Vol. 52 No.6 (Founded in 1972—Our 609th Consecutive Issue)

out front:

company LOTS Group two years ago. Expanding through acquisitions, the unique partnership fields multiple crews and focuses on managing trucking logistics and achieving economies of scale to increase efficiency and profitability. From left: Marshall Bowers, Wes Cheatham, Udell Sims, Pierce Lee, Matt Moldenhauer, Lamar Strong. Story begins on Page 8.

June 2023

A Hatton-Brown Publication

Phone: 334-834-1170

Fax: 334-834-4525

www.southernloggintimes.com

Publisher David H. Ramsey

Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Senior Editor Dan Shell

Managing Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director Cindy Segrest

Ad Production Coordinator Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING CONTACTS

DISPLAY SALES

Eastern U.S.

Kathy Sternenberg

Tel: 251-928-4962 • Fax: 334-834-4525 219 Royal Lane Fairhope, AL 36532

E-mail: ksternenberg@bellsouth.net

Midwest USA, Eastern Canada

John Simmons

Tel: 905-666-0258

29 Bugelli Dr. Whitby, Ontario, Canada L1R 3B7

E-mail: jsimmons@idirect.com

Western Canada, Western USA

Tim Shaddick

Tel: 604-910-1826 • Fax: 604-264-1367 4056 West 10th Ave. Vancouver, BC V6L 1Z1

E-mail: twshaddick@gmail.com

Kevin Cook

Tel: 604-619-1777

E-mail: lordkevincook@gmail.com

International Murray Brett

Tel: +34 96 640 4165 +34 96 640 4048

58 Aldea de las Cuevas • Buzon 60 03759 Benidoleig (Alicante), Spain

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane

Tel: 1-800-669-5613 • Tel: 334-699-7837

Email: bdevane7@hotmail.com

Southern Loggin’ Times (ISSN 0744-2106) is published monthly by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscription Information—SLT is sent free to logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel in the U.S. South. See form elsewhere in this issue. All non-qualified U.S. subscriptions are $65 annually; $75 in Canada; $120 (Airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.southernloggintimes.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Southern Loggin’ Times magazine are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Southern Loggin’ Times. Hatton-Brown Publishers, Inc. reserves the right to reject any advertisement which it deems inappropriate. Copyright ® 2023. All rights reserved. Reproduction in whole or in part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed In USA.

POSTMASTER: Send address changes to: Southern Loggin’ Times, P.O. Box 2419, Montgomery, AL 36102-2419 FEATURES 4 ● JUNE 2023 ● Southern Loggin’ Times Other Hatton-Brown publications: ★ Timber Processing ★ Timber Harvesting ★ Panel World ★ Power Equipment Trade ★ Wood Bioenergy

And True 20 Through The Years Southern Stumpin’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Bulletin Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 From The Backwoods Pew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Industry News Roundup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Machines-Supplies-Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Safety Focus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Iron Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Coming Events/Ad Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

14 Jeremy Proctor Tried

(Photo by David Abbott; inset photo by April Mays)

By David

By David

STUMPIN’

Lots About LOTS

ment consulting firms, headquartered in Boston, Mass. “We were working with executives in Fortune 100 and 500 firms, solving some of their toughest problems in areas like strategy, organization, and performance improvement,” he says. “In the process of working there you learn an incredible amount about problem solving and leading extraordinary teams and it makes you hungry to do it yourself. But also, while you’re constantly advising other people what they should do (in business), you never have to do it yourself. So I was interested in getting into this because I wanted to get my hands dirty. Sometimes I say I wanted to go from playing business to doing business.”

outside the industry’s culture and bring in a fresh perspective.

“It’s an easy industry to love from a work standpoint,” Moldenhauer says. “You’re outside, the products that come from it are amazing and valuable, so it’s very easy to get your arms around waking up and doing this every day But underlying that are all these challenges that I think come down to, rudimentarily, business challenges, where I felt like I had a lot to add, or organizational challenges, which is a big reason we added Pierce, because he has ^�very strong organizational and leadership back-ground.”

team and how they came to be in the business.

I have often observed that people don’t generally choose to get into logging as a business investment. What I mean is that Wall Street venture capitalist types, people who don’t come from a timber background, don’t ordinarily say, “Where can I invest my money to get rich? I know; I’ll buy a logging crew!” No, most people in this industry have some kind of background or familial connection with forestry. They do it because it’s what they know and love, often what they grew up with. And, if they work hard and do a good job of managing it all, and have a little luck, many can end up doing quite well for themselves, eventually. But it’s a big investment of money, time and sweat, pretty high risk and low yield, relative to some other investments, and it’s a long way from a sure bet. There are dozens of factors stacked against you, few of which you can really control. Anyway, it’s been my observation: from what I have seen, very few people who don’t already have some connection to forestry choose to get into this business from the outside, as a financial investment.

Then I met Matt Moldenhauer, President and one of the owners at LOTS Group USA/Bellwether. Here is a guy, with no personal background or family history connected to forestry at all, a business guy with an MBA, who decided to invest in a logging company. Along with his partners and leadership team, he’s applying the knowledge from his background to managing the logistics of a timber harvesting and hauling operation. Instead of what we more commonly see, loggers who learn to be businessmen, here we have businessmen learning to be loggers.

A Different World

Before buying Bellwether in 2016, Moldenhauer, now 38, had worked in the Chicago office of Bain & Company, one of the world’s top manage-

Burned out with that white-collar world, he wanted to try something different, something more fulfilling that he could build over the long term. “Instead of three to six month projects where you won’t directly experience the results or have longlasting relationships with the team, here you have real personal relationships, you try to build something for everyone and you can make real change,” the former consultant says. “It’s not just six months; I’ve been doing this for six and a half years now. Some days it can feel like you’re not making any progress, but then you look back and you’ve made a ton of progress.”

It wasn’t entirely true that Moldenhauer had never had any exposure to forest products at all. His first job out of college was at a printing company called Quad/Graphics, which printed magazines and catalogs. There he bought paper from Abitibi Bowater, and bid against R.R. Donnelly for magazine printing contracts. “I went through IP’s paper school; that was part of the story I told people in the first year so they thought I was credible,” he recalls. “But how much did I actually know about forestry? Nothing, really.”

Moldenhauer isn’t the only one at LOTS with that background. Late last year he brought in Pierce Lee, 31, to serve as Chief Operating Officer. Lee had also been with Bain, though in the Atlanta branch. Before business school, Lee served in the U.S. Marine Corps for five years.

“It is so common for people to leave consulting that they have an exit function,” Moldenhauer says. “If you’re at Bain and getting burned out, there is a department that will privately and confidentially help you find your next thing.” Moldenhauer called someone he knew in that role, seeking a South Carolina native to leave Bain and join him at LOTS. More than two years later, a mutual colleague introduced him to Lee through that process.

“My favorite thing in the world is to lead teams, and Matt gave me an opportunity to do that,” Lee says. He grew up hunting on land that was often logged, but he never knew anything about logging. The first time Lee had ever been on a logging job was his first day on the LOTS job. “That’s an advantage,” Moldenhauer believes, to come from

LearningCurve

Bellwether founder Will McKenzie, a native of the Camden area, had a forestry economics degree but no family background in the woods, so he had also brought an outside perspective that proved successful. “He had limited experience, but he learned it,” Moldenhauer says. “He’s a very smart guy and thought very differently, much akin to us, so when we looked at the business we knew we had some shared DNA.”

After 10 years building his company, McKenzie wanted a change and started looking for buyers. He caught the attention of Moldenhauer and his partners, entrepreneurial young investors looking for opportunities to grow existing businesses.

“I started out knowing nothing,” Moldenhauer admits, but he knew business and finance, and approached it from that angle. Still, he needed to know specifics about the industry he was entering. With even less background in forest products than his predecessor, he got to work learning. McKenzie stayed on for two years to mentor him, and when other loggers invited him to visit their crews, he watched and asked questions. “I think that is one of the cool parts of this industry,” he says. “People are so giving of what they know Everybody knows one another and it’s a close knit community.”

Similar operations, like Log Creek Timber (another South Carolina company) and Pierce Timber (in Georgia), also influenced Moldenhauer’s approach. “(They) have some management infrastructure, and they have invested in much the same stuff we have,” he says. “In fact I have looked up to them over the six years of learning. They do a really great job.”

Nearly seven years into this venture, Moldenhauer thinks he’s right where he needs to be. “We wanted to experience a different challenge, and actually impact people, not just an app or something. That’s what excited me: it is an industry that is not going away, that is huge, that is severely under-professionalized and under-invested. At the end of the day, when I got into it, I believed strongly that we could add value to the industry, and I think we do.”� SLT

6 l JUNE 2023 l Southern Loggin’ Times

SOUTHERN

334-834-1170 • Fax: 334-834-4525 • E-mail: david@hattonbrown.com

Abbott • Managing Editor • Ph.

Something Different

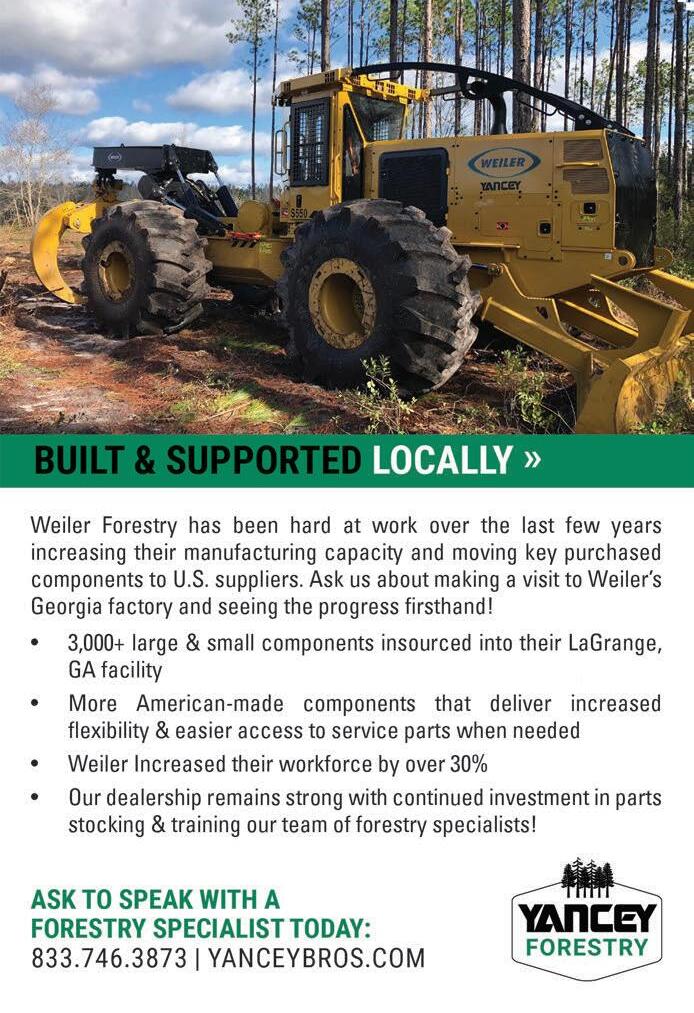

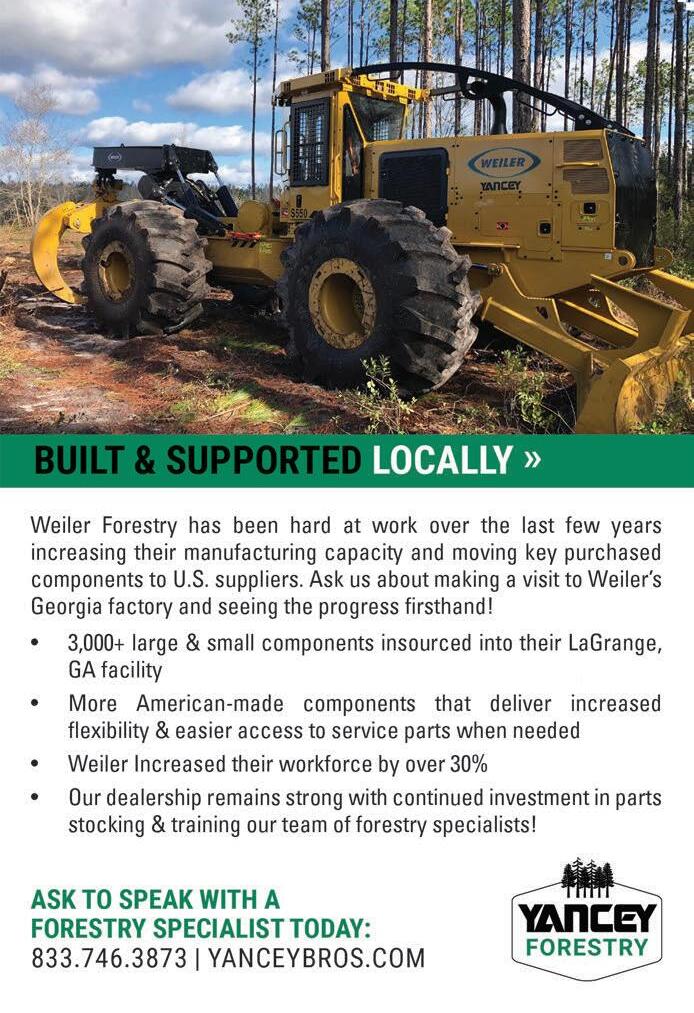

■ Formerly Bellwether Forest Products, LOTS USA represents a different model of logging business.

machines can make more profit than the large operation with a lot of brand new iron. But the opposite can also be true. Sometimes bigger can be better…if you’re bigger in the right ways.

Exhibit A: LOTS Group USA, or Bellwether Forest Products as it was called until somewhat recently, is a timber harvesting/hauling and procurement company in South Carolina that currently fields 10 crews and 58 trucks. That’s pretty big. The LOTS strategy is to create a financially healthier and safer business through management and economies of

to scale the business: to grow, not just for the sake of getting bigger, but so that production becomes more efficient, with costs, both fixed and variable, spread out and shared. A more cost effective operation lowers the cost of production per ton hauled on average, thereby increasing profitability.

Bellwether/LOTS USA President and part-owner Matt Moldenhauer explains, “With a logging company, there is only limited benefit from running multiple crews. But in trucking, it is far better to run 40 trucks than four. When buying timber, in most

better. I think that’s why the (timber) dealer exists.” Dealers, after all, can represent a lot of supply capacity with all the contractors operating under their banner. “They aggregate these suppliers so they can have one conversation with the mill; but in our experience it doesn’t always represent the logger’s and trucker’s best interests if they don’t have firsthand experience running operations.”

Such consolidation, smaller companies merging into bigger ones, is a common phenomenon in free market economies for a reason. Moldenhauer believes, “All industries are going to

aren’t inviting to typical outside investment, so it takes a special kind to even want to begin tackling these problems. The second is you have a very entrenched culture in the woods of independence and not wanting to be part of a big thing.” It can be a task persuading such an independent business owner why it can benefit them to be part of something bigger.

Bellwether Background

Founder Will McKenzie formed Bellwether in 2006, initially as a timber buying entity, eventually

8 l JUNE 2023 l Southern Loggin’ Times ★

Bellwether had always bought green Mack trucks,butsincethemergerwithLOTS madethemcorporatesiblingswithNavistar,they’vestartedaddingblackInternational trucks.These first additions to the fleet were only on day two in earlyApril.

adding his own harvesting crews and trucks. In 10 years he built the company into a successful integrated wood fiber supplier, logging and trucking operation with two woods crews, and he was ready to do something different.

Enter young business professional Moldenhauer and his partners, Gant and Lauren Elmore. They had been looking to buy and operate a small business, and came upon this opportunity from completely outside the timber industry, with no background in forestry or logging at all. “I was a consultant previously at Bain & Company in Chicago”, Moldenhauer reveals. He was looking to leave that world for something more hands on, hoping to invest in an existing, functioning business and grow it from there. “It gives you the chance to do something entrepreneurial without having to start it from scratch.” (See Southern Stumpin’, page 6.)

The transaction closed in August 2016. McKenzie stayed on for two years, mentoring Moldenhauer. “I learned a lot from him. The rest, I was just in the field with these guys

The new owners found logging markets difficult in 2017-2019. “We were learning and knew that building the company without decades of equity like some of our competitors would take a lot of capital and a long time,” he says. “We’d need a lot of money for trucks, equipment and the new management and technology investments we felt were critical for success in the long-term.”

By 2021, Bellwether had drawn the attention of LOTS Group AB, a Swedish subsidiary of Traton Trucking Group, which includes Navistar (parent company of the International brand) and Scania AB, a well-known European truck brand. Traton is itself majority owned by Volkswagen. LOTS sought to acquire a smaller business in the U.S. market. “They had looked at around 100 companies that ran trucks in the U.S., mostly across four sectors: hub-to-hub trucking, agriculture, forestry and mining,” Moldenhauer says. Their goal was to gain a better understanding of the needs of their end-use customers (trucking companies) and to establish a presence in North America; they were at the same time acquiring an established logging company in British Columbia, which is now the LOTS Canada division.

LOTS determined Bellwether would fit its purposes. “At the time, I thought, this will never work,” Moldenhauer admits. “This is too far afield, it’s crazy.” But he also realized that much of what he was trying to do with logistics and scale

Southern Loggin’ Times l JUNE 2023 l 9

TheLOTSmanagementteamattheweeklyproductionmeeting

lined up with the LOTS concept, especially on the trucking side, where LOTS had the most to offer (LOTS stands for Lean Optimized Transportation Solutions).

“All the risk is on the road with the trucks, and all the money is on the road with the trucks, and that was what they had expertise in,” Moldenhauer explains. “From the beginning I felt like our differentiating factor was trucking, and I felt like they would help us with that. So that’s really where we have focused since partnering with them.”

With mutual benefits to gain, Moldenhauer and his partners, while remaining part-owners, agreed to bring LOTS in as the majority equity partner, with all the resources and expertise it could add to the team.

“Anybody trying to do a quick-hit investment is in the wrong place,” Moldenhauer says. “My original partners and I are generally buy-andhold operators and investors, so our goal was to build a strong business that would care for its people, solve customer problems, and succeed over the long term. With LOTS, we are continuing to think for the long term by building the business with an eye toward best-in-class operations and the future of advanced technologies.”

Growth, Acquisitions

Since 2016, the company has grown mostly through acquisitions. “We’ve bought out other logging crews, quality operations that we can integrate into our company,” Moldenhauer says. From the first two Bellwether crews, they now have 10, though there were back and forth steps in between. They acquired a three-crew operation shortly after buying Bellwether, then started another crew. “But 2017-2018 was not a great market, so we shrunk a bit, shut some crews down.” With improved conditions since then and the merger in 2021,

they acquired a one-crew and another two-crew operation in 2022.

Starting with Bellwether, Moldenhauer has bought five logging companies in seven years, retaining much of the talent with each one. Udell Sims, a Bellwether crew foreman under McKenzie, is now logging operations manager for LOTS, with the various crew foremen reporting back to him. One seller now does road building, including for LOTS. The fourth seller works for LOTS as foreman of his former crew, and the brother and grandson of another seller stayed on to work with LOTS as well.

“In this industry, people matter above all else,” Moldenhauer believes. “If you get the right individuals in seats of leadership, you can begin to create a culture and a career path around accountability and achievement. It’s why we mainly try to promote from within.”

In general, Moldenhauer says, loggers approach him about buying their crews, not the other way around. “We try to find a mutually beneficial arrangement,” he says. “The best situation is that of a retiring owner without a succession plan. There aren’t many people looking to buy those businesses; it’s either auction, and they wonder what happens to their people, or something like us. So we take those phone calls and try earnestly to figure out how we can help them meet their goals or transition out while improving our company.”

He continues, “We are trying to take on companies we think have good bones, whether it’s equipment, people, or processes. There’s a ton of logging assets that are underutilized because they don’t have enough trucking capacity, or they are in unproductive timber, or they aren’t reinvesting because the pricing structure is not sufficient. With a larger entity we have more resources and options to fix bottlenecks like truck-

10 l JUNE 2023 l Southern Loggin’ Times

Fromleft:JimMcGee,safety/compliancemanager;inback,StilesBrunson,timberbuyer;in front,JessicaCampos,digitalconsultant;PierceLee,COO;MattMoldenhauer,President; Jessica Garbarino,business controller; Elizabeth Privette,administrative assistant; back, WesCheatham,leadtimberbuyer;front,UdellSims,loggingoperationsmanager;Alden Crapps,logisticscoordinator

ing. You really want to get to the point that the foreman just needs to worry about logging, which is what they’re really good at.”

That’s part of Moldenhauer’s pitch. “Do what you’re good at, and let us do what we’re good at. I can tell you what I’m not an expert at: logging,” he admits. “I cannot do what Udell can. He knows logging and he’s really good at it. One owner whose company we purchased still works here as a floating supervisor. Generally he’s really happy because

this took all the pressure of running the business off of him, but he still gets to log for a living.”

Importantly, Moldenhauer asserts, independent loggers need not fear losing their independence, or importance. LOTS COO Lee Pierce explains, “We are paid for the tons we deliver, and working with people who know or can be taught how to log safely and efficiently with limited oversight is key. Part of scaling is the understanding that we can’t be on every

crew every day. So, we need the right people on our team who can think and act independently day-today in our absence.”

Management

What Moldenhauer and his team bring to the table, instead of running machines and managing production in the woods, is their talent for managing business, finances and logistics from the office and in the field. As Moldenhauer sees it, that’s an

increasingly crucial, and perhaps too often overlooked, component of success for today’s logging companies. “Once upon a time logging businesses were not this complex,” he notes. “But now, costs are increasing, demand is volatile and technology is changing.” Especially in trucking, where loggers compete with other industries while keeping up with federal and state regulations, he believes management is a must.

To coordinate efforts, the core leadership team starts each morning with a brief daily pulse meeting to go over KPIs (key performance indicators) and keep everyone on the same page. The full leadership team, including managers, key administrators and timber buyers, also gather for a longer weekly production meeting. Spreadsheets present useful data about every facet of the enterprise, and the team plans meticulously and well in advance: which crew will harvest what tract and haul which products to what mill, working around any bottlenecks or roadblocks that may occur.

Meetings convene at a LOTSowned office building right off the interstate. It is partially under construction to set up offices, a maintenance shop and a control tower for truck dispatch. Until it is finished, they rent a shared office in downtown Columbia to use as the central dispatch tower. From here, dispatch operators track real time information from mills and stay in contact with crew foremen to keep trucks on the optimum hauling routes throughout the day.

“Rainbow Fleet”

Among its 10 crews, LOTS USA has more than 40 machines, 58 trucks and 85 trailers. As much of this came by way of acquiring other crews, they have what Moldenhauer calls a “rainbow fleet” of equipment and trucks—a mix of different brands.

New logging equipment is both Tigercat and John Deere. “We like the Swiss Army knife equipment,” Moldenhauer says. The goal is versatility of application. “We work across a lot of different job types: thinnings, clear-cuts, big tracts, small ones.” In general they prefer Tigercat 234B loaders, John Deere 748L-II or Tigercat 630 skidders, and Tigercat 720G cutters. Each crews has one loader, skidder and cutter. Equipment dealers are Tidewater in Newberry for Tigercat and Dobbs in West Columbia for John Deere.

Prior to the merger, the only trucks Bellwether bought new were green Macks from Shealy Truck Center in Columbia. Since the partnership with LOTS makes them part of the same corporate

12 l JUNE 2023 l Southern Loggin’ Times

McLendon and Pitts are the most common in the mix.

Each crew aims for an average of 55 loads per week, but the natural volatility of the business means actual results can fluctuate from 40 to 80. “Everyone likes to discuss how many loads per week they are moving, but you never know until you see the data. And when you do, most crews aren’t averaging as high as they think they are,” Moldenhauer says. Among multiple outlets, the core markets include International Paper in Eastover and Augusta, Canfor Southern Pine in Camden, New Indy in Catawba, West Fraser in Augusta and Newberry, Swiss Krono in Barnwell, Enviva in Greenwood and GeorgiaPacific in Prosperity.

Safety is highly prioritized, especially for truck drivers. To monitor performance, all trucks currently have SIM card dash cameras. The team is currently rolling out a new cloud-based camera system with AIdriven safety features across all of their trucks. The current Verizon system shows things like speeding and hard braking, but if the cloud system does as advertised, it will record more complete data (e.g., following other vehicles too closely or running stop signs) and generate a thorough driver report each week. The report highlights not only what needs improvement but also areas that deserve praise.

“In addition to the liability protection, this will help us coach our drivers,” Moldenhauer says. It’s more

The truck driver shortage, he thinks, has been leveling off in tandem with freight labor markets gen-

torically had more attractive wages. The logging industry needs to keep an eye on other local trucking jobs or

The Future Of Trucking

Another LOTS goal is to plan how to navigate the various segments of the trucking industry with some of the developments expected to come down the road, such as the eventual advent of autonomous (selfdriving) and electric vehicles. Large OEMs are wise to look ahead, but Moldenhauer doesn’t foresee tree-length forest products being where battery-electric vehicles will be seen first. “Given the conservative nature of the industry and numerous other challenges, I think electric and autonomous vehicles are likely still a ways out for loggers in the U.S. Southeast,” he says. “Electric will likely come sooner than autonomous, if the infrastructure can be built, but that can also be quite expensive. Most predict autonomous will hit simple hub-to-hub routes first. It’s already taken hold in mining and will be there in a larger way in the next 24 months. But without question I think the logging industry will still have a need for good people in trucking and in logging for a long time.”

COO Pierce Lee concurs. “I’m not sure this industry in the U.S. is going to be an early adopter of (electric vehicles). At the end of the day it will come down to those technologies, through subsidy or other, getting to a price point where you can run it and not pay more. I don’t think this industry is going to say, ‘We’re going green and we’ll pay $1 more.’ It’s going to need to be $1 less. It will have to be cheaper because tight margins don’t allow logging businesses to absorb extra costs; there isn’t another dollar.”

Still, figuring out how all this might work if and when it does come is part of the point of this venture for LOTS and its parent companies. “We’re thinking through these weird questions,” Moldenhauer says. “Like, what’s the residual value of an electric truck when the battery dies and there’s no engine in it? Who do you resell that to? What does it cost to put in a new charging station? There are a lot of questions around this topic, but truck manufacturers are all grappling with the same questions and they are asking for different perspectives, and that’s part of why LOTS picked these four huge sectors.” SLT

supplier relationship is typically transactional rather than a collaborative partnership. I think the industry operates in a fixed win-lose mindset, versus trying to grow and create a win-win scenario for all parties. More true collaboration is going to be needed with key suppliers to create businesses that are sustainable, competitive and can drive costs down in the long term.”

With everything LOTS offers—the scaling and dispatch plans, a full driver pipeline, benefits and 401k for all employees, annual training—Moldenhauer is confident it will all be worth it in the long run. “We have done a lot of good things, and now the question is: is that valued in the market? Can we pay for all of that and still reinvest?” When everything goes well, he says, the answer is yes, they can and do. But things like mill quotas and hiring challenges are among the bottlenecks that constrain them. They’re still determining the right business model to get to the point that it’s consistently beneficial enough to allow for continued reinvestment. “Adjusting for our scalable overhead, we already are producing at a lower cost per ton. Our management makes us the most efficient when markets are good, but can make us more expensive when demand is down. But, I’m confident if we do what’s right and find the right partners we will continue to solve some really tough industry problems and build a great company in the process.” SLT

Southern Loggin’ Times l JUNE 2023 l 13

Now And Then

■ Jeremy Proctor grew his business through the tried-and-true method of blood, sweat and tears.

By David Abbott

CLARKSVILLE, Ark.

Apersonal note from Southern Loggin’ Times editor David Abbott: the last time I visited Arkansas logger Jeremy Proctor was in the spring of 2006, fully 17 years ago. Proctor and I are about the same age, born a month apart; we were both 27 then, and we were both just a year into our respective careers. Jeremy had been working in the woods for a while, having grown up around the business, but he had only started his own company in 2005. Around the same time, I had just started as a rookie reporter at Hatton-Brown Publishers in March 2005. I was still very green by the time I wrote the feature article on him, which appeared in the October 2006 issue.

In March 2023, we got together again for a follow-up story. A lot of things have changed since we last saw each other. For one thing, our hair’s grayer, or mine would be if I

sons, Nathan, 16, and Logan, 14, Proctor’s grown in the 18 years more logging equipment.

sons, Nathan, 16, and Logan, 14, Proctor’s grown in the 18 years more logging equipment.

★

InearlyMarchtheProctorcrewwasperforminga final harvest on a 130-acre mature pine stand.

and three Western Stars—in addition to contractors. His trucks pull Pitts, Viking and FMI trailers. “They’re good people,” Proctor says of FMI (Fryfogle Mfg. Inc.) President Gordon Fryfogle and sales manager Larry Williamson. FMI is based in Lucedale, Miss., not too far from here, so Proctor has had the chance to get to know them over the years.

Cat Man

Proctor is and always has been a Caterpillar man, even though he’s run plenty of other brands. He started out with Timberjack and HydroAx, and in the past has run John Deere and Franklin when he was working for other loggers in his younger days. “A lot of wood was moved with an old 7 International skidder, some big logs,” he recalls. “But when I was a kid, if you had a Cat, you were a high-class logger.”

He is partial to Cat because it seems to him they hold up the best in the rugged hill country he often works. “The C model Cats are probably one of the best that Cat built in the last 15 years,” he believes. His preference is evident on his job site today. He’s shopped around to find good used Cat and Prentice machines from Suttle Equipment and Riggs Tractor.

The registry includes 2016 model 2484C and 2014 model 2384C Prentice loaders; a 2010 Prentice 2670 feller-buncher and a ’16 Cat 563C cutter; and several Cat 535C and 545D skidders, 2009-2012 models. The loaders have Rotobec grapple saws and CSI pullthrough delimbers, and the Prentice cutter actually has a John Deere head on it; that’s how it came when he bought it six years ago.

He has enough machines in the woods to split into two crews, or to have a spare for every piece. “I have invested in all this equipment to keep things moving if one goes down, say with a busted hose,” Proctor explains. The machines are all in good condition and well maintained. The crew changes oil and filters on schedule and greases every two days. “That is the life of everything,” the logger believes. It’s in his blood to take good care of things and make them last. “It’s how I was raised, and I’ve kept that mentality.” If any repairs come up beyond what he and his men are equipped to handle, he turns to the service departments at Suttle and Riggs.

The newest thing in his stable is a 2022 Peterbilt, bought brand new a year ago. An older truck kept breaking down and he had a good driver who was getting frustrated with it, so Proctor knew he needed an upgrade. He wasn’t necessarily

From left:Steve Curtis,Gary Pruett,Jeremy Proctor,Tony Proctor,James Clark; Inset:Jeremy Proctor in 2006

From left:Steve Curtis,Gary Pruett,Jeremy Proctor,Tony Proctor,James Clark; Inset:Jeremy Proctor in 2006

a brand new rig, but he thought he’d look into it at least. He called Peterbilt to ask if they had any new trucks, and after discussing it with them, he realized he couldn’t pass up what they offered him for his old truck in trade-in value, so he just made the deal for the new truck. It’s been one of the best investments he’s made, he says, because it hasn’t had many breakdowns and it’s covered under warranty for whatever it has needed.

Proctor runs 28L PrimeX tires on

the skidders.

He gets his oil (Rotella 15w40) from River Valley Oil in Lamar and Motion Fuels in Clarksville, and stores it at a shop near his home along with filters and other spare parts. He refills off-road fuel at stations in the tanks on his service truck.

Amerisafe covers his workers’ comp, and his truck insurance has been with Progressive since he started buying his own trucks in 2014. “They have done me good,”

caught fire and burned to the ground. They said it was electrical and gave me no problems about it.”

In the foreseeable future he may expand his operations just a hair, and he’s considering adding a track cutter, maybe a Timber Pro or a Tigercat. When it comes time to replace his current Cat/Prentice lineup, probably within five years, he says he’ll likely go with either Tigercat or Weiler, which is now carried in his territory by both the

Don’s Hydraulics). Being a Cat fan from way back, he’s interested in how Weiler does. “I think Weiler has really improved a lot of things on Cat,” he says.

Roots

Proctor grew up in a family that was in and out of and all around logging over the years. His great grandfather did it way back when he was skidding with horses and

16 l JUNE 2023 l Southern Loggin’ Times

mules, and his uncles and his dad used to do short pulpwood. As a kid Proctor used to go to the woods with his dad when he worked for other loggers. By the early ’90s his dad, Tony Proctor, was driving a log truck for the late Jerry English, and the younger Proctor joined him on the crew, manning a skidder. That’s when he grew fond of Cat skidders because that’s what he first learned on.

“I was always fascinated with the idea of being in business as a logger

for myself,” he says. Sometime in the mid-’90s, Tony decided he and his son would strike out on their own. They worked together till 2005, when the younger Proctor knew, “It was time for me to step up, be my own boss and take a chance in life.” He bought out his dad’s equipment, and grew the business from there.

It’s been a real family operation from day one. Tony went to work for his son, where he’s remained ever since. His mom, Annette

Leavell, worked for him for a year or so too. In 2009 she was in a bad car wreck when a driver under the influence hit her. She survived the accident but is limited now in what she can do physically. Proctor’s paternal grandfather also worked on the crew till he died in 2014 at the age of 79, and his uncle, Tony’s brother Tandy Proctor, worked here till he passed last November.

Along with Jeremy and Tony, who mostly runs a skidder, the crew today also includes Steve Curtis,

James Clark and Alicia Proctor’s brother, Gary Pruett. The company hosts an annual employee Christmas party and makes different tshirt designs for the guys on the crew. The Proctors are members of Arkansas Timber Producers Assn.

Land, Markets

“Markets lately are kind of booming,” Proctor reported in early March, before spring officially sprang. “It has been pretty good the last few months, after a slow fall. We just have had so much rain, almost seven inches the other day.”

Jeremy Proctor Logging is a subcontractor for Green Bay Packaging (Arkansas Kraft Division), strictly cutting timber they buy. That takes the headache from him of finding tracts to cut. When Southern Loggin’ Times visited, the crew was working a 130-acre, 39-year-old pine plantation clearcut. Proctor expected the job would take about four weeks to complete, if mills and weather cooperated. After that, he knew Green Bay would have another job ready for him to start. “I work with a bunch of good guys and Green Bay has been good to me,” he says. “They keep the wood lined up for us.”

Proctor’s goal is to haul 60 loads a week, though on rare occasions the crew has gotten 100+ loads, when everything is clicking. They average 12-15 loads a day, working five days a week unless quota or weather cuts them off.

Production from Proctor’s crew makes its way to all the local markets around the area, within a 50mile radius. “We go where Green Bay sells their timber,” the logger says. They haul pulpwood to Green Bay’s chip mill in Morrilton and pine logs to Pinecrest Lumber Division, a Green Bay sawmill in Plumerville. Logs go to West Fraser in Russellville, and PotlatchDeltic at Ola is also a common destination.

When he’s not in the woods working, Proctor wants to be in the woods hunting. He was getting excited for turkey season when SLT was there. “I go to Kansas and Nebraska chasing turkeys,” he says. “I’d rather do that than about anything else.”

It takes a special breed to be a logger, Proctor is convinced. “This is a hard industry. You have to stretch every dollar you can.” But he counts himself privileged. “I do it because it’s a passion to me. I work with good guys, I get to see different countryside, I get to see sunrises and sunsets, and wildlife. I love what I do.”

SLT 18 l JUNE 2023 l Southern Loggin’ Times

Looking back over the years.

1976

1997

2020

SLT Scrapbook ■

Feb

June

Dec

April2010

1996

Dec

Nov 1994

May 2020 May2021

The Chicken Cannon

Scientists at NASA built a special cannon to launch six-pound, whole dead chickens at the windshields of airliners, military jets and the space shuttle, all traveling at maximum velocity. The idea was to simulate the frequent incidents of collisions with airborne fowl to test the strength of windshields.

Part Of The Problem With The World Today Is That No One Snaps Green Beans With Grandma Anymore

Engineers working on a Bullet Train project heard about the cannon and were eager to test it on the windshields of their high-speed trains. Arrangements were made, and a cannon was sent to the Bullet Train engineers.

The engineers were excited to see the results of years of hard work and planning. They set up the experiment and even invited several government officials to attend that had championed the funding of this project. They had a grand ceremony with a countdown. The train roared down the test track at over 200 MPH and the engineers fired the chicken cannon.

Afterward, they stood in shock as they viewed the damage. The shatterproof glass was smashed to smithereens, there was a huge hole in the control console, the driver’s seat had the head rest blown off, and the chicken was embedded into the back wall of the engine’s cabin. No one was hurt in the unmanned test, but the collective engineers’ pride was shattered because a dead chicken had trashed their modern marvel.

Engineers began assessing the damages, took numerous photos and measurements and sent a full report, along with their pages of scientific designs to engineers at NASA. An attached message asked: “Please help us understand how to resolve this issue. We followed all standard protocols and double checked every safety precaution.”

Bullet Train engineers were shocked by the rapid response, which was sent in bold, capital letters: “DEFROST THE CHICKEN FIRST!”

Affirming Quotes For Kids

Children are born with an innate sense of wonder and infinite potential. Nurturing their curiosity and encouraging them as they grow tells them that they’re valued and loved for who they are—an essential part of helping kids grow into confident and capable adults.

When children feel safe and encouraged, they are more likely to take risks and try new things. When they receive positive reinforcement, it boosts their self-esteem and self-worth and helps build a strong sense of identity. Throughout all of their inevitable growing pains, it’s important to remain a sturdy presence and to affirm that they are safe, loved and capable. Here are some encouraging and affirming quotes that will help young ones along the way:

l The time is always right to do what’s right. —Martin Luther King, Jr.

l Never let the fear of striking out get in your way. —Babe Ruth

l We all have different gifts, so we all have different ways of saying to the world who we are. —Fred

Rogers

l Winning doesn’t always mean being first. Winning means you’re doing better than you’ve ever done before. —Bonnie Blair, Olympic speed skater

l He that can have patience can have what he will. —Benjamin Franklin

l If you care about what you do and work hard at it, there isn’t anything you can’t do if you want to.

—Jim Henson

Not On The Same Page

As he stood to preach one Sunday morning, a rural Baptist minister decided to change his sermon, saying he felt compelled to dwell on the pitfalls of drinking alcohol.

He gave examples of wrecked lives, family tragedies, fatal car crashes, criminal charges, business failures, sexual misconduct and so on.

At the end of his fiery oratory, he thundered: “If I had all the beer in the world, I’d pour it in the river. If

I had all the bourbon in the world, I’d pour it in the river. And if I had all the wine in the world, I’d pour it in the river.”

Turning to the music leader, the preacher asked, “Brother, what hymn are we concluding with today?”

The music leader responded: “Shall We Gather At The River.”

Life Lesson Ticket

Jack took a long look at his speedometer before slowing down: 73 in a 55 zone. Fourth time in six months. How could a guy get caught so often?

When his car had slowed to 10 miles an hour, Jack pulled over, but only partially. Let the cop worry about the potential traffic hazard, he thought. Maybe some other car will tweak his backside with a mirror.

Jack recognized the cop as he came forward. Bob? Bob from church? Jack sunk farther down in the seat. This was worse than the coming ticket. A Christian cop catching a guy from his own church. A guy who happened to be a little anxious to get home after a long day at the office. A guy he was about to play golf with tomorrow. Jumping out of the car, Jack approached a man he saw every Sunday, a man he’d never seen in uniform.

“Hi, Bob. Fancy meeting you like this.”

“Hello, Jack.” No smile.

“Guess you caught me red-handed in a rush to see my wife and kids.”

“Yeah, I guess.”

Bob seemed uncertain. Good. “I’ve seen some long days at the office lately. I’m afraid I bent the rules a bit, just this once.” Jack toed at a pebble on the pavement. “Diane said something about roast beef and potatoes tonight. Know what I mean?”

“I know what you mean. I also know that you have a reckless reputation behind the wheel.”

Ouch! This was not going in the right direction. Time to change tactics.

“What’d you clock me at?”

“Seventy-one. Would you sit back in your car, please?”

“Now wait a minute here, Bob. I checked as soon as I saw you. I was barely nudging 65.” The lie seemed to come easier with every ticket.

“Please, Jack, in the car.”

Flustered, Jack hunched himself through the still-open door. Slamming it shut, he stared at the dash. He was in no rush to open the window. The minutes ticked by. Why hadn’t he asked for a driver’s license? Whatever the reason, it would be a month of Sundays before Jack ever sat near this cop again. At a tap on the door, Jack jerked his head to the left. There was Bob, a folded paper in hand. Jack rolled down the window a mere two inches, just enough room for Bob to pass him the slip.

“Thanks.” Jack could not quite keep the sneer out of his voice. Bob returned to his car without a word. Jack watched his retreat in the mirror. Jack unfolded the sheet of paper. How much was this one going to cost? Wait a minute. What was this? Some kind of joke? Certainly not a ticket. Jack began to read:

Dear Jack,

Once upon a time I had a daughter. She was six when killed by a car. You guessed it, a speeding driver. A fine and three months in jail, and the man was free. Free to hug his daughters. All three of them. I only had one, and I’m going to have to wait until heaven before I can ever hug her again. A thousand times I’ve tried to forgive that man. A thousand times I thought I had. Maybe I did, but I need to do it again. Even now…Pray for me. And be careful. My son is all I have left.—Bob Jack twisted around in time to see Bob’s car pull away and head down the road. Jack watched until it disappeared. A full 15 minutes later, he too pulled away and drove slowly home, praying for forgiveness and hugging a surprised wife and kids when he arrived.

Life is precious. Handle it with care.

24 l JUNE 2023 l Southern Loggin’ Times

Remember When People Had Diaries And Got Mad When Someone Read Them? Now They Put Everything Out There And Get Mad When People Don’t

Some Days I Wish I Could Go Back In Life— Not To Change Anything But To Feel A Few Things Twice

FROM THE BACKWOODS PEW You Never Ride Alone

While many foresters work alone, or spend a lot of time in their trucks alone, they are never really alone. While Elvis may have sung about never walking alone, he was speaking spiritually, not physically— unless he had a bodyguard or

groupies that he couldn’t shake. Where were we? Oh yeah, being alone. That’s most days for the forester. But Elvis was more right than he knew, because foresters who work in the Southeastern Coastal Plain are never alone. Hav-

ing driven into the swamp for the day’s adventure, the forester must open the door to enter the woods. When he does, in comes the company. Mosquitoes, looking for a new place to buzz, flood the truck. Flies, looking for adventure, come in like they were summoned from Egypt… as in plagues…Moses…anyone home?

Where were we? Oh yeah, flies

and mosquitoes flooding the truck compartment as the forester opens the door, and now he is no longer alone. Back on track now. Did we talk about spiders? As the forester walks the woods, he often will pick up hitchhikers, and unnoticed, they also will be brought back into the truck, which now resembles a bus. The hitchhikers are spiders and ticks, in no particular order or number, but the ticks could be plentiful.

So, the lonely forester now has riders in the form of bugs, that have given up their homes in order to accompany him to his. The mosquitoes really suck as co-riders, but they will get you into the HOV lane. The flies are really confused however, as they cling to the windows, trying to figure out if they are moving and thus the blur outside, or is it the other way around?

Spiders hear the mosquitoes and flies, and instantly start working on acquiring lunch. It is not uncommon to open the door of a forester’s truck the following morning and find that a web has been spun, reaching from the steering wheel to the headrest. They aren’t interested in catching the forester again, after all they already caught him once and he tasted like chicken.

The ticks are another story all together. They can make a forester jump out of a moving vehicle. A forester, who finds a pod of seed ticks numbering in double digits on his pant leg while driving, will slam to a stop and hop out searching for industrial-strength bug spray.

No sir, never alone!

But many people today feel like they have been abandoned, or forgotten. Life, it seems, has dropped them off at the end of the pavement, and never looked back. They live with the echo of past voices and the memories of happier times. Perhaps the death of a spouse or family member has left them alone, or maybe it was a sudden change in circumstances; and when the dust settled…even the fly on the window has left.

Where is the hope for love, for life, for fulfillment when there is no one to share life with? Where are the words of encouragement when there is no one at the door, or no one calling on the phone? Jesus, who knew all about being abandoned, did not intend for such loneliness.

“If you love Me, keep My commandments. And I will pray the Father, and He will give you

26 l JUNE 2023 l Southern Loggin’ Times

another Helper, that He may abide with you forever—the Spirit of truth, whom the world cannot receive, because it neither sees Him nor knows Him; but you know Him, for He dwells with

you and will be in you. I will not leave you orphans; I will come to you.”— John 14:15-18

Maybe you want to write verse 18 out and keep it handy. It can help

on those long nights when everything reminds you of a lost loved one, or every sound brings to mind the harsh words of a betrayal. Jesus shared these words to his disciples in the hours before his arrest. Judas had already slipped out to betray him. Jesus knew that he would be in a grave in less than 24 hours. And as he looked at his group, he knew that they were soon to run, leaving him alone. He knew the Father would soon turn his back on him, as he bore the sins of the world. He would hang forsaken, all alone in the world that he had created… Emmanuel, which means “God with us,” on a cross. While we use that name mostly at Christmas, we must carry it with us every day. For God is with his children.

“But the Helper, the Holy Spirit, whom the Father will send in My name, He will teach you all things, and bring to your remembrance all things that I said to you. Peace I leave with you, My peace I give to you; not as the world gives do I give to you. Let not your heart be troubled, neither let it be afraid.”—John 14:26,27

So, take cheer. If you are a child of God, then these promises are for you. You are never alone. But many in our communities do not have such a promise. They are truly alone. That is where you and I have a job to do. Here is how Jesus ended his talk with the disciples that night:

“But that the world may know that I love the Father, and as the Father gave Me commandment, so I do. Arise, let us go from here.” —John 14:31

Arise, and LET US go from here. Already he was telling them that they were with him. But we are called to go from where we are, to those who are in need, to those who long for a friend, a comforter. We need to tell them about Jesus, about his promises. Maybe it’s a meal, maybe a conversation, maybe it is in an invitation, or helping with repairs. But let us arise from here, and go share the love of Jesus.

Bradley Antill is a forester and author. Excerpted from Woods, Worship, and Wasteland. Visit www. onatreeforestry.com for more.

28 l JUNE 2023 l Southern Loggin’ Times

Hood Industries Plans New Plywood Mill

Hood Industries announced plans to invest more than $200 million to build a plywood manufacturing facility in Beaumont, Miss. and create 265 direct jobs. The announcement was part of a groundbreaking event at Beaumont held May 4, and it comes 40 years after Hood Industries took over operations at Beaumont Plywood in 1983.

The new facility will operate at twice the capacity of the previous facility, which was made inoperable by a tornado on April 17, 2022. Construction will begin this summer, and manufacturing will commence in early 2025. Hood Industries plans to fill the jobs over the next four years.

“The mill has been one of the cornerstones of our company because of the support received from the community of Beaumont, Perry County and surrounding areas and the hard work of our excellent employees,” commented Warren Hood, Owner and CEO, Hood Companies. “We are excited to be able to rebuild the facility into one of the most modern plywood plants in North America.”

Mississippi Development Authority is providing assistance for infrastructure improvements and site development. AccelerateMS is providing a Mississippi Works grant to support the critical training needs of Hood Industries and will support the company’s long-term workforce goals and objectives for this project. Perry County and the town of Beaumont also are assisting with the project.

“After a devastating tornado shut this plant down, some would have left. But not this team, and not this company,” adds Gov. Tate Reeves. “Today’s groundbreaking is the launch of an incredible comeback story. This $200 million investment will bring 265 good-paying jobs to Beaumont and Perry County and have a tremendous impact on the local community. I congratulate Hood Industries on this exciting day and thank them for their enduring commitment to our state.”

Hood Industries is a mix of wood manufacturing and distribution operations that also includes a plywood manufacturing plant in Wiggins, Miss. and four sawmills in Waynesboro and Silver Creek, Miss., Bogalusa, La. and Metcalfe, Ga., and 15 wood products distribution operations.

Hood resumed plywood operations at Beaumont after the previous owner, Weyerhaeuser, had shut it down in 1982 during a recession.

Weyerhaeuser had purchased it in 1979 from Delta Industries, which built the plant as Delta Pine Plywood in 1971.

Parallel to the starting of operations at Beaumont in the 1980s, Hood also began plywood operations at Wiggins, Miss., which Hood continues to operate today.

Kronospan Announces New OSB Operation

Kronospan announced it will begin construction of a new oriented strandboard (OSB) manufacturing plant on its 460 acre site in Oxford, Ala. Employing 125 , the new facility will have a footprint composed of 44 acres of new development, including substantial areas designated for product storage, rail spur and loading docks. Groundbreaking for the $350 million facility is scheduled for later this year.

“We’re very pleased to announce the next project at our Oxford site,” says Hans Obermaier, CEO of Kronospan’s North American companies. “This is not only an opportunity to further expand our portfolio of wood panel products in the United States but also meets our customers’ growing need for high quality construction materials. Just like the other plants on our site, the OSB plant will be constructed with our sustainability principles in mind and will further enhance our negative carbon footprint status.”

This latest expansion is one of several new investments Kronospan has made in recent months. New equipment for the site includes an extension of its existing medium density fiberboard press, a new water treatment plant, expansion of manufacturing capacities of its existing particleboard plant and the ongoing construction of a new wood yard. Capital projects of more than $89 million have occurred in the last six months or are currently in progress at the Oxford site.

“Kronospan is very proud of our commitment to job creation in Calhoun County and east Alabama,” says John Connell, Director of Human Resources at Kronospan. “As we continue to grow our operations in the U.S., we are very conscious of the impact on our local communities and are consistent in our philosophy of creating a sustainable future for generations to come.”

Pactiv Evergreen Has Closed Canton Mill

Pactiv Evergreen Inc. has closed its Canton, NC paper mill as part of

the company’s restructuring of its Merchandising and Food Merchandising businesses. The company also continues to explore alternatives for its Pine Bluff, Ark. mill and Waynesville, NC facility.

After over a century of service providing the town with thousands of jobs, the Canton paper mill sounded its final bell May 24, signaling the permanent closure of the

iconic site. Layoffs due to the mill’s closure number more than 1,000.

Upon the final ringing of the bell many Canton residents came together on the lawn of Sorrells Street Park directly across from the mill to see it off. Emotions were high in residents of all ages but perhaps most of all in Canton’s senior citizens, many of whom had worked at the mill for their entire lives.

30 l JUNE 2023 l Southern Loggin’ Times INDUSTRY NEWS

ROUNDUP

Enviva Announces

First Quarter Setback

Enviva, the world’s largest producer of industrial wood pellets, released its quarterly report in early May, and it rippled through the wood-to-energy ranks.

“The plans and initiatives underway to improve productivity and costs across Enviva’s current asset platform continue to fall behind expectations,” commented John Keppler, Executive Chairman of the Board. “While the board of directors remains convinced of management’s ability to deliver the originally forecasted operational and financial performance over time, it is clearly taking longer than expected.”

Keppler said to more conservatively underwrite that plan and ensure the ability of the company to capture the value of the fully contracted growth ahead, and after careful consideration with management, the board of directors has decided to revise Enviva’s capital allocation framework, eliminating the company’s quarterly dividend in order to preserve liquidity and a conservative leverage profile, while maintaining its current growth trajectory, and potentially accelerating future investments in new fully contracted plant and port assets, and implementing a limited share repurchase program.

With the elimination of the dividend, management expects to retain approximately $1 billion in incremental cash flow during the period 2023 to 2026, providing incremental liquidity and investment into the productivity and operational improvements in its current assets and further reduce the need to access the capital markets to fund its current growth

plans, which include the construction of the company’s fully contracted wood pellet production facilities in Epes, Ala. and near Bond, Miss.

Under the share repurchase program, the company can repurchase up to $100 million in shares of the company’s common stock opportunistically from time to time in the open market, or in privately negotiated transactions at prevailing market prices.

President and CEO Thomas Meth added, “We recognize this is an important departure from the plan we laid out at our Investor Day a month ago, but a lot has changed since then. Compared to our expectations, while our cost position has trended in the right direction, it has done so at a much slower pace than we had anticipated, in part due to slower volume growth, and in part due to a higher spend profile for the volume growth we did achieve.”

Meth continued, “We know what the specific issues are: Contract labor is too high, discipline around repairs and maintenance spend is insufficient, wood input costs need to come down further and stay there, and utilization rates at specific plants need to improve and stabilize at those improved levels. Because of where we are in our journey to bend our cost curve down while bending our production curve up, we feel it is prudent to take a much more conservative view of what our business can realistically achieve over the next eight months.”

Enviva reported delivered volumes of approximately 1.3 million metric tons during the first quarter, which was 20% higher compared to firstquarter 2022, but short of management’s expectations of approximately 1.5 million MT.

The company reported a net loss of $116.9 million for first quarter, as compared to a net loss of $45.3 million for first quarter 2022, and reported adjusted EBITDA for first quarter 2023 of $3.4 million as compared to $36.6 million for first quarter 2022.

“Although the future continues to be incredibly bright for Enviva’s business, we have had a difficult and disappointing start to 2023,” Meth said. “Operating cost overages and production challenges were key drivers behind the first quarter’s poor performance. While plant production is increasing and we are reducing our operating cost position, neither improvement is materializing at the rate we forecasted a few months ago. Based on results from the first four months of the year, we believe it is prudent to take a more conservative view on the timing of our ability to deliver these improvements.”

Management is reducing its estimates for full-year produced volumes in 2023 to be approximately 5 million to 5.5 million MT, as compared to a prior forecast of 5.5 million to 6 million MT. Enviva continues to forecast that total capital expenditures (inclusive of capitalized interest) will range from $365 million to $415 million for 2023.

Meth added, “I am pleased to note that given the strong future contracted growth we have in hand, the pace of our investment continues to be on track, and with the changes we have announced today, we have the opportunity to continue to deliver this growth with lower risk and limited needs to access the capital markets.”

CM Biomass Adds To Pellets Lineup

Jackson Pellets, LLC held a ribbon cutting March 22 at its new wood pellet manufacturing plant at the Jackson Port, Alabama. Todd Bush, CEO of CM Biomass North America, the parent company of Jackson Pellets, told the group that the Jackson plant is the crown jewel of all the facilities he’s been a part of.

The mill represents a $21 million investment and is expected to employ 45 to 50.

CM Biomass, a company based in Denmark, has 10 other facilities in the U.S. Bush said that everything they have learned from building other facilities has been applied at Jackson in building the mill from the ground up. He said that the product manufactured in Jackson will go to Mobile as does product from other facilities in Mississippi, Tennessee and Alabama.

CM Biomass reports that its North American production facilities are primarily supplied with byproducts from the sawmilling industry, but it also developed a facility in Douglas, Ga. that converts peanut hulls. The

company lists the following facilities: Huntsville, Tex.; Douglas, Ga.; Ideal, Ga.; Effingham, SC; Brookhaven, Miss.; Jackson, Ala.; Quitman, Miss.; Jasper, Tenn.; Crosville, Ala.; Fruitdale, Ala.

CM Biomass Partners was founded in 2009 as a response to the European Union’s increased demand for sustainable green energy solutions and the EU RED 2020 targets. Since the beginning, the company has benefitted from the close connection to the CM group with its many years of experience within commodity trading, shipping, warehousing and wood pellet bagging. In the meantime, helping suppliers meet sustainability requirements has also become an important and fast-growing task.

Today, they trade more than 3,600,000 MT of wood pellets per year, which makes them one of the largest independent wood pellet trading companies in the world.

CM Biomass Partners employs around 225 in Denmark, Sweden, Germany, UK, Holland, Italy, Latvia, Russia, Singapore, Vietnam and the U.S.

In 2021 United Shipping & Trading Co. acquired a majority stake in CM Biomass.

Sierra Pacific Plans Expansion In Alabama

Sierra Pacific Windows, a division of Sierra Pacific Industries, is expanding its roots in high-end window and door production by unveiling plans for a manufacturing campus in Phenix City, Ala. following the acquisition of 610,000 sq. ft. of manufacturing and warehousing space that’s located on 113 acres, once home to a textiles plant.

The added space will allow Sierra Pacific Windows to increase its production capacity and more efficiently respond to nationwide customer demand for its wood and vinyl products that has grown ten-fold in the last decade. Products manufactured will mirror what is produced at the company’s existing California and Wisconsin locations

“This expansion of our windows manufacturing capacity is a reflection of our confidence that customers value the distinctive product quality and service associated with Sierra Pacific Windows,” says Sierra Pacific Industries CEO Mark Emmerson. “Our unique seed-to-window approach starts by planting trees that take at least 50 years to mature. We always take a long-term, sustainable view to business. We also pride ourselves on being a place our employees feel valued for their contributions and stay for long careers.”

“The attractiveness of Alabama as the right location for our company to advance is undeniable,” adds Sierra

32 l JUNE 2023 l Southern Loggin’ Times

Pacific Windows President Tom Takach. “We wanted a location that gives us the room to grow and expand. With our significant and rapidly growing demand for our windows and doors, locating in Phenix City is an obvious choice, from easy access to transportation corridors to the skilled labor forces in the greater Russell County area.”

The 610,000 sq. ft. building is just the beginning of the company’s investment in Phenix City. New equipment is already on order and fasttracked to outfit the greenfield build of Sierra Pacific’s most high-tech window and door plant to-date. Combined with the company’s existing locations in California and Wisconsin, the addition of the new facilities brings Sierra Pacific to a milestone of more than 2 million combined sq. ft. of manufacturing space for its Window division.

The company credits local municipal and elected officials as being instrumental in drawing their attention to the area. The Phenix City region and the State of Alabama were a supportive force that furthered Sierra Pacific Window’s confidence in putting down roots in this region for their Eastern U.S. windows manufacturing operations.

SPI is a third-generation, familyowned forest products company based in Anderson, Calif. The company owns and manages more than 2.4 million acres of timberland in California, Washington and Oregon. Along with being a windows manufacturer, it is one of the largest U.S. lumber and millwork producers including 18 sawmills and eight biomass-fueled cogeneration power plants.

Softwood Lumbermen Have Cautious Outlook

Timber Processing magazine’s annual Sawmill Operations & Capital Expenditure Survey indicates lumbermen have toned down the optimism they carried for the past two years.

According to the results of the most recent annual survey, 42% of the softwood lumbermen forecasted their lumber business situation as excellent or good for the remainder of 2023 and 2024, and of that only 2% said excellent while the remaining 40% said good.

Nearly half (49%) of the respondents forecasted 2023-2024 as fair, compared to 11% a year ago, while

9% said poor, compared to 3% a year ago.

“Not as good as the previous couple of years. Headwinds for sure until interest rates drop,” commented Timothy Biewer, principal of Biewer Lumber, which operates two new sawmills in the South and several mills in Michigan and Wisconsin.

The 23-question survey was e-mail blasted in April to sawmill management subscribers of Timber Processing. It drew responses from representatives of approximately 175 U.S. softwood lumber sawmills. Responses came from owners, presidents, vice presidents, general managers, regional managers, other executives, plant managers and supervisory personnel.

One question asked softwood lumbermen how much new capital expenditure in machinery and systems their mills had allocated or committed to for 2023 and 2024. More than half, 53%, said at least $1 million.

The survey ended with two openended questions. One was what are lumbermen’s biggest concerns with regard to keeping their mills running efficiently. Comments included:

l “Downtime and maintenance”

l “We have constant labor shortages. Not a lot of turnover but a con-

stant need of consistency in coming in to work!”

l “High costs, in particular raw material”

l “Legal environment”

l “Lead times are a challenge on replacing old equipment.”

The final question invited lumbermen to address how they foresee lumber markets, their business situation and the “general state of things.”

l “Rough 2023 and 2024. Long term very positive.”

l SYP grade lumber market will continue to get over-saturated in the SE USA.”

“The general outlook is still negative due to rising interest rates and slowdown in housing. We are also seeing significant volume that is being imported from European markets.”

l “Lumber markets will eventually stabilize when interest rates stop rising.”

Westervelt Announces Leadership Change

The Westervelt Company announced that President and CEO Brian Luoma will retire at the end of 2023, and current COO Cade

34 l JUNE 2023 l Southern Loggin’ Times

Warner will succeed him.

Luoma joined Westervelt in 2017, and his tenure has been marked by growth of the company, most notably the expansion of the lumber business through the construction of a new lumber mill in Thomasville, Ala.

Warner was recently appointed to the Board of Directors. He joined Westervelt in 2017 and has held roles in strategy and planning, sustainability and continuous improvement.

“We have been working toward this transition for some time, and both Brian and Cade have created an opportunity for a seamless shift in leadership,” says Rob Taylor, Chairman of the Board. “Brian has done an excellent job leading the company, especially during the uncertainty of the pandemic years, and we appreciate his dedication to growing the company and the capability of our employees. We are eager to welcome Cade to the Board and into his new role. His experience and passion for this industry will be essential in continuing to guide the growth of the company.”

Luoma comments, “When I joined Westervelt, I found a company loaded with talent. I am very proud of everything we accomplished as a team, particularly the continued development of our people and their relentless commitment to our customers and the quality of our products and services. Throughout the remainder of this year, Cade and I will continue to work closely together as we transition leadership. Sustainability has been a core value for Westervelt for more than a century, and it will continue to expand under Cade’s leadership. I am very excited to see what the future holds for Cade and the next generation of leaders at The Westervelt Company.”

Huber Acquires Compass Land

Huber Resources Corp. announced the acquisition of certain assets of Compass Land Consultants, Inc., which will grow and expand HRC and its Sewall Forestry and Natural Resources Consulting business globally in key service areas including timberland management, timberland appraisals, forest inventory management, and forest modeling.

J.M. Huber Corp., parent company of HRC, has a long history of timberland management dating back to the 1940s, and HRC continues JMHC’s legacy of forest management through the stewardship of more than 1 million acres for clients throughout the US.

HRC’s full suite of forest management services include forest operations, management planning, sustainable harvest modeling, road building and maintenance, full service admin-

istrative and accounting services and timber harvesting and marketing.

SFNR offers forestry and natural resource consulting services, including forestland appraisals, forest growth and harvest modeling services

to aid clients with critical business decisions for current or future operations, land purchase due diligence and inventory analysis. Additionally, SFNR provides a variety of consulting services to its forestry clients

including litigation support and market pricing and cost analysis.

CLC offers a heritage of value and stability, as well as a diverse suite of services important to investors, agencies, and landowners.

Southern Loggin’ Times l JUNE 2023 l 35

MACHINES-SUPPLIES-TECHNOLOGY

Tigercat Dual Winch

The Tigercat 612 series skidder platform was created to manage the extraction function in challenging terrain selective felling applications,

while preserving the value and quality of the residual stand. The machine can be equipped with a dual winch, a movable back shield and fairlead system, as well as a crane, and front blade tongs.

drive system, the 612 impressively handles adverse terrain while minimizing wheel spin.

A narrow stance allows easy navigation through tight trails and rough ground conditions. The movable shield can be used as an anchor while winching. The dual winch and moving fairlead system allow the operator independent control over two separate cables when operating in tight stand conditions. The optional heavyduty crane and blade tongs offer even

viding clear sightlines. Creature comforts include a climate-controlled cup holder and dedicated storage. Key to ergonomics and operating the machine effectively is the Turnaround seat. Turnaround provides increased comfort, clear sightlines, and easy entry and exit from either side of the machine. The operator enjoys full control of all machine functions in any position within the 220° range. Visit tigercat.com.

36 ● JUNE 2023 ● Southern Loggin’ Times

Felled Tree Strikes Crew Cab Truck

BACKGROUND: On a summer morning in the Southeastern U.S., a crew cab truck transporting three logging company employees was traveling to the deck to begin their shift. Conditions were clear that day and weather was not a contributing factor.

UNSAFE ACTS AND CONDITIONS: The tracked feller buncher operator was cutting alongside the haul road fully aware that additional crew members would be arriving soon to start their workday.

ACCIDENT: The employees in the company crew cab had traveled approximately four miles through the woods on the haul road en route to the deck. The crew cab stopped along the haul road before arriving at the deck to drop off the skidder driver close to his machine. The truck continued traveling to the deck

were located. Other crew members had arrived onsite approximately 45 minutes earlier and had already started their workday. The tracked feller buncher operator began cutting along the side of the haul road near the deck. The feller- buncher

began cutting a 20-in. (DBH) gum tree measuring approximately 80 ft. in height. As the tree was being severed from the stump, the operator lost control of the tree and it started to fall back toward the machine. Instinctively, the operator used the cutter arm to push the tree away

from the cab and toward the haul road. At the exact moment the operator was pushing the tree away from the feller-buncher, the crew cab truck was arriving at the deck. The felled tree struck the crew cab and came to rest on top of the truck. The feller-buncher operator alerted the other crew members and they assisted with removing the top of the tree from the cab.

INJURY: The crew extracted both employees from the crew cab truck and transported them to the intersection of the haul road and state highway to meet EMS personnel. The injured workers were transported to the local hospital where both were treated and released later in the day. One was diagnosed with a cervical fracture and referred to a neurosurgeon for further evaluation.

RECOMMENDATIONS FOR CORRECTION:

l Always be aware of other crew members’ location, especially while conducting felling operations

l Properly assess the weight and balance of trees prior to felling to minimize accident risk

Supplied by Forest Resources Assn.

38 ● JUNE 2023 ● Southern Loggin’ Times

IRONWORKS

TOLL FREE: 1-800-669-5613

CLASSIFIED AD RATES: Classified advertising rates are $55 per inch. Space is available by column inch only, one inch minimum.

DEADLINES: Ad reservation must be received by 10th of month prior to month of publication. Material must be received no later than 12th of month prior to month of publication.

CONTACT: Call Bridget DeVane at 334-699-7837, 800-669-5613, email bdevane7@hotmail.com or visit www.southernloggintimes.com

6209

4433

42 ● JUNE 2023 ● Southern Loggin’ Times

Southern Loggin’ Times ● JUNE 2023 ● 43 WANT TO PLACE YOUR CLASSIFIED AD IN IRONWORKS? CALL 334-699-7837, 1-800-669-5613 OR EMAIL: CLASS@SOUTHERNLOGGINTIMES.COM 2687 2891