You know what “they” say: Many times it's the second owner who makes work what the first one couldn’t quite do. That’s precisely the kind of energy most in Lakeview, Ore., and many others in the woody biomass industry, are hoping Lakeview RNG, a wholly owned subsidiary of NEXT Renewable Fuels, can bring to the once completely dead Red Rock Biofuels development.

The project has bounced around like a ping pong ball, plagued by cash-related issues, process re-engineering drama, bankruptcy of a key supplier and then of course, the big C—COVID-related delays doomed the project. Earlier this year, on everyone’s favorite female editor’s birthday in fact, was a major payment deadline for nearly $355 million back principal and interest payments on certain Economic Development Revenue Bonds issued by the state of Oregon set via foreclosure notices published in a local paper. When that fated Saturday came and went earlier this year, a property auction was slated to take place just five days later. It was then postponed to early March. It was then postponed a third time. Finally, a savior appeared—in the form of a Texas financier and company, NEXT. The purchase price of the facility remains undisclosed.

The new owner is pivoting completely away from the idea of the plant using biomass from regional forests to produce sustainable aviation fuel (SAF), which was boosted by a $75 million Dept. of Defense grant and fuel commitments from FedEx and Southwest Airlines, plus state and local incentives and infrastructure improvements.

Instead, the newly born Lakeview RNG, taking the estimated 70% of completed construction at the site, has commenced with a redevelopment plan focused on completing construction of certain aspects of the site while replacing or enhancing others. When completed, the Lakeview RNG facility is expected to be capable of converting forest waste into renewable natural gas (RNG) and clean hydrogen.

Christopher Efird, CEO and Chairperson of NEXT, has said NEXT has no interest in making liquid fuels in Lakeview, and will be using an entirely different gasification process, run at much higher temperatures, to con-

vert the wood slash into streams of methane.

Red Rock Biofuels was founded as a sustainable aviation fuel (SAF) operation in 2011, and was being built to produce drop-in fuels from woody biomass and manufacture approximately 20 million (U.S.) gallons (≈ 75.7 million liters) per year of low-carbon intensity renewable biofuels. The facility finally broke ground in summer 2018 but remained incomplete.

“Acquiring the Lake County clean fuels infrastructure is another advancement in our mission to decarbonize the transportation industry and produce low carbon fuels at scale,” says Efird. “This acquisition represents a major step toward our clean fuel production capabilities and pathways to meet growing demand for clean fuels along the west coast of the United States while helping to address the critical concern of forest health.”

Lakeview RNG will process wood waste and turn it into a low-carbon gaseous fuel. Local Lake County residents and leaders are pleased that the facility has new life, and that the promises of economic development will finally be realized.

“We have been anxiously awaiting this day and are very happy that the facility will be put into operation rather than sold for parts,” comments Michele Parry, Lakeview City Manager. “Lakeview’s location is strategically important because of our proximity to regenerative feedstock sources and to the pipeline distribution system that can get the clean fuels to market.”

Lakeview RNG has evaluated the potential feedstock supply in Oregon and determined that all of its wood waste needs could come from within 150 miles of the facility.

NEXT is also currently permitting and developing a 50,000 barrel-per-day/750 million gallon-per-year renewable diesel (RD)/sustainable aviation fuel (SAF) refinery at Port Westward on the Columbia River outside Clatskanie, Ore. The project is advancing through permitting and expects to begin construction upon completion of an Environmental Impact Statement currently underway with the U.S. Army Corp of Engineers.

We will all just have to wait and see, perhaps, if the Almighty They is right. Lakeview RNG: We’re all pulling for you.

Cover photography: It’s a mad, mad wood-to-energy world out there, but one thing remains true—without some quality in-woods chipping and grinding nothing would happen. (Photo courtesy of Morbark)

Volume 15

Number 3

Hatton-Brown Publishers, Inc.

Street Address ■ 225 Hanrick Street

Montgomery, AL 36104-3317

Mailing Address ■ P.O. Box 2268

Montgomery, AL 36102-2268

Tel: 334.834.1170 ■ Fax: 334.834-4525

Publisher/Adv. Sales Manager ■ David H. Ramsey

Chief Operating Officer ■ Dianne C. Sullivan

Editor-in-Chief ■ Rich Donnell

Managing Editor ■ Jessica Johnson

Senior Editor ■ Dan Shell

Senior Editor ■ David Abbott

Publisher/Editor Emeritus ■ David (DK) Knight

Art Director/Production Manager ■ Cindy Segrest

Ad Production Coordinator ■ Patti Campbell

Circulation Director ■ Rhonda Thomas

Online Content/Marketing ■ Jacqlyn Kirkland

Advertising Sales

North American Sales Representative

Susan Windham ■ P.O. Box 2268

Montgomery AL 36102-2268

334.834.1170 ■ Fax: 334.834.4525

E-mail: windham.susan4@gmail.com

International Sales

Murray Brett ■ 58 Aldea De Las Cuevas, Buzon 60

Benedoleig 03759, (Alicante) Espana

+34 96 640 4165 ■ Fax: +34 96 640 4048

E-mail: murray.brett.aba@abasol.net

Classified Advertising Sales

Bridget DeVane ■ Tel: 334.699.7837 ■ 800.669.5613

E-mail: bdevane7@hotmail.com

Wood Bioenergy (ISSN 1947-5306) is published six times annually (February, April, June, August, October, December) by Hatton-Brown Publishers, Inc., 225 Hanrick St., Montgomery, AL 36104. Wood Bioenergy is free to qualified readers in the United States, including owners, managers, supervisors and other key personnel. All nonqualified U.S. subscriptions are $50 per year, Canadian subscriptions are $60 and foreign subscription are $95 per year (U.S. funds). Subscriber Inquiries and Back Issue Orders—TOLL-FREE: 800.669.5613. Fax 888.611.4525. Subscribe or renew online: www.woodbioenergymagazine.com and click on the “Subscribe” button. When requesting change of address, please specify both old and new. Periodicals postage paid at Montgomery, Ala. and at additional mailing offices.

Postmaster: Please send address changes to: Wood Bioenergy, P.O. Box 2419, Montgomery, AL 36102-2419

All advertisements for Wood Bioenergy are accepted and published by Hatton-Brown Publishers, Inc. with the understanding that the advertiser and/or advertising agency are authorized to publish the entire contents and subject matter thereof. The advertiser and/or advertising agency will defend, indemnify and hold any claims or lawsuits for libel violations or right of privacy or publicity, plagiarisms, copyright or trademark infringement and any other claims or lawsuits that may arise out of publication of such advertisement. Hatton-Brown Publishers, Inc. neither endorses nor makes any representation or guarantee as to the quality of goods and services advertised in Wood Bioenergy. Copyright ® 2023. All rights reserved. Reproduction in whole or part without written permission is prohibited. Printed in USA.

Enviva, the world’s largest producer of industrial wood pellets, released its quarterly report in early May, and it rippled through the wood-to-energy ranks.

“The plans and initiatives underway to improve productivity and costs across Enviva’s current asset platform continue to fall behind expectations,” commented John Keppler, Executive Chairman of the board. “While the board of directors remains convinced of management’s ability to deliver the originally forecasted operational and financial performance over time, it is clearly taking longer than expected.”

Keppler said to more conservatively underwrite that plan and ensure the ability of the company to capture the value of the fully contracted growth ahead, and after careful consideration with management, the board of directors has decided to revise Enviva’s capital allocation framework, eliminating the company’s quarterly dividend in order to preserve liquidity and a conservative leverage profile, while maintaining its current growth trajectory, and potentially accelerating future investments in new fully contracted plant and port assets, and implementing a limited share repurchase program.

With the elimination of the dividend, management expects to retain approximately $1 billion in incremental cash flow during the period 2023 to 2026, providing incremental liquidity and investment into the productivity and operational improvements in its current assets and further reduce the need to access the capital markets to fund its current growth plans, which include the construction of the company’s fully contracted wood pellet production facilities in Epes, Ala. and near Bond, Miss.

Under the share repurchase program, the company can repurchase up to $100 million in shares of the company’s common stock oppor-

Meth added, “We recognize this is an important departure from the plan we laid out at our Investor Day a month ago, but a lot has changed since then. Compared to our expectations, while our cost position has trended in the right direction, it has done so at a much slower pace than we had anticipated, in part due to slower volume growth, and in part due to a higher spend profile for the volume growth we did achieve.”

Meth continued, “We know what the specific issues are: Contract labor is too high, discipline around repairs and maintenance spend is insufficient, wood input costs need to come down further and stay there, and utilization rates at specific plants need to improve and stabilize at those improved levels. Because of where we are in our journey to bend our cost curve down while bending our production curve up, we feel it is prudent to take a much more conservative view of what our

of where it will allocate its capital. “We believe we have more accretive capital allocation alternatives, which start with improving returns from our existing fleet of assets, growing our fully contracted asset base, managing liquidity and leverage, and also include the potential to opportunistically repurchase our shares in the open market, which we believe have traded below their intrinsic value for some time,” Meth said.

Enviva reported delivered volumes of approximately 1.3 million metric tons during the first quarter, which was 20% higher for compared to first-quarter 2022, but short of management’s expectations of approximately 1.5 million MT. Enviva said delivered at port cost per MT declined by $9 throughout first quarter 2023, but remain higher than management’s expectations.

The company reported a net loss of $116.9 million for first quarter, as

compared to a net loss of $45.3 million for first quarter 2022, and reported adjusted EBITDA for first quarter 2023 of $3.4 million as compared to $36.6 million for first quarter 2022. Enviva updated certain full-year 2023 guidance metrics, including revising net loss to a range of $186 million to $136 million, and adjusted EBITDA to a range of $200 million to $250 million.

“Although the future continues to be incredibly bright for Enviva’s business, we have had a difficult and disappointing start to 2023,” Meth said. “Operating cost overages and production challenges were key drivers behind the first quarter’s poor performance. While plant production is increasing and we are reducing our operating cost position, neither improvement is materializing at the rate we forecasted a few months ago. Based on results from the first four months of the year, we believe it is prudent to take a more conservative view on the timing of our ability to deliver these improvements.”

Enviva’s liquidity was $634.4 million as of March 31, 2023, which included cash on hand, including cash generally restricted to funding a portion of the costs of the acquisition, construction, equipping and financing of its Epes and Bond facilities, as well as availability under its $570 million senior secured revolving credit facility.

Management is reducing its estimates for full-year produced volumes in 2023 to be approximately 5 million to 5.5 million MT, as compared to a prior forecast of 5.5 million to 6 million MT. Management continues to expect net revenue per ton to be approximately $234 per MT for full-year 2023.

Enviva continues to forecast that total capital expenditures (inclusive of capitalized interest) will range from $365 million to $415 million for 2023.

Meth added, “I am pleased to note that given the strong future contracted growth we have in hand, the pace of our investment

continues to be on track, and with the changes we have announced today, we have the opportunity to continue to deliver this growth with lower risk and limited needs to access the capital markets.”

Enviva owns and operates 10 plants with a combined production capacity of approximately 6.2 million metric tons per year in Virginia, North Carolina, South Carolina, Georgia, Florida and Mississippi, and is constructing its 11th plant in Epes, Ala. and is planning to commence construction of its 12th plant, near Bond, Miss.

Jackson Pellets, LLC held a ribbon cutting March 22 at its new wood pellet manufacturing plant at the Jackson Port, Ala. Todd Bush, CEO of CM Biomass North America, the parent company of Jackson Pellets, told the group that the Jackson plant is the crown jewel of all the facilities he’s been a part of.

The mill represents a $21 million investment and is expected to employ 45 to 50.

CM Biomass, a company based in Denmark, has 10 other facilities in the U.S. Bush said that everything they have learned from building other facilities has been applied at Jackson in building the mill from the ground up. He said that the product manufactured in Jackson will go to Mobile as does product from other facilities in Mississippi, Tennessee and Alabama.

CM Biomass reports that its North American production facilities are primarily supplied with byproducts from the sawmilling industry, but it also developed a facility in Douglas, Ga. that converts peanut hulls. The company lists the following facilities: Huntsville, Texas; Douglas, Ga.; Ideal, Ga.; Effingham, SC; Brookhaven, Miss.; Jackson, Ala.; Quitman, Miss.; Jasper, Tenn.; Crosville, Ala.; Fruitdale, Ala.

CM Biomass Partners was founded in 2009 as a response to the Eu-

ropean Union’s increased demand for sustainable green energy solutions and the EU RED 2020 targets. Since the beginning, the company has benefitted from the close connection to the CM group with its many years of experience within commodity trading, shipping, warehousing and wood pellet bagging. In the meantime, helping suppliers meet sustainability requirements has also become an important and fastgrowing task.

Today, they trade more than 3,600,000 MT of wood pellets per year, which makes them one of the largest independent wood pellet trading companies in the world.

CM Biomass Partners employs around 225 in Denmark, Sweden, Germany, UK, Holland, Italy, Latvia, Russia, Singapore, Vietnam and the U.S.

In 2021 United Shipping & Trading Co. acquired a majority stake in CM Biomass.

European Commission welcomed the provisional agreement reached between the European Parliament and the Council to reinforce the EU Renewable Energy Directive. The agreement raises the EU’s renew-

able target for 2030 to a minimum of 42.5%, up from the current 32%, and almost doubling the existing share of renewable energy in the EU. Negotiators also agreed that the EU would aim to reach 45% of renewables by 2030.

The agreement reaffirms the EU’s determination to gain its energy independence through a faster deployment of home-grown renewable energy, and to meet the EU’s 55% greenhouse gas emissions reduction target for 2030. A massive scaling-up and speedingup of renewable energy across power generation, industry, buildings and transport will reduce energy prices over time and decrease the EU’s dependence on imported fossil fuels, according to the participants. Permitting procedures will be easier and faster under the new law.

The revised directive strengthens annual renewables targets for the heating and cooling sector and for renewable energy used in district heating systems. It introduces a specific renewable energy benchmark of 49% for energy consumption in buildings by 2030 to complement EU buildings legislation and guide Member States’ efforts.

The agreement establishes a target to reach 42% of renewable hy-

drogen in total hydrogen consumption in industry by 2030. The agreement also reinforces the regulatory framework for renewable energy use in transport (14.5% greenhouse gas intensity reduction or 29% share of renewable energy in final energy consumption).

The agreement strengthens the bioenergy sustainability criteria, in line with the increased climate and biodiversity ambition of the European Green Deal. In the future, these criteria will apply to smaller installations (equal or above 7.5 MW) rather than the 20 MW threshold under the current directive.

The agreement includes provisions to ensure that forest biomass is not sourced from certain areas with a particular importance from a biodiversity and carbon stock perspective. In addition, the agreed rules establish that woody biomass will have to be used according to its highest economic and environmental added value (cascading use). However, financial support will be banned for energy produced through the use of saw logs, veneer logs, industrial grade roundwood, and stumps and roots.

The provisional agreement requires formal adoption by the European Parliament and the Council. Once this process is com-

pleted, the new legislation will be published in the Official Journal of the Union and enter into force.

Major industrial wood pellet producer and exporter, Enviva, welcomed the news that the European Union’s trilogue negotiations concluded with an agreement on the Renewable Energy Directive III (REDIII) and that woody biomass will continue to be recognized as a renewable energy source in the EU.

Although the final text of the agreement has yet to be released publicly, Enviva understands that the agreement does not impose restrictions on “primary woody biomass,” which will be counted as 100% renewable, provided sustainability criteria are fulfilled.

Enviva notes that the agreement is also expected to include: Assurances that electricity-only plants already receiving subsidies will continue to do so, meaning Enviva’s existing off-take contracts are not expected to be impacted; continuing availability of financial support to electricity-only installations where Bioenergy Energy Carbon Capture and Storage (BECCS) is used; and the availability of financial support for all other end uses of woody biomass.

“The REDIII agreement is the last major step towards the end of an 18-month process that is now drawing to a favorable conclusion for the environment,” comments Thomas Meth, President and CEO of Enviva. “While there will be some conjecture over the coming weeks, based on information that we have received thus far, I am fully confident that the final text will enable our business to continue to support the EU’s journey to net zero and will strengthen the platform for Enviva’s growth, especially in light of current high carbon prices.”

Global renewable energy leader, Drax Group, also welcomed a positive conclusion of the REDIII discussions, noting the agreement recognizes the importance of sustainably sourced biomass within

the region, providing renewable, reliable power while displacing fossil fuels and supporting good forest management.

“Counterproductive and arbitrary proposals presented during the legislative process, such as a cap on the use of ‘primary woody biomass,’ have been rejected. These would have had serious consequences for EU’s energy security and forest health,” Drax stated. Continuing, “The agreement demonstrates the EU’s continued support for sustainable biomass and will strengthen sustainability standards to reflect good forest management practices and align with the cascading principle to ensure that wood is utilized to its highest economic and environmental added value.”

The updated directive reaffirms sustainably sourced biomass as a 100% renewable energy source, as well as includes provisions to ensure that biomass goes to the highest value application, including BECCS, in which Drax plans to become a global leader, according to Drax.

Canadian Minister of Natural Resources, Jonathan Wilkinson, announced a $35 million investment to Whitesand First Nation owned Sagatay Co-Generation Ltd. Partnership to deploy a combined heat and power facility using locally sourced wood waste to produce energy for the communities. Once constructed, the facility will reduce the use of diesel fuel for heat and electricity in Whitesand First Nation, and the communities of Armstrong and Collins, Ontario.

Once operational, the 6.5 MW facility will connect to the local micro-grid and provide power for the three communities, displacing diesel consumption and improving local air quality. The facility will power clean and renewable industrial growth in the region as the electricity generated will also pro-

vide heat and power to a new wood pellet plant and a fully electric wood merchandising yard.

“On behalf of Whitesand First Nation, I would like to personally thank Minister Wilkinson for Canada’s continued support for our Bio-Economy Centre project. Whitesand’s vision of energy independence and economic growth began in 1992 when we proposed a biomass cogeneration facility,” comments Chief Allan Gustafson of Whitesand First Nation. “Although that proposal was not accepted, and despite the many barriers we have faced through the years, we did not give up and today our vision of a sustainable future through the use of our local forest is at hand.”

The micro-grid currently includes an annual diesel consumption volume equivalent to more than 1.3 million liters. This initiative will reduce this rate while

driving down costs and emissions.

Federal funding for this project is provided by Natural Resources Canada’s Smart Renewables and Electrification Pathways (SREPs) program, a $1.56 billion program that provides support for smart renewable energy and electrical grid modernization projects, including projects that support capacity building.

This program will significantly reduce greenhouse gas emissions by enabling increased renewable energy capacity that will provide essential grid services while supporting Canada’s ongoing transition to a net-zero economy by 2050 as well as Canada’s commitment to achieving a 100% net-zero-emitting electricity system by 2035.

Natural Resources Canada previously provided $4,168,000 in funding for this project for pre-development work from the Clean Energy for Rural and Remote

Communities (CERRC), a $453 million program that strives to reduce reliance on diesel in rural and remote communities by deploying and demonstrating renewable energy projects, encouraging energy efficiency and building local skills and capacity. The program is part of the government’s Investing in Canada plan, a more than $180 billion investment in public transit projects, green infrastructure, social infrastructure, trade and transportation routes and Canada’s rural and northern communities.

The ReEnergy Black River $50 million 60 MW biomass power facility, which has been responsible for supplying all of the U.S. Army base Fort Drum’s electricity, was expected to close at the end of March.

The plant was known as “the largest renewable energy project in the history of the U.S. Army.” Black River relied on a contract with the New York State Energy Research and Development Authority (NYSERDA), but the agreement expires in May.

After the Climate Leadership and Community Protection Act was passed in 2019, bioenergy was not included in renewable energy resources.

“Although we enjoy strong local support, including our local state legislators, we were unable to se-

cure the support we needed from the State Legislature or Public Service Commission,” says ReEnergy CEO Larry Richardson.

“This will be a blow not only to our employees, but also to the many logging companies and mills that rely on the facility as an endmarket for their low-value wood that has no other use,” Richardson adds.

During most of April, employees were expected to perform layup activities so the facility is properly mothballed, and after that the facility’s bondholders will determine the future of the facility.

ReEnergy said that Fort Drum is expected to return to purchasing electricity from the regional electricity grid.

Some state lawmakers attempted to keep the Black River power plant at Fort Drum from closing by changing the state’s definition of renewable energy to

include the burning of wood, or forest biomass. But apparently the legislation stalled.

ReEnergy says it supports 300 direct and indirect jobs and spends $25 million annually as it buys wood chips and scraps.

In March Enviva Inc. received its construction permit from the Alabama Dept. of Environmental Management (ADEM) for its Epes plant under construction in Sumter County, Ala. The revised permit enables Enviva to build a state-of-the-art industrial wood pellet manufacturing facility at a brownfield site.

In 2020, Enviva acquired more than 300 acres of land on the coast of the Tombigbee River in Sumter County for its forthcoming Epes plant. The Enviva Epes site location resides on the former manufacturing site of a wood products company that had closed in recent years.

“Enviva is excited to repurpose a former business site and construct a brand-new state-of-the-art manufacturing facility, jumpstarting economic growth and bringing employment opportunities back to the community,” comments Thomas Meth, President and CEO of Enviva.

Enviva has been active in Sumter County since its initial assessment of the site in 2018. Enviva has partnered with local government, first responders, and the faith-based community to help fulfill unmet needs and provide empowering programming for families. Once operational, Enviva’s Epes plant will be one of the largest taxpayers in the county.

Enviva started preliminary construction of its fully contracted Epes plant in July 2022. The plant is expected to have a capacity of 1.1 million metric tons per year and is expected to be in service in 2024 and fully ramped in 2025.

Enviva issued a statement thanking the Mississippi Dept. of Environmental Quality’s (MDEQ) permit board for unanimous approval for the construction permit of Enviva’s Bond, Miss. facility. The permit was issued after an extensive review process that included a public comment period, a well-attended public hearing, and numerous public comments.

The proposed facility will be designed to produce 1.2 million oven dried tons (ODT) per year of wood pellets.

Once operational, the facility in Bond will support approximately 350 direct and indirect jobs.

City officials in Prineville, and Crook County, Ore. are one step closer to building a biomass power plant in

their central Oregon town after the U.S. Forest Service (FS) recently awarded a $1 million grant to the city and its Prineville Renewable Energy Project (PREP).

According to Prineville City Manager Steve Forrester, PREP is a proposed 24.9 MW biomass power plant that is anticipated to increase the pace and scale of ecological restoration activities in the region by reducing their cost and providing a sustainable renewable power source. If completed, the facility will provide a much-needed additional market for biomass hog fuel material coming off forest thinning and fire-reduction projects in the region and help make such projects more viable.

The $1 million grant is from the FS Wood Product Infrastructure Assistance Program will be used to fund continuing permitting and design work to move the project forward.

Event host Wood Bioenergy magazine has announced that the eighth Wood Bioenergy Conference & Expo will be held Tuesday-Wednesday, March 12-13, 2024, and once again in the Grand Ballroom North of the Omni Hotel in downtown At-

Wood Bioenergy Conference & Expo will again immediately precede the Panel & Engineered Lumber International Conference & Expo (PELICE), which will be held Thursday-Friday, March 14-15, also in the Grand Ballroom North. Both events are supported by Wood Bioenergy and Panel World magazines and Georgia Research Institute. Many exhibitors and attendees participate in both events.

The 2022 event will be remembered as one of the first conferences coming out of the pandemic, while the 2020 conference was one of the last in-person events as the pandemic hit. The 2022 conference featured 12 keynote talks from representatives of leading wood energy companies such as Drax, Enviva, Fram, Strategic Biofuels, and NovoPower, as well as representatives from several industry support organizations. Overall, 30 presentations were delivered, while 60 exhibitors showcased their technologies and supplies to 300 participants.

“As we head toward the eighth Wood Bioenergy Conference & Expo, it’s important that we emphasize our continued focus on wood-to-energy, wood-based fuels, woody biomass byproducts procurement and in-woods chipping,” comments Rich Donnell, event co-

ing that when our event ends, the participating companies and personnel walk out fully informed on the current state of wood bioenergy, on the latest technologies and on the industry’s trending forecasts, policies and issues.”

All exhibitors sign up as either Gold, Silver or Bronze sponsors. The sign-up process has begun, as has the solicitation of speakers and the development of the conference agenda.

For exhibitor information, contact Fred Kurpiel: fredkurpiel@ gmail.com.

For speaker and topics information, contact Rich Donnell: rich@ hattonbrown.com.

European Panel Federation reports that a new group of 14 EU trade associations including the providers of high-quality wood-based products, fiber-based, paper and board products and packaging, and renewable energy solutions, supported by EU forest owners and managers, has launched a coalition to present EU policymakers with an ambitious common vision leading toward a circular bioeconomy.

“Now, more than ever, is the time to embed into EU policy the circular bioeconomy as a fully integrated, resilient European value chain,” states the EPF news release. The coalition has made available a paper detailing common challenges, needs, and solutions (visit europanels.org).

Jointly, coalition members represent 3% of the EU’s GDP, €520 billion in turnover, and 20% of its manufacturing companies. They are an integrated part of the EU bioeconomy, using local renewablysourced materials, made and recycled in Europe, and using European technology. But their contribution could go much further. They hope to work with the EU institutions towards creating an enabling policy environment for their sectors to collectively reach climate change miti-

gation equivalent to 30% of EU annual CO2 emissions. In 2019, this figure stood at 20%.

The coalition’s ambition will require consolidating the EU’s global leadership as a provider of sustainable and competitive alternative solutions for today, and innovative opportunities for tomorrow. Europe’s wood and fiber-based value chains are widely considered a laboratory for the future circular bioeconomy.

“In order to be climate neutral by 2050, the EU needs to work with the coalition to accelerate the uptake of bio-products, encourage investments in green technologies for production processes and supply chains, and support a shift towards sustainable consumption while putting in place policies to boost the competitiveness of sustainable manufacturing industries,” the news release states.

The competitiveness of the overall European industry has been impacted by the energy crunch and issues related to the supply of strategic raw materials. Wood-based products, fiber-based paper and board products and packaging, and renewable energy solutions offer resilience and ensure European strategic autonomy and competitiveness

via the sustainable management of sources of valuable raw materials, and secondary raw materials and related technology.

EPF Chairman Martin Brettenthaler stresses: “EPF is proud to be part of this coalition using naturebased products to help realize Europe’s goal of net-zero climate neutrality. Wood-based panels are integral to this journey using sustainable materials for furniture, construction, packaging and in multiple everyday applications. As a European global champion in this field, we urge policy makers to work with us to place industry, especially the circular bioeconomy, at the heart of this social, economic and environmental transition.”

Huber Resources Corp. (HRC) announced the acquisition of certain assets of Compass Land Consultants, Inc. (CLC), which will grow and expand HRC and its Sewall Forestry and Natural Resources Consulting (SFNR) business globally in key service areas including timberland management, timberland appraisals, forest inventory

management, and forest modeling.

J.M. Huber Corp. (JMHC), parent company of HRC, has a long history of timberland management dating back to the 1940s, and HRC continues JMHC’s legacy of forest management through the stewardship of more than 1 million acres for clients throughout the U.S.

HRC’s full suite of forest management services include forest operations, management planning, sustainable harvest modeling, road building and maintenance, full service administrative and accounting services and timber harvesting and marketing. SFNR offers forestry and natural resource consulting services includes forestland appraisals, forest growth and harvest modeling services to aid clients with critical business decisions for current or future operations, land purchase due diligence and inventory analysis. Additionally, SFNR provides a variety of consulting services to its forestry clients including litigation support and market pricing and cost analysis.

CLC offers a heritage of value and stability, as well as a diverse suite of services important to investors, agencies, and landowners.

Mercer Holz broke ground in early March at its first Growing Forest – Growing a Future (GFGF) tree-planting event in Schierke, Germany. It was attended by Martin Stöhr, Managing Director of Mercer Holz; Wolfgang Beck, Senior Vice President of Global Wood Sourcing, Mercer Europe; and Bill Adams, Vice President of Sustainability & Innovation at Mercer. Mercer Holz was pleased to be joined by Deputy Mayor of Schierke Jens Weidlich, Michael Selmikat, forest ranger for the Wernigerode region and Thorsten Nothwehr from HOFOS.The journey to Schierke through the Harz stunned the attendees of the event: The landscape bears witness to the

enormity of the European spruce bark beetle devastation. “Merely five years ago, the Harz was verdant with healthy, green spruce trees,” Stöhr stated. “Today it is bare, with mere stumps and dead branches. As far as the eye can see, it bears the brutal effect of the bark beetle. Sure, if we left the area alone to regenerate from spruce cones, in 80 years there will be another forest. However, it will only be yet another spruce forest. We need mixed stocks to strengthen our German forests and restore it to a more natural state.”

The first seedlings mark the start of a multi-year tree-planting program to collaborate with landowners in Germany to reforest areas lost to climate change and the bark beetle epidemic. Through the program, Mercer Holz will provide participating forest owners across Germany with a careful selection of seedlings to help replenish their forests. In line with the recently released guidelines by the European Commission, the seedlings are of a mixed variety. The majority of forests in Germany are monoculture (spruce). Although the single variety forest stuns in its uniformity, it lacks the immunity to withstand pests such as the bark beetle and climate change events. The seedlings provided through the GFGF program are a diverse mix of trees, simultaneously increasing biodiversity, pathogen resistance and resilience, as well as providing cultural and recreational value to the German public.

Mercer Holz is the wood purchasing organization for Mercer International’s German operations: Mercer Rosenthal, Mercer Stendal, Mercer Torgau, and Mercer Timber Products. For more than 15 years,

Mercer Holz been supplying pulp mills and sawmills with large quantities of industrial wood, sawlogs and wood chips. In addition to supplying Mercer’s German mills, it offers industry-leading procurement, harvesting, and logistics services for third-party customers.

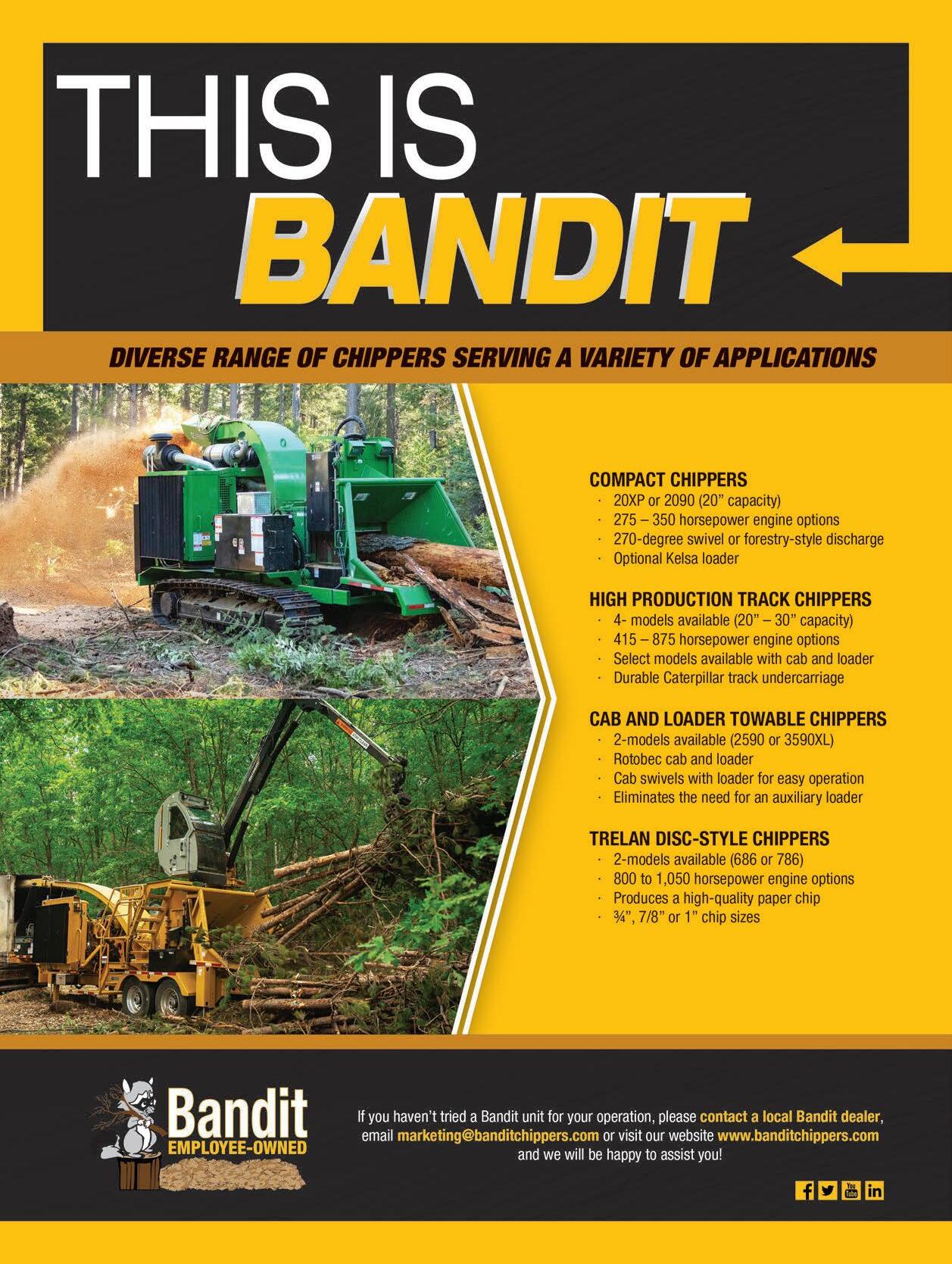

EDITOR’S NOTE: The following companies submitted these editorial profiles and images to complement their advertisements placed elsewhere in this issue. Please refer to those advertisements for web site and contact information. All statements and claims are attributable to the companies.

Bandit has manufactured whole tree chippers since 1988 and was the first to develop a self-propelled model. In 2005, Bandit expanded the whole tree chipper product line by producing a drum-style chipper, called the Model 2090. Since then, a complete line of highly productive drum-style chippers have been engineered. In 2021, Bandit announced the purchase of the Trelan company. Trelan has produced quality disc style chippers since the 1970s. This acquisition further enhanced Bandit’s line of whole tree chippers by now offering a diverse line of disc and drum style chippers.

How will a Bandit whole tree chipper make your operation more efficient? When original founder Mike Morey Sr. started Bandit, he was determined to build a quality chipper line built heavy-duty reducing customer downtime. Since 1983, this philosophy has not changed as each chipper is built with the highest quality components and steel. The drum inside each Bandit whole tree chipper is extremely durable. These drums feature reinforced knife pockets and thick drum skins to provide years of dependable service. To compliment this durable design each Bandit whole tree chipper is standard with a five-year or 3,000 hour “guts” warranty covering the Bandit manufactured components of the feed system and drum.

All Bandit drum-style chippers feature the patented slide box feed system. This system is known for providing unmatched pulling and compressing power reducing the need to reposition material simplifying feeding. The slide box feed system allows the top feed wheel to travel straight up and down providing direct down pressure as material is feed into the chipper drum.

When you need to go deep into the woods to grind you need to go prepared with a HogZilla track mounted tub grinder. HogZilla track mounted tub grinders come standard with a CAT engine, torque converter drive, available in models HTC-1464T and HTC-1462T, and offer unparalleled production and mobility.

A HogZilla on tracks saves hours a day mobilizing the grinder from pile to pile, allows for grinding in wet weather or on soft terrain, eliminates the need to build roads to get HogZilla moved and eliminates towing a truck and grinder on the job site, therefore saving hours a day resulting in increased production. Clean up around and under the grinder is easier, which in turn, reduces maintenance. Because the HogZilla on tracks is operated using a remote control, allowing for one-person operation, the loader/excavator operator can stay in the cab while moving the track mounted HogZilla to different locations using remote control.

CW Mill Equipment Co., Inc. has been manufacturing track mounted tub grinders for over 20 years. A HogZilla tub grinder on tracks is one of the most rugged, heavy-duty track mounted machines on the market.

But what happens when you are back at the yard? You need a reliable, monster grinder there, too. Our most popular model the TC-1564P will out grind all the others when you need production at the highest! CW has been building grinders for over 40 years now and the TC remains the gold standard when it comes to grinder orders.

Whether it’s a HogZilla on tracks or a portable model on wheels, HogZillas were designed for performance, built for reliability, and have been proven on the toughest jobs with years of service. CW Mill is always looking ahead to see what can be improved for our customers, each HogZilla is built custom, how the customer wants. CW believes in service after the sale; HogZilla customer support and parts availability are top rated in the industry!

In-wood harvesting is one of the fastest and most economical ways to generate needed biomass feedstocks for processing facilities. Transportation of these feedstocks can be challenging from the field to the plant. They need a trailer built for both blowing the materials into the trailer as well as offloading at the factory.

Building the trailer to be tough enough to handle rough trails/roads yet light enough to maximize the payload for each trip is imperative. Racking back and forth while fully loaded puts the greatest strain on the trailers. Adding components to the trailer that adds to the trailers’ rigidity as well as well as not taking away from payload, is critical to maximizing profits.

Hallco has been building live floors unloading systems for nearly five decades. Our expertise in the wood and biomass industry allows our systems to marry perfectly with your trailers. Our self-contained drive frame and 2 in. x 1 in. subdeck adds nearly 30% additional rigidity to a trailer, helping to minimize trailer fatigue from racking.

Choosing the right floor slat profiles are also key to ensure a long life of your trailer and floor systems. Hallco offers standard slats in 1/8 in., 3/16 in. (industry standard), 7/32 in., 1/4 in., and 3/8 in. thick. When specifying a trailer, you choose the floor with the least amount of cost and weight while providing the longest life of the floor. The Hallco 3/16 in. has been the choice of the wood industry for decades. Married to our I-4000 3 in. drive unit capable of 35-ton capacity, you have the prefect combination for any woody biomass haul.

Trust your trailer unloader to the company that has 50 years of experience and the service team that is there to back it up. Proudly made in the U.S. Hallco systems have a standard two-year warranty. Three-year warranty available with the installation of a high-pressure hydraulic filter prior to the trailer going into service.

Every Morbark drum chipper is designed for high-volume biomass production, and we know from decades of experience that durability and reliability are critical to every chipping operation. That’s why the heart of our 50/48, 40/36, and 30/36 whole tree chippers is our Advantage 3 Drum which produces more consistent chips, while the heat-treated AR-450 drum skin provides longer wear life resulting in lower replacement costs and less downtime. In addition, our feed system is more efficient due to a staggered knife configuration and contains fewer moving parts, reducing maintenance. The Advantage 3 Drum assembly can come as 10 knives for fuel chips or 20 knives for micro-chip applications. A directional flow discharge chute is hydraulically adjustable by remote control for maximum chip loads. And an aggressive, sloped live floor and large top and bottom feed wheels ensure positive feed or brushy tops and limbs.

Recently, we had the opportunity to spend time with customer John Robbins, Falling Oak Timber, located in Lexington, NC, who runs five crews supported by four 40/36 and one 50/48 whole tree drum chippers, to find out why he chose Morbark whole tree drum chippers for his operation.

“I’ve owned Falling Oak Timber since January 2014. We started with one skidder, one loader, and no trucks, and we have grown our company with enough equipment to run five crews, and our plan is to continue to grow,” Robbins explained. “We’ve tried other brands, but the Morbark chipper is more robust and durable, and it’s just so much better in the woods for our production. I can remember thinking while demoing my first 40/36, ‘That’s the way to go!’ So we bought the machine, and I instantly started hoping that one wouldn’t be enough.”

“Our whole tree drum and disc chippers have long been the industry standard for high-production, in-woods fuel chip and micro-chip applications,” added Michael Stanton, Morbark’s Vice President of Sales and Marketing. “The reason behind this longevity is our focus on minimizing downtime, increasing production, and a commitment to overall customer success. This commitment’s proof can be seen daily through customers like John Robbins, who inspire us to achieve more daily.”

Peterson drum chippers are a reliable and consistent solution for biomass producers seeking to capitalize on the growing demand for renewable energy sources. With the ability to process a wide range of feed material, including brush, small feedstock and logs up to 24 in. in diameter, the Peterson 4300-series of drum chippers is ideally suited for high-volume producers.

These drum chippers use heavy-duty knives to produce cleancut edges and more consistent product sizes than ground material. They can yield chips from 1/8 in. to 1 1/4 in. (3-31 mm) depending on the rotor and knife configuration. This dynamic size range allows for increased profit potential by allowing producers to explore multiple biomass application possibilities.

The 4300-series features a hydraulic clutch, sloped feed deck for ease of feeding the chipper and wear-resistant AR 400 wear surfaces on the drum pockets and shell. Further enhancements are available, including optional material sizing grates to provide greater filtration of twigs and a chip accelerator to pack wood chips tightly, ensuring maximum load capacity and increased efficiency. These enhancements can be of great benefit in biomass production, when it is important to maintain product consistency by limiting fines and spears, which can cause material blockages.

The 4310B is a highly mobile and versatile machine that can be used in various settings. Mounted on a tracked undercarriage, it can be easily transported and positioned on-site, even in difficult terrain and remote locations. The mo-

bile version is available with end-load or top-load spouts for loading trailers.

Production from Peterson drum chippers will vary depending on the wood species, chip length and tree size. Typical production from a 4300-series machine with a six-pocket drum making 7/8 in. length chips is approximately 80 tons per hour. Microchip production making .25 in. (6 mm) chips with a 12-pocket drum will yield about 50 tons per hour.

When it comes to material handling machines for wood processing industries, the Sennebogen purposebuilt 830 M-T is a 91,000 lb. (41,400 kg), 225 HP (168 kW) front-runner. It’s a machine built specifically for log handling and trailer-pulling applications. A specially reinforced undercarriage features dual transmissions, providing powerful 4-wheel traction to handle the stresses of pulling heavy log trailers loaded with up to 64,000 lbs. through muddy yard conditions.

Its high-stacking capability instantly increases your operation’s capacity and simplifies inventory management. The compact footprint with stable 360˚ lift radius allows efficient loading and faster mobility between tight rows. The exclusive Maxcab elevating operator station allows a clear view to the top of infeed decks, trailer loads, and log piles for accurate, smooth loading and sorting. It offers a wealth of features that are ideal for a variety of businesses, including biomass:

l Efficient infeed of logs and bulk materials for chippers and grinders

l Sorts material and loads conveyors for energy production

Whatever your operation needs, a Sennebogen 830 M-T can make a big difference, especially when it comes to uptime. The HydroClean 3-micron filtration system cleans hydraulic oil with 99.95% efficiency to protect hydraulic components from contamination by water or particulates, and extends oil change intervals. Special engine mounts isolate vibration, leading to less wear on components as well as lower sound levels. Intelligent cooling technology with fast, large-dimensioned reversing fans extend machine life in tough environments. It all adds up to productivity.

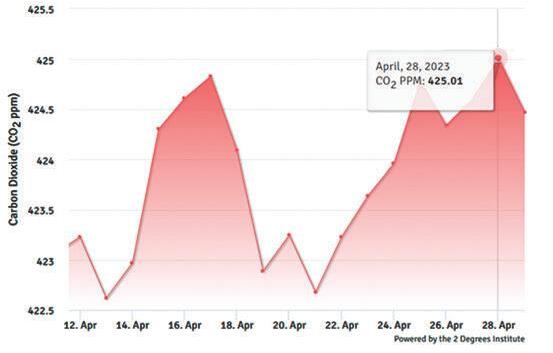

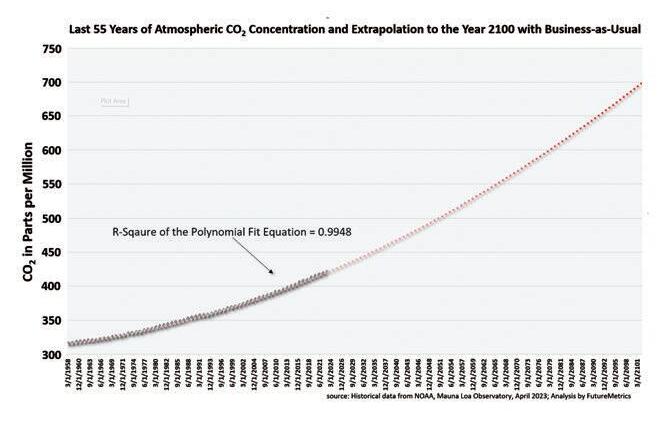

Atmospheric concentrations of carbon dioxide (CO2) hit another record high on April 28, 2023, of 425.01 parts per million (ppm). The implications are dire. This white paper makes it clear that urgent meaningful action on carbon emissions policy is needed.

Figure 1 below shows CO2 concentrations in the atmosphere over the past 800,000 years. The temperature variations from the long-term average over that span of time are also on the chart (black line). When historical CO2 levels rose rapidly due to natural forces, temperatures spiked until CO2 levels dropped.

mum CO2 levels, it begs the question: Will the resulting rise in temperature be significantly higher this time? The likely answer is yes!

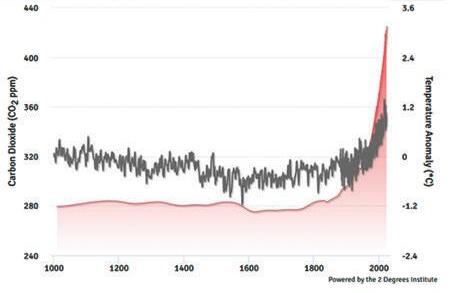

As Figure 2 below shows, CO2 levels for the last 1000 years had plateaued at an average of around 280 ppm. Over the past 150 or so years, CO2 levels have risen at rates and to levels that are nowhere to be seen in the historical record that includes humans and their ancestors.

The red line at the far right shows an extremely rapid rise in CO2 concentration to unprecedented levels within an unparalleled short span of time. Given historical temperature responses to much lower maxi-

CO2 is called a “greenhouse gas” because, just like the glass or plastic roofs in greenhouses, CO2 prevents solar energy in the form of heat from escaping back into space. The relationship between higher atmospheric CO2 levels and less solar energy escaping is a scientific fact.

The impact of the rapid increase in atmospheric CO2 levels is that the atmosphere and the oceans are storing more heat. The rate of increase is extremely rapid. The complex nonlinear feedback loops that govern

ecological equilibrium make it very challenging for most people to understand the dynamics that are causing the climate chaos that is already unfolding. And linear systems do not govern how the earth’s systems work.

“Linearity is a trap. The behavior of linear equations is far from typical. But if you decide that only linear equations are worth thinking about, self-censorship sets in. Your textbooks fill with triumphs of linear analysis, its failure buried so deep that the graves go unmarked and the existence of the graves goes unremarked. As the 18th century believed in a clockwork world, so did the 20th in a linear one.”—Ian Steward, Does God Play Dice? The Mathematics of Chaos, 1989.

Complex models using massive computer power produce climate forecasts. A precise forecast of the future climate due to the rapid changes in climate forcing inputs is challenging. But there is no lack of consensus: If we keep doing what we are doing, the future will not be what we want it to be.

Zooming in on the last few months of data, Figure 3 below shows the new record high in CO2 levels reached just two days ago (this paper was published on May 1, 2023). This is not the first new record high in 2023. There have been several including the April 17 high shown in the chart. And it is likely that there may be more as 2023 unfolds because previous peaks in the seasonal cycle have been in May.

gas) has caused the carbon in those fuels to be converted into CO2 during combustion. That carbon was originally captured over a very long geological span by the natural balance between plants and air breathing organisms. Over many millions of years, much of the dead biomass transformed from carbohydrates into hydrocarbons that became part of the earth’s geology.

We are now releasing millions of years of captured carbon over a span of hundreds of years. The impact on earth’s systems is highly disruptive and the consequences are and will be negative.

When emissions cause negative consequences, they are called pollution. Many of the byproducts of industrialization have been regulated to preserve a healthy environment. Some pollutants were early to be regulated because they produced obvious dirty air and dirty water that had a direct impact on quality of life. The impacts of some pollutants are more “in your face” than others. Higher carbon dioxide levels have no direct sensory input to humans. There is no sensory perceptible signal to respond to! Without data and analysis, the link between CO2 emissions and the more frequent and more extreme weather resulting from climate change would not exist.

But even without the alarms being sounded by most climate scientists, it is becoming more obvious now that CO2 emissions are creating “in your face” consequences. The signal that is becoming perceptible to even those that cannot grasp the complexity of earth systems science (or are in willful denial) is not dirty air and water; the signal is the rapidly increasing cost of doing business-as-usual in a world in which the probability of adverse unpredictable events is increasing rapidly.

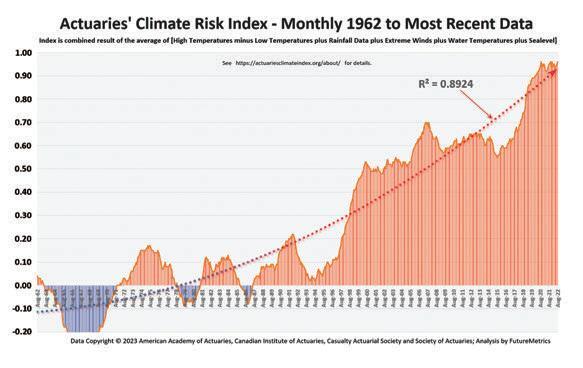

Figure 4 below is produced by the experts that quantify risk for insurance companies. Higher risk means higher insurance cost. The higher the insurance cost, the higher the cost of doing business. This is a direct threat to profits and the viability of some firms. Depending on the degree of dependence on fossil fuels, the already increasing risk

This new high of 425 ppm is approximately double the average over the last 800,000 years and about 125 ppm higher than the highest peak in that time span. It is not volcanoes, sun cycles, or any other natural influence that is causing this change in CO2 concentration. It is the use of fossil fuels.

Mining minerals, including hydrocarbons, is part of how humans have created the civilization we enjoy. But we are at a hydrocarbon turning point that could not be

Over the past 150 or so years, the use of petroleum, coal, and methane (commonly referred to as natural

premium from the consequences of climate change will have a multiplier that is greater than one for those exposed to the uncertainty of the fossil fuel future.

So, there is growing business-related pressure for somehow mitigating the impacts of climate change. The BIG question is can that pressure and the overwhelming and compelling scientific forecasts about the dire consequences of unfettered rapid climate change translate into meaningful action. Before this white paper concludes with thoughts on that critical question, it will review a few more charts to help those with a lingering hesitancy to grasp the need for urgent action.

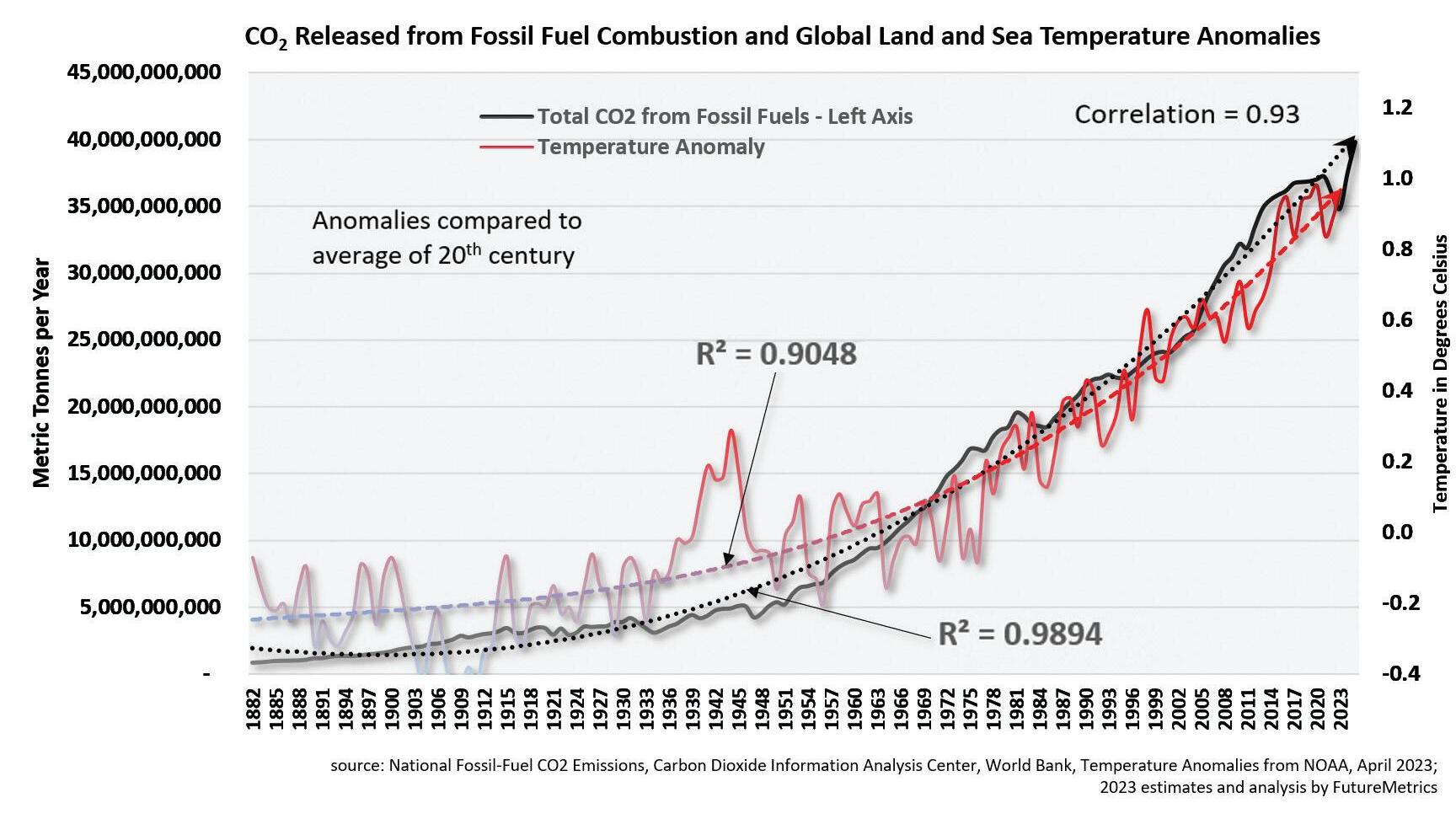

Figure 5 below shows the rapid exponential increase in the tonnes per year of CO2 from fossil fuel combustion. Plotted with that time series is the NOAA data on land and sea temperatures.

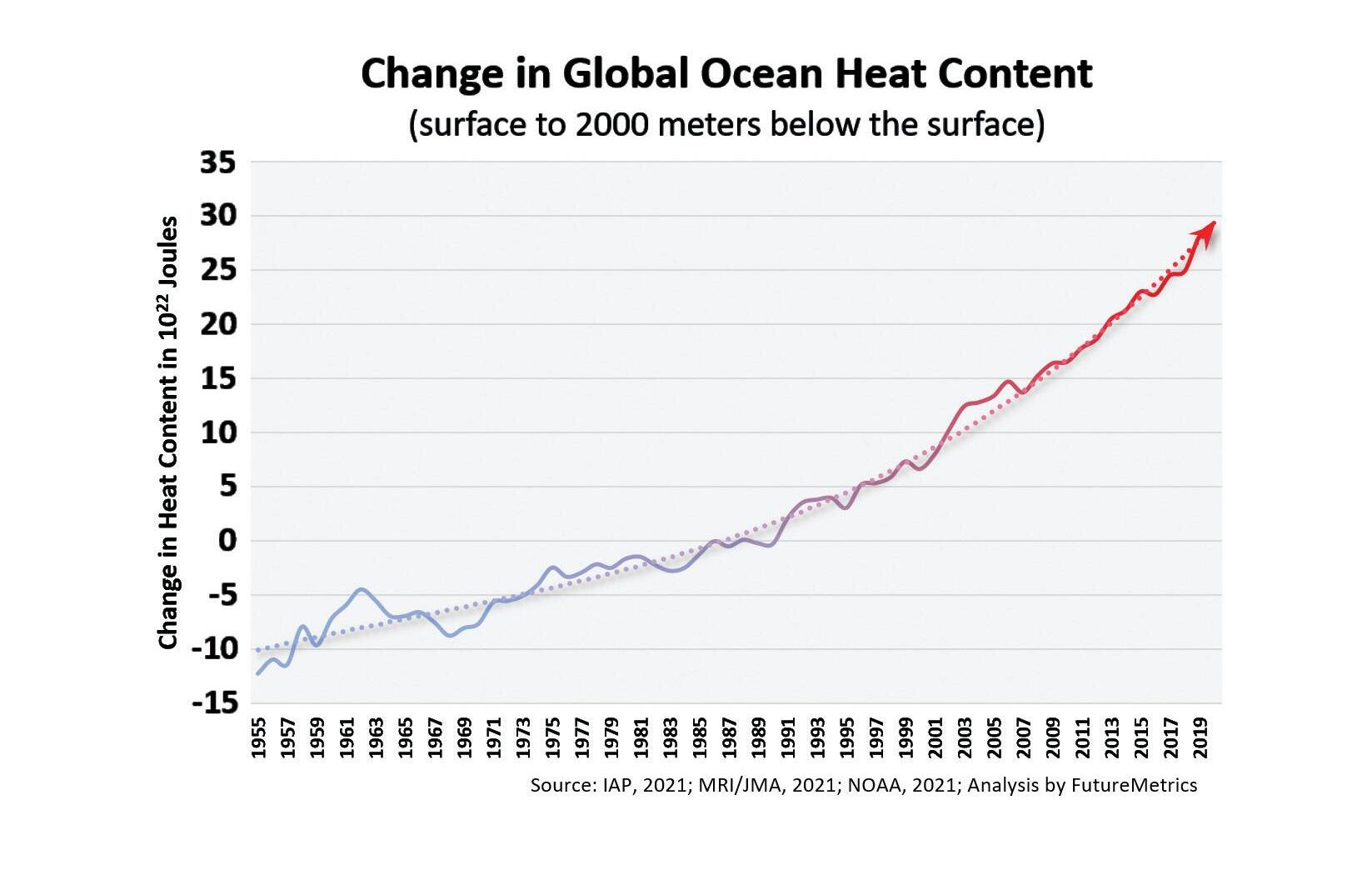

The only significant dip in CO2 emissions (the black line) was from the economic shock induced by the Covid-19 pandemic. The increasing amounts of CO2 pollution have a high correlation with the increases in land and sea temperatures. It is not just weather and the increasing frequency of so-called black swan weather related events. The oceans are changing rapidly and with very dire consequences. Figure 6 below shows the

average of three time series that are measuring the total energy content of the oceans.

For context, the increase in heat stored in the oceans in 2020 of about 29.3 x 1022 joules equals the energy in 69,878,928 one megaton hydrogen bombs. Warmer temperatures and higher atmospheric CO2 are changing the ocean’s acidity. Figure 7 shows how pH has steadily decreased (increasing acidity) while the concentration of free CO2 in the seawater has increased.

The impacts are as follows:

“When CO2 is absorbed by seawater, a series of chemical reactions occur resulting in the increased concentration of hydrogen ions. This increase causes the seawater to become more acidic and causes carbonate ions to be relatively less abundant.

“Carbonate ions are an important building block of structures such as seashells and coral skeletons. Decreases in carbonate ions can make building and maintaining shells and other calcium carbonate structures difficult for calcifying organisms such as oysters, clams, sea urchins, shallow water corals, deep sea corals, and calcareous plankton.

“These changes in ocean chemistry can affect the behavior of non-calcifying organisms as well. Certain fish’s ability to detect predators is decreased in more acidic waters. When these organisms are at risk, the entire food web may also be at risk.

“Ocean acidification is affecting the entire world’s

oceans, including coastal estuaries and waterways. Many economies are dependent on fish and shellfish and people worldwide rely on food from the ocean as their primary source of protein.”—NOAA

Finally, a critical question: What could be the consequences of a failure to curtail the combustion of hydrocarbons and to take action to remove CO2 from the atmosphere?

Figure 8 is a simple time series best fit equation that is allowed to generate values to about the year 2100. The complexity of the earth systems and the fact that fossil fuels are a depleting resource that probably will not be mined in sufficient quantities to match the quantity needed to get us to over 700 ppm means that the future shown in the chart seems unlikely. However, the trajectory we are currently on would get us there if there were no limits to the growth of fossil fuel use and policy totally fails.

Imagine our climate under those conditions. Imagine sterile oceans. Imagine the chaos that sits between now and that dismal future.

So far, the aggregate global response to this clear and present crisis has been poor. Perhaps there is too much inertia:

“And it ought to be remembered that there is nothing more difficult to take in hand, more perilous to conduct, or more uncertain in its success than to take the lead in the introduction of a new order of things. Because the innovator has for enemies all those who have done well under the old conditions, and lukewarm defenders in those who may do well under the new. This coolness arises partly from fear of the opponents, who have the laws on their side, and partly from the incredulity of men, who not readily believe in new things until have had a long experience of them. Thus it happens that whenever those who are hostile have the opportunity to attack, they do it like a partisan, whist the others defend lukewarmly” (Machiavelli, 1515, p. 27).

But perhaps the increasing cost signals from the markets will turn the tide. Perhaps leaders in business and those in political power will value critical thinking skills, fact-based decision making, and put pragmatism over opportunism.

Darwin’s simple message holds the key:

“It is not the strongest of the species that survive, nor the most intelligent, but the one most responsive to change.”

Maybe those leaders resisting change will realize that they are on the wrong side of history.

“Heavier than air flying machines are impossible.” (Lord Kelvin, Royal Society, 1895)

“There is no likelihood that man can ever tap the power of the atom. The glib supposition of utilizing atomic energy when our coal has run out is a completely unscientific Utopian dream, a childish bug-a-boo.” (Robert Millikan, Nobile Laureate, Physics, 1923)

“There is not the slightest indication that nuclear energy will be obtainable.” (Albert Einstein, 1932)

showed up for the ceremony and spoke at the event.

2023 marks Bandit’s 40th anniversary and much of its success is contributed to quality products, dealer network, loyal customer base, and their dedicated hardworking employees.

companies and hundreds of individual lumber, veneer, plywood, engineered wood products and wood pellet mills registered for the 2022 TP&EE. They viewed 170 exhibitor companies who displayed their equipment and technologies in a sold-out Hall E.

Bandit Industries, Inc. celebrated the acquisition of a facility in Mount Pleasant, Mich. with a ribbon cutting ceremony on April 5. This facility formerly owned by Burch Tank is situated on 24 acres with 60,000 sq. ft. of manufacturing space.

“These buildings and this property will be so instrumental in growing our company as we continue to ramp up to meet the growing demand for our products,” stated Bandit CEO Jerry Morey during the ceremony.

One goal of this location is to draw employees from a farther distance away to accommodate the current need for new employees. The proximity to the highway also serves as a convenience for accessibility.

The location includes Bandit’s electrical team, consisting of wiring harnesses for all Bandit products. Components for the whole tree chipper and horizontal grinder product lines also are produced at this new location. Future plans include moving the rebuild department from the main headquarters. The rebuild department specializes in the refurbishment and service of existing Bandit machines.

“The primary facility of this site is ideal for producing one of our major product lines,” Morey adds. “We will be adding a new paint room before we move a line here.”

A variety of attendees ranging from Bandit employees, community members and elected officials

Bandit became an employeeowned company (ESOP) in 2018. During his speech, Morey briefly talked about how Bandit became an ESOP: “We initially looked at selling to another manufacturing company and then an investment banking company, but backed out of those offers over concerns for our employees and the future of the company.”

Over the next couple of years, Bandit will likely need an additional 200 employees and hope to fill 95 open positions by the end of 2023.

In addition to the new Mount Pleasant facility, Bandit invested an additional $14 million throughout 2022 conducting several expansions at their main campus nearby at Remus, Mich., including adding an 80,000 sq ft. steel room featuring new cutting and machining equipment and robots. Once added together, the total manufacturing space across all Bandit locations equals 560,000 sq. ft.

Hatton-Brown Expositions LLC announced that the next Timber Processing and Energy Expo (TP&EE) will be held September 25-27, 2024 at the Portland Exposition Center in Portland, Ore. The 2024 show will be the sixth biennial TP&EE to be produced since 2012 by HattonBrown Expositions, LLC, an affiliate of Hatton-Brown Publishers, Inc. and of Timber Processing, Panel World and Wood Bioenergy magazines. All of the TP&EEs have been held at the Portland Exposition Center. The 2020 event was canceled due to the pandemic.

More than 1,200 representatives of 112 wood products producer

While the show has traditionally emphasized lumber manufacturing, the 2022 event revealed increasing attendance from the wood-to-energy industries, and since the 2022 show, several announcements have emerged indicating a growing wood biomass industry in the Northwest, including several planned wood pellet facilities. This means that the 2024 event should truly live up to its Timber Processing & Energy Expo billing!

“We realize that the city of Portland continues to receive negative publicity for various reasons, but in the end the Portland Expo Center remains the best site because of its spacious equipment staging and move-in capacities—compared to other facilities we’ve looked at—as well as its centralized location for the Northwest forest products industry,” comments Show Director Rich Donnell.

The 2024 first stage of the TP&EE exhibitor space renewal program has begun. For exhibitor information, contact Jessica Johnson: jessica@hattonbrown.com.

Canada-based biomass carbonization technology provider Airex Energy Inc. has announced it has concluded a Series B funding round valued at $38 million Candian, which Airex Energy states will fast-track its growth initiatives, including a Québec biochar project tying in with its partnership with France-based environmental quality developer Suez, which aims to significantly boost biochar production in Europe and North America by 2035.

Led by Canada-headed “clean-

tech” venture capital and impact investor Cycle Capital Management, the most recent round welcomed the FTQ Fonds de solidarité, which joined the syndicate of existing investors including Investissement Québec, Desjardins-Innovatech, Export Development Canada (EDC), and Cycle Capital.

With proprietary technology Airex Energy produces biochar, which sequesters carbon in the ground and in other materials; biocarbon, which is used to produce green steel and other metals; and biocoal, an environmentally friendly fuel and coal replacement.

“From the outset, we have been convinced of decarbonization’s potential, particularly in polluting industries, as well as of Airex’s patented technology. As we get ready to launch the large-scale commercialization of biochar and biocoal, we look forward to con-

tributing to Airex’s growth, alongside Airex’s team, strategic partners such as Suez, and renowned investors like the Fonds de solidarité FTQ, Investissement Québec and Desjardins,” notes Andrée-Lise Méthot, Founder and Managing Partner of Cycle Capital.

Forest Pro, Inc., a logging equipment dealership in Virginia, is partnering with DEVELON, formerly Doosan, to begin offering heavy equipment at its three locations: Scottsville, Manquin and Keysville. All three locations will feature the full line of DEVELON construction equipment, including crawler, wheel and mini excavators, wheel loaders, dozers and articulated dump trucks, for general contractors, landscapers and loggers.

Each location also provides parts and service for its customers.

Joel Matteson, general manager at Forest Pro, Inc., says, “Our company has been serving logging customers for over 30 years and continues to provide the highest level of customer service available in the forestry industry. We look forward to the future and to building strong relationships with customers and the community.”

Forest Pro employs 40 experienced sales, parts and service staff at the three locations.

As part of Combilift’s celebrations for its 25th anniversary, the Irish materials handling specialist has announced that it is donating its 75,000th truck—an Aisle Mas-

ter articulated forklift—to Convoy of Hope, a non-profit humanitarian and disaster relief organization.

Convoy of Hope works alongside communities and its wide network of volunteers aims to alleviate poverty and hunger and to bring help and hope wherever they are most needed in the world. As this type of aid is sadly always in demand, operational expansion has also seen a corresponding increase in the requirement for warehousing capacity to accommodate the vast volume of supplies that are stored and ready for delivery to areas in need.

The World Distribution Center is based in Springfield, Mo., and from this location at the “Crossroads of America” truckloads of relief supplies and food are sent on their way across the USA and further afield around the globe.

Combilift supplied its first Aisle Master for this site four years ago, and a further three units were delivered last year.

The announcement was made at a gala dinner in Chicago during the ProMat trade fair, and Combilift CEO and Co-Founder Martin McVicar commented: “The work that Convoy of Hope does is invaluable to relieve suffering around the world and we wanted to make our own contribution by donating our 75,000th truck to this very worthwhile charity.”

ensures reliable detection of ignition sources in the visible or infrared light wavelengths, even in the presence of dense material flows. The SD300-EX also features a 180° wide field of view, ensuring no blind spots, potentially resulting in a reduction in the quantity of detectors required.

Spark Detection and Extinguishing System by IEP Technologies has recently received third party approval by Factory Mutual (FM), meeting the detailed requirements of the latest version of FM 3265:2020 examination standard for spark detection and extinguishing system.

The National Fire Protection Assn. (NFPA) specifies that spark detection and extinguishing systems are subjected to third party testing and certification before being put into operation. By selecting an Atexon system with FM approval, users can be reassured that all the required testing and examination has already been conducted by a globally established, nationally recognized testing laboratory.

A key component in the Atexon System is the innovative SD300EX series spark detector, which

For certain applications, they can be mounted without the need for welding, providing more installation cost and time efficiencies. These detectors feature corrosion resistant stainless steel (AISI 316L) housings.

Alongside gaining the globally recognized FM approval, the Atexon system also recently underwent an overall design upgrade, providing users with even more application, operational and installation benefits.

Visit ieptechnologies.com

TerraSource Global’s flagship brand, Jeffrey Rader offers a wide range of versatile equipment and solutions for various industries, including several stages of woody biomass processing—with equip-

ment in operation by companies such as Weyerhaeuser, Dominion Energy, West Rock, GE Energy, and International Paper.

The wood hogs, re-chippers, grinders efficiently process log ends, branches, stumps, overs, and a variety of other material variants into smaller, more manageable pieces.

The EnduraHogs product line is a pioneer with its innovative housing and service-focused design. The product’s ultra-large access doors make maintenance quicker, safer, and more efficient, without sacrificing its high-performance and durability. This feature allows for easy access to hammers, rotors, and liners, ensuring timely routine maintenance and minimal downtime.

Beyond the Classic model used for wood and biomass materials are the SuperSlugger and ChipSizer models. The SuperSlugger is the best choice for sizing large wood infeeds such as railroad ties and timber because its rotor incorporates heavier and wider hammers. Its swing hammer design, unlike solid rotors, helps minimize damage when uncrushable material, such as steel, enters the machine.

While the first true no-knife rechipper, The Chip-Sizer employs a “soft touch” semi-swing technology to precisely control the size of the wood chips. This innovative technology enables higher recov-

ery rates and tighter top-size control, making the Chip-Sizer unique from other machines in the market. Because they utilize specialized chipping hammers rather than knives, no sharpening is required, which extends and optimizes maintenance intervals and minimizes downtime.

Jeffrey Rader’s screening equipment separates wood and biomass from other debris like rocks and soil. The Jeffrey Rader Disc Screen (RDS) is the industry’s undisputed workhorse and removes oversized rejects from unscreened wood chips, hog fuel, or bark.

The Raderwave Fines Screen offers maximum fines removal while saving valuable fiber, even under fluctuating conditions. While, the DynaGage provides high-capacity chip thickness screening without rotating wear surfaces.

Overall, TerraSource Global’s Jeffrey Rader products offer efficient and effective processing equipment that can handle a variety of wood and other biomass materials, streamlining your operations.

Valmet will be converting Helen Ltd.’s coal-fired district heat boiler to bubbling fluidized bed (BFB) combustion to enable wood pellet firing at the Salmisaari ‘A’ power

plant in Helsinki, Finland. The conversion promotes the company’s goal of phasing out coal, while at the same time strengthening the construction of a sustainable energy system.

“Our goal is carbon-neutral energy production in 2030. Sustainable bioenergy is part of the overall solution to achieve our goal. The versatile production structure ensures reliability of heat supply even in freezing weather. This project is an important step for us on the way to carbon neutrality. We trust Valmet’s abilities to complete this demanding project on time,” says Juhani Aaltonen, responsible for Helen’s sustainable energy solutions.

The project is a continuation of other projects the two companies have completed. Most recently, in 2018, Valmet started-up a 92 MW pellet-fired heating plant at the Salmisaari power plant area, and later this year the heat recovery plant belonging to the Vuosaari bioheating plant will be completed.

This order is included in Valmet’s orders received of the second quarter 2023, and the converted boiler will be handed over to Helen in January 2025.

“Converting an existing coalfired boiler to biofuel combustion is a quick and cost-effective way to transition from fossil to renewable fuels,” says Niina Ollikka, Director, Energy Business Unit, Rebuilds and Conversions, Valmet.

Valmet’s turn-key delivery includes a fuel conversion from pulverized coal to wood pellets on a hot water boiler. It will be modified to a bubbling fluidized bed boiler with a fuel capacity of 150 MW.

The delivery includes a flue gas cleaning system and a heat recovery system and modification to the Valmet DNA automation system, as well as all necessary auxiliary systems. After the conversion, the plant will produce district heat with extremely high efficiency— the flue gas temperature at the stack will be only 13° C.