March 2023

VOLUME 30 • ISSUE 3

6 Back to the Future at IFPE: Are We There Yet?

Efficiency and what it means for fluid power system designers.

8 Gauge Ports Make Life Easier

MAIN Manufacturing makes flanges and participates in the SAE and ISO technical committees.

17 IFPE Show Supplement

Fluid Power Industry Bets on IFPE in Vegas

Amid economic uncertainty, the triennial confab carries on.

41 Test Your Skills

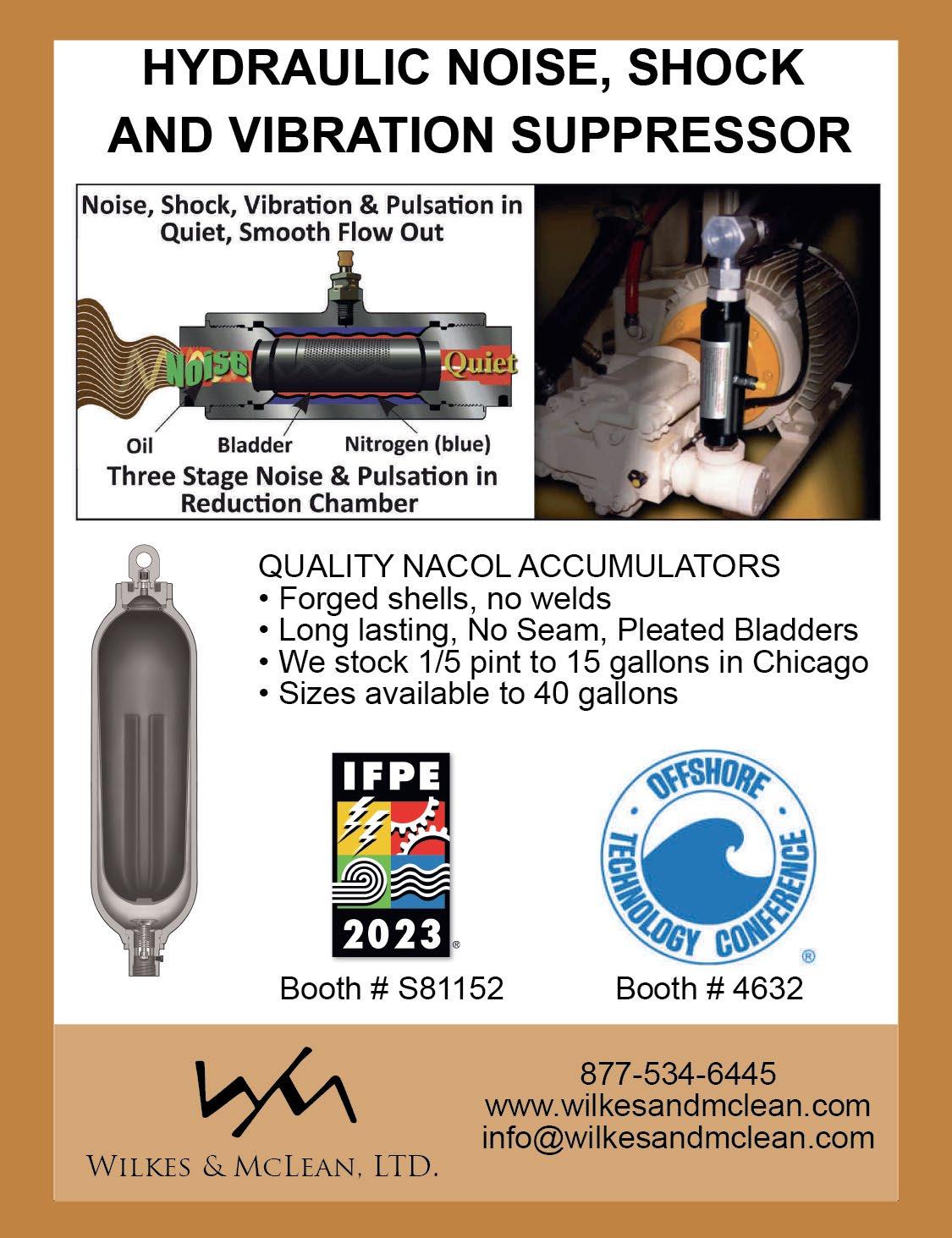

Why Accumulators Fail

42 Productivity in Crushing & Screening

What miners once did with manual labor they now do with automated mobile production lines.

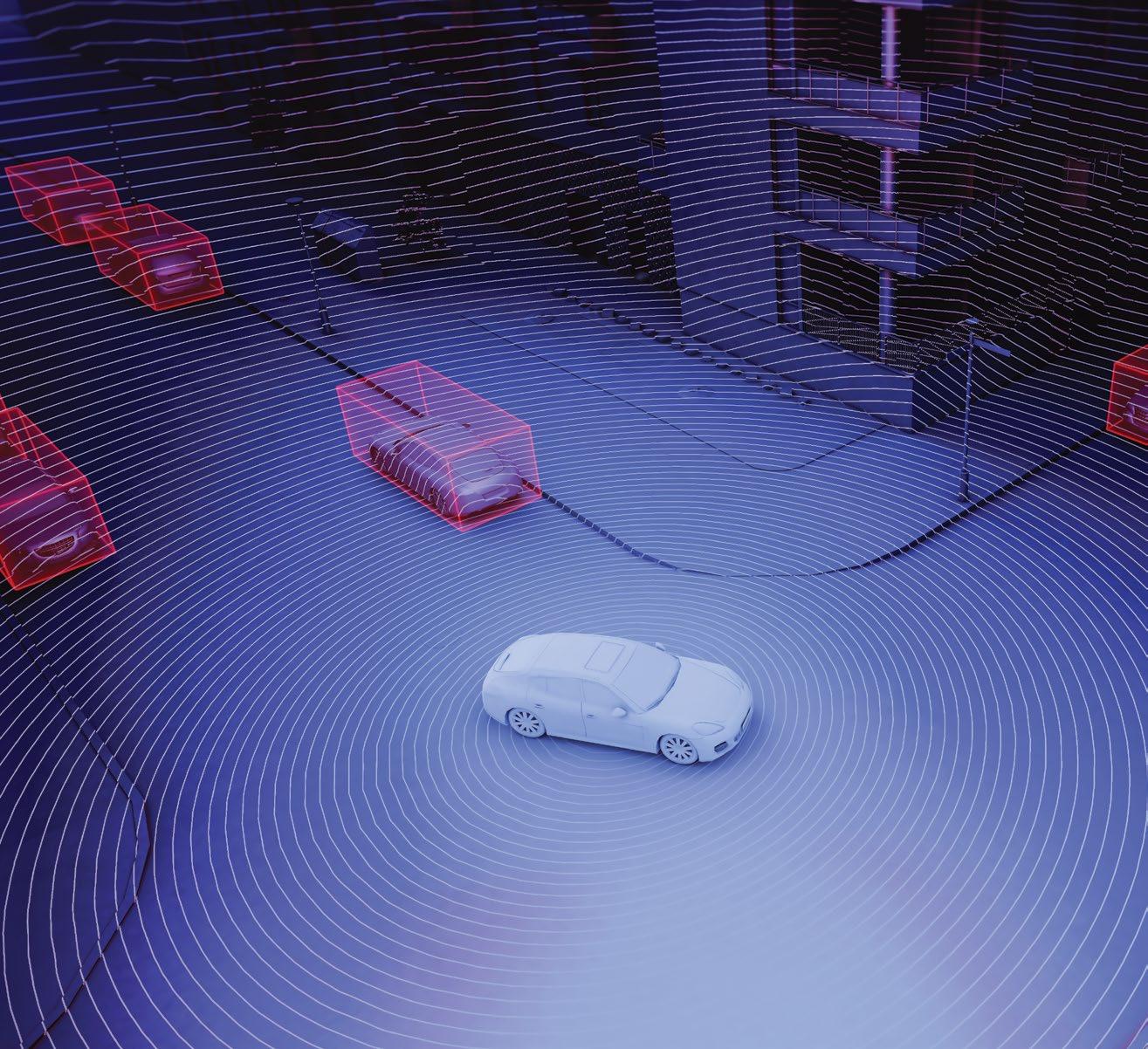

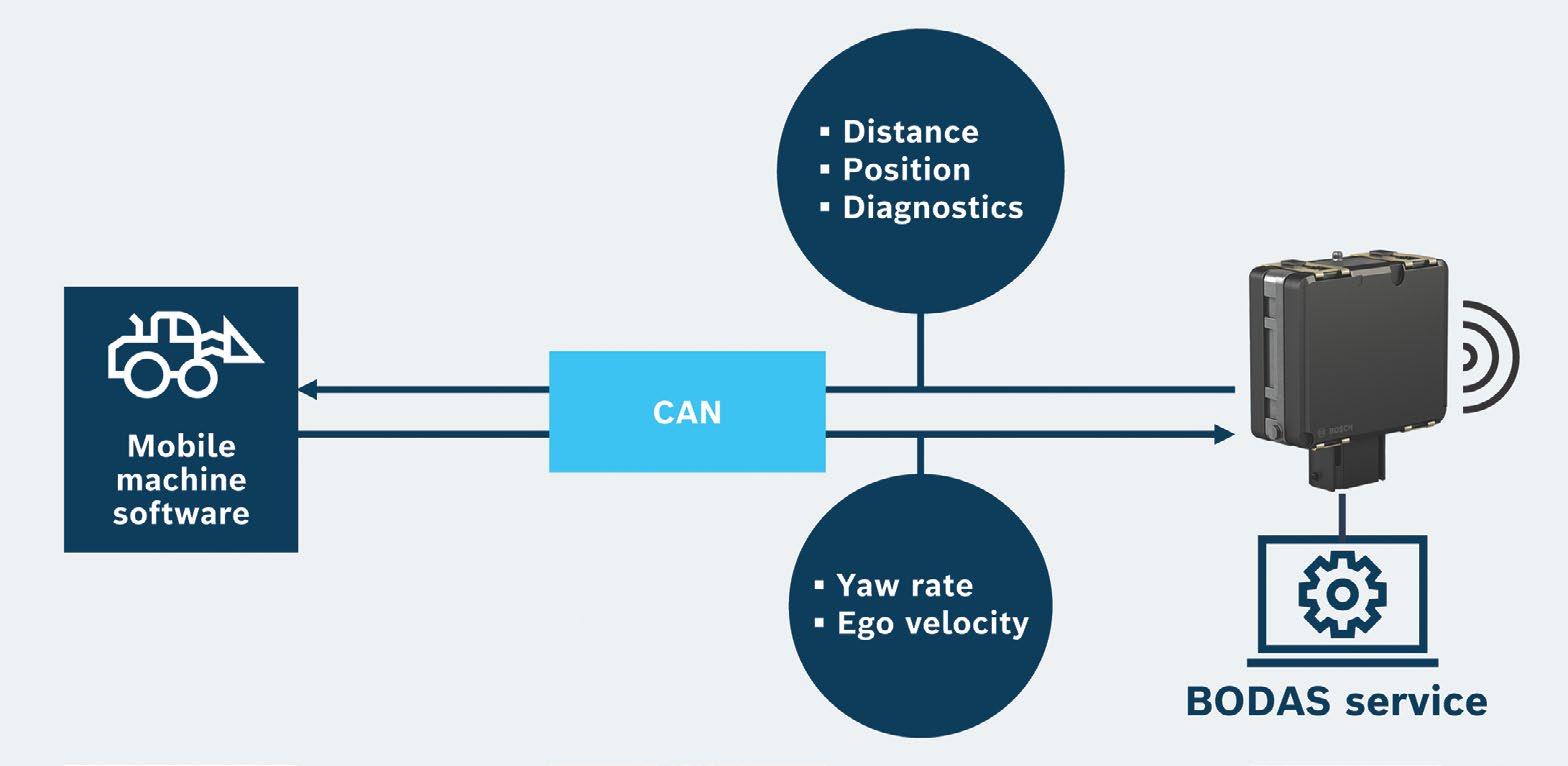

46 Off-Highway Safety: Surround Sensing for Mobile Machines

The technology enhances collision avoidance and operator safety.

Publisher’s Note: The information provided in this publication is for informational purposes only. While all efforts have been taken to ensure the technical accuracy of the material enclosed, Fluid Power Journal is not responsible for the availability, accuracy, currency, or reliability of any information, statement, opinion, or advice contained in a third party’s material. Fluid Power Journal will not be liable for any loss or damage caused by reliance on information obtained in this publication.

»MANY ARTICLES ABOUT certification focus on benefits to the individual, and I certainly don’t disagree with them. But I work for the International Fluid Power Society and look at it a little differently: What are certification’s benefits to an employer?

According to Phillip Barnhart’s 1997 Guide to National Professional Certification Programs, “Certifications are portable, since they do not depend on one company's definition of a certain job.” Certifications provide potential employers with “an impartial, third-party endorsement of an individual's professional knowledge and experience.”

For employers, certification is a screening tool that helps identify potential employees applying for jobs. Certification ensures that the candidate possesses at least base-level knowledge and skill.

that the company values their skills and knowledge. Another benefit to employers could be less turnover; satisfied employees usually don’t leave their employer. One concern expressed by some companies is a fear that if they train employees, those more highly valued professionals may leave to work somewhere else. There are many reasons to leave an employer, but I’ve never heard anyone say, “it was because they trained me too well.”

While trained individuals won’t necessarily increase production, they can help reduce downtime when faults in a system occur. Skilled professionals can quickly identify the fault’s cause and modify the system to ensure that it doesn’t reoccur.

Customers also benefit from well-trained and knowledgeable employees. They recognize that capable and credible professionals are serving them, and they see that a company holds its employees to the highest professional standards.

I obtained certification in 1990 because my boss at the Vickers Training Center decided that all instructors should be certified by IFPS, known at the time as the Fluid Power Society. My colleagues and I had been teaching for several years, but the explanation made sense: fluid power certification adds to our credibility, and it makes the training we offer relevant to the industry’s needs.

Some working professionals aren’t certified but possess the aptitude and attitude to obtain certification if they can get the right training. Employers should make certification a priority by providing the training employees require. Certification not only increases safety awareness, knowledge, and skills among employees, it yields benefits such as improved quality and increased productivity. Certification can result in less machine downtime.

Well-trained employees not only boost safety and productivity, they also improve engagement with the employer, as employees recognize

Companies benefit when they invest in their employees. When Vickers mandated that the sales force become certified, other manufacturers followed suit. Credentialing a sales rep as a Certified Fluid Power Specialist differentiates their company as better suited to design a hydraulic system. That doesn’t mean that noncertified professionals are not capable; many of them are. But certification assures customers that your company draws on an established foundational base of knowledge and skills.

As I reflect on my career in fluid power, I observe that my certification as a Certified Fluid Power Specialist opened many doors. It provided opportunities for professional growth that I would not have known otherwise. Over the years, I have known and worked with many of the industry’s great minds, and I am indebted to them for their mentorship and friendship.

Certification ensures that a job candidate possesses at least base-level knowledge and skill.

Employers should make certification a priority by providing the training employees require.

PUBLISHER

Innovative Designs & Publishing, Inc.

3245 Freemansburg Avenue, Palmer, PA 18045-7118

Tel: 800-730-5904 or 610-923-0380

Fax: 610-923-0390 • Email: Art@FluidPowerJournal.com www.FluidPowerJournal.com

Founders: Paul and Lisa Prass

Associate Publisher: Bob McKinney

Editor: Michael Degan

Technical Editor: Dan Helgerson, CFPAI/AJPP, CFPS, CFPECS, CFPSD, CFPMT, CFPCC

Marketing and

Social Media Consultant: Kristy O'Brien

Graphic Designer: Nicholas Reeder

Accounting: Donna Bachman, Sarah Varano

Circulation Manager: Andrea Karges

INTERNATIONAL FLUID POWER SOCIETY

1930 East Marlton Pike, Suite A-2, Cherry Hill, NJ 08003-2141 Tel: 856-424-8998 • Fax: 856-424-9248

Email: AskUs@ifps.org • Web: www.ifps.org

2023 BOARD OF DIRECTORS

President: Scott Sardina, PE, CFPAI, CFPHSWaterclock Engineering

Immediate Past President: Denis Poirier Jr., CFPAI/AJPP, CFPHS, CFPIHM, CFPCCDanfoss Power Solutions

First Vice President: Jeff Hodges, CFPAI/AJPP, CFPMHM- Altec Industries

Treasurer: Lisa DeBenedetto, CFPSGS Global Resources

Vice President Certification: James O’Halek, CFPAI/AJPP, CFPMIP, CMPMM - The Boeing Company

Vice President Marketing: Chauntelle Baughman, CFPHS - OneHydraulics

Vice President Education: Daniel Fernandes, CFPECS, CFPSSun Hydraulics

Vice President Membership: Garrett Hoisington, CFPAI/AJPP, CFPS, CFPMHM - Open Loop Energy

Stephen Blazer, CFPE, CFPS, CFPMHM, CFPIHT, CFPMHTAltec Industries

Cary Boozer, PE, CFPE - Motion Industries

Bruce Bowe, CFPAI/AJPP - Altec Industries

Bradlee Dittmer, CFPPS - Norgren/IMI Precision Engineering

Brian Kenoyer, CFPHS - Cemen Tech

Wade Lowe, CFPS - Hydraquip Distribution

Jon Rhodes, CFPAI, CFPS, CFPECS - CFC Industrial Training

Mohaned Shahin, CFPS - Parker Hannifin

Randy Smith, CFPHS - Northrop Grumman

Ethan Stuart, CFPS, CFPECS - Quadrogen

Bradley Wagner, CFPAI/AJPP - Manitowoc Crane Group

Brian Wheeler, CFPAI/AJPP, CFPMM, CFPMIPThe Boeing Company

CHIEF EXECUTIVE OFFICER (EX-OFFICIO)

Donna Pollander, ACA

HONORARY DIRECTOR (EX-OFFICIO)

Ernie Parker, CFPAI/AJPP - Hydra Tech

IFPS STAFF

Chief Executive Officer: Donna Pollander, ACA

Communications Coordinator: Victoria Piro

Technical Director: Thomas Blansett, CFPS, CFPAI

Assistant Director: Jenna Mort

Certification Logistics Manager: Kyle Pollander

Bookkeeper: Diane McMahon

Administrative Assistant: Beth Borodziuk

Instructional Designer and Layout: Chalie Clair

Fluid Power Journal (ISSN# 1073-7898) is the official publication of the International Fluid Power Society published monthly with four supplemental issues, including a Systems Integrator Directory, Off-Highway Suppliers Directory, Tech Directory, and Manufacturers Directory, by Innovative Designs & Publishing, Inc., 3245 Freemansburg Avenue, Palmer, PA 18045-7118. All Rights Reserved. Reproduction in whole or in part of any material in this publication is acceptable with credit. Publishers assume no liability for any information published. We reserve the right to accept or reject all advertising material and will not guarantee the return or safety of unsolicited art, photographs, or manuscripts.

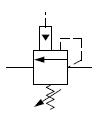

»THE ABOVE CIRCUIT drawing for a hydraulic press was upgraded after 10 years of continuous 24/7 operation. They replaced the main directional valve, added valve 3B unloading circuit, and installed a separate pilot pressure pump. This was all done to reduce the heat that was thought to be caused by the high flow through the directional valve when the cylinder retracted and omitted a 75 psi (0.5 MPa) back pressure check in the main pump line that supplied external pilot pressure to the valve.

The press was operational, but it still had the overheating problem that the upgrade was supposed to fix. They did find that the pilot line circuit was extremely hot going to the directional valve, and the line from check valve #2 to the tank was even hotter. The case drain line from the main pump to tank was warm like the original design.

What could be the problem?

See page 54 for the solution.

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.

ARE WE THERE YET?

By Rance Herren, Founder, Fluid Power SME

By Rance Herren, Founder, Fluid Power SME

charging electric vehicles. This is not an isolated incident domestically or globally, nor is it the only time extreme weather has affected EV drivers. It is well documented. Another concern is the availability of lithium, an essential element in rechargeable batteries.

The demand for lithium has increased at least 30 times between 2000 and 2015 and is expected to increase by another 1,000% by 2025 as compared to 2015. As of 2021, Australia accounts for 52% of global lithium production and was the number one lithium producing country in the world. Chile ranked second with its 24.5%, followed by China at 13.2%. Overall, Australia, Chile, and China have nearly 90% of lithium production in the world. The U.S. shares sixth spot with Portugal, having only 0.8% global share. The only existing lithium producer in the U.S. is in Nevada, and according to the U.S. Geological Survey, the country holds only an estimated 3.6% of global lithium reserves. China has the largest known lithium deposits in the world and will dominate the future lithium supply. Going forward, obtaining lithium may not be as easy given geopolitical concerns between China and the West. An inability to produce enough lithium would result in severe delays and disruptions to the roll out, implementation, and sustainability of electrification. Kind of rings of that whole dependence-on-foreign-oil-situation, doesn’t it? This is not to mention the environmental impact of lithium mining for batteries, the oppressively high cost to replace a battery, or the enormous cost and environmental impact of disposal. There are plenty of articles available to satisfy that curiosity should one care to know more.

So what does that have to do with fluid power systems used on industrial machinery and mobile equipment? More than one might think. From an electric grid perspective, battery-powered heavy construction, mining, and even agricultural equipment will be sharing and working in the same space as electric vehicles. That is unless diesel power generators are at hand. Yes, Rome was not built in a day, but many entities are moving full-speed ahead with their agendas, but with seemingly little attention being paid to the immediate and long-term impacts.

Among the many lessons from the COVID-19 pandemic we should have learned is how vulnerable our manufacturing base is to disruption. Another lesson is that supply chain is more than just manufactured products; it is about workers. Skilled workers. The fact is we are in a crisis. Let me say that again. We are in a crisis! Much like the hard sciences, the skilled trades are suffering an alarming drain on the talent pool. The number of individuals coming into and staying in the trades compared with those leaving or retiring is strikingly disproportionate. It has even become a matter of national security. In a September 2022 article in Foreign Affairs magazine, the authors argued, “Washington must acknowledge that education is no longer just a domestic policy issue but a national security issue on which the very future of the United States depends.” What this means is that as a country and a society, we need to put as much passion into educating those who will manufacture and maintain the equipment of the future as we do in developing and deploying the technology itself.

For the past several years, we’ve seen a regimented march to a steady drumbeat to abandon fluid power as a primary source of power transmission in many applications, and many are happy to see it relegated to a place where no other technology will suffice, regardless of efficiency, ease of application, and flexibility of installation. Many in our own industry are willing to cede the fight if they can cling to the power density argument. Unless the plan is to negotiate a peaceful surrender, it is time to ask ourselves some serious questions.

How well have we used the technologies and tools that we have available to us in the here and now? How many responsible for evaluating the various available technologies or designing fluid power systems are even aware of ISO/TR 22164, Application Notes for the Optimization of Energy Efficiency in Hydraulic Systems, or, for the pneumatically minded, ISO/TR 22165, Application Notes for the Improvement of the Energy Efficiency of Pneumatic Systems? These documents provide advice on how to design hydraulic and pneumatic systems with increased energy efficiency while maintaining the intended functionality of the machine. They are checklists of sorts to prompt the user of the many considerations for defining machine architecture, functionality, and duty cycle as well as component specification and selection, the use of software for system validation and optimization. This document does not tell one how to design a hydraulic or pneumatic system; rather it provides broad reminders of the technologies, tools, and best practices that are available to us right now.

Are we clinging to outdated technologies and rules of thumb from the past? Fluid power manufacturers are developing more energy efficient pumps, motor controls, and accessories. From energy efficient hydraulic fluids to variable frequency pump drives and electronics to manage power demands. How well are we embracing and adopting these technologies? Are reservoirs being grossly oversized based on antiquated rules of thumb or components being incorrect specified based on nominal flow rates? Are we really serious about STEM and skilled trades education for all trades, or just those that fit in the environmental box? Is skill-specific training and certification something worth investing in, or just another nuisance expense?

I will admit, I am not as hip and trendy as I would like to think I am. Somewhere I heard the phrase FOLO. Not knowing what it meant, I googled it. FOLO is an acronym for fear of losing out. It also turns out that FOLO has infested the business world too. Many leaders invest and prioritize their model based on hype, trends, and perceptions of what others are doing, rather than their own business strategy. They see a competitor going down a path, and they think they must do so too, often based on erroneous, incomplete, or biased data. They might not even fully understand or agree with what they are embarking on; nevertheless, they participate because everyone is doing it. There is also a lot of external pressure from nonfinancial factors, such as ESG – environmental, social, and governance – activism as part of their analysis and decision-making process. This is occurring posthaste, with equal intensity in consumer, commercial, and industrial markets.

None of this is to say that innovation, including electrification, is not important. But it would be ridiculous and disingenuous to claim we have made best use of all available fluid power technologies and best practices, and that, as a society, we have sufficiently invested in the infrastructure to support it. Please do not get me wrong: I do not hate electrification or any other form of alternative energy. It has many benefits that will ultimately outweigh the drawbacks, and fluid power must fight and earn the right to keep its place. But until we get where we want to go with electrification, maybe we pump the brakes a little, lest we go into an uncontrollable skid from which the industry may not recover.

We should all want to be good stewards of the planet we live on. But as noble as it may sound, at this juncture zero emissions means nothing more than transferring the source of pollution from one form of energy to another. And in many instances, we may be worse off than where we started.

Are we there yet? No. But we will be eventually. Maybe. •

Sometime ago, at CONEXPO-CON/AGG, it was possible to climb a stepladder, pass through a hatch, and sit next to the hydraulic brake motor of a large dump truck. However, just looking at the motor gives you less information about what is happening to the system than a diagnostic port.

In the last show, a vendor set up a stage with joysticks, gauges, and video screens for visitors to operate construction equipment several states away in real time. The conditions this equipment operates in could be the cold of the Arctic Circle to heat of the Sahara Desert. The equipment could be 5,000 feet under the ocean surface or in outer space. Note that the Colorado School of Mines now offers degrees in space resources (mining on asteroids). It is vital to know what is happening to the hydraulic components and fluids in this equipment. One way to do this is to extract a sample of the fluid or measure the fluid’s pressure and temperature. This article discusses the requirements of diagnostic gauge ports and explores available components to make life easier. MAIN Manufacturing Products has been putting gauge ports in flanges and making gauge port adapters for decades. MAIN has made flanges for over 65 years and participates in the SAE and ISO technical committees so we can speak of the market with confidence.

One of the first places to start is SAE J1298 Hydraulic System Diagnostic Port Sizes and Locations. This document was stabilized in 2016 by the SAE FCCTC subcommittee and is the consensus of fluid power manufacturers, OEM equipment manufacturers, and users. Stabilized means that the standard does not need regular review, as it is the best information currently available. It is not identical to ISO 8925 because SAE J1298 has additional metric and inch connections. SAE J1298 gives requirements for the manufacturers of self-propelled work machines and recommendations distilled from much discussion. Indoor equipment like presses and molding machines may not need the larger diameters of gauge ports specified, but the locational information in the standard still applies. It is a good idea to have a copy of the standard as it contains additional requirements. SAE J1298 covers only ports, not fittings, which have their own standards.

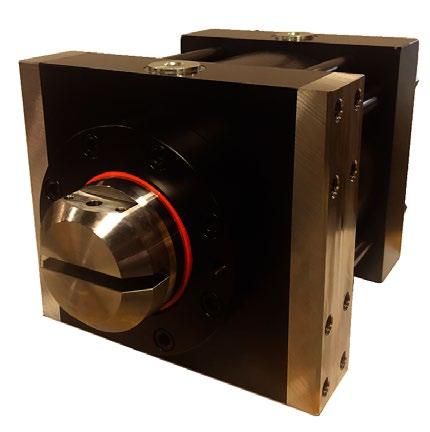

One of the first items to think about is what type of gauge port is needed. SAE J1298 requires M14 x 1.5 (ISO 6149), 3/8-18 (SAE J1926/ISO 11926 (SAE straight thread)), or SAE J518 flange ports for larger sizes. The “/” represents that SAE J1926 and ISO 11926 are generally technically identical. At MAIN, we see, in order of market preference:

MAIN manufactures flanges with gauge ports daily. The industry is trying to move to using elastomeric sealing specified in the SAE straight thread (SAE J1926) and ISO 6149. Metal-to-metal sealing, like the NPTF and some BSP threads, is discouraged because of its tendency to leak, although usage is very common.

Next is the size of the port. At MAIN, the 1/4 inch (#4) size is the most common, with 3/8 (#6) next. ISO 6149 ports are not common but MAIN does machine these in. The 9/16-18 thread corresponds to the #6 SAE straight thread size. SAE J1298 says for temperature, pressure, and sampling, the size should be the M14 X 1.5 ISO 6149 or the #6 SAE straight thread. It uses the larger size to improve fluid flow in colder situations. MAIN was involved with a distributor that was reconfiguring equipment that was transferred from oil fields in Alaska to oil fields in Saudi Arabia. When designing equipment, it is important to consider the life of the equipment and all possible environments in which the equipment could be used. Appropriately larger sized ports can also be used to measure flow. Ports should be located in places to get the most accurate readings. This is generally in the fluid stream. A requirement of SAE J1298 is to have at least one port at the main system relief valve. Other suggested places are the inlet and outlet ports of the following locations:

It is a good idea to consider the requirements of OSHA, or other nations’ equivalent organization, of assuring that the system is de-energized before working on it. Although gauges can malfunction or break, showing zero pressure on each side of a hydraulic component is a first step to assuring no hydraulic pressure in the component.

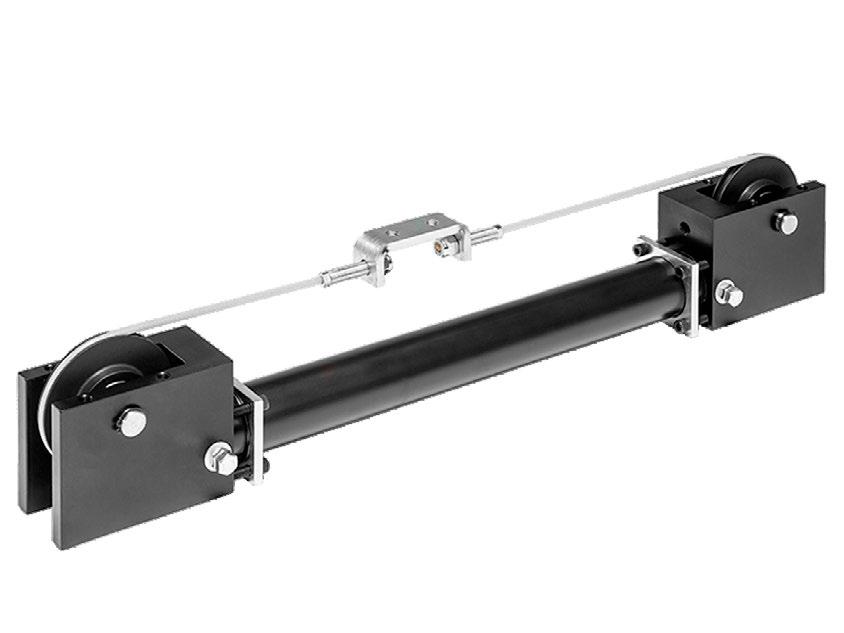

Finally, around the diagnostic port make sure that there is at least a 3 inches (75 mm) diameter and a 8 inches (200 mm) high area of no interference to allow for clearance for the connection to be made. This space allows the gauge or coupling to be installed. A type of fitting to consider is the push-to-connect under pressure fittings. These are hydraulic fittings designed to allow coupling and decoupling under pressure. With this fitting, gauge or sampling equipment does not have to be attached to the system at all times, or even most of the time. Many companies manufacture push-to-connect under pressure fittings, and they are available from many sources and can make the determination of location easier.

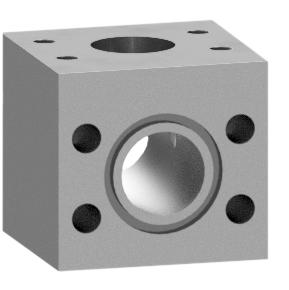

gauge port adapter plates discussed below, the reducing run tees are blocks with #12 or #16 SAE straight threads or other ports. They are regularly 2 inches or more thick. While the run of the tee can be made in any port style, most are straight threads, flanged (having a flange port), then NPTF.

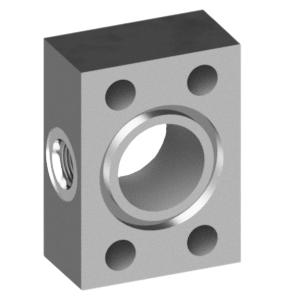

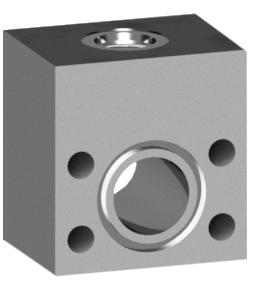

Another convenient way to add a gauge port to hose or pipe with flange ports is with gauge port adapters. Gauge port adapters are plates between 1 and 1.5 inches

thick, ground on one side and O-ringed on the other. A gauge port is put in the side of the long way of the bolt pattern. Some manufacturers put an NPTF on one side and an SAE straight thread on the other side.

BOOTH #S84057

Gauge port adapters have the appropriate bolt pattern for the size of the flange. These parts get sandwiched in between the flange fitting and the component using longer screws. No machining is required and the port can be added very quickly in retrofit situations. The thickness of the plate is determined by the size of the gauge port. Many manufacturers offer these from stock in popular sizes and ports. MAIN has gauge port adapter plates stocked in all popular sizes, such as 1/4-inch and 3/8-inch NPTF, and #4 and #6 SAE straight thread. BSP (T or P) in 1/4 or 3/8 inch are manufactured regularly with very quick delivery times. The ISO 6149 ports are not as common in the U.S. MAIN has quick delivery times on them but many manufacturers and distributors do not stock them or have even offer the plates with ISO 6149 ports.

For system maintenance and troubleshooting, not all the systems have gauge ports where needed. The gauge port adapters lend themselves for use by maintenance workers and distributors trying to troubleshoot a system. They organize sets of adapters with longer screws and a gauge and putting this group into a pelican type case. When the troubleshooter arrives, they sandwich the gauge port adapters in-line with the gauge installed and get the information or sample they need to quickly and precisely analyze the system. •

The IFPS Spring Meeting will be held in person and virtually Feb. 27–March 2 in New Orleans.

Why attend? You’ll meet a dedicated (and fun) group of professionals who exchange ideas and technologies, on ways to improve and educate the fluid power workforce. Our board members have diverse backgrounds and work in many different segments of the industry. So the discussion is lively and informative. Imagine the things you’ll learn!

Each of our committees – Education, Certification, Membership, Marketing, and Finance – follow a mission statement, and each team works together on projects to meet those goals. Our members’ input is vitally important, so if you can’t participate virtually or attend in person, consider joining one of our committees. Contact vpiro@ifps.org.

In addition to committee meetings, tours, and networking, a technical workshop titled A Deep Dive into Cartridge/logic Valves and Pilot Operated Check Valves will be conducted by Ernie Parker, CFPAI, and will be held on Feb. 27, 8 a.m. to 2 p.m. [CST].

Parker will take a deep dive into some of the most popular components in a fluid power system. He will cover pilot-operated check valves outlining proper applications, sizing the correct ratio for different applications, designing circuits with pilot-operated check valves, and why orifices are often needed. In addition, he’ll cover counterbalance valves detailing proper applications, adjusting counterbalance valves as compared to other pressure control valves, sizing the correct ratios for different applications, determining when one should use internal pilot, external pilots, or both, designing various circuits where counterbalance valves are needed and using counterbalance valves versa a flow control to increase efficiency when variable speeds are needed and safety concerns of over pressurization. Also, designing efficient, cost-effective circuits using standard type components that will have a relativity short payback, covering: how to properly apply flow dividers, when to use a proportionator (rotary type) or a spool type flow control, examples of efficient circuits, designing a mobile system using dual reservoirs for contamination reasons and to reduce maintenance, applying a cylindrical reservoir with proper filtration and cooling and new best practice inlet plumbing, correcting mistakes that have been made for years. Register at www.ifps.org.

»NOMINATIONS FOR THE Fluid Power Hall of Fame are open until April 15.

The fluid power industry's success is through the efforts of dedicated individuals – innovators, researchers, application engineers, educators, and sales and service personnel. These people are the reasons our industry continues to thrive.

The Fluid Power Hall of Fame was established to acknowledge those individuals who have dedicated their careers and have made significant contributions to fluid power technology.

Any person can nominate an individual, living or deceased, who demonstrated excellence within their 25-plus year fluid power career –one nomination per category (living or deceased) per person.

A panel of judges will review applications and select inductees. The inductees will be announced on June 19, Fluid Power Professionals Day. Inductees will be honored during the IFPS awards dinner in New Orleans.

»THIS ONLINE AT-YOUR-OWN-PACE training module takes the IHM and MHM study manuals and brings them to life! The mechanic training modules heavily emphasize maintaining, repairing, and troubleshooting hydraulic systems. These modules also include the basic principles of fluid power and the operation and construction of the most common hydraulic components found in the system.

These modules are a great tool for someone preparing for an IHM or MHM certification tests, someone looking to boost their skills, and even makes an excellent onboarding tool for entry-level mechanics!

Our IHM and MHM certification study manuals were transformed from traditional black/white print into a full color, animated, interactive online learning platform!

• Schematics are color coded and animated

• Contains ISO 1219 symbology

• Full-color graphics

• Chapter review questions - interactive (you’ll know immediately if you’ve grasped the chapter information)

• Voice-over for text for auditory learners

• Three additional online pre-tests

• Safety and Energy Tips throughout

Cost is $349. Multiple-user pricing for five or more!

E-mail sales@ifps.org for details.

»A RECENT STUDY found that more than 68% of participants cited a lack of confidence as the biggest stumbling block to a student’s ability to succeed in math. If math is a stumbling block for you, or if you are preparing to take a certification test, this online at-your-own-pace training module transforms the IFPS math book into an interactive learning tool!

Dan Helgerson, CFPAI, will teach fundamental fluid power math skills and build on that foundation to explain the calculation of more complicated formulas. Each section includes step-by-step video instructions on how to solve complex fluid power math problems.

1. Welcome to the Fluid Power Math Workshop

2. Understanding the Order of Operations –PEMDAS

3. Units used in IFPS Fluid Power Math Equations

4. Math Basics

5. Circles

6. Various Math Equations

7. Fluid Power Formulae

8. Calculating, Volumetric, Mechanical and Overall Efficiency

9. How to Size and Select a Fluid Power Cylinder

10. Calculating Fluid Velocity

11. Detailed Explanation and the Importance Triangles in Fluid Power

12. Understanding Reaction Forces

13. Jib Boom Calculations

14. Understanding Toggles

15. Misc. Reservoir Equations

16. Understanding Compressed Air

17. Coefficient of Velocity

18. Sizing Accumulators

19. Coefficient of Friction

20. Understanding Cartridge Elements

21. Electric Formulae - Ohm's

Cost is $199. Multiple-user pricing for five or more!

E-mail sales@ifps.org for details.

UPCOMING TRAINING

Primary and Secondary Air Preparation

When: Feb. 17, 12-1 p.m. [ET] Presented by Ed Rybarczyk, CFPAI

Fluid Power Basics

When: April 27, 12-1 p.m. [ET]

UPCOMING VIRTUAL LEARNING

Deep Dive into Cartridge, Logic, and Pilot

Operated Check Valves

When: Feb. 27, 8 a.m. to 2 p.m. [CST], virtual or in-person, Embassy Suites, New Orleans

Presented by Ernie Parker, CFPAI CFPE

Cost: $150

For more information and to register, visit www.ifps.org.

UPCOMING WORKSHOPS

Accredited Instructor and Authorized Job Performance Proctor Workshop

When: March 28-29, IFPS Headquarters, Cherry Hill, New Jersey

Accredited Instructor (AI) and Authorized Job Performance Proctor (AJPP) Workshops

The AI workshop is a one or two-day workshop to acquaint you with the IFPS certification program and to assess your instructional abilities. It is not a program to teach instructor skills, but rather, to measure your instructor skills. IFPS AIs have extensive backgrounds and instructional experience in the fluid power industry. In addition to their instructor accreditation, they are committed IFPS members and hold various levels of IFPS certifications. IFPS AJPPs are certified to proctor all mechanic and technician and Connector & Conductor job performance (hands-on section) tests. An individual must hold the certification they plan to proctor and must be an IFPS member. Registration deadline is March 1.

For more information or to register, call (856) 424-8998 or visit www.ifps.org/certified-accredited-instructor.

December 2022

AUTHORIZED JOB PERFORMANCE PROCTOR

Seth Davis, Pueblo Community College

CONNECTOR & CONDUCTOR

AUTHORIZED JOB PERFORMANCE PROCTOR

Seth Davis, Pueblo Community College

ELECTRONIC CONTROLS SPECIALIST

David Vos, TriHQ

HYDRAULIC SPECIALIST

David Steere, Alfred State College

Adam Becker, Triad Technologies

Jake Bethel

Kevin Briggs

Christian O'Neal, Altec Industries

Gabriel Cooks, SUNY Alfred State College

Harkanwaljeet Singh

Jarred Mathers, Connector Specialists of Alabama

Jesse Holman, Triad Technologies

Mark Suber, Triad Technologies

Michael Osborn, Dana

Shaun Maconaghy, Blue Origin

Jonathan Stanbro

Weston Alberts, Akkerman

INDUSTRIAL HYDRAULIC TECHNICIAN

Karl Lueck

MOBILE HYDRAULIC MECHANIC

Michael Esposito, Comed

Chance Chromcak, Entergy

Chad Paustian, Comed

Dan Calderone, Atlantic City Electric

Darren Provost, Comed

Dylan Falcone, Altec Industries

Eric Snyder

Garrett James

Jacob Leuthold, Comed

James Jennings, Altec Industries

Keith Masse, Altec Industries

Keith Tindall, Atlantic City Electric

Kenneth Purcell, Comed

Kenneth Stephens, Georgia Power Company

Leo Kohs, Comed

Nicholas Hall, Mississippi Power

Oakley Blamey, Georgia Power

For more information, visit www.ifps.org.

Ryan Schulte, Liberty Utilities

Scott Full, Comed

Scott Simonelli, Altec Industries

Stephen Streaker, Delmarva Power

Wesley Cooley, Mississippi Power

MASTER MECHANIC

Sean Wynne, The Boeing Company

William Cooper, The Boeing Company

PNEUMATIC MECHANIC

Guy Roberts, The Boeing Company

John Nason, The Boeing Company

Mark Mayberry, The Boeing Company

Sean Wynne, The Boeing Company

Tyler Crabb, The Boeing Company

William Cooper, The Boeing Company

PNEUMATIC SPECIALIST

Christopher Raschke

Jonathan Randich, IMI Precision Engineering

SPECIALIST

Christopher Raschke

ALABAMA

Auburn, AL

Birmingham, AL

Individuals wishing to take any IFPS written certification tests can select from convenient locations across the United States and canada. IFPS is able to offer these locations through its affiliation with the consortium of college Testing centers provided by National college Testing association.

contact Kyle Pollander at Kpollander@ifps.org if you do not see a location near you. Every effort will be made to accommodate your needs.

Calera, AL

Decatur, AL

Huntsville, AL

Jacksonville, AL

Mobile, AL

Montgomery, AL

Normal, AL

Tuscaloosa, AL

ALASKA

Anchorage, AK

Fairbanks, AK

ARIZONA

Flagstaff, AZ

Glendale, AZ

Mesa, AZ

Phoenix, AZ

Prescott, AZ

Scottsdale, AZ

Sierra Vista, AZ

Tempe, AZ

Thatcher, AZ

Tucson, AZ

Yuma, AZ

ARKANSAS

Bentonville, AR

Hot Springs, AR

Little Rock, AR

CALIFORNIA

Aptos, CA

Arcata, CA

TENTATIVE TESTING DATES FOR ALL LOCATIONS:

April 2023

Tuesday 4/11 • Thursday 4/27

May 2023

Tuesday 5/9 • Thursday 5/25

June 2023

Tuesday 6/6 • Thursday 6/22

July 2023

Tuesday 7/11 • Thursday 7/27

JOB PERFORMANCE TEST LOCATIONS

Arizona

California

Colorado

Florida

Georgia

Maine

Michigan

Minnesota

Montana New Jersey

Nova Scotia Pennsylvania Texas Washington Wyoming Western Australia

Tallahassee, FL

Tampa, FL

West Palm Beach, FL

Wildwood, FL

Winter Haven, FL

GEORGIA

Albany, GA

Athens, GA

Atlanta, GA

Carrollton, GA

Columbus, GA

Dahlonega, GA

Dublin, GA

Dunwoody, GA

Forest Park, GA

Lawrenceville, GA

Morrow, GA

Oakwood, GA

Savannah, GA

Statesboro, GA

Tifton, GA

Valdosta, GA

HAWAII

Laie, HI

IDAHO

Boise, ID

Coeur d ‘Alene, ID

Idaho Falls, ID

Lewiston, ID

Moscow, ID

Nampa, ID

Rexburg, ID

Twin Falls, ID

ILLINOIS

Bakersfield, CA

Dixon, CA

Encinitas, CA

Fresno, CA

Irvine, CA

Marysville, CA

Riverside, CA

Salinas, CA

San Diego, CA

San Jose, CA

San Luis Obispo, CA

Santa Ana, CA

Santa Maria, CA

Santa Rosa, CA

Tustin, CA

Yucaipa, CA

COLORADO

Aurora, CO

Boulder, CO

Springs, CO

Denver, CO

Durango, CO

Ft. Collins, CO

Greeley, CO

Lakewood, CO

Littleton, CO

Pueblo, CO

DELAWARE

Dover, DE

Georgetown, DE

Newark, DE

FLORIDA

Avon Park, FL

Boca Raton, FL

Cocoa, FL

Davie, FL

Daytona Beach, FL

Fort Pierce, FL

Ft. Myers, FL

Gainesville, FL

Jacksonville, FL

Miami Gardens, FL

Milton, FL

New Port Richey, FL

Ocala, FL

Orlando, FL

Panama City, FL

Pembroke Pines, FL

Pensacola, FL

Plant City, FL

Riviera Beach, FL

Sanford, FL

LOUISIANA

Bossier City, LA

Lafayette, LA

Monroe, LA

Natchitoches, LA

New Orleans, LA

Shreveport, LA

Thibodaux, LA

MARYLAND

Arnold, MD

Bel Air, MD

College Park, MD

Frederick, MD

Hagerstown, MD

La Plata, MD

Westminster, MD

Woodlawn, MD

Wye Mills, MD

MASSACHUSETTS

Boston, MA

Bridgewater, MA

Danvers, MA

Haverhill, MA

Holyoke, MA

Shrewsbury, MA

MICHIGAN

Ann Arbor, MI

Big Rapids, MI

Chesterfield, MI

Dearborn, MI

Dowagiac, MI

East Lansing, MI

Flint, MI

Grand Rapids, MI

Kalamazoo, MI

NEW JERSEY

Branchburg, NJ

Cherry Hill, NJ

Lincroft, NJ

Sewell, NJ

Toms River, NJ

West Windsor, NJ

NEW MEXICO

Albuquerque, NM

Clovis, NM

Farmington, NM

Portales, NM

Santa Fe, NM

NEW YORK

Alfred, NY

Brooklyn, NY

Buffalo, NY

Garden City, NY

New York, NY

Rochester, NY

Syracuse, NY

NORTH CAROLINA

Apex, NC

Asheville, NC

Boone, NC

Charlotte, NC

China Grove, NC

Durham, NC

Fayetteville, NC

Greenville, NC

Jamestown, NC

Misenheimer, NC

Mount Airy, NC

Pembroke, NC

Raleigh, NC

SOUTH CAROLINA

Beaufort, SC

Charleston, SC

Columbia, SC

Conway, SC

Graniteville, SC

Greenville, SC

Greenwood, SC

Orangeburg, SC

Rock Hill, SC

Spartanburg, SC

TENNESSEE

Blountville, TN

Clarksville, TN

Collegedale, TN

Gallatin, TN

Johnson City, TN

Knoxville, TN

Memphis, TN

Morristown, TN

Murfreesboro, TN

Nashville, TN

TEXAS

Abilene, TX

Arlington, TX

Austin, TX

Beaumont, TX

Brownsville, TX

Commerce, TX

Corpus Christi, TX

Dallas, TX

Denison, TX

El Paso, TX

Houston, TX

Huntsville, TX

Laredo, TX

WYOMING

Casper, WY

Laramie, WY

Torrington, WY

CANADA

ALBERTA

Calgary, AB

Edmonton, AB

Fort McMurray, AB

Lethbridge, AB

Lloydminster, AB

Olds, AB

Red Deer, AB

BRITISH

COLUMBIA

Abbotsford, BC

Burnaby, BC

Castlegar, BC

Delta, BC

Kamloops, BC

Nanaimo, BC

Prince George, BC

Richmond, BC

Surrey, BC

Vancouver, BC

Victoria, BC

MANITOBA

Brandon, MB

Winnipeg, MB

NEW BRUNSWICK

Bathurst, NB

Moncton, NB

NEWFOUNDLAND AND LABRADOR

Carbondale, IL

Carterville, IL

Champaign, IL

Decatur, IL

Edwardsville, IL

Glen Ellyn, IL

Joliet, IL

Malta, IL

Normal, IL

Peoria, IL

Schaumburg, IL

Springfield, IL

University Park, IL

INDIANA

Bloomington, IN

Columbus, IN

Evansville, IN

Fort Wayne, IN

Gary, IN

Indianapolis, IN

Kokomo, IN

Lafayette, IN

Lawrenceburg, IN

Madison, IN

Muncie, IN

New Albany, IN

Richmond, IN

Sellersburg, IN

South Bend, IN

Terre Haute, IN

IOWA

Ames, IA

Cedar Rapids, IA

Iowa City, IA

Ottumwa, IA

Sioux City, IA

Waterloo, IA

KANSAS

Kansas City, KS

Lawrence, KS

Manhattan, KS

Wichita, KS

KENTUCKY

Ashland, KY

Bowling Green, KY

Erlanger, KY

Highland Heights, KY

Louisville, KY

Morehead, KY

Lansing, MI

Livonia, MI

Mount Pleasant, MI

Sault Ste. Marie, M

Troy, MI

University Center, MI

Warren, MI

MINNESOTA

Alexandria, MN

Brooklyn Park, MN

Duluth, MN

Eden Prairie, MN

Granite Falls, MN

Mankato, MN

MISSISSIPPI

Goodman, MS

Jackson, MS

Mississippi State, MS

Raymond, MS

University, MS

MISSOURI

Berkley, MO

Cape Girardeau, MO

Columbia, MO

Cottleville, MO

Joplin, MO

Kansas City, MO

Kirksville, MO

Park Hills, MO

Poplar Bluff, MO

Rolla, MO

Sedalia, MO

Springfield, MO

St. Joseph, MO

St. Louis, MO

Warrensburg, MO

MONTANA

Bozeman, MT

Missoula, MT

NEBRASKA

Lincoln, NE

North Platte, NE

Omaha, NE

NEVADA

Henderson, NV

Las Vegas, NV

North Las Vegas, NV

Winnemucca, NV

Wilmington, NC

NORTH DAKOTA

Bismarck, ND

OHIO

Akron, OH

Cincinnati, OH

Cleveland, OH

Columbus, OH

Fairfield, OH

Findlay, OH

Kirtland, OH

Lima, OH

Maumee, OH

Newark, OH

North

Royalton, OH

Rio Grande, OH

Toledo, OH

Warren, OH

Youngstown, OH

OKLAHOMA

Altus, OK

Bethany, OK

Edmond, OK

Norman, OK

Oklahoma City, OK

Tonkawa, OK

Tulsa, OK

OREGON

Bend, OR

Coos Bay, OR

Eugene, OR

Gresham, OR

Klamath Falls, OR

Medford, OR

Oregon City, OR

Portland, OR

White City, OR

PENNSYLVANIA

Bloomsburg, PA

Blue Bell, PA

Gettysburg, PA

Harrisburg, PA

Lancaster, PA

Newtown, PA

Philadelphia, PA

Pittsburgh, PA

Wilkes-Barre, PA

York, PA

Lubbock, TX

Lufkin, TX

Mesquite, TX

San Antonio, TX

Victoria, TX

Waxahachie, TX

Weatherford, TX

Wichita Falls, TX

UTAH

Cedar City, UT

Kaysville, UT

Logan, UT

Ogden, UT

Orem, UT

Salt Lake City, UT

VIRGINIA

Daleville, VA

Fredericksburg, VA

Lynchburg, VA

Manassas, VA

Norfolk, VA

Roanoke, VA

Salem, VA

Staunton, VA

Suffolk, VA

Virginia Beach, VA

Wytheville, VA

WASHINGTON

Auburn, WA

Bellingham, WA

Bremerton, WA

Ellensburg, WA

Ephrata, WA

Olympia, WA

Pasco, WA

Rockingham, WA

Seattle, WA

Shoreline, WA

Spokane, WA

WEST VIRGINIA

Ona, WV

WISCONSIN

La Crosse, WI

Milwaukee, WI

Mukwonago, WI

St. John’s, NL

NOVA SCOTIA

Halifax, NS

ONTARIO

Brockville, ON

Hamilton, ON

London, ON

Milton, ON

Mississauga, ON

Niagara-on-the-Lake, ON

North Bay, ON North York, ON

Ottawa, ON

Toronto, ON

Welland, ON

Windsor, ON

QUEBEC

Côte Saint-Luc, QB

Montreal, QB

SASKATCHEWAN

Melfort, SK Moose Jaw, SK

Nipawin, SK

Prince Albert, SK

Saskatoon, SK

YUKON TERRITORY

Whitehorse, YU

UNITED KINGDOM

Elgin, UK

GHAZNI

Kingdom of Bahrain, GHA

Thomasville, GHA

EGYPT

Cairo, EG

JORDAN

Amman, JOR

NEW ZEALAND

Taradale, NZ

CFPAI Certified Fluid Power Accredited Instructor

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HYDRAULIC SPECIALIST

May 1-3, Mukwonago, WI, MSOE. Written test: May 4.

CFPE Certified Fluid Power Engineer

CFPS Certified Fluid Power Specialist (Must Obtain CFPHS & CFPPS)

CFPHS Certified Fluid Power Hydraulic Specialist

CFPPS Certified Fluid Power Pneumatic Specialist

CFPECS Certified Fluid Power Electronic Controls Specialist

CFPMT Certified Fluid Power Master Technician (Must Obtain CFPIHT, CFPMHT, & CFPPT)

CFPIHT Certified Fluid Power Industrial Hydraulic Technician

CFPMHT Certified Fluid Power Mobile Hydraulic Technician

CFPPT

Certified Fluid Power

Pneumatic Technician

CFPMM

Certified Fluid Power Master Mechanic (Must Obtain CFPIHM, CFPMHM, & CFPPM)

CFPIHM

Certified Fluid Power

Industrial Hydraulic Mechanic

CFPMHM

Certified Fluid Power Mobile Hydraulic Mechanic

CFPPM

Certified Fluid Power Pneumatic Mechanic

CFPMIH

Certified Fluid Power

Master of Industrial Hydraulics

(Must Obtain CFPIHM, CFPIHT, & CFPCC)

CFPMMH

Certified Fluid Power

Master of Mobile Hydraulics

(Must Obtain CFPMHM, CFPMHT, & CFPCC)

CFPMIP Certified Fluid Power

Master of Industrial Pneumatics

(Must Obtain CFPPM, CFPPT, & CFPCC)

CFPCC

Certified Fluid Power Connector & Conductor

CFPSD Fluid Power System Designer

May 8-11, Fairfield, OH, CFC Industrial Training, Written test: May 12.

Aug. 14-17, Fairfield, OH, CFC Industrial Training, Written test: Aug. 18.

Dec. 4-7, 2023, Fairfield, OH, CFC Industrial Training. Written test: Dec. 8, 2023.

ELECTRONIC CONTROLS SPECIALIST

July 24-27, Fairfield, OH, CFC Industrial Training. Written test: July 27.

PNEUMATIC SPECIALIST

June 19-22, Fairfield, OH, CFC Industrial Training. Written test: June 23.

Nov. 13-16, Fairfield, OH, CFC Industrial Training. Written test: Nov. 17.

CONNECTOR & CONDUCTOR

May 23-24, Fairfield, OH, CFC Industrial Training. Written and JP test: May 25.

Nov. 15-16, Fairfield, OH, CFC Industrial Training. Written and JP test: Nov. 17.

MOBILE HYDRAULIC MECHANIC

March 27-30, Fairfield, OH, CFC Industrial Training. Written and JP test: March 31.

June 26-29, Fairfield, OH, CFC Industrial Training. Written and JP test: June 31.

Oct. 23-26, Fairfield, OH, CFC Industrial Training. Written and JP test: Oct. 27.

Online Mobile Hydraulic Mechanic certification review for written test is offered through CFC Industrial Training. This course surveys the MHM Study Manual (6.5 hours) and every outcome to prepare you for the written test. Members may e-mail for a 20% coupon code off the list price. Test fees are not included.

INDUSTRIAL HYDRAULIC MECHANIC

June 5-8, Fairfield, OH, CFC Industrial Training. Written and JP test: June 9.

INDUSTRIAL HYDRAULIC TECHNICIAN

April 17-20, Fairfield, OH, CFC Industrial Training. Written and JP test: April 21.

MOBILE HYDRAULIC TECHNICIAN

Sept. 18-21, Fairfield, OH, CFC Industrial Training. Written and JP test: Sept. 22.

PNEUMATIC TECHNICIAN and PNEUMATIC MECHANIC For dates, call CFC Industrial Training at (513)874-3225 or visit www.cfcindustrialtraining.com/.

JOB PERFORMANCE TRAINING

CFC Industrial Training offers an online Job Performance Review that includes stations 1-6 of the mechanic and technician Job Performance tests. Members may e-mail IFPS for a 20% coupon code off the list price. Test fees are not included. CFC also offers live distance learning Job Performance Station Reviews. To register or purchase, contact CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com/.

Whether you are in need of some assistance that will build your brand through traditional media, or are looking for some nontraditional solutions, we are here to help. Simple to complex— we will work with you to clearly understand your project and translate those creative concepts into effective solutions. Let us launch your project forward and help bring your business to new heights.

idpcreative.com

PA | 484.546.0402

MARCH 14-18

3150 Paradise Rd

Las Vegas, NV 89109

The International Fluid Power Exposition is a trade show dedicated to integrating fluid power with other technologies for power transmission and motion control applications.

Aggregates

Asphalt Concrete Safety

Business Operations Concrete

Engines & Drivetrains

Hauling

Infrastructure Maint.

Jobsite Support

Land Clearing

Portable Power Safety

Technology Solutions

Trucking

Underground

Earthmoving Lifting

Business Operations

Earthmoving Haulling

Jobsite Support

Land Clearing Lifting Safety

Technology Solutions

Aggregates Asphalt

1st Level

Equipment Components

Infrastructure Maint.

Portable Power

Trucking

Underground

Earthmoving

2nd Level

IFPE

Engines & Drivetrains

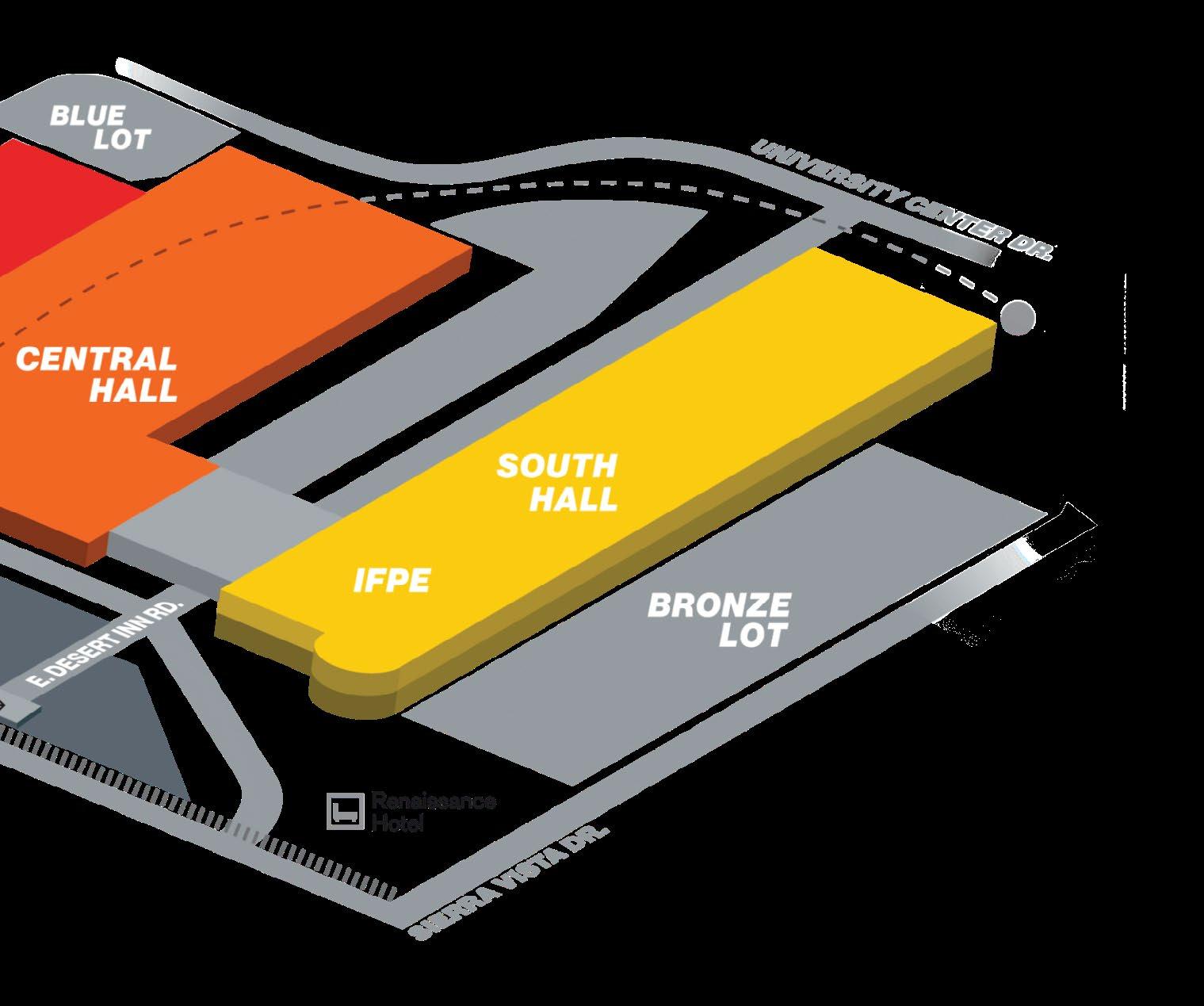

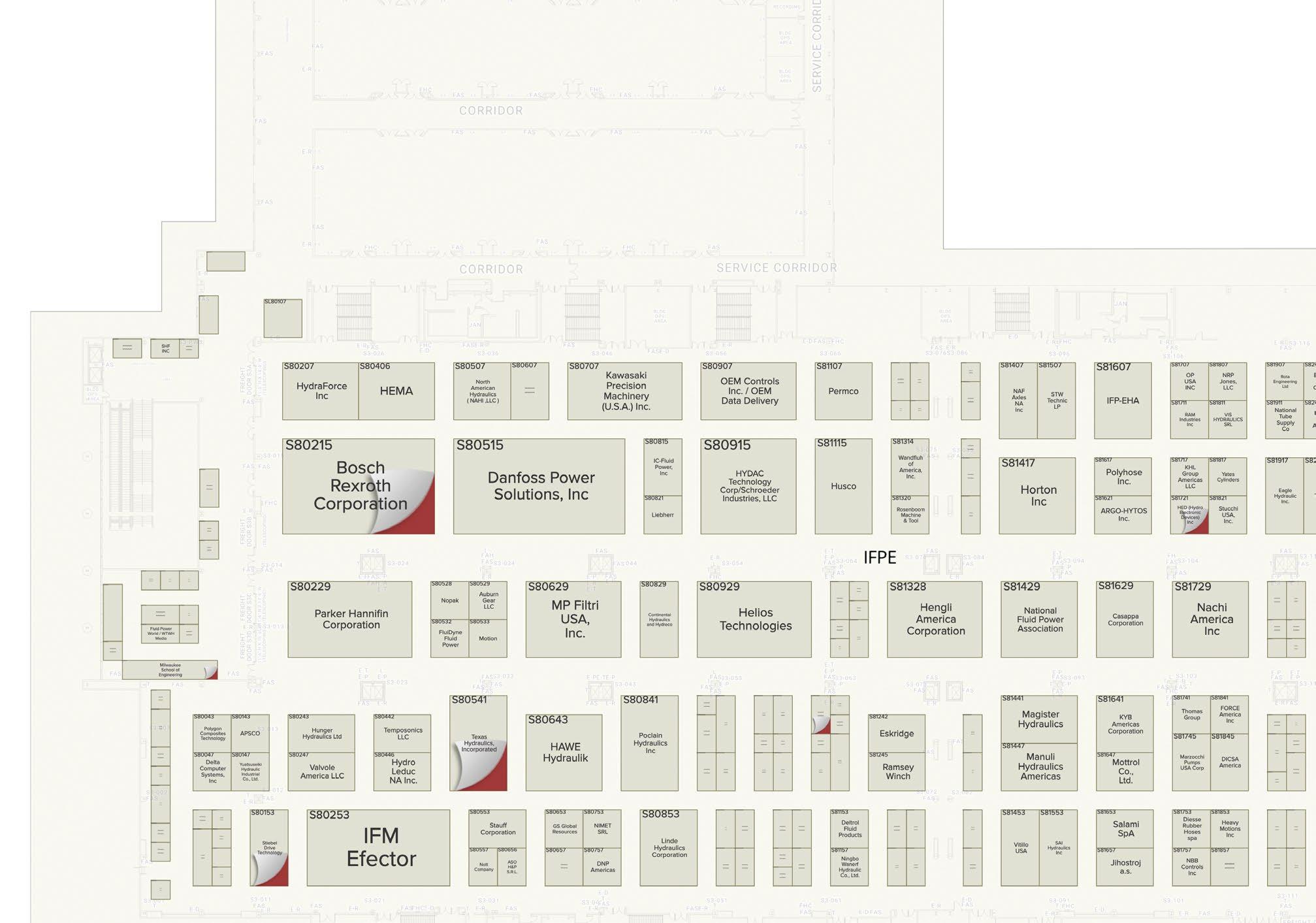

» DATES AND LOCAT i ON Held every three years, IFPE takes place March 14-18 at the Las Vegas Convention Center. IFPE is co-located with CONEXPO-CON/AGG, one of the world’s largest gatherings for the construction industry.

IFPE attracts design engineers and other decision-makers from industries including off-highway vehicles, material handling, manufacturing, production, automation, machine tools, automotive and commercial vehicles, defense and aerospace, and amusement and entertainment technology.

Loop Loop Station

Monorail

Hotel

» EXH i B i TS

IFPE exhibits showcase the latest technologies and innovations in equipment, products, and services for fluid power, motion control, and power transmission. The show also features product-focused and international exhibit pavilions.

The International Fluid Power Exposition, March 14-18 at the Las Vegas Convention Center, is open during the following hours:

The International Fluid Power Exposition, taking place March 14-18 in Las Vegas, is the leading trade show for the fluid power industry.

TUE: 9a.m. - 5p.m.

WED: 9a.m. - 5p.m.

THU: 9a.m. - 5p.m.

FRI: 9a.m. - 5p.m.

SAT: 9a.m. - 3p.m.

IFPE offers targeted education events that provide crucial information on new fluid power, power transmission, and motion control technologies to engineers and others involved in the design and manufacturing process.

Leading industry organizations and media participate as supporting organizations.

At IFPE, more than 375 exhibitors showcase the latest innovations in fluid power, power transmission, and motion control. Attendees have access to 170 education sessions and workshops providing professional development hours. IFPE co-locates with the CONEXPO-CON/AGG construction trade show at the Las Vegas Convention Center.

IFPE brings industry segments together to display new technologies and products, share knowledge, network, and buy equipment. Every three years at IFPE, industry stakeholders encounter the innovations and insights that equip fluid power engineers and manufacturers for the never-ending quest to increase efficiency, contain costs, and improve the performance of their hydraulic and pneumatic applications.

The Association of Equipment Manufacturers, producer of CONEXPO-CON/ AGG and IFPE, expects the event to be the “biggest in history” and “nearly 5% bigger” than the 2020 record.

The increased crowds can get around the convention center’s campus a little easier this year thanks to a new underground transportation system designed by Elon Musk’s The Boring Company tunnel construction business, which will, for free, shuttle attendees around the campus in under two minutes with Tesla vehicles.

For international attendees, the International Trade Center, which CONEXPOCON/AGG and IFPE have brought back for this show, helps overseas visitors “connect across oceans and languages,” organizers said.

“The ITC is a really useful resource for international salespeople,” an organizer said. “Having an area with translators on call in a quiet environment where we can offer an overseas visitor hospitality is valuable. I also find the input and presentations from the staff at the ITC to be useful.”

As always, IFPE offers a plethora of seminars and education sessions, including workshops with professors from the Milwaukee School of Engineering. MSOE’s Medhat Khalil, director of professional education, leads Fundamentals of Hydraulic Systems 101 on Monday at 8 a.m. Then, Paul Michael, an MSOE research chemist, presents Hydraulic Fluid Properties, Efficiency and Contamination Control at 1 p.m.

IFPE is owned by the National Fluid Power Association and the Association of Equipment Manufacturers, which is the show’s producer.

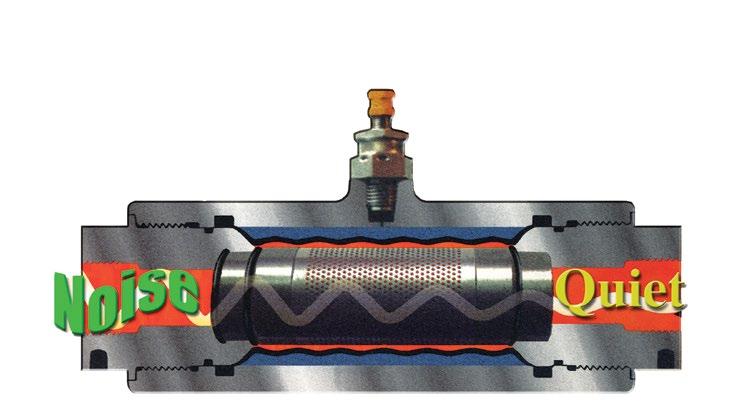

FLEXIBILITY AT ANY LATITUDE AND ANY TEMPERATURE

FLEXIBILITY IN OPERATION AND INSTALLATION

EXTREME BEND RADIUS

HIGH ABRASION & FIRE RESISTANCE COVER

Hydraulic high pressure spiral hoses’ range – Alfabiotech Evolution Minetuff and Evolution LT – designed for applications from 3,000 to 6,000 psi, in diameters from 1/4” to 2”, with minetuff or supertuff covers.

MSHA cover on Alfabiotech Evolution Minetuff. Evolution LT rated for extreme low temperature -67 °F (-55 °C).

Visit us at CONEXPO-CON/AGG 2023 Las Vegas, NV

March 14 – 18, booth S – 83329 www.alfagomma.com

AALBERTS SURFACE TECHNOLOGIES

AC Business Media

Accumulators, Inc.

Adaptall

There’s no substitute for quality. And when it comes to your equipment, you need it operating at peak performance with minimal downtime—which is where quality comes in. From our factory-trained technicians to our on-theshelf OEM New & New Aftermarket parts availability, we’re your go-to source for quality repairs for your equipment. All backed by a 12-month warranty.

To learn more, give us a call or visit us at HYDRAULEX.COM.

1-800-422-4279

sales@hydraulex.com

www.hydraulex.com

National Tube Supply’s fluid power products are precisely manufactured and expertly finished to minimize leakage and ensure longer seal life and optimum performance.

Our experienced team is always available to help customers identify the best product for their project specifications, quality requirements and bottom line. We’ll even work with you to set forecasts for JIT delivery management!

Hydraulic Fluid Line Tubing

Cylinder Barrels

Pneumatic Cylinder Tubing

Pump Barrels

Honed Steel Tubing

Chrome ID Tubing

Chrome OD Tubing

DOM Tubing

Seamless Steel Tubing

Chrome Plated Piston Rods

1045 Steel

Ductile Iron & Alloy

We have a massive inventory at your disposal with 4 locations across North America – most orders ship next day!

The Right Supply, Right On Time.

More Choices. Greater Savings.

When you need pneumatic rodless actuators look no further as W.C. Branham has designed and manufactured a wide range of popular rodless cylinders that can be integrated into endless industrial automation applications. Band, Magnetically Coupled, and Cable.

ISO, UNITOP, CNOMO, Low Profile, Guided, Short Stroke.

W. C. Branham teams up with Artec SRL in the U.S. and Canada. Artec is a leading 40-year Italian rod cylinder manufacturer with ISO9001:2015 certification. Standard and Stainless Steel configurations. Interchangeable with other brands. Many bore sizes. Custom designs welcome. Friendly.

IFPE’s education program covers technical topics and trends for executives, engineers, managers, technicians, mechanics, and other fluid power professionals. Below are the general topic areas for IFPE 2023’s education sessions. For more information, visit www.ifpe.com/visit/education.

• IoT- Smart Systems/Connected Systems

• Electrification of Vehicle Powertrains (hybrid to fully electric)

• Electrification of Motion Control

• Equipment Uptime Optimization and Availability

• Energy Efficiency

• Machine Safety

• Autonomous Equipment/Machines

• Professional Development, including career, workforce issues, and economics

8

Presenter: Medhat Khalil, Director of Professional Education, MSOE

This presentation increases awareness of the fundamental concepts of fluid power technology. It will cover some rules of physics about fluid pressure and flow, as well as the generic structure of a hydraulic system, and construction and principal operation of the main components, e.g., pumps, motors, valves, cylinders, and rotary actuators. The course summarizes how to manage all these components in the form of a system that works safely and efficiently. Topics covered will include gauge versus absolute pressure, Pascal’s law, laminar versus turbulent flow, basic construction of hydraulic systems, hydraulic pumps and motors overview, hydraulic valves overview, reciprocating actuators overview, hydraulic accumulators, actuators, and basic hydraulic circuits.

1 – 4 p.m.

Presenter: Paul Michael, Research Chemist, MSOE

In this course, participants will learn about the composition of oils, the properties of lubricants and how hydraulic fluids can affect machine performance. Conventional, multigrade, synthetic and biodegradable fluids will be discussed. Research studies examining fluid efficiency effects in hydraulic

motors, piston and gear pumps will be presented. The principles of oil analysis and filter selection will be outlined. The seminar concludes with case studies that demonstrates how filter debris analysis can be used to troubleshoot hydraulic system contamination control problems. Topics covered will include hydraulic fluid base stocks and additives, multigrade and synthetic hydraulic fluids, fluid properties and hydraulic system efficiency, basics of in-service fluid analysis and filter selection, and in-service filter analysis case studies.

9:30 – 10:15 a.m.

Addressing the Workforce Gap

Presenter: Jon Goreham

This session will cover the Fluid Power and Applied Mechatronics Training and Employment Network, a new workforce development model developed by NFPA aimed at forging stronger connections among local technical colleges, industry partners, and high schools.

9:30 – 10:15 a.m.

Contamination Control and Filtration

Presenter: Paul Michael MSOE

Contaminated fluids can cause damage to hydraulic equipment and reduce machine productivity. But keeping up on cleanliness requirements and

understanding all the options for filtration technology can be challenge. This session will discuss how to evaluate fluid cleanliness and implement strategies to ensure that hydraulic fluid starts out and stays clean.

Presenter: Danny Richards

The presentation will begin with an overview of Global Data, its research capabilities, and offerings. This will be followed by a discussion of Global Data's Economic Forecast and scenario analysis. Because Global Data's economists judge that the outlook for growth is highly uncertain, especially in the U.S. and Europe, several U.S. outlook scenarios will be reviewed: This presentation will conclude by highlighting examples of industry-specific forecasts and scenarios for the manufacturing sector in the U.S.

Presenter: Lane Oltmanns, Gates Corporation

The purpose of this session is to present a simple, yet powerful, online engineering application that can calculate hydraulic system efficiencies from a pressure drop and piping system perspective. Bring your pump output (GPM), hydraulic oil viscosity (cP), and specific gravity (g/ml) and we can run some numbers to get an idea of your piping system efficiencies and losses.

1 – 1:45 p.m.

Presenter: Donna Pollander, ACA

The International Fluid Power Society certification tests provide an objective, third-party assessment of an individual's technical skill level and are recognized industry-wide. The certification offerings keep pace with changing fluid power and motion control technologies. This session will review training resources and highlight updates taking place with the Society and certification.

1 – 1:45 p.m.

Presenter: Jonathan Meyer

Electronic control on hydraulic equipment has been exponentially increasing over the past two decades. Previously electronic control has primarily focused on increasing the fuel efficiency while maintaining the same level of performance. As machine controllers become more powerful and new sensor technologies emerge, the focus is now switching to operator efficiency. Automation has already become part of our daily lives by having thermostats that can automatically adjust the temperature and devices that can order supplies when low. This automation is expanding into hydraulic machines by simplifying repetitive tasks, assisting when navigating crowded work spaces, and helping less experienced operators

perform better and faster. This presentation will cover some of the latest technologies that are helping operators get more work done quicker and present what is coming in regard to fully automated machines.

2:15 – 3 p.m.

Presenter: Jon Jensen, SMC Corporation

A brief discussion of demand-side targets for energy efficiency. Topics covered will include methods to improve energy intensive uses of compressed air, pressure control, leak remediation, flow monitoring, and general best practices. The focus will be on how to identify those low-cost projects and design improvements that will reduce demand for compressed air while maintaining productivity.

Fluid Power Forum Presents:

Presenters: Eric Lanke, Stephanie Scaccianoce

Keeping the pool of fluid power professionals full is no easy task. The workforce shortage is one of the most challenging issues the industry is facing. This session will cover how critical partnerships with tech schools and engineering colleges are to educate and promote careers in the industry through hands-on laboratory experience and internship programs with

major fluid power companies. Brought to you by Fluid Power Forum, a podcast that features interesting and innovative applications of fluid power (hydraulics and pneumatics).

9:30 – 10:15 a.m.

Presenters: Andrea Vacca, Zifan Liu

This research demonstrates a novel design for an electrohydraulic unit made in collaboration between the Maha Fluid Power Research Center of Purdue University and Bosch Rexroth. In this unit, a permanent magnet (PM) electric motor with an internal gear pump are integrated in one housing, eliminating the shaft connection of traditional electric motor and hydraulic pump. When the unit is operating in pumping mode, the stator with electric windings is electrically inverted thus the rotor with permanent magnet is properly actuated and rotate at desired speed or torque). Therefore, the press-fit pump's ring gear is driven, causing the meshing pinion gear to rotate. That provides pressurized fluid to the actuators. For cooling of the stator windings, a small portion of fluid is circulated around the stator windings, through a cartridge orifice between hydraulic pump and electric motor chambers. This electro-hydraulic unit can also operate in motoring quadrant during braking and unloading of actuators for energy recuperation, improving system efficiency.

9:30 – 10:15 a.m.

What Can You Do to Make Your Machine More Efficient?

Presenter: Rance Herren

10:45 – 11:30 a.m.

Electrohydraulic Lunchbox Session

Presenter: Carl Dyke

10:45 – 11:30 a.m.

How Ecosystems are Driving Successful IoT Deployments and Delivering Real ROI to the Industry

Presenter: Adam Livesay

IoT 1.0 was a lot of buzz words with fancy dashboards and companies claiming to provide the complete end-to-end solution to solve every problem. IoT 2.0 is comprised of ecosystems that have formed to deliver high-value solutions to the market. These ecosystems have evolved from the traditional fluid power and industrial supply chains to true IoT ecosystem partners that work together to deliver the right solution to the marketplace. We will examine use cases where industrial supplies, OEMs, IoT providers, and customers work together to design, develop, and deliver the solution.

1 – 1:45 p.m.

Presenters: Austin Sowinski, Eric Lanke, Tim Opperwall

Do you know the effect a single mA of error has on a final grade? Traditionally, construction and agricultural machines have been designed and tuned for an expert operator. There is a closed loop relationship between operator and machine that is changing with the adoption of electro-hydraulic controls, modern sensors, and computational power. Today’s job site requires a machine suited for operator augmentation and automation. This presentation walks through the challenges in enabling the controls transformation through a real-world system example and proposes how future hydraulic control architectures may look. Brought to you by the Fluid Power Podcast.

1 – 1:45 p.m.

Presenter: Adam Livesay

The mobile machine industrial IoT playbook has been used by hundreds of suppliers, distributors, and OEMs to develop an IoT strategy, manage a successful IoT

project, and deliver industry-leading solutions to the market that return real ROI and value to the OEM and their customers. This playbook was developed over several years by industry insiders. We will examine use cases for each phase of the playbook to allow you to leave with a framework to design, develop, and execute a successful IoT initiative.

2:15 – 3 p.m.

Presenter: Miguel Onandia, Poclain

Compact mobile equipment, such as small loaders, compactors, or material-handling machines, is experiencing important changes driven by increased environmental consciousness and focus on global warming. The goal is to reduce carbon dioxide emissions in every way possible, pushed in many countries by both governments and customers, so that machine's manufacturers must be prepared to adapt. To support this trend, Poclain's teams have developed innovative solutions such as electrohydraulic transmission, which is taking

the best of both worlds thanks to hydraulics high performances solutions and electrics systems. Poclain is also offering data acquisition systems (IoT technology) to optimize machine's transmission thanks to better understanding of the mission profile.

2:15 –

Sensors – Data and Performance

Presenter: Carl Dyke

9:30 – 10:15 a.m.

Fluid Power Forum Presents: Contamination Standards Prevent Machine Failure and Boost Cost Savings

Presenters: Barry Verdegan, Eric Lanke, Ivan Sheffield

Machine failures are costly. Contamination is the root cause of 80% of hydraulic failures, and 90% of these failures are preventable. Standards, such as those created by ISO or national standards bodies, establish a level playing field to allow manufacturers, suppliers, and users to speak a common language and use best practices to develop and implement contamination control programs. Standards developed by ISO

TC131/SC6 and other technical committees allow you to measure particulate contamination in fluids, set required cleanliness levels, choose appropriate filters for your application, compare products and identify false claims, and monitor the success of contamination control efforts. The speakers use real world examples to demonstrate the financial benefits of standard based contamination control programs. Brought to you by Fluid Power Forum, a podcast that features interesting and innovative applications of fluid power (hydraulics and pneumatics).

9:30 – 10:15 a.m.

The Value of Telematics: featuring (Live) Use Cases

Presenter: Chad Repp

Learn about telematics, specifically data logging and leveraging the data through analytics to set notifications for predictive maintenance, predetermined alerts for operator safety (collision avoidance), and how this all converts back to ROI for the OEM.

10:45 – 11:30 a.m.

Advancing Autonomy from Operator Assist to Driverless Vehicles

Presenter: Peter Bleday

In this session we will discuss the technical, social, and economic factors that are needed to advance vehicles in the construction industry from their current state to a state of high operator assistance and augmentation, and then to a state of driverless automation. This discussion will include some of the significant challenges OEMs and suppliers face with new technologies and "edge case" management around the vehicle and job site. During the discussion we will also focus on how to overcome these challenges and the future of the construction autonomous vehicle industry.

10:45 – 11:30 a.m.

Functional Safety requirements under the Machinery Directive 2006/42/EC

Presenter: Matthias Haynl

Functional safety standards can be a challenge to apply in particular if not considered early on in the life cycle. This session will discuss how to identify and apply the relevant functional safety standards for construction/agriculture/mining machinery.

1 – 1:45 p.m.

Cybersecurity

Presenter: John McDonald, TUV Rheinland

Smart devices have infiltrated every aspect of our lives, and equipment, vehicle, and manufacturing environments aren't exempt from the onslaught. Customers that used be worried only about price

and capabilities are now questioning manufacturers on the quality of the cybersecurity in their devices, since a single hacker can take control of a vehicle and run rampant, resulting in significant vulnerability for the manufacturer. The industry has started to address these issues with standards such as IEC 62443, but many manufacturers are just starting to wonder how they can implement a cybersecurity program. This session will review the relevant cybersecurity standards in this space, the elements you need to consider when implementing a product cybersecurity program and suggest an approach to help you get started.

–

Presenter: Cameron Guernsey, Product Manager at Danfoss Editron

As the world moves towards net-zero goals, there is a stronger focus than ever on electrifying all types of applications, including mobile machinery. Acknowledging these trends, Danfoss has invested in the zero-emission future through its Editron division. The next step in Danfoss' journey is the development of its eSolutions portfolio, which builds upon Danfoss' existing PLUS+1 platform by applying the same machine application knowledge to control electrified machines.

–

Presenters: Jenny Tuertscher, Rob Johnson

Often fluid power is overlooked when it comes to machinery safety. This presentation will provide attendees with an understanding of the requirements for the control of hazardous energy using lockout, tagout, or alternative methods as they relate to fluid power. We will share the requirements from OSHA 29 CFR 1910.147 and ANSI/ASSP Z244.1 and the B11 series of standards for machinery safety.

Presenter: Dan Helgerson, Fluid Power Journal Technical Editor

While a great deal of effort is being made to produce more efficient compressors, pumps, and motors, there has not been enough attention given to providing more efficient systems. The new floating cup pumps developed by INNAS DV have overall efficiencies of better than 95%, but when dumping flow across a relief valve, the system is 100% inefficient. Efficient components do not guarantee an efficient system.

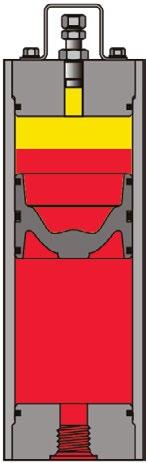

There are a number of reasons why a bladder or diaphragm in an accumulator typically fails.

The most common reason is that the compression ratio is exceeded. The compression ratio is determined by dividing the maximum system pressure by the precharge pressure. Typically, a compression ratio of less than 4:1 is acceptable for a bladder-type accumulator and 6:1 for a diaphragm accumulator. Maintaining a proper compression ratio is necessary to ensure that excessive flexing of the bladder or diaphragm doesn’t occur.

Another common failure is due to incorrect precharge pressure. It is necessary that the precharge pressure be less than the system minimum operating pressure. If the bladder-style accumulator was precharged to a higher pressure than manufacturer specifications, the bladder may fail. Under normal operation, the bladder is compressed in the shell by hydraulic oil and only expands to rest against the anti-extrusion poppet valve in the bottom of the accumulator when the system is off. Higher-than-specified precharge pressures can cause the bladder to pound against the poppet valve in the bottom of the accumulator when system pressure drops but is still within the operating range of the machine. This makes the bladder fail where it is pushed against the anti-extrusion poppet valve. Hydraulic fluid leaking into the gas side of an accumulator effectively reduces the working volume of the accumulator.

Another possible failure with rapid cycling that fully discharges the accumulator is that the bladder can get pinched under the poppet valve as shown in figure 1. This may also occur if the precharge occurs too rapidly.

High oil temperature may also cause the bladder or diaphragm to prematurely fail, as the polymers used in the construction of a bladder or diaphragm have reduced life expectancy at elevated temperatures. It is also important to understand that when precharging the bladder or diaphragm, it is necessary to perform this slowly, as rapidly expanding gas will cause the temperature to decrease rapidly and may subject the polymers to brittle fracture due to the extreme cold.

A leak in the bladder will cause the gas precharge to escape into the hydraulic system. This may result in a sponginess in the actuators. It can also allow hydraulic fluid to enter the bladder. A pinhole leak on the side of the bladder is difficult to diagnose. The bladder may effectively seal the hole when the hydraulic side pressure is low but expose the hole when the hydraulic pressure is increased and the gas compresses, moving the bladder away from the accumulator wall.

In a piston-style accumulator, the dynamic seal wear allows the gas to escape and permits hydraulic fluid to migrate into the gas chamber. As shown in figure 2, the hydraulic fluid in the gas chamber reduces the effective working volume of the accumulator. •

A higher-than-specified precharge pressure in a bladder-style accumulator:

a. is recommended so it doesn’t have to be checked as often.

b. can cause the bladder to be damaged by pounding against the poppet valve.

c. drops as the fluid heats up.

d. results in greater fluid storage during operation.

e. seals any pinhole leaks on the side of the bladder.

See page 54 for the solutions.

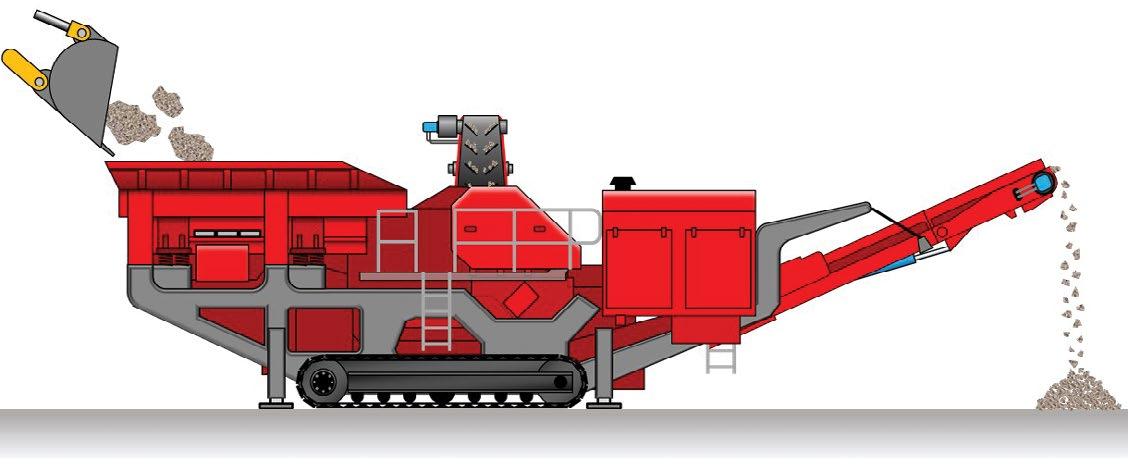

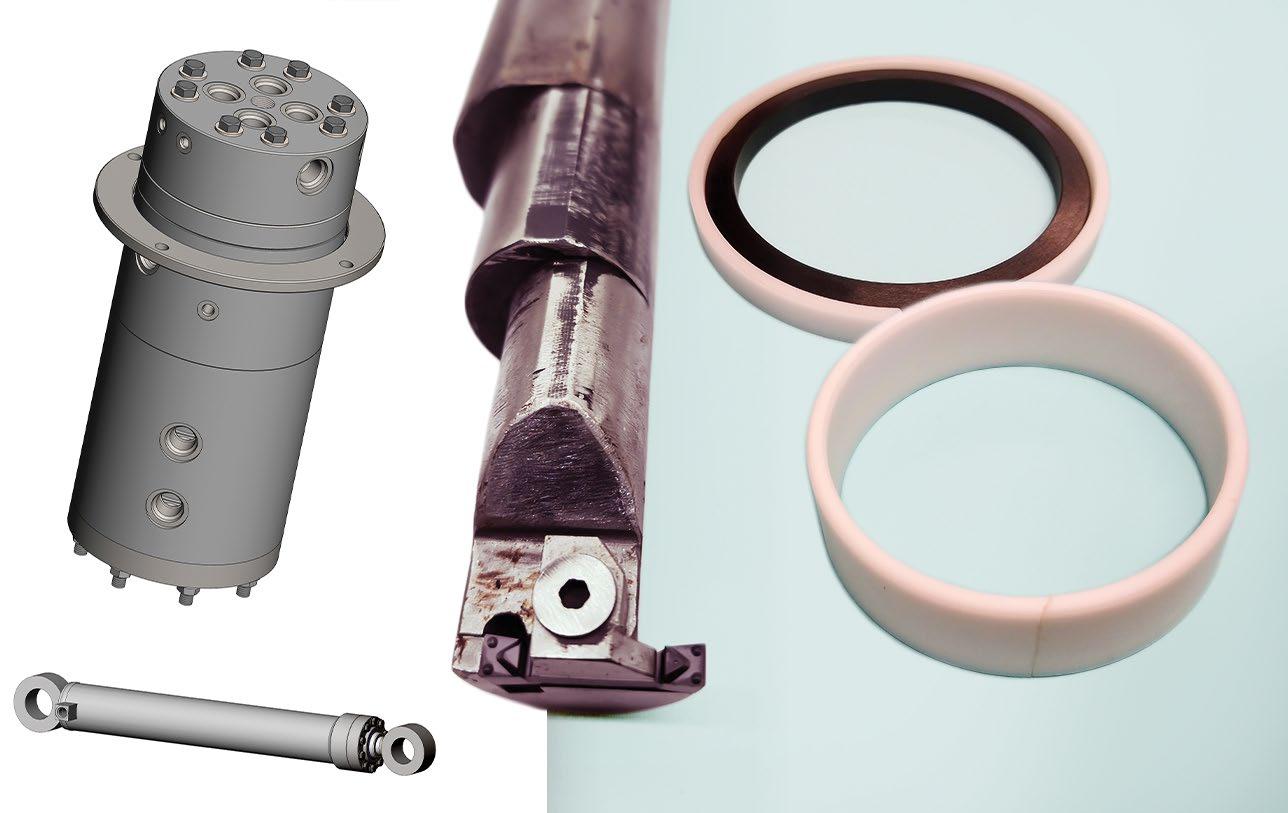

Forthousands of years, quarrying has supplied building materials, often carried out under arduous conditions far from home by simple, hard-working folk who measured daily output in baskets of rocks. Over the years, what was accomplished with a pickaxe and a shovel evolved into highly automated, mobile production lines that are thousands of times more productive than manual labor. Today, modern workers require rugged solutions that are simple to use and maintain, and in which problems are easily resolved by operators with minimum delay.

Crushing and screening in modern quarries involves crushing large pieces of material into smaller ones and sorting into similar-sized fragments. The starting material is typically freshly quarried or excavated rock or demolition material. Crushing machinery uses different crushing mechanisms, depending on the material. Where a considerable size reduction is required, the output of one crusher can feed a second one, and in some cases, a third may be necessary. Traditionally, material crushing has occurred in permanent locations where heavy-duty tipping trucks transport material to the plant. Recently, mobile crushing plant has proved practical and cost effective. Such equipment moves with wheels or caterpillar tracks to a convenient position. The same principles used in crushing and screening are now also applied to shredding, washing, and recycling machines that shred and sort waste for recycling.

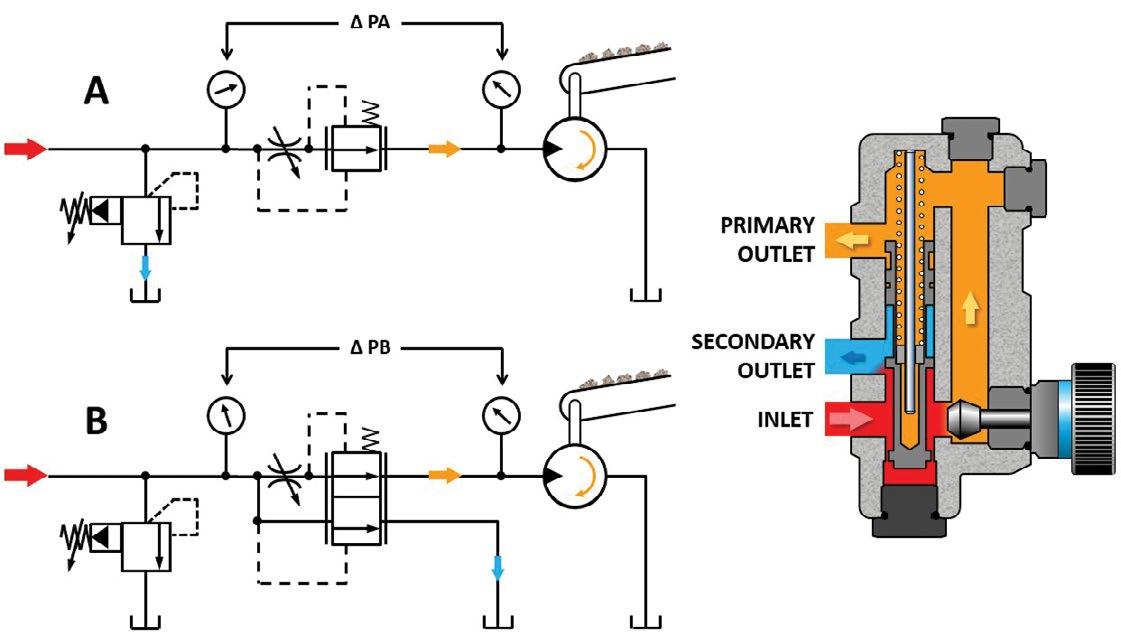

The Webtec VFC Series of pressure compensated flow control valves ensure that actuator speeds remain virtually constant over all load conditions. When controlling the speed of a hydraulic motor powering a conveyor, for example, the motor rotates at the same speed, regardless of the amount of material on the conveyor belt. This ensures a consistent delivery position of the material. Once set, the weatherproof adjusting knob can be locked in position to avoid any inadvertent adjustment.

If a two-port flow control valve is used with a fixed displacement pump, then the excess pump flow has to pass across the system relief valve at full pressure. The excess pump flow is the flow the pump creates above the flow control valve’s setting. If the hydraulic motor (or other controlled actuator) is operating lightly loaded, then a large pressure difference across the flow control valve occurs. Flow passing across the relief valve and the large pressure drop across the flow control valve create inefficiency that results in heat.

When used with a pressure-limiting variable displacement pump, the pump flow rate automatically reduces to the rate determined by the flow control valve’s setting. But if the motor is lightly loaded, the pump outlet pressure remains at its maximum, i.e., the set pressure of the pump compensator. Since power in a hydraulic system is a product of flow multiplied by pressure, the output of a variable displacement pump only partially matches the power requirements of the actuator. Varying the pump displacement matches the flow requirement, but the pressure at the pump outlet can still be higher than what’s required by the actuator’s load. A lightly loaded actuator is still likely to cause a large pressure drop across the flow control valve, causing inefficiency and consequent heat generation. Two-port flow control valves are therefore best suited to variable pump systems in which the actuator only operates lightly loaded for short periods of its duty cycle. They can, of course, be used outside of these parameters by making provision for adequate fluid cooling.