6 minute read

Bringing in the new Atotech

Polish market. The share of exports in our sales is not high so far, but we are trying to change that. We have our agents in Sweden, Finland and Switzerland, and are looking for suitable agents in Germany and Russia”, says Mr. Chwesiuk

Bialcon’s clothes are available mainly in Poland’s medium-sized cities. Its sales network comprises of about 200 points of sale located throughout the country, including 120 multi-brand shops, 40 franchised shops and 20 affiliated shops.

Dresses for the evening and the office

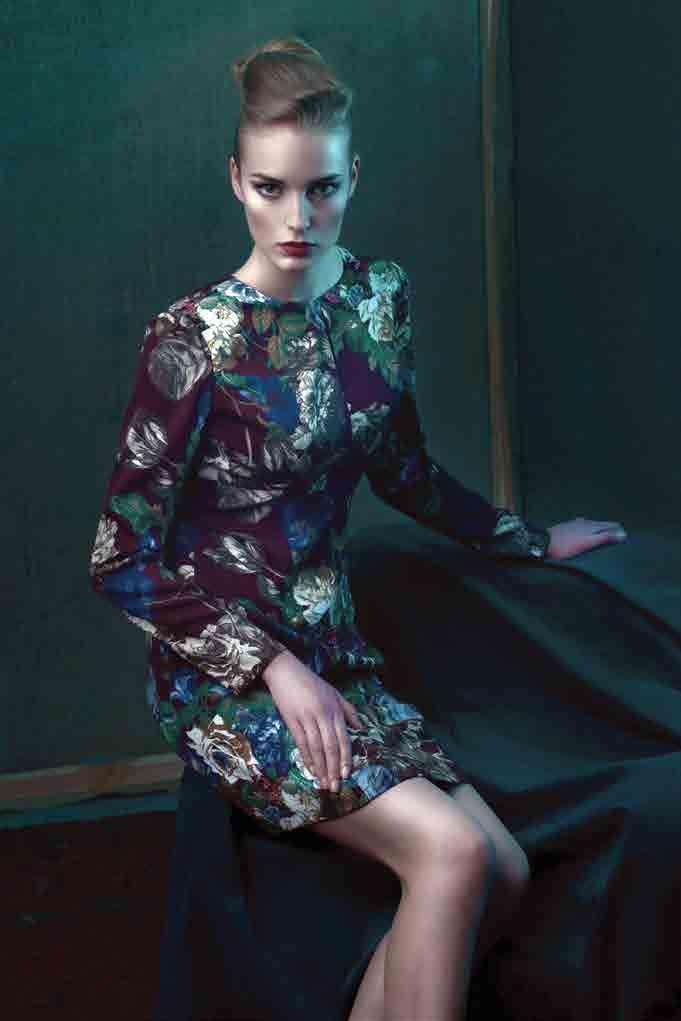

Creative, professional employee; responsible, caring wife and mother; colleague and comrade; world voyager - all these features reflect the roles a modern woman fulfils in her life. This idea serves Bialcon as a starting point to create its collections. Bialcon’s wide range is focused on formal and office clothing, such as women’s jackets and dresses. Each season is a new challenge for the company since it creates a collection consisting of about 500 designs plus 200 designs for its new Rabarbar brand. So, Bialcon’s partners have a wide selection of products to choose from and can select those that meet the requirements of their specific group of customers.

The Bialcon range also includes a collection of nightgowns inspired by fashion from past decades. Harmony with nature, natural materials, mainly cotton and silk, as well as a celebration of femininity revealed in a retro style - simple cuts with muted colour palette - are the main features of the Bialcon by Night collection. All nightgowns are carefully finished with French and Italian top quality lace and decorative ribbons.

In 2010 the company decided to expand its offer with an additional brand of Rabarbar (the name means Rhubarb in Polish). “The collection is aimed at those women for whom fashion is a challenge and is a form of fun, experimenting with different styles and conventions. The Rabarbar brand is inspired by Polish folk, art and craftsmanship. It creates colourful collections for self-confident women who like to mix conventions and styles. The production process uses traditional tech-

niques, and some of the products are handmade. The brand is committed to ecology and fair trade rules”, explains Mr. Chwesiuk.

Clothing fabrics used by Bialcon come from selected foreign and domestic textile suppliers, including Andropol SA, a company with one hundred years of tradition and state-of-the art technical and technological standards in the Polish textile industry; as well as Bielstyl from Bielsko Biala, and wholesale fabrics, such as Renex or AJA, a company that has a leading position in the Polish textiles market.

Three areas of development

Bialcon’s plans include further organic development, especially in three areas. Firstly, the company would like to enhance its presence in the bigger cities. It is now present in Warsaw, Poznan and Lodz. This year it will open its flagship store in Wroclaw. Secondly, it plans to strengthen its internet sales. “We do not generate high volume of sales on the Web at the moment but it is good for the company’s image to be there”, says Mr. Chwesiuk.

And finally, acquisition of new agents is the third region of the Bialcon development plan. “We are looking professional agents throughout Poland and abroad. We will offer them very interesting commission system”, assures Mr. Chwesiuk. n

For 10 years, our company has dealt with the distribution of the lining fabrics all over the country. Thanks to many-years experience and the reliability we gain the trust of many renown garment companies. We have established cooperation with many warehouses of the similar profile in the territory of Poland as well as in Eastern and Western Europe.

The detailed description, characteristics and application of the particular articles you can fi nd on our website. The continuity of deliveries, constant and well-developed cards of colours, punctuality and reliability, free delivery within 24 hours are our assets and reasons why it is worth to cooperate with us.

We are the main suppliers of Bialcon fabric linings.

F.H.U. MATEX Michał Rachwał ul. Oriona 26, 80-299 Gdańsk, Polska www.matexpodszewki.com tel.: +48 58 557-22-11, +48 58 746-38-34 fax: +48 58 746-38-33, +48 58 585-81-30 mobile: +48 0608-354-912 email: biuro@matexpodszewki.com

Atotech, one of the world’s leading suppliers to the printed circuit board, IC-substrate and semiconductor industries, is announcing the international launch of the brand new PallaBoard process in 2014.

BRINGING IN THE NEW

Atotech is a division of the Total Group, with headquarters in Berlin, Germany and about 4000 employees in over 40 countries. About a quarter of all staff work in one of the four locations in Germany: Berlin, Feucht, Neuruppin and Trebur. The company believes that its huge network of worldwide employees plays an integral part in not just forming the company culture, but also contributing to its overall success. The commitment and the effective global network have certainly paid off in impressive growth: In the past five years alone, Atotech sales have grown by 24 per cent and the workforce has increased by 30 per cent.

The regional headquarters with application centres are based in Rock Hill (USA) and Yokohama (Japan) supported by 40 regional service centres, of which 18 are specialised as TechCentres, providing advanced analytical and technical support. With 14 production plants for chemistry and two for equipment, Atotech ensures fast, on-time delivery all over the world. Focus on GMF and Electronics

With its core business units being General Metal Finishing and Electronics, the company achieved annual sales of €965 million last year. Its specialist know-how is called for in the areas of semiconductors, advanced packaging, printed circuit boards, functional electronics, decorative coatings, corrosion- and wear-resistant coatings, as well as paint applications.

Atotech focuses on providing systems solutions for key end-use markets such as automotive, consumer electronics, IC-substrate, industrial and medical, sanitary, furniture and construction. Customers are found in the field of world leading job shop plating, printed circuit board and IC-substrate and semiconductor companies, as well as in tier I, tier II, tier III, electronic manufacturing services and original equipment manufacturers.

New challenges in the industry

New technical requirements, as well as cost and environmental regulations, require a constant search for alternative manufacturing solutions for the printed circuit board industry. Finer lines and spaces, higher frequencies, improved solder joint reliability and new challenges in wire bonding – both with existing wire technology such as Al and Au or novel types such as Cu or Cu-Pd – are just a few examples of technological advancements for surface finishing in the printed circuit board manufacturing process.

Additionally, the reduction and elimination of toxic and hazardous materials, as well as the drive to further reduce the manufacturing costs, are common ways to support the industry and enable it to progress in a sustainable and economical manner. Owing to its commitment to sustainability, Atotech is always at the forefront of technologies that minimise waste and reduce environmental impact.

PallaBond – new direct pure EP and EPAG

Atotech’s answer to these challenges is a new direct Palladium surface finish process named PallaBond, with an optional gold