FOR

Substrate (Solid Aluminium Panel, ACP, Acrylic Sheets & More)

Display Equipment (A-boards, Roller banner & more)

Rigid Boards (Internal foam board, PVC & more)

Digital Media (One-way vision, roller banner material & more)

LED Lights (Neon-flex, Strip lights & more) & More

publisher

Image Publications Pty Ltd

ACN 056 489 699

PO BOX 613, Brighton

South Australia 5048

T > +61 1300 001 393

E > info@imagemagazine.com.au

W> www.imagemagazine.com.au

editor

Stephanie Gaddin

T > +61 449 775 494

E > editor@imagemagazine.com.au

advertising

Janet Maitland (Publisher)

T > +61 1300 001 393

E > info@imagemagazine.com.au

Welcome to the August issue of Digital Image Magazine. July saw Visual Impact return to Brisbane and it did not disappoint, with a 20% increase in attendance over the last show which was held in 2018. In this issue, we bring you all the highlights from the show, including all the latest new product launches fresh off the back of FESPA and drupa earlier this year, and the latest applications that are shaping our industry.

During Visual Impact, FESPA Australia held an open house at SS Signs, one of Australia’s leading signage companies. SS Signs has taken its signage production capabilities to a new level by investing in a stunning new purpose-built head office production facility in Cleveland, Queensland. With workflow and automation, a focus, they have also recently installed Australia’s first Digitech TruFire LTX2 flatbed printer. Don’t miss page 29 of this issue where Steve Lambourne, owner of SS Signs, shares his journey so far in an exclusive interview with Digital Image Magazine.

With 2030 looming and with government led recycling initiatives in place for the packaging and textiles industries it seems only a matter of time before our wide format and signage industry is impacted as part of the broader

manufacturing sector. Recognising this trend, our Publisher, Janet Maitland, who has been in the industry since 2005, recently conducted a “study tour” in Europe. Her goal was to investigate existing legislation and best practices in the European wide format and signage sector. The aim being to provide valuable insights on practical steps that local industry leaders can take to prepare for and adapt to these impending changes. As part of Janet’s findings, this month we are proud to present a Special Feature: Sustainability Spotlight - Recycling wide format and signage waste – Have we reached the tipping point? which you will find on page 16.

As always, we love to hear and share your stories so please reach out to us at editor@imagemagazine.com.au To stay up to date with the latest industry news and events, visit imagemagazine.com.au, register for our weekly newsletter including our industry leading classifieds, and make sure to follow us and tag us @imagemaganz on social media. We look forward to connecting with you and seeing you at upcoming eventss.

Warm regards,

Stephanie

oOh!media is launching a trial to assess the impact of reduced energy consumption across its large format digital network as part of an ongoing commitment to lead the Out of Home industry to a more sustainable future.

The first phase will see a black out of 70 large format LED sites across Australia between 1am to 4am each day for a period of six months. It follows an initial month-long test at one of oOh!’s sites in Sydney’s inner west, which showed an estimated energy saving of 6% if the site was blacked out during these hours.

“We are continually exploring ways to advance

our sustainability agenda through innovation. This large format digital trial, the first of its scale for oOh!, will provide valuable insights and learnings on how we can transition the digital network to reduced and renewable power sources,” says Sarah Young, Group Director of Environmental, Social and Governance (ESG) at oOh!.

While oOh! is accelerating its move towards renewable energy, the company is also reducing power consumption by investing in LED technology, which enables sites to consume less power when blacked out.

oOh! will bring additional sites into the program

Spicers has announced an exclusive Hahnemühle Digital Fine Art range distribution agreement.

Ken Booth, General Manager - Product & Marketing at Spicers, says, “This significant partnership is a testament to our unwavering commitment to providing the highest quality products to our customers and elevating our offerings to the next level.”

Booth adds, “We are particularly excited to bring the Hahnemühle sustainable range to the Australian market, which includes the innovative Hahnemühle Sustainable Photo Satin and the exceptional Hahnemühle Photo Silk Baryta X. The Sustainable Photo Satin is a groundbreaking alternative to traditional PE-based inkjet photo papers, featuring a new bio inkjet coating that is free of plastic composites and 100% recyclable through the wastepaper cycle. Its bright white, velvety smooth surface is ideal for sustainable photo and poster printing.

“The Photo Silk Baryta X, with its cellulose base and optimised inkjet coating, offers a traditional silver halide photo paper feel. This smooth, creamy white paper with a silky gloss finish ensures outstanding print quality for both photo and poster prints, making it perfect for daily use.

over time, and money saved on electricity will be reinvested into oOh!’s transition to renewable energy across the network.

MOVE 1.5 data shows a minimal audience reach of 1% to 2% between the hours of 1am and 4am and oOh! clients will be unable to book these trial sites during the power down hours.

“This initiative is a key part of our broader ESG strategy and reinforces our commitment to creating a more sustainable business. We are excited to see the outcomes of this trial and its potential impacts,” concludes Young.

“The introduction of these new products is yet another reason why our partnership with Hahnemühle is perfect. Spicers is dedicated to sourcing products from manufacturers and suppliers committed to smart and greener practices. We are delighted to be the Australian distributor for Hahnemühle and to deepen our commitment to this esteemed partnership. Together, we will continue to set new standards in digital fine art and sustainable printing solutions,” concludes Booth.

swissQprint showcased an automation option at drupa 2024, designed to maintain high productivity in flatbed printing by relieving operators of unloading tasks.

The new automation module removes processed media up to 3.2×2 metres from the flatbed printer’s table, streamlining the handling of large runs. Loading would continue to be done by hand.

swissQprint gathered initial customer feedback as part of the development process. “drupa is the perfect opportunity to show the conceptual study and collect broad-based feedback that will go into final development,”

explains Carmen Eicher, Chief of Sales and Marketing Officer at swissQprint. Once tailored to market needs, the finished product is expected to be available in 2025.

Phil Trumble, Managing Director Pozitive Sign & Graphics Supplies, demonstrated the product to Image Magazine, explaining, “People who buy a swissQprint machine love the fact that its flexible. You can print tandem, front and back of the table, you can print full sheets, small sheets, etc. However, we also have clients that have bigger runs and higher production volumes. As the machines have become faster the more automation has become a focus for swissQprint because the faster the machine

prints, the more human interaction is required for unloading and loading the sheets.

“SwissQprint has developed this unloading option to enhance productivity. The idea is that the machine will unload the sheets for you, so the operator is still manually loading the sheets on to the onto the table, but they are no longer having to also remove the sheets. This means that you only need to have one operator just feeding the machine constantly as the sheets are being unloaded automatically. Also the automation module is an option and can be added at any time, it can also be docked when not in use,” concludes Phil.

Currie Group has partnered with Italian finishing manufacturer Neolt Factory at Visual Impact. Neolt Factory will supply a range of loading, unloading and finishing systems for the Canon Colorado M-Series printer range.

Currie Group will be the exclusive agent in the ANZ region for the Neolt Wallpaper Factory solutions. These include ‘jumbo roll in – jumbo roll out’ systems, which increase the capacity for long run lengths of products like wallpaper without operator intervention, and jumbo roll-to-cut solutions, which allow rolls to be converted automatically straight off the printer.

Paul Whitehead, Currie Group Business Unit Manager – Sign & Display, says the Neolt

Wallpaper Factory will deliver huge advantages, particularly for businesses doing large runs of wallpapers or similar products or multiple smaller runs of wallpapers or trimmings that require post-production finishing.

“The benefits of automation are wellestablished,” Paul points out. “Higher productivity is an obvious advantage, but importantly this can be achieved more profitably and while maximising the value of your staff resources by removing touchpoints in the production process and making the entire end-to-end process simpler and more streamlined.

“The Neolt systems will allow Canon Colorado

M-series users to lift their productivity with no additional labour requirement by fully utilising the automated features of the printers and enabling longer unattended production runs as well as in-line converting.

“This is a particular advantage for businesses in markets like Australia and New Zealand where qualified staff are in short supply, and wages running at a premium,” he says.

Under the new agreement, Currie Group is the exclusive agent for the Neolt Wallpaper Factory product suite across New Zealand and Australia, where the company also supplies the Canon Colorado and Canon Arizona printer ranges.

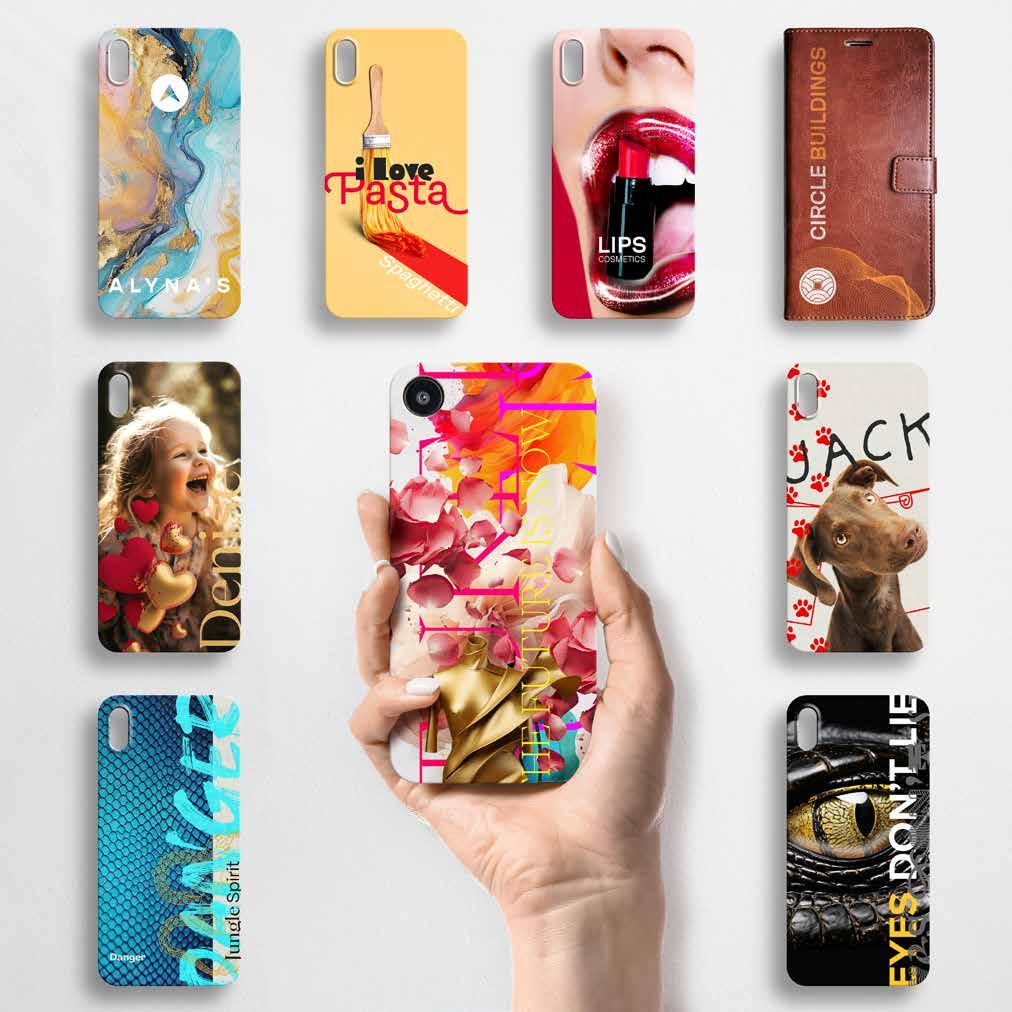

The Mutoh stand featured the Australian debut of the XpertJet 1462UF following its release at FESPA last year.

Russell Cavenagh, Managing Director of Mutoh Australia, says, “Since its launch at FESPA in 2023, it’s been very well received by the Australian market with over ten units installed locally already.”

“It is perfectly suited for direct-to-object printing, which is a highmargin growth category. What we’re finding is that many clients already have a desktop flatbed. They’ve built volume, and they’re looking to grow their business. The XpertJet 1462UF enables them to offer a broader range of niche products to the customers they already deal with. Made in Japan; it prints on anything up to 150 mm thick, has staggered heads with CMYK white and varnish. It is a single pass machine and does everything in one go.”

Also on stand was the XpertJet 661UF UV-LED flatbed printer which includes a larger printable surface area, updated touchscreen panel, improved LED lamp and more. The MUTOH XPJ-661UF allows for layered printing to create fine-textured prints and Braille, all of which will instantly add value to any print. The product has been in the market for some time and has over one hundred installations in Australia.

“For those starting out, Mutoh also offers the “business builder” a 1370mm or 54-inch eco solvent printer. It’s a small, lightweight, but very fast eco-solvent printer. You can print 10 to 15 square meters per hour, but it’s only 80 kilos, so it’s easy to carry into a small area rather than fitting in a 220kg 1.6m wide printer. It is CMYK and is based on existing technology that we’ve had for some time, but we’ve added all the Accufine print heads to it and some other IP to make it faster,” concludes Cavenagh.

Smartech showcase an expanded range of hardware brands

Smartech showcased its expanded portfolio of hardware at Visual Impact.

On stand was the new HP630W HP Latex 630W printer. The printer features a 1.63 m maximum media width, 1-litre ink cartridges, and supports rolls up to 42 kg. It operates at up to 14 sqm/hr speeds and includes white ink capabilities. “Smartech is a full-line distributor of HP with exclusive access to the HP Stitch” explains Brett Wark, NSW Sales and National Product Manager Sign & Display.

Another new offering is the OKI and Graph Tec label printer and finishing system designed for short-run labelling. This combination is designed to reduce the amount of labour required, as the finishing system slits top and

bottom, as well as weeding and laminating to produce finished labels.

Also on the stand was the Epson SureColour 80600 64” large-format printer, which offers a wide choice of inks for a variety of print applications, including high-value largeformat photo imaging, PANTONE-certified POS and signage, back-lit displays and window decorations, wallpapers, surface finishes, décor.

A more recent addition to the Smartech portfolio is the AGFA line of industrial printers available exclusively through Smartech. Whilst there was no product on the stand, there were videos of the latest application called the “high 5”, where two robots are paired to create an

automatic pallet on a pallet-off capability, resulting in significantly improved efficiency. Also on stand was AGFA expert Phillip Burns, who was available to answer questions about the full range of AGFA industrial printers.

Smartech has also recently announced a partnership to become a distributor for Canon Production Printing.

Brett Wark says, “It’s been an exciting 12 months, with the expansion of our product portfolio and new partnerships making us a onestop shop for print service providers. Smartech has a warehouse in each state with both sales support and service technicians, offering our customers potential for growth and peace of mind that they have backup and support.”

Ball & Doggett made their mark at Visual Impact Brisbane 2024 with a stand themed around sustainability. The stand was constructed entirely from Australian-made EnviroCore board, highlighting the company’s commitment to eco-friendly practices and supporting local manufacturing.

The MetaMark architectural film range made its debut at the show. It featured a good range of colours, all of which are in stock in Australia. The MetaMark team travelled from the UK for the launch and some advanced training sessions with the local team.

The new DTF Eclipse A-620 MAX printing solution was also launched. It is a complete (printer + powder shaker + fixation unit), fully automated system designed to create DTF film transfers. DTF (Direct To Film) is an alternative printing process to DTG (Direct to Garment), White Toner Transfers and HTV

Innovative applications was the focus of the Currie group stand, including a range of features released at drupa.

A highlight of the stand was the Canon Colorado M series with FLXture for Micro-texture printing for special Effects, which is the latest in UV Gel innovation released at drupa. This five-ink-layer printing technology adds micro-texture to large format prints for subtle surface detail, replicating the luxurious and sensory feel of materials such as wood and leather. The Canon Colorado M series itself was printed and wrapped in magnetic material showcasing short life situations for use in education, events and hospitality such as switching menus according to the time of day.

Other applications available to touch and feel were elevated prints up to 4mm which were printed using the Colorado Arizona combined with the PRISMAelevate XL software which was also released at drupa.

The stand itself was printed by Spyder Displays in Brisbane on an EFI

(Heat Transfer Vinyl). Once heat-pressed, the water-based ink is transferred to the garment in just seconds. No Weeding, Pre-treating, B-Papers and being limited to certain substrates. It has quickly become one of the most popular technologies for garment decoration. These machines offer an entry-level, cost-effective solution for high-volume garment decoration.

Also on the stand was the Kornit Avalanche HD6 Direct to Garment printer. Rob Brussolo, General Manager of Sign & Display, said, “The recently announced Kornit partnership is very exciting for us. We are employing engineers across Australia to provide robust service and support to clients.” Brussolo sees the future of garment decoration in Australia, focusing on customised designs, short runs, and quick turnarounds. There were also HP R1 Hybrid Flatbed demonstrations, printing on corrugated foam board and Australian made EnviroCore Board.

Fabrivu 340i +using fully back lit material and there were a range of samples from the full EFI range of printers including roll to roll, hybrid and dedicated flatbed machines, as well as samples from the EFI Regianni direct to fabric printers and the EFI Nozomi high speed corrugated packaging solution.

Also on stand were samples of tooling and substrates cut using the Elitron range of cutters which are distributed exclusively by Currie Group.

Celmac features a range of print, cut, and finishing solutions

On stand was the Kala Mistral 1650 65-inch dual roll laminator. Suitable for high volume runs, the dual roll setup provides increased productivity because whilst one roll is being used, the operator can prepare the next roll, meaning less downtime and greater operator efficiency. This machine is also an inline slitter that slits as it laminates. It also has a remote control, allowing operation from anywhere in the workshop.

Complementing the laminator was the Kala XY Cutter, which cuts and slits at the same time. This model also has a roll-to-roll feature for the wallpaper market.

Also on stand was the Epson SureColour 80600 64-inch large format printer that offers a wide choice of inks for a variety of print applications, including high-value large format photo imaging, PANTONE certified POS & signage, back-lit displays and window decorations, wallpapers, surface finishes & décor. “It comes with standard colour sets and also has a red and an orange ink with the ability to have white or metallic silver as well,” explained Jonny Rumney, NSW State Manager at Celmac. For those needing precision colour management, the Celmac stand featured the

high-end Barbieri Spectrophotometer LFP QB, which measures reflective and transmissive allowing for the measuring of backlit film.

The stand also had the HP Latex R1000 showcased, a hybrid printer that can operate roll-to-roll or flatbed, it uses generation four latex inks with the white, suitable for small to mediumsized businesses. Celmac and FESPA Australia hosted an open-house at SS Signs showcasing the Digitech TruFire LTX2 printer paired with an Aristo 6m long cutter, you can read more on Page 29.

Graphic Art Mart had four stands at the show in Brisbane, highlighting their range of signage, equipment, rigid substrates, vinyls and films. The company showcased various new products at this year’s show.

On display were Aslan Dichromic Films. The SS70 translucent and SS71 opaque films are designed to change colour with light variations, creating unique visual effects. Complementing these are Aslan’s holographic and specialty films, which are ideal for signage, retail, point of sale, and exhibition graphics.

The General Formulations portfolio now available through Graphic Art Mart, previously an Amari brand, was also on display. This collaboration brings a comprehensive range of digital and signage products to the market, ensuring highquality solutions for various applications.

Speaking about the consolidation of Amari into the Graphic Art Mart brand, Mark Carnarvon says, “It’s going well. Placing all consumables,

services and solutions under a unified brand allows us to provide complete end-to-end solutions to meet customer needs.”

Newly launched and on display at the show was the Mimaki TXF150-75 DTF Printer – attendees saw demonstrations of the seamless workflow from printing to heat transfer onto garments.

Also on the stand were:

Arlon’s new non-PVC sustainable VITAL range of cast films for car wrapping, launched at FESPA this year, reflects the growing demand for environmentally friendly products. Arlon’s premium colour change range has expanded colours and features FLITE technology, ensuring easy application and long-term removability.

3M’s traffic reflective products, including the DG3 prismatic products and the new 610

Series Beaded Reflective Class 100, are also on display. These products offer exceptional visibility and durability, which makes them ideal for temporary signs and stickers.

Avery Dennison’s paint protection films are another highlight, featuring the Supreme PPF Extreme car wrap film, which provides 10-year protection and is available in gloss and satin finishes. The SP1504 Easy Apply, launched on day one of Visual Impact, was also available on the Graphic Art Mart stand.

On the hardware front the company featured the Wazer 220V/50Hz Cutters, Forte DTF Powder Shaker, and SignMaster 1700 AG Laminator, demonstrating their commitment to providing comprehensive solutions for the signage and printing industry.

The new model replaced the previous SC-F9460 and SC-F9460H, offering outstanding image quality, significant speed improvements, extended colour support, and convenient consumables management in a more compact package. Epson’s show theme, “Beauty in Every Dimension,” was embodied by the SC-F9560, highlighting current trends and future growth in merchandise production, signage, and fabric production.

The SC-F9560 is easy to operate, featuring a large touch panel display with integrated help and Edge Print software that shows users on-screen previews. It delivers high productivity with heavy-duty motors and a 2.64-inch PrecisionCore printhead, supporting various media types on rolls up to 45 kg with a bulk ink system. The compact design includes a low profile, integrated heater, high precision auto take-up, and a roll loader for single-operator management.

The 6c SC-F9560H model can be configured with LcLm ink for fine gradation, OrVi for maximum gamut, or FyFp fluorescent ink for brightness. Users benefit from lower running costs, low power consumption, and a high degree of self-maintenance, leading to a low total cost of ownership. The printhead is covered under a 12-month warranty, extendable up to five years via Epson’s CoverPlus.

The SC-F9560 integrates with Epson’s Cloud Solution PORT, offering web-based and mobile access for reporting, tracking, and costing. It also supports user self-replacement of the printhead. The optional Epson SD-10 spectrophotometer enables easy spot-colour matching and enhanced profiling.

The SC-F9560 also conforms to Epson’s environmental goals with reduced packaging, recycled content, and consumables that produce less waste.

Key features of the new printer include:

• Quality output at up to 80 sqm/hr and sellable output at up to 147 sqm/hr

• User-replaceable PrecisionCore printhead with 6400 micro-fine nozzles on the 4c model and 9600 nozzles on the 6c

• Variable dot sizing for optimal colour expression

• Media support up to 1625 mm wide in rolls up to 250 mm diameter

• Quiet operation at only 59 dB

Other products demonstrated at Visual Impact were:

• SureColor F1060 compact desktop DTG and DTFilm printer

• SureColor V1060 compact desktop UV printer

• SureColor P20560 64-inch aqueous printer

• SureColor F160 compact dye sublimation printer

• SureColor S80660L 64-inch eco-solvent printer

• Epson SD-10 spectrophotometer with Auto Table

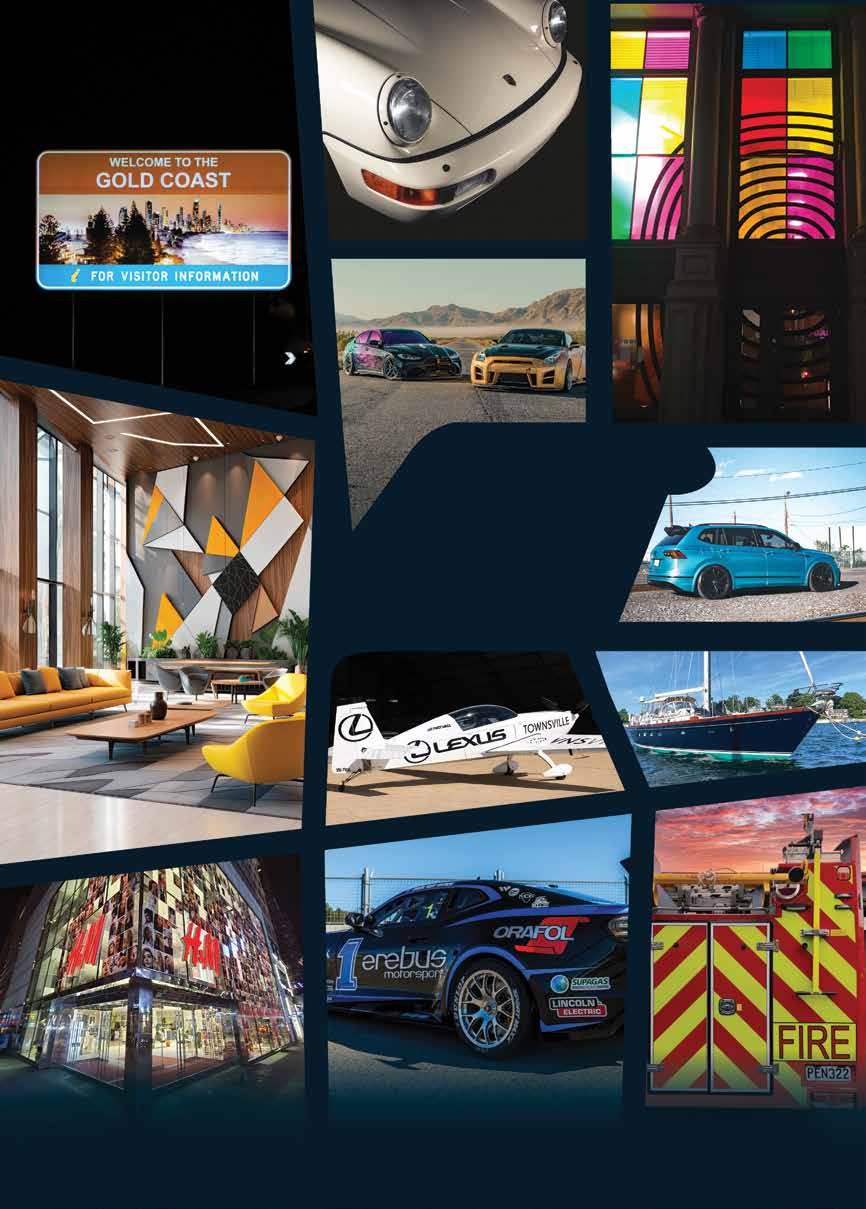

Roland DG Australia has debuted the EU-1000MF large format UV-LED flatbed printer at Visual Impact in Brisbane.

The printer can print on a wide range of materials up to 95mm thick for various applications, including sign graphics, event and store displays, décor, and small-lot and high-mix custom goods.

The EU-1000MF is available in two models, 4-colour or 6-colour, with printheads in a staggered array for printing up to 27.6m2/h in 720 x 600 dpi CMYK mode and enabling it to handle approximately nine rigid 1,220 x 2,440 mm boards per hour. The UV ink is cured instantly, eliminating the need for post-print drying. At the same time, the ability to print directly onto various materials such as acrylic, PETG, PVC, foam, PC, wood, and aluminium composite boards further reduces

post-processing time and costs.

Also showcased was the MO-240 VersaObject the company’s newest direct to object printer, superseding the LEF2 Series. The printer has a higher clearance of up to 200mm high, and a bigger print bed. It also has new eUV5 generation inks offering expanded colour gamuts. Typical applications include the promotional market but at a high volume, and industrial applications such as switchboards, computers.

The VersaStudio BD-entry level UV printer aimed at smaller businesses was also demonstrated at the show, it is similar to the MO240 but with a smaller footprint. Ideal for personalising items in smaller volumes, suited to retail, or smaller business operations.

Spicers brought an impressive lineup to Visual Impact Brisbane, highlighting their strong partnership with 3M and a broad range of renowned brands. Underscoring this approach is the new distribution agreement with Neschen. Attendees explored the Neschen EasyDot range, on show for the first time in the Brisbane market.

The stand also featured the new RollsRoller Signature Plus, equipped with auto leg adjustment, addressing OH&S concerns and enhancing operational safety. Visitors had the opportunity to see top products from Mimaki, Roland, and General Formulations.

Wayne Hood Visual Communications Portfolio Manager, Spicers says, “We are also

The latest Summa S3 made its Australian debut on the Pozitive Sign & Graphic Supplies stand.

The S3 has the same tangential technology as its predecessor, the S2, allowing the knife to lift and rotate, significantly increasing cutting precision. The new S3 model features a new lighting system with blue, green, and red lights, improving visibility and accuracy during operation. Warren Davey, National Equipment Sales Manager, says the S3 also has creasing capability, enabling it to be used for small box production using light boxboard, as it can cut and fold.

Additionally, the new software in the enhanced S3 optimises cutting lines for maximum efficiency, while an advanced camera system replaces the traditional scanner, offering instant mark recognition for much faster processing. The upgraded motor in the S3 further boosts its performance.

Visitors to the Pozitive stand were also treated to demonstrations of the versatility of the Summa F series flatbed cutter, capable of performing ten different applications in just 40 minutes, and the entry-level S1 cutter, offering a cost-effective yet high-quality cutting solution.

celebrating a decade-long partnership with 3M, which has seen Spicers expand its range of 3M products from standard graphics and colours to architectural and window film tapes, adhesives and reflectives. It’s a very broad portfolio and we are celebrating with the 10 of three promotion which is ‘10 years of 3M’ and there are some really good prizes to be won by those purchasing 3M products through Spicers.

This years’ stand showcased Spicers’ commitment to being a ‘House of Brands’ and leveraging our excellent relationships and support from the stable of well-known brands for our customer’s benefit,” concludes Wayne.

HP presented its latest technologies at Visual Impact Brisbane 2024, with the Australian debut of the HP Latex 630W printer. The printer features a 1.63m maximum media width, 1-litre ink cartridges, and supports rolls up to 42 kg. It operates at up to 14 sqm/hr speeds and includes white ink capabilities.

In addition to the printer, HP showcased innovations from drupa, including the Live Production Printer Remote Control software, designed to improve productivity for small— to medium-sized print service providers. This software enables users to manage their workflow remotely from any PC or mobile device, allowing unattended printing and streamlined production.

Another key focus for HP was education, explains Craig Hardman, ANZ Country Manager Large Format Printing at HP. “HP Learn is a series of educational workshops that teach you anything, from how to use your printer to how to create applications. There are already over 100 videos available that include training from industry experts like Jeremy Brew. It allows print service providers to be able to learn and train on the go and that’s all included with their solution. So not only are they doing obviously controlling their business, they’re able to learn more about how to do new things.”

Visitors could also see the latest upgrades to its Design and e-commerce software. Recognised by the European Digital Press for its Web-to-Print solution, this software simplifies the creation of print-ready PDF files for large-format applications like canvas

and wall coverings. The new functionalities enhance compatibility with various websites and support on-demand quotation processes, helping print service providers reach new online customers.

Mimaki unveiled a range of upgrades and cutting-edge printing technologies at the show, highlighting their commitment to innovation and quality.

The TXF 300 made its Australian debut and generated significant interest, with all available stock sold out. This model is twice as fast as its predecessor, the TXF 150, and is noted for its vibrant print quality, exceptional white ink performance, and soft feel of the print.

Mimaki also introduced the UCJV-330, an upgrade to the UCJV-300. Featuring brand-

new print heads, this machine nearly doubles the speed of its predecessor while maintaining the same high-quality output. The UCJV-330 is a versatile print-and-cut system capable of producing textured prints. Mimaki’s UV printand-cut technology continues to be a popular solution for various applications.

Another highlight was the TRAPIS system, which demonstrates its ability to print onto paper and press onto a variety of textiles without the need for pretreatment. This system combines the vibrancy and washability of sublimation printing with the capability

to produce cotton and blends, offering unmatched versatility. Applications were on display on the Mimaki stand.

JFX 600 PRINTER AND CFX 600

On display at the Mimaki stand were applications from the JFX Printer and the CFX 600 printer and cutter, with applications shown on reBoard.

The KEBAB HS (High Speed) cylindrical printer was a standout, offering three times the speed of the previous model. Unique to this printer, the print head remains stationary while the object moves under it, setting it apart from other similar devices.

FESPA Australia is holding its Annual Conference in Sydney on Friday October 25th 2024. With its theme of Transform, Inspire, Lead, the FESPA Annual Conference will encapsulate the journey of your business, from adapting to change and innovation (Transform) to motivating and empowering individuals (Inspire) and ultimately leading with effective leadership (Lead) towards sustainable growth and success.

Kicking off the proceedings and setting the scene and tone for the day will be key note speaker Gus Balbontin, former Executive Director and CTO of Lonely Planet, who is renowned for his innovative thinking and transformative insights. With a rich history of navigating and shaping the future of industries, Gus will share his expert predictions and strategies that can help you and your business adapt and thrive in our ever-evolving market. His session promises to be both inspiring and thought-provoking, providing valuable takeaways you can implement immediately. Gus will also facilitate an interactive Leadership Workshop where you will learn first-hand key strategies to assist you in your leadership journey.

Following this session you will hear insights and debate as to why succession planning and exit strategies are crucial components of a business’s long-term success and sustainability. These strategies will help you focus on preparing future leaders and ensuring business continuity. Together, they will help create a resilient, forwardthinking organisation capable of effective navigational leadership changes and ownership transitions.

Other sessions will focus on better relationships with younger and new staff. There is no denying a cultural disconnect between a manager or business owner now in their 40s or 50s and a school leaver in their teens or early 20s. To survive and thrive, businesses need to make the most of new talent that joins their ranks by offering diversity and inclusion in a supportive environment.

Another topic to be discussed is how the print industry’s sales role has evolved significantly over the last few years, with a substantial shift towards digital engagement, consultative selling, and

integrating technology solutions. Sales professionals need a blend of digital literacy, technical knowledge, and adaptability to grow in this new environment. Participants will hear about the trends in B2B and B2C sales. The importance of personalised, multi-channel engagement and the adoption of integrated systems to ensure a seamless, efficient operation from marketing to invoicing.

Sustainability continues to be a hot topic, and participants will hear how regulatory demands are forcing more businesses to rethink and take action. Learn from initiatives that are taking place in Europe and how this will assist you in your day-to-day sustainability journey.

If all these topics are not enough to keep you awake at night, Dr Toby Ford will present how to deal with stress and burnout! Dr. Ford is a respected expert in this field and will offer practical guidance and strategies to help you maintain your well-being and sustain high performance. His session will provide you with the tools to better manage stress and the pressure of running a business, ensuring you remain resilient and productive.

Networking has always been a cornerstone of the FESPA Annual Conference, and this year, we are taking it to the next level with curated specialised networking sessions that will provide you with the tools, insights, and connections necessary to navigate the future of our industry successfully. Make sure you mark your calendar and join us in October for an event that promises to be enriching and inspiring. We look forward to seeing you there!

Tickets are available on the FESPA Australia website fespaaustralia.org.au . For more information, email membership@ fespaaustralia.org.au

A survey by the Australian Chamber of Commerce and Industry (ACCI) has found that almost half of small business owners have considered closure in the past year, with rising input costs, skills and worker shortages, and increased government regulation all taking their toll.

ACCI, Australia’s largest business network, polled small business owners from around the country to understand how they were faring in the current economic and regulatory environment, and the findings were concerning.

Among its specific findings, the survey results showed:

• 45 per cent of small business owners have considered closing or leaving in the past 12 months.

• 82 per cent of small business owners said that red tape significantly or moderately impacts their business.

• 50 per cent of respondents said they were spending more time on red tape than 12 months ago.

• 40 per cent said they would make a reduced or significantly reduced profit this financial year compared to the previous year.

• More than 50% said their biggest expense was overcoming skills and worker shortages.

Mick Harrold, President of the Australian Sign & Graphics Association, agreed and said the findings were concerning but were in line with the feedback the association is receiving from its members across the sign, display and broader graphics sector, echoing the comments of ACCI chief executive officer Andrew McKellar saying small businesses are ‘the backbone of our economy’ but are being ‘strangled by red tape’ and often neglected when it comes to policy making, legislation and regulations.

“SMEs make up a huge proportion of the businesses in our sector, and they are

facing some of the toughest conditions we’ve seen for years, with input costs rising almost daily, a global skills shortage and an increasingly confusing regulatory environment,” Harrold says.

“ASGA joins with other industry associations in calling on governments, policymakers and regulators to ‘do better’ for small businesses by focusing on initiatives which put downward pressure on the cost of essential inputs like energy, make it easier to create jobs and employ people, and reduce unnecessary regulation and red tape.”

While the full impact of the government’s changes to industrial relations law has not yet fully been felt, they were already a significant concern for business owners who said they fear a damaging, or highly damaging, impact – both from compliance obligations and the potential for unions to interfere with their decision-making.

“There is no question that the regulatory environment continues to become more complex and confusing every year,” Mick says.

“While governments are always keen to introduce new legislation, they often do so without proper consultation with the industries that will be most affected, and without much effort to ensure impacted businesses have the information, resources and supports they need to understand changes and comply.

“For small businesses, time is quite literally money. Additional administration and compliance obligations can quickly eat into profits; conversely, saving time on administration and compliance can boost productivity and profitability.”

With a lack of resources and support provided by the government, Harrold says the role of associations like ASGA has become ever more important, providing vital information, support and resources to help businesses address these key areas.

“At ASGA, our focus is to help businesses with their administrative, regulatory and HR functions so that they can concentrate on doing what they do best,” he says, pointing to a newly expanded range of Member Benefits that includes legal, HR and WH&S resources, regulation and technical support, a comprehensive employment guide, and templates for everything from employment and sub-contractor contracts to enterprise agreements.

“In addition, we have formed a partnership with MEGT to assist businesses in finding and employing apprentices and trainees, and with Australian Business Lawyers & Advisors to provide a full range of workplace relations and employment law advice via our dedicated ASGA Workplace Advice Line,” Harrold says, adding that all businesses in the sector are welcome to email mande@signs.org.au, to discuss concerns or issues at any time.

“The sole purpose of the ASGA is to represent and support businesses across the sign, display and graphics sector. We will continue to build our range of Member benefits and resources and ensure our voice is heard on important issues impacting our members.”

A complete list of ASGA member benefits can be found on the ASGA website.

Ball & Doggett and GALE Pacific recently announced an exclusive partnership to bring Ecobanner by GALE Pacific to the Australian market at Visual Impact in Brisbane.

The innovative Ecobanner is the only Australian-made, PVC-free flexible banner fabric capable of offering a 100% closedloop recycling solution.

Ecobanner is the first product of its kind to be manufactured in Australia with closed-loop recycling capability. This eco-friendly banner material supports local manufacturing and aligns with the growing demand for sustainable and environmentally responsible products.

As the 2024 Sustainability Award winner at the World Out of Home Organization (WOO) Awards, this is a groundbreaking material for the Sign & Display market. Ecobanner can be recycled back into the same product, avoiding landfill.

The polypropylene composition makes it a robust and versatile material, perfect for both indoor and outdoor applications by ensuring durability and vibrant print quality on latex and UV Inkjet printing technology. Ecobanner is available in Back Lit (white/white) and Front Lit (grey/white) banner options and generous 1600mm or 3200mm widths.

Furthermore, Ecobanner is part of a traceable full circular loop program, allowing for the complete recycling and

repurposing of used banners. This contributes to a sustainable lifecycle and minimizes environmental impact. Unlike greenwashing claims, this Closed Loop Program is already in full swing, and its impact is measurable, demonstrating a genuine commitment to sustainability.

“We are thrilled to bring Ecobanner to the Australian market,” said Rob Brussolo, Ball & Doggett General Manager – Sign, Display & Digital. “This initiative underscores our commitment to providing innovative, high-quality, and sustainable solutions to our customers. Ecobanner not only meets the rigorous demands of flexible banner advertising but also sets a new standard for environmental stewardship in our industry.”

“Ecobanner not only meets the rigorous demands of flexible banner advertising but also sets a new standard for environmental stewardship in our industry”

Rob Brussolo

Healthy stock volumes of Ecobanner are available across all Ball & Doggett locations. The fabric is wellpositioned for the signage market and for socially conscious business brands aiming to enhance their sustainability narrative.

Ball & Doggett’s extensive distribution network and deep market knowledge will ensure that Ecobanner reaches a wide array of customers, from local businesses to large enterprises, empowering them to make sustainable choices for their advertising and signage needs, and to provide sustainable options for their clients.

2030 is a crucial milestone for sustainability and Australia’s international commitments to the United Nations Sustainable Development Goals (SDGs) and the Paris Agreement. While these commitments are broad-reaching, 2030 is also a key milestone for more focused programs outlined in the National Waste Policy and the Recycling and Waste Reduction Act (RAWR). The RAWR Act provides a framework for managing Australia’s recycling and waste reduction objectives. A key objective of the Act is to encourage the development of a circular economy, including through product stewardship. The Act provides for three levels of product stewardship: voluntary, coregulatory and mandatory.

While the paper industry is well developed in its circularity, let’s consider two other categories that generate large volumes of printing. Firstly, the packaging industry which has been focused on sustainability since 2011. Targets for packaging are set according to the Australian Packaging Covenant, with 2025 as the deadline to ensure 100% of all packaging is reusable, recyclable or compostable; 70% of all packaging is recovered, recycled or composted; packaging includes an average of 50% recycled content; and that problematic and unnecessary single-use packaging is phased out.

Secondly, let’s consider the textile industry. In 2021, clothing textiles were placed on the Federal Minister’s Priority List for Product Stewardship, with the industry required to reduce clothing sent to landfills. In 2023, the Hon. Tanya Plibersek MP launched Seamless, which aims to create a circular clothing industry by 2030, where responsible stewardship and citizenship are embedded across the entire clothing lifecycle. A recommended 4c/ per garment levy will be used to create programs to incentivise clothing design that is more durable and recyclable, foster new circular business models, close the material loop and expand clothing collection, sorting and recycling. In launching the program, Plibersek issued a clear directive that the scheme would be mandated if not taken up by enough businesses, “I want to see industry leadership… But if I don’t see enough movement in a year, then I will regulate.”

Whilst there is currently no legislation for wide format printing and signage, it seems only a matter of time before we are impacted as part of the broader manufacturing sector. Earlier this year, I undertook a “study tour”, the objective being to learn more about some of the legislation that exists and best practices in the wide format and signage industry in Europe, to understand and bring insights about some of the

tangible actions that could be applied locally by our industry leaders. I attended FESPA and drupa, and I visited and spoke to a number of stakeholders, suppliers, industry experts and print service providers.

In this spotlight on sustainability, I begin with some of our industry’s key global suppliers of self-adhesive film, whose leadership and stewardship are critical to reducing greenhouse gas emissions, developing PVC-free alternatives, and developing a circular economy. Recycling PVC has, to date, been in the too-hard basket, but as you will read, we now have tangible second-life and third-life options being developed overseas.

The solutions are complex, with multiple factors at play, including material separation, collection, avoidance of contamination, storage, conversion into a recycled waste stream and having enough manufacturing capacity, ideally domestically, to consume the waste streams. Developing and implementing a solution in Australia is multi-dimensional and requires collaboration between purchasers of signage, signage service providers, suppliers, associations and the government to incentivise circularity and domestic manufacturing.

As business owners in the wide format and signage industry, we stand at a crossroads. The choices we make now will shape not only the future of our businesses but also the industry’s sustainability profile. Are we ready to lead the change, or will we wait for regulation to force our hand?

Janet Maitland is the Publisher of Image Publications, the premier publishing company for wide-format, signage, graphics, and textile printing businesses in Australia and New Zealand. A longterm member of the industry since 2005, Janet is dedicated to leveraging Image Publications’ media platforms to facilitate industry growth and knowledge sharing among its members.

If you wish to have further discussions about sustainability in our industry or to discuss potential partnerships, please email janet@ imagemagazine.com.au

Metamark was founded, in the UK thirty-two years ago and was a family-owned business until seven years ago when a group of employees, headed by the company’s then CEO, Paul French and backed by private equity, took over the business in a management buyout.

Since then, Metamark has made significant investments in new product development and growing manufacturing capacity. The company has grown year-on-year and experienced considerable international expansion. Metamark is represented in Australia by its distribution partner, Ball and Doggett.

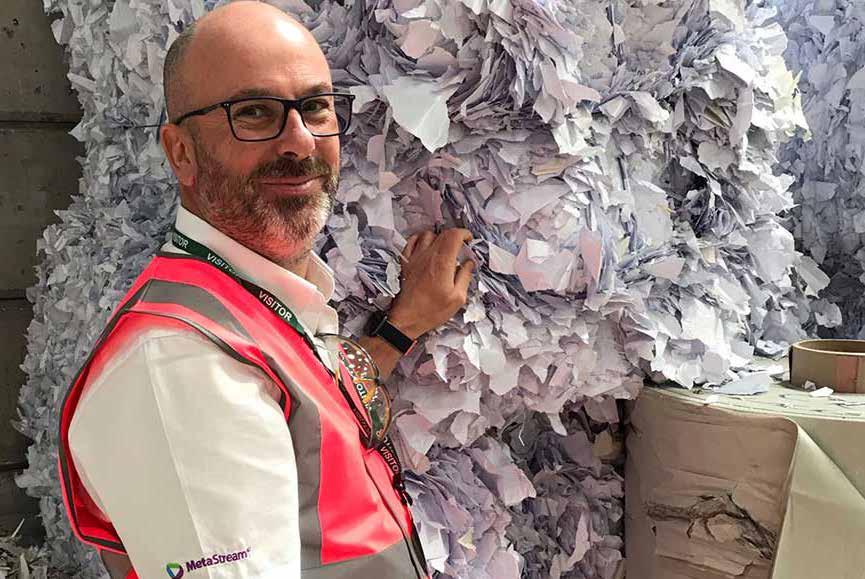

Metamark’s primary manufacturing facility and corporate headquarters is in Lancaster in the Northwest of England, which is where I caught up with Iain Wallace , Strategic Development Manager, who’s the creator of MetaStream®, the company’s recycling initiative for Metamark, for an exclusive factory tour and interview about it and Metamark’s broader sustainability programme.

By Janet Maitland, Publisher, Image Publications

“Environmental responsibility has always been a big part of our culture at Metamark,” said Iain. “Our Environmental and Social Governance Policies recognise our responsibilities toward the planet, our employees’ and partners’ wellbeing. and our operational and business ethics.

“From a manufacturing perspective, we run three shifts daily, six days a week. We have developed fifty different liners, sixty different films and twenty different adhesives, which are combined to create over 3,500 SKUs. We are ISO9001, ISO14001, ISO50001 certified and are in the process of becoming EcoVadis certified.

“In addition to developing a range of PVC-free products, we also want to help the industry become more environmentally responsible, which is why we have invested heavily in developing MetaStream. MetaStream is a recycling initiative which recovers production waste and end-user products that use qualified Metamark materials and turns them into useful articles that can themselves be recycled multiple times.

“MetaStream was developed during COVID and initially started as a program to help us achieve one of our manufacturing ESG objectives, ‘Zero to Landfill,’ explains Iain. “We began by focusing on finding a way of recycling unlaminated film and then refined our processes to

include laminated and printed materials. This waste stream is mixed with other recycled content and virgin PVC and used to make items such as traffic cones,” says Iain.

“Over time, it has become more sophisticated so that now the processer can make two or three variations of the output waste stream, and depending on demand at the time It can go into gum boots, flooring, fence posts and traffic cones among other things.

“These products can themselves be recycled at end of life, so while it is not a truly circular solution as we are not turning graphics products back into the same graphics products, we are enabling second, third, and fourth life articles. This reduces the amount of potentially useful materials end up in landfill or incineration waste streams.

“There are other solutions around for graphics waste, such as shredding, and that may generate one additional life, but where does it go after that? Much of it ends up, again in landfill. One motivation for developing MetaStream, using the processes we have, is the desire to engage genuine recycling and offer it as an option. The other positive impact is that the buyers of our qualified materials are buying a reduced carbon product as Metamark has already paid the carbon footprint for the virgin material through its carbon offset projects.

“The next step is to get our supply chain to do the same thing so that this contributes to our decarbonising,” says Iain. “Wanting to recycle all elements of the product, we then focused on liners. We work closely with James Cropper PLC, a global market leader in advanced paper products based in the UK. James Cropper had already developed a process to recycle PE-coated paper coffee cups. Coffee cups and liners share a little DNA. Two of our liners already qualified for their recycling program, and we went on to develop a third liner specifically for the program.

“James Cropper has capacity to recycle the equivalent of 500 million coffee cups each year, and they use the “Cup Cycling” fibres to make luxury paper and packaging products for global brands who require a large amount of recycled content for their products”, explains Iain.

“From a manufactured volume perspective, 65-70% of the products we ship are fully recyclable. The rolls come in a cardboard box, which can be fully recycled. The end caps can go straight into the plastics recycling bin, or we can take them back. The core is cardboard and can be recycled too.

“Regarding logistics, our customer aggregates waste and either palletises it, bails it or compacts it into a special bag that we supply. We manage the logistics to collect

this waste as part of our scope two emissions. We also connect like-minded customers so that a smaller sign shop that may not have the volume can take their waste to a larger sign shop nearby that does.

“We end up with more liner than film because the film is out there doing its job and most of it isn’t production waste. Our customer rolls the liner back onto the core. In terms of sorting, it is pretty simple: Metamark-qualified products need to be separated into PVC or liner streams.

“In terms of cost, like any other waste management service, the cost is born by the consuming business. One tonne of baled PVC waste is about 7,000 Sqm of vinyl. A palletised bale is approximately 400kg, so the shipping cost of 2.5 pallets divided by the 7,000 Sqm is a small cost per square metre and a business overhead which more and more businesses are building into pricing already,” explains Iain.

“We’ve had the program independently audited, and moving forward once we gain accreditation, EcoVadis will be the process that audits it. While it is currently only available in the UK we have designs on taking the initiative much wider and continuing to innovate with the processes and logistic models at the core,” concludes Iain.

Rob Brussolo, General Manager Sign and Display for Ball & Doggett says. “Metamark are always pushing the boundaries of innovation in terms of sustainability, whether it is through their products or services and Ball & Doggett are excited to be partnering with such a progressive company. We believe working closely with our supply partners enables the Australian market to gain access to world leading initiatives that we can expand into Australia.”

“Sustainability is on everyone’s agenda, whether socially, politically or ethically and our consumers are demanding solutions by key industry suppliers. While Australia may not be as advanced as other countries in regards to plastic recycling, the willingness to recycle used materials have gained momentum in recent years and Ball & Doggett understands the urgency to provide solutions.”

“Ball & Doggett are also excited to announce that Metamark will be launching their range of PVC free products later this year which will be stocked locally in Australia. These new products provide choices for the Australian sign industry that would like to take the next step in their sustainable journey. Whilst MetaStream is not available in Australia at this point in time it gives an excellent window into the future of what is possible and what we should be progressing towards as we move forwards in our sustainability journey,” concludes Brussolo.

M E TA M AR K INTERIO R A R C H ITE C TU R A L FIL M S .

B E T T E R . F OR E VE RYO N E.

MiA™ is a new range of interior architectural lms from Metamark. MiA transforms interior infrastructure so you don’t have to replace it. That costs you and the planet less, and prolongs the life of building fabric and xtures. MiA isn’t just better. It’s better for everyone.

There’s no need to replace costly internal infrastructure when you can easily transform it SUSTAINABLE. cleaned, hardwearing, and they last for years DURABLE.

The MiA range includes contemporar y wood soft matt BEAUTIFUL.

Available through these leading distributors:

Once you’ve decided to use MiA, you won’t want to wait You don’t have to The range is in stock now AVAILABLE.

Hexis Head Office Frontignan, France

Headquartered in Frontignan in the south of France, Hexis is a family owned company established in 1989 by husband and wife team Michel and Michèle Mateu who started with a vision to produce adhesive PVC films for the advertising and visual communication industry. Today the business is run by their children Caroline and Clément and has grown to manufacture over 3,000 products, with more than 500 employees, two research and development labs, 10 subsidiaries including Hexis Australia which was established in 2018, and over 20,000 customers worldwide. I visited Hexis Frontignan and met with Christophe Inigo, Director of International Sales and Guillaume Leonardon, Director of Quality and Sustainability, for an exclusive factory tour and to discuss the company’s recently launched PVC recycling program.

By Janet Maitland, Publisher Image Publications

“Hexis has always been extremely committed to ongoing sustainability and supporting our industry to do the same,” says Guillaume Leonardon, Director of Quality and Sustainability, Hexis. In Europe beginning in 2025 the Corporate Sustainability Reporting Directive (CSRD) requires businesses with more than 250 employees and turn over greater than €40 million to use the European Sustainability Reporting Standards (ESRS) to provide audited reports on the impact of corporate activities on Environmental, Social and Governance (ESG) related risks. “The ESRS are considered equally important as financial reports so we have been investing heavily in resources, adding two new people to our team in the last 12 months just to manage sustainability,” says Guillaume.

“Our manufacturing facilities are ISO9001 (Quality), ISO 14001 (Environmental) ISO 45001 (Health and Safety and the Frontignan plant is also IATF 16949 (Automotive Quality) certified. We have achieved multiple Corporate Social Responsibility (CSR) certifications including accreditation from the UN Global Compact, the Forest Stewardship Council for the purchase of liner from responsible forests and we were awarded a Gold Medal by Ecovadis. Our ESG initiatives are focused on reducing our impact on the environment, ensuing ethical business practices and creating a safe and inclusive working environment that enables everyone to achieve their full potential,” explains Guillaume.

“From a manufacturing perspective a key focus this year has been to analyse our carbon footprint across our whole supply chain and to put in place programs to reduce our greenhouse gas emissions. We have also implemented projects around safety and recycling in the

factory,” says Guillaume. “One of the key things we have learnt that applies to any business, is that it is critical to invest in getting accurate figures to establish a baseline that you can report and measure against every year, then set targets for future improvement.”

“In addition to our manufacturing initiatives we also have developed recycling programs to support our customers in becoming more responsible,” says Christophe Inigo, Director of International Sales.

“We started by developing a system to recover and reuse Hexis end caps. The end caps are collected from the printer, sorted and reintroduced directly back into the HEXIS packaging process. While it can only apply to HEXIS end caps due to the variety of end caps used by different adhesive manufacturers, the impact is still significant with more than 60,000 caps recovered and reused in 2023,” explains Christophe.

End caps returned to the packaging line

“We then began researching how we could recycle liners and PVC. We are proud to be one of the first companies in the world to launch a recycling program for kraft liner, PET liner, PE liner, and PVC films,” says Christophe. Officially launched at FESPA Amsterdam in March 2024, the recycling program which was developed and trialed in France for six months, was expanded to include Spain, Italy, France, Germany, Switzerland, and the Scandinavian nations, with further expansion to Netherlands, UK and Belgium to follow.

The PVC recycling program includes the collection of all brands of printed/laminated PVC films. The customers bail or palletise it and ship it back to the HEXIS warehouse in five pallet lots. HEXIS then consolidates it and delivers it to the processors who convert it into raw material waste streams for products that include recycled content such granules and micronized PVC for use in non potable PVC pipes.

The liners recycling program applies to Hexis kraft, PET and PE liners which are then converted into insulation products.

“Hexis is proud of our family-oriented culture where we are all encouraged to act as managers and focus on working closely

with customers to find solutions, which is important when you are pushing the boundaries of what is happening in the marketplace,” says Christophe. “Finding ways to improve waste management is very important to all business owners in France across all industries as the government uses taxes as a tool to reduce waste. We developed this program and trialled it with fifty companies in France to create a clear set of processes and agreements between participating companies and Hexis. Leadership and staff engagement at the printer is a key success factor, as is education in specifically controlling materials sorting at the printer to avoid contamination of the waste stream, which can become expensive if it gets rejected by the converter.”

When asked about plans to introduce this program in Australia/ NZ, Christophe did not rule it out but noted that “The program is very localised as it relies on a network of like-minded strategic partners, including printers, transport companies, converters, and manufacturers, to work together, and these strategic partners vary between each country.”

With revenue of more than $US 8.4b and over 36,000 employees, Avery Dennison (NYSE: AVY) is a global materials science and digital identification solutions company that provides a wide range of branding and information solutions that optimise labour and supply chain efficiency, reduce waste, advance sustainability, circularity and transparency, and better connect brands and consumers. Its products and solutions include labeling and functional materials, radio frequency identification (RFID) inlays and tags, software applications that connect the physical and digital, and a variety of products and solutions that enhance branded packaging and carry or display information that improves the customer experience. Serving an array of industries worldwide — including home and personal care, apparel, general retail, e-commerce, logistics, food and grocery, pharmaceuticals and automotive. I visited Soignes, Belgium for an exclusive tour of Avery Dennison’s largest graphics production facility, and to meet with Jordy van der Heijden Global Technology Platform Director, Advanced Materials Solutions, Avery Dennison Materials Group to gain a deeper insight into the recycling and circularity sustainability initiatives of one of our industries’ largest suppliers.

By Janet Maitland, Publisher, Image Publications

Global Technology Platform Director - Print & Media

I was first exposed to Avery Dennison’s sustainability program at a product launch at FESPA in 2018, where the presentation was less about the new product and more about their highly sophisticated and comprehensive ESG framework, the targets that had been set and the initiatives and measurement tools that had been put in place to reach those targets. Today, Avery Dennison targets include reducing Scope 1 and 2 GHG emissions by 70% by 2030 (2015 baseline), and reducing Scope 3 GHG emissions by 30% by 2030 (2018 baseline).

The Avery Dennison ESG framework comprises three sustainability goals.

1. Deliver innovations that advance the circular economy

2. Reduce our environmental impact in our operations and supply chain

3. Make a positive social impact by enhancing the livelihood of our people and our communities

Jordy van der Heijden Global Technology Platform Director, Advanced Materials Solutions explains “Taking a leadership position in sustainability has been part of our DNA for many years, it is an integral part of everything we do. We develop products with sustainability in mind, from the materials we use, to how they’re constructed or treated at end-of-life. We are developing solutions for advancing the circular economy. We are particularly focused on increasing materials recyclability and using recycled content in our products.

“Our Global Technology team is focused on developing key product components, such as PVC-free films which are chlorine free and reduce emissions of volatile organic compounds (VOCs). We have also developed a high performing innovative adhesive platform called iA Tech™ Adhesive which contains no solvents. This innovation reduces the use of fossil material compared

with solvent adhesives, saving an equivalent of around 1.6l1 of oil per roll (1.23m x 50m), which is equivalent to reducing the emissions generated from 15km driven by an average gasoline-powered car.”

“We have also reduced material usage through the development of dot adhesive products which use 60% less adhesive than standard adhesive coating. These components form the basis of our Sustainable Advantage Portfolio.”

In terms of recycling programs AD Circular is a European recycling program which enables manufacturers and brands to recycle used label liners from any manufacturer. Companies use an online web app to schedule pickup and transportation of used label materials to one of our recycling partners, at a cost comparable to landfilling or incineration. The used label liners are converted into recycled film liners for labels making it a truly circular solution. The web app also provides useful data in the form of regularly updated analytics and certificates on the amount of recycled liner material, the amount of CO2 emissions users have avoided as a result. With 100,000 labels generating over 100kg of label liner waste it has the potential to have a significant impact.

In the graphics sector, Avery Dennison Australia has led the way being the first to launch a Plastic End Cap Recycling Program in April 2022. Through this program, customers collect their discarded end caps in designated bulk bags provided by Avery Dennison. When the containers are full, the waste management company will pick up the bags and aggregate the waste before

sending them to the recycling centres. The recycler will clean and process the plastic end caps into granules to be reused as raw materials. These plastic granules are then used to manufacture new products made of recycled plastic materials such as outdoor furniture or gardening products.

In addition to recycling initiatives locally, Avery Dennison Asia Pacific Graphics Solutions business has set one of their 2030 sustainability goals to have 50% of all graphic sales come from the Sustainable Advantage Portfolio driven by PVC-free films and Solvent-free adhesive platforms. To this

end they recently launched the Sustainable Print SP1504 EA film technology platform at Visual Impact in Brisbane. This new product has a 53% reduction in Greenhouse Gas Emissions as measured in kgCO2e, versus its current premium PVC equivalent. It contains no chlorine, phthalates or other halogens and has a reduced level of Volatile Organic Compounds (VOCs).

The new technology delivers the same printing and application performance in line with the MPI 1105 EA RS technology. It can be matched with the Non-PVC Sustainable Laminate DOL 6460 but also compatible with current PVC Cast laminates, ensuring seamless integration into existing workflows. The SP 1504 Easy Apply RS is covered by the ICS Warranty program to the same level of the incumbent MPI 1105 EA RS & DOL 6460 Series.

Jordan Leach, Business Director, Avery Dennison Graphics Solutions says “This innovative film technology maintains price parity with existing premium PVC products. Our value proposition is simple: we offer the same sustainable performance, the same sustainable print quality at the same sustainable price.”

Chris Sherry, Senior Strategic Marketing Manager - CX & Sustainability APAC says “This technology has been under development for more than five years. The SP1504EA is the first product of many to follow across 2024 and beyond. Materials science is at the core of what we do, and we are focused on the long-term health of our business, the planet and our communities.”

For a wrapping film that combines supreme performance and application speed, look no further than Avery Dennison Supreme Wrapping Film. This dual-layer film combines colour, texture, and clear protective

providing a smooth, paint-like finish that’s both durable and dazzling. For a limited time only, Graphic Art Mart is offering Image Magazine readers 25% OFF Avery Dennison Supreme Wrapping Film for those who purchase online. Simply use the coupon code GETITATGAMSWF at checkout.

Women in Print hosted a networking drinks function at Visual Impact in Brisbane. The event doubled as a fundraiser for Share the Dignity in the lead-up to the charity’s August Dignity Drive. Attendees included the National Board of Women in Print, women from print and signage shops across Brisbane, and exhibitors from the show floor. The event followed the 2024 AGM of Women in Print.

A Share the Dignity collection box was filled with donations on the night, including various period, incontinence, and baby care products. Stephanie Gaddin, Chair of Women in Print, gave a short welcome, thanking the Event Backers, Lettertech and Bounce LED for generously sponsoring the catering and drinks for the evening.

Following the event in Brisbane, Women in Print will support the Dignity Drive Fundraiser for Share the Dignity through August in Perth, Adelaide, and Melbourne.

“We’re thrilled to host the Dignity Drive Fundraisers through August and bring our Women in Print community together for an important cause. Share the Dignity does

incredible work, and it is fantastic to see our industry rallying to support women in need. This is another opportunity for us all to connect, make a difference, and show the strength of our network.

I look forward to seeing our community contributing to this worthy cause,” says Gaddin.

SS Signs , one of Australia’s leading signage companies, has taken its signage production capabilities to a new level by investing in a stunning new purpose-built head office production facility in Cleveland, Queensland. Not only have they invested in a leading-edge production facility, but they have also invested even more heavily in their people. With workflow and automation a focus, they have also recently installed Australia’s first Digitech TruFire LTX2 flatbed printer. Steve Lambourne , owner of SS Signs, shared his journey in an exclusive interview with Digital Image Magazine.

With over 3800 sqm of custom-designed, purpose-built signage manufacturing capabilities, SS Signs is a facility that is truly aspirational. A full-service signage company with eleven in-house installers, the company-owned installation kit includes two cherry pickers, two scissor lifts, a 22m all-terrain boom, crane truck, 2.5t excavator and a tilt tray, making them totally self-sufficient, a must as any project manager will attest to. SS Signs has in-house steel fabrication complete with cranes, gantries, and all the necessary fabrication and safety equipment, fabricating over 150 tonnes of steel per year and 30 tonnes of ACP. Combine that with a custom-built spray booth large enough to fit a B-double truck, and there is nothing too big for this facility to fabricate, spray or wrap.

When asked what inspired the design of the new production facility, Steve said, “It took me about a year to come up with the design after continually refining it based on my experience in other buildings and creating a space for what our future business looks like. We put installation at the heart of our business because when a job goes wrong, the installers often get the blame, and they’re the ones working at 4.30 am in the morning. So, we focus very hard on delivering our installation team the absolute best experience they can get. The installation bay where the trucks are loaded is in the centre of the building, where everything culminates. We ensure we have the right materials, the right people, detailed site specifications and job instructions, and that the truck is stocked straight from our installation bay, so no lost time running to Bunnings. As a result, we are now installing double what we used to install this time last year.”

Another key driver was to create a fantastic work environment for our staff because they are the most important part of our business, says

Steve. “These days, there are nowhere near as many people coming into the industry and through the ranks as there have been in the past. We employ eleven apprentices between Brisbane and Melbourne and focus very hard on their training and development as they are a massive part of our future. We employ many young people, especially since my two sons, Luke, who runs operations, and Jake, who runs installation, have joined the business as all their mates end up working for us. We find that we’re not looking for signage people so much anymore, but we are looking for young, hands-on technical minds that can operate computers and the latest flatbeds and cutting technology, which then frees up the workload from the more experienced staff to create the time and space teach the young people what to look for as they haven’t learned that eye for detail yet.”

“A great example of this is Glenn Clark, who has worked for my family for the last 46 years and was my tradesman when I did my apprenticeship. He has worked solely on transferring his knowledge to our apprentices for the last two years before his recent retirement. Our apprentices have taken out first, second, or third at the last three ASGA awards, which we are really proud of.”

Asked how he got into the business, Steve responded, “I’ve been in it all my life, it’s all I’ve ever known. Skreencraft was founded by my parents in 1972 in Tingalpa. After working for Mum and Dad for about 16 years, I decided I wanted to do my own thing, so my wife Selina and I started SS Signs in 2006. Initially, SS Signs did a lot of trade work for vehicle wrap installations. Within six months, we had grown to have four staff dedicated solely to vehicle wraps, eventually growing the company to a team of ten people to become one of the leading signage companies in Brisbane. Since then, most of our growth has been through acquisition, which started when Mum and Dad retired and we bought out Skreencraft in 2017. Our continued growth came from acquiring the experience of other sign companies, including Civic Media, Brand Productions and Vehicle Wraps Australia. We also diversified into 3D and grand format printing. To help broaden our reach and better serve our national customers, SS Signs moved into Melbourne through the acquisition of Glenbrae Signs in early 2023 and expanded by opening a new factory in Kilsyth, Victoria.

“Another key feature that has underpinned our growth is our investment in workflow automation and equipment that is fit for purpose. We recently installed Australia’s first Digitech TruFire LTX2 printer paired with a 6m long conveyor and Aristo cutter, which is printing and cutting more than 60 8’ x 4’ sheets an hour with a single operator.

“The Digitech met our needs in terms of weighing up speed, quality and price. We particularly liked how they have simplified the electronics and inner workings of the machine to make an industrial printer as bullet proof as possible so that if we needed to, we feel comfortable fixing it should something go wrong. We’ve also been impressed by the service from both Digitech and Celmac. The installation was really seamless. The unit was delivered at 9 am, unboxed, and up and running later that day. Digitech sent someone out to spend two weeks with us and Celmac training us on the unit. In addition, Celmac has sent two of its technicians to the US for further training.

“The impact on the business has been massive. We were secondguessing ourselves for the first two weeks, thinking we didn’t have much work on, but what was actually happening was that we were outputting all of the work that would go onto our flatbeds in two hours instead of running a printer all day. It has significantly increased our capacity, which we need in order to achieve our growth targets,” concludes Steve.

Wayne McIntyre, owner of Celmac said, “It’s been a fantastic venture partnering with Digitech over the past three years as they have extended their product range, with a singular focus on producing the latest technology in printing, combined with more efficient workflow to save labour costs, but at the same time increase quality output for print service providers.

“This has now become a reality in Australia with the installation of the first printer direct to cutter Digitech solution installed into the new state of the art sign shop at SS Signs Queensland. Steve Lambourne and his team have been perfect partners for leading the implementation of this innovative workflow solution across the sign, wide format, graphics market, enthusiastically embracing the latest technology and the power that it gives,” concludes Wayne.

ADS Australia has recently expanded its capabilities by investing in a Canon Colorado M5W printer. Partnering with Currie Group for this purchase, ADS Australia aimed to enhance its production efficiency, print quality, and overall customer satisfaction.

Established 23 years ago, ADS Australia started as a small screen-printing business. Over the years, it has become a key player in the digital printing market, serving various industries with a broad range of printing needs. Known for its commitment to quality and innovation, ADS Australia continuously invests in the latest technology to meet clients’ evolving demands. The company is also committed to sustainability, continuously working to recycle as much material as possible, including paper and plastics. This commitment to eco-friendly practices is increasingly important to their clients and has become a significant aspect of their business operations.

Dean Wright, Managing Director and founder of ADS Australia says the company’s decision to purchase the Canon Colorado M-series printer was driven by its need to keep up with increasing workloads and the market demand for high-quality, fine-text prints. According to Wright, their existing ageing printers could no longer handle some projects’ volume and specific requirements, particularly those involving smaller stickers and bespoke signage work.

Thanks to Currie Group’s expertise, the printer installation was remarkably smooth. “The machine and technician arrived on the same day, and within hours, they had efficiently unpacked and positioned the printer in place, configuring and automatically calibrating it without any hitches. The technician demonstrated extensive knowledge about the installation process, showcasing the

high level of expertise and professionalism that Currie Group consistently brings to their service. They ensured everything was executed smoothly. It is always a pleasure interacting with anyone from Currie Group,” observes Wright.