the best aren’t noticed

edge finish e x c e l l e n c e a w a r d s excellence awards

Master Joiners display their talent

top drawers

the art of storage

the best aren’t noticed

Master Joiners display their talent

the art of storage

Register now for an evening of German food, beer and the latest Product Innovations from Häfele.

The team at Häfele New Zealand are excited to bring our virtual event and platform to you in June - named “Häfele Discoveries”. We want to use the platform to show you the benefits of our credo “More Life per m2” as well as the innovations for 2021/22 in a wide variety of areas such as the Kitchen, Office or Hotel. In addition we will be presenting our Own Häfele ranges in a virtual environment using digital 3D.

Join us at one of our three showroom events or book an appointment with your local representative.

Wellington 9th June

Christchurch 17th June

Auckland 22nd June

www.hafele.co.nz

GoldenEdge HMR0 is the proven MDF that provides a perfect paint finish. It’s that simple.

Eco friendly GoldenEdge HMR0 (high moisture resistance zero emissions) is rated E0 and comes in 9mm, 12mm, 16mm, 18mm and 25mm thicknesses.

It’s recommended for kitchen units, cabinets,

bathroom vanities - everywhere a perfect paint finish is required.

GoldenEdge HMR0 is just one of the many MDF products provided by Nelson Pine Industries using the advanced technology of the Küsters continuous press and offering an unsurpassed range of board densities and thicknesses.

Master Joiners 4

Paul Ingram in his last column as president gives us some parting thoughts that he hopes will assist us in business and life.

Laminex Update 16

Mike Arthur speaks warmly of his conference experience and supplies some encouraging figures from the release of the latest residential consent data.

NKBA report 78

The NKBA welcomes the NZESAG’s introduction of an RCS accreditation programme for stone and quartz fabricators designed to reduce the risk of respiratory diseases.

Steering a Course 82

Ian Featherstone provides 10 questions to ask ourselves to determine who are our best clients, likely suitable projects and most profitable work.

Due Process 84

Geoff Hardy explains the intricacies of placing and removing caveats and shows that they can be a useful tool in collecting debt.

News & Info 4 - 18

Education 25

NZJMF membership 86

NKBA membership 90

Product Focus 94

Classifieds 96

Advertiser index 96

The winners of the Master Joiners Annual Excellence Awards were announced at its conference in Hamilton in late March, displaying once again the best in manufacturing and design talent in NZ. We profile the winners.

Near invisible finishes with multi-profile tooling ensuring the panel comes off the machine virtually ready for assembly are becoming standard options for those looking to upgrade their edgebander. We profile several manufacturers who have made recent purchases.

Click and twist, tool-less installation, easy adjustment, assembly and dis-assembly, strong durable connections. Common themes amongst a range of connectors designed for a variety of specific circumstance. We look at some of them.

Ingenious use of and access to space mark modern drawer and storage design. There is also a strong legacy of innovation built on innovation to deliver not only a drawer system for every purpose but also provide a platform for added value for both manufacturer and end user.

With the installation and commissioning of a new veneer slicing machine at its Kopu plant, NZ Panels Group is looking to increase the volume of NZ native veneer available to the market.

This will be my last column for JOINERS Magazine as president of Master Joiners. Thank you Bob for allowing more space for my ramblings. I would like to offer up a few parting thoughts, my Top Ten …

Coming in at number TEN is Succession planning . This is important in life, community, and business and I’ve always thought it a good idea when you first find yourself in a role to consider who will follow after. Planning for succession allows continuation of the good work you have done. Also, we have an ageing workforce and the baby boomer generation are eyeing up retirement and looking to exit our industry and their business’s. Who will take over those organisations? For those of us with baby boomers within our team we need to think about how critical roles will be filled as our experienced people hang up their tools. Even for business owners who still have a distance to run, it is important to think about how someone else might take over one day. Are there systems in place that will make that easy? Joinery firms have invested in a lot of expensive technology and that makes them worth more than ever before, think about how a new owner can be financed in?

NINE Ethics and standards. This is at the heart of what sets a Master Joiner apart from the competition. Ethics and Standards establish and uphold our reputation. The wearing of or displaying of the Master Joiners brand infers that your credibility is endorsed by membership of a respected industry group. The Master Joiners Code of Ethics and Standards is available to download in the members section of our website. It is important that you are familiar with what is required of being a member. Martin Luther King said “The time is always right to do the right thing”.

Customers have high expectations of us and the products we produce. Better quality, more functions, new technology, cheaper and faster. Sometimes we come unstuck, especially when communication

around expectations isn’t clear. So, at number EIGHT is Disputes One of the speakers at conference was Trevor form the Disputes Resolution Institute and he had some useful strategies for dealing with complaints. Master Joiners have engaged Trevor to help develop a process that is available to members and consumers. Most of us will find ourselves with an issue to resolve at some stage. For me, its important to protect my brand and reputation. Think about the long run, perhaps losing a battle so you can win the war. Often a complaint presents an opportunity to do a great job of putting something right with the result being a satisfied customer and potentially even an advocate. So, my parting thought on this one – look for a quick resolution and get on with the next job.

SEVEN Get involved ... Is your email inbox over flowing? Do you divert Master Joiners stuff directly to a folder with good intention at looking at it when you get a chance? Do you have time to attend events? If you’re not getting involved, if you’re not “putting in” then you’re likely not getting much out. There has been a lot on offer recently, certainly post 2020 lockdown and overall. I have been disappointed with the level of engagement from members. I too find that it is difficult to make time but once I am there or “zoomed in” it’s worthwhile and I always come away with something that’s going to help tomorrow. Please support what is offered and if we have the content wrong or you feel like you’re being told how to suck eggs, then let us know. Your regional president is a great person to have that conversation with. Even better have a crack on your regional or national executive – you will broaden your perspective and be a part of progressing our industry. There is much to be gained by time invested with Master Joiners.

SIX Risk and Resilience. The Staples Rodway Baker Tilley presentation at conference gave some insight into risks that exist with small business. Practical advice was given on checks and balances, distributed authorities and duties. This area is one that is likely in the too hard basket for many of us. It

is an area that would be well worth investing some time and a bit of money into getting systems in place that will protect everyone in your organisation. Trust is not a control. We have all been exposed to risk recently in the form of a worldwide pandemic. One of the risks has been financial viability and liquidity. We are all busy now and with that profitable – this is a time to build resilience with some reserves and to reflect on the strategies that were required to keep people employed and business afloat during and following lockdown. There are operational risks too related to work we produce and there are many regulations to have awareness of and comply with. Gas regulations, appliance ventilation requirements, weather tightness, and building code compliance. So, my parting thought on this is one is making sure you avoid the risk of supplying noncompliant joinery. We have a fully tested suite with JMF and all that is required is to build as per the manual and apply the tags. A no brainer really – why wouldn’t you?

Accepting that there will always need to be change. FIVE Progression. The status quo is comfortable and there are times when consolidation and “if it isn’t broke, don’t try and fix it” apply. But the last video rental store has just closed and I’m probably one of the few that still have a cassette tape collection. The challenge when a new idea comes along is to not begin by thinking of all the reasons to not do that thing. Even when the ship has been righted, if it stays at anchor you won’t get very far. There is a world of opportunity out there and it’s often the early adopters that prosper the most. What happens if the competition progresses and we don’t?

FOUR Train for the reality of now and for the future. How many geometric stairs do you build? How many people in your organisation work on the factory floor compared to those at a computer in an office? Which group are we training and recognising as qualified professionals? Do you still have a spindle moulder? What should new recruits for your team look like, your next apprentice? Does the makeup of your team reflect the population? Diversity of gender, thought, backgrounds, ethnicity should be something our industry is paying urgent attention to. Has technology changed the way you do things? Where in your organisation are the skills shifting to? The government is changing the way vocational education is governed, managed, and delivered. This is the time to push and have a voice for what the reality of skills required in our industry is and adapt training and apprenticeships to reflect that and what we expect the future will hold.

THREE Engage with talented and knowledgeable people. Bring them in and use their expert skills to help you. Raise the bar in your organisation with advisors, consultants, and coaches. Business plans, sales coaching, Lean continuous improvement, strength-based coaching as well as legal and financial advice can all be readily accessed and often there is funding available. It may not be about growth, it could be increasing resilience, minimising risk, identifying easy to track production indicators, or building a business that is easer to transition

(continued over page)

out of one day. Often experts present at regional Master Joiner events. The Master Joiner online Webinar series and Professional Development programme have covered off many of these topics as a taster of what can be gained and there is more to come soon. You can’t expect to be an expert in everything. Be great at what you do and use talent from others to help you achieve.

TWO Look after your people

Engage with them, ask them if they are happy in their work, are they worried about anything? are they interested in any other roles within your company? Listen. Keep them in the loop, tell them where the business is going. Feed the culture and make it a positive one. I have been dealt some tough lessons recently and have needed to take a good look at what sort of a leader I’ve been. Covid and lockdowns have increased stress levels and we are time pressured. Beware, looking after your people is not something to leave on auto-pilot, make sure they feel special and appreciated, be life friendly.

NUMBER ONE. The greatest strength that we have as a membership organisation is our members. So, at the top of my top ten is Don’t go it alone. I am a Liverpool FC fan. The club’s fans adopted “You’ll never walk alone” by Gerry and the Pacemakers as their anthem. I have visited Anfield Stadium and it is a special place. I wasn’t there on a game day unfortunately, but I imagine that to hear “the Kop” singing that anthem to their players must be an almost spiritual experience. I’ve visited many of the Master Joiner regions to attended events and checked in at factories. What I hear in all the regions is reference to the Master Joiners network. Things like finding a piece of board, sharing work when there is insufficient capacity, or someone is a bit light on work, or when there has been a machine breakdown. Often, it is the chance to catch up over a beer and talk about issues with Worksafe, HR, product, subcontractor, or supplier challenges. The saying goes “a problem shared is a problem solved”. We might not have an anthem, but I have found the “human” side of members helping each other and putting aside being competitors inspiring. This peer support and review is what helps lift the standards of our industry

by setting Master Joiners members apart from those that are not. Living our Ethics and Standards and conducting business in a way that is for the good of the game. There is a network up and down the country that is only a forum question, an email, or a phone call away from helping solve a problem or offer support.

This has been one of my favourite life chapters. I am going to miss being president of Master Joiners and I look forward to supporting the next president. I would like to acknowledge and thank our National Associate members for supporting our industry, our allied membership organisations for working with us and strengthening our voice, the regional presidents and secretaries for glueing everything together, the rest of the executive, advisory, and Ian Lothian for being on the bus and governing our progress. Our strategy leads Myles, Nathan, and Rueben have their respective elements by the scruff of the neck and I look forward to the objectives they will lead and achieve. A special nod in the direction of Anthony Neustroski who championed much of the progressive thinking we have adopted. I am proud to have carried on where you left off Anthony. Last but by no means least, thank you Allison Delaney our Operations Manager whom we presented the brief to help guide our organisation in thinking more strategically and you have delivered. Allison has achieved a tremendous amount and empowered those around her to achieve as well.

So that’s it. My hope is that my columns have been received in the way I intended, that they have promoted thought, enlightened, prompted questions, acknowledged the good work, and possibly mildly entertained. If I’ve touched a nerve or sparked a conversation and you’d like to talk more, I’ll be stoked if you drop me a line. paul@leebrothers. co.nz. Thanks for reading.

Go well

magazine

Official Publication of the New Zealand Joinery Manufacturers Federation

Editor Michael Goddard michael@joiners.net.nz

Publisher Bob Nordgren bob@joiners.net.nz

Paul Ingram National President Registered Master Joiners

42 Aldersgate Rd, PO Box 27 - 513, Mt. Roskill, Auckland, 1440, New Zealand.

Ph: 64-9-624 4680

ISSN 1173-6836

JOINERS Magazine is the official publication of the New Zealand Joinery Manufacturers Federation. It is distributed to members of the joinery, cabinetmaking and kitchen manufacturing industries and is published quarterly in March, June, September and December. Advertising statements or editorial opinion are not necessarily those of the publisher, its staff, the

An ISO 5660 Class 3 Fire Rated two pack, waterbased polyurethane finish system

• Excellent clarity & nude look on timber.

• Silky to the touch.

• Excellent mar resistance.

• Low reflectivity

• Excellent non-yellowing properties.

USES:

500 Amerthane is designed as a high quality finish for kitchens, shop fittings, cabinets, desks, paneling, partitions and most interior wood.

For more Information please contact PPG

DISTRIBUTORS

Whangarei Paint Centre

Whangarei (09) 430 2414

Wairau Paint Centre

Auckland (09) 443 3430

PPG Industries NZ Ltd

Auckland

(09) 573 1620

Grayson Auto Colour Centre

Auckland

(09) 278 0685

Autolink Distributors Ltd

Hamilton

(07) 846 1443

Linkup Paints (BOP) Ltd

Tauranga

(07) 571 8921

Complete Paints Ltd

Napier

(06) 843 1122

Total Paint Supplies Ltd

New Plymouth (06) 769 9415

Total Body Shop Ltd

Wellington

(04) 586 6681

Paintco

Nelson (03) 546 6660

PPG Industries NZ Ltd

Christchurch (03) 384 0255

Rainbow Paints Ltd

Dunedin (03) 474 0659

Southern Paints

Invercargill

(03) 218 4664

Apprentice Awards p.24

The Master Joiners Conference and the Annual Excellence Awards for 2021 held in Hamilton are the centrepiece for our June issue which shows all the winners and a feature on the Supreme Award winning staircase from Firman Joinery. The first conference since Invercargill two years ago, was a real success run from the Claudelands Events Centre – an ideal venue. We welcome a new President of the NZJMF in Andrew Reilly and thank departing president Paul Ingram for his energetic and incisive leadership. I look forward to hearing where the next Conference will be held in due course.

Not only is this year the 75th anniversary for well known machinery supplier W & R Jack Ltd but it also marks the retirement of owner Robin Jack. There is a commentary from him which I’m sure many will want to read, in this issue. An interesting feature (and one we do annually) is a look at the ever evolving technology of edgebanders with contributions from all the leading suppliers. It always amazes me how they continue to innovate with new and better ways to edgeband product.

An interesting item is a look at the latest in furniture fittings and connectors. This is an often forgotten part of the cabinetmaking and furniture industries. We have a pictorial on some of the latest in this field. Speaking of cabinetry, we also have a look at the latest in drawer systems now available from some of the leading suppliers. Some really interesting product here.

Of special note is the editorial from the NZ Engineered Stone Advisory Group. This addresses the latest developments in the engineered stone manufacturing sector and for those involved in it, a worthwhile read. This issue is in fact very much a full on one with lots to read and digest. As we head into winter things still look very promising for all those in the industries we cover. Here’s hoping the issue of supply works its way through quickly

Bob NordgrenWell known amongst architects, designers and those in the kitchen trade, Moira Smith from Blum NZ recently retired after some thirty years in the job. Bob Nordgren from JOINERS Magazine spoke with Moira about her time with Blum.

Moira joined Stu and Mel Sanders at Sanco NZ Ltd back in 1991 as they had the agency for Blum in those days. “I started out working in the office at their Rosebank Road address not far from where Blum is today”, Moira recalls. “Part of the job was to record all sales, which had to be done manually in a docket book. How times have changed!” In 1998 they decided they needed a dedicated rep calling on all the architects and designers. “I piped up, let me do it, and they agreed, so off I went in the company car with the expense account to visit architects and designers all around the North Island. It was the start of a love affair with the job.” She was Blum’s sole architect and designer rep until approximately three years ago when she started working very closely with her friend and colleague Kate Ward, who is to be Moira’s replacement.

In what is no doubt a competitive world, how did you survive?

I think the main thing was a passion for the product. This was helped by the short range of Blum product - hinges, drawers and lift systems – which enabled me to specialise and focus when I saw the architect or designer. I quickly came to realise how to interface with who I needed to see. For example, architects like you to be timely, and knowledgeable while designers want you to be informative and kept up to date with new products and literature. Rather than just presenting a brochure, I have always taken working models around with me, be it a hinge or a drawer or whatever, heavy work, but worth it. It helped to demonstrate the use and quality of the Blum product. Above all, I never cold-called; I always made an appointment and called when I had something new or interesting to talk about.

Around 2010 Mel and Stu at Sanco decided to move on, and Blum in Austria decided to set up shop on their own here in NZ. What did that mean for you?

Blum have always been a great employer to work for. It’s a family-owned operation, and they made you feel like you were part of their ‘family’ even though New Zealand was many thousands of miles away from their base in Austria. It was no different when they established their own operation in 2010 just down the road from Sanco’s old site in Rosebank Road. They bought in Mike Hawkins as their Managing Director, who had also worked for Sanco when they had the SCM agency. No jobs were lost, and we all felt much reassured. For me, it was business as usual but with the confidence of the direct backing of Blum.”

Thirty years is a long time. What were for you in terms of product the most significant developments in that time?

The big change was undoubtedly the emergence of the full extension soft close drawer systems. It transformed storage in the kitchen. Of course,

that is not to say the evolution of the humble hinge, with integrated soft close and the exciting electrically driven SERVO-DRIVE for both drawers and lifts, have also had a significant effect as well.

Blum is an internationally based and highly regarded company. What opportunities did that provide?

I had the opportunity to travel to some of the famous trade shows such as Interzum, Eurocucina and AWISA, which really opened my eyes. Some were a bit daunting for the first time, size wise and in some ways, some of the designs were not always practical but spectacular, especially Milan, which is considered to be the design capital of the world. The best part was the Blum Factory tours, which took place prior to the Eurocucina fair. So many of our Cabinetmakers and Designers have made the commitment to travel to the other side of the world to see our production facilities in Austria. Locally, of course, there was the NKBA and Master Joiners Conferences over the years which kept me in touch with local industry developments. For me, it was the people I met that helped shape the way I thought.

It has been a delight to work for Blum. Every part of the process, from the joiners/cabinetmakers through to the designer, the architect and of course, all those at Blum, has been important to me. Blum offered me the opportunity to meet a great diversity of people, and being able to work through to the age of 65 has been a privilege, I think. Being involved in the kitchen industry and making sure people were looked after wherever it may be has been a big part of my life, let alone my job. I’m now really excited about the next chapter in my life.

The last weekend in April kicked off a year of celebration for Jacks who mark 75 years in business. The Jacks team and partners spent a long weekend together enjoying a wide range of activities in the

Nelson and Tasman region. At a celebratory dinner Robin Jack looked back at the previous 75 years of the company from humble beginnings as saw doctors in Wellington, and including a hands-on demonstration of

one of the company’s first ever products. There was a chance to look forward too, with Robin Jack’s retirement announcement being recognised, and a public hand over to incoming CEO Richard Bealing.

Further 75th anniversary events, including a significant in-house exhibition, will take place during the next 12 months.

www.jacks.co.nz

The Auckland chapter of Master Joiners recently held their AGM at the new Auckland home for mechanical security manufacturer Allegion in Rosebank Rd, Avondale. It was a good opportunity for members to go on a guided tour of their impressive, purpose built facility after their meeting. Allegion these days are known for some thirty brands including Schlage and Brio.

Master Joiners Conference 2021 - this year’s trade stand area used for breakfasts and other breaks during the Conference was fully subscribed with some 19 stands from trade suppliers. Here are a couple of examples.

Interzum; the largest furniture trade show in Europe. Every other year in May, Blum New Zealand sends a selection of staff members to Europe to join a handful of our customers for the hands-on and innovative experience. But in 2021, travel to Europe was out of the question.

Blum CONNECTS is our way of keeping you in touch with the latest product innovations and concepts from us – anywhere in the world. Gain new insights into

the world of Blum products with our Interzum highlights and hear from the creators themselves. With Blum CONNECTS, you’ll meet MERIVOBOX, reveal REVEGO and discover Digital Technologies!

Sign up online and find out what all of the fuss is about with Blum CONNECTS! www. blum.com/connects

On Saturday May 15th, 2021, Taranaki Master Joiners gathered to celebrate 50 years of Master Joiner excellence. Held at the Plymouth Hotel, a cabaret show put on by the New Plymouth Operatic Society was enjoyed by all who attended

Bryan Frank, President of Taranaki Master Joiners felt humbled to see several attendees driving long distances to participate in the celebrations. “It was a pleasure to see those who travelled from afar”, Bryan said; “Taranaki members appreciate that effort and participation, which included former Members and suppliers and Sponsors from across the North Island. Despite the busy times, Bryan Frank with his team, Stretch and Fay Rice worked diligently planning, communicating, and preparing for the celebrations.

The AGM was held on the Friday night before the big event where Rhys Powell was presented with a trophy thanking him for his work on behalf of the region by Bryan Frank. Rhys Powell was further presented with life membership for his contribution to the region. Bryan Frank had Master Joiners National President; Paul Ingram (also in attendance)

present the award to Rhys during the festivities. Rhys was certainly taken by surprise and later said of the award “A sly move by the committee, not sure how that got past me, that is for sure, very surprised”. He went on to say; “Being involved with Master Joiners, you get the friendships and the business knowledge, the sharing is valuable in business and in joinery practice. Rhys started out his apprenticeship with Jones and Sandford, (also members of Master Joiners) and appreciates the value of giving back, he is keen to see more of the younger joinery practitioners add to what has been achieved in the region.

It was also with Jones and Sandford where Graeme Paul trained as an apprentice. Graeme Paul is well known as the Taranaki Secretary, and formerly a Taranaki President, having served the profession in his own business, retirement meant he was also able to continue to contribute to the profession. Graeme is now retired from his Secretary role. The Taranaki Master Joiners extend sincere thanks to Graeme for his steady guiding contribution.

While the joinery profession looks and feels similar all around the country, it is getting along to the Master Joiner meetings which tell the story of what the value of membership is all about. Individuals in their own way can contribute as much or as little as their time allows to advance the profession in the region as demonstrated by Rhys Powell, Graeme Paul, Bryan Frank, and we know there are more of you in Taranaki who have contributed, shared and served the profession.

Congratulations Taranaki on this milestone and to all those who have contributed over the 50 years. Certainly, there is more to do and many hands make light work … welcome to the next 50 years in Taranaki and welcome to the new members In-House Kitchens, and Mode Kitchens, from New Plymouth.

Taranaki Master Joiners sincerely thanks Blum NZ, Hettich, New Plymouth ITM, Laminex, Hafele and NZ Panels Group for supporting the Taranaki Master Joiners 50th celebrations.

morbidelli x200 / x400

The new generation of Nesting CNC machining centres meets the needs of a market increasingly oriented towards flexible and batch-1 production, combining excellent performance, maximum configurability with increased flexibility and productivity.

Capable of any machining process without removing the spoilboard and even in 3D thanks to the X-PODs and the JQX (Just Quality eXtreme) 5-axis electrospindle.

Nesting processing at 50 m/min, saves 60% of time on drilling cycles thanks to the new drilling heads (also with double saw blade) and less than 15” for the tool change thanks to the FAST tool changer directly installed on the mobile unit.

Thanks to the X-Vacuum System, the vacuum is condensed into the area of the worktable where the workpiece is being processed. Perfect to process small workpieces or highly breathable materials.

The ultimate solution to simplify work: cell version, available to configure the machine no matter the material flow required.

Hafelewelcome Simon Lount back to the team at Hafele New Zealand. Many of you may remember his familiar face … Simon previously worked with Hafele New Zealand from 2005 - 2018, before making the move across the world to join the team at Hafele’s head office in Nagold, Germany. After spending three-and-a-half years looking after Trade Partners across the world, Simon has now returned to Hafele New Zealand in the role of General ManagerSales and Marketing.

Simon can be contacted at simon.lount@hafele.co.nz

The Archant Showroom is now open, and provides an interior design retail experience in down-town Wellington

We are excited to share with you that from late June 2021 our warehouse and office will operate from our newly built facility in Higbrook east Tamaki, Auckland. In just over 3 short years and with the support of our loyal customers, we have outgrown the multiunit site that has housed Hutchco for the past 20+ years. We have an expanded range of colour matches and offerings that are continuing to grow, the newly built multi-purpose facility in Highbrook offers

more than double the storage capacity. As announced in March, we installed a custom built multi-blade calendar machine, designed to custom slit standard rolls and calendar cut 275mm master rolls, we are now nearing the end of the commissioning phase and the new facility gives us the space to take this service to the next level.

Check out www.hutchco.co.nz for further information and updates

Choosing to collaborate with VidaSpace - a designer timber and veneer supplier - instantly created a space that is a distinct destination for Wellington's architectural and design community. Nestled at the bottom of College Street in Te Aro, this showroom embraces the natural and the new through an eclectic connection between VidaSpace' timber and Archant Stone, all under the same showroom roof.

The design was led by Dorian Minty and his team at Studio Pacific Architecture. With an aim to create an 'award-winning' space which was not to be just a showroom, but a meeting and social space that Wellingtonions feel truly connected to. Oozing with collaboration and full of experience-driven displays, the showroom allows designers and architects to not only see and view the product, but experience the product.

Marble Marquinia, was selected as the hero stone for the space to create a certain grandeur and luxury. This deep and moody marble colour is a replication of the Spanish Nero natural granite which while beautiful, boasts the uncompromising functionality of a porcelain. To further dramatize

the space, large-scale 1 metre square tiles clad one side of the wall, creating a brilliantly eclectic effect with the dynamic range of rusted metals, gold marbles and cement like porcelain colours.

While the space is dramatic and large-scale, no detail has been missed. The showroom features a centre sink unit, fabricated entirely out of Archant Porcelain with detailed mitred edges and an integrated porcelain sink. This unit is at the centre of any design conversation and showcases a selection of Archant's state-of-theart food preparation sink stations by Franke. The beautiful details of these sinks and accessories are a real celebration of an intense attention to detail and quality in product design. And of course, the Archant Handle collection is displayed in a downsized manner of the stone samples. By fitting the handles to 300mm square boards, the displays featuring a range of modern and traditional designs in brass, black, anthracite, nickel, antique brass and other finishes.

It's an indelible experience that this showroom aims to create ... a true Wellington retail experience which is endowed with the quality of Archant's many European design-houses offered to the New Zealand market. So, we invite you to visit the new showroom and experience the Archant difference for yourself.

Laser edgetape now available

A collection of six finished woodgrain panels that are rich in colour and texture.

• Supplied as finished panels so no coating or lacquering is needed

• Consistent colour and pattern

• UV stable for indoor use

• 2800x1220 sheet size

• Matching 22x1mm textured ABS and 22x1.2mm laser edgetape

• Recommended for vertical use

• 7 year warranty

View laminex.co.nz for full range, swatches and brochure. Contact your Laminex representative to find out more.

laminex.co.nz

Textured Finish

Consistent Pattern Repeat

UV Stable Indoor Use

Versus natural timbers

Weattended the Master Joiners Conference for 2021 in Hamilton recently. It was my first conference, the first for Laminex New Zealand as Host Sponsor and what a pleasure it was to be there.It was great to meet so many of the industry’s best in one room (despite how busy we all are!). I thoroughly enjoyed the thought-provoking key-note presentations, particularly that of Rob Waddell and Mike King and meeting so many customers. Before conference kicked off, we held a tour of the Laminex Hamilton site, where we press our Melteca product range. We had a fantastic turnout and were pleased everyone enjoyed learning and gaining insights into how we work and schedule your orders. The Master Joiners Committee will be preparing for the next conference, and we look forward to the opportunity to catch up as an industry, share learnings and continue to focus on improving our collective high standards.

Our business recently took people leaders through a workshop focused on Safety Leadership. Well-being was a strong recurring theme and it’s no surprise given the environment we’ve worked across over the last 12 months; this strongly resonated with what Mike King discussed at conference. It’s important we are finding ways to help and support each other to manage stress and fatigue, and to recognise success rather than just focussing on safety improvement initiatives.

The latest Residential consent data for the year to March 2021 reached an all-time record of 41,028, surpassing the previous record from 1974 and up 9% on the same period in 2020. March was also the highest monthly figure on record with 4,128 consents issued. Townhouses continue to show strength, up 40% in the year to March 2021, with the Auckland region being a major driver of growth, up 58%. Non-residential (Commercial) consents also showed promising signs, with the year to March 2021 seeing a 5% increase. Education, storage, and office buildings were the largest contributors to growth. All of this bodes well for our industry over the next year and beyond.

We appreciate and listen to feedback on how we can better serve our customers. A frequent comment we’ve heard from laminate fabricators is the restriction of delivery method on online ordering. Based on your feedback we’ve updated the platform to enable laminate fabricators to receive delivery by courier! Online ordering provides the option to see in real time expected delivery dates for your order. If you haven’t given online ordering a go, now is the time! Visit www.laminex. co.nz/e-commerce-registration to apply.

If you have any feedback you want to share directly, please feel free to get in touch!

Mike Arthur General Manager Laminex New Zealand

Sheng Lim has joined the onthe-road Service Team after almost 2 years in-house, gaining training and experience across a wide range of machinery and accessories, but particularly CNC and edgebanders. Coming from a joinery background Sheng is already very familiar with the technical challenges faced by kitchen and cabinet-makers.

Troy Hubbard is moving from a product specialist and demonstrator role in the Jacks Sales team to becoming a Service Technician. Troy brings a background in mechanics and software. And a familiar face to many customers around NZ, Matt Fulton has returned to Jacks - his edgebander and Weinmann skills particularly welcome in such a busy market.

These three add much-needed capacity to the 14-strong NZ service team at time when workshops are busy across the country, with demand on Service Technicians at an all time high. For service from Jacks please call 0800 522 577.

Leitz was established back in 1876 in Germany, some 145 years ago. It’s New Zealand subsidiary was set up in 2006 based in Auckland. It is a global leader in the manufacture, service and supply of cutting tools for wood, plastic and advanced materials.

The company continues to grow it’s presence and are excited to announce representation in the South Island. Anthony Barrett, a Cantabrian based in Christchurch, comes with many connections from within the industry having sold imported timbers for a number of years throughout the South Island after some nine years on workshop floors manufacturing furniture and joinery.

Anthony will make contact with many South Island joinery shops in the coming months. Meanwhile if you have any tooling requirements please feel free to call Anthony on 021 824 181.

Biesse Group, has announced the expansion of its international network with new branches opening in Israel, Japan and Brazil to strengthen its presence in markets identified as strategic. The Group believes that international development, together with technological and organisational

investments and opportunities for inorganic growth will be key to achieving its future objectives. Since it opened its first overseas branch in the United States in the late 1980s, globalisation has been one of the cornerstones of the group's strategy.

Thisyear’s Conference, held at the Claudelands Events Centre in Hamilton was well received by all who attended. It came as a welcome relief to be finally underway given the tumult of Covid in 2020 that led to it’s earlier cancellation. With a rearranged format with the ‘inspired to perform’ theme the Conference kicked off on the Thursday with tours to the Laminex Melteca plant in Te Rapa followed by a visit around the Wintec Joinery Workshop. This was followed by The Gathering in the late afternoon and into the evening, a chance for everyone to catch up and then watch some entertainment from Greg Ward who combined singing with comedy. It worked well.

The Friday started with breakfast in the trades which gave sponsors time to meet delegates to the conference on their stands. A goodly number of trade suppliers were on hand. The rest of the day was busy with Keynote speakers Jim Hainey talking about recruitment processes, Trevor Slater on conflict resolution and a discussion of how to mitigate risk with Bakers Tilly. The afternoon was notable for the Break-out session concept where a series of sessions on various subjects were held to which you could choose to attend. I had a look at the Compliant Timber Joinery session which was a really good update on the latest NZS4211 processes and the progress with

JMA NZ Ltd that runs it. Other sessions included Floating floors, Lean manufacturing, immigration trends, insurance and the latest in edgebanders. All practical subjects that were tailored for Master Joiners. A highlight of the conference was the Keynote speech late in the day from Mike King on mental health and safety in the workplace. This was well attended and received.

Of course the showcase event was the Annual Excellence Awards Gala Dinner on the Friday night.

Congratulations must go to the Supreme Award winner Firman Joinery from Oamaru with their outstanding staircase. We have coverage of this and all the other winners in this issue. There were some 180 entries this year which is impressive given the impact of Covid over the last year. Congratulations must also go to the two new Life Members Peter Leith and Gary Turner. It was also a pleasure for me on behalf of JOINERS Magazine to once more (for the 25th year in a row) be able to present the Annual Apprentice Awards along with the main sponsor Desiree Keown from NZ Panels Group. These apprentices including a very talented young woman this year, are the life blood of this industry as always. Congrats to all of them.

The Saturday was meant as a fun day. Delegates could choose from a range of activities including a Camjet Tour, paintball adventure, a Raglan Tour and a Brewbus Tour. No prizes guessing which one I went on: the Brewbus Tour! Run by Brewbus (www. brewbus.co.nz) you get to go to a

winery followed by two craft beer breweries. On a beautiful day the dozen of us on the bus kicked off with a visit to Vilagrad Winery. After a short tour and some really nice samples (and some nice nibbles) in a quite picturesque location just out of Hamilton we went to the first of two breweries for a tour and some sampling. The day just got better and better! I had no idea how good these craft beer places are let alone where they are but I learnt fast. If you are looking for a great team day out and some nice liquid refreshment and a great tour guide then contact these guys.

By about 4 in the afternoon we were back at base and while some left for parts unknown there were a few who met up for an informal finale at the Sky City Zone in Hamilton’s main drag. All in all a good conference. Thanks must go to the Conference organisers who this year were from Master Joiners themselves led by Operations Manager Allison Delaney and her team. Coming out of challenging times, a great result.

This year’s Winner of the Supreme Award is a superbly constructed staircase from Firman Joinery out of Oamaru. It is the firm’s second Supreme Award having also won back in 2018.

“For their new home,” comments owner Gary Firman “our clients wanted a stair that would be a feature when you came in the main entrance to their home. The stair was designed to sweep out into the entrance hall giving a feeling of grandeur when entering the house.”

To enhance the look of the stair, they went with a cut stringer to the exposed side of the stair. The lower treads and risers have curved fronts and mouldings to the underside of the treads. All the risers have been mitred into the cut stringer to ensure a seamless finish. “Some time was spent setting out the curved bottom of tread to ensure it complied with the Building Code” says Gary.

The inside curve portions of the stringers are laminated MDF. The stair has been finished with an impressive wrought iron balustrade manufactured by Apex Engineering.

“This was a satisfying project that met the client’s brief. From design to completion our craftsmen were involved at every stage. Their technical expertise and pride in their work shines through while creating the feature our client was looking for.”

Firman Joinery, owned by Gary and co owner Hamish Kane, are long time members of the Master Joiners, being established some thirty years ago with most of its work being found in the Central Otago/Oamaru region. While producing a full range of joinery and cabinetry the business works closely with a number of regular

building clients. A medium sized operation with some fourteen staff and a 1200m2 factory site, they have also done architectural work in places like Queenstown.

The entry also won the Best Stairs Award.

For more information contact Gary Firman 03 434 1561 or visit www.firmanjoinery.co.nz

The Supreme Award is sponsored by Carters

BEST FITMENT OVER 2 YEARS

BEST FITMENT UNDER 2 YEARS

BEST TIMBER PROJECT OVER 2 YEARS

HIGHEST JUDGED FOR WORKMANSHIP & SKILL

* AWISA - Master Joiners Peoples Choice Award over 2 years

BEST TIMBER PROJECT UNDER 2 YEARS

AWARD SPONSORS - JOINERS Magazine & The NZ Panels Group

Craig Tuapawa is an experienced tradie. Having recently been named the BCITO Timber Joinery Most Promising Apprentice, he shared his intriguing journey with us.

Hamilton-based Craig left school to start a plumbing course. He worked in the plumbing and gas-fitting industry for two years before moving into building and construction. His motivation to pursue joinery developed from an increasingly sore hip alongside a realisation that he preferred the finer details of the trades.

“It was actually my boss who brought the idea of moving trades to me and introduced me to the team at NT Joinery. Joinery seemed like the natural next step. I get a lot of satisfaction from thinking things out and focusing on the small details. It was an opportunity to improve my skills.”

Whaea McBeth, Business Support Manager at NT Joinery in Hamilton, says Craig is the most accomplished installer the business has.

“Craig came on board a couple of years ago after sparking an interest in cabinet making. After six months, when we decided to establish our inaugural install teams, Craig put his hand up and hasn’t looked back since.”

“While always being a humble guy, he is a really skilled and efficient worker who is great at troubleshooting. We nominated him for the BCITO Timber Joinery Most Promising Apprentice award and were delighted when he won.”

Craig says it feels fantastic to win the award. He did his apprenticeship through BCITO and thinks that the organisation has been helpful for his learning.

“I was surprised when I won. It feels good to be recognised for my skills in the industry. My training provider Scott was great. I could contact him at any time on email or phone, and he always gave me notice as to when he was coming in to assess me. I always knew what was required of me.”

Craig encourages other people to consider a career in the trades. “It’s wonderful to make something

from raw materials and transform it into something that makes our clients happy. The morale boost is huge.”

BCITO needs more skilled people to become tradespeople. Find out more about how to get started with industry training and understand what support is available, at www.bcito.org.nz/ employers.

Gartshore have earned themselves a reputation as leaders in the interior fitout and joinery industries, having operated nationwide for more than 60 years.

Continually reinvesting profits back into the business enables Gartshore to have the most current plant, processes, systems, technology, and staff training, ensuring they can meet the demands of some of New Zealand’s most prestigious fitout projects both now and in the future.

This is reflected in the fact that Gartshore have recently won two awards at the Master Joiners Awards 2021 held in March. The awards programme recognises commitment to standards and craftsmanship and celebrates professional excellence within the industry. Receiving these awards on the back of several awards at the NZ Retail Interior Awards late last year demonstrates Gartshore’s continual drive to deliver high

quality projects time and time again. Gartshore were awarded the Best Region (Waikato-Bay of Plenty) Award and Best Use of Colour Award for Naumi Studio Hotel in Wellington.

Housed in an iconic heritagelisted building, the hotel lobby bar and restaurant went through an extensive top-to-toe renovation, transforming it into a visual feast for the senses, with eclectic spaces inspired by seafaring, the literary world and enduring love. The client’s brief – delightfully eccentric maximalism – was brought to life by Gartshore’s bespoke joinery supply and install.

The project was completed in late 2020 and is a unique experience that immerses guests from the moment they walk through the door. Greeting them is a large scale painted floral backdrop covered in gold leaf, featuring bespoke 3D origami flower lights and a framed portrait of Lady Naumi, as well as three aged patina brass counters with foot rails and kick plates.

The sensory overload continues to Lola Rouge Bar, which truly showcases exceptional joinery craftsmanship. One of the most eye-catching features is the stunning light fixture that hangs overhead, requiring hidden structural steel work within a suspended ceiling. The bar top is made from a translucent LED Illuminated Corian Stone, with aged patina brass fins, foot rails and kick plates and encircled in tiles, individually cut to match the contours of the bar.

In the adjoining lounge, one can find a purple mosaic tiled fluted breakfast table, which took over 200 man-hours to create. Each 20mm x 20mm glass tile was cut individually to ensure a seamless transition through the arches to the underside of the tabletop – a true feat of skill and perseverance.

A seemingly endless array of materials and finishes including 17 different types of tiles, several different glass finishes, wallpapers, fabrics, leathers, solid timber, brass, metals, stone, and veneers were seamlessly integrated into the project and doing so was a huge accomplishment for the joinery and installation team.

The Gartshore team worked tirelessly for weeks to complete an outstanding project which they are incredibly proud of.

www.gartshore.co.nz

The edgebander is one of the key pieces of machinery in ensuring the smooth flow of panel through the factory. Near invisible finishes with multi-profile tooling ensuring the panel comes off the machine virtually ready for assembly are becoming standard options sought after by many looking to upgrade their edgebander. Over the next few pages we provide several case studies of recent buyers relating their initial criteria and subsequent experience.

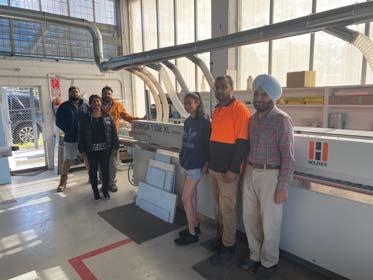

Daljit Kaur and Hardeep Bains started SLEEK Kitchens NZ in October 2020. With just over 6 months under their belt and no previous experience in joinery or manufacturing, they’re already in a position whereby they can pick and choose the jobs they take on.

Daljit came from a background as a Business Analyst while Hardeep is experienced as a Business Intelligence Specialist. You could say they have a good handle on how to run a business. However, it’s one thing to collect and analyze data, but quite another to start up and run a manufacturing business in an industry you know very little about.

As if starting a kitchen and cabinetry business wasn’t challenging enough, Daljit and Hardeep also had an interest in manufacturing stone benchtops. When an opportunity to purchase an existing stone benchtop business became available, they jumped in. As it happened the 500m2 unit next door to the stone benchtop business was available to lease, providing the perfect location for the kitchen and cabinetry business. Unlike the stone benchtop business which came fully set up and operational, Daljit and Hardeep were starting from scratch with their kitchen & cabinetry business.

After much research, visiting potential suppliers and talking with friends in the industry, Daljit and Hardeep decided to put their faith in advice and machinery supplied by Jacks. Hardeep reflects on those early days. “We did a lot of research because we were new to the industry. We looked at the all the options. The team at Jacks are in a league of their own and had the experience and know-how we needed.” Daljit and Hardeep decided a CNC

and good quality Edgebander were the two most important pieces of machinery to ensure they’d be efficient and competitive from the outset. They settled on a Format-4 profit H08 CNC and a Homag 1440 Edition Edgebander with lasertape processing capability. They also invested in 3rd party design-to-machine software, Polyboard.

While waiting for the CNC to be installed, the first few kitchens were cut on a panel saw. Hardeep says the panel saw is hardly used at all now with their cutting and drilling being processed on the Format-4 CNC. They construct their cabinets with a mortice and tenon join which speeds up assembly and results in a strong cabinet. Together with the quality of edgebanding coming off the Homag 1440, these advantages have quickly become selling points to their customers. “The Homag has definitely met our expectations” says Hardeep. “Our staff are big fans. Parts come off the edgebander finished and ready for assembly. We do next to no manual cleaning of the parts after the edgebander.”As well as the laser capability the Homag 1440, it’s fast and easy to set-up with all processing units adjustable from the control panel. The multiprofile tooling enables a very high quality finish across a wide range of materials.

Daljit & Hardeep started conservatively with one or two kitchens per week. They now average three or four kitchens per week. They’re also manufacturing flat pack cabinetry and undertaking some cutting & clashing jobs for other cabinetry businesses. Not bad after just six months and no previous industry experience!

Made in Germany by portable tooling specialists Mafell, HIT-M is the first and only mobile edgebander capable of processing laser tape to achieve a zero-join between tape and board. The HIT-M hot-air system can process all commercially available pre-coated or post-coated laser edge tape without the need for glue.

The HIT-M can be used for both straight and curved workpieces, as well as edging of bevelled edges up to a 50° when used freehand and 55° when used in the machine stand. The working temperature is reached within a couple of minutes after switching the unit on and as there is no gluepot, there is no need for time-consuming glue colour changes.

Included with the HIT-M package is a machining table for stationary work of larger workpieces, meaning you get the perfect entry-level option to get you started in the zero-join laser edging revolution.

SCM Showed off its latest edgebanding technology at the recent Interzum Guangzhou, China’s biggest woodworking and panel processing show.

Taking centre stage was the Stefani XD, the most current SCM technology for industrial edgebanding, an ideal solution for the production of components for furniture with the most advanced design and the use of state-of-theart materials.

The key advantages include:

• a surprising finishing quality thanks to the AirFusion+ technology that allows you to edge without glue, making the joint between the edge and panel invisible;

• maximum versatility: all the panel's parameters can easily and rapidly be changed

(type, colour, edge thickness, position and depth of the mortise, management of the protective film, panel dimensions etc.) without ever interrupting the production flow.

• The edgebanding machine will be integrated with an industrial articulated robot for the automatic loading, reintroduction and unloading of the panels.

• A further guarantee of optimisation and simplification of the process is given by the software coordinating the robot's work:

• on exiting the vertical storage, all the information about the panels (sizes, colour, materials etc.) can be acquired thanks to the software, by reading the QR code;

• the same information is used by the software to coordinate the robot and edgebanding machine during the various passages through the machine to unload the pieces.

Also in evidence was the Stefani MD, the perfect edge bander for companies who require continuous production of a large number of panels even though they are all different from one to another.

High productivity and extraordinary level of finishing quality find in this model a perfect combination. Perfect joint line and great versatility of use are guaranteed by the "SGP" glue pot which allows you to use both EVA and Polyurethane glue with a top gluing quality.

The range has a new look even on the software side with Maestro active edge for error free usage and maximum performance.

www.machinesrus.co.nz

Recommended for use without any preparation such as sanding, Proadec PROPAINT PVC edging is highly rated among users who value durability, superior performance and time savings. The main technical feature of PROPAINT is the primer coated surface giving a stronger bonding ability to commonly used furniture paint systems.

We asked Christchurch based furniture spray painter and owner Mark Benson of B & W Furniture Finishing where they see Propaint used “work[ing] well for kitchens, bathroom cabinets, bookcases, open shelving units, island back panels, wardrobe doors, laundry joinery”. Mark mentions he is noticing the usage of Propaint among joiners is increasing and “would rate the performance as excellent and highly superior to custom-wood edging”.

These sentiments are echoed by Tony Kelly, owner & Managing Director of Contemporano, an Auckland based manufacturing partner of mid to high end joiners and cabinet makers across the North Island –“All our clients

lacquered projects are now done in Propaint, we are seeing an increasing demand for it from new clients” Tony goes on to say “ as a preference, we will only use PUR glue on Propaint, with a thinner near invisible glue line the end results are great and seems to be a lot more durable than any alternatives currently available.”

Propaint is available in 22mm through to 65mm wide both in unglued and preglued options.

See www.hutchco.co.nz for more information or to request your sample.

Tony and Craig Hewetson are brothers and co-owners of Hewe Kitchens & Interiors. Craig started the business out of his parents’ garage back in 2002 and shortly thereafter moved to a workshop in Glenfield employing two staff. One of which is Glen Ingham who is still with the business today.

After eight years living in London, Tony and his wife returned to New Zealand in 2009 to raise a family. Tony had been working in the building and cabinet making industry in the U.K. and as such was an ideal addition to the Hewe Kitchens & Interiors team. Working with family can be challenging. However, Craig and Tony have forged a productive working relationship that combines their respective strengths and experience. “As brothers we can be very honest with each other” says Tony with a grin. Craig is a trained cabinetmaker and as such looks after design and detailing.

Tony focuses on running the business and as a mechanic by trade, identifying the business’s machinery requirements.

One of their first big steps towards automation and efficiency came in 2012 with the purchase of a CNC and their first hot-melt edgebander. While these machines have served them well, about 18 months ago they decided the edgebander needed upgrading. Tony could see they weren’t getting the quality of finish from their old edgebander and the process was slow, with many hours spent manually cleaning panels after edging.

With Tony’s background as an automotive engineer, he was very thorough when assessing the options. Tony explains: “We take our time – we want to know what we’re getting”. Much research and background checking ensued – including tapping into the local network of industry colleagues to fact-check the information and after sales service claims made by potential suppliers. Feedback was

positive regarding the German made Homag 1440 Edition edgebander, supported locally by Jacks. Tony explored using PUR glue and processing with laser-edged tape, but eventually decided they would stick with standard EVA glue, safe in the knowledge that if the trend in laser tape continues to grow the Homag 1440 is prepared to enable the retrofit of an AirTeclaser tape processing unit in the future.

Pre-milling and corner rounding were also on the shopping list. These units eliminate the need to buzz workpieces prior to edgbanding and automatically round the corners. Tony explains “parts now come off the edgebander with very minimal manual post-processing or cleaning required. Although the Homag is faster, speed wasn’t critical, but it’s also appreciated. And even though we process a wide range of materials, everyone in the factory can use the Homag due to the capability to save and recall programs and easily adjust the processing units through the control panel.”

The top end of the market is where Hewe concentrate their efforts. So much so that there is a name change in the wind to “Hewe Architectural Cabinetry”. With 95% of their business going into high-end residential fit-outs, the quality of the edgebanding finish is critical to satisfying customers with high expectations.

The Homag 1440 is certainly delivering. Walking through their impressively clean and intelligently laid-out factory, it’s easy to appreciate the level of professionalism and craftmanship on display. With highly trained and dedicated staff such as Gunnar Friese their German designer and Lance Barnes their operations manager who came from the Super Yacht industry in 2010, they have a combination of talented staff and modern machinery to satisfy the most discerning customers.

Ryan’s Kitchens and Joinery in Christchurch prides itself on manufacturing high quality kitchens and joinery at competitive prices. Owner Ryan Butler has been in the building industry for many years, and has built up a reputation for both quality and accuracy in the design and manufacture of kitchens and house lot joinery. He has invested in state of the art Biesse machinery to ensure the quality and cost effectiveness of the finished product.

We asked Ryan for a quickfire response to some questions on the purchase and use of his current edgebander, a Biesse Akron 1440 with AirForce capability.

What were your criteria in the initial purchase and how did you settle on Biesse and the Akron 1440?

I had purchased a Biesse CNC prior and was impressed with the machine and the backup so buying an edgebander from Biesse was an easy decision.

The Akron 1440 is our second edgebander from Biesse, we upgraded to this one to have a machine with the Airforce unit and so capable of doing ‘laser edge’ work, which is becoming increasingly sought after.

How has the machine performed since your purchase several years ago?

The machine has performed brilliantly.

Our staff find it easy to use and being the "servo" model we can make adjustments from the control without having to open the machine cabinet.

We run Airforce tape whenever possible and even on the majority of our carcasses. The near invisible laser edge is a big selling point for our designers and our clients love the look.

Any particular qualities about the machine you or your staff really appreciate. The servo adjustment of the working units on the machine is a real timesaver, making the operators job easier and eradicating a lot of potiential for error.

How important has the ongoing relationship with Biesse been?

It's been very important as when our Biesse stops our factory stops. I couldn't speak more highly of their service team. We are using their Sophia parts online system, we have 24/7 access to spare parts pricing, availability and ordering.

Any comments on your business’ future machinery purchases.

We are growing as a business and new Biesse machinery will certainly be part of this growth.

The Auriga 1308XL Series from Holzher offers the latest in edgebanding technology with a versatile, robust machine with a variety of features that suit virtually any job situation.

Bob Nordgren from JOINERS Magazine spoke with two custom joinery and cabinetmaking operations who have recently bought from the Holzher range: Simon Molloy from Molloy Joinery Ltd in Napier with an Auriga 1308 XL and Harry Paneser from AK Cabinets Reno Ltd in East Tamaki, Auckland with the first Auriga 1308XL Power version to find out why they bought them.

Harry Paneser, who runs his family business AK Cabinets & Reno Ltd from premises in East Tamaki, Auckland told me “I wanted to run a joinery and cabinetmaking operation offering my clientele the best product I could. The Auriga 1308XL Power inline edgebander gives me that: a super finish using high gloss acrylic for a good price and impressively, upon install by the team at TechMS, the machine was up and running in just two hours.”

The 1308 XL Power version offers intelligent tool correction that allows adjustment of all milling and scraper operations. “The f.a.s.t technology is really impressive as it allows us to perform various processes simultaneously. This can save time and money.” comments Harry.

The machine allows for three finishing units: corner rounding, scraper and buffing for a better high gloss finish. The finish provides for invisible joints with Glu Jet film technology along with iTronic for the intelligent

automation of various processes and diamond tipped cutters as standard features. “This machine has other really good setup processes: totally automatic cleaning and a heating up time of just two minutes before full operation by only one operator. We can also use both EVA and PUR glues. It pretty much looks after itself. We have had the machine about a year now and the improvements in quality and time saving has been quite noticeable.”

Harry commentsMolloy Joinery Ltd based in Napier, are a long established business having been started by Simon’s father back in 1976. “I took over the business in 2015 and have continued producing joinery, cabinetry, exterior timber joinery and benchtops for our local market.” comments Simon. Simon explains they had been on the lookout for a replacement edgebander for some two years. “We had an older Holzher dating back to 2003 and needed to update.” The Holzher 1308XL caught his eye as a logical step up. “It offered us a degree of familiarity whilst giving us some new features we were looking for such as premilling, more efficient clean up and the automation of several processes. It enabled us the flexibility to move from using glue slugs to pellets or the PUR system as required.” remarks Simon.

A noticeable improvement in productivity and quality of finish followed. “Training was short and simple while the install by Mike and Rajan from TechMS was quick and efficient. It all made for what we saw as a good decision. All this, the brand and the adaptabilities the machine has offered made the little more we had to pay well worth it.”

For more information about AK Cabinets & Reno Ltd contact Harry Paneser on 021 251 1699, email akcabinetsreno@gmail.com

For information about Molloy Joinery Ltd contact Simon Molloy on 06 843 5037, email simon@ molloyjoiners.co.nz

Glue quantity control, see exactly how much glue is remaining, reduce or increase the glue quantity at the touch of a button, automatic purge control for easy colour changes designated purge channel and stainless tray for easy clean-up.

fa.s.t. or “set up in the gap” is one of the major themes for efficient edging operations, fa.s.t. enables you to run different machining processes at the same time for example, it is possible for the operator to switch on the corner unit intelligently, without having to empty the machine for the set-up procedure.

Cut to size service contract provider Cutshop recently won the APAC Business Award for Best Contract Cabinetry Cutting Specialist - New Zealand. Born out of a need to provide a service that cuts, edges, drills and delivers sheet material, the company has provided a successful point of difference in the last ten years culminating in its recognition as a specialist supplier of flatpack cabinetry.

The Cutshop ® journey began back in 2009, at a time when one of the current owners was frustrated at not being able to get a combination of kitchen, vanity, and wardrobe cut to size for his newly developed property. As it turned out, this job was either too small for a cabinetmaker, or too big for a commercial hardware store! Today, Cutshop® has expanded its services and improved upon them to become a preferred supplier of flatpack cabinetry to the kitchen and shop-fitting trade, and a preferred manufacturing partner for designers of bespoke furniture and products - whether that be for a DIY home renovation project, a motorhome fitout, or a custom line of wooden toys.

The service provided by Cutshop® is distinctively different from the current industry provisions, where

the belief has long been held that one has to do everything from A-Z together with all the machinery, factory, and individuals that requires. The Cutshop® concept, turned this conventional thinking upside down, providing largescale contract cutting capacity to customers who either need support for jobs they cannot manage by themselves, or to those who do not have their own machines and prefer to use a manufacturing partner. In fact, many of the customers that Cutshop ® works with do not want the responsibility and expense of managing equipment and premises, or employment of extra people to handle these services in their businesses.

Though it may have taken a while for Cutshop® to get its message across about its uniqueness in

the industry, it soon caught on with many trade businesses, homeowners and DIY pros alike. Now, it has been well established that there is a demand for this concept and associated services from the trade, commercial shop fitting, and kitchen manufacturing areas of business, motorhome fitouts, as well as many other industries.

Since opening its doors and beginning its concept in 2009, the success has continued to flow for Cutshop ® . The same year also saw the opening of Cutshop® Mt Wellington, before brand and trademark registrations were formalised in 2011. 2012 saw Cutshop ® start work on its franchise model, and the franchisor was in place by 2014. After that, it all became about delivering outstanding service

whilst continuing to grow. 2015 and 2016 saw the respective openings of Cutshop® North Shore and Cutshop® Waikato, before a refresh of the brand and messaging in 2017. Finally, 2019 saw the firm celebrate ten years in business, and it did so by introducing a bespoke business model option. Despite the Covid-19 challenges, with multiple lockdowns, 2020 was another record year for Cutshop®

Ultimately, Cutshop® is a firm that provides services that are truly outstanding, and necessary at many different times in people’s lives. How often has a kitchen been designed, only to find that a specific size needs to be bought in order to fit into a gap? That is the service provided by Cutshop®, and its success is fully deserved.

www.cutshop.com

When sizing panel material, generally tools are used which, due to their structural design, are noisy and heavy. The result is stress for man and machine. The light and low noise Diamaster WhisperCut jointing cutterhead is specially designed to meet this challenge. Due to its low weight, noise pollution is significantly reduced and the quality of the workplace is improved. The resharpenability of the system with exchangeable blades also guarantees high cost efficiency. As an option, users can quickly and easily replace the blades on site.

At a Glance

■ Light metal tool body

■ Excellent chip collection through DFC®-technology

■ Optional blade exchange on site or maintenance in the Leitz Service Centre

■ The WhisperCut is resharpenable up to 3 times

■ The WhisperCut PLUS is resharpenable up to 10 times

■ For all conventional machines

■ Diamond tipped

Light, low noise and reusable

■ Considerable noise reduction of up to 5 dB(A) through optimized tool body shape and weight halving

■ Reduced load of spindle and machine through light metal tool body

■ Saving resources due to reusable tool body

How costs are reduced

■ Less tool costs by reusable tool body

■ Reduced costs per running metre by resharpenable cutting edges

In case of cutting edge exchange on site:

■ No service times or exchange tool required

■ Shorter set-up times through constant diameter

■ Optimum knife utilization by exchanging unused cutting edges within the tool

For perfect results on the edge

■ Clean workpiece finish through trouble-free chip ejection and excellent chip collection with DFC®-technology

■ Perfect quality even with demanding panel materials

Freephone: 0800 578 665

email : sales@leitz.co.nz

Diamaster WhisperCut light, low noise and efficient

Click and twist, tool-less installation, easy adjustment, permanent or reversible, strong durable connections. Common themes amongst a range of connectors designed to join a wide variety of materials and for use in a wide variety of circumstances. We spoke to several New Zealand companies with strong furniture and panel assembly connector ranges and asked for some examples of their latest innovations.

Hidden panel fasteners designed and manufactured by NZ company Fastmount. p 45

Made in Ireland, the OVVO® award-winning invisible connector range eliminates hours of assembly time and ensures a close-fitting seamless join.

• No tools, glue or screws

• Covers boards of different thicknesses and material

• Works across a range of joint angles

• Available in releasable and permanent versions

• Joint strength exceeding industry standards

Zipbolt connectors have a unique integrated gearing system driven by a universal hex drive offering easier, stronger and faster tensioning power that is unrivalled. With Zipbolt, you can tension the bolt with hand-held hex driver or power drill in seconds. Zipbolt connecting systems have many applications including counter tops, furniture construction, flat pack furniture, staircase assembly, joinery and more.

NEW! Nesting range available from Fit now.

Striplox suits use on timber, MDF, composite panels, aluminium features, balsa wood etc. Fully adjustable and highly customisable, Striplox is ideal for numerous applications providing leading edge design solutions. Surface or rebate mounted in vertical, horizontal, under mount or top mount positions, Striplox can be used for permanent or reversible assembly and reassembly.

All available from Fit - www.fit-nz.co.nz

Our Joinery Supplies team are here to support your business by providing a

Our team are here to support your business a variety of solutions in one stop.

We partner with the best-known brands in the market and understand the products needed by joiners for the perfect finish.

We with the best-known brands in the market and understand t fin

Latest range of Melamin colours available at your local CARTERS today.

Bestwood Melamine

Both in the cabinet maker/joiner sector and also the furniture industry, the efficient use of resources is more important than ever. There is a high demand for fittings that reduce assembly times. At the same time, chipboard with a lower bulk density is becoming more common practice.

The new C100 10 mm Minifix spreading bolt provides you with both the possibility of quick and easy installation and maximum hold in chipboard with lower bulk density. This is made possible by the innovative spreading sleeve, in which four wings spread out into the panel material.

A common customer requirement is for quick and easy shelf repositioning without damaging the drill hole by repeatedly unscrewing and screwing in fittings.

Häfele provides the answer to this market requirement with the new C20 5 mm Rafix spreading bolt - rounding off the Rafix product family in a perfect way. The quick and easy insertion of the spreading bolt by hand also reduces assembly times and the number of mistakes during use.

Discover more products like these at one of our Discoveries events – or contact your local representative.

New Zealand based manufacturer of hidden panel fasteners, Fastmount, has added two new clips to its Stratlock® Range: the SLFC and SL-M10.

The SL-FC / SL-FC-FR has been designed for solid-style substrates such as sheet metal, fibreglass, MDF or plywood, for customers who don't use framework but want the benefits of flexible panel installation that the Stratlock Range provides.

The SL-M10 combines the qualities of the SL-M18 (single or triple screw install, dual detent fixing) with a new lower pullout load of 10kg, for panels that require more frequent access to services.

The Stratlock Range was originally developed as a heavyduty hidden panel mounting

solution for installing large interior panels onto aluminium extrusion framework. A purposebuilt system, the Stratlock Range is the only product on the market that provides versatility in modular design and adjustable panel installation, thanks to its patent pending dual locking function.

“The SL-FC is ideal for applications where framework or grid structure is not available, bringing greater flexibility to large

or heavy panel installation onto solid substrates. We see the SLFC being used particularly with pre-existing walls being fitted with large panels in contract fitout settings,” says Gregg Kelly, MD & Head of Innovation at Fastmount.

The screw-fix male (SL-M10/ SL-M18) features a double-detent shank which locks into the load chassis of the flush fit SL-FC. Upon the first click, the panel is supported, with a 4mm adjustable

tolerance in any direction to find the correct panel position. The second click then locks the panel into position, secured with a 10 or 18kg pull out load per clip set, making the system ideal for large or heavy decorative panels.

The new SL-FC and SL-M10 is available now from authorized Fastmount distributors worldwide.

www.fastmount.com