3 minute read

ASK JOE POWDER

© Kevin Biller

The electrode at the gun tip creates a corona field that charges the powder particles as the pass by.

I was just wondering if there was anything basic that I could be missing or a variable that I have overlooked in order to give better results. I understand if you aren’t willing to divulge such information and if you have any questions for me, please do not hesitate to ask. Kind regards, James Breen, BSc Bio Med Quality Technician - Northern Ireland

Hello James, Thank you for your question and it’s great to hear from Northern Ireland. I hope all is well in Newtownabbey. It sounds like you’re getting rather frustrated in getting good parts off your finishing line. You are wise to select the materials and process you are trying to make work. Blasting the metal is a good idea and the dual coat approach gives a very durable finish. To make this work, the devil is in the details. The biggest problem seems to be getting a good second coat on these primed parts. The first place to investigate is “are you getting a good earth to your parts?” If you are seeing starring and poor film build, you probably have poor electrical continuity to the earth. Checking for earth requires a megohmmeter which not only measures resistance but also provides up to 500VDC which helps define resistance more accurately. You want to have 1 megohm or less resistance. If it is greater than 1 megohm start looking for poor contact points including hooks, hangers, racks and conveyors. Regarding the powders I would stick with the original powders and work on the application process. It is wise to undercure (or “gel”) the primer prior to applying the second coat then fully bake the two coats. This provides the best inter-coat adhesion. I hope this helps. Please let me know if you have any further questions. Warm regards, Joe Powder

·Xylexpo 12-15 0ctober 2022 Milan

The Most Important Industry Events at Your Fingertips: ipcm® Launches the myFAIR Web App

The ipcm® team is pleased to present myFAIR, a new web app to stay up-to-date with all major events happening in the surface treatment industry.

Today’s world is marked by sudden and unpredictable changes and moving at a rapid pace towards an increasingly digital ecosystem. This led us to rethink our annual Trade Show Calendar, listing the main events to be held in the surface treatment industry. We chose to better meet the sector’s need by approaching our calendar in a new way and transforming what was previously a digital and printed brochure into a web app accessible from any device: myFAIR.

Why a web app

A web app is a versatile tool that can be accessed from both desktop and mobile devices, which does not require downloading from the store. Nevertheless, it is possible to create a shortcut directly in the smartphone menu, making access to the app quick and easy. myFAIR is therefore a free, up-to-date, and highly interactive tool at the service of professionals in the surface treatment industry (and beyond) for the organisation of their trade fair agenda, both as exhibitors and visitors. Through the myFAIR web app, users can browse, filter, add to favourites, trigger alerts, and get up-to-date information on the world’s most important events happening in the industrial finishing sector.

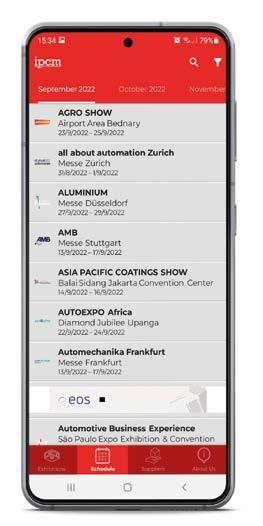

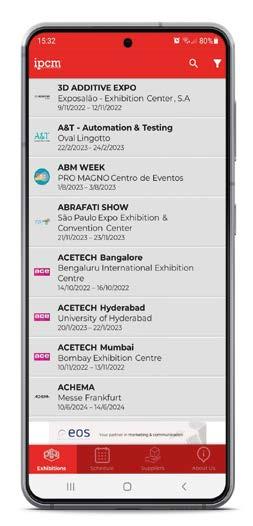

Exhibitions section

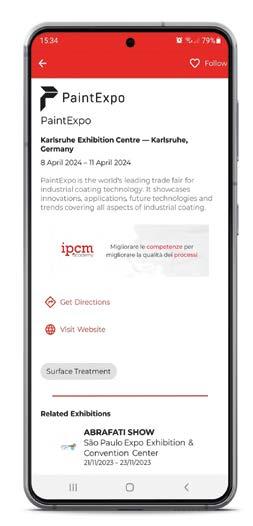

The Exhibitions section shows all trade fairs in alphabetical order. The list can be filtered by country and category. It is also possible to type the name of an exhibition directly into the search bar for even faster access to information on a particular event. Tapping on the name of a trade fair takes the user to the specific tab

The Exhibitions section with the (filterable) list of all trade fairs in the app and the trade fair tab with detailed and up-to-date information on each event. The Schedule section, showing all trade fairs divided by month.