HATTON-BROWN PUBLISHERS, INC.

Street Address: 225 Hanrick Street

Montgomery, AL 36104-3317

Mailing Address: P.O. Box 2268

Montgomery, AL 36102-2268

Telephone (334) 834-1170 Fax 334-834-4525

Publisher David H. Ramsey Chief Operating Officer Dianne C. Sullivan

Editor-in-Chief Rich Donnell

Managing Editor Dan Shell Senior Editor David Abbott Senior Editor Jessica Johnson

Publisher/Editor Emeritus David (DK) Knight

Art Director/Prod. Mgr. Cindy Segrest

Ad Production Coord Patti Campbell

Circulation Director Rhonda Thomas

Online Content/Marketing Jacqlyn Kirkland

ADVERTISING SALES REPRESENTATIVES

SOUTHERN USA

Randy Reagor (904) 393-7968 • Fax: (334) 834-4525

E-mail: reagor@bellsouth.net

MIDWEST USA, EASTERN CANADA

John Simmons (905) 666-0258 • Fax: (905) 666-0778 E-mail: jsimmons@idirect.com

WESTERN USA, WESTERN CANADA

Tim Shaddick (604) 910-1826 • Fax: (604) 264-1367

E-mail: twshaddick@gmail.com

Kevin Cook (604) 619-1777

E-mail: lordkevincook@gmail.com

INTERNATIONAL

Murray Brett +34 96 640 4165 • + 34 96 640 4048 E-mail: murray.brett@abasol.net

CLASSIFIED ADVERTISING

Bridget DeVane 334-699-7837 bdevane7@hotmail.com

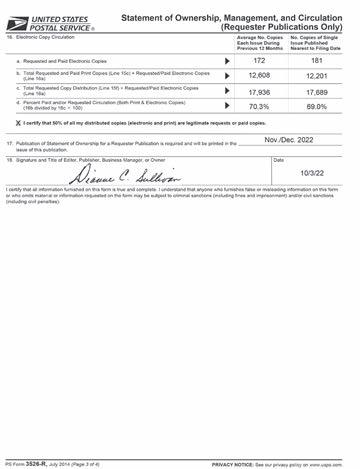

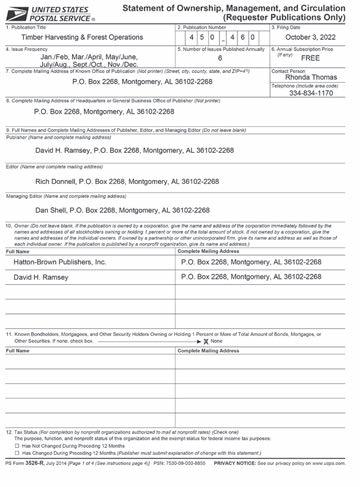

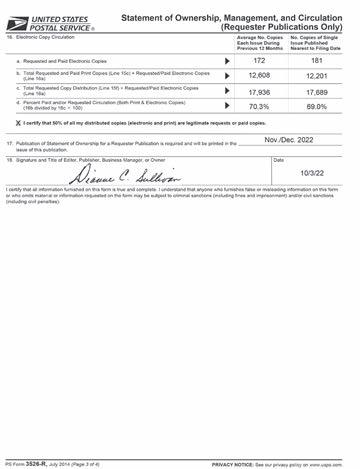

Timber Harvesting & Forest Operations (ISSN 2154-2333) is published 6 times annually (January/February, March/April, May/June, July/August, September/October, November/ December issues are combined) by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Subscriptions are free to U.S. logging, pulpwood and chipping contractors and their supervisors; managers and supervisors of corporate-owned harvesting operations; wood suppliers; timber buyers; businesses involved in land grooming and/or land clearing, wood refuse grinding and right-of-way maintenance; wood procurement and land management officials; industrial forestry purchasing agents; wholesale and retail forest equipment representatives and forest/logging association personnel. All non-qualified U.S. subscriptions are $50 annually; $60 in Canada; $95 (airmail) in all other countries (U.S. funds). Single copies, $5 each; special issues, $20 (U.S. funds).

Subscription Inquiries—TOLL-FREE 800-669-5613; Fax 888-611-4525. Go to www.timber harvesting.com and click on the subscribe button to subscribe/renew via the web. All advertisements for Timber Harvesting & Forest Operations are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold Hatton-Brown Publishers, Inc. harmless from and against any loss, expenses, or other liability resulting from any claims or lawsuits for libel violations or right of privacy or publicity, plagiarism, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Timber Harvesting & Forest Operations. Copyright ® 2022. All rights reserved. Reproduction in whole or in part without written permission is prohibited. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices. Printed in USA.

POSTMASTER: Send address changes to TIMBER HARVESTING & FOREST OPERATIONS P.O. Box 2419, Montgomery, AL 36102-2419

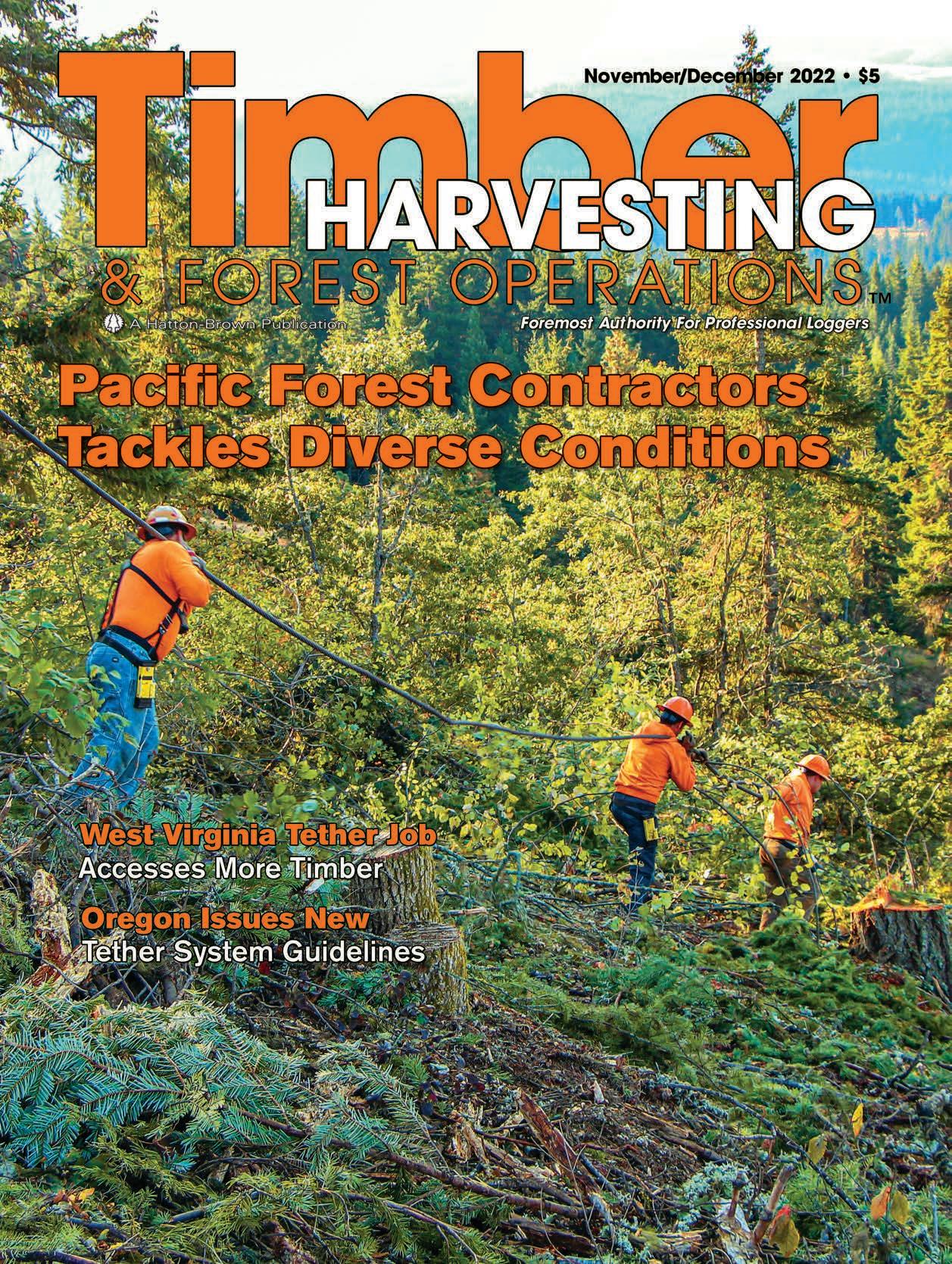

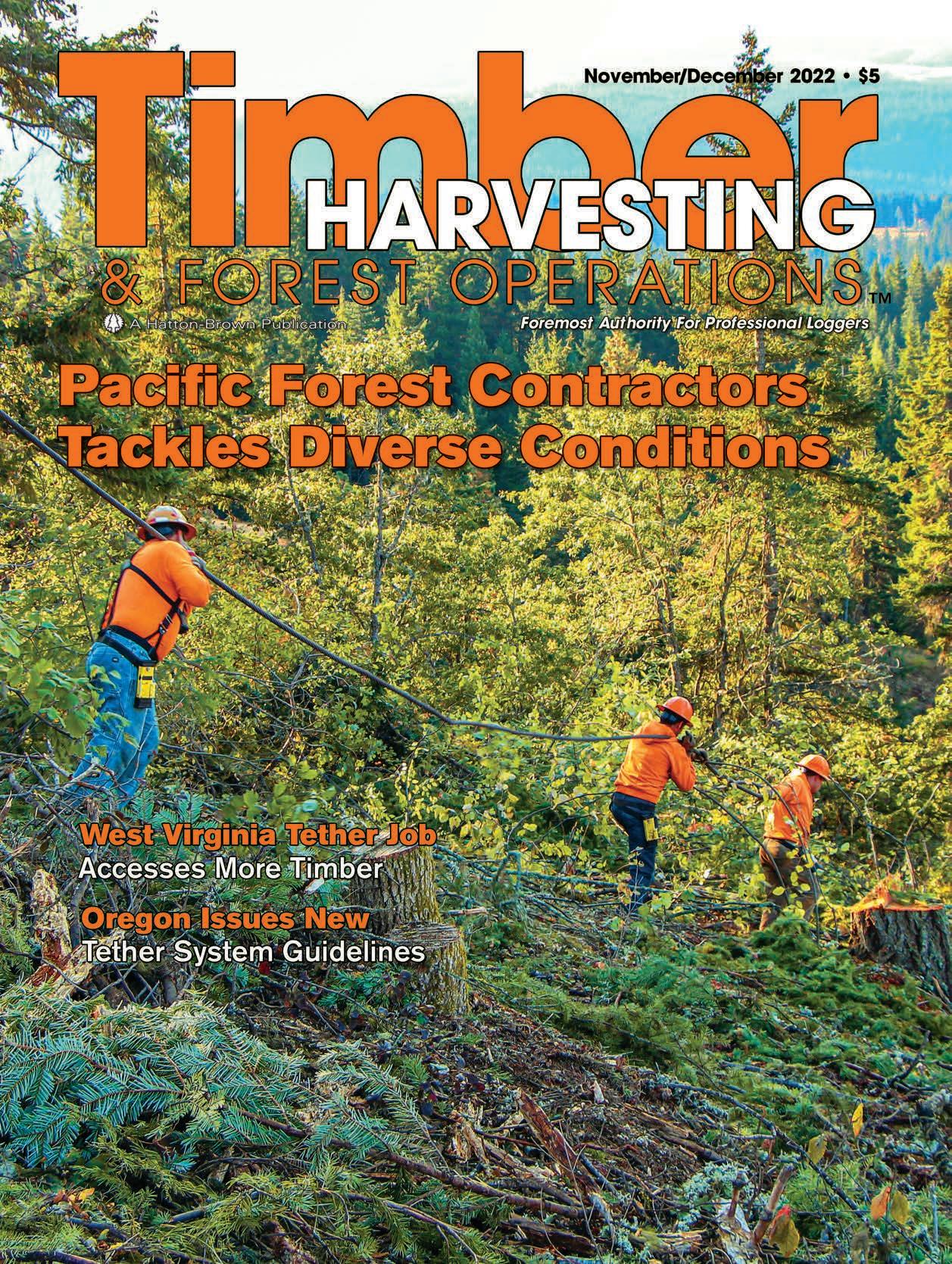

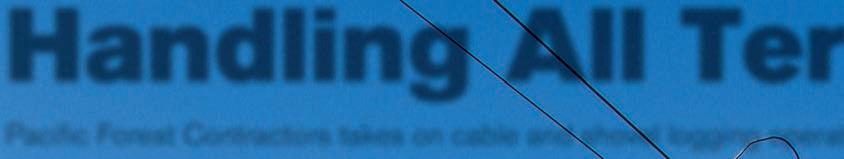

A Hatton-Brown Publication Foremost Authority For Professional Loggers Browse, subscribe or renew: www.timberharvesting.com Vol. 70, No. 6: Issue 695 November/December 2022 Pacific Forest Contractors’ yarding crew begins a new set by rigging up on private land in south central Washington. Read more about the operation on PAGE 10. (Dan Shell photo, design by Shelley Smith) My Take _________________________________________________ 4 NewsLines _______________________________________________ 6 Innovation Way _________________________________________ 22 Equipment World ________________________________________ 25 Select Cuts ____________________________________________ 26 THExchange ____________________________________________ 27 Ad Index 30 Other Hatton-Brown Publications: Southern Loggin’ Times • Wood Bioenergy Timber Processing • Panel World • Power Equipment Trade OurCover OurFeatures OurDepartments WV Cable Logging Collins Finds Tethering Benefits Oregon Tether Guidelines OR OSHA Makes Update ALC Annual Meeting Loggers Gather In Missouri 20 148 16 Steep Slope Logging Top Suppliers, Products

Member Verified Audit Circulation

ALC Rising To Challenges

Organization gives loggers a national voice.

One really bright spot concerning the American Loggers Council is the organization’s resilience as the pandemic slowly fades away: Many organizations and trade associations took a beating during the pandemic, but the ALC is surviving remarkably well and moving ahead on a variety of fronts.

Two news items this month underline the importance of having an association like the ALC to provide a national voice for the logging industry as various issues come up.

The news that Strategic Biofuels in Louisiana is working with the Forest Service and other groups on biomass standards is big news. Developing a Renewable Fuel Standard system to make it easier to incorporate forestry feedstock into biomass and green energy initiatives and projects by ensuring raw materials meet sustainability standards and qualify for various favorable state and federal tax policies is going to make utilization of woody biomass more attractive—and that’s good for the logging industry.

Having such a system is yet another tool to aid in the increased utilization of wood as a sustainable energy source. Strategic Biofuels is taking the lead in developing an auditable system to track feedstock qualification, source-origin and chain of custody data to support its Louisiana Green Fuels project that will use woody biomass to produce renewable diesel and naphtha.

Julie Tucker, National Wood Innovations Program Manager of Bioenergy, Biofuels, and Bioproducts, U.S. Forest Service, notes that “Historically, forest residuals have been a disposal challenge. The Renewable Fuel Standard helps change that by giving the renewable energy sector a financial incentive to convert these unwanted forest residuals to high value biofuels and renewable electricity.”

While the development group is being led by the Forest Service

and Strategic Biofuels and the full team is still being assembled, members will include representatives from the National Assn. of State Foresters and the American Loggers Council as well as groups representing industrial and non-industrial landowners, tribal interests and others. It’s critical to have ALC involved as part of the process to help develop such a system that has national implications for increased biomass utilization—and help ensure loggers’ concerns are heard as biomass standards and tracking systems are established.

NW Chips Explode

Interesting note in the most recent North American Woodfiber & Biomass Markets newsletter from Fastmarkets RISI that chip exports are taking off in the Northwest, with

also West Coast chip mill projects currently hit with construction delays, the newsletter said.

Longer term, there are ongoing pulp capacity expansions in China, according to Fastmarkets RISI analyst John North. Those capacity increases will greatly expand demand for chip imports and that will have long-term impacts on global markets going forward, he added.

Remember these market dynamics are occurring without a major wood energy demand from Asia. If economies such as Japan, Korea and China move toward significant pellet consumption as Europe has it would be a fiber market game changer on the West Coast.

Highest Value Use Wins?

The other news item that bears watching in context of larger developments is the recent purchase of 29,000 acres in Michigan that will be used to create “carbon projects” by a joint venture and management company that’s already managing more than 90 forest carbon projects across 4 million acres.

So far, so good, until you read that no logging is planned until some level of forest growth is achieved, and then a selective logging program will be offered at some future date. Again, so far, so good—everyone pursuing their economic interests—until you realize that’s 30,000 acres essentially taken out of production.

A future selective logging program is on the drawing board, but nothing is planned.

Douglas fir chip prices at West Coast shipping terminals recently setting all-time highs.

Reasons behind the strong markets include now-familiar supply chain issues but also true growth pending in the export market, according to RISI.

Currently, slowing lumber production on the West Coast and strikes at multiple Weyerhaeuser sawmills have made chips harder to source. Japanese demand is also up thanks to black liquor green energy credits being offered to Japan’s paper sector. Complicating the market, there are

At the ALC meeting in 2021 in Couer d’Alene, Id., ResourceWise CEO Pete Stewart (parent of Forest2Market) spoke on this very topic of carbon credits and said it bears watching closely: That the financial industry’s expansion of carbon credit markets may eventually lead some to view forestland as valued more as an accounting entry that mitigates polluters’ smokestack impacts than as a source of sustainably managed forest products and associated businesses and jobs.

It’s definitely a trend that bears watching closely.

4 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

TH

MyTake

DAN SHELL

Defining the future of biomass and forest values

Appeals Court Denies Maine Transport Law

A federal appeals court has overturned a Maine law that sought to restrict state trucking companies and large landowners from hiring anyone who is not a “resident of the United States” to drive a vehicle to “transport forest products” within the state.

The law, which included fines up to $25,000 per violation, was enjoined earlier in 2022 when a U.S. District Judge blocked it from going into effect. The ruling agreed with trucking indus try and mill interests that had filed suit alleging the law was unconstitutional and preempted by immigration laws.

The law, approved by the state legislature last year, prohibits trucking companies and landowners owning at least 50,000 acres of Maine forest land from hiring anyone who is not a “resident of the United States” to drive a vehicle to “transport forest products” within the state. Fines can run as high as $25,000 per violation under the law.

The Maine law was supported by legislators who claim foreign competition is squeezing the state’s forest products industry and the use of work visas for Canadian drivers is depressing wages for Maine loggers and their employees.

Diesel Fuel Theft Arrest Made

In Louisiana

Following reports of fuel thefts in the area that date back to late winter, a Leesville, La. man was arrested in August and accused of stealing fuel from two different logging operations and also causing criminal damage to equipment during one theft.

In Vernon Parish, one logging company had multiple thefts including sand put into a skidder fuel tank, and another logging operation had 50 gallons of diesel stolen in February.

OLC Announces New Technology Program Details

Officials with the Oregon Logging Conference recently released details for the 85th Oregon Logging Conference program at the February 23-25 event. The popular OLC panel topic Better Ideas / New Technology in Logging will be presented on Friday, February 24 and includes loader cells

for towers; new hardhat technology; simplified control systems for processing heads and created a completely connected forest to manage the entire forest products supply chain.

Theme for this year’s OLC is “Green Trees Matter. Healthy Forest = Healthy Future.” Hands on seminars will take place, along with business seminars, better ideas/new technology in logging, and Oregon and Washington Forest Practices seminars.Registered companies and individuals can earn Professional Logger credits and three Forest Practice credits for attending these sessions. Visit oregonloggingconference.com

Bluesource Buys Michigan Upper Peninsula Timberland

Bluesource Sustainable Forests Co. has purchased 29,019 acres of forest land across five counties in Michigan’s Upper Peninsula from affiliates of The Lyme Timber Co. Bluesource is a joint venture between Oak Hill Advisors, L.P. and Anew Climate, LLC, and this is its third forestland acquisition since its formation in October 2021.

The U.P. property will add to the more than 90 North American forest carbon projects spanning more than 4 million acres that Anew currently manages in partnership with landowners, 11 of which are also located in Michigan.

According to company officials, no logging is currently planned for the holding, though they do say a selective logging program will eventually be adopted after carbon stocks are increased through forest growth.

Mississippi Sawmill Will Feed New Pallet Block Facility

BID Group announced a partnership with ArbaBlox Inc. to build a state-of-the-art turnkey composite pallet block plant in Winona, Miss. BID will manage, design, build, install and

provide startup services for the $53 million project, the largest of its kind in the country.

Work on site will begin in the fourth quarter of 2022 and commissioning of the facility is scheduled for the first quarter of 2024. Fiber supply for the plant will come from Biewer Lumber’s Winona, Miss. facility, which com menced operations in January 2022.

ArbaBlox and the BID Biomass Team will begin the development phase of a second project late in 2022.

“We would like to thank ArbaBlox for their trust in our people and inte grated solutions,” says Travis McDon ald, Executive Vice President, Inte grated Solutions at BID. “The Arb aBlox projects will be the first of many for the BID Biomass Division which intends to deliver value-added solutions for sawmill residual products.”

Interfor Acquires Two Sawmills

Interfor has reached an agreement with an affiliate of the Kilmer Group to acquire 100% of the equity interests in the entities comprising Chaleur Forest Products for $325 million (Can). Chaleur owns two modern and well-capitalized sawmill operations in Belledune and Bathurst, New Brunswick, with a combined annual lumber production capacity of 350MMBF.

Chaleur also operates a woodlands management division based out of Miramichi that manages 30% of the total Crown forest in New Brunswick.

Interfor’s total annual lumber production capacity will increase to 5.1 billion BF, of which 44% will be in the U.S. South, 19% in Eastern Canada, 15% in the U.S. Northwest, 15% in British Columbia and 7% in Atlantic Canada.

The completion of the acquisition is subject to Canadian and U.S. regulatory reviews and customary conditions for a transaction of this kind and is expected to close in the fourth quarter of 2022.

SmartLam Announces Alabama Glulam Facility

SmartLam North America, reportedly the largest manufacturer in North America of cross-laminated timber (CLT), announced it will build a $50 million glulam manufacturing facility

6 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

NewsLines

in Dothan, Ala.

The new SmartLam facility, to be built adjacent SmartLam’s existing CLT facility in a 144,000 sq. ft. struc ture, will manufacture 84MMBF annu ally of glulam beams and columns that are required to serve the mass timber market. SmartLam has chosen to part ner with Ledinek to build a turnkey, state-of-the-art glulam facility. The new glulam facility is expected to be 100% operational in October 2024.

SmartLam North America will also spend an additional $24 million to fully automate the existing Dothan and Columbia Falls, Mont. CLT facilities. This additional investment will allow each facility to produce 2 million cubic feet annually.

UGA Researchers Seek To ‘Reengineer’ Poplar

A multidisciplinary team of re searchers at the University of Geor gia and two partner institutions have been awarded a $15.8 million grant over five years from the U.S. Dept. of Energy to reengineer poplar trees to be used as a sustainable energy source.

The researchers will use state-of the-art biotechnology approaches to breed the trees as a multipurpose crop that can be used for bioenergy, biomaterial and bioproduct alternatives to petroleum-based materials.

The project aims to fabricate new types of poplar through genetic modification.“What we propose is to genetically engineer poplar to make it a multipurpose crop by changing its architecture and engineering it to produce different things in the leaves and wood,” Team Leader Robin Buell says, adding that the team will try to engineer several different types of poplar trees in the study to take advantage of different plant materials for different uses.

Auburn University Team Looks At Needle Blight

A research team in Auburn University’s College of Forestry, Wildlife and Environment (CFWE) is working to find solutions to an increasing threat to pine forests needle blight. Through a $2.1 million U.S. Forest Service grant, Lori Eckhardt, a professor of forest health, and her team members in

Strategic Biofuels Working On Biomass Standards

Working under a cooperative agreement with the U.S. Forest Service (FS), Strategic Biofuels, which is building a negative carbon footprint renewable fuels production facility in Louisiana, is also developing an auditable cloudbased system for demonstrating forestry feedstock compliance with the Envi ronmental Protection Agency (EPA) regulations under the federal Renewable Fuel Standard (RFS).

“Innovative biofuels technologies are emerging at a time when our forests, especially those with high wildfire risk conditions, need them the most,” says Julie Tucker, FS National Wood Innovations Program Manager of Bioenergy, Biofuels, and Bioproducts. “Historically, forest residuals have been a disposal challenge. The Renewable Fuel Standard helps change that by giving the renewable energy sector a financial incentive to convert these unwanted forest residuals to high value biofuels and renewable electricity.”

The project seeks to develop a user-friendly, cost effective, and fraud-resis tant tracking system that enables forestry feedstock suppliers to provide raw data that can accurately and conveniently be transmitted to the biofuel pro ducer and validated by a third-party auditor for EPA compliance.

the college—Joseph Fan, associate professor of forest ecology and statistics; Lana Narine, assistant professor of remote sensing and modeling; and Janna Willoughby, assistant professor of population and conservation genetics—are aiming to determine the impacts on productivity and biological causes of needle blight.

Insect pests and fungal diseases are a great concern to the forest industry, as costs associated with damage caused by non-native pests and pathogens within forests throughout the U.S. were estimated to be valued at approximately $4.2 billion annually.

Alabama Forestry Commission (AFC) has been receiving phone calls since early spring from landowners and the public regarding pine needles suddenly turning brown. Many of these calls have come from counties in the northwest and northeast re gions of Alabama. The disease has

been confirmed in 36 of 67 Alabama counties.

Historically, the disease has only infected longleaf pines, or Pinus palustris, but in the last few years, the disease also has begun to infect loblolly pines, or Pinus taeda, in young and mature stands.

Peak Renewables Plans

SE Alabama Pellet Mill

Vancouver, Canada-based Peak Renewables plans to build a 180,000 metric tons per year wood pellet mill in Dothan, Ala. The $30 million project will utilize residuals from Rex Lumber sawmills in the area.

Construction on the facility is ex pected to be completed by mid-2023. Peak is building the plant adjacent the SmartLam cross-laminated timber plant and upcoming glulam facility in Dothan.

NewsLines Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 7

Oregon OSHA Modifies Tethering Guidelines

EDITOR’S NOTE: A recent report from Associated Oregon Loggers’ David Grim, safety and health manager, detailed several changes that safety au thorities have made to Oregon’s tethered logging equipment regulations.

Working with the Forest Activities Advisory Committee, which AOL and AOL member companies are members of, Oregon OSHA has revised its general provisions for all currently active tethered logging research variances in an effort to better ensure worker safety and to assist employers. While the revised provisions contain minimal changes, significant changes were made to provisions 4, 7, 8, and 11, and are described here.

Key Changes to Provision 4—The revised research variance provisions clarify previous and current cab protec tion requirements for base machines if employers allow employees to occupy the base machine cab during tethered logging operations. If employers allow employees to occupy base machine cabs while a tether line is under tension from steep slope machine movement, the base machines must be equipped with a

cab that provides tip over protection in accordance with OAR 437 007 0775 (14) (a), (b), and (c).

Key Changes to Provision 7—The revised research variance provisions changes the following tether line inspection and replacement requirements:

Inspections of the entire length of tether lines are no longer required prior to the start-up of each tethered logging project. Instead, only the portion of line used during the previous project plus an additional 100 feet must be inspected prior to the start-up of each tethered logging project.

Replacement of tether lines are no longer required after 2,000 hours of use, unless the line is damaged beyond repair, or the tether logging system manufacturer requires replacement after a specified number of hours of use. Instead, inspection of the entire length of each tether line and drum connection must be conducted by a competent person at least every 2,000 hours of use.

The Provision 7 language now reads—At a minimum, tether line inspections must be conducted by a competent person as follows:

Daily line inspections: Inspect the first 50 feet of each tether line prior to use. Such inspections may be conducted at the end of the day in preparation for the next day of use by the same operator.

Unit startup line inspections: Inspect the maximum portion of tether line(s) used during the previous project plus an additional 100 feet. Such inspections may be conducted at the end of a project in preparation for the next project startup.

2,000-hour line inspections: Inspect the entire length of each tether line and drum connection after 2,000 hours of use. Such inspections may be conducted anytime during the year and can substitute a project startup inspection if done between projects. Lines may be upended during annual inspections following any tethering system manufacturer’s recommendations and specifications.

Key Changes to Provision 8—The revised research variance provisions specify that if communication between the steep slope machine and base machine becomes weak or is lost, discontinue work and move back to where there is an adequate communication signal. Also, the changes emphasize that base machines must be set up to minimize unintended movement, and that a device that senses excessive base machine movement must be effectively used and maintained to immediately notify the steep slope machine operator during operation.

Base machine anchorage and movement-sensing devices must be inspected daily prior to use and after excessive base machine movement.

Key Changes to Provision 11— The revised research variance provisions specifies that base machines must not be repositioned or moved while tether lines are under tension from the steep slope machine.

TH

This article is reprinted from the AOL Mainline newsletter. For the complete 2022 Revised Tethered Logging Research Vari ance Provisions language, see Oregon OSHA.

8 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

more.

Changes cover line inspections, occupied base machines, communication issues and

Handling All Terrain

Pacific Forest Contractors takes on cable and shovel logging operations.

EAGLE CREEK, Ore.

Moving into new applications and adding productive capacity with its first tethering machine is expanding Pacific Forest Contractors’ (PFC) capabilities while adding a measure of mechanization and extra safety. While tethered equipment systems for felling and skidding on steep slopes have been around the Pacific Northwest for a while now, PFC founder Brent Parries, 58, and vice president and part owner Alex Davis say they’re both more of the late adopter wait and see a little longer types than many logging contractors when it comes to new systems like tethering.

“We held off at first because of the costs,” Parries says. Davis adds that they not only wanted to see tethering systems at work initially, another issue was getting commitments from landowners to use it as well.

Yet the labor concerns and the promise of enhanced safety and mechanized production on more ground led to the decision. Parries adds that the operator was closely consulted when they began looking at tethering systems before deciding on a winch-assist system from Summit Attachments.

Though both are quick to compliment PFC employees for their hard work and dedication, finding enough employees long term is a big concern.

10 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

DANShell

Background

Pacific Forest Contractors operates three logging sides: a cable tower yarding crew and two shovel logging operations, as well as a roadbuilding company. Parries’ background in the industry dates to the 1970s when he cut firewood and also trapped beavers for Publisher’s Paper when he was a teenager. Publisher’s gave him an opportunity to do some small thinnings and pre-pole work. That eventually grew into full logging jobs and expanding into more equipment, first shovel then cable logging. Parries founded PFC in 1996.

Davis, 34, has worked for PFC since he was 18. His father worked there as well. Though he says he tries to check in on all the sides in some manner each day, he spends most of his time working with the cable crew, which has more moving parts and risk and requires more planning.

“I also do some looking at jobs and can fill in anywhere if someone is out,” Davis says, adding that he’s most effective when he’s not bogged down on a specific site and can work to coordinate operations and try to stay ahead of the next situation that pops up—whatever that may be.

“The main thing we’ve always pushed is quality,” Davis says, adding that “If you produce and operate safely, everything else falls into place.”

One testament to the company’s attention to detail and quality and the ability to operate quickly and with care is its Oregon Dept. of Forestry (ODF) Southwest Oregon Region Operator of the Year for its work in

2019 after a major February snow storm severely damaged a thousand-acre tract of private timberland near the community of Yoncalla in Douglas County. Almost 50% of the stand had been knocked down, and owner Campbell Global needed emergency salvage work.

The jack-strawed condition of the downed timber led to safety issues that Pacific Forest Contractors’ mechanized cutters and contracted manual cutters faced with plenty of stems that still had tension. In addition, much of the job was near a sensitive, salmon-bearing stream that is considered a community water source and had to be protected. There was also a vineyard along the haul route.

The operation not only conducted “time critical salvage…while protecting a salmon-bearing stream,” accord-

ing to the award, the job was completed safely and with minimal impact to the community.

In addition to the award three years ago, PFC won its first ODF award in 2003 after completing a sensitive shovel-logging operation in northwest Oregon.

Labor Issues

Watching the the yarder crew get rigged up and producing on a job site, Davis says the biggest difficulties they face aren’t in the woods: Instead, it’s external factors like struggling with competition for employees. PFC is headquartered on the edge of the greater Portland metro area, and there are plenty of employment opportunities in the city and along the I-5 corridor.

Traditionally loggers have coun-

Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 11

Company has two state forestry awards for professional logging operations.

Alex Davis: Charting a sustainable future

tered “town wages” with higher pay that reflects the rugged work of logging, but the challenges are bigger than that, Davis believes, adding that the industry “really needs to surpass” that mindset. Two issues he’s identified are getting more young people interested in the logging and forest industry as a career and the lack of compensation from log markets that keep

contractors from competing strongly for labor.

“I can’t say enough about our people and the hard work they do every day, but finding people to do it is a big long-term concern going forward,” Davis says.

Parries says most of the hires he makes are people moving around within the industry, with few employ-

ees new to the industry. He adds that he’s excited about a potential Oregon version of the popular Shasta College equipment operator training program in California being discussed for development in the state of Oregon.

On Site

Timber Harvesting finds two of PFC’s crews working the same tract in south central Washington, just outside the Columbia River Gorge corridor. The job site offered a variety of conditions across roughly 60 acres that’s broken up into seven tracts. The overall holding had been logged and thinned in the past and Pacific Forest Contractors was removing some of the last stands before replanting.

Pacific Forest Contractors’ roadbuilding crews had built a high quality access and haul road into the the property, which is scheduled to be subdivided. The company had worked some of the job in late winter 2022 and produced around 650MMBF and this past September had moved back onto the tract after a summer of fire restrictions. The job should yield near

12 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

Industry needs to change its mindset when it comes to logger investment, Parries says.

1.5MMBF when complete, Davis said.

Fire concerns had continued into the fall: On the day TH visited the cable crew had to shut down at noon, though the shovel logging side was able to work all day.

The job was in a good location barely 20 miles from the mill: Purchased by SDS Lumber in Bingen, Wash., all logs were going to the nearby SDS facility along the Columbia River that features a sawmill, plywood plant and chip mill.

The location meant drivers could get roughly four loads a day—and that’s big, Davis says, noting that many jobs are in remote areas where drivers are lucky to get two loads a day if that much.

The cable yarding side features a Madill 071 yarder flying an Acme Skycar slack-pulling carriage with Fortronics electronic choker release systems. At the landing, a Deere 2454 loader clears each turn and moves logs for a Deere 2954 machine with Waratah processor that handles final delimbing and bucking.

Working with the yarder crew is a Deere 959 steep slope shovel ma-

chine that’s doing some shoveling but also working in coordination with the crew to build piles and bundles that can be more easily yarded to the landing while minimizing road and corridor work.

They don’t usually work on the same tract but the mixed ground on the job site had one of the shovel logging crews working nearby with a Link-Belt 5040 shovel machine, Link-Belt 4040 with 623 Waratah

processing head and a Link-Belt 3740 shovel machine that was also loading trucks.

At the time, the other shovel logging crew was moving onto a new job at the Weyerhaeuser St. Helens Tree Farm. That side features Deere 2554 and 2454 shovel machines and a Deere 2954 processor with 623 Waratah head. PCF’s mechanized felling is with a Tigercat 870, plus contract fallers when needed. TH

Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 13

Site barely 20 miles from the mill helps keep logs rolling during TH visit.

East Coast Cable

BIRCH RIVER, W.Va.

Operating his family’s fifth generation of logging as Secondhand Tradition that he started in 2006, owner Lindsey Collins, 43, is finishing an exciting two years after being named West Virginia’s 2022 Logger of the Year by the West Virginia Forestry Assn. this past summer. He’s also completing his first full year operating a winch-assisted tethered system, allowing him to harvest timber in steep terrain that would be otherwise inaccessible by conventional means.

Cable Curious

Collins started using the tethered system in August 2021. “We are running out of mechanized feller-buncher ground,” he says. “We’ve had the feller-bunchers for 25 years and we’ve caught up to the ground they perform well on. So we had to go to something (different) because Weyerhaeuser is big on no power saws and they don’t want people on the ground, they want to try to do it as safe as they can.”

In spring 2021, Collins went out West, to Oregon and Washington, to watch this technique in action. Ricer Equipment sales rep Pat Garrett ac-

companied him on the trip to learn about tethered logging. “We put it on paper and agreed that tethering with a bogie skidder and an 855 (track cutter), he could harvest ground that would be impossible to harvest without roading the heck out of it,” Garrett recalls. “It was just too steep to log conventionally. But we could tether it where Weyerhaeuser needs it harvested. That way he has been able to harvest safely and mechanically with no one on the ground. The 855 really shined with the tether.”

Collins adds, “We decided that was the way to go, and it’s been great. Now we do jobs we wouldn’t even look at before. We’ve done jobs they’ve had laid out for 15 years, but we didn’t do them because they were too steep and too rough.”

Skidding downhill is really pretty revolutionary in West Virginia, Garrett says. “The state forester agreed to let him try this type of harvesting, and it has left the ground in much better condition than it would have been if he conventionally logged it. There is just minimal soil disturbance.”

Secondhand Tradition uses a John Deere 350G LC excavator as an anchor. The excavator rests on stable ground, positioned with the boom fac-

ing the slope, downhill, and winches the cable down to either the cutter or skidder, alternating one at a time. Collins is considering getting a second winch/anchor machine set up so they can tether cut and tether skid at the same time.

Collins already had his excavator years before he started tethering. He bought the 2015 model Deere from Leslie Equipment in Cowen, W.Va. Last year he removed the counterweight and shipped the machine to Kelso, Wash., for winch supplier Summit Attachments and Machinery to add the winch and extend the boom 16 ft.

“(Summit’s Eric Krume) went through all the pains of building and rebuilding these to learn where they needed to pull,” Collins says. “You would think the tether would pull the machine over the hill. But the more weight is put on the tether, it actually pushes the machine further down in the ground. It gets more stable.”

This technique requires skill, and practice. “I don’t think I knew what I was doing when we first brought the tether here,” Collins admits. “But I had seen enough jobs that I felt like we could make it run.” A big component of that confidence was the support from

Eric Krume at Summit At-

Hardwood mountain logger Lindsey Collins accesses more West Virginia timber safely with tethered felling and skidding.

DAVIDAbbott

Tethering system allows Collins to harvest timber that’s in areas too rugged to log traditionally.

tachments. “He’s a super good guy. He comes with the machines and spends a couple weeks with you while you work. He’s a logger himself and makes sure you perform well.” The first tethered job the crew tackled was a tract called Big Run 2. “(Krume) came with us to get us started and didn’t leave until we were comfortable with what we were doing. I would say it was a home run, in my opinion, for the first job.”

Equipment

Aside from the Deere excavator and a Deere 850K dozer, Secondhand Tradition uses all Tigercat machines in the woods: two skidders (’21 model 620H and ’22 model 625H), ’21 model LS855 track cutter, and two 250D loaders, ’15 and ’21 models, one with a longer boom with a high rise cab. Collins adds that he has good working relationships with both Ricer Equipment (Tigercat) and Leslie Equipment (Deere).

The logger purchases a PM agreement on most machines, letting the dealers handle it under warranty. “We just keep them fueled up and greased and turn the rest over to them,” he says.

Collins runs all his own trucks, a fleet of Peterbilts from 2007 to 2020 models, pulling Pitts trailers. Setout trucks are old Autocar and Internationals.

Production

The crew was working on Weyerhaeuser land when TH visited in late summer. Secondhand was delivering veneer logs, in this case all wild cherry, to the Turkey Creek veneer yard, a

Weyerhaeuser staging area adjacent the tract, at the bottom of the hill. “Every main port to their land, they have a yard at the mouth of it to handle their veneer,” Collins says. Weyerhaeuser timber buyers Laurel “Mountain Laurel” Kemmerling and Dan Abston were working on the log yard, scaling logs unloaded from Secondhand’s trailers. “Our set out trucks bring the stuff out of the woods and drop it so on-the-road trucks don’t have to wait or go so far off the beaten path.”

Weyerhaeuser takes the veneer logs (cherry, hard maple, curly soft maple and various oaks) from here. Secondhand hauls chip wood to Weyerhaeuser’s OSB mill in Flatwoods (Heaters), W.Va. sawlogs go to Laurel Creek

hemlock go to the WestRock mill in Covington, Va. The crew produces an average 45 loads a week.

The good thing about timber left in these steep slopes, Collins says, is that no one has been able to get to it for 30 years, so it’s where the higher quality wood is. “The benefit to doing steeper, rougher ground, you are actually getting better timber. You are getting high value veneer logs.”

Collins estimates the crew averages 70% OSB chip wood and 30% sawlogs or veneer. “The flip of the veneer is up to the buyers,” he notes. “Sometimes they might take half of that 30% for veneer, but this time of year, the sap is up. Mainly what we do is even-age management or clear-cutting when we run that ratio of 70% pulpwood to 30% logs; that’s actually a pretty good tract if we can still get 30% sawlogs.” The crew works almost entirely in hardwood. “Our pine in West Virginia only runs in high elevation, 3,500 ft. and up,” he says. The job Secondhand Tradition was working when TH was on-site pushed 3,900 ft. Here they cut some hemlock and red spruce for fence rails.

Collins believes this July may have been the wettest on record, and it showed, even on the high ground. “In this high elevation, there shouldn’t be standing water. About the last six weeks we have had horrible rain. If we hadn’t been tethering it would have been a very low production summer but since we were tethering we were able to keep producing.”

Hardwoods in Richwood, W.Va. Hayes Scott Fence & Lumber in Mill Creek buys their softwood. Pine pulp, hickory, locust and

TH Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 15

Collins travelled out West to watch tethering before investing in his own system.

Collins, wife Megan, father Roy and kids Lorelei, Madison and Lincoln celebrate award. Roughly a third of production is high grade sawlogs and veneer logs.

Clark Tracks For All Conditions

Clark Tracks Ltd, part of Nordic Traction Group, specializes in developing and manufacturing forest machine tracks to suit almost all cut-to-length machines and skidders. We can supply tracks in various sizes and designs to suit virtually all terrain, climate, and machine types.

Our demanding class of tracks are specially designed for climbing and will take you fur ther on steep slopes. Performing to the highest of standards we have CS Climbing Special and CX Climbing Xtreme. Both models are developments of our popular Grouzer track and are suitable for use on harvesters as well as on small to medium forwarders under 15 tonnes. The first development is CS, this track has qualities that have established it as the pinnacle of climbing tracks. The CS track has its traction ability maximized through the use of an ag gressive spike pattern. Our Climbing Special track has two different spikes, wide paddle spikes towards the center of the track plate and long shovel spikes along the edges of the plate. The Climbing Xtreme track is a further development. This model features the wide paddle spikes from CS; however, they are doubled up on the track plate for peak performance and unsurpassed climbing abilities. Visit nordictraction.us

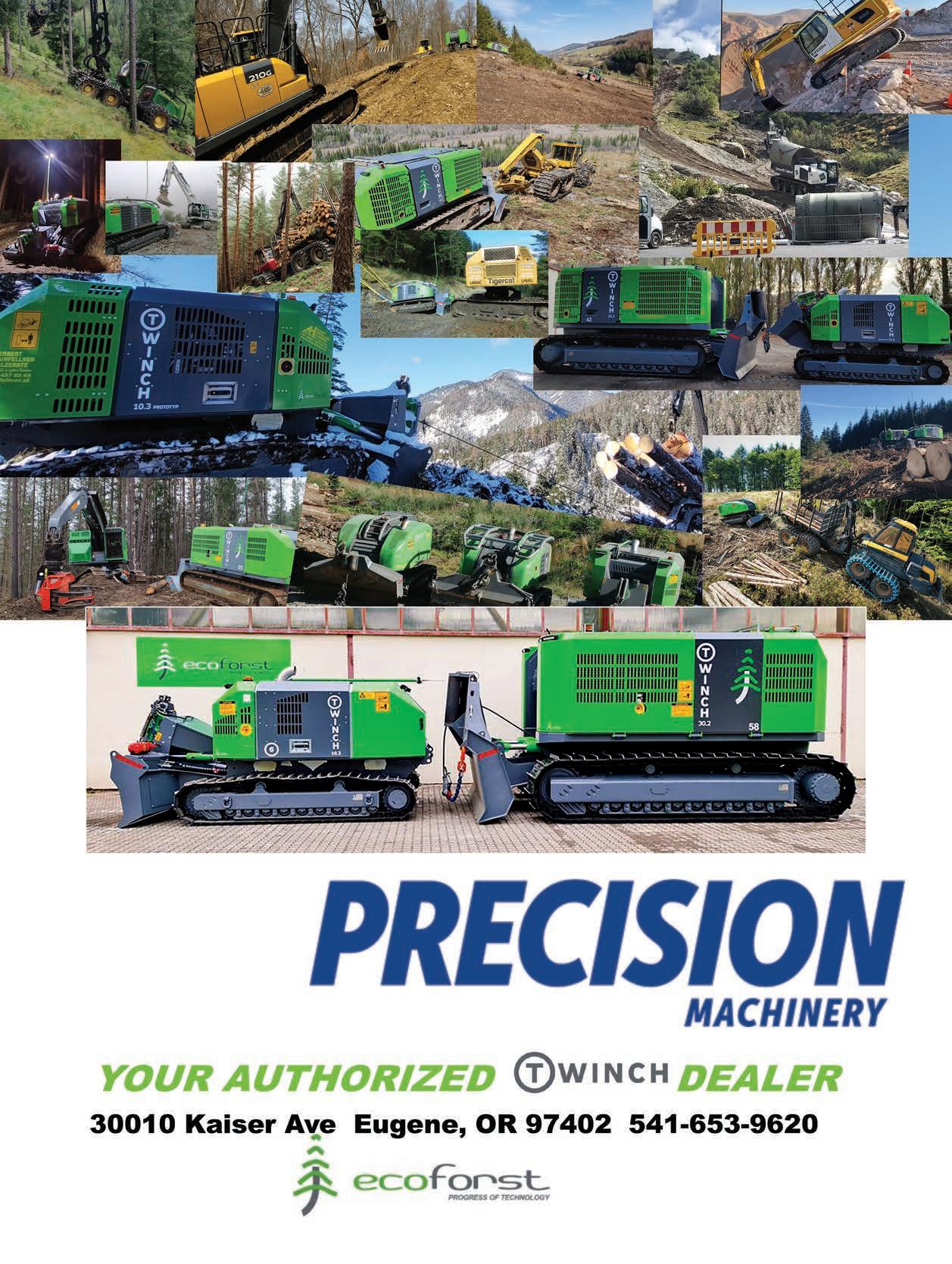

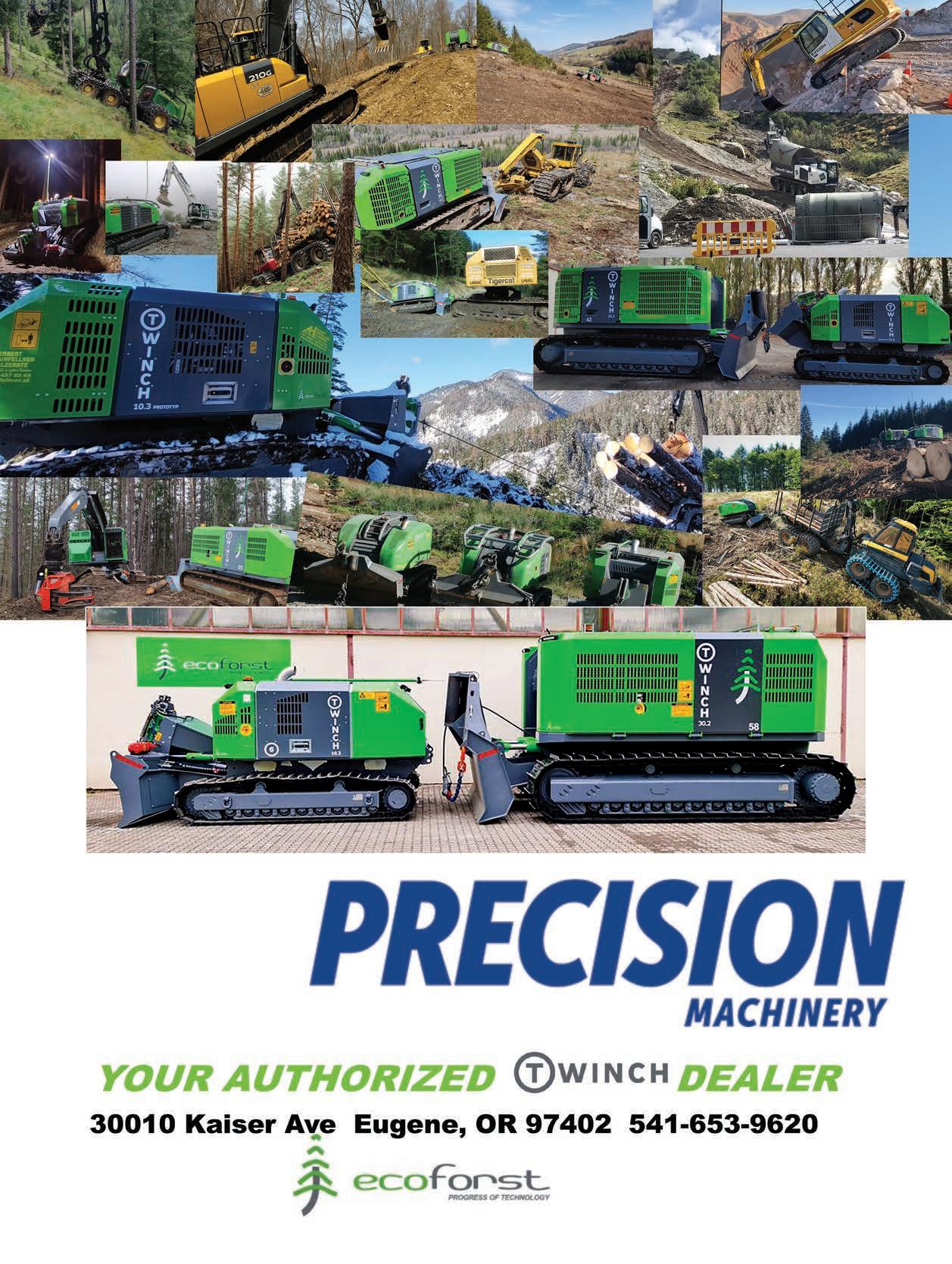

Ecoforst T-Winch

The TWinch by Ecoforst combines the latest technology with decades of experience in the logging industry. This is a stand-alone system that gives you the flexibility to tie off any machine.All you need is an attachment point and you are ready to go.Not only can the TWinch help you make money by helping you get to the timber that would otherwise be out of reach, but it saves money in fuel consumption, and adds an element of safety that is unmatched.The 10.3 gives you 22,000 lbs. of pulling force, which can support a machine up to 121,000 lbs. depending on the slope.The 30.2 offers over 40,000 lbs. of pulling force and can support a machine up to176,000 lbs. Contact Casey Ferguson at Precision Machinery in Eugene, Ore. for details.541-653-9620

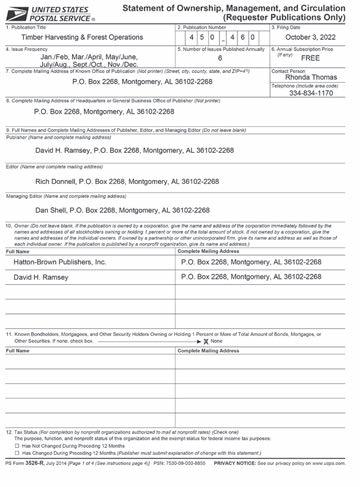

Forest Chain Protection

Forest Chain’s wide range of ring skidder chains, are available in fixed ring, multi ring, and studded with 9/16, 5/8 or 3/4 tag chains to fit all popular tire sizes. Designed to give as much as 60% more traction to your skidder, Forest Chain Skidder Chains provide quicker skid times, more production and increased bottom line profits. Forest Chain premium Multi-Ring heavy duty chains offer superior traction putting steel in strategic points providing protection from rocks, stumps and site debris, protecting your expensive rubber tires.and are available in 9/16, 5/8, 3/4, 7/8 and 1". The Double Diamond configured chains equipped with U-shaped studs are especiallyeffective in the worst conditions like mud and snow, the deep biting lugs dig deeply into the terrain to keep production moving. All Forest Chains are manufactured with top quality materials and workmanship and designed toprovide puncture protection from rocks, stumps and debris. Repairsare easy using common welding techniques and materials for longer life. Call 800-288-0887; emailforestchain@gmail.com

KMC Mulcher: Rugged Brush Work

The KMC Hydrostatic Rear Engine Tracked Mulcher is the solution for all your land clearing projects on slopes from 40-60%.

In addition, it is the ideal machine to go where other mulchers can’t go to reduce and manage forest fuels to mitigate fire risks and also perfect for vegetation management and even brush control and grooming on a ski slope!

Many harvested sites and development projects have large amounts of logging slash –piled material that must be disposed of. The high powered KMC Mulchers can rapidly reduce the brush, piled stumps and slash piles… into chips to meld into the topsoil.

The forest industry is continually seeking ways to improve its fuel management strategies, and utilizing the KMC Mulcher is one way to address the overgrown state of our forests. KMC has the proven capability and advantages over other types of mulching machines with the following key features:Cummins powered 200-450 HP, hydrostatic track drive, long life steel track, independent suspension, steep slope operations, more maneuverability, more speed, higher and faster production, and an extended working season.

The KMC Tracked machine is environmentally friendly with low ground pressure which means less soil compaction–important issues for silviculture projects and meeting government requirements in areas with sensitive soil. KMC is a design-build manufacturer specializing in skidders for harvesting; off-road tracked fire e ngines (Skidgens) for fire suppression and clean up as well as Mulchers for all your land clearing projects.

Why buy a KMC Mulcher?

Because one machine does it all… on all types of terrain and in all weather conditions.No excavators, No dozers, No tub grinders, No burning, No haul trucks…Just a KMC! Visitkmc-kootrac.com

16 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS SteepSlopeSystems

Olofsfors Boosts Skidder Efficiency

Olofsfors is a Swedish based company founded in 1762 with North American operations in Brantford, Ontario, Canada. Olofsfors is the market leader in bogie tracks for CTL machinery and wheel tracks for skidders and wheeled feller bunchers.

Specific to skidders, Olofsfors offers ECO-Wheel Tracks to boost productivity and increase traction. ECO- Wheel Tracks are traction aids developed and designed to suit the most demanding terrain and machine sizes. ECO-Wheel Tracks provide numerous benefits over conventional chains including increased traction, less spin and grab, easier and less maintenance, and can fit on used tires.

ECO-Wheel Tracks are available for tire sizes 23.1 x 26 to 35.5 x 32 and come standard with the 1" link system. ECO-Wheel Tracks are only available in one model which is based around the bestselling ECOTrack model.

For the CTL machines, Olofsfors offers a wide range of bogie track models and linkage systems for various machine configurations and ground conditions. Most track models are now available in the next generation of curved cross members for increased flotation, less ground disturbance and easier machine turning.

New for 2022 is the continued development of the larger track cross members. Along with ECO HD, the next model is Kovax+. Kovax+ is thicker and stronger compared to standard Kovax and is a great option for the newer 29mm link system. Visitolofsfors.com

Ponsse Steep Slope Productivity

Harvesting on slopes is becoming increasingly popular worldwide, and Ponsse forest machines have opened up a completely new range of possibilities. By making it possible to work on steep slopes and in similarly demanding conditions, Ponsse forest machines make it possible to harvest timber on previously inaccessible land. For steep slope opera tions, the cut-to-length method have proven to be very efficient way to do logging in slopes as it enables all harvesting types from selective thinning to final cutting with low ground impact. Ponsse has developed solutions, which are enabling usage of the machines in very steep slopes yet doing it in an environmentally sustainable way. It all starts from an eight-wheel machine. An eight-wheel machine is productive in steep slopes because of its stability, lower ground pressure, and better tractive effort compared to traditional six-wheel machine. The structure of the eight-wheel Ponsse machines are optimal for the steep slopes as the crane is located on a separate frame from the operator’s cabin. This improves ergonomics as the forces from the crane are not transferred to the cabin, but what is even more important is that the operator’s inclination angle remains stable even if the crane is turned – without lateral swaying. Today, over 90% of the total terrains, the requirements for other components of the machines have also grown higher. One of the biggest differences in the productivity of different machine makes comes from the crane’s properties and the stability of the machine. Also, the machine’s center of gravity must be kept low when working in slopes. Ponsse cranes are offering low center of gravity, sufficient tilting angle and strong slewing. Visit ponsse.com

Tigercat Steep Slope Systems

Tigercat continues to lead the industry in steep slope technology. With continued focus on safety when logging on steep terrain, Tigercat machines are stable, powerful, efficient and comfortable.

Leveling track machines—Optimized for steep slope work with innovative features and technologies, Tigercat’s leveling track machines are used in a wide range of applications including felling, harvesting and shovel logging. Tigercat’s patented super-duty, leveling undercarriage provides exceptional stability on steep slopes. It uses two massive hydraulic cylinders and heavy steel sections for a solution that is simple, robust and reliable. Unlike competing systems, the Tigercat leveling system leans into the hill when leveling to the side which further improves machine stability and operator comfort.

To further enhance the ability of Tigercat’s track machines to work on slopes, an optional cable assist mount is available. The tether anchor bolts firmly to the main carbody structure of the undercarriage and allows either single or double cables to be at tached to the track machine. A variety of third-party winch systems can be used to assist the track machine up or down slopes.

Rubber tire machines—Tigercat also produces skidders, harvesters, and forwarders with unique innovations to enhance productivity on steep or soft terrain. The drivetrain components, including the pump drive, transmission and bogie axles, are engineered and built by Tigercat for extreme forest duty, long life and high uptime. The use of either long bogie arms or mechanical balanced bogies reduce bogie lift, increasing stability on steep terrain.

Tigercat wheel harvesters feature leveling upper turntables which levels both the cab and the boom to provide strong swing torque and added operator comfort for working on slopes. The 1085C forwarder is available with a 25-degree tilting crane. The centre oscillation joints used on both harvesters and forwarders provides exceptional stability while travelling. The machines have heavy duty lugs incorporated into their frames to accommodate winch assist systems. Forced lubrication systems are being used on critical components in these machines.

Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 17 SteepSlopeSystems

up. It

Trygg Chain Durability

Trygg case-hardened Netlink Forestry Chain is designed strictly for forestry use for skid ders, forwarders, and loaders with a quality second to none. Double studs on top of the verti cal links provide extreme traction. Also for forestry the Trygg Giant U chain combines the sta bility of our U-Grip with aggressiveness of our Netlink. The chains are made in 16mm dimen sions with double diamond pattern as standard. U-studs are welded under the horizontal chain links and stand upright throughout the whole lifetime of the chain. This construction gives good grip and reduces link wear. Tightening rail is standard for 55 profile and lower and is op tional for all other tire sizes. We recommend use of our chain tightener tool when mounting this chain. Call 208-267-6215;visit whitemountainchain.com

Wallingford’s Offers pewag, BABAC

Wallingford’s Inc. is now a member of pewag group, and is the North American distributor of pewag forestry traction products. The bluetrack perfekt has been the standard model recommended for a climbing application until recently. Recognizing a need for a track better suited to extremely steep terrain, pewag has been testing differ ent designs and through this testing has developed a new extreme track. pewag bluetrack extreme BTPX16 is specifically designed for extremely steep applications. It is also focused for use on very heavy machines with a much stronger cross bar. We look forward to the upcoming arrival of the new extreme tracks in North America. Wallingford’s Inc. is also a wholesale distributor of BABAC traction chains. We are pleased to offer multiple design options of traction chains suited for steep slope logging, including BABAC’s Ring chains that provide excellent traction for operating in mud or snow on steep slopes. All models feature alloy lugs that, unlike most other chains, are butt and wrap welded for unsurpassed strength and durability. Our slanted half links take out pre-load as the chain goes over the tire. This reduces friction and wear and allows for free tag chain movement. It is a standard feature on all of our ring chains.

BABAC chains have been made in the U.S. since 1986, and are available at dealers throughout the continent. We specialize in designing and building tire chains for custom applications and odd tire sizes, utilizing our in-house computer-aided design capabilities. BABAC also offers a variety of tools and spare parts to properly maintain and repair, when necessary, your chains for long life and maximum performance. Our G200 and G202 chain tensioners facilitate installation and maintenance requirements, resulting in longer chain life from properly tightened chains. BABAC Black Pin Load Rated Shackles are ideal for skidder tire chain applications. Visit wallingfords.com

Cable logging—The new Tigercat 180 swing yarder is purpose-built from the ground

combines the speed and stability of conventional yarders with the mobility and simpler controls of excavator-based yarders. The result is a powerful and versatile yarding machine for extreme terrain logging applications. Visit tigercat.com

18 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS SteepSlopeSystems

ALC Recap

Kids auction raised $56,000 for the Missouri Children’s Miracle Network Hospital. A separate auction was held to benefit Thomas Johnson, a logger from DeRidder, La. who is fighting cancer.Two items—a Duck Dynasty autographed duck call display donated by Skeet from Louisiana and a chain saw donated by the Louisiana Loggers Assn. and Stihl—raised over $38,000 to help with Johnson’s medical bills. The chain saw was auctioned and then donated back to be auctioned again a total of 10 times!

During the President’s Farewell Dinner on Saturday night, Timber Harvesting managing editor Dan Shell presented the Timber Harvesting Logging Business of the Year award to South Carolina’s Great Woods Companies owners Bob and Cindy Lussier. Bob and Cindy shared the honor with their entire crew.

BRANSON, Mo.

Billed as “Back to the Start” with this year’s meeting in the same state where what was to become the American Loggers Council (ALC) held its first meeting way back in 1994, more than 250 timber industry represen tatives from all over the U.S. traveled to this year’s ALC meeting in Branson.

The conference started Wednesday night with an axe throwing competition among teams representing loggers from the East, South, Midwest and West. The West Team (Tim Christopherson and Mark Mahon from Idaho and Matt Hegerberg and Jean Pierre Fontenot from Oregon) took the top spot.

Thursday’s logging tour, sponsored by John Deere, featured a visit to meet ing host (and 2020 ALC president) Shannon Jarvis’ logging crew, which was harvesting marked timber and pro ducing beautiful bucked hardwood

sawlogs at a site near Springfield. The tour concluded with a visit to the large aquarium at the original Bass Pro store and campus in Springfield.

Friday’s seminars, with the theme “Tomorrow’s Timber Industry,” tackled topics like antitrust and contract law, timber cooperatives, public image and emerging markets.

On Friday night, a Log-A-Load For

ALC also recognized some of those who were present at that first meeting 28 years ago: Jim Carey (Michigan), Eric Mayranen (Minnesota) and Charles Johns (Florida). Also, standing in for some who are no longer with us, first ALC President Earl St. Johns was represented by his grandson, Jordan St. John, and his great-grandson, while Bruce Zuber, current ALC Western Regional Representative, accepted recognition on behalf of his dad, Marvin Zuber.

Finally, outgoing President Tim Christopherson symbolically passed the gavel to incoming President Andy Irish of Maine. In gratitude for his leadership during the pandemic and last year’s transition from former Executive Director Danny Dructor to his successor, Scott Dane, ALC presented Christopherson with a plaque and Loggers Edition Rifle.

Irish will host the 29th American Loggers Council Annual Meeting in Maine the first week of October, 2023.

TH 20 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

TH Logging Business of the Year Great Woods celebrates.

Seminar sessions covered a variety of logger concerns.

Logging tour featured hardwood harvesting, sponsored by John Deere.

Log-A-Load auction raised $56,000.

Loggers gather in Missouri for annual meeting.

Deere Disc Felling Head

John Deere an nounces its newest for estry attach ment offering with the FR27 disc saw felling head. Now standard on the John Deere 953M and 959M feller-buncher models, and avail able as an upgrade on the on the 853M, 859M and 903M feller-bunchers, this felling head attachment has a larger cut capacity compared to previous felling head models. Building upon the suc cess of the FR24B, John Deere has suc cessfully designed the durable FR27 as a solution aimed to increase productiv ity on the job.

The FR27 is designed to take on a variety of timber applications, from large single stem cutting to mid-sized accumulation, and boasts an all-new de sign and overall rebranding from previ ous John Deere felling head models. In addition, this robust, high rotation fell ing head features excellent cut and ac cumulation capacity, offering top-ofthe-line productivity compared to previ ous models. The FR27 features an im pressive cutting capacity of up to 27.2" and an accumulation capacity of up to 7.5', improving capability in the woods.

Building upon the success of the field proven FR24B, the FR27 features an updated frame and wrist design, which includes a tall horn, long harvesting arms and continuous hose routings that promote easy machine clean-out.

Additionally, the FR27 offers bolt-on saw housing for improved serviceability, with three separate saw housing sections with integrated skis getting you back on the job sooner. The incorporated large side chip exhaust chute minimizes build up and plugging, keeping your machine up and running. The side chip exhaust chute also includes a cover that can be added or removed depending on application. Visit johndeere.com.

Tigercat Harvester Control

trol and user interface. The system offers powerful functionality, simplicity and intuitive operator navigation.

There are two types of bucking control available for D7. Priority-based bucking logic utilizes a list of operator-entered log specifications sizes to determine how best to process the tree.

D7 Optimization level uses a value-based logic. Using multiple layers of matrices correlating price, demand, and production limits to each log size under each tree species, the control system optimizes each processed tree to achieve the best value. These matrices are usually programmed by the timber buyer.

Both Tigercat D7 Priority and Optimization levels offer StanForD Classic, StanForD 2010, and PDF production reporting based on contracts, operators, species and product groups. The reports provide total quantity and volume, as well as per species and product group quantities and volume. D7 also sends production volume data to RemoteLog, Tigercat’s optional telematics system.

The Tigercat D7 control system combines a solid and field proven hardware and bucking control system with a Tigercat developed head con-

D7 can be equipped with a GPS re ceiver and the GeoInfo software. This provides an active navigation applica tion using the machine’s current posi tion on a georeferenced map. Work site maps can be viewed on the in-cab display screen, allowing the operator to easily view the site layout, track the movement of the machine, and view production information. Re stricted areas can be marked with boundary alarms.

D7 is currently available for the Tigercat 534 harvesting head. Visit tigercat.com.

Komatsu Processor

Control downtime and drive productivity with the robust, dependable and fuel-efficient Komatsu PC230F-11 processor. Delimb, cut and stack timber with this powerful and maneuverable processor designed specifically to meet the demands of forestry work.

Large trees can be moved more

InnovationWay 22 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

easily thanks to a powerful swing system and a large swing circle. With exceptional reach of up to 29' (8,951 mm), the excellent maneuverability of the PC230F-11 helps drive productivity.

Designed with a high and wide undercarriage, powerful swing motor and ability to withstand high-debris conditions, the PC230F-11 is backed by excellent service, easy access to parts and an industry-leading warranty. Built to tackle demanding forestry processing environments, the PC230F-11 has exceptional reach, a high and wide rugged undercarriage and a powerful swing system.

When operators are working in high-debris conditions, the robust wide-fin radiator is protected by heavy-duty forestry screens and a variable pitch reversing fan helps improve airflow.

Offering excellent ground clearance, the PC230F-11, provides reliable maneuverability in tough forestry environments thanks to a high and wide undercarriage designed with larger class-size components.

Operators can adjust quickly to a sudden change in load weight without losing productivity with the Auto Power Max feature.

An extra-rugged exterior protects against falling limbs with a 1.26" thick (32 mm) polycarbonate front window and metal designed to withstand demanding environments. The PC230F-11 features heavy-duty service undercover guards and rear compartment doors, and a right corner guard with a standard tree deflector. Visit komatsu.com.

Vermeer Max Grinder Tip Line

Vermeer is enhancing its grinder tip line with the long-lasting max grinder tips. They contain the maximum amount of carbide to provide durability grinder operators can count on, which translates into more time on the job and less time spent changing tips. These durable grinder tips are designed for a precise fit, eliminating the time required for modifying tips to fit your Vermeer grinder.

The premium grinder tips feature additional welds on the ends and a single weld on the sides for an extended life span. Pro grinder tips have both ends and sides welded to provide a standard life span. The difference is the amount of carbide that is put on during the welding process. The max has a higher carbide content, which results in longer wear life.

The three grit options can be paired with different grinder tip styles to match jobsite requirements. Six tip styles are available—wide block grinder tips; abrasion-re sistant grinder tips; wing grinder tips; impact-resistant grinder tips; narrow block grinder tips; sharp grinder tips. Visit Vermeer.com.

InnovationWay 24 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

Ponsse NA Expands To Southern U.S.

Ponsse North America, Inc has expanded its operations to Midway, Fla., right outside of Tallahassee. The main factors that influenced this development are the growing demand for cut-to-length wood and an increase in machine sales in the South as Ponsse officials seek to provide their customers with the best parts and service performance they can offer.

“Forestry is our focus and all we do. We are extremely excited about our expansion to the South because of the number of mill investments with new facilities opening, reopening of shut down mills and capacity increases. It is time for cut-to-length to be more dominant in the South like it is currently in the northern part of the USA. We want to provide all our customers with the best machines in the world, exceptional service and the best parts availability in the industry,” states Pekka Ruuskanen, President and CEO of Ponsse North America, Inc.

Ponsse North America, Inc is a subsidiary of Ponsse Plc and was established in 1995. The headquarters is currently located in the heart of the cut-to-length region in Rhinelander, Wis. Ponsse has branches in Wisconsin, Michigan, Minnesota, Oregon and now the latest addition in Florida. Ponsse also has full-line dealers and service dealers in various locations around the nation. Ponsse Plc is one of the world’s largest manufacturers of rubber-tired cut-to-length forest machines. The family-owned company is still based in Vieremä, Finland in the same location in which it was founded in 1970. Ponsse forest machines are based on envi-

ronmentally friendly cut-to-length (CTL) logging, where trees are felled, delimbed and bucked to length before they leave the forest.

Ponsse’s product range covers all size categories of forest machines, from first thinning and the harvesting of forest energy to heavy-duty regeneration felling, as well as all logging sites, from soft soil to steep slopes. Ponsse products and their key components are designed and manufactured by Ponsse in Vieremä. This guarantees the company remains at the forefront of development and that its products meet the requirements of forest professionals. Ponsse develops and manufactures sustainable and innovative harvesting solutions based on customer needs.

Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 25 EquipmentWorld

Get In the Wheelbarrow

SCOTT DANE

Super Bowl champion quarterback Kurt Warner sent a letter to the American Loggers Council that was shared at the Annual Conference. In it, Kurt conveys a story regarding a symbolic reminder to the 1999 Super Bowl champion, St.

Louis Rams football team during their practices. Their coach Dick Vermeil had a blue wheelbarrow on the sidelines. It was a visual motivational reminder to inspire the team and was based on the following story:

There once was a man who traveled from town to town performing a tightrope act. In one town he proclaimed that he would walk on a rope spanning a nearby wide river canyon. He boasted he would do it pushing a wheelbarrow.

Townsfolk didn’t believe him, so he practiced flawlessly just five feet off of the ground on a rope tied between a pair of trees. After seeing the tightrope walker practice one farmer said he believed the man could cross the river canyon. He even bet $10 to prove his faith in the man’s skills.

The man asked the farmer if he really had faith that he could do it? The farmer said, “I sure do.” The tightrope walker said, “Okay, get in the wheelbarrow!”

The moral of the story is some believers stand on the sidelines and believers that get in the wheelbarrow. Kurt’s letter closes with:

“Success in any field begins with faith. Faith in yourself. Faith in your teammates. Faith in coaches. And in my case faith in God. The championship teams that I played with had faith. We climbed in the wheelbarrow together. So – Keep the Faith.”

Kurt Warner was an American underdog who got his chance to play for the St. Louis Rams in 1999 after having been passed over by other teams. The American Loggers Council got its chance in St. Louis, Mo. in 1994 when the “team” was formed by a bunch of American underdogs who had faith – faith in themselves, faith in each other and faith in God. They got in the wheelbarrow together and over the past 28 years crossed many canyons while building a championship team. They didn’t stand on the sidelines, they got in the game. They took the hits, but they carried the ball and scored! The American Loggers Council is a championship team!

Kurt also autographed a poster titled Legacy which said: “Legacy – Live a Life that Inspires Others to Dream Bigger, Try Harder, Do Better and Accomplish the Unexpected.”

Dane ➤ 30

26 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

We (ALC) See It

SelectCuts As

Foremost Authority For Professional Loggers NOVEMBER/DECEMBER 2022 27 24 Hour Ad Placement Service: 1-800-669-5613 TH Exchange 2687 5078

24 Hour Ad Placement Service: 1-800-669-5613 28 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS TH Exchange EUREKA! EUREKA! EUREKA! OWNERS HAVE OVER 30 YEARS COMBINED EXPERIENCE! We can save you money on Saw Teeth. Hundreds of satisfied customers. Rebuilt Exchange or New. We specialize in rebuilding Koehring 2000, Hurricana, Hydro Ax split teeth and all other brands. Call Jimmy or Niel Mitchell. Quantity Discounts! EUREKA SAW TOOTH CO., INC. 4275 Moores Ferry Rd. • Skippers, Virginia 23879 PH./FAX (day) 1-434-634-9836 or Night/Weekends • 1-434-634-9185 NOW ACCEPTING CREDIT CARDS 7180 1926 2583 2687

24 Hour Ad Placement Service: 1-800-669-5613 TH Exchange 13666

Those that came together to form the American Loggers Council in Missouri in 1994 have left a legacy because they inspired others to dream bigger, try harder, do better and accomplish the unexpected. They had faith and got into the wheelbarrow. Today’s American Loggers Council is their legacy. Some of them were in Branson and were recognized. Representing the first President, Earl St. Johns, was his grandson, Jordan St. Johns, and his great-grandson. Also present and recognized were inaugural representatives Jim Carey (MI) and Eric Mayranen (MN) and Charles Johns (FL). Representing Marvin Zuber (OR) was his son, Bruce Zuber, Western Regional Representative of the American Loggers Council.

The legacy of the American logger has been recognized. It was an nounced at the conference that a Res olution was introduced in the U.S. Senate to designate October 12 as Na tional Loggers Day. This resolution honors the American Logger for their role in building America; producing products for Americans from the re newable timber harvested; creating jobs; and forest management which

EventsMemo

results in healthy forests that provide recreational opportunities, animal habitat, clean water, carbon sequestra tion and reduction of wildfires. The designation of this National Loggers Day was achieved because (team) members of the American Loggers Council worked together to garner this overdue national recognition. So loggers, on October 12, take a mo ment to proudly reflect on what you do, on what your fathers and grandfa thers did, and how it contributes to building America every day. Without loggers, America would not be the great country it is today. You are an American legacy.

Kurt Warner and his wife Brenda run the First Things First Foundation which is dedicated to impacting lives in a lasting way by promoting Christian values, sharing experiences, and providing opportunities to encourage everyone that all things are possible when people seek to put “first things first.” When Kevin Smith, American Loggers Council Director of Communications and Marketing, contacted the First Things First Foundation and explained to them that the American Loggers Council is the national spon-

sor of the Log-A-Load For Kids program and that we would be holding a fundraising auction at the conference, Kurt responded with the letter and autographed Legacy poster.

With great success comes great responsibility. Kurt Warner accepts this and so does the American Loggers Council, which was formed to ensure that there is a viable future for the next generation. They came together to be responsible corporate stewards and support their communities. They came together to be part of a team, a winning team, and to make a difference –and what a difference they made!

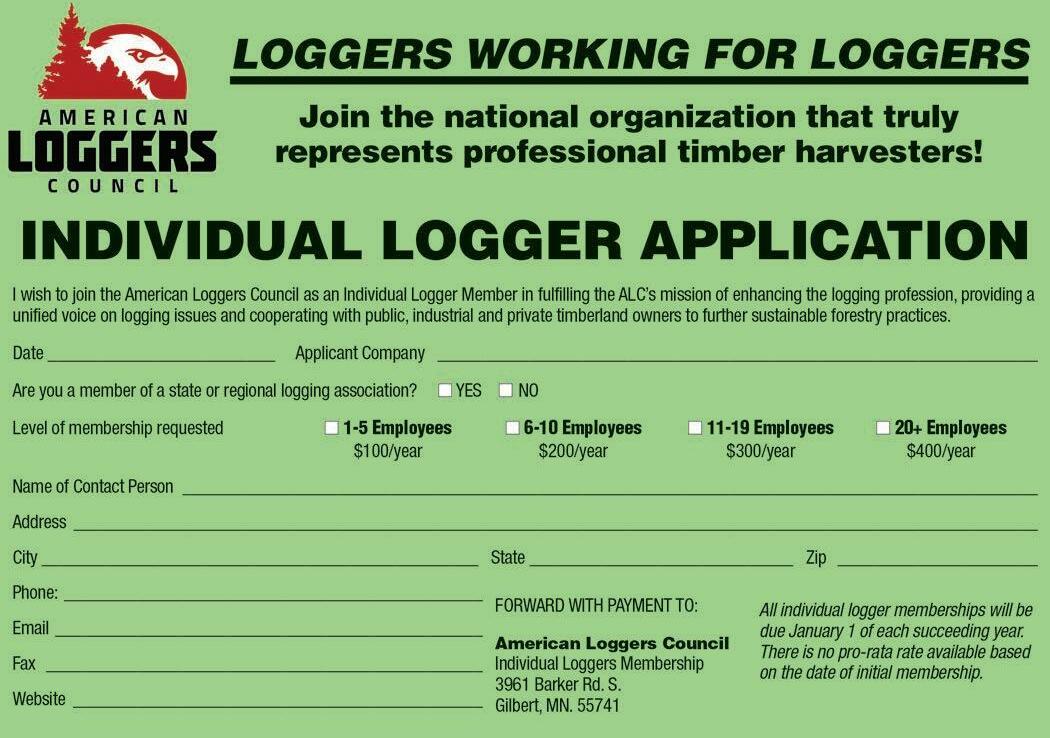

The American Loggers Council now represents loggers in 38 states. If you are reading this, and you are not a member of your state logging association or the American Loggers Council, don’t be a believer that stands on the sidelines, be a believer that gets in the wheelbarrow. Be a part of the team!

Scott Dane is the Executive Director of the American Loggers Council. ALC is a 501(c)(6) trade association representing the interests of timber harvesting and timber hauling businesses across the United States. For more information visit www. amloggers.com.

AdLink

Listings are submitted months in advance. Always verify dates and locations with contacts prior to making plans to attend.

February 22-26, 2023—Appalachian Hardwood Manufac turers annual meeting, Ponte Vedra Inn & Club, Ponte Vedra, Fla. Call 336-885-8315; visit appalachianhardwood.org.

February 23-25, 2023—Oregon Logging Conference & Show, Lane County Convention Center, Eugene, Ore. Call 541-686-9191; visit oregonloggingconference.com.

February 24-26, 2023—South Carolina Timber Producers Assn. annual meeting, DoubleTree Resort by Hilton, Myrtle Beach, SC. Call 800-371-2240; visit scloggers.com.

March 22-24, 2023—Hardwood Manufacturers Associ ation’s National Conference & Expo, JW Marriott, Nashville, Tenn. Call 412-244-0440; visit hmamembers.org.

March 28-30, 2023—Kentucky Forest Industries Assn. annual meeting, Embassy Suites, Lexington, Ky. Call 502695-3979; visit kfia.org.

March 30-April 1, 2023—Southeastern Wood Producers Assn. annual meeting, The Okefenokee Fairgrounds, Way cross, Ga. Call 904-845-7133; visit swpa.ag.

Easy Access to current advertisers! http://www.timberharvesting.com/advertiser-index/

This issue of TIMBER HARVESTING is brought to you in part by the following companies, which will gladly supply additional information about their products.

American Loggers Council 29 202.627.6961

Bandit Industries 9 800.952.0178

Cleanfix North America 13 855.738.3267

Colorado Timber Resources 21 970.725.3687

Forest Chain 22 800.288.0887

KMC Kootrac-Kootenay Tractor 19 800.562.5303

Nordic Traction USA 12 207.487.1984

Olofsfors 23 519.754.2190

Ponsse North America 1,2 715.369.4833

Precision Machine & Manufacturing 31 541.484.9841

Precision-Husky 5 205.640.5181

Prolenc Manufacturing 24 877.563.8899

Tigercat Industries 32 519.753.2000

Wallingford’s 26 800.323.3708

Western Trailer 26 888.344.2539

White Mountain 25 800.439.9073

ADLINK is a free service for advertisers and readers. The publisher assumes no liability for errors or omissions.

30 NOVEMBER/DECEMBER 2022 TIMBER HARVESTING & FOREST OPERATIONS

SelectCuts 26 ➤