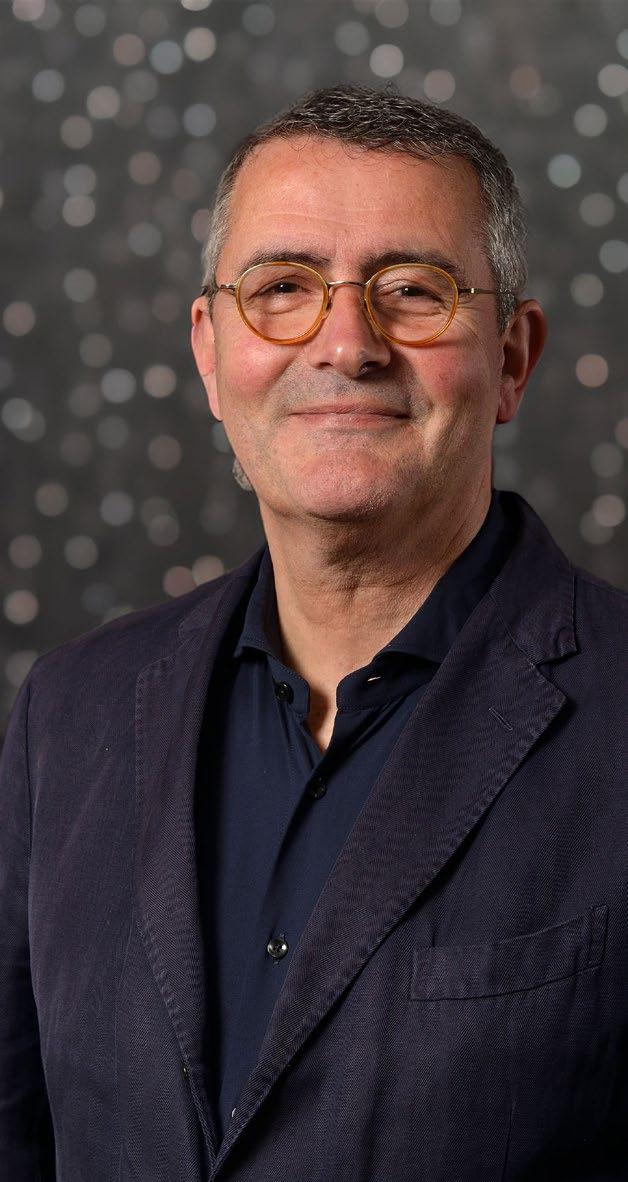

Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

In June, Nvidia became the most valuable company in the world, worth a staggering USD 3.3 trillion. It slid past Microsoft (USD 3.32 trillion) and Apple (USD 3.27 trillion). Its growth in its first years as a public company is even more impressive than the performance of the other two giants it surpassed. A household name for its graphics cards in gaming systems, Nvidia’s next step has been its biggest milestone: processors that power Artificial Intelligence systems, generative AI included.

As with all emerging technologies, adoption is in itself a process. In a recent article, The Economist asked, where is the highly-anticipated AI revolution? It noted that it has yet to make any significant economic impact, arguing that, although solutions are becoming available, their rate of adoption is lagging behind. “For AI to fulfill its potential,” the article argues, “Firms everywhere need to buy the technology, shape it to their needs and become more productive as a result.”

This is not to say AI is a passing trend or a niche technology. It is nowhere in the vicinity of the retro road of the DVD or the path less traveled where the e-book reader roams. On the contrary, it’s the next IT avenue: PwC evaluates AI as the defining technology of our age, noting that many industries are already implementing it in one way or another. As with most deeply transformative innovations, there are stages to adapting and using its benefits, which are nothing short of revolutionary.

As they adapt and incorporate Generative AI, business models are changing, with new opportunities to help build strategies (you can read more about this in the pages of this issue). Production efficiency is a key point where manufacturing can benefit from AI; it can bring predictive maintenance to the next level, with the potential to significantly reduce maintenance costs, unexpected equipment failures and downtimes.

AI-assisted quality control means virtually perfect results for every single unit and minimum waste, if any. It can provide the tools to maximize production efficiency, backed by powerful algorithms: anything from production planning to automatization, resource optimization and increased flexibility. It’s only a matter of ‘when’ and ‘how’, no doubt about it! The AI road, not traveled yet, is already under construction: Nvidia sales figures show that the first bricks have been laid. Exciting changes are ahead.

Catalina Mihu

CASE COMPLETE!

Complete solutions are an attractive proposal for bakeries. It is particularly relevant when considering the hassle of compatibility issues and process inconsistencies between parts being transferred to the experts, together with a wish list of what a production line should be able to do.

IT’S BOOGIE TIME (IN CROATIA AND NEW YORK)!

This spring, music-loving Boogie Lab, a lively artisan bakery and bar from Zagreb, took a bold step out of its home country of Croatia and opened its first US micro-bakery in New York. It brings an innovative approach to bread-making across the ocean.

REDUCING PRODUCT WASTE IN INDUSTRIAL BAKERIES

Minimizing raw material loss during production contributes greatly to the efficiency of any operation and helps combat food waste, even as it is being manufactured.

CHIP CZULADA, RBS PRESIDENT:

“THIS TECHNOLOGY REVOLUTIONIZES THE MIXING PROCESS FOR CRACKER PRODUCTION”

There is a clear trend for bakeries worldwide to seek a sustainable and efficient energy source. Electric ovens are an emerging favorite on this path, and they are starting to populate production facilities.

RENÉ VAN ASS, BUSINESS DEVELOPMENT OFFICER:

“COOLING DOWN IS JUST ONE ASPECT OF THE PROCESS”

Verhoeven Family of Companies launched its latest technology, its vacuum cooling and baking technology, remotely. However, equipment testing and adjusting the process to the specifics of the destination environment is key to capturing all the opportunities that vacuum has to offer. 28

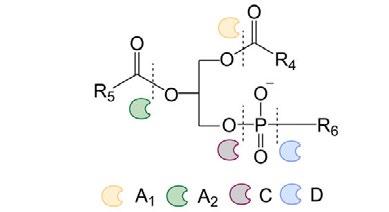

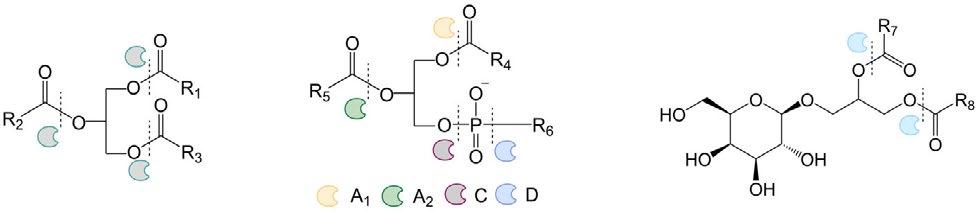

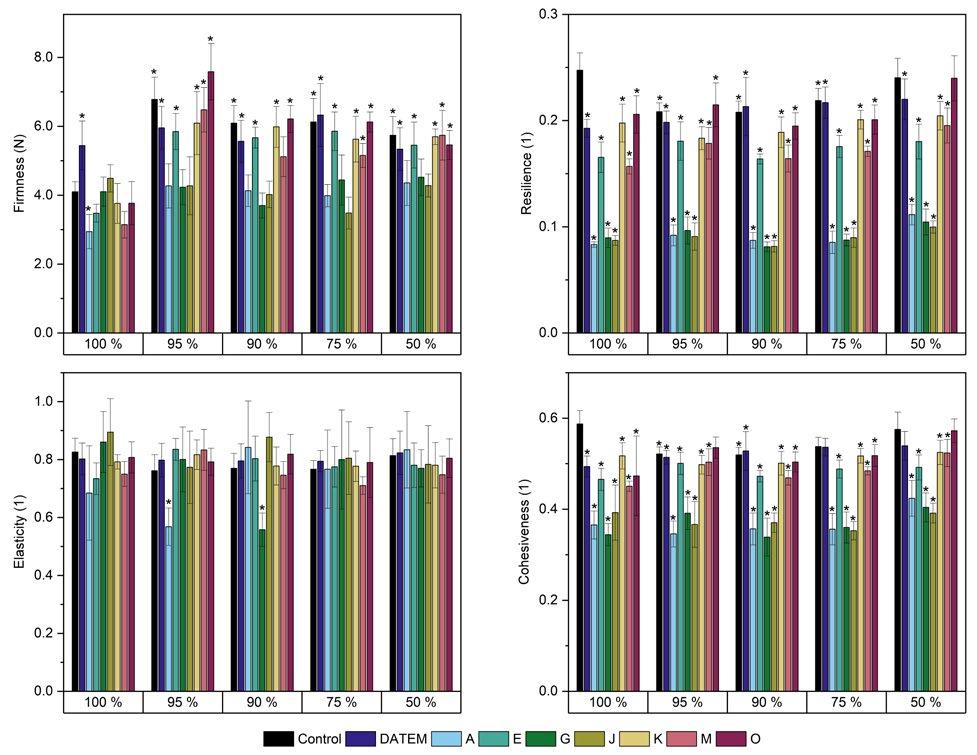

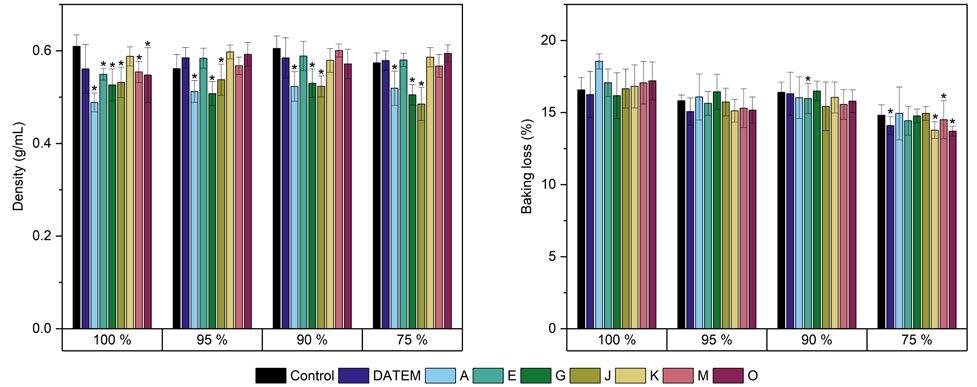

BAKING LIPASES IN CAKES: POTENTIAL IN RECIPE CHANGES

Baking lipases have been used for decades as clean-label baking aids in bread. Recent studies show that they are also suitable for improving the baking quality of fine bakery goods such as cakes, by releasing surface-active molecules. Their potential in reformulating the recipe of an egg-free cake was then investigated in more detail. 40

06 Chip Czulada, RBS: “This technology revolutionizes the mixing process for cracker production”

28 René van Ass, Verhoeven: “Cooling down is just one aspect of the process”

10 Turnkey lines: Case complete!

26 Precisma: Tray cleaning solutions, precisely for the purpose

BAKERIES

20 Boogie Lab: It’s boogie time (in Croatia and New York)!

SUSTAINABILITY

36 Andrey Bulatov, AMF: Reducing product waste in industrial bakeries

BAKING EFFICIENCY

38 RBS: It’s in the (electric) oven!

40 KIT: Baking lipases in cakes: Potential in recipe changes?

EGG SUBSTITUTE

48 BOYENS : Glazing and browning also work without eggs MARKETS

50 Tony Hunter: Gen Alpha, meet Gen AI & Generative AI CAKES

54 Dawn Foods: Versatility for a whole world of cakes

Food2Multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

baking+biscuit international

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors. Published six times a year in the English language. Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presentation of the state of the art in process engineering.

The f2m dictionary translates bakery terms into a mulitude of different languages.

Chip Czulada embarked on a new role as the President of Reading Bakery Systems (RBS) at the beginning of 2024. He shares with Baking+Biscuit International magazine his view on the first six months at the helm of the company where he has been working for over 20 years.

+Catalina Mihu: You took on the new role at the start of 2024. How would you describe your first six months as President of Reading Bakery Systems?

Chip Czulada: My first six months as President of Reading Bakery Systems have been both exciting and challenging. The primary focus has been on fostering a culture of innovation and collaboration within the company. I've spent a significant amount of time meeting with various teams, understanding their workflows, and identifying areas where we can enhance efficiency and creativity. Overall, it’s been a period of laying a strong foundation for future growth.

Mihu: You Joined RBS in 2003 – how does your extended knowledge of all facets of the company shape the strategy you are building going forward?

Czulada: Having been with RBS for over 20 years, I’ve had the privilege of understanding the intricacies of our operations, from production to finance to leadership. This comprehensive knowledge allows me to craft a strategy that is both ambitious and realistic. I aim to build on our strengths, such as our commitment to quality and innovation, while addressing any gaps that may hinder our progress. My goal is to create a cohesive strategy that aligns with our long-term vision, ensuring sustainable growth and continuous improvement.

Mihu: What is the company’s current strategy, and what are some of the changes you have introduced since the beginning of the year?

Czulada: Since the beginning of the year, our strategy has focused on enhancing our competitiveness and expanding our global presence outside the United States. Recognizing the growth opportunities in international markets, we are investing in market research and tailoring our products to meet the specific needs of diverse markets. We are also dedicating significant energy to improving customer care. We believe that exceptional customer service is key to building long-term partnerships and ensuring customer satisfaction. We are working on a comprehensive customer care program that includes enhanced support services, and personalized solutions to address our customers' unique challenges.

Mihu: What factors convinced you that RBS was the company where you wanted to build your career? What

personal development opportunities are currently made available to employees?

Czulada: I was initially drawn to RBS because of its strong reputation for quality and innovation in the baking industry. I was also very impressed with the existing management team and the company’s local reputation. Over the years, the company’s commitment to its collaborative culture has reinforced my decision. Recently, we have started focusing on personal development, and now offer a range of opportunities, including continuous education, and leadership training. We believe in investing in our people, as their growth directly contributes to the company’s success.

Mihu: On the other hand, what are the biggest challenges for people and businesses in the baking industry today, in your experience?

Czulada: The baking industry faces several challenges, including rising costs, workforce shortages, supply chain disruptions, and evolving consumer preferences for healthier options. For businesses, staying ahead of these trends and adapting quickly is crucial. For individuals, continuous learning and embracing change are essential to navigating these challenges successfully.

Mihu: How does your unique perspective as the company’s former CFO influence your planning and decision-making process?

Czulada: As the former CFO, I have a deep understanding of our financial health and the economic forces impacting our company. This perspective allows me to make informed decisions that balance innovation with fiscal responsibility. I am particularly focused on ensuring that our investments

Chip Czulada’s career spans more than 35 years in financial and manufacturing management. Czulada joined RBS in 2003 and has since overseen all facets of the company’s daily operations, including accounting, parts sales and manufacturing, information technology, human resources, and Reading Thermal. Most recently, he served as RBS executive Vice President and chief financial officer, before taking on the President role. He succeeds Joe Zaleski at the helm of RBS.

“I

am particularly focused on ensuring that our investments in new technologies and processes deliver tangible returns and contribute to our long-term sustainability and profitability while keeping our customers’ needs in check. ”

in new technologies and processes deliver tangible returns and contribute to our long-term sustainability and profitability, while keeping our customers’ needs in check.

Mihu: RBS is regularly launching new equipment designs into the market. What resources does the company allocate to R&D, and what improvements/new developments is the team focusing on?

Czulada: We allocate a significant portion of our budget to R&D, recognizing its critical role in maintaining our competitive edge. Our R&D team is currently focused on developing more energy-efficient equipment, enhancing automation capabilities, and improving the user-friendliness of our machinery. We are also exploring the integration of AI to offer smarter solutions to our customers.

Mihu: What are the biggest innovations in technology for cracker production at RBS over the past 20 years?

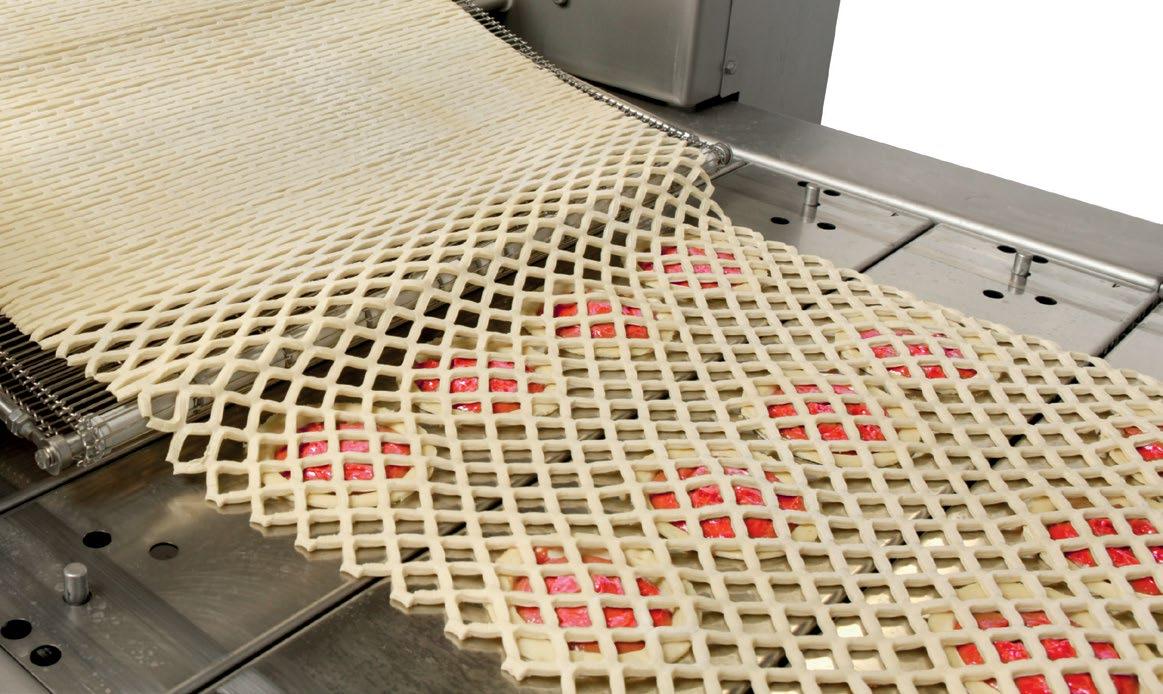

Czulada: One of the most significant innovations at Reading Bakery Systems has been the development of our continuous mixing technology for crackers. This technology transforms the mixing process by providing a consistent dough to the production line at the same rate that it is being used. This eliminates the problems associated with batch cycles and produces a consistent product all day, every day. Continuous mixing reduces labor, cuts costs, improves consistency and simplifies the mixing process.

Our most recent innovation is the introduction of our Emithermic XE oven zone, which replaces traditional Direct Gas Fired (DGF) baking technology. The Emithermic XE oven zone eliminates all direct gas-fired burners, simplifying cleaning and maintenance, and improving cracker baking performance. It also enhances energy efficiency and reduces operational costs, making it a game-changer for cracker production.

Mihu: Given that the snacking market is one of the most dynamic segments in bakery, and the US market leads in innovation and product launches, what big steps do you anticipate for new developments in solutions that will improve manufacturing? What emerging ideas could bring significant process improvements in snack manufacturing?

Czulada: To keep pace with the dynamic snacking market, we are leveraging our Innovation Center to accelerate product development and reduce the time to market for new products. This facility allows us to work closely with our customers to test new ideas quickly, ensuring that we can meet consumer demand for innovative and exciting snack options.

Advancements in automation are playing a crucial role in improving manufacturing efficiency and reducing labor costs. Technologies such as continuous mixing and instant hydration are revolutionizing the production process by providing consistent, high-quality results with less manual intervention. These technologies not only enhance product

consistency, but also streamline operations, making it easier to scale production to meet increasing demand. Additionally, we are seeing a growing trend among snack manufacturers to invest in flexible technology. This flexibility allows manufacturers to quickly adapt to changing consumer preferences and introduce new products quickly. By incorporating modular equipment and flexible production lines, manufacturers can easily switch between different product types and formulations, ensuring they stay competitive in the fast-evolving snack market.

These steps reflect our commitment to helping our customers stay ahead of the curve by providing them with the tools and technologies needed to produce high-quality, innovative snacks.

“Our R&D team is currently focused on developing more energy-efficient equipment, enhancing automation capabilities, and improving the user-friendliness of our machinery. We are also exploring the integration of AI to offer smarter solutions to our customers. ”

Chip Czulada, President, Reading Bakery Systems

Mihu: Trade shows usually influence innovation cycles and launches. What new developments, solutions, and services should manufacturers expect from RBS and its brands ahead of next year’s show lineup that includes iba in Europe and IBIE in the US?

Czulada: Manufacturers can expect to see several exciting new developments from RBS at next year’s trade shows including the new WCX Wirecut machine with iris cutter capabilities, and the latest baking technology, including the Emithermic XE and electric oven options from RBS. We will also unveil new capabilities in the RBS eZone, our proprietary customer care portal. The eZone is the only system where customers can view 3D models of their specific equipment to easily select the parts they need and see how to assemble/disassemble machines. The eZone also offers the ability to download manuals, schematics, and view maintenance and training videos.

Mihu: How does a technology specialist remain innovative over time?

Czulada: Staying innovative requires a commitment to continuous learning and a willingness to embrace change. At RBS, we encourage our teammates to stay updated with the latest industry trends and advancements. Fostering a culture of curiosity is key to maintaining a high level of innovation over time. +++

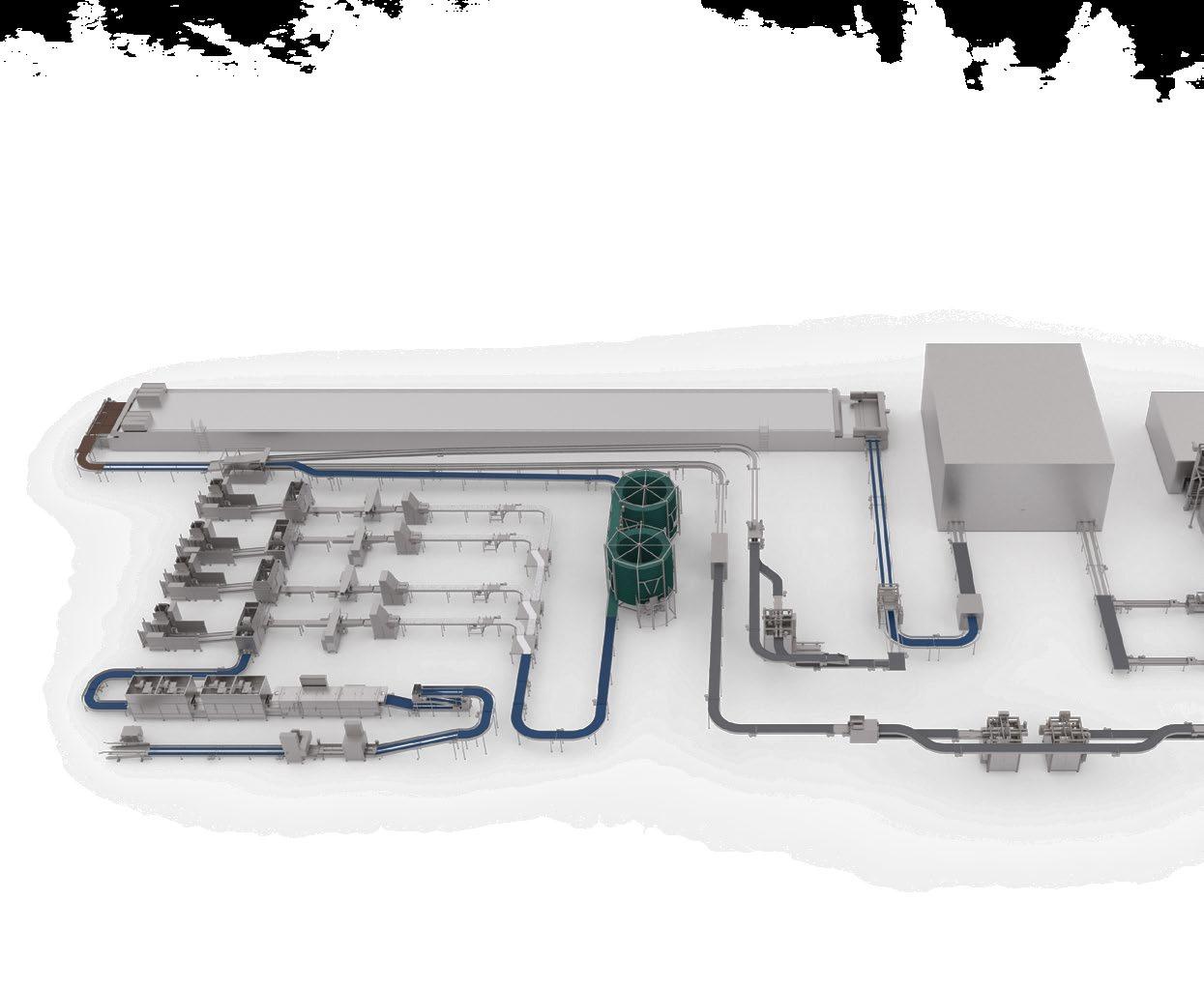

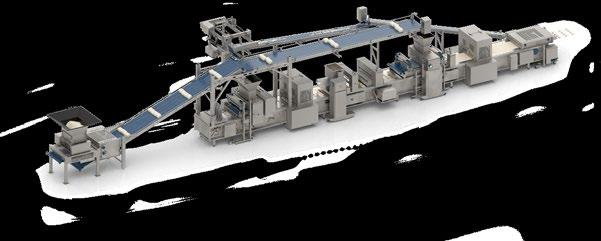

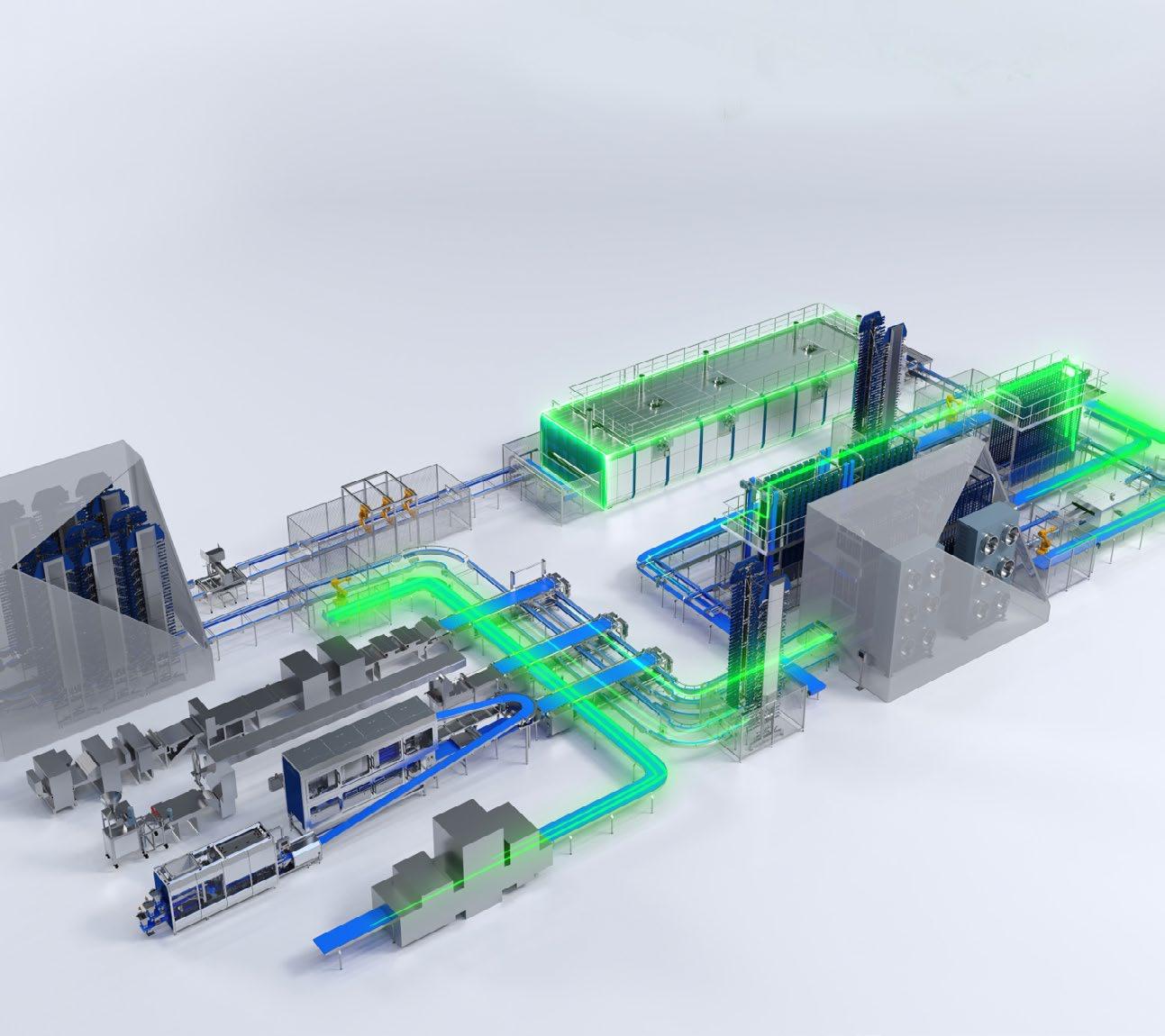

Complete solutions are an attractive proposal for bakeries. It is particularly relevant when considering the hassle of compatibility issues and process inconsistencies between parts being transferred to the experts, together with a wish list of what a production line should be able to do.

+There are numerous challenges in integrating solutions for a turnkey project, starting with ensuring compatibility between various pieces of equipment. These include meeting specific production needs and maintaining high standards of quality and efficiency throughout the process.

Coordinating multiple suppliers with components coming from different manufacturing locations, managing timelines, and ensuring that all components work seamlessly together can be added to the list of significant challenges in a turnkey project. “It requires meticulous planning and collaboration across all stakeholders to ensure that the project remains on schedule and meets all specifications,” underlines Andrey Bulatov, Sales Support Engineer, AMF Bakery Systems.

Compatibility problems can arise in several areas, such as working with differing software protocols between machines, mechanical mismatches (e.g., when using imperial vs. metric systems), and varying electrical requirements. AMF suggests addressing such issues by:

+ Standardizing interfaces, ensuring that all equipment integrated into the line uses standardized communication protocols;

+ Custom engineering, modifying equipment to meet specific requirements;

+ Comprehensive testing – conducting thorough pre-installation testing to identify and resolve issues early.

Flexibility is key when developing a turnkey project for the production of a wide range of breads. All pieces of equipment must be versatile enough to handle different types of dough and product specifications. Customization and modularity in design help address these issues, allowing for easy reconfiguration and adjustment. “AMF’s strong added value for bakeries is that we can deliver complete integrated lines worldwide, from mixing to packaging and post-packaging. This will ensure seamless integration and one supplier for support and maintenance, with less chance of issues,” Bulatov highlights.

Meeting all the intended production requirements is also a must. To ensure this, all functional specifications are defined in minute detail by the technology specialists’ project team together with the future owner of the turnkey line. Aspects

clarified at this stage include all product requirements, production volumes, and quality standards. Now, feasibility studies are conducted to determine the best solutions and technologies. AMF provides testing support at this stage, in the AMF Innovation Center, to ensure that products meet the desired specifications.

Ensuring flawless integration and functionality is a reiterative process: “Plans are evaluated through a series of reviews and validation processes, including technical reviews to assess the feasibility and compatibility of proposed solutions, product trials to ensure the equipment meets production needs, and risk analysis to identify potential technical limitations such as capacity constraints or material compatibility issues. These steps help to ensure that the proposed solutions are practical and effective in meeting the customer's requirements,” AMF’s expert explains. In the design stage, testing and simulation include considering several scenarios and solutions until the best fit is defined with the baker.

Once the task has been clearly defined, the development stage can begin. The turnkey project team manages input from sales, engineers, designers and bakers. This close collaboration is necessary to ensure all systems are integrated seamlessly. Progress is regularly tracked, to resolve any issues that might occur and make any necessary adjustments. Continuous testing and refinement are conducted to optimize performance, so that the final product meets all specified requirements.

Unexpected challenges can trigger changes to the original planning; they can include technical issues or unforeseen problems during testing. The baker’s feedback also leads to adjustments based on changing requirements, and compliance with new industry standards or regulations. “The project manager works closely with the customer to

make these adjustments, ensuring that all changes are documented and communicated effectively,” Bulatov explains.

Newly designed lines are first assembled at AMF's production facilities. The setup stage entails initial assembly where components are assembled and tested, and validation testing to ensure all systems operate correctly together. It is then disassembled and shipped to the factory for the final installation.

“AMF’s strong added value for bakeries is that we can deliver complete integrated lines worldwide, from mixing to packaging and post-packaging.”

Andrey Bulatov, Sales Support Engineer, AMF Bakery Systems

Installation can temporarily disrupt standard operations, so careful planning is required to minimize downtime. “Steps can include phased implementation to gradually integrate new equipment and maintain production continuity, while providing staff training to ensure smooth operation of the new systems,” he adds.

On location, Factory Acceptance Tests (FAT) involve assembling at the factory site to validate designs. In addition, integration testing ensures that all systems work together smoothly, the expert from AMF details. Throughout, “Coordination is ensured through project management tools to manage timelines, tasks, and communication, and maintain open lines of communication between all team members and stakeholders.”

The line will then be ready to make real-time adjustments to optimize production and maintain consistent product quality. AMF Bakery Systems include several self-correcting features, which include monitoring equipment performance and product quality in real-time, adaptive controls that automatically adjust parameters to maintain optimal conditions, and predictive maintenance that identifies and addresses potential issues before they cause disruptions. “Many bakeries have already incorporated the Sustainable Oven Service for tunnel and continuous ovens, by Den Boer and Baketech. They receive real-time data monitoring and recommendations, plus immediate savings on gas!” the specialist shares.

Evaluating and perfecting a production line is far from over once it’s been green-lit to start operating; it’s an ongoing process, so the line can respond to new and changing needs. Its modular design allows it to be reconfigured

easily to add new products if needed. Software updates will help accommodate new recipes and processes in the future, as well as incremental integration. “Examples include integrating new mixers, dividers, tunnel oven modules, and packaging machines to expand product offerings,” Bulatov lists, adding that,” With AMF Bakery Systems, customers receive strong support during all stages of the project, from the first introduction meeting to post-sales customer care.”

AMF’s timeframe for developing a turnkey project typically ranges from several months to a year, depending on its complexity. This is broken down into 3-6 months for planning and design, 3-9 months for manufacturing and testing, and 1-6 months for installation and commissioning. The process is tailored to meet the specific needs and timelines of each bakery, ensuring a seamless transition and optimal performance of the new production line.

HEUFT Industry not only stands for industrial baking ovens, as the company also specializes in project planning and designing complete production lines, custom-made for individual requirements, product ranges and production steps, working with longstanding partners. Looking at the entire process, some issues may occur when changing production volumes per hour, or the baking times. Having a clear understanding of the technical limitations of the proposed solution is usually a straightforward solution, in this regard. There are plenty of capacity ranges to choose from, when customizing the setup. The best option may also vary according to the product to be manufactured. “With multiple deck tunnel ovens, it is possible to have huge volume variations, because smaller production runs can simply be set up by using fewer decks, for example,” illustrates Simon Tabruyn, Sales Director Export, HEUFT Industry GmbH.

thermal oil ovens are never a bottleneck, since multiple decks can be installed. The oven technology can be the heart of any type of production line, running anything from bakery products to pastries. “Process reproducibility is a big advantage of baking with thermal oil: 24/7, the same baking quality will always be achieved,” the specialist highlights, concluding that, when designing a line, “It’s important that all parties agree 100% with the list containing the product ranges and desired capacities per hour, peelboard or tray layouts, and baking times.”

Coordinating the systems selected to make up the line comes with knowing what to expect from all the

“Process reproducibility is a big advantage of baking with thermal oil: 24/7, the same baking quality will always be achieved.”

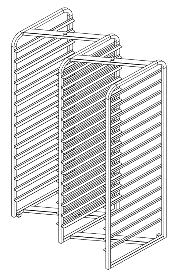

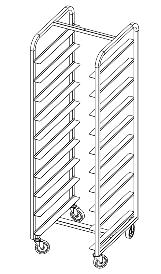

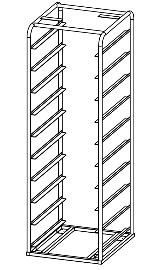

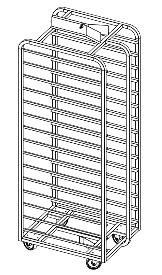

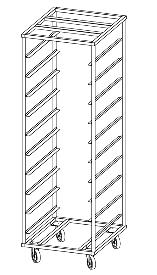

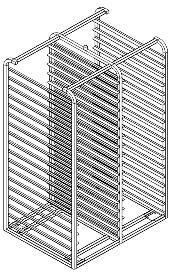

The global baking industry has many different standards for bakery racks and so do individual bakers. That is why we produce high-quality stainless steel racks made to meet the unique needs of each of our customers.

• Material: Heavy-duty stainless steel construction for strength and durability.

• Size: Racks made to fit any size pan or oven system.

• Frame: Variety of frame types from single, double, z-type, and more.

• Rungs: Use a standard amount and assortment or create a unique design.

• Castors & Wheels: Heavy-duty castors and wheels available in various materials with a range of features.

• Accessories: Choose accessories such as steering and fixings to meet your bakery’s needs.

to ensure the oven and the rest of the equipment pieces along the line are perfectly synchronized. This is why HEUFT relies on long-term partnerships, to build on the experience earned from past projects. Having finalized several projects together, they are now able to seamlessly create the optimal machine coordination, explains HEUFT.

When the design plans are first perfected, sticking to the plan usually leads to the best results, rather than making adjustments on the go, HEUFT learned, because changes in plans usually come with compromises. However, “If adjustments need to be made during the process, we always work together with the customer for the best possible solution in terms of timing, price and baked goods.” Such adjustments may include considering new products, different baking times than those originally defined, or additional capacities.

That’s not to say the line is not flexible; it can always be used to manufacture new products, once it’s been commissioned. One caveat, though: “The product will have to be adapted to the existing line, mainly regarding the capacities and the baking times,” HEUFT observes.

HEUFT first assembles a newly built line in its factory or at its partners’ facilities. HEUFT ovens are always assembled in Germany, as a company policy. The final installation in the production plant is planned with its beneficiary in advance, to limit disruptions to daily operations to a minimum.

The timeframe of a turnkey project managed by HEUFT can vary greatly according to the producer’s wishes and the size of the project: it can take several months before the product list is finalized and eventual baking tests are done, anywhere from a month to over a year. “There are so many factors that influence this process, starting with building permissions, possible subventions, to market changes and more,” HEUFT explains.

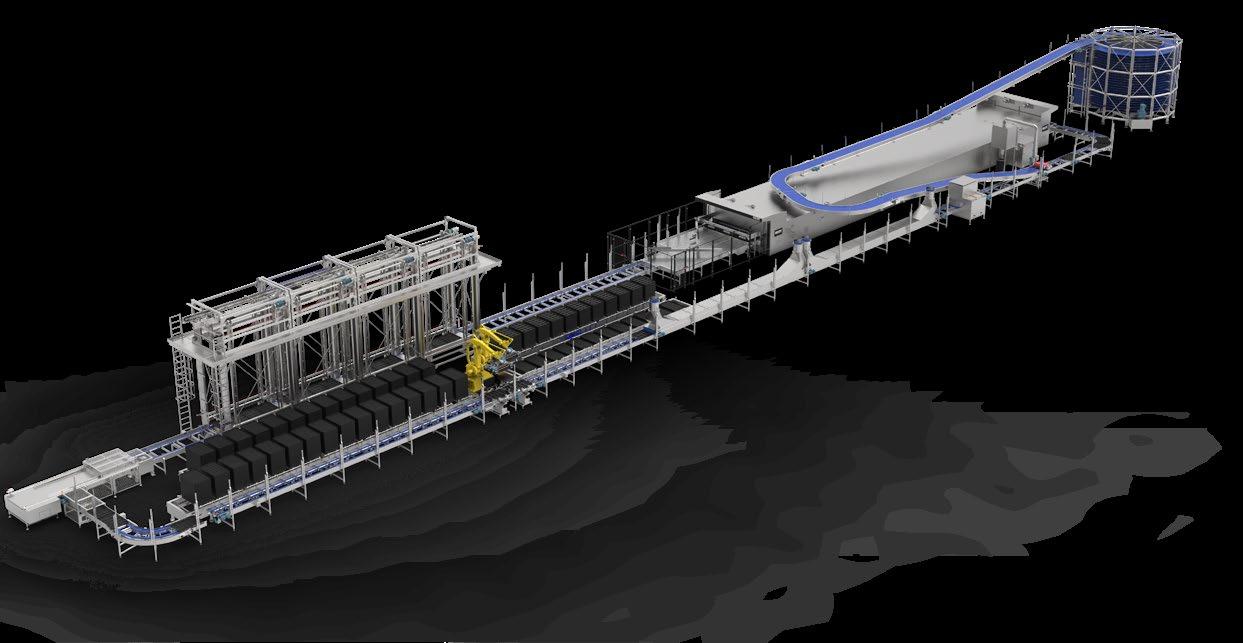

Founded in 2006, Koenig opened a branch in 2017, dedicated to planning turnkey project solutions and complete production lines for bakeries – large-scale and automated systems, covering all production steps from mixing to dough processing and cooling/freezing. It is called Koenig Technology, with headquarters in Verona, Italy. When developing turnkey solutions here, almost all components and lines are supplied by the Koenig Group, thanks to the variety of solutions in its portfolio. Ovens, for example, range from the simple single-deck tunnel oven to the multi-deck tunnel oven, the PU Integral plate circulation oven and the SDD EOS high-temperature oven for products such as pizza.

Harald Burgstaller, CEO of Koenig Technology, shares a walkthrough of the workflow for a turnkey project: “Standardized interfaces on the mechanical side and standardized control components are the key to simple and successful integration for our customers.” The solutions developed by Koenig Technology range from dough mixing, make-up lines, proofing and baking to cooling and freezing. In addition, the Koenig Group has a high level of vertical integration in the supply chain, with nearly all of the mechanical parts manufactured at their six production sites. “This allows us to act very independently and flexibly,” Burgstaller says. Producing the majority of components in-house also eliminates compatibility issues.

Koenig begins assessing the design of a turnkey line from the end products, then defines the processes, respectively the line requirements, together with the baker. “The end product requirements are precisely evaluated and which restrictions could occur. Mostly, limitations can arise regarding baking, for example, in terms of varying baking times of individual bread rolls. We advise customers on the implementation of their product list, fully automated or semi-automated, and

support them in the most economical production of the individual products,” Burgstaller explains.

Next, the degree of automation is defined. While partial automation can provide greater flexibility, it will increase the manpower requirements in some areas.

“It is important to us to simulate real conditions so that the installation at the customer’s bakery runs even smoother.”

Harald Burgstaller, CEO, Koenig Technology

Looking at individual machines and corresponding processes, Koenig starts a turnkey project by selecting the right oven (with numerous options to choose from, such as single or multi-deck tunnel ovens, plate circulation ovens, or rack ovens). This choice will ultimately influence the speed of the line, which is closely dependent on baking times. Proofing is defined next, based on the type of product and its bakeware, followed by make-up, conveying and cooling, as well as freezing. The team at Koenig Technology creates the completed concept layout and then checks how the proposed solution fits into the building. In the offer phase, the layout is finalized, including the line’s dimensions. Any necessary changes from the original concept are integrated, now (they may include changes in the available space, or related to the product list). All ensuing details are managed next, for smooth installation.

To ensure easy integration when using in-house systems together with solutions from project partners, Koenig set

internal standards that all suppliers must meet, for a turnkey line. This eliminates any mechanical or control-related issues. “We carry out risk analyses for individual components and also for each Koenig Technology plant as a whole by external companies. This means that a full CE certificate is issued and thus, we guarantee the highest standards of safety and quality for the systems.

The oven and proofing systems are built to maintain consistent product quality, with no external influences on the process. “The Koenig proofers feature their own climate unit, which is customizable, and are fully insulated. They have self-correcting features built-in: If the temperature rises in the building, the proofer automatically adjusts to reach the target values of, for example. 90% humidity and 38 °C. Constant proofing consistency is guaranteed,” Burgstaller adds. The robotic scoring solutions can be adapted in real time, with changes in tools and patterns carried out within a few minutes.

The line can later be modified to make additional products by introducing new modules. For example, new stamping tools can be introduced in the dough make-up area. “All in all, the product specification needs to fit with the speed of the line, particularly the oven and the baking times. But generally, there is always a certain flexibility, also in our turnkey lines for customers to react to market trends,” the specialist highlights.

Once selected to be included in the turnkey project, the make-up lines, ovens, proofers and spirals are built in the Koenig production sites, where factory acceptance tests are also carried out, with the actual recipes and ingredients they will process in the production facility. “It is important to us to simulate real conditions so that the installation at the customer’s bakery runs even smoother,” Burgstaller underlines.

The last step is moving the line to its final stop, with as little disruption to the day-to-day production schedule as possible: “The oven is usually the first item in the installation plan (which is agreed with the customer), because it takes the longest. Conflicts are avoided through detailed coordination with the customer. Our team on site obeys the very high standards in the food industry and the installation will not interfere with the continuous production in the bakery,” he details.

The timeline of a project Koenig manages is around 14 months, from the initial inquiry to the start of production. Support is available after installation, including remote service. Tried and tested methods are available to deliver the solution best fitting to the production needs, in the most convenient way. +++

Lotus Bakeries reported consolidated sales of EUR 599.3 million in the first half of 2024. This represents a year-on-year increase of 19.6%, or EUR 98.1 million. The sales growth is primarily driven by a “robust and broad-based volume increase of more than 16% across geographical segments and across the three strategic pillars of Lotus ® Biscoff ® , Lotus™ Natural Foods and Lotus ® Local Heroes,” the company reports.

Lotus Biscoff saw volume growth of more than 20%. The growth of Lotus Biscoff in the first half of the year was particularly strong in Continental Europe, the UK, the US and Asia-Pacific. In Continental Europe, the growth is – amongst others –driven by larger consumer markets like Germany, the Netherlands and Spain. Notable gains were also recorded in Canada and Australia. In June this year, Mondelēz International and Lotus Bakeries announced a strategic partnership to expand and grow the Biscoff® cookie brand in India, and to develop new chocolate products combining the Biscoff taste and texture with Mondelēz’s Cadbury, Milka and other key chocolate brands in Europe, with potential options to expand into additional markets and/or adjacent segments.

Lotus Natural Foods also continues to outperform the market, with double-digit growth. International Lotus Natural Foods activities outside the UK grew again by almost 30% in the

first six months of this year and account for more than onethird of total Lotus Natural Foods sales. Besides the good performance of BEAR ® in the US, nākd ® and Kiddylicious ® also show relevant distribution gains in several European markets.

Also in the UK, Lotus Natural Foods saw growth across all core concepts, supported by promising innovations. The nākd Protein Bar and the BEAR Fruit Splits are two new products, launched in 2023. Another interesting innovation in the UK was the TREK Power Biscoff bar, which was launched in 2024 and already became a top-selling bar in the category, the company highlights.

The third pillar of Lotus Bakeries’ strategy is to focus on the ‘local heroes’ in the home markets of Belgium, the Netherlands, France and Sweden. While the sales increase in 2023 was primarily driven by pricing, the local heroes’ portfolio delivered mid-single-digit volume growth in the first half of 2024. Belgium and France were the main contributors with increases for both pastries (driven by the Cake Donut launch) and waffles (driven by the growth of the Liège Waffle).

Lotus Biscoff’s volume growth of more than 20% stands out, building on continued momentum for the brand and on the Biscoff ® growth strategy initialized in 2023. The Biscoff plants in Lembeke (Belgium) and Mebane (US) have delivered record output to fulfill this additional volume.

The increased production capacity was supported by increased advances in full and continuous production and shift regimes, increased productivity on prior years’ production line start-ups and the commissioning of a new production line in the plant in Mebane (US). In the meantime, the greenfield project in Thailand is progressing according to plan and remains on track to go live with commercial production in the first half of 2026 at the latest.

The outlook for Biscoff in the second half of the year remains positive. “The first production line in Thailand is planned to start up in the first half of 2026 at the latest. Until that step-up is realized, production planning and output need to be diligently balanced with evolution and mix of demand,” the company anticipates.

The company plans to accelerate its expansion plans: “Therefore, the previously announced investment program of EUR 200 million for 2024 and 2025 combined will be increased to EUR 275 million and is anticipated to be almost evenly split over the two years,” it concludes. +++

Coca-Cola® and the OREO® teamed up as ‘Besties’ for their first collaboration release: the OREO® Coca-Cola™ Sandwich Cookie and Coca-Cola ® OREO ™ Zero Sugar Limited Edition. The campaign comes with several unique digital and physical experiences, OREO -maker Mondelēz announced. Both products feature a unique design and packaging, adorned with the distinctive OREO ® cookie embossments and stacked Coca-Cola bottles. The cookie features two signature chocolate base cakes paired with a Coca-Cola-inspired taste. The base cakes are embossed with Coca-Cola designs, with a smooth white-colored creme and studded with red edible glitter. +++

Mars reached an agreement to acquire Kellanova for USD 83.50 per share in cash, for a total consideration of USD 35.9 billion. Kellanova’s net sales in 2023 were USD 13 billion. It is present in 180 countries and has around 23,000 employees. Kellanova is home to iconic snacking brands including Pringles ® , Cheez-It ®, Pop-Tarts ®, Rice Krispies Treats ®, NutriGrain ® and RXBAR ® , as well as food brands including Kellogg’s ® (international), Eggo ® and MorningStar Farms ®. Mars’ portfolio includes snacking and confectionery brands like SNICKERS ®, M&M’S ®, TWIX ®, DOVE® and EXTRA ®, as well as KIND ® and Nature’s Bakery ®. Mars had 2023 net sales of more than USD 50 billion. +++

This spring, music-loving Boogie Lab, a lively artisan bakery and bar from Zagreb, took a bold step out of its home country of Croatia and opened its first US micro-bakery in New York. It brings an innovative approach to bread-making across the ocean.

+ The first international home of Boogie Lab’s micro-bakery, Boogie Bakery, is in the US. Since April, the Croatian bakery has been selling sourdough-based breads, pastries and sandwiches to New Yorkers. In May, it opened a second Boogie Lab at the Arena Center, in Zagreb.

With a team of around 250 people, the business produces anywhere from 50,000 to 100,000 products per day, an impressive volume for a sourdough-only bakery – for now, with plans to soon boost this capacity. Boogie Lab’s bakery works with fully automated lines producing 100% sourdough products of artisan quality and style – in recipe, structure and texture.

For ingredients, the best materials on the market are selected, from flour and butter to extra virgin olive oil. Their recipes contain flour, water and salt, and occasionally olive oil, or olives, according to the specialty made. Nothing else. Their most-loved products, which helped establish the brand, are the sourdough focaccia line and the classic sourdough loaves: country, rye and corn with more advanced versions such as whole grain with oat porridge. “Our most special offering is our double bread: buy one, give one bread. You can learn more on doublebread.org,” Karlo Vulin, co-owner, highlights.

The company was founded by Karlo Vulin, a trained food technologist and artisan baker and Mladen Vidović, a hospitality specialist. Their passion for new technology and culinary innovation is instilled into the Boogie project: “In each part of our company, someone is working on process improvements. We operate as a tech startup but still sell the end product –bread,” Vulin shares.

The wholesale baking company started sourdough production almost 10 years ago. Then, the Boogie Lab brand and hospitality venue was opened a year ago with two locations now in Croatia. “The business plan was simple: we wanted to develop a bakery concept that would be our showroom, through which you could learn everything about our mission and principles. Nutrition and sustainability play a big role in all of our products,” Vulin explains.

“In each part of our company, someone is working on process improvements. We operate as a tech startup but still sell the end product – bread.”

René van Ass, Karlo Vulin, co-founder, Boogie Lab and Boogie Bakery

Aside from the eclectic music tastes and theme, Boogie Lab has a unique approach to bread making, in which a key step is a patent-pending precision fermentation technology. Its sourdough fermentation technique combines artificial intelligence with traditional techniques, they explain, which helps improve bread quality, the process efficiency and enables the business to expand the accessibility of its products. The proprietary AI fermentation technology incorporates smart fermentors and advanced sensors, to provide precise control over the baking process. The result: consistently perfect loaves with an unmistakable artisanal touch. “We use AI in combination with our smart fermenter. At the moment, it is learning the craft of building the perfect sourdough starter for each product,” reveals the bakery’s co-founder.

“With years of artisan practices, and a background in food science, our team has developed proprietary

technology that will allow us to become the first scalable artisan bakery,” added Vulin. “What makes our bread so revolutionary is that we intertwine the power of nutrition with the power of technology. By using artificial intelligence, we ensure our baking methods produce distinct bread that is perfectly baked every time. We use only three ingredients to craft bread that is both minimally processed and easy to digest.”

The bakery also has a zero-waste policy, meaning it adopted unconventional practices (for a bakery) such as minimizing all inedible materials going to waste, to upcycling everything that is edible.

Boogie Lab is a full-service format of the retail Boogie bakery. It consists of breakfast, brunch, lunch, and dinner with cocktails. Its mission is to bring grains back into the spotlight. It currently has two locations in Croatia, with a third in the finishing stage. In addition, an international location opened in New York, with two more in the pipeline.

Product quality, industrial performance, and sustainability. At MECATHERM, we aim to support you everyday as you explore new ideas to stay ahead, and overcome challenges while reducing your carbon footprint. We are developing numerous innovative and sustainable solutions to optimize your energy efficiency throughout your entire production line. Let’s discuss and discover the array of options awaiting you.

New York is a brave new world for the Croatian bakery: “This step is a big milestone for us. It took a lot of preparation and transfer of know-how to build a team that could run the business overseas,” Vulin tells us. The Croatian business wanted to set foot on the US market because they observed that consumers are already familiar with sourdough products, but there is a big gap in the accessibility of the products.

Boogie Lab USA has made a significant impact since its Q1 2024 launch, quickly gaining traction in the US market. Its parbaked frozen sourdough products have been rapidly adopted by major food service distributors, including The Chef's Warehouse, enabling nationwide availability for food service operations. “Concurrently, we are engaged in promising discussions with leading retailers across North and South America, positioning Boogie Lab for further expansion in the consumer market,” the bakers anticipate.

In the months since the launch, the downtown Manhattan location has been transformed into a wholesale customer hub and technology showroom, driven by robust growth. This space now serves as a bakery showroom where chefs, industry professionals, and buyers can experience product presentations and collaborate on customizations. “Our first retail bakery is slated to open at a new Manhattan location in 2025. This strategic shift allows us to better serve our expanding wholesale clientele while preparing for our future retail presence,” he adds.

“Boogie Lab's proprietary fermentation technology is the foundation of both our retail bakeries and wholesale operations, enabling us to efficiently produce 100% sourdough bread on an industrial scale while maintaining artisanal quality,” the co-owner adds.

Dennis Turcinovic, the co-owner of Delmonico's restaurant in New York City, is also the co-founder of the USA business venture. Their partnership was sealed when he tried some of Boogie Bakery’s bread, while he was searching for better baked goods for his establishments. He was immediately convinced the Boogie Bakery bread would be successful in the country. This is why the US operations are located right next to Delmonico’s on Beaver Street, which it supplies.

Boogie Lab’s business approach also paves the way for fully automatic production lines, so the company can scale up rapidly. Its technology sets out to revolutionize both production capabilities and retail expansion, for scalable growth without sacrificing the integrity of our artisanal sourdough. “When I say scalable in terms of retail baking, it means that you can open it with a medium-skilled workforce,” Vulin details. And expanding it is part of the plan, with new openings expected soon. “Our mission is to make better bread more accessible, in both ways – so consumers can find it wherever they want and that it becomes cheaper. This is why we have invested so much time into learning and automation. Hopefully, this will make Boogie a household name when it comes to sourdough bread!” +++

• Reduce carbon footprint with alternative fuel and electric ovens.

• Reduce energy costs with better insulation, stack heat reclamation, lighter oven belts, and recipe-driven baking profiles.

• Retro-fit Ready: Easily convert gas ovens to electric power.

• Replace DGF ovens with Emithermic XE technology.

• Reduce sanitation time with SafeShield® design protocols.

• Increase operational sustainability with fully automated controls.

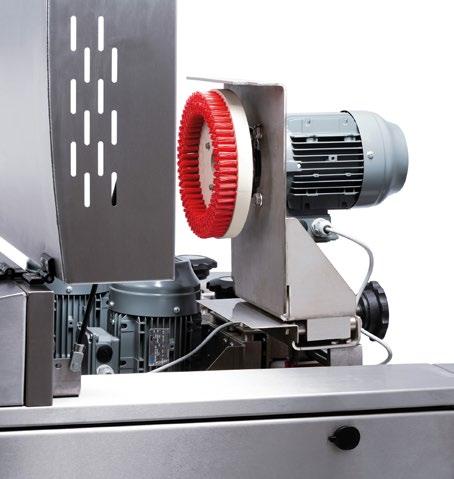

Austrian specialist Banss Maschinenfabrik GmbH offers Precisma baking tray cleaning technology as tailor-made solutions to individual bakery needs. The latest range of Kobra machines meets process needs as well as strict hygiene requirements.

+ Precisma has been placing particular emphasis on individual and tailored baking tray cleaning machines, release agent applicators and pre-dusters, as well as conveyor and handling systems – for over a decade. The machines manufactured are being updated to the latest technology developments, following Austrian traditions of precise bespoke work. Complete solutions are developed as a one-stop shop for every customer, from budgeting, planning, drawing up requirement specifications and design, to the manufacture, commissioning and maintenance of the machines, Precisma makers explain. Banss Maschinenfabrik GmbH recently took over Precisma, an acquisition that resulted in an additional boost for the development of solutions for bakeries. Amongst these was the new Kobra

range of baking tray cleaning machines, a highlighted solution at iba 2023.

The Kobra cleaning technology has recently been made available to international customers. In its home market of Austria, the brand is already known for efficiently cleaning baking trays. “Hygiene is one of the most stringent demands in bakeries. This includes cleaning baking trays, of particular importance when so many trays need daily attention. And this is where Kobra, almost maintenance-free and very robust, demonstrates its strength,” the specialist explains. “The Kobra baking tray cleaning machine has been designed to ensure efficient cleaning of large quantities of aluminum flat baking trays (perforated or unperforated) as well as baking trays with two rims”, underlines Alois Aichinger, Project Manager, Banns GmbH.

This baking tray cleaning system is available for doublerimmed trays measuring 580, 780 and 980 millimeters.

Headquartered in Wels, Austria, Banss took over the Precisma business in 2023, to strengthen its presence in the food industry. Precisma specializes in tailor-made systems for baking sheet cleaning, as well as machines for release agent application, scattering, conveying and handling.

Kobra is easy to use, its maker highlights: the baking trays are fed in with the baking side facing upwards; brush rollers are there to insert the trays for cleaning, which prolongs the baking tray’s life, as opposed to conventional transport systems generally used by tray cleaning equipment. Integrated disk brushes ensure even and clean brushing by automatic change of direction of rotation. The inner rim is also targeted for cleaning, so no spot that comes into contact with the product is missed.

The machine has a toothed belt drive to virtually render maintenance unnecessary. The Kobra range of cleaning systems is manufactured entirely of high-quality stainless steel, which allows high-pressure cleaning without having to dismantle the brushes. Individually adjustable disk brushes ensure optimum contact between the cleaning brush and the baking tray. Moreover, Kobra's quick-change system allows the machine's round brushes to be removed by hand for cleaning, with no additional tools required.

planned and precisely tailored to the cleaning requirements.

In addition to the Kobra, Precisma offers a wide product portfolio, including:

+ ‘Belt Standard’ universal-baking tray cleaning machines – designed for cleaning large numbers of baking trays with up to four rims, as well as baguette and burger trays in bulk. Flour, sesame, poppy seeds, or dough residues are effectively removed.

+ ‘Belt Industry’ baking tray cleaning system for baking lines – well suited to integration in baking lines, in the form of an automatic system that can be individually

+ ‘Easy Belt’ small business-baking tray cleaning machines – specially developed for small business operations that need to clean many different baking trays in small quantities. Almost all types of baking trays can be dry-cleaned.

+ ‘FBU’ universal mold cleaning machines – developed for artisan bakeries in particular. They are best suited to remove baking residue such as flour dust, sesame seeds, poppy seeds, or lightly baked dough residues.

Precisma baking tray cleaning solutions are currently in demand, especially in burger bun production, the company reveals. More details on www.precisma.com +++

Verhoeven Family of Companies launched its latest technology, its vacuum cooling and baking technology, remotely. However, equipment testing and adjusting the process to the specifics of the destination environment is key to capturing all the opportunities that vacuum has to offer.

+ Catalina Mihu: One of the most recent solutions launched by the Verhoeven Family of Companies, the VACTORR Vacuum Cooling and Baking range, was introduced in 2020 in an online event that even included remote unveiling. How has the company adapted to the constraints of the past 3-4 years?

René van Ass: Given our recent theme, symbolizing space and future, looking back gives us a measure of how fast things are developing. With events such as the pandemic, you are forced to think in a different way, to adapt and continue. Since we very much believe that personal contacts and personal business contribute to the success of our company, we staged the event online to launch the VACTORR, despite temporary isolation measures. The machine was ready, the concept was ready. However, we knew that it would be impossible to sell the vacuum cooling and baking concept without testing and live demonstrations. We certainly would not advise our clients to buy it before testing, because seeing and testing is believing, and ultimately, efficiently producing. But, this opportunity was not available during the pandemic. We decided to launch the machine (virtually) and attract attention, with the aim of encouraging potential clients to book appointments and test it for themselves. Testing provides many opportunities, depending on individual situations, ranging from products, recipes, and volumes, to floor space and many other factors that are unique to each bakery.

Being forced to use remote tools meant developing and adopting new technology. One of the biggest changes we made, which is still in practice today, was performing Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT) online. It’s always best to choose the best option: is it necessary for us to be on-site or not? What technology can we use to achieve our goal?

CM: A ‘COVID-proof’ launch event introduced the company’s concept for vacuum technology. What were the development stages of the VACTORR range, including a timeline?

RvA: The technique itself comes from different sectors. By entering the bakery market, the process evolved from a two-dimensional perspective, where the machines were used to cool products down, to a new approach where the technique became a part of the process, as opposed to being used after the manufacturing process. It was first used to cool down vegetables or rice, for example, when the product was ready, in its final form. For us, vacuum technology is used while baking, it is a part of the baking process. Since its role is much more complex than just cooling things down, testing is essential to getting the best results from it.

The challenge is that it was initially introduced and used, in our view, in an overly simplified way – because cooling down is just one of the aspects of the process: in addition, you can improve your product and its shelf life, if the process is carried out correctly. We have been involved in vacuum processing for more than 10 years and VACTORR, our latest range, enhances the identity of our solutions. The launch itself was part of an extended repositioning and rebranding process that would give a face to and put a name on the solutions we propose. Testing and customizing according to specific parameters is not only made for the VACTORR range, but most of our products are custom-designed. But, if you have a challenge in communicating a concept such as vacuum cooling and baking, which is so difficult to convey because of all the individual elements in its successful implementation, it is good to have a practical element encompassing the theory.

The name, ‘VACTORR’, combines ‘vacuum’ and ‘Toricelli’, to pay homage to the Italian physicist and mathematician Evangelista Torricelli, who was the first to demonstrate the existence of vacuum. Through the name, we gave the machines, respectively the solutions, a ‘face’. The first machines were all custom-made, over 10 years ago. Now, there is an entire portfolio in this family of equipment: VACTORR A (for R&D), B (for batch production), C (a continuous baking solution), D (ijko)* and C+ (the custom-made range).

We decided to have the launch event online, first of all, because Martijn van Gruijthuijsen, the Deputy of Economy and Innovation for the Dutch province of Brabant, could not travel to unveil the equipment (because of pandemic travel restrictions), so we developed the means for him to push a button and to introduce them remotely. It was important to prove that it could be done – the machines were connected and the curtain fell to reveal the machine at the touch of a button located in his office, 25 km away from our facility. Technology is part of our portfolio, and it is increasingly using smart tools – including AI as of late, so it was a relevant point for us to make, too.

CM: Speaking of AI and carrying out tasks at a distance, the way we work has changed and fundamentally improved. What changes in the company’s workflow have proved to be significant upgrades and which will remain going forward?

RvA: Monitoring our equipment remotely is very much a part of our service. We will continue to monitor machines and provide service from a distance, as well as carrying out SAT. Integrating such new tools into our daily business and regularly using them effectively is how we can really stand to profit from being able to perform tasks at a distance, as a general observation.

CM: You mentioned rebranding – a big part of it was the repositioning of the organization with the introduction of

“We will create the environment, tie the knots and put together the entire production unit for the specific project. ”

the Verhoeven Bakery Equipment Family, in July 2020. Could you explain the current structure?

RvA: The Verhoeven Bakery Equipment Family is part of the Verhoeven Family of Companies, which consists of two divisions: bakery equipment and internal transport – material handling for a variety of industries. Over the years, we have extended our focus to the bakery market.

Of the group’s four labels, which come from mergers and acquisitions, BVT was the first one to join the Verhoeven company, coming from the Netherlands. NewCap was then formed, incorporating a part of Capway. Next came Vacuum Cooling and Baking Solutions, joining forces with Patrick Duss. Bakepack, our fourth label, was developed in-house. There was some overlap between the specialties of each brand and to avoid any confusion regarding who does what, we felt the need to present ourselves more as an entity. It is important to show that we work together, and we belong together. It is vital to know which label does what, of course; but, it’s even more important to show that we are able to provide clients with many solutions for several process steps, through our various labels, and that there is synergy between them. This synergy comes from working together, being very straightforward and open to each other. As a family, we work together to provide a total solution. To a certain extent, there is some overlap between the solutions the companies provide, between Newcap and BVT, for example. But, it is by choice, to allow us to diversify our offers. Together, as Verhoeven Bakery Equipment Family, we are able to provide a huge variety of solutions. Discarding valuable names and the reputation behind them was not the best solution for us, so we preserved the brands as members of the Verhoeven family. We built a ‘roof’ under which these brands could work and benefit from the synergies between them.

In this way, we can provide turnkey solutions, complete projects, which is what makes our company stand out. We can flexibly include machines from a wide range of our equipment and, if necessary, solutions from an external party. This is likely soon to become the norm, in our view, as product lines are becoming more and more complicated to incorporate new-generation technologies such as AI features, which leads to challenges that sometimes cannot be solved from the client's side alone. After all, they are specialized in baking, purchasing and the economics of the business, and not necessarily in building a line. This is where we can help, by providing whole solutions integrating ovens, instead of standalone labels.

Verhoeven means complete solutions

CM: Speaking about building and refining an identity, are you focusing more on the Verhoeven name, or communicating its brands? What would you like the new identity to be known as?

RvA: The Family positioning is the future. We know that this transition takes time. People are used to labels, and we do acknowledge that labels represent values, which we are not throwing away. It is a matter of people getting used to the new image, which, in bakery, is not always the fastest process. It will take some time to build on this. And until it is completely clear that BVT is part of the Verhoeven Family, we will still work with both ways of communication, while reinforcing the message that it is all just one family. Another reason for the positioning is that new developments within the organization, or a new specialization with its separate company name, they could be mistakenly perceived as an individual company instead of showcasing the full power of the entire company.

“Packaging

does not start at the end of the production flow, it starts at the beginning for us. We look for ways to integrate certain elements in the production process to be able to get the final product to leave the factory in the best possible conditions. ”

René

van Ass,

Business

Development Officer, Verhoeven Family of Companies

CM: BVT also coined its recognizable and commonly used abbreviation. Are you proposing a new abbreviation for the Verhoeven Bakery Equipment Family?

RvA: I agree, and this is a challenge. Not everyone might be open to a new abbreviation, and we don’t use one ourselves. We shorten the name to ‘Verhoeven’, which is enough of a challenge in itself, perhaps, as a Dutch name.

CM: How do the companies within the Verhoeven Family –BVT, NewCap, Vacuum, Bakepack work together now, on day-to-day operations and on developing new solutions? Please illustrate.

Looking at Bakepack, for example, which specializes in packaging, it also integrates the other solutions; packaging does not start at the end of the production flow, it starts at the beginning for us. Packaging may handle the finished

Get ready to experience a match made in pastry heaven as we bring together the delights of Dawn and Royal Steensma. From celebrations big and small to those everyday moments, our combined expertise and talent for taste will bring you even more sweet inspiration and innovation. The perfect mix of sweet bakery ingredients and your partner for bakery success.

Why settle for one when you can have the best of both worlds? After all, some things are just meant to be together. Dawn & Royal Steensma: Simply Irresistible

products and prepare them to be shipped out, but we already have it in mind during the production process, for stages where certain things can be set in place that will be vital to final packaging. So, packaging isn’t considered as the end stage, but rather looked at as a whole and how certain elements can be integrated in the production process to ensure the final product leaves the factory in the best possible conditions. Many aspects are considered here, including shelf life.

CM: What can each label bring to an integrated, complete offer? How do the Verhoeven companies build complete projects together?

RvA: It depends on which development the client aiming for: is it for a full project, or is it because they have heard about the vacuum cooling and baking technology, and they know that we are able to integrate it into existing lines? Is their goal to expand their capacity in the existing facility with a new line, or to build a new factory? To answer such different requests, there is a constant flow of communication within the company. This is why we only offer tailor-made solutions, in which all our labels must play a certain role. We are not on the market to simply provide ‘just’ ovens; there is, sometimes, an emotional component to choosing an oven. This should be honored, but should not limit the baker, as we can support them by creating a whole line around their oven of choice. This is where our strength lies as a combination of labels. We are able to create complete solutions, including parts that are not made by us, when they are needed. In this case, we will create the environment, tie the knots and put

together the entire production unit for the specific project. This type of service is becoming more important, we believe, as the technology is becoming increasingly more complex.

CM: You made an interesting reference, mentioning Patrick Duss. With the rights transfer from Aston Foods, the brand name of one of the pioneering organizations in Vacuum Cooling was reunited with its founder, Patrick Duss, in 2019. What is the timeline of developments regarding this innovative technology, that culminated with this move?

RvA: This was more of a defensive move on our part, in the scenario that the brand would keep the name and develop in a new direction. We wanted to prevent misconceptions in that sense, had the company re-entered the market from a new direction but under the same name. In 2019, we were able to acquire the intellectual property of the Aston name, so we could prevent it from going on a path we did not want it to take.

CM: Moving on to a topic you like, considering the futuristic concept of Verhoeven’s iba booth in 2023: how will the new structure influence developing solutions for the baking industry going forward?

RvA: Good question! Our R&D and our engineering have always been one department, and not four separate ones, corresponding to each brand. Of course, there are people with different specialization fields, but they are part of a unitary team. Our R&D is one department. It would be a waste to have it otherwise, because there is a strong interaction between labels. And, at the end of the day, it is

Created to optimize your direct food–contact conveyors, The Intralox® FoodSafe™ System is an unrivaled, in-depth approach to meeting your plant’s daily production goals sustainably.

“We are not on the market to simply provide ‘just’ ovens; there is, sometimes an emotional component to choosing an oven. We can support clients by creating a whole line around the oven of choice.”

René van Ass, Business Development Officer, Verhoeven Family of Companies

the same client we are talking about, so it would be a waste of energy and functionality to have this department fractured. It already was the case, before our rebranding. We are now simply communicating the way it’s always been, an entity.

CM: So, the rebranding was the last step, and the company was already functioning as a family?

RvA: Exactly. It is possible that a new or existing label could be added, and the same structure will be preserved.

CM: That is an interesting perspective. What would Verhoeven consider an interesting focus for an additional label, seeing as the existing four complement each other?

RvA: That depends on how the market develops. One possible scenario could be growing an existing brand, or innovating something new. Let’s take vacuum technology for an example – if the concept was mentioned 20 years ago, it would not seem to fit the baking process. We think that there are still a lot of new innovations out there to gain from. Recycling, for instance, is an aspect that should be a part of a new production line. Adding new techniques will definitely be a focus for the future.

A dedicated group is studying trends internally, focusing on the bakery of the future. This is partly the answer to what comes next after our demonstration in Munich, where our motto was, ‘The Sky is Not the Limit’. Then, we introduced our focus for inspiration from and for space programs. We are nowhere near the limit, and we may never reach it. It’s an ongoing journey.

What does the future hold? With all the developments in our society, we sometimes have to rethink what we do and find solutions to the new challenges we face. Sustainability, establishing better connections between production and the market, growing an ever-wider portfolio – there are many challenges we can try to include in the solutions we offer. In that sense, I think there are many challenges for us in the future that could be potentially solved by either developing a new label, acquiring one, or joining forces with another company. So, the Sky is Not the Limit! We’ve only just begun.

CM: What are you focusing on for innovation?

RvA: The products are changing. We see a lot of fusion concepts and hybrid creations now; in the past, bread was bread. We were recently testing new products that can certainly not be defined as bread. This is a challenge as well, determining how food develops, together with consumer preferences. Are we going to seek more variety? I think so. We could be slowly heading towards a completely new fusion style of eating, worldwide. Entirely new products are being developed and are increasingly entering the markets. Bakery also will expand its reach outside of the classic understanding of the industry, and go more into food development. This is going to happen.

CM: Is there a certain geographical market that you are specifically focusing on, or one that could be the source of such innovative types of products?

RvA: The global market is and will remain our market. The majority of our turnover comes from non-domestic clients. We love innovation, so we will support new developments, no matter where they emerge, from the Midde East to Africa and beyond.

CM: And how is R&D revolving around the needs of smaller operations as well as those of large industrial bakeries?

RvA: Innovation is key to solving many challenges. Vacuum cooling and baking could help smaller operations increase their output with the same amount of people. For bigger organizations, it’s worth remembering that they are still people-run businesses. The bakery industry is an old one – we may tend to forget that some things that are part of our daily lives are very important. It’s not always about figures and statistics alone. In that sense, bigger organizations can learn from smaller ones.

The VACTORR family is a good example of solutions that can fit both small and big operations. They are completely scalable, and the technology can be used in any production environment. For us, it is very important to design them this way. All in all, it is down to the people in the organizations and the technology that can support them.

Minimizing raw material loss during production contributes greatly to the efficiency of any operation and helps combat food waste even as it is being manufactured.

By

+Product waste is a critical issue in industrial bakeries, reflecting broader concerns about food waste globally. In Europe alone, food waste exceeds 88 million tonnes annually, with significant portions arising from the manufacturing and processing sectors. This waste represents a substantial loss of resources and contributes to inefficiencies, reduced Overall Equipment Effectiveness (OEE), and financial losses. To address these challenges, bakery operational teams are focusing on both technological improvements and organizational strategies to minimize scrap and enhance operational efficiency.

Product waste in industrial bakeries can arise from several factors, each contributing to the overall inefficiency of the production process. Understanding these causes is crucial for developing strategies to mitigate waste.

Ingredient variability: Changes in the content of basic ingredients can lead to formula deviations, producing off-spec products. For example, long fermentation times, such as the four hours required for burger buns, make it difficult to detect issues immediately after the first mixing stage. When deviations are detected late, entire batches may need to be rejected.

Implementing stringent control over incoming ingredients, with rigorous testing and certification checks, is a possible solution, in this case. Advanced automation, including sensors for temperature, humidity, and moisture content within flour silos, can provide early warnings of deviations. Training operators to adjust water and yeast contents and mixing times in response to detected anomalies can further mitigate waste.

High dough temperatures can cause over-fermentation, particularly detrimental for soft bread and buns. Maintaining

low dough temperatures is crucial, especially during summer months, when ambient temperatures rise.

Utilizing effective cooling systems helps in this scenario, such as AMF Bakery Systems’ mixers equipped with glycol cooling jackets. These systems maintain ideal dough temperatures throughout the mixing process. Additionally, cooling the rounder table ensures that the dough maintains its integrity through subsequent stages.

“Regular

training for operational staff can prevent errors and ensure consistent product quality.”

Andrey Bulatov, Sales Support Engineer, AMF Bakery Systems

Variations in dough piece weights can result in underweight or overweight products, leading to potential product rejections.

A possible solution is to regularly inspect and maintain dough dividers and use advanced technologies, such as AMF’s Flex technology. This technology utilizes servo-driven pumps to ensure precise control over dough weight, significantly reducing deviations. Operators should also continually monitor and adjust settings as needed to maintain consistency.

Proper proofing and baking are critical to maintaining product quality and minimizing waste. The proofing process involves allowing the dough to rise under controlled temperature and humidity conditions. The final proofing produces an aerated dough with optimum shape and volume when baked. Baking sets the final structure of baked goods, involving simultaneous heat and mass transfer phenomena.

Thermal logging involves using data loggers to record temperature profiles during proofing and baking. This

technology helps in understanding the heat and mass transfer phenomena occurring in these processes, ensuring the dough reaches optimal conditions for baking. Thermal loggers provide insights into temperature fluctuations and enable bakers to adjust parameters for consistent product quality. By maintaining optimal proofing parameters and adjusting baking zones, bakeries can significantly reduce product waste and improve equipment utilization.

Incorrect settings on equipment like depanners, coolers, and sealers can cause significant product and packaging waste. Examples of product loss due to machinery settings may include:

+ Depanners: excessive vacuum pressure can damage the product.

+ Coolers: insufficient cooling timing can lead to slicing issues.

+ Sealers: incorrect sealing temperature can cause both product and packaging waste.

A possible solution is to develop and adhere to Standard Operating Procedures (SOPs) to maintain correct machinery settings. Regular training for operational staff can prevent errors and ensure consistent product quality.

High-value ingredients, such as sesame seeds, are often wasted if not applied efficiently. Traditional seeders using the waterfall principle distribute seeds across the entire baking pan, leading to significant waste.

The material application can be optimized, by using advanced seeders such AMF's target seeder, which applies seeds directly to the product top, reducing waste by up to 55% compared to the waterfall system. This precision application ensures that fewer seeds are wasted, significantly reducing costs.

Inefficient application of preservatives such as alcohol can lead to waste and workplace hazards. Traditional spray nozzles can cause alcohol waste through evaporation and improper application.

In this case, implementing precise spraying technologies solves potential issues by applying preservatives directly to the product, which minimizes waste and improves process safety. For example, using shower technology ensures that alcohol is applied efficiently, reducing waste and ensuring better preservation.

Recycling dough waste is a viable alternative to landfill disposal. Options include:

+ Partnering with fish farms or pet farms that can use dough waste as feed.

+ Collaborating with biogas producers to convert waste into energy.

Effective recycling of baked scrap can involve sorting and processing it for animal feed or energy production. This not only reduces waste but also creates additional revenue streams and supports sustainability efforts. Developing partnerships with local farms or renewable energy companies can help bakeries efficiently recycle their waste, contributing to a circular economy.

The choice of packaging materials also impacts waste levels. Non-recyclable or overly thick materials increase waste and costs.

Opt for fully recyclable, thinner packaging materials to reduce waste and costs. Advances in packaging technology allow for the use of materials that are both sustainable and cost-effective.

Reducing waste in industrial bakeries requires a combination of technological advancements, stringent process controls, and continuous staff training. By addressing the root causes of waste and implementing best practices at every stage of production, bakeries can improve efficiency, reduce environmental impact, and achieve better financial performance. +++

Andrey Bulatov has a 16-year background in engineering, including food production. His expertise revolves around delivering complex project management solutions and optimizing high-speed automated line equipment maintenance.

His first role in the baking industry was as Chief Engineer for a Grupo Bimbo bakery in Ukraine, in 2019. Throughout his tenure at Bimbo, Bulatov was at the forefront of implementing numerous energy-saving projects.

In 2024, he joined AMF Bakery Systems, where his focus shifted from bakery operational engineering to application engineering and sales support.

BAKING EFFICIENCY

There is a clear trend for bakeries worldwide to seek a sustainable and efficient energy source. Electric ovens are an emerging favorite on this path, but companies are seeking the flexibility to invest in gas ovens now, with the option to convert to electric in the future.