R. N. I. No. MAHENG/2009/29760 Published and Posted on 1st of every month at Mumbai Patrika Channel Sorting Office, Mumbai 400 001. License to post without prepayment WPP Licence No. MR/Tech/WPP-199/West/2017 Postal Regd. No. MCW/120/2015-2017

the leading electrical & electronics monthly

VOLUME 8 ISSUE NO. 8 APRIL 2017 PGS. 104

IEEMA JOURNAL VOLUME 8 • NO. 8 • APRIL 2017

ANNOUNCING ALL NEW ELECRAMA, 10-14 MARCH, 2018

ISSN 0970-2946 Rs. 100/-

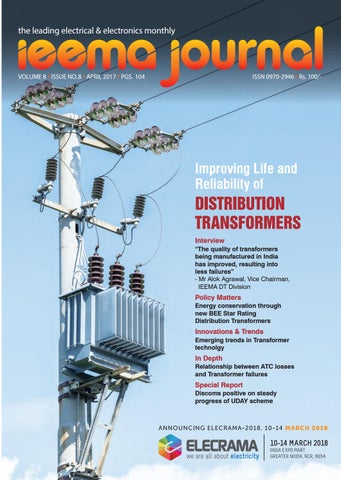

Improving Life and Reliability of

DISTRIBUTION TRANSFORMERS Interview “The quality of transformers being manufactured in India has improved, resulting into less failures” - Mr Alok Agrawal, Vice Chairman, IEEMA DT Division

Policy Matters

www.ieema.org

Energy conservation through new BEE Star Rating Distribution Transformers

Innovations & Trends Emerging trends in Transformer technolgy

In Depth Relationship between ATC losses and Transformer failures

Special Report Discoms positive on steady progress of UDAY scheme concurrent events

104

From the President’s Desk

Dear Friends, The Indian power sector has undergone a visible transformation across its complex value chain. Recently the Power Ministry decided to phase out 25 years old thermal power plants and convert them into ‘super critical plants’ to augment generation capacity and reduce pollution. Such plants are six to eight time less pollutant and will be able to generate more power. About 190 of the 400 odd thermal power plants are more than 25 years old, representing a combined power generation capacity of 55,000 MW. These old plants tend to consume more coal, operate less efficiently when converting heat to electricity, and require frequent and costly maintenance. These plants are also more polluting in nature, having been set up as per specifications of the 80s. This announcement opens up a huge opportunity for various stakeholders in the thermal power sector over the next five to 10 years. Earlier this month, Shri Piyush Goyal had predicted that India’s solar power generation capacity will cross 20,000 MW in the next 15 months, from the current 10,000 MW, and said drastic reduction in costs of solar power is proof of maturity of the sector. There is some good news for the rural India as Prime Minister Narendra Modi-led government is expected to fulfil its promise of bringing electricity to all the villages of the country by the end of 2019 well before the deadline. More than 65,000 new customers were registered in February 2017 and 86,000 new connections have been given in this month so far. Betting on the technological advancements, new connections are uploaded live on the website along with meter and contact details. The government has also triggered off an electrification impact survey on villages that have been electrified for more than six months. This month’s special focus of IEEMA Journal is on Distribution Transformers which are an indispensable part of the electricity supply in distribution network. Hence their proper functioning is a must for the stability and reliability of the supply in distribution network. Various transformer tests and preventive maintenance procedures can be deployed at different points in time to maintain distribution transformers health and ensure uninterrupted supply to consumers

Sanjeev Sardana

6

April 2017

Samvaad...

Dear Members, After formation of the State Government in Uttar Pradesh, the new government will need to meet immediate challenges of ensuring quality power supply. Amongst the top priority of the new State government one important would be to improve the quality, quantity and availability of power supply. The measures needed to achieve this would include reduction of technical and commercial losses of electricity. Simultaneously collection efficiency would also be needed to improve through effective metering and billing. Development of transmission and sub-transmission network, increasing renewable energy generation and adopting energy efficiency measures will also need to be part of roadmap. Uttar Pradesh was among the first few states to join the Centre’s Ujwal Discom Assurance Yojana (UDAY), aimed at reviving distribution companies, and expected to get a net benefit of Rs 33,000 crore. Uttar Pradesh Power Corporation Limited official while speaking to IEEMA Journal stated that, “We have started performance monitoring and management and the feeder improvement program for network strengthening and optimization is underway. The recently announced demonetization has helped, as significant amounts of revenue were recovered through payments of outstanding electricity bills. We have also brought down intra-state transmission losses from above five percent to below five percent, which is an achievement for a state of UP’s size.” Last month in my dialogue I spoke about the concerns of SCADA contracts given to Chinese companies. Keeping this threat in mind the Government of India has set up four Sectoral Computer Emergency Response Teams to address Cyber Security Threats in Power Systems. Shri Piyush Goyal, Power Minister, said that these CERTs will address Transmission, Thermal, Hydro and Distribution sector. The relevant stakeholders of Smart Grid have been advised to identify critical infrastructure and use end to end encryption for data security. All utilities have been asked to identify a nodal senior executive as its Chief Information Security Officer (CISO) to lead the process of strengthening organizational systems with respect to cyber security and implement an Information Security Management System as recommended by rules framed under the Information Technology (IT) Act 2008.

Sunil Misra

April 2017

7

Contents

the leading electrical & electronics monthly

Volume 8 Issue No. 8 April 2017 CIN U99999MH970GAP014629 Official Organ of Indian Electrical & Electronics Manufacturers’ Association Member: Audit Bureau of Circulation & The Indian Newspaper Society

6

From the President’s Desk

28

7

Samvaad 8

Index to Advertisers 26

Appointments This new space in the IEEMA Journal will incorporate recent important appointments in the power and related sectors.

28

Cover story Improving reliability and life of Distribution Transformers A transformer is an electrical device which, by the principles of electromagnetic induction, transfers electrical energy from one electric circuit to another, without changing the frequency. The energy transfer usually takes place with a change of voltage and current. The step down transformers used for electric power distribution purpose are referred as distribution transformer. There are several types of transformer used in the distribution system.

10

32

Interview Mr Alok Agrawal, Vice Chairman, IEEMA Distribution Transformers Division speaks to IEEMA Journal on the issues concerning the Division

34

Special Report

distribution companies found themselves in. The scheme has now started making a difference and is moving towards realising its objective of a financial turnaround and a revival of DISCOMs, which have only accumulated debt over the past decades.

38

Issue Monitoring Planning for Condition Monitoring

UDAY-new path for discom revival

The Ministry of Power under Piyush Goyal had launched Ujwal DISCOM Assurance Yojana (UDAY) in 2015. The aim was to find a permanent solution to the financial mess that government-o wn ed el ectri ci ty

Transformer owners work hard to ascertain and digest the right data to make critical decisions confidently, but the volume of data can be overwhelming. What looks like a critical piece of information at first glance could easily be a diversion with no real importance.

April 2017

Contents

40

48

58

Policy matters

Innovations and trends

Guest article

Energy conservation through NEW BEE STAR Rating Distribution Transformers

Emerging trends in Transformer Technology

Electricity is one of the most vital infrastructure inputs for economic development of any country. The demand for electricity in India is enormous and is growing day by day. The gap between demand and supply is also widening day by day.

44

In depth

Day to day increase in electricity consumption has invented new trends in transformer design concept and manufacturing process. The following recently developed constructions has resulted much energy efficient and cost effective transformers, benefitting the state electricity boards besides consumers.

April 2017

surge

Smart solution in electric sector of smart country

50

62

Expert speak

Reference

Proven Natural Esters demonstrates better performance & Reliability with fire Safety

64

Relationship between ATC losses and transformer failures

The ATC Losses in several States are at an unsustainably high level. There is a burning necessity to reduce the ATC Losses in these States. The Discoms will continue to bleed financially and the future of all the stakeholders, including the Government, Banks, Consumers of Industry, Domestic, Non Domestic, Rural, Manufacturers of equipment, and Employees of the Discoms including pensioners shall be in jeopardy.

Lightning protection, protection & earthing

Opinion 66

SME Focus

An electrical grid’s reliability is directly affected by transformers which majorly depends on its design, loading, maintenance policy and ambient conditions. Furthermore, new grid conditions, including distributed generation, may create additional disturbances for the interconnection of network with various transformers.

67

Tech Space Selection and Application of Surge Arrester

54

In focus Smart Way of Controlling Frequency Linked Component of Availability Based Tariff Frequency linked tariff which is known as Availability Based Tariff has been implemented at regional level in India in 2002.For maintaining Grid discipline the third component of ABT, Unscheduled Interchange must be under control.

Electrical equipment like transformer, Generator, CT’s, PT’s and motor requires to be protected from over voltages. Surge arrester is used to protect these equipments from lightning and switching over voltages.

11

Contents

75

88

Tech Space

National News

Smart Embedded Electrical Power Generation for Housing Society

Four Sectoral Computer Emergency Response Teams to mitigate Cyber Security Threats in Power Systems Wind installations expected to cross 4000 MW

90

Corporate News ABB India reaches 4.5GW milestone in delivering wind power generators made in India The domestic embedded power generation based wind-solar system for housing society is developed in hardware and MATLAB software. REPGMMACR Algorithm is developed for optimization of power management, power penetration to micro grid, various loads, energy storage (i.e. super power capacitor and batteries) in hardware and software model. The conventional inverters and ups are replaced by proposed hardware model.

86

International News

KEC International shares rally 5% on transmission, solar orders

92

Power Scenario Global Scenario Indian Scenario

94

IEEMA Database Basic Prices & Indices Production Statistics

96

Canadian Solar (CSIQ) Signs PPAs with SECI to Develop 80 MWac Solar Power Projects in India

IEEMA activities

India looks to Australian Coking Coal For Steel Production And Power Generation

ERDA News

97

99

Product Showcase 101

Out of Box

Editorial Board Advisory Committee Founder Chairman Mr R G Keswani

Chairman Mr Sanjeev Sardana

Members Mr Sunil Misra Mr Naveen Kumar Mr Mustafa Wajid Mr Vikram Gandotra Mr Vijay Karia Mr Sunil Singhvi

Sub Editor Ms Shalini Singh

Advertisements Incharge Ms Vidya Chikhale

Circulation Incharge Ms Chitra Tamhankar

Statistics & Data Incharge Mr Ninad Ranade

Designed by: Reflections Processed at: India Printing Works

Regd Office - Mumbai 501, Kakad Chambers, 132, Dr A Besant Road, Worli, Mumbai 400 018. Phones: +91(0) 22 24930532 / 6528 Fax: +91(0) 22 2493 2705 Email: mumbai@ieema.org Corporate Office - New Delhi Rishyamook Building, First floor, 85 A, Panchkuian Road, New Delhi 110001. Phones: +91 (0) 11-23363013, 14, 16 Fax: +91 (0) 11-23363015 Email: delhi@ieema.org Branch Office - Bengaluru 204, Swiss Complex, 33, Race Course Road, Bengaluru 560 001. Phones: +91 (0) 80 2220 1316 / 1318 Fax: +91 (0) 80 220 1317 Email: bangalore@ieema.org Branch Office - Kolkata 503 A, Oswal Chambers, 2, Church Lane, Kolkata 700 001. Phones: +91 (0) 33 2213 1326 Fax: +91 (0) 33 2213 1326 Email: kolkata@ieema.org Website: www.ieema.in Articles: Technical data presented and views expressed by authors of articles are their own and IEEMA does not assume any responsibility for the same. IEEMA Journal owns copyright for original articles published in IEEMA Journal. Representatives: Guwahati (Assam) - Nilankha Chaliha Email: nilankha.chaliha@ieema.org Mobile: +91 9706389965 Lucknow (U.P. and Uttarakhand) Ajuj Kumar Chaturvedi Email: anuj.chaturvedi@ieema.org Mobile: +91 9839603195 Chandigarh (Punjab & Haryana) Bharti Bisht Email: bharti.bisht@ieema.org Mobile: +91 9888208880 Jaipur (Rajasthan) Devesh Vyas Email: devesh.vyas@ieema.org Mobile: +91 8955093854 Bhubaneshwar (Odisha) Smruti Ranjan Samantaray Email: smrutiranjan.samantaray@ieema.org Mobile: +91 9437189920 Hyderabad (Andhra Pradesh) Jesse A Inaparthi Email: jesse.inaparthi@ieema.org Mobile: +91 9949235153 Srinagar (Jammu & Kashmir) Mohammad Irfan Parray Email: irfan.parray@ieema.org Mobile: +91 9858455509

For subcriptons quiries write to: chitra.tamhankar@ieema.org Edited, Printed and published by Mr Sunil Kumar Misra on behalf of Indian Electrical and Electronics Manufacturers’ Association, and Printed at India Printing Works, India Printing House, 42, G. D. Ambekar Road, Wadala, Mumbai 400 031 and Published at 501, Kakad Chambers,132, Dr. Annie Besant Road, Worli, Mumbai 400 018.

12

April 2017

IEEMA Publications Name of Publication

Rates (Rs.)

ELECRAMA Directory 2016 [Printed + CD combined] INTELECT Directory 2015 [Printed] INTELECT Directory 2017 [Printed]

1500

1000

100

200

RESEARCH REPORTS IEEMA PWC Industry Status Report -2010-2011

10000

IEEMA FTA ( Free Trade Agreements) Report

5000

IEEMA GUIDELINES IEEMA Recommendation on Technical Specification for Instrument Transformer IEEMA Surge Arrester Industry Report IEEMA Guidelines for Testing of Surge Arresters Power Transformer – Standardisation Manual

18

Rates (Rs.)

REFERENCE VOLUMES OF IEEMA SEMINARS AND CONFERENCES

DIRECTORIES IEEMA Directory 2016 [Printed + CD combined]

Name of Publication

150

100

100

1000

Coffe Table Book

5000

Swicon 2011 [Switchgear & Control gear (CD)

2500

Swicon 2015 (Pen Drive)

2500

Elroma 2012 (Electrical Rotating Machines)

2500

Cablewire 2011

2500

Metering India 2013 (Meter)

2500

Metering India 2015 (Meter)

2500

Insulec 2015 (Insulating Material)

2500

Capacit 2011 ( CAPACITORS) (Printed)

2500

Capacit 2014 ( CAPACITORS) (Printed)

2500

Trafotech 2010

2500

Trafotech 2014

2500

Trafotech 2016

2500

Tech IT - 2010

2500

Tech IT - 2014

2500

Trafotech Compendium (1982 to 2006) (DVD)

2500

Insulec Compendium (1980 To 2009) (DVD)

2500

Cablewire Compendium (1983 To 2008) (DVD)

2500

Elroma Compendium (1983 TO 2008) (DVD)

2500

Swicon Compendium (1984 TO 2008) (DVD)

2500

April 2017

the leading electrical & electronics monthly

the leading electrical & electronics monthly

VOLUME 7 z ISSUE NO. 2 z OCTOBER 2015 z PGS. 108

ISSN 0970-2946

z

Rs. 50/-

Face2Face Mr Anil Swarup Secretary, Ministry of Coal

ISSN 0970-2946 z Rs. 50/-

Cover Story

Special Feature Promoting ELECRAMA Globally Cover Story IEEMA Annual Convention & 68th AGM

VOLUME 7 z ISSUE NO. 3 z NOVEMBER 2015 z PGS. 114

Discom Revival... is this the solution?

15 20nce orn

a fere e on olg l C ntr 15 na Co r 20 tio r & be a rna gea ovem i, Indi Inte itch 27th N ba 9th Sw 6th & Mum 19

Interview Mr Hitesh Doshi CMD, Waaree Energy Ltd InDepth AT&C Loss Reduction – Best Practices

Thought Leader of the Month Vijay Karia, Ravin Cables Special Feature Promoting ELECRAMA Globally

2

15 20

n eo nc ar fere e on olg 5 l C ntr 201 na Co r tio r & embe a rna gea Nov i, Indi Inte itch 27th umba & 3 th M 2 9 Sw 6th 2

1000/1800/2400/-

The price of per copy of IEEMA JOURNAL has been revised from Rs 50 to Rs 100 effective from January 1, 2016 1000/-

1800/-

For advertise queries contact to: Vidya Chikhale, Cell: 9833479435

4

2400/-

leading electrical and electronics monthly

PLUG INTO THE RIGHT CONNECTION ADVERTISEMENT TARIFF W.E.F.1ST APRIL 2016 the leading electrical & electronics monthly

VOLUME 7 ISSUE NO. 5 JANUARY 2016 PGS. 126

ISSN 0970-2946 Rs. 100/-

Cover Story Electrical Equipment Industry - Half Yearly Industry Review - FY15-16

Special Features T&D Conclave 2015 SWICON-2015

SME Talk

Mr Hartek Singh Hartek Power Private Ltd

The countdown begins... 13-17 February, 2016, Bengaluru, India

CH ce TE feren ers RO Con rrest EP onal e A 16 RG rnati Surg il 20 Delhi SU Inte ls on th Apr New

a n, 5 nd 11 co tori & 29 idie Se m Tu 28th Mer No. ge Le cu el Hot

Pa

IEEMA Journal is the leading electrical and electronics monthly and an official organ of Indian Electrical & Electronics Manufacturers’ Association (IEEMA). IEEMA Journal is the publication registered with Registrar of Newspapers

for India (RNI). IEEMA Journal is member of the Indian Newspaper Society (INS) whose circulation is audited by Audit Bureau of Circulations (ABC). IEEMA Journal covers original techno-commercial articles, interviews, international, national and corporate news, statistics, product showcase, country profile, seminars, exhibitions and services.

Publication Date

1st working day of the month of the issue

Cover Pages

210 GSM Art Paper *

Inside Pages

70 GSM LWC Paper *

Magazine Size

A - 4, 297 mm x 210 mm

ADVERTISEMENT TARIFF W.E.F. 1ST APRIL 2016 HEIGHT X WIDTH Cover Positions:

RATE PER INSERTION (Rs.) Rates for 4 colours and non bleed

Front (GateFold)

260 mm x 390 mm

1,37,500

Front (GateFold) - Half

260 mm x 180 mm

88,000

Inside Front

260 mm x 180 mm

93,500

Inside Back

260 mm x 180 mm

88,000

Back

260 mm x 180 mm

93,500

BackFold

260 mm mm

x

390

1,21,000 Rates for 4 colours and non bleed

Special Positions: Page 3 (5)

260 mm x 180 mm

71,500

Page 4 (6)

260 mm x 180 mm

60,500

Since its inception in the year 1981, this Journal is published and posted on its scheduled dates. At present 10,300 copies of this journal are posted on 1st working day of every month. It is the only trade journal in India that enjoys readership of around 1,00,000.

Page 5 (7)

260 mm x 180 mm

66,000

Page 9 (11)

260 mm x 180 mm

55,000

Page 15 (17) & onwards each

260 mm x 180 mm

52,800

Advertisers stand to benefit considerably through advertising in IEEMA Journal being a very cost effective medium. In India, it is circulated to Ministries of Power, Finance, Commerce, Defense, Railway, Information Technology; Utilities like NTPC, NHPC, DVC, PGCIL, etc, all State Electricity Boards, Engineering Colleges, Research Institutes, Foreign Missions in India, Indian embassies in overseas countries etc. The overseas circulation includes all Indian Missions abroad, counterpart electrical associations of IEEMA in countries like Japan, Taiwan, Australia, Germany, Spain, China, Italy, Malaysia, Korea, US, France, UK etc and also to a number of technical institutes, libraries and other subscribers in overseas countries.

Rates for 4 colours and non bleed

Ordinary Positions: Full Page

260 mm x 180 mm

44,000

Half Page

130 mm x 180 mm

24,750

Double Spread

260 mm x 360 mm

88,000

Insert

305 mm x 215 mm

88,000 Rates for 4 colours and non bleed

Appointments: Full Page

210 mm x 165 mm

27,500

Half Page

100 mm x 165 mm

13,200

Extra Charges: Full Bleed

: 20 % Extra

Specific position

: 20 % Extra (other than page numbers mentioned above)

Special Colour

: Rs 5,000/- for every special colour

Series Discounts: Applicable on the basis of number of advertisements released in 12-month period counted from first release. Series Discount not applicable for cover pages. For 6 or more releases - 7.5 % discount For 12 or more releases - 15 % discount *Subject to change at the sole discretion of Publisher, without notice.

APPOINTMENTS Mr SS Roy appointed Directort (Technical-LWR), NPCIL Mr Jeet Chhatwal appointed Additional Director, Distinguished Hartek GroupScientist S Singha Roy has been appointed as Director (Technical-LWR) of the Nuclear Power Hartek Group, an Limited. engineering, procurement and Corporation of India He will be holding the post till the date of(EPC) his superannuation, or untilthe further orders. construction firm, has announced appointment of power industry veteran Jeet Chhatwal as a director on

Mr SK JhaA appointed Director (P &leadership M), MIDHANI its board. power sector expert and trainer

The Committeeinofthe theEPC Cabinet (ACC) with Appointments 37 years of experience domain in has the approved the proposal of the Department of Defence power, oil and gas sectors, Chhatwal will be responsible Production of Mr S K Jha to the current post of for setting for theappointment pace for the Hartek Group’s Director (Production & Marketing) in Mishra Dhatu Nigam operations and scaling up its future growth in his capacity Limited (MIDHANI), Hyderabad for a period of five years. as Additional Director, the company said in a statement.

Mr UC Muktibodh appointed Director (Technical), Mr Upendra Tripathy appointed interim Director NPCIL General, International Solar Alliance

Distinguished Scientist UC Muktibodh has been appointed Directora (Technical) of theofNuclear Power Mr UpendraasTripathy, former secretary the renewable Corporation of India energy ministry, hasLimited. been appointed interim director general of the International Solar Alliance (ISA), which Mr Chinmoy Gangopadhyay selected as Director brings together countries with abundant sunshine with (Project), PFC solar energy costs. the aim of lowering

Chinmoy Gangopadhyay has been selected for the post MrDirector NK Singh appointed Official Director, of (Project) in thepart-time Power Finance Corporation Limited HCL (PFC) by the Public Enterprises Selection Board (PESB).

Mr NK Singh, IFoS (GJ:87), has been appointed as partArno HarrisDirector joins Azure Power’s Board time Official of the Hindustan CopperofLimited. He is also the Joint Secretary in the Ministry of Mines. Directors

Azure Power, India’s leading solar power company, Ms Ruby Srivastava appointed Director (Finance), announced the appointment of Arno Harris, Former NPCIL CEO and Chairman of Recurrent Energy, one Founder, of North America’s leading utility-scale solar project Ms Ruby Srivastava, IRS (IT:86),director. has been appointed as developers, as an independent

Director (Finance) in the Nuclear Power Corporation of Govt. announces Additional SecretaryIndia Limited under several the Department of Atomic energy for a period up to her superannuation on February 28, 2022 level appointments or until further orders. Her appointment is vice R The Appointments Committee of the CabinetPreman (ACC) Dinaraj, IA&AS(1984). has approved several Additional Secretary-level

appointments, including that of Ms. Shalini Prasad as Mr Vipin Chander Additional Secretary,Bhandari, Ministry of appointed Power.

Director(HR), Engineers India LimitedService (IAS) Ms. Prasad, an Indian Administrative officer of the 1985 batch (Uttar Pradesh cadre), presently Mr Vipin Chander Bhandari, Executive Director, has in her cadre, will succeed Mr. Badri Narain Sharma, IAS been appointed as Director (HR) of the Engineers India (RJ:1985) on his appointment as Additional Secretary, Limited, NewofDelhi. Department Revenue, Ministry of Finance. An official press release said that Ms. Madhulika P Sukul, IDAS (1982), presently in her cadre, has been 26 appointed as Additional Secretary, Department of

Consumer Affairs, Ministry of Consumer Affairs, Food and Public Distribution vice Mr. G. Gurucharan, IAS Mr NB Gupta recommended for the post of (KN:1982) on his appointment as Secretary (Performance Director(Finance), PFC Management), Cabinet Secretariat. Mr. Rajani Ranjan Rashmi, Additional Mr Naveen Bhushan GuptaIAS has(MN:1983), been selected for Secretary, of Commerce, Ministry of the post of Department Director (Finance) of the Power Finance Commerce been appointed as Corporation and (PFC),Industry Bhushanhas is currently the General Additional Secretary,ofMinistry of His Environment, Forest Manager (Finance) the PFC. selection to the and Climate Change vice Mr. Hem Kumar Pande, IAS Director (Finance) post was made at a Public Enterprises (WB:1982) on his appointment as Secretary, Department Selection Board meeting held on March 9. As many as 13 of Official Language, Ministry of Home Affairs. persons were interviewed for the post.

Mr. Girish Chandra Murmu, IAS (GJ:1985), Additional Secretary, of Expenditure, Ministry ApplicationDepartment invited for Director (Production), HECof Finance has been appointed as Additional Secretary, The Public of Enterprises has Department Financial Selection Services, Board Ministry(PESB) of Finance invitedMs. applications eligible candidates for the poston of vice Snehlatafrom Shrivastava, IAS (MP:1982) her appointment as Secretary, DepartmentCorporation of Justice, Director (Production) in Heavy Engineering Ministry of Law and Justice. Ltd (HEC). Director (Production will be overall incharge of three manufacturing plants: Heavy machine Building Ms. Amita Prasad, IAS (KN:1985), Joint Secretary, Plant, Heavy Machine Tools Plant Foundry Forge Ministry of Water Resources, Riverand Development and Plant. He has to manage the three plantsasas per the Ganga Rejuvenation has been appointed Additional corporate policies. The last date ofForest submission of the Secretary, Ministry of Environment, and Climate Change vice Mr. Susheel Kumar, IAS the (UP:1982) on form is May 8, 2017. Candidates can avail information his as Secretary (Border Management), fromappointment the official websites of PESB. Ministry of Home Affairs.

Application for(MN:1984), Director (Technical), CIL Mr. Nikhileshinvited Jha, IAS Additional Secretary, Ministry of Water Resources, River Development and The Public Enterprises Selection Board (PESB) has Ganga Rejuvenation has been appointed as Additional invited applications from eligible candidates for the post Secretary and Financial Adviser, Department of Food and of Director (Technical) in Coal India Limited (CIL). Director Public Distribution, Ministry of Consumer Affairs, Food (Technical) in charge of allMr. technical operation of field and Public Distribution vice Prabhas Kumar Jha, IAS activities and safety of mines. The last date of submission (UP:1982) on his appointment as Secretary, Ministry of of the form is May 8, 2017. Candidates can avail further Parliamentary Affairs. information from the official websites of PESB.

Mr. U P Singh, IAS (OR:1985), Additional Secretary, Ministry of Petroleum Natural(Finance), Gas as Additional Application invited forand Director BEL Secretary, Ministry of Water Resources, River Development and Mr. Nikhilesh Jha. The Ganga Public Rejuvenation Enterprises vice Selection Board (PESB) has invited applications for the post of Director (Finance) in Bharat Electronics Limited. The Director (Finance) will have an overall charge of finance and accounts functions of the organization, and is responsible for evolving and Bureau of Energy Efficiency formulating related policies and their implementation. Post: Secretary The last date of submission of application is May 8, 2017. Bureau of Energy Efficiency is ainformation statutory body The interested candidate can (BEE) avail the from under the Ministry of Power has invited applications from official website of PESB.

VACANCIES

the officers of Central or State Governments holding a post not below the rank of Deputy Secretary to the Government of India in the parent Aprilcadre 2017for the post of Secretary in Bureau of Energy Efficiency on deputation basis

CoverStory

transformer is an electrical device which, by the principles of electromagnetic induction, transfers electrical energy from one electric circuit to another, without changing the frequency. The energy transfer usually takes place with a change of voltage and current. The step down transformers used for electric power distribution purpose are referred as distribution transformer. There are several types of transformer used in the distribution system. Such as single phase transformer, three phase transformer, pole mounted transformer, pad mounted transformer, and underground transformer. Distribution transformers are generally small in size and filled with insulating oil. Distribution transformer also provides the final voltage transformation in the electric power distribution system, stepping down the voltage used in the distribution lines to the level used by the customer.

A

Distribution transformers normally have ratings less than 200 kVA, since distribution transformers are energized for 24 hours a day (even when they don’t carry any load), reducing iron losses has an important role in their design. As they usually don’t operate at full load, they are designed to have maximum efficiency at lower loads. To have a better efficiency, voltage regulation in these transformers should be kept to a minimum. Hence they are designed to have small leakage reactance. The primary coils are wound from enamel coated copper or aluminum wire and the high current, low voltage secondaries are wound using a thick ribbon of aluminum or copper. The windings are insulated with resin-impregnated paper. The entire assembly is baked to cure the resin and then submerged in a powder coated steel tank which is then filled with transformer oil (or other insulating liquid), which is inert and non-conductive. The transformer oil cools and insulates the windings, and

28

protects the transformer winding from moisture, which will float on the surface of the oil. The tank is temporarily depressurized to remove any remaining moisture that would cause arcing and is sealed against the weather with a gasket at the top. Pole-mounted transformers often include accessories such as surge arresters or protective fuse links. A selfprotected transformer includes an internal fuse and surge arrester; other transformers have these components mounted separately outside the tank. Pole-mounted transformers may have lugs allowing direct mounting to a pole, or may be mounted on cross arms bolted to the pole. Aerial transformers, larger than around 75 kVA, may be mounted on a platform supported by one or more poles. Distribution transformers may include an off-load tap changer to allow slight adjustment of the ratio between primary and secondary voltage, to bring the customer voltage within the desired range on long or heavily loaded lines.

Efficiency of Distribution Transformer Distribution transformers are the second largest loss making types of equipment in power net-work, after transmission lines. High efficiency DTs present economic benefits in terms of lower operating cost, reduced green house gases emission, improved reliability and potentially large service life. The efficiency of distribution transformer is defined as the ratio between output power to input power of the transformer at full load condition, but in case of a distribution transformer, the concept is a little bit different as the possibility of running a distribution transformer at its full load condition is nearly nil. The efficiency of the transformer is maximum at 50% of full load.

April 2017

CoverStory

A transformer has mainly two types of losses, these are, iron losses and copper losses. Iron loss, which is also referred as core loss, consists of hysteresis loss and eddy current loss. These two losses are constant when the transformer is charged. That means the amount of these losses does not depend upon the condition of secondary load of the transformer. In all loading condition, these are fixed. But the copper loss which is also referred as I2R loss entirely depends upon load. A distribution transformer cannot be run with constant load throughout 24 hours. At day peak time it’s loading is high, whereas in night lean time its loading may be negligible. So selecting a transformer depending upon its conventional efficiency is not practical and economical, too. As a solution of these problems, the concept of all day efficiency of distribution transformer came into the picture. So this efficiency is same as the efficiency of distribution transformer. In this concept, we use the ratio of total energy delivered by the transformer to the total energy fed to the transformer, during a 24 hrs span of time instead of ratio of power output and input of the transformer. Hence, all day efficiency is determined as, total kWh at the secondary to the total kWh at the primary of the transformer for a long specific time period preferably 24 hrs. i.e, All day efficiency =

Output in kWh Input–total losses = Input in kWh Input

This is very much useful to judge the performance of a distribution transformer, whose primary is connected to the system forever, but secondary load varies tremendously throughout the day. Bureau of Energy Efficiency initiated the standards and labeling programme for equipment and appliances to help consumers make an informed choice about energy savings and the cost-saving potential of products. Energy efficiency labeling programme are aimed at reducing the energy consumption of appliances without diminishing their performance. The scheme has been invoked for 21 kinds of equipment/appliances, including distribution transformers. In the BEE labeling programme, the total losses have been defined at 50 percent and 100 percent load. The highest loss segment is defined as Star 1 and the lowest loss segment as Star 5.

transformer. There are mainly two types of maintenance of transformer. One is routine basis, and second is as and when required. For getting smooth performance from a distribution transformer we have to perform some maintenance actions in regular basis. Some other type of maintenance of transformer we perform as when they are required. But if one performs regular maintenance properly, it may not have any provision of performing emergency maintenance. The regular checking and maintenance of distribution transformer is also known as condition maintenance. Hence by proper condition maintenance one can avoid emergency and breakdown maintenance. As 100% condition maintenance causes 0% breakdown of an equipment. There are many different maintenance action, to be performed on a distribution /power transformer. Some of them in yearly basis, some of them are monthly basis, some other are quarterly, some are half-yearly basis. The activities cover under different periodic maintenance are as follows:

Daily Basis Maintenance and Checking The main things which to be checked on a distribution/ power transformer in daily basis are : 1.

Oil level checking.

2.

Color of silica gel in breather. If silica gel becomes pinkish, it should be replaced.

3.

Leakage of oil from any point of a transformer. If oil leakage is found take required action.

4.

Cleaning of dust and dirt.

Oil when topped up shall be of the same make. It may lead to sludge formation and acidic contents.

Maintenance of Distribution Transformer: Transformer is the heart of any power system/network. Hence preventive maintenance is always cost effective and time saving. Any failure to the transformer can extremely affect the whole functioning of the network/organization. A distribution transformer is most costly and essential equipment of distribution system. So for getting high performance and long functional life of the distribution transformer, it is desired to perform various maintenance activities. Not only that, a distribution transformer also requires various maintenance actions including measurement and testing of different parameters of the

April 2017

29

CoverStory

Monthly Basis Maintenance of Transformer

Periodic Testing

Preventive Maintenance action to be taken on distribution transformer in monthly basis are:

Range of testing procedures is employed for the confirmation of specifications and performance of electrical power transformers. These tests can be performed either at the manufacturing premises before the delivery of the transformer or at the consumer site before it is commissioned. In addition many periodic tests are recommended on a regular or emergency basis through out a transformers service life.

1.

The oil level in oil cap under silica gel breather must be checked in one month interval. If it is found the transformer oil inside the cup comes below the specified level, oil to be top up as per specified level.

2.

Breathing holes in silica gel breather should also be checked monthly and properly cleaned if required, for proper breathing action.

3.

If the transformer has oil filled bushing the oil level of transformer oil inside the bushing must be visually checked in the oil gage attached to those bushing.

4.

If it is required, the oil to be filled in the bushing upto correct level. Oil filling to be done under shutdown condition.

Maintenance of Transformer on Half Yearly Basis The transformer oil must be checked half yearly basis that means once in 6 months, for dielectric strength, water content, acidity, sludge content, flash point, DDA, IFT, resistivity for transformer oil. In case of distribution transformer, as they are operating light load condition all the time of day remaining peak hours , so there are no maintenance required.

Yearly Basis Transformer Maintenance Schedule 1.

All the bushings of the transformer to be cleaned by soft cotton cloths yearly. During cleaning the bushing should be checked for cracking.

2.

Oil condition of OLTC to be examined in every year. For that, oil sample to be taken from drain valve of divertor tank, and this collected oil sample to be tested for dielectric strength (BDV) and moisture content (PPM). If BDV is low and PPM for moisture is found high compared to recommended values, the oil inside the OLTC to be replaced or filtered.

3.

All marshalling boxes to be cleaned from inside at least once in a year. All the terminal connections of control wiring to be checked an tighten at least once in a year.

Tests at the Manufacturing premises Type test, routine tests and special tests are carried out at the manufacturing facility before the transformers are dispatched for delivery. Type tests are conducted to confirm the basic design expectation and consumer specification of a particular transformer. They are done in prototype unit, not in all the units of a manufactured lot of transformers. The purpose of routine tests is to confirm the operational performance of individual transformer units in a production lot. They are carried out on every manufactured unit. Special tests are conducted according to consumer requirements to obtain information that will be useful in transformer operations and maintenance.

On-site Tests These tests are conducted at the site where the electrical transformer is installed to determine its electrical, thermal and mechanical suitability for the system in which it will be used. They include pre-commissioning tests, periodic maintenance tests and failure tests. Pre-commissioning tests are performed before the commissioning of the transformer at the site. They assess its post installation condition and carryout a comparative analysis of the test results of all low voltage tests with report of tests conducted at the manufacturing premises. Periodic maintenance tests performed during the service life of equipments provide valuable information about its state of deterioration. They help in predicting the possibility of future transformer failure. Failure tests are employed to identify the cause of transformer breakdown.

Conclusion Distribution transformers are an indispensable part of the electricity supply in distribution network. Hence their proper functioning is a must for the stability and reliability of the supply in distribution network. Various transformer tests and preventive maintenance procedures can be deployed at different points in time to maintain distribution transformers health and ensure uninterrupted supply to consumers. â–Ş

4.

The pockets for Oil Temperature Indicator & Winding Temperature Indicator if any, on the transformer top cover to be checked and if required oil to be replenished.

5.

The proper function of Pressure Release Device must be checked annually.

6.

Insulation resistance and polarization index of transformer must be checked with megger.

M. Phil (Renewable Energy), PHD Scholar

7.

Resistive value of earth connection and rizer must be measured annually with earth resistance meter.

M.P. Electricity Regulatory Commission Bhopal (M.P.)

30

Ashok Upadhyay BE (Electrical), M Tech. Hon. (Ind. Engg.) Dy. Director (Generation)

April 2017

Interview

Mr Alk Agrawal Vice Chairman, IEEMA Distribution Transformers Division speaks to IEEMA Journal on the issues concerning the Division

Please share your views on the issue of dual certification on Distribution Transformers upto 2.5 MVA both by BIS and BEE With the introduction of mandatory BIS certification of distribution transformers, which is welcome step, the dual certification by BEE is of no relevance. The distribution transformer is perhaps the only industrial item covered in BEE list which is not sold in open market. It is purchased mainly by Discoms under a tendering process where detailed specifications are laid and strict type testing and inspection requirements are specified. The purpose of BEE labelling is to educate the ignorant consumer, but in the case of distribution transformers the customer is fully knowledgeable. The BEE labelling is only leading to delays and is a wastage of time, cost and energy without serving any useful purpose as all the qualitative criteria is being met under BIS certification scheme. It will be better if the BEE labelling scheme is made optional or restricted to testing of energy efficiency levels only.

What are your views on the Delay in testing of transformers at CPRI and ERDA The requirement of routine, type and special test on transformers has increased manifolds due to mandatory requirement of BIS certification. There are over 350 BIS certified manufacturers in India and looking to the numbers of type, rating and energy efficiency levels and testing requirement of BIS there is a delay of approx 2-3 months. The testing laboratories really need to gear up the resources and manpower to minimise the waiting time.

Implementation issues of Electrical Transformer Quality Control Order The Electrical Transformer quality control order has been issued by DHI but no mechanism has been

32

adopted for proper implementation of the same. In many parts of the country NON BIS marked transformers are being manufactured and purchased. An extensive awareness campaign in news media is required to promote and educate the consumers about the mandatory BIS certification and implication of non conformity.

What do you think about the gaps in testing facilities at CPRI/ERDA As such there are no gaps in testing facilities for testing of distribution transformers, but the same have to be scaled up so that minimum time delays.

Do you think there is need for setting up of testing laboratory in northern region of the country Definitely, there is an urgent need of setting up a testing facility in northern region as majority of BIS certified manufacturers are based in Rajasthan, UP, Punjab & HP etc and they have to send their equipments for testing to ERDA/ CPRI which leads to extra time and cost.

Share your views on the root cause analysis of failure of Distribution Transformers and its preventions With the amended IS 1180/2014 covering all aspects of transformers and mandatory BIS certification on Transformers and CRGO, the quality of transformers being manufactured in India has improved and the failure on account of manufacturing defects is now very low. Now the focus should be on the best practices of installation & maintenance of transformers as majority of transformers are now failing due to mishandling in the field. ▪ - Shalini Singh, IEEMA

April 2017

SpecialReport

T

he Ministry of Power under Shri Piyush Goyal, Minister for Power, Coal, New and Renewable Energy and Mines had launched Ujwal DISCOM Assurance Yojana (UDAY) in 2015. The aim was to find a permanent solution to the financial mess that government-owned electricity distribution companies found themselves in.The scheme has now started making a difference and is moving towards realising its objective of a financial turnaround and a revival of DISCOMs, which have only accumulated debt over the past decades. Given failure of past attempts (one-time settlement 2003 and FRP 2012) to revive the ailing discoms, this time too there are apprehensions about success of project UDAY. So, what is different this time? there are three key issues, at large, which would underscore success of the scheme. Addressing legacy losses: States in the past were not in a position to take over the debt burden, given the FRBM and borrowing ceiling limits amidst weak finances. This scheme gives the states enough flexibility in managing the interest payment on debt taken over, within their available fiscal space in the initial few years. Enforcing financial discipline to ensure sustainable solution: Past plans lacked teeth to put the onus of turnaround on the state governments. With the banks amply cautioned against loss funding and UDAY holding states responsible for any discom losses, addresses the structural issue of the distribution sector by enforcing financial discipline through alignment with state finances. Improve operational efficiencies of discoms over next 2-3 years: UDAY has outlined a 2-3 year turnaround plan. Accordingly, the centre will work with the states to ensure timely tariff revision, reduction in power costs,

34

compulsory metering, investing in improving AT&C apart from lowering interest costs. The scheme has been adopted in 22 states and has helped DISCOMs there come out of the debt trap. Rajasthan, Haryana, Chhattisgarh and Punjab have emerged as the big gainers. Dakshin Haryana Bijli Vitran Nigam in Haryana has eliminated losses for the first time ever since its establishment. The DISCOM, which had reported losses of more than Rs 2,088 crore in 2014, registered a profit of Rs 78 crore. In Rajasthan, DISCOMs have projected a saving of Rs 4,697 crore. Another major achievement is the announcement of power tariffs in 18 of the 22 states, which means they are maintaining financial viability. The Finance Ministry has allowed 12 of the 22 member states to issue bonds worth Rs 194,681.49 crore to alleviate the debt crisis.The ministry has taken other initiatives to restore the financial viability of these DISCOMs too, primarily by making their operations more efficient through training and streamlining of the bureaucratic red-tape. When UDAY was launched, there was ample scepticism about the scheme being yet another attempt to recapitalise lossmaking businesses with no accountability. Its success seems to have alleviated some concerns. Â

State

Month of Joining

1

Andhra Pradesh

June 2016

2

Assam

January 2017

3

BiharÂ

February 2016

April 2017

SpecialReport

State

Month of Joining

4

Chhattisgarh

January 2016

5

Goa

June 2016

6

Gujarat

February 2016

7

Jammu & Kashmir

March 2016

8

Jharkhand

January 2016

9

Haryana

March 2016

10

Himachal Pradesh

October 2016

11

Karnatka

June 2016

12

Madhya Pradesh

August 2016

13

Maharashtra

October 2016

14

Manipur

July 2016

15

Punjab

March 2016

16

Puducherry

August 2016

17

Rajasthan

January 2016

18

Tamilnadu

January 2017

19

Telangana

January 2017

20

Uttar Pradesh

January 2016

21

Uttrakhand

April 2016

22

Sikkim

February 2017

The are some states who have started showing positive results from the scheme. Power distribution company Dakshin Haryana Bijli Vitran Nigam (DHBVN) has recorded a profit for first time ever since its inception in July 1999. From losses of more than ` 2,088 crore in 2014, the discom registered a profit of `78 crore in the first half of the current financial year. Now, DHBVN officials aim to double the profit by the end of current financial year. In comparison, Uttar Haryana Bijli Vitran Nigam (UHBVN) has reported a loss of `1,233 crore in the first half of financial year 2016-17 against a loss of ` 336 crore in the last financial year, reported an analysis by Rural Electrification Corporation Limited (REC).

year to a profit of more than ` 78 crore. The review was conducted to ascertain the progress of various major operational and financial indicators as per UDAY on the basis of data submitted by discoms and visits by UDAY teams. The analysis report, released early this month, pointed out that the state incurred a loss of ` 815 crore in financial year 2015-16 for both discoms combined and gave a loss projection of ` 2,911 crore and `1,878 crore for 2016-17 and 2017-18 respectively. The review commended DHVBN for turnaround from loss to profit. “We focused on replacing old and defective electric meters, placing meters outside buildings, meter sealing, check on thefts, increasing number of feeders, recovery of pending amounts and controlling transmission and distribution losses through various means. We hope to double the profit by the end of this financial year,” said Arun Kumar Verma, managing director, DHBVN. REC also observed that DHBVN has improved on billing efficiency and reduced aggregate technical and commercial (AT&C) losses while UHBVN is falling short on this front as well. In its review, the REC observed that a major cause of concern in Haryana was high average cost of supply (ACS) that is ` 8.37 per unit in current financial year as against the national average of ` 6.66 per unit. The State of Rajasthan reduced ACS-ARR gap from Rs. 1.68/unit as on FY 2015-16 to Rs.0.83/unit during H1 FY 2016-17 (on input energy basis). Gujarat, Uttarakhand, Chhattisgarh & Maharashtra have achieved reduction in AT&C losses to 13.64%, 33.25%, 26.66% and 20.25% respectively during April-September, 2016 compared from 16.15%, 35.41%, 27.33% and 20.59% respectively during the corresponding period in 2015-16. 15 out of 18 UDAY States/UT have filed Tariff Petition (including MYT) for 2016-17 UDAY States have reduced their avg. cost of power supply by 12.83% (Rajasthan), 12.25% (Bihar), & 7.83% (Punjab) from FY 16 to H1 2016-17. Manipur DISCOM-MSPDCL has taken up the installation of Pre-paid metering to reduce the outstanding consumer debts, energy theft and improve the billing efficiency. The revenue collection has gone up from Rs. 88.61 Crore

DHBVN has been reeling under losses worth crores ever since it was created along with UHBVN and two corporations – Haryana Vidyut Prasaran Nigam and Haryana Power Generation Corporation (HPGC). DHBVN supplies power to 11 districts of southern Haryana and has always recorded losses worth ` 2,000 crore or more due to electricity theft, non-payment of dues, transmission and distribution losses and increasing fuel surcharge. A half-yearly analysis by REC, under Ujwal DISCOM Assurance Yojana (UDAY), has revealed that DHBVN reported a remarkable achievement with a turnaround from losses as steep as `471 crore in last financial

April 2017

35

SpecialReport

Officials positive about steady Progress Currently, the states of Haryana, Gujarat, Bihar, Punjab, and Rajasthan have fulfilled close to 30-45 percent of the commitments made under the UDAY program, stated a MNRE official. Eight states including, Bihar, Uttar Pradesh, Jharkhand, Chhattisgarh, Goa, Uttarakhand, Rajasthan, and Andhra Pradesh have shown a decline in distribution losses, which is a big positive, added the MNRE official. The UDAY program is a revival plan, not just a bailout package, and it takes time to make DISCOMs robust so that they do not fall under heavy debt again. It’s not that there has been no progress. Developers want a fast rollout of packages and benefits, but they should understand the enormity of the work at hand. Progress is slow, but there is progress, stated another MNRE official. There has been a positive reduction in cost of power in states that are more dependent on thermal power. States like Bihar and Punjab where thermal power is the mainstay, have shown a decrease in the cost of power due to cheap domestic coal and this is a result of UDAY, stated an official at North Bihar Power Distribution Company Limited (NBPDCL). Bihar joined UDAY program at the right time and we are seeing some positive changes. The program has given hope to the distribution sector in an agrarian and industrially backward state like ours, stated an official at South Bihar Power Distribution Company Limited (SBPDCL). In Bihar, we are using new billing software to help reduce AT&C losses and electricity theft is a major issue for DISCOMs in the state, added the official at NBPDCL. The state government has also issued bonds worth Rs.23.32 billion (~$348.32 million). The government is strengthening the transmission network and is working towards reducing coal price. Through the electrification program the state is trying to lessen incidents of electricity theft by connecting more households to the grid, stated an official at Uttarakhand Power Corporation Limited (UPCL). In Haryana, positive results have already been seen; DHBVNL is making a profit. The state is working to cut down AT&C losses and inclusion of large parts of the state into the National Capital Region has helped, stated an official at Haryana Electricity Regulatory Commission (HERC). Electricity is reaching new areas in the state due to better grid infrastructure which has also contributed to the state DISCOMs improved finances, added the HERC official. Cheap coal has helped Punjab, stated an official at Punjab State Power Corporation Limited (PSPCL). In addition, payment of pending electricity bills by government departments and organizations in the state has helped, added the PSPCL official. Smart-metering is also underway in the state. Our state has issued the largest number of bonds, both in terms of bonds issued directly by state government and by state DISCOMs, stated an official at Ajmer Vidyut Vitaran Nigam Limited. One other practice that is helping is cutting power to areas with high AT&C losses, this allows us to sell electricity to regions where payments are made timely. Payment of state government bills has helped, stated an official at Jaipur Vidyut Vitaran Nigam Limited. In Rajasthan, we have implemented 100 percent feeder and consumer metering as well as asset and consumer mapping. All of this has helped, stated an official at Jodhpur Vidyut Vitaran Nigam Limited. Loss reduction targets at the sub-division level and distribution of responsibility amongst the government departments to achieve these loss reduction targets has helped. We have cut down AT&C losses and Gujarat DISCOMs are amongst the best in India, stated an official at Paschim Gujarat Vij Company Limited (PGVCL). Improved efficiency of thermal power projects has also helped, added the PGVCL official. Implementation of DDUGJY program in mainly tribal Jharkhand has helped the state, said an official at Jharkhand Bijli Vitran Nigam Limited (JBVNL). The AT&C losses have been brought down to close to 40 percent, but massive grid infrastructure [overhaul] needs to be done in the state to connect more consumers to the grid and help the DISCOM generate revenue, added the JBVNL official. We have started performance monitoring and management and the feeder improvement program for network strengthening and optimization is underway. The recently announced demonetization also helped as huge amounts of revenue was recovered through payments of unpaid power bills, stated an official at Uttar Pradesh Power Corporation Limited (UPPCL). We have also brought down intra-state transmission losses from above five percent to below five percent, which is an achievement for a state of UP’s size, added the UPPCL official.

36

April 2017

SpecialReport

in 2012-13 (Rs. 7.38 Crore Monthly Average) to Rs. 175.95 Crore in 2015-16 (Rs. 14.66 Crore Monthly Average).

State’s Initiatives: A Summary Rajasthan: Has launched “Mukhya Mantri Vidyut Sudhar Abhiyan” to reduce AT&C losses through various technical and anti-theft measures.100% feeders have been metered. 100% consumer metering including smart metering, for highend, domestic commercial, industrial consumer is being rolled out. Proposed to make all R-APDRP feeders communicable by end of January 2017 and balance by June 2017. Haryana: “Mhara Gaon Jagmag Gaon” is a scheme to provide the 24 Hours power supply in rural areas. The supply hours of these feeders were increased from 12.00 hrs to 15.00 hrs. After allowing for the specified quantum of technical losses below 20%, if the village pays bills to the extent of 90%, their electricity supply will be increased from 18 to 21 hours. Manipur: Name & Shame-Campaigns using Public Hoardings, Newspaper notices with Consumer Details, Radio announcements and Other Social-Media like Facebook, Whatsapp etc. are being carried-out to bring down the AT&C from the present level of 42%to35% in 2016-17 Bihar: To reduce AT&C losses, DISCOMs of Bihar have implemented their own billing software in Urban and Rural areas and started Spot billing through web-based Mobile app with feature of image of meter reading on the consumer’s bills for better satisfaction of the consumers.

Challenges Regulatory treatment of 25% DISCOM debts, Related Problems in issue of DISCOM bonds, Working capital & loss financing; approach of RBI against grain of Cabinet decision Financial re-engineering has resulted in reduction of ACS-ARR Gap & Interest Cost, but further efforts are required for improving billing and collection efficiency; in order to meet AT&C Loss reduction targets under UDAY. Cost of power for NTPC had reduced; but Coal price hike, Clean energy Cess, Railway freight Increase and RPO results in increased cost of power. Also Risk allocation with respect to coal supply & transportation is

unfavourable for power plants Installation of Smart Meters remain a challenge due to high investment requirements. Mr Sandeep Modi, Executive Director (Fin) CSPDCL Raipur opines, “CSPDCL has benefited by way of takeover of 75% of eligible loan as on 30.09.15 i.e. Rs. 870 cr. This has substantially reduced th interest burden on the company. The Company has been able to reduce theft by various loss reduction schemes such as HVDS( High voltage Dist. System, AB cabling of overhead conductors etc. Spot billing with photo of meter is being taken up for accurate billing. Circlewise targets have been set for reducing AT&C losses. Feeder separation, smart metering is being planned.”

Road ahead The success of UDAY scheme is critical for the India’s economic growth aspiration and government’s vision of supplying affordable and accessible ‘24×7 power to all’. Efforts towards 24X7 affordable power supply cannot be achieved without turnaround in the operational and financial performance of Discoms. In addition, default on bank loans by financially stressed Discoms has the potential to seriously impact the banking sector and the economy at large. The comprehensive UDAY focuses on revival of power sector by luring the Discoms and state governments to perform efficiently through various incentives. The states have to forgo their claims on the IPDS and DDUGJY grants if the operational milestones under the UDAY are not achieved and also, the states have to bear a part of future losses of Discoms, if any, in a graded manner. To ensure performance of Discoms under UDAY, monthly monitoring mechanism has been formulated under the tripartite Memorandum of Understanding (MoU) signed between the Discoms, states and the MoP. CMD/MD of the respective Discoms shall monitor the performance of Discom on monthly basis based on financial, operational and managerial parameters. Article 13 As per MoP, if the milestones under UDAY are achieved on time as determined, almost all DISCOMs will be profitable by FY19. Achieving the milestones under UDAY may not be an easy affair, especially the reduction of AT&C loss to 15% by FY19. Achievement of other target likes reducing power theft, installation of smart meters, improvement in collection of dues, and upgradation of power supply infrastructure will require strict and aggressive measures by states. The government has extended the timelines for joining UDAY by one year to March 31, 2017, in order to facilitate all states which could not join the scheme in 2016. Going forward, the joining of the remaining states especially the larger states with highly loss making Discoms such as Tamil Nadu, Madhya Pradesh, etc. would remain crucial for the complete revival of power distribution sector. As a whole, the success of UDAY scheme would remain dependent upon the active participation, effective implementation and monitoring by all stakeholders, in the absence of which, it may end up becoming a financial revival scheme instead of a comprehensive reform measure.▪ - Shalini Singh, IEEMA

April 2017

37

IssueMonitoring

T

ransformer owners work hard to ascertain and digest the right data to make critical decisions confidently, but the volume of data can be overwhelming. What looks like a critical piece of information at first glance could easily be a diversion with no real importance. Having the appropriate tools and solutions in place to help navigate all the available data is the best way to simplify the process and ensure the real red flags are addressed quickly.

Motivations for Condition Monitoring Condition monitoring platforms are on-line systems that can yield real-time information to support up-to-theminute decisions and long-term asset replacement plans. Data and analysis provided by these systems can improve your understanding of asset condition in between times of scheduled testing, maintenance and inspections. Sometimes conditions can change more rapidly than scheduled off-line testing can show us. Having this timely information gives you the power to target your intervention activities, reduce O&M costs, avoid preventable failures and reduce business interruption costs.

When it comes to more comprehensive monitoring, you will need bushing Power Factor/Tan-Delta, operational (SCADA), partial discharge (PD), dissolved gas analysis (DGA) and a means to correlate data. Power transformers can fail from dielectric, thermal and mechanical causes. If there are particular issues with a transformer – suspect bushings or a tap changer prone to rapid thermal deterioration – targeted condition monitoring should be included in the application of an advanced suite of tools. Transformer failure rates can be closely related to specific designs and can also depend on operation regimes. However, a failure rate of much less than 1% a year is commonly achieved. PD from a bushing overlaid by leakage current provides more context for analysis.

Where do I start? The best approach for condition monitoring is to choose a flexible monitoring platform that can gather and analyze

What problem are we trying to solve? Condition monitoring should be based on a simple initial question: “What problem are we trying to solve?” If we are looking to monitor the general health of a transformer, then general use monitoring, including dissolved gas analysis and temperatures may be sufficient. This will not detect all potential problems, and there is still the risk that certain failure modes can occur without warning.

38

April 2017

IssueMonitoring

Typical bushing partial discharge data

data from an individual asset or at an individual station. The benefit of a scalable platform is that you can grow your system as needs and conditions change. Today you might want to watch one unit, but two years from now you might need a comprehensive view of all transformers at a particular station. A platform that aggregates data across different transformers to data-mine the larger data set and seek out anomalous behaviour is a powerful approach to data collation and analysis.

Planned Responses

clear and well-communicated plan, any response plan falls apart and it becomes just another protocol that collects dust on the shelf. When data comes in, a detailed plan helps you make sure: hh The information and the alerts are going to the right people hh The appropriate people know what the data and alerts mean hh They understand what requires a response hh They know how to respond

It’s not enough to just hook up various monitors for DGA, partial discharge, temperature. It’s knowing what to do with the valuable information that equipment can provide. Agreed response and action plans should be in place before a monitoring platform provides alerts, alarms or notifications. Working out what to do in the middle of an event will always be more difficult and confusing. Monitoring platforms are supposed to aid our asset health and maintenance initiatives, not hinder them. Without a

April 2017

With a plan in place, when a critical change has occurred, the team knows what to do, who has to do it and how soon it needs to happen. With all this planning in place, we can then apply appropriate condition monitoring and then benefit from its application. â–Ş Tony McGrail Solutions Director: Asset Management and Monitoring Technology, Doble Engineering Company

39

PolicyMatters

E

lectricity is one of the most vital infrastructure inputs for economic development of any country. The demand for electricity in India is enormous and is growing day by day. The gap between demand and supply is also widening day by day. Today, India’s 315 GW of installed electricity generating capacity (by end of February 2017) is significantly higher than 153 GW of peak demand. Despite installed capacity exceeding power demand, some parts of the country face acute power shortages. The critical reasons are – high level of Aggregate Technical & Commercial (AT&C) losses and poor financial health of utilities. The country is facing huge Aggregate Technical & Commercial (AT&C) losses in the order of 25%, or even more in some utilities. AT&C loss is nothing but the sum total of technical and commercial losses and shortage due to non-realization of billed amount in the transmission and distribution sectors. There are two ways of balancing the demand and supply: hh

To set up new generating stations to generate the additional required power (Long term)

hh

To reduce the Aggregate Technical & Commercial (AT&C) losses to meet the demand (Short term)

Distribution Sector considered as the weakest link in the entire Power Sector and this Sector account for a substantial percentage (more than 60%) in the total AT&C losses. To bring down these losses and strengthen the subtransmission and distribution networks in Rural and Urban areas, the Ministry of Power, Government of India has come up with two prestigious projects viz. Deen

40

Dayal Upadhyaya Gram Jyoti Yojana (DDUGJY) and Integrated Power Development Scheme (IPDS) . Distribution Transformer contributes major part of the transmission and distribution loss in the Distribution System and one of the last equipment in supply chain of electricity to the consumers. It’s performance affects the reliability and quality of power supplied to the consumers to a large extent. In this process high efficiency distribution transformers (with lower losses) play a vital role. Keeping in view of the same, the Rural Electricity Corporation (REC) has finalised the technical specifications of Distribution Transformers in line with latest IS-1180 (Part-1): 2014 with minimum losses of Energy Efficiency Level-2 and also incorporated the concept of Total Owning Cost (TOC). Even the specifications adopted by State Distribution Companies with maximum allowable losses defined as per IS-1180 (Part-1): 2014 are not high enough to promote purchase of high energy efficient distribution transformers and the same can be reviewed time to time. Keeping in view to improve the efficiency of the distribution network, recently, the Bureau of Energy Efficiency (BEE), Ministry of Power, has upgraded the losses of Distribution Transformers and covered all Three Phase Distribution Transformers, capacity ranging from 16 kVA to 2500 kVA, 11 kV under mandatory labelling scheme vide amendment No. 1 to gazette Notification No. SO.4062 (E) dated 16th December 2016. Please refer below table of new STAR ratings & losses, defined by the BEE. These new BEE STAR rating and losses shall come into force from 1st July 2017.

April 2017

PolicyMatters

Scandard Losses in watts up to 11 KV Class Rating

Star 1

Star 2

Star 3

Star 4

Star 5

(kVA)

SO % Load

100 % Load

50 % Load

100 %Load

50 % Load

100 % Load

SO% Load

100 % Load

50 % Load

100 % Load

16

135

440

120

400

108

364

97

331

87

301

25

190

635

175

595

!58

541

142

493

128

448

63

340

1140

300

1050

270

956

243

870

219

791

100

475

1650

435

1500

392

1365

352

1242

317

1130

160

670

1950

570

1700

513

1547

462

1408

416

1281

200

780

2300

670

2100

603

1911

543

1739

488

1582

StandardlossesinwattsuptoII KVClass(Forratingsabove200kVA) Star I Rating (kVA)

% Impedance

Star2

Star3

Star4

50 % Load

100 % Load

50 % Load

100 % Load

50 % Load

100 % Load

50 %. Load

100 %

Star 5

Load

50 % Load

100 % Load

250

4.5

980

2930

920

2700

864

2488

811

2293

761

2113

315

4.5

1025

3100

955

2750

890

2440

829

2164

772

1920

400

4.5

1225

3450

1150

3330

1080

3214

1013

3102

951

2994

500

4.5

1510

4300

1430

4100

1354

3909

1282

3727

1215

3554

630

4.5

1860

5300

1745

4850

1637

4438

1536

4061

1441

3717

1000

5

2790

7700

2620

7000

2460

6364

2310

5785

21701

5259

1250

5

3300

9200

3220

8400

3142

7670

3066

7003

2991

6394

1600

6.25

4200

l1800

3970

11300

3753

10821

3547

10363

3353

9924

2000

6.25

5050

15000

4790

14100

4543

13254

4309

12459

4088

11711

2500

6.25

6150

18500

5900

17500

5660

16554

5430

15659

5209·

14813”;

With this new gazette Notification & amendment no.1, the

Transformers Qty ‘Nos.)

Transformers MVA

NORTH

282,854

11,773

loss values of earlier STAR 3 (Energy Efficiency Level-1 (EEL-1) as per IS-1180 (Part-1):2014) become obsolete from 1st July 2017 and earlier STAR 4 / BIS energy efficiency level 2 become STAR 1, and earlier STAR 5 / BIS Energy Efficiency level 3 become STAR 2 and also derived losses for new STAR 3, 4 and 5 for Distribution Transformers. Case Study on Economic Savings & Benefits by new BEE STAR rating Energy Efficient Distribution

EAST

17,260

1,985

WEST

92,583

4,463

SOUTH

129I 049

7,726

Total

521,746

25·,947

And these utilities buying Distribution Transformers as per below pattern:

Transformers:

BIS EEL-1 (or) Old BEE STAR-3

40%

A case study has been performed by taking the total

BIS EEL-2 (or) Old BEE STAR-4

51%

BIS EEL-3 (or) Old BEE STAR-5

9%

population of Distribution Transformers of capacity 16 kVA to 2500 kVA, three phase, 11 kV purchasing through direct bidding by state utilities (published tenders during FY 2016-17) of worth Rs.3900 Cr.(Approximately), Quantity @ 5,21,746 No. across India:

April 2017

Economic Savings and Benefits expected to accrue due to purchase of Energy Efficient Transformers as per new BEE STAR:

41

PolicyMatters

Following are the assumptions considered for this sample study:

hh

Further, 30 MW of permanent demand can be avoided at 11 kV side, translating to 56 MW* of installed capacity avoidance, which is equivalent to saving of Rs.336 Crs.** (approx.) on Capital investment of Generation addition.

hh

If all Distribution Companies, adopt new STAR losses issued by BEE as against existing technical specification losses of respective discoms

hh

Number of hours of operation of Distribution Transformers : 8400 / annum

*56 MW = (30 MW x 1.12 (T&D losses upto 11 kV – 12%) / 0.60 (PLF – 60%)).

hh

Average Energy cost : Rs.3.78 / Unit (Ref: A&B factors of IPDS/DDUGJY specification)

**Rs.336 Crs=56 x 6 (Rs.6 Crs. / MW capital investment on Generation)

hh

Rate of Interest : 10% (Ref: A&B factors of IPDS/ DDUGJY specification)

hh

Arriving saving of total losses (watts) at 50% loading of Transformers

Note: The savings are even more, if we consider the capital investment to set-up proportionate transmission and distribution networks.

Sample calculation Transformer BIS Energy Efficiency Level-1 (or)

Rating

Old BEE STAR-3

on

New BEE STAR • 3

one

520

100

New BEE STAR·4

kVA

New BEE STAR·5

Un-touched Advantages hh

More no. of consumers can be catered, in parallel, with the available resources

hh

Saving in losses means not only avoidance of energy cost, but also saving of fossil fuels thereby reduction of CO2 emissions making a contribution to reduce global warming.

Additional Investment and Payback:

Saving Total Total @50% Total Loss at Loss loading Loss at 50% at 50% 50% per Loading Loading annum Loading (w) (w) (w) (kWH) 100kVA

number

392

1075

352

Saving Total @50% Loss at loading 50% per Loading annum (w) (kWH) 1411

317

Savnig @50%

1705

{(520-392) X 8400 X 1}I 1000

If above calculation is applied to all 5,21,746 no. transformers, the energy savings are as follows: New BEE STAR 3

New BEE STAR 4

% increase (approx.)

loading per annum (kWH)

New BEE STAR 5

BIS EEL-1 (or) Old BEE STAR-3 BIS EEL-2 (or) Old BEE STAR-4 BIS EEL-3 (or) Old BEE STAR-5

Energy savings (Differential total 251 MU / Losses at 50% annum loading, with respect to the respective Discoms Technical specifications - EEL-1/ EEL-2/EEL-3)

345 MU / annum

428 MU / annum

Note: The savings are even more, if we consider the purchase of Transformers from EPC contractors (Project purchases) & Private Industry also.

Highlights from above table: hh

42

With the new BEE 3- STAR rating transformers, all Discoms together across India, shall going to save 251 MU per annum, resulting into saving of Rs.95 Crores (Approx.) annually.

21%

Extra Investment on New BEE STAR.3 Rs. Crs. 325

14%

279

7%

24

Total

628

Even though the high efficient transformer (New BEE STAR 3 / 4/ 5) costs more initially (approximately 7% to 10% increase, for each one STAR up), there will be an attractive payback (4 years) due to its lower operating cost, which saves money over its life.

Balance between Demand & Supply – Short term method: The Government of India has targeted for Solar generation of 100 GW by 2022. In order to achieve the proposed target capacity of 100 GW, the overall investment required would be around Rs.6 lakh Crs. at the rate of Rs. 6 Crs. per MW at the present cost. In addition to the capital investment, scarcity of land in India is also a bigger challenge to achieve this target.

April 2017

PolicyMatters

If Discoms start buying Transformers as per new BEE STAR-3 from next 5 years, the accumulative installed capacity saving of 840 MW (56 MW per year) at the end of 5th year (please refer below table). It is equivalent to saving in capital investment of Rs.5040 Crs. towards establishment of Solar Generation Unit. In addition, to set up 840 MW solar generation plant, it requires approximately Rs.3360 acres of land. Whereas, the additional investment towards buying of new BEE 3 STAR Transformers for the next 5 years is only Rs.3140 Crs. MW

FY FY FY FY FY 2017-18 2018-19 2019-20 2020-21 2021-22

FY 2017-18

56

FY 2018-19

56

56