CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

HATTON-BROWN PUBLISHERS, INC.

Street Address: 225 Hanrick Street

Montgomery, AL 36104-3317

Mailing Address: P.O. Box 2268

Montgomery, AL 36102-2268

Telephone (334) 834-1170

Fax 334-834-4525

Publisher David H. Ramsey

Chief Operating Officer

Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Managing Editor Dan Shell

Senior Editor David Abbott

Senior Editor Jessica Johnson

Publisher/Editor Emeritus

David (DK) Knight

Art Director/Prod. Mgr. Cindy Segrest

Ad Production Coord Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING SALES REPRESENTATIVES

SOUTHERN USA

Randy Reagor

(904) 393-7968 • Fax: (334) 834-4525

E-mail: reagor@bellsouth.net

MIDWEST USA, EASTERN CANADA

John Simmons (905) 666-0258

E-mail: jsimmons@idirect.com

WESTERN USA, WESTERN CANADA

Tim Shaddick (604) 910-1826 • Fax: (604) 264-1367

E-mail: twshaddick@gmail.com

Kevin Cook (604) 619-1777

E-mail: lordkevincook@gmail.com

INTERNATIONAL

Murray

Brett

+34 96 640 4165 • + 34 96 640 4048

E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane 334-699-7837 bdevane7@hotmail.com

Timber Harvesting & Forest Operations (ISSN 2154-2333) is published 6 times annually (January/February, March/April, May/June, July/August, September/October, November/ December issues are combined) by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscriptions are free to U.S. logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; businesses involved in land grooming and/or land clearing, wood refuse grinding and right-of-way maintenance; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel. All non-qualified U.S. subscriptions are $50 annually; $60 in Canada; $95 (airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds). Subscription Inquiries—TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.timber harvesting.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Timber Harvesting & Forest Operations are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Timber Harvesting & Forest Operations. Copyright ® 2023.

POSTMASTER: Send address changes to

TIMBER HARVESTING & FOREST OPERATIONS

P.O. Box 2419, Montgomery, AL 36102-2419

in

or in

Periodicals

mailing offices.

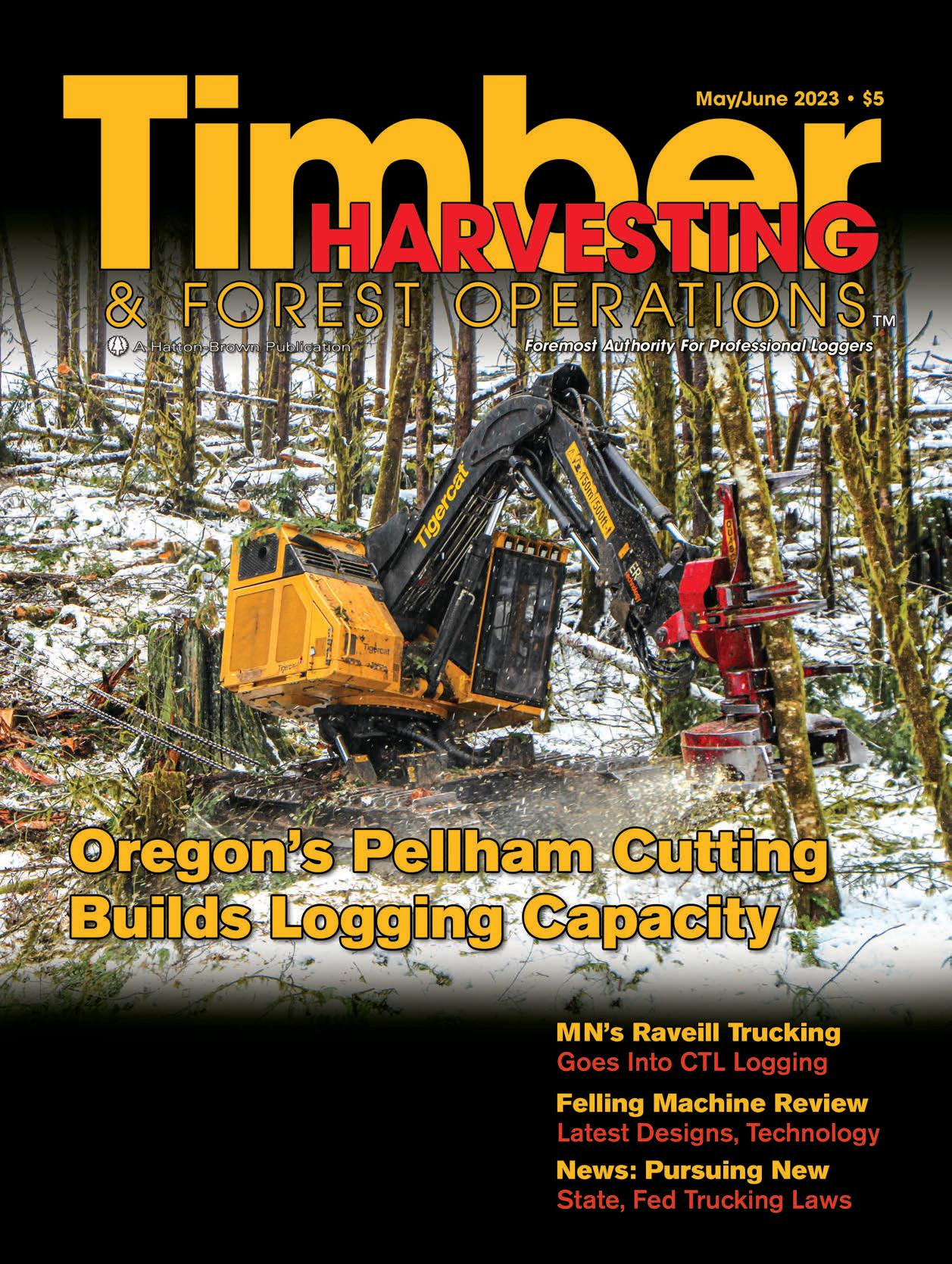

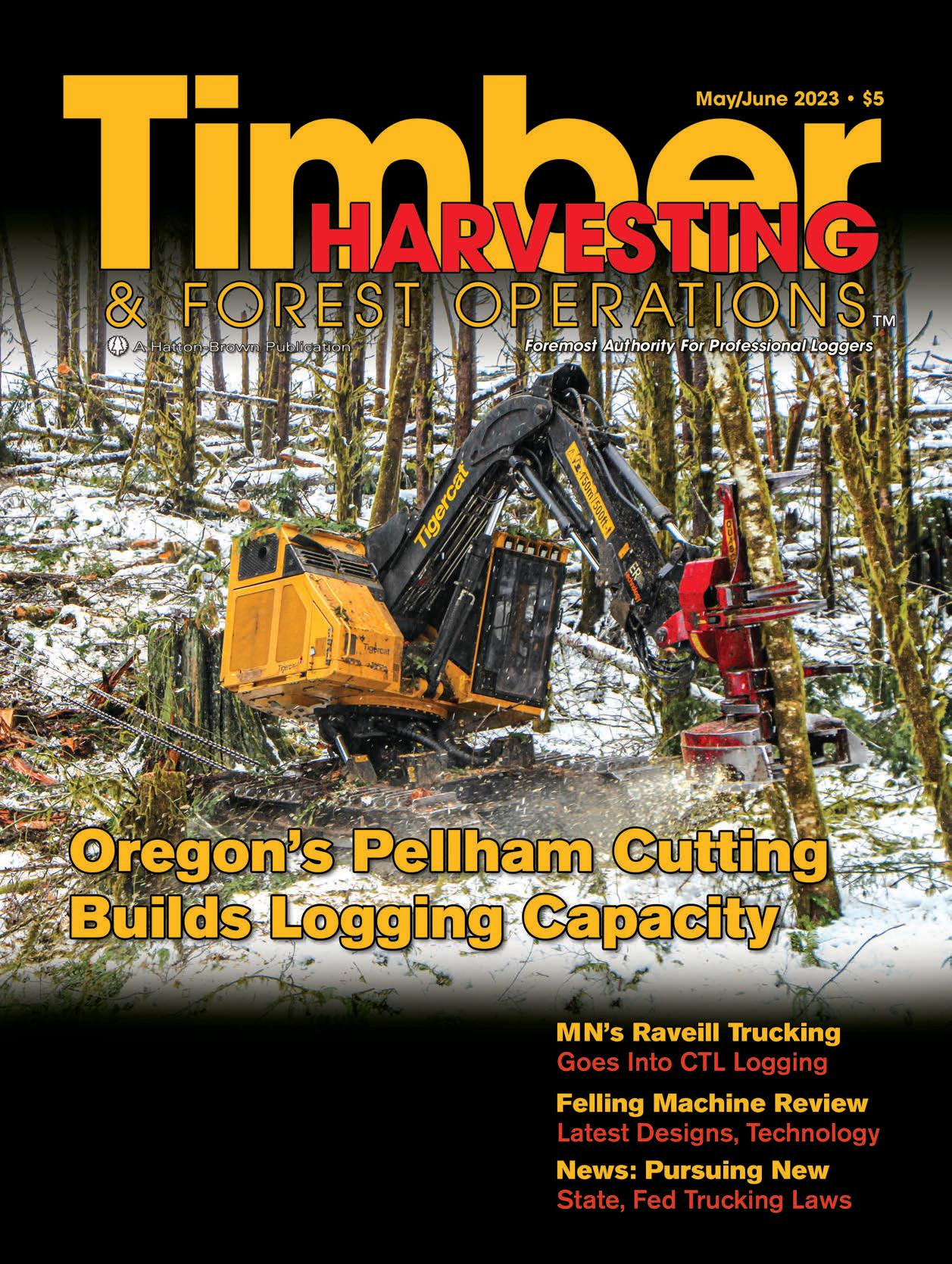

in USA. A Hatton-Brown Publication Foremost Authority For Professional Loggers Browse, subscribe or renew: www.timberharvesting.com Vol. 71, No. 3: Issue 698 MAY/JUNE 2023 Pellham Cutting, Inc. in St. Helens, Ore., offers stump to dump logging services, plus trucking. Article begins on PAGE 12. (Dan Shell photo, design by Shelley Smith) MyTake __________________________________________________ 4 Newslines ________________________________________________ 6 Equipment World ________________________________________ 24 Select Cuts ____________________________________________ 27 THExchange 28 Ad Index _______________________________________________ 30 Other Hatton-Brown Publications: Southern Loggin’ Times • Wood Bioenergy Timber Processing • Panel World • Power Equipment Trade OurCover OurFeatures OurDepartments Minnesota’s Raveill Trucking Diverse Companies, Great People Learning To Be Safe Don’t Miss An Opportunity Innovation Way New Product Focus 22 18 21 Felling Equipment New Machines, Technology 10 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

All rights reserved. Reproduction

whole

part without written permission is prohibited.

postage paid at Montgomery, Ala. and at additional

Printed

Loggers Making An Impact, Moving The Needle On Issues

While pulling together and working on this issue, which includes contributions from Associated Oregon Loggers Safety Manager David Grim and Ray Higgins of the Minnesota Timber Producers Assn., it hit me how many good people there are across the country and in this industry working to improve the prospects of logging contractors.

Then I saw the news item about Idaho loggers visiting their state capital, and the new American Loggers Council “As We See It” came in that detailed the recent Fly-In to work with federal officials in Washington, DC, and the depth and breadth of the collective effort becomes even clearer. Hey, we’d love to have sweeping national pro-logger policies come to fruition overnight, but we’re also just as happy to see logger interests worked out and promoted at the state and local level—and the cool thing is there are hundreds, maybe thousands across the country working to make it happen.

Working with Timber Harvesting, America’s only national logging magazine, I do my best to highlight loggers’ efforts both big and small: Everything from mucking around with U.S. Senators in Washington, DC to working out a county roads issue that’s affecting efficiency. It’s always tough knowing there’s never enough room to highlight them all.

A couple months ago, the American Loggers Council hosted its first DC Congressional Fly-In in four years following cancellations due to the pandemic and ALC’s change in leadership. This year’s Fly-In was the first since 2019 and the first under Executive Director Scott Dane. ALC brought together 75 timber industry representatives from 21 states and conducted nearly 100 meetings with members of the U.S. Congress.

Events included a Congressional Reception at the iconic Willard Hotel, where ALC’s DC office is located.

Five Congressman—LaMalfa (CA), Westerman (AR), Collins (GA), Bergman (MI), Golden (ME)—and two Senators—Baldwin (WI) and HydeSmith (MS)—attended. Congressman Golden and Westerman were presented the inaugural ALC Congressional Leadership Award for the House of Representatives and Senators Collins (ME) and Baldwin (WI) were the recipients for the Senate.

Additional Congressional staff from other offices attended the reception along with representatives of the United States Forest Service, John Deere, and the Biomass Power Assn. The Reception was sponsored by ALC Gold and Platinum Members (Tigercat, International Truck, John Deere, Cat, Southern Loggers Cooperative, Fuel & Resources, Morbark, Bitco Insurance Companies, Bandit, and Ponsse) with specific portions also sponsored by International Truck, International Union of Operating Engineers, the Louisiana Loggers Assn., the Louisiana Logging Council, Southern Loggers Cooperative, Walsh Timber, the Great Lakes Timber Professionals Assn., the Associated California Loggers, and the Professional Logging Contractors of Maine.

The day on the Hill saw timber industry representatives from Louisiana, Maine, New York, Pennsylvania, Rhode Island, Vermont, Connecticut, New Hampshire, South Carolina, Florida, Georgia, Virginia, Alabama, Mississippi, California, Michigan, Wis-

consin, Minnesota, Idaho, Oregon, and Maryland meet directly with their respective state Congressional Representatives and their staffs. These industry representatives left their logging operations in the woods to bring the U.S. timber industry’s voice to the halls of Congress and the White House.

More Fly-In coverage page 27.

Paper Market Woes

East Coast paper markets have been jolted this spring with closures at major wood-consuming facilities in Maine and North Carolina.

Already hard hit by pandemic issues, lack of fiber log markets and a tough winter with lots of weather-related downtime, loggers in Maine took another lick after Nine Dragons announced an indefinite downtime at its Old Town, Maine, pulp mill claiming rising fiber and energy costs and an eventual evaluation for “a potential restart.”

Professional Logging Contractors of Maine Executive Director Dana Doran said, “Since 2020 we’ve seen a 30% reduction in logging contractors. The markets aren’t there; wood prices are depressed; and there’s inflation. The contractors have had enough.”

Meanwhile, farther south mid Atlantic loggers were rocked by the announcement that the Pactiv Evergreen Canton Paper Mill, which has operated more than 100 years, is closing. The facility consumed about 1.5 million tons a year, roughly 50-50 hardwood and softwood.

The closure affects 1,100 direct mill jobs and many more in other companies that worked with the mill. According to a report in the Fastmarket RISI North American Woodfiber & Biomass Markets newsletter, the Canton closure is one of seven uncoated paper machine or mill closures since 2020.

North Carolina state officials also say that closing the Canton plant would be a “clear breach” of a $12 million economic development agreement with the Department of Commerce. The breach would require full repayment of money that was paid to Pactiv Evergreen from 2015-2021. TH

4 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

DAN SHELL MyTake

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

ALC presented new Speaker of the House Kevin McCarthy (third from left) with a custom gavel made of different wood from throughout the country.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NewsLines

New Safe Routes Act Reintroduced For Session

U.S. congressional representatives from Wisconsin and Maine have reintroduced a version of the Safe Routes Act that would allow logging trucks that meet state weight limits to drive on interstate highways.

U.S. Reps. Mike Gallagher of Wisconsin (R) and Maine’s Jared Golden (D) are sponsoring the bill, and Gallagher, who introduced similar legislation in 2019 and 2021, says he hopes Republican control of the House gives it a better chance to get through committee and attached to legislation, though he admits getting the bill through the Senate is the biggest challenge.

Once a priority of the American Loggers Council (ALC), the Safe Routes Act is still supported, but state groups and other organizations are currently working state-by-state for “carve-out” interstate waivers that allow logs trucks on certain segments of interstate since such blanket national policies are so tough to pass, legislative experts say.

Trucking Tax Credit Bill Reintroduced

Bipartisan legislation to address truck driver shortages that includes a two-year refundable tax credit of up to $7,500 has been re-introduced in the U.S. House of Representatives by Abigail Spanberger (D-VA) and Mike Gallagher (R-WI).

The bipartisan Strengthening Supply Chains Through Truck Driver Incentives Act would create a two-year refundable tax credit of up to $7,500 for truck drivers holding a valid Class A commercial driver’s license (CDL) who drive at least 1,900 hours in the year. The legislation would also establish new incentives for potential drivers to enter registered trucking apprenticeships.

According to American Loggers Council Executive VP Scott Dane, raw material transportation is the weak link in the forest products industry supply chain, which is challenged by a lack of drivers, rising fuel prices, crisis level insurance premiums, tough operating conditions and demographics.

Noting that “Virginia forest logging

businesses are reporting a major shortage of qualified commercial drivers, and this is also occurring across America,” Virginia Loggers Assn. Executive Director Ron Jenkins says VLA strongly supports the legislation.

Lolo NF Approves Montana Fire Reduction Activities

Officials with the Lolo National Forest have approved a series of forest health improvement projects in the Petty Creek drainage area west of Missoula.

down its ruling denying the appeal in early April.

Hampton Lumber Mills and Skagit Log & Construction are the main contract holders for the project, which also includes recreational area infrastructure improvements on the forest.

Idaho Arsonist Receives 10 Year Prison Sentence

Following an Idaho Dept. of Lands (IDL) collaborative investigation with the Idaho State Fire Marshall’s Office and law enforcement a north Idaho man has received a 10year prison sentence after pleading guilty to multiple counts of third-degree felony arson in relation to fires in Bonner County.

The approval authorizes a variety of activities including commercial timber harvest, thinning, slash reduction and prescribed burning on an almost 17,000 acre project area. Multiple concerns have been taken into account and affected the project, including potential impacts on lynx, grizzly bear, elk and fish habitat.

The project includes 5,300 acres of logging projects, including 28 clear cuts that average 50 acres apiece. Total harvest volume for the project is just over 89MMBF.

FS Wins Appeal For WA Vegetation Project

Forest recovery and vegetation management projects can now go forward on the South Fork Stillaguamish Vegetation Management project in northwest Washington’s Mt. Baker-Snoqualmie National Forest.

Seven years in the planning stages, the project seeks to thin overstocked timber stands on between 2,0003,000 acres scattered across the forest northeast of Seattle. The project had survived an earlier court challenge, but in 2020 the North Cascades Conservation Council appealed the decision to the 9th Circuit, which turned

Ryan Greene was sentenced for six counts of Arson III for burning forestland on both state and federal lands. The fires were reportedly extinguished before growing very large. In summer 2022, IDL investigated 287 wildfires and of those, 132 were investigated as human caused.

Prineville, OR Gets Biomass Project Grant

City officials in Prineville, and Crook County, Oreg. are one step closer to building a biomass power plant in their central Oregon town after the U.S. Forest Service (FS) recently awarded a $1 million grant to the city and its Prineville Renewable Energy Project (PREP).

According to Prineville City Manager Steve Forrester, the PREP is a proposed 24.9 MW biomass power plant that is anticipated to increase the pace and scale of ecological restoration activities in the region by reducing their cost and providing a sustainable renewable power source. If completed, the facility will provide a much-needed additional market for biomass hog fuel material coming off forest thinning and fire-reduction projects in the region and help make such projects more viable.

The $1 million grant is from the FS Wood Product Infrastructure Assistance Program, and it will be used to fund continuing permitting and design work to move the project forward.

6 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Montana cable thinning

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Idaho Loggers Take Issues To The Capitol

The annual “Loggers and Haulers Day at the Legislature” was a success as 20 Idaho loggers made the trip to Boise for the March event sponsored by Associated Logging Contractors-Idaho.

According to a report from ALCIdaho President Mark Mahon, the group met with members of the Idaho Land Board, worked with the Idaho Dept. of Lands and Idaho Dept. of Transportation and also met with key offi cials including the speaker of the house, lieutenant governor and governor.

“We had a great turnout, and we enjoyed the opportunity to share time with folks who really don’t have a clue what we do for a living,” said Mahon, who added a reception headed by ALC-Idaho Executive Director Shawn Keough was a great success, and he saw several instances of loggers sharing logging photos and videos with legislators.

Interstate Hauling Moves Forward In Arkansas

Arkansas SB 494 has reportedly passed in the House with a 94-0 vote and is on its way to the Governor’s desk. This pending new law compels the Director of State Highways and Transportation to request that the Congress of the United States amend 23 U.S.C. § 127 concerning the vehicle weight limitations on the Dwight D. Eisenhower National System of Interstate and Defense Highways to allow logging/fiber trucks to haul 85,000 lbs. on a segment of the interstate highways no more than 20 miles. A permit would have to be obtained from the Arkansas Highway Police Division of the Arkansas Department of Transporation before traveling on the interstate.

Currently, haulers are not permitted to travel on the federal interstate system in Arkansas with the 85,000 ton legal weight limit (state), because it

exceeds the federally-established weight limits on those roadways. This means log trucks traveling to mills are traveling through communities, passing businesses and pedestrians, including grade schools, high schools, and colleges. These trucks also have to negotiate roundabouts and difficult turns.

Rerouting trucks to the interstate system is a solution in addressing issues and concerns for safety. There are also economic and efficiency implications as well, as utilization of the highway system versus using alternate rural routes and community roads can reduce travel and delivery times. Keeping large trucks out of community neighborhoods also means mitigating truck noise and exhaust.

8 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

NewsLines

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Looking for better haul routes

Maine Strengthens Ash Product Restrictions

The Maine Department of Agriculture, Conservation and Forestry’s (DACF) Maine Forest Service (MFS) on March 31 announced the expansion of its Emergency Order restricting the movement of ash trees, green ash waste, ash firewood and any other materials that may be a means of emerald ash border (EAB) transportation. The expansion follows the discovery of EAB infestations in Corinna and Newport in Penobscot County and Andover and Woodstock in Oxford County. The infestations are suspected to be the direct result of human movement of EAB.

The expanded Emergency Ordercovers Androscoggin, Kennebec, Knox, Lincoln, Sagadahoc, and Waldo counties and parts of

Aroostook, Franklin, Oxford, Penobscot, Piscataquis, and Somerset counties. The expansion is in addition to areas described in the existing state quarantine, Maine DACF, Agriculture Rules, Chapter 275, which includes regions of Maine and other states and Canada.

Regulated ash products include: Rooted ash (Fraxinus spp.) for planting (excluding mountain ash); hardwood firewood that has not been certified heat treated; ash sawlogs and pulpwood and roundwood; and green ash lumber.

New GA Pellet Mill Could Be World’s Largest Producer

Loggers may have a new pulpwood and chips market with the development that Spectrum Energy Georgia LLC plans to begin construction this summer of an industrial wood pellet facility in Adel, Ga. and expects to commission the plant in summer 2024. The plant will operate at the site of an idled particleboard facility.

“One of the principle reasons we chose Adel was for the considerable infrastructure that was on site,” comments President Michael Ainsworth.

Weyerhaeuser built the particleboard mill in 1968 and operated until Weyerhaeuser sold it to SierraPine in 1999, before the plant shut down in 2014 upon SierraPine’s sale to Flakeboard.

The plant will have the ability to receive and process all forms of biomass, including sawmill residues (chips, sawdust and shavings), pulpwood, top wood, and in-woods chips.

Phase I of the project will build a 600,000 tons annual production capacity plant that will be increased during a Phase 2 construction to 1.32 million tons annually, which would make the site perhaps the large pellet production facility in the world.

Enviva Moves Forward With Epes, AL Pellet Mill

In March Enviva Inc. received its construction permit from the Alabama Dept. of Environmental Man-

Foremost Authority For Professional Loggers MAY/JUNE 2023 9 26 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

NewsLines

Have A ‘Near Miss’? Try To Learn From It

How to turn ‘almost accidents’ into opportunities for learning how to be safer.

DAVIDGrim

When was the last time you or your crew talked about a near miss that occurred on the jobsite? Near miss reporting and follow-up discussions can help show you where the hazards are on your jobsite, or help to show some areas that you might have otherwise not thought as a concern.

This approach is proactive to injury prevention. Near miss reporting can identify where more training is required, give you information to enable a change in procedure to negate the near miss, and even help you to fix faulty equipment. Knowing where the near misses occur can also help to prevent a serious accident from occurring before one happens. And reporting can improve your culture of safety, by encouraging the idea of “see something, say something.”

What counts as a near miss? According to OSHA, a near miss is an unplanned event that did not result in injury, illness, or damage, but had the potential to do so. Here are some examples of near misses:

● Slipping on the platform of a log loader

● Almost getting struck by rolling debris or log

● Almost walking a machine off the road, from inattention to the task

Here is a safety article from an actual near miss that was reported to the Washington Department of Labor and Industries, discussing an incident that occurred on a tethered logging site:

“An operator had a close-call, when cutting through one of the lines of the tethered machine.

The operator of a dual line tether system was using a bunching head to fall large hemlock trees on 80% slope. Operator had 15 years of experience running equipment, and six years of experience working on the rigging. Individual had operated this system for five months.

The base machine had its bucket dug in and tracks parallel to the hill slope on a large landing. Chains con-

nected to the tether machine were shackled to spliced-eyes on the lines from the base machine. The lines were in-lead, with both machines and separated by stumps.

The operator would walk the machine down slope and cut the way back uphill. When cutting back upslope, operator would sever the trees from the stump, lift them over the tether lines, then bunch them on opposite side of the lines.

The operator had just finished cutting a tree when the base machine slid slightly forward. This caused the tether machine to slide slightly downhill. The shift was not enough to acti-

ence led the operator to react by grounding the boom when the tether machine slid, in turn cutting the chain. Because the lines were separated by stumps, only one chain was cut.

When the line was cut, the tether machine was positioned with the boom facing uphill. Without having the second tether line as a secondary stopping device, the tether machine would have slid down slope.

Recommendations

● Ensure the base machine is properly secured.

● Employ a secondary stopping device when using a buncher head.

● Consider using a grapple head or a retractable hot saw on extremely steep slopes.

● Keep lines spaced out by stumps or terrain when using a buncher head.

● Only allow experienced operators to use tethered machines.

● Avoid operating over tether lines.”

This incident is an excellent example, to show the importance of near miss reporting and follow-up discussions. This incident in Washington can

The near miss on a Washington tethered felling operation summarized here shows the importance of training and experience, and also provides an opportunity for the whole crew to learn how to prevent such events in the future.

vate the movement sensor. If the movement sensor in the base machine had been activated, the tether machine would have been able to move for half-a-wrap on the drum while drum brakes were being applied.

The operator’s reaction was to get the boom grounded immediately. Operator dropped the tree being cut into the standing timber, then began to swing the head around to ground it. In the process, operator accidently cut one chain.

After grounding the machine and ensuring it was stable, the operator assessed the situation. Operator determined the best option was to unhook the lines and walk the tether machine downhill to the lower road. Operator walked the machine ahead to get slack and unhooked the shackles.

He called the owner and informed them of the situation. The operator replaced the cut chain, inspected all components, dug-in the bucket better, and began cutting again.

In this situation, all safety mechanisms worked properly and as designed. Years of training and experi-

help to improve operational safety of tethered logging systems to an entire industry, not just for the company experiencing the incident.

There are multiple important lessons that can be learned from this near miss, i.e., when you are using a rotary saw cutting head, do not swing it closely over tether anchor lines.

Use this example in your next safety talk or monthly safety meeting. Be sure to discuss the identified recommendations, and see if your crew can help to identify other ideas that would prevent an incident like this from happening to them. You can also refer to the Oregon OSHA guidelines for using tethered logging systems, and go over OSHA’s current guidelines.

Do you have a system to report near misses? If you do, let us know because we would like to hear about your successes to learn from close calls that prevented future safety malfunctions. TH

This article appeared in the Associated Oregon Loggers (AOL) April 2023 AOL Mainline publication. David Grim is AOL Safety and Health Manager. Visit oregonloggers.org

10 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Pellham Cutting: Quality Creates Work Demand

Oregon’s Greg Pellham has built a diverse, full-service logging company.

ST. HELENS, Ore.

Though he had been in the business 20-plus years as a contract timber cutter and large log hauler, Greg Pellham, owner of Pellham Cutting, Inc. in northern Oregon, still wanted to run his own full scale logging company, like his father and grandfather before him. Since 2016 he’s gotten his wish and more as he’s now running four logging crews, plus contract thinning and chipping operations.

Pellham, age 55, says that in a way he sort of “waited my turn” to get into logging in 2016 as a changing industry and aging contractor base combined to help create his opportunity. The company’s quality, consistent work and satisfied landowners have done the rest, helping him build

DANShell

12 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

Harvestline mobile yarding system includes motorized hydraulic grapple with camera.

capacity. “Always do the customer a good job,” Pellham says. “Dad always told me that even if you bid the job wrong, you’ve still got to do it right. Don’t take any shortcuts on the job—and that it always pays off in the end.”

Background

Last year Pellham Cutting, Inc. celebrated a rare feat—for any company, not just logging—making it to 2022 and 30 years in business after he started it in 1992 as a contract cutter with a chain saw and a pickup truck. Even with the moves into trucking and now full-scale logging, the name has stuck all these years.

The third generation logger had grown up around his father and grandfather’s logging jobs, running a chain saw and skidder, but he had always wanted his own company.

“I had been contract cutting for a few years before I started Pellham Cutting,” Pellham said. “All I had back then was a chain saw.”

His first mechanized machine was a Timberjack feller-buncher. Pellham spent some time doing nomad contract cutting in the region, working all the

way into Idaho and Montana at times and living out of a camp trailer.

He eventually sold his feller-buncher and went to work driving a truck and occasionally operating a loader part-time. Along the way, he kept expanding his trucking fleet that now totals 28 rigs.

By 2012 Pellham was looking to get into logging, but couldn’t find a clear opportunity. He had begun doing some right-of-way work for Weyerhaeuser and let them know he’d like to do more. The company approached him in 2016 about having work for two crews if he still wanted it. Pellham stepped up, geared up and went to logging.

Soon after, upon recommendation from a forester, Pellham Cutting, Inc. did a job for a large independent landowner that liked the company’s work and soon had two crews working for them. The company also has a smaller contract thinning side, and is also

On Site

Timber Harvesting finds one of Pellham Cutting, Inc.’s crews on a snowy day in late February, working an 85 acre tract for Weyerhaeuser just south of Rainier, Ore. The combination unit includes both yarder and shovel ground plus some steep tethering slopes. The cable ground has been logged, and on site are a Tigercat 830D self-levelling feller-buncher with Technical Forest Solutions Tractionline two-cable tethering system utilizing a Caterpillar 330 as a base unit. A busy landing includes a Cat 320 with Waratah processor head bucking logs, a 4040 Link-Belt sorting and decking and a Link-Belt 3240 loading trucks. A Tigercat 855 self-levelling shovel moves logs uphill on a nearby slope.

On this cold gray day the crew is moving a bit cautious in the slick conditions, and weather plays a big role in the logging system used. “Generally with dryer weather we can do steeper ground (with the shovels), but when it’s wet it limits what we can do,” Pellham says.

● Pellham Cutting, Inc.’s yarding

doing some contract chipping in cottonwood plantations in the Lower Columbia River valley.

doing some contract chipping in cottonwood plantations in the Lower Columbia River valley.

Foremost Authority For Professional Loggers MAY/JUNE 2023 13

Pellham sought a clear opportunity to get into logging and has provided key logging capacity in northern Oregon.

Pellham Cutting, Inc.’s crews offer several different logging systems and work for large landowners like Weyerhaeuser and also smaller private landowners.

crew consists of a Technical Forest Solutions Harvestline mobile yarding system mounted on a Link-Belt 4640 RB excavator base machine. The system features a Hawkeye motorized hydraulic grapple with camera system that uses visual technology to target fallen and bunched logs without the labor requirements of traditional cable logging.

Alongside the yarding system, a Link-Belt 4040 excavator works the landing chute and clears log turns. A Tigercat 875 runs a Waratah processor; and a Link-Belt 3740 loads trucks.

● A mechanical logging side includes a Tigercat 830D leveling feller-buncher, Link-Belt 5040 shovel logging machine, Tigercat 875 with Waratah processing head, and a LinkBelt 3740 handles loading.

● A shovel logging side operates a Link-Belt 4040 shovel machine with a Cat 517 grapple skidder, Link-Belt 4040 with Waratah processing head and a Link-Belt 3740 log loader.

Aside from a new Tigercat 830E that’s replacing the older cutter, Pellham says there are no machines in current need of replacement.

It depends on the machine and its operating conditions, but Pellham says he probably trades cutters more often, around four years, and shovel logging machines soon after since they take a lot of abuse. “The loaders that just load trucks, we’ll rebuild them” to get more life on those units, he adds.

Moving logs to the mills, Pellham Cutting, Inc. operates an all-Kenworth fleet, most specced out nearly identical: 46,000 lb. rear ends, 18speed manual transmissions and a Kenworth airbag suspension. He buys and runs on Michelin tires. (While he does acknowledge automatic transmissions might make it easier to find drivers, he’s a firm believer that they just aren’t designed for woods work.)

All the company’s trailers are Whit-

Log, and roll with Vulcan scale systems. The rigs are all also outfitted with Samsara dash cam systems that have already paid for themselves many times over in the three years the trucks have run with them, Pellham says.

Pellham Cutting, Inc. has just moved into a new shop in St. Helens at the end of 2022. Pellham says the whole company is excited about the larger space “We’re still working on getting everything organized.”

The service-maintenance side of the business includes five mechanics who are all cross-trained to work on both woods equipment and trucks. Two service trucks are outfitted to make inwoods calls, while two other service trucks are dedicated to truck work.

Pellham says it’s a joy having both his wife, Dawn, and son, Blake, closely involved and key contributors to the business’ success. As an exCPA, Dawn’s experience and skills have proven invaluable in managing such a growing company, he adds.

Blake, 23, manages the yarding side and operates the processor on the crew. He’s got a big interest in and an aptitude for the logging business, and Pellham says he feels good about having a line of succession identified for Pellham Cutting, Inc. and its future.

If things continue going well, Pellham hopes to pull back in about five years or so and let Blake take on a larger role in the organization. TH

14 MAY/JUNE 2023

TIMBER HARVESTING & FOREST OPERATIONS

EMS North American distributor Technical Forest Solutions supplied Tractionline system through Oregon dealer Feenaughty Equipment, which also carries the Harvestline yarding system. Pellham was sold on the 2-cable system—and recently bought another one.

Moving logs that have already been yarded on snowy, 85 acre combo tract.

Pellham Cutting, Inc. runs Waratah processors.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Raveill Rolls In Woods And On The Road

Choosing cut-to-length logging system as all-weather option.

During a Wednesday morning in the McGregor, Minn. office of Raveill Trucking and Timber Transport, Curt Raveill sits at the dispatch desk with a ton of orders neatly organized. One of the companies’ drivers is discussing the day’s plan for his truck. A computer screen shows the continental U.S. with the up-to-the-minute location and status of each truck around the country. The phone is ringing at the reception desk, with other needs and concerns on the other end. Plus, there are a couple of logging crews to keep track of.

When Raveill’s cell phone rings, it’s concerning one of his trucks currently out of commission in Tennessee, on its way to Atlanta with a load of paper from Cloquet’s Sappi mill. There are always fires to put out. This is just the latest.

“They found a repair facility, but they’re saying they can’t look at it until Friday,” Raveill says. “That can’t happen.”

Such is life in today’s world of supply chain issues, parts shortages, industry regulations and constant scheduling challenges. Raveill and wife Lisa run the businesses with a total of 80 employees across three companies but manage to juggle it all without letting a ball drop…very often. In fact, for now, Raveill is running the dispatch office while their normal person deals with a medical issue. Whatever it takes to get the job done.

“What people have said about us is he’s the big picture guy and I’m the detail person,” Lisa says.

“And we have great employees,” Curt says. “You have to find the right people and we’ve been able to do that.”

Entrepreneurial Instincts

Starting with ice sales at age 10, Raveill has always had entrepreneurial instincts, comes from a family who operated a gas station and whose father

The business has grown from a single flatbed to now encompass a fleet of more than 50 trucks that haul everything from logs and paper to general merchandise through a national OTR company and a logging and log hauling company as well.

drove trucks and hauled logs, lumber and pallets. Raveill says he’s never had a paycheck from an employer; he’s always been able to figure out a way to get a business going and stick with it.

After finishing high school in 1980, Raveill started his own trucking business: one rig with a flatbed, hauling whatever he could find. In 1984 he began working with longtime family friend and local logger and trucker Jerry Demenge—a relationship that continues to this day—and was able to begin expanding the business with the

regular work.

Over the years the business grew. Wood was flowing pretty well through the 1980s and 1990s. But still, there are always ups and downs in the flow of timber. When there wasn’t any wood, Raveill looked for other uses for his trucks.

“There were times when we were buying wood and we couldn’t keep up, then other times when there was no wood to buy,” Raveill says. “Then you have to have something to do with your trucks, so we fought that and fought

18 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

RAYHiggins

Raveill has invested in the latest trucking technology to better manage the business and its many moving parts.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

that. We kept looking for different things to haul.”

A breakthrough came in 2005, and it changed Raveill’s company forever. Sappi had purchased the Cloquet paper mill from Potlatch a couple of years before, and Raveill thought there might be an opportunity.

“One summer, we had absolutely nothing to do,” he says. “I had my own trucks. I was doing some over the road freight at that time, and that’s when I contacted Sappi about hauling their paper.”

Sappi thought that was a good idea, to have Raveill haul its finished product throughout the country. Today, Raveill Trucking has 56 trucks hauling Sappi paper to all 48 contiguous U.S. states.

“We haul general freight too,” Raveill says. “We haul Menards freight, furniture, we haul a dozen loads a week for KwikTrip, just general merchandise. That just grew as the overthe-road business grew, and the overthe-road business grew because the timber business has its ups and downs.”

By 2007 it was just Raveill, Lisa, and one mechanic on-site in McGregor, plus a dozen or so truckers. The country was in the midst of the Great Recession. “But we chose not to participate,” Raveill says.

In 2008, the business had doubled in size. They doubled again in 2009. By 2010 new opportunities were presenting themselves and the Raveills decided the time was right to seek even more.

Logging Effort Evolves

“We had some good people in place,” Raveill says. “We just decided at that point, we have the people in place to start growing. Sappi wanted more trucks, and they wanted some growth and to grow with them, so we agreed to do that. We just built from there.”

At its core, the company remains deeply tied to timber and forest products, through its relationships with Demenge and other area loggers and also through hauling paper for Sappi. The company hauls wood for area loggers under the banner of Timber Transport, the Raveills’ company for timber hauling. There’s a third entity called Timber Transport Logging that harvests its own timber and markets it, either through Demenge or through Raveill’s own markets.

“The first time I cut wood was in the ‘90s,” Raveill says. “We’ve gotten in

and out of it over the years as markets have changed. I was one of the first MLEP members and have always kept current with that. Then in 2008 I was at an auction sale and bought a skidder, hired someone to run it, and that winter bought a buncher and a slasher.”

The logging effort was seasonal and some years non-existent if markets weren’t there. With a nudge from employees who were looking for yearround work, Raveill decided in 2019 to go all in on logging, but with cut-tolength equipment. He adds, “The only way I could figure we could log yearround is with cut-to-length.”

Today, Timber Transport Logging operates two Ponsse Ergo processors and four Ponsse Buffalo forwarders across two crews. The harvests are mostly hardwood thinnings, aspen clearcuts, or pine thinnings, and the wood is marketed by either Raveill

or Demenge to Savanna Pallets, Sappi, Louisiana Pacific, Nelson Wood Shims, PotlatechDeltic, Woodline Sawmill, or a couple of nearby Amish mills. Between Timber Transport and Timber Transport Logging, there are eight trucks and drivers, and six employees on the two woods crews. If additional hauling capacity is needed because of commitments with Demenge, another logger or his own timber production, trucks from Raveill Trucking that normally haul over-the-road can be pressed into service.

It should be pointed out that the Raveills have had their share of obstacles to overcome over the years: Lisa survived a nasty bout with cancer in 2010. And six years ago in 2017, a fire burned the main truck shop along with some offices to the ground that really set things back. But they wasted no

Foremost Authority For Professional Loggers MAY/JUNE 2023 19

Logging side includes two crews, each with a harvester and forwarder.

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Raveill Trucking specializes in Sappi paper but also hauls many other products all over the country.

time in starting the rebuild and managed to come back bigger and better than before.

“We’ve been through a few things, and we’ve never really missed much work because of it. We just figure it out,” Lisa says. “Curt just doesn’t miss a beat. He doesn’t let anything stop him. He’s hard for me to keep up with. He wears me out just watching him.”

The couple and their companies have embraced technology to keep things running smoothly, with electronic logs that integrate with the dispatch software, for example, because they’ve found they can keep a better handle on deliveries and on maintenance and repairs, like the situation with the truck and driver in Tennessee.

“We have always been above the norm in technology for our size company,” Lisa says. “Our goal has always been to be an industry leader.

“The drivers have all the information they need sent right to their truck,” she continues. “We can communicate with our customers as well, so they have up to the minute locations of the trucks.”

The information is entered into the dispatch software system that integrates with the e-logs in the drivers’ trucks and customers through EDI for invoicing and tracking capabilities. The system is also used for driver payroll and customer invoicing. “And we have excellent office staff who takes care of all that data, enters it in, bills it out. It is a very efficient system,” Lisa says.

One emphasis is on finding backhauls, so trucks don’t return to McGregor empty. It’s more difficult to do on the Timber Transport trucks hauling wood to mills. But for the general freight loads through Raveill Trucking, the company has a pretty good track record, to say the least.

“We do back hauls every chance we get,” Raveill says. “We’ve come home empty only twice in five years. That was this (past) year to get a couple of guys home for Thanksgiving.”

Lisa says it also helps that Raveill

is a pretty good mechanic in his own right, with the ability to diagnose problems over the phone. That’s saved a lot of time and money over the years.

“He can do it over the phone with the mechanics or drivers or with a quick look,” she says. “When he’s asked how he knows this stuff he says, ‘Because I’ve broken most everything there is to break on a truck and had to fix it myself.’ He gets calls from other loggers and truckers all the time asking how to fix something. He can always figure it out. It amazes me. It’s a great asset to our business. We’ve saved thousands of dollars over the years fixing the actual problem instead of buying unneeded parts only to do it again.”

Then there’s the nearly four-decade relationship with Demenge that’s more than just trucking. Raveill and Jerry have fished together, and their families have traveled together, so it’s much more than a business deal that’s worked out extremely well.

“It’s tremendous,” Demenge says. “It goes beyond just hauling wood. It goes right into his shop, the repairs on

my trucks. We spent a lot of nights at midnight either stuck somewhere or fixing something so we could get out of the woods and get home—a lot of nights. We’ve had a lot of fun. A lot of those fishing stories—he’d probably like to be reimbursed for all the fish I made him lose. But it’s all gone well. I hope I’ve helped him as much as he’s helped me.”

These days, there are seven in the office and a total of four mechanics keeping trucks on the road. There’s also a terminal in Superior, Wis. With the continental U.S. as an operating area, the company has drivers living around the country in places like Sioux Falls, Grand Forks, even in Dallas.

That’s a lot to keep track of, and it takes a lot of teamwork to keep it going. “Lisa and I work well together,” Raveill says. “But we couldn’t make it happen without a great bunch of employees in the office, in the woods, and out on the road.” TH EDITOR’S NOTE: This abridged article originally ran in the Nov.-Dec. 2022 Timber Bulletin, published by the Minnesota Timber Producers Assn. Ray Higgins is Editor-in-Chief.

20 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

Don’t Forget... • 2023 Logging Business of the Year Nomination • 2023 Logger Survey visit timberharvesting.com CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Curt and Lisa Raveill: “Curt just doesn’t miss a beat. . . he wears me out just watching him.”

Deere L-Series II Wheeled Feller Bunchers

Work in the woods can be demanding, and John Deere machines help provide its customers with the solutions needed to enhance productivity and performance. The John Deere L-Series II Wheeled Feller Bunchers were designed based on extensive customer input, resulting in a lineup of machines that improve operation, maintenance, and reliability.

When the going gets tough, you need a machine that can handle anything thrown its way. That’s where the John Deere 843L-II Wheeled Feller Buncher comes in, equipped with heavy-duty axles that deliver unrivaled balance and hill-climbing power. With optimal weight distribution and a long wheelbase, this beast maintains excellent stability when conquering hills and controlling trees.

The L-Series II models are a game-changer in the logging industry, thanks to their sleek design and enhanced functionality. These machines have undergone several crucial part changes that have significantly reduced complexity, making them a joy to service. One notable improvement is the electrical and hydraulic systems, which have been revamped to streamline their routing and enhance reliability. The wiring and hoses are better protected against wear and bending, and the durable electrical-harness components help extend wear life, making for a rugged, powerful machine in the woods.

The 843L-II offers a spacious cab, designed to provide a luxurious and quiet environment with a large expanse of the front glass, operators can enjoy unobstructed visibility. The spacious 2.94 cubic meter (104 cubic foot) cab is designed to provide a luxurious and quiet environment, and with a large expanse of front glass, operators can enjoy unobstructed visibility. Visit johndeere.com

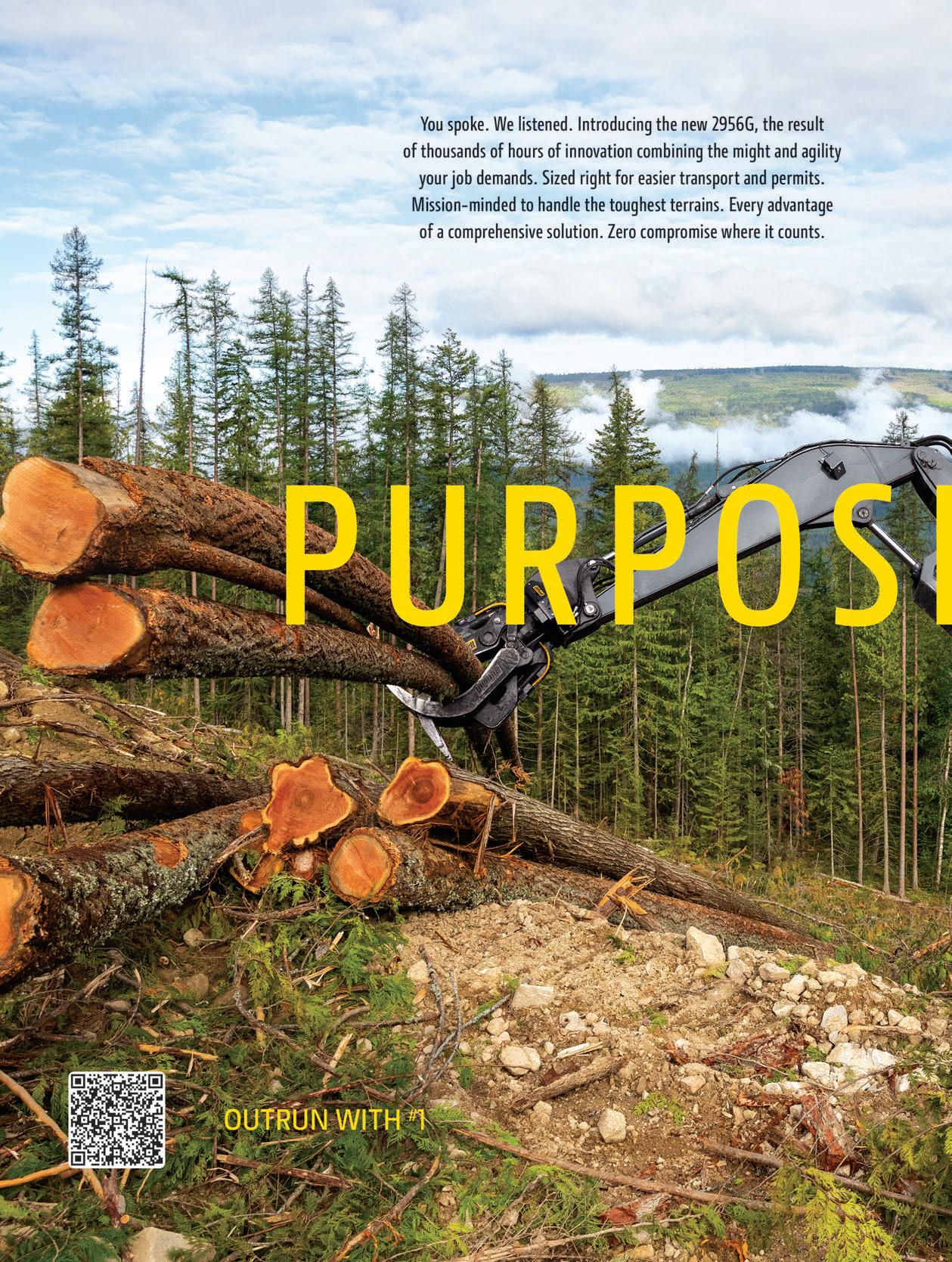

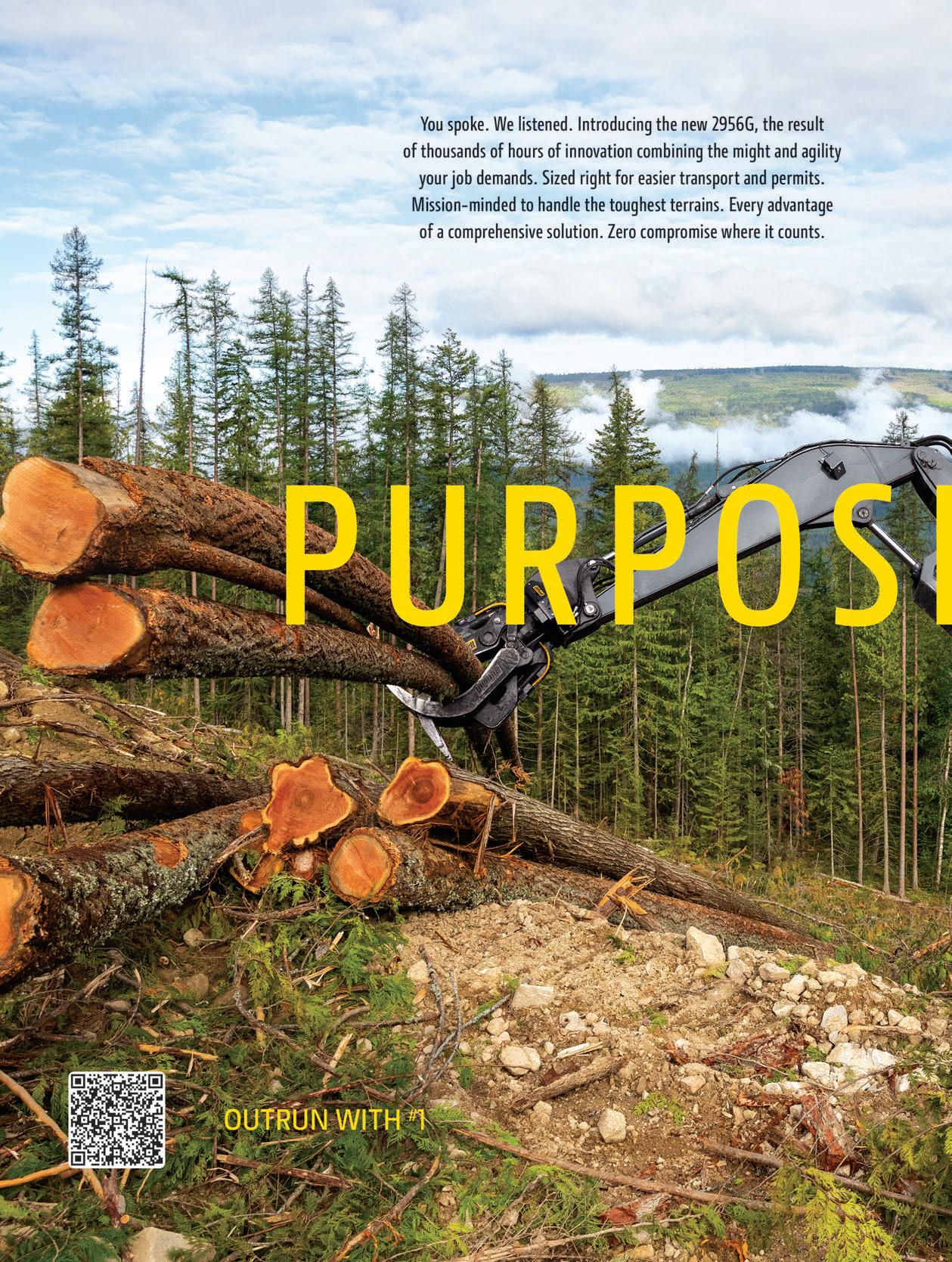

Ponsse’s New Scorpion Giant

The newest member of the Scorpion family seamlessly complements the entire Ponsse harvester range. Developed according to requests from our customers, Ponsse Scorpion Giant conveniently fulfills the gap between Scorpion King and Bear in the Ponsse harvester line-up comparison. The Ponsse Scorpion Giant can be equipped with the H8 harvester head. Smaller heads are available for customers who mainly require more lifting power. With the new C50+ crane offering more lifting power and more tractive force, the Ponsse Scorpion Giant is right at home when working with larger trees, even in snow, slopes, soft and wet grounds.

The Scorpion Giant is still a beast of a harvester, while it is now more modern, stylish and comfortable. The best properties are still there–just upgraded from the feedback of operators. The entirely new cabin is full of features that improve visibility, safety ergonomics and usability. This increases the operator’s comfort, while the completely new air conditioning system, larger storage spaces and dozens of other small details add finishing touches. When you step into the spacious and quiet new cabin, you can experience a new kind of dignity never seen in work machines before. The new stylish design, high quality upholstery and more space make you feel that everything is in its right place, but with a higher level of quality.

The incredible stability of Ponsse Scorpion Giant comes from its eight wheels and active stabilization system. This patented system is based on detecting the crane’s direction and position, on the basis of which the rear frame is pressed in the working direction. Pressing the rear wheels against the ground and the weight of the rear frame improve the machine’s stability significantly when working on the side of the machine–also when the machine is moving. Visit ponsse.com

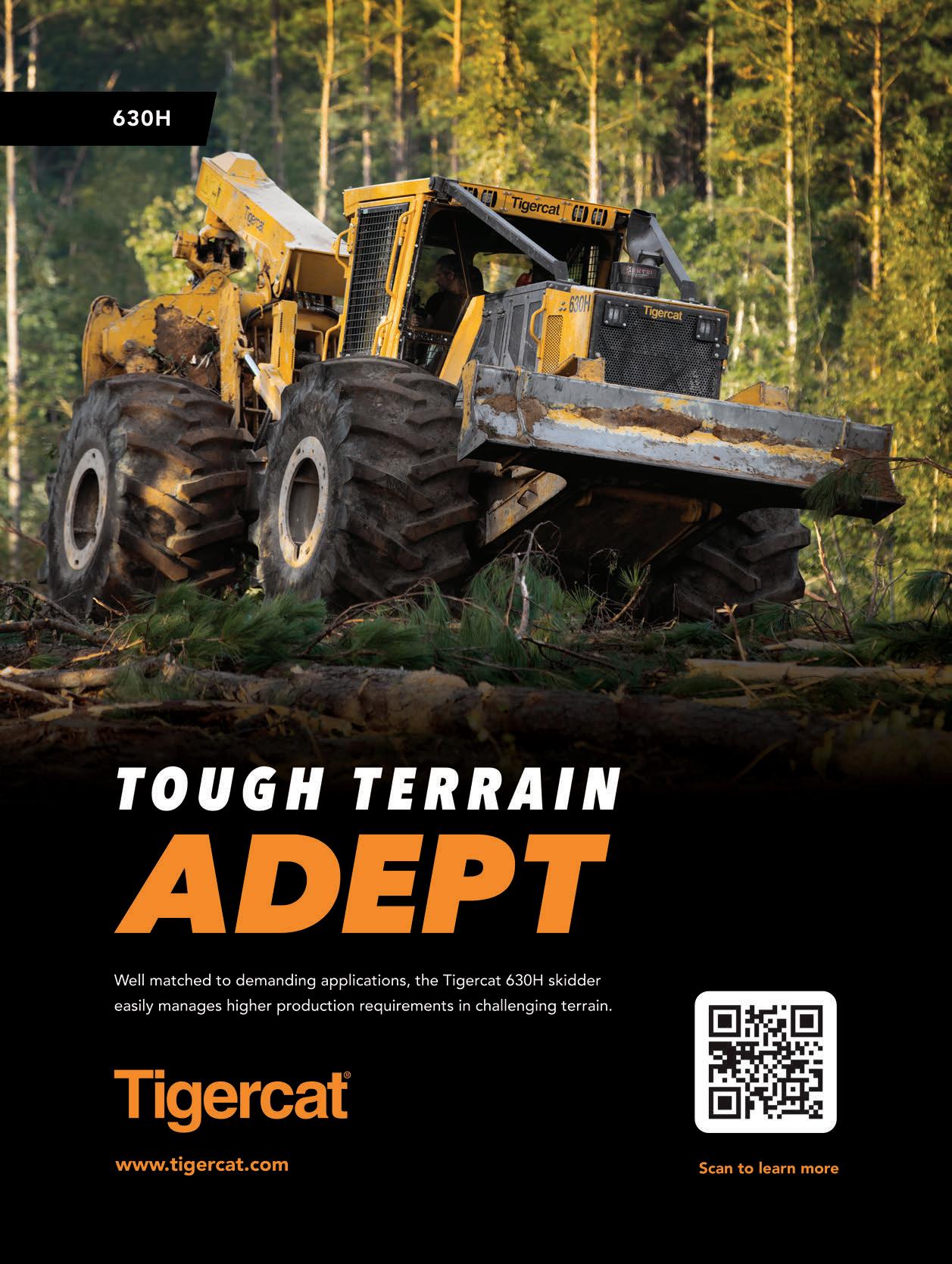

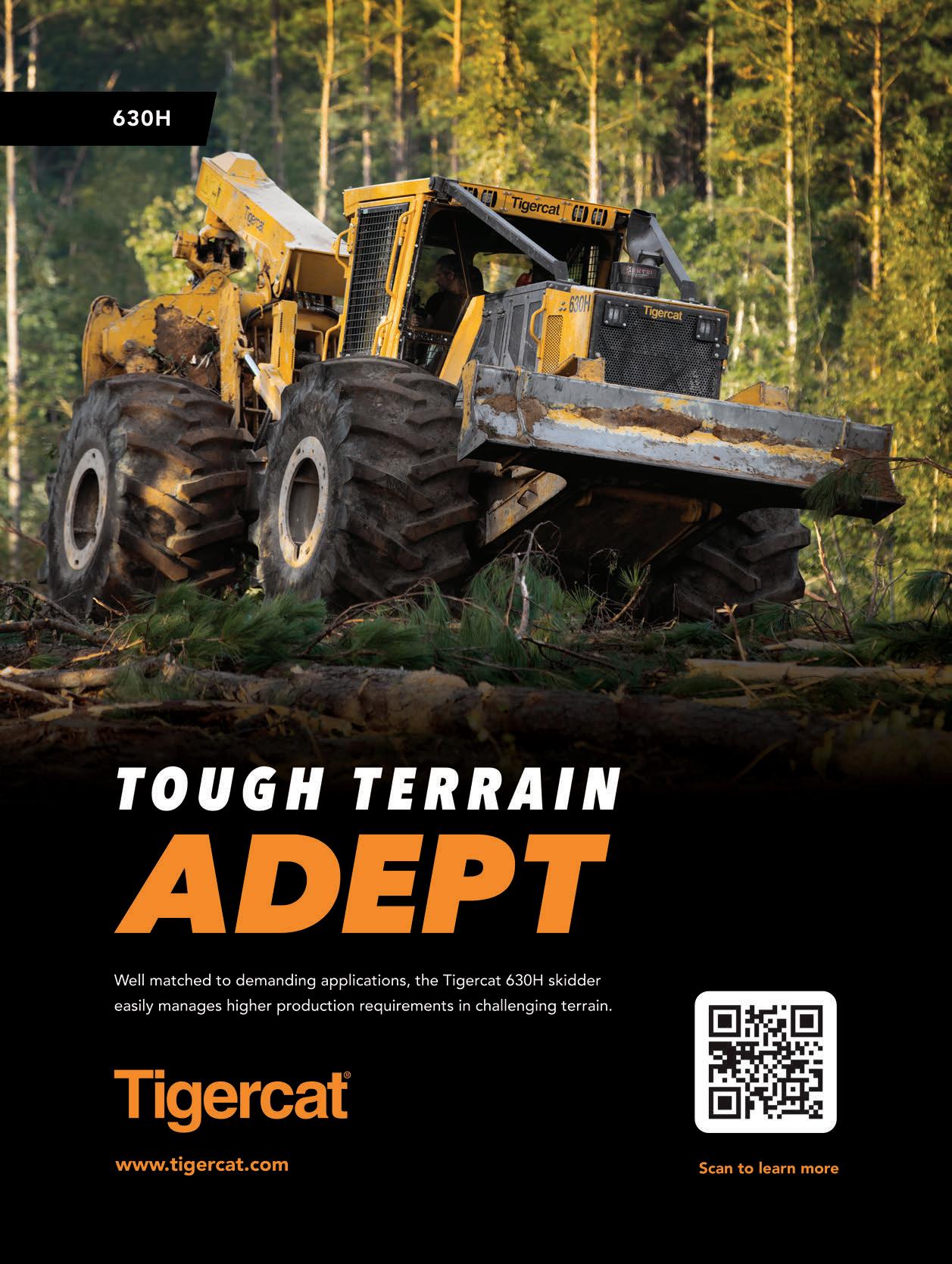

Tigercat Feller-Buncher Options

Tigercat builds drive-to-tree feller bunchers for the full range of thinning and final felling duties. The 720G and 724G are designed for thinning and clear fell applications, and the large capacity 726G fells large diameter timber in tough terrain. The G-series machines’ cabs are designed for productivity and operator comfort. Visibility is enhanced with a larger front window and larger rear quarter windows. The view over the back tires is the best in the industry–an asset in thinning applications.

Only Tigercat offers WideRange, the infinitely variable transmission for drive-to-tree feller bunchers. WideRange allows the operator to travel more quickly than conventional two-speed transmission equipped feller-bunchers. Quicker travel boosts productivity and reduces cost per ton in high production thinning and final fell applications. Tigercat’s WideRange drive system is standard on all G-series feller bunchers. A two-speed transmission is optional on the 720G and 724G. The Tigercat LX830E is a high production leveling feller buncher with near zero tail swing. Featuring the powerful Tigercat FPT C87 engine and closed loop drive system, the LX830E is well equipped to handle a variety of felling applications on steep slopes. The powerful lift capacity, tight-tuck ER boom geometry, and compact tail-swing make the LX830E perfect for selective felling where minimum site impact is important. A redesigned engine enclosure provides improved roof access for cleaning debris. A boom slider also reduces debris build-up in hard-to-reach areas. The clamshell style enclosure and dropdown side platform allow easy access to all sides of the engine. The updated cab includes a durable, roomy, air ride seat with heating and cooling. The full-length front window and narrow side posts give the operator an excellent view of the tracks and surrounding area. Visit tigercat.com

FellingEquipment Foremost Authority For Professional Loggers MAY/JUNE 2023 21 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Tigercat Dual Winch Skidder

the 2956G crawler log loader features an overall shipping width of less than 11' 6". The design on the 2956G not only helps simplify transportability, but also helps save on costs relating to transport due to its less restrictive transportation requirements. In addition, the new mounting of the log deflector adds additional strength to the right-front corner of the machine and the new, clean, and simple design of the hood profile, aligned with counterweight, helps to enhance debris shedding.

The 2956G crawler log loader features excellent engine power for a machine of this size. When combined, the engine power and hydraulic flow significantly boost loading capability, speed, and the capacity to run the Waratah 624. Also, customers looking to increase efficiency in roadside processing can expect improved productivity when running the Waratah 624 head as compared to the 2654G.

The Tigercat 612 series skidder platform was created to manage the extraction function in challenging terrain selective felling applications, while preserving the value and quality of the residual stand. The machine can be equipped with a dual winch, a movable back shield and fairlead system, as well as a crane, and front blade tongs.

The 612 is equipped with the Tigercat FPT N67 Stage V engine, delivering 155 kW (208 HP). Combined with Tigercat’s efficient drive system, the 612 impressively handles adverse terrain while minimizing wheel spin.

A narrow stance allows easy navigation through tight trails and rough ground conditions. The movable shield can be used as an anchor while winching. The dual winch and moving fairlead system allow the operator independent control over two separate cables when operating in tight stand conditions. The optional heavy-duty crane and blade tongs offer even more versatility for extracting, maneuvering and sorting logs.

The operator’s cab is spacious with generous sized windows providing clear sightlines. Creature comforts include a climate-controlled cup holder and dedicated storage. Key to ergonomics and operating the machine effectively is the Turnaround seat. Turnaround provides increased comfort, clear sightlines, and easy entry and exit from either side of the machine. The operator enjoys full control of all machine functions in any position within the 220° range. Visit tigercat.com

Deere Crawler Log Loader

Designed for logging contractors of all sizes, John Deere offers the new 2956G crawler log loader as a machine that provides the best combination of engine horsepower and hydraulics capability, while maintaining a machine weight of less than 90,000 lbs.

Aimed to help ease transportation,

Visibility enhancements have also been prioritized in the design of the new 2956G. Enabling additional visibility to the right track, as well as reduce overall impact, the RH front corner log deflector has been strategically moved to the back on the machine. A rearview camera, light and JDLink antennas have been integrated into the counterweight for additional protection. Visit johndeere.com/forestry

Link-Belt 40B Forestry Series

The Link-Belt 3440B Processor, 4040B Timber Loader, and 4640B Timber Loader are now available in the U.S. and Canada. The new 40B Series of forestry equipment features design improvements to increase cooling performance, debris management, and serviceability. The new line made its debut at Triad Machinery’s booth during the 85th annual Oregon Logging Conference in February.

The 4040B TL is gaining a substantial increase in engine HP, by 21%. Coupled with increased cooling and airflow management, the 4040B TL is sure to put in the work for the long haul. With serviceability and debris management, removal of the dust screen from the ground or catwalk is quick and effortless.

An All-new 3440B PH machine dedicated to forestry timber processing features a 177 HP Isuzu tier 4 final-compliant engine. Boasting an upsized cooling package compared to the previous generation l, the 3440B PH offers superior performance and productivity compared to its predecessor model.

“LBX is excited to introduce the all-new 40B Series for-

InnovationWay 22 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

estry product line,” says Adam Woods, General Manager of Innovation and Product Portfolio Strategies at LBX. “The partnership we have with our dealers has given us the opportunity to use the feedback directly from our customers as the basis of this new 40B series. From increases in productivity to the enhancements in the safety and service of the machine, we’re very excited about what this means for the future of our forestry equipment.”

40B Series machines were developed with site awareness in mind. The 270° birds-eye view with WAVES (Wide Angle Visual Enhancement System) is now standard. Couple all this with industry-leading fuel consumption and productivity, it’s a winwin. Visit lbxco.com

Biodiversity & Carbon Tracking Tool

CollectiveCrunch, creator of the AI-powered platform that enables sustainable forestry at scale, is launching Linda Planet, a new trustworthy tool that enables forestry professionals to assess the health of forests by monitoring and tracking changes in both forest biodiversity and carbon storages in near real-time.

“Our goal is to change the world’s understanding of forests by providing the most accurate, scalable and timely forest analytics possible,” says CollectiveCrunch Co-Founder Rolf Schmitz. “Through solutions like Linda Planet, we can enable sustainable forestry, assist in the mitigation of carbon losses, and bring transparency to forest carbon markets to spearhead the fight against climate change.”

The AI-based Linda Planet solution provides a scientific and data-driven approach to forest carbon management. It does this by helping mitigate forest carbon value loss by tracking changes and potential damages in near real-time, and assists in forecasting the growth and loss of forest carbon stocks.

Nominal checkups with 5-year manual auditing cycles of forest carbon assets have proven to be insufficient. In order to have foolproof understanding of the progress and permanence of the natural capital, continuous and accurate visibility into the assets is essential—which is what Linda Planet offers. Linda Planet is uniquely posi-

tioned to bring credible baselines to the market at large scale.

A transition to sustainable forestry at a global scale requires analytics ranging from deforestation and carbon stock changes to habitat destruction and biodiversity loss. Ensuring that the world’s forests are on a path toward increased resilience and enhanced biodiversity requires access to the best available intelligence.

CollectiveCrunch is a solutions provider that is approved by Verra, a nonprofit organization that operates standards in environmental and social markets, including the world’s leading carbon crediting program, the Verified Carbon Standard (VCS) Program.

CollectiveCrunch has been developing state-of-the-art AI-based technologies for the forest sector since 2016. Visit collectivecrunch.com

InnovationWay

Foremost Authority For Professional Loggers MAY/JUNE 2023 23 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

EquipmentWorld

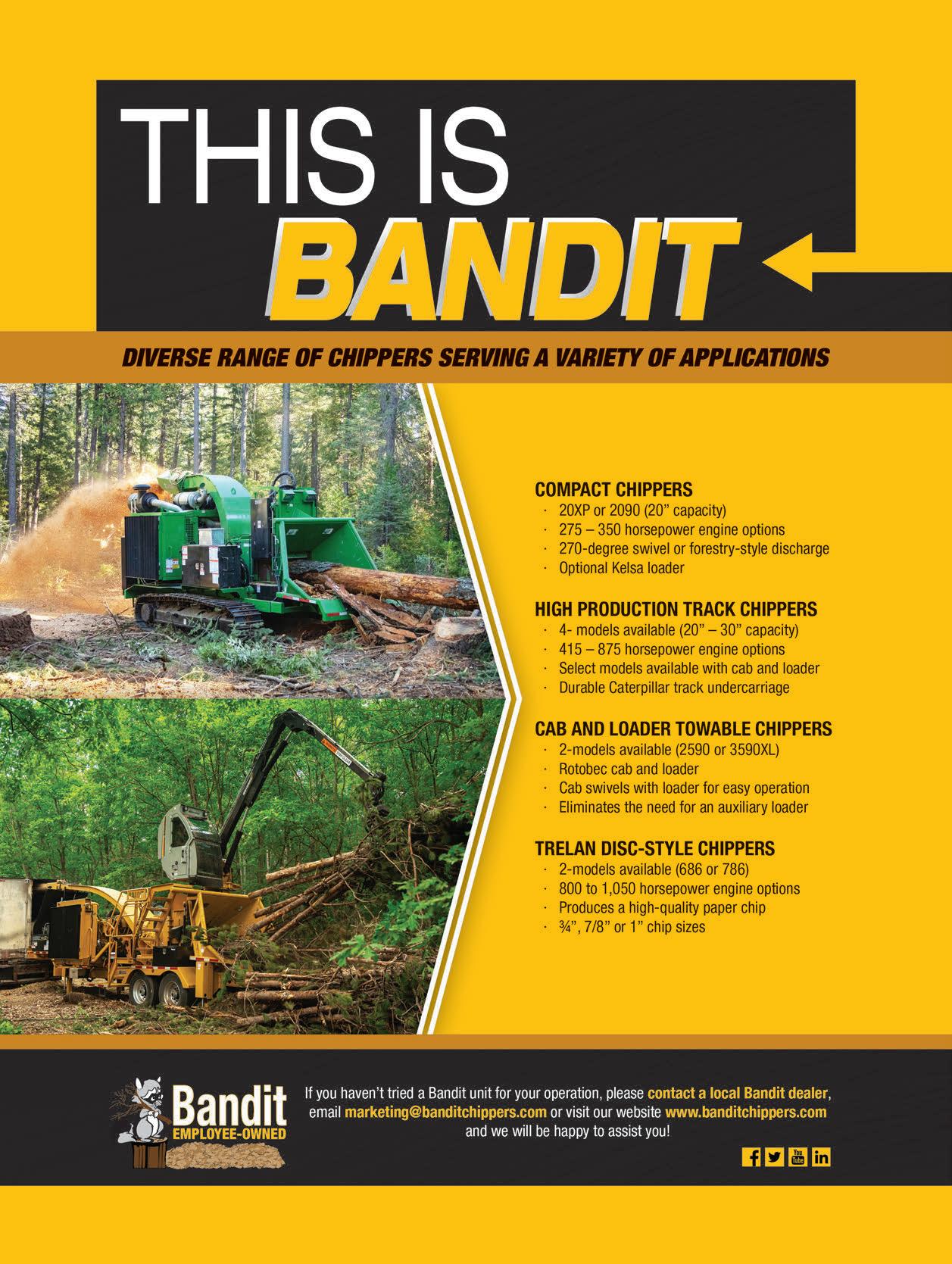

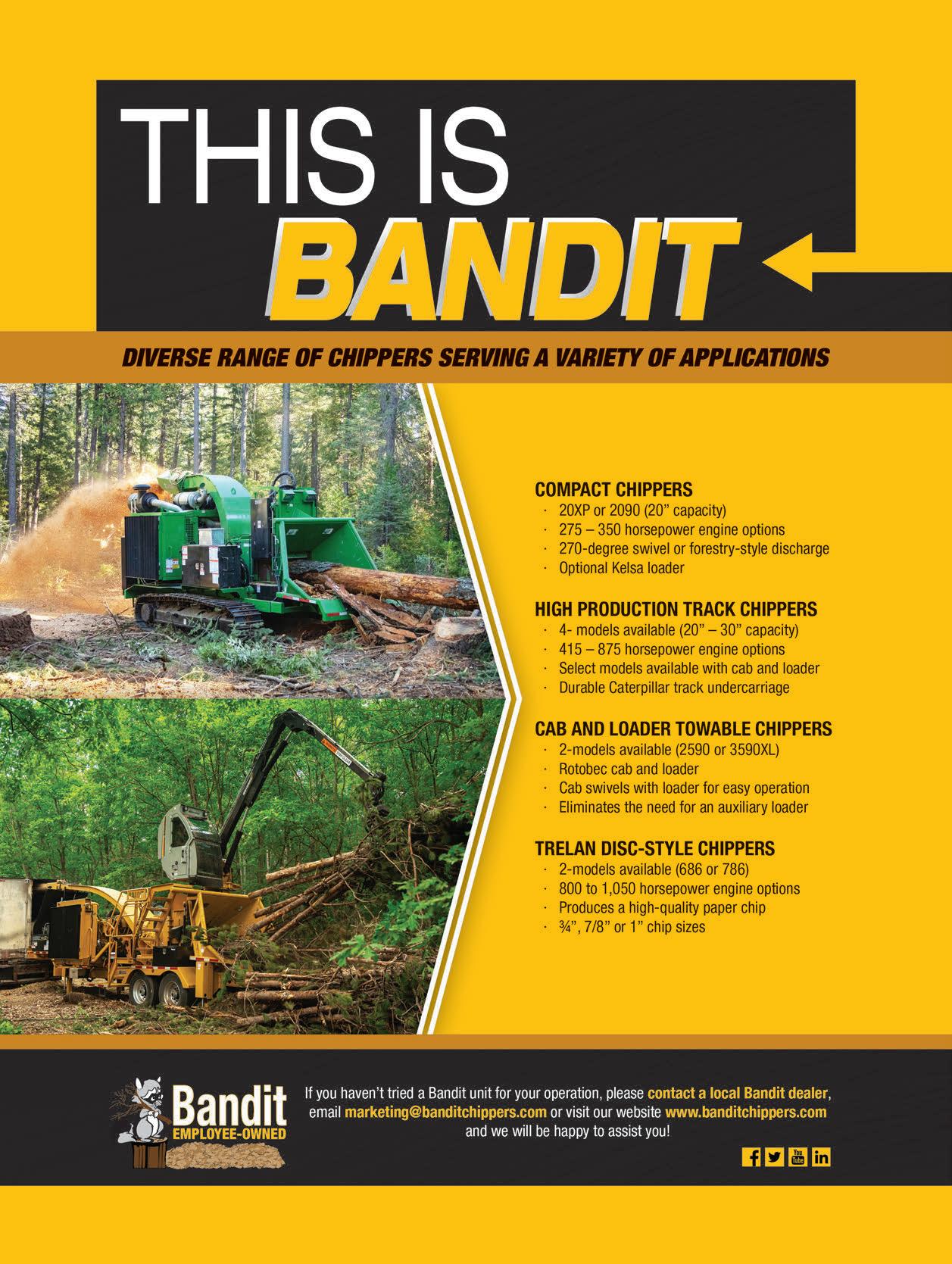

Bandit Industries Continues Recent Growth Pattern

Bandit Industries, Inc. celebrated the acquisition of a facility in Mount Pleasant, Mich. with a ribbon cutting ceremony on April 5. This facility formerly owned by Burch Tank is situated on 24 acres with 60,000 sq. ft. of manufacturing space.

“These buildings and this property will be so instrumental in growing our company as we continue to ramp up to meet the growing demand for our products,” stated Bandit CEO Jerry Morey during the ceremony.

One goal of this location is to draw employees from a farther distance away to accommodate the current need for new employees. The proximity to the highway also serves as a convenience for accessibility.

The location includes Bandit’s electrical team, consisting of wiring harnesses for all Bandit products. Components for the whole tree chipper and horizontal grinder product lines also are produced at this new

location. Future plans include moving the rebuild department from the main headquarters. The rebuild department specializes in the refurbishment and service of existing Bandit machines.

“The primary facility of this site is ideal for producing one of our major product lines,” Morey adds. “We will be adding a new paint room before we

move a line here.”

A variety of attendees ranging from Bandit employees, community members and elected officials showed up for the ceremony and spoke at the event.

2023 marks Bandit’s 40th anniversary and much of its success is contributed to quality products, an amazing dealer network, loyal customer base, and their dedicated hard-working employees. The current product line consists of hand-fed and whole tree chippers, stump grinders, wood waste grinders, and Arjes slow speed shredders.

Bandit became an employee-owned company (ESOP) in 2018. During his speech, Morey briefly talked about how Bandit became an ESOP: “We initially looked at selling to another manufacturing company and then an

24 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Jerry Morey, CEO of Bandit Industries, handles the big scissors at the ribbon cutting ceremony for a new facility.

investment banking company, but backed out of those offers over concerns for our employees and the future of the company.”

Over the next couple of years, Bandit will likely need an additional 200 employees and hope to fill 95 open positions by the end of 2023.

In addition to the new Mount Pleasant facility, Bandit invested an additional $14 million throughout 2022 conducting several expansions at their main campus nearby at Remus, Mich., including adding an 80,000 sq ft. steel room featuring new cutting and machining equipment and robots. Once added together, the total manufacturing space across all Bandit locations equals 560,000 sq. ft.

Forest Pro Adds DEVELON Lineup

Forest Pro, Inc., a logging equipment dealership in Virginia, is partnering withDEVELON, formerly Doosan, to begin offering heavy equipment at its three locations: Scottsville,

Manquin and Keysville.

All three locations will feature the full line of DEVELON construction equipment, including crawler, wheel and mini excavators, wheel loaders, dozers and articulated dump trucks, for general contractors, landscapers and loggers. Each location also provides parts and service for its customers.

Forest Pro employs 40 experienced sales, parts and service staff at the three locations.

“Forest Pro has had much success over the years since they know the logging industry very well,” says Matt Pixler, director of sales at DEVELON.

Business Finland Aids Ponsse, Epec

Forest machine manufacturer Ponsse and technology company Epec believe that the emissions and environmental impact of mobile work machines can be significantly reduced with new technology. In the field of mobile work machines, there are sev-

eral development targets towards sustainable development.

Business Finland has granted EUR 10 million in funding to Ponsse’s FORWARD’27 program in its challenge competition for leading companies. The funding is used to accelerate the product development of mobile work machines.

The aim of Ponsse’s FORWARD’27 program is to significantly reduce emissions from mobile work machines, reduce their energy consumption and improve productivity. Improving operator working conditions with auxiliary functions and automation are also among the key components.

“Ponsse aims to be a technological pioneer in CTL forest machines and it aims at producing carbon neutral, sustainable and increasingly competitive solutions. With funding granted by Business Finland to leading companies, we can accelerate our development of sustainable and digital solutions for mobile work machines”, says Juho Nummela, Ponsse President and CEO.

EquipmentWorld Foremost Authority For Professional Loggers MAY/JUNE 2023 25 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

agement (ADEM) for its Epes plant under construction in Sumter County, Ala. The revised permit en-

ables Enviva to build a state-of-the-art industrial wood pellet manufacturing facility at a brownfield site.

In 2020, Enviva acquired more than 300 acres of land on the coast of the Tombigbee River in Sumter County for its forthcoming Epes plant. The Enviva Epes site location resides on the former manufacturing site of a wood products company that had closed in recent years.

“Enviva is excited to repurpose a former business site and construct a brand-new state-of-the-art manufacturing facility, jumpstarting economic growth and bringing employment opportunities back to the community,” comments Thomas Meth, President and CEO of Enviva.

Enviva started preliminary construction of its fully contracted Epes plant in July 2022. The plant is expected to have a capacity of 1.1 million metric tons per year and is expected to be in service in 2024 and fully ramped in 2025. Once operational, the Epes plant is expected to support approximately 350 direct and indirect jobs, including in adjacent industries such as logging and trucking.

26 MAY/JUNE 2023

TIMBER HARVESTING & FOREST OPERATIONS

NewsLines 9 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

As We (ALC) See It ALC Pursues Strong DC Legislative Agenda

Famous bank robber Willie Sutton, when asked why he robbed banks, replied, “Because that is where the money is.”

So why do loggers go to Washington, DC? Because that is where the policy and legislation (money) is made that affects the logging industry. Same concept.

Before its recent Fly-In to Washington, DC to visit with government officials, the American Loggers Council prepared a comprehensive 24-page Congressional Briefing Package that provided background on the legislative priorities and served as informational literature to share with the Congressional Offices. The issues advocated for include: Biomass inclusion in the Renewable Fuel Standard; Future Logging Careers; Interstate Access; Truck Driver Incentive; Elimination of the Federal Excise; National Loggers Day; and Increased

Federal Forest Management.

The consensus from all states was that their meetings and interaction were met favorably, and the Congressional Representatives and staff were more engaged and supportive than in some prior meetings. Those that attended and participated opened doors that the ALC will continue to take advantage of in our follow-up and push to pass our legislative priorities.

The ALC representatives provided Congress and the Administration with the information and opportunity to address some of the threats and challenges to the timber industry. Some of these Bills have been introduced with bipartisan support in both the Senate and the House.

Future Logging Careers Act

Introduced in the Senate and House on March 7, 2023, by Senator Risch (ID), Senator King (ME), Congressman Thompson (PA), and Congress-

man Golden (ME). Additional cosponsors include Senators Crapo (ID), Senator Collins (ME), Senator Scott (SC), Senator Cornyn (TX), Congressman Fulcher (ID), and Congressman Pingree (ME). This bipartisan, bicameral legislation will allow logging families the same opportunity to pass on experience as farming families can as they prepare for the succession of these multigenerational family businesses.

Safe Routes Act

Bipartisan support (Congressman Gallagher (WI) and Congressman Golden (ME)) for the Safe Routes Act was demonstrated with the recent introduction in the House of Representatives.

This is a safety bill, first and foremost. It would simply allow (as has been established by precedent in numerous states) for current state weight limits for logging trucks operating on non-federal roadways to be extended to the interstate system. Representative Gallagher drove in a logging truck transiting the current non-inter-

Cuts Foremost Authority For Professional Loggers MAY/JUNE 2023 27 30

Select

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

24 Hour Ad Placement Service: 1-800-669-5613 28 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS TH Exchange EUREKA! EUREKA! EUREKA! OWNERS HAVE OVER 30 YEARS COMBINED EXPERIENCE! We can save you money on Saw Teeth. Hundreds of satisfied customers. Rebuilt Exchange or New. We specialize in rebuilding Koehring 2000, Hurricana, Hydro Ax split teeth and all other brands. Call Jimmy or Niel Mitchell. Quantity Discounts! EUREKA SAW TOOTH CO., INC. 4275 Moores Ferry Rd. • Skippers, Virginia 23879 PH./FAX (day) 1-434-634-9836 or Night/Weekends • 1-434-634-9185 NOW ACCEPTING CREDIT CARDS 7180 1926 2583 2687 2687 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

Foremost Authority For Professional Loggers MAY/JUNE 2023 29 24 Hour Ad Placement Service: 1-800-669-5613 TH Exchange 2687 5078 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

SelectCuts

state route through communities, rural roads, school zones, intersections, and single-lane routes and then the alternative interstate route this legislation would allow.

“It’s crazy how inefficient it is,” Gallagher said. “it’s bad for the truck, it’s bad for the trucker, it’s bad for the road, it’s bad for the environment, it’s less safe, so it absolutely makes no sense.”

Safe, Modern Trucks Act

With bipartisan Congressional support from Congressman LaMalfa (CA) and Congressman Pappas (NH) the Safe, Modern Trucks Act was introduced. This legislation recognizes that the 100-year-old 12% federal excise tax on new trucks and trailers de-incentivizes investment in new trucks by adding $30,000 to the price. The excise tax on heavy trucks is the highest excise tax levied on any product in the country. Half of America’s trucking fleet is over 10 years old, is less fuel efficient, and emits greater emissions. “On one hand, regulators want operators out of older trucks, but on the other hand, this tax penalizes them for trying to update their equipment,” said Congressman LaMalfa.

EventsMemo

Strengthening Supply Chains Through Truck Driver Incentives Act

Introduced by U.S. Representatives Spanberger (VA) and Gallagher (WI) the Strengthening Supply Chains Through Truck Driver Incentives Act, the legislation would provide a short-term, fast and straightforward incentive to attract and retain new drivers.

“During the pandemic, truckers didn’t have any remote options – yet they went to work every single day to keep our economy moving and our communities strong. Our country needs to step up and recognize their hard work – and we need to encourage more Americans to enter this industry,” said Spanberger.

The Bill would create a two-year refundable tax credit of up to $7,500 for drivers with valid CDL-A who drive at least 1900 hours per year. It would also create a new refundable tax credit of up to $10,000 for new truck drivers enrolled in a registered trucking apprenticeship and who meet other requirements.

The “Ask” was for Congressional Representatives to support and sign

AdLink

May 19-20—Northeastern Forest Products Equipment Expo (Loggers’ Expo), Cross Insurance Center, Bangor, Maine. Call 315-369-3078; visit northernlogger.com.

May 19-20—Montana Logging Assn. annual meeting, Holiday Inn Downtown, Missoula, Mont. Call 406-752-3168; visit logging.org.

May 23-25—Council On Forest Engineering annual meeting, Little America, Flagstaff, Ariz. Call 240-382-2633; visit cofe.org.

July 13—The Warnell Logging Cost Analysis Course, Alabama Forestry Commission, Montgomery Ala. Visit conted.warnell.uga.edu/courses/lca_2023.

August 11-12—Southwest Forest Products Expo, Hot Springs Convention Center, Hot Springs, Ark. Call 501224-2232; visit arkloggers.com.

August 17-20—Virginia Loggers Assn. annual meeting, Hotel Roanoke, Roanoke, Va. Call 804-677-4290; visit valoggers.org.

onto these pieces of legislation. The goals and objectives are to get some, if not all, of these legislative priorities across the finish line (President’s desk).

There is nothing more persuasive than for Congressional Representatives to hear firsthand from the men and women that actually work in the woods and drive logging trucks about the challenges that they face and how Congress can help ensure this vital industry survives.

The world is run by those that show up. If you are not at the table, you are probably on the menu. The American Logging Council members showed up and were at the table. But the work is not finished. All timber industry representatives are encouraged to contact their respective Congressional Representatives and request their support and sponsorship of the Bills referenced.

Scott Dane is the Executive Director of the American Loggers Council. ALC is a 501(c)(6) trade association representing the interests of timber harvesting and timber hauling businesses across the United States. For more information visit www. amloggers.com.

This issue of TIMBER HARVESTING is brought to you in part by the following companies, which will gladly supply additional information about their products.

30 MAY/JUNE 2023 TIMBER HARVESTING & FOREST OPERATIONS ADLINK is a free service for advertisers and readers. The publisher assumes no liability for errors or omissions. Bandit Industries 31 800.952.0178 BITCO Insurance 8 800.475.4477 John Deere Forestry 16-17 800.503.3373 Forest Chain 26 800.288.0887 Mid-South Forestry Equipment Show 11 601.354.4936 Olofsfors 5 519.754.2190 PA Timber Show 24 814.863.2873 Pacific Logging Congress 27 360.832.1745 Ponsse North America 2 715.369.4833 Precision-Husky 7 205.640.5181 Southwest Forest Products Expo 9 501.224.2232 Technical Forest Solutions 15 503.282.2566 Tigercat Industries 32 519.753.2000 VPG Onboard Weighing 25 800.237.0022 White Mountain 26 800.439.9073

to current advertisers! http://www.timberharvesting.com/advertiser-index/

Easy Access

Listings are submitted months in advance. Always verify dates and locations with contacts prior to making plans to attend.

27 CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

CLICK HERE IF YOU HAVE NOT ALREADY OPTED IN!

doing some contract chipping in cottonwood plantations in the Lower Columbia River valley.

doing some contract chipping in cottonwood plantations in the Lower Columbia River valley.