The global exchange of products, processes and knowledge is a matter of course in the baking sector nowadays. Consumers in Asia know and love syrup waffles, for example, which originated from the Netherlands. Baguettes, ciabatta, pizzas and even croissants are enjoyed in the Middle East, and coffee “to go” with a matching brownie, a traditional cake from US-American cuisine, are appreciated even in Russia. Manufacturers have adapted products to regional preferences and consumer expectations in some places. Thus the wheat bread in South America is sweeter than in North America. A crisp, splintery crust on a baguette is considered a quality characteristic in France. In Asia, however, a baton should be nice and soft, if you please!

++ Bastian Borchfeld, Editor-in-Chief

The baking sector is a winner as a result of globalization, and has profited from it for many years. Thus not only have various regional baked products become established around the world, so have the manufacturers of the plant and machinery with which the baked goods are produced. As a publishing house, we participate equally in the success story of “Baked goods round the clock and around the globe”. Nowadays, due to the internationalization of markets, we publish specialist magazines in English, Russian and German. We editors notice again and again the size of the worldwide demand for information in the baking sector.

For example, part of the readership is especially interested in the outlook on developed, mature markets in Europe, whereas another part is fascinated by success stories from Asia or South America. As editors, we try to fulfill these wishes with varied and exciting stories.

However, globalization also leads to upheavals; dietary, consumption and living habits change. For a few consumers and producers, this leads to uncertainty that is not infrequently reflected in a defensive attitude towards globalization.

Below the line, however, we should all be aware that up to now globalization has produced more winners than losers. There has been an increase not only in the diversity of foods but also in their safety. New niches and marketing channels have opened up.

Changes always demand a certain amount of courage. Although it’s easily said, there’s no guarantee that courage will be rewarded, and “it was all better in the past” is only a saying, not a solution to challenges. Standing still cannot be in the best interests of consumers and producers, and new ideas cannot emerge without an exchange of knowledge. I believe that the baking sector in particular, with all its facets, its history and its connection with the regions, is a good example of the benefits of globalization.

Ours knows a good deal. Industry-specific processes, integration of machines and systems, monitoring and reporting, traceability, quality management and much more.

The CSB-System is the business software for the bread and bakery goods industry. The end-to-end solution encompasses ERP, FACTORY ERP® and MES. And best-practice standards come as part of the package.

Bastian Borchfeld

Bastian Borchfeld

Would you like to know exactly why industry leaders count on CSB?

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany

+49 40 39 90 12 27 www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil

+49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld

+49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk

+49 40 39 60 30 61 baumfalk@foodmultimedia.de

Silke Liebig-Braunholz

+49 (0)40 386 167 92 liebig-braunholz@foodmultimedia.de

ADVERTISING DEPT.

International sales director

Dirk Dixon

+44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Wilfried Krause

+49 40 38 61 67 94 krause@foodmultimedia.de

DISTRIBUTION

+49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide Linda Langhagen; design@landmagd.de

PRINTED BY

Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department. No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid

price list: 2018

Building up competence across the entire process chain and putting automation into practice, not only for customers but also in the company itself – are clear objectives for Zeppelin’s Food Business Unit.

+Zeppelin Systems GmbH Managing Director Wolfgang Horn, and Michael Piepenbrock, Head of their Food Business Unit, are convinced that modern production processes can no longer manage nowadays without automation, and conversely automation cannot do without detailed process competence. It is no secret that Zeppelin is showing interest in expanding their own process competence in relation to the raw materials handling of dry substances and liquids, fermentation and dough make-up. The Food Technology Center at the Rödermark site has just been successfully enlarged by adding the “Continuous Dough Make-up” process step. Top priority is given to organic growth via exploiting further market potentials. However, cooperations or possible acquisitions are not excluded either. There has been a clear advance in the company on the subject of automation. Horn says: “We recently organized a “Hackathon” (Hacker + Marathon) here in our unit, and asked the hackers to have some ideas about spare parts supply platforms. The results were amazing, and although not all of them were realistic, many really did stimulate ideas for our work.”

The task is currently the responsibility of an interdisciplinary team focusing on standardizing and modularizing plants. This team has now established a comprehensive data base covering all the components that are used, and has created modules for engineering purposes from it. The aim is to

KOKEISL technology offers various benefits compared to a conventional metering screw. The KAD component does not need any additional closure cap to prevent unwanted after-flow at the end of the metering process. The curved agitator discharges the product gently, thus enabling even sensitive products, e.g. chocolate buttons or pieces, to be metered without damage. The space requirement is

become more joined-up and faster in spare parts supply and in service provision, as well as in design. According to Piepenbrock: “Colleagues everywhere in the world can access the data via our global network. In this respect we not only have in mind simply the supply of spare parts, but also controller upgrades, preventive maintenance, and also the ‘modernization’ of components where necessary.” The aim is to increase plant availability, and to use “smart components” to improve line efficiency. “Smart components” are accessible via an App, and not only report their whereabouts, but can also provide data, e.g. about their operating lifetime, maintenance cycle

considerably smaller for the same performance. Overall, enormous potential savings are created by eliminating costs for installation and the control technology. Control of the metering is self-teaching and self-optimizing. The data for the respective batch are archived in a data base, thus enabling constant high metering accuracy to be guaranteed, even with fluctuating raw materials qualities.

etc. Specifications, spare parts lists, instructions about commissioning, operating, service/maintenance and service intervals together with their documentation over the course of time can also be viewed in the underlying data base. The App also contains a function for a “service chat” through which there can be contact with experts who can in turn upload explanatory images and videos when required. According to Piepenbrock, the next step would be convert cyclical service/maintenance into state-dependent service/ maintenance.

The second goal of Zeppelin’s automation initiative is aimed at continuous process monitoring through networked communication. Data recorded continuously at various measurement points in the process allow the operator to draw conclusions about the progress of the process and the behavior of raw materials, and may highlight the need for regulation. For example, this approach would permit fluctuations in raw materials quality to be examined much more quickly and precisely, and the volume of production wastes to be reduced.

Little by little, Zeppelin has enlarged the Rödermark Technology Center, which was opened in 2012, into a Dough Technology Center. Customers can take part in seminars or technology days there, in which systems and solutions for fresh and long-life baked products are demonstrated, or can run trials using their own raw materials. The available plants include a combination of metering, a Dymomix and a continuous Codos mixer. The Dymomix uses water or yeast solution to wet the freely falling solid. According to Zeppelin, the “preliminary stage” produced in this way reduces the

mixing time needed by a conventional batch mixer by up to 30%, and increases the amount of water absorbed by the flour by up to 2% at the same time. The mix leaving the Dymomix is metered directly into the Codos kneader, or the plant can also be used to mix flour, water and a sourdough culture. After the mixing process, the dough is then transferred to the fermentation container.

To discharge the sponge dough, the excentre screw pumps previously used are replaced by twin-screw spindle pumps,

since the latter consist entirely of stainless steel and are thus more hygiene-friendly and easier to clean. They also have high suction capacity.

A double-walled model of the sponge dough container and pipework, which mean it is no longer necessary to use heat

exchangers, is currently undergoing trials. Another innovation is a plant cooperation with the Handtmann dough divider. The combination of dough preparation by the Codos with the dough divider is currently being tested in the Dough Technology Center for pan bread, toast-bread, as a strand or as 4-pieces, and a special molding process for buns.

Modern

They are equally at home in the confectionery industry as they are with sugar or cereals producers, but Rödermark’s focus is on baked products, regardless of whether they are fresh or refrigerated, or as long-life baked goods in the form of cookies. Because their manufacture needs dry and liquid ingredients systems just as much as fat temperature control equipment, salt dissolvers, fermentation plants, flour cooling, and machines that process the rework so finely that it can be metered back into the dough production step as a slurry, and of course the dough production equipment, which in the case of Zeppelin Systems includes the continuous Codos and the Dymomix. The latter is still a recent development in which dry materials in free fall are wetted with water or yeast solution, allowing a homogeneous liquid dough to form.

Zeppelin’s silos are fabricated from both aluminum and stainless steel, delivered prefabricated or complete, or only fabricated on the building site. Also included is a wide assortment of process technology solutions, e.g. sieving machines, fluid beds, airlocks, track switches, filters or screw conveyors.

Zeppelin also became famous for its “Reci Pure”, a system with which raw materials can be stored, metered, mixed and transported without risk of any unwanted cross-contamination occurring. This technology is used mainly for convenience mixes, baking ingredients or infant food.

The Zeppelin Group, which operates with 7,646 employees at 190 locations worldwide, earned revenues of EUR 2.36bn in the 2016 financial year. The Zeppelin Group organizes its Group-wide collaboration in a management holding company and six strategic Business Units: EU Construction Machines (sales and service of construction machines), CIS Construction Machines (sales and service of construction and agricultural machinery), Rental (leasing and project solutions for the building trade and industry), Power Systems (propulsion and energy systems), Plant Construction (engineering and plant construction) and Z-Lab (new digital business models). Zeppelin GmbH is the Group’s holding company, with its legal domicile in Friedrichshafen and the headquarters in Garching bei München. More information at www.zeppelin.com. +++

++

metering technology – a fluidized bed (microporous coating) on the cone creates an air cushion that loosens dry substances such as flour or powdered sugar and meters large quantities of them vertically downwards through the pipe. Subsequently, small amounts of them are metered precisely via the metering screw leading away from it sideways. This allows large capacities with simultaneous exact weight accuracy© Zeppelin

Fedima and AIBI invite to a joint symposium on Bread Promotion Activities in Europe taking place on April 18, 2018 in Brussels/Belgium.

+A day dedicated to learning about the importance of bread, being inspired by campaigns, sharing best practices, and more. The event brings together all partners in the bakery sector to discuss ways to promote the bread category across Europe.

Part 1

Perspectives on bread and its promotion opportunities

This session will give participants background information and introduce several perspectives on bread in the diet as well as the challenges linked to bread consumption. In addition, the organizers want to talk about the specific EU policy to promote agricultural products and how this could benefit the bread sector in particular.

Part 2

The different bread campaigns in Europe

Get inspired by other bread promotion activities across Europe! The aim of this session is to show participants what promotion possibilities are out there, even on a small scale. Projects and learning from different countries and/or regions will be presented.

Part 3

Workshop: setting up your bread promotion campaign

The organizers will organize breakout sessions to brainstorm about potential bread promotion campaigns. Participants will have an opportunity to sit together with potential partners in the bakery supply chain to exchange views and ideas for the launch of promotion activities.

Event Venue:

Martin’s Hotel EU

Boulevard Charlemagne 80, 1000 Brussels/Belgium

Participation fee: 190 EUR + VAT

AIBI, the International Association of Plant Bakers, was founded in Paris in 1956. At present, 16 national member organizations are affiliated to the AIBI. The association’s headquarters have been established in Brussels Grand Place since early 2011. AIBI holds contacts to key Members of the European Parliament and the European Commission services. The association’s presence in Brussels also facilitates collaboration with other chain partner associations located in Brussels. AIBI’s key task is to represent its members’ interests, especially vis-à-vis European and international institutions (EU Commission, European Council and European Parliament).

Web site: www.aibi.eu

For more information and to register, please visit the web site: www.breadpromotion.eu or contact the AIBI – Grand Place 10 – 1000 Brussels/Belgium, per E-mail addressed to info@aibi.eu or by phone at +32 2 361 1900. +++

Fedima is the European Federation of Manufacturers and Suppliers of Ingredients to the Bakery, Confectionery and Patisserie Industries. The members are likewise national associations across 14 EU Member States. Fedima helps their members to have access to a EU single market in order to facilitate their business activities within the European Union. Whenever requested, the Association also provides expertise to EU institutions on items related to bakery ingredients. Web site: www.fedima.org

- Dough Make-Up

- Proofing

- Seeders, Toppers, Pan Shakers & Water Splitters

- Ovens (Tunnel, Conveyorized, Serpentine, Tray, Rack and Deck)

- Cooling

- Pan & Product Handling Systems

- Packaging & Distribution

The former Heathrow Bakery owners invested GBP 15m. (approx. EUR 17m.) in the newly founded Panificio Italiano bakery. Production at the new, optimized location near London’s Heathrow Airport obeys the “Baked to Perfection” principle.

Production at the British “Heathrow Bakery” founded in 1991 in Iver, Buckinghamshire near London, has been relocated. The newly founded Panificio Italiano bakery is situated almost directly opposite the former production site, on the other side of the road. The entire workforce together with the plants are now in a freshly renovated production building. Owner Piero Scacco invested around GBP 15m. (approx. EUR 17m.) to restructure the business and introduce new production technology. The bakery’s aim includes stronger growth with frozen baked products, as well as further optimization of the quality of the baked goods and production process, and winning new customers.

For this, for example, Scacco invested in new outdoor flour silos, new mixers and a new frozen product warehouse. The new location also has enough space for further growth, because the restructuring is also designed to win new customers, e.g. the food retail.

The company employs around 170 staff. Production is in two shifts, six days a week. In addition to various small baked goods, the Iver bakery also produces breads, ciabatta and other specialties. All from wheat flour, and two in-house product developers ensure a constant stream of new products. The main purchasers nowadays are still food service and catering companies.

However, General Manager David Taylor and Sales & Marketing Manager Andrew Gibson see growth opportunities, especially in the frozen food area. Owner and Chairman Piero Scacco, whose roots are in Italy, shares this view, and says:

“We expect the sector to change, particularly due to Great Britain’s planned exit from the European Union, and we are currently adjusting to that. Thus we anticipate a rising demand, especially in the retail, for frozen baked goods produced in England.” Consumers will also happily continue to purchase specialties such as ciabatta, focaccia or ciapini produced

Italian style with olive oil. The Panificio Italiano bakery’s team is confident of this. To produce high-quality baked goods, the company also attaches great importance to various plants, as well as to high-quality raw materials such as extravirgin olive oil. In this respect, most of the plants are from the Austrian machine constructor König in Graz. Piero Scacco explains that “I have collaborated with König for around 40 years, and I particularly appreciate the good support.” But the production facility also contains a mixer carousel from San Cassiano in Italy, ovens from the German thermo-oil oven builder Heuft, and GBT plants.

Thus the staff use several König plants for dough production, including an Industrie Rex AW with a KGN proofer plant for sandwich rolls. The Industrie Rex AW (accurate weight) has a weight range from 22 to 160 g and is used for dough dividing and round molding. The weighing and molding system that was developed, and the continuously adjustable uniform pusher plate pressure, ensure high weight accuracy, even with a variety of dough consistencies. Panificio Italiano operates it at a maximum rate of 18,000 pieces/hour.

After dividing and molding the dough, the dough pieces go into a proofer with 340 swing trays and a proofing time of approx. 8 minutes. Next the dough pieces are pressed flat in

a shaping station, and folded to create sandwich bread rolls. After another proofer with a 6-minute proofing time and 250 swing trays, they are then deposited and carried after rounding onward for final proofing and baking.

A König Certo Pan M dough sheeter is used to manufacture various specialty baked products. A rotation principle in the system guarantees weight accuracy with no scrap dough. To avoid joints and associated irregularities in the dough, the dough feed is rotated in a drum. Oscillating cutting blades are then used to shape the rotating dough into a continuous endless dough sheet. The Panificio Italiano bakery has a Certo Pan M plant with interchangeable cutting rollers for 1- to 5-row operation. The number of rows can be changed by manually repositioning the belts. In 5-row operating mode, for example, the plant’s capacity is 6,000 pieces/hour. For greater weight accuracy, there is also a weighing device upstream of the punch to cross-cut the dough strands. The plant also includes crosscutting tools for various baked product shapes, e.g. lozenges.

The plant also has an additional round molding station for circular baked products, a three-belt poppy-seeder/strewer with automatic strewing material recycling, a water-bath to

moisten the dough pieces from below and an overhead spray unit for additional top moistening. This is followed by a scrabbler with a 600-mm working width.

Bread roll plant

The bakery also depends on Austrian plants to manufacture small baked products. The König KGV Combi has a 6-, 5and 4-row Industrie Rex I dough divider-molder that is continuously adjustable for 10 to 50 strokes/minute. The plant also has a 30 – 100 g weight range. The associated KGV Combi proofer has more than 400 loadable swing-trays and integrated long rollers. The plant can manufacture both split-top rolls and stamped Kaiser rolls. A direct feed route can be selected to bypass the proofer for products without any proofing time. The air-conditioning has a heater and humidification, controlled via a thermostat and a constant humidity device. There is also a sterilization plant with cold-cathode UV lamps for empty swing-trays, and a drying zone with a blower, again for empty swing-trays. The proofer is followed by a shaping station to long-roll and fold the dough pieces and press them flat. Finally, this is followed by an Industrie-type scrabbler with a maximum scrabbling length of 950 mm that can be operated on three sides.

The dough pieces are deposited onto Diane baking sheets and trays. General Manager David Taylor explains that “Our

ADVERTISEMENT

experience with the French tray coating and pans has been good.” Taylor is also satisfied with the GBT paternoster proofer and loading/unloading technology. Products are baked either in Heuft thermo-oil rack ovens or in a 5-deck tunnel oven with stone plates, also from the oven builder Heuft. The bakery also invested in a new spiral freezer at the new site. Another bread roll plant is being installed. A new line for bread production is also planned. In addition to the planned new frozen products warehouse, the packaging section is also currently being automated to achieve the aim of market leadership with the motto “Baked to Perfection. +++

■ Short learning times through intuitive operational concept, modeled on mobile devices

■ Adjustable user interface

■ Simple bespoke user permissions management

■ Modifications are possible during the ongoing baking process

■ Calendar function allowing for multi day programming

■ Operable with thin gloves

■ Manual baking mode www.wiesheu.de/en

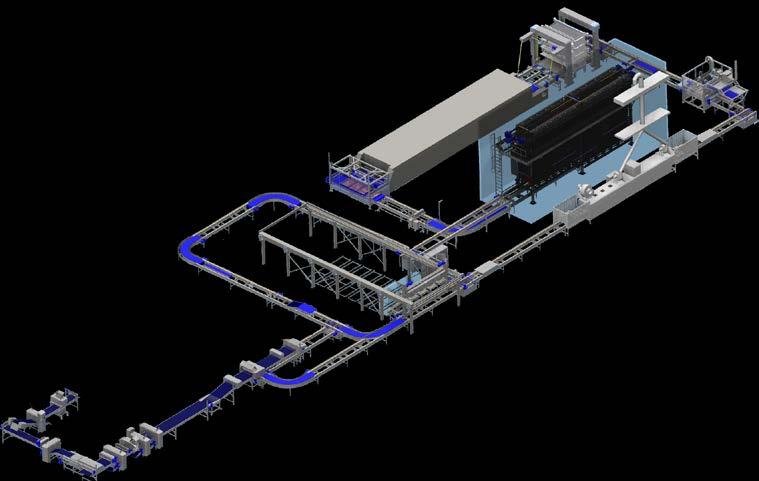

The Middleby Bakery Group, with its primary US location in Plano, Texas is intent on more growth, including further acquisitions. The aim is for clients throughout the baking sector to be offered complete turnkey solutions for all their production needs, with delivery times for completed plants being reduced considerably.

The portfolio of the Middleby Bakery Group is extensive and steadily growing and includes dough make-up plants, proofers, handling systems and a wide variety of ovens including tunnel, conveyorized, and serpentine. Mark Salman, President of the Processing Group that includes the Middleby Bakery Group, oversaw the acquisition of several companies in 2017 in order to strengthen the bakery division, namely, the Burford Corporation based in Maysville, Oklahoma and the Sveba Dahlen Group located in Fristad, which includes Glimek and Varimixer. Further acquisitions followed with the most recent being the purchase of Scanico, a specialist in coolers and freezers and spiral proofers for the industrial baking industry. The Group’s objective is to ensure that all customers receive the lowest overall costs of ownership possible. Innovations in equipment construction are designed not only to reduce operating costs but also to minimize the

++ In December 2017, Middleby announced the acquisition of Scanico A/S, a leading manufacturer of industrial cooling and freezing equipment for the food processing industry. Scanico a Danish based company, with more than 25 years’ experience, designs and constructs spiral systems for different applications, including IQF freezing, chilling, steaming and proofing for the world’s leading food-processing companies.

customers’ capital expenditures/investment costs with the aim of also increasing output.

The Group offers a variety of solutions for both industrial and artisan bakers, although the focus is more on industrial bakers and for this reason the engineers from Baker Thermal Solutions developed the 960 Hurricane tunnel oven, which reduces overall costs by decreasing energy consumption and increasing output. Another addition, aimed at industrial bakers, is the Auto-Bake Serpentine, which saves space and cost due to its compactness and lower energy consumption.

The company sees growth opportunities primarily in Asian markets, closely followed by Europe and South America. Salman adds, “We are also concentrating our efforts on

The Middleby Corporation today announced the acquisition of Hinds-Bock Corporation. The company is a leading manufacturer of solutions for filling and depositing bakery and food product, an integral part of the industrial baking and food processing line. The company is based in Bothell, Washington and has approximately US-Dollar 15 million in annual revenues. “For decades, Hinds-Bock has been a leader in filling and depositing technologies serving industrial baking, food processing and other specialty areas. This acquisition allows Middleby to offer a customized and complete integrated solution for their high volume baking and processing needs,” said Selim Bassoul, Chairman and CEO of The Middleby Corporation. “Hinds-Bock technology

emerging markets and on highly competitive markets where low overall costs are important.” However, the Middle East and Russia are also strategic markets for the Middleby Bakery Group. The Group also recently opened a new Innovation Center in India in late 2017.

The company is exhibiting at a wide variety of trade fairs, with IBA in Munich being the most important exhibition for the Group during 2018. The Group will be demonstrating several

Using coatings from Anneliese will save you cash and help the environment.

+ No more release agent costs

+ Far easier cleaning

+ Reduced production time

Custom made with your specifications to perfectly suit your needs.

Increase efficiency while keeping the artisan style of your sandwiches!

+ Highly adaptable for your use

+ Versatile and flexible

+ Ergonomic, everything in reach

+ Mobile, easy to move and adjust

will highly complement the existing bakery and processing systems of our current brands. We can now offer our customers more with one supplier.”

Hinds-Bock is a top manufacturer of standard and custom depositing machines and fully automated lines for the baking industry for depositing batters such as muffin, cupcake and cake, depositing fruit pie fillings, mini cake lines, icing equipment and dry toppings such as streusel and nuts. Food factories also rely on Hinds-Bock for liquid bottle filling, high speed meal filling systems, value added protein applications and expertise in the integration of standard and custom filling machines for vertical and horizontal form fill seal applications.

updated designs and innovations across the entire equipment portfolio including a new oven under the Auto-Bake brand.

The Group is also working intensively on a solution to considerably reduce equipment delivery times. Mark Salman says, “Naturally, every customer would like to have their lines installed immediately and as a result of our increased production capacities, we should be in a position in the very near future to reduce delivery times considerably. +++

Bundy Baking Solutions is the USA market leader in the area of trays, pans and coatings. The American company, which also produces mixers (Shaffer), for example, would like to develop new markets and make further investments.

+Bundy Baking Solutions currently employs a workforce of around 1,000. Purchased acquisitions in 2017 alone brought in around 300 new employees. For example, the Group took over the FBS Prestige company in Great Britain in 2017. The agreement comprised the acquisition of three coating plants in Great Britain together with a production facility in Romania. Gilbert Bundy, CEO of Bundy Baking Solutions, added this explanation: “Combining the innovation and market knowledge of American Pan and FBS Prestige excites us greatly. It results in the optimization of two industryleading companies, and the opportunity to provide a fast, comprehensive tray and coating service to our clients in Europe and the Middle East as well as North Africa.” The CEO also explained that “Bundy Baking Solutions plans to make significant investments both in the fabrication business and in the coating business.” CEO Gilbert Bundy

confirmed that a lively exchange of experience and view already exists between the factories in the USA and the works in Romania.

Bundy Baking Solutions is considered to be the clear USA market leader in the area of trays and pans. CEO Gilbert Bundy explains that “Like our customers, we grow globally.” The company’s export ratio six years ago was still around 15%. Referring to the growth strategy, the CEO says “Today it is approx. 50%.” Bundy Baking Solutions manufactures trays, e.g. for hamburger buns, and cake tins, as well as the matching coatings, under the brand name American Pan ® Altogether there are 26 agencies worldwide – from Urbana, USA, and Baura, Brazil, to Nottingham, UK, and Alexandria in Rumania.

The company offers a comprehensive spectrum of services in the trays and pans area. For example, customers can arrange for trays to be collected. Where necessary, the trays are straightened/repaired, cleaned and recoated, e.g. with AMERICOAT ® Plus silicone release coating.

This cleaning, straightening and recoating service is also available for baking pans (e.g. pans with the non-stick coatings American Pan DuraShield ® , OptiShield or Excoat from Excellent Coatings). At least 3,000 baking cycles are guaranteed for the leading DuraShield coating for most products, and more than 5,000 baking cycles have been documented by a few leading global bun bakeries.

In addition to its coating and maintenance service, the company also offers customized industrial baking trays. Jason Tingley, Vice President of American Pan and responsible for design, technology and innovation, explains that American Pan’s corresponding fabrication, design and highly-developed machining capabilities enable the company to produce individually customized baking pans that can fulfill any bakery’s requirements. He also says American Pan’s baking trays and baguette pans can be designed to any size and used in any industrial oven system. They can be supplied stackable and with the exclusive TabLock design, which uses a patented system to fasten the baking surface into the frame without requiring rivets or welded seams. The company also offers the American Pan ® SMART Pan Tracking ® system. This involves using a laser to engrave a code and number onto the tray or pan. The code and number are linked to a bakeryspecific database containing information about the pan type, dimensions, size, expected lifetime of the coating and number of baking cycles per pan. Sensor technology is integrated into the bakery’s production lines to record each pan and transmit the data to a secure web site which the customer can access. According to American Pan Vice President Jason Tingley “The system records the data very precisely and prepares analyses for the bakeries, e.g. to monitor the lifetime of the coating, line efficiency and numerous other important process parameters.” For example, the system can detect and analyze the number and length of gaps between pans. Optimum plant capacity utilization can increase the throughput of baked products.

There are continuous improvements in the silicone and Teflon coatings for trays and pans, and the shape of the trays is also being optimized. Bundy explains “For example there is the E-Pan, which depending on the pan is 30 to 50% lighter and at the same time more sturdy than comparable pans.” At present, customers generally prefer to order large trays and pan clusters. The CEO promises that the new design will be exhibited at the iba trade fair.

Andrew McGhie, Sales Director for Shaffer Mixers, will also present innovations in the mixing and kneading area at the trade fair in Munich. The Group is making big investments in Research and Development for this. McGhie promises “In the mixer field, the engineers are currently developing many innovations in the Hygienic Design area, and these will also be on show at the iba trade fair in Munich.” For example, the bowl cooling jackets have also been reengineered to allow dough to be cooled more uniformly and faster and to control the dough temperature even more accurately.

In this respect, the VerTech ™ cooling jacket was designed specifically for kneading machines and a patent filed for it. Shaffer Mixers guarantees a five-year warranty on the new cooling jacket, which is said to operate using glycol. Andrew McGhie explains that “The VerTech™ cooling jacket also needs less energy to circulate the coolant, without reducing the effective heat transfer, thus ensuring maximum cooling. The energy saving is noticeable with every dough batch processed in the mixing machine.” Other topics include an improved plant hygiene design and the restriction of downtimes to a minimum. Shaffer also offers roller-bar, singlesigma, double-sigma and other mixing machines in a large number of sizes designed for the specific needs of each product and each plant.

According to CEO Gilbert Bundy: “Whether it’s improvements in hygienic design in plant construction or the development of new trays and pans, Bundy Baking Solutions’ customers motivate the whole Group to develop innovations in all areas.” He says the company wants to continue growing globally through these innovations and ideas. +++

The 21st Bakery China – an international trade fair for bakeries and confectioners –takes place in Shanghai/China from May 9 to 12, 2018.

+Bakery China is one of the leading trade fairs in the Asia-Pacific region, and covers the entire value-added chain of baked product and confectionery manufacture. The event in 2018 will occupy 200,000 m 2 in the Shanghai New International Expo Center. Participating companies will present their latest developments on more than 10,000 stands. At the previous event last year, the event organizers counted 2,034 exhibitors and 123,000 visitors that had travelled to the trade fair from 105 countries.

The exhibitors in Shanghai also included the Austrian company Koenig, which will present its baking equipment with daily demonstrations at this year’s Bakery China show. It will also include the G2000 roll line, a compact line with stamping station, and a folding/long rolling station with a Mini Rex as the head machine. The line has an output rate of 2,000–2,500 pieces per hour, and if the head machine is swiveled out, it can even produce up to 4,800 pieces without a proofer. An adjustable height, single-row discharge belt is responsible for easy manual product removal. The line features a stamping station with easily changeable stamping tools (e.g. Kaiser shape). At 2,000 pieces per hour, the proofing time is approx. 6 min. A folding and long rolling station is integrated and, with an optional driven upper belt, even hamburger buns can be produced. The G2000 can be easily operated with PLC control and an integrated touch panel.

Another exhibit is the Rex Futura Multi dough dividing and rounding machine. Based on the gentle dough processing technology of Koenig’s established “Rex” system, the company says it sets another milestone with the Rex Futura Multi by

extending the weight range from 17 to 245 g for round-molded products and up to 600 g for products that are only divided. The machine enables a simple change of the dividing drum ledges for different weight ranges or to change the number of rows. It has a maximum hourly capacity of up to 9,000 pieces at 6-row operation (corresponding to 25 strokes/min.). The Rex Futura Multi reaches an optimum rounding result for various doughs by means of exchangeable rounding plates and an electrically adjustable rounding eccentric. To increase product variety, the machine can be combined with various downstream units (e.g. a forming station and/or seeding unit).

+ Founded in 1997

+ Frequency: once a year

+ Exhibitors in 2017: 2,034 from 30 countries and regions

+ Visitors in 2017: 122,284 from more than 105 countries and regions

+ International, HK, Macao & Taiwan Exhibition Area: 10,000 m 2 (Exhibits: Ingredients, Equipment, Machinery, Packaging Solutions)

+ Coffee, Beverage & Fine Food Exhibition Area: 15,000 m 2

+ Organizer: China Association of Bakery and Confectionery Industry (CABCI); Bakery China Exhibitions Co., Ltd.

+ Website: www.bakerychina.com

UrkornCakeMix combines modern baking technology with the age-old knowledge of traditional grains. Successful baking of timeless classics, like sheet and shaped cakes, or trendy American Cookies has never been easier. www.backaldrin.com

It’s a balancing act between tradition and modernity. The Pappert Bakery in the Rhön district in Germany relies on a mix of artisan work and automation in its production operations. These have taken the company on the road to success.

+Bernd Pappert and Manfred Klüber, Managing Directors of the Pappert family business, could be pleased at the opening of their 107th specialist shop in late 2017. The bakery wants to grow further in 2018 as well. The sales region in this respect extends to a radius of about 100 km around Fulda in the states of Hesse and Bavaria, northwards as far as Philippsthal and Obersuhl, westwards to the Rhein Main district and southwards to Schweinfurt and Würzburg. A total of 1,300 employees work to ensure the company’s success. The bakery’s headquarters in Poppenhausen is only a few kilometers from Fulda. Around 130 staff work in the production area, with a daily output of up to 12,000 breads, 200,000 bread rolls and 45,000 pieces of small baked goods. Work takes place in two shifts, seven days a week. Master Baker Martin Schiller, who shares responsibility for the production operation, explains that “Snacks and bread rolls in particular are growing at the moment.” Schiller views the bread and rolls areas among the bakery’s core competences.

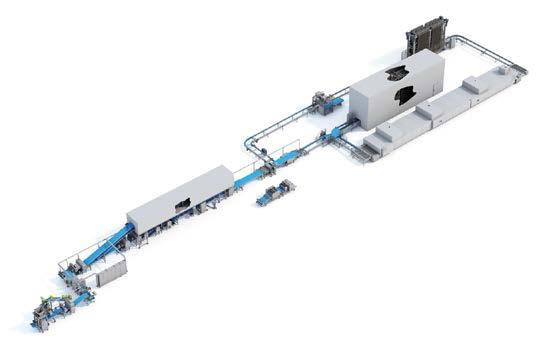

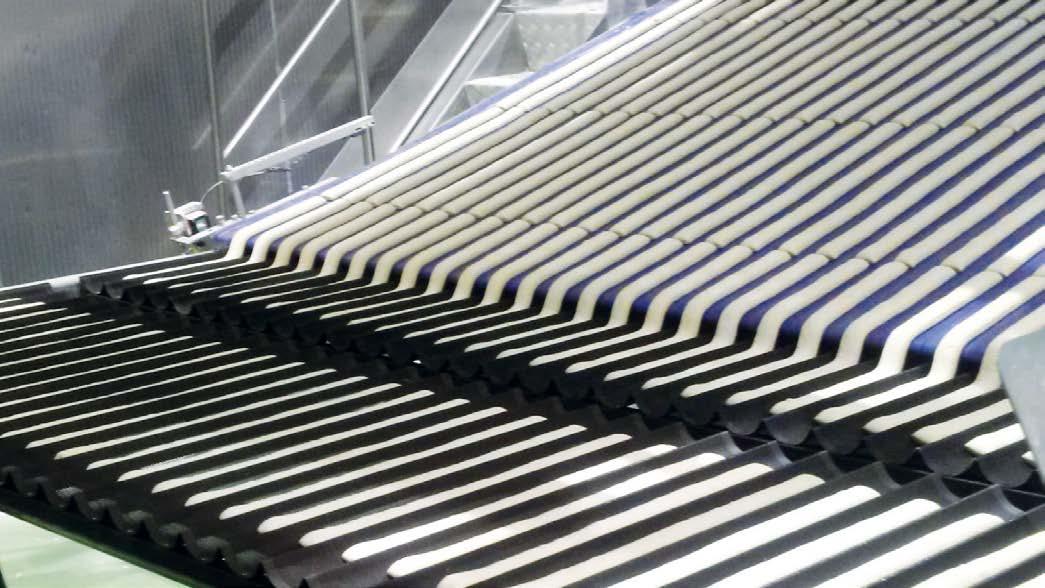

To raise production capacity and increase the quality of the small baked products, the bakery recently invested in a new Crusto bread/bread roll plant from the Dutch plant constructor Rademaker. The medium-sized bakery’s requirements for this were high. For example, on the one hand there is a need

to systematically reduce the use of baking agents, and on the other the new line must process doughs with a higher dough yield and longer dough resting time. The plant must also be flexible at the same time, e.g. to allow the production of new baked product shapes such as diamonds.

Martin Schiller adds “We had some more requirements for the plant constructor.” As a result of the bakery’s organic growth, the baking area had also expanded continuously due to various additional structures and expansions. It was therefore necessary for the Crusto bread/bread roll plant to be integrated into the bakery’s new extension building during ongoing production. Master Baker Schiller says “With a total plant length of only 20 meters, there was also a requirement to include manual workstations to give the baked products an individual artisan touch.” A challenge for plant constructor Rademaker. The solution is a Crusto bread/bread roll plant that produces a dough sheet gently by using a stress-free Double Chunker system (DSS). Ewald Kümmel, responsible for Sales and Marketing in Rademaker Deutschland GmbH, explains that “The system represents the gentlest possible dough handling. This is especially important when processing doughs with very long dough resting times and a high TA (Dough Yield).”

First of all, a bowl tipper loads the dough into the line’s dough cones at the start of the line. From here, the dough is transferred in a gentle, controlled way into a second, lower

and slightly oiled cone. Next the system uses a double star roller to portion out dough pieces each weighing 20 to 25 kg. The dough pieces then go onto a flour-dusted conveyor belt whose plastic limiters at the sides ensure the formation of a continuous dough strand. In this operation, the dough pieces from the DDS are deposited in such a way that they have a 50% overlap.

This is followed by a first roller to reduce the dough thickness, and the dough strand is transferred to another flour-dusted conveyor belt. This belt is positioned under the DDS unit. A continuous dough sheet is formed, on which the transitions between the individual overlapping dough pieces are still easily visible after the first finishing station, because the dough sheet is rolled out and reduced very gently. Further finishing stations and a cross roller unit ensure that the dough sheet is rolled out to the required thickness, e.g. 15 mm. Various flour dusters that are manually refilled by employees are installed to enable the reduction.

Production Manager Schiller explains that the new plant allowed an immediate three points increase in dough yield. It is also possible to achieve the desired open pore pattern for certain products like ciabatta. The plant also has a working

width of 600 and 800 mm respectively (dough sheet production 600 mm / dough sheet make-up 800 mm). Hourly output capacity ranges from approx. 500 kg/h to approx. 1,500 kg/h. This corresponds to approx. 6,000 to 18,000 bread rolls per hour, depending on the dough and weight range.

The line is divided into various modules to guarantee the highest possible flexibility. Each of these modules is also moveable and can be removed from the plant, e.g. to wash it. In this respect, the entire machine is laid out on the “Design for Wash-down” principle (D4W), i.e. it can be wet-cleaned without using high pressure. Moreover, to simplify cleaning and drying the plant, all the belts can be loosened quickly and without using tools.

Another special feature is provided by the moistening unit, which operates airlessly and very precisely targeted and efficient, so no water mist is formed either.

The dough sheet is cut into the required number of dough strips by longitudinal cutter rollers, and its edges are trimmed. The resulting scrap dough is collected and recycled to the production unit’s trimmings. The continuous dough strips are spread apart to peelboard loading spacing, and fed into the following bottom-seeder/strewer module. Here the dough strips are moistened with water from below by a moistening roller and immediately laid into the strewing material, which is continuously spread over the whole width of a conveyor belt running underneath. An adjustable-height driven roller presses the dough strips gently into the strewing material to assist adhesion. This allows grains, seeds and semolina to be applied to the lower surface of the dough pieces without the need to turn the latter over. This enables a uniform strewing pattern even on triangular bread rolls, diamond-shaped rolls or pierced baguettes. A compact mobile recycling device (air-free) is then used to return excess unattached strewing

material to the feed cone. Production Manager Martin Schiller confirms that it’s “a very flexible, hygienic solution.” After the bottom-seeder/strewer module, an electromechanical guillotine uses either a guillotine knife or various punches to pre-portion the dough pieces.

Strewing the upper surface is carried out upstream of the finishing station, using a universal strewing device that rolls

The company’s own delivery trucks (six HGVs and fifteen box vans) supply branches with baked goods up to twice daily. The employees freshly bake dough pieces in instore ovens on the spot. The Pappert bakery focuses on its own sales outlets and less on the supply business. The sales outlets are located within a radius of up to 110 km around the bakery.

The bakery operates various sales concepts as a supplement to its core bakery business:

+ Pappiamo: Pappiamo represents Italian hospitality and supplies customers with pizza and pasta, which are freshly prepared in front of the customers.

+ zuTisch: zuTisch (“lunch is ready”) is Pappert’s fast food concept (not just at midday). It allows customers to put together their lunchtime meal from various modules on the building block principle.

+ Giovanni L.: Giovanni Lasagna stands for a very special kind of ice cream creations. Using the best raw materials and highest quality ice cream, entirely in the Lasagna family’s traditional style.

+ Zweittag (day two): The previous day shop for baked goods returns and surpluses is a solution combining a baked products counter and on-the-spot consumption.

AMF Bakery Systems’ Spiral Conveyor incorporates the most sanitary design elements, including a patent-pending monopiece cage bar, for efficient cleaning and maintenance. Equipped with plastic modular belting using the Intralox DirectDrive™ System, the Spiral Conveyor eliminates product movement on the belt to minimize potential jams. This custom-configured solution is suitable for a variety of product applications including intermediate dough proofing, product proofing, cooling, and freezing.

Your bakery is our world.

VISIT AMF BAKERY SYSTEMS AT: MODERN BAKERY, MOSCOW FOOD & HOTEL ASIA, SINGAPORE BAKERY CHINA, SHANGHAI

the grains into the upper surface. Martin Schiller explains that “The combination of the universal strewing device and the bottom-seeder/strewer module enables creative strewing combinations to be achieved on the upper and lower surfaces, and it has also allowed a reduction in the loss of strewing material over the whole process.” An adjustable-height flipping edge allows the dough pieces to be turned flexibly depending on whether they are to be deposited onto peelboards (and are turned again before baking on trays) or directly onto the baking trays.

A depositor belt and retraction movement deposit the dough pieces onto either two proofing peelboards (600 x 400 mm) or one baking tray (580 x 780 mm). For this, the peelboards are automatically unstacked from a peelboard magazine and cycled under the depositor. The peelboards magazine for the plant was also built by Rademaker, and is refilled by hand.

Before the peelboards are removed and stacked, the Rademaker line also includes a manual work track where employees can give the dough pieces an additional special individual shape.

All the product-related tools, cutting knives, molding punches etc. are kept ready on a generously-sized tool trolley for quick product changeover. Production Manager Schiller explains that “It takes us about 10 minutes to carry out a product changeover.” Production using the new plant is now altogether more uniform, i.e. the quality of the baked products is homogeneous, there is less wastage, and the strewing pattern is more uniform. The plant’s output performance limit has not yet been reached, so the bakery still has capacity, e.g. to pre-produce dough pieces. Using the new line does away with a total of three intermediate steps compared to the previous production method. This has increased performance while reducing personnel deployment at the same time. Schiller says “Pressure on the staff has been significantly reduced, and we have also been able to improve working conditions.”

Dough pieces deposited onto peelboards are baked off by the staff in the sales outlets. Each branch has one or more Miwe or Debag instore ovens for this purpose. The total number of peelboards in circulation is around 30,000.

Pappert’s new plant cannot produce split-top rolls. According to Kümmel: “In general, this is possible by installing a corresponding module, but there was simply no more space for it in the enlarged production unit.” So in the future Martin Schiller wants to invest in a new, compact split-top roll plant with a peelboard connection. The master baker could also imagine using robots in the production operation, e.g. to automatically stack loaded peelboards.

The growth limits of the Poppenhausen site have now been reached with the latest expansion of production and logistics. Martin Schiller says “This is why optimized workflows and automated processes on the existing area are top priority. The new Rademaker Crusto special bread roll line has helped us greatly in this respect.” +++

“Pappert goes green” is the bakery’s dynamic idea to work more sustainably. Communications and Marketing Manager Thomas Bertz explains: “We deliberately described the guiding principle as a process, not a finished construct.” This process already contains the following:

+ purpose-made refillable, reusable beakers

+ purpose-made cotton bags

+ a 20 Cent price discount for anyone who uses a reusable beaker to buy a hot drink

+ Avoiding the use of plastic carrier bags. Paper carrier bags instead

+ the to-go beakers are compostable

+At the Pro Sweets trade fair in Cologne, the cutting specialist Döinghaus presented the Ultracut Kondus, a new cutter for baking businesses that need high product throughput. The Ultracut Kondus has two cutting stations, each with its own conveyor belt. The cutting portal automatically alternates between the two stations. While cutting is taking place at one cutting station, a new product can be fed into the second cutting station. Different tray types or recipes can be run on the stations at the same time. If a multiple cutting head is used, the cutting knives automatically adjust to the product type when the stations change over. The machines are also equipped with the KnifeGuard knife protection system developed by Döinghaus cutting and more. This involves a microcontroller that checks an electro-pneumatic control loop in 35 millisecond cycles, and stops the machine instantly if specified threshold values are exceeded. This avoids the knives being significantly damaged. Depending on the arrangement of knives, the Ultracut Kondus cuts in formats including 100 x 600 mm (4 pieces on a carrier plate), 200 x 600 mm, 400 x 600 mm and 800 x 600 mm, and circular products up to 380 mm in diameter (2 pieces on a carrier plate). Smaller cake trays are passed through the machine on carrier plates.

This makes their handling easier and enables a higher product throughput. +++

++ A video at the link: https://youtu.be/HaZ3pJhmNck shows how the knife on the “Ultracut Kondus” type of machine moves apart and together again. The knife on the “Ultracut Terbia Duo” model can also be driven apart, or part of it can be moved up if necessary, as can be seen in the video at https://youtu.be/AZ87URY0CqY.

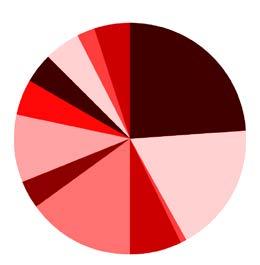

The “European Food Trends Report”, a study that demonstrates the aspects of eating and how they are linked to trends, shows that: “We no longer eat because we are hungry, but because it has become part of our identity.”

+The topic of eating has rarely been charged with as many expectations as it is today. If we are to follow and share the thoughts the authors of a study entitled “European Food Trends Report” published by the respectable Gottlieb Duttweiler Institute (GDI) in Switzerland, the reason we eat is not because we are hungry and want to experience its enjoyment, but because it has become part of our identity, because it is supposed to be fun, because it is how we communicate and because we show the world a portrait of ourselves through images of our eating. We strive to use eating to optimize ourselves and our bodies, because we hope it will

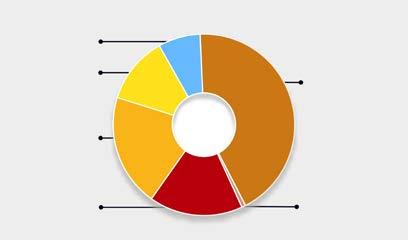

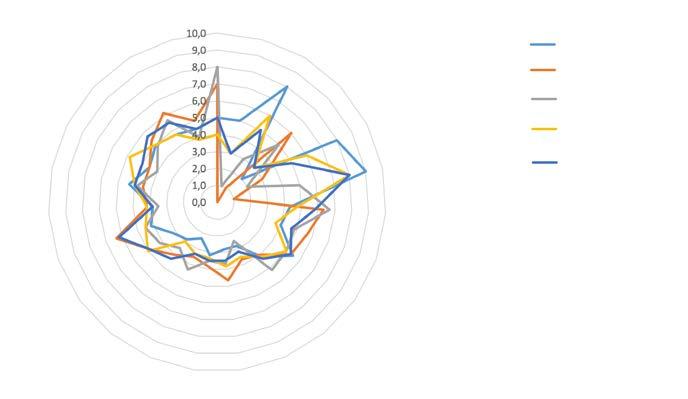

invigorate our social relationships and help us cope with the routine of daily life. From these functions, the authors have developed a Food Trend Map in which the aspects of eating (green) are shown bigger and more important when they are associated with a greater number of trends (orange).

For anyone who is puzzled by the spot labelled “Investment” in this illustration, it refers to the larger investments made by companies for some time, both in startups and in consolidating themselves, their business areas and their data pools.

Like the data produced by the GfK (Consumer Research Association), this study also shows that morals and ethics are gaining ground, although in this case they are divided into various components such as morals, sustainability and religion. “A rather new phenomenon is the active, even aggressive moralizing component of eating. Eating meat is bad, and only organic products are good enough. The food industry is a work of the Devil, and in any case one should buy products only from regional farmers.” Not only is nutritional science said to have acquitted the avoidance of animal proteins from deficiencies long ago, it is even claimed that a person can increase their life expectancy by relying only on proteins from vegetable sources. Vegetable proteins are also said to be more ecological. Nevertheless, it is said that laboratory-cultured meat and insects as a protein source are not yet generally accepted as a substitute for meat up to now.

Digestive Wellness: consumers nowadays define “health” not merely as the opposite of “sickness”, but also see it as also involving wellness and fitness extending as far as a hoped-for strategy to prolong life expectancy. Physical and mental health are seen as a function of digestion and intestinal health, and switching to special diets then becomes almost mandatory, even if there is no compelling need due to allergy or intolerance.

The trend towards “bio-hacking” goes even further. This is understood to mean an effort to gain understanding and the ability to influence

one’s own body in such great detail that one achieves the aim of “becoming the best version of oneself”, either through natural stimulation, e.g. by “natural” superfoods like chia seeds etc., by specifically blended nutrient fluids like astronaut

The fine organic retail chain Whole Foods, now owned by Amazon, has identified ten food trends for 2018:

1. Flower power – blossom fragrances such as hibiscus, lavender, elderflower etc. for drinks, desserts or as a decoration

2. Powder play – powders like matcha, cacao or turmeric are finding uses in lattes, smoothies, energy bars and even in baked products

3. Mushroom flavor – the majority of dried mushrooms have a rich flavor and are often considered to be healthy. Reason enough to use them not only in soups but even in chocolates, for example

4. Flavors of the Middle East – hummus, pita and falafel are no longer just fast food, they are part of a regional cuisine whose diversity delights people

5. Transparency 2.0 – more is better, chiefly with regard to information about raw materials, their origin, their extraction etc.

food or dietary supplements, or by metabolic function monitoring via a microchip under the skin. Modern nutritional science creates a personalized diet and links it both to the needs of the individual’s intestinal flora and to the

6. High-tech plant-based nutrition – this can also be described as ersatz, but has now become very high quality and its taste is also at a level to which even gourmets resort with a clear conscience

7. Puffs – puffed cereals contribute new textures to products

8. New tacos – these all-Mexican favorites are now available made with different raw materials, e.g. algae or filled. For good measure, they are recently also being served at breakfast time or as a dessert

9. No trash – avoiding trash by eating everything. Celery leaves, for example, turn up in salads, and so do melon seeds, and broccoli stems go into hotpot

10. New bubblyjuices – strictly speaking these are drinks with novel flavor mixtures such as mintelderberry or ginger-citrus-coffee, carbonated and marketed in bottles or cans

individual’s genome – keyword nutrigenetics. The GDI authors focus on the subject of packaging, among other things, although the debate is less about classical functions and more a question of the kind of information that can only be viewed using a smartphone or a special augmented reality headset. This would enable supermarket customers, for example, to see at a glance whether the rice has been produced under fair conditions, or the potato crisps are free from palm oil. It is true that both trends are still in their infancy, but the study says they have already become socially acceptable.

The GDI detects two megatrends in the world as perceived by consumers and which appear contradictory only when seen for the first time. Firstly Science – as the desire for the scientific penetration and improvement of end products, not by using additives but by optimizing processes. Also the creation of new products and processes, not of additives. The creation of new products and processes – e.g. molecular cuisine – also belongs in this area. Secondly there is a desire for emotionality and a sense of security by romanticizing “the way our grandparents ate” and an uncritical view of traditions. However, the GDI sees a slow disappearance of the caveats brought against the use of scientific knowledge in food production nowadays, because there is growing transparency and an avoidance of artificial additives in agriculture and the food industry, and traditional boundaries are shifting. This definitely brings the two opposites, science and romance, closer together, as if cultivation and processing are shifting back into the regional or even urban environment, and products can be ordered directly from a local producer via online platforms without any middlemen.

Mintel is a globally active market research agency whose key focuses include documenting and analyzing newly introduced products. Here are its suggestions as to the trends that will become increasingly important for the market in future years.

1. Radical openness: widespread mistrust forces food and drink producers to be completely open about their manufacturing process, ingredients and supply chain. Consumers want naturalness and the fulfillment of ethical and environmental claims.

2. Self-care: the hectic of modern life, perpetually on-call, omnipresent distrust and divisiveness in politics and the media lead many consumers to seek ways of escaping from this negativity. Therefore many people concentrate on self-care. In future, consumers will keep a lookout for ingredients, products and combinations of food and drink that ensure they obtain both the correct nutrients and the physical and emotional benefits that guarantee self-care.

Late November last year in the FiE (Food Ingredients Europe), the market intelligence agency Mintel heralded what awaits us in the superfood area in 2018:

1.Siberian chaga mushrooms: chaga mushrooms are used as a traditional medical remedy because the mushroom contains large amounts of beta-glucan, antioxidants and B-vitamins. As a rule, chaga is ground to a fine powder from which tea is brewed

2. Green banana flour: green banana flour is nothing more than flour made from unripe bananas, but it is gluten-free and rich in digestion-resistant starch

3. Hempseed: the seeds of the hemp plant contain amino-acids and proteins, and contain many nutrients, e.g. vitamin E and omega-fatty acids

4. Blue algae: algae are already “In”, and the blue ones also provide color. They are currently used in coldpressed juices, protein powder, and sometimes even in milk products.

Apropos Food Delivery, into which the GDI lumps together both food deliveries and the delivery of ready-to-eat meals from restaurants, the authors of the study estimate that this market will grow worldwide and will consolidate at the same time. It will become a market for big venture capital players, who on the one hand have mastered data technology in all its variants and can derive benefit from the data, and on the other can raise enough money to get their own logistics up and running. “Data sovereignty will be a decisive factor. Whoever has the most data about his market, his customers and his competitors will emerge victorious.” +++

3. Novel sensory impressions: texture is currently an instrument that is supposed to appeal to the senses and provide experiences that are worth being posted. The search for new experiences offers opportunities for multisensory foods and drinks that use an unexpected texture.

4. Preferred treatment: in view of the potential to save time and money, consumers try out numerous channels and technologies when buying their food and drink, including home delivery, subscription services and automatic refilling. Manufacturers and retail can use these technologies to save consumers time, effort and energy through personalized recommendations and cross-sectoral pairings.

5. The triumph of science: newly developed technologies will compete with conventional food production. Novel, more nutritious foods and drinks will become the alternative for nutrition-conscious consumers, as well as for people who look after the nutrition of mankind.

In-depth knowledge of dough technology is a key ingredient required for the production of high-quality bakery products. With over 35 years of experience in the bakery industry, Rademaker is expert in this field. This knowhow, combined with specific sheeting process expertise, overall production process insights and cost of ownership calculations, are used to develop the very best bakery equipment solutions that will work for you.

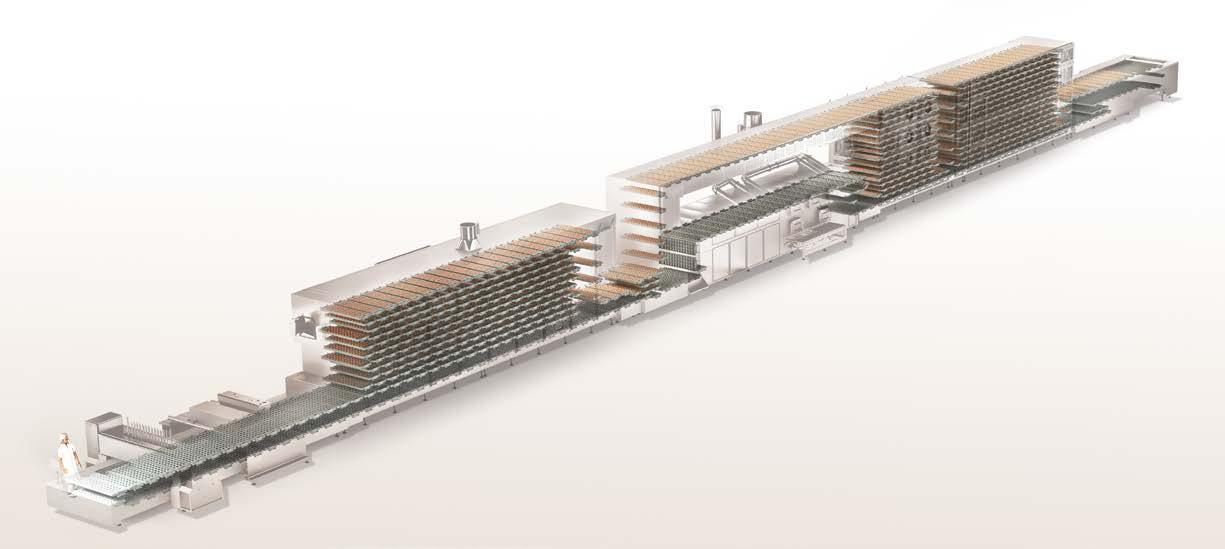

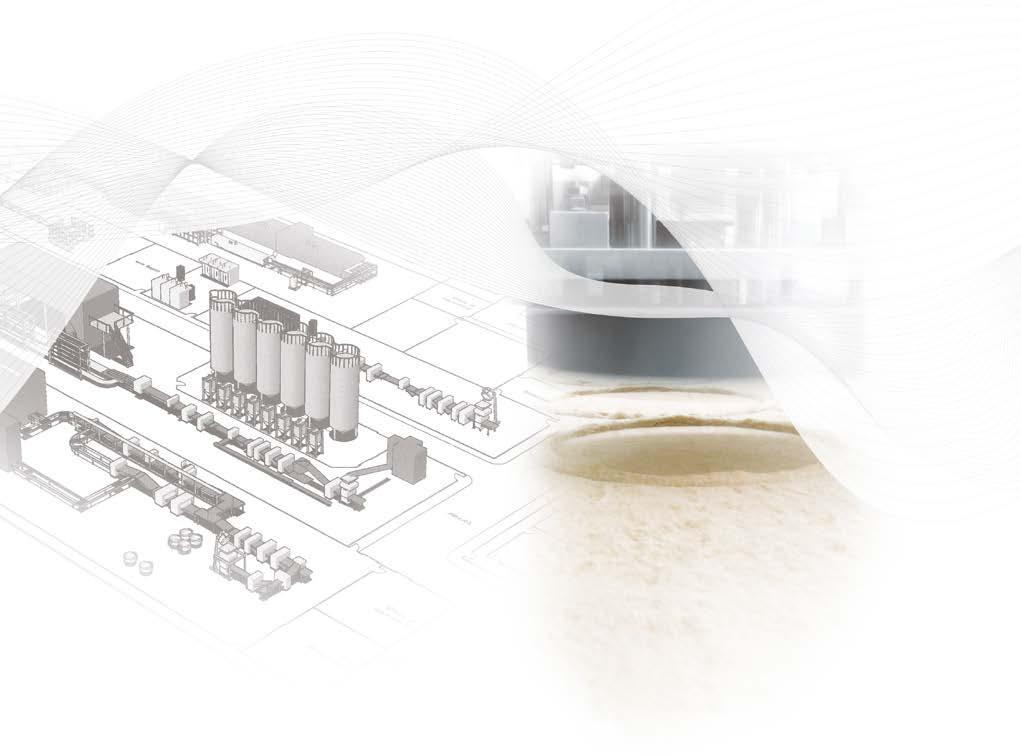

The Swiss company Jowa AG has invested more than CHF 60m. (approx. EUR 51.8m.) in the Gränichen site. A new generation of breads made from soft doughs with long dough rest times has been produced since 2017.

Migros is owned by one of Switzerland’s biggest retail chains, and Jowa AG is one of the retailer’s production companies. Jowa operates a total of eleven regional bakeries, a hard wheat mill, a pasta factory, a site manufacturing gluten-free baked products and around 100 instore bakeries in all Switzerland’s regions. Jowa is one of Switzerland’s most important food producers, with more than 3,000 employees, around 3,000 different products, and an annual production volume of over 166,000 metric tons. The company invested around CHF 60m. (approx. EUR 51.8m.) in the Gränichen site in 2017. It built a new bakery in which the employees produce a new generation of baked goods. The characteristic features of these breads are a crisp crust, a crumb with large pores, and a long shelf life. These properties are achieved by a combination of natural ingredients such as water, flour, yeast, salt and time. The other ingredient is modern industrial manufacture. The outcome is the company’s new range of breads.

Explaining the approach when planning the new production facility, Gränichen’s Site Manager Ivo Signer says: “We wanted to follow our own innovative paths when planning the new production unit.” Technology Manager Ingo Raff supported Signer in relation to a variety of questions, e.g. how modern baking technology can be used to process particularly soft doughs with a high dough yield on an industrial scale. The ground-breaking ceremony for the bakery then took place in 2015. Production already began in 2017.

Jowa uses a few prototypes for dough makeup and processing at the new site. That’s why the names of most of the bidders for the plants should not be mentioned. Explaining the concept, Ingo Raff says: “We didn’t want copies of existing concepts, so we needed plant constructors with a lot of innovative ability for the new plans.” The new production facility is now running very well, and the Gränichen site’s approx. 640 employees develop more products month by month, thus constantly enlarging Jowa’s product range. Site Manager Ivo Signer says: “We are now operating with two shifts, seven days a week.” The new line’s capacity utilization is about 60% and is steadily being raised.

The concept for the new generation of bread already starts with the use of sponge doughs and soaked grain. After preparation, these are stored in large stainless steel tanks in separate controlled-climate rooms. The doughs, made from wheat flour, water, yeast and salt have time to develop and rest for a period of six hours. Grains and other seeds, if they are included in the respective recipe process, are intensively pre-soaked. According to Ingo Raff: “Soft doughs and long dough resting times give the breads a very prominent flavor.” The baked products also stay fresh for longer due to the high TA (dough yield).

To increase dough yield, the bakery also uses a system to increase the proportion of water in the doughs during kneading, while introducing as much oxygen as possible into the doughs

at the same time. In addition to special mixers, Jowa is also testing the Bühler JetMix to exert an effect on dough quality. The JetMix offers a method for uniformly hydrating flour. Each flour particle is uniformly wetted. A sponge dough is formed in seconds. The JetMix has not yet been fully integrated into the production process. Ingo Raff says: “We are in the process of integrating this plant into the process to increase the quality of our baked products even further. By mixing flour and water uniformly in the JetMix, we obtain a sponge dough that can shorten the whole of the mixing process and make a beneficial change in the dough’s rheological properties.” (see also the report "A new modern bakery line", baking+biscuit international, Issue 05/2017).

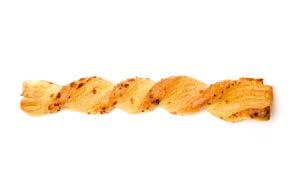

Dough make-up takes place via a dough sheeter plant to which the dough (minimum TA = 180) is transferred by a bowl tipper. A star pre-portioner divides off corresponding pieces of dough, followed by longitudinal and cross-roller stations that gently reduce the dough sheet. There are also manual workplaces, which the bakery uses as an opportunity to allow the staff to give the baked products an individual touch. Some baked goods, e.g. the “Twister”, and kind of organic quality twisted baguette, obtain their typical appearance in this way.

Nevertheless, the plant is highly automated, because Jowa wanted a very flexible plant. Thus various of the plant’s modules can be exchanged, e.g. to manufacture even round molded products rationally. The flour dusters, for example, are refilled automatically. Cutting the dough pieces is also automatic. Robots undertake this task. Altogether, only a few employees are needed to look after the plant. The plant’s hourly production capacity is up to three tons of dough, to which neither enzymes nor ascorbic acid are added. Site Manager Signer says “It really is a highly complex plant with many opportunities to intervene during the production operation.” The company is unwilling to mention further details or names, only that the latest nebulizing is used during proofing.

A thermo-oil stone oven is used for baking, to obtain a prominent baked product flavor. Around 10 tons of Italian granite are built into each deck of the tunnel oven (total 40 tons). This gives a total baking area of 280 m 2. A wood chip plant housed in a building alongside the bakery is responsible for heating the thermo-oil for the oven. Corporate Communications Manager Heike Zimmermann explains that “Around 60% of the energy is obtained in this way by burning wood chips, which are obtained from the region.” Thanks to the new wood-fired heating plant, the company saves around 3,000 tons of CO 2/year. Explaining the company’s strategy further, Zimmermann says “The aim is CO 2-neutral production by 2040.”

The employees produce around 4,500 breads per hour in the building, whose total length is around 250 meters. The entire manufacturing process, including cooling, freezing and packing, lasts more than nine hours. In two-shift operation, the new Jowa bakery has a total annual capacity of more than 12,000 tons of new-generation stone oven bread. So far, 12 different new types of bread have been delivered via the central warehouse in Neuenhof to Migros Switzerland’s 600 branches, where they are baked-off.

The baked products cost between seven and nine Swiss Francs per kilo (from around EUR 5.17 to EUR 7.75 per kilo). Today there are 12 new products. Further products are at the preparatory stage. The breads contain around 90% organic flour, and the flour originates from Switzerland. Heike Zimmermann explains that “We have expanded our collaboration with Swiss farmers to enable this 90% to be maintained in the future as well, and we also emphasize cereals and flour from integrated production.” The company wants to use the new production facility at the Gränichen site to further increase bread consumption in Switzerland. The market obviously exists, and the premises as well: space for the second line is already available. +++

The baking industry in Switzerland is dominated by two big retail groups, Migros and Coop, both operating their own factories to supply their markets with baked products.

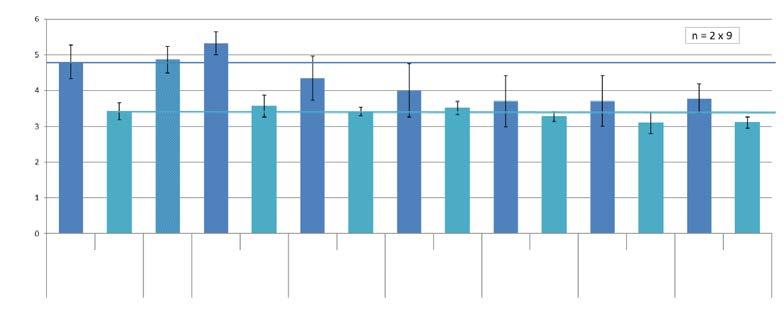

+In a few retail outlets, both Migros and the Coop also operate what are known as “instore bakeries” that produce, decorate and bake on the spot. Furthermore, Migros and Coop also buy in specialties from other manufacturers. The major suppliers have a share of the Swiss baked goods market lying between 75% and 90%, depending on the definition and viewpoint. The task of the annual sector review is to focus on how artisan businesses in Switzerland are faring alongside the majors. This review is prepared by the Swiss Association of Master Bakers & Confectioners (SBC) in collaboration with the SBC Trustee and Corporate Consultancy for Bakers and Confectioners, and is based on actual figures for around 500 of the Trust’s clients in 2016 and surveys by the SBC and others. The Association represents a total of 1,500 commercial operations with their own sales business, and 780 inactive members, mostly former bakers. This means the figures are probably representative of the Swiss artisan sector.

The general economic situation report stresses problems that are currently occurring in other European countries as well: shortages of skilled labor, regulatory density, changed consumer behavior, rising raw materials prices and labor costs. With their talk of “homeland, origin, artisan”, the “market trends” also sound very similar.

The Association’s membership trend clearly shows that multibranch operating has also commenced among artisans in Switzerland. Its membership list in 2010 still included just short of 300 colleagues more than in the previous year, whereas the number of branches they operated alongside their main business in 2017 was more than 300 higher.

The total number of active businesses reported in the SBC’s statistics in 2012 was 1,660. Of these, 57.2% or 950 generated less than SFR 1 million of annual turnover, if trade goods business is not included in the calculation. The total number of active businesses in 2016 was 1,563, although of these, only 42.7%, i.e. 667 businesses, were still to be found with this turnover volume. Thus the difference in this turnover category is 283 businesses, although the total reduction among the SBC’s active members was only 97 departures. Thus nearly twice as many must have successfully broken through the one million boundary.

This calculation based on basis figures from the sector review clearly shows that moving up in the turnover category extends across all the orders of magnitude, although the number crossing a boundary becomes smaller. Anyway, the group comprising those businesses with annual turnovers of more than CHF 4 million grew by 44.3% in these five years.

The change into the next higher turnover category was in no way associated with a large boost in multi-branch operations or increased opening of cafés linked to main businesses. The SBC statistics show only just 202 businesses that operated a branch in 2016. The figure in 2012 had been 178. An increase of more than 10% in percentage terms, but actually just 24 businesses.

This indicates that even businesses operating only a main outlet were able to increase their annual turnover so far that they moved up into the next higher turnover category. However, a more exciting finding by far is that of the 163 additional branches throughout the whole of Switzerland reported by SBC members in 2016 compared to 2012, the majority were opened by businesses that already operated branches. Therefore, in a similar way to Austria and Germany, “Local Heroes” also evolve in Switzerland and dominate entire towns or regions with their networks of branches.

There was even a downturn in number of those that not only operate the sale of baked goods but also provide for consumption on the premises in the form of a café. Although the percentage stayed approximately the same, their total number fell, and the number of café operators among the bakers/confectioners also dropped by at least 29 businesses. This coincides with the impression gained in several journeys that up to now only a few artisan bakers have been able to acquire a taste for the fixed position out-of-house market, and are instead expanding their locations into a popular rendezvous for various consumer groups. A range of services certainly exists for customers who take a quick pot of muesli or a filled sandwich with them on their way to work or to school. In many cases, however, it is clearly apparent that they identify only slightly with this part of their business, and prefer to offer traditional snacks rather than stay ahead in the rapidly changing world of food consumption styles. If anything, exceptional instances of gastronomic competence like Bachmann in Luzern or Füger in Steinach confirm the rule. +++

+

Modular principle

ovens at FRITSCH GmbH, explains the design: “We build wood-fired ovens one above another like a cassette deck.” It would even be possible to replace individual hearths, e.g. if there is a fault. Explaining the system’s additional benefits, Barth says: “The modular principle allows customers to start with just two or three hearths, and subsequently enlarge the oven to a maximum of six hearths depending on demand.”

The high environmental requirements are another challenge –keyword: fine dust pollution. These must be complied with, of course. Two entirely newly developed and patented burners per hearth ensure the wood pellets are burnt as residue-free as possible, thus fulfilling the environmental authorities’

requirements. The baking chamber is directly fired until the temperature specified in the baking recipe is reached. Reto Weber explains: “We were able to do without additional filter plants due to the good initial values and optimization when burning pellets left in their natural state.”

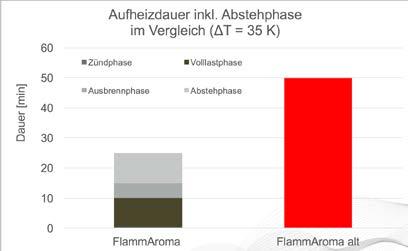

The heating-up time of the new Flamm Aroma Turbo is considerably improved compared to its predecessor model. For example, the output capacity of the new oven generation is double that of ovens dating from 2015. Fritz Barth explains that “As well as new burners, we have entirely redeveloped significant parts of the plant. The plant has also been designed for continuous operation in an industrial production unit.” The controller is intuitive, and coordinates heating up as well as loading and unloading the hearths. A loader/unloader manufactured by Ahlborn is available for this. A built-in dust/ash vacuum cleaner cleans the baking chamber before each loading process. After unloading baked goods from the hearth, sensors also check whether any baked product remains in the oven. If this happened, it could be severely overheated during the next heating process. Thus potential damage to downstream plant components is excluded. Moreover, additional smoke alarms are installed on the loader to enable a fast response if the need arises. A special feature of the baking chamber is the refractory clay that is used. This is pressed, not cut, thus forming a very smooth baking surface. Each hearth has a 3.6 m2 baking area. The loading technology is fully automated. Secured by a cage, the technology drives on rails to the required position on front of the four oven towers, and starts the loading or unloading process. There are no production employees to be seen in front of the ovens. Before the baking process, the dough pieces are processed by hand on a manual workbench at the proofer exit. Depositing dough pieces for the oven loader takes place automatically. The manual workbench can also be driven up to the manual workbench via software, depending on the requirement and product.