CLEAR INTENTIONS

Jason Dhillon sets his sights on a supply chain career

Local procurement

AI in manufacturing

Optimizing data in supply chains

The Nissan Pathfinder Supply chain networks

Jason Dhillon sets his sights on a supply chain career

Local procurement

AI in manufacturing

Optimizing data in supply chains

The Nissan Pathfinder Supply chain networks

To stay competitive and get ahead, you need innovative, scalable and safe solutions. These solutions can help with better storage, distribution, fulfillment or any combination that can grow with your business as it adapts to change.

As your partner in facilities evolution, you can count on Konstant to transform your facilities. Collaborate with our team to optimize your facility today and evolve, anticipate, adapt and imagine the facility of your future.

Get integrated logistics solutions: racks, shelving, trucks and robotics from our partners including Johnston Equipment and GNJ Automation.

Access comprehensive services for your project lifecycle, from planning to ongoing management with a skilled team ensuring quality at every step.

For more than 50 years, Konstant has served businesses across Canada, adapting our services to evolving facility management needs.

| 1-866-202-0064

For the next few months, few geopolitical spectacles will attract as much attention as the US presidential election. All eyes will be on the race to the White House, with Republican former president Donald Trump yet again running for the top job. As of this writing, President Joe Biden has just stepped out of the race, with VP Kamala Harris as the frontrunning Democrat for the ballot on November 5.

Canada will, of course, watch the process closely. We share a 5,061km land border with the US – the world’s longest. That border handles over $2 billion in trade and thousands cross for business or pleasure.

And as Christian Sivière points out in his article about supply chain networks on page 20, roughly 77 per cent, or about three-quarters of Canada’s goods exports, go south of that border.

So, from a supply chain perspective the outcome of the election in the fall, and who exactly winds up President after the election, makes a big difference here.

We already know how disruptive the politics of our southern neighbours can be. Indeed, the first Trump presidency presented more than a few headaches for Canada regarding trade. Trump threatened to withdraw the US from the NAFTA. That resulted in the agreement’s renegotiation and rebirth as the Canada-United States-Mexico Agreement, or CUSMA (USMCA in the US).

The agreement is due to be renewed in 2026, roughly two years after the election. So, the winner of the US election will no doubt have a bearing on whether the trade agreement gets renegotiated once more, or if the potential to scrap it altogether is again raised.

In his article, Sivière also notes that Trump has threatened a 10 per cent flat tariff on all imports into the US, from all countries. Granted, the truth is that both Trump and the Democrats are fairly protectionist when it comes to trade. Yet Trump has signalled that he plans to ramp up the protectionism if re-elected. He may be less open to sitting at the negotiating table than a Democratic counterpart such as Harris.

What can Canada do? One course of action is to broaden our roster of trading partners. We’ve actually been trying to do this since at least the early 1970s, when then-Prime Minister Pierre Trudeau, the current PM’s father, dealt with similar threats from President Richard Nixon of slapping a 10 per cent tariff on goods entering the US

Trade deals such as the one with the EU, the Comprehensive Economic and Trade Agreement (CETA), at least signal progress in this regard, as over 90 per cent of the deal’s measures have already come into force.

The current Liberal government is also pushing a “Team Canada” approach to the spectre of a second Trump administration. Ottawa is ramping up diplomacy in the US, which is a good move regardless of who wins the election. After all, Harris seems to have similar views on trade as Biden and opposed the CUSMA deal as a senator.

Either way, this isn’t Canada’s first proverbial trade rodeo. And yet again, the stakes remain as high as ever in ensuring the smoothest trade relations possible with our Southern neighbours.

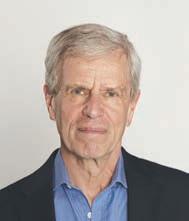

EDITOR

MICHAEL POWER 416-441-2085 x7 michael@supplypro.ca

PUBLISHER

FARIA AHMED 416-441-2085 x 5 faria@supplypro.ca

DESIGN

Art Direction ROY GAIOT Design Consultation BLVD AGENCY

EDITORIAL ADVISORY BOARD

LORI BENSON Procurement Compliance, L&D, Engagement and Knowledge Lead | Business Enablement, Ernst & Young LLP

THOMAS HUDEL Manager, Purchasing and AP, Esri Canada Ltd.

WAEL SAFWAT Procurement Director, Black & McDonald

SHERRY MARSHALL Senior Manager, Meetings, Travel & Card Service, PwC Management Services

KIRUBA SANKAR Director, Program Support, Purchasing and Materials Management— City of Toronto

JEFF RUSSELL Corporate Purchasing Manager & Inventory Manager, Miller Waste Systems Inc.

iQ BUSINESS MEDIA INC.

Vice President

STEVE WILSON 416-441-2085 x3 swilson@iqbusinessmedia.com

President & Executive Publisher ALEX PAPANOU

PUBLICATION MAIL AGREEMENT NO. 43096012 ISSN 1497-1569 (print); 1929-6479 (digital)

CIRCULATION

Mail: 126 Old Sheppard Ave, Toronto ON M2J 3L9

SUBSCRIPTION RATES

Published six times per year Canada: 1 Year $ 99.95 CDN

Outside Canada: 1 Year $ 172.95 USD Single price per copy $18.00 CDN

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised.

Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. © 2021 iQ Business Media Inc. All rights reserved. Printed in Canada.

I don’t know if you watched the debate between Donald Trump and Joe Biden on June 27 but my family and I did. The event, in its totality, was the funniest thing I’ve seen since I don’t know when.

There were multiple comic moments and as evidence let me quote. For example, there was an exchange about who was the better golfer and I’ll quote from the official CNN transcript. But I’ll have to do some editing (without taking anyone out of context). Trump: “I just won two club championships, not even senior, two regular club championships. To do that, you have to be quite smart…” Biden: “I got my handicap, which, when I was vice-president, down to a six.” Trump: “I’ve seen your swing, I know your swing … Let’s not act like children.” Biden: “You are a child.” I went to bed with a huge smile on my face.

But in the middle of the night, I woke up concerned. Everyone –including global money managers – saw what I did. What would it mean to the markets? We had enjoyed an extended period of time without a huge sell-off and some people thought that we were due. The realization that the next president of the United States of America and leader of the Free World would be one of these men would surely send a shock wave through the financial markets. When I got out of bed, I checked the S&P 500 futures. The market on 6/27 closed at 5,482, then

opened the next morning at 5,488. It was unchanged for all intents and purposes.

On one hand, this made no sense. Hadn’t everyone seen the debate? Yet on the other hand, it made all the sense in the world. Because the machine, and by this, I mean the economic machine is so robust, so powerful, that it doesn’t matter who occupies the Oval Office. There is a consensus in North America around some basic principles: A belief in property rights, the agreement that markets need regulation, and a bi-partisan understanding that the national debt doesn’t matter much, because whether it is a Democratic or Republican regime, all we’ve seen for the past six presidential terms (Bush twice, Obama twice, Trump, and Biden) are huge deficits year after year after year.

What did the late singer Meatloaf once say? Two out of three ain’t bad. But it’s not optimal, either. That’s because the single variable that could upset the economic apple cart is the amount of government debt on both sides of the 49th parallel. Canada’s debt to GDP currently stands at 70 per cent while in the US it is an astonishing 125 per cent.

Now, there is a good reason why the US can get away with this and it’s because the US dollar remains the world’s reserve currency. But as I’ve discussed before in this column, back in the summer of 2023, this doesn’t mean it will be the case forever. If there were ever widespread global abandonment of the Greenback, it would

mean a spiking of interest rates and a severe recession, if not depression.

And this is what should concern those who are responsible for public policy in North America. We’ve had eras before where the national debt soared. The postSecond World War era is a good example. Robust economic growth fixed the problem because it led to government revenues exceeding government expenditures and the resulting debt reduction. In the 1980s, under Ronald Reagan in the US and Pierre Trudeau and Brian Mulroney in Canada, debt swelled, only to be brought under control in the 1990s. But not through the particular virtue of government. Rather, it was by a technology boom which led to productivity gains that were unimaginable, that is, until they happened.

There’s a joke I heard recently that I absolutely love. What’s the difference between an optimist and a pessimist? The pessimist says, “things can’t get worse.” Meanwhile, the optimist says, “of course they can!”

I think we can apply this to North American sovereign debt. And don’t get me started on private borrowing. But for those of us that have children and care about their future, it is time to get our fiscal house in order, so when my son reaches the age of majority he won’t be exclaiming “what was wrong with my dad’s generation!?” SP

“The economic machine, is so robust so powerful, that it doesn’t matter who occupies the Oval Office.”

When speaking with operations, business, or supply students I often ask, “what is it that you wish to become or achieve when you’ve successfully completed your studies?” Many times, the immediate answer is “I want to be a professional!”

But have your ever asked yourself, “what exactly does it mean to be called a professional?”

Whether you’re studying in hopes of joining a profession, have just started your career journey, or are already a seasoned veteran, what is it exactly that makes you stand out in a positive way as a professional? Do the expectations of being a professional expand as your work experience or your educational credentials expand?

The answer is a lot deeper than simply studying or working in a chosen field and earning a paycheque. Being a professional is not the job that you do, it’s how well you do the job. Everyone’s job is different, so how do you gauge if you’re being successful and professional in what it is that you do?

It’s certainly not an exhaustive list, but here are seven fundamentals which you can develop to help build your foundation toward a successful and professional supply chain career.

Competency: It all starts with a detailed examination to determine what exactly your job entails, striving to do it to the very best of your ability while meeting, if not exceeding, the standards and expectations that matter. If you’re not aware of what your standards or expectations are, or should be, perhaps you should consult with your boss? These guidelines will form your

personal metrics to help you self monitor your daily key performance indicator (KPI) checklist.

Strive to be not only competent but proficient, qualified, and deeply skilled in your work, while being mindful to manage your conduct and execution. Don’t be afraid to ask for support when necessary either. Be proactive and collaborative, participating in opportunities to demonstrate your abilities and competency, while being a team player.

Make it easier by beginning your workday with an on-time (if not earlier) arrival, manage your time well, and be productive. Why be late and set an immediate bad example? Why not impress and inspire direct reports and coworkers? Being on time shows respect not only for your employer but those who you may mentor or interact with as part of your job. It also underscores your own self-respect, control, and competency.

Knowledge: Strive to master your job every day. Keep adding to what you know about your particular role and how you can make it better. Gain a strategic perspective by determining not only your role in the company, but how it interacts and can affect other individuals (like your boss) and other departments. Seek out how you specifically can add value to the company as a whole. Put your knowledge into action and diplomatically illustrate what you know, not for shameless self promotion, but to help yourself and those around you succeed.

Conscientiousness: True professionals plan and prioritize their work and hold themselves accountable for their words, thoughts, and

actions. Set your own high standards and show that you care about every aspect of your job. Be dependable. Be reliable.

Integrity: Often it may be hard, but your best job is when both your beliefs and behaviour are in sync and you’re honest not only to yourself, but with those you work with. Be true to your word, even if it means taking a harder path. Only then will people see you’re being genuine and a true professional. Ethics is everything.

Emotional Awareness: Manage your emotions and strive to have a perspective of other people’s feelings or biases in certain situations. Be diplomatic in showing your appreciation for their feelings with empathy and convey your thoughts on how to best solve a problem or proceed with an appropriate solution. At all costs, keep your thoughts and emotions professional while working under pressure. Perhaps when confronted with a situation, instead of an immediate “hey, that’s not my job,” maybe an affirming “perhaps I can help in some way?” is more appropriate in the long run.

Appropriateness: Endeavour to be self-aware and determine what might be the best (not just appropriate) way of conducting yourself in various situations. It’s not simply a matter of how you dress, your personal grooming, or your body language. Don’t forget, you’re representing your organization. It’s also about how you speak, write, the topics you choose to discuss, and how you behave when interacting with others.

Confidence: Take on new challenges and don’t worry about damaging your professional reputation

“True professionals plan and prioritize their work and hold themselves accountable for their words, thoughts, and actions.”

if things go wrong. It’s a better path toward being seen as a leader and a successful go-to person in the attempt, than someone who fails by declining the invitation of a new challenge. Not only will it boost your confidence, but it also makes it easier for you to influence, reassure and motivate others. SP

Amazon has replaced 95 per cent of the plastic air pillows from its North American delivery packaging with paper filler, working toward full removal by the end of the year. This will be Amazon’s largest plastic packaging reduction effort in North America and will avoid nearly 15 billion plastic air pillows annually.

Last year, Amazon announced an automated fulfillment centre in Ohio to eliminate plastic delivery packaging, including the transition from plastic air pillows to paper filler. This allowed them to transition to paper filler for 95 per cent of shipments in less than a year. To achieve this, the company collaborated with suppliers to source paper filler made from 100 per cent recycled content, while coordinating the transition across hundreds of fulfillment centres.

Through testing of paper filler, Amazon discovered that it offers the same or better product protection than plastic air pillows. The paper filler is also curbside recyclable and made from 100 per cent recycled content.

Ottawa is investing $76 million to help York Region build an electric bus fleet. The region, just north of Toronto, will get 180 zero-emission buses, 91 battery electric chargers, and 14 on-route chargers.

Provided through the federal government’s Zero Emission Transit Fund, the electric buses require less maintenance than traditional diesel buses, the government said.

The vehicles are expected to reduce emissions by about 15,982 tonnes annually. York Region’s three existing transit facilities that will house the zero-emission buses will also get solar power and battery energy storage systems.

The project is also supported by a $136-million loan by the Canada Infrastructure Bank.

Purolator has released its sixth annual Sustainability Report, titled Going the Extra Mile. The report outlines the company’s 2023 achievements in its commitment to people, communities and the planet, and details how Purolator is advancing its goal to be an industry leader in corporate sustainability.

Among its sustainability achievements in 2023, Purolator saw an 11 per cent reduction in absolute Scope 1 and Scope 2 emissions and transitioned over 500,000 litres of fuel from diesel to renewable diesel. It also reduced emissions from

electricity use by 70 per cent through renewable sources. The company exceeded its 2030 landfill waste diversion goal, reaching a 72 per cent diversion rate from landfills seven years ahead of schedule.

Other highlights of the report include: Purolator reported, for the first time, against the Task Force on Climaterelated Financial Disclosures (TCFD).

Achieved a 48 per cent reduction in lost-time injury frequency. Developed a DEI governance framework and published an Accessibility Plan.

The Montreal Port Authority (MPA) has completed its project to optimize rail capacity. Phased in over three years at a cost of $62.4 million, the project extends from Bourbonnière Avenue to Panet Street, near the Jacques-Cartier Bridge, and will increase the port’s rail capacity.

About 45 per cent of the port’s cargo is carried by rail at a rate of 60 to 80 trains per week. The project aims to strengthen and optimize this

senior VP

Dematic has named Michael Oren as senior vice-president of sales for the Americas region. Oren will join Dematic at its Americas headquarters in Grand Rapids, Michigan to lead a sales team of about 95 people. He will be responsible for developing the sales strategy, including nurturing and retaining accounts, driving company growth initiatives, and building relationships with strategic partners.

Oren joins Dematic from Xerox where he served as vice-president of global services. In this role, Oren oversaw global software and services, strategy, business development, partnerships, and more. Over the course of his 20-year tenure at Xerox, Oren held several additional leadership positions, including US vice-president enterprise services, vice-president of global sales, and vice-president of central and eastern US sales.

Oren completed executive master’s courses at the University of Navarra, Harvard Business School, and Stanford University, and he received his bachelor’s degree in marketing and social psychology from Miami University in Ohio.

strategic infrastructure at the hub of Greater Montreal’s supply chain. The project features: Two tracks totalling 6km of additional track and six switches to serve the 14 terminals.

Retaining walls totalling over 1km in length.

Relocation of the Port Road and all related infrastructure (sewer, water supply, power, and telecom networks).

BY JACOB STOLLER

“Do they want command-and-control where their managers are sheriffs who monitor keystrokes of the remote worker, or do they want collaboration and teamwork, where their managers are mentors.”

One of the many outcomes of the COVID-19 pandemic has been a debate about whether the practice of allowing employees to work from home should be permanent, or whether companies should revert to a more traditional model.

Much of that question revolves around productivity – are remote workers, who might be subject to the various distractions of the home, as productive as they would be in the office? Are they more productive because they are freed from the distractions that often come with office environments?

In asking these questions, people often assume that if we maintain the productivity of each individual in a remote scenario, then the company will perform as well as an in-person environment.

There are numerous examples where individual productivity doesn’t necessarily correspond with company performance. Take for example a sales rep for an HVAC contractor who, encouraged by an incentive to make the

quarterly numbers, brings in a large order, perhaps with some modifications and special discounts to close the deal. The sales rep is then judged to have had a productive quarter.

The spike in volume, however, along with the concessions to close the deal, overwhelms installation staff in the service department, forcing them to incur the expenses of temporary staff or overtime, and to expend extra hours accommodating the modifications. Therefore, while sales department productivity is higher, that effort might have caused the service department productivity to drop.

The principle applies in any scenario where there are handoffs. A procurement person might score high on individual productivity for slashing material costs, but if there are quality issues in the materials, or if the volume of the order causes storage problems and clutter in the plant, that work could be reducing the productivity of the production department.

The lesson here is that in terms of creating value for customers, the only productivity gains that matter are increases in productivity of the entire team that the customer depends on for quality and on-time delivery. From that perspective, the result is not attributable to an individual, but the team.

Team productivity, however, doesn’t just happen because people are in the office. The lack of coordination that causes problems with remote workers are just as counterproductive onsite.

“A useful operational definition of a team is the collaborative and coordinated efforts of people working together in an atmosphere of voluntary trust,” says Kelly Allan, a Deming Practitioner and principal of Kelly Allan Associates, Ltd. “That’s what makes it a team sport. If you don’t have that, you don’t have a team.”

Before they start measuring, therefore, leaders must ask some fundamental questions. “Leaders get to decide how they want to manage their companies,” says Allan.

Many companies are sitting on the fence on this issue, aspiring to build a team culture while engaging in practices that defeat it. Tools such as apps that track mouse activity and keystrokes, therefore, while effective at measuring individual productivity, are counterproductive with regard to creating an environment where team productivity can thrive. Much of this has to do with trust.

“If you look at the data from companies that track things like employee theft, you’ll find that about 5 per cent of employees are always looking to take advantage of their employers,” says Allan. “But monitoring keystrokes for the remaining 95 per cent is counterproductive, because in doing that, I’ve upset them and lost their respect. Furthermore, if you think that the number of employees who are cheating you is a lot higher than 5 per cent, then I would suggest to you that there’s opportunity for improving the culture that has been set by management – and with it, profitability.”

The statistics suggest that many companies have yet to address this issue. According to a 2023 Gallup survey, only 30 per cent of employees are actively engaged in their work, while 17 per cent are actively disengaged.

Creating a collaborative team culture involves a significant departure from the conventional command-and-control management approach that is taught in business schools. This fundamentally changes the role of managers – instead of being enforcers who tell workers what to do, they become coaches and mentors who help their people succeed. This alternative approach is the cornerstone of Lean management and of the closely related Deming principles that Allan applies when he works with clients. Essential to this approach is

making sure that the purpose of the company is clearly understood.

“Employees need to feel connected to the purpose and understand how their jobs contribute to it,” says the 2024 Global Culture Report from the O.C. Tanner Institute, noting that purpose needs to be other than profits, but how the organization makes a difference in the world.

“Once they do, their work takes on meaning. Organizations should clearly articulate the connection between work and purpose.”

A Deming approach that Allan uses with his clients is the dismantling of incentive systems that reward employees for results that could be harmful to other team members. In fact, one of Allan’s clients, an Ohio based HVAC contractor, achieved extraordinary results by removing the traditional commission-based sales incentive system and moving to a systemic approach that reflected how the var-

“A strong supplier will also offer additional support such as a product performance reporting and service level agreements (SLA).”

ious team members interact and depend on each other.

“What this did is take away any structural hurdles to collaboration between the different siloed sales groups,” says Air Force One CEO Greg Guy. “And the outcome was fascinating. All of a sudden, collaboration, team spirit, and sales productivity increased dramatically. We were selling

better deals to better clients that were healthier for the overall enterprise.”

With a strong collaborative culture in place, the question of whether employees are working in the office or at home becomes irrelevant. “Some of our clients who are advanced in applying the Deming principles allow their employees to work where they want and when they want,” says Allan. “The organization has certain things that have to get done, and these people know that – and they make it happen. Additionally, when people are finding joy in their work, people do more work.” SP

is the author of the upcoming book Productivity Reimagined, on which this article is based, to be released October 14. His website is www. jacobstoller.com.

24_006371_Supply_Professional_AUG_CN Mod: July 3, 2024 8:52 AM Print: 07/12/24 page 1 v2.5

ORDER BY 6 PM FOR SAME DAY SHIPPING

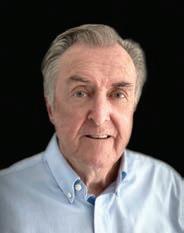

BY MICHAEL POWER

It’s a common story for those in the supply chain profession: they stumble into it as if by accident from other professions, like finance or operations. Especially in the past, practitioners rarely chose the field with the intention of making it their career.

That’s changing. In recent years, supply chain has gained exposure and risen in popularity as a career option. More than ever, recent graduates and young professionals consider supply chain as they survey the job market.

One such young professional is Jason Dhillon, vice-president of supply chain at ITWAL Limited. Uniquely, Dhillon’s supply chain journey began when he was in school. In 2007, he completed an Honours Bachelor of Business Administration (BBA) at Wilfred Laurier University in Waterloo, Ontario, with a major in supply chain management. At the time, there was less interest in supply chain, as it was in the early stages of becoming an academic field. Of 650 graduates in the BBA program that year, only 18 went into supply chain.

“I remember heading into our last year of my graduation,” Dhillon recalls. “That’s when they came out and said ‘there’s a major in supply chain management.’ I thought I want-

ed to do accounting, finance, HR, marketing –you name it. And I was like, ‘you know what? This is different, let’s try it out.’”

Supply chain positions were scarce at the time, so Dhillon decided on post-graduate studies. While searching for a program, he discovered the program run by what is now the National Institute of Supply Chain Leaders (NISCL) and the Certified Supply Chain Leader designation (formerly the Supply Chain Management Professional, or SCMP, designation). The designation’s instruction was at Humber College in Toronto, the closest location to Brampton, where he lived.

Dhillon enrolled and found himself among the youngest participants in the program. Yet he was impressed with the calibre of the other students and the organizations they worked for – Canadian Tire, Bell Canada, CBC, and Maple Leaf Foods, to name a few.

Dhillon stuck with the program and began applying for jobs. He eventually applied for a procurement manager position at The International Centre – a 548,000-square-foot conference centre adjacent Toronto’s Pearson International Airport. The role, which Dhillon accepted, was a food and beverage position.

“It was great experience; they let me cover everything,” he says. “Chemicals, uniforms, food and beverage, produce, meats, dairies, what have you.”

After spending almost two years in that position, a buyer role opened at Tim Hortons’ head office in Oakville, Ontario. Dhillon had recently gotten married and was looking for a larger position. Originally, the position was a 12-month contract, although the company made it a permanent job after meeting him.

“They were pretty impressed with how much I covered,” he recalls. “Even though I came from a smaller company and that was my first foray, you could say, into tier one.”

Dhillon enjoyed a lot of autonomy and scope at the company. Starting in early 2013, he spent two years working several strategic projects at Tim Hortons as a buyer for restaurant equipment and “smallwares,” which encompasses hundreds of different products like utensils, cookware, glassware and so on. “It may not sound like a lot, but it was millions and millions of dollars, only because it’s Tim Hortons,” he says.

Another firm eventually acquired Tim Hortons, and Dhillon found himself laid off through redundancies. The next day, Maple Leaf Foods called him, and he eventually accepted a manager role at the company in 2015. The position again had a broad scope, with Dhillon involved in procurement, customer service, logistics, and other areas.

Dhillon spent the next five years helping to develop and roll out the capital purchasing process for the company’s 20-plus manufacturing sites across Canada. He eventually focused on packaging categories, with a mandate to capture cost savings. At that task, he was consistently the lead contributor on a team of about 14 members.

“I decided to leave Maple Leaf Foods due to a new opportunity at my current employer, ITWAL, where I was given a wide band of responsibilities that included managing a procurement team, a customer service team, and being responsible for third-party logistics and all systems data management via our legacy ERP system,” Dhillon says.

ITWAL has a national network of independent, diversified retail and foodservice wholesale distributors, and provides a distributor alternative. Its member distributors provide a full range of products supporting business operators including convenience stores, drug stores, gas bars, independent grocers, foodservice restaurants, and others.

Soon after he joined the organization in late 2019, the COVID-19 pandemic hit full force. Dhillon was only a few months into the role and hadn’t yet completed a full 12-month cycle that

would have better informed him of how to manage different promotions and seasons. He found himself working from home with a laptop. That was a nerve-wracking time, he notes, as he worked to get up to speed on what the job entails.

Dhillon has now had several years to learn the position. Effectively, he is responsible for all operations within ITWAL’s distribution business. And like many people in the field, each day can offer a new challenge or opportunity he must address. That said, his days do have some routine. The first set of reports he looks at is the outbound fill rates that typically highlight any chronic issues that need to be addressed. That’s usually followed by dealing with issues related to customer service, where requests must be prioritized.

Then, most days, there are reviews of existing or new vendor programs along with new SKU listing opportunities to ensure the organization is looking at all cost drivers and potential for growth. His team is also constantly reviewing and scrutinizing logistics costs, with Dhillon ultimately approving those costs to ship product downstream.

He has also recently taken over responsibility for warehouse operations and building maintenance. It’s an exciting opportunity to put operations under one team and allow cross-functional team members to improve how they work together, Dhillon notes, as they all now report to him.

Dhillon has five major pillars regarding his responsibilities: procurement; customer service; logistics; he has a system support analyst who updates the organization’s ERP system; and the recently added warehouse responsibilities. Managing those pillars is challenging, as Dhillon must divide his time between all areas he’s responsible for. “I literally have people used to having ‘X’ amount of my time in my existing departments,” he says. “Now that time is shorter because I have to spend more time in the warehouse. And I have to make sure that the distribution manager has a lot of my time because I support him. So yes, there’s a lot of things that I’ve got to cover.”

Dhillon credits his education and professional designation for many of the skills he uses on the job. He has put to use much of what he learned during his education over the years, he notes. “That program was a catalyst for everything that’s happening to me right now, along with hard work and dedication,” he says of his NISCL designation.

Dhillon is especially proud of several career milestones, including being a project lead on an outsourcing US distribution project at Tim Hortons. He also developed and trained for

Capital Purchasing Process and was the top cost savings contributor for packaging categories at Maple Leaf Foods. He is also proud of taking on a diverse set of responsibilities at his current position at ITWAL.

Yet the part of his career that stands out the most involves people. In the past, when Dhillon was told someone on his team wasn’t suited to a role, he’s been able to work with them so that they ultimately excel. Having the right people in the right positions allows him to focus on more strategic initiatives.

“The moments I am most proud of are being part of hiring and developing key team mem-

bers and seeing them progress within their careers,” Dhillon says. “Early in my career, I was given a staff member the organization was thinking to get rid of. However, I was able to work with this person to where they eventually won the Employee of the Year Award. Also, I have hired some fantastic team members who either continue to excel in their

roles, or most recently where one of our buyers got promoted to procurement manager.”

Another example involves a long-time ITWAL employee – one of Dhillon’s direct reports – who was recently promoted to customer service team lead. The organization has also named the employee a 2024 Star Women in Convenience, an internal award.

During his career, Dhillon has sometimes had to manage people significantly older than him. Those employees have tended to be experienced and well-versed in what they do. To gain their respect and have them perform at their best, Dhillon has focused on putting them in the right positions, empowering them, and being a good listener. When you remove barriers and provide high-level guidance, people often perform at their best.

“Sometimes it works out great, and sometimes I get some pushback,” Dhillon notes. “But for the most part, I got the engagement that I got because they actually feel there’s some value I’m bringing to the organization. I would only have gotten to the level that I did by getting people that are really good at their jobs that are reporting to me to be successful.”

Dhillon’s dedication to the field has paid off through recognition. While at Maple Leaf Foods, on two separate occasions, he was one of 100 employees out of thousands nominated for top employee. Dhillon considers it an honour to even have been nominated for the position, which requires a sponsor along with endorsements from colleagues.

“Depending on what your employer wants from you, what their objectives are, and where they want to go, that’s what you focus on,” he notes. “That can be cost savings, that can be just bringing efficiency, that could be fill rates, it can be anything. Supply chain covers so much and if you’re really good at it, you can move from logistics to procurement, to warehouse management, to a systems analyst. Typically, if you’ve got good adaptability, a good resume, it should show you’re good at a lot of different things instead of being a one trick pony.”

That diversity has become more important since the COVID-19 pandemic. Since 2020, says Dhillon, supply chain professionals have had to adapt, since some old processes don’t always work as they once did. Pre-pandemic, large organizations had an easier time negotiating with vendors for lower costs. But due to post-pandemic supply challenges, that strategy has largely changed to working with suppliers as partners to get products.

“It was more of a big shift to supply,” Dhillon says of the pandemic era. “We’ve got to get supply. We’ve got to get product for the customer.

“The moments I am most proud of are being part of hiring and developing key team members and seeing them progress within their careers.”

If that supplier came back and said ‘look, the prices went up 30 per cent,’ you don’t have that much leverage to say anything because you have a business to run. Whether you’re running a manufacturing line, a restaurant business, any of the distribution businesses, it didn’t matter. Everybody wanted product, and it was so hard to get product. So, the biggest shift for procurement, especially, and supply chain, was, where is product?”

This led to scrutiny of some supply chain approaches, such as just-in-time, Dhillon says. Organizations had to increase safety stock levels to offset supply disruptions. Adaptability is key as supply chains continue to deal with these disruptions.

Proper and upfront communication is paramount in setting expectations, Dhillon stresses. Keeping people aware of challenges, and that everyone must be patient, helps organizations get ahead of the narrative amid disruptions. Conversely, not communicating leads to frustrated customers wondering where their product is.

“That disruption that’s been occurring and, quite honestly, it’s not completely gone yet, is what I’ve found has been the biggest challenge that people still to this day haven’t fully gotten over,” Dhillon says. “It’s learning that the world is different now and we have to adapt.”

As vice-president of supply chain, and having recently taken on responsibility for warehouse operations, Dhillon says he’ll spend the next several months identifying opportunities for collaboration between procurement, customer service, logistics, warehousing, and the data systems teams. Those functions are interconnected, and ultimately report to him, so he’s excited to determine the best overall metrics and results for the business – which will keep him busy for some time.

Dhillon also stays abreast of industry developments. He follows what’s going on in the convenience store and gas station sectors, for example, as those businesses represent a significant part of his organization’s customer base.

“As far as recommitting to any further education, it’s probably just maintenance,” he says of his future plans. “I’m at the point in my career where I probably don’t need to do something like an MBA, quite frankly. It probably wouldn’t give too much value to me. Not saying it’s not

valuable, of course it is, but the ROI probably wouldn’t be there, considering where I’m at.”

Dhillon and his wife have two young daughters, so he devotes much of his spare time to family and decompressing at home. He works out at home and tries to find time to take up golf. He and his family have been getting into travel recently and went to Jamaica and, more recently, Italy.

“But I’m a pretty private person and I spend most of my time at home and I try to do something with the kids,” he says.

During his career, Dhillon has worked for both large and small organizations. That mix has given him an interesting perspective on supply chain, he says, and both have pros and cons. A smaller company, for example, requires skill at fostering relationships. It’s easier to get lost in the shuffle if you haven’t built those relationships. You must also hone negotiation skills, helping to ensure customers get the products they need. Taking that experience and skill to a larger company can help lead to success, Dhillon says.

“But I will say, having that differentiation in experience and company sizes has been absolutely instrumental to my success,” he says. “I can go into procurement, supply chain, what have you. It’s something people don’t talk about often.”

For supply chain professionals new to the field, Dhillon recommends exercising patience. Don’t try to skip career steps. Many people want to go quickly from an entry-level position, to manager, to director, and so forth. But time is the best teacher, Dhillon says.

“I had a boss one time who told me, ‘Jason, I believe if you haven’t made any mistakes, you’ve never learned anything.’ Is that ever true. Sometimes people want to have that pristine resume and that track record. And if you have this perfect track record, I can bet you everything, you didn’t push it.”

For more experienced professionals, nothing beats further education to advance one’s career. Investing in education, then combining that learning with existing skills and experience, can make an employee highly valuable to an organization.

Finally, remember that no career advances in a straight line, Dhillon says. There will be peaks and valleys. It’s easy to feel that you’re on the wrong track or moving backwards. But stick with a goal, and you will eventually arrive.

“People think they want to progress their career,” Dhillon says. “What I’m trying to say is that it’s not a straight line. It’s almost like a jagged line. But looking at the long-term trend, it usually goes in one direction if you’re willing to move around and take some risks.” SP

BY SARAVANAN PARISUTHAM

The fashion industry, which has substantial environmental and social impact across communities, is becoming more sustainable, circular, and fair. Manufacturers and retailers are increasingly setting ambitious ESG targets, although the path to those targets isn’t immediately clear. Change requires knowing what’s going on in the supply chain in detail, so brands understand where to focus efforts for improvement and measure them. They’re also looking to prove to customers and regulators that their products are made with responsible materials and good working conditions, but need evidence to back up their claims to avoid the risk of greenwashing or losing customer confidence. As a result, supply chain transparency and product traceability – knowing your full supply

chain and how each product has been made – becomes more important than ever.

The ideal solution is a fully digitized supply chain with easily trackable and shareable records between third parties, where updated, validated data is always available. However, few organizations are set up to do so – and the industry isn’t either (though they will be in the future, this is a work in progress). A large part of the supply chain, and in particular the lower tiers, are relying on offline documents, meeting requests for information with emails, Excel sheets and pdfs.

While some tier 1 and tier 2 companies are adapting their reporting and records to share data and enhance efficiency, others need help to transition and move toward top-to-bottom traceability. By embracing a hybrid solution that combines existing digital records with processes to transcribe and digitize physical records, forward-thinking businesses can improve efficiency immediately instead of waiting for the creation of an industry-wide, fully digital solution or standard.

For now, if companies set ambitious transparency or compliance goals without knowing exactly how to meet them, a hybrid technological approach becomes critical to bridge this data gap and effectively manage the transition.

During this transitional phase, in which physical and digital records are common, the hybrid model for supply chain traceability combines real-time data collection for digital records with processes to transfer hard-copy records into digital format. This process has often been done through data entry, but more advanced solutions leveraging AI and optical character recognition (OCR) are streamlining a lot of this work. As long as data collection processes can vary from one part of a supply chain to another, with some being highly digitized and others largely paper-based, attempts at

“Hybrid traceability solutions offer faster, easier access to more data than early digitalonly solutions.”

all-digital solutions won’t optimize workflows and could lock businesses into processes that make it more difficult to share data.

Some solution providers promote fully digital solutions, but even the most advanced offerings cannot yet eliminate or automate the analog or physical records in most supply chains. That requires connecting every actor to the system. Hybrid traceability solutions offer faster, easier access to more data than early digital-only solutions, resulting in time savings for compliance needs or audits.

This makes the hybrid approach ideal for the near- and medium-term, maximizing use of available tools while avoiding investment in unproven systems or workflows that may become obsolete or be incompatible with industry-driven standards. Once a fully digital supply chain becomes available, brands can optimize their supply chains further with readily searchable real-time product databases; automated summaries of on-time shipments; historical pricing or volume changes; and more.

But that requires industry cooperation. An optimized, end-to-end digital traceability system must be open-source to enable maximum efficiency and applicability, and an open-source system requires access to third-party records with buy-in from the entire industry. Every company has the right to protect and silo its own data, but those choosing a protectionist approach may end up with higher compliance costs and miss out on the ancillary benefits of a shared data ecosystem.

Before an open-source, all-digital solution can come to fruition, we must educate industry players about the benefits of a digital system to empower streamlined supply chain

transparency and traceability. It will also be vital to discuss the approach to data privacy and security, as collaboration requires the trust and assurance of participants to ensure reliability and fair use. Until full digitization becomes standard across the industry, we expect a range of data sharing permissions to persist among different levels of the supply chain, such as small vendors that largely rely on paper and major corporations that are already heavily digitized. Therefore, making data migration easy will be necessary for any future open-source solution. Hybrid solutions that enable direct control over data, including migration assistance, can help companies prepare to leverage innovations or new platforms.

An industry-wide solution would rely on an independent mediator or “clearinghouse” that sets and upholds universal data standards and processes, while providing a centralized location for the open-source data to be shared and verified or certified. But as mentioned, this will take some time.

Attitudes about collaboration and data sharing are evolving with more solution providers combining efforts and streamlining centralized record keeping to aid access and efficiency. This cooperation is vital to help us move from reactive to proactive data collection to manage supply chain risk, compliance and impact. SP

BY NOELLE STAPINSKY

In today’s data-driven landscape, the challenge for supply chain professionals often lies not in the scarcity of data, but in the ability to harness the full potential of diverse, unconsolidated data streams. And there is certainly no lack of sophisticated tools to measure the efficiency of a fulfillment operation, monitor equipment, and evaluate supplier reliability. However, according to Brett Webster, director of product management at Dematic, the true power of these analytics is frequently untapped due to the compartmentalization of systems.

“By integrating these disparate data sources, we unlock a comprehensive perspective, enabling more informed decision making. Such integration doesn’t just add value; it transforms the entire approach to strategic business intelligence,” says Webster.

Supply chain management is, of course, heavily tied to forecasting. It might take days or even weeks to adapt to a shift in demand or supply, and anticipating those changes is the key to minimizing inventory holding costs while also reducing possible supply disruptions.

“The use of centralized supply chain collaboration systems is increasingly popular. These systems provide tools to monitor suppliers, transportation providers, and enterprise-scale

operations, including order distribution and global inventory management,” says Webster. “They leverage the cloud to support large-scale data and enable integrations that offer automated data sharing and shared benefits. It’s critical for supply chain management tools to consider all available information, including the current state of the enterprise, the weather, current trends, and global events that can all play a significant role.”

The Internet of Things (IoT) is a significant source of data across the entire supply chain. Webster says that use cases of such data include cold-chain and environment tracking, predictive maintenance on warehouse or fleet assets to increase reliability, location tracking and more. “IoT also plays a crucial role in sustainability, such as monitoring power consumption and tracking noise levels in work environments,” he adds.

Digging into the management of fleet assets and transportation offers up a plethora of data that can streamline the de-risking of supply disruptions. Every shipment generates data, such as common delivery locations, delivery times, frequent order times and other data points that businesses can consider in a number

of applications, according to Mingshu Bates, chief analytics officer for AFS Logistics.

“Tools and technologies, including transportation management systems (TMS) can help shippers capture these critical metrics,” says Bates. “As a third-party logistics (3PL) provider and one of the founders of the freight audit and payment (FAP) industries, the more than $39 billion in annual transportation spend visibility we have across multiple modes flows into our systems from over 1,800 customers of all sizes and industries. Such transportation data can be extremely informative in structuring and optimizing logistics networks to help control costs and improve service levels.”

This access to such an enormous amount of data gives the AFS team strategic insights about rate levels for parcels, less-than-truckload and truckload modes that help its customers negotiate contracts and discounts with carriers from a more informed position and realize cost-saving opportunities by shifting between services or modes.

“To give a real-world example, an industrial fastener manufacturer came to us for help aligning their distribution centre locations with customer locations. We conducted a data analysis of their network and found their network

featured redundant supply lanes and low productivity,” says Bates. “After presenting multiple proofs of concept, we recommended they reduce their distribution centres (DCs) network from three DCs to two, which enabled the manufacturer to still offer a two-day transit time for 97 per cent of their shipments, with a 13 per cent reduction in their carrier spend.”

Indeed, data can be used to diagnose and help protect against supply chain disruption risks in a variety of ways, including increasing optionality and planning.

“In recent years, many businesses have been looking to add geographic and carrier diversity to their networks to avoid too much of a reliance on a single location or provider in the event of severe weather, geopolitical tensions, instability, business specific issues or other disruptions,” says Bates. “As a general rule, operations with multiple DCs should locate their facilities at least 800 kilometres away from one another to minimize the risk of a single geographically isolated disruption from impacting multiple facilities. Using data to understand the geographic distribution of not only customers, but critical shippers, can help businesses to distribute their inventory more carefully, and also temporarily adjust if needed.”

State-of-the-art TMS technologies available on the market today are helping manage everyday freight tasks automatically, from accessing invoices and creating bill of lading documents to tracking shipments and filing claims. And some of these systems can be fully integrated with enterprise resource planning (ERP) systems. This allows for real-time updates to help streamline processes and capture critical information.

“More advanced technology generally enables greater data capture and visibility, but that is only the first step. Large volumes of data do not automatically translate to meaningful insights. In fact, many find themselves in a ‘data rich, insight light’ situation, where their business generates a lot of data, but that data can be complex and cryptic, so it can be difficult to understand what exactly it means and how they can use it for their business,” says Bates. “The other common challenge we encounter among shippers is the data cleansing process, including standardization and normalization. This is a very important part that is often overlooked, but it serves as a foundation for any analysis. Working with a trusted partner whose reporting is built on a robust data cleansing process and who can help translate all of that data into clear, actionable insights is key.”

Webster agrees, “Data analytics within the warehouse and supply chain can provide significant benefits, but it’s important to properly

“More advanced technology generally enables greater data capture and visibility, but that is only the first step.”

understand your business goals before focusing on specific areas. It’s also critical to ensure you have the right data, and that it’s timely and accurate enough for decision-making. The best advice is also the simplest: think big and act small. Have a big plan, but focus on getting quick results and incrementally build out the use cases you are most interested in.” SP

BY LARRY BERGLUND

Sustainability in supply chains often involves deliberations on buying from local businesses or buying Canadian-made goods and services. Yet defining local is subjective and mired in ambiguity. Initially, the purpose of a local business was to offer unique products or services that weren’t readily available and for which there was a demand. From a supply chain sourcing perspective, the problem is that local is often affected by loyalties to small business owners with personal ties to the buying entity. There are emotional attachments based on familiarity with local businesses. Consumer buying habits and retail sales are rooted in being identified as local. Trade agreements do not allow for local preferences.

Smaller, established communities want to support local or independent businesses but may do so based on an address – not usually an objective decision. Larger rural areas are less concerned with tough negotiations with their local businesses on goods and services than their urban counterparts. Many local purchases by a town are not large budget items

and can be met by a local supplier. Small budget items, but big impacts for local businesses.

In smaller locales, supply contracts are intended to support local employment and are often influenced by elected officials. The supply of fleet vehicles or construction equipment may come from a local distributor, but the brand of equipment itself could seldom be referred to as local. Smaller communities are trying to ensure a local business presence and not default to buying from a lower-cost, multinational corporation (MNC).

Smaller, established communities with only a few service providers can be in a conflict of interest when tendering for goods or services. For businesses buying goods and services, there needs to be a strategy which considers small and medium enterprises (SMEs), social enterprises (SEs), and MNCs. Value for money could be compromised to support local businesses where a bias favours a small owner or contractor. This practice has led to unfair advantages for local suppliers and unethical/illegal procurement practices by elected officials when awarding contracts.

To add to the confusion around local is the definitions of what is a city, a village, a town, a hamlet, a resort community, a district, a regional district, a neighbourhood, a rural municipality, an urban municipality, an unincorporated settlement, or a region. Canada also has multiple definitions for businesses. A brief literature search found 23 definitions for various types of businesses, including local.

Buyers can take an all-or-nothing approach. This involves buying as much as possible from the lowest-cost source, regardless of locale, as long as the seller meets the specifications – strictly price-based. Other buyers, for resiliency, will buy a certain percentage at the lowest cost and the balance from one or more other suppliers to avoid shortages.

Running a competitive bid with a couple of local suppliers is not going to achieve a competitive out-

come. If one supplier fails, there is lesser competition in the long term. Running a competitive bid without a sufficient number of bidders could invite collusion. Small towns might only be 30 minutes apart, so how could officials objectively decide which is more local?

It is common for larger buying organizations to award long-term contracts for the majority of their operational needs, wherever possible. Setting aside the need to have flexible or resilient sources, reducing the cost of goods and services is a prime motivator for buying organizations. Where we see this strategy being tempered, is where there is a concern that economic development and social interests are an integral part of an organization’s purpose for being in business.

MNCs or other large employers located in smaller communities do provide opportunities to contribute to the local social and economic development. The large employers can ensure they source locally produced goods or services. Maintenance, operating, and repair supplies are ideal to source from local distributors, and repair shops to complement supply contracts. These larger buyers can unbundle their requirements to target local SMEs, SEs, or Indigenous suppliers. Many suppliers are able to support a percentage of locally made goods as part of a larger supply contract. Municipal entities, as well as school districts, universities and hospitals, can direct a percentage of their supplies to local companies.

Resiliency requires a strategy that is inclusive of SMEs and SEs to complement conventional supply chains. Hospitals and universities buy tonnes of food. Making fresh produce one of the criteria in a contract favours local supply and does not compromise trade agreement obligations. Stating that service response times in a contract must be within an hour will draw more local companies. Tracking the spend allocated to local is information stakeholders like to know.

Unbundling larger contracts and having the aggregate demand met through several smaller contracts,

supports economic and social development interests. Unbundling intentionally creates more opportunities for businesses to participate economically. Unbundling can encourage larger organizations to partner with local SMEs and SEs to provide ancillary services in the value chain. The economic multiplier effect can measure the incremental shifts of unbundling demands as opposed to the allor-nothing supply models.

In general, buying local is aimed at supporting family-owned farms, local produce, locally made artisanal items, small lots of fabricated goods, or having requisite services provided by local trades along with apprenticeship programs. A local SME can’t provide larger components of capital equipment or infrastructure projects. However, SMEs and SEs should be able to participate in these works, although they will seldom be the major supplier, contractor, or investor.

I am advocating for conscientious procurement decisions in the retail, as well as public and private, sectors. Knowing how buying goods and services locally impacts a community is just as important as fiscal responsibility. When spending by P-card, think local first. Enjoy an MNC coffee and remember that a local coffee shop at one time inspired an MNC investment. SP

ASI OFFERS THE ONLY METAL PARTITIONS WHERE PRIVACY IS ENGINEERED INTO THE DESIGN. DON’T SETTLE FOR AN ADD-ON PRIVACY STRIP AS AN AFTERTHOUGHT. AT ASI, PRIVACY ISN’T OPTIONAL. IT IS OUR STANDARD.

ASI’s proprietary, Integrated Privacy ™ partitions are engineered with built-in privacy and manufactured as one color matched unit, o ering complete privacy without the need for any retrofitted components. Exactly what building occupants want and deserve. See the di erence at asi-globalpartitions.com/privacy.

BY MARIETE F. PACHECO

The manufacturing industry is a major indicator of development for any economy and faces continuous challenges to maintain efficiency while minimizing downtime. Technology drives much of the efficiency gains over the decades in manufacturing and other industries. One popular technology, artificial intelligence (AI), is having an explosive moment as its usage spreads across many industries due to its increased accessibility through the launch of ChatGPT by OpenAI in November 2022. A major transformative technological solution in recent years is the integration of AI in preventative maintenance. By predicting potential equipment failures in advance, AI-driven preventative maintenance programs can help ensure smoother operations, reduce costs, and can improve productivity.

Traditionally, maintenance in manufacturing has been reactive or, at best, time-based. For example, preventative maintenance completed at predetermined intervals based on how long a motor, engine, or piece of equipment has run or how many components have been produced by a machine. Reactive maintenance addresses issues only after a piece of equipment breaks down or a failure occurs. This often leads to significant downtime and higher repair costs. Time-based maintenance, scheduled at regular intervals, can help prevent unexpected breakdowns, but may lead to unnecessary maintenance activities and wasted resources.

Artificial intelligence’s innovative approach to preventative maintenance enables more effi-

cient predictive maintenance. Using AI, equipment maintenance is performed just-in-time; neither too early nor too late. This approach combines the power of equipment use and performance data with machine learning to forecast and anticipate equipment failures, allowing for an intervention before the equipment breaks down. AI-driven preventative maintenance relies on various technologies, including sensors, data analytics, and machine learning algorithms. Here’s how these elements work together to create an optimized preventative maintenance program. Modern manufacturing equipment is often equipped with sensors that continuously collect data on various parameters such as temperature, vibration, noise, and pressure. This data is transmitted to a centralized system for analysis such as equipment monitoring of performance and state of health. Artifical intelligence systems process the collected data to identify patterns and anomalies. Machine learning algorithms, trained on this historical data, learn to distinguish between normal and abnormal operating conditions.

The AI system then uses predictive analytics to forecast potential upcoming equipment failures. For example, an increase in vibration levels may indicate an impending bearing failure. The system can then predict when the failure is likely to occur, giving maintenance teams advanced warning to provide time to address the maintenance issue such as ordering parts or scheduling of repairs. The AI system provides actionable

insights and recommendations. Artificial intelligence, when combined with human expertise, can help to prioritize maintenance tasks based on the severity, probability and timing of the upcoming failure or breakdown. This ensures that the most critical issues are addressed first before they become critical and have a greater impact on the business.

The adoption of artificial intelligence for preventative maintenance in manufacturing offers numerous benefits: reduced downtime, cost savings, extended equipment life, enhanced safety, and resource optimization. By predicting failures before they occur, AI helps minimize unplanned downtime. This ensures that production schedules are maintained and reduces the risk of costly interruptions. Preventative maintenance can significantly reduce repair costs. Early detection of issues allows for smaller, less expensive repairs instead of major overhauls after a failure. Regular, well-timed maintenance can extend the lifespan of equipment. By addressing minor issues before they escalate, AI helps preserve the integrity of machinery. Equipment failures can pose safety risks to workers. Predictive maintenance reduces the likelihood of catastrophic failures, creating a safer work environment. AI helps optimize maintenance schedules, ensuring that resources are used efficiently. This reduces unnecessary maintenance activities and helps allocate personnel more effectively.

Many industries have already seen significant improvements by integrating AI-driven preventative maintenance into their operations. AI systems have been used to monitor assembly line robots and machinery for early signs of wear and tear. Predictive maintenance has reduced downtime and improved overall production efficiency in these applications. In chemical plants, AI monitors critical equipment such as pumps, compressors, and heat exchangers. Predictive maintenance has prevented leaks and breakdowns, ensuring continuous and safe operations. Food and beverage manufacturers use AI to monitor refrigeration units and processing equipment. This ensures that production runs smoothly and meets safety and quality standards.

For manufacturing companies considering the adoption of AI in their preventative maintenance programs, several considerations are required: assessment and planning, data infrastructure, algorithm development, integration, training and support, continuous monitoring and improvement. Assess the current maintenance processes and identify areas where AI can add the most value. Develop a plan that outlines goals, timelines and required resources. Ensure that the necessary data infrastructure is in place. This includes installing sensors on equipment and establishing strong data collection and storage systems. Working with artificial intelligence experts to develop machine learning algorithms tailored to the needs of the operation can be paramount to the success of the AI preventative maintenance program.

This involves training the algorithms on historical data to recognize patterns and predict failures. This may be done in conjunction with the machinery’s manufacturer to capture lifecycle of components along with live data from the organization’s own real-time equipment usage as factors such as environmental conditions may alter components’ lifecycle, such as temperature.

Reflect on the ability to integrate the AI system with existing maintenance and enterprise resource planning (ERP) systems. This ensures seamless communication and coordination between departments and enables time savings for parts or supplies ordering, inventory management, and service scheduling. Ensure maintenance teams are trained on how to use the new system; both how to interpret its results as well as verifying the information. In addition, it’s critical to provide ongoing support to address issues and ensure continuous adoption of the new preventative maintenance program. AI systems need to be continuously monitored and updated to ensure accuracy. Regularly review the system’s performance and make adjustments to improve its predictive capabilities.

“By predicting failures before they occur, AI helps minimize unplanned downtime.”

While the benefits of AI-driven preventative maintenance are significant, there are challenges to consider such as data quality, integration complexity, change management, and cost. The accuracy of AI predictions depends greatly on the quality of the data collected. Inconsistent or incomplete data can result in incorrect predictions and lead to equipment failures. Having extensive data both from the operations team as well as the equipment’s manufacturer can go a long way to building a robust dataset to strengthen the quality of the predictive analytics model. Integrating AI systems with existing infrastructure can be complex and require sig-

nificant investment in time and resources just like any new technology integration. Implementing AI-driven maintenance requires a cultural shift within the organization. Employees must be open to new technologies and processes, which may require comprehensive change management strategies.

Lastly, like many new technologies, the initial cost of implementing AI systems can be high. However, the long-term savings in maintenance costs and improved efficiency often justify the investment if there is a great deal of costs associated with unplanned equipment failures such as catastrophic equipment breakdowns, safety concerns or customer penalties due to late orders.

AI-driven preventative maintenance represents a major technological leap forward for the manufacturing industry. By leveraging the power of data and machine learning, manufacturers can predict and prevent equipment failures, reduce downtime, save on costs, and enhance their overall productivity. As AI matures, its adoption will become increasingly essential for companies looking to maintain a competitive edge in a rapidly shifting market. SP

BY CHRISTIAN SIVIÈRE

Efficient logistics is critical to a company’s success and profitability. It’s also key to market differentiation – when customers have a choice between similar products priced at the same level, the company offering the most efficient logistics service generally gets the order. This comes at a price. In 2023, for example, logistics costs in the US were US$2.4 trillion from a baseline of US$1.5 trillion pre-pandemic. These increased costs reflect our times, with inflation and volatility the key drivers. How to design a logistics network that’s both robust and flexible? The objective is always to decrease lead times, align production, transportation, distribution, and delivery routes, and whenever possible, lower costs. It involves

devising the optimum sourcing, production, transportation, inventory, and location strategies to achieve the best service at the lowest cost, keeping in mind the customer service goals and expectations. Designing a logistics network involves considering all supply chain data points and selecting solutions that meet budget and service targets. Consider the following: where the customer demand is concentrated; warehouse location (preferably close to customers); what’s the required inventory position to meet anticipated demand; how to design the network to ensure efficient deliveries at reasonable cost; and how to align with available transportation resources. To reduce logistics costs, the goals are to shorten distances, decrease delivery times, and reduce the routes and transfer points to deliver products. The processes involved are to assess the required capacity of distribution centres and fleet requirements; model scenarios based on transport routes; determine and optimize workflows; budget inventory, warehousing and delivery costs. These include facilities, labour, financing, insurance, and transportation costs. Performance must be monitored once your logistics network is running, to measure potential gaps between planned and actual outcomes, assess customer satisfaction and close those gaps, if any, to maintain, and even improve the company’s value proposition.

Where to locate new facilities like distribution centres and warehouses is a unique opportunity to make things good from the start, as opposed to adapting existing assets. Consolidate in the most efficient location, close to your main existing or target markets, considering real estate, taxes and incentives, labour availability and costs, available transportation networks, flexibility, and room for growth.

“Designing a logistics network involves considering all supply chain data points and selecting solutions that meet budget and service targets.”

New transportation routes trigger negotiations with carriers and may generate savings. Environmental issues are important, as companies have growing ESG responsibilities, for example designing energy-efficient facilities, use the right tools and vehicles to reduce greenhouse emissions, and rationalizing routes. In Canada, transportation accounts for 28 per cent of GHG emissions, with the largest portion from road transport. Establish a structure minimizing kilometres driven, maximizing equipment utilization and ideally, reducing trips. Using the right modes of transportation is important. Can you use barges, rail or intermodal and minimize air or express deliveries, leaving those for the last-kilometre leg?

Logistics costs can vary depending on the type of products and a supply chain’s complexity. In retail, for example, the logistics costs of e-commerce merchants are over three times those of brick-andmortar retailers. The main drivers of logistics costs are fuel, equipment, and labour. For companies with global suppliers or customers, geopolitical risks, potential delays, trade restrictions, and customs duties (also called tariffs) can play a big role in the cost equation.

In warehousing, investing in automation technology and robotics is key to achieving cost savings, enabling greater outcomes with less time, effort, and resources. Some companies see subcontracting or outsourcing to a 3PL as the magic

bullet, although it’s often for shortterm financial gains. An example demonstrating the limits of subcontracting is the Boeing fiasco. For years, Boeing was a role model for superior products, until a new president from the finance world focused on cost cutting and increasing shareholder value. Under his leadership, some operations were spun off then subcontracted, including the production of fuselages in Wichita. Finally, Boeing repurchased that subcontractor to align production with safety requirements.

In Canada, the main considerations are, increased technology use to improve efficiency and speed; sustainability and the energy transition, including electric vehicle benefits; omnichannel fulfilment, resulting from e-commerce growth, and maximizing intermodal transportation use, for cost savings and reduced carbon emissions. Finally, our eyes are rivetted to the US presidential election in November, with the prospects of a second Trump presidency. Three quarters of our exports go to the US and over half of our imports come from there. There’s also the threat of a 10 per cent import duty put forward by the MAGA team. We’re not the only ones worried. A recent IMF report warns that a fresh wave of tariffs would revive inflation and that “the potential for significant swings in economic policy as a result of elections this year has increased uncertainties.” Best fasten your seat belt. SP

By Ruth Alfson

With the push for fleets to make a transition from the internal combustion engine (ICE) vehicles to electric vehicles (EV), organizations may find themselves adding EVs to meet sustainability quotas or regulatory requirements. Transitioning to EVs can be an expensive proposition if not carefully considered and planned for. Adding an EV to the fleet involves more than just purchasing it and using it. There are three general questions that you need to ask before planning for the transition:

How am I going to charge the electric vehicles?

How will they fit into my fleet?

How much will they cost over time?

While these questions appear to be simple, the answers have serious implications for the cost of fleet operations and must be accounted for in a detailed transition plan.

First, before contemplating which vehicle should be added to your fleet, you need to have a plan for charging it. Planning costs less than construction. A good plan should save thousands of dollars when it comes time to install infrastructure because everything was thought out beforehand. In addition,