Catalina Mihu, Editor-in-chief

Catalina Mihu, Editor-in-chief

Your

commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.deMay was the 12th month in a row of record-breaking temperatures, worldwide. The Copernicus Climate Change Service (C3S), funded by the European Commission, observed that we’ve just had the warmest May on record, this year. Science-based projections estimate there is a 61% chance that 2024 will break last year’s record as the warmest ever recorded, going as far back as 1850 (source: NOAA). As much as we’re eagerly ready to enjoy our summertime, this is the grain of salt of our reality this year, and every year from now. ‘Talking about the weather’ is departing from the small talk list of topics it ruled over and is now a loaded topic.

It wasn’t by coincidence that the first topic of conversation at the AIBI Congress, held in May, was sustainability. All facets encompassing sustainability were open for discussion, and what each means for the entire supply chain. Moving forward, making connections in a fragmented market is the challenge. It was one of the conclusions of the insightful conversations we were a part of, at the association’s gathering in Hamburg. Turn the pages for more details about the event and the perspectives shared!

Regulations determining actions on sustainability efforts and goals were among the aspects under discussion. As with most things, the engine of implementing changes runs on money. It is always implied, but it can sometimes go unmentioned. Coincidentally, on the very same day the baking industry was discussing sustainability, energy, climate, automation and the workforce – all interconnected topics – Reuters published a special report that shed a new light to this elephant in any room where sustainability is assessed and investigated. The news agency ran a large-scale data analysis and found that a program meant to help developing nations fight climate change is funneling money back to rich countries, in the billions of dollars. They have been sending funds for ‘support’ with climate-related woes to parts of the world in need over the past years, and did so with interest rates or other strings attached that benefited the lending nations. For example, Ecuador sought funding to fight the effects of climate change, of which, a recent one was the 2023 flood, but it received “more loans than grants”, Reuters’ investigation showed. The fact that the world’s cocoa supply is growing more unstable by the season, with Ecuador being the fourth biggest producer worldwide, is a direct consequence. The effects are already being felt in the baking world too – even if we do choose to look away from the humanitarian crisis; after all, the Earth will go on fine without humans for about 8 billion years still.

But, back to banking on humans (since it’s the only choice with humans in it), I am hopeful to see changes in progress, starting with the hardest one of all – the change of mind. There is hope that things will turn around yet, and there are signs that they are in motion, and sustainability will be the way to do it. Sustainability targets are down to all of us!

For now, it’s not all doom and gloom. I hope that everyone enjoys summer, every day of it!

Catalina Mihu

The 38th AIBI Congress brought the baking industry together this year for the moment’s most important topics, decision-making meetings and long-awaited reunions. The International Association of Plant Bakers organized this year’s event with the theme ‘21st Century Breeze over the Bakery’, and a picturesque location to match it: the city of Hamburg.

True to its motto, ‘Standing still is a step backward’, Kempf successfully completed its ambitious relocation project in little over a year. The new pin at Reutfeld 1, in Rohrbach, has officially been dropped on its brand new headquarters, reminiscent of a New York atmosphere.

ENERGY CONSUMPTION MONITORING IN BAKERIES

Engaging in energy consumption monitoring offers invaluable insights into energy usage patterns, trends, and opportunities for improvement.

importantly, dough separating: the quality of several product ranges relies on perfect, consistent laminating and sheeting. Achieving the desired number of layers in the exact thickness desired, for the optimum characteristics of each end product, can be a matter of only setting up the right production line correctly.

An entire fleet of iconic crackers built its consumer base on their open, flaky texture, which is produced by layering the dough. Reading Bakery Systems designed a new, 90-degree technology concept for the laminators manufacturing this dough.

From the beloved classics to the unexpected modern creations, the finest viennoiserie and puff pastries enjoy unwavering commitment from consumers. Along with the enthusiasm around all things patisserie, expectations are also rising.

06 AIBI 2024 Congress: 21st century breeze over the bakery

14 Kempf: A new HQ with a NY state of mind

AND SHEETING

20 AMF Bakery Systems: Watch this space (between dough layers)!

26 Reading Bakery Systems: New laminating technology design, at the right angle DIVIDING AND ROUNDING

24 Koenig: Accurately divide and conquer!

TURNKEY LINES

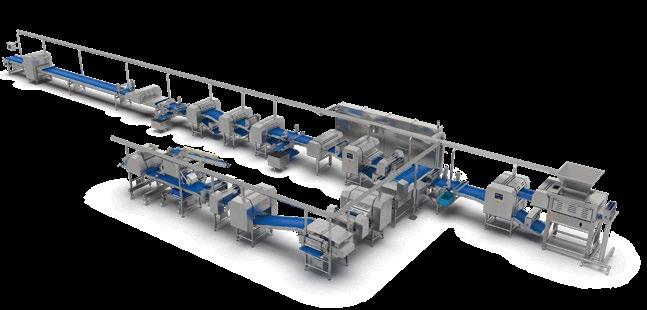

28 Rademaker: Men at work, on automated lines

30 New Era Machines: Mission code name: soft dough biscuits

32 MECATHERM : The French flair 36 Delifrance: Seven rising trends in 2024

38 Sustainable efficiency: Intelligent energy consumption monitoring in bakeries

42 Fedima: Emphasis on enzyme safety

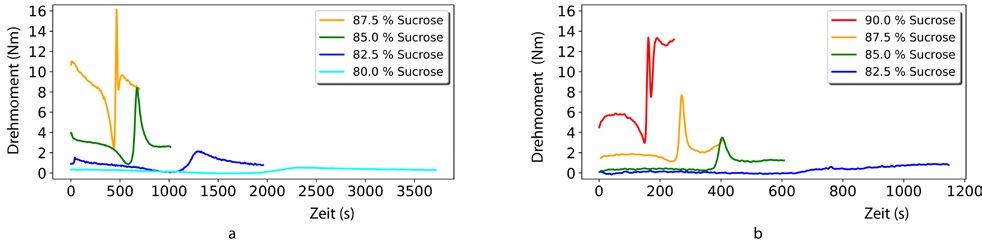

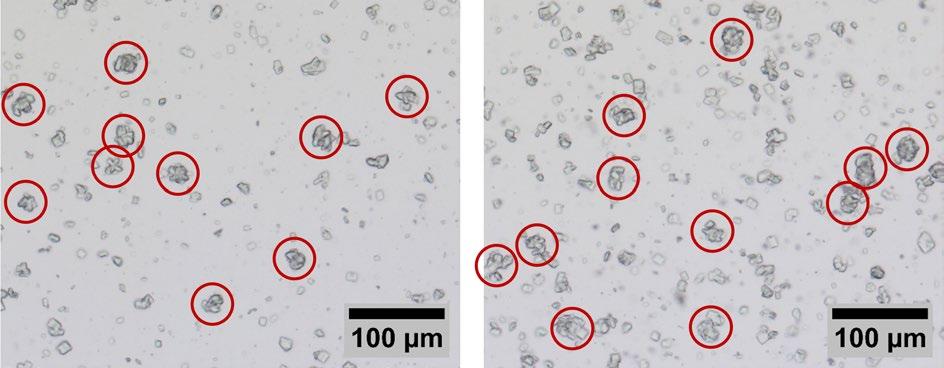

48 Fondants: Flow and crystallization behavior

56 FMCG Gurus: The right breakfast to start the day

Food2Multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

baking+biscuit international

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors. Published six times a year in the English language.

Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presentation of the state of the art in process engineering.

The f2m dictionary translates bakery terms into a mulitude of different languages.

The 38th AIBI Congress brought the baking industry together this year for the moment’s most important topics, decision-making meetings and long-awaited reunions. The International Association of Plant Bakers organized this year’s event with the theme ‘21st Century Breeze over the Bakery’, and a picturesque location to match it: the city of Hamburg.

+For three days, the Grand Elysee Hotel in Hamburg became the capital of the baking industry, hosting the event organized by the International Association of Plant Bakers (AIBI). The fixed points in the agenda included the association’s General Assembly, a full day and a half day of presentations, panels and information exchanges, and networking time, from May 22 to 24.

As one of the last formal tasks of his two-year tenure at the helm of the association, Georg Heberer introduced the new AIBI president, elected at the General Assembly: Jean-Manuel Lévêque returns to the leadershipof the industry association, after his first mandate from 2015 to 2017. He is chairman and co-owner of Novepan, a medium-sized company specializing in the premium bake-off industry with six factories in France. In his previous role within AIBI, he was a Vice President and also represents the French Federation of Industrial Bakers (FEB), as its Treasurer. A respected name in the industry, Lévêque spent the bigger part of his career within the Grands Moulins de Paris/ Delifrance Group, including the role of Delifrance CEO, which he held for 15 years. The announcement was made in a festive environment, during the gala dinner organized at the Rickmer Rickmers, Hamburg’s landmark museum ship and restaurant. The new Vice Presidents were also announced – Guido Vanherpe and Kari Meltovaara. In his introductory speech, the new president outlined the organization’s biggest priorities for the following weeks and beyond, which include “sustainability and the reputation of

our industry, which will be the most compelling argument that will enable us to attract new talents.”

As he later noted as he moderated the ‘International developments’ session, held on the last day of the Congress, the industry is, at the moment, navigating intense transformations, which include high-profile mergers and acquisitions, while also undergoing radical changes in response to sustainability priorities, raising the bar on digitalization, and the availability of raw materials and energy.

AIBI’s newest members were introduced to the Congress attendees, a sign of the organization's ambition to grow its ranks and reflect not just a resilient industry, but a thriving one: associations from Slovakia (Slovenský zväz pekárov, cukrarov a cestovinárov SR – SZPAC) Poland (Polish Bakers Association – Stowarzyszenie Producentów Pieczywa –SPP) and Ukraine (Ukrainian Bakers Association – UBA). Representatives from Ukraine were, regrettably, unable to join the event. The new expansion brings the number of AIBI member associations up to 16, plus three associated members: BakeHellas (Greece), Rabobank (the Netherlands), and Coop Genossenschaft (Switzerland).

Class

The suite of insights and panel discussions at the AIBI Congress is traditionally highly anticipated. This year, the moment’s hot topics ranged from sustainability and regulatory updates to labor force issues and advances in AI.

Ample spotlight space was given to sustainability and energy, in a session moderated by a traditional partner of AIBI events – Cyrille Filott, Global Strategist, Consumer Foods, at Rabobank (and sponsored by Puratos). The brainstorming endeavor set out to find how to move the sustainability agenda forward as the industry is facing tensions related to raw materials and energy, while aiming to meet rising consumer expectations at the same time. Perspectives on energy management were analyzed, with topics focusing on EU Sustainability Agreements, the wheat carbon footprint, and navigating a greener future.

It’s not all bleak news, as Pierre Tossut, Puratos CEO, underlined in his address: “Bread is already very low in the rank of carbon footprint per kg of product, among foodstuffs.” It accounts for 1.6 kg, while 1 kg of fruit equates to 0.4 kg CO 2 emissions, as expected for a natural product. For further reference, coffee accounts for 28.5 kg and beef is at the top with the highest carbon footprint, with a staggering

“AIBI’s biggest priorities for the following weeks and beyond will include sustainability and the reputation of our industry, which will enable us to attract new talents.”

Jean-Manuel Lévêque, President, AIBI

99.5 kg, according to the data he provided. Moreover, “85-95% of a bakery’s emissions are not coming from the factory, but upstream,” added Fillot.

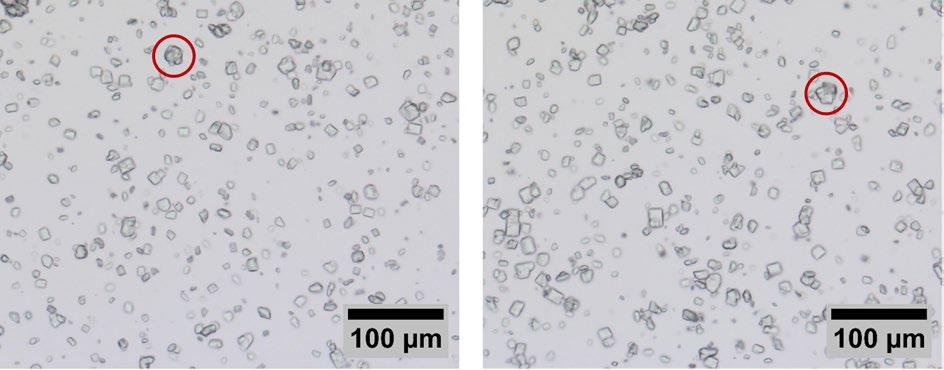

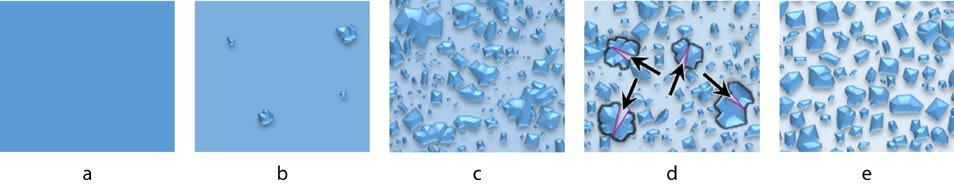

EU sustainability agreements were analyzed during this session, as they shape all strategies formed in Europe. Article 210a is of particular relevance in this regard, on agriculture sustainability, with guidelines published in December 2023. “Cooperation between different levels of the supply chain is key to the industry’s resilience,” the EU Commission representative concluded.

The session’s panel discussion welcomed to the stage Guido Vanherpe – CEO, La Lorraine Bakery Group, Pierre Tossut, Michael Gutting - Managing Director, Bindewald and Gutting Group, Maria Paz de la Cuesta de loz Mozos – Policy Officer, EU Commission, and Els Bedert – Product Policy and Sustainability Director, EuroCommerce.

In its own dedicated session, workforce and digitalization issues were disseminated, with highlights including AI and automation. Established principles were combined with practical experience knowledge, in the session moderated by AIBI Board member Kari Meltovaara, Managing Director, Leipomo Rosten Oy. Digitalization goes a long way not just to make processing more efficient, but also to make the sector more attractive to a new generation of people who would want to build a career in it. The conversation in this field is very much open. “We need to explore all the digital benefits at our disposal, because we don’t make use of all opportunities at the moment, currently,” observed

Raymond Nogael, the newly-appointed President of MECATHERM , the company that sponsored the session.

A very relevant approach to attracting people to join and stay in the industry is finding meaning in work. “Hire for attitude, train for skill,” was a key takeway proposed by Pia-Maria Thorén, from Agile People consultancy. A practical, real-life example of the importance of hiring and training the right people for the right task, and how it can help a company grow, while also upgrading for more automation, came from George Mavromaras, BakeHellas. A key question to consider is how to select new management, aside from making a straightforward, compelling argument on what production improvements will translate into for the staff, training included.

Industry leaders who joined this session’s panel discussion included Frank Kleiner – CEO, Harry Brot, Sebastian Gooding – CEO, Ditsch/ Valora Group Management, and Peter van den Berg –CEO, Pandriks Group.

The session on international developments, moderated by Jean-Manuel Lévêque and sponsored by Lesaffre, included interesting insights from Irene Mínguez Pablos –Global R&D Director, Grupo Bimbo (representing the Latin American perspective), Lévêque (EU’s point of view), and Eric Dell – President and CEO, American Bakers Association. Remote interventions also came from

“Bread can drive a wedge between us, Europeans, too. If you don’t consider geopolitics, geopolitics will consider you, and for companies, that is bad news.”

Peter Eitel, Senior Manager, PricewaterhouseCoopers Germany

Taipei, South Africa and Australia, offering a picture of unique markets and issues that each is confronted with. It reflected AIBI’s objective to establish closer connections with new bakery organizations and even more manufacturers.

On the topic of international developments, bread has always been an early warning indicator of geopolitical crises: the French Revolution and the Arab Spring, for example, and now the war in Ukraine, argued Peter Eitel, Senior Manager, PWC Germany. He analyzed what it means to bake in a fragmented world, which is becoming even more deeply fragmented as a result of overlapping crises. “Bread can drive a wedge between us, Europeans, too. If you don’t consider geopolitics, geopolitics will consider you, and for companies, that is bad news,” he warned. The researcher’s recommendation is to find a balance and have a futureoriented yet proactive approach to business. Upcoming events to watch, and calculate for because of their worldwide impact, include the US elections and the dynamics between Russia, China and the US, the expert anticipates, as Russia is bound to become a more important food producer, due to climate change. The assessment is especially relevant in light of overlapping this list of countries with that of the world’s biggest wheat producers, which are, in order: China, India, Russia and the US.

This concentrated agenda of sessions offered, nothing short of an advanced University syllabus, was a necessary, veritable boot camp in baking business inspiration, entirely justifying the high expectations built around it.

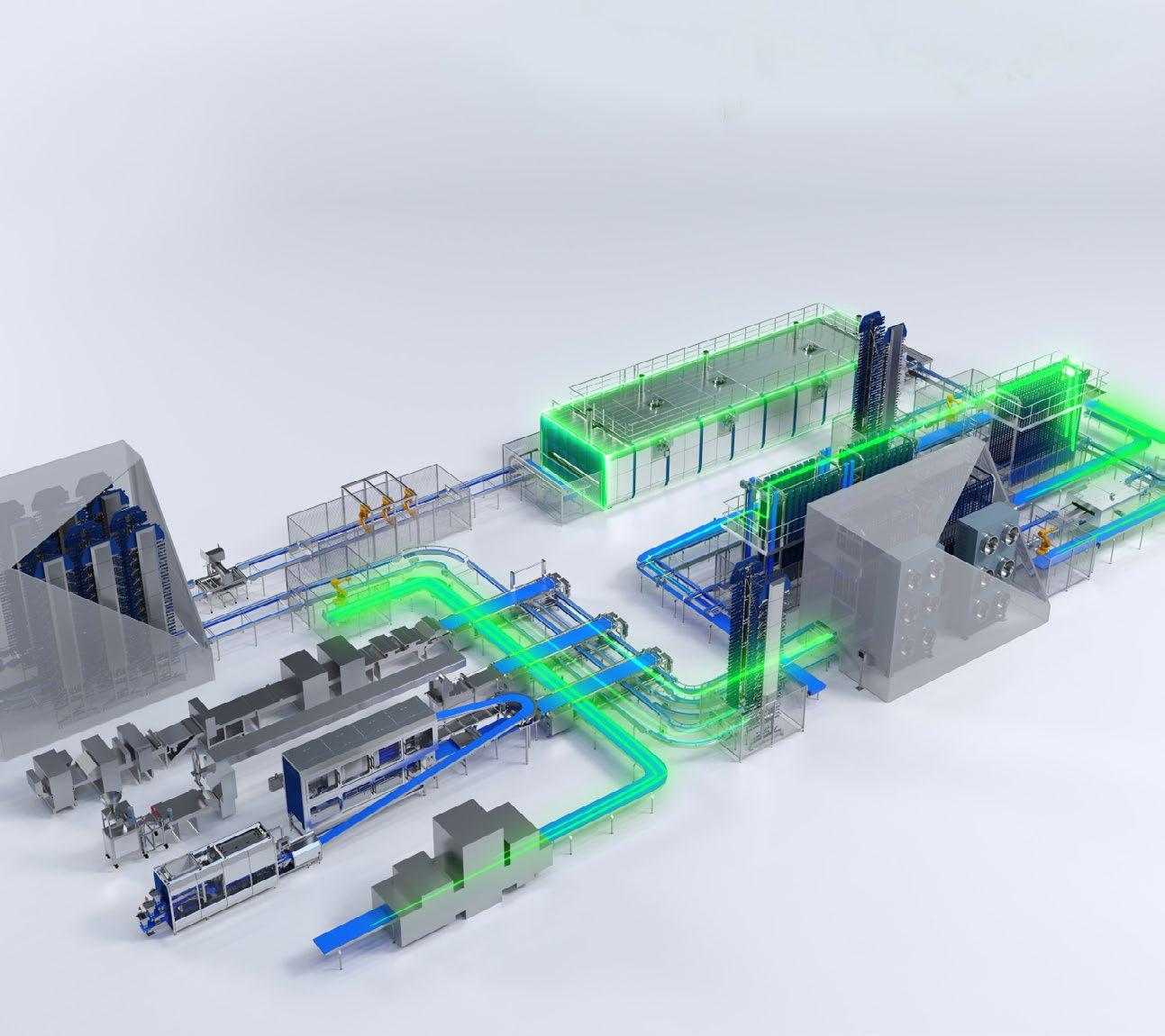

Product quality, industrial performance, and sustainability. At MECATHERM, we aim to support you everyday as you explore new ideas to stay ahead, and overcome challenges while reducing your carbon footprint. We are developing numerous innovative and sustainable solutions to optimize your energy efficiency throughout your entire production line. Let’s discuss and discover the array of options awaiting you.

For the first time, a market tour was also organized, a new, hands-on opportunity to catch – and taste – a glimpse of Hamburg’s bustling baking scene and the city itself. Pierre Nierhaus served as the guide of the tour, a trend expert for the hospitality industry who regularly observes and travels to the most inspiring metropolises worldwide. Several different kinds of businesses were selected to be a part of the tour, for a hands-on experience of different trend interpretations. The first stop highlighted Hamburg’s retail: one of Edeka’s supermarkets, headquartered in Hamburg. It offers many product choices in the bakery aisle and the in-store baking area, including an interesting array of premium and better-for-you bread products, fresh and packaged.

Mutterland with its unique retail concept was also on the itinerary. The fine food retailer has a restaurant, bakery, chocolate shop and a supporting online shop. It sells around 5,000 delicacies from 200 German manufacturers. Its Hamburg headquarters won the ‘Store of the Year’ award from the German Retail Association, in 2022. Next door is a well-known bakery in Hamburg, Junge Die Bäckerei, which was also chosen to represent the city’s baking scene in the tour. This family business, now in its fourth generation, has a network of over 200 shops and bakery cafés in the north of Germany. The business is the proud recipient of several awards acknowledging its products and employees. The Copenhagen Coffee Lab was another highlight, with its Danish products. It is found in the Rindermarkthalle St. Pauli marketplace, alongside around 30 other small, local shops.

To end the tour on a very high note, Hotel Tortue was the last stop, with a visit to its themed restaurants: from the rooftop space reminiscent of a beach bar (plus an urban skyline and a view of the new Hamburg State Opera building, a city landmark), to the beautifully decorated Asian restaurant Jin Gui, and Chez l’Ami – another dining space with Francophile culinary accents. The complex, presented by the owner, Marc Ciunis, also features several bars and a working space always decorated with carefully crafted arrangements of fresh flowers. The interest in the tour with limited seats available was clear, with a waiting list to prove it. Lutz Birke, Head of the Department of Economics and Innovation, City of Hamburg, offered in the opening speech of the Congress a quaint picture of the industry, as it could be observed during the tour, too: “In every loaf of bread, we taste tradition and innovation. The German bread market is a picture of vibrant diversity.”

As customary, the next edition of the AIBI Congress will be held in two years, in its President’s home country – France. The time and place: to be announced! +++

True to its motto, ‘Standing still is a step backward’, Kempf successfully completed its ambitious relocation project in little over a year. The new pin at Reutfeld 1, in Rohrbach, has officially been dropped on its brand new headquarters, reminiscent of a New York atmosphere. Not one to stand still, the bakeware specialist’s team brought German efficiency into the scene and is already at work in a new and improved home.

By Catalina Mihu

By Catalina Mihu

+ November 2022: Seven shovels breaking ground on a crisp morning marked the first visible sign of a long-thought-out expansion project. All things considered, including an unstable geo-political environment in Europe and beyond, supply chain disruptions and global inflation worries, Kempf made the timing work and built a 20,000 sqm headquarters containing the necessary expansion of its production facilities, with space dedicated to logistics and modern office spaces. One year and around EUR 30 million later, what started as an ambitious blueprint became a fully functional building for Kempf’s 140 employees currently working at the Rohrbach facility (and counting, with hirings underway, there should be 160 by the end of the year).

The factory gradually moved, line by line, over four months, before the end of 2023. Throughout this time, production never completely stopped. Desks, computers, favorite cups and all office logistics were transferred last, in the days between Christmas and the New Year. In early May 2024, baking+biscuit International was invited for a factory tour, this being one of the first visits Kempf received at the new address, prior to the official opening event, which will be staged after the summer. As the very last details were finalized, production was already 100% operational in May.

“Our goal is that we provide, in the end, PFAS-free coatings that have even better performance – better non-stick effect, easier to clean, and longer lifetime – compared to today’s fluoropolymer solutions.”

Guido Kempf, CEO, Kempf

The goal was to automate the production floor wherever possible and to bring onboard new technologies to increase efficiency and productivity. The move was required, on one condition: the business had to stay in Rohrbach, the small town where it started, some 50 km north of Munich. An opportunity came about for Kempf to buy the necessary land from local farmers, and the rest is history!

The new coating plant was the first facility to turn on its lights and start operating at the new address. It was the first glimpse of the development that was being prepared around it, and which f2m witnessed during our first visit, a year ago. The coating plant was designed with room for further capacity expansion right from the beginning.

Despite some unavoidable delays with construction logistics, the land around the hall designated for coatings quickly saw the rest of the building rise. Kempf is not only building, but also constantly seeking and researching new technologies it can use in its work. An important priority is sustainability, in this regard. This is why the new building’s roof is covered with over 6,000 solar panels, for instance. With the 2,100 kWp photovoltaic system, Kempf is sourcing electricity for its own production needs and for the building itself: “The floor of the entire production area has floor heating and cooling, for perfect working conditions,” Guido Kempf says, as he underlines, “Our workers are our biggest asset and as we continue to search for the best people, we want to offer the best environment.” This is why the walls of all production areas have perforated panels that help reduce the noise levels, too.

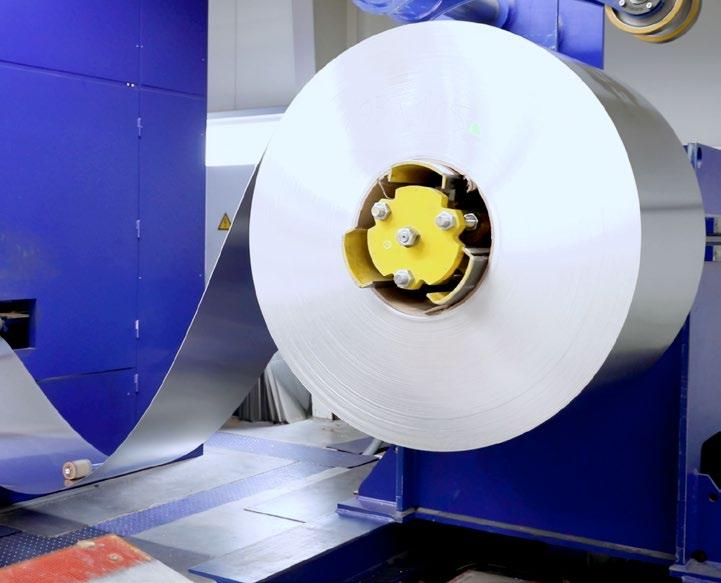

Today, the production capacity has been expanded by around 20%, compared to the old factory. However, the new production floor has, by design, free space around all existing lines, so it can still accommodate new equipment. For example, if a new perforation or a bending line is required in the future, it can be incorporated with no disruption to the processing flow. Materials, sourced directly from the plants and not via intermediaries, are delivered in coils, meaning that the trays can be produced without any scrap, as they are already the required size when they are sent to the automatic line for perforation. Because coils of different sizes are stored here, production can start within hours of placing an order. The punching unit can make up to 1,000 perforations in one motion. This translates into a perforated sheet for a standard 60 x 40 cm tray produced every 4 seconds. The parts that are punched out of the sheet are sent back to the aluminum plant, where they can be immediately melted and reused. Next, the sheet is flattened and sent to the automated bending units. Since the highest possible level of automation was a goal from the start, all standard products are made without any need for manual labor.

Production is planned over two shifts at Kempf, with a completely automated third shift being carried out with robots, overnight. The workers load the machine at 11 p.m., and it will run independently until 6 a.m. the next day, when the morning shift arrives. Standard trays for craft bakeries are usually produced on the night shift, and a stock of standard sizes is always maintained, for faster delivery times.

A section of the production area is dedicated to bakeware that needs a certain level of manual operations, such as

custom requests, or small quantity orders. Baguette trays go through here too: “We make them semi-automatically, although they are made in large numbers, because every bakery has its own requirements about the specifications of the convolutions,” Kempf explains. This is why they are always made to order and there are no stocks. Once the correct convolutions are made, the trays are sent for coating and then returned, to be assembled on their frames. The frames can and usually are reused, up to four times.

Kempf’s newest investment was a robotic solution that automates cutting 6 m-long tubes. Welding also uses a robot. A separate section handles peelboard production, including larger sizes, which have recently been requested more. A dedicated production line makes deep-drawn tin sets, with numerous tooling options. A similar line is operating at KeyBAKE, the Dutch company Kempf acquired last year.

The storage area is used for standard-size tray stocks, as an in-between stop for trays going to and from coating. It also has a section that works like a ‘tray hotel’, where

customers’ second set of trays can be stored long-term, on request (and for a small fee). Kempf’s main market is European, but it ships trays as far as Australia.

At Kempf, the R&D team continuously looks into product innovation, for all its product ranges: baking trays, most of which are perforated, trays with molds (e.g., for buns, croissants, and cakes), tin sets (for products such as toast bread and sandwich bread – also a big part of Kempf’s business), and trays for industrial systems – such as large baguette trays, as well as stainless steel racks. Another distinct category is customized solutions, developed to respect unique sets of requirements, such as baking branded products, and solutions to support tracking and tracing bakeware.

Among new developments, Kempf recently developed lightweight trays for Mecatherm production lines. “We have many possibilities to lower the weight; we can work together with our customer's technical teams to identify the critical

2100 lines installed worldwide and we are always around the corner.

Tasteable quality secured by over 85 subsidiaries worldwide

Ben Baker

parts on the line and adjust them accordingly. In the end, every kilogram we can reduce from the tray’s weight will save a lot of energy and money per year, while it works on a 24/7 production schedule,” Kempf observes. The demand for this type of tray is growing.

The field of coatings is particularly dynamic, especially in light of the highly expected EU regulation regarding the use of PFAS, which currently holds the undisputed biggest market share. The regulation is bound to affect all industries in Europe, since PFAS are even used in clothes, for example, not just in baking, and will very likely be delayed from the tentative 2025 timeline, Kempf anticipates. But, it is a matter of ‘when’ (and ‘how’) and not a matter of ‘if’.

Silicone can already provide a possible PFAS-free alternative, and its adoption is on the rise. “For baguette lines or bake-off stations, it is still one of the best options because of its excellent baking results. Its open-pore structure has the ability to retain some of the water during the proofing process, and return it to the bread while baking. The result: uniform colorization and a crunchy crust, the perfect attributes for a baguette,” Kempf explains. By comparison, a baguette baked on Teflon will have less color and a drier crust.

In addition, the company has perfected a new solution, unique to Kemp, ahead of the ban on PFAS: plasma coating. “We’ve had very good results for all types of perforated trays, as well as bun trays,” Kempf says. Because of the application method currently used, the current limitations of this coating are deep molds – for toast, tin bread, or sandwich bread – and products high in sugar such as cakes. But, using plasma coating is very new and very much a work in progress, which is already showing very promising results. “The trays we are using on lines now are passing the 5,000 cycle mark, and on a smaller installation, this coating has already exceeded 10,000 runs and the

coating is still as good as new. Plasma has the potential to be one of the best solutions for the future,” Kempf observes. “The problem with PFAS is not the Teflon we have in the frying pans at home or the Teflon we use here, in the plant, nor the Teflon used in the bakery; it stems from chemical plants using – and mishandling – the raw materials going into it, years ago. The current concern has to do with removing the risk of a new spillover in the future. I think this is not the best approach to this problem,” Kempf believes.

The new solutions join an older PFAS-free solution, which has been on the market for over a decade: ceramic coating. This comes with pros and cons – it is very abrasion-resistant, but using it regularly for baking makes its non-stick effect wear off very fast. This makes it a non-starter for baking.

Completely removing PFAS in coatings is virtually impossible in several industries, so drafting a functioning proposal is an ongoing conversation, the specialist notes. A possible scenario for a timeline could be for a consensus to be reached by 2026, followed by an extended transition period before eliminating PFAS, Kempf anticipates. This would allow ample time for new developments that will also ‘cover’ deep, molded pans, and additional solutions altogether. However, there are always companies that are early adopters when new regulations are established, so the request for PFAS-free solutions could become a real trend in the not-so-distant future.

Kempf currently recommends that bakers test the available alternatives, while their utilization is not compulsory and production rates will not be influenced. “Our goal is that we provide, in the end, PFAS-free coatings that have even better performance – better non-stick effect, easier to clean, and longer lifetime – compared to today’s fluoropolymer solutions,” Kempf anticipates. The plasma coating is a step in this direction. Acting as a surface treatment, it comes with the benefit that it cannot be damaged, i.e.,

peeled off while cleaning the tray with various cleaning agents.

Kempf added KeyBAKE Bakeware & Coatings to the group at the beginning of 2023, around the time when construction for the expansion project was starting in Germany. Perforated (bun) trays make up its main business, with a portfolio including bread pan straps, baking trays, baking forms, peelboards, coatings and racks. With a team of 35 people, it is also actively hiring, as it is increasing its production capacity to a two-shift operation. KeyBAKE is mirroring Kempf’s growth; coincidentally, it also relocated to a bigger headquarters spanning 3,000 sqm in the Netherlands, in a newly-renovated building, in November ’23. With the move, it invested in several machinery upgrades, including a 2,000-tonne press that can make trays up to 2,000 x 1,200 mm from a single piece of metal – in line with the trend of increasingly using bigger baking trays.

New HQ is more than the workplace for Kempf’s team,it’s a place where they now enjoy many new process automation upgrades; it is also a meaningfully thought-out socializing space, where everyone can feel they are appreciated and equally belong. People who work and celebrate together stay together: in a series of in-house events celebrating the new facility, employees can show family members around so they can see for themselves last year’s work in person, which came in addition to their day-to-day tasks.

Everything was planned in detail around the building itself too, with scenic areas including selected trees, and functional parking and loading/unloading spaces. If required, there is still adjacent land available for further expansion in the long term, when the time comes. +++

Dough folding, dough rolling and, most importantly, dough separating: the quality of several product ranges relies on perfect, consistent laminating and sheeting. Achieving the desired number of layers in the exact thickness desired, for the optimum characteristics of each end product, can be just a matter of setting up the right production line correctly.

+Production lines for sheeting and laminating dough are usually built around the characteristics of certain product ranges, which are in production at a certain point or are planned to be introduced. However, this equipment can have the flexibility to support changes regarding the look, feel, shape and style of products. Having in mind the ability to provide any conceivable possibilities with mini mum physical and financial effort, AMF Bakery Systems is focusing on increasing the flexibility of its sheeting and laminating equipment by having quick changeovers, to minimize downtimes.

“Engineered with the master baker in mind, AMF Bakery Systems’ dough sheeting and laminating technology is developed with a focus on sanitary design to facilitate easy and low-maintenance operation.”

Lex van Houten, Marketing Manager, EMEA and APAC, AMF Bakery Systems

Automation is not just a time- or cost-saving feature for this stage; in line with any other station on the bakery floor, the lack of skilled bakers and operators is a major challenge for dough forming, too. Automated equipment can, by and large, make up for missing staff, or for assigning the team to more meaningful tasks. “This is why our level of automation can help bakeries grow their productivity with

changeovers that do not need any tools to be carried out, we have recipe-driven production programs, so that very little time is required from an operator to run the line,” highlights Lex van Houten, Marketing Manager, EMEA and APAC, AMF Bakery Systems.

New and improved sheeting and laminating line design: AMF Tromp technology

While challenges related to high (and then higher) production volumes are, to a great extent, under control, today’s to-do list in automated equipment prioritizes food safety, hygienic design, cleanability and sustainability. AMF Tromp laminating and sheeting systems have been updated around these considerations, while maintaining

complete process control and high output rates via intuitive recipe management systems for a variety of products, with unique shapes, sizes, decorations and inclusions.

“Engineered with the master baker in mind, AMF Bakery Systems’ dough sheeting and laminating technology is developed with a focus on sanitary design to facilitate easy and low-maintenance operation. The open-frame construction of our dough sheeting equipment allows for full wash-down sanitation, ensuring that hygiene standards are meticulously maintained,” the specialist highlights. At iba 2023, the company showcased its latest advances in hygiene for sheeted bread lines, incorporating a new sanitary design and “revolutionary new features for stress-free, gentle dough sheeting, reduction and handling of highly-hydrated doughs,” the technology specialist described.

volumes and corresponding massive factories, a sign that the industry has understood the assignment and is preparing to meet a rising demand for baked goods. Numbers justify the trend: currently, the world population is 8.1 billion, and this will have risen by 73.4 million before the year ends; the world population should reach the 9-billion mark in the next 13 years and is expected to grow to 10 billion by 2057 1

“Luckily, healthy food options that are in demand, such as gluten-free, bio, vegan, and many other trends entering the market can also be produced with the same kind of

1 Source: https://www.worldometers.info/world-population/. Accessed: May, 2024.

laminating technology that is today used for an already extended range of goods,” van Houten explains. So, these systems can turn profitable quickly. Adding additional features can open the door to even more product choices: a Tromp depositor can be used for various fillings in pastry snacks, sweet or savory, vegan or meat-based.

For practical purposes, laminating lines are usually designed in an L- or U-shape, so that the layer creation and laminating process are set up on the corners of these layouts. It is a setup that works best for the production of many types of laminated dough, including Dutch and French crust. But, a block laminator is also an option, which is usually employed to pre-fabricate blocks of laminated dough, which will be sold as such or are used in the production of pastry products on a different line, the specialist from AMF shares the alternatives available.

Possible setups can vary significantly from one region to the next, each with its specific traditions; AMF automates processes on systems that meet these requirements. While the equipment integrated on an AMF laminating and sheeting line may vary according to specific builds, a fat or butter pump is a mainstay. An extruder is another popular addition, as a method of creating the dough sheet.

Dough band-forming solutions adopted may vary, as it will always depend on the products the system will make, as to whether the dough needs to be extruded or sheeted, or whether it contains fat or it needs to be applied and folded into layers. Laminated dough can be created at high speeds and volumes, with as many as 1,000 layers if

Several parameters are critical to achieving optimum results, including the temperature of the bakery, the temperature of the dough itself and the temperature of the fat. The AMF Tromp butter and fat pump is able to maintain product temperature and moisture consistently, with little stress to the fat, ensuring its integrity is maintained while it is applied to the dough. “No piping is used, so cleaning is easier, and no crystallization takes place in the process,” the specialist explains. The pump is built on a C frame so it can easily be wheeled in and out to be integrated into the Tromp (and any other) laminating line.

It can handle a large variety of fats, including margarine and real butter, but also newer alternatives such as vegan, or bio varieties. “We tested this with our ingredient partners from the industry, such as BUNGE, and they are quite happy with the results,” van Houten underlines. When working with butter, using low pressure ensures that the fat remains intact and water will not be separated while it is pumped onto the dough.

The Tromp laminating lines keep the entire process under complete control, by using recipe-driven software and controls. Different automation levels are available, starting from semi-automatic pastry/laminating lines, when a baker is responsible for a small make-up line, scaling up to fully automated systems usually found in high throughput production facilities. For the latter, AMF can build complete systems that include laminating and sheeting processes, starting from mixing through to baking, cooling and freezing.

This technology always has room for growth, both to increase production volumes and product ranges that are made with it. The expansion will be defined case by case, as floor space is also a part of this equation. This aspect is established in the first design conversations, regarding the products that are immediately intended and including any ‘wishlist’ ideas. New features can be added as production expands.

Introducing the new 893 C.

Closing up to 120 bags per minute with state-of-the-art motion control, ethernet, and wireless communications, the speedy 893 C Automatic Bag Closing Machine has efficiency baked right in. LEARN MORE AT KWIKLOK.COM

Correct and consistent dough dividing will amount to valuable material savings over time. At this stage, less (extra dough unnecessarily going in every product) is definitely more (process efficiency).

+Every gram of raw material going into bakery products in excess of the intended product volume adds up to considerable amounts lost throughout the year. The bigger the production rates, the more room for significant material and margin loss – without any added benefits to the ‘extra generous’ products. True-to-life accuracy in dough dividing is the answer to this problem.

The Mini Rex Multi, an entry-level machine developed by Koenig to support automating production, is one solution that excels at dividing and rounding dough consistently and also covers a very high range of weights: from just 8 g up to 330 g per single dough piece. The dough pieces can be round-molded from 8 g to 150 g or unrounded up to 330 g, which means it can offer a wider range of applications in terms of weight. “The machine achieves this thanks to the innovative interchangeable ‘Multi‘ system: stamping ledges with 1 – 4 rows can be combined with matching, also interchangeable rounding plates to achieve the desired weight ranges and rows,” explains Robert Sauseng, Design Department Team Lead – dough dividing and rounding, Koenig. The new compact divider has a total output of up to 1,200 pieces per hour for single-row production, and 4,800 pieces per hour when they are made in four rows. The switch between products of different weights can be made in a few minutes. Afterward, the desired program is selected on the display interface. The weight range can be defined and set up for each stamp size using a handwheel. Different weight ranges can be made by exchanging stamping ledges. Interchangeable rounding plates are available for each row. “The Mini Rex Multi runs in a continuous, one-man operation and therefore offers greater

“We achieved its compact design by arranging some of the work processes one above the other, such as the dough feed, which is positioned above the dividing area. Round molding takes place directly on the dividing drum.”

Robert Sauseng, Design Department Team Lead – dough dividing and rounding, Koenig

efficiency than a conventional grinding machine,” Koenig highlights, featuring a roller feeding hopper for approximately 15 kg of dough.

When designing the Mini Rex Multi, the development team also focused on space-saving, to occupy the smallest possible footprint. “We achieved this by arranging some of the work processes one above the other, such as the dough feed, which is positioned above the dividing area. Round molding takes place directly on the dividing drum. After molding, the dough pieces are immediately transferred to the outfeed belt with the support of a take-off roller. This direct process saves additional space while at the same time being gentle on the dough,” Koenig specialists explain the solution they found.

The Mini Rex Multi receives the dough manually into the feed hopper. Integrated flouring of its dough feed rollers ensures the material will travel through without sticking. Next, star rollers portion optimal portions into the weighing area. Depending on the selected weight range, the level of

dough in the weighing area is automatically adjusted with the use of an optical sensor. A horizontally movable dough pusher presses the dough into the openings of the dividing ledges, and the surplus dough is gathered by a scraper and conveyed back into the dividing area.

The dividing drum is then rotated at a 90° angle, allowing the dough pieces to be round-molded with an oscillating rounding plate. “The speed of the rounding plate and the deflection of the rounding eccentric can be adjusted for optimum rounding results according to different dough consistencies and weights,” Koenig specialists explain. The dividing drum is equipped with four identical dividing ledges. The machine can have the drum bars and rounding plates easily changed to achieve a wide weight range, allowing ample product variety.

The Multi Rex Mini can be used as a stand-alone machine and have the dough pieces discharged onto a continuous outfeed belt. But, it can also be used with a forming station – in this setup, the divider is mounted at an angle to the forming station and the dough pieces are discharged onto a spreading belt. The forming station can be used to produce hamburger buns, hot dog buns, milk buns or even teleras, plaited buns and bolillos, Koenig illustrates: “The dough pieces are pre-rolled on the infeed belt of the forming station and stamped accordingly on the forming station.” Baguettes and toast bread can also be produced in the higher weight range. In this setup, the system can

process wheat doughs and mixed doughs with up to 20% rye. The dough yield ranges from 148 to 162, depending on dough.

Various other modules made by Koenig can be added to the Mini Rex Multi to achieve an even greater variety of products and even configure a full, compact bread and roll line. “In addition to the forming station, a compact seeding station can also be integrated, or a convoluting station. For stamped and sliced products, the system can be supplemented with a G2000 proofer system with a stamping station for round products weighing 30 - 75 grams and a slicing unit for long-rolled products weighing up to 85 grams. The GS2000 proofer even offers up to 220 filled swings and also the option of stamped or sliced rolls,” Koenig specialists detail.

Hygiene and easy maintenance were also considered in the Mini Rex Multi’s design: the components that come into contact with the dough are conveniently accessible, so they can be easily cleaned. The roller hopper and the weighing hopper can be opened from the operator’s side without tools. In addition, certain parts can be removed for cleaning; and the entire machine is made of stainless steel for hygiene and durability.

The machine is part of Koenig's ‘Self Installation’ series. Detailed video tutorials are available for safely unpacking, assembling, installing and starting the machine, as well as for regular cleaning and maintenance. Specialist services can also be included, provided by Koenig specialists who will install and commission the machine on location. Once the new Mini Rex Multi has been comfortably seated, it can begin its work alongside the bakery’s team on a comprehensive range of products. Bakeries often start to automate and optimize their production with the Mini Rex Multi and while the bakeries are growing, they are growing with the equipment, Koenig observes. Its dough dividers and rounders can reach capacities of up to 50,400 pieces per hour. +++

An entire fleet of iconic crackers built its consumer base on their open, flaky texture, which is produced by layering the dough. Reading Bakery Systems designed a new, 90-degree technology concept for the laminators manufacturing this dough.

+Accuracy over time is essential to creating consistent sheets of dough that will then be cut and baked, to become enticing cracker products. The end result relies on stable processing and process efficiency. Technology needs to provide both. For cracker manufacturing, laminating dough is one of the key steps that immediately influences the end product characteristics. Lamination provides a slightly expanded structure, often characterized as a tender bite. Because most laminated crackers have a fat content of several percent, the crackers become softer in texture.

“Most laminated sheeted crackers will receive between four to eight laminations. Process speeds can vary from 10 to 50 meters per minute.”

Cameron Johnston, Senior Director of Innovation, RBSSpecializing in solutions for the automated, large-volume production of virtually any type of cracker product, Reading Bakery Systems (RBS) recently perfected a new laminator design that answers multiple processing needs. The latest design in the company’s Thomas L. Green equipment is a 90-degree laminator that is suitable for any traditional, wheat-based cracker dough, as well as non-traditional doughs. The straight-angle layout offers a shortened footprint, which is great news for saving valuable floor space. The compact design is especially useful when plants already have tight room between processing lines, while also handling the dough gently. Machine uptime and hygiene features were also improved: “Our frame design has a more open construction for ease of sanitation and maintenance. Most bearings have routine greasing services that can be completed while in operation, allowing for longer production runs between shutdown maintenance intervals,” explains Cameron Johnston, Senior Director of Innovation at RBS.

+ A dough sheeter may be installed to the side or directly above the laminator for a compact and efficient production layout

+ Multiple configuration options are available, depending on product ranges and available plant space

Before arriving at the laminator, the dough sheet is first created, usually with a three- or four-roll sheeter. The initial sheet usually ranges between 4 mm to 10 mm in thickness. The dough sheet is transported onto a turning conveyor, which gently rotates the sheet to 90 degrees and then places it onto the laminator infeed conveyor.

Lamination speeds with the new machine can vary greatly, so the process always correctly matches the requirements coming from variations in the number of dough layers. If fat flour is used, it is applied between dough sheets to impart distinct layers. “Most laminated sheeted crackers will receive between four to eight laminations. Process speeds can vary from 10 to 50 meters per minute,” the specialist separation of individual sheets.

says. Downstream equipment and related processes also influence laminating speeds: the oven’s length and baking times are among these factors.

For flexibility, the laminator can come with a bypass feature, so that it can allow the system to produce both laminated and non-laminated crackers. “This is extremely helpful for expanding the number of sheeted snacks capable of being produced on a single line,” Johnston highlights. The new laminator processes dough with precision, from receiving to stacking and delivering the sheeted dough to the discharge conveyor, for reduction and forming.

The new design also makes cleaning easier. Cleaning can be carried out by simply opening the guards and brushing or blowing off any debris. A damp cloth should be used to wipe down interior and exterior surfaces, belting and belt scrapers, RBS recommends. Common sanitation chemicals may be used on surfaces coming into contact with the product.

Crackers make up a creativity-filled segment of snacking options, with all signs pointing to further growth. Market

figures already paint a vibrant picture: 75% of the people surveyed for the latest ‘State of Snacking’ report by Mondelēz International say they consume snacks during a special moment of the day, and 59% of them declare themselves to be ‘snacking adventurers’ who are open to new proposals. As people increasingly favor quality offerings, technology updates bring new features, leaner processes and more capabilities. Combined innovation on the side of the technology developer and the user is key. +++

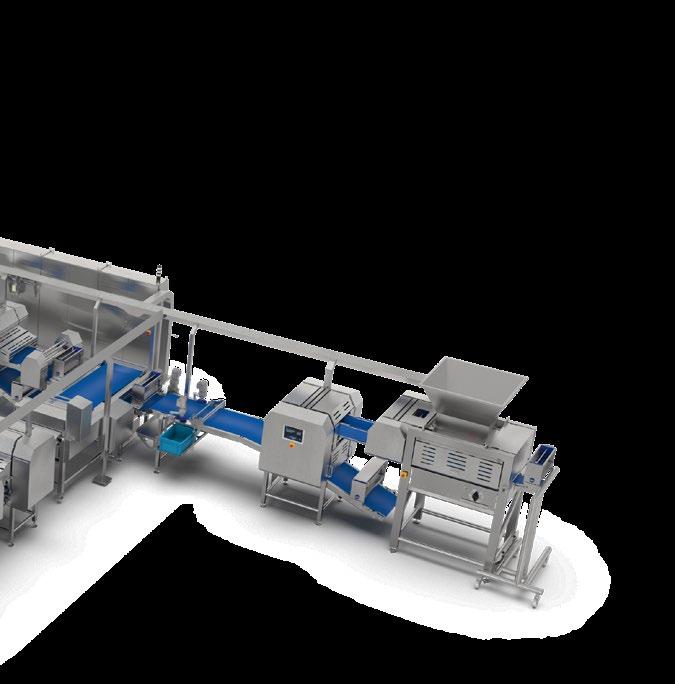

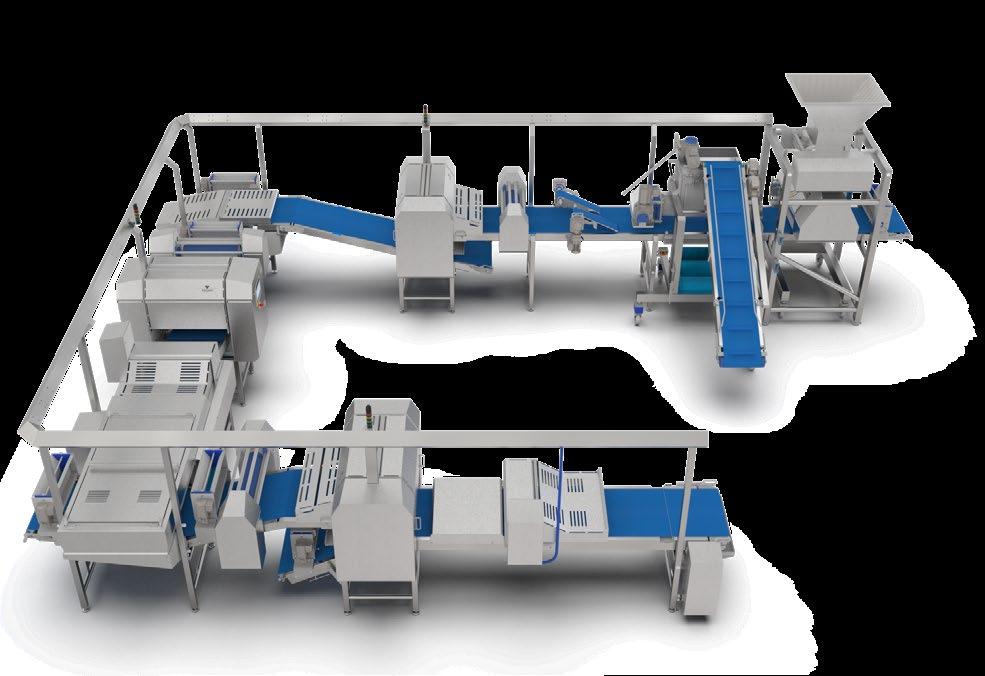

Automated production lines are the solution to optimizing production and optimally allocating resources, including a critical one: the people on the production floor. Designing the turnkey line that fits best with a given environment throughout each process step also starts with people: the design team tasked with bringing together only the perfect pieces of the puzzle that will become a new line.

+Turnkey lines integrate solutions, often from different suppliers, to work together on specific requirements. Finding the right suppliers with the most suitable equipment, who are also open to working together, is critical. The task of the project design team is to ensure good process transitions are arranged between them, while it manages communication between suppliers and controls the automation of the turnkey line. To avoid any compatibility issues that may arise, the specialists managing the design project focus on ensuring each supplier has a clear insight into the scope they cover in the project and understands all its details around critical milestones.

Given the task of building a turnkey line for maximum flexibility around the types of breads and rolls it can produce, its functional specifications are defined together with the baker. Douglas Hale, Director of Systems Integration North America at Rademaker, explains how such a project is kick-started: “We partner with the customer, starting with a detailed process flow that describes all of the different products and their specifications. Many times, the customer does not have all that information in the design phase, so you need to build into the design the ability to modify and adjust for the unknown.” Packaging is the more difficult area to set up, in their experience.

“Due to this modular architecture and often customer floor space constraints, multiple units can be delivered in a mobile variant to cater to production needs.”

Olaf Stok, Product Manager Bread Lines, RademakerThe initial list of requirements is closely analyzed and managed by the turnkey specialist in close communication with the baker, while the overall design is created, managed and agreed on. Flexible planning is key to flexible lines, as differences in initial views on the project are not uncommon: “Many times, what the customer wants will either not fit and/or work within the budget constraints so meeting regularly helps the decision process go faster and keeps the project schedule moving forward,” Hale points out.

Comprehensive testing is then carried out in the design stage at Rademaker’s dedicated facilities. If the project entails processes new to the bakery, testing will validate the design and ensure the product’s characteristics are on target.

“Many times, what the customer wants will either not fit and/or work within the budget constraints so meeting regularly helps the decision process go faster and keeps the project schedule moving forward.”

Douglas Hale, Director of Systems Integration North America, Rademaker

For a smooth installation process and timely startup, the entire project team takes part in the line design phase: the installation project managers together with those in charge of controls and commissioning. Once the design phase is completed, the formal quoting is submitted, which is used as the basis for the project’s milestone dates. Rademaker works with all suppliers who are involved in the project to map out the progress and, ultimately, the commissioning date. At the same time, its project management team also works closely with the bakery, as they assess the current process flow and product ranges. They may even spend some time in the facility to better understand the standard practices and the production team’s level of expertise. At this stage, they also assess if there is an established training process in place at the facility: “If needed, we can provide the customer with training for the Rademaker equipment, provided by the Rademaker Academy. The project managers are able to provide mechanical training on other pieces of equipment that are not made by Rademaker,” Hale explains.

A flexible line needs to also be update-friendly, for additional features that can be integrated at a later time, to expand and/or upgrade the line. Rademaker turnkey lines are created to be flexible, especially in sections such as packaging and pan handling. “Helping the customer to consider the future and what those changes would or could look like is something that we do in the design phase. Showing theoretical future lines or future expansions as part of the overall layout is something that is requested many times,” the American system integration specialist details.

In the scenario of a project designing an industrial bread line, Rademaker’s bread line is incorporated, meaning that its modular architecture can readily support revisions long after its initial build, so that production stays ahead of (future) consumer needs with incremental technology revisions. “Due to this modular architecture and often customer

floor space constraints, multiple units can be delivered in a mobile variant to cater to production needs,” Olaf Stok, Product Manager Bread Lines, points out. Fast changeovers are also an important part of this plan, and are also supported by the modular design. The flexibility of this line comes at no expense to its efficiency: “Our focus on ingredient optimization (if applicable) and waste reduction ensures maximum efficiency throughout the production process,” Stok adds.

There are several options – and challenges – when upgrading an existing turnkey project. For example, system integration becomes more complex and the resulting line will require more floor space when working with multiple types of pans, peelboards and/or baking trays. “Think about changes from one type of pan to another, or switching to trays. This can be done manually or can be fully automated. Then, add to this equation stacking robots and storage for different carriers. These solutions will claim additional space in the layout and need to be well organized in the daily production planning, illustrates Dennis Everaers, Bakery and Process Technologist at Rademaker. The company also provides solutions to such considerations in their turnkey projects.

When a newly designed line is completed, it is always set up first in the assembly hall in Culemborg, in the Netherlands. Test runs are carried out to verify that expectations for product design are met. A Factory Acceptance Test (FAT) is done with the line’s new owner, to confirm that all their requirements are met. This step is unique to Rademaker, according to its systems integration specialist. Multiple lines can be assembled at the same time (detailed scheduling is planned).

The last stage, the arrival of the new line at its final destination, in the production area, also requires careful planning that needs to consider how to minimize the impact on the daily work, so that production continues throughout the installation process. “This is a challenging area. We help the customer with plans to isolate daily production from the area where the new process is being installed,” Hale details. The Rademaker Integration team is trained and certified in food safety and can run daily process checks, to ensure safety and smooth operations during the building phase.

Soft dough biscuits are among the popular snacking choices worldwide. Their success comes, in no small part, from their diversity, combining flavor offerings and playful shapes. Recipes may call for inclusions or enrobing, to further expand the variety of this exciting product segment. Flexibility is a must for the corresponding technology to support this level of creativity.

+Inviting with their diverse iterations, biscuits are, nevertheless, a delicate business to master. Following careful preparation, the fragile products are thoroughly inspected so that they may begin their journey to the consumer in great condition, and remain that way until snack time. The competition for attention matches their diversity, which is, at the same time, their unique selling point.

New Era Machines designs and develops turnkey industrial production lines for molded soft biscuits. This line was developed with the purpose of maximizing production versatility, the specialists of the Indian company highlight: “Through extensive research and innovation, we engineered the line to accommodate a wide range of dough consistencies and formulations, allowing for the production of various biscuit types.” The line’s flexibility is achieved by incorporating adjustable parameters and versatile machinery components, they explain, to accommodate an extensive array of biscuit products and achieve the desired end-product quality.

The line comes with a modular feeding system, specially designed for biscuit production. It offers several benefits, starting with streamlining the dough feeding process. This is done by automating the distribution of dough to the forming system, which reduces manual labor while also ensuring consistent dough quality and accurate portioning, resulting in enhancing product uniformity. Additionally, the modular design means that the line can be easily customized and scaled, facilitating seamless integration into existing production setups and accommodating future expansion needs. The design of this line’s forming system also takes into consideration diversity in product demands. “We learned from the operators and customers running our machines for decades and have employed all the features necessary for quick changeovers of the molding roll and the endless belt, as well as variable speed settings to meet the process requirements and a wide range of baking times,” according to the specialists from New Era Machines. Customizations are also possible; for example, the machine can be built so that it is suitable for wash-down cleaning.

The New Era lines for soft biscuit production can also integrate equipment with various techniques of applying inclusions. They are equipped with precision dosing systems and deposition mechanisms to accurately deposit

inclusions such as salt, sugar, sesame, or nuts on the surface of the dough. Next is the oven – arguably one of the most scrutinized pieces of equipment on a line. For the production of soft biscuits, convection technology is widely the oven of choice, for its baking efficiency. As care for resources spent has become a ubiquitous concern, New Era observes that hybrid ovens have become the most popular request. The company meets this demand with its oven technology, which is designed to optimize energy consumption and product quality: “By combining direct heating and convection, our hybrid ovens provide precise temperature control and rapid heat transfer, ensuring consistent baking results with minimal energy usage. Additionally, advanced insulation and airflow management features further enhance efficiency, reducing heat loss and maximizing oven productivity,” the specialists describe.

“By combining direct heating and convection, our hybrid ovens provide precise temperature control and rapid heat transfer, ensuring consistent baking results with minimal energy usage.”

New Era Machines specialists

Hygiene and product safety are also high on the priority list, with a decisive uptick over the past few years, which is reflected in equipment R&D. The latest developments in line design at New Era Machines prioritize hygienic design principles and product safety standards: key features include smooth, easy-to-clean surfaces, sanitary construction materials. “Our machines are also equipped with advanced safety features such as interlocking guards, emergency stop buttons, and comprehensive safety protocols to protect operators and ensure compliance with industry regulations. Based on the installation country, CE, UL or CSA can be certified,” the specialist highlights.

Optional features that can be added to New Era biscuit production lines include customized decorating systems, automated packaging solutions and custom solutions for specific requirements.

The lines can be designed to evolve together with the manufacturer and keep up with later plans for additional

product ranges. For instance, if a manufacturer is installing a soft biscuit line today but wants to keep their options open and also be able to produce hard biscuits in the future, several features can be considered from the initial design stage, including necessary space for future expansions, oven technology suitable for both hard and soft biscuits, the technology specialists illustrate.

Process controls play a crucial role in ensuring consistent product quality and operational efficiency. New Era Machines biscuit production lines are equipped with control systems that monitor key parameters such as temperature, speed, and power throughout the production process. These controls enable operators to make realtime adjustments, optimizing production parameters and minimizing waste. Additionally, comprehensive data logging and analysis capabilities allow for continuous process improvement and quality assurance.

To achieve a balance between product diversity and optimum process efficiency, careful planning is required.

“To maximize efficiency without sacrificing product variety, manufacturers should focus on streamlining production processes, optimizing equipment utilization, and investing in flexible machinery solutions,” New Era says, recommending the implementation of modular production systems, standardized workflows, and advanced automation technologies, to ensure production adaptability. Additionally, continuous monitoring and improvement of key performance metrics can help identify areas for optimization, they note.

The newest developments in biscuit production machinery at New Era focus on enhancing performance, flexibility, and sustainability. Key advancements include improved automation capabilities, enhanced energy efficiency features, and fine-tuning technology for product innovation and differentiation. +++

FOR YOUR PERFECT BUNS.

MODULAR LINE IN EASY CLEAN DESIGN Artisan SFM EC Dough Sheeting Line

The Artisan SFM EC stands for gentle dough processing and efficient working. You can process both fine and large-pored doughs with a high water content. There are no limits to what you can do: whether you want to make corn corners, round rose rolls, ciabatta or bread - you can process doughs from a dough consistency of 160.

FOR OPTIMIZED CLEANING Easy Clean Design »EC«

Save valuable time for cleaning and changing products. The innovative „Easy Clean“ design with its new frame structure ensures optimized hygiene and accessibility.

From the beloved classics to the unexpected modern creations, the finest viennoiserie and puff pastries enjoy unwavering commitment from consumers. Along with the enthusiasm around all things patisserie, expectations are also rising.

+The love of pastry and viennoiserie products is unbothered by cost-of-living worries; on the contrary, the appreciation for fine bakery is growing, as it provides an important moment of indulgence and affordable luxury, when other experiences have had to leave shopping lists. The global pastry market, in which Europe ranks first, is estimated to be around EUR 61 billion this year, and projections show it could reach EUR 72.27 billion in five years – a CAGR rate of 3.44% . Consumers increasingly expect unique flavors, premium ingredients (including healthier options and sustainable options), innovative recipes and craftsmanship, regardless of the type of shopping channel at hand.

Specialized equipment that allows close control of the entire manufacturing process is a considerable advantage in industrial bakeries. How to mass-produce delicate creations that look, feel and taste on par with hand-crafted offerings? Dedicated lines are involved. Looking at the endless product possibilities, a flexible line is needed, to answer various production demands, while also ensuring accuracy with no exception.

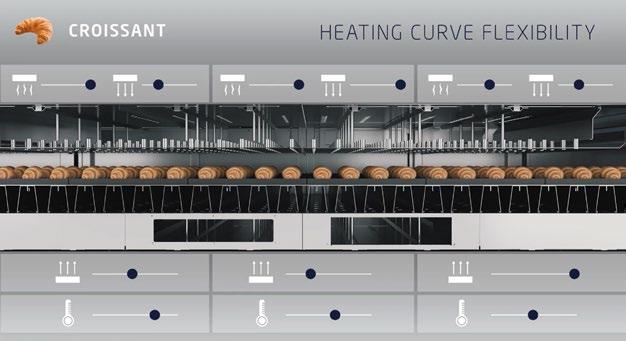

Bringing French flair to viennoiserie and French technology into production, MECATHERM offers a concept line that can help manufacture many types of viennoiserie (and other products such as morning buns): the Mecacroissant production line, with equipment covering all processes from proofing to cooling and freezing. The company develops solutions that reliably produce croissants matching the French product quality standard.

The line ensures smooth handling of the product throughout its processing cycle, to guarantee its iconic shape is preserved. But, MECATHERM also tailors this line to meet the product characteristics of any international product range in this segment. Besides the traditional flaky French croissant, made from laminated Danish dough, a very popular trend in Eastern Europe is the brioche dough croissant, for example. Both of them can also be topped or filled, which brings additional challenges in industrial production.

“The software plays out different production scenarios on the 3D model of the manufacturer’s production line to help them achieve the best availability rate and the lowest changeover times.”

Mecatherm specialists

The Mecacroissant line can be adapted to run as a multiproduct line, as the machines in its setup are suitable for different types of products. The M-TA tunnel oven is designed to support extended product ranges with precision; the same goes for the M-UB proofer, which is also suitable for a wide range of products, including the most delicate ones, with any type of filling. Mecacroissant lines can produce up to 35,000 baked regular croissants per hour.

François Retailleau (Production Lines Manager), Fabrice Bourion (Equipment Product Manager) and Xavier Gotti (Ovens Product Manager) share MECATHERM’s perspective

on processing pastry and viennoiserie products and how to utilize the Mecacroissant to fully make use of all its benefits. This production line is adapted to each project and to the products, processes, constraints and production rates of each manufacturing site, the specialists explain. The process stages may remain unchanged for all types of viennoiserie; however, perfecting each specific product is in the details, with parameters to match their size and unique profiles.

For example, proofing times can vary: they are usually longer for long shelf-life products – which can take up to eight hours – compared with frozen products, which only require two hours for proofing. This process step poses challenges to preserving product characteristics; the proofing temperature must not be too high, so that it doesn’t alter the fat, and the proofing time must be adapted to the desired shelf life. MECATHERM credits the M-UB proofer and cooler for smooth product handling, which is essential to preserving the unique shape of delicate viennoiserie such as croissants.

In a different scenario, if various types of products need to be produced on indented or flat trays, the equipment will be similar in both cases; but, the operators will have to change the trays between batches. “To make this operation fully automated, we can add a storage gantry to the production line, which can manage several sets of trays,” the specialists add.

The Mecacroissant can also be adapted according to the process required by the final product. “For a product with a long shelf-life or premium quality products, it is important to be able to precisely adjust the baking curve and the heat transfer mode; the M-TA oven is particularly adaptable for that, for example. On the other hand, to optimize industrial performance, footprint and energy efficiency, the vertical oven is a very good alternative,” MECATHERM ’s team illustrates. The oven’s baking curve can be adjusted by fine-tuning the heating mode (radiation or convection):

+ To obtain the expected crust coloration: color contrast or even coloration

+ To customize the texture and volume: from crispy to flaky, with a more or less open crumb

+ To manage the moisture content (which impacts the product shelf-life).

The production of viennoiserie, and, in particular, layered pastries filled with cheese or meat, is a considerable endeavor in terms of hygiene, as these ingredients come with strict requirements. “To meet these challenges, the M-TA oven can be equipped with an access window for easy cleaning and a stainless steel belt to reduce clogging. With these options, it becomes an excellent solution for products that require a high level of hygiene, as it provides very

precise and flexible baking in a full wash-down oven. Its hygienic design makes it especially suitable for the production of sensitive products,” MECATHERM’s specialists explain.

Flexibility is also a major challenge to be addressed when manufacturing fine bakery, and is particularly reflected in the baking process, respectively the oven technology behind it. “To meet this challenge, we recommend the M-TA oven, which is very flexible thanks to its very precise and customizable baking curve. It allows manufacturers to produce even the most demanding clean-label products, formulations that have no additives and are made with natural ingredients, as well as free-from and better-for-you product ranges (such as gluten-free, or wholemeal recipes) – both important trends in the viennoiserie market,” MECATHERM’s team underlines. The M-TA is also the best oven choice from MECATHERM's range when producing a diverse range of products or when a precise adjustment of the baking curve is needed, as it features independent baking zones. “The adjustable parameters make it possible to have either convection or radiation at the top or bottom,” MECATHERM’s specialists highlight. The hygrometry can also be adjusted on this oven, which is particularly beneficial for products with a long shelf life.

If the product requires convection baking only, then the vertical oven solution is the recommended technology – a compact solution designed to optimize industrial performance.

“In order to better manage the perfect hygrometry level in the ovens, both types of ovens are compatible with the Hygro Control System, which will be launched soon. This innovative solution will allow the automatic adjustment of the hygrometry inside each oven module independently,” MECATHERM ’s team explains.

Both of MECATHERM’s oven technologies come with a unique profile, a list of benefits that includes the potential for energy savings. The vertical oven significantly limits energy losses through its walls, conveyors and fumes, thanks to its compact design. Moreover, using convection means that

they can bake at lower temperatures, while benefiting from an even heat transfer around the product, again translating into energy (and time) savings.

MECATHERM is also developing new solutions to optimize energy consumption, starting with the Hygro Control system, which will offer automatic hygrometry management, reducing CO 2 emissions and energy losses due to fumes. The Energy Recovery System is another soon-to-be-launched solution, which will make it possible to save additional energy throughout the line by recovering the energy produced by the baking vapor and converting it into pre-heated dry air. The energy recovered can be used to preheat the oven with dry air, but it can also be used for other pieces of equipment along the line, including the proofer, the steam boiler, or even beyond the line, such as the building's hot water circuit. Moreover, “Most of MECATHERM ’s ovens will soon be compatible with an electrical heating source,” the specialists note, which will not only save resources, but will also limit C0 2 emissions.

The fill level of the oven and the production rate are also considered, so that the oven is heated accordingly: the parameters will automatically adapt, thanks to modular burners. “Our oven convection technology limits the flash heat effect thanks to the convection baking mode and a high rate of air renewal in the baking chamber,” the oven specialists explain.

Perfecting the baking curve for each product guarantees the best results with optimum resource allocation. Both of these priorities can be fulfilled along the entire production line, for increased sustainability in production, on one condition: that all processes are under complete control. Here, smart features play a decisive role.

For example, the pastry line can integrate the EYE-Q quality control system, developed by MECATHERM’s sister company, ABI LTD. The system is driven by AI to perform real-time quality control for every single product on the line – not

just samples selected at random every 100 items or every 15 minutes. “The EYE-Q classifies the products and provides a trend analysis to improve line performance,” the specialists explain. The smart inspection system can be positioned at any critical point on the line, such as depositing, where it can ensure that no double dough pieces are entering production and that each piece is correctly positioned at the center of the conveyor. Another possible placement is at the exit from the proofer, to inspect that the level of the dough rise is correct.

The greatest enemy of productivity is, undoubtedly, sudden production stops. The company can integrate a buffer on the Mecacroissant line to save production when such stops occur: it will store the products in the oven so the batch is not lost.

And this is not the only waste management mechanism that is utilized (on all MECATHERM solutions) to limit product loss. Most of the machines ensure smooth product handling, to avoid bringing any shocks to it (such as the M-UB handling system), and are designed to minimize necessary manipulations/transitions, to further avoid damage. Overall, “The precision of the equipment guarantees production homogeneity, limiting product losses,” the team adds.

Correct planning also contributes to baking more sustainably. The M-plan simulation tool can be used to optimize production scheduling. Its batch follow-up feature also allows for changeover management optimization and minimizing waste: “The software plays out different production scenarios on the 3D model of the manufacturer’s production line to help them achieve the best availability rate and the lowest changeover times,” they explain.

The setup of the Mecacroissant line supports product innovation, as it can easily introduce new creations into production. To optimize settings and formulations, new products can be tested at MECATHERM’s Demo Center in Barembach, with support from the company’s team of master bakers.

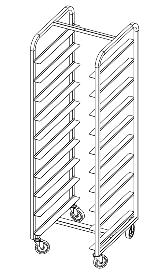

The global baking industry has many different standards for bakery racks and so do individual bakers. That is why we produce high-quality stainless steel racks made to meet the unique needs of each of our customers.

• Material: Heavy-duty stainless steel construction for strength and durability.

• Size: Racks made to fit any size pan or oven system.

• Frame: Variety of frame types from single, double, z-type, and more.

• Rungs: Use a standard amount and assortment or create a unique design.

• Castors & Wheels: Heavy-duty castors and wheels available in various materials with a range of features.

• Accessories: Choose accessories such as steering and fixings to meet your bakery’s needs.

+Part of the French cooperative group VIVESCIA, Délifrance creates bakery, viennoiserie, pastry and savory products for foodservice providers, bakers and retailers. Founded in 1978, it offers its specialties in 100 countries.