Innovation, automation and sustainable solutions to futureproof your facility. Industry-leading innovation and automation: RBS Booth: Hall 1 Stand B70. www.bakingbiscuit.com 02 23 Production Pies, cakes, donuts Packaging special Sealing the deal; Gentle handling interpack 2023 “Sustainability is the number one topic”

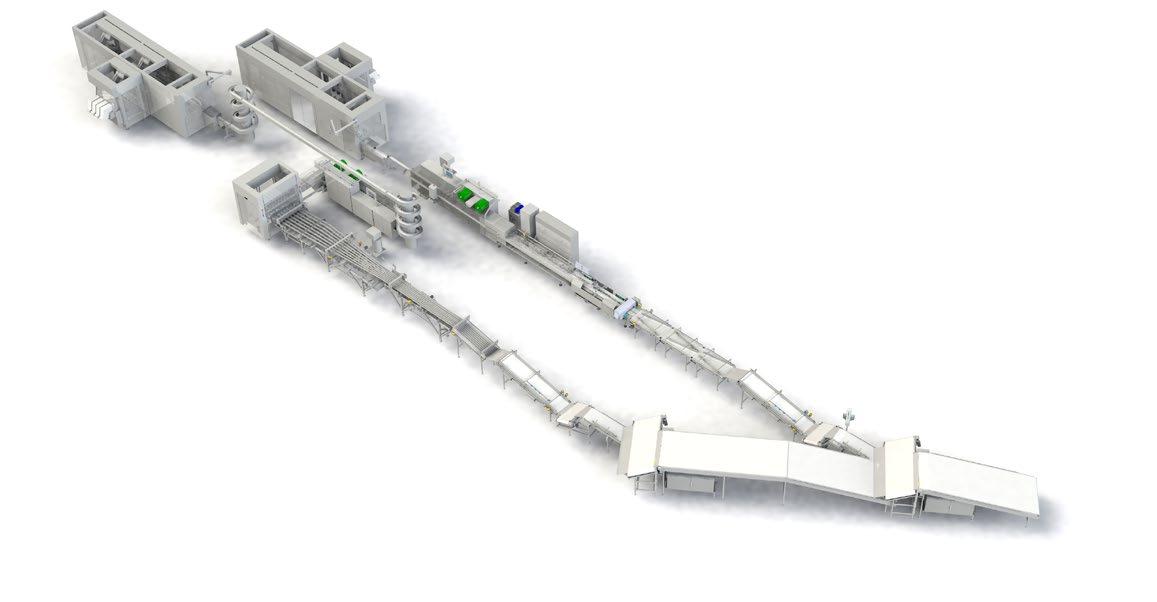

Verhoeven Bakery Equipment Family has a long and successful history of tailor-made development, engineering and production for the food industry. In the bakery market the family labels have established a strong position due our innovation and creative turnkey solutions. We sell high end production lines and state-of-the-art machines. Developed and made by a wonderful team of dedicated people. They make us proud. We would love to show you why.

HANDLING Conveying Robotizing Depanning END OF LINE Packaging solutions System integration CONDITIONING Cooling / Freezing Vacuum Cooling The Neth erlands - T +31(0)412 630 545 - info@verhoevenfamily.com MAKE UP Laminating Sheeting lines Universal lines Donut lines Pie lines

IT’S ALL IN THE FAMILY we make to bake PRE-CONDITIONING Product conditioning Proofing VERHOEVEN BAKERY EQUIPMENT FAMILY WWW.VERHOEVENFAMILY.COM

What is versatile packaging?

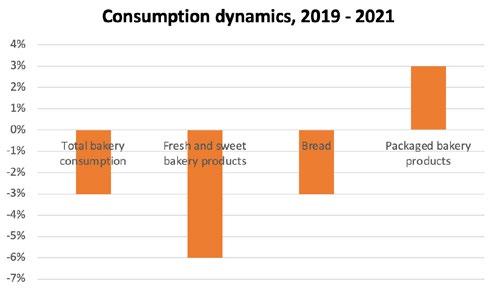

We are now quickly approaching interpack, the long overdue packaging and processing show. Just like that, a worrisome winter is behind us and we are gearing up to experience packaging and processing innovation returning to Düsseldorf after six years. The worst is behind us, hopefully. However, the uncertainties of the past months do follow us into spring: the cost of living remains high, doubled with recession fears, and unsettling failures in banking systems, in addition to the underlying energy crisis. On top of these, the war in Ukraine that started this snowball effect of disruptions continues.

The turmoil will, no doubt, show the mark it has made in packaging and processing. It already reflects in the global packaging trends Mintel announced. “Pressures from the environmental perspective, the conflict in Ukraine, global inflation, social issues, legal challenges, extended producer responsibility, and other forces mean packaging must navigate new and more challenging routes to market,” commented David Luttenberger, CPPL, Global Packaging Director at Mintel, when the 2023 packaging trends were revealed.

Catalina Mihu, Editor-in-chief

Economic uncertainty determines consumers to rethink their spending; to address budget cautiousness, brands are showing consumers how packaging can stretch their resources. “Offering packaging that represents financial value propositions, while not compromising quality, convenience, freshness, safety, and environmental responsibility, will be a differentiator in 2023 and beyond,” according to Mintel.

Not all change is bad; in light of all circumstances, transparency in communication through clearer labeling and sustainability efforts are at the top of opportunities in packaging in 2023, welcomed by the consumers’ wish to be informed. Mintel envisions packaging to paint a picture of the brand’s equity, in this regard. The communication path is established and consumers are seeking answers to hard topics, from people’s health to the health of the environment. Energy efficiency, for example, is under scrutiny by manufacturers and consumers, too. “In the future, brands seeking to be trusted partners in the kitchen need to take energy consumption into account and deliver packaging that enables energy-efficient cooking,” Mintel suggests.

In all aspects, sustainability is the #1 priority in the industry and at interpack this year. “It is no longer an add-on, but is increasingly becoming a duty, as we are dealing with a change in purchasing behavior,” Thomas Dohse, interpack Director, told us in an interview you can read in the pages of this magazine. For a glimpse of several interpretations meeting trends, improving processes and sustainability, you’ve come to the right magazine. We hope you enjoy reading it.

Have an excellent trade fair, everyone!

We look forward to seeing you there.

Catalina Mihu

03 EDITORIAL

or

Your commments

suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

INTERVIEW

Sustainability is the underlying theme of interpack and a core trend in baking and confectionery. It is no longer “an add-on, but is increasingly becoming a duty”, Thomas Dohse, interpack Director, tells baking+biscuit international , in an interview before interpack 2023.

INTERPACK

As preparations are in full swing for interpack 2023, exhibitors share solutions they are focusing on, information about new technologies that bakers can see at the fair, as well as their views on the trade show and the industry.

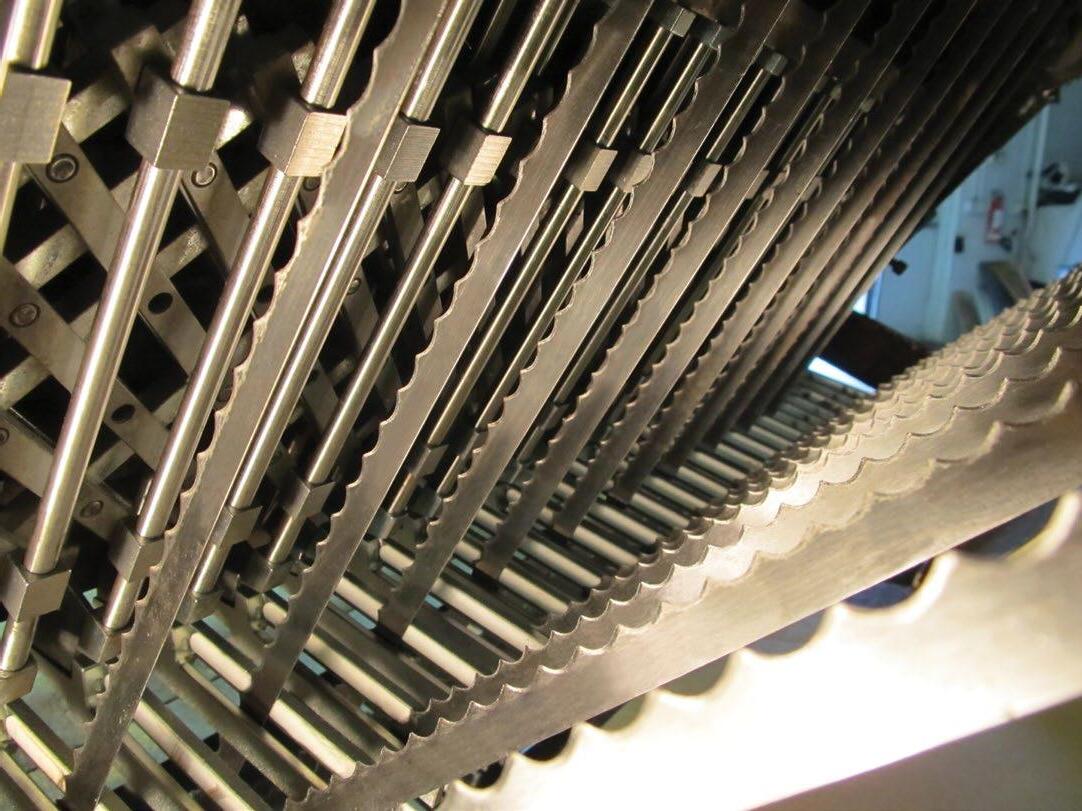

CONVEYOR BELTS

Cleaning baking oven belts can be a dirty, time-consuming task, causing downtimes of two days or even more.

PIES, CAKES, DONUTS

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently.

PACKAGING SPECIAL

Identifying the best packaging process and materials ensures all types of baked goods make it from plant to table, exactly as intended.

PROOFING

There are clear requirements for the proofing process. The dough may be resting, but its transformation process does nothing but rest.

www.bakingbiscuit.com 02/2023 CONTENTS 04

COVER STORIES 06

16 40

30

HIGHLIGHTS 10

©

© Messe Düsseldorf, Constanze Tillmann © Sea Wave –stock.adobe.com © Alen-D –stock.adobe.com © sergey–stock.adobe.com © RBS 34

Messe Düsseldorf, Constanze Tillmann

INTERPACK 06 10 PIES, CAKES, DONUTS 16 24 26 PRODUCTION 30 34 46 PACKAGING SPECIAL 40 44 BAKERIES 46 MARKETS 50 SUSTAINABILITY 54 setting a sustainability strategy SCIENCE 58 Campden BRI: Mitigation of product safety issues in bakery CAREERS 64 Dawn Foods: Sponsoring women leaders REG ULARS 03 Editorial: What is versatile packaging? 62 News 66 Advertiser directory Cover photo: Reading Bakery Systems advertisement FOLLOW US ON LINKEDIN Kempf GmbH | Carl-Benz-Straße 3 | 85296 Rohrbach ++49 8442/9669-0 | www.kempfgmbh.de bakeware and coating www.bakingbiscuit.com 02/2023 ADVERTISEMENT

“Sustainability is the number one topic”

Sustainability is the underlying theme of interpack and a core trend in baking and confectionery. It is no longer “an add-on, but is increasingly becoming a duty”, Thomas Dohse, interpack Director, tells baking+biscuit international , in an interview before interpack 2023.

+Catalina Mihu: What will the main differences be between this year’s interpack and the previous edition six years ago, organization-wise?

Thomas Dohse: interpack 2023 is a very special trade fair for us, that’s for sure. We are pleased to finally be able to bring the whole world of packaging and processing to Düsseldorf again. Around 2,700 exhibitors from 60 countries will demonstrate the industry’s capabilities here, discuss current trends and set the course for the future. The range of products and services is, therefore, as impressive as ever. What has changed for us, as trade fair organizers, since the last edition, are certainly the digital services and offers, which are taking on a much greater role. We see ourselves as a connecting and forward-looking platform 365 days a year. This year’s event is particularly about networking exhibitors together with visitors. But, digital tools for organization and an improved trade fair experience and time management have also become enormously important. This is where we want to continue to lead the way.

Mihu: How has the area dedicated to bakery and confectionery evolved?

Dohse: You will find the confectionery and baked goods area directly at the new south entrance to Messe Düsseldorf. Here, an impressive foyer and the new Hall 1 have been created since the last interpack, giving the trade fair a new face. More beautiful, wider, brighter, to put it briefly. The areas are fully booked again this year. Confectionery and bakery solutions and machines have been a large part of interpack, since the beginning. It is no coincidence that our logo is a replica of a classic sugar tong.

Mihu: What concepts regarding the exhibition structure and layout have been updated? Why were the changes necessary?

“Confectionery and bakery solutions and machines have been a large part of interpack, since the beginning. It is no coincidence that our logo is a replica of a classic sugar tong.”

www.bakingbiscuit.com 02/2023 TRADE SHOW 06

Thomas Dohse, interpack Director © Messe Düsseldorf, Constanze Tillmann

Dohse: This year, we can finally implement our new hall concept, which sets clear focal points and makes the exhibition more effective for visitors. The confectionery and bakery sector is concentrated in Halls 1, 3 and 4. Packaging materials and packaging means are also important focus points and can be found as a cross-sectional area for all target groups in Halls 7 and 7a, 8a, 9 and 10.

Mihu: What recommendations would you like to share with baking professionals who are visiting the show?

Dohse: Plan enough time, there is so much on offer. Use our digital tools for preparation, such as the exhibitor and product database, the MyOrganziner, or our app. And follow us on our social channels to always be up to date.

Mihu: How are the main trends in packaging for bakery products reflected at this year’s show?

Dohse: Sustainability is the number one topic in the packaging sector; it is no longer an add-on but is increasingly becoming a duty. We are dealing with a change in purchasing behavior. Sustainable packaging is in demand and the industry offers numerous solutions that we will see at interpack. Other consumer trends such as greater health awareness also have an influence on the design of packaging and the information contained on it. The topic of convenience continues to be a perennial favorite, as does innovative packaging design.

Mihu: Sustainability is an underlying theme of interpack 2023. What different approaches to sustainability will be represented with dedicated solutions at the show, particularly in response to manufacturing bakery products?

Dohse: Circular economy is the defining theme in order to be able to use materials again as high-quality materials through intelligent processes. In this context, the focus is on packaging that is easy to recycle, mono-material packaging, the use of recyclables and design-for-recycling. In addition, the conservation of resources is gaining importance at all levels. Companies today are faced with the challenge of acting sustainably and responsibly, making the best use of scarce resources, while increasing efficiency in production. CO 2 neutrality is an important topic among exhibitors and visitors.

Mihu: What can be learned from major, global disruptions such as the ones we currently experience, and how can this knowledge contribute to the food production industry being better prepared in the future?

Dohse: Global crises such as COVID-19, natural disasters, wars and conflicts have brought many lessons for the entire industry. The need to diversify supply chains is at the top of the agenda, to better respond to future disruptions and avoid over-dependence. This is currently a very big problem for many because the industry still needs to fill orders; so, companies increasingly have to deal with the issue of risk management. However, we also see a digitalization push, especially due to the COVID crisis, which brings with it great opportunities and progress. Companies are investing in automation, robotics and digital services. This ensures more efficiency and continuity in production. There is still a lot of potential here.

Mihu: What changes have you observed in exhibitors’ responses as the show was rescheduled, then adapted and updated?

Dohse: The postponement and eventual cancellation of interpack 2020 was a great disappointment for everyone involved. But, the uncertainties were simply too great at the time to meet the demands of a leading trade fair. Everyone agreed on that. We felt great support from the industry. At the time, an overwhelming majority of exhibitors retained their spaces for 2023. For the industry, personal encounters and the live experience of complex technology, in particular, remain enormously important.

Mihu: What attendance figures do you anticipate, compared to the previous edition of interpack?

Dohse: We are optimistic that we will once again be able to attract the global processing and packaging industry to interpack, and the registration figures to date are good. However, geopolitical influences and travel restrictions that still exist in some places certainly also have an impact, so it is difficult to make an exact forecast. However, we are very pleased that now having returned from our worldwide press conferences, we received very good feedback everywhere. People are looking forward to the fair and those who can will come. +++

www.bakingbiscuit.com 02/2023 TRADE SHOW 08

© Messe Düsseldorf, Constanze Tillmann

Fast

2100 lines installed worldwide and we are always around the corner.

.

Tasteable quality secured by over 85 subsidiaries worldwide

Ben Baker

interpack 2023 highlights

As preparations are in full swing for interpack 2023, exhibitors share solutions they are focusing on, information about new technologies that bakers can see at the show, as well as their views on the trade show and the industry.

AMF Bakery Systems

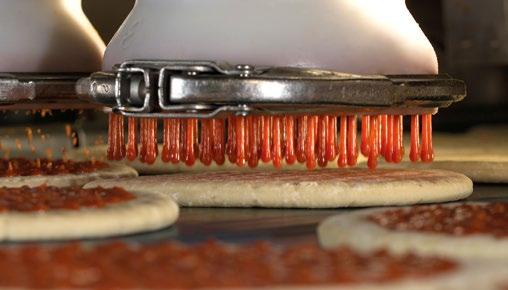

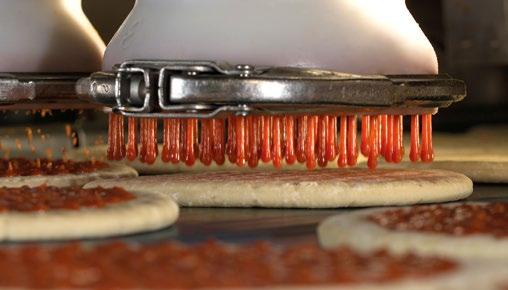

AMF Bakery System introduces a new, sustainable machine: the AMF Tromp Powershot – a sauce applicator that can be used for pizza and flatbreads, to deposit sauces and oils. Its new design does not use compressed air and has low energy needs. It has a hygienic, EHEDGE-compatible design, with IP69 components, and optimizes raw material usage.

AMF cake production lines and systems are also among the highlights with solutions for snacks and premium products, single-packed cakes, cupcakes and muffins – from entry-level to high-volume production. Equipment includes turnkey solutions, depositors, conveying systems for trays, decoration units, impingement tunnel ovens and decoration modules (topping, injection).

AMF also focuses on sustainable baking ovens. “This topic is hot and current; solutions are needed more than ever. AMF Den Boer tunnel ovens can bake with electricity and hydrogen. Existing ovens can be retrofitted with the required burners,” AMF says. The company can provide electric and hybrid ovens.

The company is looking forward to interpack’s comeback, ahead of the other major trade shows this year, iba and Gulfood. “The world wants to meet, and people like to meet people. We switched quickly to all digital channels

over the last few years, as that was needed anyhow. The customer journey is becoming more diverse, so we have to be where our customers are,” AMF concludes.

Reading Bakery Systems

RBS is focusing on achieving sustainable and flexible operations at interpack. The company is featuring its new sustainable and electric baking capabilities, continuous mixing technology, and its lowpressure extruded snack systems.

Returning to interpack after the show’s hiatus, RBS focuses on innovation. “During the pandemic, we reframed our energy around people, the planet, and prosperity; how we can improve every step of our value chain. The results are impactful for our customers, such as new digital offerings like educational webinars, RBS eZone, a 24/7 selfservice parts portal, improved systems automation via RBSConnect for greater efficiency, intelligent and lean design/build protocols for manufacturing, as well as the SafeShield program for easier cleaning and sanitation,” RBS says.

The company is expecting a successful trade fair as it observes that customers are looking to manufacturers to solve some of their operational challenges, like energy

www.bakingbiscuit.com 02/2023 TRADE SHOW 10

Hall 1 A69

Hall 1

B70

© Messe Düsseldorf, Constanze Tillmann

© AMF Bakery Systems

© Reading Bakery Systems

efficiency, sustainability, labor and material shortages, and new product development. “Customers need partners with innovative system solutions, not just equipment suppliers.” RBS anticipates that today’s industry trends will become standard operating procedures very soon, regarding automation, sustainability (e.g., electric ovens, labor-saving operating systems) and increased flexibility.

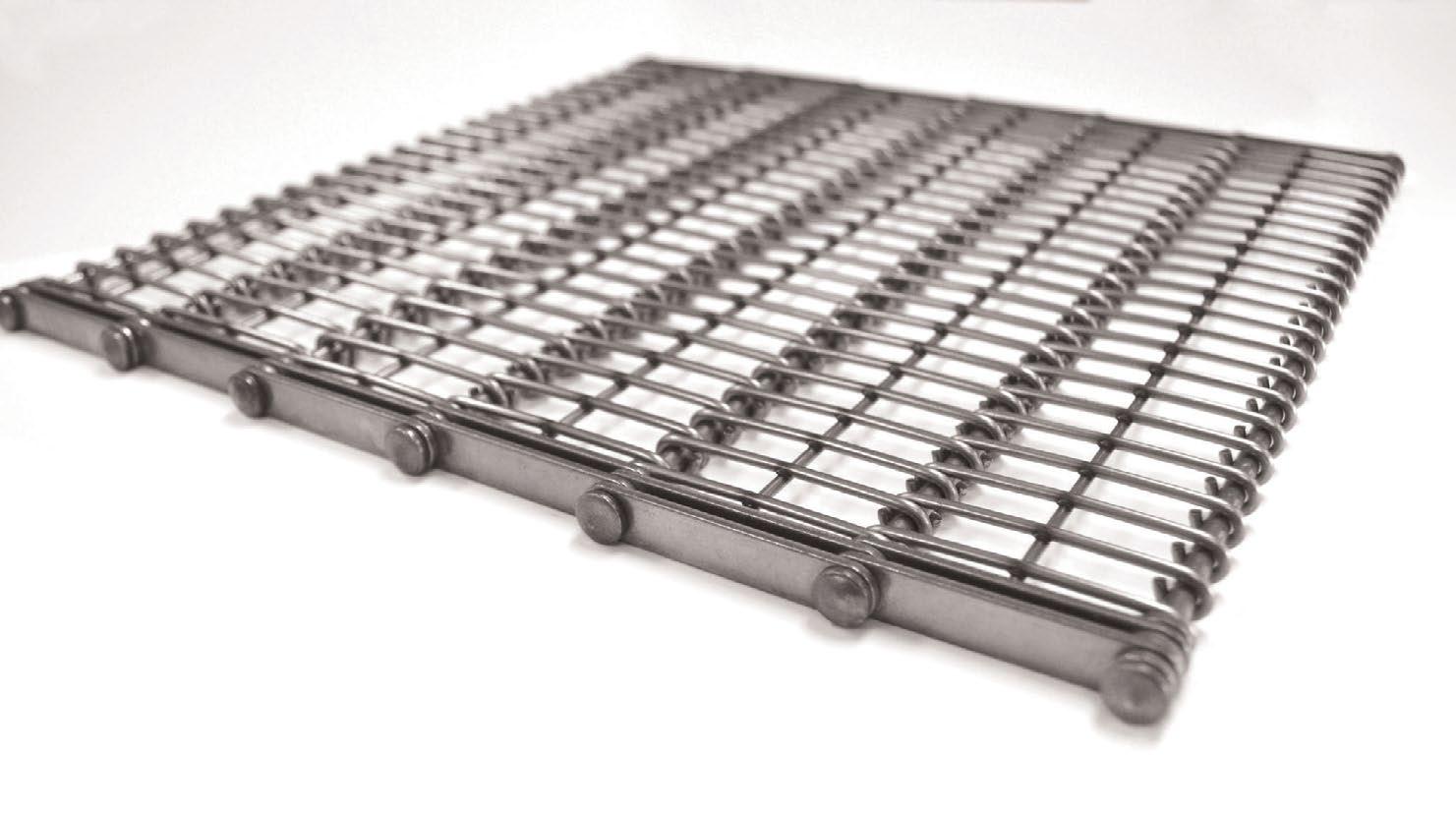

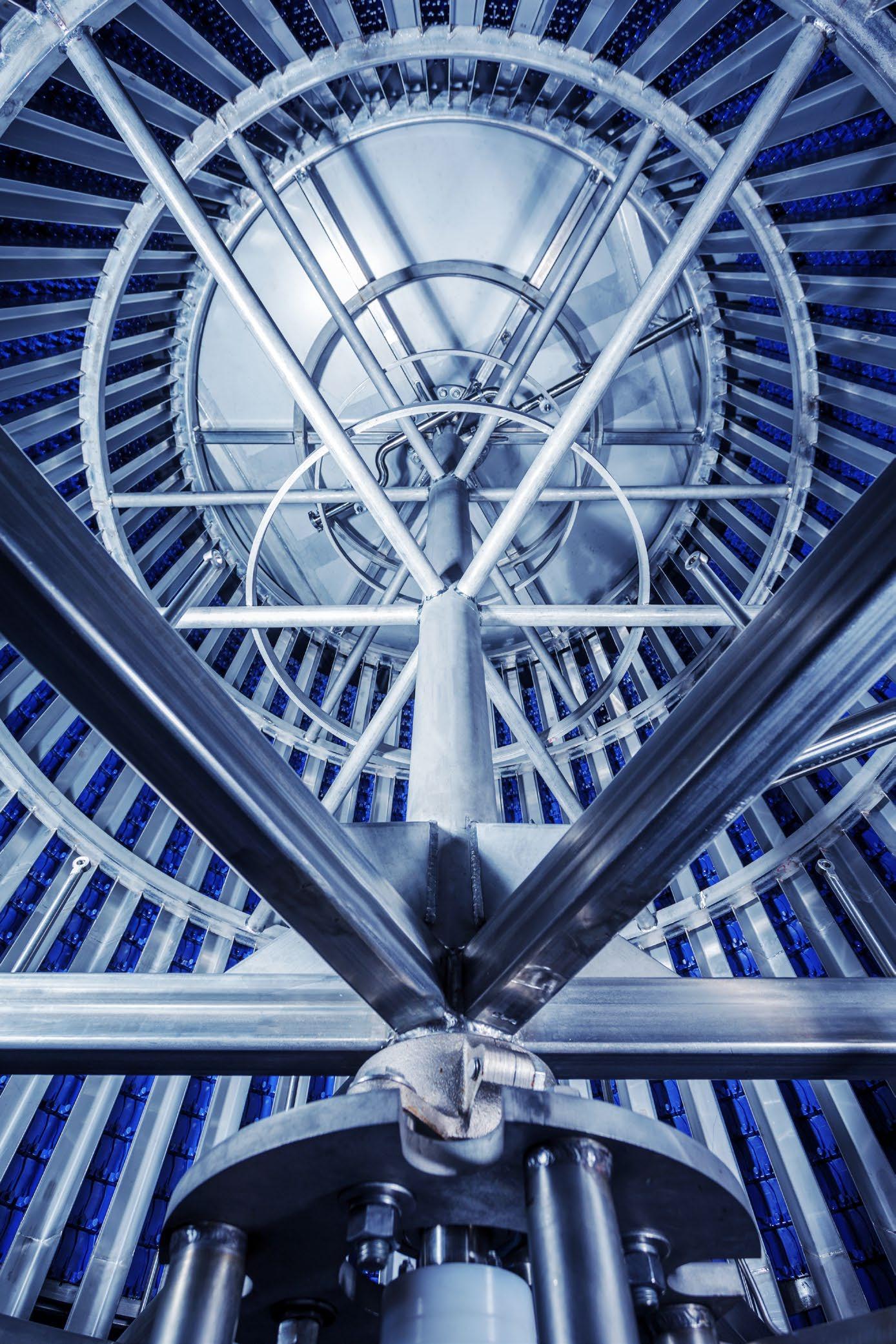

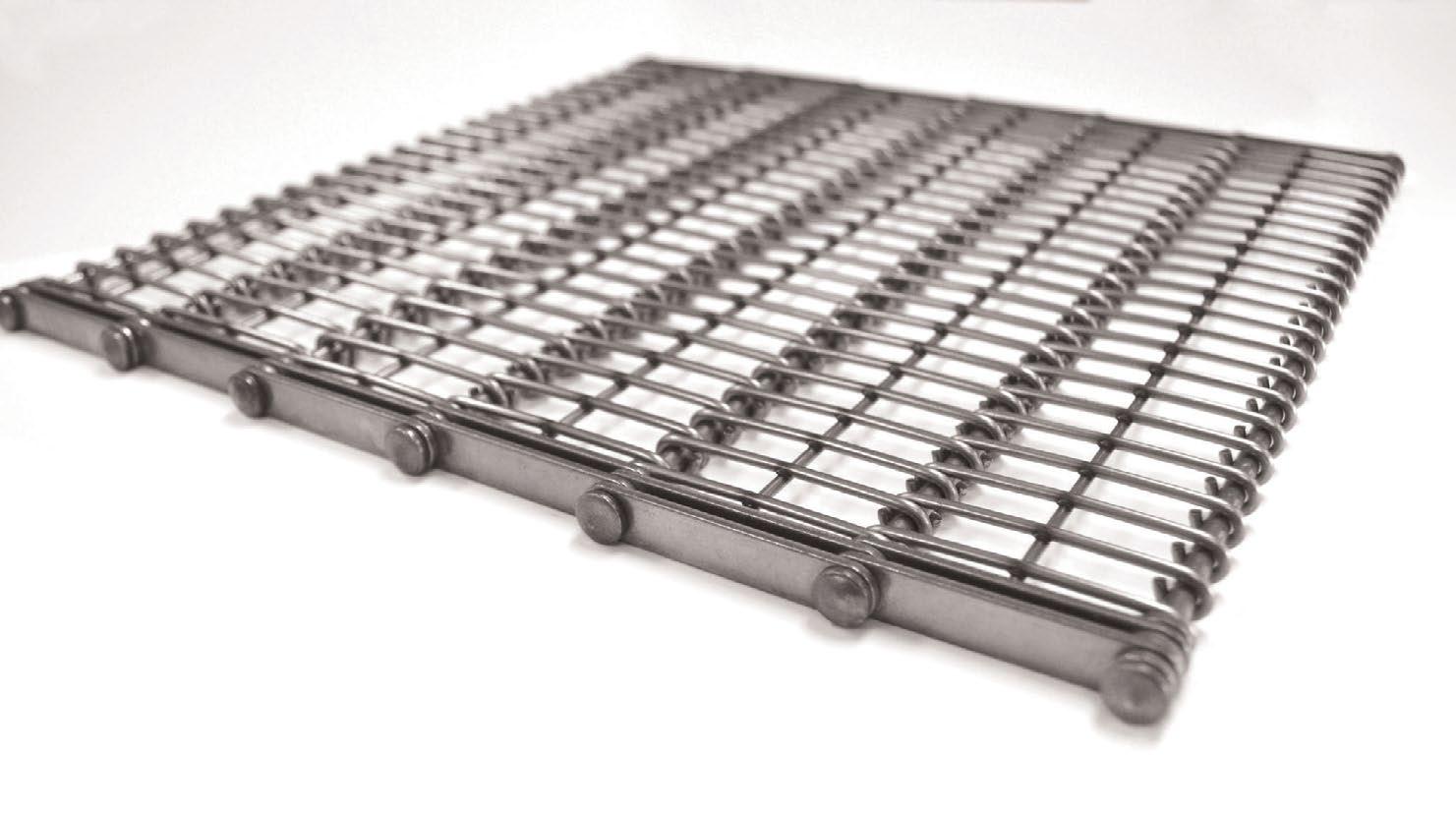

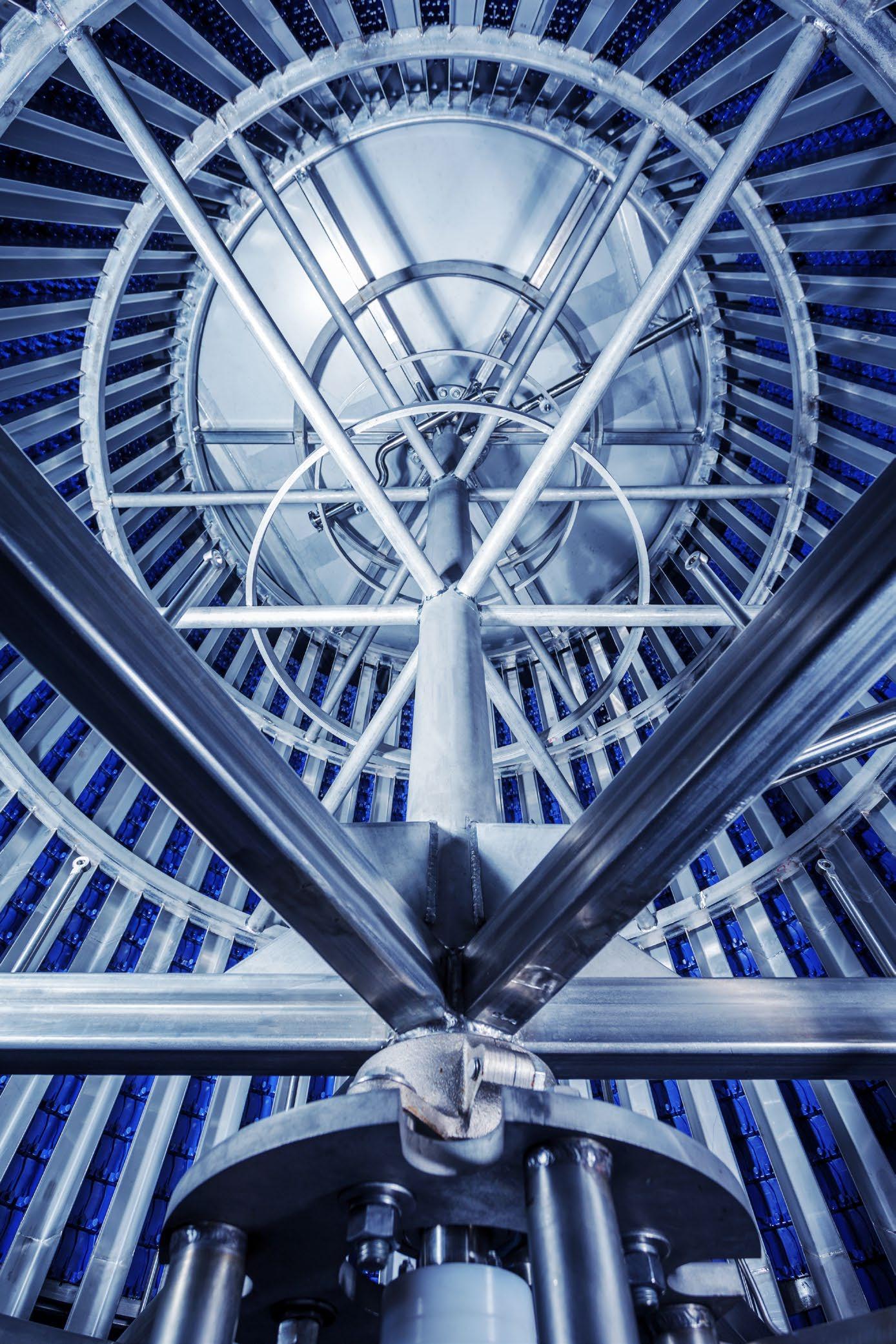

Ashworth Belts B.V.

Ashworth brings the PosiDrive, its direct-drive solution for spiral systems to the fair, which can be used with new systems and as a retrofit for existing lotension spiral systems. The PosiDrive provides product stability and stable operation in demanding situations (high belt load, heavy product, greasy application), the company explains. The SmartSpiral is also among the stand highlights, providing trending data (graphs) for temperatures, belt tension, oil quality, bearings, etc. Ashworth also offers plastic belts for lotension- and direct drive spiral systems (Best of Both Worlds) and belts, parts and Factory Service assistance for self-stacking spiral systems (ExactaStack). “Ashworth does not only manufacture belts, but also provides customers with Parts, Audits and Factory Service Assistance, all over the world (Ashworth Factory Service – AFS). AFS in the US is often hired by European OEMs to repair and assist with installing their equipment in North America,” the company shares.

Its SmartOven ™ is among the innovations it brings to the show, a solution similar to the SmartSpiral, but for tunnel ovens, with sensors collecting data on uniform heat distribution on the belt and vibration in the system.

IPCO

IPCO highlights chocolate forming systems at interpack, designed for the production of industrial ingredients – chips, chunks, drops and blocks –and decorative products such as shavings, rolls, pencils, blossoms, etc.

“These have applications across the bakery industry, with ingredient products used in everything from cookies and cakes to brownies and muffins, and decorative products used to add value to cakes, pastisserie and other premium products,” IPCO details.

The main highlight will be its flagship Rotoform system, with a fully operational unit at the stand. Rotoform is a rotary drop depositor that produces chips of highly uniform size and shape and this is the foundation on which all of IPCO’s

high-capacity systems are built. “Chips are free-flowing for easy handling, storage and dosing. The system is also extremely versatile in that chips of different sizes – from 30,000 to 300 pcs/kg – can be produced by simply changing the shell,” IPCO explains.

Among the company’s latest solutions is its piston depositor that uses a D-motion to deliver chocolate or compound directly onto a moving belt.

This is the first time IPCO joins interpack with its new brand name. “Six years ago we were still Sandvik Process Systems so, if any visitors are unfamiliar with the IPCO name, it will be an opportunity to reintroduce ourselves and help them make the connection!”

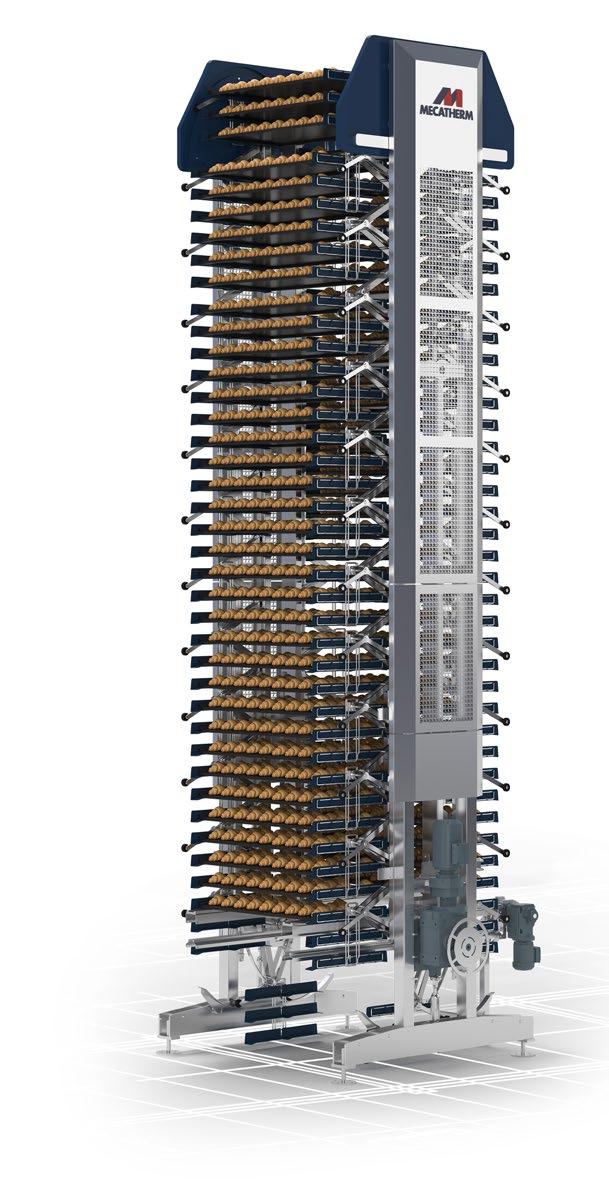

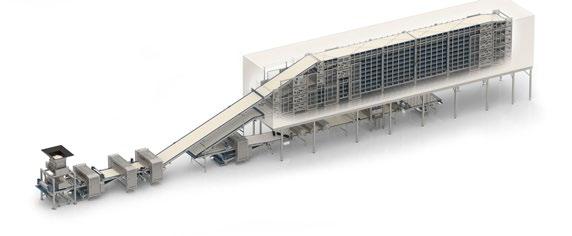

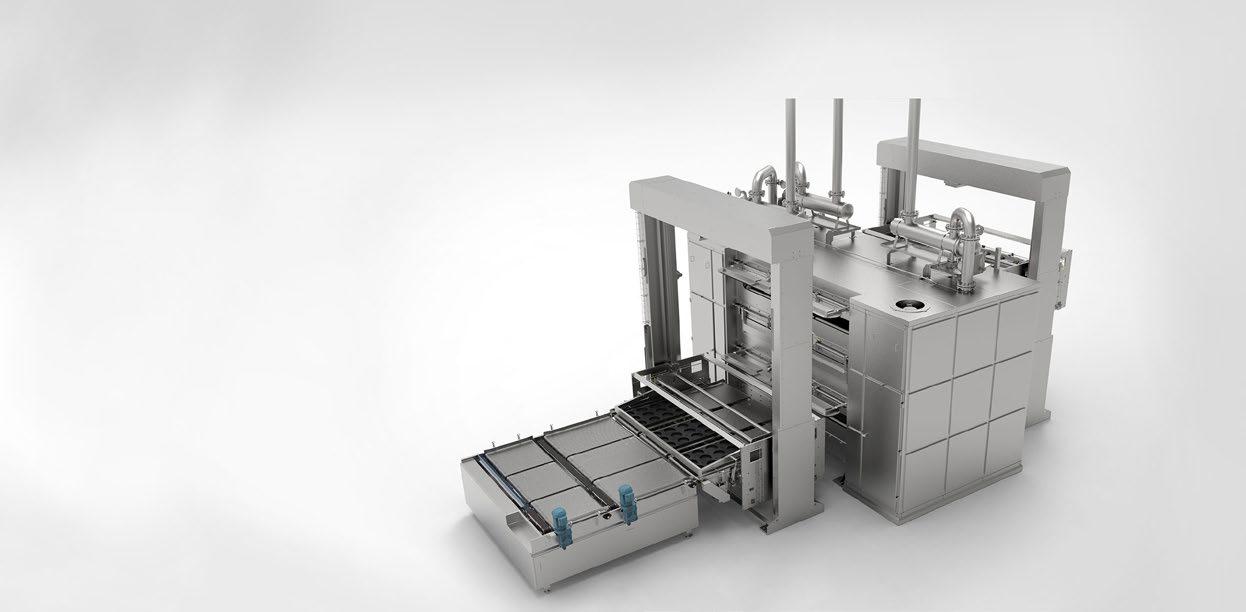

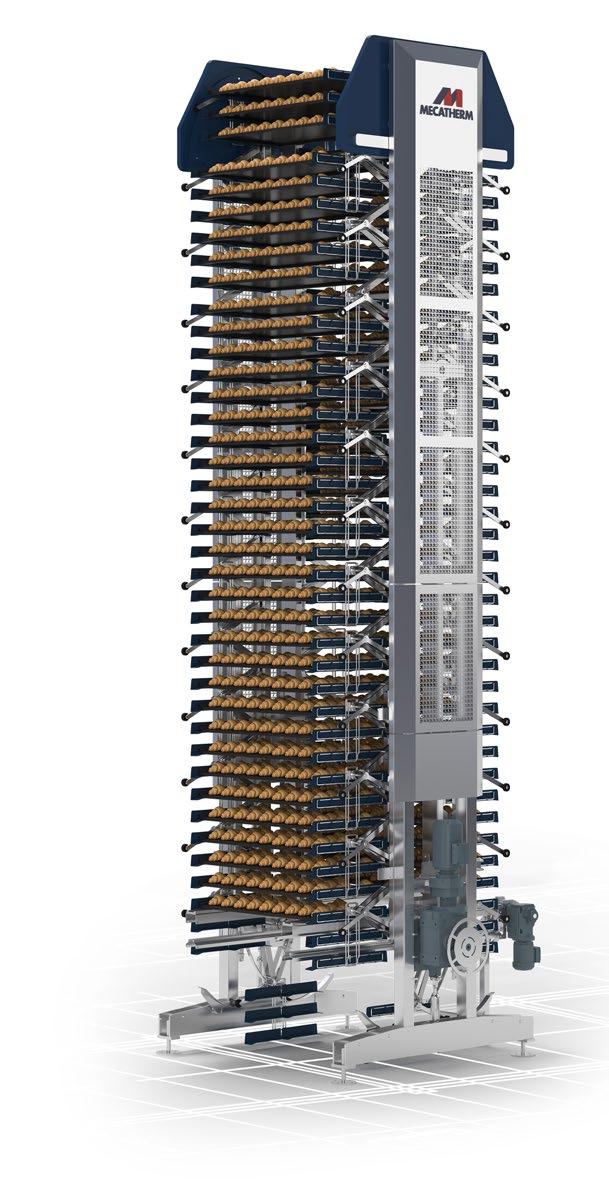

MECATHERM

This year, the French specialist focuses on solutions for energy efficiency, the new, easy-to-clean M-DAN oven and new digital solutions for industrial performance.

MECATHERM is launching the new M-DAN Oven, with an improved hygienic design that includes wash-down capability. It can be used for a wide range of food products such as dairy desserts, or pastry products with liquid fillings, with easy changeovers to reduce product waste. The company also highlights the M-Care, its new predictive analysis solution that enables industrial bakers and sweet goods manufacturers to detect anomalies (such as drifts) in equipment early and provide operators guidance for easy initial maintenance checks to optimize their machine availability.

In addition, its experts will share specific insights on how to achieve energy savings. First, they will explore oven designs, such as compact vertical ovens or tunnel ovens, and how different ways of operating these ovens provide opportunities to reduce energy losses. Then, it will underline how

11 TRADE SHOW www.bakingbiscuit.com 02/2023

Hall 3

D20

Hall 3

D22

Hall 1 B82

© IPCO ©

© Ashworth

MECATHERM

convection heating can optimize baking time and reduce the temperature of fumes. MECATHERM ovens are all equipped with convection heating technology, either as the main heating mode (vertical ovens), in combination with radiant heating (M-TA and FTM Ovens), or as an option in a specific heating zone (FTP Oven). Moreover, many of its ovens are compatible with an electric heating source. The company will showcase its MECAFLEX Line, which includes the M-TA Tunnel Oven and the M-UB Handling System to produce a wide range of products from different process combinations with diverse baking tray types and formats.

Koenig

Koenig comes to interpack with a focus on industrial baking. “We are looking forward to discussing the respective needs with our visitors in individual talks, especially in the area of complete turnkey solutions for buns or breads,” the company says.

Since the last interpack, Koenig has continuously developed its products. “In our opinion, energy and production efficiency will continue to concern customers this year and it is a main issue in the bakery industry.” Koenig is addressing this with smart and energy-efficient oven technology, with the ‘Save Energy’ series, or process optimization such as vacuum conditioning. Koenig has also launched new machines and lines for dough processing in the ‘Easy Clean’ design. In addition, further development has been made to the KGV system in EC design, which will be introduced with an expanded production output in Autumn 2023. Koenig will present solutions like these to its visitors in multimedia at its interpack trade fair stand.

Koenig has high expectations for trade shows this year. “We expect a challenging market environment in 2023 and interpack will give a good impression on the investment barometer for this year. The highlight will be iba in October, with the entire world of baking meeting in one place.”

to meet. At interpack, “We expect an in-depth exchange and the opportunity for extensive networking,” it anticipates.

Automation and digitalization will be a constant focus for DIOSNA's customers, to better position themselves for the future, the company shares, observing that end customers also influence industry trends with their desire for healthier products that are also manufactured in a resource-saving fashion.

Berndorf Band Group

Berndorf Band Group comes to interpack with its steel belts for the baking and food industry, which are designed for extreme mechanical and thermal stress, to support various processing steps, and to meet all hygiene requirements for food production. The surface is also abrasion-resistant, which facilitates the cleaning of product and grease residues.

Additionally, Berndorf Band Group offers a new surface technology. “Our new easy-release surfaces have evolved from a batch to a continuous process. Whether PTFE-based or SolGel-based coatings, we are working on the requirements and production issues of our customers. Instead of using very expensive cleaning methods, we focus on the concept of permanent clean and efficient production conditions,” the company explains.

The company shares their views on today’s trends: “We focus very much on sustainability and energy efficiency. One example is the use of energy-efficient solid steel belts, which are lighter and consume less heat than other belt technologies. Another trend is the easy and energy-free cleaning of the steel belt surface through our new coating technology, which is designed to prevent caking on the belt’s surface. We want to be a positive role model with our environmentally friendly production, the use of a photovoltaic system, our own hydroelectric power station and a ‘zero waste philosophy’.

DIOSNA

DIOSNA showcases its solutions for the food industry regarding fermentation, granulation and mixing. Additionally, “We will focus on automated, secure processes and systems. For example, AGV systems and the advantages they bring in symbiosis with our machines,” DIOSNA details.

Recent challenges saw DIOSNA shift its focus to process digitization. The company anticipates that interpack, and fairs in general, are still a special occasion for the industry

www.bakingbiscuit.com 02/2023 TRADE SHOW 12

©Koenig

Hall 3

E47

Hall 4

C23

Hall 4

©

©

C39

DIOSNA

Berndorf Band Group

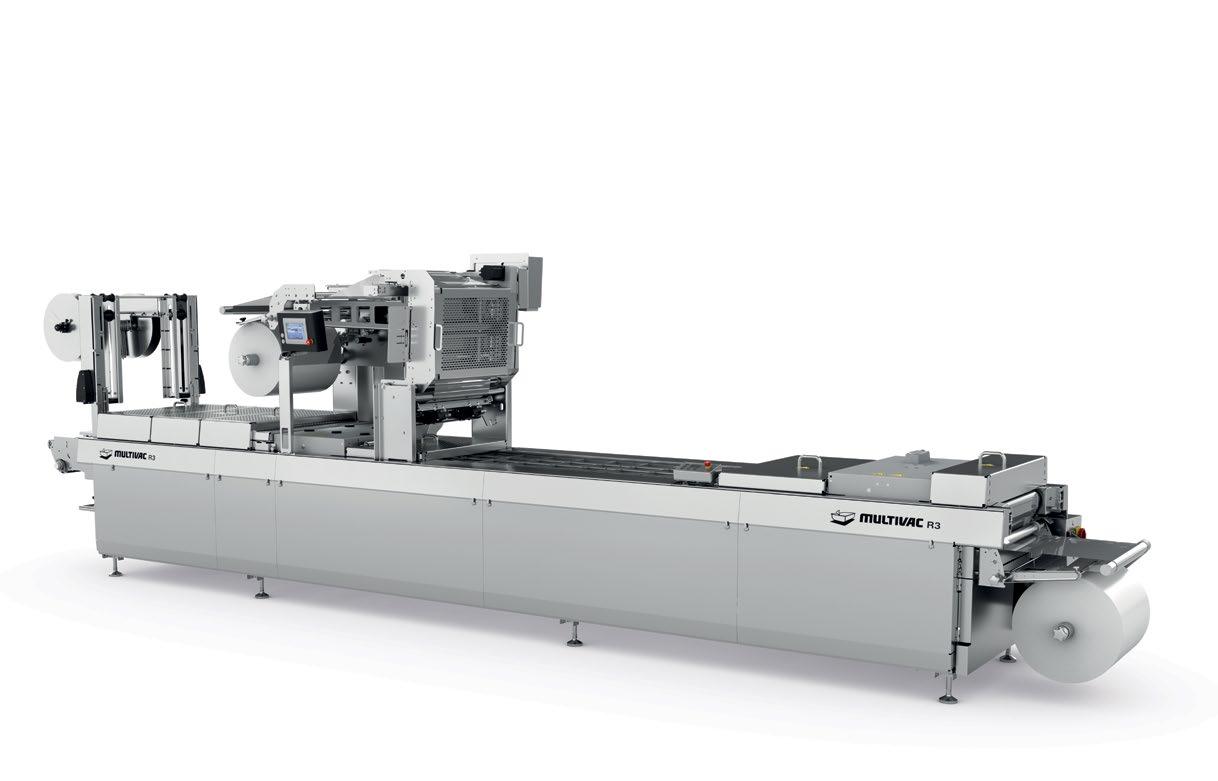

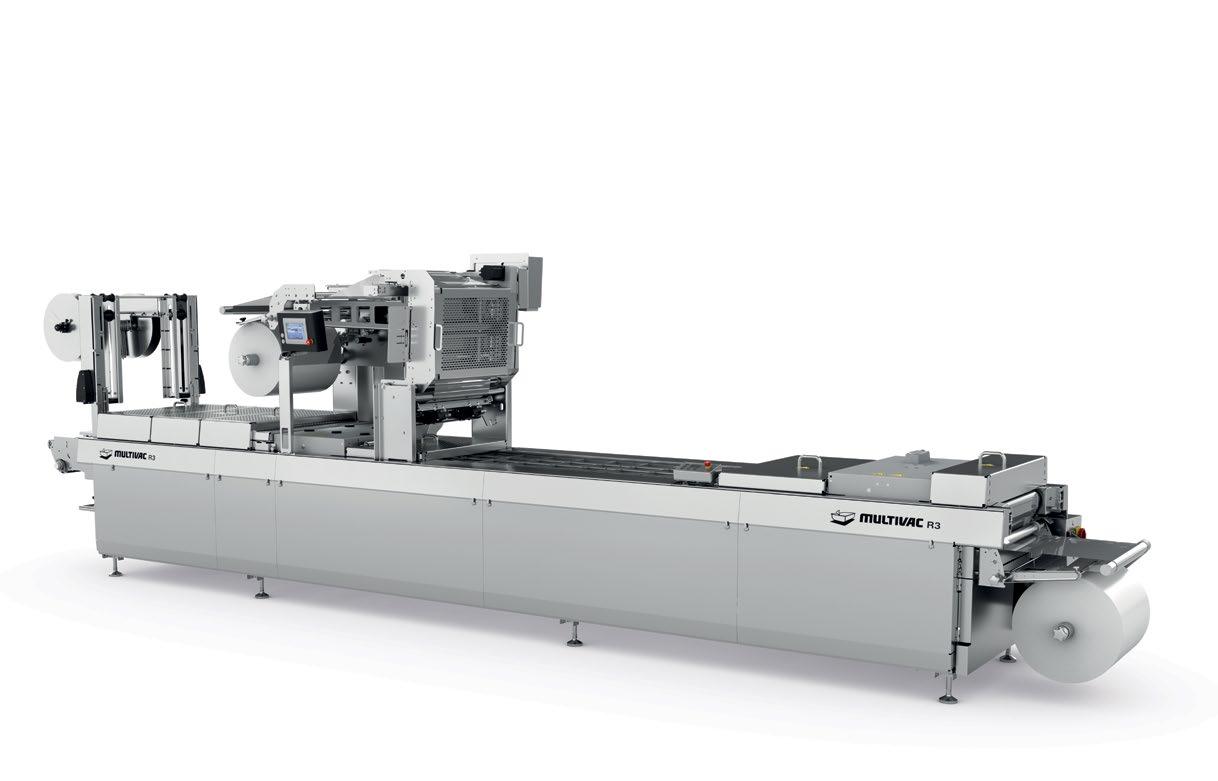

Handtmann

Handtmann focuses on integrative solutions for food and baked goods production from processing through to packaging, which are modular and flexible to configure. Live demonstrations include fully automated solutions for versatile products such as deposited products. “These modern processing methods will be supported by a large number of smart digital solutions that have been developed in-house by Handtmann and specifically adapted to these processes,” it anticipates. The new solutions showcased at the stand include a fully automated dosing process, comprising the modules Handtmann VF 808 S vacuum filler and DS 552 dosing system with transfer to the denester and tray sealer packaging solution by its partner MULTIVAC. The DS 552 offers direct multi-lane dosing of a wide variety of products into thermo-forming packaging and trays or dough sheet systems. The automatic dosing process runs on 2 to 24 lanes and allows a production output of up to 200 cycles per minute. The dosing principle with return suction without filling pistons and valves can dose fluid to semi-viscous filling products with high precision. A large selection of dosing nozzles further extends the wide range of products. “The

patented, servo-driven flow divider in the depositing system ensures a constant product flow without pressure fluctuations, resulting in the most accurate weights in every single lane.” The technology concepts Handtmann presents include digitalization and automation features. “As a food innovator, Handtmann welcomes trade shows to bring its courage, creativity, understanding of trends and technological know-how to rethink classical products or develop concept products with this initially rather challenging novelty to the market.”

Hybrid made easy.

13 TRADE SHOW www.bakingbiscuit.com 02/2023

With our new hybrid heating system you can heat with an electric and/or any other alternative energy source. The choice is yours!

ADVERTISEMENT

Curious?

Hall 5 C38 ©

Handtmann

Syntegon

Syntegon presents flexible systems for cookies and bars, an Innovative Intelligent Direct Handling system that offers format flexibility for cookies and crackers, a high-speed bar system for maximum efficiency with new wireless HMI, and sustainable packaging for cookies and bars made of paper and mono-material.

The new Syntegon IDH is at the heart of a line that flexibly packages cookies and crackers in trays and flow wraps made of mono-material. A new pick-and-place technology with integrated linear motors ensures gentle product handling. Linear motors also feature in various feeding modules in both lines to prevent product damage during handling and boost flexibility. In addition to gentle handling, the system for bars that will be on show offers high levels of sustainability and digitalization. The line is equipped with a paper-ON-form forming shoulder and wraps bars in paper before placing them in glueless formed cartons in the TTM1 topload cartoner with an integrated lock-style forming station. Moreover, Syntegon will present a new wireless Human Machine Interface (HMI) that allows operators to access all available information and digital services at any time.

Another solution launched at interpack is the new wireless HMI 4.0 – a new feature that boosts efficiency, especially in large, fully automated systems. It allows operators to control and monitor the entire line via a single interface.

The Schubert Flowpacker will also be highlighted, a solution which allows quick switching between flowpack films with different properties. It enables both recyclable mono-plastic films and paper-based flow-wrapping films to be used in a single machine. Schubert will demonstrate this with a system that combines an ultrasonic unit for longitudinal sealing with a flexible cross-sealing unit.

Schubert

Some of the highlights at Schubert’s stand include cobots for the rapid feeding of different packaging components on a line and an entirely new, efficient, resource-saving feeding system for carton blanks. In addition, the packaging machine manufacturer developed a concept study for a new generation of machines, in combination with a new type of transport system that will increase automation, flexibility and efficiency. The company also presents a wide range of new services for more environmentally compatible packaging, including the new five-point Packaging Perspectives program.

The new Schubert tog.519 cobots, now ready for series production, are presented for the first time to an international trade fair audience. One cobot will be processing bars, chip bags or highly reflective pouches, demonstrating the advantages of its AI.

American Pan

American Pan is highlighting its latest designs and coatings, including the ePAN designs for bread, bun, roll and cake products. Some ePAN designs have been proven to save up 8% on oven energy usage.

“With our recent partnership with Turbel, we are also able to offer new coatings including a silicone resin coating that is an ideal choice for cake-type products,” the company details. In addition, the new American Pan refurbishment center in Wassenberg, Germany will be featured, an operation that was added as a result of this recent partnership.

“We also continue to offer custom and stock bakeware, coatings and bakeware refurbishment services, now with a wider selection to help attendees find the right solution for their projects,” American Pan highlights.

“It is very exciting to be back at interpack after 6 years. In that time innovation has not slowed down, in fact, it seems to have accelerated in the baking industry. It is very exciting to see the new technologies and partnerships that are moving the industry forward.” +++

www.bakingbiscuit.com 02/2023 TRADE SHOW 14

Read more from the exhibitor Q&As, on www.bakingbusiness.com

Hall 14 D01

Hall 15

C 38-2 6 A31

Hall

© Schubert

© Syntegon

© American Pan

DIOSNA Innovative Mixing in Hygienic Design

For dough at its best

The Wendel Mixer of the Hygienic Design series connects high performance mixing with an open construction to allow easy cleaning, and thus a very fast switch between di erent recipes.

As it is typical for DIOSNA Wendel Mixers the method of gentle processing of the dough by folding allows perfect dough development in shortest possible time, avoiding crushing of seeds and fruits if used in the recipe. The WH240 ”A” model allows fast succession of batches by the easy change of mixing bowls.

DIOSNA enjoys worldwide recognition as specialist for dough processing and pre-dough fermentation on a large scale. Machine equipment and biotechnology represent the ideal interaction for best results in food production.

→ Ideal for all types of dough, masses and bars

→ Gentle dough and ingredient processing

→ Optimal integration in existing line production

→ Easy cleaning - reduced downtimes

→ Hygienic design mixers with changeable bowl or direct ground discharge

VISIT US # 4C23

VISIT US # 4C23

Easy as pie

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently. They are also designed to be operated with ease and safety.

By Catalina Mihu

By Catalina Mihu

More often than not, technology lines for pie manufacturing are dedicated to certain varieties only, which means they can enjoy the benefits of a high degree of sophistication. Different modules can also easily handle variation or volume expansion when needed.

AMF Tromp pie line

However, the automated line designed by AMF Tromp can flexibly support a wide range of pies, too, either savory or sweet, in a baking tray, in foils, or in paper cups. They can bake the pie shells only, pies with the top opened or closed and pies with or without a lattice decoration. “With this wide range, we can make almost every pie from any culture or continent. We love a good challenge, and our Innovation Center is also open to developing new pies together with

”Sweet and savory pies may look alike, but can also be very different, depending on culture and eating habits.”

potential customers,” says the specialist responsible for pie systems at AMF Tromp, Hans Besems (Executive Product Manager). This diversity is apparent in AMF’s installations making pies worldwide.

Different modules are behind this wide variety: depositors are used for all types of fillings, from more liquid, quiche types, to chunky fillings such as meat for the traditional

www.bakingbiscuit.com 02/2023 PIES, CAKES, DONUTS 16

+

© AMF © AMF © Sea Wave –stock.adobe.com

Hans Besems, Executive Product Manager, AMF Tromp

British pie. “Sweet and savory pies may look alike, but can also be very different, depending on culture and eating habits,” Besems explains. Usually, the spot depositor – or piston depositor – is selected for the process on the AMF Tromp pie line, as the option best suited to pie fillings and the ingredients in them. This system is designed for accurate volume dosing of semi-liquid fillings as well as fillings with large inclusions such as meat chunks or fruit pieces.

Universal depositors from the Unimac series can also be used for different fillings, sweet or savory. In this range, the Unimac XL is the most frequent choice, as it is suitable for fillings such as almond paste or cake batters.

Applying various toppings on pies requires a different depositing solution: the Tromp Target Applicator. It can handle crumble (streusel) toppings, sugar, sprinkles, nuts, or chocolate. This equipment accurately deposits the ingredients in the center or pre-defined spots on round pies, so that no ingredients are lost, which not only saves materials but also keeps the production belt clean.

Aside from these depositors, a spraying system can also be integrated for water or glazes. It can also spray egg yolk to create a crust. Other decorations such as sprinkles, nuts, chocolates and sugars are dispersed via roll strewers. For even more decoration options, shapes can be added with a rotary molder.

For (pre-)baking the pies, AMF recommends a Den Boer Multibake tunnel oven with impingement heating or a direct-fired system. “Depending on the type of pie, we advise the best possible Den Boer tunnel oven, which fits the process and products baked in it,” Besems explains. It is chosen for the equipment lineup of the pie line because of the baking results it offers for pies, along the entire width of the oven belt. Its airflow and sustainability features also back the recommendation, AMF highlights. “The ROI on ovens like this is very high, and maintenance very low.”

The AMF Vesta Spiral Conveyor is also a part of the pie line, to cool the pies gradually and consistently, before freezing and packaging. It also creates a buffer for large amounts of products coming out of the oven, which supports high-volume manufacturing. Alternatively, a step cooler could also be an option, also offered by AMF Den Boer.

Personalized lines – check

AMF has installed numerous pie lines worldwide, most of them very much dedicated to one type of pie or only a few, as requested. Variations in production mostly mean different shapes or sizes. With the dough remaining the same in most cases, it is mostly the fillings that may vary more frequently.

PIES, CAKES, DONUTS ADVERTISEMENT

AMF Tromp pie line, process steps for sweet pie:

+ Foil cups de-nester

+ Placing cups or foils in baking trays

+ Depositing dough billet in foil

+ Pressing the pie shell

+ Depositing filling sweet

+ Top lid placement (a dough sheet, a lattice, or from a rotary molder)

+ Crimping unit to press the top and bottom halves of the pie together, with decorative edges possible

+ Optional decorative deposit on top of the pie

+ Glaze or egg yolk application for a shiny, appealing crust

+ Crumble application

AMF Tromp pie line, process steps for savory pie:

+ Foil cups de-nester

+ Placing cups or foils in baking trays

+ Dough billet deposit in foil

+ Pressing the pie shell

+ Depositing filling, both warm and cold

+ Top lid from a dough sheet (shortcrust or puff pastry options are possible)

+ Pressing top to bottom halves of the pie with a crimping unit

+ Glaze or egg yolk application – crust

+ Pop decorations with cheese, seeds, herbs or other toppings, with applicators or strewing units

Pie-making is a complex technical setup. For flaky pies, specific systems are used for carrying and detecting the foils in which the pie base is created, for example. “Not one pie line is exactly the same as another; but, AMF Tromp pie lines can support quick changeovers between various types of pies, because of the configuration set up before even building the line,” Besems explains.

AMF’s pie line can handle entry-level volumes up to highcapacity production. “If it’s a dedicated line for a single type of pie, production volumes are often higher, compared to more flexible lines that do several changeovers per shift,” the specialist adds. To optimize production, and mitigate staff shortage, more steps can be automated.

For new product development, AMF Tromp can make changes on existing lines, or create a side step in the process, to allow the production of an additional type of

pie. “For instance, two or three pie lines making use of one giant tunnel oven could be very efficient,” Besems suggests. Or, at the beginning of the process, an AMF horizontal mixer can be set up to feed several pie lines – a step up in efficiency, since the pie shell recipe is often the same.

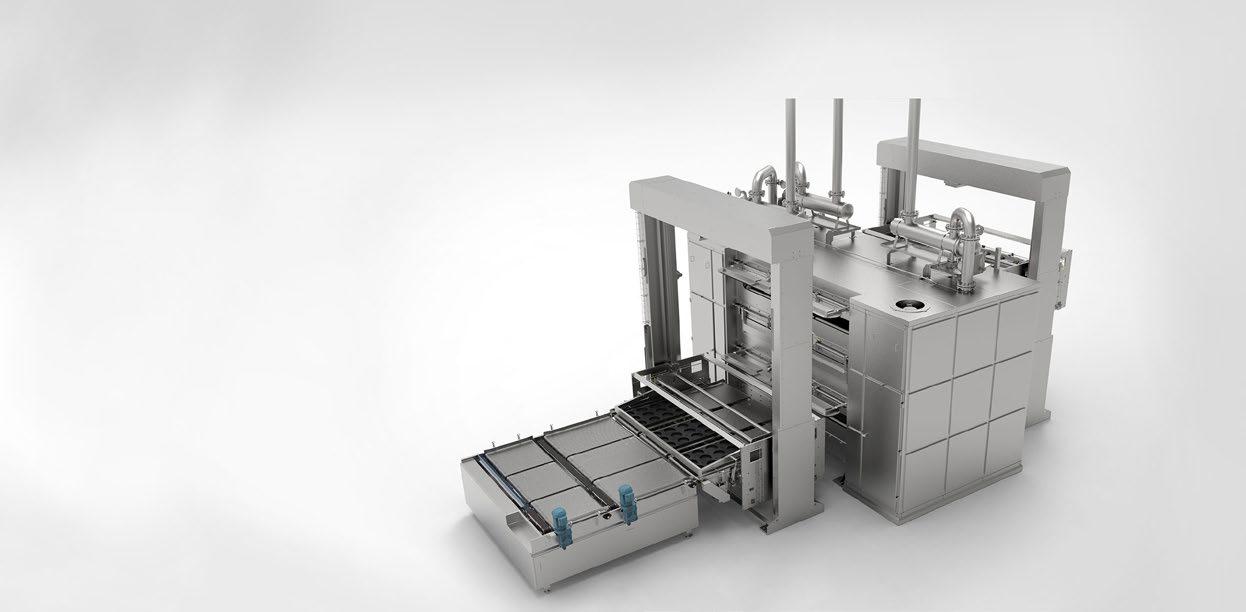

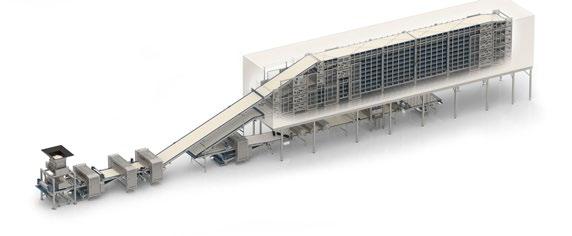

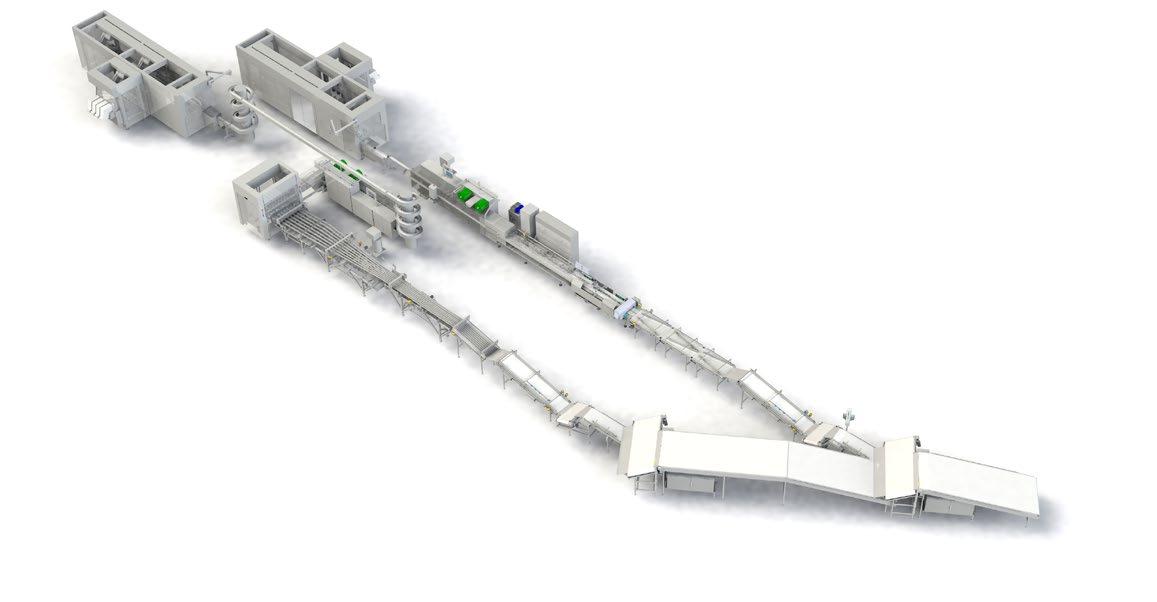

Pie, tart and cake line –Verhoeven Bakery Equipment Family

With BVT’s turnkey line, product variety extends beyond sweet and savory pies, which by themselves make up for a diverse product range, to begin with. The fully automated Pieline can handle all types of pies, tarts and cakes. All kinds of dough can run on this line, from puff pastry to Danish pastry, or shortcrust pastry, yeast dough, and dough for cakes, muffins, and even chiffon cakes, and more. To further add to the possible variety, all kinds of fillings can be combined with the doughs, meaning meat, fish, quiche lorraine, or sweet fillings, to give some examples. Furthermore, all sizes are also on the NPD table with this line, from small forms to full trays. Various shapes are also possible – round, square, or oblong. Lidding the top surface can further extend product variations, as well as lamination. The capacity of a BVT Pie line extends from approximately 1,000 pieces per hour to more than 45,000 dough pieces per hour. Product sizes can start from 30 grams, and go as high as 2,800 grams.

To optimize the possible process/product combinations with various degrees of automatization, BVT customizes each line to the unique requests of the manufacturers. “Sometimes, we even combine tarts, cakes and pies on one line, from the make-up to the packaging,” Verhoeven Bakery Equipment's team details. The company designs turnkey solutions that can also include its known vacuum cooling technology. “There are some boundaries to the customizations we can provide, but not many. We can combine different product groups in one line, even with different processes,” they add. An underlying focus throughout the various types of equipment integrated into this industrial line is process automation, so that there would be no manual interference from make-up through to packaging.

BVT can incorporate any depositor from its portfolio onto the Pieline. The company works with the customers to identify the best choice for the particular job, analyzing aspects

www.bakingbiscuit.com 02/2023 PIES, CAKES, DONUTS 18

© BVT

VERSATILE SMART TECHNOLOGY & BELTING SOLUTIONS

Ashworth Bros., Inc. revolutionary “Smart Technology” products report real-time remote monitoring, and when paired with the Eye-Link belt provides the best of both worlds for your baking manufacturing facility.

SMARTSPIRAL®

Remotely monitor multiple spirals at different plants in real time.

EYELINK®

Versatile steel conveyor belts can be designed and manufactured to satisfy the most demanding of applications.

SMARTOVEN®

Monitor key metrics used to identify changes in equipment operating parameters.

us today

forward,

+31 20 581 3220 or visit us at www.ashworth.com/bakingandbiscuit

Contact

to let us help you move your business

Call

VIEW OUR RECENT SMARTSPIRAL® SUCCESS STORY!

EYELINK

SMARTOVEN SMARTSPIRAL

”Cooling times can be dramatically reduced; for example, a big apple pie takes around 150 minutes to cool down. With vacuum cooling, this time is brought down to three minutes.”

Verhoeven Bakery Equipment specialists

such as the viscosity of the fillings and desired volume variations.

To fully tailor its turnkey line, BVT offers a comprehensive array of options. Looking at the makeup stage, choices can be made between:

+ Paper/tray feeding the forms machine

+ Equipment to support different kinds of dough

+ Different types of pressing heads

+ Different types of depositors

+ Rotary molder for the top cover

+ Bypass line for the top cover

+ Decoration cutters

+ Decoration food printers

+ Decoration strewers

Handling can also be completely automated: trays are swapped and stored, loaded into the oven and then unloaded, after baking. Automatic depanners are in place, adjusting to the requirements of vastly different products, from pies and cakes to tarts, muffins, or quiches.

Packaging is also included in the BVT turnkey line (BakePack End of Line Solutions), with options for dedicated systems for primary, secondary and tertiary packaging.

“For us, every request is a new request. We reverse engineer the products; so, when you know the end products you want to achieve and the required capacity, we design the lines,” BVT explains.

Vacuum cooling

Vacuum cooling technology is a major component of the Pieline, BVT underlines. “Cooling times can be dramatically reduced; for example, a big apple pie takes around 150 minutes to cool down. With vacuum cooling, this time is brought down to three minutes. Next to the reduced cooling time,

energy and time can be saved up to 40% of the oven capacity.” Vacuum cooling also provides better product quality, with optimum organoleptic properties and more volume, compared with conventional cooling, BVT says. It also has a positive outcome over the shelf-life of the products. This technology also saves precious floor space, as it will occupy, at the most, 20% of the space required by traditional coolers.

To optimize operations with this line, it should be regarded as an entity, and not as an assembly of various individual machines, BVT recommends. “An end product is the result of all individual machines throughout the line. Its success is a measure of how well they all work together.”

Pie and quiche line – Rademaker

The Rademaker Pie and Quiche line is developed to produce an extensive assortment of pies and quiches from all cultures, ranging from meat pies, fruit pies, egg tarts (such as the beloved Pasta del Nata) and cheesecakes, to Melton pies, pork pies and even quiches; pies with an open top or closed with a dough lid, or crumbled top. Products can be made in different foils, paper containers, metal baking trays, hoops, tins as well as indented baking trays.

The line can be built with working widths ranging between 600 mm to 1,200 mm wide. Depending on the width and the product size, production capacities can go as high as 20,000 pieces per hour – for pies 80 mm in diameter. For 250 mm-diameter pies, the hourly production capacity can reach 5,200 pieces, while for egg tarts or Pastel de Nata, it sits between 9,000 to 36,000 per hour. It can also produce 3,000 – 7,200 quiches per hour, to illustrate some of the main product categories.

This versatile line can be used interchangeably for a wide product variety without the need to make any changes to

www.bakingbiscuit.com 02/2023 PIES, CAKES, DONUTS 20

© BVT

Proven to Lower Energy Costs

ePAN® designs from American Pan have been proven to save bakeries money on every bake. In fact, one customer reduced gas usage by almost 8% year over year by switching to an ePAN.

Energy solutions like wind turbines and solar panels are a major investment and require a large amount of dedicated space. ePANs can fit on your existing bakery line and save you money from the very first bake. Here’s how:

DECREASED OVEN TEMPERATURE

Oven temperatures have decreased by up to 30°C when using ePANs.*

REDUCED BAKING TIME

Baking times have been reduced by up to 45 seconds.*

REDUCED WEIGHT OF BAKING TRAYS & TINS

Trays and tins are up to 30% lighter, requiring less energy from bakery systems and employees for handling.*

*Results from real bakery experience. Results may vary based on specific bakery conditions.

Jesper Albertsen | VICE PRESIDENT OF SALES +45 23 68 51 85 | jalbertsen@americanpan.com FIND US IN: Germany | Romania | Spain | Sweden | Turkey | UK | USA Visit us in Hall B1 - Stand 110!

its configuration. When changing product sizes, the only changeover required is that of the product-specific parts (e.g., the size and shape of the foils and platens, the size of the blocking and crimping head). And changing from sweet to savory pies is simply a manner of switching to the desired filling in the depositor. Of course, fillings are widely varied in consistency – here, Rademaker recommends the best-fitting depositor for the specific product/range: “Either a spot depositor, mono pump or gearwheel depositor can be used, in combination with nozzles that can have both ‘shut off’ and ‘blow off’ functionality. In some instances, ‘shower head’ nozzles are used to deposit through multiple outlets over the surface of the pie,” Rademaker’s specialists illustrate. Before the pie line is delivered, filling accuracy is optimized for the characteristics of the desired fillings in the operator panel, and the settings are saved.

”By thinking through these ‘what ifs’ in advance, the goal is to achieve a line design that can allow different depositors or applicators to be placed at different locations or stages through the process.”

Rademaker specialists

Depositing accuracy is ensured with direct-drive servo motors, which allow repeatable, recipe-controlled position settings from the beginning of the run. Multiple depositing parameters are defined and can be controlled, including target weight, speed, or starting and closing time of the nozzle (and many more that will further fine-tune the process). “Some features such as ‘no product- no deposit’ can be designed into the line. For example, if a foil is missing on the conveyor, then the depositor does not deposit into the empty spot,” Rademaker shares.

For product decoration, there are several available options with this pie and quiche line, including dough lids with different designs, in addition to lattices and crumbs.

Drawing from the wish list

To design a line that produces complex products to specifications, Rademaker collects all possible ‘wish list’ items

Rademaker pie and quiche line specifications

+ Working widths between 600 mm to 1,200 mm wide

+ Production capacities of up to 20,000 pieces per hour (for pies 80 mm in diameter)

+ Quiche production ranges from 3,000 to 7,000 per hour

+ Egg tarts/Pastel de nata capacity between 9,000 to 36,000 per hour

first. “By thinking through these ‘what ifs’ in advance, the goal is to achieve a line design that can allow different depositors or applicators to be placed at different locations or stages through the process. It is also important to understand the ingredient delivery to the production line that these products may require,” the specialists explain.

Rademaker’s R&D has recently focused on improving the line’s safety, maintenance and hygiene features. The pie and quiche line allows fast removal of essential parts for easy access during cleaning and maintenance operations.

“Of course, all parts are designed within the ergonomic Rademaker Sigma ® guidelines with a special focus on rounded edges and process visibility,” Rademaker’s team explains. For improved safety, access to various key parts is controlled by sensors. The same guidelines are also reflected in the line’s hygienic features, as they take into consideration various standards and certification requirements, such as the machine’s finishings, angled surfaces, food-contact-approved plastic parts in the standard blue color, and having hinges and bolts reduced to an absolute minimum. It is also entirely designed with washdown in mind.

Servo controls have also been optimized, to accurately control positioning as well as motion. Rademaker details: “For example, the servo control of a production line ensures the proper positioning for each of the units’ operations, which is critical if the line is required to run multiple sizes.” Digital line control, whether PLC or PC-based, is given, and utilized for recipe management and line performance monitoring.

With this and any fully automated production line, process optimization is a direct result of several factors, from the setup and ensuring it is maintained in good condition. The consistency of the incoming ingredients and operators’ skills also contribute to operational efficiency. Continuous specialization in running and maintaining technology is as important as having the latest-generation technology. It spells success for the people, the production line, and the quality of the products – for any of today’s and tomorrow’s favorite pies, too. +++

www.bakingbiscuit.com 02/2023 PIES, CAKES, DONUTS 22

© Rademaker

1000+ INSTALLATIONS WORLDWIDE DIRECTDRIVE™ SYSTEM

When Intralox invented the original low-tension spiral conveyor solution in 2012, it raised the bar for spiral technology beyond the reach of other belting manufacturers.

The One and Only DirectDrive System delivers:

Improved production

Reduced maintenance

Simplified sanitation

Scan QR code to see it in action.

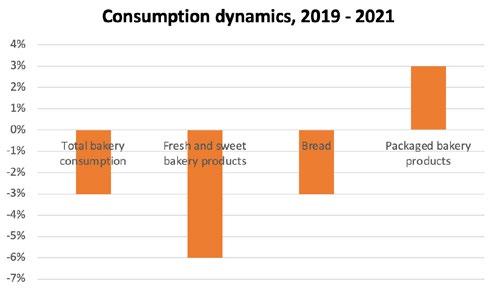

Europe enjoys authentic American tastes

Consumers across Europe are embracing American sweet bakery favorites, donuts included. This growing demand is met with ingredient solutions that can help formulate popular choices – from blondies to New-York-style cheesecakes and peanutbutter fillings – and any number of trendsetting creations inspired by America’s darling flavors.

Dawn Foods’ consumer survey found that 4 out of 5 European consumers who tried American sweet baked goods said they liked them. In addition, Gira’s recent research shows that a fifth of all fresh pastries consumed in Europe were US-style products. UK consumers, in particular, enjoy them – the ratio is 62% for them.

Experts from Dawn Foods, a bakery ingredient company with deep roots in American bakery, share expert insight into this dynamic market including different formulations, manufacturing insights and guidance into donut innovation and American-favorite sweet bakes.

Consumer demand for American-style sweet bakery goods is on the rise in Europe. Sarah Browner (Market Research & Insights Manager EU & AMEAP) illustrates: “In retail, for example, the annual average new product launch is up by 16% for donuts and 13% for cheesecake, over the past five years.” (Source: Mintel Database)

Wanted: ‘Authentic American’

Dawn Foods recently launched three new solutions that meet the growing trend for American-made flavors in Europe: a Blondie mix, a New York Style Cheesecake mix and a Crunchy Peanut Butter filling, all part of its ‘Authentic American’ range.

+ The Dawn Blondie Mix

This mix helps create a variety of new pastries to add to brownie offerings, helping with consistent results even with variations in the production process. It is designed for easy depositing and can be used with the recommended recipe, or to create new, unique blondie specialties. “Blondies need to be chewy, sticky, and gooey

in the middle,” Alexandre Deschamps (International Application Manager), explains.

+ The Dawn New York Style Cheesecake Mix

A true New York-style cheesecake needs to bake gently, without cracking its surface, or over/underbaking it. This mix can help solve such challenges, to bake cheesecakes consistently and with less room for errors in the process. It also brings versatility to the NPD table: it can be combined with several fillings and flavors.

+ The Dawn Balance Crunchy Peanut Butter Filling

This true-American product can be used as a filling or topping, pre- and after-baking. Made with 100% peanuts, it is naturally vegan and has no added sugar, packed with proteins and fibers.

While they come with several recipe ideas and recommendations, there are no limits to how all the ‘Authentic American’ products can be used. “They can be easily combined: think Peanut Butter Blondie or even combining the three into a Blondie with Peanut Butter & Cheesecake filling. You can also play with shapes, formats and flavors: Cheesecake on a stick, Peanut Butter filled cookies, or bring exciting flavor combinations by adding Dawn Compounds and/or Dawn Delifruit Fruit Fillings to cheesecake applications,” Dawn Foods‘ Alexandre Deschamps (International Application Manager) tells us. Ultimately, the new products are designed for creativity in developing signature applications.

An American donut in Europe

It’s donuts’ time on the European market. It is a landscape that has been advancing over the past decades and it’s going up by leaps and bounds today as consumers are

www.bakingbiscuit.com 02/2023 RAW MATERIALS 24

+

all pictures: © Dawn Foods

enjoying their donuts with exciting new icings, fresh tastes and better-for-you properties.

Donut shops of all kinds, from multinational franchises to independent craft businesses, have been opening at an impressive rate over the past 20 years. Product innovation is also matching this growth: donut launches in Europe peaked in 2022 (Source: Mintel research), and more donut launches are expected this year and beyond, Browner anticipates. Widely popular on both sides of the Atlantic Ocean, there are different approaches to donuts – in preparation and indulgence. For example, donuts are more of a morning choice or a snack that has a texture closer to bread in the US, while in Europe, consumers and manufacturers regard it more along the lines of cakes – softer, with a delicate structure, and are more popular with the afternoon coffee or tea, Marie Frigo (Category Marketing Manager Dry EU & AMEAP) said.

Over the next years, donut creations will continue to evolve and break boundaries with new flavors, textures and formats. Tapping into several emerging consumer trends, Dawn predicts even stronger growth for donuts in the coming years. One of the rising trends is veganism; as it continues to grow in all bakery products, innovation in donuts also looks into joining in with exciting, new offers. “According to our recent Global Bakery Trends Survey, 61% of European consumers who have tried vegan sweet baked goods, said that they liked it. Dawn has made it easy for bakers to start their donut vegan journey with a wide assortment of high-quality mixes, icings and glazes – all vegan or vegan suitable,” Browner detailed.

regardless of the experience of the staff in each shift. Dawn Foods introduced donut mixes on the market, which help with the consistency in product quality. Offering new and exciting choices is always key to having a competitive edge. It’s also true for donut innovation with the potential to entice new consumer groups. Dawn offers solutions for new flavor profiles, or product segments, such as the vegan mix, for example.

Looking at the manufacturing process next, achieving quality consistently is an acquired skill. “We like to say that 50% is in the bag of mix and 50% is in technical know-how,” Eikemper says. With this mindset, the company offers customized ingredients solutions and supports the bakers in selecting the right ingredients and optimizing production. Answers are found on all donut-related topics: “Do customers require large-scale production, to decorate orfill the donuts, or do they want different shapes? What ingredients are needed and what type of equipment?”

A yeast-raised donut, for example, needs to be cut into shapes with a dough cutter, which means the sky is the limit to the products that can be made, from rings, donut holes and long johns to twists, pumpkins, hearts, or stars. By comparison, a cake donut, which is deposited, only allows a limited range of shapes; but, it shines when made into mini donuts, whereas yeast-raised donuts do not handle miniature sizes well. Depending on the intended outcome, Dawn claims it can provide the ingredients and recommend the type of equipment that is best suited.

Guidelines to good donuts

To support bakers with new product development in donuts, Dawn shares their extensive experience and research findings, on which the company builds its new product innovation. The specialist addresses the most difficult challenges with the solutions it offers. The most difficult one has nothing to do with any particular step in donut production, and everything to do with the production process overall – namely, the lack of skilled people. Herman Eikemper (Sr. International Application Manager): “The biggest obstacle is finding skilled labor that can operate the donut production line. We know the equipment and the processes through and through and have formulations that work in every situation. They have been developed to save time, to be ‘foolproof’, to ensure a consistent outcome every time,”

Dawn’s donut mixes can be used following the recommended instructions, but they can also serve as a base for a lot of other new creations. Take, for instance, the Dawn Exceptional Raised Donut Base: it can be the start for donuts with various fillings, icings, or glazings, and it can also be used for deep-fried pastries, or sweet and savory yeast pastries, and yeast dough. Dawn partners with equipment suppliers to support bakeries in their effort to perfect donut creation, with a complete view of the product and the proces. Earlier this year, the ingredient specialist teamed up with RONDO for a seminar where each shared their expertise on making and baking donuts to perfection and to even better service and support donut manufacturing customers. +++

25 RAW MATERIALS www.bakingbiscuit.com 02/2023 ADVERTISEMENT Markenqualität und Frische aus Tradition. The Nut specialists KOENIG Motiv3 91x53.qxd 07.02.2007 11:23 Uhr Seite 1 · Almond- and Hazelnut-Products · roasted, sliced, diced and slivered · Sugar–coated and salted Products · Specifications KOENIG BACKMITTEL GMBH & CO. KG • Runtestr. 22 • D-59457 Werl Tel. 02922/9753-0 • Fax 02922/9753-99 E-Mail: info@koenig-backmittel.de • Internet: www.koenig-backmittel.de Quality-brand and freshness with long tradition

”The ‘Authentic American’ ingredient solutions can be easily combined: think Peanut Butter Blondie or even combining the three into a Blondie with Peanut Butter & Cheesecake filling.”

Alexandre Deschamps, International Application Manager, Dawn Foods

Dough-How, donut-how

Each process stage, from mixing to creating the dough band and donut shapes, through to baking, contributes to their final quality. It also holds opportunities to optimize production, such as correctly introducing re-work dough into production, for semi-automated and fully-automated operations.

Earlier this year, Dawn Foods’ Europe & AMEAP team held a seminar together with RONDO, where specialists from both companies pooled together their expertise in everything donuts. It was held at RONDO’s Dough-How Center in Burgdorf. RONDO and the ingredient specialist worked on being able to speak the same language when visiting common customers and working on improving their donut manufacturing process, Alexander Weissbach, Head of Technology and Product Management at RONDO Burgdorf AG, pointed out.

Semi-industrial and industrial donuts, all donuts

Depending on the automation level of the operation, RONDO can provide training about the recipe, the process, and the critical control points in manufacturing. Some of these points that startup bakeries should master can be handling the dough and the dough band tension, managing the size and the weight of the product, how the dough should progress along the line, what temperature parameters should be maintained throughout the process, and using re-work dough. It acts like sourdough; as it starts to ferment and swell, it builds up taste, and the water is better bound to the flour. “There are no downsides to using re-work dough; on the contrary, it is beneficial to include it as it makes the donuts denser, tastier and it helps to keep the donut fresher for longer,” RONDO’s specialist points out.

For semi-industrial operations that want to upgrade and/or expand, the focus of guideline recommendations will be on achieving a constant production flow. A process based on manual operations can afford to have resting last for some minutes longer than optimum when making smaller product batches; however, on a semi-automated or fully-automated line, the dough rheology should be always consistent, or it will impact the final shape of the products, Weissbach

explains. “At this stage, all the process guidelines should be followed strictly. All critical control points must be in check,” he recommends.

Going out of optimum parameters here will influence the dough sheeting process and, ultimately, the roundness of the product. RONDO offers an example in this regard: a bakery cutting the dough manually for their donuts upgraded to a Cutomat automated machine from RONDO. At first, they were not able to perform the cuts to obtain the donut shapes out of the dough band: the dough would not be cut all the way through, or there was too much tension on the dough. The sheeter was the prime suspect initially, but the issue came from incorrect dough development. The dough had not been mixed long enough, making it hard to sheet and then cut.

Another scenario where process and ingredient knowledge help optimize donut production is when reintroducing re-work

www.bakingbiscuit.com 02/2023 PRODUCTION 26

+

© RONDO © RONDO

THE ONLY BAG CLOSURE THAT’S HOME COMPOSTABLE.

dough into production. The recipe needs to be slightly adapted from time to time. It may cause the dough temperature to rise when it is introduced into the mixing bowl, so the balance needs to be restored to bring the dough on the line at the correct temperature. On semi-automatic systems (batch production using equipment such as automated sheeters and cutting tables), the scrap dough mesh is automatically removed from the line, then collected in boxes to be brought back to the mixer by an operator. Four or five people need to run this type of line, for tasks including dough scaling, sheeting, cutting and panning. Each of these processes can be gradually automated on the semi-automated line.

For semi-automated lines (continuous sheeting lines), several process steps are automated. Depending on the level of automation, the number of operators can be reduced to 1-2, while increasing output two- or three-fold, compared with a semi-automatic system. The Smart Donut line is an example of such a line.

For continuous production on fully-automated lines, cross conveyor belts can bring the re-work dough back to mixing. The correct amount of re-work dough will be added into the mixer, also automatically (around 50% of the full volume being prepared), no manual scaling is required. An automated line requires only one operator and achieves even higher outputs.

When having a new line installed, operators receive specialty training from RONDO’s master bakers. They are instructed on how to check if the setup is done correctly and what the dough band looks like when it isn’t (the dough surface is no longer smooth). They also learn what adjustments they need to make in such cases.

From dough band to donut

Once the dough band is formed in the desired width and thickness, product variations will only involve swapping the stamping die, for unlimited shape options, from the classic ring and circular shapes to more unusual patterns (stars, apples, pumpkins, etc.). This changeover is done in a matter of seconds, RONDO explains. In addition to variety in shapes, RONDO equipment is also flexible around different recipes. Dough bands made of sweet yeast dough, gluten-free dough, free-from products such as egg-free dough, or free-from additives can run on the sheeting line with the same setup. ‘Donut-adjacent’ products can also be made in the same way – coffee rolls or cinnamon buns, for instance. In this case, the dough band is made slightly thinner than required for donuts, and then sprinkled with cinnamon and rolled into shape.

Some types of dough pose more challenges than others. Free-from doughs, for example, are more fragile and stickier. The laminating and sheeting line can be easily adjusted to overcome challenges; flour can be dispersed on the dough band, the specialist illustrates.

Some of the biggest donut producers in Europe work together use RONDO sheeting and laminating fully-automated equipment. Well-adjusted processes and recipes are run continuously, without encountering problems over the years. +++

www.bakingbiscuit.com 02/2023 PRODUCTION 28

”There are no downsides to using re-work dough; on the contrary, it is beneficial to include it.”

Alexander Weissbach, Head of Technology and Product Management, RONDO

© RONDO

THE INTERNATIONAL NEWSFEED YOU NEED. Subscribe to the Bakery Mirror newsletter, delivered to your inbox every other Wednesday. www.bakingbiscuit.com © carl-heyerdahl-unsplash.com

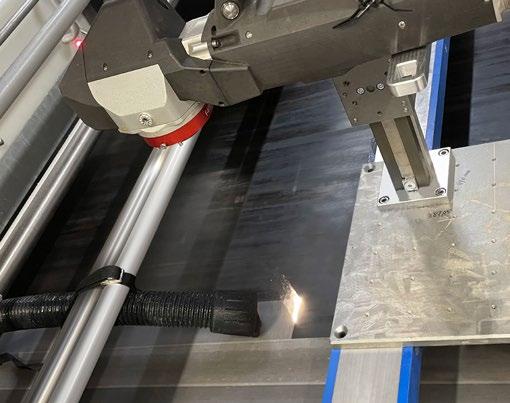

BELT

CLEANING

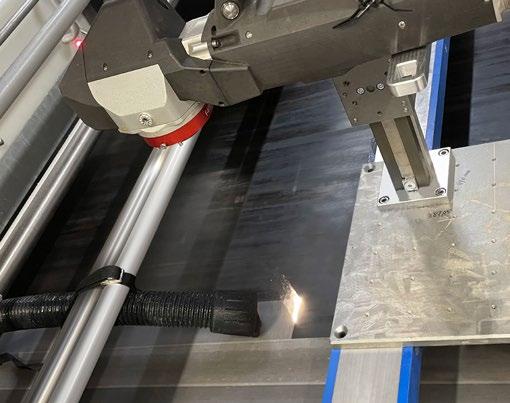

A clean start

Cleaning is an essential aspect of belt maintenance. It is important in terms of complying with food regulations as well as ensuring visually appealing baked goods. Looks are not everything, though: clean belts also guarantee product safety, for every production run.

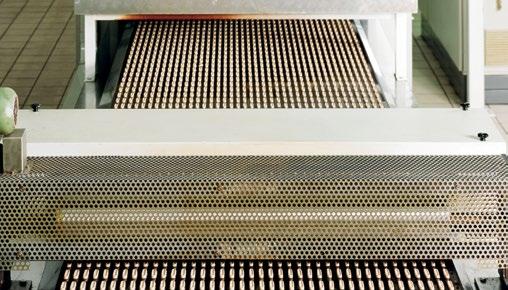

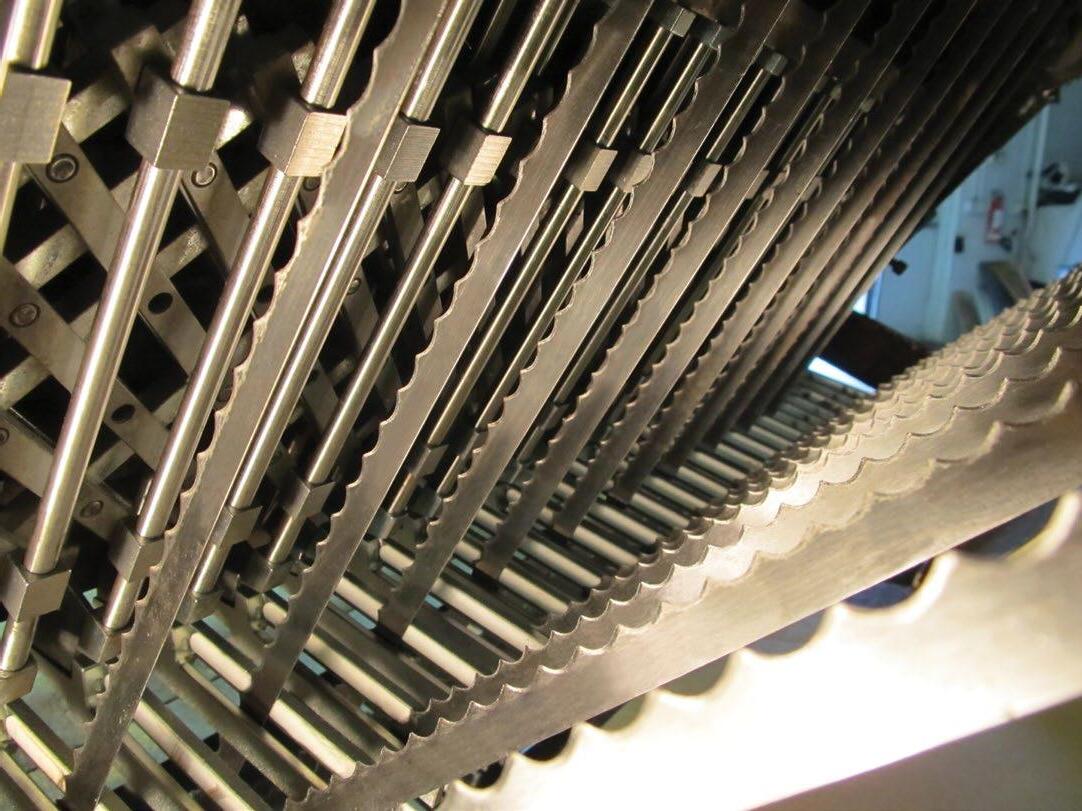

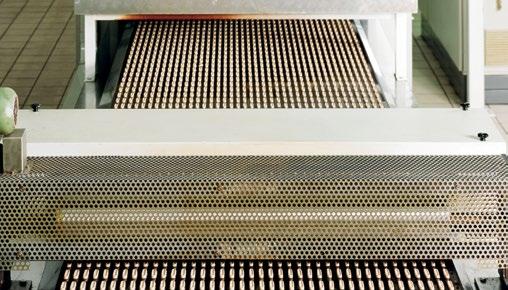

Cleaning baking oven belts can be a dirty, timeconsuming task, causing downtimes of two days or even more, when done with any of the traditional methods – chemicals, detergents, or dry ice. This spells considerable loss in production runs. Even more so, when the first batch baked right after the cleaning is usually discarded, for safety.

Cleaning requirements for baking belts are mainly determined by the type of product being baked and its ingredients; some might have higher fat or oil contents, some can be covered in flour, while others might be high in sugar or contain fruit. Sugar crystals are usually the most challenging material to clean off oven belts, as the sugar sticks on the belt tightly and can scratch its surface if it builds up on parts inside the oven, explains Marko Leber, Global Product Manager, Food, IPCO.

Planning cleaning cycles is another major factor that influences the belt cleaning process. “We learned from experience that some oven users delay the job to keep production running; but, that only makes it more difficult. When cleaning is put off for too long, the layer of baking residue becomes so thick that it’s impossible to remove by hand,” Leber points out. Finding the right balance for the right cleaning times depends on the ingredients in the bakery products. To expedite the process, IPCO recommends laser cleaning where applicable.

Laser cleaning vs. traditional methods

The immediate benefits of using laser cleaning technology for baking belts are the convenience and speed of the

process. With it, cleaning can be carried out at a rate of 10-15 sqm/hour, depending on the level of build-up. “This means that a typical baking oven belt can be cleaned in a day, depending on the belt size and accumulated buildup,” Leber highlights. What’s more, production can begin right away, with no wasted batches. Product discharge is also considerably improved.

Laser cleaning has zero impact on the structure of the belt itself, as it is an entirely contactless process. By comparison,

”The belt drive is turned on and, as the belt travels under the laser, baking residues are burned off.”

Marko Leber, Global Product Manager, Food, IPCO

www.bakingbiscuit.com 02/2023 PRODUCTION 30

+

© IPCO ©

sergey–stock.adobe.com

scrapers or brushes are abrasive and can impact the belt’s lifespan. “Using caustic soda (NaOH) to soften the residues before manually scraping them off, aside from being an extremely time-consuming and dirty process, also requires rinsing in abundance, to avoid contamination, and then immediate drying of the belt, to prevent it from rusting,” he explains. Using ice, on the other hand, can be a more effective method than chemicals. But, there are also some drawbacks to it, including the time needed for preparation as well as challenging (and costly) transportation and storage requirements.

Another major benefit is that this is a much cleaner process than other technologies, environmentally friendly and, in most cases, will not require closing down adjacent lines, IPCO’s specialist adds.

How does laser cleaning work?

IPCO has recently started providing laser cleaning services, for solid and perforated steel belts, using a high-power industrial laser. “The laser head is installed above the belt on a manually controlled carriage rail and the beam is focused on an area approximately 70 mm wide. The belt drive is turned on and, as the belt travels under the laser, baking residues are burned off,” explains Leber. Once the strip has been cleaned along the entire length of the belt, the laser head is moved across the carriage rail to the next section; this process is repeated until the full belt width has been cleaned.

The system is equipped with an external vacuum system that collects any remaining carbon residues, while also extracting any fumes that might be generated while cleaning. “Any residual debris left on the belt will be trapped by the scrapers or can easily be removed by hand,” adds the specialist.

The whole process is set up and managed by a single technician, including dismantling it when cleaning is completed. For safety reasons, a specialist from IPCO will perform the entire procedure, wearing appropriate protective gear for eyes and ears. A laser hazard zone must be established for the cleaning process, covering an area of at least 5 m from the equipment, in all directions (measured from the center of the belt at the spot were the device is placed). While cleaning operations are underway, only authorized staff may access the area, wearing laserprotective eyewear.

In Europe, the system needs a 380 V / 50 Hz power supply in the form of two 5-pin, 16 Amp connections. The oven must also be capable of running at a speed of 4 m/min or less and needs to be at room temperature before cleaning can begin (there are slightly different requirements in North America).

MDI Stratos

The indirectly heated multi-deck tunnel oven MDI STRATOS is an extraordinary combination of compact design, modularity, power and control. The heat transfer to the product takes place mainly by radiation, but also by contact and natural convection. The decks are totally independent, also allowing the management of different production rates and/or different products to be baked simultaneously.

SDI Pharos

The indirectly fired single-deck tunnel oven SDI PHAROS takes advantage of the same technology developed for the MDI STRATOS oven, yet with variable working widths available and burners in tower configuration.

SDD EOS

The directly fired single deck tunnel oven SDD EOS has been custom designed and realized for baking flat bread and typical pizza to perfection. This oven can reach incomparably high temperatures (500°C), yet it can also be widely modulated down to 150° C for baking any type of rustic product.

Koenig Group Baking Equipment 8045 Graz · Austria info@koenig-rex.com · koenig-rex.com

TUNNEL OVENS FROM KOENIG

CRAFT. FOR YOUR PERFECT BUNS. 4.-10.05.2023 Visit us at our booth at Interpack in Düsseldorf! Booth No. 3E47 PRODUCTION ADVERTISEMENT

TECHNOLOGY MEETS BAKER‘S

The added bonus is that it’s an essentially green process: no water, detergents, or chemicals are used, so there is no waste going into the drains.

Cleaning all belts

Every bakery set up has its preferred cleaning methods; some might steer clear of using water in the production area, and many will use high-pressure air. Whenever possible, moving pieces of equipment to a dedicated cleaning room might also be a practice. “Whatever method is chosen to clean belts and equipment, it must include a complete inspection to ensure that cleaning is satisfactory,” underlines Jonathan Lasecki, Director of Engineering, Ashworth.

running high-pressure air on them regularly might be all that is required to blow off any residues. However, this does not replace the periodic, thorough cleaning and rinsing that only hot water can provide, Lasecki illustrates. Belts that come in contact with wet dough products, on the other hand, require frequent cleaning to prevent debris build-up. In this case, “Hot water and or hot water under steam pressure may be required to control and remove product build-up on equipment. Each baker must determine the requirements necessary for their products and processes,” he adds.

Ashworth custom designs its belts with cleaning in mind: they include wide openings to allow debris to be easily removed. Where support openings need to be smaller, the surrounding areas within the belting are made smooth and as curved as possible to minimize product from adhering to the belt surfaces. “Our Omni-Grid 360 belting features a built-in hygienic design where the edge welds are specifically designed for easy cleaning. The welds are smooth and completely cover the hole through which the rod protrudes. This minimizes the areas for product to collect and the smooth surfaces allow easy removal of product that may collect on the weld surfaces during processing,” Lasecki details.

Working and cleaning

Monitoring should help determine the best cleaning schedules. Changes in the drive amp consumption are a good indicator that the belting might require cleaning, Asworth’s specialist explains: “As the ‘soils’ build up on the belt and system, drag friction will increase and the power consumption used to drive the belt will increase.” Another indicator could be belt tensioning, which may increase due to product contamination that increases belt drag.

To minimize downtimes for cleaning conveyors, Ashworth recommendations include planning and having well-trained staff on standby. “A well-trained staff with the necessary equipment that is readily available and understands sanitation requirements will minimize cleaning/sanitation time.”

New belts start with a ‘run-in’ period, to ‘settle’ all moving components. “For metal belts, this might take up to 24 hours or more, while plastic belts may only need a few hours. Regardless, the belt needs to be thoroughly cleaned after this run-in period to remove manufacturing and any wear debris that may have been generated,” the specialist explains.

Belts for different jobs will have different cleaning approaches. If they carry dry bakery products, for example,

One person can manage cleaning a small transfer conveyor, while a large cooling spiral conveyor may require three-four trained workers to complete a cleaning routine in the required time. Equipment-wise, belt washers placed at the infeed or discharge of the conveyor will clean the belt as it passes through, while spirals’ CIP systems wash and sanitize the enclosure. Depending on the cleaning task, cleaning solutions that can be used may include high-pressure water, high-pressure air, or steam.

Alternatively, in some cases, simple tools will be called into action: a bucket and a scrubbing brush. +++

www.bakingbiscuit.com 02/2023 PRODUCTION 32

”As the ‘soils’ build up on the belt and system, drag friction will increase and the power consumption used to drive the belt will increase.”

Jonathan Lasecki, Director of Engineering, Ashworth

© warut–stock.adobe.com

ONE CONTINUOUS PERFECT BAKE FROM END TO END TOP OF THE LINE Breads | Buns | Cookies | Crackers | Cakes | Muffins | Pastries | Pies | Pizzas MIDDLEBY’S TURNKEY BAKERY SOLUTIONS HAVE GOT YOU COVERED. Middleby optimizes best in the industry end-to-end solutions and provides you with top tier lines for all your baking needs, with complete customer support throughout equipment development, installation, and production. HUNGRY FOR MORE? Bread Dough Make-up Machinery Complete Biscuit & Cracker Solutions Professional Baking Machinery AGV Robot Loading | Unloading High-Capacity Bread and Bun Conveyorized Systems Interleaving | Stacking Interleaving Materials Freeze | Chill Steam | Proof Automated Guided Vehicles Proof | Bake | Cool Pan Shakers | Topping Applicators Water Splitters | Closure Systems High Capacity Serpentine Solution for all Bakery Categories Washing | Sanitizing Drying Professional Mixers Deposit | Portion | Fill | Pump Automated Logistic Solutions See you at Interpack Düsseldorf, Germany, May 4-10, Stand 1/B31 & 3/A55!

The proof is in the technology