BALL & DOGGETT PARTNER WITH KORNIT DIGITALSHOWCASING AT VISUAL IMPACT 16 UPPAREL CREATING A CIRCULAR FASHION SOLUTION 30 INVEST IN THE FUTURE AT VISUAL IMPACT BRISBANE 18 JUNE 2024

If you’ve been waiting for the ideal time to expand your garment decorating business, or even start a new one, the time is now. Purchase the Brother GTXpro direct to garment printer and start printing any design on practically anything, using DTF or DTG technology.

Great deals for high-volume print shops too

For print shops ready to take your business to the next level, the Brother GTXpro B is designed with your mass production dreams in mind.

For more information scan this QR code or visit dtg.brother.com.au

now, order

EOFY

Act

before

CONTENTS 04 FROM THE TEAM PUBLISHER'S LETTER 05 LATEST NEWS LATEST PRODUCT RELEASES FROM AUSTRALIA AND AROUND THE WORLD 16 COVER STORY BALL & DOGGETT PARTNER WITH KORNIT DIGITAL 18 FEATURE INVEST IN THE FUTURE AT VISUAL IMPACT BRISBANE 22 FEATURE WHAT'S NEW FROM SISER ANZ 25 FEATURE COAST IMAGEWEAR: CAPTURING NEW MARKETS WITH DTF 28 FEATURE WHAT'S UP AT WAZZUP? 30 FEATURE UPPAREL CREATING A CIRCULAR FASHION SOLUTION 18 30 16 JUNE 2024 COVER STORY INVEST IN THE FUTURE AT VISUAL IMPACT BRISBANE FEATURE ARTICLE UPPAREL CREATING A CIRCULAR FASHION SOLUTION FEATURE ARTICLE BALL & DOGGETT PARTNER WITH KORNIT DIGITAL - SHOWCASING AT VISUAL IMPACT 3 imagemagazine.com.au THIS ISSUE

PUBLISHER'S LETTER

JANET MAITLAND PUBLISHER

Welcome to the June issue of Textile Image Magazine. Since the last issue, I have been lucky enough to attend two of the major trade shows of 2024. FESPA in Amsterdam, and drupa in Dusseldorf.

Traditionally held every four years, drupa was held for the first time since 2016, and with a massive 17 halls, it was huge. Billed as the world's biggest printing show, it was primarily focused on wide format, commercial print, packaging and labels, with a small number of exhibitors showcasing textile printing. FESPA Amsterdam, on the other hand, had a much more comprehensive range of printing technologies to suit all textile printers, whether you print apparel, uniforms, yardage or soft signage. There was also an interesting range of expert speakers at the Personalisation Conference.

Sustainability was not only a theme at the show but also throughout Europe. I observed multiple examples of clothing collection schemes for recycling, with John Lewis, the UK department store, even incentivising people to participate with cash-back offers. But it's not just

happening in Europe. Don't miss our special feature on UPPAREL, a Melbourne-based textile recycling company that partners with major retailers and charity organisations to collect, reuse and recycle our textile waste, creating truly circular products. Looking for a trade show closer to home? Make sure you visit Visual Impact in Brisbane from July 17 to 19 at the Brisbane Convention Centre. The show is sold out and will be full of new ideas and applications to inspire, not to mention the opportunity to speak with experts and network with colleagues and friends. I look forward to seeing you there.

Best Regards, Janet Maitland

PUBLISHER

Janet Maitland

Image Publications Pty Ltd

PO Box 613

Brighton SA 5048

E info@imagemagazine.com.au

P 1300 001 393

W imagemagazine.com.au

EDITOR

E info@imagemagazine.com.au

P 1300 001 393

ADVERTISING

Janet Maitland

P 1300 001 393

E info@imagemagazine.com.au

SUBSCRIPTIONS

Available FREE to all IMAGE MAGAZINE subscribers

DEADLINES

TEXTILE IMAGE is published

3 times per year.

Next issue: October 2024

Booking & material deadline: Friday Sept 7 2024

DISCLAIMER

The opinions expressed in this magazine are not necessarily the views of the publisher. While every effort has been made to ensure the accuracy of information contained in this magazine no responsibility is accepted by the publisher for any omissions, inaccuracies, typographical errors or printerʼs errors. No responsibility will be accepted for any changes to information after publication.

16 30 VISUAL IMPACT BRISBANE 18 JUNE 2024

FROM THE TEAM 4 JUNE 2024

EPSON'S NEW SURECOLOR SC F11000 DYE SUBLIMATION TEXTILE PRINTER

Epson has extended its SureColor range with a new 1.93 metre (76-inch) dye sublimation printer for high-speed, highvolume textile production. The SureColor SC-F11000, has been designed for maximum up-time and features a new optional Jumbo Roll, for up to 300kg.

The new Jumbo roll feature enables continuous production and reduced downtime due to less frequent media changes – ideal for uninterrupted highvolume production.

The printer is suited to applications in fashion, sportswear, home furnishings and soft signage and follows the success of Epson’s 76-inch (193cm) SureColor F10000 and F10000H industrial largeformat printers (LFPs) for textiles.

More colours

The SC-F11000H features CMYK ink configuration and includes the addition of one of three ink sets: orange and violet; fluorescent yellow and fluorescent pink; and light cyan and light magenta.

“In the dye sublimation sector, customers demand fast turnaround times, consistent performance, high-quality output and reliability,” says Phil McMullin, head of sales for commercial and industrial at Epson in the UK.

“With these requirements in mind, we’ve developed an industrial-level dye sublimation printer that, we believe, sets new standards. The SC-F11000 offers the highest throughput of all Epson LFPs and is equipped with four PrecisionCore Micro TFP printheads and a ‘hot swap’ bulk ink solution that’s designed to keep businesses running. Our heritage is built on innovation, and this is one of

those moments in which we’re raising the benchmark for productivity in dye sublimation.”

The SC-F11000, and SC-F11000H, is capable of speeds of up to 255 square metres per hour.

Other features include Epson Precision Dot Technology, blending three dedicated technologies for dye-sub: Halftone, LUT and Micro Weave.

It also features easy media setting with a media loading lever front and back, auto-adjustment technology including an integrated RGB camera, and Advanced Auto Tension Control (Ad-ATC) for accurate and stable media feeding.

It is equipped with a dryer for less ink transfer to media reverse and wrinkle elimination and a nine-inch LCD touch panel and it offers a bulk ink solution with 10-litre or three-litre ink boxes supported by the “hot-swap” function. It is fitted with user-replaceable parts including printheads.

For consistency, quality and reliability of supply, Epson manufactures all the components for the SC-F11000 and SCF11000H including printheads, ink and Epson EdgePrint Pro software.

DTF AUTOMATION WITH HEAT PRESS CAROUSEL

Sublistar showcased their latest DTF Intelligent Automated Heat Press Carousel at FESPA in Amsterdam.

“The machine is designed to meet the bulk printing needs of apparel manufacturers and can be used for a wide range of applications, including heat stamping, polyethylene film, DTF transfer paper and heat sublimation

paper. It has a high-precision, 3cm solid aluminium heat plate that promises uniform heating along with a “highquality, hot stamping effect”, explained a company spokesperson. Features include a programmable touchscreen, automatic film release, automatic heat pressing, automatic film tearing, and automatic clothes heat pressing.

NEWS 5 imagemagazine.com.au

MIMAKI LAUNCHES ENVIRONMENTALLY CONSCIOUS TEXTILE TRANSFER PRINTING SOLUTION TRAPIS

Mimaki Europe has officially launched its textile pigment transfer printing system, named “TRAPIS” at FESPA Amsterdam. Following the preview of the technology at ITMA 2023, this commercialised version, available later this year, offers an environmentally friendly and easy to operate solution for textile applications – saving almost 90% of wastewater compared to conventional methods.

TRAPIS provides a simple two-step process, consisting of an inkjet printer and a calendar. The design of choice is printed by the inkjet printer with a dedicated ink onto transfer paper, which is then transferred to the application via a calendar. Unlike both analogue and digital conventional dye-printing methods, TRAPIS generates almost no wastewater, only that which is produced during the printer’s automatic maintenance. Due to no pre-treatment or washing of the fabric being needed, this saves around 14.5 litres per square meter of water when compared to digital dye printing1.

Additionally, this eliminates the need for wastewater treatment facilities, which can be both expensive and constrictive when it comes to where the solution is installed.

Due to the smaller size, it is possible for the TRAPIS system to be installed in a limited space, or even at the front of a printshop.

TRAPIS also offers print service providers an easy-to-use option for textile printing. As the process only involves printing and transferring, it does not require specialised skills to operate when compared to the more complex seven- or eight-step system for digital and analogue conventional printing. The lack of a fabric conveyor belt in the system further minimises the need for time intensive maintenance.

Further simplifying the process, TRAPIS is able to print on a wide range of materials, including natural fibres like cotton and silk in addition to blended fabrics, with just one type of ink. Due to this, the process can be flexible and adapt to customer demand, even with multimaterial short runs. The accompanying ink has also achieved the ZDHC MRSL

Lv.3*2 certification and is bluesign® APPROVED, to ensure that it is both worker and consumer safe, as well as an environmentally friendly product. Like with Mimaki’s existing textile solution portfolio, the prints produced with TRAPIS maintain stretchability and colourfastness, without impacting aspects like breathability and water absorbability, important for sectors like home textiles, activewear and fashion.

Arjen Evertse, General Manager Sales, Mimaki Europe, comments, “After the positive reception we received when we initially showcased the technology last year, we’re pleased to now announce the release of this solution commercially at FESPA. Conscious of the evolving sustainability standards and customer demands, we created TRAPIS as an innovative and seamless system for print service providers looking to produce high-quality and vibrant textile applications, while keeping cost, time and environmental impact to a minimum.”

1. According to Mimaki’s original research, digital dye printing generates significant amount of wastewater by textile printing conveyor belt washing and fabric washing after dye fixation (steam). 2. ZDHC is a non-profit organization based in Amsterdam, the Netherlands, that works to eliminate the emission of hazardous substances in the textile and leather industry.y

NEWS 6 JUNE 2024

BALL & DOGGETT ANNOUNCES EXCLUSIVE PARTNERSHIP WITH KLIEVERIK

Ball & Doggett, distributor of printable materials, press consumables, and printing equipment, is excited to announce its strategic partnership with Klieverik, a global leader in rotary thermo-processing equipment for advanced textiles. With over 40 years of experience, Klieverik specializes in designing, manufacturing, installing, and maintaining innovative industrial machinery, including advanced dye sublimation and fixation calender heat presses.

Klieverik's dye sublimation and fixation calender heat presses enable textile manufacturers to achieve superior results while optimizing production processes. Whether it's creating custom apparel, promotional items, or interior décor, Klieverik's presses deliver exceptional quality, durability, and performance.

"We are delighted to partner with Klieverik, a renowned name in the field of advanced textile processing," said Rob Brussolo GM for Sign Display & Digital at Ball & Doggett. "Their expertise

in dye sublimation and fixation calender heat presses perfectly complements our commitment to providing cutting-edge solutions to our customers. Together, we are poised to redefine industry standards and drive innovation in textile printing."

"At Klieverik, we are dedicated to pushing the boundaries of textile processing technology," said John Buitenkamp Area Sales Manager at Klieverik. "Our partnership with Ball and Doggett represents an exciting opportunity to expand our reach and deliver our innovative solutions to a broader audience. Together, we will empower textile manufacturers to enhance their capabilities and achieve new levels of efficiency and productivity."

In addition to providing cutting-edge technology, Ball and Doggett and Klieverik are committed to delivering exceptional service and support to their customers. This includes support for the current install base of Klieverik's equipment. Ball and Doggett's staff will undergo training to ensure they are equipped to provide knowledgeable and responsive support to customers utilizing Klieverik's machinery.

COMFORT COLORS REBRANDS ITS PROPRIETARY CLEAN DYE PROCESS, PIGMENT PURE™

Comfort Colors, has announced that its proprietary dyeing process, the recipe behind the weathered hues for which Comfort Colors has come to be known, has a new name and look –Pigment Pure.

Built on years of research and development, Pigment Pure dyeing technology uses, on average, three times less water, consumes less energy and has a quicker processing time versus other traditional dyeing processes.1 In addition to a lower-impact dyeing process, Comfort Color uses 100% ring-spun U.S. cotton to make durable, long-lasting and comfortable t-shirts that are “Made with Respect”.

“From soft fabrics to colorful dyes, Comfort Colors is a brand that’s all about spreading good vibes and making you

feel good, and we are doing that with Pigment Pure, a unique process that helps us create colors inspired by nature using fewer resources2,” says Emma Budzisz, Vice-President of Marketing at Gildan Activewear SRL. “Thanks to this technology, our customers can take comfort in knowing that our clothes are always soft, and even softer towards the planet.”

7 imagemagazine.com.au NEWS

1. The data on the Pigment Pure™ process are based on approximate comparisons with conventional reactive dyeing. 2. Compared to a conventional reactive dyeing process.

BALL & DOGGETT TO DISTRIBUTE COLDENHOVE

Ball & Doggett have announced a strategic partnership with Coldenhove, manufacturers of high-quality paper products for dye sublimation printing.

The collaboration merges Ball & Doggett’s expertise in materials with Coldenhove’s innovative paper technologies for dye sublimation printing. The two companies aim to redefine printing solutions, offering businesses unmatched quality and performance. Both companies say the partnership will ensure supply continuity to existing Coldenhove users.

Dye sublimation printing is recognised for its vibrant colours and versatility across various applications, from textiles to signage and personalised gifts. However, the industry has sought alternatives to traditional dye sublimation papers due to concerns about environmental impact.

Coldenhove's products are Forest Stewardship Council (FSC) certified, reflecting their commitment to conservation and responsible forest management worldwide.

AMERICAN APPAREL RELAUNCHES IN ANZ

American Apparel is expanding its reach in the Australian and New Zealand markets with the release of its entire 2024 product line through a dedicated e-commerce website.

“We are thrilled to be increasing access to American Apparel for shoppers in Australia and New Zealand, who can now buy this iconic brand with just the click of a button,” says Chuck Ward, President of Sales, Marketing, and Distribution at Gildan Activewear SRL. “We will also be bringing our newest collections and styles of American Apparel® to those markets and will be supporting the brand with our Craft the Culture campaign. With this campaign, we're encouraging our customers to channel their creativity, express their individuality, and create

timeless memories through our products."

The new B2C website offers a seamless retail experience for style enthusiasts in the region, with expedited shipping options and dedicated customer support. The site offers the latest styles within American Apparel’s 2024 collection, including the new ReFlexTM lightweight fleece, the new Heavyweight cotton garment dyed t-shirt and muscle tee, the Pique unisex mockneck t-shirt and matching unisex gym shorts, the Sueded unisex t-shirt, and the Unisex CVC henley t-shirt, reinforcing the brand’s commitment to premium quality and style, and enhancing customers’ ability to choose clothing which best represents their uniqueness.

"We are excited to collaborate with Coldenhove to pioneer innovative solutions in the dye sublimation printing industry," said Rob Brussolo, General Manager, Sign Display & Digital at Ball & Doggett. "Ensuring continuity of supply to customers is a focus, and with our extensive converting capabilities in Australia, we can offer custom lengths and sizes to support the sublimation market. By combining our expertise, we aim to provide our customers with superior printing materials that meet their needs and exceed expectations.”

Coldenhove says it shares the enthusiasm for the partnership and its potential impact on the industry. "At Coldenhove, we are committed to pushing the boundaries of printing technology. We look forward to working with Ball & Doggett to deliver cutting-edge solutions to their customers, ensuring our clients receive their products even faster. It's a testament to our ongoing commitment to improvement and exceeding expectations," said Gert Jan Breukink, Senior International Account Manager at Coldenhove.

In addition, American Apparel staple products such as the 2001 Fine Jersey Unisex t-shirt and the 1301 Heavyweight Cotton Unisex t-shirt will also be available for purchase on the site. American Apparel’s range of styles will continue to be available for wholesale purchase as well.

NEWS 8 JUNE 2024

GJS INKS DISTRIBUTION DEALS WITH EXILE TECHNOLOGIES AND BBC INDUSTRIES

GJS has announced two new strategic distribution partnership deals designed to expand its reach further and broaden its offering in the screen-printing equipment space.

The first distribution deal is with EXILE Technologies, an imaging solutions manufacturer specialising in applications such as computer-to-screen (CTS) printers and exposure units. The second distribution deal is with Black Body Corporation (BBC) Industries, an industry leader in heating technology, heating components, drying equipment and systems.

The company says advanced computerto-screen (CTS), exposure units, manual screen printing presses, flash and conveyor dryers and digital accessories are now available.

“GJS has a long and proud history in the screen printing space spanning more than 45 years,” said Greg Stone, managing director, GJS. “The availability of both EXILE Technologies and BBC Industries products via GJS means that we can now provide an even broader product offering to the local Australian market, meeting the needs of customers asking for this type of equipment and associated peripherals,” Stone added.

EXILE Technologies offers multiple direct-to-screen printer solutions to drive productivity in screen production areas. Many high-production Australian print shops are adding computer-to-screen (CTS) imaging systems to their pre-press workflow. CTS imaging eliminates film, reduces labour and overhead costs, and produces screens in a fraction of the time it takes to accomplish the same effort traditionally. A direct-to-screen printer can also provide an immediate quality improvement if it replaces an inkjet or toner-based film workflow.

BBC Industries offers solutions catering to the screen and direct-to-garment (DTG) printing industries. Its patented emitter technology converts almost all the energy produced into clean, even heat across the entire face of the element, with durability surpassing anything comparable in the industry. As a result, BBC’s highly efficient heating products, including infrared heaters, flash curers, and conveyor dryers, deliver excellent emissivity, with many of its trademarked components being the cornerstone of other industry dryer technology.

“Both Exile Technologies and BBC have been in the industry for over thirty and forty years, respectively, so there

are many similarities between them and the GJS brand”, Stone continued. “Each of our new partners’ proven track records is matched by their passion for innovation, partnership approach to helping customers achieve success and integrated offerings that complement our existing product portfolio.

“As I mentioned when we announced our partnership with ROQ last year, we are continually being asked by customers and prospects for highproduction, end-to-end systems, and integrated workflow solutions. The appetite for these products will be demonstrated when we make several new ROQ customer installation announcements later in 2024,” Stone added.

“These two new distribution deals with EXILE Technologies and BBC Industries means GJS will be able to solve the pain points of more Australian print customers, provide them access to cutting-edge, high-production, computer-to-screen (CTS), digital and analogue drying devices, all backed by GJS’ renowned service and support,” Stone concluded.

For more information, free call GJS on 1800 457 888 or email: sales@gjs.co

9 imagemagazine.com.au NEWS

EPSON LAUNCHES ITS FIRST ENTRY LEVEL DTG PRINTER AT FESPA

Epson's SureColor-F1000 DTG printer is the first entry-level DTG printer that can print directly onto dark and light fabrics.

Completing Epson's industry-leading range of hybrid DTG and DTF (Direct-toFilm) printers, the SC-F1000 will be of particular interest to hobbyists, retailers and businesses that require a costeffective solution with the flexibility to print on a wide range of fabric types.

The SC-F1000 is the only printer in its category to include white ink, enabling it to print directly onto dark garments and on film. This allows producers to print on many items such as t-shirts, hoodies, bags, sweatshirts, and cushions, and it is ideal for companies providing in-store printing in a quick time.

Alongside the SureColor-F1000 was Epson's recently launched DTG hybrid SureColor F2200, designed for startup companies or medium-volume businesses requiring high flexibility, accuracy and rapid turnaround.

Designed to produce complex designs on a variety of garments, the SureColor F2200 uses Epson's advanced PrecisionCore MicroTFP printhead technology to provide faster printing and data processing speeds, resulting in a productivity increase of up to 25% over its predecessor while maintaining extremely high print quality.

BROTHER, GJS AND TAFE NSW ANNOUNCE THE INAUGURAL WINNER OF THE EXCELLENCE

Brother, TAFE NSW and GJS have announced the first Excellence in Digital Decorating Award winner, student Jiann Mobbs from Bathurst, NSW.

The award is presented annually to a TAFE NSW student studying Certificate II in Printing and Graphic Arts who demonstrates excellence in digital decoration. Students demonstrate their skills, gain acknowledgment for their dedication, and serve as an inspiration for their peers to pursue a career in print.

This year’s winner was awarded the accolade for her dedication to the course, exceptional graphic design skills and adaptability to new print technology.

“I am delighted to award the first-ever BIA Excellence in Digital Decorating to

IN DIGITAL DECORATING AWARD.

Jiann on behalf of Brother International Australia in collaboration with GJS. Witnessing the impressive display of skill and passion from a dedicated print enthusiast, I take great pride in recognising and rewarding Jiann for her efforts,” said Adam Magrin, Internal Account Manager Brother International Australia.

“Thanks to the support from Brother, GJS, and TAFE NSW for the GTXpro Bulk DTG printer, I found joy in witnessing my creations, which embody my personality and creative freedom, come to life in physical form, whether that may be on posters, banners, or T-shirts,” said Mobbs.

Mobbs plans to continue working in the print industry as a tradesperson to further develop her skills and understanding of the craft. She also plans to obtain a degree in teaching so that she can “inspire the next generation of printing apprentices and hopefully encourage people from regional areas to give the industry a go,” she adds.

The award program was launched in May 2023 as a collaboration between Brother International Australia, TAFE NSW, and GJS Group Australia. It aims to foster the growth of aspiring digital

decorators and garment designers by providing them with access to technology and educational support. Installing the Brother GTXpro Bulk direct-to-garment (DTG) printer at TAFE NSW enhanced the learning experience. It facilitated the award for students pursuing a career in printing and graphic arts, particularly in digital decoration.

Brother says the award indicates its commitment to empowering the next generation of print entrepreneurs and contributing to the evolution of the printing industry.

“The collaboration facilitated by GJS between TAFE NSW and Brother enriches the educational experiences of our students venturing into printing and graphic arts, particularly in digital decoration. Brother's sustained dedication is immensely beneficial for TAFE NSW, empowering us to equip our students with resources for professional print equipment and to lay a strong foundation in the industry, whether their aspirations lie in digital print operation, design, print sales, or print management,” said Craig Rollins, Head Teacher Printing, TAFE NSW.

The next BIA Excellence in Digital Decorating will be awarded in 2025.

10 JUNE 2024 NEWS

COLORMAKER CELEBRATES SUSTAINABILITY AT LAUNCH OF NEW REVOLVE BATTERY

Not even the torrential rain could dampen the mood as Brookvale Solar Champion and Colormaker Industries owner, David Stuart, launched the new Revolve solar storage battery at a recent event held on April 5th at Colormaker’s Brookvale facility. Zali Steggall, Sue Heins and James Griffin shared their perspectives on the importance for businesses to harness the benefits of

solar energy and local battery storage and outlined some of the initiatives that are underway at all levels of government to support our local businesses transition to net zero.

Also in attendance was Michael Regan, Independent Member for Wakehurst, Councillors Grattan and Gensher, Greens candidate Ethan Hrnjak, the team from the Solar Alliance Brookvale and many

EUROPE TO INTRODUCE DIGITAL PRODUCT

By 2030 all garments sold in the European Union will be required to have a Digital Product Passport (DPP). The initial focus of Digital Product Passports will be on the apparel and consumer goods industries, two of the largest contributors to landfill.

A DPP is designed to collect full product lifecycle data to provide a complete view of its sustainability, recyclability and circularity. This will include data

from across the supply chain including raw material sourcing, manufacturing processes including printing, and the garments’ carbon footprint.

A DPP will use a unique QR code, barcode or NFC tagging combined with blockchain technology to record and cryptographically secure product data through a Digital Product Passport which will be accessible to anyone interested on a smartphone.

Whilst some companies are getting DPP ready, others are already jumping ahead of the curve and utilising Digital Product Passport technology to unlock additional use-cases related to transparency, traceability and tradability.

Colormaker friends, family and staff to celebrate Colormaker’s achievements.

The ReVolve® battery is world-first technology, combining Relectrify’s world-leading BMS+Inverter cell-level control technology with battery packs repurposed from nine Nissan LEAF EVs to store 144 kWh of energy. This industrial level of storage enables Colormaker to soak up excess solar power produced from their 100 kW solar array during the day. The stored energy can then be fed back into the grid during evening peak, making the business more energy efficient. Since installation of the 100 kW solar array, Colormaker has saved 690 tonnes of GHG emmissions.

Colormaker Industries is showcasing what businesses can achieve with a massive solar array, batteries, and multiple EVs. Not only has Colormaker significantly reduced their carbon footprint, but energy costs have been slashed below zero. Transitioning to solar is the most efficient way for businesses to reduce energy costs and examples like these will make it easier for others to follow.

PASSPORT

Take the example of Pangaia. Launching in the UK and expanding globally, fashion brand Pangaia has introduced the first digital passport-enabled resale platform. Pangaia's QR code system simplifies the resale process by allowing users to scan the QR codes of garments and automatically enter the details for the offer on Pangaia ReWear. The platform suggests resale prices based on condition and original value, with users able to set their own prices within a certain range. Most items on offer are currently selling for around 50% of their original retail price.

Whilst this has yet to be introduced in Australia we will be keeping a watchful eye as this unfolds in Europe.

11 imagemagazine.com.au NEWS

James Griffin MP, David Stuart of Colormaker, Sue Heins Northern Beaches Mayor and Zali Steggall, Federal Member for Warringah with the ReVolve® battery.

HP ANNOUNCES STRATEGIC PARTNERSHIP WITH CANVA

HP has announced a strategic multiyear global partnership with Canva to empower millions of Canva users worldwide to seamlessly design online, create visual content, and print locally.

“This partnership will deliver huge strategic value and fuel customer growth across both organizations,” said Cliff Obrecht, Canva co-founder and Chief Operating Officer.

Canva, founded in 2013, has over 185 million monthly users, including 95 percent of the Fortune 500. The launch of Canva Print in 2017 has allowed users to design and print a wide range of products—from business cards, brochures, flyers, stickers, marketing collateral, with customization options, and even apparel – experiencing exponential growth with millions of orders annually.

Through this collaboration, the Canva community will gain expanded access to professionally printed products from HP PSPs across the globe. Canva aims to expand its print service to 150 countries by 2026, enabling shorter turnaround

times and significantly reducing its carbon footprint through localized operations.

HP's automation software, HP PrintOS Site Flow, will help Canva extend its reach by automating production and shipping processes for PSPs. This endto-end solution streamlines print jobs with auto-scheduling, delivering color consistency, security, barcode tracking, optimal productivity. Additionally, HP's expansion of its PrintOS Suite with new features will equip the Canva Print Operations team with powerful tools to identify, connect and manage a global SKU catalogue across HP-enabled PSPs.

"We're excited to partner with HP to accelerate the expansion of Canva Print. HP’s innovations in cloud software, quality management, and digital print have been at the centre of our Canva Print expansion,” said Jim Towle, Head of Print and Partnerships, Canva. “With our teams working closely on new products and additional PSP locations, we can expand our world-class print capabilities and make it easier than ever for our

global community to bring their designs to life.”

Earlier this month, Canva launched Canva Enterprise, a new subscription option to cater to the growing demand from large organizations. With businesses worldwide facing the need to be more efficient and innovative, there has been an increase in demand for visual communication platforms that allow easy collaboration and interoperability. As part of the agreement, HP will implement Canva Enterprise, empowering HP's global marketing and sales teams to securely create, collaborate, and publish visual content.

12 JUNE 2024 NEWS

DMND, launches advanced merchandising solution in Australia

THE NEW BRAND WAS FOUNDED BY NICK AUDITORE, MANAGING DIRECTOR OF NAR, AND BEN ISDALE, DMND’S GENERAL MANAGER. DMND’S MELBOURNE BASED COMPOUND DOUBLES AS A SHOWROOM FOR ROQ INTERNATIONAL, SHOWCASING SOME OF THE WORLD'S MOST ADVANCED PRINTING TECHNOLOGY.

Auditore says, “Our mission is simple: offer top-tier merchandise crafted with cutting-edge technology. Having worked within global networks, I understand the thirst for reactivity, and DMND has been built from the ground up to deliver local speed at globally competitive prices,” he says.

Isdale, the manufacturing expert and General Manager, emphasises their strategic advantage. “Operating out of Melbourne with such advanced tech means we can quickly transform ideas into premium retail-ready apparel,” he says.

“Technology is ultimately at the heart of what we do but is complimented by

craftsmanship. We have pinpointed a specialist team and shaped a suite of services that cater to the diverse needs of any client,” adds Isdale.

“We’ve hit the ground running and have already turned around merchandise for global sports brands and high-profile projects like Pink’s 2024 Summer Tour,” says Auditore.

“From concept development to retail delivery, we ensure a seamless experience, and our track record backs that,” adds Isdale. “We invite any business seeking a merchandise solution to experience the DMND difference firsthand.”

FEATURE

13 imagemagazine.com.au

EPSON'S

LATEST

DIRECT-TO-FABRIC SINGLE-

STEP PIGMENT INK TEXTILE PRINTER

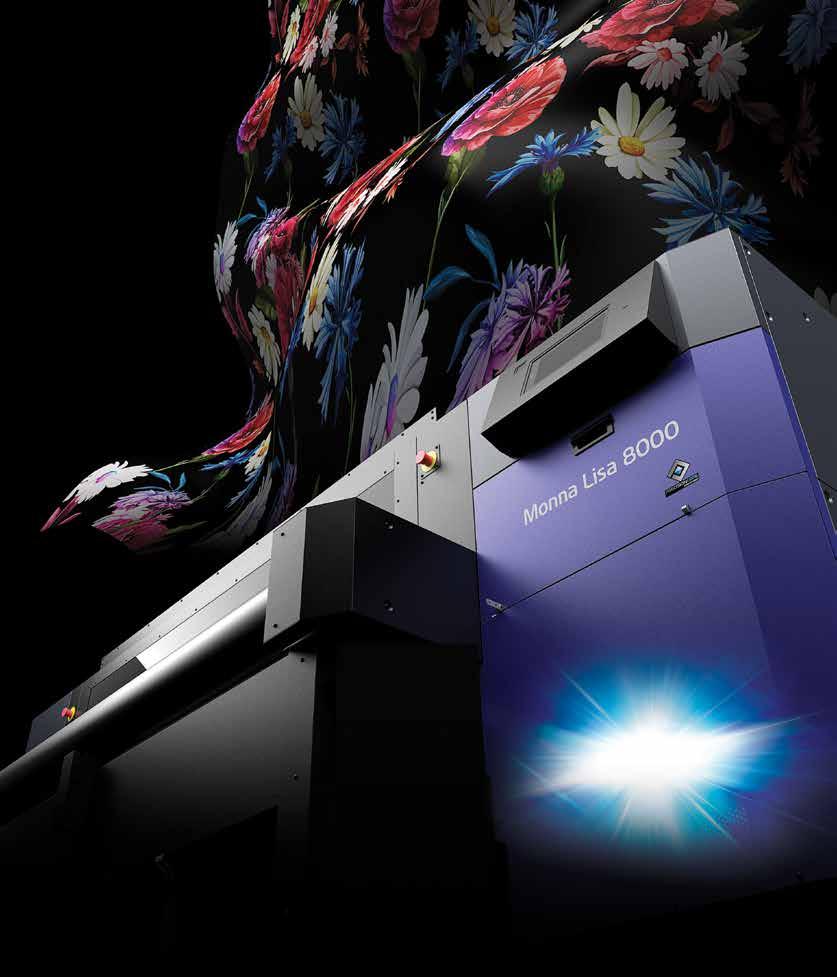

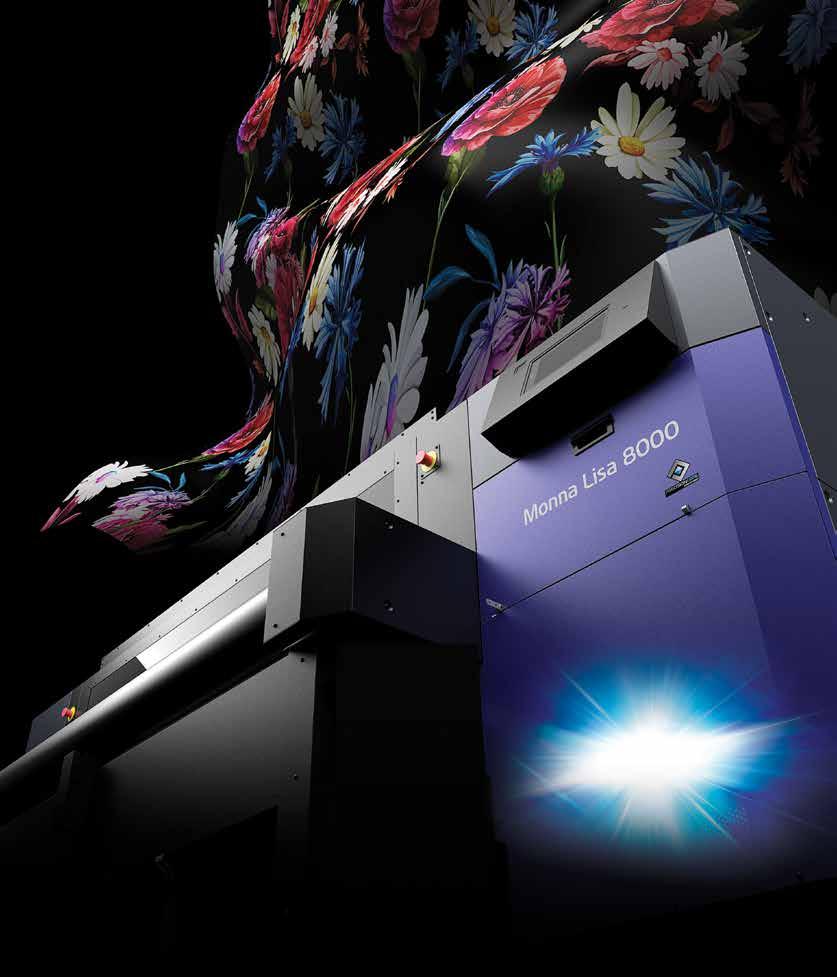

The Monna Lisa ML-13000 is an innovative textile printing solution that requires no additional equipment for pre and post-treatment, steaming and washing. The new direct-to-fabric printer has three types of pre and postprocessing chemicals (pre-treatment, over-coating, and density enhancer) and seven colour inks. This makes it possible to integrate pre and post-processing in a single-step printing solution and contrasts with other conventional textile printers that require separate processes.

Pre and post-chemicals are used only on the print area (dot-on-dot), enabling prints that bring out the texture of the fabric. The ML-13000 also enjoys a much smaller footprint than conventional textile printing equipment, allowing it to be installed in more confined and convenient working environments.

Environmental Benefits

The ML-13000 offers a far more sustainable approach to fabric printing. The traditional textile industry is responsible for approximately 20% of industrial wastewater worldwide[1]; however, the ML-13000 can significantly reduce water consumption by up to 97%[2] by eliminating pre and postprocesses required by conventional dye-based printing methods. It is also

estimated that 35% of all materials in the textile supply chain end up as waste[3]; however, digital on-demand textile printing allows one to print just the right amount, reducing stock waste and managing excess inventory. Epson's ML13000 pigment inks and pre and posttreatment chemicals meet environmental standards, including ECO PASSPORT certified, bluesign® approved, ZDHC MRSL Conformance Level 3 certified, and GOTS approved byECOCERT.

Advanced Epson Digital Printing Technologies

The ML-13000's superior image quality is delivered through Epson's high-quality PrecisonCore printheads. Epson precision-dot technology reduces banding and graininess, and its multi-layer halftone technology, which randomises the halftone dot pattern on each layer, reduces image degradation caused by dot misalignment. The ML-13000 also features symmetrical colour alignment for consistent colour

overlap during bidirectional printing, and accurate belt position control technology automatically detects the belt feeding distance to ensure highly precise fabric feeding. The result is optimal quality and productivity, with superb reproduction of colour gradations, fine details, and complex geometric patterns.

Stable Operation with Minimal Downtime

Stable operation with unprecedented usability is realised with advanced cleaning mechanisms and automated adjustment functions. Nozzle verification technology detects missing dots that indicate nozzle clogging and adjusts ink delivery to maintain image quality and reduce printing errors. An easy-to-replace fabric wiper roll continuously wipes the printhead nozzles clean automatically, reducing daily manual maintenance work. An ink-mist extraction system helps prevent ink-mist from adhering to the nozzle surface. Thanks to the high accuracy of printhead alignment technology and an automatic calibration function by an RGB camera, printhead replacement can be carried out quickly, including adjustments.

Easy Operation

Ease of use is enhanced by a 10.1-inch LCD touch panel that displays current printer status, operating instructions, and regular maintenance procedures, and by built-in & hot-swappable, dual 1.6 litre ink cartridges that allow uninterrupted production. GENESTA pigment ink and pre and post-processing chemicals provide flexibility to print on a variety of fabrics, such as natural, synthetic and blended fabrics, for a wide range of applications.

[1] World Bank, 2019 How Much Do Our Wardrobes Cost to the Environment?

[2] Fuluhashi Environmental Institute, 2024 "Report on Direct Water Input in Digital Textile Printing"

[3] National Library of Medicine, USA. https://www.ncbi.nlm.nih.gov/pmc/articles/ PMC9983045/

NEWS 14 JUNE 2024

Romano Bacci , Epson Australia

IT IN ACTION!

Arrange a demonstration today monnalisa@epson.com.au

DTF: A New Standard in Textile Printing Image Quality

Born in Italy, perfected in Japan, the Monna Lisa direct-to-fabric series has landed in Australia. Powered by no less than eight Epson PrecisionCore industrial printheads, the ML-8000 packs power and performance into a single affordable package with full local support, and the Epson GENESTA pigment inks meet global standards for sustainable textile printing, both synthetic and natural. Print on demand is now big business. Are you ready to grow?

Learn more at www.epson.com.au/direct-to-fabric

Make the

move. Fabric print on-shore with the reassurance of local support. SEE

Ball & Doggett partner with Kornit Digital – Showcasing at Visual Impact Brisbane

BALL & DOGGETT IS SET TO ASSUME THE ROLE OF THE EXCLUSIVE DISTRIBUTOR FOR KORNIT EQUIPMENT, SUCCEEDING KISSEL + WOLF, EFFECTIVE JUNE 8TH. UNDER THIS ARRANGEMENT, BALL & DOGGETT WILL PROVIDE KORNIT MACHINES, INKS, PARTS, AND SERVICING. THE COMPANY HAS ALREADY EXPANDED ITS SERVICE TEAM BY HIRING NEW ENGINEERS IN BRISBANE, QUEENSLAND, AND VICTORIA, AND HAS ALSO APPOINTED A NEW APPLICATIONS MANAGER.

This partnership represents a significant development for Kornit, granting access to the majority of print businesses in Australia. Ball & Doggett, being a premium supplier of printable materials in Australia, operating across commercial, wide-format, labels, and packaging markets, further enhances this reach.

Ball & Doggett has strategically aligned with Kornit to offer a comprehensive suite of direct-to-garment and roll-to-roll

digital printing and fulfillment services. By combining Kornit Digital's advanced technology with Ball & Doggett's extensive distribution network and expertise, this collaboration aims to streamline printing operations, reduce turnaround times, and unlock new growth opportunities for businesses.

Rob Brussolo, General Manager for Sign Display & Digital at Ball & Doggett, emphasized the commitment to sustainability and innovation inherent in

Kornit Digital's solutions. He reiterated that ensuring exceptional service for existing Kornit Digital users remains their top priority throughout this transition.

Tomer Artzi, President and Managing Director of Kornit Digital Asia Pacific, expressed excitement about the partnership with Ball & Doggett, describing it as a significant milestone. He emphasized their joint goal of driving innovation and redefining the

16 JUNE 2024

COVER STORY

Ball & Doggett to supply Kornit's DTG on-demand print systems: (l-r) Tomer Artzi, Kornit Digital, and Rob Brussolo, Ball & Doggett

COVER STORY

future of on-demand, digital textiles in the Australian market.

In line with this collaboration, Ball & Doggett aims to transition the nation's screen printing garment businesses to Kornit digital technology, akin to the shift from A3 offset printers to digital printing two decades ago. Additionally, they will offer Kornit DTG to commercial print businesses, especially in bundled packages with eProductivity Software web-to-print and ERP solutions.

Brussolo concluded by highlighting the advantages that Kornit DTG offers, such as speed of service, reduced labour requirements, and increased growth opportunities, particularly for commercial print businesses seeking diversification.

Ball & Doggett will be showcasing its new partnership with Kornit at Visual Impact Brisbane 2024. This event, expected to draw thousands of industry professionals, will take place at the Brisbane Convention and Exhibition Centre from July 17th to 19th, 2024. Attendees will have the opportunity to experience firsthand the latest innovations in digital printing and learn more about the enhanced offerings resulting from the collaboration between Ball & Doggett and Kornit.

In addition to the showcase of the new partnership with Kornit, Visual Impact Brisbane 2024 will feature other exciting displays. One highlight will be the demonstration of HP Latex technology, with a focus on the R1000 model.

Attendees can expect to explore the capabilities of this cutting-edge printing technology firsthand.

Furthermore, Ball & Doggett will be presenting its very own DTF (Direct to Film) solution. Introducing our High Volume DTF Eclipse Printing Solution, offering impressive speed and precision to meet the demands of high-output printing environments. With capabilities of up to 9 square meters per hour at 6 passes and a remarkable 12 square meters per hour at 4 passes, this solution ensures swift production without compromising on quality. Providing the complete range of consumables, inks, DTF Films, powders to compliment the growing DTF install base.

Utilizing advanced technology including the Cadlink Digital Factory V11 RIP, along with precision Epson i-3200 Printheads, and the renowned Epson

Printheads, this system provides exceptional print clarity and colour accuracy.

Featuring a tension bar media feeding system, automatic print head moistening, and ink heating functionalities, this solution maximizes efficiency while maintaining optimal print conditions. Additionally, the intelligent Powder Control System ensures precise application, enhancing the durability and vibrancy of prints.

Experience the future of high-volume DTF printing with our innovative solution, designed to elevate productivity and deliver outstanding print quality.

These demonstrations will provide attendees with insights into the latest advancements in digital printing and offer opportunities to explore new solutions for their businesses.

17 imagemagazine.com.au

HP Latex R1000

Kornit Atlas MAX

DTF Eclipse Solution

Invest in the Future at Visual Impact Brisbane

BRINGING THE VERY LATEST SOLUTIONS, TECHNOLOGIES, SERVICES AND EXPERTISE TOGETHER UNDER ONE ROOF IS THE UNIQUE VALUE PROPOSITION FOR INDUSTRY TRADE SHOWS, AND VISUAL IMPACT BRISBANE IS SET TO DELIVER. BUSINESSES WHO ARE LOOKING TO INVEST IN THEIR FUTURE SUCCESS WOULD DO WELL TO TAKE ADVANTAGE OF WHAT’S ON OFFER.

The show, which will run from 17-19 July at the Brisbane Convention & Exhibition Centre, is fully subscribed, giving visitors the widest-possible range of solutions to explore. Coupled with a lively program of snappy, focused seminar sessions which have been reimagined especially for Brisbane, show organisers are aiming to provide the best possible value for visitors.

“This is the first show in Brisbane for more than six years, and we are expecting that businesses will be keen to see, explore and evaluate the latest that industry suppliers have to offer,” says Charly Blades, Events Manager for the show’s organiser, Visual Connections.

Visual Impact is Australia’s only dedicated show for the sign, display and graphics sector, bringing a diverse showcase that covers a wide range of

applications including wide-format and textile printing, soft signage, sewing and finishing, embroidery and garment printing, and more.

This year, a key focus will be improving productivity and profitability, Charly says.

“With the current economic situation, ongoing global instability, staff shortages and other challenges, business owners and key decision makers are looking for

18 JUNE 2024

FEATURE

17-19 July, 2024

Brisbane Convention and Exhibition Centre

Connect With Success

Australia’s leading exhibition for sign, display, wide-format print, engraving, vinyl applications, textiles, digital print, routing and laser cutting.

www.visualimpact.org.au

Brisbane 2024

presented by

SCAN FOR FREE REGISTRATION

Proudly sponsored by PLATINUM GOLD

FEATURE

ways to increase profitability, create new revenue streams, and make the very best use of their people.

“The right technology – both hardware and software – can support this, not only by increasing capacity, but by improving efficiencies, reducing touch points, enhancing workflows and reducing costs. All those things are expected to be key points of discussion at Visual Impact.”

The show, supported by Platinum Sponsor Roland DG, Gold Sponsors Epson, HP, Spicers, Trotec and Graphic Art Mart, will have plenty on show, with a list of exhibitors covering virtually every facet of the sector.

“The floorplan is looking great, with plenty of particular interest to those in the textile printing, soft signage and garment industries,” says Charly. “As well as the larger, well-known suppliers of marketleading technologies, there will also be a host of smaller exhibitors with new ideas, innovations and niche solutions.”

For those in the textile and garment sector, the list of ‘must-see’ stands are many, but include names like HP and Roland DG and Currie Group, Pozitive Graphics Supplies and Adzon, Politape and Elizabeth Machines, among others –the full list of exhibitors, plus information on what they will show, can be found online at www.visualimpact.org.au

Complementing the exhibition will be a ‘reimagined’ seminar program featuring ‘Expert Connections’ sessions designed

to provide insights on trends and the ‘big issues’, and ‘Market Connections’ sessions which will be more product or technically-based.

“Whatever time you can invest in attending the show, we want to make sure you get the best possible value,” Charly says. “These sessions will be short and sharp, and will focus on connecting the audience with the presenter, not only delivering a more targeted and personalised experience, but also fostering connections that will deliver ongoing value.”

Of particular interest will be sessions on pressing issues like sustainability, workplace satisfaction, apprenticeships and training, and market trends, and technical presentations on everything from media, to heat printing and transfers, and from colour management to growing décor applications.

Presenters so far confirmed include Myra Anwar, Chief People & Culture Officer with Smartech, Ben Carroll, Managing Director of Velflex, Fiona Jacklyn, Business Development Manager at MEGT, Zeff Lowe, Business Development Manager – Signage & Fabric – Southern States & WA for Epson Australia; London Mills, Strategic Projects & Sustainable Green Print for Visual Media Association and Ryan Warby, National Business Development Manager – Sign & Display for Epson.

The popular ‘Try-A-Trade’ activities will also be back for the Brisbane show, with

TAFE Queensland representatives and industry volunteers primed to chat to secondary school students and engage them in activities including tee-shirt printing, traditional signage and hand lettering, laser engraving and vinyl application. The full range of Sign & Print Career Connections resources will also be available.

“In all, it’s a comprehensive offering, and one which is sure to be welcomed by businesses keen to gather the information, ideas and inspiration they need to stay ahead of the curve and plan for future success,” Charly says.

Visual Impact Brisbane will run from 9am to 5pm on Wednesday 17 and Thursday 18 July, and from 9am to 4pm on Friday 19 July, at the Brisbane Convention & Exhibition Centre at South Bank. To find out more, or register for the show, go to https://visualimpact.org.au/brisbaneexhibition-2024

20 JUNE 2024

3 New locations NOW STOCKING ECOsTRETCH!

What’s New from Siser ANZ

DISCOVER THE LATEST INNOVATIONS IN SISER ANZ'S EVER EXPANDING RANGE. FROM COMPOSTABLE SOLUTIONS TO EYE CATCHING DIGITAL PRODUCTS, SISER HAS SOMETHING NEW FOR EVERYONE.

In an era where sustainability is paramount, Siser is proud to announce the global launch of PureHT, the world's FIRST compostable heat transfer

material. While conventional materials may take upwards of 20 years to break down, PureHT naturally decomposes within just 6 months, without releasing any harmful toxins or leaving micro plastics. Available in 9 earthy colours, PureHT has a natural matt finish. It has an excellent workability, comparable with the Siser EasyWeed range and can be layered to create a multitude of designs. When paired with ethically made natural textiles, it is a conscious way to begin redefining industry standards. Stay tuned for more information, Siser ANZ is excited to be launching the range at Visual Impact in July.

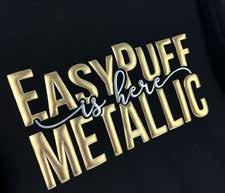

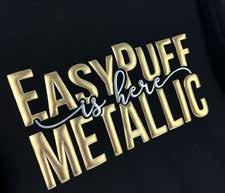

EasyPuff Metallic

Featuring the same fun puffy effect as standard Siser EasyPuff, EasyPuff Metallic adds a new twist: a brilliant shiny finish. After heat applying, simply peel the carrier hot and press a second time to activate the puff. Designs will not only expand into 3D, but they'll also give off a beautiful gold or silver sheen! Perfect for both bold artwork and creating fine, delicate designs, Easy Puff Metallic has a unique look unlike anything you've seen before.

22 JUNE 2024

PureHT

EasyGlow

If you’ve ever wanted to create a glow in the dark design that was different to the typical eerie green, then EasyGlow is for you! Easy Glow looks stunning in the daytime on any garment. But where EasyGlow REALLY shines is in the dark. When the lights go out, EasyGlow gives off an incredibly luminous appearance. Available in 5 vibrant, fluorescent colours. EasyGlow is a surefire way to light up your night.

EcoStretch

EcoStretch is a water based, ecofriendly heat transfer vinyl, that has replaced PS Stretch in the Siser Range. With a low application temperature of 120°C, and a quick pressing time of 5 seconds, EcoStretch is perfect for applications on heat sensitive elastic fabrics like Lycra and spandex. Available in 22 popular colours, EcoStretch has a lightweight - soft feel, with a true matte finish. Also available is S-Print, the digital equivalent of EcoStretch. With the same stretchability, low temperature, and time settings, it is perfect for producing designs on stretch fabrics.

ColorPrint Aurora

Add some colour-shifting surrealness to your full colour projects with ColorPrint Aurora. This iridescent digital film has a woven finish and gleams in the light as the material moves. ColorPrint Aurora has the added benefit of working with solvent, eco-solvent, and UV printer systems. If you want your printed images to be as jaw - dropping as the Northern Lights, then ColorPrint Aurora is the digital media for you.

EasyReflective

EasyReflective is Siser’s new reflective HTV with a frosted pressure sensitive (sticky) carrier. This highly reflective heat transfer vinyl is truly an exceptional polyurethane product due to its glass bead construction that illuminates in the darkest of conditions. Additionally, the pressure sensitive carrier allows you to re-stick lifting material or replace a piece that’s accidentally weeded away. Apply EasyReflective to sports garments, pet accessories, uniforms and so much more, for increased visibility and to stand out in low lighting.

Siser ANZ will be launching PureHT, at Visual Impact in July. Visit the Graphic Art Mart Stand (Stand H01) to chat with the Siser team and explore the new range in person. They’ll also have a range of digital and speciality HTV on show. Visual Impact Hall 4, Brisbane Convention and Exhibition Centre – July 17-19, 2024.

23 imagemagazine.com.au

Coast Imagewear: capturing new markets with DTF

ONE ONLY NEEDS TO FLICK THROUGH THE PAGES OF PUBLICATIONS SUCH AS TEXTILE IMAGE OR CONDUCT A SIMPLE SEARCH OF FACEBOOK GROUPS TO SEE THAT DIRECT-TO-FILM (DTF) PRINTING IS TRULY REVOLUTIONISING GARMENT DECORATION. ONE MIGHT EVEN POSIT THAT THERE HAS NOT BEEN SUCH AN INDUSTRY REVOLUTION SINCE DIRECT-TO-GARMENT PRINTING IN THE NOUGHTIES.

Revolution, however, is an oftenoverused word. In the case of DTF however, its use is justified in the dramatic change it has had for garment decorators, not only in the way that they embellish existing fabrics, but in the opportunity afforded to capture new market opportunities unobtainable with previous printing methods.

Coast Imagewear is one Australian business capitalising on the DTF revolution.

Owner Tracey Hallink purchased the Sunshine Coast embroidery business from its previous owner eight years ago and at the time it consisted of a single embroidery machine and a well-

established customer base. Since the acquisition Tracey has spearheaded a significant expansion, adding additional embroidery machines as well as offering a customised printing service.

From its home-base on the Sunshine Coast, the business serves customers all over Australia.

With its primary offering in workwear, uniforms and sportswear, a hurdle that presented itself frequently was the full-colour decoration of fabrics such as polyester, nylon and high-vis items using a technique other than embroidery, which is primarily used for small designs and logos, or with heat transfer vinyl which required a significant time investment due to weeding.

The Brother GTXpro garment printer was already on Tracey’s radar, however

25 imagemagazine.com.au

FEATURE

FEATURE

as the DTG output could only be applied to natural fibres such as cotton and cotton blends, this made it unsuitable at the time as the majority of Coast Imagewear’s products were polyester.

This all changed however when Tracey attended one of GJS’ ‘Discovering Direct-to-Film Printing’ educational events in Brisbane and learnt how a Brother GTXpro garment printer could be used to create DTF transfers, which could be applied to almost any fabric.

Building the business with a Brother GTXpro

The addition of the Brother GTXpro garment printer to Coast Imagewear has seen significant market opportunities open up for the business. The ability to

now digitally decorate both polyester and high-vis garments means that Coast Imagewear can now offer a truly complete garment customisation and branding service to its tradie customers as well as schools, local sporting clubs, the mining community, local councils and more.

“DTF and DTG have been a huge opportunity for Coast Imagewear in the workwear and uniform space. We print all our high-vis workwear with DTF, and DTG and DTF are now our preferred method of branding our products for our customers,” said Hallink.

“It is really easy creating DTF transfers with the Brother GTXpro. That’s not to say it wasn’t a learning curve, but we’re at the point now where all members of the team can print and press a DTF

transfer while the customer waits if needed. We also print DTF transfers for people that don’t have a printer but have a heat press,” Hallink added.

Growth has always been a goal for Coast Imagewear, and the Brother GTXpro and DTF solution from GJS has helped facilitate that, so much so that since its installation the business has needed to move to bigger and better premises in order to keep up with demand.

“My advice for anyone considering purchasing a Brother GTXpro is, after your research, just go for it. The printer is really easy to operate, and it has made a huge impact on our business, everyone on the team here can use it and we all love it,” Hallink concluded.

26 JUNE 2024

Tracey Hallink

Email sales@gjs.co Phone 1800 457 888 Visit gjs.co

any type of fabric with DTF including polyester and high-vis. Capture new market opportunities.

Decorate

What’s Up at Wazzup?

WAZZUP SCREEN PRINTING IS A WHOLESALE GARMENT DECORATOR SERVICING MARKETING AGENCIES, PROMOTIONAL COMPANIES, AND B2B CLIENTS. ESTABLISHED IN 1999 IN TAREN POINT, NSW, AND PURCHASED BY ADAM TEDJA OVER SEVEN YEARS AGO, THE "ONE-STOP" DECORATION SHOP SPECIALISES IN MULTI-COLOUR SCREEN PRINTING, DIRECT-TO-GARMENT DIGITAL PRINTING, DIGITAL HEAT TRANSFER, PLASTISOL INKS, SWIMWEAR, UNIFORM, AND HI-VIS PRINTING. SINCE ITS INCEPTION, THE COMPANY HAS EVOLVED CONSIDERABLY, AND MORE SO AS THE PACE OF TECHNOLOGY HAS INCREASED, INSTIGATING SIGNIFICANT CHANGES.

These days, the business is run by Adam's daughter, Shannelle, who talks to us about Wazzup's journey and evolution and elaborates on how technological advancements have led to increased production, activations, and demand for sustainable practices.

"Dad purchased Wazzup over seven years ago. He moved to Australia forty one years ago and ran WYSIWYG Design and was taking a break, when he happened to sit next to a man on a

bus in Bali and discussed the prospect of buying a business. He had always wanted to get involved in apparel printing, which was being done purely using screen printing technology at the time," says Shannelle.

Wazzup provided a perfect segway for Adam to enter the industry. The business has since invested in semiautomatic screen printing carousels that can print up to 14 colours, direct-to-film (DTF) printing, and various Roland digital print and cut systems.

Shannelle explains that while DTG was initially done in-house for a couple of years, it has now evolved into directto-film (DTF). "The way that we set out our factories was no longer viable for DTG. In addition, we were outsourcing some of our transfers with all sorts of varying results, so we decided to bring in our own DTF printer, which gave us full control over all of the production variables", explains Shannelle.

The company has a team of twelve skilled workers and specialises in Plastisol ink screen printing combined with various digital print and transfer methods for producing unique and cost-effective garment decorations. It is also able to provide short-run orders for personalised embroidery lettering or logos that are outsourced. The company prides itself on its ability to hand-check everything and provide a one-week turnaround.

Shannelle visited FESPA for the first time in March of this year and was excited by the range of advanced offerings on display. "It just confirms to me the importance of attending these shows so we can be ahead of the curve", says Shannelle.

"Screen printing is the core of our business, so it is important that we continuously invest in the latest technology. This, combined with our skilled team and a comprehensive range of inks, is vital to our success."

That said, "It's exciting to see the level and speed of automation that DTG and

28 JUNE 2024 FEATURE

FEATURE

DTF can now offer," she says, adding that she was particularly impressed with Coloreel's new digital innovations for the embroidery sector. In addition to keeping up with technology and providing excellent services to the industry on an ongoing basis, Wazzup has also been busy working on several activation campaigns this year.

"We recently did a campaign for XXXX where we customised State of Origin branded t-shirts, stubbie holders and cups printed with people's postcodes, which was a big hit with the consumers and will be repeated by us next year," Shannelle says. "We worked with the brand to create an easy online ordering process and short lead times for the campaign." This campaign is just one example of how Wazzup is able to adapt and deliver unique solutions to its clients.

Shanelle also cites a unique and popular live activation for Monkey

Shoulder Gin in Brisbane, where the brand's three monkey logos were printed on the shoulders of T-shirts, along with personalised messages on request. "The event allowed attendees to expand on their creativity and was really popular," she explains.

Having attended the FESPA Personalisation Conference in Amsterdam, Shanelle observed how fast the trend for print-on-demand is increasing. "It allows people to have a more emotional connection with the brands that they're buying, and as more and more companies are requesting personalised products, it leads us to start conceptualising the best way to deploy print on demand to make it efficient for both us and the client," she explains.

Shannelle also noticed a strong focus on sustainability and reducing waste at the conference. "While it's not really widespread yet, more and more brand

managers are now looking at the company ethos of the suppliers they are working with," she notes, using Clipsal, a recent client of theirs, as an example. "Since Clipsal is all about energy efficiency, we were asked to demonstrate what steps we are taking to make our production process more energy efficient." An increased focus on sustainability from customers has seen other changes in the businesses, such as using more sustainable inks," she says, with more sustainability initiatives in the pipeline.

Innovations such as these, coupled with the surge of technology, creative thinking and adjusting to its customers' needs, have contributed to Wazzup's endurance over nearly a quarter of a century in business. "We will continue to focus on innovations, marketing, technology and sustainability, which will be the foundation of our growth in the future," concludes Shannelle.

29 imagemagazine.com.au

UPPAREL creating a circular fashion solution

THE EU IS STEPPING UP LEGISLATION ON RECYCLED AND CIRCULAR PRODUCTS, AND UNDER THE EU WASTE DIRECTIVE, EU COUNTRIES ARE COMPELLED TO COLLECT TEXTILES SEPARATELY BY 2025. ADDITIONALLY, THE EU STRATEGY FOR SUSTAINABLE AND CIRCULAR TEXTILES AIMS TO CREATE A NEW SUSTAINABLE ECOSYSTEM FOR TEXTILES SOLD ON THE EU MARKET BY 2030..

Last year, the Australian Fashion Council (AFC) launched the National Clothing Product Stewardship Scheme "Seamless" to tackle clothing waste in Australia. The initiative aims to create a circular clothing industry and seeks to achieve this by 2030.

One large-scale textile recovery and recycling organisation driving circular fashion is Melbourne-based UPPAREL'S. It offers innovative and sustainable solutions and is chosen by hundreds of local and global brands, retailers, and organisations with textile "waste."

In this article, we learn more about the company's history, processes and success in keeping textiles out of landfill.

UPPAREL, formerly known as Manrags, is a subscription service for men's socks and underwear that was started in 2016 by the entrepreneurial husband-andwife team Michael and Tina Elias.

Three years later, after recognising how many socks they could be contributing to landfill, the couple started an anti-waste program where they took responsibility for the entire life cycle of their socks, incentivising customers to return the socks to them when they were no longer needed.

This led to further exploration of what was happening with clothes going to landfill, and in 2020, they began to accept all types of textiles, as well as shoes, and UPPAREL was born. Shortly after, it was nominated for a Premier's Sustainability Award in the Small and Medium Enterprise category.

The nomination recognised the impact made by its sock recycling program which had diverted 13000kg of socks from landfill since its inception.

Circularity

UPPAREL recognised that to realise its journey towards fashion circularity, it had to make it easy and appealing for organisations and individuals to send them their discarded items.

To achieve this, the company has provided an easy process for packing and sending items to its warehouse. Once in-house, it finds solutions for reuse before recycling and utilises as much textile waste as possible.

The company gives textiles a new life, provides quality clothes to Australian charities and drives innovative product development. This ensures that minimal resources are used to achieve its circularity goals.

UPPAREL'S entire operational ecosystem is located within Australia and New Zealand, ensuring that its processes are sustainable, traceable, and kept close to home.

How it works

UPPAREL offers a local digital Textile Collection Program. It picks up boxes from people's front doorsteps, brings them into the factory, and begins sorting items for reusing and recycling. Recycling costs start from $35, which allows 10kg of textiles to be sent out in one box.

It also offers a subscription-based recycling bin service for faulty stock, returns, offcuts, samples, uniforms, or

30 JUNE 2024 FEATURE

FEATURE

even customer drop-offs. UPPAREL'S recycling bins can be branded, highlighting the company's commitment to reducing textile waste.

There is also a free digital integration system which allows companies to offer their textile recycling service to their customers directly through the UPPAREL website.

Once the textiles arrive at the warehouse, every item is meticulously sorted and graded to identify a suitable recovery channel such as reuse, repurpose, or recycle. Items that can be reused are separated into subcategories, such as men's tops, women's pants, kids' shoes, etc.

Currently, approximately 40 per cent of the items sent to UPPAREL are in new or fit-to-wear condition. Once handsorted, they are passed on to charity partners like Save The Children, We Are Mobilise, Djirra, and many more.

UPPAREL has an open-door policy for charities, social enterprises, and not-forprofits to collect items that are still fit for wear. They can come to the company's warehouse and collect as much clothing as they need, go out and make an impact with it, and return anything that is unused, free of charge.

In addition, UPPAREL carefully examines every charity and social enterprise to ensure they are Australianbased and that the textiles provided will remain on-shore.

Textiles that are damaged, worn out, stained clothing, or uniforms with official logos can't be reused and are sorted into different categories depending on their suitable recycling channel.

Items that are not fit for wear are divided into various categories depending on their material and the decommissioning required. From there, the recycling process begins, whereby textiles are torn down into a superfine fluffy fibre. This material, called FillUP, can be used to replace virgin polyester fill for cushions and stuffed toys. The fibre can be compressed further to create UPPAREL'S revolutionary circular product, UPtex - a wholly recycled

and recyclable material for packaging, signage, homewares, and more.

UPPAREL'S goal to eradicate textile waste from Australian landfills and change the fashion industry for good has led the company to create a serious impact. By last year, it had diverted over 1,000,000 kilograms from landfill.

The company has also seized the opportunity to make a positive environmental and social impact, partnering with companies and groups such as The Bridge, Chadstone Shopping Centre, Vanish Australia, and Major Road Projects Victoria.

The scope of this initiative is huge and may be the start of further trends towards fashion circularity, inspiring other companies and industry players to roll up their sleeves and get involved.

It's easy for anyone to contribute to the cause and to feel that they are making a difference, knowing that for every 1kg of textiles that avoids landfill, they will be preventing an average of 3-4kg of greenhouse gases from polluting the atmosphere.

Indeed, "Waste isn't waste until it's wasted".

31 imagemagazine.com.au

Footnote: In our next issue we speak to UPPAREL'S Partnerships and UPtex manager Riley Aickin on overseas trends in circular fashion, potential barriers to recycling in Australia and New Zealand, and the roles the government is playing in this arena.