06 18 www.bakingbiscuit.com iba 2018 A new instore baking process Interview iba from the US perspective Production Fully automatic pizza press BAKING STORAGE PROOFING BAKING STORAGE PROOFING

Right hand model 9840 shown with optional water spray, stacked water splitter, conveyor and MPA auto fill system. SMART SEEDER CALL US TODAY +44 1638 668563 THE TOPPING EXPERTS P.O. Box 748 • Maysville, OK 73057• Telephone (405) 867-4467 • Fax (405) 867-4219 • e-mail: sales@burford.com www.burford.com Unit 4 Sam Alper Court, Depot Road, Newmarket, Suffolk CB8 0GS UK • +44 1638 668563 • e-mail: sales@burford.com

Only a few weeks have passed by since the IBA 2018 in Munich closed its doors. The impressions we were able to take with us from the IBA are still fresh in our mind. This trade fair managed to surpass even what was expected of it. It was a successful mixture of the “must haves” that are needed in everyday factory operation with a presentation of the many macro- and micro-trends that were brought close to the specialist visitors. The future was there to be seen.

++ Armin Juncker Chief Executive Verband Deutscher Großbäckereien e.V. and Treasurer and thus a member of the Executive Board of the AIBI (International Association of Plant Bakers)

There were two particularly unmistakable and conspicuous trends in this respect, and which we will certainly meet again day after day in the business, as well as at the next IBA trade fair: the trend towards automation, whether in the form of perfected mechanisms or in state-of-the-art electronics. In contrast to visitors’ comments one could sometimes read, automation is not only of interest for the industry but is also already a part of the future for artisans. The second trend is the orientation towards premium-quality baked goods and services.

The interest and premium offerings are overwhelming. The sector is trying to show what it is capable of, and it is helped in this respect by the fact that suppliers have also begun to conquer new ground. The slogan already coined by a well-known major Munich bakery many years ago: “Maximum quality at acceptable costs, rather than minimum costs with acceptable quality,” was almost palpable.

Consequently, everything was available: from a sound assortment at entry level prices to the equipment for high-priced luxury baked products. Our sector has the power to contribute decisively to a healthy, enjoyable diet in the future as well, no matter what reformulating that involves.

The IBA was a highly informative performance show. The conference of the International Association of Plant Bakeries (AIBI) in the spring of 2019 will link to it almost seamlessly. In richly traditional Manchester, there will again be an opportunity to glimpse the future of baking under the Congress motto: “The Bakery of the Future”.

Yours sincerely,

Armin Juncker

Armin Juncker

EDITORIAL

Premium

ADVERTISEMENT PosiDrive Spiral™ • High Tension • Heavy Loads • Greasy Products • Product Movement Proven Solution For: Call for System Audit +31 20 581 3220 www.ashworth.com

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany

+49 40 39 90 12 27 www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil

+49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld

+49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk +49 40 39 60 30 61 baumfalk@foodmultimedia.de

ADVERTISING DEPT.

International sales director Dirk Dixon +44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Wilfried Krause +49 40 38 61 67 94 krause@foodmultimedia.de

DISTRIBUTION

+49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide Linda Langhagen; design@landmagd.de

PRINTED BY Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department.

No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2018

www.bakingbiscuit.com 06/2018 CONTENT 04 IMPRINT

cover

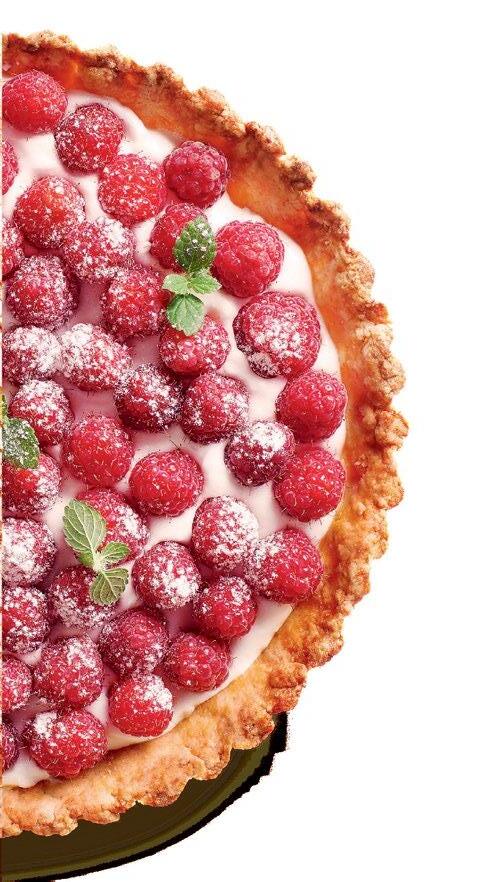

© xxx cover

© Diane © karandaev –123rf.com © cetravac 20 34 Production 34 MCS: Fully automatic – but with a touch of craftsmanship 42 Rademaker: Secondary virtues are in demand 46 Boulangerie Pain: Absolute artisan skill 54 GoodMills: Less flour dust in the bakery iba special 08 The trade fair 10 Robb MacKie: “It has been phenomenal” 16 Automation and digitalization: Who will be the technology leader? 18 Kaak: “Baker’s fingers” 20 Cetravac: A new instore baking process 22 W&P: Dividing and moulding competence 24 FRITSCH: Intelligent services 26 Kövy: Optimizing roll production 28 Slicing technology 30 Kempf: Durable coating Market 38 Online sales: The logjam has broken 44 PLMA: Private labels have big shares 50 Rützler: New food culture trends Packaging 58 Ishida: Fast, compact and flexible Product planning 60 CSB: Good planning is half the battle Regulars 03 Editorial 05 News 17 Trade fair calendar 32 News 36 News 56 News 62 News © ABA 10

photo:

photo:

Fritsch: Alexander Schmitz becomes new Managing Director

During a press conference at the iba, Klaus Fritsch, Chairman of the Supervisory Board of the Fritsch Group, announced that Alexander Schmitz (50) would take over as Managing Director on January 1, 2019. The mechanical engineer has worked for Bosch for many years, including in the field of packaging systems. +++

++ RBS Announces the passing of Thomas (Tom) Lugar

Thomas (Tom) Riley Lugar, former President of Thomas L. Green & Co., Inc., a manufacturer of biscuit and cracker baking equipment, has passed away. Tom joined his family business, Thomas L. Green & Co., Inc., founded by his grandfather, in 1957 and served as President for more than 50 years. The company became a division of Reading Bakery Systems (RBS) in 2001 and Tom remained active until shortly before his passing. Within the industry, he served as treasurer for the Cookie & Snack Bakers Assn. for more than 40 years and was active within the Biscuit & Cracker Manufacturers Assn. Tom passed away on August 9 at his home in Indianapolis. +++

++ RBS Announces the passing of Vince Pasquini

Reading Bakery Systems (RBS) announces the passing of Vince Pasquini. Vince began his long and distinguished career at RBS in 1993. He held positions of increasing responsibility including Design Engineer, Project Manager and Pretzel & Snack Technical Sales Specialist. His remarkable ability to envision mechanical solutions for the most challenging applications enabled him to excel at machinery design. He created the foundation of many of the machine designs used in the current RBS product line. Vince earned his Mechanical Engineering degree at Penn States University. Before coming to RBS, he worked at Edco, a machinery design firm. While

++ Tromp Group announces President’s departure

Tromp Group announced the departure of Richard van Heukelum, President of the Tromp Group, as of August 21, 2018. “Over the past few years, Richard has been an integral part of Tromp Group’s success. We greatly appreciate Richard’s contributions during his time with the Tromp Group. We wish him continued success in his future endeavors.” stated Markel Food Group CEO Ken Newsome. +++

++ Fabiano Malara appointed General Manager

Tromp Group announced the appointment of Fabiano Malara as Vice President and General Manager at September 10, 2018.

“We are excited to have Fabiano on board.

Fabiano is a strong leader and Certified Master in Lean disciplines.” stated Markel Food Group CEO Ken Newsome. “I am excited about Tromp Group,” stated Mr. Malara. “When I see the convergence in

working there he designed a pretzel cutter for a local pretzel company, and this design got the attention of RBS. Vince passed away on August 17, 2018. +++

++ Klavs Berzins appointed Managing Director of Fazer Bakery Baltic

Klavs Berzins has been appointed Managing Director of Fazer Bakery Baltic and member of the Fazer Bakery Business Area management team. The Fazer Bakery Baltic business unit was established in 2014 by uniting Fazer’s bakery businesses in three countries - Estonia, Latvia and Lithuania. Fazer has operated in Estonia since 1993, and in Latvia and Lithuania since 2001. Currently Fazer Bakery Baltic employs over 620 people. +++

ProSweets Cologne: On the pulse of the market situation

ProSweets Cologne offers the complete range of supplies for the sweets and snacks industry: from innovative ingredients to pioneering packing solutions, and through to optimized production technologies. In conjunction with ISM, the world's leading trade fair for sweets and snacks, ProSweets Cologne covers the industry’s entire value chain. From 27 to 30 January 2019 the trade fair duo is placed once again in the industry's focus. In total, over 300 companies from the manufacturing, packing and ingredients sectors are expected in Cologne. ProSweets Cologne is accompanied by an extensive event program, which includes for instance expert lectures in the “Speakers Corner” as well as diverse special events on the themes of newcomers, ingredients and packaging. +++

technologies with Tromp Group and AMF, the market potential is significant.“ Newsome added, “Fabiano is an example of a leader of the future in the industry. He brings passion and a customer focus plus skills and knowledge from being a leader at Danaher and Phillips.” +++

++ Hans Herman Doude appointed Vice President Marketing & Sales

The Tromp Group announced the appointment of Hans Herman Doude as Vice President Marketing & Sales as of October 4, 2018. “With his many years of great Industrial experience at WP Kemper and his International experience, he will lead the Marketing & Sales department. Hans Herman will lead the Tromp Group and AMF Sales teams in Europe, Middle East and China,” stated Markel Food Group CEO Ken Newsome. +++

++

05 NEWS ++ NEWS ++ NEWS www.bakingbiscuit.com 06/2018

©

©

©

Tromp Group

Tromp Group

RBS

The Future of Science –

Summary: Innovations have many fathers and mothers

Science: Highlights for the baking industry – What the scientists are currently working on Round Table: Leading production managers discussed the future of bakery production Market View: Mixing + Kneading, Dough Processing, Ovens, Cooling + Freezing Company Reports: Profiles of 26 major suppliers to the bakery market

– Technology

Technique

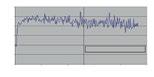

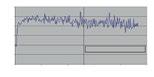

++ Brand new! ++ thermal energy for the baking process. Practical advantages of VCB technology are well documented in the literature, especially regarding the high temperature applications often investigated at LSTM in the past, e.g. VCB applications in the glass or aluminum melting industry, gas turbines, paper dryers, boilers or fuel cells. On the other side, in order to apply this technology in the low-temperature processes, as sensitive as bread baking, new baking oven concept was proposed, developed and tested within this work, from purely theoretical consideration up to the fully functional prototype in the industrial scale. Motivation in numbers Continuous growth of population, further industrialization and technology oriented life style, are leading toward both a further global energy demand growth and continuous increase in the food demand. International Energy Agency (IEA) estimates that the energy demand will grow by more than one-third over the period up to 2035 [1]. Today most of the world total primary energy supplies (over 81 %), comes in of fossil fuels and additional 10 % in the form of renewable – bio fuels [2]. Study published by the U.S. Department of Energy (DOE), estimates that fossil fuels will continue to satisfy almost 80 % of the world energy demand until 2040. Furthermore, DOE estimates a pronounced global shift away from the use of oil and coal toward the use of natural gas and renewables in the period 2010-2040, with the natural gas as the fastest-growing fossil fuel in the outlook, with global consumption increase of 1.7 % per year [3]. In the Federal Republic of Germany, the primary energy demand has the similar structure, where around 80 % of primary energy requirements are provided by the combustion of fossil fuels [4]. According to the Federal Statistical Office of Germany, the food industry is at the sixth place in the list of the most energy-intensive industrial branches, with the annual energy demand 75 % higher than for example German automotive industry [5]. On the other hand, analysis of the German bread market shows two major tendencies, i.e. the production centralization and an increase of the annual turnover. In their report from 2016, Association of German Bakeries e.V. reports that the number of bakeries in Germany has been continuously reduced from over 20,000 in the year 2000, to 12,550 in the year 2015 [6]. In the same time, the number of Bake-Off-Station in Supermarkets and Self-Service-Bakery increases (industrial production), as well as the total turnover which increased from 15.7 billion year 2000 up to 19.5 billion € in the year 2015 [6]. That practically means that in average, more than 460 bakeries are closed every year, while in the same time the average turnover increases for more than 235 million €/year. It becomes more difficult to stay competitive in such a market situation, especially for small and middle size bakeries. Therefore is the continuous reduction of the production costs through the reduction of the energy requirement in the production sector, possibility to adjust fast to new products and/or shortening of the production time essential for ever producer, independent of its size and annual turnover. The energy demand for the production of bread and baked goods can reach values up to 4.8 MJ/kg, from which only one third is effectively used for heating the baked goods. Cited inefficiency and the high energy demand affect especially small and medium-size companies (SME). Accordingly, baking industry has an acute need for innovations that increase the energy efficiency, reduce the required baking time and other improvements of production ecology and economy, while securing the baked goods quality. In this way the designed baking oven offers advantages especially for SME, which are characterized by variety of products and variable production load. Our goal This work was based on the assumption that the VCB-based baking oven technology can profit from the previously known advantages of the VCB technology in general, i.e. high thermal radiation output, broad modulation range, excellent dynamic + The energy demand in the production of high quality food products is and always was generally significant. The food industry is therefore commonly among top ten or even among top five most energy demanding industrial branches. This results in constant need to improve existing technologies or to introduce novel ones, which is oft significant ecological and economical challenge. In the case of food industry, additional challenge is that improvement or replacement of existing technologies must not compromise neither food quality nor its safety. That means that many of the novel technologies and solutions, commonly applied in other industrial branches, cannot be simply transferred to the food industry. Exactly this kind of technology transfer of the relatively young VCB combustion technology from high to low temperature application was in the focus of interests in the research project AiF 17735 N. Research was recently done by the scientific teams of Prof. Antonio Delgado, Institute of Fluid Mechanics (LSTM) at FriedrichAlexander University (FAU) in Erlangen and Prof. Thomas Becker, Chair of Brewing and Beverage Technology at the Technical University in Munich (TUM), together with the industrial partners supporting this project. The core of the novel baking oven concept is the use of the porous volumetric ceramic burner (VCB) as the alternative, highly radiative source of the VCB based baking oven concept –efficient, innovative and flexible Experience gained in the high temperature applications, enables the use of the porous volumetric ceramic burner (VCB) technology for the food production and opens a wide spectrum of new, economically and ecologically attractive, possibilities. Jovicic EMERGING TECHNOLOGY SCIENCE EMERGING TECHNOLOGY SCIENCE 10 + In joining forces, the two industry leaders are collaborating in the development, sale and distribution of 3D printers. The initial launch will take place in the U.S. in 2019 with potential to expand into Europe in 2020. “We are very excited about what this opportunity can mean for the food industry,” said CSM’s President and CEO Marianne Kirkegaard. “Our agreement with 3D Systems has the potential to re-shape the food industry,” she said. “Across a number of industries, 3D printing has helped transform industries and there’s every reason to think the same can be true for the food industry. We are looking forward to partner with 3D Systems, the company that invented 3D printing, and continue to expand capabilities and opportunities in the culinary market with their platform.” Vyomesh Joshi, 3D Systems President and CEO, expressed similar optimism about the agreement. “Our extensive and versatile portfolio of materials addresses the widest range of applications and performance in 3D printing – from culinary to industrial,” he said. “As we continue to drive innovation and explore strategic partnerships with industry leaders, our partnership with CSM is a perfect fit to leverage our technology and capabilities to expand applications and materials.” 3D CRAFTED DECORATION Shaping the Future CSM Bakery Solutions and 3D Systems are working together to transform the world of culinary art with the first commercial-grade 3D food printer. With CSM as experts in the bakery arena, and 3D Systems as experts in the printing arena, this is a great opportunity to contribute to the future of the food industry as a whole. 3D printing is already used successfully in many industries and we have great confidence that 3D technology can be used efficiently in food. This opportunity creates world of possibilities. For now, we will start with what we know best, sugar, and see where it takes 3D printing allows the creation of highly complex shapes and designs in relatively short time with limited effort; and, in many cases, these printed products can be replicated to create many items at once. 3D Printing Technologies At this moment there are number of general 3D printing technologies available in the market: + Extrusion + Light Polymerization + Laminating + Wiring Powder Bed As we explore these technologies we see three as most feasible to be used edible material: Extrusion – Fused Depositing Modeling A defined process in which material is joined solidified to create a 3-dimensional model by adding the material together layer by layer until the object is finished. Printing CSM Bakery Solutions b d e Systems Solutions Systems Solutions 3D FOOD PRINTING 19 SCIENCE 3D FOOD PRINTING SCIENCE Stammen: The speed of the changes has altered. Things we do today may possibly still be valid tomorrow, but already out of date on the day after. This involves not only processes, but also products and the half-life of knowledge. Another point is the requirement for transparency, which I notice every day. At the process level we must know what is happening, and when and where it is happening. Industry 4.0 supplies many data sets for this, but how do we turn them into relevant information? In my world, it is impossible to draw any real distinction between costs and quality leadership, since costs constitute a part of quality and vice versa. That’s why having cost transparency is a good thing, to enable an explicit examination of customers’ demands in conjunction with the knowledge about quality requirements. Customers’ wishes and the product being offered must match at all points. Keil: Up to now you have all talked about the changed demands placed on you by the market in widest sense. But what was the situation in engineering and technology; were there any groundbreaking innovations in that area? Lötz: As said, the cleanroom. + Schirmer: And lamination technology and dough sheeters also emerged in this period. + Stollmeier: One current revolution is certainly vacuum cooling. They exist in few bakeries as batch coolers, and are increasingly appearing in the industry. was already able to look at continuous plant for fresh bread in Spain couple of years ago, which was very interesting. Keil: What does the position regarding continuous mixing look like? Stollmeier: Continuous mixers are rarely good for quality ... Lötz: I don’t agree – it’s question of what my requirements are, and for which product. For few products, what matters is a continuous supply of dough. Batch mixers are rather a disadvantage in that case, and continuity of dough supply must be rated much higher in qualitative terms. + Schirmer: The fear of continuous mixing is also derived more from the fear of being restricted by it. It makes fast, flexible product changeover more difficult and needs high level of specialist knowledge. Sehnert: There’s nothing better for the continuous production of pretzels with a defined weight. Schirmer: Has there ever been well-known mixer manufacturer who worked actively on researching and developing continuous mixers? Most batch mixer producers show no great interest in making flexible continuous mixer ready for the market. Lötz: Innovation is driven not only by the machine builders but also by ourselves as users. Our needs for targeted solutions are what bring forward. Of course at the time we are ones who are driven. customers want very specific product with particular properties, we must devise the plant and set up the processes in such way that they create the corresponding products according to the customer’s requirement. + Stollmeier: Nowadays, we no longer adapt any dough to the plant. No more quality compromises are made today. Not in relation to energy consumption either. Borchfeld: Energy efficiency as an investment criterion is an issue; what is current situation regarding a comprehensive energy concept for plants or production facilities? But quality and safety/security management have also changed very significantly in the past twenty years, not just line technology. + Conen: Operating a line without baker would have been unimaginable twenty years ago. That is now possible even with non-specialist staff. The decisive employees nowadays are those that can handle a PC and the control system, regardless of whether they were trained as bakers. Today, specialist knowledge must be put into the controller and programming by middle management. Stollmeier: have the good fortune that can look back over 34 years, and for me the most important development has taken place in production safety. 34 years ago, there were practically no laboratory checks or metal detectors in any bakery. Both are now standard practice, and we are now talking about X-ray equipment for foreign body monitoring. Again in my view, the second big change was the introduction of frozen products, with which at first there was competition with classical artisan bakers. Quality standards are significantly higher nowadays. They are complied with mainly by modified processes, with sponge doughs and sourdoughs, long dough management times etc. In my opinion, the Industry 4.0 topic already exists in the areas of silos, sourdough preparation and the whole of raw materials management. It has merely been talked about in the make-up area up to now. + Schirmer: The emergence of bake-shops has changed production in the industry. Anyone who offers par-baked nowadays must achieve high level of quality to ensure that the quality attained after instore baking withstands any comparison with freshly-baked products. TABLE ROUND TABLE ROUND ROUND TABLE 88 + manufacture of bread fermented goods, whatever the scale, requires the use of significant quantities of increasingly expensive energy. Around 60% of energy used in bread manufacture associated with the conversion dough to bread in the oven. Reducing energy requirements in a bakery is not simply case of shortening the baking time or using a lower oven temperature as is the interaction between the dough and the conditions in the oven that does much to decide what the final products qualities will be. The transition of dough to bread during baking (and batter to cake) is complex and described by cereal technologists as being a ‘foam to sponge conversion’; the ‘foam’ being the dough and the ‘sponge’ the structure of the baked loaf (Cauvain, 2015). Foams are characterised by having lots of small gas bubbles trapped in matrix and this is case with bread dough (and cake batter). The trapped gas bubbles will be expanded by the carbon dioxide gas coming from yeast fermentation (baking powder in the case of cakes). In the oven the setting of the structure by heat bursts the gas bubbles and a rigid, open structure is created – the ‘sponge’ (the term is used in the generic rather than specific sense. The impact of heat input in the oven is important but the factors which are most critical are those which been built into the dough (foam) before it reaches the oven. This means that most of the product qualities and to significant extent, opportunities for process and energy efficiency are associated with dough mixing and processing. Mixing Understanding the basis of bread quality can be likened to building a house (Figure 1). You start with the foundations recognising the value of having strong base on which to build the frame of the house. The development of a suitable gluten network is the foundation of breadmaking and Improving the processing of dough to bread Most of the product qualities and to a significant extent, opportunities for process and energy efficiency are associated with dough mixing and processing. comes from the hydration of the wheat flour proteins and the input of mixing energy. Gluten development requires the input of energy even if the dough is mixed by hand. In most breadmaking process, mechanical means are used to input energy and the main control of the process is by time; longer mixing equals a greater energy input. Some breadmaking processes, for example the Chorleywood Bread Process (Cauvain and Young, 2006) mix to a fixed energy input. The friction between the developing dough and the mixer impeller blades can be examined using the energy graph generated during the mixing process. An example of such a mixing curve is illustrated in Figure 2. At the start of mixing there is little resistance from the ingredient mixture but as the gluten network begins to develop, dough resistance increases and the graph begins to rise reaching a maximum value before slightly falling before the end of mixing. Keen-eyed readers will note the similarity of the curve shape to that of the Brabender® Farinograph and similar laboratory test equipment used for the assessment of flour quality (Cauvain, 2018). A key difference however, is that the curve in Figure comes from an industrial mixer with full recipe and faster mixing speed than commonly used with Farinograph testing. Further the illustration in Figure 2 also includes a physical change part-way through the mixing (the application of partial vacuum) with corresponding change in the shape of the curve. Few bakers think to interrogate mixer performance using such data but at BakeTran we have used this approach to explain why apparently ‘identically set-up’ mixers (baker’s description) deliver slightly differing bread qualities. Through the detailed examination of mixing data it is possible to reduce unwanted variability in bread quality. Controlling final dough temperature Along with the input of energy during mixing comes the inescapable generation of heat, so that the final dough temperature is greater than the weighted average of the ingredients at the start of mixing. The control of final dough temperature is the most critical control point of bread quality in the bakery and key to process efficiency. Control of the dough temperature coming from the mixer should be a ‘simple’ case of optimising energy input during mixing; once that is achieved then the temperature rise factor will be constant and variations in flour temperature can be compensated by adjusting the input water temperature. This is process control in baking at its most basic. In some cases achieving low enough water temperature may require the addition of part of the ‘liquid’ as ice or chilled saline solution (making use of the fact that salt lower the freezing point of water). Using ice provides practical way of controlling final dough temperature but may 2 PLC reading Mixing conditions changed Mixing time (sec) 2.50 0.00 BakeTran Ingredients which improve gas retention (improvers) Carbon dioxide production by yeast to inflate bubbles bubble nuclei AA Oxidation of the gluten Roof Foundations Oxygen Flour protein hydration and development of gluten network Work input in mixing Control of dough temperature House of ‘Bread Quality’ Example energy curve from commercial dough mixer SPITZMARKE SCIENCE 36 PROCESS INNOVATIONS SCIENCE PROCESS INNOVATIONS hygiene-friendly and easier to clean. There are also no longer any dry running problems with these pumps. A plant cooperation with the Handtmann dough divider is also new. A combination of dough preparation by the Codos with the dough divider is currently being tested in the Dough Technology Center for bread and toast-bread as or as four pieces, as well as via a special molding method for buns. Bühler’s machine construction group also “entered the ring” in 2017 with a continuous mixer. Its JetMix continuous mixer can be used both to hydrate raw materials and to produce all kinds of sponge doughs. Up to now, models with an hourly capacity of tons are available as a standalone version for sponge dough production. When mounted directly on a tank, the system achieves an output capacity of up to 3.5 tons/ hour. In addition to the JetMix, Bühler also showed its sponge dough and sourdough solutions for industrial baked goods production for the first time last year. Installation of pilot plant for technologies relating to dry and wet raw materials is also planned in the near future, to allow the complete materials handling process to be demonstrated. Dough extruder has added the ContiMix dough extruder to expand its range of plants for industrial bakeries. The continuously operating twin-shaft extruder combines two decisive processes: mixing the ingredients and kneading the dough. The plant is suitable for preparing consistent doughs for laminated products, e.g. puff pastry dough, flat products such as pizza dough and shaped products like breads toast-breads. The ContiMix also has recipe-controlled metering system for dry and liquid ingredients, zones for vacuum or pressure treating the doughs, a cooling zone and easily interchangeable extruder shaft modules. Bühler says this allows fast configuration of the new dough extruder to the required dough specifications exactly according to the recipes. According to a company statement, baked products manufactured using the ContiMix above all in the case of laminated products, show improved volume and crumb structure, and are said to have more intense flavor. Finally, it goes on to say that the continuous process allows an additional dough rest and the associated dough handling to be omitted. The dough immediately goes forward to the next production phase, which decisively shortens the entire production time. Orientation towards sponge dough The French company VMI has also been among the suppliers of continuous mixing systems for many years. Its VERYMIX continuous kneader or the CONTINUUM, the latest patented continuous mixer boasting vacuum capabilities, are specifically adapted to spongy products such as sandwich or buns. + Anyone who believes bakery technology is so mature that there can never be any more big changes and innovations is mistaken. Customers’ requirements have again changed enormously, especially in the past three to five years. The demand is not only for more efficiency and cost savings but also for better operability, more hygiene, more control options, and in many cases more flexibility as well. The baking sector is compelled to adjust to fewer and less qualified staff, and that has repercussions on machine constructors. The editorial staff of baking+biscuit international have summarized the most important changes in machine construction, although without making any claim to completeness. It is both a retrospective review and a prospective outlook, and shows which opportunities are open to the sector. Continuous dough preparation Zeppelin’s advanced developments include a combination of a DymoMix and Codos continuous mixer. The DymoMix wets free-falling solids with water or yeast solution, while inputting energy at the same time. According to Zeppelin, the “precursor stage” produced in this way reduces the mixing time with conventional batch mixer up to 30%, and achieves up to 2% increase in water uptake by the flour. The mix leaving the Dymomix is metered either directly into the Codos mixer or into an appropriate container for further fermentation. To discharge the pre-dough, the previous progressive cavity pumps are replaced by double screw spindle pumps, because the latter consist entirely of stainless steel and are thus more

left: JetMix of Bühler can be used to hydrate all kinds of raw materials produce sponge doughs of all types right: The DymoMix of Zeppelin is positioned directly conti-mixer The twin-shaft Bühler zones for treating the dough vacuum or pressure Continuum kneader is specifically designed for the sandwich bread, buns spongy product industry f2m MARKET 107 TECHNOLOGY MARKET TECHNOLOGY Rüdiger Stollmeier, Project Manager, Europol S.A. Norbert Lötz, Managing Directo Production and Engineering Harry Brot GmbH We need know-how in our own organization Those responsible for production in the Austrian, German and Polish baking industries met in Hamburg in late May. At f2m’s invitation, they discussed the current state and future of bakery production. Mario Jekle, of the Cereals Technology Research Group München Franz-Josef Managing Director Bonback Silvio Steinert, Managing Director Kronenbrot Axel Technical Managing Director Markus Stammen, Managing Director, Production, Supply Chain, IT, Rudolf Ölz Meisterbäcker & Co KG Markus Schirmer, Managing Director GmbH Bilder der Diskussionsrunde

Baking Technology f2m food multimedia gmbh – Ehrenbergstr. 33 – Hamburg – Germany – info@foodmultimedia.de Phone: +49 40 39901227 – Fax +49 40 39 90 12 29 – www.foodmultimedia.de Order now! Hard copy • 208 pages EUR 45 incl. VAT + delivery costs www.backwelt.de/the-future-of-baking.html Also available as USB stick.

IBA 08

The trade fair

The iba is quite simply the trade fair for the international bakery sector. National and international bakery business representatives were already obtaining information from exhibitors on the first day of the fair – all very targeted and focused. The visitor stream observed by the f2m team didn’t dry up until the last day of the fair. The overall mood can be described as good to very good – among both visitors and exhibitors. Raw materials suppliers and plant builders showed that companies had tackled many issues. In addition to new developments, however, exhibitors also presented further developments of existing machines, together with interesting ideas for production – the keywords here being automation and digitalization. The f2m team was on the move in search of innovations almost without interruption during the entire trade fair. The editorial office had already organized a number of topics, as can be seen on the following pages. And we are continuing to work to inform our readers with commentaries and reports in forthcoming issues of our publications. +++

09 IBA

“It has been phenomenal”

At the 2018 IBA in Munich, baking+biscuit international was able to sit down with Robb MacKie , American Bakers Association (ABA) President & CEO.

bbi: What is your impression of IBA 2018 here in Munich?

+ MacKie: It is a Wow. The innovation and new products has been phenomenal. I think what is interesting is that the crowd is strong, but I’m sensing and seeing more serious buying going on than maybe in the past. I can tell you from the US perspective that we have about 60% of our ABA Board of Directors here, so the major US commercial baking companies are here. Many of our supplier members are also here including the equipment, yeast, and other ingredient companies, but not so much on packaging. Anybody that has an international presence on the supplier side is here. There are so many here that I am struggling to get around to see everybody.

+ bbi: What do you think is the most important difference between IBA and the International Baking Industry Exposition (IBIE) in Las Vegas?

+ MacKie: I think IBA is a great show, as a more traditional trade show. Always with the latest innovation in equipment, ingredients, and processes. The difference between IBA and IBIE is that education is a bigger component at IBIE. The demand for education is so great that in addition to the morning educational programming, we added another day of education at the beginning and we have had no trouble filling those spots. All the education sessions are designed as part of a multi-faceted, multi-track education programing. There will be on floor sessions and hands-on demonstrations. There will also be content on efficient management and energy management for the larger commercial bakers. There will be different segments, including sweet goods, bread, artisan bread, covered very heavily. In my mind, education is the biggest difference. We have been doing a lot of international delegation meetings talking about IBIE. In every single one of those meetings, regardless of the country we met with, the desire for training and education has been front and center.

+ bbi: Which innovation impressed you most at IBA?

+ MacKie: It is hard to pick one thing. There are just little things here and there. Some of the ingredient companies in the craft and artisan space have really stepped up their game at this show. I would say there are a couple of things in the packaging space that are what I would consider a nontraditional baking packaging that would allow for instance a sandwich offering that would preserve freshness without having soggy bread. Some of those vacuum packaging systems have also been really interesting. The robotics is always neat and cool. The IBA Virtual Reality session was also very impressive. There is a company that is doing steam doughnuts, so instead of putting the doughnut into a fryer with the fat and other issues they are baking it with steam. I don’t know if it is applicable to a high speed, high volume operation.

Robb MacKie is the President and CEO of the American Bakers Association (ABA). He previously served for 11 years as Vice President of Government Relations. The ABA is a trade association representing the interests of the $102 billion wholesale baking industry in Washington, D.C.

Mr. MacKie previously served on the steering committees of several issue-oriented coalitions including co-chairing the National Coalition on Ergonomics and the Food Industry Coalition on Hours of Service Regulations. Before joining ABA, Mr. MacKie worked for a Congressman and Trade Associations.

Mr. MacKie provides strategic guidance as a member of the Kansas State University Grain Sciences Program Advisory Committee. In addition, he serves on the Board of Directors of BIPAC’s Prosperity Fund and the US Chamber of Commerce’s prestigious Committee of 100. MacKie is a graduate of Frostburg State University with a degree in Political Science.

www.bakingbiscuit.com 06/2018 IBA 10

+

Robb MacKie

Source: www.americanbakers.org © ABA

Doughnuts sell like crazy anyway, but if you can offer a doughnut that was as high quality with less fat and less calories, that would be huge. A couple of bakers have whispered to me that they have seen it.

+ bbi: Do you think it is worth for an American baker to visit Munich IBA?

+ MacKie: Yes, absolutely. Our participation has grown over the last three shows and I give a lot of credit to Joe Turano from Turano Baking Company who is the IBIE 2019 Chairman, as well as to Erin Sharp from The Kroger Company and ABA Chair of the Board of Directors. They made a big appeal to all of the American bakers to come and participate. We have probably more first time US commercial bakers attending IBA than we have ever had, and it is because of their leadership. The bakers have been really blown away. We have asked them to be ambassadors for IBIE and that is the role they have embraced really well. They have participated in numerous meetings and interviews, Erin Sharp sat in on probably four of the international delegation meetings. The highlight was a joint meeting with our board of directors and the board of directors for AIBI, which is our counterpart organization for the EU, and it was a very productive conversation. IBA is also a great place to spot trends. For example, two IBAs ago I was with one of our members and he was very interested in the Middle Eastern flatbreads and now has two lines that do nothing but produce Middle Eastern flatbreads and they have been very successful. It is a great place to see many of the different global baking taste and trends and then maybe bringing those over to the United States and adapting them to the US consumer.

+ bbi: Is the IBA show a networking place for you and IBIE?

+ MacKie: Yes, the world is getting smaller and it is really interesting the issues are essentially the same, no matter if it is in developed countries and in Europe or in some of the emerging markets like India and South Africa. The issues include: fad diets, free from diets, wheat quality issues, food safety, all of these issues to differing degrees and different scopes are similar globally.

+ bbi: Do you see a chance for more cooperation between IBA and IBIE?

+ MacKie: Absolutely, we have the same target markets. As we have learned it is not a competitive situation. Speaking from the US Baker perspective, a lot of the US bakers will come to IBA to talk to an equipment company or an ingredient company. They will come here with a challenge they are trying to solve, or they are thinking about a new product, or a new process and then next year they will be ready to make the purchase or vice versa. We are having conversations about an even closer collaboration.

+ bbi: Why should European Bakers come to visit IBIE in Las Vegas? Other than going to Las Vegas?

+ MacKie: Las Vegas is a big draw. I also think these are the two shows that the serious buyer can come and spend time in a

++ Since 1897, ABA has represented the interests of bakers before the U.S. Congress, federal agencies, and international regulatory authorities. ABA advocates on behalf of more than 1,000 baking facilities and baking company suppliers

meaningful way. It is an opportunity to see, even in just a year, what innovation is out there. It is not consumer electronics with a revolutionary new product every 6 months, but the baking technology is turning faster. We notice especially in the sustainability and sanitation areas. It is also another opportunity to network with their global baking peers, IBA and IBIE provide that opportunity, we get a lot of positive reaction from the European bakers. If you look at a lot of the exhibitors here you are going to see the exact same exhibitors at IBIE. It is also an opportunity for those who could not make it to IBA to see many of the exhibitors that they missed.

+ bbi: When walking around you see some key words at several booths. One of them is automation. Is it important for the United States’ process automation?

+ MacKie: Yes, absolutely, especially now with the United States approaching record low unemployment and the number one issue and challenge facing the US bakers is access to skilled, talented employees. I think in Europe and in the EU particularly they have been through that situation. What we are seeing here is interesting because some of the new equipment and new process automation makes it easier to be used. The goal of buying a highly automated piece of equipment used to be to lower cost by reducing employees, but now every single one of those employees will be retrained in a different part of the baking process. The ROI equation for a piece of equipment has changed, and then that allows them to specialize and retrain the existing workforce and maybe attract a different workforce. I think that it is a needed and necessary development, whether we like it or not. I think this is an opportunity to start thinking about that.

+ bbi: Another keyword is data mining and data analysis to achieve a higher level of quality or higher level of efficiency as well?

+ MacKie: Yes, absolutely a huge issue in the United States. In the US there is a lot of conversation around big data. We can collect all kinds of data. For instance, I was talking to a couple of exhibitors who, like with your automobile, have added capability to do equipment diagnostics through a cell

11 IBA www.bakingbiscuit.com 06/2018

phone app. My first car I could do all the maintenance on it, because it didn’t have any on-board electronics Now you can plug your cellphone into your car and do diagnostics. It is similar with the baking equipment, I have talked to two suppliers here, where you can go walk with your phone and it will connect to a chip inside the equipment that will say the oil lubrication is running low, the bearings are going out, etc. It is the same concept, but saves a tremendous amount on maintenance.

+ bbi: It requires a lot of investment to do these things, a baking line lasts for 20 years or more. Is it a problem to bring it into all these lines?

+ MacKie: It’s a slow process but if I can walk down the line with an iPhone app and see next week we need to do this maintenance now instead of in a month when originally planned, you could avoid a very costly breakdown at the plant. Those unscheduled plant shutdowns due to maintenance activities are so expensive, with the lost product and lost productivity. I think the emphasis on preventive maintenance and the tools that can help bakers do that is very exciting.

+ bbi: What about sanitary design of a manufacturing line?

When you see those lines nowadays, they are high-end.

+ MacKie: High-end, and sometimes a low-tech solution and approach to it, so it does not always have to be the latest technology. In 2007, when the US had a huge food safety issue with the peanut butter recall due to salmonella, we changed our food safety law for the first time in 40 years. As a result, our processes have changed and our association was in the middle through the legislative process and is now on the regulatory compliance side. We also realized as an industry we needed to step up and take ownership and we worked with BEMA (Bakery Equipment Manufacturers & Allied) and AIB (American Institute of Baking) and other partners in the baking space. Now, two times a year, we host sanitation workshops that are specifically designed to look at pieces of equipment and how to change the pieces of equipment and how to improve the sanitation process. That has been enlightening. Our working group who are fanatical about food safety have

commented that even after just two IBAs and two IBIEs, the equipment has changed. It is one thing to get together and talk about sanitary design, but you are actually seeing equipment being changed and there are many examples of that here at IBA. I am impressed how quickly the equipment manufacturers have stepped up. Sometimes it is even a very simple solution with welding and open spaces. No longer can bakers afford to just take a hose and spray all the equipment down, you can’t do that anymore, that creates its own issues. It is too expensive for bakers not to improve the sanitation process. So kudos to the equipment manufacturers for being very responsive on this.

+ bbi: What about waste control and sustainability?

+ MacKie: Controlling waste is right to the bottom line, it’s not always easy but if you can control... Let’s start with the energy side. In the United States we have something called the Energy Star Program, so as an industry we accepted the Energy Star Challenge, which means the bakers are going to reduce their energy usage by 10% within five years. The last time I checked, we had 140 facilities that have participated the challenge. Not all of them are through it yet because it takes some time. I can remember coming to IBA, two IBAs ago, and energy sustainability was a big issue, so I brought that observation back and we challenged the equipment suppliers going to the next IBIE to showcase their energy savings and they responded in a big way. Even though the US is very fortunate to have low cost energy compared to the rest of the world, it still affects the bottom line, if a company can reduce their energy footprint by 10% to 25% then they have more money to invest in other things. The other piece of waste control is packaging waste and including the packaging of incoming ingredients. We have bakers that are moving to zero waste and several that have achieved it. What that means is anything that comes into the facility is recyclable. It is a challenge because in different parts of the country there are different levels of the sophistication with recycling programs. The bakers are working with vendors and any of the plastic that comes in has to be a recycled material as well as working to reduce the amount coming into the

www.bakingbiscuit.com 06/2018 IBA 12

++ The ABA works on well over 50 legislative and regulatory issues

IBA

++ ABA and BEMA* co-founded the International Baking Industry Exposition (IBIE) *BEMA: Bakery Equipment Manufacturers and Allieds

POWER BERRY ARONIA

Life is colourful. Let the unmistakeable intensity of Aronia – nature’s power berry –infuse your assortment with new life and vitality today.

www.backaldrin.com

facility. A baker in the Midwest is working with their flour supplier and has changed the composition of the bulk bags, so now it has natural fibers in it and is much easier to recycle. This zero waste also includes scrap metal being collected and recycled. Often in the US, people do not think of water conservation as a cost driver, but it can affect bottom line. On the ABA website we have a sustainability web page which includes things like checklists and tips and tricks to accomplish that from a practical bottom-line perspective.

+ bbi: Is GMO a big topic in the US?

+ MacKie: Yes, we saw about 20 states pursuing their own GMO labeling programs, and there was a lot of inconsistency. We have one regional baker in the Northeast that covers eight states, all within a couple of hours drive from their bakery and they were going to have four or five different GMO labeling requirements. There is just no way to comply with that, so we were part of a broad coalition in Washington D.C. that said the federal government needs a standard both in terms of defining what is GMO and then how to communicate that to the consumer. How does labeling work, does it have to be on the pack label, can it be a mobile app, maybe it can be some combination thereof. The US Department of Agriculture is working on that right now. As a matter of fact, recently we had the Secretary of Agriculture come and speak to our group. We have provided a comments and feedback with a lot of lowlevel meetings. Some time in November or December we are expecting to get the requirements published for public comment. It is a huge issue. We are about transparency, but we want to make sure that the consumer is educated from a scientific and fact-based information about what it is and what it is not, and then we want common standards around the country. So, if you’re producing product for Rhode Island, one of the smaller States, or California or Texas you would have a common standard to comply with.

+ bbi: What major trends on the US bakery market are coming from product or consumer side?

+ MacKie: No different than what’s going on in Europe, the move towards artisan product is very big, even commercially produced artisan products. We do not have quite the extensive network of small craft bakers that serve multiple retail outlets, we really don’t have that model in the US. There is either a small corner bakery or the large retailers that are distributing products. There are some in between, like a Panera. The American consumer is looking for that artisan, and that craft feel. The other thing that we’re seeing is a move towards denser, more high-moisture breads, more variety breads with a lot of seeds, and high fiber content and even ancient grains. We are also seeing some experimentation in the use of non-traditional grains. I don't know if that’s going to take off or not, but non-traditional flours and alternative flours –I am very curious to see where that goes because some of them have been reported to have healthier components and are supposed to be higher in fiber content or more nutrients. It is very early in this process, but it always comes down to taste quality and functionality for the bakers, but I think

++ ABA members produce bread, rolls, cookies, crackers, bagels, sweet goods, tortillas and many other wholesome, nutritious, baked products. The baking industry generates more than $153 billion in economic activity annually and employs more than 799,500 people

there’s some experimentation going on at a low level right now. Some trend in different product categories, like the indulgence side, is moving towards smaller portions. This allows you to have the same really good traditional product, but the smaller packaged product and label has fewer calories, fat and sugar than buying the full-sized product. I think there is a lot of consciousness around serving size.

+ bbi: Are these trends all over the States or is it trends you can see mostly on the coasts?

+ MacKie: The coasts always drive the trends. A lot of those trends are not in the Midwest yet, maybe except in some of the major urban centers. Generalizing, I think the people in the Midwest are closer to their food as there is a lot more heritage about the agriculture sector, even people who live in a big city like Chicago came off a farm out of Iowa or Nebraska. In general I think there is more connection to food in the Midwest.

+ bbi: Is there a change/exchange between the American Bakers Association and the European baking associations? How does it work?

+ MacKie: We talked a lot about these trends. We talked a lot about government regulations, we talked a lot about food safety. It is interesting because the issues – and they might have a different priority, different scope – but the issues are very similar. What are consumers’ dietary patterns is obviously a big topic, workforce issues is a bit of a different dynamic in Europe but access to skilled talented employees and we find similar issue in the United States. People love the idea of going to work for their little bakery down the street and getting flour on their hands and so there doesn’t seem to be as much a challenge in attracting people to small bakeries, but if you’re doing a larger scale operation it’s very difficult. It is the number one issue facing US Bakers, a top 3 issue facing European Bakers.

+ bbi: Thank you for your time today. +++

www.bakingbiscuit.com 06/2018 IBA 14

Lower Your Cost of Ownership

•Lower Maintenance Cost

•Servo Driven

Burford’s seeders, toppers, sifters and pan shakers are a perfect match for our Bun Divider

BUN

LINE

HIGH SPEED

MAKE-UP

•Hygienic Wash-down Design

•Lower Formula Cost (Scaling Weight & Dough Conditioners)

•Toolless Design Reduces Time for Clean Up & Changeover

•Up to 150 Cuts per Minute

+1 469 464 5411 | stewart.sales@stewart-systems.com

have been making

for over a decade. We listen to

and

We

Make-up Lines

you, the baker,

innovate.

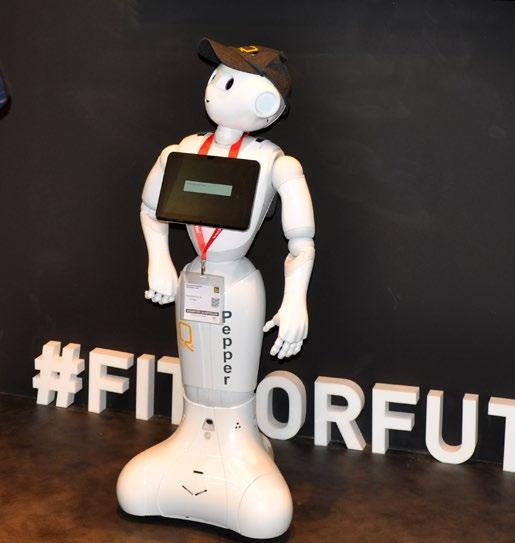

Automation and digitalization –who will be the technology leader?

+Many suppliers can do many things and talk about many more, but the big achievement that will convince everyone is still far from reality, which is why not a few visitors fear they will just be cajoled into buying a lot of expensive sensor technology that really doesn’t get them much further forward. Not entirely without justification. Engineers – and machine constructors are no exception in that respect – are besotted with everything that can be counted, measured or weighed, especially if new technologies such as cameras or infrared can be used for the purpose. In their excitement, they tend to forget to assess the usefulness.

Healthy skepticism is good, but making it the sole yardstick is fatal, because automating and digitalizing production lines will increase quality, adaptability and efficiency, and will thus also decide the competition in the future. However, the absolutely crucial question is who on earth will implement this “revolution” in bakery technology. There are few reasons to believe it will be today’s bakery technology suppliers.

A quick glance at the automobile industry – not at the morals of its senior management but at the production sheds –will suffice to gain a rough idea of this. When you buy a car nowadays, the control system will be from Bosch, the sat-nav from Google and the consumer electronics from Apple, all three of them interchangeable with similar global technology companies. Nowadays, carmakers themselves are now just hardware assemblers who are themselves reliant for their own production on external control system specialists and robotics constructors.

This is all less about predatory competition and more a question of who sets the standards that define the rules by which technologies and control systems will talk to one another in future, and how open these standards will be for each supplier. But also for users, since if someone, based on an intimate knowledge of his processes, wants to influence a situation or a development in his production line at a point that he considers important for quality or efficiency, he must

first of all be able to record it. For this he will look for suitable sensor and will then integrate it into the overall control system, provided the standards are open. This point is important, because it involves a deep level of baked products manufacturing know-how. Know-how that is at best rudimentary as codified knowledge nowadays, and scarcely still exists as empirical knowledge. Thirty years ago, a senior journeyman would have had a reliable instinct for when a dough was ready to go into the oven, but nowadays a clock is set without anyone being able to say any longer with certainty to the hour, minute and second why precisely now.

We will need to retrieve this knowledge, and that will not be easy. Together with the University of Wageningen, the Kaak-Gruppe has taken an initial step and has developed a “baker’s finger” that will attempt to access this knowledge by being pressed against the surface of the dough piece.

At the iba trade fair, Zeppelin presented yet another approach which, although still in its infancy, promises to be exciting. The route is virtually in the opposite direction. It involves trying to develop a model by analyzing end products assessed as being “perfect” – namely dough at the end of the mixer in Zeppelin’s case. After that, a great variety of sensor technologies are used to find out which adjustable variables affect this quality in any way, and these are then used to control the plant in such a way that one always comes closer to the optimum. The whole thing ends in a self-learning optimization loop.

There are many indications that worldwide automation and digitalization standards are being written not by bakery equipment suppliers but by the multinational technology and IT companies of this world.

Maybe companies like Siemens, who have already gathered a large amount of expertise through their SPC controllers, will belong to this group, but perhaps it will also be IT specialists such as Oracle or SAP, who approach the topic via the Internet of Things.

© Maksim Kabakou –123rf.com www.bakingbiscuit.com 06/2018 IBA 16

As might have been expected, machine and plant controller automation and digitalization were one of the major topics at the iba trade fair.

Bakery equipment suppliers, provided they don’t want to become mere metal-bashers like the car makers, will need to stuff bakery-type know-how into their controllers. Probably in many cases they will first of all have to develop or disentangle this knowledge.

As a rule, that’s because the quality of a product is modified by whole packages of influences, and these influences are not independent of one another, but can mutually supplement, counteract or potentiate one another. Much research work will still be necessary.

If the bakery technology sector does not live up to this requirement, it will dig its own grave, or it will become just a part of a general foodstuffs production technology, or perhaps simply of a general production technology. Processes such as mixing, molding, extruding and air-conditioning are not intrinsically specific to bakeries.

For this, it begins by making the expertise that is involved. Equally, however, this question is shared with the users. Do they want a machine-building sector specializing in their needs, or are they willing or able to take on this role themselves? This is quite certainly impossible with today’s R & D budget, and IT and controller departments would probably

also need to grow significantly in that case. On top of that, it would require the science as well, and that would need to be not just contract research but certainly basic research as well.

Oh yes, and there’s something else. Of course there was also a lot of talk at the iba trade fair about “predictive maintenance”, the kind of anticipatory maintenance that minimizes downtimes because one constantly has a monitoring finger on the pulse of every individual component. Maybe observing energy input is actually enough to enable a prompt response, instead of laboriously analyzing motor noises. On this building site, a glance over the fence at neighboring sectors would help. Incidentally, that’s also true in the case of support for plant operators or the bakery’s own technicians. Hopefully, the statement by a not entirely insignificant machine constructor that there are engineers sitting in the head office who then provide help by telephone is not meant to be taken seriously, if only because these engineers are available to the global clientele only during normal headquarters office hours.

One way or another, the next five to ten years will be very exciting; they will revolutionize the bakery machine sector, and probably also make clear to the baking sector that the race is not to the strong, but to the swift. +++

Trade fair calendar 2019

January 27-30, 2019

Cologne/Germany

ProSweets Cologne + ISM – Trade Fair for Sweets & Snacks

www.prosweets-cologne.de ww.ism-cologne.com

February 23-26, 2019

Madrid/Spain

INTERSICOP 2019

www.intersicop.ifema.es

March, 12-15, 2019

Moscow/Russia

Modern Bakery Moscow

www.modernbakery-moscow.com

May 6-9, 2019

Shanghai/China

Bakery China 2019

www.bakerychina.com

May 15-17, 2019

Baku/Azerbaijan

WorldFood Azerbaijan/ Ipack Caspian 2019

http://ifw-expo.de/exhib/worldfood-azerbaijan-ipack-caspian_2019_en

June 18-21, 2019

Tehran/Iran

iran bakery + confectionery

www.iran-bakery.com

September, 7-11, 2019

Las Vegas/USA

IBIE – International Baking Industry Exposition www.ibie2019.com

September, 21-24, 2019

Stuttgart/Germany

südback

www.messe-stuttgart.de/suedback/en

17 IBA www.bakingbiscuit.com 06/2018

© rclassenlayouts –123rf.com

“Baker’s fingers”

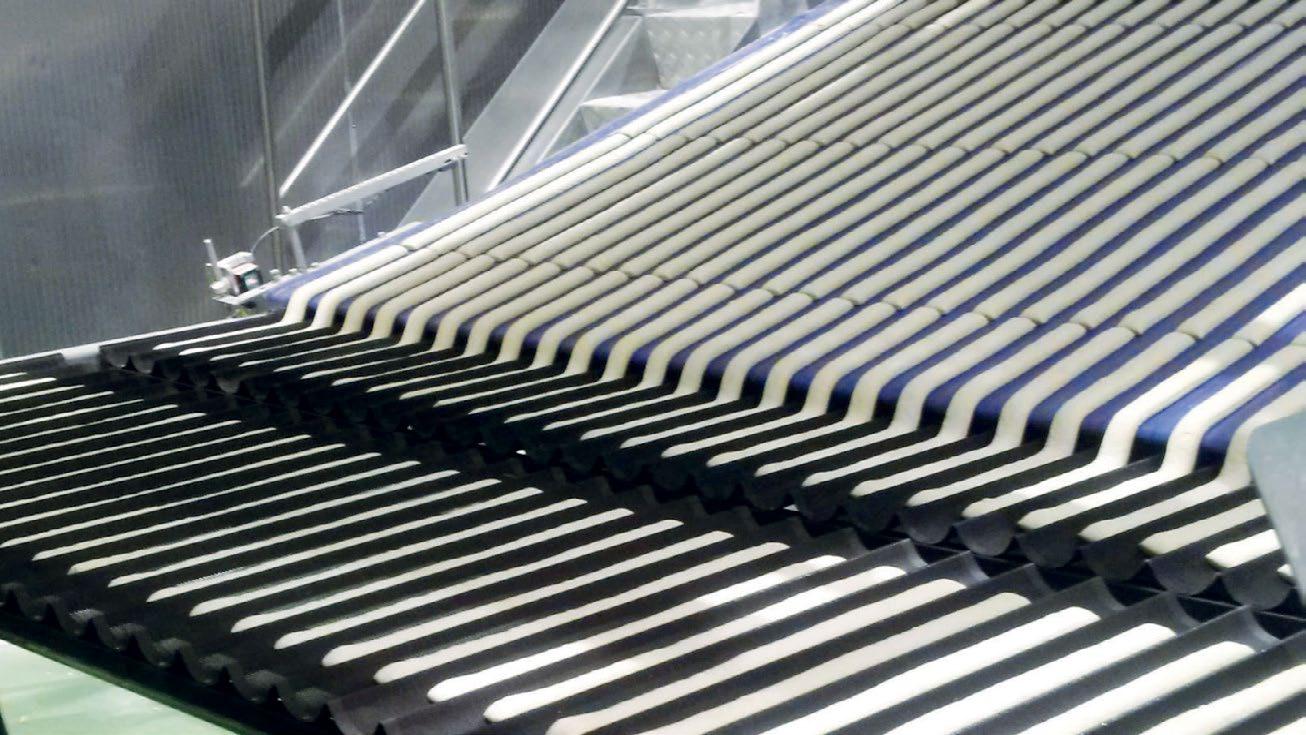

Kaak is working to improve the future of iBake Care and to offer additional benefits to customers by researching new technologies. One such technology is called "Dough Sense" that would provide real-time feedback on dough quality.

+The idea behind Dough Sense is that it could replace the baker’s fingers when feeling the dough for quality. It would provide a value to what a baker “feels” when they press on the dough.

Dough Sense technology uses a sensor combined with a burst of air, a camera, and a laser to measure the initial height of the dough and the return depth after a low pressure air burst. It captures measurements at the beginning, middle and final depth of the proofer. This provides values for the deformation and relaxation of the dough. Using these measurements, the Dough Sense calculates the elasticity and viscosity to evaluate the viscoelastic properties of the dough. This provides continuous and real-time values about how the dough is behaving. It could potentially identify any changes in the dough and alert the baker to an issue with the recipe or the environment for a batch of dough. Dough Sense could help ensure consistency from batch to batch and identify any deviations from target product. The sensor is currently being tested on the proofer side, but the idea is that this could be placed in other parts of the

process. The sensor could be placed anywhere in process where the dough can stop moving for a couple of seconds. At different locations in the process, it could help identify different changes, like if there was a change in the dough due to ingredients, recipe or due to the mixing process.

Currently, the technology is being validated and will need more work to validate various recipe and environmental changes, and on various types of dough. This includes more research to see how gluten free doughs would behave with this technology. There are some challenges that could also affect the data gathered including, for example, if the dough was not placed in the middle of the tin, if the dough was folded, or if in a strange shape.

This technology is not ready for market as it is still in the early stages of development, and needs more research to ensure effectiveness across various recipe changes and dough types. In the future, this technology could be a valuable tool for a baker to ensure they are producing a consistent, quality product every batch, every day. +++

www.bakingbiscuit.com 06/2018 IBA 18

© Kaak

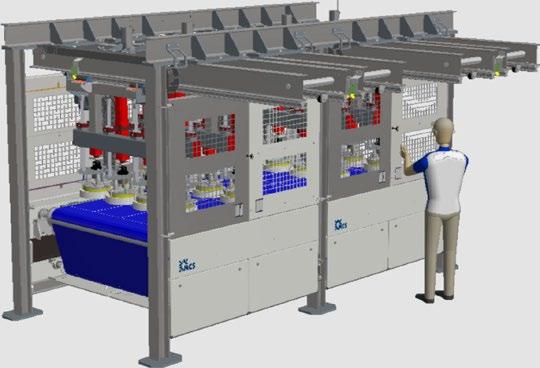

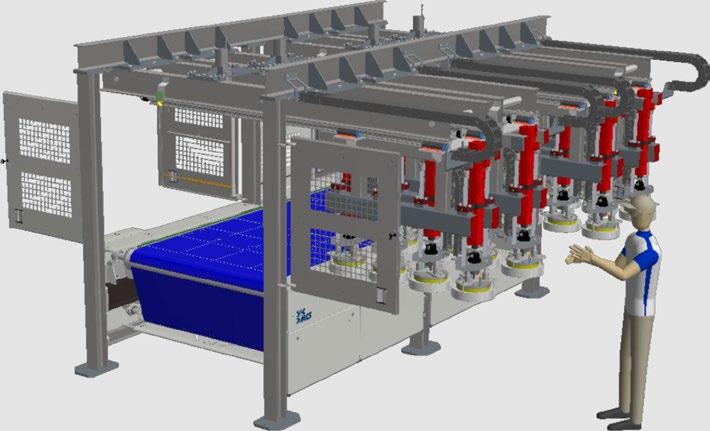

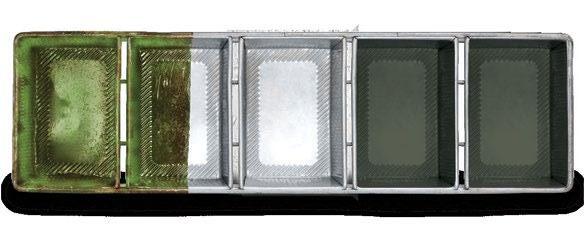

A new instore baking process

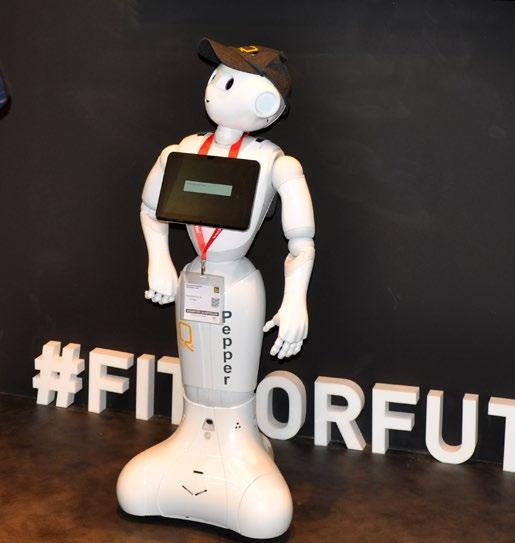

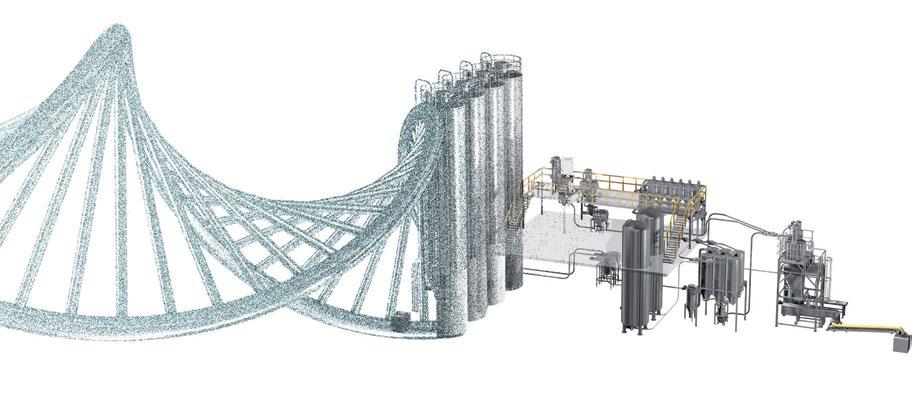

The equipment was so small that the description “inconspicuous” really isn’t an insult. Nonetheless, the “UDO” made by Cetravac AG in Switzerland was awarded a trophy at the iba trade fair, and attracted a large amount of attention. We asked its inventor, Adolf Cermak , what really lies behind it.

+bbi: A small equipment built into a wall – precisely what have you actually presented to the world that has caused such a stir?

+ Cermak: Don’t jump to conclusions about its importance from its size. What we mainly wanted to do by exhibiting the Snack Oven in Munich was to demonstrate that of course the principle also functions on different scales, and may even revolutionize instore baking.

+ bbi: Then please start by just explaining that principle to us ...

+ Cermak: I will explain it to you by using a frozen par-baked pizza as an example. First of all, the frozen product is put into the oven, which has previously been brought to operating temperature (approx. 160°C), and a vacuum is created in about 15 – 20 seconds. This sucks the air out of all the product’s pores and clears the way for the steam which then flows in. The steam heats the crumb and crust stepwise to at least 80 – 85°C. Since heat transfer from the steam to the crumb/ crust structure takes place with otherwise unattainably high efficiency, the duration of this process lasts only a few seconds and, in contrast to the use of microwaves, is associated with an improvement in crumb quality and an increase in crumb moisture. The as yet un-gelatinised starch gelatinises, which heightens the impression of freshness. At the same time as the steaming, infrared radiation elements heat the product’s coating/surface with a wavelength specifically matched to the process. At the end of the baking process, a short (approx. 15 – 20 seconds) vacuum cooling phase is started (in the oven, which is still hot), and the ready-to-eat product can be removed at a palatable temperature.

+ bbi: So how long does the entire process now take, from loading the pizza into the oven until it is removed, and what are the specific benefits compared to other processes?

+ Cermak: It takes about 60 to 90 seconds. The time it takes to prepare a coffee is sufficient to optimally bake a pizza and cool it down again. The process is considerably faster when compared to a circulating air oven, and in contrast to the microwaves that are often used, there is no adverse effect on the dough structure. Also, there are none of the “sideeffects” caused by unequal heat uptake in a microwave, which can result in the consumer biting into an extremely hot piece of tomato that was covered up by a distinctly cooler slice of cheese.

+ bbi: But the oven is small nonetheless. Not much more than a pizza would fit into it. Will there also be bigger ovens in the future?

+ Cermak: This Snack UDO is only a forerunner for a whole series of vacuum baking ovens that Cetravac will launch onto the market in the near future. The spectrum ranges from a domestic appliance to instore ovens in all the usual sizes. The instore ovens will differ from the Snack series in that they will operate with circulating air, thus also enabling conventional baking followed by a vacuum cooling phase. However, the main application in a bakery branch is aimed at the ultrafast baking-off of pre-baked special and large breads in only four to eight minutes, even for breads weighing 750 – 1,000 grams that were stored at “ambient” temperature or frozen. This will enable artisan bakers to recapture

www.bakingbiscuit.com 06/2018 IBA 20

© LANDMAGD ©

cetravac

++ Udo – the global novelty in the snack business

the bread business. One advantage of our method is that there is no weight loss in spite of the cooling phase that is included in the entire process.

+ bbi: In the planned instore oven, is there also a function for vacuum, steam and infrared, or just circulating air baking as in the past, and faster cooling down by vacuum –or to put it another way: can I also bake bread rolls and croissants quicker in it?

+ Cermak: It’s similar – the infrared elements are replaced by circulating air, but the whole of the baking process continues to be “vacuum-assisted”, i.e. there again the absence of air in the pores is used to accelerate the baking process and to bring about gelatinisation/re-gelatinisation of the starch, thus leading to considerably longer shelf life and freshness retention. There can always be a vacuum cooling phase at the end, whatever is being baked, and that’s a unique selling point which represents an absolute guarantee of success for the Internet trade, where it’s a question of being able to dispatch freshly baked bread as quickly as possible. And of course, the benefits of increasing and stabilising volume can also be fully utilised in that situation, at all times and for every product.

+ bbi:

So what was the feedback at the

iba trade fair?

+ Cermak: Very positive and very wide, as far as the spectrum of potential customers was concerned. Of course, many bakery specialists from all over the world were there, as well as people from the trade and food service, who were interested in this oven because it allows such a fast response to consumers’ wishes. But equipment supplier also showed great interest, including those from the USA, because it opens up a completely new worldwide market.

+ bbi: So what will you do now?

+ Cermak: We have an absolutely unique world market position with this equipment design concept. In the coming weeks and months, together with a small but very potent group of future users from the two key areas, snacks and baked products, we will define a series of machines corresponding to the needs in the years to come, and these machines will be on the market in 2019.

+ bbi: Thank you for the interview, Mr. Cermak. +++

www.bakingbiscuit.com 06/2018 IBA ADVERTISEMENT

©

cetravac

Parallel to el to BUY ADMISSION TICKETS ONLINE NOW AND SAVE UP TO 45%! Koelnmesse GmbH Messeplatz 1 50679 Köln, Germany Tel. +49 1806 383 763 Fax +49 221 821-991360 visitor@prosweets-cologne.de www.prosweets-cologne.com The international supplier fair for the sweets and snacks industry 27.01.–30.01.2019 PRODUCTION AND PACKAGING TECHNOLOGY PACKAGING AND PACKAGING MATERIALS RAW MATERIALS AND INGREDIENTS OPERATING EQUIPMENT AND AUXILIARY DEVICES PSC 2019 Anzeige Baking Biscuit intl 90x265mm Intl GB indd 1 PSC_2019_Anzeige_Baking_Biscuit_intl_90x265mm_Intl_GB.indd 1 01 10 18 07:5 01.10.18

++ The Cetravac crew after the award of the iba trophy

Dividing and moulding competence

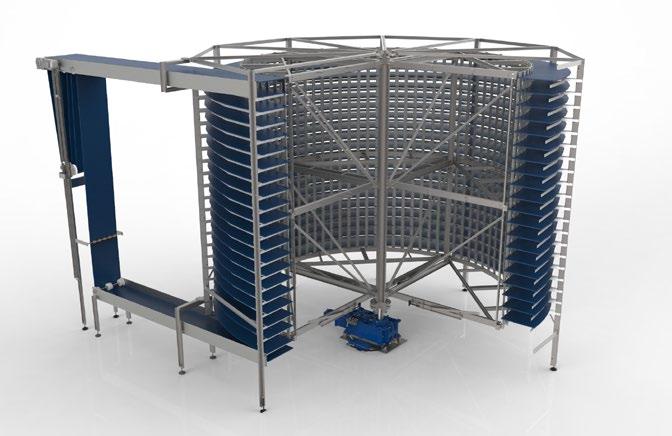

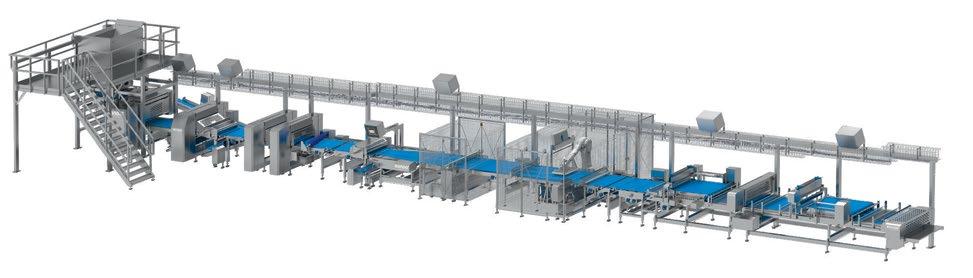

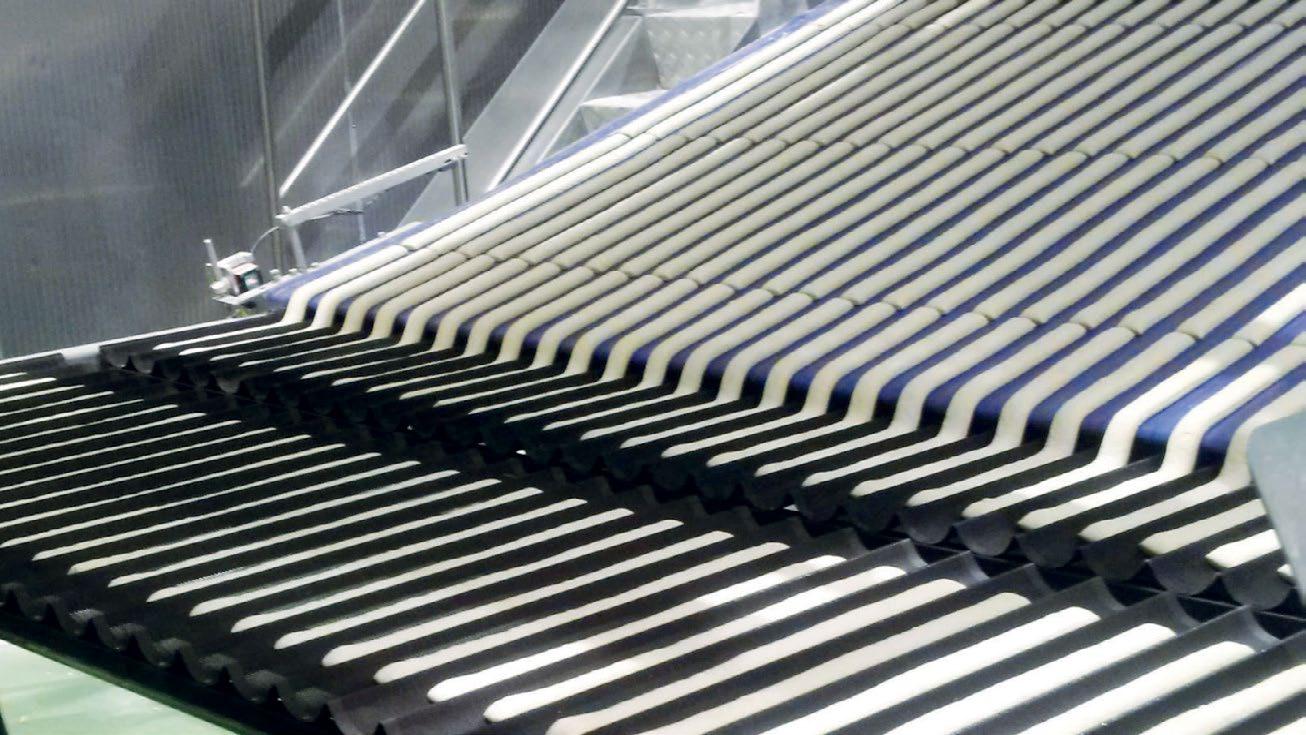

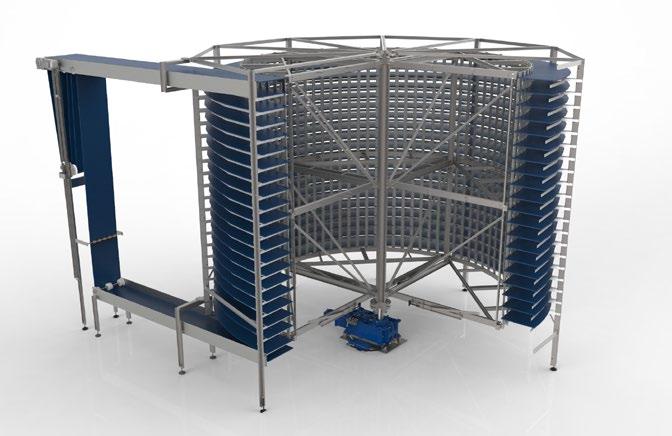

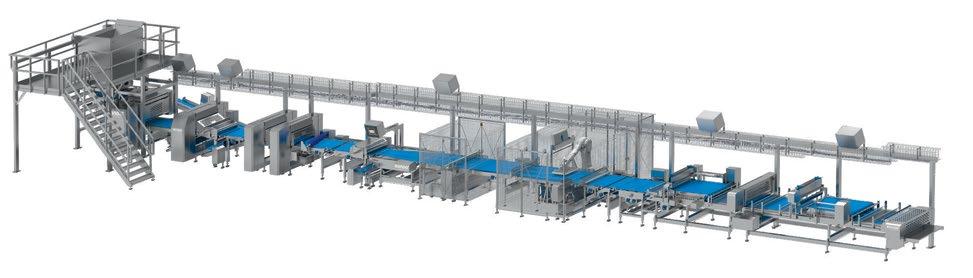

The Werner & Pfleiderer (W&P) TEWIMAT is designed for industrial 24-hour operation and is available in two high-performance variants: TEWIMAT SOFT and TEWIMAT BIG BALL.

+The TEWIMAT SOFT and TEWIMAT BIG BALL have been designed to perfectly process long maturing, soft dough as well as larger weights. The equipment can be combined and can be further expanded according to the area of application with the TW PLUS remoulding station.

As the centerpiece of industrial processing lines for bread rolls, breads, pizza, tortilla, flat bread and many other products, the TEWIMAT’s high quality in dividing and moulding and its absolute weight accuracy for up to 30,000 dough pieces per hour are very convincing. The new TEWIMAT SOFT variant was given a unique mechanical design so that it processes dough that has pre-proofed for a longer time with a yield over 170 particularly soft and gentle. In conjunction with the BIG BALL equipment, the weight range can thus be expanded to 100 g to 600 g.

The additional remoulding station, the TW PLUS, achieves optimal round-moulding results of the dough pieces in higher weight ranges. Ideally suited also for further processing into products, such as pizza. Thanks to the double moulding time and the twice as long moulding path, the process of additional remoulding provides the opportunity to optimize pressure and speed to ensure that the dough structure is retained. Industrially produced dough can thus be prepared with artisan quality.

Dough divider

The TEWIMAT dough divider and moulding machine can be integrated in all semi- or fully-automatic systems. The machine can be used in a wide weight range from 30 g to 600 g and is available with 2 to 10 lines. Depending on dough quality and dough weight, an hourly output of 2,000 to 3,000 pieces per line can be achieved.

The suction divider technology that uses no feed rollers and dividing knives and the drum moulding system render the TEWIMAT particularly gentle on the dough. A range of interchangeable chamber drums is available for the different weight ranges to achieve best round-moulding results. Output, working intensity and weight can also be individually programmed to suit the respective dough requirements.

The dividing process which is oil-free for most dough avoids effects on the dough structures and minimizes operating costs. Maximum dividing precision can still be guaranteed at a low filling pressure, the basic prerequisite for a dough-friendly work method, since the patented de-gassing system allows air pockets to escape during the dividing process.

The TEWIMAT is easy to clean thoroughly. To avoid soiling from the outset, the drive-controlled part is physically separated from the part that handles the dough. This prevents the dough from falling onto drive components, such as gears. The dough-handling part of the TEWIMAT can also be fully disassembled as well as removed and reinstalled largely without tools. Because it is so easy to access, the TEWIMAT is also very maintenance-friendly.

++ Because it is so easy to access, the TEWIMAT is also very maintenance-friendly

www.bakingbiscuit.com 06/2018 IBA 22

+++ ©

© W&P

W&P

++ TEWIMAT is designed for industrial 24-hour operation

Introducing Hydrobond from Exact Mixing

Want superior hydration without adding excess heat to your dough? New Hydrobond technology delivers. Not only does it blend dry and wet ingredients with unmatched efficiency, it also:

• Requires no additional floor space

• Reduces your total mixing time

• Cleans quickly and easily

• Reduces heat attributed to mixing energy

• Allows you to mix more dough with same size continuous mixer

BY READING BAKERY SYSTEMS

BY READING BAKERY SYSTEMS

Perfect your mixing process with new Hydrobond technology. Visit exactmixing.com for details.

Advanced hydration technology is here.

A Markel Food Group Company EXACT

MIXING

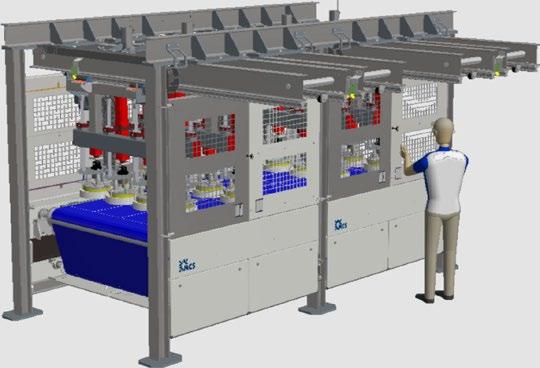

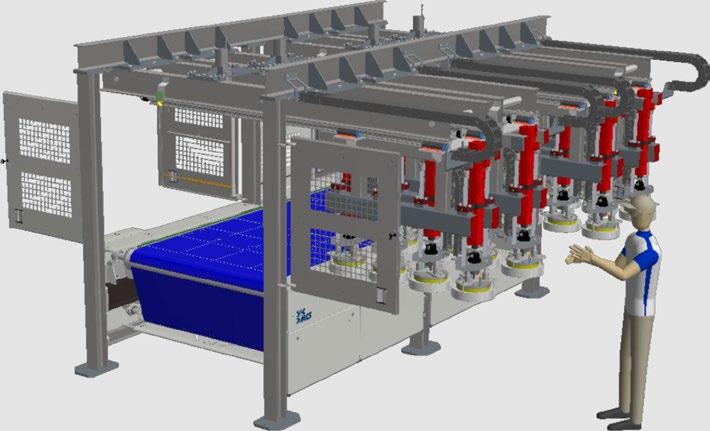

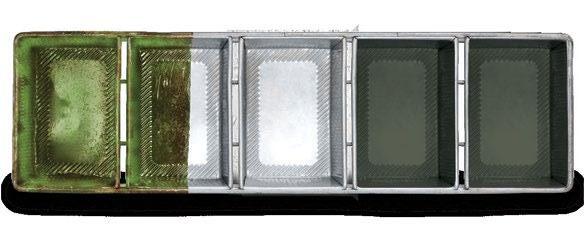

The optimal complement to our line technology