High-quality solutions for powder coating ... we have everything covered SEPTEMBER 2022 read online www.surfaceworld.com – follow us on twitter @surfaceworldmag – visit www.surfaceworld.com 4th & 5th October 2023 NEC, BIRMINGHAM www.surfaceworld.com

Welcome to the SURFACE WORLD team!

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com / nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com / janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus

e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus

e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House

2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd.

Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2022 ISSN 1757-367X

COMPANY SPOTLIGHT

EQUIPMENT MODERNISATION PROGRAMMES E.M.P. 4

QUALICOAT UK & IRELAND WHY SPECIFY QUALICOAT FOR RESIDENTIAL INSTALLATIONS? 8

BRITISH SAFETY COUNCIL INTERNATIONAL SAFETY AWARDS LAUNCHED FOR 2023. 12

SURFACE ENGINEERING ASSOCIATION (SEA / BSTSA) THE VOICE OF THE SURFACE ENGINEERING INDUSTRY, REPRESENTING THE COMPANIES WITHIN IT. 16

SURFACE WORLD 2023 10 GREAT REASONS TO EXHIBIT AT SURFACE WORLD 2023. 18

INDUSTRY NEWS BASF COATINGS INAUGURATES NEW ELECTROCOAT RESEARCH CENTER. 20

OLDFIELD APPOINTMENT STRENGTHENS SENIOR TEAM AT BOROUGH. 22 MICHAEL HANSEN TO SUCCEED LARS PETERSSON AS CEO OF HEMPEL A/S. 24 FISCHER INSTRUMENTATION (GB) OPEN NEW CUSTOMER APPLICATIONS & SUPPORT CENTRE. 28

FRASER TECHNOLOGIES SUPPLIES PIONEERING MIELE PROFESSIONAL AQUEOUS CLEANING SYSTEM. 30 COLOURFUL CAREERS IN COATINGS WITH HMG PAINTS. 32 NEW DIGITAL SOLUTION FROM INTERPON. 36

AVIATION & AUTOMOTIVE SOLVING THE VARIED CLEANING TASKS EFFICIENTLY AND SUSTAINABLY. 38

OVENS, SPRAYBOOTHS & PROCESS HEATING

BURN OFF OVENS OFFER EFFECTIVE PROCESS. 42 LANEMARK IN-HOUSE PROCESS GAS BURNER TEST FACILITY. 44

HAVILAND LIMITED - MANUFACTURERS AND INSTALLERS OF PRETREATMENT AND FINISHING SYSTEMS. 46 SIX AREAS OF ENGINEERING EXPERTISE. 50

PAINT & POWDER

ELCOMETER 415 COATING THICKNESS GAUGES FOR INDUSTRIAL AND POWDER COATINGS. 52 E-BOOTH COLORX SERIES. 54 FENTON PACKAGING SOLUTIONS HELPS SILBERLINE TO REDUCE ITS CARBON FOOTPRINT. 56

PURMO GROUP UK GOES GREEN. 58

HEMPEL COATS 3000 SHIPS WITH HEMPAGUARD. 60 XMAKE UK DEFENCE WELCOMES UK’S LEADING INDEPENDENT PAINT MANUFACTURER. 62

INTERPON COATINGS SUPPORT ESSE. 64 FIT OUT UK CHOOSE METAVATE. 66

PRODUCTS & PROCESSES

GENERAL PURPOSE INDUSTRIAL SOLVENT CLEANERS. 68

NANOINDENTATION FOR DLC COATINGS. 69

NAUTICAL CENTREPIECE COMPLETED. 71

MATERIAL & EQUIPMENT SUPPLIERS 72

TRADE FINISHERS 79

1SEPTEMBER 2022 CONTENTS

SEPTEMBER 2022 - VOLUME 29 - NUMBER 9 twitter: @surfaceworldmag Specify QUALICOAT for all your architectural aluminium powder coating requirements qualicoatuki.org

Spray Booth Cost Per Cycle 2020 Oct 2022 Standard Spray Booth £10.23 £36.57 Junair EcoPlus Spray Booth £2.92 £10.39 SAVING £7.31 £26.18 01706 363555 sales@junair.co.uk www.junair.co.uk how will you navigate the energy crisis? Figures have been calculated in partnership with ECA Business Energy and can be provided on request. Switching to a Junair EcoPlus spray booth would save £31,427 per year in energy based on a typical spray booth running 25 cycles per week. Your investment would pay for itself in less than 2 years. Can't afford to invest? You can't afford not to!

Straaltechniek UK Shot Blast & Shot Peen

Equipment Modernisation Programmes

E.M.P.

With over 150 years of combined experience Straaltechniek UK can offer extensive Equipment Modernisation Programmes for all types of Surface Preparation Blasting & Shot Peening Equipment at a fraction of the cost of new installations.

Why EMP? Jay Dorling (Sales Director) at Straaltechniek UK explained ‘that many of our customers we service and supply spare parts to have older generation shot blast and shot peening machines and although well maintained by the Straaltechniek UK Service Division for various reasons do not fulfil the latest health & safety legislation and

increased production demands of improved modern day processes.

This usually results in the request for significant capital investment for the latest new design modern replacements.

However, in highly competitive industries this investment may not be forthcoming straight away but in the short & medium term all is not lost! Older machines can be retrofitted and upgraded with the latest technology.’

What are the Main Drivers for EMP?

1. Health & Safety

2. Manufacturing Method Changes

3. Inability to meet Output Demands

4. Increased Cycle Times

5. Superior Cleaning Standards Required

6. Higher Levels of Contaminant to be removed.

7. Production Demands V Preventative Maintenance

8. Dust Emissions legislation changes.

9. Increase Profitability of Older Equipment

10. Limited Investment Budget in difficult times

Straaltechniek UK have a wide range of EMP programmes to assist customers when legislation and production demands require more from their existing equipment. Health & Safety, Dust Filtration, House-keeping, Handling & Ergonomic issues are classic examples. The health & safety of all employees is paramount in any modern businesses who must comply with the latest

Access Platform & LadderSimple Safety Interlock COMPANY SPOTLIGHT 4 SEPTEMBER 2022 read online: www.surfaceworld.com

4th & 5th October 2023, NEC, Birmingham

If you are interested in booking a stand call

Nigel Bean on 01442 826826 or send an email to nigelbean1@aol.com

H&S regulations. Straaltechniek UK can assist these businesses with advice and upgrades to meet with these mandatory demands. Whether it is working from heights, near to powered moving machinery, excessive noise, dust or ergonomic issues Straaltechniek UK can provide the latest bespoke solutions.

Many customers are operating without suitable Simple Safety Interlock Guarding, Light Guarding, Laser Guarding, Maintenance Access Ladders & Platforms, Bulk Automatic Abrasive Replenishment, Acoustic Enclosures, Handling Systems and ATEX Dust Filters.

Jay went on to say ‘that if Companies are unsure of their obligations Straaltechniek UK would be happy to help with any issues they may perceive they have including any other process, production or operational issues with their shot blasting equipment that our EMP Programmes may help them with’.

Telephone: +44 (0) 1142 571077

Email: info@straaltechniek.co.uk

Visit: www.straaltechniek.co.uk

Two Dimensional Laser Beam Guarding System (Costly Mechanical Guards Eliminated)

Bulk Abrasive Replenishment Minimum Manual Handling of 25kg bags

Acoustic

Two Dimensional Laser Beam Guarding System (Costly Mechanical Guards Eliminated)

Bulk Abrasive Replenishment Minimum Manual Handling of 25kg bags

Acoustic

Enclosures & Noise Attenuation >85DBA

5SEPTEMBER 2022twitter: @surfaceworldmag COMPANY SPOTLIGHT

UK

DFT Instruments UK LTD

Long Drive,

Berkhamsted, Herts

16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

01442 879494

t: 01442 879494

01442 879595

01442 879595

www.dftinstruments.co.uk

DeFelsko

e: sales@dftinstruments.co.uk

sales@dftinstruments.co.uk

Proud supplier of DeFelsko Inspection Instruments DFT Instruments

LTD 16A

Meadway,

HP4 2PN t:

f:

PosiTector ® Inspection Unrivaled probe interchangeability for all of your inspection needs. Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012. Customized Inspection Kits... Build your own kit from a selection of gauge bodies and probes to suit your needs. Coating Thickness Surface Profile Environmental Conditions Ultrasonic Wall Thickness HardnessSalt Contamination Coating Thickness Probes n Ferrous n Non-Ferrous n Combination n Ultrasonic Surface Profile Probes n Depth Micrometer n Replica Tape Reader Environmental Conditions Probes n Integral n Cabled Magnetic Probe n Anemometer Probe n 1/2” NPT n Infrared Hardness Probes n Shore n Barcol Salt Contamination Probe n Bresle Method Ultrasonic Wall Thickness Probes n Corrosion n Multiple Echo Thru-Paint n Precision n Low Frequency n Xtreme NEW DesignandFeatures Proud supplier of

Inspection Instruments

f:

www.dftinstruments.co.uk e:

NEW DesignandFeatures

Why Specify QUALICOAT for Residential Installations?

By Angus Mackie - QUALICOAT UK & Ireland Chair

Over the last decade members of the Association have seen a huge rise in QUALICOAT specifications for powder coating on a wide range of bespoke installations across the UK and Ireland. More wide ranging than BS EN 12206, the QUALICOAT Specification differs from the recently updated British Standard, requiring twice yearly, unannounced, third party accreditation visits for all its licensed members which ensures that the latest QUALICOAT specification is being followed. Any member failing an inspection will be given a short time to comply, failure to comply will result in the coating company losing its QUALICOAT licence.

A QUALICOAT specification is not just aimed at commercial projects, the specification is relevant to all architectural aluminium powder coating requirements, commercial and residential. It is crucial therefore that aluminium used in residential installations receives the same care when choosing and specifying its surface treatment. Members

now report that they are coating a growing number of residential aluminium systems for home improvement, as the demand for aluminium windows and doors continues apace.

Whilst systems companies products will generally carry a QUALICOAT approved powder coating applied by a licensed coater, the Association recommends that if in doubt, all home improvement companies should seek confirmation that they are receiving a QUALICOAT powder coated product. In fact, the specification should appear in all home improvement contracts with homeowners, which it turn, will offer purchasers further peace of mind when choosing aluminium. It is important to note here that a QUALICOAT specification should be no more expensive that a BS EN 12206 powder coating specification.

Whilst supplying a standard QUALICOAT approved coating is suitable for most residential applications in the UK there are some some options which we should be aware of. It is obvious that a colour reference is required, but there is also gloss levels to consider, the range reference is generally as follows:

‘Matt Powders’ are usually between 20% and 30% gloss level

‘Semi-gloss Powders’ are usually around 60 to 65% gloss level

‘Gloss Powders’ at least 80% but can be up to 85% gloss level

Gloss levels are easily checked using a hand held ‘Gloss Level Meter’, colour can be measured using a hand held ‘Colour Meter’. On more complex home improvement projects it may be necessary to colour/gloss match different products such as pressed cills, column casings and spandrel panels. A close match can be obtained by careful specification, but any QUALICOAT powder coater should be able to take a range of

Angus Mackie - QUALICOAT UK & Ireland Chair

8 SEPTEMBER 2022 QUALICOAT UK & IRELAND

CONTINUED ON PAGE 10

twitter: @surfaceworldmag

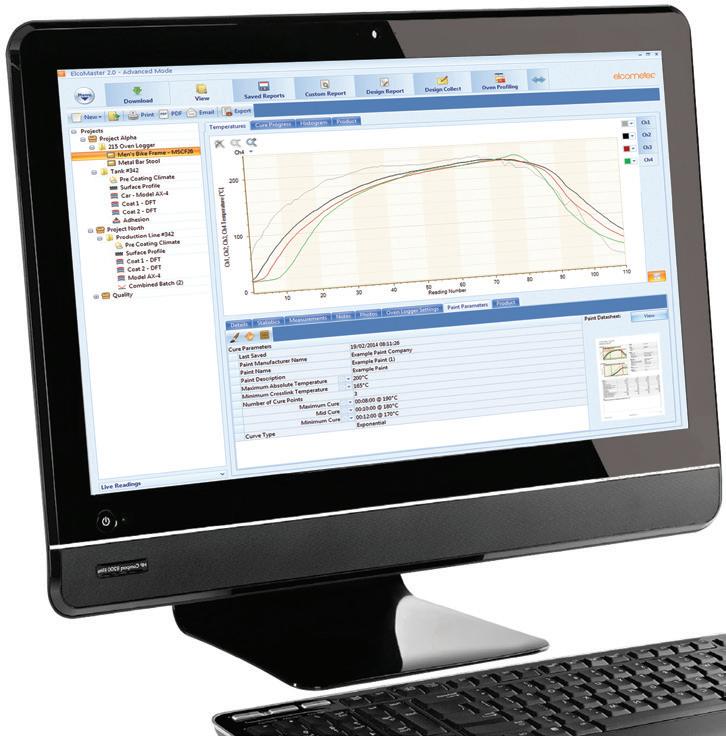

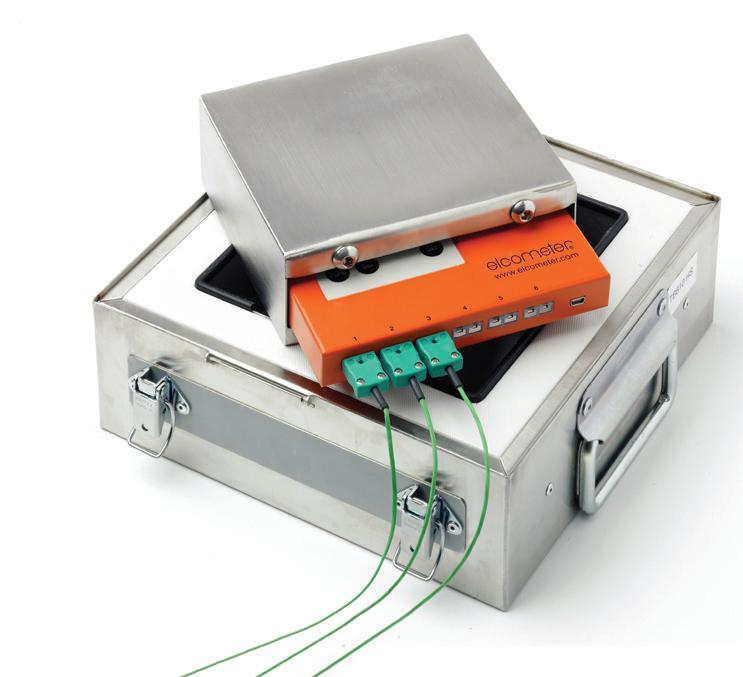

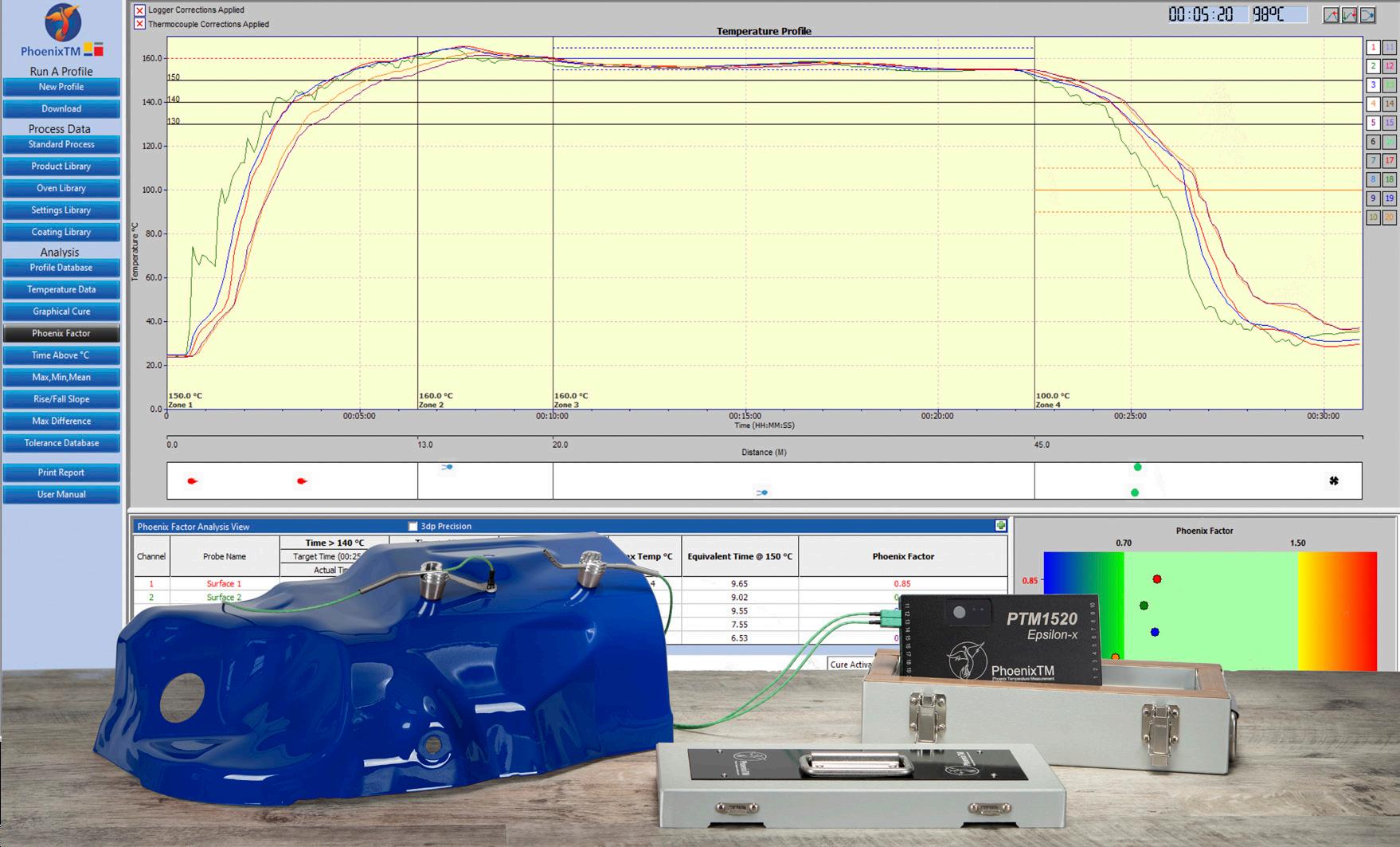

Accurately measure your product and oven temperature profiles with the Elcometer 215 Oven Data Logger together with ElcoMaster® software. elcometer.com PROFILINGMeasure · FAST · REPEATABLE · ACCURATE · DURABLE OVENTEMPERATURE Surface World - September 2022.indd 1 15/09/2022 14:57:41 WE’RE OBSESSED WITH COLOR YEARS OF EXPERIENCE IN RESEARCH & DEVELOPMENT OF CUSTOMIZED INDUSTRIAL COATINGS brands of The Sherwin-Williams Company A complete range of industrial coatings Waterborne | Powder | Solventborne | High solid | E-coat The Sherwin-Williams Company, Goodlass Road, Speke, Liverpool, L24 9HJ, United Kingdom | T: +44 (0)151 486 0486 | e-mail: liverpool.sales@sherwin.com

unfinished profiles and pressings from various providers and powder coat the complete project in one batch, which ensures a high quality colour and gloss consistency.

Finally, one important area which has caught out many a home improvement installer, is obtaining the correct specification when powder coated products are installed close to the coast. Contrary to popular belief, a powder coating finish is microporous, so if the pretreatment is not properly applied, corrosion under the surface can occur which will lead to premature surface coating failure.

A QUALICOAT Seaside Class of coating ensures that the pretreatment system is applied in a more robust way and offers a better adhesion and life expectancy in these harsh environments. A quick call to your local QUALICOAT powder coater, given the location of the installation, will offer advise and if needed offer the home improvement installer a more robust ‘Seaside Class’ coating specification and warranty for the homeowners and installers peace of mind.

Growing rapidly, there are currently twenty QUALICOAT licenced powder coat applicators across the UK and Ireland with a further four who will gain their applicator licences and join in 2022 after undergoing rigorous quality checks on equipment and processes. Members details are freely available on the new QUALICOAT UK & Ireland website and the Association would suggest that all home improvement companies should seek out a local applicator who can offer free advice on the correct coating specification for any residential application. Getting the coating specification correct for any project does not take long but it does ensure that as a provider of home improvement systems you are offering your customers the very best of what is achievable.

Also important is the level of coating problems or possible failures you may be experiencing will drastically reduce as a result.

The worldwide QUALICOAT Specification is continually and incrementally revised in real time with regular update sheets, the specification is completely rewritten at year end to include all updates. The Specification, its appendices and any update sheets are always freely available for download at www.qualicoat.net.

For details on the availability of various colours and finishes contact any QUALICOAT UK & Ireland member for more information.

For updated information about the use and specification of QUALICOAT in the UK and Ireland, please visit the UK & Ireland Association website at www.qualicoatuki.org.

10 SEPTEMBER 2022

QUALICOAT UK & IRELAND Call Nigel Bean for more information on +44 (0) 1442 826826 read online: www.surfaceworld.com

Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

EASY OPERATION . DOUBLE PRODUCTIVITY. SuperCenter EVO Powder preparation & supply center • Ideal for frequent & fast color changes • High degree of automation for optimum efficiency • Double-designed fresh powder station for increased productivity wagner-group.com Contact

International Safety Awards launched for 2023

The British Safety Council’s International Safety Awards 2023 are now open for applications.

The International Safety Awards are an internationally recognised accolade for health, safety and wellbeing excellence and this year will be the 65th year they have taken place. The awards recognise an organisation’s commitment to excellent standards of health, safety and wellbeing management.

In 2022, 549 organisations of all sizes, types and sectors won an International Safety Award. The winners included businesses from the UK, Africa, Asia, India, mainland Europe and the Middle East. A full list of 2022’s winners can be found here.

Businesses of all sizes, types and sectors around the world can apply. There are 12 award categories for 2023, including seven that are free to enter and three additional categories that are new and free for Indian businesses to enter this year.

Launching the International Safety Awards for 2023, Chief Executive of the British Safety Council, Mike Robinson said:

“As we continue to emerge from the Covid pandemic, the importance of everyone’s health, safety and wellbeing at work has never been more at the forefront of people’s minds. So, it is only right that we pause to celebrate the massive contribution people who work every day to prevent accidents, injuries and ill health in their workplaces have made this year.

“The British Safety Council’s prestigious International Safety Awards offer companies, teams and individuals the chance to be recognised for their hard work and achievements in protecting and enhancing the health, safety and wellbeing of their organisations’ workers. I urge all organisations and leaders around the world who are proud of their track record to put themselves forward for an award in 2023.”

Businesses applying can be recognised as ‘best in class’ across four categories:

The Sector Awards will recognise overall ‘best in class’ submissions by organisations to the International Safety Awards, by industry sector category

The Best in Country Awards will recognise the highest scoring and best overall application from individual countries where there are more than four applications from the given country

Best in Company Award is for organisations with 50 or more participating sites and recognises the site(s) with the most outstanding applications

Chief Adjudicator’s Award will recognise the most outstanding applications from this year’s entrants. Previous winners have been exemplars in their respective areas and evidenced this through their application responses.

Winners of the Sector and Best in Country will only be awarded where there is an applicant who has achieved a Distinction in their 2023 International Safety Award application.

Seven of the awards are completely free-toenter with three new additional categories that are free for Indian businesses to enter this year whether or not they have applied for an International Safety Award. These are:

Best contractor Safety Initiative: This recognises organisations based in India, that have implemented a significant initiative to improve the health, safety and wellbeing of the contractual workforce, which was started and concluded between 1 January 2021 and 31 December 2021

Best Fire Safety Initiative: This recognises organisations based in India that have developed and implemented innovative policies and processes, which were started and concluded between 1 January 2021 and 31 December 2021, to enhance fire safety in the workplace

Outstanding Road Safety Initiative Outside Work Premises: This is aimed at organisations based in India and rewards them for pioneering initiatives they have undertaken to enhance road safety outside work premises in the supply chain between 1 January and 31 December 2021.

Applications and nominations for the wider free-to-enter awards are invited regardless of whether an organisation is applying for an International Safety Award. These are:

Seize the Opportunity Award: This award recognises organisations that have gone the

extra mile to seize health, safety or wellbeing opportunities resulting from a crisis.

CEO Award: This recognises the leadership and strategic vision of CEOs who have made a vital contribution to the health, safety and wellbeing of their business and to the wider society during 2022. The award recognises how an individual CEO has taken an active role in aligning and championing their organisation’s health, safety and wellbeing interests with their internal and external stakeholders.

Health and Safety Transformation Award – sponsored by Croner-i: The Health and Safety Transformation Award is for organisations that have significantly changed or transformed any aspect of health, safety or wellbeing to a significant extent through the use of information.

Health, Safety and Wellbeing Ambassador of the Year Award: This recognises an employee who, in the opinion of the organisation or person nominating them, has played a significant role in ensuring the health, safety and wellbeing of colleagues and others.

Team of the Year Award: This recognises outstanding achievements resulting in a significant improvement to health, safety or wellbeing, from a collaboration of stakeholders, which may include members of the organisation, suppliers, subcontractors and/or the wider community.

The James Tye Award: This recognises an organisation or a team of individuals who have developed and run a campaign in 2022 that has made a significant impact on health, safety or wellbeing in the workplace. It is named after British Safety Council’s founder, James Tye, who campaigned tirelessly on issues such as life jackets and seat belts.

Wellbeing Initiative Award – powered by Being Well Together: This recognises and rewards those organisations that have demonstrated a proactive and effective approach to improving employee wellbeing. The closing date for applications is Friday 10 February 2023 and the results will be announced on Friday 11 March 2023. To apply go to: https://www.britsafe.org/ awards-and-events/awards/internationalsafety-awards/

12 SEPTEMBER 2022 BRITISH SAFETY COUNCIL

twitter: @surfaceworldmag

Solutions for Parts & Paint Spray gun cleaning WASHERS ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water. ATEX certified • High quality alloy pumps Stainless steel construction • Wash cycle controlled by timer • Wash & rinse • Hot water wash • Inbuilt water recycling • Inbuilt solvent recycling Air extraction • 2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit: 6 K-type thermocouple ports High temperature stainless steel barrier box for long run times Download, view, and analyze data using PosiSoft Desktop Software or export to .CSV Oven Temperature Logger Measures and records oven temperature profiles 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Customizable PDF Reports Prices starting at: Oven Temperature Logger .......... £1895 Temperature Probes ............ £100 Wide variety of spring clamp and magnetic temperature probes available NEW

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

SURFACE ENGINEERING ASSOCIATION

The voice of the surface engineering industry, representing the companies within it

Spanning the entire surface engineering and finishing sector, the SEA is the voice of the industry, working at every level to ensure that our members are informed and fairly represented in parliament in the UK and EU. We take an active role on UK and EU committees and working groups where legislation, standards, and codes of practice are developed, making sure that our views – and those of our members – are heard.

This representation on regulatory affairs ensures that we are always ‘in the know’ regarding new, or amended, legislation on health and safety or environmental issues that will impact the surface engineering industry. Our findings are fed back to members regularly via our website, committee meetings and conferences.

The Surface Engineering Association is leading the way in the future of the industry

Together with our members we are at the forefront of the advancement of the surface engineering industry, helping with the development of new environmentally friendly coatings and less hazardous plating methods.

We hold regular meetings, seminars and conferences to keep our members informed on the important issues affecting our industry, and we provide the platform for all members to present potential issues, so we can report these to the right people in the places that matter. In addition, these are ideal events for

meeting fellow members, including manufacturers and suppliers, to discuss areas of mutual interest or even contention.

Membership of the Surface Engineering Association amplifies your voice where it matters

We understand the challenges that companies working in our sector face –especially the smaller enterprises that have neither time or specialist resources to keep ahead of legislation, industry issues or get involved at government level. The SEA is your voice in areas that affect the surface finishing industry.

Membership is not just about amplifying the voice, but offers a whole host of member benefits:

Free technical and commercial advice.

Free 24-hour business support helpline providing valuable advice on tax, VAT, PAYE and employment issues.

Up-to-the minute information on legislation changes or proposed controls that affect materials or processes used in surface finishing.

Substantial savings on company energy bills.

Bespoke commercial insurance specifically for those operating in surface engineering that offers flexible, comprehensive cover with no claims discount up to 50%.

Free entry in the SEA Buyers’ Guide App and the SEA website.

Regular publications, including the SEA Newsletter and Surface Matters.

A range of attractive discounts on products and services such as car hire, hotel booking and private healthcare.

Discover for yourself the benefits of being a member of the Surface Engineering Association

If you are involved in any aspect of the surface engineering industry, you should be involved in the Surface Engineering Association. Not only for the many benefits that membership offers, but also for the opportunity to be involved in shaping the future of the industry. We particularly welcome young people coming into our exciting sector and we provide opportunities for them learn and contribute to the world of surface engineering.

Find out more about the benefits of membership

You can apply for membership by completing our online application form. However, if you would like to discuss in more detail about the benefits of membership or have any questions, please contact us on 0121 237 1123 or email us at membership@sea.org.uk.

16

SEPTEMBER 2022

read online: www.surfaceworld.com

elcometer.com INSPECTIONKITS Elcometer · FAST · REPEATABLE · ACCURATE · DURABLE COATING The Elcometer Powder Coating Inspection Kit covers all eventualities in the powder inspection process. Surface World - September 2022.indd 2 15/09/2022 14:57:09 WASHING SYSTEMS EFFICIENT - ROBUST - RELIABLE INNOVATION FOR ALL YOUR WASHING NEEDS • SMALL BATCH WASHING TO CONVEYORISED SYSTEMS • SPRAY, SOAK , ULTRASONIC OR COMBINATION MACHINES. • FULL AFTER SALES SUPPORT • IN HOUSE TEST FACILITY • EUROPEAN WIDE CUSTOMER BASE • STANDARD AND BESPOKE SYSTEMS AVAILABLE • COMPLIMENTARY CHEMICAL RANGE AVAILABLE Call 01543 675800 or visit our website www.unitechwashers.uk.com

10 great reasons to exhibit at Surface World 2023

If your business is attracting new customers from advertising and word of mouth, it can be very tempting to write trade shows off as something that you don’t need to do to attract new customers. But trade shows can be one of the most rewarding forms of marketing when approached with the right strategy. Trade show veterans will attest to the fact that the ROI (return on investment) achieved from a successful trade show is often impossible to match in comparison to other forms of marketing.

So before you write off trade shows as secondary to your current marketing tactics, it pays to learn about their benefits. Here are ten reasons which explain why trade shows should be at the top of your list.

1. Meet and connect with prospective customers

One of the greatest advantages of exhibiting at a trade show is that it allows you to meet and connect with prospective customers in person instead of communicating with them over the phone. Research has shown that in-person meetings are 34 times more successful than those made via email or by phone. When meeting in person, you become someone that they know, recognise, and want to connect with.

Another advantage is the trade show host uses their database to invite prospective customers to the event, using various marketing tools on your behalf to get footfall through the door. Where else can you meet

hundreds of prospective business opportunities all under one roof?

2. Strengthen your bond with existing customers

Just like trade shows give you the opportunity to better connect with prospective customers, exhibiting at a trade show also allows you to meet your existing customers face-to-face. While most of today’s business is conducted over email or phone, face-to-face meetings are undeniably a fantastic way to do business.

Trade shows are often a place for customers to approach you with their long term plans and big orders – orders that can be incredibly lucrative for you as an exhibitor. Utilising your attendance to plan meetings at the show will save you valuable time and money, rather than trying to see each in turn at their place of business.

3. Learn about new developments in your industry

When your business attends an industry event, it puts you at the centre of the action. Trade shows are a place for businesses to announce and display their latest innovations and developments.

In a competitive industry, would you rather be aware of your competitors or out of the loop? Exhibiting at a trade show doesn’t just give you the opportunity to make new sales and connect with existing customers, it gives you the chance to

look at cutting edge developments in your industry and the opportunities they also create for you.

When you are at the show take a few hours out of your stand and see what other exhibitors are doing, this helps to keep you up to date with new technologies, techniques, products and industry trends.

4. Meet new companies that can help your business

Your attendance gives you the chance to network with both prospective customers and prospective vendors. This makes a trade show more than just an opportunity to expand your distribution, but a chance to expand your supply chain.

While your sales and marketing team focus on connecting with prospects to make new sales, your Purchasing Manager can connect with new vendors and contractors that can help your business grow. This makes a trade show a two-sided opportunity for your business –to expand sales, and to expand supply chains.

5. Close deals with new customers during the show

There are few situations more tense than the average outbound sales call. From the

18 SEPTEMBER 2022

SURFACE WORLD 2023

twitter: @surfaceworldmag

endless objections of the prospective customer, to the stress of losing a valuable sale, it’s natural to face rejection and nervousness as a salesperson.

At a trade show, however, the atmosphere is different. Almost half of trade show attendees make purchases at trade shows. A staggering 91 percent of all trade show attendees claim that shows are ‘extremely useful’ to their product and service sourcing efforts.

When you speak to a Purchasing Manager or Director on the phone, you’re often dealing with someone that’s already juggling a variety of obligations and deals in their mind. As such, they’re understandably disinterested. At a trade show, you’re dealing with prospective customers that have made the journey to fulfil a requirement they currently have.

Unlike traditional outbound marketing, in which rejection is the norm, trade shows are one of the few environments in which your sales team benefits from an audience of prospective customers that are genuinely interested in buying your products and services.

6. Strengthen or establish your brand

Trade shows are one of the few environments where you have the same amount of access to prospective customers as your larger competitors do. This makes them a valuable opportunity not just for direct sales and marketing, but for strengthening your brand and positioning your business as a leader in its industry.

From free giveaways to trade show displays, there’s no better opportunity to give your brand a sizeable boost than a trade show. If you create an exhibition stand that attracts the right type of attention, a single exhibition can be all it takes to change your brand from up-andcomer to an established industry leader.

7. Learn what your competitors are doing right

In the world of business, it pays to keep your customers close and your competitors closer. Exhibiting at a trade show allows you to observe what your competitors are doing right and apply their tactics to your own business.

Is there a particular competitor in your industry that seems to be growing at a rapid

pace? While your sales team uses the trade show as an opportunity to meet existing customers and connect with prospective ones, spend a moment looking at the other exhibitors to see what they’re doing differently from you.

Great businesses are aware of their competitors, and trade shows are one of the best opportunities to connect with competitors and understand their sales strategy, their pricing, and the reasons for their success.

8. Rapidly expand your database of sales leads

While skimming through the phone book might give you thousands of unqualified phone numbers, nothing gives you qualified leads quite like a trade show. While cold calling and online marketing might not have the same initial expense as a trade show, there’s no greater way to fill your contact book with prospects than a successful trade show effort in a much shorter time frame.

9. Speak directly to your target market

Email surveys are a fantastic way to learn more about what your customers want and don’t want. Unfortunately, their low response rate makes them useful only to businesses with a large enough email list to tolerate very few responses.

Trade shows allow you to solicit a huge amount of feedback by talking directly to visitors that have been invited to attend from various avenues within your industry. You can then use this valuable information after the show to help your business expand and improve.

A great way to get useful feedback and valuable sales leads at the same time is by conducting a short survey on your exhibition stand, and rewarding participants with vouchers or gifts from your business. Where else but a trade show can you generate new leads and valuable feedback at the same time?

10. Optimise your sales and lead generation strategy

Trade shows are an excellent opportunity to expose your sales team to hundreds of different prospects in a short period of time. A perfect opportunity to test new sales tricks and marketing strategies in a very responsive environment.

If you want to test and optimise your lead generation strategy, you’ll find no better place than a trade show. Try several different sales pitches on prospects and you’ll quickly learn which ones work and which ones don’t, allowing you to perfect your sales strategies in just a few days. You can then use these honed skills when out on the road or at future trade events.

The next Surface World is to take place on 4th and 5th October 2023 at the NEC in Birmingham. Reservations are already being taken.

If you are interested in exhibiting at the show or would like to advertise in the Surface World magazine or on the website, please call Nigel Bean on +44 (0) 1442 826826 to discuss your requirements. Or you can send an email to nigelbean1@aol.com.

Surface World – Re-Connecting The Industry

Surface World – Re-Connecting The Industry

19SEPTEMBER 2022

read online: www.surfaceworld.com SURFACE WORLD 2023

BASF Coatings inaugurates new electrocoat research center

The newly built e-coat research center offers BASF Coatings unique technical possibilities worldwide

With this innovative research center, BASF’s Coatings division is making a further contribution to its customers’ success

In addition to quality and efficiency, occupational health and safety were given high priority in planning and construction

BASF Coatings has inaugurated a new research center for electrophoretic dip coating at its headquarters in MünsterHiltrup, Germany. The electrophoretic or cathodic dip coat (e-coat) protects the surfaces, edges and cavities of a car body against corrosion, and evens out the roughness of the pre-treated metal surfaces,

thus providing the optimum basis for the application of the subsequent paint layers.

“We invested 15 million euros in the new building at the Münster site,” said Mathias Schöttke, Managing Director BASF Coatings GmbH. “The health and safety of our colleagues is particularly important to us at BASF. This is why, during the planning stage, we have not only given high priority to the quality and efficiency of the coating process, but also to ergonomics and occupational safety right from the start.”

Frank Naber, head of the Automotive OEM Coatings Solutions EMEA business unit at BASF Coatings emphasized: “In our new e-coat research center, we can simulate our customers’ processes and paint systems. We can coat pre-treated original parts of our customers under the conditions of their individual paint lines in a 2,000-liter dip tank and bake them in a chamber oven. These parts can be doors, fenders or hoods.”

In addition, the research center has two ultra-filtration and filtration stands with which the quality and stability of new e-coats can be tested under the conditions of the customers already before the tank is being filled for the first time. “In this way, we can ensure that the coating quality is at a very high level immediately after having changed over to a new e-coat material, and that it meets the customer’s specification. Thanks to these technical conditions, we are making another significant contribution to the success of our customers,” said Naber. The center will mainly be used for

the CathoGuard® 800 e-coat technology, which has already been applied to more than 100 million vehicles worldwide. The product does without organic tin compounds and has a very low solvent content. An optimized film thickness distribution permits material to be saved and, at the same time, guarantees protection of the entire body thanks to its good throwing power. The product also contributes to sustainability by reducing wastewater, which in turn reduces the amount of fresh water required for the process.

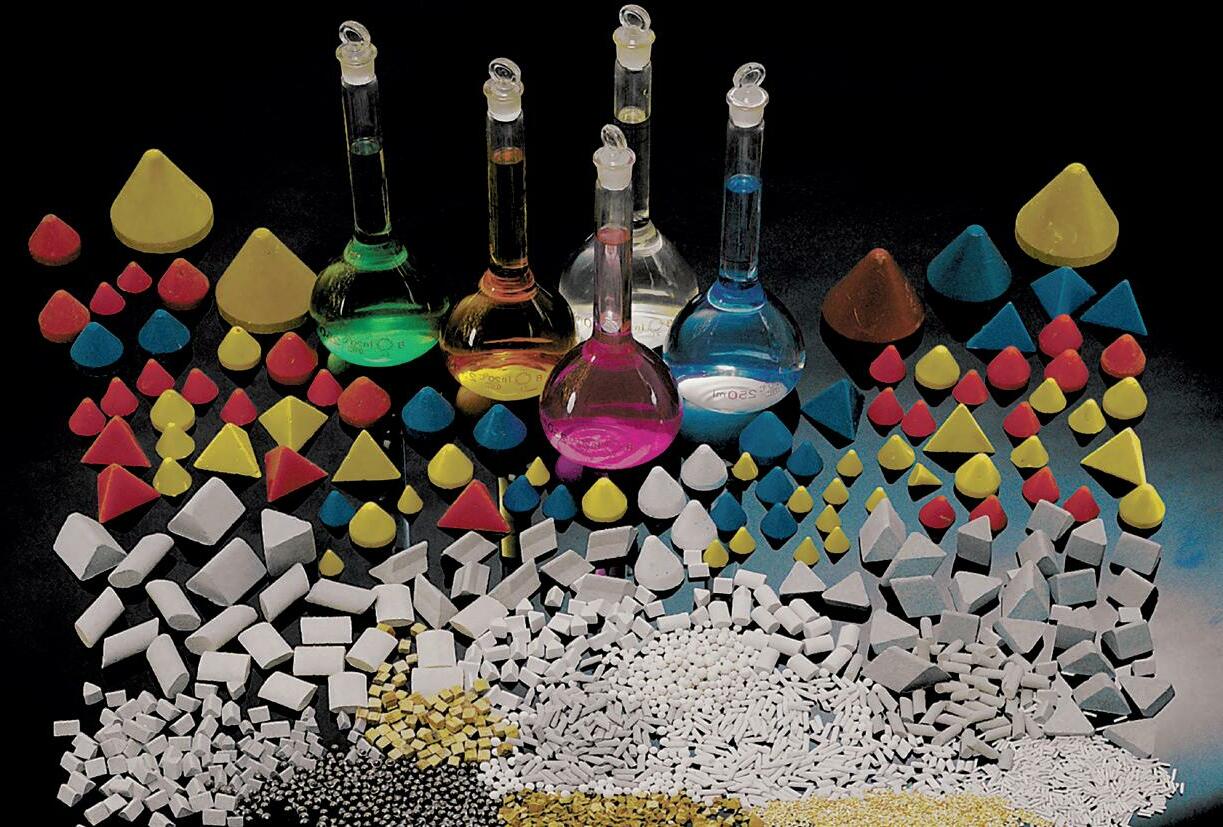

About BASF’s Coatings division

The Coatings division of BASF is a global expert in the development, production and marketing of innovative and sustainable automotive OEM and refinish coatings, decorative paints as well as applied surface treatments for metal, plastic and glass substrates in a wide range of industries. This portfolio is supplemented by “Beyond Paint Solutions”, which enable new applications with innovative surfaces. We create advanced performance solutions and drive performance, design and new applications to meet our partners’ needs all over the world. BASF shares skills, knowledge and resources of interdisciplinary and global teams for the benefit of customers by operating a collaborative network of sites in Europe, North America, South America and Asia Pacific. In 2021, the Coatings division achieved global sales of about €3.44 billion.

Solutions beyond your imagination –Coatings by BASF. For more information about the Coatings division of BASF and its products, visit www.basf-coatings.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. Around 111,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio comprises six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €78.6 billion in 2021. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S.

Further information at www.basf.com

20 SEPTEMBER 2022 INDUSTRY NEWS

The new research center for electrophoretic dip coating at BASF Coatings’ headquarters in Münster, Germany. Pre-treated original parts can be coated in a 2,000-liter dip tank and baked in a chamber oven. read online: www.surfaceworld.com

Color-on-Demand Powder Coating

Maximum flexibility – coat any colour, at any time!

Nordson’s Color-on-Demand® powder coating system provides automated ultra-fast contamination-free colour changes. Thanks to the efficient production management, it minimises work-in-progress by dynamically adapting to production requirements. The system can accommodate up to 28 colours at one time for more colour changes per shift, higher throughput, and just-in-time manufacturing for zero inventory and improved production efficiency.

Explore the unique features of our powder coating systems online www.nordson.com/hdlv or get in contact for more information!

Oldfield appointment strengthens senior team at Borough

Injection moulding and chrome plating specialist Borough Ltd, has announced the appointment of Darren Oldfield as Production Planning & Business Development Manager, as the Southend-based firm continues its drive to grow and diversify.

Oldfield brings a wide and extensive knowledge of business systems and manufacturing to the role, shaped by a decade with global automotive parts

manufacturer, Kongsberg Automotive and more recently board positions within the construction industry supply chain.

Borough Director David Brereton said of the appointment: “Borough is in a good position to kick-on, following the recent challenges of the global pandemic and its impact on the automotive industry, so it is gratifying to be able to attract to our business, individuals of Darren’s calibre.

“For more than 60 years, Borough has been providing high-quality moulded plastic and

chrome-plated components, assemblies and systems, to the automotive industry's leading brands; Darren is here to help us grow and expand in new sectors.

“Darren’s list of contacts across the automotive industry and beyond, both locally and internationally, is very impressive and should prove valuable as we look to grow our business, improve our processes and increase efficiency throughout our manufacturing operations.

“He has brought a fresh approach to the challenges we face in what is a competitive global market and we expect great things from him as he gets to grips with our business, in all its complexities, to support the senior team’s strategic growth ambitions.”

New Production Planning & Business Development Manager, Darren Oldfield commented: “The opportunity to work with the senior team at Borough, to challenge the industry status quo and do things a little differently, was too good to pass up.

“Given the increasing pressure on global supply chains, already stretched taut following years of problems, the need of British manufacturers to onshore their supplies, is a great opportunity for growth for businesses such as Borough.

“This is a business ready to embrace change to drive further growth through its ongoing commitment to delivering the highest quality products and achieving operational excellence - both areas that align with my personal experience and expertise.

“Borough has become pre-eminent in moulding high-quality plastic components and chrome plating them, but we know there is more we can do to bring chrome plated parts to new audiences that will appreciate its durability, finish and quality for uses beyond the automotive sector.

“I’m looking forward to working with the experienced senior team at Borough to ensure in the years ahead we are the plastic component moulder and chrome plater of choice, for those clients seeking unrivalled quality of manufacture from a British supplier.”

Telephone: +44 (0)1702 425425 Visit: www.borough.co.uk

22 SEPTEMBER 2022 INDUSTRY NEWS

twitter: @surfaceworldmag

Bathing in non-reflective glory

When you are looking to push the boundaries of light, color and design, especially with an ultra matt surface, our Précis Ultra Matt range has the answers. With a finer mica effect that enables an ultra matt surface to change appearance depending on the way the light reflects on it, you can create a finish that not only looks amazing, but also offers stunning levels of superdurability.

With innovative solutions that push the boundaries of what’s possible, a vast range of sustainable products backed by industry leading certifications, and the best performing powder coatings on the market used and respected by architects around the world, your imagination starts with our finish.

architectural.interpon.com

architectural.interpon.com

Michael Hansen to succeed Lars Petersson as CEO of Hempel A/S

Michael Hansen announced to succeed Lars Petersson as Group President and CEO of world-leading coatings company, Hempel A/S. Michael will step into his new position on 15 October 2022.

Michael Hansen joined Hempel in May 2017 as Chief Commercial Officer and has delivered remarkable results as a central driver of the global transformation in Hempel. Today, Michael is part of the Executive Group Management as Executive Vice President, Energy & Infrastructure.

“Michael Hansen has extensive knowledge of Hempel, its markets and customers.

With his great leadership qualities and the strong results he has delivered, Michael has shown that he is the perfect successor to take over as CEO and continue Hempel’s growth journey. I am very pleased that the natural choice of a new Group President and CEO is an existing top leader from within Hempel. The Board and I look forward to continuing the great collaboration with Michael and his executive management team,” says Richard Sand, Chair of the Board of Directors of Hempel A/S.

“I am truly honoured to be appointed CEO of Hempel – a unique, global company. With more than 7,500 dedicated colleagues serving customers in more than 100 countries, a strong value-based culture, a sharp customer focus and strong social engagement, Hempel is a company where we all work together to deliver on our strategy and to reach the ambitious goals we have set ourselves,” says Michael Hansen. “We will continue our strategic journey, Double Impact, with the purpose of

shaping a brighter future through sustainable coating solutions. I am proud to be leading a company, which makes a real, positive impact on the society that we are a part of, both directly through our products and solutions, and by creating opportunities for our colleagues around the world.”

“I would like to thank the Board of Directors for the trust they have shown in me and I look forward to taking on the new role and contributing to strengthening the position of Hempel in the coatings industry, together with the rest of the Executive Group Management and our talented colleagues,” Michael adds.

Richard Sand comments on Lars Petersson’s departure:

“The Board would like to thank Lars for a truly exceptional and dedicated effort. Lars has headed and accelerated the global

transformation of Hempel with remarkable results under very challenging and fastevolving external conditions.”

Lars Petersson takes on the position of President and CEO of VELUX Group on 1 November 2022. Until 14 October, Lars will continue his engaged daily work for Hempel and contribute to an optimal hand-over to Michael Hansen and the Executive Group Management.

Michael Hansen holds a degree from Copenhagen Business School, as well as an Executive MBA from IE Business School in Madrid, Spain. Prior to joining Hempel, Michael Hansen worked 19 years for Maersk, where he held the position, among others, of Vice President, Global Head of Sales & Marketing in Maersk Line.

Visit: www.hempel.com

24 SEPTEMBER 2022 INDUSTRY NEWS read online: www.surfaceworld.com

elcometer.com Elcometer’s range of high performance abrasive blast equipment is engineered to last longer, work harder & perform better. dry abrasive blast machines | precision media valves blast hose | blast nozzles | personal protection equipment TAEB engineered EDAM NI RG E A T BRITAIN FABRIQUÉ EN GRANDE-BRETAGNE H E R NEINNATIRBSSORGNITLLETSEGengineeredEDAM I N E U ROPE FABRIQUÉ ENEUROPE H E NITLLETSEGRAPORUE LAUQ YGOLONHCEGNINIART Surface World - June 2022.indd 1 09/06/2022 16:11:23

Detects holidays, pinholes, and other discontinuities using pulse DC High voltage Holiday Detector n Lightweight, ergonomic design reduces opera tor fa tigue n Regula ted pulse DC volta ge output ±5% accuracy n Industr y standard connectors and ada ptors for compa tibility with nearly all existing electrodes n Volta ge calcula tor fea ture choose one of 11 interna tional standards and input the coa ting thickness to automa tically calcula te the required test volta ge n Removable lithium ion ba tteries provide long lasting po wer Ch f ide us m SPECIAL DISCOUNTED RATE PosiTest HHD Basic Kit (HHDKITB) £ 1 9 5 0 + VAT sa ve over £400 Limited time only In stock t: 01442 879494 www.dftinstruments.co.uk Proud supplier of DeFelsko Inspection Instruments t : 0 1 4 4 2 8 7 9 4 9 4 n w w w d f t i n s t r u m e n t s c o u k n e : s a l e s @ d f t i n s t r u m e n t s . c o . u k

Surface Finishing is our DNA AM Solutions Shot Blasting Individual systems engineering and intelligent process solutions –reliable and energy efficient The full solution provider for 3D post processing equipment and 3D printing services Mass Finishing Efficient systems engineering and innovative technologies – powerful and economical Rösler UK Limited| 1 Unity Grove | Knowsley Business Park | Prescot | Merseyside | L34 9GT Tel: +44 (0)151 482 0444 | Fax: +44 (0)151 482 4400 | rosler-uk@rosler.com | www.rosler.com

Fischer Instrumentation (GB) open new Customer Applications & Support Centre

As part of its culture of Continuous Improvement, Fischer Instrumentation (GB), part of the global Helmut Fischer Group, set a plan to be more easily accessible for its customers and more centrally based in the UK, after being sited previously in the south of the country, in Hampshire.

The company has now completed a successful relocation to a new Customer Applications and Support Centre in Pershore, Worcestershire.

Darin Enefer, Fischer GB General Manager, explained more:

“We took the opportunity during the pandemic lockdown to step back from the business and make decisions that would help provide optimised customer service, whilst supporting our business growth ambitions.

We are pleased with our Pershore facility and welcome new and existing customers to discuss their measuring requirements and challenges, evaluate their materials and samples, try our range of measuring equipment, and participate in useful ‘hands-on’ learning workshops.’’

The relocation has helped the company grow sales and this has been achieved through supporting clients in Aerospace, Automotive, Engineering, Electronics and Precious Metals sectors, with high quality measuring

solutions, supported by pro-active service and maintenance plans.

‘‘We know from survey feedback how much our customers like collaborating with a supplier that has UK based service personnel, available parts, and country wide support. Customers can be supported on site or alternatively use our fully equipped Service Centre at Pershore.

We hope our new location will help to continue to support our customers and enable us to continue our current business uplift’’

The Company

As a full-service supplier in the field of surface testing, Fischer has been developing instruments for non-destructive material analysis, coating thickness measurement and material testing since 1953.

Fischer offer a wide range of measuring devices for different industries: from simple

handheld devices for quick testing on the go to fully integrated, high-end systems that automatically monitor your production.

Darin believes that the company is leading the way in terms of product quality and customer service.

“We have a high customer service orientation and a passion for helping the customer measure more accurately, more reliably, and efficiently.

Our core values include Expertise and Passion, along with Trust and Commitment. These values help drive our behaviours and activities.

The whole aim is to make our customer’s lives easier, underpinned by our Fischer mantra ‘‘Measuring Made Easy!’’

www.fischerinstrumentation.co.uk

28 SEPTEMBER 2022 INDUSTRY NEWS twitter: @surfaceworldmag

Detergents for Industrial Parts Cleaning

Manchester / United Kingdom

+44 161 866 2800, Fax +44 161 866 2801 www.buhlergroup.com

Borer Chemie AG Gewerbestrasse 13 4528 Zuchwil / Switzerland www.borer.ch Bühler Ltd. Unit 8/9 Mercury Park, Mercury Way, M41 7LY Urmston,

Tel.

Fraser Technologies supplies pioneering Miele Professional aqueous cleaning system

Fraser Technologies Ltd., specialist supplier in the component cleaning market, is now offering the SlimLine PLW 6011 & PLW 6111 aqueous cleaning systems from Miele Professional.

The exclusive supplier of this equipment in the UK, Fraser Technologies works with customers to create a bespoke cleaning system and process to meet their individual needs and standards. These machines are single chamber aqueous cleaning systems offering time, energy and cost-saving efficiencies, and can meet the stringent cleaning requirements for high-reliability industrial sectors.

At only 65cm wide, the footprint is very compact, whilst still providing a large and flexible internal chamber space. This size, flexibility and smart load system allows a variety of components to be cleaned highly efficiently all at once, whilst utilising much less space compared with a standard sized machine.

Suitable for a wide variety of components and specialist electronics cleaning applications in the automotive, medical devices and aerospace industries, the Miele SlimLine PLW 6011 & PLW 6111, combined with the right chemical combination, are especially effective for flux removal and for other parts cleaning and degreasing applications.

Aqueous chemical cleaning solutions, which can be used in this system, can be applied to a variety of metals such as copper, stainless steel, and brass to remove grease, cutting fluids and general particulate.

Graham Fraser, Managing Director of Fraser Technologies, said: “The equipment offers a high level of flexibility with intelligent controls, including a wide range of load carriers and accessories. And with the added value of our custom made chemical isolation tank, this system can recirculate and reuse the chemistry, further reducing costs and environmental impact.

“We have already completed a number of successful customer trials with the system and have a fast-growing customer base. This includes a specialist in the assembly of PCBs, who were so impressed by the results of the Miele system in their trials that they placed an order immediately. We also switched a leading defence systems manufacturer from an inline batch cleaning

system to the new Miele system, saving time and space, reducing energy costs, and increasing efficiency.

“We have a strong relationship with Miele after years of collaboration, and very much share their values for high quality, sustainable and innovative cleaning systems. As the only UK distributor of this equipment, we have been really pleased with the results our customers have seen to date. We’re looking forward to rolling the system out to more manufacturers across the country.”

Fraser Technologies offers trials and personalised customer service to ensure products are correct for individual business and performance requirements. For further information, visit frasertech.co.uk.

read

www.surfaceworld.com

30 SEPTEMBER 2022 INDUSTRY NEWS www.surfaceworld.com

online:

Solutions for recycling SOLVENTS Save Money | Recycle Any Solvent High Yield | Low Waste ASK FOR A FREE QUOTE SYSTEMS Units available for any quantity and application Safe and easy to use Recycled solvent as good as new Atex certified for flammable solvents The number one choice with over 38,000 units worldwide BUY OR LEASE info@solutex.co.uk | 01691 622 225 For more information visit: www.solutex.co.uk

Colourful Careers in Coatings with HMG Paints

The UK coatings industry faces a shortage of skilled staff, and an ageing workforce at a time when it is experiencing increasing demand for improved product performance and sustainable solutions.

As the UK’s leading independent paint manufacturer, HMG Paints are investing significantly in staff recruitment across the business including in their research and development facilities and pro-actively working to attract experienced coatings formulators whilst also developing the next generation of staff to handle these challenges.

“People are at the heart of HMG and we’re always looking to create the best environment for our people to thrive” commented Steve Crossman, COO. “Be it the annual staff BBQ, 1pm Friday Finish or Christmas & New Year off we always try to ensure we provide a great work life balance where our staff can develop professionally and personally.”

The nature and variety of HMG’s customer base & product portfolio means that there is a broad range of roles and opportunities within the company from apprentice and graduate opportunities in production and operations to roles for experienced chemists within the Laboratory. These roles include

technical positions such as paint technologists, research & development chemists and colour specialists with one eye on a sustainable, net zero future. Believe it or not the company even have roles that require watching paint dry.

HMG’s portfolio of wet paint and aerosols cover virtually every type of surface imaginable across a whole host of industries including industrial, commercial vehicle, decorative, automotive, defence, toll manufacturing, wood finish and arts & craft and the company is now looking to further develop its staff to handle increased customer demand.

Colourful Career Opportunities

One area HMG has really pushed the boundaries over the last few years is within their Advanced Colour Design department. The success of the department means that HMG are now looking to further expand its colour development and formulation team who are responsible for the companies library of over 90,000 colour formulations.

The Advanced Colour Design team work very closely with customers to develop bespoke colour options and solutions for customers in a variety of fields including decorative, automotive, model and hobby.

The team have worked on a number of high-profile projects including the Jaguar CX-17 (F-Pace), paint for Aston Marin Racing that was revealed at the Geneva Motor Show, a unique gold for angel statues at the Parisian Hotel and Casino in Macau, interior design palettes for leading decorative brands and the team even worked on the restoration of Emerson Fittipaldi's iconic Lotus F1 car along with many other projects.

Training and Development

“HMG Paints has a long and proud history of developing our own technical team and we have some very exciting opportunities available as our business continues to grow”

32 SEPTEMBER 2022 INDUSTRY NEWS

twitter: @surfaceworldmag

commented COO, Steve Crossman. “Having started myself as an apprentice in the laboratory I know first hand about the exciting challenges and opportunities that lie within HMG Paints. We have a great track record of nurturing our own talent in-house but also combining that with attracting experienced professionals within the coatings industry.”

After various roles in the laboratories including development chemist and Technical Director, as COO Steve is now keen for the next generation of talent to be developed within HMG. A key facet of this is utilising the knowledge and experience of existing lab staff and combining that with training organisations, courses and guidance provided by PRA, BCF and OCCA.

The coatings industry and HMG’s broader appeal can be further strengthened with links to academic institutions, illustrated recently by HMG’s participation with the Chemistry in Industry module conducted by OCCA at the University of Salford.

This route has helped HMG produce a number of home-grown coating chemists over the years including Darren James, who is a previous recipient of the British Coatings Federation Student of the Year award. This award is presented to the student who, in the opinion of the tutors of the Coatings Training Institute, has consistently demonstrated the highest level of understanding and achieved outstanding scores in examinations and practical work when completing their training modules.

“I was over the moon! Being up against people who had much more chemistry experience behind them, I didn’t think I was going to win. The help and guidance of my

colleagues at HMG really helped with my development. I now work on some very innovative projects for our customers and it’s a very proud feeling when you see products you developed being used in the real world to solve customers’ problems.” said Darren.

Another success story of HMG’s investment in staff and training is, HR Assistant Melissa Strowbridge. Melissa has recently completed her Degree Apprenticeship at the University of Salford and has also talked at the Houses of Parliament about the importance of apprenticeships. Melissa added, “The benefits of doing the degree via an apprenticeship route was that I was able to apply my learning directly to the workplace. Throughout the programme I developed both professionally and personally and I can now bring these skills into the workplace. I have a fantastic grounding for the future thanks to the University of Salford and HMG.”

Varied Products

HMG Paints provide coatings across a spectrum of industries which creates great variety in the projects their technical team work on. Many of the projects are also innovative within the coatings industry.

HMG were the first paint manufacturer to develop and commercialise Graphene containing coatings for a variety of

industries, with the coatings today being used on Commercial Vehicles across the UK.

On the other end of the development spectrum, Graduate Apprentice Avese Umar has recently led the redevelopment of the company’s artist Oil Colours. The range originally developed in the 1940’s has been reformulated to combine traditional performance with modern and sustainable raw materials. The range is used by leading artists including Carl Melegari, Frank Auerbach and Jake Attree, with artworks that use the range hanging in galleries across the globe.

To see a full list of HMG Paints products and services visit www.hmgpaint.com via the website you can also find out more about the company’s history, partners and career opportunities.

If you are interested in a career with HMG Paints Limited, please contact:

John Fenton

HMG Paints Human Resources Director

Email: jfenton@hmgpaint.com

33SEPTEMBER 2022

read online: www.surfaceworld.com INDUSTRY NEWS

TAILOR-MADE SOLUTIONS PRODUCT INNOVATION EXPERT TECHNICAL SUPPORT URBAN FURNITURE APPLIANCES GENERAL INDUSTRIAL FUNCTIONAL COATINGS AGRICULTURE & CONSTRUCTION EQUIPMENT (ACE) ARCHITECTURAL TRANSPORTATION FURNITURE Markets: “OVER 100 NEW ENQUIRIES FROM SURFACE WORLD LIVE 2022” - WE’VE GOT YOU COVERED!

Product Overview

Manual Monorail Systems

Unit loads up to 3000kg

Handling Solutions

Stewart Gill Conveyors Ltd have been supplying overhead conveyors into all sectors of industry for over 70 years.

As a long time member of the Railtechniek van Herwijnen BV Group based in the Netherlands, Stewart Gill Conveyors can offer a comprehen sive range of overhead conveyor products which are capable of handling unit loads up to 7000kg.

Monorail Chain Conveyors

Unit loads up to 300kg

Stewart Gill Conveyors Ltd offer complete manufacture, installation and commissioning, coupled with fully documented instruction, operation and maintenance manuals.

We do:

In-House 3D CAD engineering

In-House manufactoring in the UK and EU

Power & Free Conveyors

Unit loads up to 7000kg

In-House design of PLC/PC control systems

Industry 4.0

Worldwide installation and commissioning

Remote support, service & inspection

Part of the

Floor Conveyors

Unit loads up to 500kg

641424

Stewart Gill Conveyors Ltd Unit 3&4 Brook Business Park Brookhampton Lane Kineton, Warwickshire CV35 0JA, United Kingdom Tel: +44 (0)1926

info@stewart-gill.co.uk www.stewart-gill.co.uk

New digital solution from Interpon helps customers bring colors to life

AkzoNobel Powder Coatings has innovated a new web application 3D color visualization tool within its Interpon webshop to help customers better understand how a powder coating’s color, texture and finish that looks good in theory, will actually appear in reality.

The tool gives customers instant access to thousands of colors in the Interpon range. Through the clever use of a 360-degree dynamic camera and simulated lighting, the customer is given a true-to-life image of how the color performs to a degree of accuracy and realism not possible before in a virtual environment.

Rather than the image being ‘flat’, the customer can orientate the ‘virtual’ panel to see how the light reflects and the color looks from different angles. It gives a true impression of how surfaces coated in special

finishes and metal effects will appear in a way that it unprecedently realistic. They can also see multiple colors, multiple gloss levels and various surface finishes before deciding upon which is best. Customers can experience color as if they looked at panels in their hands without having to order a sample and waiting for it to arrive.

Remco Massen van den Brink, Marketing Director of AkzoNobel Powder Coatings, says the new tool is part of the company’s commitment to keeping its customers one step ahead: “Through ceaseless innovation, we are supporting our customers in the way they imagine and use powder coatings, developing practical, easy-to-use digital tools that they can access 24/7.”

“Through building meaningful partnerships with our customers and marketing insight studies, we understand the vital importance of choosing the right colors and textures to keep them out in front. That’s why we have so many colors to choose from and have

developed this first-of-its-kind solution to inspire our customers into making the right decisions, any time.”

Pim Koeckhoven, Director of Color Technology at AkzoNobel, says that this is another step on the road to digitizing part of the customer interface: “High quality and accurate digital representations of our products allow our customers to experience colors to a new level. Years of collaboration with academics and technology partners have taken us and our customers to a place we have never been before, and there will be more innovations like this to come.”

The 3D visualization tool, which was developed in collaboration with Dutchworkz, can be found on the Interpon webstores in Europe and North America, and can be used on all major platforms: Windows, macOS, Linux, Android and iOS.

To find out more, visit https://www.interpon. com/gl/article/webshop

read online: www.surfaceworld.com

36 SEPTEMBER 2022 INDUSTRY NEWS

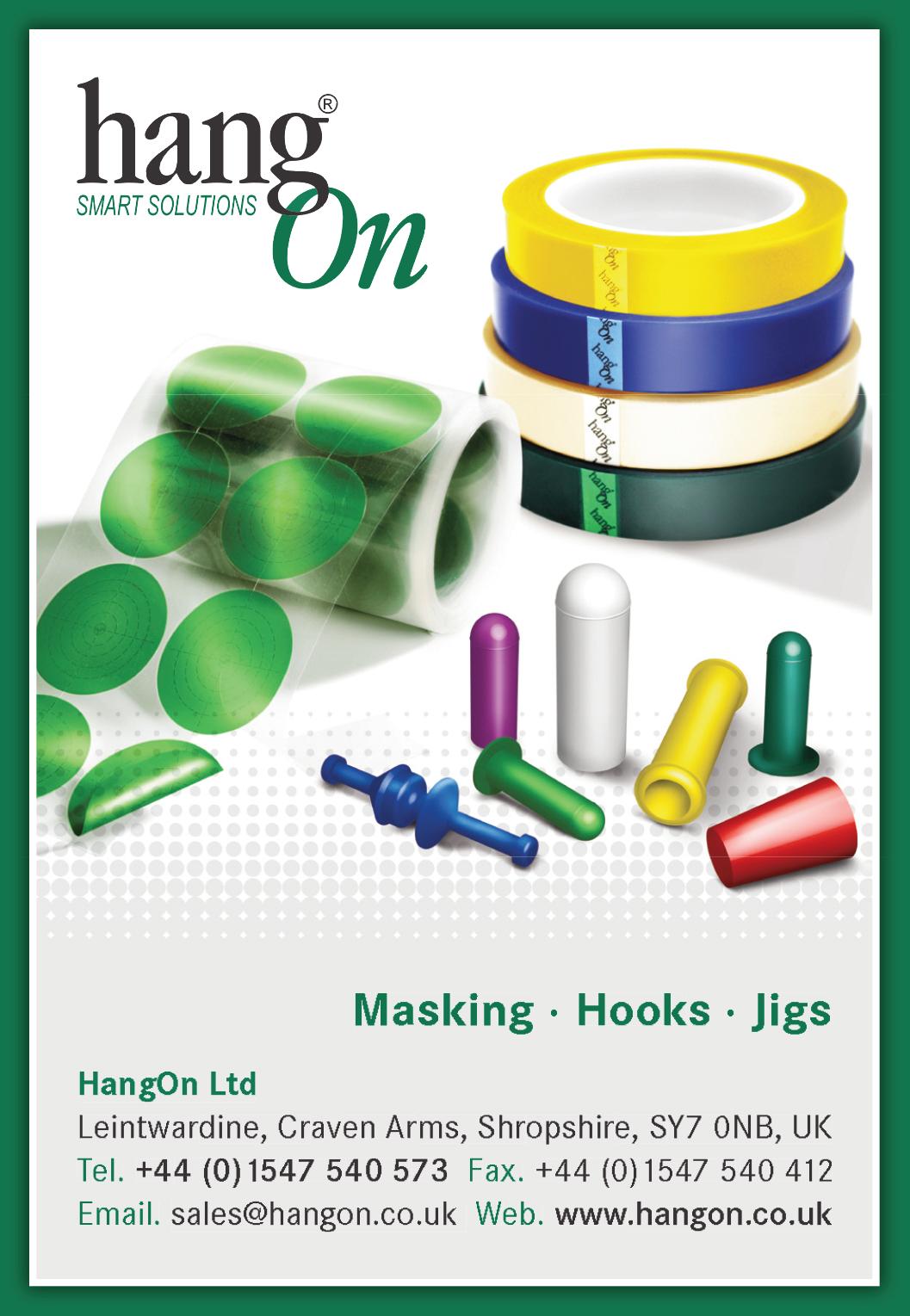

THIS IS HANGON

HangOn is a partner who helps customers to nd smart solutions to increase the e ciency in their coating process and improve their pro tability. We develop and produce in own factories. Our products are distributed from our warehouses into more than 40 countries.

WEB www.hangon.co.uk

sales@hangon.co.uk

HangOn Ltd. Leintwardine, Craven Arms, Shropshire, SY7 0NB

01547 540 573

EMAIL

TELEPHONE

Ecoclean: The experts for parts cleaning and surface treatment in the aviation industry

Solving the varied cleaning tasks efficiently and sustainably

Cleaning of parts and surfaces is one of the most quality-related and thus essential production processes in the aviation industry. In maintenance and repair of aircraft components application-oriented cleaning processes secure quality and functionality as well. Ecoclean offers efficient cleaning solutions that are optimally tailored to these challenging and varied tasks.

The quality of downstream processes such as heat treatment, coating and bonding depend on part cleanliness just as much as the long-term flawless function of components and units like engines, turbines, gear units and undercarriages, as well as electronic systems. In this context, increasingly high cleanliness specifications are to be met consistently. Therefore the cleaning of parts and surfaces is one of the essential production processes in the aviation industry. Parts used in maintenance, repair and overhaul (MRO) that are suitably and reproducibly cleaned are a prerequisite for these high-quality tasks and the safe and reliable functioning of components. Current and future developments such as energy-efficient engines, emission-free flying, e.g. with fuel cell engines and the increasing commercial use of drones are driving changes in parts, manufacturing technologies and processes. This also leads to new and modified requirements for the cleaning of components.

Expertise and technologies for cleaning parts for the aviation industry

As a full-range supplier of future-oriented, globally available equipment for industrial parts cleaning, surface processing and automation, Ecoclean and UCM - the division of SBS Ecoclean Group specializing in fine and precision cleaning - develop and manufacture cleaning solutions that are optimally adapted to the highly varied tasks in the aviation industry. They are based on extensive technological expertise, profound knowledge regarding applications and certifications in the aviation industry as well as numerous projects implemented for manufacturers, suppliers and maintenance staff around the globe.

The comprehensive portfolio contains standard and special solutions for batch and single part cleaning with aqueous media and environmentally-compatible solvents. Adapted to the specific requirements and applications of aircraft manufacturers and suppliers (e.g. production process, manufacturing technology, component dimensions, material, type of contamination and cleanliness

The EcoCvelox combines deburring and cleaning of e.g. hydraulic parts with high-speed automation so that these processes can be carried out efficiently in a single machine.

EcoCwave which is designed for immersion and spraying processes with aqueous media contains a vacuum-proof work chamber and covers a range of applications from coarse via intermediate to fine cleaning.

The combination of wet-chemical and low-pressure plasma cleaning enables the user to achieve the required surface properties for subsequent coating or bonding efficiently and reproducibly in one process.

The EcoCvelox combines deburring and cleaning of e.g. hydraulic parts with high-speed automation so that these processes can be carried out efficiently in a single machine.

EcoCwave which is designed for immersion and spraying processes with aqueous media contains a vacuum-proof work chamber and covers a range of applications from coarse via intermediate to fine cleaning.

The combination of wet-chemical and low-pressure plasma cleaning enables the user to achieve the required surface properties for subsequent coating or bonding efficiently and reproducibly in one process.

38 SEPTEMBER 2022

AVIATION & AUTOMOTIVE

CONTINUED ON PAGE 40 twitter: @surfaceworldmag

requirements) as well as providers of MRO services, they ensure that the required particulate and thin-film cleanliness are achieved in a reproducible and sustainable way. For the deburring and cleaning of hydraulic components in one process for example, they provide innovative developments such as EcoCvelox. This also applies to effective and consistent removal of thin-film chemical contaminations, e.g. before coating. Innovative solutions for the selective in-line treatment of functional surfaces, e.g. before a bonding process or the cleaning of additively manufactured parts round off the program. Ecoclean's dry cleaning technologies (steam, CO2 and plasma-based cleaning processes) have also proven their effectiveness in a wide range of applications in the aviation industry and MRO sector.

For complex tasks in precision cleaning, UCM designs and builds future-oriented, multi-level ultrasonic cleaning systems. They are used in aircraft component manufacturing just as much as in maintenance,

repair and overhaul. One of these is the new UCMSmartLine ultrasonic multi-bath immersion system, which can be configured almost freely from standard modules and expanded at any time.

Complementary to industry-specific expertise, it is possible to perform cleaning tests with originally soiled parts in technology centres for every cleaning task in component manufacture and for the MRO under near-production conditions. Based on the respective material, component geometry, type of contamination and cleanliness requirements, this enables us to develop individually tailored flexible cleaning solutions that are both technically and economically optimized and sustainable. They include continuous monitoring and recording of the key cleaning parameters.

Comprehensive services round off the portfolio offered by the cleaning experts. These include the IOS and Android Service App for maintenance and repair tasks, tailored service and maintenance concepts, developments related to digitizing cleaning processes, options for modernizing and adapting systems, as well as training programs for customer employees.

Visit: www.ecoclean-group.net

Call Nigel Bean for more information on +44 (0) 1442 826826

10 great reasons to exhibit at Surface World 2023

Meet and connect with prospective customers

Strengthen your bond with existing customers

Learn about new developments in your industry

Meet new companies that can help your business

Close deals with new customers during the show Strengthen or establish your brand

Learn what your competitors are doing right Rapidly expand your database of sales leads

Speak directly to your target market

Optimise your sales and lead generation strategy http://www.surfaceworld.com/surface-world-live/ floor-plan-exhibitor-list/

The cleaning of bipolar plates for emission-free engines is one of the most demanding tasks in the production of fuel cells.

The UCM multi-stage ultrasonic cleaning systems for precision cleaning are used for the most different tasks in production and the MRO of aircraft components including applications in a cleanroom environment.

40 SEPTEMBER 2022

AVIATION & AUTOMOTIVE

read online: www.surfaceworld.com

Burn off ovens offer effective process to remove plastic, paint coatings or contaminants

Burn off ovens (also commonly known as pyrolysis ovens or burnout ovens) offer an extremely effective process for the removal of plastic or paint coatings and contaminants from process machinery and components. This burns off the unwanted residue and preserves the original machinery part with minimal damage, offering prolonged lifetime and multiple usage. Our burn off / burnout ovens are custom built here at Longworth and can therefore house and clean a wide range of items and sizes.

How does a burn-off oven work?

Burn-off ovens use a process known as pyrolysis. They remove or break down organic materials that have adhered to metal parts. This works by heating the parts in a reduced oxygen atmosphere where a reaction takes place and reduces the contaminant to a residue that is richer in carbon. Any emissions that are given off during this process are put through an afterburner that heats these gasses to 850°C for a minimum of half a second. By heating these gasses to such a temperature turns them into H2O and CO2.

Longworth burn off ovens are constructed to exacting standards to suit the particular requirements of individual clients. To achieve the precise control our customers expect, each oven features a number of distinct burn-off or pyrolysis temperature profile settings. These profiles can be used to gradually break down the contamination whilst preventing the overheating of the component being processed.

Although our standard selection includes several models in various sizes – on the rare occasions that our selection doesn’t offer something to suit your requirements, we will design an oven to address your specific needs.

Features

Several models which come in various sizes, bespoke options available to suit requirement.

Incorporates PLC control, Touch screen HMI and on screen fault finding facility.

Oven interiors can be lined in stainless steel to avoid damage to internal insulation sustained via everyday knocks and scrapes.

Online oven maintenance option allows remote maintenance and fault finding from engineers in our Blackburn (UK) office.

Benefits