Interview

Bühler

südback

Interview

Bühler

südback

Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

‘No politics at the dinner table.’ Very polite, very demure; this expression hasn’t aged so well, though. It feels as if it came out of a black-and-white movie now, with politics making its presence felt abruptly and even dictating the entire dinner menu recently, in 8k ultra HD color and with very little courtesy. Even if the subject doesn’t come up once, it is the ‘elephant’ in the room.

Looking only at the effects of current dynamics, a quick glance will catch the anticipation that oil prices are expected to surge, with the consumer having to bear the brunt of this increase, in one of the more recent developments. Germany, seeing butter and sugar skyrocket in the past months, and along with them, the prices of bakery and confectionery goods, tends to wait out the inflation wave rather than invest – in bakeries.

In addition to several national-level elections bringing changes to the political scene in the second half of the year, the new European Parliament was elected in June – chosen to represent about half a billion people who live in the member states. The European baking sector intently observed all these changes and is collaborating closely to ensure its continued resilience. Recently, some of the industry’s major organizations prepared a vision document with their common perspective on the critical role of bread in healthy nutrition and, consequently, the importance of supporting bakeries and their sustainability work. The associations lobby for a businessfriendly environment with relevant, supporting regulations. You can read more about the Bread Initiative and the vision paper drafted by the representatives of the supply chain and Europe’s bakeries, later in the pages of this magazine.

On the other hand, consumers are shifting their worldview, too, with a similar sentiment. One of the global consumer trends Mintel identified for 2025 is ‘tradition in transition’: “The way things have always been done is changing by force as much as choice.” This change balances moral values and basic needs, the researcher found, concluding that “Brands will need to embrace this inevitability to sustain progress and relevance.” Consumers have internalized that climate change and AI are not abstract concepts, but immediate realities they need to adapt to. This brings perception changes regarding food and drink, too, and with them – new trends. For example, Mintel’s ‘hybrid harvests’ global F&B trend is noteworthy: “Food and drink companies will need to demonstrate how technology and agriculture work together to benefit consumers, farmers and the environmenti.”

In conclusion, sustainability can only grow in relevance in 2025 and beyond. This is the ‘elephant’ we want in the room, in any conversation. For us, it is an overarching topic in all aspects of the industry, which we diligently investigate. As proof that we talk (and write) the talk, we gladly invite you to read and gift your German-speaking partners our latest book investigating all the latest in all aspects of sustainability. You can be among the first to browse it, at südback – see you there!

Catalina Mihu

FLATBREADS

As flatbreads grow to become a valued staple worldwide, technology provides answers to all its production challenges, to match traditional handcrafting techniques.

THE FUTURE IS NOW

Inspiration for next year and beyond takes center stage in Stuttgart, with the 30th edition of südback lining up the best and latest solutions for bakery, confectionery, coffee, chocolate, logistics, training and more. It’s time to plan for interesting updates and meetings.

LIKA, LIKE AND SUBSCRIBE!

From its home base in Zaandam, Lika Bakery shows its excitement and skill in product innovation. Its new, award-winning creations are proof, joining an inviting product portfolio.

© Messe Stuttgart GmbH 42

PREPARED FOR THE FUTURE

Morten Riisager , Head of Business Unit Biscuit, Bühler Group, and Managing Director, Bühler Denmark, shared his thoughts about developing solutions for the production of biscuits.

COOKIES MAKE THE WORLD GO ROUND, EITHER WAY YOU MIX IT

Cookies speak the universal language of taking a moment for a delicious treat, anytime, anywhere. The stakes are high to produce the next favorite creation; but, technology provides different mixing methods to guarantee a perfect start.

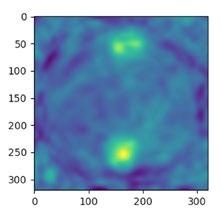

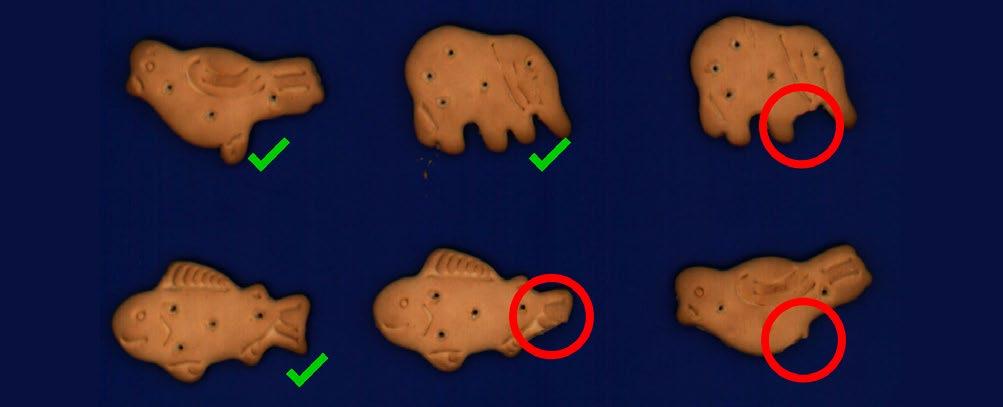

FROM VISION TO REALITY: HOW AI IS RESHAPING PRODUCT INSPECTION Emerging machine learning applications take the guesswork out of quality control.

06 Part I – Plentz Bakery & Confectionery: One step ahead

10 Part II – Plentz Bakery & Confectionery: “Baker Plentz, they are one of us”

30 Lika Bakery: Lika, like and subscribe!

PIZZA, FLATBREAD LINES

14 Part I – AMF Bakery Systems: Naan, bread of the kings

18 Part II – Farhat: That’s a wrap! Lavash and pita, flatbread heroes

20 Part III – Rademaker: Pizza in any shape and form

22 backaldrin: Flatbread meets Aronia

60 Grainar: The rise of cricket flour vs the ‘yuck’ factor

CONVEYOR SYSTEMS, BELTS

24 Ashworth: Follow the blue, plastic road!

26 IPCO: A tight, steel belt on energy spending COOKIES

34 VMI: Cookies make the world go round, either way you mix it

TRADE SHOWS

36 südback: The future is now

40 Gulfood Manufacturing: Spotlight on game-changing technology

42 BÜHLER : Morten Riisager, Head of Business Unit Biscuit, Bühler Group, and Managing Director, Bühler Denmark: “Prepared for the future”

38 RONDO: (B)read all about it! Bread lines

50 Rademaker: Every pie season sparks joy

AUTOMATION, SOFTWARE, MONITORING

54 KPM Analytics: From Vision to reality: how AI is reshaping product inspection

64 FMCG Gurus: Dos and don'ts: functional ingredients

66 Business: The Bread Project

Food2Multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

baking+biscuit international

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors. Published six times a year in the English language.

Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presentation of the state of the art in process engineering. The f2m dictionary translates bakery terms into a mulitude of different languages.

More went into the decision to purchase a new bread roll line than Plentz Bakery & Confectionery had expected. Several aspects were important, including the practiced social values of the company.

By Helga Baumfalk

+With nine branches and 170 employees, Plentz Bakery & Confectionery from Schwante in Brandenburg is not a huge company, but a powerful, healthy craft business, as bakery boss Karl-Dietmar Plentz himself puts it. When the old bread roll line reached its limits, a new one was needed. “And one that suited the size of our business and our requirements.” It had to be not too big, not too small. One that is flexible and compact at the same time, that doesn’t have to deliver exorbitant output, but that can produce up to 10,000 rolls per day, and one that leaves room for growth. Plentz: “When we looked into it, we soon realized how deep an issue it is. It’s not just about a machine, but about a process that includes new refrigeration technology and new processes.” It is definitely a pioneering investment. “You don’t buy bread roll lines in a hurry.”

During his market research, he came across many good solutions, but it was a visit to südback 2022 that pointed the way forward.

”Investing in a bread roll line is not just about a machine, but about a process that includes refrigeration technology and new processes.“

Karl-Dietmar Plentz, Managing Director of Plentz Bakery & Confectionery

“A line that suits us”

The new version of the Eco Twin, which bakery machine manufacturer Koenig was introducing in Stuttgart at the time, was not actually a favorite of the bakery boss. A visit to the Koenig stand changed this. “There was a stalemate between two solutions. That’s why I took the opportunity to see the Eco Twin live in operation at the social service provider Diakonie in Bielefeld. Together with our project manager, I stood in front of the machine one night and we noticed that the operator, a man with an

The bread roll line from Koenig is designed for artisan use. Almost all common types of bread rolls such as sliced rolls, Kaiser rolls, plaited rolls, etc. can be produced on it. For easy cleaning and maintenance, the line has been designed to ensure easy access to all modules.

Technical specifications:

+ Maximum hourly output (depending on the working width of the line): 4,200 to 6,120 pieces

+ Can be combined with various tools from the Koenig Rex series for 6-, 5- and 4-row operation with end position adjustment

+ Compact design: length: 3,770 mm, height: 2,525 mm

+ Working width: 800 mm, with direct depositing as standard for the production of dough pieces

+ Interchangeable cutting station with 3-, 4- or 5-pass guillotine; also available with 6-pass guillotine, at 800 mm working width

+ Automatic UV disinfection system for sterilizing the empty hangers before each refill

+ Adjustable depositing patterns via software, which ensures the exact positioning of the products on the most common proofing trays or baking trays

+ Dough pieces can be continuously adjusted in length and step; 800 mm working width equipped with pull-out tray as standard

+ Intuitive, freely programmable PLC control for cleaning and maintenance

+ Hangers and pressure cups can be easily removed from the system for cleaning

+ Smooth surfaces, including on the rear of the system, and large doors for viewing the production process and for better cleaning

for various punching and forming tools

apparent disability, was able to handle the technology. And that, I thought, was a very strong argument.”

In addition to the ease of operation, he was impressed by the uncomplicated changeovers and the line’s ease of cleaning. The fact that the after-sales service is guaranteed was also decisive, as was a balanced price/performance ratio. “In some details,” says the bakery boss, ”Koenig is one step ahead of others, in my opinion.” He cites the frameless doors as an example, which have the advantage that there are no corners that have to be laboriously cleaned.

Six days a week, for four to five hours early in the morning, the new bread roll line in the bakery in Schwante is now in operation. But, as the company’s owner believes, it isn’t running quite at the right time yet. “Because we want to be an attractive employer, our original aim was to bring production from the night into the day. We have not yet been able to flip this switch definitively, but we have at least created the technical prerequisites.”

One person is enough to operate the system. “We have given the main responsibility to a young employee who has

completed his training as a baker with us. The line is now his project. That in itself was very motivating.”

Before commissioning, the bakery was increased in size with a 200-square-meter extension in order to create space for the bread roll line, the handling of the peelboards, and 50 square meters of additional cooling space. A new lifting tipper was also installed. It now feeds both the bread roll line in the new building and a second dough-processing system in the existing building. This was “An important step to make our work easier,” says Plentz. Batch sizes were subsequently reduced and doughs and dough resting times were adapted to the new processes.

With more automation, consistency in dough quality is now more important. Dough temperatures are now documented and a recipe control system is being developed. “In the early days, there were quality fluctuations associated with the remaining dough. They caused a variability that could not be accounted for. But, everything has settled down now.”

The bakery uses the Eco Twin line to produce all its round and oblong small baked goods, while the ‘square range’ is produced on another, semi-automatic machine. The new line processes rolled, sliced, or stamped baked goods with three stamping tools, including around six types of wheat and seeded rolls, cheese rolls, dough pieces for crumble rolls and products locally called ‘pancakes’ (Berliners).

Roll production is now more efficient and profitable again. “We are currently establishing a purely machine-produced roll as an entry-level price product that is below the level of our hand-pressed rolls.” The hand-pressed rolls for EUR 0.50 are the absolute best-sellers in the range, explains the boss. The dough is produced with equipment, but shaped by hand.

Depositing the dough pieces is program-controlled and runs in five rows at Plentz. “Koenig provided us with an experienced specialist to put the setting patterns in place. The specialist came to the plant initially to provide training and a second time, a month later, to make a few adjustments. On a self-critical note, we should have defined the details more precisely: “What should be put on which support, how and where?” At this point, Plentz recommends that every baker considers exactly what they want, in great detail. This makes training easier.

After processing, the dough pieces are placed on peelboards, gently passed over a cooling curve – not frozen –and delivered to the stores by refrigerated truck. Sometimes they have to be re-cooked in the store. “Ideally, they are

”Because we want to be an attractive employer, our original aim was to bring production from the night into the day. We have not yet been able to flip this switch definitively, but we have at least created the technical prerequisites.“

Karl-Dietmar Plentz, Managing Director of Plentz Bakery & Confectionery

three-quarter cooked and only need to be turned and heated a little before baking.” Baked goods that are sold in smaller quantities and are therefore only baked two or

ADVERTISEMENT

three days a week (such as raisin rolls, snails, or spelt bars) are placed in the freezer and selected as required for the next day.

For the future, Plentz is thinking about the automated production of a fava bean roll and how the potential of a special stamp – the Houski stamp, which the bakery is not yet using, can be exploited. Karl-Dietmar Plentz: “The stamp creates a plait pattern. You almost think the plait is real. A high product value can therefore be achieved with a manageable amount of effort. I can well imagine the stamp being used for a high-priced, seeded pastry, perhaps for a sesame plait.” +++

“Baker Plentz, they are one of us”

The Plentz bakery has been embracing regionality for years, long before the topic became trendy.

+“In 2002, we started growing our own grain, an old variety with the illustrious name, Champagne rye,” says Karl-Dietmar Plentz, not hiding the challenges. “You have to be a bit patient. In 2023, we were worried whether we would even have enough baking capacity.” The bakery also uses locally sourced blueberries, strawberries and eggs and, because it tells its customers about its valued regional partnerships, the concept also works. “Alternatively,” he says, ”For the sake of complete transparency, no bakery can function purely regionally.” After all, no sesame seeds are grown in Brandenburg.

The bakery uses convenience where it is needed and buys in the odds and ends. They are open about this. Plentz: “In return, we fully showcase our passion for craftsmanship in our own baked goods and strive to bake products that are not comparable, such as the field bean bread or our wood-fired breads. That is our strategy.”

The wood-fired oven baking days

Fridays and Saturdays are wood-fired baking days. Farmhouse breads, herb breads and crumble cakes are baked in the brick-built wood-fired oven opposite the main store. The offer is popular and even attracts customers from Berlin, around 25 km away, to make the trip to Brandenburg. Many like to stock up and take two or three more loaves home. “People buy for the feeling, not to be full,” Plentz is certain. Bread and rolls each account for around 30 % of sales. In the sweet segment, pastries such as snails are less in demand,

”With our own baked goods, we fully showcase our passion for the trade and strive to bake products that are not comparable.“

Karl-Dietmar Plentz, Managing Director of Plentz Bakery & Confectionery

but sheet cakes (22 varieties) and Berliners – which are sold all year round – are all the more popular. In the last quarter of the year, handmade dominoes topped the sales rankings. Snacks are a growth market (12.5% share of sales).

The bakery sells most of its products through nine of its own stores. All of them are high-turnover locations with a focus on bakery stores and an adjoining café. As much as 5% of

revenue comes from the online business, which only does really well in the last few months of the year. A marginal share comes from the delivery business.

The company works for and in its community. This is expressed, among other things, in literal interaction with customers. “In the places where we are represented, we live with the people.” Plentz explains: “We have our door open when the fire department calls and asks for a discount on the bread rolls for the fire department festival. We organize oven or harvest festivals, donate to soccer clubs, work with cultural groups, choirs, or allotment associations.” He also knows: “Bakery cafés like the ones we run are sometimes the last meeting place that still works in rural areas. Young mothers meet in our cafés to exchange ideas, and there are regulars' tables for postal workers or entrepreneurs. We really encourage these encounters.” The company boss sees the proximity to customers as one of the greatest strengths of his business. “We like to be hosts, it is in our DNA. And customers know that: Baker Plentz, they’re one of us.”

Closeness is also practiced among the team of 170 employees. No wonder staff turnover has not been an issue so far. However, as is the case everywhere, there is now a slight outflow of staff. As far as trainees are concerned, Karl-Dietmar Plentz has nothing to worry about. “We have more suitable applicants than vacancies.” The company is also well-positioned in production. The challenge lies in sales due to a high sickness rate.

The company boss sees the added value of the newly created position of personnel developer. “He trains our junior managers and team leaders, coaches on tasks such as, 'How do you criticize without hurting?' or, 'How do you prepare the annual evaluations?' He helps me as a mediator when friction arises among employees and he accompanies our company handover process.”

The bakery remains in the family's hands. Karl-Dietmar Plentz still holds the majority of the shares. He is gradually handing over responsibility to his daughter Emelie Albe (authorized signatory and responsible for sales), son-in-law Ralph Keidel (Commercial Director) and son-in-law and master baker Maximilian Schöppner (Head of Production). His sons, Alexander and Max Plentz, also work for the company, as the marketing team leader and a baker, respectively.

The branches are open six days a week, but never on Sundays. “I know for a fact that we would do good business on Sundays. Nevertheless, my wife and I decided from the very beginning that Sundays are for the family. We follow the old Christian rule. In terms of employees, this is to our advantage because it makes us attractive to applicants from the restaurant business. We have a lot of good salespeople who come from the restaurant business. They don’t see the customer as a customer, but as a guest. There is a big difference in that.” However, Karl-Dietmar Plentz emphasizes: ”I don’t disapprove of anyone who works seven days a week. But we have chosen this path.” +++

American Pan understands the importance of finding the right pan for your bakery’s unique products and needs. Our team of experts can design an innovative solution tailored for your bakery, offering a variety of materials and pan strengthening features, as well as:

• Sizes & Arrangements: Customize your overall pan size, cavity arrangements, and dimensions.

• Cavity Designs: Choose a standard muffin or cake cavity or create a unique design for signature products.

• Coatings: Select one of our world-class, proprietary coatings, designed to aid in the easy release of a variety of dough formulas.

Want to prolong the life of your bakeware? Your pans can be cleaned, recoated, and returned to your operation like-new with our bakeware refurbishment services.

Laborious leavening and skill scarcity made naan bread a nutritious yet elusive delicacy for centuries, first reserved for India’s royalties and nobility. As flatbreads grew to become a valued staple worldwide, technology has provided answers to all its production challenges, to match traditional handcrafting techniques.

+Naan bread is made with flour, water, salt and yeast, to which other ingredients are sometimes added, such as oil or butter. Yeast is traditionally used, but it can also be made without it. A lot has changed since the first historical recording of naan bread, around 1300. It was first cooked in Dehli’s Imperial Court. Mentions of it were found some 200 years later, when it was still reserved for the menus of royalties, because of challenging leavening techniques, and ingredient scarcity. In the 2000s, naan now belongs to everyone; the bread is enjoyed as a side to flavorful dishes, everywhere in the world – in ethnic restaurants, and it has its own established seat in supermarket aisles, too.

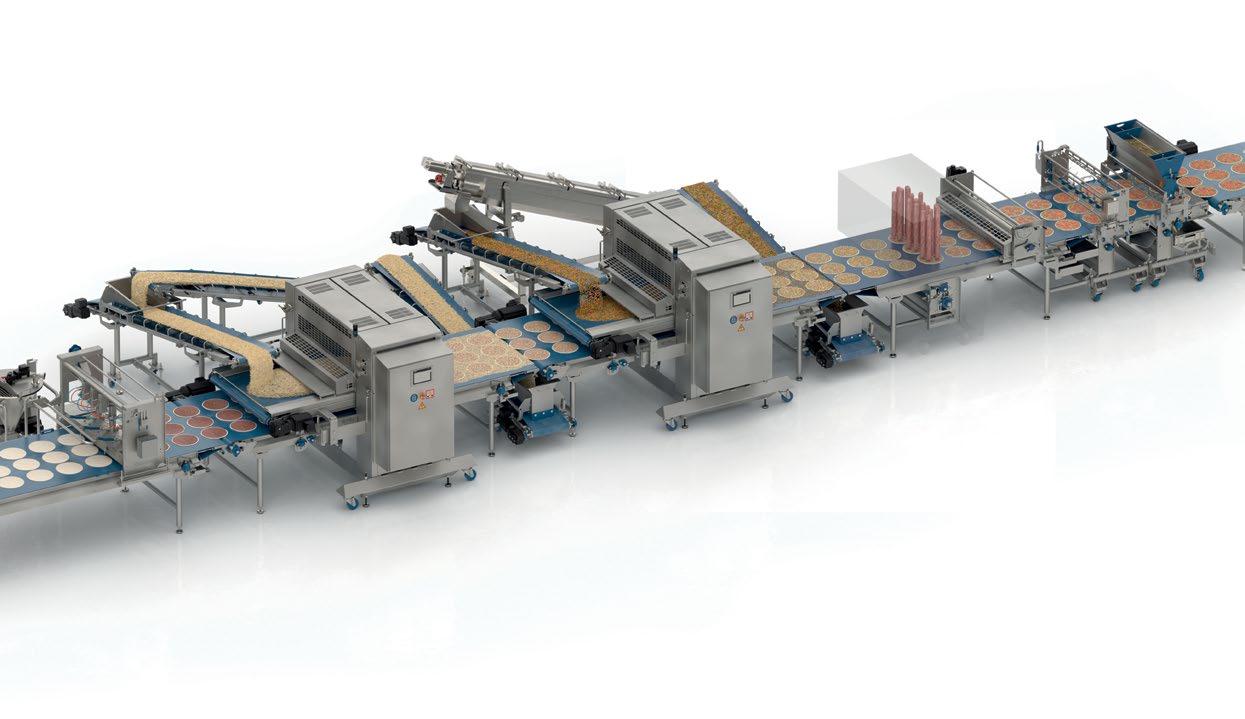

Technology was developed to replicate the qualities of the naan bread made in the traditional tandoor, clay ovens. AMF Bakery Systems has developed equipment lines that fully automate the production of naan and other flatbread specialties, baked with traditional ingredients but upscaled to higher production volumes. With these lines, naan breads can be cut into the traditional teardrop shape and baked on a Den Boer brick tunnel oven, all of which contribute to the bread preserving its traditional feeling.

The technology allows for endless arrays of product variations, either leaning toward more typically industrial products, or focusing on enhancing a traditional, artisan look and feel. “The product category of flatbreads, naan and pita is very wide, and we have tested many at our AMF Innovation Center. Variations in thickness, diameter, with inclusions in the dough or without, with decorative toppings such as

herbs and spices, different baking times, and proofing times – changes in all these factors will result in a different end product, so the possibilities are literally endless! This is why we invite everybody to visit the Center for a demo or test run,” in the Netherlands, the specialist highlights.

Given their diversity, naan and flatbreads can be made in various ways, to achieve the best results for unique specialties and in different environments.

”Saving on gas and electricity, using less compressed air, and conducting life cycle analyses for each AMF machine is our goal, in order to know and manage the complete life cycle, and to report about it.“

AMF Bakery Systems specialists

A dough sheeting line can be incorporated, where products are cut from a dough sheet, proofed and then baked at high temperatures, for a short time. To form the sheet, the mixed dough is cut into chunks of the same size and weight. These pieces are then formed into an endless sheet of dough using several roller and multi-roller systems in the Tromp sheeting line. When the desired thickness of the sheet has been reached, a continuous cutter cuts out the shape of the pita, naan, or flatbread. The leftover dough is separated by the sheeting line, to be reused in the mixer

or elsewhere in the process. Depending on the recipe and process, it can be reintroduced in the mixer, together with the fresh dough.

Another dough-forming method with its corresponding technology is working with dough balls: the dough is created with AMF extruders, and the resulting dough balls are either pressed or rolled out into a thin piece of dough. The product then follows a similar route as those created with a sheeting line, proofing, and quick baking at high temperatures. Baking can be done in a tunnel oven – on a stone or mesh belt, depending on the style of the flatbread.

To select the adequate technology for the product, “It all starts with the recipe and the final look, structure, crispness and the intended aspect of the product, artisan-style or not. When these characteristics are defined, the

best solution and make-up process can be determined. In general, most products can be sheeted using a low-stress dough sheeting line by Tromp,” AMF’s specialists explain.

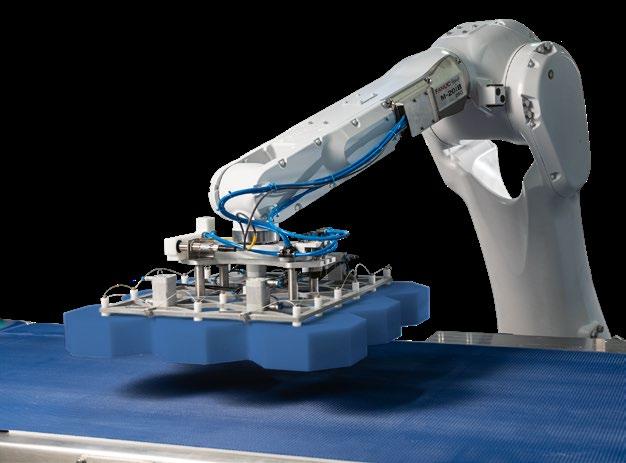

some steps contributes significantly to efficiency. “A robot never gets tired or needs a break, for example; these extra hours of production or increased speed can be great improvements in the process,” the specialist observes. In choosing the best-suitable equipment lineup, the final product/recipe is always the first aspect to consider, to which capacity, ingredients, production hours/staff, future plans and flexibility are also added, among factors influencing the selection. “Capacity and throughput are always scalable in our design philosophy. But the specific shape of a product, a specific proofing, baking, or decorating process, means tailored solutions to design a line like this. In most cases, this is solved by using standard technology and machines, sometimes tailored to a specific need. And always by integrating in existing situations, for fluent flow and process control,” AMF explains.

Consistency is key in industrial baking. The AMF sheeting lines and extruders reliably ensure consistent results and are built for 24/7 use, if required. For mixing, horizontal batch mixers can be selected, or continuous mixers for higher production volumes. “Sheeting lines are configured to current volumes and future growth projections, while proofers and ovens can also handle high capacities, in a stable, climatized environment,” the specialist says.

The line’s capacity and volumes produced will determine the production speed, as well as resting times and baking times: “These factors are all calculated, engineered and built accordingly for our customers, “ AMF highlights. The process delivers consistency in results: with stable factors

such as temperatures, dough quality, energy, hygiene, and people, an AMF production line ensures stable results.

Service and maintenance support also contribute to increased productivity and are provided. Lines covering the entire production process are designed and engineered, turnkey solutions starting from mixing up to packaging and post-packaging.

“Lines are mostly tailored to customer needs and have the flexibility to include additional pieces of equipment later, e.g., equipment units on c-frames that can be used for depositing and be removed when changing to other products. Upgrades to more automation, more capacity, less operator intervention are all possible in later stages,” the specialist illustrates. One line can be dedicated to a single type of product with variations in sizes and shape, but it can also be designed for entire product families, according to the bakery’s needs. AMF TROMP and Den Boer turnkey lines allow wide variations for flexibility.

The naan and flatbread line receives regular technology upgrades. For instance, AMF has recently revised the concept of its sheeting and extrusion lines, adding new features.

In addition, smart, AI solutions are now available for toppings, and its Sustainable Oven Service can be used for better oven performance and lower gas consumption. “Saving on gas and electricity, using less compressed air, and conducting life cycle analyses for each AMF machine is our goal, in order to know and manage the complete life cycle, and to report about it. This also helps with raw material savings/recycling,” AMF underlines. The line now has a more hygienic design so it can be washed down easily and prevent health hazards and contamination risks.

To develop new technology concepts, the R&D team follows customer feedback and market trends and new developments around naan and flatbreads. For example, smart AI-driven solutions are now part of the manufacturer’s digital strategy. AMF also sees sustainable solutions as an absolute must for any future developments. +++

Our plastic belts offer excellent airflow, optimum product support, a unique load sharing design for improved strength, and an easy to clean link rod interface.

Metal belts allow the end user optimal production possibilities, while ensuring strength and durability for the most demanding applications.

There is nothing average about these flatbread heroes: lavash and pita each bring powerful personalities to diverse culinary creations. Wraps alone offer a world of eating experiences, and consumers are eagerly taking note. Under such promising circumstances, only one question remains: how to optimize production with consistent, quality results?

+To best describe lavash with just one word, ‘versatility’ would be a first choice. This thin, soft flatbread owes its texture to the fine flour it uses, and its soft consistency to the production technique. In this way, it becomes a canvas for exciting creations, from wraps to quesadillas, and is also enjoyed as a standalone side snack. By comparison, pita is made for a different approach to eating, as it is often used for pocket-shaped creations, and is a popular choice for falafel and gyros sandwiches.

Beirut, Lebanon-based Farhat Bakery Equipment recently upgraded their production lines so that they can produce both. The company founded by Mahmoud Farhat, a pita baker, some 50 years ago, combines traditional techniques with latest-generation technology for its flatbread production lines. Replicating flatbreads’ handmade, artisan quality through automated production is a critical challenge in industrial baking. Modern continuous sheeting lines developed by Farhat achieve this through strict process control: “Automated lines can closely replicate the traditional kneading, resting, and baking processes by precisely controlling temperature, humidity, and timing,” the specialist explains. In this way, the resulting breads have the same texture and flavor as artisan products. Automating the processes, in turn, ensures consistent product quality, which is a challenge in artisanal production due to frequent variations. “Advanced control systems ensure that each flatbread maintains the same texture, taste, and appearance,” at the same time, says Farhat.

Much like the lavash and pita products, the lines are versatile to accommodate recipe diversity and various baking techniques, so they can meet production requirements for

”The latest generation of machinery ensures exceptional accuracy, allowing for consistent dough sheet thickness, even for the thinnest flatbreads.“

Farhat Bakery Equipment specialists

bakeries and culinary cultures anywhere in the world. Farhat’s lavash and pita production lines streamline processes to improve baking operations. Automation features reduce manual work required, as well as production times. The lines are designed to ensure consistent quality and focus on accuracy and speed for high-volume production. Ease of use and maintenance were also considered in their design: “The automation control systems are intuitive, allowing operators to select from a list, or introduce new recipes quickly,” Farhat’s specialists explain.

Consistent quality pita and, by extension, any flatbread specialty, relies on the characteristics of the dough. To ensure the dough stays within set parameters, Farhat incorporates continuous sheeting systems into its lines. The sheeting process involves rolling out the dough into flat sheets of uniform thickness: the dough is first calibrated, as it passes through a series of rollers, to achieve the desired thickness, and then cut into the required shapes – whether circular, square, or custom geometries, before moving to the proofing and baking stages, where the shaped dough is baked with the advanced infrared tunnel oven.

This controlled sheeting process ensures thickness consistency, which is crucial for flatbreads like pita, which require a

specific texture and pocket structure. For industrial production, the improvements that continuous sheeting production brought are nothing short of revolutionary in flatbread manufacturing, the Lebanese specialists observe. Its continuous sheeting lines provide several advantages:

+ Flexibility in production: the lines can produce a wide variety of flatbreads, including pita, lavash, naan, Cypriot pita, souvlaki bread, and other traditional flatbreads in various sizes, shapes, and thicknesses. The fully customizable lines can process a wide variety of products, matching individual needs – flatbreads and other bakery products. They are commonly used to produce a wide range of flatbread types, including pita, naan, lavash, and other traditional flatbreads.

+ Fast changeovers: the line can also be modified to produce different specialties by swapping the rotary cutter. “One of the standout features of Farhat Bakery Equipment's Continuous Sheeting Line is its adaptability, which allows bakeries to quickly shift between different shapes and product sizes without extensive downtime, making the production process more versatile and efficient,” the specialist highlights.

+ Volume production: the system's capacity to handle large production volumes makes it ideal for medium to industrialscale operations, Farhat highlights: “Production can reach 3,500 kg dough per hour, ensuring consistent output without compromising quality.”

+ Consistency and exact shapes: automated controls ensure that each bread maintains the exact geometry and uniform thickness, which is particularly useful for delicate flatbreads where thickness can be as low as 0.6 mm.

+ Customizable shapes: the machines can be adapted to produce flatbreads of virtually any geometrical shape, for unlimited product variety.

The design of Farhat’s newest continuous sheeting lines incorporates the latest technological advancements: they

are fully automated, covering all processes from dough preparation to extrusion, calibration, cutting, proofing, and baking, through to cooling, stacking, and packaging. “Each production stage, including dough brushing and dusting, is seamlessly integrated,” Farhat specialists underline. In addition, by having all the components designed and manufactured within the same engineering department and factory, ensures a seamless production flow. Also, each machine is perfectly compatible with its ecosystem. Moreover, the processes are minutely controlled on the line, for enhanced productivity and quality assurance. And last but not least, “The latest generation of machinery ensures exceptional accuracy, allowing for consistent dough sheet thickness, even for the thinnest flatbreads,” Farhat’s specialists highlight.

In line with modern technology concepts, Farhat’s continuous sheeting lines are modular, allowing easy integration of new products on existing lines: new flatbread products can be added by simply switching or adding minor units to the existing setup. “The flexibility extends beyond flatbreads to other bakery items, such as pizza bases or Greek pita, with minimal adjustments,” the company highlights.

The modular design also means the lines can easily be expanded and updated with new technology improvements, which may include new features such as enhanced control systems, faster changeovers, or additional product handling units.

With energy efficiency topping all priority lists, anywhere in the world, Farhat made savings central to the design of the lines: “All components, from motors to burners, are selected for optimal performance and energy efficiency. The lines are equipped with the latest-generation technology from high-end suppliers focused on energy-saving solutions.” They come complete with an efficient infrared tunnel oven, with high-performance burners and insulation to minimize energy consumption and reduce heat loss.

The growing appetite for ethnic and traditional flatbreads, from lavash to pita and including any flavorful interpretations, gives wings to promising baking business, with plenty of technology innovation to support it. +++

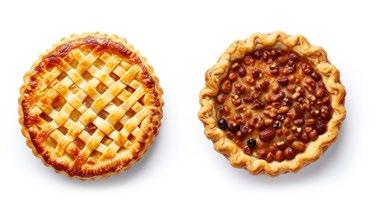

Ever the safe-choice favorite, but never a boring idea: pizza enjoys great diversity, to match all tastes, eating occasions, and curiosity for new taste experiences. A steadily growing appetite for pizza is met with interesting new offerings, including plant-based, premium, and limited-edition launches. Technology meeting these trends is a must for efficient pizza baking.

+Pizza launches have seen a 2% growth over the past four years, driven by innovations in dough fermentation techniques and diverse baking methods like stone, wood, and convection ovens 1

Europe is home to the most new product launches and reigns in pizza sales worldwide. This is where limited editions, unexpected flavors and premium creations thrive. New products include diverse varieties of cheese, chargrilled vegetables and smoked ingredients, Innova Market Insights research shows. This is not to say pizza’s popularity is dimmed elsewhere: the fastest growth in sales value has been recorded in the Asia-Pacific region for the past two years in a row. Here, new product development favors seafood-topped pizzas, combinations of cheese with vegetables, and mushroom and meat toppings 2

Health and flavor rule the product positioning trends. In September this year, Innova ranked the top five positionings in the pizza market worldwide, as follows: no additives or preservatives, vegetarian, traditional, source of protein, and gluten-free. In addition to these, GMO-free, no trans fats, halal and plant-based are other notable claims gaining ground for pizza.

Pizza comes in all shapes and sizes, each with its own recipe, ingredients and process steps, now with more diversity than ever. Automated manufacturing, especially large-scale, is far from easy to capture in one process, Rademkaker explains: “From pan pizza to classic varieties and Neopolitan styles, understanding each process is key to creating the best pizza

on the market.” Rademaker helps customers finetune and perfect their recipes and processes at its Test Centre, supporting the wide range in pizza processes. Products can range from thin and crispy pizza to fluffy and airy bases, folded edges, and stuffed crusts, for example.

”We have also upgraded certain dough sheeting units in our production lines so that the dough quality and consistency are improved. We are excited about these new technology features and will be introducing the new equipment at iba 2025.“

Wouter van der Veek, Product Manager, Rademaker

The company has a strategy dedicated to improving its pizza manufacturing equipment. Within this program, “Continuous research and development is carried out toward improving the efficiency and profitability of the Rademaker production lines,” Wouter van der Veek outlines. This includes focusing on the continuous improvement of weighing the products, to help pizza manufacturers reduce the giveaway of expensive topping ingredients.

Some of the latest R&D efforts focused on the production of the dough sheet: Rademaker brought new improvements to its pre-sheeter, which can now handle very liquid, pre-fermented soft and airy dough batches and transforms them into a consistent dough sheet, the company highlights. The sheeter contributes to the production of premium, artisan-

looking pizza and pinsa product ranges. More improvements are on the way, in addition to these developments: “We have also upgraded some of the dough sheeting units in our production lines so that the dough quality and consistency are improved. We are excited about these new technology features and we will introduce the new equipment at iba 2025,” Rademaker anticipates. The equipment going into Rademaker pizza topping systems has also been revised and upgraded, and a new topping line will also be showcased at iba in Dusseldorf, in May next year.

Also new in Rademaker’s pizza solution roster are new techniques to make stuffed crust and folded pizza edges, available through its partnership with Form & Frys Maskinteknik – a Danish company specializing in folding, forming, and filling machinery pastries and baked goods. In 2023, this agreement established Rademaker as the exclusive representative of Form & Frys solutions in several European countries, including Austria, France, Germany, Ireland, Switzerland, and the UK, as well as across the North American continent. “This equipment can be integrated into the Rademaker lines and serve as an alternative solution, building on the existing knowledge Rademaker has of this specific process,” van der Veek explains, adding that “The development of new equipment is a co-operation between our Pizza Product Group, the R&D department and our customers.”

New equipment is designed for integration into new and existing lines, too. Pizza topping equipment for ingredient depositing and cheese application, for example, is easily retrofitted and comes with standalone control systems.

Resource optimization is always a must-have, regarding energy as well as raw materials – which often come with a high price tag, especially when baking the now-trendy premium and limited edition pizzas. When used as toppings for pizza, cheese and proteins can be particularly expensive ingredients, making up the bulk of the costs for an end product. “Recirculating these ingredients when applying

them ensures nothing is lost,” Rademaker highlights. The process prioritizes maintaining the optimal ingredient flow through this loop, with little to no spillage in the first place. High accuracy in depositing ingredients on each pizza makes this possible, as it prevents waste and the over-application of these ingredients, which would result in giveaways.

Moreover, Rademaker’s sheeting lines come with dough recycling systems that return valuable ingredients making up the pizza base back into the mixers or at the front of the line, where they re-enter the dough production process. “Trials at the Rademaker Technology Centre ensure that specific customer recipes are finetuned to support this,” the Product Manager explains how the process is optimized.

Processing efficiency is at the top of the list, but not the only requirement for automated pizza lines. The flexibility to produce diverse specialties is an equally important priority. A latest-generation line can be customized to meet any production plans and specific markets. Rademaker specialists observe: “Daily fresh production has different market requirements than deep-frozen topped pizza for home baking. We think it is important to constantly look at market developments and trends.” Production equipment that can adapt to any number of developments and trends – and do so while maintaining process efficiency and high product quality – is key to making strides and creating tasty pizzas, either fresh or frozen. +++

The flavorful landscape of flatbreads is rich with choices for a wide range of products in unusual, creative interpretations. Aronia brings a new flavor and color inspiration.

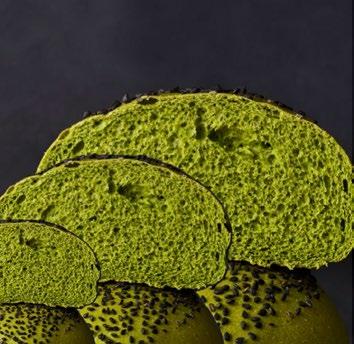

+Aronia is known as an ornamental plant. Its sour berries, called chokeberries, can also be eaten –fresh, or made into jams, juices, syrup and wine. A new ingredient developed by Austrian specialist backaldrin International and launched this spring brings a fresh addition to the ever-versatile flatbread recipes: chokeberry flavor. While the fruit gets its name from its astringent flavor that might make some mouths pucker, Aronia-tasting flatbread promises a mouth-watering experience, with an exciting, vibrant purple hue. What’s more, Aronia’s fruit provides a wealth of secondary plant substances, such as anthocyanins – antioxidants known to have many health benefits, including anti-inflammatory activity. An established power fruit, the chokeberry confidently enters the scene of flatbread creations.

The AroniaMix developed by backaldrin proposes a visual and taste novelty in the production of flatbreads. It brings spectacular shades of purple to the crumb of assortments, thanks to the anthocyanins in the Aronia fruit. The mix consists of dried, crushed chokeberry pomace, fine aromatic wheat sourdough and apple juice powder. The key ingredient is the star of the show: the Aronia pomace. It is obtained during juice production and then gently dried. “The antioxidant substances found directly under the skin of the Aronia berries and in the seeds were a determining factor in the composition of our mix,” backaldrin underlines. It is a clean-label product, containing no additives and no E-numbers. In keeping the product clean label, it was a must to use only easy-to-recognize ingredients and no artificial ingredients. For example, “The mix also contains apple juice powder, which adds a subtle sweetness to baked goods,” the specialists describe. The Aronia pomace gives baked goods a mildly fruity, pleasantly sour taste, while the notes of apple juice and the mild aromas of wheat sourdough gently round off the bouquet.

To perfect the AroniaMix, backaldrin used inspiration from the variety of colors in nature. “We wanted to develop a clean-label product with an appealing color and taste. In addition, we were looking for ingredients that have not been widely used in bakery or patisserie and that can have health benefits,” backaldrin reveals about the new development that marks its 60th anniversary, this year.

To enjoy its benefits, the Aronia Mix should simply be added to the flatbread recipe. “For optimal taste and color, we recommend a dosage of 20%,” backaldrin suggests. The baked flatbreads can be sold ‘as is’, or can be further personalized with any variety of fillings to create delicious snacks.

In addition to flatbreads, the AroniaMix is versatile to allow use in any type of bread recipe, including fine yeast dough recipes, and even patisserie products such as muffins. Recognizing the growing popularity of flatbreads in Europe, backaldrin also created a recipe folder, which includes suggestions and snack inspiration. Unique flatbread ideas include, but are not limited to Aronia, chickpea, rapeseed, or purple wheat. +++

Our solid and perforated steel belts have helped bakeries produce premium quality products for almost 100 years.

Flat, straight, durable and easy to clean, they provide a baking surface that’s ideal for everything from rich, chewy all butter cookies to traditional biscuits and crackers.

We can also support you with a wide range of conveyor components covering everything from tensioning, drive stations and drums to tracking systems, break points and graphite stations. Talk to your local IPCO service team and we’ll work with you to improve the performance, productivity and reliability of your oven through process enhancement and system upgrades.

High productivity wide belts up to 3500 mm.

Maximum versatility – bake more on an IPCO steel belt.

Energy efficient – lighter belt means lower carbon footprint.

High power laser cleaningfaster, cleaner and greener than traditional cleaning.

Installations, upgrades (mesh replacement), repair, maintenance and spare parts.

Plastic conveyor belts bring unique characteristics to the table - they are light, hygienic and easy to fix. In bakeries, plastic belt systems can be configured for several operations, as they provide a great solution to driving the products through processing steps.

+Just like their metal counterparts, plastic belts can be customized to meet specific requirements for several processes in a bakery, including cooling, proofing, and freezer applications. They can be successfully used for smaller products, too, and can perform tight transfers. Why plastic? “Plastic offers release properties that metal may not allow. Plastic belts can also run quieter and can often be repaired quicker and with simpler tools than metal belts,” explains Jonathan Lasecki, Ashworth’s Director of Engineering. Their smooth surface lends it to minimal product sticking, as does the reduced contact area.

”Plastic offers release properties that metal may not allow. Plastic belts can also run quieter and can often be repaired quicker and with simpler tools than metal belts.“

Jonathan Lasecki, Director of Engineering, Ashworth

Ashworth’s plastic belts, for example, are tested for over 100,000 fatigue cycles, under all the conditions needed for cooling, proofing and freezing in a bakery. They are designed for use in spiral systems predominantly, but can also be used in other conveyor segments. Possible configurations can be flexibly designed: “These belts will operate on both inclining and declining systems and all typical belt paths, straight through, 90-degree, etc. They can also be used on straight running and turn-curve conveyors,” Lasecki details. Both belt models made by the American specialist,

SpiralSurf ® 100 and SpiralSurf® 200 (with 1” and 2” pitch –the distance between rods), can be used in bakeries, and are particularly well suited for conveying baked or packaged products. They come in one surface style (as pictured), designed with openings and patterns that can accommodate various products. Plastic belt systems can have multiple uses. But, sticky products such as raw dough should not be placed directly on the belt for freezing, the manufacturer notes, as they have more strict conveying requirements when being conveyed, on any type of surface.

Ashworth SpiralSurf ® belts are manufactured with either Acetal (POM) or Polypropylene (PP) components. The first option, POM, is suitable for use between -40°C and 93°C (-40°F to +200°F), while PP should be used for processes running at temperatures in the 5°C to 104°C range (+41°F up to +220°F). To customize the belts, plastic or stainless steel rods are available. For products that may move on the belt, guard edges are an optional feature that can be requested. For product sorting, lane dividers are also available.

Assembly is another benefit of plastic belts. Setting up Ashworth’s SpiralSurf ® belts is simple and requires no special tools: “Connect the ends and insert a connecting rod to make it continuous. General construction rules used for belt conveyors apply,” Lasecki explains, adding that suitable guarding should be installed for personnel safety. As long as the conveyor is correctly set up, the belt will track and run as intended: “A proper take-up system must be part of the conveyor construction, to allow for variations in

belt length due to tension, wear and/or temperature variations,” the specialist observes. The SpiralSurf ® 100 has smaller open areas to support smaller products safely, while the SpiralSurf® 200, which has larger open areas, allows for better airflow.

While lifespan may vary according to utilization, Ashworth belts are guaranteed to run for well over 100,000 cycles, where a fatigue cycle is a load/unload of tension in the belt. As a general consideration, the operating speed influences the belt’s longevity: a belt running slow will last much longer than a belt running at fast speeds. In general, belts should run at maximum speeds of 30 m/min (100 ft/min); however, some processes require belts to run at considerably higher speeds. In this case, a corresponding shorter lifespan should be expected, as well as more frequent service/maintenance work throughout.

Cleanliness is also critical to extending the plastic belt’s life. “Allowing product debris or fine dust particles to accumulate on the belt will create abrasive wear and lead to belt stretch and/or component failure,” the specialist underlines. Ashworth recommends what to consider to extend their lifespan: “Plastic belting is affected by harsh cleaners, UV light and the lack of or improper monitoring of the belts’ operation. Plastic belts will typically break either at the hinge rods or the belting modules themselves,” he adds.

One of the advantages of plastic belts is that only the damaged section can be replaced, by removing a pin ahead and just after the damaged section, and then adding a new section that matches the previous one in length. The old part is sent off to recycling, while the new part is installed by joining the ends and inserting the necessary connecting pins.

In day-to-day operations, the belt must always remain perfectly aligned and its tension must be uniform across its width. Misalignment of only a few mm can lead to belt damage; uneven tension leads to mistracking and causes the belt to stretch and break over time, causing downtimes unless prevented. Belts should be inspected frequently (relative to the process), to avoid this, Ashworth recommends. “Inspection checklists must be established at each installation, based on the system and process parameters,” Lasecki underlines. System alignment is critical to proper belt operation.

Setting up a production line with plastic spirals (or other suitable conveyors) is not only a choice helping with process efficiency, but also proof that there are still applications where plastic is a great choice. +++

Spending energy with the utmost caution is not a present-day, circumstantial trend. For bakeries, it is a hard reality and will only continue to become more important going forward. Energy savings and sustainability improvements start in the oven.

+A complex set of factors and metrics encompass sustainability in bakeries. There is no fixed algorithm to work with, either, as there is a different set of variables that characterize every bakery. There are several ways to assess – and then improve – the sustainability of an operation. Environmental impact is among them, which includes managing carbon footprint and energy consumption.

For baking ovens, the characteristics of the steel belts are one aspect to consider when looking for sustainability improvements. Equally important, however, is to look at the big picture over time and consider the lifetime of the belt. Both solid and perforated steel belts have a considerably longer lifespan, compared to other types of belts. Their working life is typically 20 years or more, often much longer. Steel belts twice this age can still be in operation and perform well. “They are less susceptible to damage, be it through impact, wear and tear, stretching or deformation,” IPCO underlines. This extended timeframe significantly factors in the overall return on investment.

Energy savings when baking depend on numerous factors, including (but not limited to) the design of the oven itself, the product being baked, and the parameters of the baking process. There are other factors to be taken into account in analyzing the efficiency of the baking process, including the energy used in heating the belt throughout the baking process, and in actually moving it through the oven.

Steel belts are lighter than wire mesh so less energy is needed to heat them to the required temperature. “Each time the belt exits the baking chamber, it begins to cool and has to be heated up again. We estimate potential energy savings to be in the region of 30 % for solid steel belts and even more for perforated. Given that as much as

25% of an oven’s energy consumption goes into heating the belt, the savings can be considerable,” IPCO’s specialists calculate. The lighter weight not only benefits the energy spent in baking, but also means less power is needed to ‘drive’ the belt through the oven.

”The laser is installed above the belt and the beam is focused on an area approximately 75 mm wide. As the belt travels under the laser, carbon deposits are burned off and collected by a vacuum system.“

Marko Leber, Global Product Manager, IPCO

Various perforation designs make steel belts even lighter than solid ones – good news for the energy needed and for the baking process, too. IPCO perforated belts are available in five standard perforation patterns, with circular

hole diameters ranging from 2.0-5.5 mm. Each pattern determines the amount of air that can pass through the belt, allowing different rates of air circulation within the oven. “Tests can be made to determine the optimum perforation for the type of product being baked,” IPCO explains. In most cases, one of the standard patterns will be a suitable choice. If not, custom perforations can be engineered for specific requirements, with hole diameters as small as 0.8 mm, if needed.

Determining the exact parameters of the steel belt goes a long way to efficient baking, for a long time. The design of the oven itself and the product portfolio will dictate the best-suitable choice. The type of product being baked is very often the determining factor: “Certain goods – real butter cookies for instance, or chocolate brownies – need the flat, solid surface of a steel belt. Otherwise, the fat would melt into the oven, with the resulting risk of starting a fire. A solid steel belt will also usually be the preferred choice for products such as biscuits, pastries, shortbread and granola bars. Alternatively, perforated steel belts can be a ‘best of both worlds’ option, opening up the possibility of producing both ‘mesh’ and ‘solid belt’ products on the same line,” the baking oven belt specialist illustrates.

Another important aspect, when looking at the operating cost throughout its lifetime and the environmental impact of a product, is the repairing process. This is especially relevant for steel belts, given their extended lifespan. This is where they shine, given their durability and ease of fixing: “Small areas of damage can be patched and larger areas cut out and replaced. Hairline cracks caused by fatigue can be welded, and edge burrs can be filed back,” the specialist details. If a belt is showing signs of deformation, it can be straightened to its previous flat surface, with equipment such as IPCO’s Shotpeener Pro repair tool. “This is a portable unit that is used to blast steel balls at high pressure across the width of a belt as it turns around the terminal drum. This equalizes stresses on both sides of the belt to remove deformations,” its manufacturer explains.

However, steel belts are extraordinarily durable pieces of equipment, so any sign of damage is usually a symptom of a problem elsewhere on the line, rather than a problem with the belt itself. The cause should be addressed to return the process to its initial productivity. But, should such damage occur, it can almost always be rectified.

While steel belts do enjoy a money-saving, long lifetime, they can operate within all efficiency parameters considerably longer, if used correctly. TLC might usually stand for

‘tender loving care’, but also: “The three most important things in terms of maximizing the working life and day-to-day performance of a steel bake oven belt are tracking, lubrication and cleaning (TLC),” IPCO underlines.

In terms of tracking, under perfect conditions, a high-quality belt on a properly designed conveyor will run straight and true. However, such conditions are rare in a working environment – temperature changes alone will cause the belt to track one way or the other over time – so steel bake oven belts require some form of tracking. For retrofit installations, the company usually recommends its Compact Belt Tracking 2G system, which uses an optical sensor to monitor the position of the belt edge and enables immediate corrective action, in case of any deviation. “For clean-sheet installations or system upgrades, we can provide integrated active tracking that also incorporates belt tensioning,” says the specialist.

Lubrication minimizes friction, reduces wear, prevents belt distortion, and mitigates the risk of rust caused by condensation. Graphite skid bars are usually the answer, but IPCO can recommend other solutions if needed.

Cleaning, probably the most important maintenance task for bake oven belts, is often a task that can be dirty, difficult and time-consuming. Caustic soda, dry ice, detergent and baking release agents are traditionally used. As a new

First announced in July, the acquisition of the French Mademoiselle Desserts Group was successfully completed. Swiss milk processor Emmi is expanding its market presence in the strategic niche of premium desserts, with this move. The product group currently accounts for 9 % of Emmi's total sales, with Mademoiselle Desserts accounting for around 17 %.

Mademoiselle Desserts specializes in premium patisserie, with 12 production sites in France, the UK, the Netherlands and Belgium. The bakery generated annual sales of around EUR 420 million in 2023 and has around 2,000 employees. Mademoiselle Desserts products are available both in retail, particularly in the in-store bakery sector, and in food service. “We are thrilled to officially join the Emmi Group, a key player in the international dairy market. This integration marks an important milestone in the history of our company, opening new opportunities for growth and innovation by creating the ‘Desserts Powerhouse’ with Emmi Group’s factories based in Italy and the United States. We look forward to working hand in hand to continue offering our customers high-quality, delicious, healthy and safe products, always

development for efficient cleaning, IPCO offers a laser cleaning treatment that does the job in about half the time. “The laser is installed above the belt and the beam is focused on an area approximately 75 mm wide. As the belt travels under the laser, carbon deposits are burned off and collected by a vacuum system. Cleaning can be carried out at a rate of between 10-15 m2/hour, depending on the level of build-up, and the entire process can be managed by a single IPCO engineer,” the specialist explains.

The more efficient the overall system, the greater the energy efficiency. All components contribute to optimum processing if they are set up and managed correctly. For conveyors and their belts, the bigger picture means checking that, “The terminal drums, rollers and skid bars are aligned horizontally and at right angles to the center line of the longitudinal axis of the oven line. Checks should also be made to ensure that terminal drums and all rollers are rotating freely and the tension device is functioning correctly,” IPCO recommends.

Energy savings are made starting with the oven and all related components, one of which is the conveyor belt. But, savings (or unexpected losses) come from any piece of machinery and process setup. While some things are meant to work unchanged for a long time (steel belts), new developments and approaches are coming in to help bake more efficiently. +++

with a touch of indulgence, while preserving our core mission to provide the best cakes and desserts to everyone. We are embarking on this new adventure with delight, passion, and commitment,” Mademoiselle Desserts wrote in the acquisition announcement. +++

From its home base in Zaandam, Lika Bakery shows its excitement and skill in product innovation. Its new, award-winning creations are proof, joining an inviting product portfolio.

+Historic windmills, picturesque canals and traditional Dutch architecture: Zaandam is a beautiful city in the Netherlands. It made such an impression on Monet during his months-long stay there that it inspired several paintings. It’s not only its beauty that makes Zaandam a popular destination among tourists; the town is also renowned for its delightful local cuisine. Lika Bakery proudly contributes to the region’s flavorful culinary offers, coming from the town known as ‘the Dutch true food capital’, thanks to its history and diversity in the food industry. The business founded in 2016 thrives on experimenting and baking. From ideas to fully realized products, Lika Bakery is getting inspiration from cultures all over the world to combine traditions and innovations, for its flatbreads, world breads and buns. Products from Lika Bakery are sold all over Europe, in retail and foodservice.

Their reach and curiosity do not stop there: in March, Lika’s team and ideas traveled to Japan, where they took part in Foodex 2024, as a part of the Dutch pavilion of exhibitors. Its trade show travel agenda also included PLMA and SIAL.

In March this year, the Dutch bakery received an innovation award for Best Bakery Product for its vegetable breads, at IFE’s World Food Innovation Awards. It was their second time exhibiting at the event in London. What makes these breads unique is their distinct color, which comes from the real vegetables used in the recipe. The range includes spinach, carrot and beetroot breads, “A clever and quite transparent way to add vegetables to a meal and diet,” underlines Mariana da Silva, Marketing and Sales at Lika Bakery. “Our vegetable breads are rich in fiber, low in

sugar and low in salt, making them perfect for healthy meals,” she adds. And, a new acknowledgement recently joined the bakery’s collection, for winning the Plant Based Taste Awards.

It’s been a year of different accomplishments for Lika: seven months ago, the business earned the BRC A certification, the highest level of compliance within the BRC Global Standard for Food Safety.

In the spring, the company also launched its new website, available in several languages, and designed for professionals in the retail and food services industry, including cafeterias, supermarkets, restaurants and in-flight catering services. In addition to an introduction to the company, it serves as a platform for an open invitation for collaborations. The bakery shares the thought process behind the enticing creations it suggests “We want people to realize that Lika bread can be enjoyed every moment of the day. If you want

something sweet for breakfast, try our flatbread with some good chocolate paste and some delicious strawberries. For lunch, why not have a flatbread stuffed with hummus and some vegetables? Also, don’t forget the delicious Dutch cheese. And, for dinner, you can have a super gourmet salmon burger, served with our trendy-looking street-food bun.” Its bread assortment is meant to invite culinary creativity.

‘The power of flour’

Lika Bakery draws inspiration from Lebanese bakery in its creations and traditional techniques, from flatbreads to burger buns. They use ingredients from local sources. All its flour, for example, comes from a local artisan miller, George Pijnappel and the Four Winds Mill, which has been in business for over 100 years. Lika chose this supplier because of its artisanal quality, 100% made in Holland, as well as the values they share with the family business: good breads needs natural flour. The authentic Lebanese smell and taste of the bread comes from this special blend of flour. It’s one of the reasons why Lika uses ‘The power of flour’ as a motto.

“We try to source our raw materials according to core values, prioritizing sustainability and environmental responsibility.

”Embracing the power of details is part of our philosophy. We don’t want to overlook anything. We strive to be sharp in every aspect. Continuously surprising. Our goal is ambitious: to become a global player in bread.“

Sustainability in action: Recycling bread waste saves waste in production.

Bread that cannot be sold due to visual defects does not have to be thrown away. Waste bread recycling, where the bread waste is crushed, liquefied and added back to the dough, allowing them to be put to good use – and even improves the quality and taste of the dough.

We have the solutions to make your plant suitable for bread waste recycling: With our specifically designed components, bread waste rises to the occasion.

We try to maintain our supply chain in the Netherlands, to avoid deviations and complications in the chain,” the bakery explains. As production is always adjusted according to the demand to prevent waste, its raw material inventory fluctuates accordingly every month, making it more practical to source locally.

All of Lika’s product ranges are baked daily in its Zaandam bakery. Two production sites are set up, with the offices right above them. From here, they are delivered anywhere in Europe, from Amsterdam to Dusseldorf or London: “ordered today, delivered tomorrow”.

The bakery currently produces flatbreads in five variations: white, wholewheat, with carrot flavor, spinach and beetroot (and there are already some exciting ideas for other new, unexpected and delicious flavor proposals). The recipe changes have no impact on the process, so the resulting quality remains consistent. As the production site’s doughmaking operation was just starting, it took extensive trial and error to perfect the original flatbread, Bangin Yussif, Lika Bakery’s owner recalls. The search for the right materials led them across the world, for the perfect combination of raw materials. “That is when we thought to include vegetable scraps into the flatbread. We reached out to companies –mostly juice producers, as they leave quite a lot of vegetable leftovers behind. This is how the recipes were perfected. And, there is also a sustainable component to our breadmaking,” he explains. At Lika Bakery, they pay close attention to sustainable practices.

A Mediterranean favorite, the flatbreads created by Lika are focused on the trends of the Western markets. “Bringing a variety of flavors and diversity to your table is our goal,” da Silva says. “We have Lika Bread ourselves for lunch, every day at the office and I love how diverse the assortment is; everyday we eat something different. My personal favorite might be the Turkish Simit, or the buns,” she tells us.

”Our vegetable breads are rich in fiber, low in sugar and low in salt, making them perfect for healthy meals.“

Mariana da Silva, Marketing and Sales, Lika Bakery

Flatbreads are only one of the specialties Lika pays close attention to. Six bun varieties and several world breads with halal, vegan and high-fiber labels. Production varies according to demand and seasons. “For retail, flatbread is the most sold item, while for food service, our most popular choices are the buns and a variety of breads such as Turkish bread, Turkish simit, Surinamese Puntjes and even pitas,” da Silva details.

Innovation requires constant learning and development, Lika strongly believes. A message recently shared on LinkedIn perfectly crystalizes Lika’s business approach as it advances. In their own words, “Sometimes, late at night, you can still see the lights on at Lika Bakery's office. That’s when we’re still working on a pitch, a new product, or another improvement of our products. Embracing the power of details is part of our philosophy. We don’t want to overlook anything. We strive to be sharp in every aspect. Continuously surprising. Our goal is ambitious: to become a global player in bread.

Lebanese flatbread, brioche buns, Surinamese buns, Turkish simit... we're making good progress. Follow us on our journey.”

It promises to be an exciting one, and new partners are welcome, to grow together, as Lika Bakery aims to produce ‘everything that is flat’ and introduce the world of traditional breads to everyone. +++

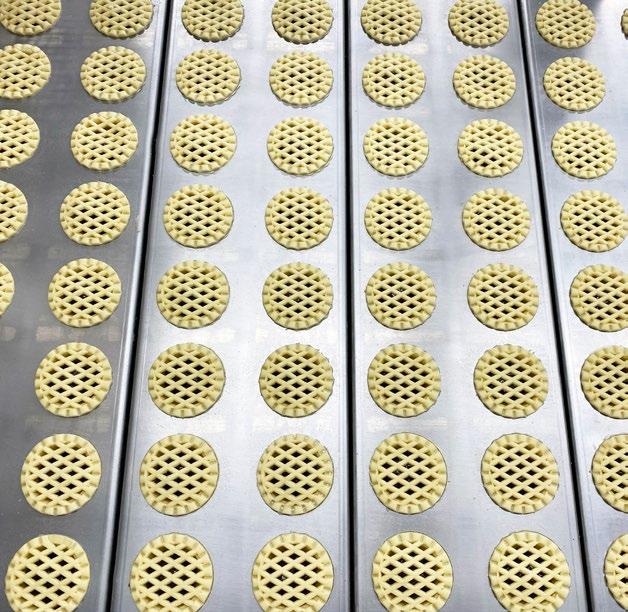

Cookies speak the universal language of taking a moment for a delicious treat, anytime, anywhere. The stakes are high to produce the next favorite creation; but, technology provides different mixing methods to guarantee a perfect start.

+The first step that can make (or break) a great cookie is mixing. When making cookies from scratch, the order of incorporating ingredients plays a crucial role in achieving the desired texture. Generally, the fats go first –usually butter – together with the sugar. The liquid ingredients then join the mix, including eggs, with the powder ingredients (flour) being the last to be added. The challenge lies in managing adjustments to this order and the temperature of the fats used. French mixing specialist VMI recommends using softened butter, and avoiding fats that could be too hard.

“If the butter is too firm, you will need a longer mixing time to achieve the right consistency,” VMI explains. To control the texture, preventing the gluten network development makes cookies softer; in this case, “Avoid overhydrating the flour and do not overmix the dough,” recommends the mixing expert.

However, an optimal approach cannot be set in stone, because best practices will vary significantly according to each cookie recipe. Finding the right balance is where the challenge lies.

Batch mixing is particularly beneficial when there are frequent recipe changes, when flexibility is required, and when running smaller production volumes. It accommodates different production capacities and recipes effectively. When using batch mixing technologies, there are several factors that can enhance the mixing process:

+ Choosing the right mixing tool

Selecting an appropriate mixing tool is essential: a paddle/beater with discontinuous flats or twisted paddle/ beater is often ideal, VMI recommends, as it promotes

better circulation of the dough within the bowl. This ensures effective mixing, even distribution of inclusions, and the ability to break down and incorporate fat blocks evenly. Alternatively, using regular spirals can be another efficient mixing option that gives good results.

+ The number of tools

Using a double-tool mixer can improve efficiency and speed up the mixing process.

+ Speed control

Adjusting the mixing speed is crucial for optimizing the process. A mixer offering speed variation can help by making more precise adjustments.

”It’s best to evaluate the specific product, recipe, and mixer to determine the exact equipment size needed for the required production volume.“

VMI specialists

Taking into consideration all of these factors for each recipe and specific production scenario, will considerably improve the efficiency of the mixing process for cookie dough. To determine the optimum batch size for the equipment and optimize energy consumption while using a batch mixer, a multi-angle approach is the answer: “It’s best to evaluate the specific product, recipe, and mixer to determine the exact equipment size needed for the required production volume,” VMI explains. Usually, the batch size that can be processed with the same equipment typically ranges between 30% and 100% of the machine's nominal capacity. The specialist illustrates: “For example, with one of our spiral mixers with a 400 L bowl, batches as small as 80 kg can be processed, and as large as 250 kg, depending on the dough’s density, consistency, hydration, ingredients, etc.”

Continuous mixing is synonymous with large-scale production. For this technique, efficiency and consistency are paramount. The corresponding technology, continuous mixers, are usually fully automated, ensuring that quality is maintained consistently throughout the process, from dosing to mixing. They are the most efficient for processes with few changes in recipes. Furthermore, these mixers offer great control over dough temperature, which can help to reliably achieve the desired texture and consistency in industrial cookie production.

However, using continuous mixers for cookies involves navigating some key differences compared to continuous mixing for baked goods like bread. One primary distinction is ingredient introduction, VMI notes: “Continuous mixers generally require a specific order: powders are added first, followed by liquids, to ensure proper pre-hydration

before mixing in the main mixing chamber. In contrast, cookie production often involves a different sequence, where fats and inclusions need to be incorporated effectively at various stages of the process. The inclusion of mix-ins like chocolate chips requires careful management to ensure they are evenly distributed and remain intact, preserving the desired texture and appearance of the final product. For this reason, they will often be added later in the process.” The design of the continuous mixer and its dosing units must take these elements into account. The tool should also be suited for mixing unstructured doughs effectively.

Addressing all these unique requirements maximizes the efficiency and consistency that continuous mixers can offer for cookie production.

To navigate the differences and make the most out of both techniques, thorough recipe testing is a must, along with expert help with the technology. Mixing processes can be tailored to accommodate any variations needed, for best results. +++

Inspiration for next year and beyond takes center stage in Stuttgart, with the 30th edition of südback lining up the best and latest solutions for bakery, confectionery, coffee, chocolate, logistics, training and more. It’s time to plan for interesting updates and meetings.

+The most anticipated event of the year is almost here. International exhibitors are bringing the latest developments for the baking and confectionery industries to südback; several competitions will crown this year’s excellence in craftsmanship and innovation, and a full agenda of forums will be hosted for knowledge sharing.