Markel Bakery Group Company

Markel Bakery Group Company

Markel Bakery Group Company

Markel Bakery Group Company

The iba trade fair (International Bakery Exhibition) takes place every three years. Nearly 1,300 exhibitors will be present in Munich from September 15 to 20, 2018. The event organizers again expect more than 77,000 visitors from the whole world. It’s simply the leading trade fair for the baking sector worldwide this year. But other event organizers have also done their homework well, and the IBIE (International Baking Industry Exposition) in Las Vegas (September 8 to 11, 2019) is likewise without question a world-class trade fair, and Interpack (May 7 to 13, 2020) is also always worth a visit. Fortunately, the event organizers have arranged the dates in such a way that the corresponding international trade fairs don’t all occur in the same year, and there are no overlaps. And to ensure that life in the sector doesn’t become boring, there really are more trade fairs such as the südback, Bakery China and Modern Bakery, as well as trade fairs in the Middle East etc. etc.

++ Bastian Borchfeld, Editor-in-Chief

Your commments or suggestions are always appreciated: phone: +49 40 39 90 12 28 borchfeld@foodmultimedia.de

But the one that is about to take place is the iba. During a round of discussions with leading European baked products manufacturers, I asked why the trade fair is visited. The unanimous answer: On the lookout for innovations, and cultivating and expanding the network. The trade fair offers visitors both. Many plant constructors show their latest developments, and raw materials suppliers also present themselves and their products. Maintaining and expanding contacts simply happens incidentally.

At the same time, however, a question that arises over and over again is whether there is enough on offer for visitors from smaller businesses. There are still many artisan bakers, especially in Germany, for whom an industrial line, e.g. to produce baguettes or hamburger buns, means absolutely nothing. The iba responds to this with an artisan guide, for example, or celebrates “German Bakers’ Day” or the “German Confectioners’ Day” on September 16 and 19 respectively. These are certainly smart ideas and approaches to a solution.

Personally, I can recommend a visit to the trade fair to everyone. It’s simply a performance show of plant construction as well. And for smaller bakeries, it’s also worthwhile looking at how the industry works, and at the kinds of ideas that can possibly be put into practice, or discovering trends and counter-trends. Therefore I wouldn’t allow myself to be drawn into making a distinction between “industry” and “artisans” in the first place, because there’s no clear answer or a clear division in any case.

Admittedly, every one of us would like to know what our neighbor is doing, and the iba gives exhibitors and visitors an opportunity to look outside of the proverbial box for once.

I also look forward to the visit, and hope to see many familiar faces again in Munich, as well as getting to know some new ones.

Best Regards,

Ours knows a good deal. Industry-specific processes, integration of machines and systems, monitoring and reporting, traceability, quality management and much more.

The CSB-System is the business software for the bread and bakery goods industry. The end-to-end solution encompasses ERP, FACTORY ERP and MES. And best-practice standards come as part of the package.

Would you like to know exactly why industry leaders count on CSB?

Production

06 Fireking Baking Company:

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany

+49 40 39 90 12 27

www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil

+49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld

+49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk +49 40 39 60 30 61 baumfalk@foodmultimedia.de

Silke Liebig-Braunholz

+49 (0)40 386 167 92 liebig-braunholz@foodmultimedia.de

ADVERTISING DEPT.

International sales director

Dirk Dixon

+44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Wilfried Krause +49 40 38 61 67 94 krause@foodmultimedia.de

DISTRIBUTION

+49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide Linda Langhagen; design@landmagd.de

PRINTED BY

Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department. No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2018

photo: ©

Gregory Acerra founded the Fireking Baking Company in Boston, USA, in 1995 to offer freshly-baked European-style bread to restaurants, clubs and catering companies. Within a short time. Fireking became well-known as a baking industry innovator.

The restaurateur Gregory Acerra, founder of the American Fireking Baking Company, Braintree, Massachusetts, has already received various awards for his entrepreneurial skills, e.g. from “The Small Business Administration” (SBA). The SBA honored the Fireking Baking Company as “Manufacturer of the Year 2016 for Massachusetts”. Robert Nelson, District Director von SBA Massachusetts, explained that Gregory Acerra received this distinction not only for creating many new jobs in the region but also because he manufactured baked products with their own unique quality. Since founding the bakery in 1995, Acerra has made a name for

himself as a baking industry innovator. It all started with his Tosca Restaurant in Hingham. Gregory Acerra really wanted to offer his guests high-quality artisan-made bread. But none of the suppliers fulfilled the requirements.

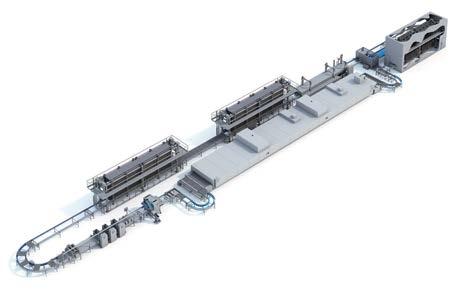

Fortunately for the restaurateur, a vacant gas station opposite the restaurant was up for sale – so Acerra bought the building and opened the Fireking Baking Company together with a bistro. Half of the building was used as the restaurant, and two former service sheds were converted into a small bakery where two employees then produced baked goods for Gregory Acerra’s restaurants. Only a few months later, a major restaurant chain in Boston was enquiring about breads, and the news spread by word of mouth that the high-quality breads at the Fireking Baking Company were distinctly different from other baked products. Demand grew, the bakery also grew, and so did the distribution area. The operation soon moved to a building of around 40,000 ft2 (approx. 3,720 m2) in Braintree, MA. Around 114 staff now produced fresh and frozen baked goods, which were bought by customers from the entire USA. Growth was sustained, and a 25,000 ft 2 (approx. 2,320 m 2) enlargement of the production facility was necessary. Today the company employs a workforce of more than 140, and the range of baked goods in the premium segment has grown. In addition to various bread rolls, the bakery produces hamburger buns, brioche variants, ciabatta and focaccia as well as European-style special breads.

The range of baked products now includes over 300 types of baked goods produced for the catering trade, the retail and as private label. For example, items baked using fresh herbs or fresh eggs are produced to continue to distinguish them from competitors. Extra native olive oil is also used. Fresh goods are produced every day, but customers can also order frozen products through a national distribution network. The production unit operates on six days a week. On the seventh day the production facility is intensively cleaned and the plants serviced.

Gregory Acerra says “Although artisan breads are still baked and manufactured by hand, the majority of the baked goods are produced using a gentle semi-automatic manual process.” The ultimate aim is to produce European-style baked goods, so consequently most of the plants in the production facility are from Europe. Explaining his strategy, Acerra says “I obtained information about European plant constructors, at the iba trade fair in Munich for example, and had the various machines explained to me during the trade fair.” Good experience with the supplier Koenig in Graz, Austria, has led to a wide variety of machines being present in the factory. For example, the employees have used Koenig’s DW 240-H twin twist mixer since 2016, the “H” standing for hygiene model. This allows the mixer to be completely wash-down with low-pressure water.

Other characteristic features include:

+ The machine frame and machine head have a fully-sealed welded design

+ Stainless steel claddings and switchgear cabinet

+ Drain holes in the baseplates of the machine frame and machine head

+ Stainless steel friction wheel adapter

+ Friction wheel adapter with low-pressure water drain

+ Dust-tight mixing bowl cover

+ Touch-panel has IP65 ingress protection

The mixer’s two tools with a special spiral work at an angle to each other, thus increasing the input of mechanical energy

into the dough, which shortens the mixing time. This method also incorporates more air and oxygen. This is why the twin twist mixer machine with a 240 kg dough capacity is especially suitable for wheat and fine pastry doughs.

Fireking relies on a Menes dough sheeter with an 800 mm working width for dough processing. The plant has an infeed system. With all usable grades of dough, especially soft doughs with a rather long bowl resting time, the infeed creates a uniform, structurally homogeneous dough sheet from gently divided blocks of dough sheet. In addition, the infeed has an option to superimpose two dough sheet halves to assist the volume yield and dimensional stability of the products.

The infeed is followed by a Twin-Sat. The Twin-Sat double satellite head is an essential component of every Menes plant. It produces a practically stress-free dough sheet. At the same time, the double satellite head uses two satellite roller heads arranged one above the other to reduce high mechanical stressing.

The Twin-Sat is followed by a vibro-roller station to widen the dough sheet. The dough sheet is guided through a cylindrical upper roller and a conveyor belt below which there is a screwshaped shaft. The dough thickness is reduced by pulsating movements, and the dough is gently pushed outwards from the center. The eccentric arrangement also causes the dough

to experience repeated short-duration relaxation during the treatment process. Moreover, a cross-roller and smoothing roller station ensure that the dough sheet thickness is further reduced. Next, a longitudinal cutter unit cuts the dough sheet into dough strands which a cross-cutter cuts to length and/or shape. Scrap dough is picked up by a conveyor belt specially designed for this purpose, and can be fed via a transverse belt into the mixer, for example. Fireking’s Menes line also has a molding station to long-roll and wrap the products. The bakery uses the line to produce items such as ciabatta, baguettes, special breads, hotdog buns, hoagies or hamburger buns.

Furthermore, Fireking has three bread roll lines in the bakery, two operating with a Rex Futura Multi und the newest roll line features an Industrie Rex for higher performance. “We are really excited about that machine. It is very fast, very accurate and it makes a great product. We make products like crusty rolls, lobster rolls, molded products, mini rolls with 16 or 18 grams and rolls with up to 150 grams,” says Gregory Acerra.

All lines have bowl tippers and large dough cones. The Rex Futura Multi dough divider-rounder machine produces a wide variety of dough pieces in a broad weight range from 17 to 245 g (for molded dough pieces) and up to 600 g (for unmolded dough pieces). Downstream of that, the plants have a molding station to fold in, wrap and/or long-roll products, e.g. for hoagies, hotdog buns or hamburger rolls. A side discharger ensures sideways discharge to automatically transport trays with manual tray input on one side of the line and manual removal on the other side.

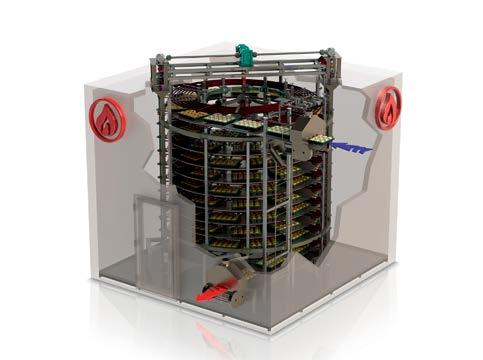

For baking, Fireking uses several multi-deck ovens together with rack ovens. The equipment being used includes 10 Roto Passat SE rack ovens. The bakery is Koenig’s first Roto Passat customer in the USA, Gregory Acerra is very happy with the ovens: “I’m convinced, those ovens are the best in the industry. I had taken out 7 ovens and I put in 10 in the same footprint. Baking time is also down, one of the products we baked for 55 minutes, we now bake for 35 minutes. The product is fresher, softer, tremendous eye appeal.”

The ovens are in the “SE” version, SE standing for “Save Energy”. Compared to the predecessor model, this version of the oven has an energy-saving potential of up to 20% of the energy. The designers also improved the external insulation, resulting in a lower surface temperature. The air-flow control, which uses an electrically adjustable flap, enables product-specifically correct energy use. There is also a labyrinth system installed below the rack’s turntable, which is used to protect against deposits of accumulated dirt.

Owner Gregory Acerra also wants to invest and grow further in 2018 and 2019. He intends to buy more equipment, such as rack ovens to allow a higher capacity production of “highend baked goods”. The career-changer sees further growth opportunities in the frozen product area and also wants to use more high-quality fresh raw materials. The entrepreneur already plans to move into a new production facility with more than 200,000 ft² (around 18,500 m2) to fit all of his ideas and visions of high-quality baked goods. +++

Several European initiatives are aimed at working on the image of bread and stimulating its consumption. The symposium “Bread Promotion Activities in Europe” organized jointly by the AIBI and Fedima in Brussels/Belgium focused on these activities.

+Bre ad consumption in Europe has been in decline for several years. Whereas average annual per capita bread consumption in 17 European countries in 2014 was 67 kg, it was only 63 kg in 2016*. The reasons? Many and various. Negative media reporting (e.g. about gluten) is probably a factor, and (as a consequence of this) skepticism on the part of some consumers who think bread is unhealthy, but also the growing availability of foods that compete with bread, such as mueslis or yoghurts.

There will probably be no magic formula for a reversal. Several European initiatives are aimed at working on the image of bread and stimulating its consumption. The symposium “Bread Promotion Activities in Europe” organized jointly by the AIBI (International Association of Plant Bakers) and Fedima (Federation of European Union Manufacturers and Suppliers of Ingredients to the Bakery, Confectionery and Patisserie Industries) in Brussels/Belgium focused on these activities. The Symposium’s aim was to give participants from the national organizations an overview of the activities and to offer them an opportunity to learn from one another in a reciprocal exchange of views.

In their opening presentations, Fedima President Johan Sanders and AIBI President Joseph Street welcomed around 50 participants from the industry sector to the event. Dr. Fred Brouns, Maastricht University, reported in his contribution that bread was “under fire” nowadays. He said incomplete information was damaging bread’s image and leading to misunderstandings. Prof. Brouns provided scientific knowledge, about wheat among other things, and refuted popular misgivings. A question often asked, for example, is whether modern wheats contain more gluten than older varieties. Based on a study of 150 varieties of wheat, he demonstrated that newer varieties contain less gluten and more starch than

older types. He said that as a result of the study it was also clear that the type and composition of the peptides differ depending on the cereal’s genome. Whether this affects the occurrence and severity of adverse symptoms due to wheat is the subject of a series of international studies. Prof. Brouns referred to the WoW Project (Well on Wheat), which is investigating the health aspects of wheats. Results are published on the web site www.um-eatwell.nl/wow/index.html.

Elodie Clerc from the EU Commission for Agriculture and Rural Development presented the new EU Funding Policy for Agricultural and Processed Agricultural Products – e.g. bread. She said a total of EUR 179 million is available for funding programs in 2018. She gave advice about what must be taken into account when making an application. According to her, the main precondition for funding to be approved is: the message must be European. (You can find more information and examples for co-financed campaigns here: https://ec.europa.eu/chafea/agri/content/info-day-calls-proposals-2018)

One such EU-funded campaign is Bread from Europe, a Belgian-Netherlands project whose participants include the Netherlands Bakery Center (NBC) and the Belgian Institute for Bread & Health. Presenting it, Zsuzsan Proos (NBC) said “If we want to halt the drop in consumption, we must ensure bread remains part of our daily diet. Bread needs a positive boost.” The project required three markets - the Netherlands, Flanders and Wallonia – to be brought under one roof. Therefore it began with a search for values for bread that hold true in all three markets. The campaign’s main message

is: Bread from Europe – a magnificent story. The aim is to communicate how versatile, tasty and nutritious bread is. Bread is convenient and bread is a part of European culture. As a quantitative objective, the aim was to stabilize the market volume in the Netherlands and Belgium at 1.271 million tons by 2020. The plan is to address a broad target group, principally consumers, but also food professionals. Belgium and the Netherlands were each given their own campaign plans. For example, tastings in supermarkets, bakeries or schools were or will be carried out and radio spots produced, as well as TV spots and videos, including with Peter Bienefelt, a well-known Dutch baker, and posted on YouTube. (Link: https://youtu. be/i12NIeG9QcA) The campaign includes other social media and PR campaigns that went public in March 2018. Scientific

Saves even more energy. And is ahead in most other aspects, too. Your next MIWE roll-in e + 3.0.

Unique: atmospheric baking. Makes you independent of climatic conditions

Flexible baking characteristics: MIWE delta-baking

Is stingy with energy – from connected load to overall efficiency

Bakes to perfection: core temperature sensor

Ergonomically brilliant: soft close door, remote display, large screen

Stabilize total bread volume in NL and BE at 1.271.065 mln ton in 2020 (Inhome and out-of-home) CAMPAIGN

++ Th e aim of the Bread from Europe campaign is to stabilize the market volume in the Netherlands and Belgium at 1.271 million tons by 2020

17-4-2018

Bread from Europe – A great story

contributions were produced to address to food professionals, and a round table is scheduled for June 2018. The associated web site is available online in four versions (Dutch, Flemish, Walloon and English at: www.breadfromeurope.eu). The campaign, which is organized for three years until 2020, has an estimated total budget of EUR 6.75 million, 80% of which is contributed by the EU Commission.

The aim of the Bread from Europe campaign is to stabilize the market volume in the Netherlands and Belgium at 1.271 million tons by 2020.

The Belgian Bread and Health Institute* also takes up the subject of bread. As Kathou Wagemans of the FGBB (Federation of Large Bakeries of Belgium) explained, the aim of this initiative, which is addressed to consumers, food professionals and bakers, is to provide objective, scientifically backed information about bread, and to restore bread to its place as part of a healthy diet. Furthermore: its objective is to become THE benchmark in Belgium as far as bread is concerned. But how to reach that objective? Wagemans says: “Talk about bread, talk to scientists about it and encourage others to talk about bread.” She then presented the initiative’s plan of action:

+ Establish an independent “information provider” (i.e. the Institute)

+ Create a network of common interest groups

+ Initiate research: what does the target group know about bread? What are their attitudes?

+ Build a web site

+ Draw attention to the web site, generate traffic through social media, Google or press releases, or produce a newsletter.

+ Examine online activities

+ Organize a crisis communication chain

+ Work on visibility

She says “Building up trust and retaining trustworthiness” is decisive for an initiative of this kind, and it is absolutely essential that it must act independently. She said it is also important to address negative aspects such as the subject of

gluten intolerance. The Institute provides information about cereals, bread varieties, ingredients, health aspects, nutrition and legal matters on its Bread and Health web site (Link: www.broodengezondheid.be) and answers frequently asked questions.

Jana Ramuš from the Slovenian Chamber of Agricultural and Food Enterprises talked about a promotion in Slovenia through a quality label. To obtain the Gold Award, manufacturers submit their bread, baked products, cakes, cookies or pasta to assessment tests. The “test specimens” must fulfil certain quality criteria from the outset, e.g. not contain any trans-fatty acids. The prizes are awarded during a ceremony. Testing continues even after a prize has been awarded. Twice a year, jury members take random samples of prizewinning products from the shelves and re-assess them. If the quality is not correct, the manufacturer is reprimanded. According to Ramuš, the label stimulates a Slovenian baked goods market worth EUR 261 million. “Overall baked goods

COUNT ON A NEW THOMAS L. GREEN PRISM OVEN FROM READING BAKERY SYSTEMS.

Thomas L. Green Prism Ovens put the latest advances in baking technology to work for you.

• Increase product output with better baking technology.

• Improve product quality using hybrid ovens.

• Reduce energy costs with better insulation, stack heat reclamation, lighter oven belts and recipe driven baking profiles.

• Reduce sanitation time with more oven access doors.

• Replace your oven within a 4 week shut down period.

quality improved. Manufacturers use their Gold Award in their advertising and publicity. The label is well-known and recognized, both by retailers and by consumers.”

Martin Lundell of the Association of Swedish bakers & confectioners supplied much discussion material with his report about a campaign in Sweden which, although rather unusual, is probably also successful for that reason - “Bread the Future or: How can insects be used to sell bread.” It took its starting point from studies showing that 83% of the Swedish population said they liked bread but only 36% think bread is part of a balanced diet, and even fewer, namely 25%, held the opinion that bread is an environmentally friendly product. In his own words, however, the most shocking discovery is that individuals who place value on environmentally friendly products are more likely to buy less bread. Something extraordinary would be needed to counteract this, not least against the background of a tight budget. Lundell says: “To save the planet, according to the media, you would have to begin eating insects. That was the lead we picked up, and we added the advice: ‘Don’t wait for the future. Go for environmentally friendly eating today. Eat bread’.” The campaign started with a 2-minute video posted on social media. The main character is Berit From The Future, a fictional half human half robot character, who shows the audience – while using a long tongue to pick up a grasshopper at the same time – how differently and rather bizarrely people will live in Sweden in the future. The real message comes in a later scene in which she is baking bread: “Only one thing stays like it is. Bread is still environmentally friendly.” As the next initiative in the framework of the campaign, schools were visited and the schoolchildren served sandwiches with insects, while their reactions were filmed and also posted on social media. The young people posted the initiative themselves on their own channels. Other media, e.g. TV broadcasts and newspapers, also took up the subject. Accompanying advertisements were also inserted and notices posted with the message: “Prolong the Earth’s minimum use-by date. Eat Bread.” Lundell reports that 1.7 million people have already seen the Berit video, and the campaign was understood. “Eating bread is good for the climate - 10% of consumers held this opinion before the

Stefan Cappelle, Business Unit Director, Sourdough andGrains at Puratos, and Martina Goernemann closed the series of presentations with their contribution about an emotional bread promotion, about the book “Sourdough – Four days to happiness” to be precise. In this book, author Goernemann documents her travels to meet people in various places all over the world who have stories to tell about bread and about sourdough. The book has been published in English and German, and is available through Prestel UK (Email: sales@ prestel-uk.co.uk).

campaign, and afterwards 41% of the consumers who saw the campaign also took this view.” On top of that, there was another prize for Bread the Future: den ROI Award 2016 for the best Return-on-Investment campaign.

The final part of the symposium was an interactive workshop in which the participants had an opportunity to sit down together with partners in the baked products supply chain and exchange ideas for promotional activities. +++

*The Bread and Health Institute was brought into being in 2014 by three Belgian associations, the Federation of Large Bakeries of Belgium (FGBB), Unifa (Society of Belgian Bakery Raw Materials Producers), the KVBM (Royal Association of Belgium Millers), and Prof. Jan Delcour (Leuven Food Science and Nutrition Research Centre, LFoRCe).

The Heiner Kamps Foundation “Brot gegen Not” (Bread Against Poverty) helps teenagers and young adults who spend their lives on the streets and are refugees or victims of disabilities, war and natural catastrophes. The Foundation provided a multi-deck oven for a training bakery in the Gambia, but it needed a full overhaul. The Heuft group of companies in Bell/ Eifel then carried out all the necessary maintenance and repair work on the oven. The equipment was supplied with a package of spare parts for emergencies, and can now be brought into use in the training bakery in which five young people have been receiving training in the baker’s craft since September 2017. +++

The Cologne trade fair has employed a new business segment manager for the Nutrition and Nutritional Technology competence area in the Trade Fair Management Division. Anne Schumacher (37) takes over responsibility as of July 15, 2018 for the Cologne trade fair’s Anuga, ISM, Eu’Vend & coffeena, vegan department, Anuga FoodTec and ProSweets Cologne, together with the overarching strategy and communications of the “Global Competence in Food and FoodTec” and including the associated foreign trade fairs. Anne Schumacher’s most recent post was with the international trade fair organizer UBM EMEA in Amsterdam. She succeeds Dietmar Eiden, who has managed the area since 2012. +++

Doris Dieplinger will strengthen corporate communications at the international bakery raw materials manufacturer backaldrin. Social media and online agendas place additional requirements on the family-owned company’s communications work. The team headed by Wolfgang Mayer, Executive Board Member, Corporate Communications and Sponsoring, has therefore been expanded. 32-year-old

agronomist Dieplinger already gathered professional experience with the agricultural machinery manufacturer Pöttinger, at the University of Natural Resources and Life Sciences, Vienna, and most recently with the pickled vegetable producer efko Frischfrucht- and Delikatessen GmbH. With her broad specialist knowledge gained from her studies and previous professional work, the Vienna University of Natural Resources graduate will supplement the team led by Doris Strugl and Lena Thalhammer.

Debag Deutsche Backofenbau GmbH is investing in its Bautzen site. New parking spaces for 85 employees are being created in front of the company’s head office. Additional structural modifications have also been carried out inside the company’s building, e.g. the amenities rooms for the production workers have been completely renewed. Managing Director Jost Straube explained that “We closed the 2017 financial year very successfully, and were able to continue our international growth path.” As Debag itself says, it is one of the world’s leading manufacturer of ovens, baking and proofing technology and refrigeration technology. The company currently employs 200 staff and delivers to more than 50 countries worldwide.+++

The WP subsidiary Haton opened its new Competence Center in Panningen, the Netherlands, yesterday (June 7, 2018). Managing Director Henk Snellink said:

“We have thought of everything in the new premises, in which transparency is combined with an industrial touch. In addition to the workplaces, which are attractive but also relaxing, there are high-tech conference rooms, an inner courtyard and a multistory office tower. Departments that collaborate directly with customers will be accommodated here: Distribution/ Sales, Service, Project Management and Marketing. That links people together internally and ensures optimum external collaboration.” +++

With 100 years of combined experience, GEA Comas and GEA Imaforni have been engineering high quality solutions for the baking industry. With that kind of history behind us, we have gained world-leading knowledge and expertise to offer you complete production solutions, from dough making to packaging and everything in between, customised to suit the precise requirements of your line of products.

Our range of baking equipment ensures you maximum productivity whilst maintaining the best product quality. With fully automated plants able to run non-stop, we reduce the need for human interaction, thereby reducing the risk of human error and product contamination.

You can also take full advantage of our new Bakery Experience Centre where you’ll be able to test your own products on our equipment, and utilise the knowledge of our specialist food technician to help refine your recipes or make a new product. Experience for yourself the winning combination of our equipment and expertise. After all, the proof is in the pudding. Enquire now at gea.com/bakery

We look forward to meeting you at iba 2018 Hall A6 – booth 211 in Munich, Germany from 15 – 20 September 2018.

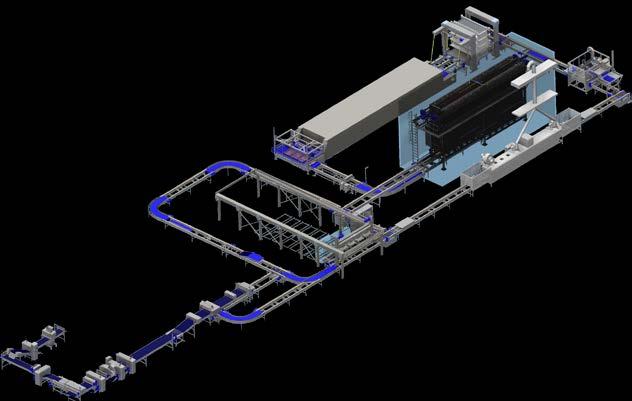

WP IB (Werner & Pfleiderer Industrial Bakery Technologies) has developed a new thermo-oil-heated tunnel oven that combines the constant radiant heat typical of thermo-oil with real turbulence, and can also operate without conveyor belts.

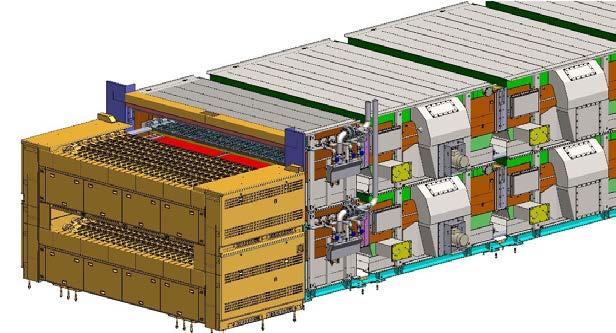

+D ieter Knost is, with the greatest respect, an old hand when it comes to developing thermo-oil-heated tunnel ovens, but one particular characteristic has repeatedly troubled him. As a general rule, the heat-carrying thermo-oil flows through closed radiator panels through which air cannot circulate, or at best holes for this can be installed at the transitions between the panels. Real turbulence is something different, and the result of his development work will enter into service in a twin-deck oven in Sweden later this year. It will bake a wide diversity of toast-bread variants with d ifferent product weights in open and closed pan clusters. Due to the twin-deck design, the length of the oven including the inlet and outlet is 39 m, but it delivers 9,000 breads/ hour none theless.

Some of the 12 modules, each 3 m wide and 3 m deep, are still nearing completion in Dinkelsbühl, where they reveal their inner workings to inquisitive eyes. There is an additional steam zone 1.5 m long at the entry point for the pans. Over the two decks, the total baking area of the whole oven is 225 m2. The 3 m module depth is owing to transport in containers, in which the individual segments are stacked lying on their sides. This does not affect the oven’s width, which can currently be chosen between 2.5 and 4 m. According to Knost, even wider ovens are entirely feasible.

Two main factors distinguish the new thermo-oil ovens from their predecessors. Probably the most important change relates to the heat-emitting radiators, and the second is the circulation fans system. Instead of closed radiator panels, Knost and his team have folded a pipe the thickness of a child’s arm in two passes so as to create a surface permeable to air but without causing any gaps in the heat transfer or any pipe radius

narrowing at the turning points. Due to the thermal inertia of the heat exchange medium, the radiant heat remains almost uniform throughout the entire oven, and is at a maximum temperature of 310°C. (As a rule, the temperature in cyclotherm ovens is higher at the start and considerably lower at the end.)

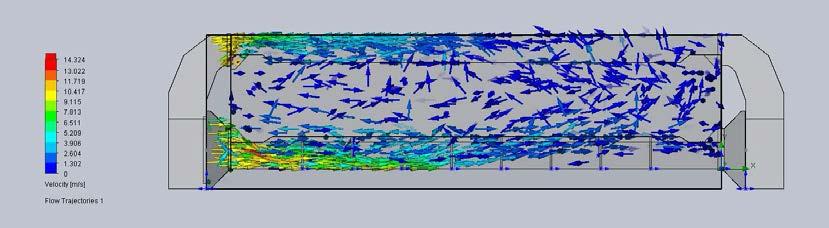

The radiator panels allow air to pass through, and to make certain that the interstices of the pan clusters are also supplied with enough hot air, a circulating fan at each of the two sides of each module ensures sufficient air movement by blowing in and drawing out up to 6,000 m 3/hour of air. In case of doubt, the exact volume depends on the pan cluster and the dough pieces deposited in it. The decisive factor is that convection heat can flow gently around all the pans in the whole

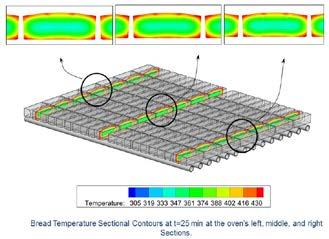

++ This image shows the simulated bread temperatures after a 25-minute baking time, in cross-section at the top, and in the middle again in the arrangement in the oven above the radiators. The temperature scale is in °Kelvin

++ The first segments of the new two-deck tunnel oven shortly before completion. The big openings for the circulating fans on both sides are clearly visible

++ A view into the oven’s baking chambers through which a wire mesh belt, steel plates or stone plates can all run equally well, and it is even possible to convey pan clusters on chains

++ Th e oven’s heating registers consist of a single piece of interwoven pipes

oven. The fans draw preheated air from the distributor duct, i.e. the space below the belt or pan transport system. WP IB conducted a research project with Erlangen University to determine where the baked goods reach which core temperature as they are transported through the oven, where and for how long they need radiant heat, and when switching on the turbulences improves the baking result. According to Knost: “We can establish a uniform flow pattern over the area, but we can also generate quite individual heat transfer profiles.”

The oven, which will go to Sweden, consists of twelve modules, each with two baking levels. More decks are feasible, and so are wider modules. The novel design offers not only a combination of radiation and real convection heat, but also an unusually high degree of flexibility in terms of how the doughs are conveyed through the oven. Anyone who wants

to use the combination can employ all kinds of wire mesh belts, or can have the pan clusters pulled through the baking zone almost free-floating on chains.

These chains can also be fitted with plates, either metal or stone plates. In that case, however, one must do without part of the convection, and the air flow over the baked goods is then only from above. A central steam generator can supply steam for the steaming zone. A new system whose functioning is similar to that of an instantaneous water heater is being installed in Sweden.

There is a whole series of additional details on this oven that are worth reporting. We have marked the procedure “for resubmission”, and hope we will be able to provide you with a report about the ongoing operation in the fall.

A selfie, baby photos, logos, marriage proposals or other messages – photo-cakes with a chosen theme for the chosen date – these are the core business of InterNestor GmbH, which describes itself as Europe’s market leader in this segment.

+D r. August Oetker KG holds a 49% minority stake in InterNestor, which was founded by Alexander Weinzetl and Swedish-born Henrik Svensson in 2006. Speaking after Oetker entered in February 2018, Dr. Albert Christmann (Management Board Chairman of Dr. August Oetker Nahrungsmittel KG and Oetker Digital GmbH) said: “This shareholding is an optimum supplement to our existing digital cake portfolioe.g. oetker.de, backen.de and kuchenfreude.de – and advances our expansion strategy in this segment of the future.”

According to its own statement, InterNestor is the European market leader for individualizable photo-cakes. Several thousand cakes are produced every month; sales revenues in the 2017 financial year were in the low single-digit millions range.

A centerpiece of the business model are the cake printers. They use food colorings to print chosen messages on marzipan or fondant frosting that has been rolled out flat and with which the cake is enrobed. The impression of a three-dimensional image motif is created by wrapping the marzipan and/or fondant frosting around the sides of the cake.

The ordering process is simple and runs online. The customer chooses the cake –the style variant and the size (from small, EUR 31.90 EUR, to large, EUR 79.90), uploads the photo and places the order. The company operates online shops in five countries. “deineTorte.de”

for the German market began in 2009, and was followed by France (votreGateau.fr), Sweden (dinTårta.se), the Netherlands (jeEigenTaart.nl) and Poland (twojTort.pl). The Kölnische Rundschau (Cologne Review, a newspaper) reports that the product range on offer is the same everywhere, and irrespective of where, by whom and in which language the order is placed, it always arrives at the headquarters in Cologne (Germany). InterNestor employs 60 staff, 40 of them in the production department.

Cakes with a printed photo are only a part of the business, which also includes cakes shaped like a handbag or with a “gateau princess”, Darth Vader, an apology or erotic gateaux, as well as macaroons, cake pops or brownies. +++

In 2018, the international baking industry will be dominated by iba. The world's leading trade fair for bakery, confectionery and snacks will take place at Fairground Munich from 15 – 20 September 2018.

As a premier platform, iba offers an unparalleled market overview in twelve halls with all the latest innovations and products of the industry. "The interest shown by national and international companies is huge. Apart from a few remaining spaces, iba is already fully booked," says Dieter Dohr, CEO and President of GHM Gesellschaft für Handwerksmessen mbH. More than 1300 exhibitors from over 50 countries (dated June 2018) will cover the entire spectrum of

baking goods with their range. "As the leading trade fair, iba has an eye on all the trends in the industry worldwide, as well as the relevant requirements for bakers and confectioners, restaurateurs and industry decision-makers of the food retailing sector," explains Dohr. "At iba 2018, innovations and concepts will play a central role for all sized companies in the areas of manufacturing processes, the out-of-house market, energy efficiency, automation, hygiene, digitisation

at the point of sale, and in production, shop fitting, packaging and logistics."

New iba speaker’s corner in hall A1

New legal regulations, the changing eating habits of consumers and the use of digital solutions or the demand for sustainable packaging: The baking industry is facing big challenges. In addition to the iba.FORUM in Hall B3, the new iba speaker’s corner in Hall A1 offers comprehensive orientation. There, visitors can exchange ideas with leading experts on

The first oven cleaning system to use a 500-day refill cycle.

Your staff don’t need to worry about a thing. The DEBAG service technician will take care of the logistics, refilling and disposal of the cleaning agent. Once filled, the supply of cleaning agent lasts for 500 days.* The right dosage is calculated and the programme starts automatically – meaning that no further operator action is required.

interesting topics from science to applying it in practice and get a prospect on upcoming trends.

Visitor service: The digital iba marketplace

iba also offers its visitors a new digital service. Through the online marketplace, visitors can prepare themselves better for their specific needs before the fair and have a better overview and thus orientation on site. Thanks to the new search option for "solution approaches", you can quickly find, for example, innovative snack solutions, digitisation, energy efficiency or

raw materials that will be exhibited at iba. Additionally, visitors have the opportunity to contact the exhibitors directly and arrange appointments with them. Further information is available at www.marktplatz.iba.de/en.

Also new is the topic area "iba.TO GO!" in Hall B3. For the first time, iba is combining innovations and solutions for snack

Travel by plane

From the Munich Airport you can easily reach the Fairground Munich by public transportation or taxi services. For the complete flight schedule please visit www.munich-airport.de/en.

Trave l by public transport

Public transportation is a quick and easy way from the airport to the fairground. The train station for the S1 and S8 municipal trains is located directly under the Central Area of the Munich Airport. Trains depart for downtown Munich every 10 minutes.

Tra nsfer by taxi

A sufficient number of taxis are available directly in front of the terminals. The one-way trip takes approximately 35 minutes, depending on traffic. Munich International Trade Fairs and the Munich taxi-owners' association have agreed to a fixed rate of 63,00 EUR (status as of 2017) regardless of the time of year. This offer applies only to the most direct route between the airport and the trade-fair centre in kilometers.

Trav el by airport shuttle bus

The airport shuttle bus is a convenient way to get from the airport to iba and back. The shuttle runs every 20 minutes. Arrival point at the fairground is the East Entrance.

Overview of the area

and beverage concepts for baking traders at a central contact point. There, the entire process chain of snacks is presented –from ingredients and preparation, through to sustainable packaging solutions to logistics and shop design, rounded off with many workshops and displays. The trend topic coffee is also discussed in detail by experts, starting with the coffee bean, roasting and grinding, to machines and serving coffee in china or to-go cups with a deposit system. +++

Ticket prices: One way ticket: 9,00 EUR; Return ticket: 15,00 EUR Arrival and departure points at iba: Arriving: East Entrance; Departure: East + West Entrance

Trave l by car

The fairground of Messe München is located directly on the A94 motorway with two direct exits available. A dynamic traffic-guidance system regulates the flow of traffic, guides fair-going vehicles and directs trade fair visitors to the nearest available parking at the fairground.

Driving to the fairground with a navigation System

To get to the fairground, the destination address to enter into your navigation system is "An der Point". Depending on which navigation system you use, the fairground is listed under the categories "Exhibition Centre", "Trade Fair Centre" and under the German keyword "Messe".

Travel by train and public transport

Munich is very easy to reach by train from all German cities as well as from a number of European metropolises. MVV tickets for any means of public transport can be obtained: From ticket machines at S- and U-Bahn stops, in trams and busses (single and day tickets only). At ticket offices (kiosks etc.) and in regional buses. Please note: All tickets must be validated in a blue ticketcancelling machine before you start your trip.

CAKES & MUFFINS

WAFFLES & FUNCAKES

PASTRY

PIZZAS,

SHEETED BREADS PIES

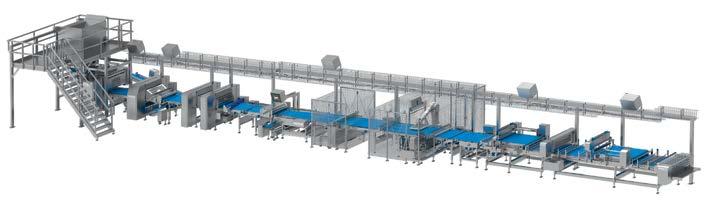

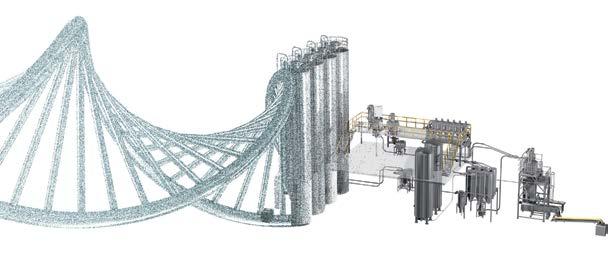

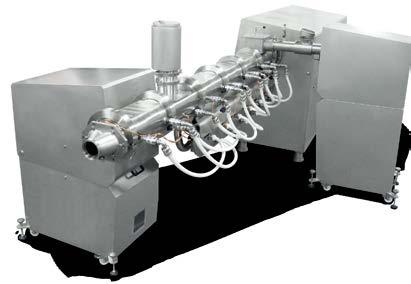

Reading Bakery Systems, a member of the Markel Food Group, has re-engineered the MX Continuous Mixer. The model now ranks as the most versatile continuous mixer, and is suitable for a broad product spectrum and a wide diversity of doughs.

The re-engineered mixing and kneading system is destined for the Tromp Group’s new Technology Center in the Netherlands. Tromp is also a member of the Markel Food Group. A short interview with Joe Pocevicius, European Sales Manager of the Tromp Group, about collaboration and the re-engineered mixer.

+ bbi: From when and where exactly can customers in Europe see and test the MX Continuous Mixer?

+ Pocevicius: The MX Mixer with Hydrobond Technology will be displayed at iba 2018 in the RBS booth- Hall B1.234. The Mixer will then be installed at the Tromp Group Innovation Center in Gorinchem, The Netherlands.

+ bbi: Is the intention to further deepen collaboration within the Markel Food Group, and what are your objectives?

+ Pocevicius: We are putting this Exact Mixing system in the Tromp Group Innovation Center for a few reasons. We would like to introduce our innovative continuous mixing technology to European customers and more easily partner with them to validate their products and demonstrate our capabilities. We also want to exhibit our partnership with Tromp Group and the ability to deliver turnkey systems from a one source supplier to their customers for products such as pastries, pizza, cakes, pies, flatbread, funcakes and more. Continuous Mixing can compliment the products and processes that Tromp Group offers, so it is a perfect match. This also allows us the ability to hold seminars in collaboration with Tromp Group to help our customers stay on the cutting edge of mixing and baking technology.

+ bbi: Regarding the Exact Mixing MX Continuous Mixer, what exactly was renewed and/or re-engineered?

+ Pocevicius: The MX Mixer is our most flexible mixer because the shafts can be reconfigured to make a wide variety of products including cookies, snacks, batters, icings, and pastes. It has been recently redesigned to produce higher dough production rates, be more sanitary and easier to clean. We have also developed a high speed developer which, when used with the MX Mixers, allows us to make highly developed doughs such as buns and English muffins.

+ bbi: Can you give a more precisely detailed explanation of Hydrobond technology, and which advantages does the system contain?

+ Pocevicius: Hydrobond Technology™ delivers instant, even hydration of a dry ingredient stream (typically flour) before it enters the continuous mixer. This uniform hydration is accomplished without adding heat to the dough, and results in shorter mixing time, with less energy required. Hydrobond Technology mixes dough on a particle-to-particle basis. It is based on the principle that mixing smaller amounts of liquid and dry ingredients together at one time is easier and more efficient. Normally the hydration step is done inside the mixer, but that takes longer and the hydration isn’t as uniform. With Hydrobond Technology, a continuous mixer can produce significantly more dough using the same size mixer. When used with a continuous mixer, Hydrobond Technology speeds up the continuous process allowing for the use of a shorter mixer, which means a smaller footprint, lower equipment costs, and lower energy costs.

+ bbi: How many kilograms/hour of dough can be manufactured by using the mixer?

+ Pocevicius: The MX Mixer is now available in larger models expanding throughput to 8000 kg/hr in a single unit. When combined with the high speed developer for breads and buns, the throughput is 7000 kg/hr.

+ bbi: The wall and shaft cooling are said to have been re-engineered. Can you please explain what improvements now exist compared to other models?

+ Pocevicius: We have maximized contact between cooled surfaces and the dough to improve cooling efficiency. This is accomplished with the shaft design and mixing action.

+ bbi: And now a question appropriate to the trade fair: what kinds of innovations will readers be able to see on the Markel Food Group’s stand at the iba trade fair in Munich?

+ Pocevicius: The RBS booth (B1.234) will display a new Exact Mixing HDX continuous mixing system for buns (MX mixer with high speed developer) on the show floor. RBS will also feature a new Thomas L. Green Servo Wirecut Machine, new Emithermic cookie oven and Reading Thermal bread and bun oven profiling solutions. RBS will also be giving away a new SCORPION ® Food Safety System at iba 2018 to one show attendee!

Tromp Group booth (B1-340) will present “All about Pizza”, Integrated Pizza Solutions for the uninterrupted production of quality products. The concept is as simple as it is efficient, with modularly-designed equipment that offers complete or stand-alone equipment. The booth will display a part of a Multibake ® HT oven. This is a directly heated oven with a stone floor for perfect pizza baking production.

The AMF Bakery Systems booth will feature a can’t-miss, immersive demonstration of our equipment-at-work through Augmented Reality. New equipment innovations will showcase AMF’s investment in sanitary re-design for core equipment solutions. The AMFConnect ™ solution, engineered for smart, connected bakeries, will allow visitors to discover how digital transformation of your bakery can improve visibility, and minimize downtime while synchronizing your entire production line. Visitors will learn first-hand how to build higher performing teams through AMFMethod ™ , AMF’s cutting-edge training technology.

+ bbi: Thank you for the interview. +++

Around the world, more food is proofed, baked, cooked, cooled and frozen on our conveyor belts. Ask

The GEA technology group has developed OxyCheck, a non-invasive oxygen measurement system for MAP packages*. It allows contactless testing of each individual pack for leak-tightness and oxygen content.

+Packing under protective gas involves introducing a mixture of carbon dioxide and nitrogen gases into packages before sealing them. Naturally, a small proportion of oxygen remains in the package, and this must not exceed a limit value. GEA OxyCheck monitors residual oxygen con tent directly in the thermoforming machine during the production operation.

GEA’s technology works by using a sensor spot consisting of a polystyrene-based fluorescent dye printed onto the inner surface of the film. Similar to an indicator strip, the dye’s wavelength changes depending on the oxygen content in the package. Sensors in the thermoformer excite this sensor spot and read it. For this, the company developed a special method to convert light emission as a function of temperature into oxygen concentration. The measuring system does not affect either line speed or the thermoformer’s throughput.

In the past, the oxygen content in MAP packs was measured on a random sampling basis – according to GEA, as a rule this was done on fewer than 0.5% of the packages produced. These were removed from ongoing production and examined by a probe. If the package did not satisfy the specification, the line was stopped and the entire production back to the last monitoring operation was destroyed. However, this required even faultless packs to be disposed of, because the needles destroyed them during testing. In contrast, firstly the OxyCheck operates in a contactless way, neither product nor material being wasted, and secondly all products in the production run are checked.

GEA OxyCheck has been approved by the U.S. Food and Drug Administration (U.S. FDA) and meets all relevant EU regulations for Food Contact Materials (FCMs). The liquid is similar to the materials used in making the packaging films. The sensors work with the pulsed light of an LED, which is safe for both products and operators. The process has no effect on either the composition of the modified atmosphere or the package content. Initially designed for use on the horizontal thermoformers of the PowerPak line, GEA OxyCheck will also be available as an optional feature or retro-fit upgrade for other equipment with MAP capabilities. In the future, GEA is planning to offer the system for other applications such as the vertical thermoformer as well.

*MAP: Modified Atmosphere Packaging

Pre-baked bread can be stored unwrapped at 3°C for six days or more without losing moisture –that’s how Johann Trenker in Toblach in the Puster Valley ensures maximum flexibility and freshness freshness.

++ One schüttelbrot (South Tyrolean flatbread) is not the same as another schüttelbrot – every baker in South Tyrol has his own recipe, and Johann Trenker has half a dozen. There’s rye-flavored handmade schüttelbrot, spelt schüttelbrot, machine-made wheat schüttelbrot, schüttelbrot with seeds and mini-schüttelbrot as a baked snack. Incidentally, schüttelbrot (English: shaken bread) is called schüttelbrot because the proofed dough is shaken on a wooden board until the large input of energy makes it spread out flat – due to its TA (dough yield) of more than 180

A lthough the Puster Valley is rather sparsely populated, thousands of tourists come to the high Alpine region around the famous “Drei Zinnen” (Three Peaks) mountain range in summer and for the winter skiing season. These extreme demand fluctuations don’t make things easy for a baker like Johann Trenker, and entail recalibrating a complex production and distribution system on a daily basis.

Trenker generates two thirds of his sales through his nine branches in the Italian part of the Puster Valley and two in the Austrian part, together with six locations in Bozen 100 km further away. In addition he supplies local caterers and

private wholesalers, who mainly distribute his rye-flavored South Tyrolean specialties down the Italian peninsula as far as Rome.

The specialty product range comprising various dry products such as schüttelbrot, lye grissini, pretzel sticks, stuzzini, pretzels etc. is an important factor to balance out the fluctuating day-to-day business, and these are offered for sale in all the local distribution channels as well as in the international food retail. Only the total is what makes up a production portfolio which, although very varied, when added together creates a coherent product portfolio that fully occupies

thirteen bakers working two shifts in the production unit. When packing, dispatch, administration and branches are included, Trenker employs a total of more than 70 staff.

His range of fresh products concentrates on bread and rolls, many of them South Tyrolean specialties with a healthy proportion of rye or spelt. Even the bread twists have a dough color distinctly darker than is usual elsewhere. Whereas bread rolls are processed directly or run through a proofing interrupter in a long-time dough method, Trenker has used a new approach since November last year. An approach that takes the breads through a Hein Flexbaker, mostly weighing 500 grams and up to 70% part-baked. They are then fully baked-off in the production unit shortly before delivery.

++

breads popular as snacks to nibble, and are a part of Trenker’s range of long-life baked products just as much as pretzel sticks, pretzels and schüttelbrot, which can be used to smooth out demand fluctuations in the fresh goods business

The Flexbaker is a modified cooling cell in which there is a consistent temperature of 3°C and a relative air humidity of 95%. Air in the cell is constantly circulated at a comparatively low velocity and passes over UV light sources in the cover area, which stops the growth of germs and mold spores. Newly-developed control software regulates the temperature, air humidity and air speed. Hygrometers measure the air humidity, and the controller feeds in additional moisture through pressure plates at the sidewall if necessary, regulated via a sliding element depending on the cell’s loading. The program has provision for 200 different levels of air speed.

Viktoria Binder’s bachelor thesis at the Upper Austria University of Applied Sciences in Wels last summer dealt in detail with the “Physical Characterization of HB (half-baked) baked products during storage in a modified cooling cell” – i.e. in a Flexbaker. The paper was written in collaboration with master bakers from the backaldrin company, Asten. To assess the effect, Mrs. Binder analyzed the water content, weight and texture of half-baked bread rolls, and four different types of bread, both during their respective storage and also after the second baking process. Tests were carried out on halfbaked rolls, a country style wheat bread, a wheat mixed bread 70/30, a rye mixed bread 70/30 and a PurPur (purple wheat) wholegrain bread. Whereas clear losses of water

occurred and the crumb firmness increased with other storage methods such as room storage or cold storage under a rack hood, Mrs. Binder discovered that: “With HB (half-baked) baked products, no water loss during storage was determined. On the contrary, a weight increase during storage was observed. Only very slight losses of water were discovered after the second baking process, so only a very small water loss was noticed. Consequently this also resulted in a softer, more moist crumb, which was also reflected in the sensory description.” According to her observation, HB baked products can be stored under these conditions for around seven to 14 days without spoilage occurring or any significant weight loss. The crumb remains elastic and soft, and there is even a further improvement in flavor. Test persons even attested to Flexbaker rolls having a better flavor compared to fresh Kaiser rolls. The energy requirement is also said to be reduced by up to 40% compared to a dough storage freezer. According to Binder, dough pieces can also be stored in the Flexbaker for two to three days without any preservation.

However, the extended storage period is less important to Johann Trenker. He achieves flavor through slow dough management, sourdough and hot-soaked grain. He is mainly interested in the great flexibility offered to him by the new system, and the opportunity it allows him to move away from refrigerating the bread. He stores bread in the Flexbaker for an average of four to six days. The yellow baskets used exclusively for internal goods transport have a closed base and open sides. This minimizes the uncontrolled scattering of strewings that have fallen off. Each basket can hold six 500 g breads. The Flexbaker holds 450 baskets. This is enough to enable a very fast response to sales fluctuations and even demand peaks occurring at very short notice.

AMF Bakery Systems’ Spiral Conveyor incorporates the most sanitary design elements, including a patent-pending monopiece cage bar, for efficient cleaning and maintenance. Equipped with plastic modular belting using the Intralox DirectDrive™ System, the Spiral Conveyor eliminates product movement on the belt to minimize potential jams. This custom-configured solution is suitable for a variety of product applications including intermediate dough proofing, product proofing, cooling, and freezing.

Your bakery is our world.

VISIT AMF BAKERY SYSTEMS AT: MODERN BAKERY, MOSCOW FOOD & HOTEL ASIA, SINGAPORE BAKERY

Combination ovens that unite at least two heat transfer systems are on the market, even specifically for the baking sector. We have tracked down a few professional appliances.

+Relevant specialist suppliers started offering the Miele Dialog Oven to ambitious hobby cooks two months ago. The press announced the oven with headlines such as “It talks to the roast” (Süddeutsche Zeitung) or “Miele has the oven of the future” (chip.de) and similar superlatives. The appliance, which looks like an oven, sends electromagnetic waves at frequencies of the kind usual in mobile phone networks into the food, where they initiate the cooking process by generating heat. However, the highlight are sensors in the oven that give constant feedback about how much energy the food has already absorbed, and adjust the frequency of the radiation to suit the cooking process.

This dialogue-loving oven cooks food without browning it or, as Miele puts it, “in depth”. For example, bread can be baked without any crust. For all those who don’t want to miss the aromas of roasted steak or baking bread, Miele combines the Dialog Oven with conventional operating modes. However, Miele’s child prodigy costs around EUR 8,000 and is only intended for hobby chefs, and according to its press office, there are no plans for a professional variant for bakeries and caterers.

Although instore oven builders are not (yet) opting for this Miele technology, they certainly do offer innovations aimed increasingly at the snack business. Of course, combination ovens that unite at least two heat transfer systems for various purposes are on the market, even specifically for the baking sector. We have tracked down a few professional appliances.

The MIWE gusto:snack from MIWE Michael Wenz GmbH, Arnstein/Germany, is a convection baking oven with additional functions (including a steam-cooking function) for the snack business. If the user employs the Quick Serve function, the oven operates with combined heat transfer by convection and top heat with radiant heat from below (griddle). According to the company, this is good for grilling or gratinating snacks. The power distribution setting can be varied. For example: 40% of the power is to be used for top heat and the rest for circulating air (this second value is then calculated automatically). A specific distribution for the Quick Serve Function is already stored (standard setting), but this can be adapted for a specific product. The total power is 3.4 kW.

The company’s latest hybrid oven, the MIWE gusto:flash, combines microwave with impingement technology. It can be used to heat ready-made snacks quickly without causing them to lose their crispness (crisp on the outside, hot inside). The oven is designed for a fast heat boost at the point of sale, both for snacks and for tomato/mozzarella-topped baguettes, meatloaf rolls or burgers. The microwaves are

generated by magnetrons located at the right and left sides of the oven. According to MIWE, more uniform distribution and thus faster heating is achieved because the energy acts on the product from both sides. Microwave power is adjustable between 0 and 100%. Impingement technology, with which heat acts on the product even more specifically compared to convection, creates powerfully accelerated air flows up to 26 m/s from above and below. It ensures crisp surfaces. Both the air speed and microwave power are adjustable between 0 and 100%. The total oven power is 5.4 kW.

*Height/width/depth

The TurboChef company, owned by the Middleby Corporation since 2008 and headquartered in Carrollton, Texas/ USA, has operated in the “fast cooking” region of the market since 1991, mainly in the catering area. It offers the sota, Panini, i3 and i5 oven variants. They operate with circulating air and microwaves, while the bullet model has an additional heating element used for radiant heat. Depending on the version and model, these ovens achieve powers from 6.2 to 9.5 kW. They are available in all the usual RAL colors, with a 230 or 400 Volt power supply and in three size variants.

Wiesheu, Grossbottwar/Germany, has now also entered the world of high-speed ovens through its new cooperation partner Atollspeed. The ovens combine microwave technology, which heats the product’s interior quickly and specifically, with impingement/hot-air technology, that uses accelerated hot air (up to 9 m/s) to ensure snacks are

Follow us on our digital channels.

WHERE THE ELEMENTS ARE IN HARMONY WITH YOUR BREAD.

fully baked crisp on the outside in seconds. The “Speed Ovens” are available in two sizes: the 300H variant with a 317 x 311 mm baking area and the 400H with a 450 x 350 mm baking area. Their power ratings are 3.3 kW (Atollspeed 300H) and 4.9 kW (Atollspeed 400H) respectively.

According to its manufacturer Welbilt, New Port Richey, Florida/USA, the Merrychef eikon e2s operates with microwaves, impingement and hot air technology. It cooks, toasts, grills, bakes and heats fresh and frozen snacks. The fast-cook system in the standard version operates at a power of 1,000 Watts for microwave use and 2,200 Watts for hot air. When combined, the two heat transfer systems need 1,000 + 1,300 Watts (microwave/ hot air). The high-power model needs 2,000 Watts for the microwave function and 2,200 Watts for preparation using hot air. In

combination, the two systems use 2,000 + 2,200 Watts (microwave/hot air). The eikon e2s variant has a footprint 60 cm deep and 35.6 cm wide, and a cooking space 31.1 cm wide.

Instore oven builders also frequently offer combinations of oven types that use different heat transfer systems and are then arranged above or alongside one another. The majority involve combinations of circulating air – for the whole range of baked products –and a (stone) deck – mostly for pizza.

Examples include the DILA-HELIOS from DEBAG Deutsche Backofenbau, the Torero convection oven, which WP also offers in combination with 1 or 2 baking compartments of the MD Store 6.4, or the Dibas 64 blue combined with the Wiesheu Ebo multideck oven. +++

July 17-19, 2018

Tokyo/Japan

7th Bakery & Cafe Japan 2018 ww.bakery-expo.com/2018/en

July 24-27, 2018

São Paulo/Brazil

FIPAN

http://fipan.com.br/?lang=en

September 5-8, 2018

Riga/Latvia

Riga Food 2018

www.bt1.lv/bt1/rigafood/?link=10000000

September 15-20, 2018

Munich/Germany

iba 2018 www.iba.de/en

October 14-16, 2018

Riyadh/Kingdom Of Saudi Arabia

SIBPE 2018

www.sibpe.com

O ctober 14-17, 2018

Chicago/USA

Pack Expo Chicago

www.tradefairdates.com/PackExpo-M1809/Chicago.html

October 21-25, 2018

Paris/France

SIAL Paris www.sialparis.com

November 6-8, 2018

Dubai/UAE

Gulfood Manufacturing 2018 www.gulfood.com

NOV

January 27-30, 2019

Cologne/Germany

ProSweets Cologne

www.prosweets-cologne.de

February 23-26, 2019

Madrid/Spain

INTERSICOP 2019

www.intersicop.ifema.es

September, 7-11, 2019

Las Vegas/USA

IBIE – International Baking Industry Exposition www.ibie2019.com

Stefan Soiné, Managing Director of IREKS GmbH in Kulmbach, celebrated his 60th birthday on June 1. Soiné joined IREKS GmbH in 1992, received power of attorney in 1993, took over the technical management of baking ingredients production in Germany as Deputy Managing Director in 1995 and then progressively assumed technical responsibility in the international company group. He has been a company Executive Director since August 1995. In addition to the technical area and internal functions, he is also responsible for the company group’s worldwide malt business and for the baking ingredients business in Germany and Austria. He is also involved in an honorary capacity in various committees and federations in the baking and brewing industry. +++

The Biscuit international group, founded in 2016 and majorityowned by the French private equity group Qualium, produces 100,000 tons of cookies and wafers. It was formed by the merger of the French cookie manufacturer Poult and the Dutch wafer specialist Banketgroep. Banketgroep in turn came into being in 2007 through fusion of Bakkersland’s confectionery division (the bread bakeries were in the process of merging into the Borgesius and Goedhart family holding) and the Van der Breggen wafer and cookie bakery. The Group operates six bakeries in the Netherlands and five in France. The CEO is Ron Priem, who started his career with Friesland Campina and worked at Goodyear-Dunlop via Kimberly-Clark, Mars, Campbell’s and VK. The Group has now taken over Northumbrian Fine Foods in Great Britain, who make gluten-free cookies and snacks. Their turnover in 2017 was GBP 27 million.

According to its own announcement, the Private Equity Group IK Investment Partners has expressed an interest in taking over the French frozen dessert and confectionery producer Mademoiselle Desserts. Mademoiselle operates manufacturing sites in France and the Netherlands, and took over the frozen food producer Ministry of Cake in the UK in early 2017. This means there are a total of nine production facilities (we reported about the production site in Thenon in Perigord in baking+biscuits international, Issue 1/2018). In its own press release, IK says it has begun discussions with the previous owners of Mademoiselle, namely Equistone Partners, Céréa Partenaire, Azulis Capital and the management team with a view to taking over the majority of the capital. According to the private equity fund’s press release, Mademoiselle Dessert had impressed the fund managers with its development in the past few years and they wanted, together with the management team, to ensure further growth via acquisitions and product development. +++

+With its I 410 model MULTIVAC Marking & Inspection offers an automatic inspection solution. Thanks to its high-resolution and height-adjustable line scanners as well as its image processing, it ensures that reliable marking and quality inspection from above and below is achieved. The space-saving inspection system can be used as a stand-alone solution at the end of a packaging machine or it can be integrated seamlessly into a line.

The areas of use for the I 410 range from completeness checks on the packs, through to presence and position inspection of the labels, and right up to checking the print – and this includes pattern and character recognition, character verification and inspection of legibility and codes. The image-capturing technology enables images in high resolution to be transmitted and verified even at the highest speeds within the packaging procedure.

The I 410 is designed for use in the food industry, and it is equipped with a separate transport conveyor. The packs can either be fed in manually or transferred from an upstream

transport unit. Since a motorised ejection device ensures that reject packs are ejected consistently, compressed air is not required to operate the inspection system.

The system is operated via the MULTIVAC HMI 2.0. Where the unit is installed in a packaging line, it is controlled centrally via the control terminal of the packaging machine, and all processes can be controlled intuitively on the 12 inch LCD touchscreen. MULTIVAC Line Control ensures that efficient line integration is achieved, and it enables product changes to be carried out very quickly since the setting parameters for the particular product are saved in the recipe. The inspection results are also transferred to the line-motion control of the MULTIVAC machine, so that packs detected as rejects can be tracked and then reliably ejected from the line.

“Thanks to its modular construction, the system offers users a high level of flexibility as regards the use of different ejection options or visual inspection modules such as cameras, barcode readers or sensors,” says Stefan Korf, Product Manager for Inspection Systems at MULTIVAC. +++

Multivac celebrated the opening of new production facility in Bulgaria. The new manufacturing plant of Multivac Bulgaria Production Ltd is located in the industrial area of Bozhurishte, near Sofia and has a total surface area of around 20,000 square metres. In addition to a factory building with the latest technology for the production of Multivac parts, the complex also includes a state-of-the-art warehouse and logistics centre, a training centre and an administration building. In addition to the Bulgarian sales and service company headed by Trifon Filipov, an international Shared Service Centre for IT, Strategic Purchasing, Design and Service will also be housed in the new building. The groundbreaking ceremony for the new production facility was celebrated in September 2016. A total of 18.8 million euros were invested. +++

In-depth knowledge of dough technology is a key ingredient required for the production of high-quality bakery products. With over 35 years of experience in the bakery industry, Rademaker is expert in this field. This knowhow, combined with specific sheeting process expertise, overall production process insights and cost of ownership calculations, are used to develop the very best bakery equipment solutions that will work for you.

This résumé rather hits the nail on the head as a description of the Bubner Bakery’s USP: traditional artisanal but with state-of-the-art technology, not over-frilly but always good for surprises. One example of its unusual products is gherkin bread.

+G herkin bread is a hearth-baked wheat mixed bread (89% wheat, 11% rye) with pickled gherkins (10%) and potato flakes. It has a light, moist crumb with a savory but not excessive gherkin flavor and a discreet hint of dill. The bread has been on the UNESCO intangible cultural heritage list since 2015.

Bubner’s produces it from Mondays to Sundays. “It’s not a common product, not even in the region,” says company boss Thomas Bubner. “As far as I know, we are the only ones in the market who manufacture it.” The idea of using gherkins is also proverbially obvious, particularly as the Spreewald area, the biggest gherkin-growing region in the Federal Republic of Germany, is just under 40 km from the parent headquarters in Doberlug-Kirchhain, from where the suggestion originated. As Thomas Bubner recalls: “We didn’t invent it, the idea of working with the topic was from a customer. A restauranteur came to us and asked whether we could develop a small bread with pickled gherkins as a souvenir product for tourists.”

Gherkin bread is moving towards being an A-product in the Spreewald branches nowadays, especially in summer. The 250 g product virtually fits into a handbag and costs EUR 1.70.

The bread has now also teamed up with a burger. Stephan Täubert, a top chef by profession and the member of the company responsible for developing products in the snack and catering area, has invested many hours of work in this project and says: “Gherkin bread as a Burger takes our bread competence into the snack area.” The result is the Lusatian Luther Burger, so called because it was created to commemorate the 500th anniversary of the Reformation (the Year of Luther, 2017), and combines a burger’s regional with its international touch. It consists essentially of a gherkin bread bun, a meat

Proprietor: Thomas Bubner

Production area: approx. 2,150 m 2

Employees: approx. 240

Branches: 19

Sales breakdown:

bread/rolls/organic: 42%, pastries: 23%, confectionery: 11%, snacks/lunchtime: 15%, hot drinks: 9%

ADVERTISEMENT

patty or in the vegetarian option a kidney bean patty, an avocado crème especially created by Stephan Täubert, and tomatoes, gouda cheese, onions and salad. Nothing comes out of a bag.

Apropos burgers, Täubert says: “We intentionally carry only a limited range. If the subject of burgers is pushed too far, customers expect many variants to be on offer. But that’s not the way we do things. We are a bakery, not a burger restaurant, and for us a burger with bread competence is only one variant of a baked snack.”

Gherkin bread and burger buns are based on the same dough, the only difference being that the dough for buns is prepared with a slightly firmer consistency. The dough is fully kneaded out before adding the dill and (drained) gherkin cubes, after which the dough is kneaded for a further two minutes. Finally the dough is pre-portioned via weigh scales. The bread and buns (100 g) are then round-molded by hand.

The Bubner Bakery’s core competence is in classical rye mixed breads, wholegrain products, bread rolls and traditional yeast tray cakes, but also in snacks. Stephan Täubert stresses that “Traditionally, we are very competent with snacks. We go to great lengths and have many of our own creations. At the same time, we endeavor not only to have regional roots but also to obtain our materials regionally.” After a successful test phase, a new addition to the product range is another regional savory bread variety: the Spreewald baguette; a country-style leavened spelt-rye baguette with sauerkraut and diced ham. A willingness to experiment, that’s the main ingredient. According to Eva Kallinich, the company’s staff member responsible for marketing: “Because we are in the open countryside here, we want to and must constantly offer our customers something new. It can be a snack with chili sauce or avocado, or licorice can be contrasted with cream. We are open to innovations, but it must remain in the artisan tradition.”

The Bubner Bakery, together with the Sonnewalde agricultural cooperative, has grown its own rye locally close to the bakery for the past three years. Bubner uses the original variety called Conduct. The 2017 harvest yielded 270 tons of rye, a quantity that covers the company’s own requirement.