Most are already aware of the quality of Scala Drawer system - but it’s also manufacturer freindly.

Smooth Liquid Dampening.

Grass SCALA drawers feature highest quality European made runners with unique liquid dampening technology for a smooth opening experience and quality that will last a lifetime.

Fast Assembly Time.

When it comes to drawer assembly, the ability to have drawer backs and bases all at the same width for every SCALA drawer provide great optimisation for a manufacturer. This means fewer parts to assemble compared to other drawer systems in the market.

Handle-Free Kitchens.

The SCALA Tipmatic soft-close system is market leading technology and is the easiest to not only install but adjust the capacity needed.

Consistency in Design.

Available in three striking colours of Ice, Silver and Stone, there is a shade to suit any design - with a range of inserts and organisers in an exact material and finish to match seamlessly!

Full Range.

Nova Pro Scala drawer sides are available in 63, 90, 122, 186 mm and now introducing 250 mm high sides.

Fast Assembly.

Handle-Free.

3. 2. 1. 3. 5. 4.

4.

5.

4.

5.

GoldenEdge HMR0 is the proven MDF that provides a perfect paint finish. It’s that simple.

Eco friendly GoldenEdge HMR0 (high moisture resistance zero emissions) is rated E0 and comes in 9mm, 12mm, 16mm, 18mm and 25mm thicknesses.

It’s recommended for kitchen units, cabinets,

bathroom vanities - everywhere a perfect paint finish is required.

GoldenEdge HMR0 is just one of the many MDF products provided by Nelson Pine Industries using the advanced technology of the Küsters continuous press and offering an unsurpassed range of board densities and thicknesses.

Master Joiners 4

Paul Ingram reflects on the diversity and differentiation of our industry and how this increases the relevance of a central association.

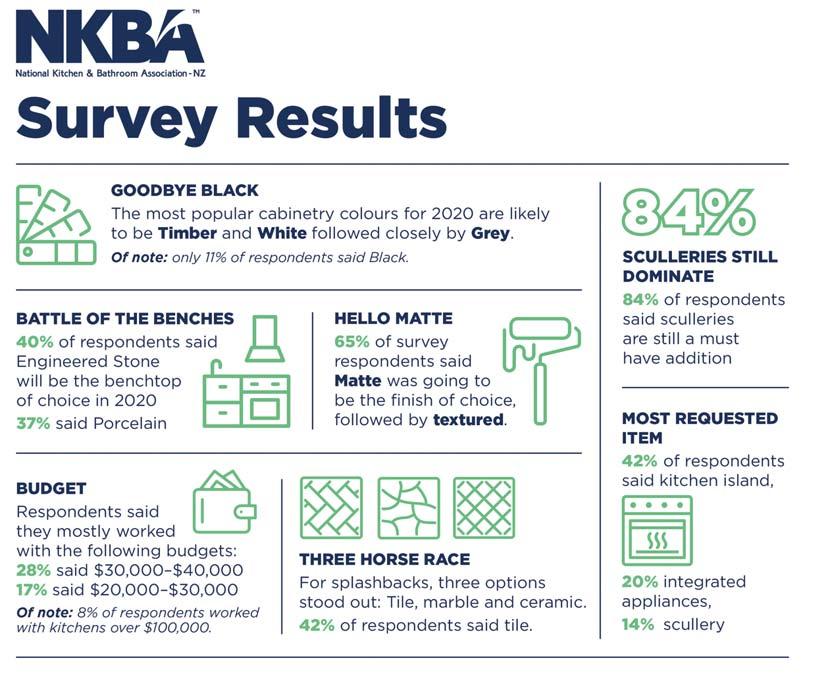

NKBA report 70

The NKBA give us a heads up on their upcoming awards and provide a peek at the results of their recent survey on kitchen trends for 2020.

Steering a Course 71

Ian Featherstone compares modern business to Darwins theory of natural selection. We either embrace and adapt to the changes occuring around us or watch our business die.

Due Process 72

Geoff Hardy informs us on the options available when you discover a mistake in your contract, there are several but it is an area where it is best to get it right first up.

CNC machinery and digital factory systems have become prevalent in the last decade as manufacturers seek improvements in labour and material use. We look at applications of this in some of the joinery and kitchen shops around the country.

Commercial and residential storage is a market segment where innovations and new options are constantly brought to market to accommodate new ideas, materials, design and needs. We asked leading suppliers what they are offering in 2020.

Hideaway Bins recently completed the development of a new laundry bin range. The Concelo Laundry Hamper runs on the same platform as the Red Dot winning Concelo waste bin and is packed with innovative features which raise the bar on what you would expect from a laundry hamper.

LED is a relatively new and cost effective way to illuminate our world. Go back ten years and it was considered a good idea but not commercially viable. We look at what has changed to make it a go to product in commercial and residential design today.

News & Info 4 - 14

Education 62

Trade Directory 74

Classifieds 80

Advertiser index 80

Taupo kitchen manufacturer SMJ Ltd’s business model is to manufacture where they can and have time, and to outsource where they can’t, don’t want to, or are too busy. Their recent purchase of a Felder P200 edgebander fits this model perfectly.

Increasingly our industry has become specialised. Traditionally a joinery company would have undertaken a wide range of tasks and produced a full suite of products. Although there are still some companies around like that especially in regional New Zealand, the trend has been for business’s to remain or to become profitable even viable by specialising in a narrower range of the trade. This hasn’t meant we have lost any diversity but rather more differentiation between joiners. We have Master Joiner members that include Cabinet Makers, Timber Window and Door manufactures, Door Prehangers, Shopfitters, Benchtop Fabricators, Stairmakers, Furnituremakers, and Site Install specialists.

Combined with this are skills and allied trades that we rub shoulders with and even incorporate into our business’s such as glazing, painting, lighting, aluminium joinery, plumbing, appliance retailing, building, drafting, and design. When that is considered the realisation is that not only is it more difficult than previously to define “joinery” but that our reach is much bigger than it might first appear. It’s also a great reason to be part of the Master Joiners network and trade referrals with members who might specialise in something your firm no longer undertakes.

Despite the diversity of business’s within our ranks, we all have common ground. Recruitment and human resources challenges, disputes resolution, insurance complexities, our own and our staff well being, remaining efficient and competitive, and immigration issues. This years Master Joiners Conference themed “Inspire to Perform” addresses these on-your-business topics along with some industry in-your-business opportunities. Registrations will be open soon and I encourage you to get along and to also consider bringing some of your team. There will be opportunity for our associated professionals, non-members and affiliated organisation members to attend too. There is a change of focus this year but also plenty of networking time and time with our suppliers and industry supporters just like we’ve experienced before. The Master Joiners Excellence Awards will recognise the best within our industry, there is a great line up of guest speakers, and both high octane and slower paced activities available.

As the recognised voice of our industry we need to have our say and when doing so consider the reach that we have. In the last 12 months as a Federation we have advocated for safe levels of dust exposure, heath monitoring, industry training, and compliance to Standards NZ, MBIE, Worksafe, and the Minister of Education. If you have an interest in strengthening our voice as a MJ member, associate, or affiliated organisation member, we welcome you and I encourage you to get in touch.

That’s about it from me for this issue. Let’s hope that the economic fallout from the Corona virus outbreak isn’t too great Oh and before I go, check out the Jobs board on the Master Joiners website. A new tool for advertising opportunities within our member companies and for job seekers to register their interest.

All the best

Paul Ingram National President Registered Master Joiners

After five years in the Sydney offices of Biesse as NSW Sales Manager, Dylan Staples recently returned to Auckland to again take up the role of NZ Manager for the Italian machinery supplier. Dylan spoke with JOINERS Magazine on being home.

Good to back?

Yeah, it was a great OE, the business experience was invaluable and Sydney is a great city to live in, but it is good to be back catching up with family and friends and renewing business contacts, we always intended returning and the birth of our second child meant the timing was good. Business is a lot more personal here which I enjoy and something I think I had previously taken for granted.

Do our markets differ?

The product mix in NZ and Australia is very similar, however the uptake of technology in NZ is probably higher. Kiwis are very open to the latest innovations, a good example being edgebanding where New Zealanders have embraced the Biesse Airforce brand and the zero glueline concept.

What does the year look like for the machinery sector?

The current climate in NZ is very positive and very competitive. The year has started well and it is an AWISA year which is always good. AWISA is really a pipeline which sets us up for the next two years sales. Also the trend to automation looks set to continue as labour continues to be the big problem for manufacturers and they look to machinery to assist with that aspect.

What are your objectives for the coming year?

Obviously to continue our strong sales path. On top of that we are always looking to improve our service, identify issues and ensure we are getting our systems right. Part of this will be the improvement in our integrated systems and processes which, as a result we will see faster spare part response times. We will also look to assess levels of priority to reflect urgency of customers needs to provide all our clients with the best service we can - perhaps refinding a little bit of old school personal touch.

We are also initiating new measures including training programs covering preventative maintenance and providing entry level technical skills aimed at improving knowledge and reducing downtime when there are breakages or issues.

The Biesse brand is extremely strong. Its systems, level of knowledge, parts operations and training structures are among the best globally. We will endeavour to make sure that continues to be the case in NZ.

magazine

The magazine for the joinery, cabinetmaking & kitchen manufacturing industries

Official Publication of the New Zealand Joinery Manufacturers Federation

EDITOR

Michael Goddard michael@joiners.net.nz

PUBLISHER

Bob Nordgren bob@joiners.net.nz

As I write this it is raining here in Auckland for the first time after the near biblical (in reverse) 40 days of no rain at all. Can’t say it is not welcome because it is. Anyway, we have a few things to brighten your day in this issue as well what with our look at the latest in CNC machinery and related developments in the software field. The ongoing move into the digital world and its integration with the functionality of modern CNC technology is becoming more and more obvious.

We will see this in the upcoming biannual AWISA 2020 event to be held in Sydney in early July: a must see for the latest for those in the trades as well as architects and designers from a design perspective. The new Sydney Convention Centre in Darling Harbour is proving to be a great venue. The world of CNC, just part of what is on display at AWISA, is not standing still: it is continuing to meet the challenge of relevancy in an ever increasingly complex and diverse business environment.

For those in the design world we have a look at some of the latest in kitchen drawer storage systems and associated wireware. It is interesting to note the steady emergence of new products this year as well, such as different board products and a new paint system. Despite the headwinds we are facing around the world such as this coronavirus thing, we should remember the economic basics here in New Zealand still look good. Being part of a sound industry related trade organisation like Master Joiners is more important than ever in uncertain times. As Paul Ingram the current Master Joiners President says in his column networking is an invaluable part of being a Master Joiner.

This is the start of our 25th year in print and we have some interesting storylines planned for the rest of the year. For Master Joiner members there is of course their annual conference held this year in Hamilton in early June which should be a great event. So read on and enjoy.

Bob NordgrenM42 Aldersgate Rd, PO Box 27 - 513, Mt. Roskill, Auckland, 1440, New Zealand. Ph: 64-9-624 4680

www.joiners.co.nz

ISSN 1173-6836

JOINERS Magazine is the official publication of the New Zealand Joinery Manufacturers Federation. It is distributed to members of the joinery, cabinetmaking and kitchen manufacturing industries and is published quarterly in March, June, September and December. Advertising statements or editorial opinion are not necessarily those of the publisher, its staff, the New Zealand Joinery Manufacturers Federation Inc., or their executives, unless expressly stated. All articles printed in JOINERS Magazine are subject to copyright and cannot be reproduced without the express consent of the Publisher or the authors therein. Advertisements and articles are accepted without liability as to the accuracy or otherwise of the factual matters represented.

James Pulehega joined Hutchco in March 2019 with over 10 years experience in b2b sales with the last two years spent as a key accounts manager to customers of paper & fiber based packaging. With his feet firmly on the ground, James is engaging all levels of industry.

“A major part of my role as the Sales Manager is to strategically grow the business by providing solution-based support in the best way possible that suits the customers’ expectations and requirements. It is one of the many reasons why Hutchco continue to demonstrate their ability as a very successful SME within a very competitive environment. Fundamentally, we want to provide the best service possible without the need to emphasize on the bottom line as without our customers, we wouldn’t be able to do what we do as a business so we appreciate our customer base for their continuous support.”

Quick Fire Questions with JamesHutchco recently brought in 3 new 1mm edgings to match the NZPG Timberland range, what are your customers saying about it? The feedback has been extremely positive with many commenting on how authentic the timber like finish is.

Industry wide there is a move toward producing only 1mm edgings, Hutchco decided to offer both 1 & 2mm for select edgings released mid-2019. How have your customers reacted to this? Colours like Melteca Raw Birch Ply & Rural Oak 2mm have been difficult to keep on the shelf with new orders off to our Portuguese manufacturers each month, so if that is anything to go by I would say better than anticipated. Although there is a notable shift to 1mm our 2mm business remains steady.

What Hutchco products are your customers raving about? The newly introduced Tekton pre-finished 0.6mm Tekton Multiplex Birch and White Oak have been hugely popular along with PROLASER PP laser edging in 22 & 45mm wide.

The AWISA exhibition from 1-4 July 2020 will again be held as the multibillion-dollar International Convention Centre (ICC) at Sydney’s Darling Harbour. The Darling Harbour facility has now proven itself to be absolutely world class. In addition, the location has all the benefits for visitors being adjacent to Sydney’s CBD, public transport, hotels, restaurants, harbour cruises and other tourist attractions.

Now Australia’s premier exhibition, convention and entertainment precinct, ICC Sydney is one of the most exciting exhibition spaces in the world with its combination of firstclass facilities, adjacent hotels and inner-city locations.

ICC Sydney has assisted in revolutionising the city’s business and entertainment offering for both locals and visitors. The complex has become a centre of innovation, underpinning Sydney as one of the world’s most desirable exhibition and conference destinations on the international stage.

It is anticipated that AWISA 2020 show will build on the stunning success of the AWISA 2018 held at the same location for the first time. In 2018 the AWISA exhibition broke past records, visitor numbers were up substantially confirming the decision of holding the exhibition back in its traditional home of Sydney.

Following the 2018 show AWISA chairman Brett Ambrose commented that exhibitors were enthusiastic about the venue. Also, the show received recognition as the largest trade show

of its type ever held in Australia. Mr Ambrose reported that, from a commercial point-ofview, feedback confirmed that the show venue exceeded expectations, was particularly industry participant-friendly, and certainly on a par with the best of the international European trade shows.

ICC Sydney features a striking contemporary design, purpose built to redefine the convention and exhibition experience, and to showcase the natural beauty of Sydney. The steel-glass complex stretches over three city blocks from Darling Harbour to Haymarket and includes an exhibition centre, convention centre and adjoining a 9000-seat theatre and Australia's largest stage.

AWISA 2020 has booked the equivalent amount of venue space as for AWISA 2018. Again, the show will be staged on two different levels of the ICC. Fortunately, AWISA is a show that has a natural split along product lines. AWISA Wood and Panel Processing, the machinery part of the show, will remain on the lower level, and AWISA Design exhibitors will be housed on the upper level there where there will be the added benefits, including a quieter and dust free environment, ‘refuelling’ stations, plenty of relaxing spaces and meeting places.

Space will also be available for companies to hold their own side events, and for industryrelated trade associations to network. AWISA 2020 will be one of the largest trade shows to be held in Australia this year.

AWISA 2020 www.awisa.com

1-4 July 2020

ICC Sydney Exhibition Centre

Darling Harbour

Sydney

AWISA DESIGN

AWISA WOOD & PANEL PROCESSING

The trade show for the cabinet, kitchen, joinery, furniture, timber and panel industries.

28,000 square metres of the latest services over the two levels of the ICC Sydney Exhibition Centre.

www.awisa.com

The 27th edition of Xylexpo, the biennial exhibition for woodworking technology and components for the furniture industry, takes place in Milan at the end of May. 400 exhibitors covering the processing of solid wood, panels and composite materials, to surface finishing, tools, accessories, paints, hardware and semi-finished products are ready to welcome visitors from all over the world. Since its first edition Xylexpo has become a prestigious fair thanks to the

innovative offers of its exhibitors and the quality of machinery demonstrations and technologies displayed. Visitors can directly experience the strength of new digital production methods and the latest updates on technology and materials to maximise efficiency and productivity. The show runs from 26-29 May 2020.

It was a busy day at the headquarters for Dezignatek, part of the NZ Panels Group based in the Auckland suburb of Highbrook in mid February when they held an open day for designers, architects and kitchen manufacturers from all around New Zealand to view their factory facility.

www.xylexpo.com

Dezignatek have been making high quality thermoform doors, drawers and panels for nearly twenty years. They also provide custom laser edging for melamine, acrylic and SoftMatt laminate panels used in cabinetry doors, drawers and end panels. NZ Marketing Manager for NZ Panels Group commented “We had well over a hundred attendees who went in groups on a guided tour through the factory. It was a good opportunity to not only see what Dezignatek do but also what NZ Panels Group do. There have been several exciting new developments including a new automated sanding line and a new automated glue line.”

Comments from attendees suggested a greater empathy for Dezignatek having seen the latest technology being used by Dezignatek and the complexity of their operation and their attention to detail to make every client a happy client.

One of the first Striebig vertical saws. Built in 1959, it is fully restored and located in the foyer of the Striebig plant in Switzerland. It featured the swivel motor with dust extraction and the strip gauge which has since been copied by many but improved by few. Ville Tec have recently gained the NZ agency for Striebig and are looking for Striebig owners, for more go to page 64 .

Machines R Us welcomes Tom Balmforth to their team of service technicians. Tom will be based in Christchurch with a focus on supporting South Island customers.

“Having trained as an electro mechanical engineer with the Royal Navy and previous service roles with Biesse and with SCM Group UK Tom is a perfect fit for our dedicated service team now numbering eight full time service technicians covering traditional machinery along with advanced edgebanders and CNC machines.” says Machines R Us Director, John Fleet.

To book a service or to log a breakdown contact Tom via the Auckland service desk on 09 820 9486.

Jacks are pleased to announce that Neil Dodunski has joined the Jacks team in the nationwide role of Projects Consultant for Advanced Timber Processing, working particularly with the Weinig range of machinery. Neil brings three decades of experience in the timber industry, from starting on the production floor through to training remanufacturing companies in correct operation, architectural detailing and production management. In recent years he was the General Manger of XLam NZ in Nelson, before taking a General Manager position at Timbalink, running their Vietnam operation.

Neil possesses a wealth of industry knowledge in timber manufacturing, and has the operational experience to understand the day-to-day realities of timber production. He is looking forward to sharing his extensive experience and helping Kiwi customers further enhance their businesses.

Neil is based at Jacks’ Auckland branch and can be reached on neil.dodunski@jacks.co.nz or 027 563 0679.

Siedel Findlay has recently joined Burns & Ferrall as Product & Marketing Manager, supporting the Nationwide Domestic Team. With a solid background in the appliance industry – starting in her families’ business and more recently with Kitchen Things for over 10 years – Siedel is looking to bring her product experience and creative skills to this new role.

Siedel will be based at Burns & Ferrall’s brand-new head office, warehouse and state-of-the-art purpose-built showroom located in East Tamaki, Auckland and can be contacted at siedel.findlay@ burnsferrall.co.nz

Mark Demus, the long-standing Technical Services Manager for Mirotone has joined NZ Panels Group in a newly created role of Technical Support Manager. Given much of the company's technical queries revolve around veneer panels, his background in this area will be valuable in assisting architects, designers and joiners with their veneer projects. He will also be providing technical leadership and support across the entire range of NZ Panels Group panel products. He started with NZ Panels Group in early March.

Enko Group, a well known Auckland based kitchen and cabinet hardware supply business has been recently purchased by the Whitehouse family: Cameron and his father Julian along with brothers Kerry and Mitchell.

Cameron, who is the Managing Director comments “Together our family will be proud to continue the legacy of what Enko stands for, a New Zealand company that’s bringing global design and innovation to our shores to add style and function to New Zealand kitchens. If you are in the kitchen and cabinetry industry we look forward to working with you closely again with our tagline ‘Smart Kitchen Systems – Made Easy’ being to the fore.”

The Whitehouse family has a strong connection to the Enko Group with Cameron having been the Account Manager for eight years (2008–16) while brother Mitchell was also an account representative for four years (2011-15). The company supplies a wide range of product for the kitchen including cabinet componentry and drawer systems, handles, pullouts and bins, hinges and door control, Shaws Butler sinks and many accessories. Enko also contract manufacture their own Enko cabinets legs and many of their aluminium handle extrusion profiles here in New Zealand.

For more information about the Enko Group contact Cameron on 021 527 495 or email cameron@enko.nz or visit their website at www.enko.nz

Twodivisions of national building products supply group PSP Limited have merged to form a new business unit within the group called SJS (Stone and Joinery Solutions). This will bring a more dedicated and focussed approach to the Joinery and Specification markets for our extensive range of products.

Based out of our manufacturing and warehousing facility in Poland Road, Glenfield, the merged operation – which comprises PSP’s Stonecraft kitchen benchtop manufacturing operation and its Joinery team - will add stability and strength to the market, and add much more for our customer base in these competitive markets, says SJS Business Manager, Vaughan Brown.

“These proven businesses are coming together in a strategic way so we can add more value to customers from Taupo northwards. SJS is all about stability, consolidation, strength, and adding to our current offering of Granite, Marble, Porcelain, Luxe Panel, Plywood, Splashbacks and Toe Kicks, plus so much more. We offer a superb range of Stone and Joinery Solutions now.

“By creating a single one-stop stone and joinery solutions shop in SJS, we are applying a concerted focus in this area - one business with a dedicated team and website, much more

tuned to the needs of designers, shop fitters, architects, joiners and kitchen companies, as well as residential and commercial developers.” Although the breadth of stone and joinery products SJS offers is already unique, SJS will also be launching new products in the coming months, Brown says.

“As high-end solutions, proven products with high warranty levels and the most advanced granite production in Auckland, we will offer customers more as we seek to help them achieve more in their projects.”

Vaughan adds that the SJS team is filled with experience and advice. “We have some great people involved in SJS, and their complementary skills will add considerably to our market offering. Adam Whitefield has been with us for ten+ years and has extremely good joinery knowledge; Rubie Dickinson comes from the granite benchtop fabrication sector and has strong interest and capabilities in interior design; and Sandra Mower, SJS’s Administration Manager has been with us for 20 years so she is already gluing the team together seamlessly. Adam and Rubie will soon be out visiting customers, so let us know if you’d like them to pay you a visit.”

For more information please visit www. stoneandjoinery.co.nz

Durable

28 Poland Rd, Wairau Valley,

Telephone: +64 9 442 5922

E-mail: info@stoneandjoinery.co.nz

FAX: +64 9 442 5603

Dezignatek, the custom door business for NZ Panels Group, has been rapidly expanding since it took over the Arborline doors business in late 2018, and is set to introduce more innovations in the coming year that will set it up as the ‘onestop door shop’ for joiners nationwide.

With a substantial increase in volume over the past 18 months, the business has invested heavily in automation across a number of fronts. A fully automated spraybooth for its thermoform doors ensures a consistently high standard of finishing. Delamination issues are avoided by repeated testing of panels in a specialist oven throughout the production day to check appropriate glue strength.

A large, German-sourced RobaTech fully automated sanding line was commissioned last year, again resulting in a more consistent finish for thermoform panels and a much faster through-put through the sanding area.

The five CNC machines are constantly busy and with a new automated tracking and scanning system, the myriad of panels associated with one project can be visually tracked at every stage throughout the production line, right through to packaging and despatch. While automation may seem to have taken over, there are more than 40 staff on the production floor involved in everything from programming the CNCs to optimally cut every project, to ensuring doors are sanded, glued, pressed, trimmed, packed and despatched without delay.

On the edge-banding side, a 45 degree edge bander offers a bevel edge for melamine doors or a straight or bevel option for acrylic doors. Two other laser edgebanding machines complete the custom-edging offer and can edge the range of soft-matt laminates from Prime Panels.

On the horizon?

With a consolidation of Arborline production into Dezignatek, you can expect to see the thermoform colour range reviewed to present a ‘best of the best’ with some new additions added to boost the range. A new online ordering system is currently being trialled with clients and following their feedback, a wider release will be available – focusing first on the edging business, and then moving to include thermoform orders.

Some additional value-add services that will reduce work for joiners is also on the cards – we’ll give you more detail in the coming months. And if you want to check on news or be sure you’re always up with the latest range, make sure you visit the refreshed website.

www.dezignatek.co.nz

QUALITY CUSTOM FINISHING

FAST AND RELIABLE TURNAROUND

Check out our new website for Thermoform colours and profiles, technical resources and edging options.

Dezignatek can provide a seamless laser edge on more than 40 melamine colours, 15 acrylic and 5 Soft-Matt laminates. Choose from 35 thermoform colours and

and panels custom-made by Dezignatek.

CNC machinery and digital factory systems have become more and more prevalent in the kitchen and cabinetry industries in the last decade as manufacturers seek solutions to scarce labour resources while looking to improve accuracy, material usage, processing speed and factory throughput.

We discuss the options available with both suppliers and users and find that 5-axis CNC’s are big sellers at the moment for both panel and solid wood users.

The high technological content of the world’s most popular machining centres, meets the requirements of wood industry professionals.

Thanks to the integration with advanced CAD/CAM bSolid , the high-tech becomes accessible and intuitive for all users.

Western Caskets in Kumeu just out of Auckland are one of New Zealands largest casket manufacturers producing over 10,000 caskets a year. Constant growth since its start up in 1979 has seen it regularly update its machinery and kept it at the forefront of technological innovations, no more so than it latest purchase, a pair of Accord fx 5 Axis machines from SCM which virtually eliminate sheet handling while enabling work on all faces of the panel.

The two SCM Accord 25 fx’s are full five axis gantry machines one set up with an individually motorised pod & rail system and the other with a high/low vacuum system, together they allow for great flexibility in handling sheet material through the casket manufacturing process.

For Western Caskets the purchase was a back up and replacement for their SCM Ergo CNC which was getting to the 15 year age mark. It represents their third generation of SCM machinery, however they are not exclusively loyal to the brand and always look around to find the right machine for the job.

“We were originally looking at a single, bigger machine,” says General Manager Alan Eastwood. “But we talked to John Fleet (from SCM dealer Machines R Us) and he suggested because of the nature of our work and high throughput a single machine would be operating at its upper limits, so suggested a set up of two CNC’s, one set largely for the manufacture of our lids and bottoms and the other to produce the carcass in between.”

“We went with that option and it has worked well. One of the SCM Accord fx’s features independently motorised pods and rails and is suited to the production of our carcass work. Once the cutting phase is complete the pods and rails automatically open allowing access for further edge work without handling or moving the piece. This wasn’t readily available elsewhere and had real appeal to us.

“The other Accord is set up with a high/low pressure vacuum system ideal for the way we manufacturer our lids and bottoms. It enables us to release waste and off cuts while keeping the components in the same place for further profile work.”

we are now able to do all panel processingnesting, edgeprofiling and horizontal drilling - without handling the panel.

“This dual set up really does give us improved flexibility and functionality. We simply select the range we are wanting to manufacture from our library and place a sheet on the machine. The pods and rails know where to go and the operation is largely hands free as it processes each sheet, doing all cutting, drilling and edge profiling until only the finished component is left.”

“We also find the onboard software, Maestro, very good. It is easy to use, suits our requirements well, and we are able to make changes on the fly (not all caskets are off the rack) to enable individual custom sizings if required. And if there is an issue at all associated with any aspect of the machine there is always only one call to make.”

“We are very happy with the purchase,” says Alan. “John and his team at Machines R Us are very good to deal with, his advice on machines and their aptness for purpose is always relevant and their service and diagnostic skills are very good if we do run into issues.”

for solid wood drilling and routing

CNC machining centre providing utmost performance with minimum investment. Designed to meet the needs of small and medium-sized companies, it combines state of the art technology with extreme ease of use for flexible productions of doors, windows, stairs, solid wood parts and for machining wooden and extra-wooden panels: plastic, composites, resins and light alloys.

The PRISMA machining heads with 5 interpolating axes are designed for the processing of solid wood. The ideal solution for windows, doors and stairs.

The MATIC bars worktable with direct transmission system and independent drive units, assures the complete set-up in seconds. Simple and quick replacement of clamps and suction cups through the exclusive rapid locking device.

At the HOLZ-HANDWERK trade fair, HOMAG will show woodworking shops the specific opportunities that digitalization already offers. Clever aids support work processes and simplify the user’s working life with small steps. Specifically, visitors to the trade fair in Nuremberg will be able to see two proven, integrated concepts that consist of machines, smart hardware and apps. These demonstrate holistic customer solutions for the networked, digital workshop, specially for joiners.

Introduction to digitalization

With the introduction to digitalization workshop concept, HOMAG is presenting simple entry-level solutions that allow the user to increase transparency in their production, recognize potential for optimization and improve existing production processes and offers the following digital assistants to support the production process:

1. Configuring furniture easily: cabinetCreator

This furniture configurator allows users to quickly and easily configure the furniture they want using their tablet, laptop or desktop PC. As part of a step-bystep process, they can draw on a selection of pre-defined basic forms, which adapt intuitively to construction parameters entered by the user. Users can also create their own libraries and save their own design rules and use them later for new models. Once the furniture has been designed, cabinetCreator creates an appropriate selection of fixtures based on fixture data from all established manufacturers. The furniture can now go into production: all data required for production, such as drawings, parts lists and CNC programs can be created directly from cabinetCreator and then exported.

2. Production data at a glance: productionManager

Many businesses still use handwritten parts lists and drawings in paper form. The productionManager—the digital job folder—is used to ensure

that the data is used consistently from the foreman's office, through production and up to the bench room. It summarizes all production-related data and replaces the individual paper documents. Users who have created their furniture in the cabinetCreator can easily import all of the data into the digital job folder with a click of the mouse and thus retrieve the data at any time via the tablet. Data from CAD/CAM systems or industry solutions can also be imported. Joiners now always have at their disposal a transparent status of all jobs and can easily add further parts.

3.Optimizing cutting patterns: intelliDivide cutting

This optimization software creates cutting patterns based on different criteria (e.g. low waste, optimal use of offcuts or simple material handling) and issues a parts list— regardless of the type of saw.

4. Label printing at the manual saw too: productionAssist Cutting

With this cutting assistant, carpenters have a digital assistant that supports them directly at the saw in the workshop. The assistant can be used flexibly in conjunction with circular saws as well as upright and horizontal panel saws—irrespective of the type, age and manufacturer.

In the first step, users transfer their cutting patterns from the intelliDivide optimization software into the productionAssist Cutting app. They then select

the specific cutting pattern they need at that precise moment. When users are cutting the parts, the productionAssist Cutting app gives them a continuous, precise overview of the status of the cutting pattern (even for manual saws): which parts have already been sawed? Which part is suggested next?

Users can then print the labels for each part at the click of a button using the label printer provided in the set. As a result, every part can be clearly identified. At the same time, every label provides the correct processing information for the subsequent edge banding machines and CNC processing centers. The result: complete production data from the first process step.

5. There’s a slot for every part: productionAssist Sorting productionAssist Sorting is the digital assistant for sorting furniture and components at the workstation in the workshop. The assistant has two decisive benefits: it ensures that all parts for the assembly in the bench room are complete and avoids time-consuming searching for components. The prerequisite for using this sorting assistant is a special sorting rack. Users scan the barcode on the workpiece and receive a suggestion of which rack compartment the part should be sorted into. In this way, the users pre-sort the parts for assembly according to the individual items of furniture. The result is a simple, fast and secure process.

At HOLZ-HANDWERK, HOMAG will showcase these new features in a workshop with the following machine technology:

Precision saw: SAWTEQ B-130

The SAWTEQ B-130 is the smallest HOMAG panel dividing saw. It costs little more than a well-equipped circular saw while providing a much more precise and efficient cutting process. A cutting length of 3800 mm is now available as an option. Amongst other things, the saw is equipped with:

• CADmatic 5:The highperformance HOMAG saw control system with intuitive operating concept and clear management functions can communicate with tapio, as well as with other machines and software solutions.

• module45:With this unit, users can also complete miter cuts on the panel dividing saw at the same time.

• intelliGuide basic: The user guidance allows for clear processes that flow well, fewer errors and thus increases output.

Edge banding: EDGETEQ S-200 (MODEL 1130 FC)

This entry-level model can process edges up to a thickness of 5 mm and workpieces up to a thickness of 60 mm. What is new for this machine is the higher feed speed of 11 m/min. Glue application can switch flexibly between EVA and PUR according to requirements— such as for the production of bathroom furniture that requires resistance to moisture.

Comprehensive CNC processing: CENTATEQ P-110

Sawing, drilling, trimming: the CNC machine can be used universally for different materials, whether they are panel materials or solid wood. The machine also offers 360° clearance and allround bumper safety technology. This allows the machine to be freely assembled and converted.

CONCEPT 2 - Networked, digital workshop - to be continued in future issue.

Exacting as many efficiencies as you can is part of operating a successful business. So it is for door manufacturer Bennett Doors based in Taupo who have recently invested in a five axis CNC machine from Holzher, the Dynestic 7535. This machine with it’s 5 axis cutting spindle and a 2.2 metre deep grid table is the flagship of the new series of nesting machines available from Holzher.

JOINERS Magazine spoke with owner Craig Bennett about the new machine and the advantages it will create for the business.

The company have been around since 1998 making a wide range of doors including interior composite and entrance doors including solid wood along with an impressive range of door handles and other accessories. They have three staff on the floor including Craig’s son Ben along with Craig.

“Up until now virtually all operations in the manufacturing process have been by hand. These doors are produced for a wide range of clients including merchants in the area for whom we make prehung doors and a range of building companies and individuals for both new as well as renovation projects.” comments Craig.

Keeping up with an ever increasing demand led Craig to look at ways to increase production.

“Efficiencies are what it is all about. This new technology with it’s solid gantry design ensures great precision and optimum cutting and drilling results through its two synchronised axis drives which give it permanent axis stability and guaranteed axis alignment. Also with the large Z axis operating range there is plenty of room to machine special projects both on raised cups or the flatbed surface. This saves time and money. The new CAMPUS software package which we are learning more about every day is quite impressive.”

The high flow nesting table ensures optimum vacuum flow. The double acting suction pads enable the clamping of doors, stairway components and such like making the five axis CNC machine a real all rounder with virtually unlimited machining options. Interestingly, the 7535 also makes it possible to process lengths over 6 metres. The liquid cooled five axis cutting spindle is supplied with 10kW power as standard with a speed range of 1000 to 24000rpm. High performance 12kW and 17kW with controlled axis locking are also options.

Drilling and cropping of door frames is a quicker and highly accurate process. With the software a library of door designs can be stored for easy retrieval. Ben has been learning the ropes with the software and has found it easy to operate. “We will have everyone eventually able to operate the machine so that we all remain multi tasked that keeps us upskilled and gives us variety on the floor” says Ben.

Craig chips in “We are in really busy times at the moment here in Taupo and we see this CNC machining centre as a means to expand the business by keeping our clients existing and new, happy and well supplied.”

The machine was supplied and installed by Mike French and his team at Technical Machinery Services who are the New Zealand agent for Holzher. They provide not only training of staff but also service back up.

Craig and Ben wish to extend their thanks to Raj, Mike, Cam and Simon for their continued support and expertise. From the initial stages of ordering through to set up, their technical advice and training has been invaluable.

www.bennettdoors.co.nz

five axis technology makes for more efficienciesSimon, Melanie, Ben, Craig, Ross and Dynestic.

“drilling and cropping of door frames is a quicker and highly accurate process”

The LUMINA series offers a unique combination for panel processing - two systems for perfect invisible joints; the Glu Jet application system for standard use of PUR glue and LTRONIC, the laser edging unit from HOLZ-HER enabling processing at unbeatable speed and cost efficiency.

The Glu Jet system is unique in its accuracy and performance as the glue is perfectly metered to the size of the board used. PUR glue is just a matter of placing the cartridge into the machine. The complete changeover process is handled by the ltronic software and takes no more than 3 minutes.

The Evolution machines on all sides to automatically produce the required workpieces from panel strips previously cut in the longitudinal direction. The XCut mode completely eliminates cross-cuts otherwise required as the machine is able to check the size of board inserted to make the components required.

French, 021 353 632, mikef@techms.co.nz

Pillay, 021 504 929, raj@techms.co.nz

“We can land a European campervan in NZ, fully kitted out cheaper than we can buy the materials we need to build one of ours here in Auckland.” With this statement Managing Director of Action Manufacturing Grant Brady lays out the stark reality of the commercial environment they’re operating in. At their Albany facility on Auckland’s North Shore, ACTION are fitting out up to 750 Recreational Vehicles (RVs) a year.

Grant’s not complaining when he points to the apparent affordability of European RVs. Instead he’s pointing out a crucial advantage ACTION have. Although apparently cheaper, a European RV is only designed for 15 – 20 of domestic use a year, for a decade or so. Compare that with ACTION’s vehicles, which are built to withstand 240+ days use a year for six years on the roads around both NZ and Australia (ACTION are exporting 40% of production into AU.) “And then they’re sold and used for another 15 years or more as someone’s private RV. It’s like the difference between buying a door handle for your house, and a door handle for a hotel,” explains Grant. “As with a hotel door handle, our RVs are designed and built with durability in mind.”

It’s this durability, alongside the consistent quality of their RVs, that keeps this proudly Kiwi company busy producing for many of NZ’s well-known RV rental companies, including Kea, Britz and Maui. Durability is what dictates ACTION use of 15mm European ply rather than the traditional 12mm. In the same vein, 2mm edgetape is standard throughout their fit-outs, and the production method is cam-and-dowel and glue. Heavierduty materials and hardware are essential to deal with the banging and scraping RVs receive during their rental years.

Durability was also a consideration when ACTION came to replace one of their aging CNCs. Having grown their production from jigs and power-tools through CNC nesting over the years, in 2019 they chose to take the next step in efficiency and invest in a complete CNC nesting cell. “We’ve proven the value of efficient manufacturing over the years” says Grant, “and so decided to step up our investment in machinery, in the expectation of even better results.”

That investment included a new Anderson Evo CNC cell, and a Homag 1650 Edition series edgebander. Just a few months in, the improved efficiency in the machine-shop is already clear. Machine Shop Team Leader Phillip Meads lays it out simply: “Our CNC processing time for

a sheet has more than halved” he says. “We can process a sheet in around 8 minutes now.” Given ACTION go through between 18,000 and 20,000 sheets of ply a year, halving the processing time is very significant.

Anderson’s EVO cnc comes with a twelvestation tool carousel for fast tool changes, while pop-up stops and vacuum zones give flexibility for processing. In addition to being fast – up to 80m a minute – there’s a scissor lifting table, a pusher and an off-loading conveyor table, all with dust extraction. After processing it’s over to the Homag for edgebanding - where a Compakto return table adds to the overall efficiency of production.

Mark Julie – Production Manager – confirms that the machines from Jacks are performing as promised. “We’ve had to change a few processes as a result of moving to a newer technology” he explains, “but in general the changes have been related to software.” ACTION have invested in AlphaCam in their busy design office, and transfer machine files to the Anderson Evo CNC via USB. CNC Operator Logan Steven Brown explains the process. “We get the design file for each vehicle from the office all fully nested. We simply open the file, run the nests on the EVO, and then put the labelled parts to our trolleys for transferring over to the Homag.”

Another critical factor in ACTION’s investment decision was the back-up and support available from Jacks. Anderson and Homag machines are renowned for their reliability, but when things do go wrong then Action need fast and effective support – or their Albany site’s assembly teams (with 85 staff) can quickly run out of materials. Jacks’ large and experienced service team can provide the timely support they need. Another back-up:ACTION have kept a couple of their older machines – a CNC and edgebander – to cope with any unexpected overflow. Although so far they’ve been largely redundant.

With their continued growth – the company is spread over three sites employing 220 staff – ACTION are a success story for NZ manufacturing. From the early days of powertools and jigs to today’s modern machine shop employing 8 staff, ACTION’s willingness to invest in new technology is reaping rewards. As Australasia’s leading quality vehicle specializer they represent the excellence and efficiency that lives behind the ‘proudly made in New Zealand’ brand.

Over45 years the Anderson Group has built a reputation based on speed, service and the outstanding reliability of its products. The company offers experience and expertise in the manufacturing of CNC machinery that few other companies can match.

Since their launch, Anderson’s award-winning GS series nesting cells have been unsurpassed in the woodworking industry. The GS is focused exclusively on nesting - without design compromises that are made to enable other types of processing. The result is the fastest nesting CNC in production - Anderson has been able to extract the maximum production capacity from the machine concept, and bridge the gap between conventional nesting routers and book-cutting beam saws.

With an average nest time of around one minute per/m2, the GS can produce up to twice the output of a traditional nesting CNC router. And because the GS does the complete process of cutting & drilling then processing times compare very favourably to using a beamsaw then drilling machine.

The GS nesting cell is the benchmark for speed and efficiency, as anyone who saw the GS in operation at the last AWISA will confirm. Using the same linear motor magnetic drive technology as used on the world’s fastest MAGLEV trains, both X & Y axis offer an agile and powerful movement. While cutting speed is always dictated to by material and tooling, the GS’s rapid vector speed is an astounding 169m/min. While rapid speeds are important, even more critical is how quickly you can get there. The advanced acceleration ramps between operations on the GS are lightning fast, making significant time savings – especially in the drilling operations where a larger proportion of the processing time is spent in rapid moves.

The GS has a bed size of 3700 x 1900 complete with four vacuum zones to suit NZ sheet sizes. Other specifications include two 300m3/h Busch vacuum pumps, a 15hp liquid cooled electro spindle complete with 10 position tool changer, and the exclusive ‘Smart Drill’ high speed boring technology with 32 vertical drills. Other features include an infeed label printing station, and auto loading and simultaneous unloading complete with outfeed conveyor.

Interested? See the future of panel processing for yourself at Jacks’ showroom in Auckland - there’s a working cell on the showroom floor. Contact your local Jacks representative for further details.

We’ve proven the value of efficient manufacturing over the years” says Grant, “and so decided to step up our investment in machinery, in the expectation of even better results.”

Leitz Tooling have been making tooling for the woodworking industry for over 140 years since the first drills were produced by Albert Leitz back in 1876 in Germany. The Leitz family has owned the business to this day.

Reliability and longevity are the keys to the success of Leitz Tooling. No more so than with the servicing of diamond tooling. The servicing of pre milling cutter heads for edgebander machines is done using the latest diamond sharpening machines and technologies in their Penrose Service Centre in Auckland. There is minimum machine downtime when you book their overnight service. They also offer a reliable tool pickup and delivery across Auckland free of charge.

“Even the best quality tool can only provide optimum performance if it is regularly maintained by experts.” comments Leitz Tooling’s New Zealand Manager Wolf Hoheisen. “We use in our Auckland Service Centre the same machinery and programmes as in our tool production at Leitz in Germany. This gives our tools consistent top quality be they brand new or resharpened from our service centre. What’s more, we can use the same technology to sharpen tooling from all manufacturers.”

Leitz Tooling has some 140 service centres worldwide where great importance is placed on quality. This is underwritten with its quality management system certified to DIN ISO 9000 standards providing a uniform quality worldwide.

Joinery IT has been serving the New Zealand market for more than 11 years now. Principal Phil Smith recently announced a few changes to the face of their business.

Beatty Smith (Phil’s mum) who has been doing a wonderful job looking after the accounts since Joinery IT was formed is to retire. Sandy (Phil’s much better half) is learning the admin role, taking up where Beatty leaves off. Customers will no doubt hear from Sandy over the coming months.

Extra support - A new guy… most Cabinet Vision users will know him already, Darryn Currill is based in Whangaparoa. He started with Joinery IT in the third quarter of 2018 bringing loads of detailing experience. A veteran user of CV with more than 10 years’ experience at DBJ Furniture.

And to the big news … the office in Matamata has been sold. The proceeds of which have been used to custom build a mobile office. We are fine tuning things locally in preparation to spend the next 2-3 years travelling the length of New Zealand. Expect to see us in your area sometime soon.

That is the big question that faces most cabinet makers at some stage. This decision point arrives at varying times and for varying reasons.

• Perhaps you are just starting your business and would like to include software from day one.

• Your business has been operating for 5 years, staff members have increased and your workload is far too heavy.

• Your business is now 10 years old, is well established, but you or a staff member are taking too much time to get jobs organised for production.

• Your customers are now asking to see some 3D prints of their project.

• You have been trying to employ another tradesperson, but have not been successful.

These are just a few of the issues that arise and will prompt you to consider a software program. At these points some businesses have researched the software issue and discovered that it is very good decision to purchase.

Why then have some businesses been reluctant to go down this path?

Let's start with the obvious reason, cost, they feel they cannot justify it. Nothing could be further from the truth. Quality software is now available for as little as $19 per day (and that is for the top level Pro Toolpath CNC linking version, much less for lower versions).

So at around $6.50 per day will give you a full design package, costing, cutting and optimising. You simply lay out your floor plan and from that point create 3D views for your client, fully dimensioned 2D views for your workshop, optimised sheets for cutting and cabinet parts lists for construction.

A job cost has also been created based on your labour times and material costs. There is a conservative 3 hour saving in the office preparation, 2 hours in the workshop and an hour on site (all cabinets and their parts are numbered automatically). As you can see the program has well and truly paid for itself in labour saving alone.

At this point some businesses dig their heels in and say “no I can't afford to pay out another cent”. This is where the head must rule. That $6.50 is already accounted for in their current production methods; It is being spent many times over. A software program not only decreases your production time, it also helps you to eliminate costly mistakes. How many times has a number been written in the wrong sequence, and not discovered until it's too late?

Another reason that is mentioned for not wanting to purchase is “we custom build; a computer program will not suit our business”. A quality program will give you the ability to set your construction methods and allow you to change your methods to suit architectural requirements.

Support; this is a big issue with all cabinet makers, who feel if they purchase software, they will be left in the dark or have to pay out for extra costly training. With all software It is vital that you receive good backup support, phone and remote assistance must be provided in the initial cost of the software. There should be no need to sign up for yearly maintenance. You purchased the program, so that should be included.

One of the big dislikes for most cabinet makers is the quoting process; it can be a very time-consuming task. The simple fact is that you must produce fast and accurate quotes; unfortunately our industry has always offered free quotes, clients expect this and don't understand all of the variables that are now possible in even the simplest kitchen.

“Please provide a quote with three different door finishes, and three different drawer styles. Not to mention the bench tops and the internal fittings”. If a miscalculation is made on a couple of doors, this can now cost you over $100.

With a software program you can quickly and accurately quote this situation. Simply place the required cabinets on the floor plan (no need to do a finished layout) add any accessories, generate a cost, then generate a different cost with any material.

Software for cabinet makers has reached the point where you can say “when will we purchase a program not will we purchase a program”. You can no longer afford to be spending wasted hours doing job preparation. Consider the software as another production tool, the same as your existing machinery.

There are many other benefits that the software will bring to your business that will help you get better organised allow you to lighten your workload. All jobs will be quoted and constructed the way you want them, provide a more professional look to your clients and help you achieve more sales.

The 3D kitchen program has been in the market place for over 26 years and has a well established client base. The software is provided in a way that all cabinet makers will understand and is supplied with construction methods set up to your individual requirements.

If you have reached the stage in your business where you know that things need to change, you will want to consider the 3D Kitchen software option. Operating a cabinet making business can be a very demanding task. You need to take advantage of anything that is able to assist you. Software is now a high priority on the list. For more information about integrating a software package into your business contact:

Harley Adamsm: 0274 813 312

w: 3dkitchen.nz

Whether you need a saw for breaking down panels or dimensioning solid timber, the Fimal Concept 350 Plus has the versatility to do it all. Ripping, crosscutting, mitre cuts, compound mitre cuts or grooving, all processes can be carried out on the Fimal Concept 350 Plus.

With its small footprint (less than half the required space of a traditional panel saw) the Fimal Concept 350 Plus is sure to attract the attention of those with space restrictions. It also significantly improves workshop safety. The sawblade is completely enclosed -

before, during and after the cutting operation - effectively eliminating the possibility of the operator coming into contact with the sawblade. Due to the pressure beam securing the material as it’s cut, the accuracy and quality of cut is also greatly improved. Even better, the pressure beam traps the dust within an enclosed area, meaning more effective extraction.

In addition to improved safety, a small footprint and versatility, the Concept 350 Plus can double panel-processing productivity: you can process 2 x 18mm panels stacked on top of each other in one cutting action.

Fimal’s Concept 350 Plus comes in 3 sizes: 2600mm, 3200mm & 3700mm. Each model can be customised with a range of optional equipment such as a laser to preview the line of cut, cutting optimisation software, digital displays and much more.

Fimal saws are available exclusively from Jacks. For more info contact your local Jacks rep, call 0800 522 577 or email sales@ jacks.co.nz

in Italy, the Fimal Concept 350 Plus combines the benefits of a Panel Saw and Beamsaw

Ithas been some four years since we last spoke to Greg O’Kane, Managing Director at Waipukurau Joinery about his business and where things were heading. A member of Master Joiners and operating from his purpose built factory site, he has continued to progress the business down the path of using the right technology for the job. The business continues to produce quality kitchens and bathrooms, staircases and other joinery components. Bob Nordgren from JOINERS spoke with Greg about the latest development.

Looming ever larger has been the manufacture of benchtops for his kitchens. “We have found we have needed a machine that can handle bigger laminate and acrylic sheet sizes as well as combining more flexibility and the inclusion of parametric software.” Greg comments. Greg turned once more to Steve Fifield at Proform CNC Ltd for the answer. Four years ago they installed a Proform AT25/13 flat router for Greg.

“That machine has been great but we needed to get a bigger machine” says Greg. So they upgraded to the Proform Fusion CNC router ATC 38/13.

“This machine had a number of improvements we were looking for.” explains Greg “First off it had a bigger flatbed (1300mm by 3800mm) so we could use bigger sheet sizes, and it has a 12 head rotary tool changer which makes things quicker without losing any of the efficiencies the earlier machine had. Furthermore the ATC 38/13 utilised parametric software which along with the other two features gives us greater flexibility in manufacturing, especially benchtops.”

The setup will allow them to have one person to operate it and make benchtops. It remains a simply operated, nested style machine with an on board computer using the Windows 10 operating system. The spindle is more powerful (a heavy duty 9kW HSD router). The rotary tool changer is ideal for

counter top manufacture and it still has a relatively small foot print at 4550mm by 1550mm as well.

Greg has had it since November 2019 and seen production improve. “It remains an efficient and reliable machine with the service from Proform second to none. It makes just in time manufacture a reality and enables us to keep close control on costs.”

And the future? “Just as it was four years ago: continuing to make good use of technology and make efficiently good quality product for our clientele.”

For more about Waipukurau Joinery contact Greg on 06 858 8313, email greg@waipukuraujoinery. com or visit their website at www. waipukuraujoinery.com

Acero have been working with one of Europe’s leading manufacturers of sinkware to develop a range of tight radius pressed bowls with a 15mm radius corner.

Very few have mastered the process of deep draw tight radius technology to produce a product to such a high standard. The corners are clean with no distortion and the finish is to the very highest European standard. Investment in robotic technology and stringent quality control ensures each bowl is produced to the same level of quality and the polish is even every time.

The range features top mount and undermount as standard, 15 litre per minute overflow capacity using waste kits from Italy, robust 1.0mm thick stainless steel and a high end silk finish

The Acero Pressato Range has four single bowls and four double bowls. Each double bowl has a slim 20mm bridge to maximise sink volume for the cabinet beneath. The PR220 features a large 450 x 400mm main bowl and a 180 x 400mm second bowl and with the 20mm bridge it will easily fit into 700mm cabinet.

Acero are very excited to be able to offer another range of sinks designed to suit the New Zealand Market that align with their standards of high-quality and value for money that they are known for.

Another exciting addition to the Acero product range is the Mercer Aurora black colour. In keeping with current trends of matt black, the black stainless steel Aurora bowl is an intense black and extremely durable. PVD colouring technology produces a

durable product that is difficult to scratch and unlike other coloured sinks on the market the colour process uses no liquid meaning it is one of the most environmentally friendly colouring technologies available. The new colour is available in all of Aceros Aurora

product range including single bowls, double bowls, taps and accessories including the range of waste kits. The black wastes kits are a perfect match for the black Duro Granite models, allowing you to swap out the stainless steel for an all black look.

The New Black Aurora range is available now, for more info go to www.acero.co.nz

Acero have been working with one of Europe’s leading manufacturers of sinkware to bring to New Zealand, a range of tight radius, pressed bowls with a 15mm radius corner. Very few have mastered the process of deep draw tight radius technology to produce product to such a high standard. The corners are clean with no distortion and the finish is to the very highest European standard.

Easy access is the hallmark of good storage systems anywhere. In the residential environment visibility and design is equally important. It is a market segment where innovation, new options and new materials are constantly brought to market. We asked our leading suppliers for their latest incarnation of some of these storage options, from cutlery drawer organisers, to portable racks for cleaning products, to pantry pull out options, and options to maximise use of the kitchens deepest darkest corners

We’ve seen a distinct move away from cupboards and towards drawer-based storage in recent years, to the point where, even if the visible cabinet panel is a hinged door, often you’ll find a stack of drawers installed behind it. And this makes sense; drawers make the most of the cabinet interior and provide accessible, ergonomic access to contents.

What’s the next step? Surely, it’s organising within each drawer not just to maximise space, but also to minimise noisy content movement and to reduce clutter, thus aiding fast retrieval of items.

Harn Ritma® System

Movable divider panels and lateral dividers to fit the Harn Ritma® soft close drawer system make it so easy for your clients to set their drawer spaces up exactly as they wish; creating plate stack spaces, slots to keep those pesky plastic lids in one place, or keeping various sorts of foodstuffs together.

When it comes to drawer trays, you, or your client, may be after a top of the line stainless steel system, budget-friendly plastic trays or a designer, flexible arrangement. Whatever the preference, Fit has options to suit:

Open Space is a flexible drawer organizing system that utilises plastic profiles, steel dividers and wooden boxes in a freeform manner. Black plastic profiles, trimmed to fit from 1200mm lengths, sit at the front and back of the drawer. Steel dividers, in 2 height options, fit into pre-cut slots in these profiles; the taller

ones are perfect for creating plate stack spaces. Wooden boxes, available in two sizes, nest within the dividers. Mix and match components to create your own customized drawer layout.

Impala Inoxa. Functional and durable, this stainless-steel drawer organiser system is completely modular so you can create the perfect cutlery drawer or utensil drawer configuration. It's also removable; ideal for easy cleaning and carrying to table or BBQ. Fit have a huge range of pre-assembled kits, or you can customise from the individual components. And, for maximum convenience, it's also dishwasher safe.

Impala Plastika. Elegant yet functional, these drawer organiser trays are made for Fit in Germany, by an ISO-9001 accredited company established in 1993. They’re made from high-quality plastic, which is selected for its suitability for this use.

Multiple sizes, easy clean surface and inserts for spice bottles and drawer knife block inserts make this system a great way to maximise kitchen drawer organisation and minimise frustrating, time consuming clutter.

For the budget conscious, Fit also offer practical, economical cutlery trays, utensil trays and spice bottle organisers. Also very popular is their anti-slip drawer

matting in black, grey and white; excellent for preventing glasses and crockery from slipping and sliding in drawers, with the added benefit of helping to reduce noise.

Contact your Fit rep, phone 0800 852 258 or email sales@fit-nz.co.nz to discuss your drawer organising requirements.

These products are all featured in Fit’s brand new 2020 issue of their general storage project book – Making Your Space Work, which covers, drawer and door systems, wardrobes systems and drawer organisers. Contact Fit to order hard copies or download a copy from https://www.fit-nz. co.nz/fit-cataloguesand-downloads

DISPENSA - Offering a clear view of the contents from either side.

Trays and baskets can be individually hung at heights to suit the contents,

Achieving optimum functionality through user-centred design has been a top priority for Vauth-Sagel of Germany since its foundation more than 50 years ago. Their expertise with wireware is well-established, with their Saphir and Premea style kitchen storage units having been available in New Zealand through Fit for several years.

Planero, launched here in 2018, is the first shelf developed by the family-run kitchen system manufacturer with a flat powder coated steel basket design; it is, in effect, the 21st century equivalent of wireware!

Planero combines high design features such as a contemporary grey colour and barely visible technical components for brilliant aesthetic appeal with established function and comfort values. This Planero pairs attractive, optimal storage and fast, simple installation with immensely practical and convenient function, such as shelves being easily removable for cleaning. Initially launched with 4 models, Planero has proven popular and 3 further models have joined the New Zealand offering.

Your clients can now select a premium Vauth Sagel Planero unit to suit their needs;

• VS TAL Larder for a fixed front pull out pantry

• VS COR Fold and Cornerstone MAXX units for blind corners

• VS Cor Wheel Pro for corner units with two opening doors

• VS SUB Side and VS SUB Slim under bench pull out units. And

• VS SUB Basket, a pull-out tray for underbench installation that also perfectly suits stacking into drawer based pantry storage.

Contact your Fit rep, phone 0800 852 258 or email sales@fit-nz.co.nz to discuss your Vauth-Sagel kitchen storage requirements.

These products are all featured in Fit’s brand new 2020 issue of their Premium Kitchen Storage with Vauth Sagel project book. Contact Fit to order hard copies or download a copy from https://www.fit-nz. co.nz/fit-catalogues-and-downloads

Boasting impressively slim sides of just 12.8mm and four available colours, LEGRABOX blends discretely with all kinds of cabinet fronts and materials. And thanks to the inspiring technology of Blum’s EXPANDO T fixing system, that includes dense or thin materials such as ceramic or Corian, starting from just 8mm!

Blum LEGRABOX drawers are a tried and tested box system, which has won a multitude of awards for design and innovation. The cabinet profile has been developed and refined with top quality in mind – meaning the quality of the motion can be felt the moment the drawer opens.

LEGRABOX is available starting from just 270mm in depth but can be used in cabinets up to 1400mm in width with a 70kg weight-bearing capacity! With multiple applications available like the SPACE TOWER pantry or SPACE TWIN narrow cabinet – no matter the project, there’s a LEGRABOX drawer to suit your needs.

Keen to see the full range?

Visit blum.com/legrabox

Find it difficult to specify the inner dividing systems BEFORE the kitchen is installed, but always have requests for it? Order an AMBIALINE Starter Pack from Blum! This handy little pack is available in all available AMBIA-LINE steel design colours – Silk white matt, Orion grey matt and Terra black matt.

Conveniently made to suit either 500mm or 550mm deep LEGRABOX drawers, the AMBIA-LINE Starter Pack includes everything you need to start your dividing journey! With easy installation and no cutting required, this little kit is the perfect pick for a smooth ordering journey.

Sign in to E-SERVICES to order now! e-services.blum.com

The single order code gives you: a 300mm wide soft touch cutlery tray, drawer frames in 100mm and 200mm widths for M height drawers, and a universal drawer frame with a magnetic adaptor to suit C height or deeper pull-outs. Large kitchen – no issue, order two packs.

Now available in New Zealand, AVENTOS HK top is ready to spec and install. Small in size but big in features! The minimalist and compact design is the only “small” detail when it comes to Blum’s newest lift system, with many features now integrated into the mechanism

itself, including a built-in angle stop now adjustable without even having to remove the cover cap. If you can dream it – you can build it.

AVENTOS HK top can handle fronts as thin as 8mm with EXPANDO T and as thick as 30mm. It’s available in three motion technologies:

Configure the latest AVENTOS HK top online! Register for E-SERVICES at Blum.com

BLUMOTION soft-close technology for handled applications, SERVODRIVE for electric handle-less opening, and TIP-ON for mechanical opening with handle-less designs.

Hideaway Bins is excited to announce the arrival of the Concelo® Laundry Hamper, solution at an attractive price. The Concelo Laundry Hamper same platform as the Red Dot bin. This means it is packed with innovative features, which raise the bar in what you should now expect from any laundry hamper.

The team at Hideaway Bins that deliver solutions to common complaints raised by and the homeowner. With this is mind, Concelo Laundry has been created to stand out in the than a ‘me too’ product.

German made Häfele Matrix Runner, the smooth, synchronized concealed runner damper ensures a seamless and premium drawers.

the door brackets, ensures there to the job for door adjustments on Concelo products!

Hamper is a one-piece Clip access to the frame and the frame and no dirt trap between the door and the frame!

Concelo Laundry has been also works with electronic push homeowner a true hands-free laundry hamper solution.

The aluminum framework that conceals the runners and holds 6-way adjustment (+/- 2.5mm vertical and horizontal and +/-

Delivering solutions to common complaints - a leader in design that stands out in the crowd.

door front. The Concelo Laundry is available in two colours popular Cinder colour to towards dark cabinetry. Or why not install a white and a cinder side by side to make it easy for the homeowner to sort dark laundry from whites!

way in waste bin and laundry

Concelo is available nationwide from March 2020, through Hideaway’s distribution partners: Häfele, Carters, ITM, Impey's, Rose City Wood Panels, and Scooters or direct from hideawaybins.co.nz/concelo

IntaWood Products Ltd, specialists in component manufacture, have recently relocated to a new purposebuilt facility with new machinery and new Egmont dust extraction system.

IntaWood have been providing the Joinery industry with flat-pack products and components for 6 years, not only throughout New Zealand but including export to USA and Europe too. The priority for John & Lisa Kay, owner and managers of IntaWood Products Ltd, was to create a productive and effective factory that allowed machinery to perform at peak production levels while maintaining a clean and safe environment.

Egmont Air carefully calculated the machinery requirements, factory capacity and specified the new dust extract system to provide powerful suction so that each machine could operate at its optimum performance and maximize up-time production.

IntaWood have installed one of the largest CNC machines in the country so it was important that it operates efficiently and without interruption. Egmont Air designed the system to allow for the CNC and all existing machines to operate simultaneously. The system was also fitted with a Pressure stabilzer that automatically adjusts airflow and suction to optimum levels as machines are utilised or turned-off and provide incredible powersaving at the same time.

Mr Kay comments “The new Egmont Air System has exceeded our expectations and made our factory virtually dust free which is enjoyed by all.. Under advice from Egmont Air we upgraded the motor to future proof us going forwards. Overall we are extremely happy with our decision and enjoy a cleaner environment."

Egmont Air offers a large range of products and solutions for joinery shops and timber processors anywhere in New Zealand. The Egmont Air dust extraction systems are a popular solution due to their modular design and heavy-duty construction design which focus on balancing high suction performance with energy savings.

Egmont Air Systems are not only limited to wood-dust, many solutions are available off-theshelf for all types of dust or fume applications including smoke, fumes, paint spray, metallic dust and more.

Contact Egmont for a FREE brochure or on-site evaluation today on 0800 781 200 or visit the website www.egmontair. co.nz