short-term, fast and straightforward incentive to attract and retain new drivers.

“During the pandemic, truckers didn’t have any remote options – yet they went to work every single day to keep our economy moving and our communities strong,” Spanberger said. “Our country needs to step up and recognize their hard work –and we need to encourage more Americans to enter this industry.”

The Bill would create a two-year refundable tax credit of up to $7,500 for drivers with valid CDLA who drive at least 1,900 hours per year. It would also create a new refundable tax credit of up to $10,000 for new truck drivers enrolled in a registered trucking apprenticeship and who meet other requirements.

The “Ask” was for Congressional Representatives to support and sign onto these pieces of legislation. The goals and objectives are to get some, if not all, of these legislative priorities across the finish line (President’s desk).

Without the successful inclusion of these priorities and the positive message it will convey to the struggling timber industry, the logging and trucking infrastructure will be hard-pressed to remain invested in the future of the forest products industry.

The message was: We are here to represent a vital sector of the forest products and forest management team. Without us, none of the other environmental, economic, or forest management benefits are possible. For the most part, we are not asking for money, we are just asking you to pass legislation that allows us to do our job, make a living, create jobs, improve safety, protect the forests, and recognize the contribution we make to improving the environment and economy.

There is nothing more persuasive than for Congressional Representatives to hear firsthand from the men and women who actually work in the woods and drive logging trucks about the challenges that they face and how Congress can help ensure this vital industry survives.

The world is run by those who show up. If you are not at the table, you are probably on the menu. The American Loggers Council members showed up and were at the table. But the work is not finished. All timber industry representatives are encouraged to contact their respective Congressional Representatives and request their support and sponsorship of the Bills referenced.

SLT 24 l MAY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

And Then It Is Winter

Time has a way of moving quickly and catching us unaware of the passing years. It seems like yesterday that I was young, just married, and embarking on a new life. Yet in a way, it seems like eons ago, and I wonder where all those years went. I know that I lived them all. I have glimpses of how it was back then and of all my hopes and dreams.

But, here it is, the winter of my life, and it catches me by surprise. How did I get here so fast? Where did the years go and where did my youth go? I vividly remember seeing older people through the years and thinking that those “older people” were years away from me and that winter was so far off that I could not fathom it or imagine fully what it would be like.

But, here it is. Like me, my friends are now gray, some stooped, and most are retired. They move slower and I clearly see an older person in myself. Some are in better and some worse shape than me. They are not like the ones that I remember who were young and vibrant. Like me, their age is showing and we are now those older folks that we used to see and never thought we’d be.

Each day now, I find that just getting a shower is a real target for the day! And taking a nap is not a treat anymore; it’s mandatory! If I don’t on my own free will, I just fall asleep where I sit!

And so, now I find myself in this new season of my life unprepared for all the aches and pains and the loss of strength and ability to go and do things that I wish I had done but never did! But, though the winter has come, and I’m not sure how long it will last, this I know: when it’s over on this earth, it’s over, and a new adventure will begin!

Yes, I have regrets. There are things I wish I hadn’t done, things I should have done, but indeed, there are also many things I’m happy to have done. It’s all in a lifetime.

So, if you’re not in your winter yet, let me assure you that it will be here faster than you think. Whatever you would like to accomplish in your life, please do it quickly. Don’t put things off too long.

You have no promise that you will see all the seasons of your life. Live for today. Say all the things that you want your loved ones to remember, and hope that they appreciate and love you for all the things that you have done for them in all the years past.

The Laws Of Life

Law of Mechanical Repair

After your hands become coated with grease, your nose will begin to itch and you’ll have to go to the bathroom.

Law of Gravity

Any tool, nut, bolt, or screw, when dropped, will roll to the least accessible place in the universe.

Law of Probability

The probability of being watched is directly proportional to the stupidity of your act.

Law of Random Numbers

If you punch in a wrong number, you never get a busy signal; someone always answers.

Law of Variation

If you change lines, or traffic lanes, the one you were in will always move faster than the one you are in now.

Law of the Bath

When the body is fully immersed in water, the telephone will ring.

Law of Close Encounters

The probability of meeting someone you know increases dramatically when you are with someone you don’t want to be seen with.

Law of the Result

When you try to prove to someone that a machine won’t work, it will, and vice versa.

Law of Biomechanics

The severity of the itch is inversely proportional to the reach.

Law of the Theater

The people whose seats are furthest from the aisle always arrive last. They are the ones who will leave their seats several times to go for food or the toilet and who leave before the end of the performance. The folks in the aisle seats come early, never move once, have long gangly legs or big bellies and stay to the bitter end of the performance. The aisle people also are very surly folk.

The Law of Coffee

As soon as you sit down to a cup of hot coffee, your boss will ask you to do something, which will last until the coffee is cold.

Murphy’s Law of Lockers

If only two people are in a locker room, they will have adjacent lockers.

Law of Physical Surfaces

The chances of an open-faced jelly sandwich landing face down on the floor are directly correlated to the newness and cost of the carpet or rug.

Law of Logical Argument

Anything is possible if you don’t know what you are talking about.

Law of Physical Appearance

If the clothes fit, they’re ugly.

Law of Public Speaking

A closed mouth gathers no feet.

Law of Commercial Marketing

As soon as you find a product that you really like, the company will replace it with a “new and improved” version.

Law of Doctors

If you don’t feel well, make an appointment with a doctor. By the time you get there, you’ll feel better, but don’t make an appointment and you’ll stay sick.

The Law of Television Entertainment

As soon as you find a TV program that you really like, it will be cancelled.

Thoughts On Winning

“It’s not wanting to win that makes you a winner. It’s refusing to fail.”

–Peyton Manning

“The greatest thing about tomorrow is I will be better than I am today. And that’s how I look at my life. That’s the beauty of tomorrow.” –Tiger Woods

“The more difficult the victory, the greater the happiness in winning.”

–Pelé

“You dream, you plan, you reach. There will be obstacles. There will be doubters. There will be mistakes. But with hard work, with belief, with confidence and trust in yourself and those around you, there are no limits.”

–Michael Phelps

“Today I will do what others won’t, so tomorrow I can accomplish what others can’t.” –Jerry Rice

“Nothing is given. Everything is earned.” –LeBron James

“Never let the fear of striking out keep you from swinging.” –Babe Ruth

“You miss 100% of the shots you don’t take.”

–Wayne Gretzky

“Obstacles don’t have to stop you. If you run into a wall, don’t turn around and give up. Figure out how to climb it, go through it, or work around it.” –Michael

Jordan

“It isn’t the mountains ahead that wear you down. It’s the pebble in your shoe.” –Muhammad Ali

26 l MAY 2023 l Southern Loggin’ Times

My shoelace broke today. Some people would irrationally blame Donald Trump, but I KNOW it’s because of global warming!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

For those who don’t want Alexa listening in on your conversations, they’re making a male version . . . it doesn’t listen to anything.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

FROM THE BACKWOODS PEW

Snowy Egrets

I was entering the swamp, midJuly, and it was hotter than the face of the sun. The swamp had shade. In fact, this southern swamp was a tupelo swamp, and the trees were in full foliage. What this meant was, as soon you entered the swamp, the canopy blocked out the sun. This reduced the heat of the day considerably, but my

eyes had to become adjusted to the dark conditions.

It was then that they lifted off, nearly a dozen snowy egrets. The birds had been wading and feeding in the shallow edges of the swamp, feasting on crawfish, minnows, worms, and assorted bugs. As they lifted off, their white feathers appeared to glow in brightness as they caught shafts of light coming through the canopy. Each bird, so

white, stood out in stark contrast to the dark swamp.

Like a distant star as it reflects the sun, standing out in sharp contrast to the dark night sky, or a lighthouse beacon, shining out into the dark night at sea, the egrets instantly had my attention. Forget about the possibility of snakes, the circling mosquitoes, or whether the next step would plunge me over my waders. The birds had my full attention. Brilliant and

shining, I began to notice them everywhere; and as I watched them flying, their feathers vibrantly reflecting the shafts of sunlight, my impression of that swamp changed. Not that I wanted to bring the family there for a picnic or anything like that…but such beauty in the midst of such gloom!

The swamp I was in would be referred to as a deep swamp, limited in tree species, with nearly yearround water coverage. A deep swamp has a sinister atmosphere; it is dark and the smell of decay is always present. Environmentalists would say deep swamps are special, special places for bio-diversity. It is even more special if they can look at it from photographs and not in person on a blistering hot July day when that bio-diversity is waiting to eat them. Many would consider a deep swamp to be a wasteland. (Not the local property tax appraiser; he will tax it like a Walmart is waiting to be built there.) Tourists, as they drive to the beach, will drive through some of these wastelands with local names like Dismal Swamp, Purgatory, or Hell’s Half Acre. These tourists shudder at the sight of the swamp, and quickly instruct the kids to roll up their windows! For the forester, these swamps have limited timber value. Tupelo and black gum have their uses, but not too many kitchen cabinets or floors are going to be made of either. These trees will typically be twisted, and often hollow. Too much of their life has been spent trying to grow in adversity, the adversity being constant floods. These factors would cause one to wonder where the value is for such a piece of land.

For you were once darkness, but now you are light in the Lord. Walk as children of light (for the fruit of the Spirit is in all goodness, righteousness, and truth), finding out what is acceptable to the Lord. And have no fellowship with the unfruitful works of darkness, but rather expose them. — Ephesians 5:8-11

Throughout Scripture, the contrast is given between light and darkness. In the darkness, sin rules and man seeks his own way. God’s way is not in the darkness. When man was kicked out of the Garden of Eden, driven from God’s presence and fellowship, he was driven into the darkness: into the wasteland, where the trials and adverse conditions of life conspire against him, to the point that life seems to have no value. Live and die, that is all you can do. Get what you can, because there is nothing after death. This is the view of so many, so many groping and hoping in the dark. If one believes there are no eternal conse-

28 l MAY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

quences to their actions, then why be hindered by morality or decency from doing what we deem to be best for ourselves?

But then there are the egrets. Into the darkness comes a glowing light, a bird that reflects not its own light, but that light coming from the sun. And suddenly we see value—as beauty in the midst of gloom, life thriving in the midst of decay. The beauty, however, is not transferred to the wasteland; it is still that. But how do you define beauty without the contrast? The contrast calls to us that something of value can be found even in the wasteland.

And so, this verse in Ephesians reminds those of us who have accepted Jesus that we are called to be a light in the darkness, to show the beauty of the Son of God. Jesus wants to use us in the wasteland to remind those living in the gloom that there is another choice—the choice of light over darkness, the choice of life over death.

“Let your light so shine before men, that they may see your good works and glorify your Father in heaven.”—Matthew 5:16

Bradley Antill is a forester and author. Excerpted from Woods, Worship, and Wasteland. For more visit www.onatreeforestry.com

30 l MAY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ROUNDUP

Bandit Industries Continues Growth Pattern

“We’re thrilled to offer DEVELON products in Scottsville, Manquin and Keysville,” says Joel Matteson, General Manager at Forest Pro, Inc. “Our company has been serving logging customers for over 30 years and continues to provide the highest level of customer service available in the forestry industry. We look forward to the future and to building strong relationships

with customers and the community.”

Forest Pro employs 40 experienced sales, parts and service staff at the three locations.

“Forest Pro has had much success over the years since they know the logging industry very well,” says Matt Pixler, director of sales at DEVELON. “By adding DEVELON equipment to their available

Bandit Industries, Inc. celebrated the acquisition of a facility in Mount Pleasant, Mich. with a ribbon cutting ceremony on April 5. This facility formerly owned by Burch Tank is situated on 24 acres with 60,000 sq. ft. of manufacturing space.

“These buildings and this property will be so instrumental in growing our company as we continue to ramp up to meet the growing demand for our products,” stated Bandit CEO Jerry Morey during the ceremony.

One goal of this location is to draw employees from a farther distance away to accommodate the current need for new employees. The proximity to the highway also serves as a convenience for accessibility.

The location includes Bandit’s electrical team, consisting of wiring harnesses for all Bandit products. Components for the whole tree chipper and horizontal grinder product lines also are produced at this new location. Future plans include moving the rebuild department from the main headquarters. The rebuild department specializes in the refurbishment and service of existing Bandit machines.

“The primary facility of this site is ideal for producing one of our major product lines,” Morey adds. “We will be adding a new paint room before we move a line here.”

A variety of attendees ranging from Bandit employees, community members and elected officials showed up for the ceremony and spoke at the event.

Bandit marks its 40th anniversary in 2023 and attributes much of its success to quality products, an amazing dealer network, loyal customer base, and their dedicated, hard-working employees. The current product line consists of handfed and whole tree chippers, stump

grinders, wood waste grinders, and Arjes slow speed shredders.

Bandit became an employeeowned company (ESOP) in 2018. During his speech, Morey briefly talked about how Bandit became an ESOP: “We initially looked at selling to another manufacturing company and then an investment banking company, but backed out of those offers over concerns for our employees and the future of the company.”

Over the next couple of years, Bandit will likely need an additional 200 employees and hopes to fill 95 open positions by the end of 2023.

In addition to the new Mount Pleasant facility, Bandit invested an additional $14 million throughout 2022 conducting several expansions at their main campus nearby at Remus, Mich., including adding an 80,000 sq. ft. steel room featuring new cutting and machining equipment and robots. Once added together, the total manufacturing space across all Bandit locations equals 560,000 sq. ft.

Forest Pro Adds DEVELON Lineup

Forest Pro, Inc., a logging equipment dealership in Virginia, is partnering with DEVELON, formerly Doosan, to begin offering heavy equipment at its three locations: Scottsville, Manquin and Keysville.

All three locations will feature the full line of DEVELON construction equipment, including crawler, wheel and mini excavators, wheel loaders, dozers and articulated dump trucks, for general contractors, landscapers and loggers. Each location also provides parts and service for its customers.

32 l MAY 2023 l Southern Loggin’ Times INDUSTRY NEWS

Jerry Morey,CEO of Bandit,handles the big scissors at the ribbon cutting ceremony.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

product offerings at their three Virginia locations, they can build upon their forestry success and expand into additional markets such as construction, landscaping and mining.”

Interstate Hauling In Ark. Moves Forward

Arkansas SB 494 has reportedly passed in the House with a 94-0 vote and is on its way to the Gover-

nor’s desk. This pending new law compels the Director of State Highways and Transportation to request that the Congress of the United States amend 23 U.S.C. § 127 concerning the vehicle weight limitations on the Dwight D. Eisenhower National System of Interstate and Defense Highways to allow logging/fiber trucks to haul 85,000 lbs. on a segment of the interstate highways no more than 20 miles. A permit would have to be obtained from

the Arkansas Highway Police Division of the Arkansas Department of Transporation before traveling on the interstate.

Currently, haulers are not permitted to travel on the federal interstate system in Arkansas with the 85,000 ton legal weight limit (state), because it exceeds the federally-established weight limits on those roadways. This means log trucks traveling to mills are traveling through communities, passing businesses

and pedestrians, including grade schools, high schools, and colleges. These trucks also have to negotiate roundabouts and difficult turns.

Rerouting trucks to the interstate system is a solution in addressing issues and concerns for safety. There are also economic and efficiency implications, as utilization of the highway system versus using alternate rural routes and community roads can reduce travel and delivery times. Keeping large trucks out of community neighborhoods also means mitigating truck noise and exhaust.

Enviva On Fast Track With Epes Pellet Mill

In March Enviva Inc. received its construction permit from the Alabama Dept. of Environmental Management (ADEM) for its Epes plant under construction in Sumter County, Ala. The revised permit enables Enviva to build a state-of-the-art industrial wood pellet manufacturing facility at a brownfield site.

In 2020, Enviva acquired more than 300 acres of land on the coast of the Tombigbee River in Sumter County for its forthcoming Epes plant. The Enviva Epes site location resides on the former manufacturing site of a wood products company that had closed in recent years.

“Enviva is excited to repurpose a former business site and construct a brand-new state-of-the-art manufacturing facility, jumpstarting economic growth and bringing employment opportunities back to the community,” comments Thomas Meth, President and CEO of Enviva.

Enviva has been active in Sumter County since its initial

34 l MAY 2023 l Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

assessment of the site in 2018. Enviva has partnered with local government, first responders, and the faith-based community to help fulfill unmet needs and provide empowering programming for families. Once operational, Enviva’s Epes plant will be one of the largest taxpayers in the county, resulting in economic benefits to the community with funding for programs like road maintenance, schools, as well as safety and emergency services.

Enviva started preliminary con-

struction of its fully contracted Epes plant in July 2022. The plant is expected to have a capacity of 1.1 million metric tons per year and is expected to be in service in 2024 and fully ramped in 2025. Once operational, the Epes plant is expected to support approximately 350 direct and indirect jobs, including in adjacent industries such as logging and trucking.

l Enviva also issued a statement today thanking the Mississippi Dept. of Environmental Quality’s (MDEQ) permit board for unani-

mous approval for the construction permit of Enviva’s Bond, Miss. facility. The permit was issued after an extensive review process that included a public comment period, a well-attended public hearing, and numerous public comments.

The proposed facility will be designed to produce 1.2 million oven dried tons (ODT) per year of wood pellets. To obtain this permit, over the last year Enviva engaged closely with the community to hear and proactively address any concerns,

as well as prove the plant will comply with all regulatory requirements to protect public health and the environment.

Enviva’s Bond plant will strengthen the regional wood market for previously unmerchantable timber. Once operational, the facility in Bond will support approximately 350 direct and indirect jobs.

Binderholz Celebrates Enfield Sawmill Opening

Binderholz Enfield LLC held a grand-opening in April to commemorate the official opening of its lumber production facility near Enfield in Halifax County, NC. Company, local community, and elected officials participated in the event alongside Binderholz’s corporate leadership from Austria.

The Enfield facility will produce southern yellow pine lumber used in residential and commercial construction. At full production, the plant will have an output capacity of over 200MMBF.

In January 2021, Binderholz acquired the assets of Klausner Lumber, which included production mills in Live Oak, Fla. and Enfield. Despite a pandemic and lingering supply chain issues, Binderholz was able to upgrade the Enfield manufacturing plant to their standards and meet state and local permitting requirements.

“We appreciate the support from Halifax County and the Enfield community during very challenging times,” commented Matteo Binder of Binderholz. “We have worked hard to get the facility operational and now we must shift our focus to getting employees to achieve full production.”

The company started as a small sawmill in Austria more than 70 years ago and grew into a multinational company with 60 sites across Europe.

“This is a major milestone, not only for Binderholz, but for Halifax County,” Halifax County Board of Commissioners Chairman Vernon Bryant said. “We are grateful to the company for their commitment to Halifax County and we look forward to a long and prosperous partnership.”

The Enfield production facility will further strengthen Binderholz’s presence in the United States market. The Binderholz Enfield plant is forecast to have 120 full-time employees by 2024. The hiring process will continue until the lumber mill reaches full production capacity.

36 l MAY 2023 l Southern Loggin’ Times CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Log Truck Driver Loses Load On Access Ramp

BACKGROUND: On a February afternoon in the Lake States Region, a log truck driver was hauling 100 in. pulpwood to a local mill. The truck was equipped with a

center mount grapple used to load and unload logs. It was a cold, sunny day, and the roads were free from ice and snow. Driving conditions were good.

PERSONAL CHARACTERISTICS: The log truck driver had more than 20 years of experience as a truck driver.

UNSAFE CONDITION: The truck driver was entering the access ramp onto the highway. The entrance ramp was slightly curved. The driver entered the turn at too high of a speed, and the load was not properly secured.

ACCIDENT: As the driver made the turn onto the access ramp, the load of pulpwood logs shifted and spilled off the truck onto the pavement. This caused the access ramp to be closed for several hours as the logs were removed from the access ramp.

INJURY: No injuries were reported.

RECOMMENDATIONS FOR CORRECTION:

l Drivers must follow posted speed limits and be aware of conditions they encounter.

l Use extreme caution when entering turns and cornering.

l Ensure loads are properly secured per Federal Regulations (49 CFR 393.116) when hauling shortwood logs crosswise.

l Logs must be solidly packed

l Each log not held in place by contact with other logs or the stakes, bunks or standards must be held in place by a tiedown. Additional tiedowns must be used when the condition of the wood results in low friction between logs.

l The end of a log in the lower tier cannot extend more than onethird of the log’s total length beyond the nearest supporting structure of the vehicle.

l When wood is loaded crosswise, it must be secured with at least two tiedowns.

l With the two tiedown requirement, they must be positioned at one-third and two-thirds of the length of the logs.

l Trailers more than 33-feet long must be equipped with center stakes and each tiedown must secure the highest log on each side of the center stake and must be fastened below these logs.

l Securement components must be built to withstand all anticipated operational forces without failure. Each of the logs on the top of the load must touch the tiedown. Each section of the load should be “rounded” to accomplish this, so that each log below the top is subject to the downward force of the tightened tiedown.

Supplied by Forest Resources Assn.

38 ● MAY 2023 ● Southern Loggin’ Times

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

IRONWORKS

CLASSIFIED AD RATES: Classified advertising rates are $55 per inch. Space is available by column inch only, one inch minimum.

DEADLINES: Ad reservation must be received by 10th of month prior to month of publication. Material must be received no later than 12th of month prior to month of publication.

TOLL FREE: 1-800-669-5613 6209 2687

CONTACT: Call Bridget DeVane at 334-699-7837, 800-669-5613, email bdevane7@hotmail.com or visit www.southernloggintimes.com

Southern Loggin’ Times ● MAY 2023 ● 41

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

42 ● MAY 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 5078 4433 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Southern Loggin’ Times ● MAY 2023 ● 43 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2891 2687 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

44 ● MAY 2023 ● Southern Loggin’ Times WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 6288 13189 7393 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Southern Loggin’ Times ● MAY 2023 ● 45 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM RECONDITIONED DELIMBINATORS!! In addition to new machines, CHAMBERS DELIMBINATOR, INC. now has factory reconditioned DeLimbinators. These units have been inspected, repaired, and updated as needed. Call us and we will help you select a DeLimbinator for your needs. WE ALSO BUY USED DELIMBINATORS Call: 662-285-2777 Email: chambersdelimbinator@gmail.com 1123 BENT SAWDISKS wear over time to extreme unbalance, occasionally requiring added weight to correct balance. CARVER SAWDISK REPAIR Washington, NC 252-945-2358 566 I specialize in straightening and balancing all makes of feller buncher sawdisks. EUREKA! EUREKA! EUREKA! OWNERS HAVE OVER 30 YEARS COMBINED EXPERIENCE! We can save you money on Saw Teeth. Hundreds of satisfied customers. Rebuilt Exchange or New. We specialize in rebuilding Koehring 2000, Hurricana, Hydro Ax split teeth and all other brands. Call Jimmy or Niel Mitchell. Quantity Discounts! EUREKA SAW TOOTH CO., INC. 4275 Moores Ferry Rd. • Skippers, Virginia 23879 PH./FAX (day) 1-434-634-9836 or Night/Weekends • 1-434-634-9185 NOW ACCEPTING CREDIT CARDS 7180 2583 FOR SALE 2018 CAT 559D Loader, Hyd trailer, CTR 426, VERY NICE $102,500 Call or Text Zane 334-518-9937 3939 visit us online: southernloggintimes.com YOU COULD BE READING YOUR AD HERE! Contact Bridget DeVane at 334-699-7837 to get in our next issue! CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

COMING EVENTS

May

8-10—Forest Resources Assn. annual meeting, The Grand Hotel Golf Resort & Spa, Point Clear, Ala. Call 202-296-3937; visit forest resources.org.

June

13—The Warnell Logging Cost Analysis Course, Alabama Forestry Commission, Montgomery Ala. Visit conted.warnell.uga.edu/cours es/lca_2023.

July

22-25—Appalachian Hardwood Manufacturers Summer Conference, The Homestead Resort, Hot Springs, Va. Call 336-885-8315; visit appalachianhardwood.org.

28-30—Georgia Forestry Assn. Annual Conference, Jekyll Island, Ga. Call 478-992-8110; visit gfagrow.org.

August

11-12—Southwest Forest Products Expo, Hot Springs Convention Center, Hot Springs, Ark. Call 501-2242232; visit arkloggers.com.

15-17—Virginia Forest Products Assn. Annual Conference, The Omni Homestead Resort, Homestead, Va. Call 804-737-5625; visit vfpa.net.

17-20—Virginia Loggers Assn. annual meeting, Hotel Roanoke, Roanoke, Va. Call 804-677-4290; visit valoggers.org.

23-25—Forest Products Machinery & Equipment Expo, Music City Center, Nashville, Tenn. Call 504443-4464; visit sfpaexpo.com.

29-31—Florida Forestry Assn. Annual Meeting & Trade Show, Sandestin Golf & Beach Resort, Miramar Beach, Fla. Call 850-2225646; visit flforestry.org.