Kori Construction scores

hattrick with leading care provider Care UK BREAKING GROUND:

Japanese Knotweed

Limited for trusted invasive plants and asbestos removal services

SRL TRAFFIC SYSTEMS: PROMOTING SITE SAFETY WITH INTELLIGENT TRANSPORT SOLUTIONS

2024 CONSTRUCTIONMAGUK.CO.UK UK Roofing Awards 2024 winners announced

July

LATEST

MILESTONE IN MANCHESTER AIRPORT TRANSFORMATION PROGRAMME

EMPOWERING

WOMEN IN BRICKLAYING

Building confidence together

Construction insurance tailored to you.

Gallagher offers the strength and positioning of a global insurance group, combined with the personalised care and attention of a local UK broker. With a rich history dating back to 1927, we believe we have the expertise and experience to meet your construction insurance needs.

CONNECT WITH A SPECIALIST

For further information, please scan the QR code.

Arthur J. Gallagher Insurance Brokers Limited is authorised and regulated by the Financial Conduct Authority. Registered Office: Spectrum Building, 55 Blythswood Street, Glasgow, G2 7AT. Registered in Scotland. Company Number: SC108909. FP909-2024 Exp. 06.06.2025. © 2024 Arthur J. Gallagher & Co. | GGBRETUK100676

TODAY.

AJG.com

The Gallagher Way. Since 1927.

Editor Maria Lapthorn

Editorial Assistant Anna Startin editorial@constructionmaguk.co.uk

Production/Design Laura Whitehead laura@constructionmaguk.co.uk

Accounts Richard Lapthorn accounts@constructionmaguk.co.uk

Sales Executive Hannah Marshall hannah@constructionmaguk.co.uk

Circulation Manager Leo Phillips subs@constructionmaguk.co.uk

Tel: 01843 808 106

Website: constructionmaguk.co.uk

Twitter: @constructionukm

LinkedIn: @constructionmaguk

Cover image by Olga Lioncat 48 Every effort is made to ensure the accuracy and reliability of material published in Construction UK Magazine however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors. No part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher. 11 21 24 30 06 34 44 08 July 2024 Contents 06 £81.5 Million Scheme Completes at Glasgow’s Candleriggs Square 08 Parliamentary Under Secretary of State Lord Cameron visits Clyde Waterfront & Renfrew Riverside 11 Kori Construction scores hattrick with leading care provider Care UK 14 Inaccurate Installation: A Route to Non-Compliance 21 Breaking Ground: Empowering Women in Bricklaying 24 Building the market for in-roof solar, by Simon Garbett 30 How to build a learning and development programme for the construction sector 34 The Retrofit Academy launches new Retrofit Designer qualification 41 Construction consumables supplier, Grayson, hires regional manager for the south-west 44 GROHE wins Sustainable Supplier of the Year Award 48 Streamline Site Security with a Unified Plan 36 36 Fuel-flexibility will help constructors follow the CLC’s route map to 2035 Published by: Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB

editor@constructionmaguk.co.uk

Construction UK Magazine - July 2024 03

CADDICK TO TAKE FORWARD HORWICH AFFORDABLE HOMES DEVELOPMENT

Caddick Construction has been appointed to deliver Rivington Chase, working on behalf of development partners, Bolton at Home and Irwell Valley Homes, to build 116 new homes in Horwich.

Work at the former Loco Works will see Caddick resume work to regenerate the former railway works, where construction was previously being delivered by Lane End Developments, which went into administration in April 2023.

Construction work will see Caddick build 38 family homes across eight terraces of four and fivebedroom homes, and two four-storey developments totalling 78 apartments. All homes will be available for affordable rent and shared ownership.

Rivington Chase forms part of a £262m regeneration scheme for which outline planning permission was granted in 2015 for 1,700 homes and additional heritage, educational, retail, leisure, health and well-being services. This includes the expansion of Chorley New Road School to serve the new homes.

Caddick’s presence in Horwich also includes the construction of a new health and wellbeing hub on behalf of United Healthcare Developments, which will provide a range of medical services for the local community.

Caddick’s appointment to Rivington Chase marks the second project to be delivered on behalf of Bolton at Home following the completion of a new extra care development in Little Lever, including 62 one and two-bedroom apartments and six bungalows for those aged over 55 years.

ESH CONSTRUCTION APPOINTED TO DELIVER £2.1M RETROFIT SCHEME ACROSS TEES VALLEY

North of England contractor to upgrade up to 120 properties after local authorities receive funding.

Esh Construction has been appointed to retrofit homes across the Tees Valley after local authorities secured up to £2.1 million of Home Upgrade Grant Phase 2 (HUG 2) funding from the Department for Energy, Security and Net Zero.

The project will include improved ventilation, loft insulation, cavity wall insulation, air source heat pumps, smart heating controls and photovoltaic panels, with each property receiving bespoke upgrades.

All properties will undergo a retrofit assessment to establish which measures will improve them to an Energy Performance Certificate (EPC) C rating. Esh, alongside its specialist supply chain, will carry out a pre-design technical survey which will allow the Retrofit Designer to complete a final design.

Esh Construction is a TrustMarkaccredited contractor and partners

with a PAS 2030 and PAS 2035 compliant supply chain. The firm is a PAS 2030 certified installer for cavity wall insulation, including that installed in party walls, energy efficient glazing and doors, external wall insulation (site rendered external wall insulation systems and pre-finished external wall insulation systems) and loft insulation.

The Home Upgrade Grant, a government-funded scheme by the Department for Energy and Net Zero, was introduced to deliver progress on statutory fuel poverty targets for England by 2030 and UK Net Zero targets by 2050 and focuses on upgrading inefficient off-gas grid heated homes to provide cleaner and more sustainable heating solutions.

The HUG 2 project prioritises homes with an Energy Performance Certificate (EPC) rating of D, E, F, or G. Low-income households who own their home can get upgrades fully funded within the relevant cost caps and do not have to contribute.

04 Project News Construction UK Magazine - July 2024

WORK UNDERWAY ON FIRST HOMES AT NEW GARDEN SUBURB IN HERNE BAY

Construction work has started on the first phase of a new 800-home garden suburb near Herne Bay.

Greenwood Gardens will feature a mix of apartments and houses, commercial space, areas of green open space and allotments on an 88acre site off the A299 Thanet Way.

The project is being delivered through a joint venture between national housebuilder Countryside Homes and leading social enterprise Places for People. The scheme will also include the delivery of the Herne Relief Road, a spine road running through the development which will link Canterbury Road to the east with Bullockstone Road to the west.

There will be a range of one and twobedroom apartments and two, three and four-bedroom houses, with the first properties due to go on sale in late summer 2024. 65 of the homes will be sold on the open market with the other 67 properties being made available for shared ownership.

Alex Hodge, associate development director for Countryside Homes, said: “This is an extremely exciting project which will create an attractive and sustainable mixed-use community on the edge of Herne Bay. Our partnership with Places for People will see us deliver a wide variety of high-quality housing which will be genuinely affordable for local people seeking to get onto the property ladder. We are expecting to hand over the keys to the first completed homes at Greenwood Gardens this autumn and anticipate that the overall scheme will be completed by 2033.”

LATEST MILESTONE IN MANCHESTER AIRPORT TRANSFORMATION PROGRAMME AS VIDEO SHOWS HUGE

NEW LINK BRIDGE LIFTED INTO PLACE

A stunning timelapse video shows the moment that a colossal 216-ton, two-storey link bridge is delicately manoeuvred into place at Manchester Airport’s Terminal Two, as work continues apace on a £1.3bn programme to transform and modernise the terminal.

The bridge will connect the existing terminal building to a new ‘pier’ currently under construction, which will offer extra aircraft gates, stands and seating.

More than 270 pieces of steel went into constructing the new bridge, comprised of metal decking and 150mm concrete slab flooring. The 90ft long, 33ft high bridge was pre-assembled on the airfield over the course of three months and then moved into its final place last week using a giant Shelf-Propelled Motorised Unit, a process which took eight hours.

More than 270 pieces of steel went into constructing the new bridge, comprised of metal decking and 150mm concrete slab flooring.

The Manchester Airport Transformation Programme (‘MAN-TP’) is scheduled for completion next year, and will see Terminal Two more than double in capacity. Around three quarters of the airport’s passengers will use the new-look terminal when it is completed. Firms working on the link bridge included Mace, which is overseeing the second phase of the MAN-TP project, and its supply chain partners, Martifer, Bethell, AMCO, LPL Construction Services and DGP.

05 Project News Construction UK Magazine - July 2024

CONSTRUCTION UNDERWAY ON BOLTON’S FIRST EVER NET ZERO HOMES AS PART OF FARNWORTH OVERHAUL

Bolton’s first ever operationally net zero homes are being built as part of a radical shake up for Farnworth town centre.

It’s been revealed that Capital&Centric’s Farnworth Green – a re-boot of the outdated precinct into a town centre neighbourhood –will feature the company’s first ever operationally net zero homes.

Several of the townhouses currently under construction on site are being built to be emission free, slashing energy bills for their residents and supporting Bolton’s Climate Change Strategy and net zero carbon ambition.

The timber frames of the net zero rental homes can be seen taking shape on site. When complete they’ll be super insulated to make them energy efficient, with reduced air leakage and triple glazed windows. They’ll also boast more solar PV panels and air source heat pumps to supply hot water.

The homes are the first low carbon testers for the social impact developer’s ‘Neighbourhood’ brand, which aims to bring city centre style

design-led homes into suburban communities. Once demonstrated, the intention is to role the approach at other brownfield sites across Greater Manchester and beyond.

Capital&Centric’s overhaul of the town centre is on track to be open by the end of 2024, with the current focus on attracting new operators to set up shop in the town.

Farnworth Green is intended to set a new blueprint for the future of town centres in a time where online shopping dominates. The trailblazing approach – supported by the council and Greater Manchester Combined Authority – is aimed at striking a balance between homes, alongside shops, retail spaces, community facilities and green spaces.

The end goal is to generate a buzz and put the town centre back at the heart of the community.

The progress follows the development reaching its highest point early this year. On a visit to the site, Mayor Andy Burnham hailed the progress to put town centres back at the heart of community life.

£81.5 MILLION BUILD-TORENT SCHEME COMPLETES AT GLASGOW’S CANDLERIGGS SQUARE

The £300 million transformation of Candleriggs Square in Glasgow’s Merchant City is continuing apace following the completion of the second major building on the site – a 346-homes build-to-rent scheme, forward funded by Legal & General (L&G). Main contractor Graham Construction has delivered the practical completion of the £81.5 million scheme, allowing L&G to progress with the internal fit-out of the building before the first residents move in later this summer.

Developed by a joint venture between Drum Property Group and Stamford Investments, the 3.6-acre Candleriggs Square site is regarded by many as the last and most important piece of Glasgow’s Merchant City regeneration jigsaw.

Designed to meet the increasing demand for high-quality city centre rental accommodation in Scotland, the 325,000 sq. ft L&G scheme provides 346 apartments together with a range of retail and commercial units at ground floor level creating an attractive and accessible public realm.

An entrance lobby opens onto Glasgow’s Trongate, providing direct access to a communal landscaped courtyard at the first-floor level, while a range of roof terraces provide spectacular views across the city.

The building’s completion was marked by the release of drone footage showing how the finished homes form a spectacular cornerstone of the Candleriggs Square regeneration.

Drum and Stamford’s joint venture launched the ambitious £300m plan to transform Candleriggs Square when they first bought the site in March 2019. Plans include a high-quality mixed-use scheme combining homes, offices, hotels, restaurants and local amenities, together with landscaped open spaces and accessible walkways, with a new public square at its heart.

06 Project News Construction UK Magazine - July 2024

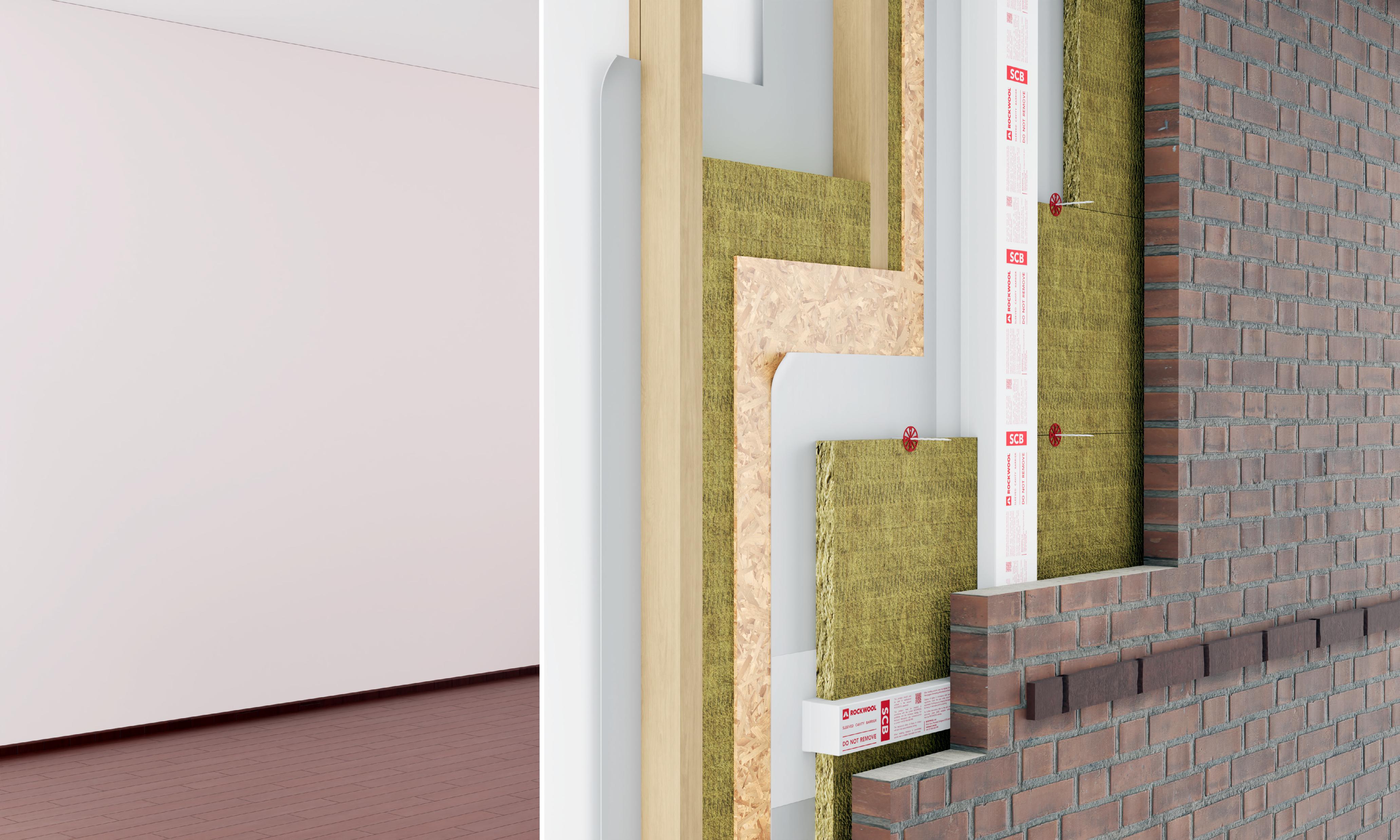

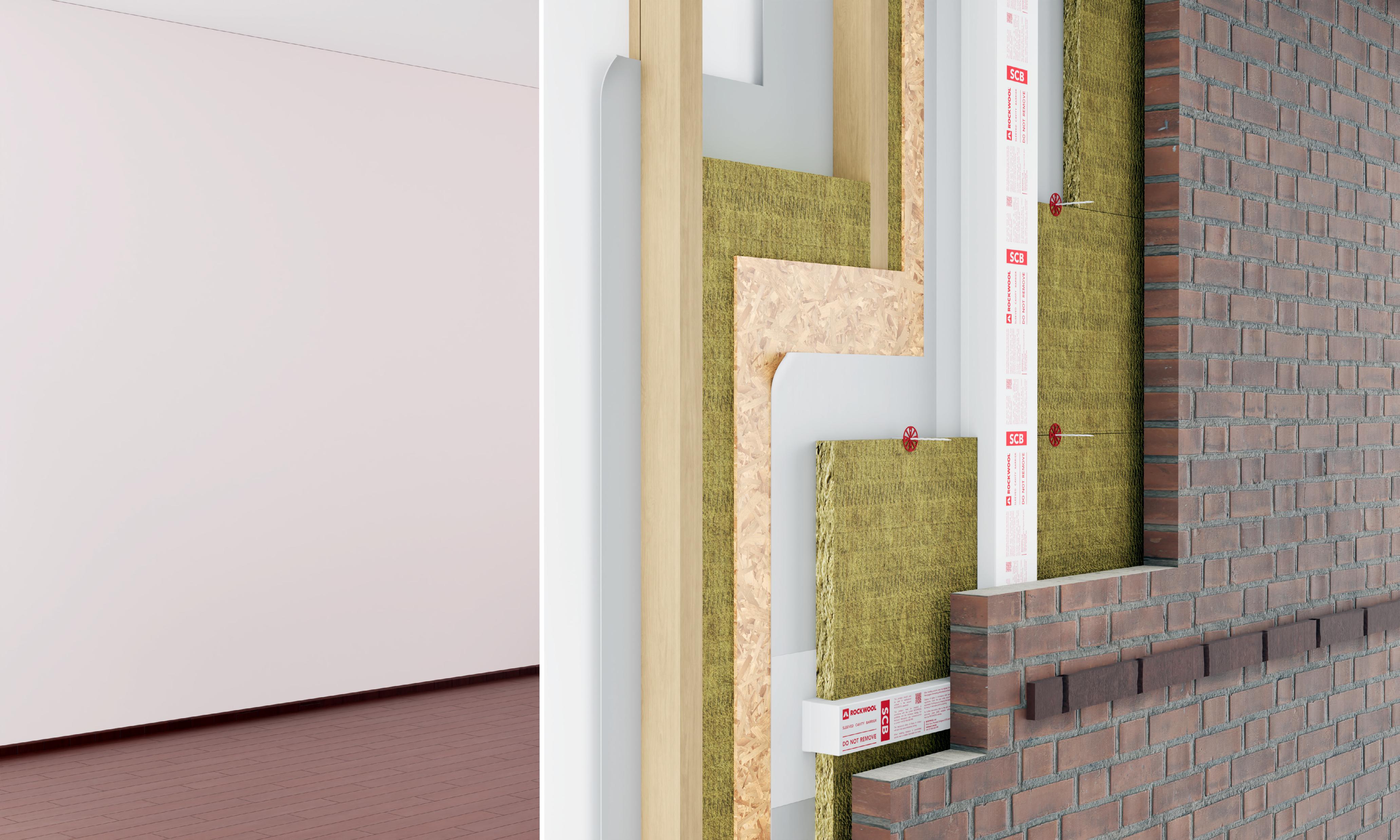

Introducing ROCKWOOL SCB

from a streamlined, EN-tested range.

ROCKWOOL SCB is suitable for use in masonry, timber frame and steel frame cavities:

• Tested to BS EN 1366-4:2021

• 110mm and 200mm widths

• Suitable for cavities up to 290mm

• Horizontal and vertical applications

• Fire rating up to E120, I45 subject to the application

ROCKWOOL SCB replaces existing TCB and PWCB products as of 15th May 2024.

Find out more: rockwool.com/uk/SCB rockwool.com/uk

RECYCLED MATERIALS DRIVE SUSTAINABLE CONSTRUCTION OF NEW M1 EMERGENCY AREAS

Recycled and sustainably sourced aggregate material totalling over 300,000 tonnes is being used on a 28mile stretch of the M1 near Sheffield as part of the national emergency area retrofit (NEAR) programme.

CR Civil Engineering is delivering for SMP Alliance and on-site assembly lead Costain on the scheme along the existing M1 smart motorway in South Yorkshire and Derbyshire. Currently, work is taking place between M1 junctions 28 and 35a, progressing in phases, with eight emergency areas (EA) under construction between junctions 30 and 31 since February and a further 21 EAs between junctions 28 and 30 under way since April.

The recycled and sustainably sourced aggregate materials being used for these works include Class 1A and 1A1 fill, pipe bedding and surround, capping material and Recycled Type 1. These materials can include a mixture of recycled aggregate such as crushed concrete, brick and blockwork retrieved from demolition projects.

To help make the operations as efficient as possible, innovative GPS technology is being used on the excavators carrying out the earthworks and drainage installation. Design models were input into the machine software to enable the operator to dig to the desired line and level, with the GPS providing an accurate guide. This technology also negates the need for an engineer or

banksman near the machine, making the operation safer too.

Additional safety technology introduced to the project included zonal working software called ‘safety shield’. This enables equipment to be programmed with the required safety parameters. It warns the operator should anyone enter the exclusion zone that has been established. A short video is recorded to show the person entering the exclusion zone, and this helps to reflect trends, allowing the team to monitor behaviours and further minimise the risk of site accidents.

Works are expected to be completed on these particular M1 schemes by the end of September 2024, with the wider NEAR programme to be delivered by the end of March 2025.

PARLIAMENTARY UNDER SECRETARY OF STATE LORD CAMERON VISITS CLYDE WATERFRONT & RENFREW RIVERSIDE

The first opening road bridge across the River Clyde has been hailed as ‘a gamechanger’ as politicians visited the site in Renfrewshire.

GRAHAM and Renfrewshire Council Leader Iain Nicolson welcomed UK Government Parliamentary Under Secretary of State Lord Cameron to see the first section of the road bridge which was installed last week.

Working on behalf of our client Renfrewshire Council the new bridge is part of the £117million Clyde Waterfront and Renfrew Riverside project, funded as part of the £1.13billion Glasgow City Region City Deal.

Since construction has commenced, GRAHAM has supported more than 950 jobs and generated hundreds of subcontract and supplier opportunities, many of which were taken up by local Renfrewshire businesses.

The new Renfrew Bridge will connect Renfrew with Clydebank and Yoker and open up work, health, education and leisure opportunities on both sides of the Clyde – with the potential for thousands of additional jobs, fresh investment and new developments brought to the riverside.

In addition to the new bridge, the project will create additional connecting roads, cycling and walking routes which will link Inchinnan Road in Renfrew with Yoker Railway Station, using the new Renfrew North Development Road.

The bridge is due to be completed ahead of schedule and be fully operational for pedestrians, cyclists and motorists in Autumn 2024.

08 Latest News Construction UK Magazine - July 2024

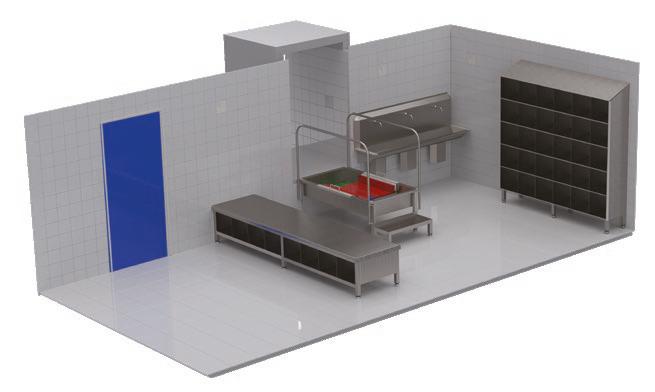

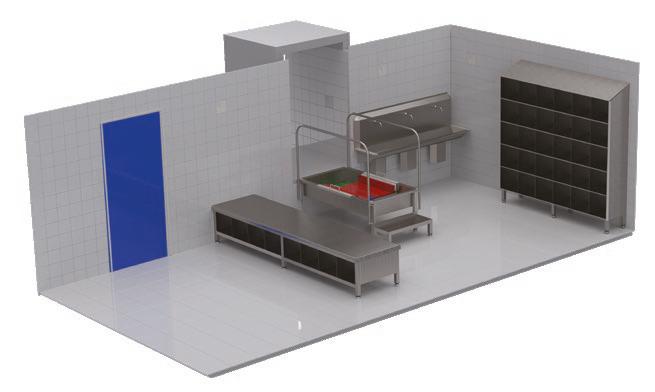

Contact us Call now on +44 (0)1603 788 833 or email mail@teknomek.co.uk www.teknomek.co.uk Book a site visit Manufacturing Designing your layout Take the easy route to hygienic room design and enquire about our comprehensive design service. We will work with you to design bespoke room designs and help integrate Teknomek’s high-quality furniture and equipment into your hygiene critical build projects. Teknomek are the UK’s premiere specialist supplier and manufacturer of hygienic stainless steel furniture and equipment. Make hygienic room design easy with Teknomek.

FARRANS OPENS NEW OFFICES IN SLIGO AND LETTERKENNY AS LONG-TERM CONTRACTS SECURED IN WEST OF IRELAND

Leading civil engineering and building contractor Farrans Construction has opened new offices in Sligo and Letterkenny following the signing of a number of new contracts which will provide a secure pipeline of work in the west of Ireland for the next seven years.

Both offices will be strategic hubs from which work across the counties in the north west of Ireland will be managed.

Farrans was recently awarded the North West region under Uisce Éireann‘s new Water and Waste Water Multi-Supplier Framework, responsible for Donegal, Sligo, Roscommon, Galway, Cavan, Leitrim, Monaghan and Mayo.

The company already has 70 direct staff and over 200 subcontractor staff engaged in this new contract, with 25 squads on the

ground working on the installation of new water mains, the rehabilitation of existing mains, leak detection and repairs. Waste water and connection and developer services will commence soon.

John Murphy, Utilities Director at Farrans Construction, said: “Our focus in Sligo and Letterkenny will be on building excellent relationships with local suppliers and council authorities.

“The demand for skills in the water sector in Ireland is continuing to grow.

“We will soon be launching a recruitment drive to bring in some of the best civil engineering talent and, with the security of a long-term pipeline, we can offer guaranteed work in the area for years to come.

“This will likely appeal to people who might want to move back to Ireland, to come home. It’s a competitive recruitment market at the moment however we know that we offer an unrivalled personal development and training programme which is why we were recently named Engineers’ Ireland CPD Employer of the Year.”

UPP SELECTED AS PREFERRED BIDDER FOR MAJOR DURHAM UNIVERSITY COLLEGE ACCOMMODATION PROJECT

UPP, the leading provider of on-campus student accommodation infrastructure in the UK, has been selected to be the Preferred Bidder to develop, in partnership with Durham University, a detailed scheme proposition for the refurbishment of the College of St Hild and St Bede and the development of new college accommodation at the Leazes Road site.

One of the key drivers for this project for both Durham University and Durham City is to increase the proportion of students living in high quality

Durham University owned or managed accommodation.

UPP is the UK’s only multi-discipline, full-service Design, Build, Fund and Operate (DBFO) company that is dedicated to the Higher Education sector. With over 25 years of experience operating in the sector and having invested over £3.5bn, UPP has a strong track record of delivering next generation campuses at scale.

UPP will now continue to work with Durham University to refine the proposal

with the scheme currently scheduled to start in 2025.

Elaine Hewitt, UPP CEO said: “UPP is delighted to be working on this incredibly important project at Durham University. This scheme is about respecting, protecting and enhancing the history and heritage of the university for the benefit of future students.

“We are excited to co-create an environment that puts student experience at its heart, building on each unique college identity.”

10 Project News Construction UK Magazine - July 2024

(L-R) Gerraint Oakley, Jaswant Singh Birdi, Krishna Birdi, Adam Sharpe

MAYOR AND MAYORESS OF COVENTRY VISIT AFFORDABLE HOMES SITE

The Mayor and Mayoress of Coventry have been to visit a site where nearly 200 affordable homes are being built.

The development at Sphinx Drive by the Sphinx Sports and Social club is managed by Platform Housing Group who are the largest social landlord in the Midlands.

Constructors Countryside Partnerships, part of Vistry group, have begun work to deliver 196 affordable homes over the next few years which will be available for both social rent and through shared ownership.

Councillor Jaswant Singh Birdi and Krishna Birdi joined members of Platform’s development team alongside people from Countryside

to look at plans for the land and see how building work was progressing.

Adam Sharpe, Managing Director for Countryside Partnerships said, “I am delighted to celebrate the start of work on these much-needed family homes that we are building on behalf of Platform Housing Group.

“Both organisations are committed to providing high-quality, affordable homes at Sphinx Drive. Together we will transform this site into a fantastic place to live and provide real opportunities for people living in the area to own a new, affordable home and become part of a vibrant new community.”

The homes are set to be delivered over the next two years.

KORI CONSTRUCTION SCORES HATTRICK WITH LEADING CARE PROVIDER

Main contractor Kori Construction has scored a hattrick with one of the UK’s leading care providers. The company, based in Corby, Northamptonshire, has been appointed to a deliver a third care home scheme for Care UK, on a former industrial site in Saffron Walden.

The £10m, 70-bed scheme is part of a larger development on the disused Pulse Packaging site in Radwinter Road, which will also include a Lidl supermarket and retirement living accommodation. Work started on the care home part of the project in April this year, with completion set to take place in winter 2025.

Jordan Connachie, Managing Director of Kori Construction, said it was an honour to have been chosen as Care UK’s construction partner for a third time.

Previous projects Kori Construction has been appointed to by the care provider include a 75 bedroom care home in Yate near Bristol which specialises in dementia and residential care, and a 68 bedroom scheme in Thame, Oxfordshire, which was completed in summer 2023.

The three-storey care home has been designed in line with the existing residential buildings that surround the site.

It will consist of light brown multi-brick masonry detailing, light and neutral vertical and horizontal cladding, and a dark tile roof to create a brokenup roofscape, with hips and gables at varying heights across the roof to break up the scale of the structure and provide a more traditional residential appearance. It will also feature landscaped gardens and outdoor spaces for residents to enjoy.

11 Project News Construction UK Magazine - July 2024

CGI image of Care UK’s latest care home in Saffron Walden

CONQUIP BULKX

The Conquip BulkX is a revolutionary excavation methodology that significantly enhances the efficiency and safety of construction projects. Designed and manufactured in-house to quality British manufacturing standards, BulkX handles large volumes of material, discharging into muck bays or directly into muck away trucks, rapidly and safely.

The Smart-Release BulkX is the latest addition that Conquip launched this year.

Fully-electric and remote-operated, this versatile system reduces plant-people interface and can be discharged in muck bays, barges, trucks or stockpiles.

Potential uses and applications

The dynamic discharge options that are available when using the Smart-Release BulkX make the skip ideal for a wide range of applications.

A maintenance-free, low energy consuming electrical system, that is unable

The dynamic discharge options that are available when using the Smart-Release BulkX make the skip ideal for a wide range of applications.

to incur fluid leaks, unlike similar hydraulic systems, ensures the Smart-Release BulkX is suitable for the comprehensive dig programmes of major excavation projects.

• BRIDGE DECK REPLACEMENT

• SHAFT SINKING

• TUNNELLING PROJECTS

• BASEMENT EXCAVATION

The key benefits

• ALWAYS OPERATIONAL

Deliver increased productivity on-site with a system that’s reliable and supported by Conquip engineers.

• SAFE & COMPLIANT

Remote operated eliminating the need for personnel to be near the Smart-Release BulkX when it is discharging. Designed by Conquip’s experienced Mechanical Engineering Team to meet all regulatory standards.

• TRIED & TESTED

Conquip’s engineers have undertaken rigorous testing over the past two to three years, both in test environments and on major infrastructure projects, including on HS2.

12 Construction UK Magazine - July 2024

REPAIR & REFURBISHMENT

KEEPING YOUR KIT WORKING, SAFE AND COMPLIANT FOR LONGER

DIRECT FROM THE SOURCE:

TRUSTED REPAIR AND REFURBISHMENT

Regular maintenance combined with organising the refurbishment and repair of equipment at the earliest possible date not only protects site personnel but it also reduces the cost of scrapping unsafe kit, which prevents unnecessary expenditure on replacements and improves sustainability by using existing equipment for longer.

Conquip Covered offers a comprehensive range of repair and refurbishment services to help keep your equipment newer for longer, saving you time and money.

What can you expect with our Repair and Refurbishment service?

▪ Repairs carried out on your site by Conquip’s expert engineers.

▪ State-of-the art workmanship on-site or at our workshop, with equipment cleaned during the work

▪ No third-party maintenance: all work carried out by the manufacturer.

▪ Easy booking process, either on the phone or via our website.

▪ Hire a replacement whilst your equipment is being repaired.

What happens during a repair or refurbishment?

▪ During your booking there will be a:

▪ Visual inspection by our in-house engineer.

▪ Manual operational inspection.

▪ Our engineer will repair or replace what needs doing, where possible, on the same day, or it will be sent back to our workshop.

▪ We will recertify the equipment and notify you of the outcome.

Our Alton (Hampshire), Stoke-on-Trent (Staffordshire) and Norwich (Norfolk) depots are all kitted out with state-of-the-art workshops to carry our equipment repairs and spray booths to ensure your kit is refurbished to the highest quality and is returned to site as good as new…or as close as possible!

GET IN TOUCH

Speak to a member of our friendly customer support team to learn more on how we can help you make after-sales support a proactive priority.

Call: 0333 300 3470

Email: support@cqegroup.com

Visit: www.cqegroup.com/uk/conquip-covered/

WE MANUFACTURE. YOU USE. WE SERVICE

Safety, Security & Fire Prevention

INACCURATE INSTALLATION: A ROUTE TO NON-COMPLIANCE

The performance and reliability of fire doors can be undone by inaccurate hardware installation. Karen Trigg of Allegion UK explains the significance of installer competence and how responsible persons should approach fire door hardware fittings to ensure lives aren’t put at risk.

For a building to be considered fire safe, it must have functioning fire doors. A crucial element of passive fire protection, fire doors are recognised as a legal requirement in non-domestic properties and houses in multiple occupation (HMOs), and as such, careful attention is frequently placed on standardised testing, specification and ongoing maintenance.

Perhaps less understood is the importance of accurate door hardware installation. Certified fire doors are tested with - and are reliant on - several components, including hinges, locks, latches and door closers for example. Though, where ironmongery products must be CE or UKCA marked, Certifire accredited and tested under separate standards, there is less regulatory emphasis placed on fire door installation specifically.

Should hardware be improperly or inaccurately fitted to a fire door, its fire resistant capabilities become compromised, leaving a building and its occupants at risk. Without functional hardware components, a fire door is rendered useless and with onus being placed on responsible persons, decision

makers simply can’t afford to neglect any stage of fire door safety - including installation.

Competence and collaboration

Installation remains a pain point for the fire safety industry. Evidence suggests that incorrect installation is one of the leading causes of fire door failure, and despite a wave of regulatory framework updates in other areas, there still remains a level of ambiguity towards the proficiency required for fitting fire door hardware.

As per the Fire Safety (England) Regulations 2022: fire door guidance, it is assumed that responsible persons possess evidence that the design, specification and installation of a fire door is adequate for its location. Section 6.7 of the legislation expands on installation further, stating that upon inspection, if there is any doubt that

a fire-resistant flat entrance door has been replaced, the resident will need to confirm that the new fire door has been ‘installed by a competent person’.

It’s clear then that fire door installation is a critical aspect of our built environment, yet, there is currently no legal requirement for fire door installers to possess a specific qualification or accreditation. For some, this presents a misconception that fire doors and their hardware can be installed by anyoneafter all, how is ‘competence’ defined? But in doing so, decision makers are often risking fire safety compliance as a result, with unskilled individuals using incorrect fixing methods and stripping certified fire doors of their FD rating in the process.

Where Phase 3 of the Building Safety Act 2022 looks to make it easier for enforcement authorities to act against non-compliance, responsible persons are urged to seek trusted, professional help when unsure - in the same way they would rely on qualified persons to assess and install a gas boiler for example. Certified professionals can demonstrate the right skills, knowledge and experience when installing fire door systems and will remove any questions surrounding competence and compliance.

Reducing the gaps

During installation, decision makers must also look to follow manufacturer guidelines and fitting instructions. Door hardware products are often unique to the manufacturer, with distinctive components, fittings and fixing points, and as a result they should never be approached as like for like installation projects.

14

Construction UK Magazine - July 2024

Safety, Security & Fire Prevention

Fire door integrity is frequently compromised by alignment issues and improper installation methods as a result of this knowledge gap. In many cases, an appropriately specified and perfectly operational door closer device can be found ineffective, solely as a result of poor installation. Consequently, a fire door may not be able to latch or close fully from its standing position, leaving gaps large enough for smoke and fire to pass through in an emergency situation. With this in mind, it’s important for responsible persons to plan ahead, appreciating that door hardware installation is a specialised task.

To further raise fire safety standards and improve installation accuracy, there’s a wealth of information and detailed walkthroughs made available from conscious manufacturers in the form of installation templates, product datasheets and video guides. Guidance can usually be found online, with product packaging, or can be requested directly from the manufacturer, and is designed to support installers throughout a project whilst also reducing installation time and enhancing the life of the installed hardware. Product information and installation guidance can also be useful post-installation. Where a responsible person is required to perform ongoing checks and regular maintenance periods as part of their obligations, some fixing instructions may assist in scenarios when hardware adjustments are required.

Fire door hardware installation is neither the first nor final step of fire door safety, but in an evolving regulatory landscape, where we’re seeing a cultural shift in fire safety accountability, responsible persons would be remiss to undervalue the significance of accurate hardware installation. Ultimately, when it comes to fire safety compliance, competence and education go hand in hand.

Construction Site Packs

Fire Protection Shops construction site packs are bundled solutions designed to ensure fire safety on construction sites. These packs include essential fire safety equipment such as fire extinguishers, wireless push button site alarms, robust dustproof cabinets and first aid stations. All tailored to meet the specific needs of construction site environments.

With these complete packs, construction sites are better equipped to handle fires promptly, whilst protecting staff, contractors and valuable equipment from extensive damage. Investing in these all-in-one fire protection solutions enhances safety compliance, minimises potential fire hazards, and ensures a safer working environment for everyone on site.

Low price guarantee

Visit fireprotectionshop.co.uk or call 0330 058 0631 for more information

15

Construction UK Magazine - July 2024

Safety, Security & Fire Prevention

PROMOTING SITE SAFETY WITH INTELLIGENT TRANSPORT SOLUTIONS

By Iain McDonald, business development director, SRL Traffic Systems

Construction remains the most dangerous sector in which to work, with 2022-3 Health and Safety Executive figures attesting to 45 workers killed in accidents – more than double the number in agriculture, forestry and fishing, the second most hazardous industry (www.hse.gov.uk/ statistics/assets/docs/fatalinjuries.pdf).

Fatalities involving vehicles ranked as one of the top three categories.

One of the main goals of contractors responsible for major construction projects such as road building programmes is to facilitate the safe and efficient flow of highways and plant vehicles around works, for the benefit of construction workers and road users alike. Another is ensuring that projects are undertaken sustainably.

As one of Europe’s largest manufacturers and suppliers of mobile intelligent transport solutions (ITS) to the construction sector, SRL Traffic Systems is at the forefront of the development of pioneering systems designed to enable customers to achieve these priorities. Created in partnership with Chevron, for use on Costain’s £330m A30 Chiverton to Carland Cross upgrade project in Cornwall, our patented, 2023 Highways Awards Product of the Year, the Haul Route PLUS system, facilitates the safe and efficient crossing of public highways by construction traffic.

16 Construction UK Magazine - July 2024

Safety, Security & Fire Prevention

Incorporating traffic signals, variable message signs (VMS) to warn drivers of upcoming crossings, work-zone protection barriers, CCTV and ANPR, it is the only temporary solution to feature integrated adaptive detection technology. SRL’s Multiphase unique detection system deploys a high accuracy radar detector to collect data about real time highway and construction traffic volumes and speeds. This enables lights to operate to timings that reflect the actual flow of traffic rather than to pre-set timings to accommodate the slowest plant and reduces carbon emissions caused by sitting vehicles. The “all red” facility ensures that barriers stay open until plant has safely traversed the crossing.

Said Chevron’s operations manager, Martin Hebditch, of the solution comprising eight sets of signals, two VMS and four barriers: “The system was used intensively

and performed exceptionally well, minimising potential disruption to traffic on the extremely busy A3075 diversion route. Both Chevron and Costain were extremely impressed.”

Haul Route PLUS was created with the safety of construction workers in mind and helps to eliminate dangerous incursions. It is the only wireless mobile crossing solution, facilitating swift and easy installation and minimising the cost and restrictions incurred by cabling which may be easily damaged. It automatically switches between main road and haul route barrier system through the detection of construction vehicles and may be operated and monitored remotely from a position of safety. All system components are solar-hybrid, which reduces the number of battery exchanges required and so too the risk to personnel working in live lanes.

Earlier this year, SRL established an exclusive hire partnership with the UK’s largest manufacturer and supplier of security gates, CLD Physical Security Systems. The deal allows customers to choose from two barriers, depending on

Haul Route PLUS was created with the safety of construction workers in mind and helps to eliminate dangerous incursions.

the anticipated project length. While the INSTABOOM barrier caters for short-term contracts, CLD’s RiseMaster HE fully autonomous solar powered automatic boom arm barrier (patent pending) is ideal for longer-term works.

Haul Route PLUS was developed at SRL’s Research and Development Centre, which provides dedicated facilities to support the design of new industry-leading solutions and the construction and testing of prototypes.

The company is one of the leading proponents of the safety of roadworks staff. The ISO 45001 (occupational health and safety) accredited business is a 2022, 2023 and 2024 RoSPA (Royal Society for the Prevention of Accidents) award winner. SRL supports and has adopted a reporting system aligned to the Stamp it Out campaign to tackle roadworker abuse.

SRL is committed to environmental sustainability. Its Achilles Carbon Reduction certificate affirms its commitment to the reduction of carbon emissions in operational activities and the company has achieved ISO 14064 (greenhouse gas emission management and reduction). SRL’s hire model promotes circularity and the business operates the industry’s largest distribution network of over 30 depots, facilitating sustainable delivery.

For further details about SRL’s Haul Route PLUS, please visit: www.srl.co.uk/pages/haulroute-crossing-systems

17 Construction UK Magazine - July 2024

Safety, Security & Fire Prevention News

NEWPORT BASED BUILDERS MERCHANTS TEAMS UP WITH DRAGONS DEN INVESTMENT WINNERS FOR SUN SAFETY CAMPAIGN

J&A Phillips Builders Merchants, a family-run business based in Newport and Solar Buddies, the multi-awardwinning sunscreen applicator business, are collaborating on a ‘Sun Safety OnSite’ campaign aimed at construction workers this summer.

The online and in-store campaign, which will focus on promoting sun safety awareness within the UK construction and building industry, comes in response to recent data highlighting the high incidence of skin cancer attributable to sun exposure in the construction industry.

According to studies carried out at Herriot Watt University, It’s estimated that an outdoor construction worker in Britain could accumulate sufficient solar UV exposure over 30 to 40 years of work to more than double their risk of non-melanoma skin cancer (NMSC).

Construction Management Magazine also finds that construction workers constitute 44% of all occupational skin cancer diagnoses and 42% of occupational skin cancer deaths each year.

The Federation of Master Builders also encourages businesses to implement a

Laura Waters and Kelli Aspland (Solar Buddies founders) and Michael Birch (Director, J&A Phillips)

sun safety policy that includes training, provision of sun protection equipment, and regular reminders for workers to prioritise sun safety.

J&A Phillips will be the first builders merchants in the UK to stock the sunscreen applicators, which will complement Solar Buddies’ existing retailers that includes Asda, Morrisons, Tesco and Boots.

Solar Buddies founders Kelli Aspland and Laura Waters appeared on BBC’s Dragons’ Den in 2023, receiving a total investment of £80,000 from business tycoons Peter Jones and Deborah Meaden.

For more information about the campaign, please visit japhillips.co.uk and solarbuddies.co.uk

SENTRY FIRE SAFETY GROUP NAMED AS ONE OF THE UK’S FASTEST GROWING BUSINESSES

Sentry Fire Safety Group, the UK’s leading manufacturer of bespoke, certified fire safety doorsets, is proud to have been recognised as one of the nation’s fastestgrowing investment-backed businesses.

100% increase in turnover and profits

Since Cairngorm Capital acquired Sentry Doors in 2019, the company has witnessed remarkable growth. A £3 million investment has equipped them with state-of-the-art machinery and a new ERP system which has helped to optimise efficiency.

The Cairngorm Capital investment, coupled with the Knowles acquisition, has more than doubled Sentry’s production capacity, and their product ranges have expanded to include the specialist finishes used by the health, education and private sectors.

This combined investment and acquisition strategy has not only enabled them to cater to new markets through Knowles’ expertise, but also positioned them to meet the growing demands arising from new fire safety legislation. As a result, these efforts have yielded a remarkable 100% increase in both turnover and profits, along with a 36% increase in EBITDA between 2020-2022.

To read the full Real Deals report, visit https://www.bdo.co.uk/en-gb/insights/ industries/private-equity/private-equityvalue-report

18

Construction UK Magazine - July 2024

Safety, Security & Fire Prevention

PROVIDING PASSIVE FIRE PROTECTION AT NEW BUILD LUXURY RESIDENTIAL BLOCK

JQ RISE, BIRMINGHAM

Passive fire protection is crucial for new builds and residential buildings in the UK to ensure the safety and well-being of residents. It involves the use of fireresistant materials and construction techniques to compartmentalize buildings, preventing the spread of fire and smoke. Once the construction had begun for JQ Rise, Element PFP were called upon to survey the 24-floor luxury residential and eventually carry out fire stopping installations across the entire building.

UK regulations, primarily outlined in the Building Regulations Approved Document B, mandate specific fire resistance ratings for various building elements and require the installation of fire doors, firestopping, and cavity barriers in new and renovated residential buildings. These regulations are enforced to ensure that all residential properties provide adequate escape time for occupants and facilitate effective firefighting efforts, thereby significantly reducing the risk of fire-related injuries and fatalities.

The Project

JQ Rise is a luxury residential apartment block based in the heart of Birmingham. It is located just 10 minutes away from the business and financial districts of Brindley Place. The 24-floor and 226-unit new build is currently being constructed and Element PFP were called upon to carry out required fire stopping surveys across the building during the construction phase. This eventually led to full scale construction project of passive fire protection installations.

Following the survey, we swiftly proceeded with our expert fire-stopping works. With unwavering precision and adherence to regulations, our skilled technicians resolved all identified breaches. By meticulously sealing off any gaps or openings that could potentially contribute to the spread of fire, we ensured that the building met the highest safety standards before the development could proceed.

In addition to our fire-stopping expertise, we also conducted steel protection works further to enhance the fire safety measures of the building. Our meticulous examination of the framework ensured that there were no issues that could interfere with critical fire safety precautions. This comprehensive approach mitigated potential risks and provided the building’s occupants with an added layer of safety.

Our meticulous examination of the framework ensured that there were no issues that could interfere with critical fire safety precautions.

We provide fire compartmentation surveys, fire door installation, fire stopping installation and fire protection services for both the private and public sectors. We work closely with clients, providing a professional, knowledgeable, and thorough service. Implementations of fire safety measures are explained clearly so our clients know exactly what work is being carried out.

We take care of every element of passive fire protection, ensuring all aspects of fire safety are taken care of. Get in touch to find out more about our passive fire protection services today and find out how we can improve fire safety for your building.

Passive Fire Protection with Element PFP

Passive Fire Protection with Element PFP

19 Construction UK Magazine - July 2024

Safety, Security & Fire Prevention News

FSI PROMAT LAUNCHES WHITE PAPER TO HIGHLIGHT

IMPORTANCE OF

ACCOMMODATING DYNAMIC MOVEMENT IN FIRE STOPPING

FSi Promat has launched a new white paper highlighting the impact dynamic movement can have on the effectiveness of penetration seals – and what can be done to ensure passive fire protection remains compliant for the lifetime of a building.

The stress that movement can put on a building can cause breaches, tears and cracks in the construction materials, including in fire stopping that has been used to reinstate the compartment to contain the spread of flames, smoke, heat and toxic gases. Despite the potentially serious impact on building safety, accommodating dynamic movement in fire stopping plans is often overlooked.

Approved Document B (fire safety) states the need for an “appropriate fire seal” that will last for the lifetime of the building. But with no formal testing mechanism under the EN1366-3 standard or European Technical Assessment (ETA) specifically for movement within penetration seals, this element often falls out of the scope of building design.

The new white paper, ‘Managing Movement: Accommodating dynamic movement in fire stopping for penetration seals’ takes an in-depth look at the impact of movement on fire stopping, existing legislation and guidance around the issue, and how FSi Promat has engineered a solution – plus the evaluation to support that solution.

Craig Abbott, Technical Director at FSi Promat – part of the Etex group, explains: “Service penetrations are part and parcel of construction and must be accommodated within passive fire protection utilising appropriate fire stopping systems.

“However, where movement is present in a building it is essential that sufficient flexibility is built into this system to mitigate the effects of dynamic movement on the performance of the penetration seal.”

Discover more about the impact of dynamic movement on fire stopping in penetration seals and how to find a solution to maintain compliance –download the white paper here.

WE TEST…

Because evidence matters. Because it enables us to respond more quickly.

Because offering transparency helps educate our customers.

Because it’s our job to inform best practice.

Because it’s our job to offer guidance. Because firestopping is complex.

Because results are worth sharing.

Because people matter. WE SHARE… BECAUSE IT’S YOUR JOB TO KNOW.

Download our White Paper, ‘Early Engagement in Firestopping’ at quelfire.co.uk/campaign

The sooner, the better.

20

Construction UK Magazine - July 2024

Women in Construction

BREAKING GROUND: EMPOWERING WOMEN IN BRICKLAYING

In recent years, the construction and engineering sectors have witnessed a remarkable surge in the number of young women undertaking apprenticeships – a staggering 366% increase, to be precise. This statistic represents a significant shift in the traditionally male-dominated landscape of these industries. However, despite this encouraging trend, women still constitute a mere 15% of the current workforce. This disparity highlights the persistent challenges and stigma that continue to impede gender diversity in bricklaying.

One of the primary hurdles faced by women entering bricklaying is the enduring stigma associated with the job. It has long been viewed as a physically demanding, male-centric career, with stereotypes often discouraging women from pursuing roles in this sector. Breaking down these misconceptions is essential to creating a more inclusive and diverse industry.

To effect real change, it’s vital to move away from this outdated stigma and embrace diversity wholeheartedly. This entails not only fostering a culture of inclusivity within construction companies but also investing in recruitment strategies that actively seek out and welcome women into the workforce. We need to see more companies invest in targeted outreach programmes, apprenticeships, and mentorship opportunities specifically tailored for women. Additionally, creating supportive and inclusive work environments is key to retaining women in bricklaying careers. Providing ongoing training, professional development, and

pathways for career advancement are essential components of fostering a diverse and thriving workforce.

The Association of Brickwork Contractors (ABC) encourages its members to sign up to the Fairness, Inclusion and Respect programme, an

industry-wide initiative that supports businesses in the built environment to meet legal obligations around equality and diversity in order to create a more inclusive sector. The programme offers training, resources and guidance so that employers can address workplace culture challenges as a way to attract and maintain a more diverse workforce.

To effect real change, it’s vital to move away from this outdated stigma and embrace diversity wholeheartedly. This entails not only fostering a culture of inclusivity within construction companies but also investing in recruitment strategies that actively seek out and welcome women into the workforce.

ABC members are also really championing female bricklaying apprenticeships as they understand the requirement to close this gender gap. Studies have shown that construction sites are more productive with women on board, which highlights the value of diversity and inclusivity in the trade.

Changing perceptions about women in bricklaying requires a concerted effort from all stakeholders including industry leaders, educators and society at large. By challenging stereotypes and showcasing the achievements of women already making waves in the sector, we can inspire the next generation of female talent to pursue careers in bricklaying and other roles in construction, not just the trades. We must work harder to showcase the diverse roles and progression opportunities available within the industry in order to dispel myths and attract more women to consider bricklaying.

The current momentum we’re seeing is promising, but there is still much ground to cover. To achieve true gender parity and harness the full potential of a diverse workforce, we must continue to advocate for systemic change. By collectively challenging stereotypes, embracing diversity, and investing in recruitment and training initiatives, we can pave the way for a future where women play a vital role in shaping the built environment.

21

Construction UK Magazine - July 2024

UK ROOFING AWARDS 2024 WINNERS ANNOUNCED

The winners of the 2024 NFRC UK Roofing Awards were revealed on the 10th May at the InterContinental London—The O2, in a glittering awards ceremony hosted by actor, comedian, Hal Cruttenden.

The Headline Sponsor for the event was Radmat Building Products, and Recticel Insulation UK Ltd were the sponsor of the drinks reception and after-show party.

The winners of each project category were as follows:

Bituminous Hot Applied Liquid Waterproofing, sponsored by Carlisle Construction Materials Ltd - Fenland Flat Roofing Ltd, working with Sika Ltd, Rhodes House

Cold Applied Liquid Waterproofing - Alpha Specialist Roofing Ltd, working with Polyroof Products Ltd—Sir John Moore Barracks, Shorncliffe Army Camp

Fully Supported Metal, sponsored by Radmat Building Products - Prestige Metal Roofing Ltd, Tidworth, Copper Dome

Green Roofing, sponsored by Bauder - Roofworx (UK) Ltd, Stour Road, Hackney

Heritage Roofing, sponsored by Glidevale Protect - Emerton Roofing (Western) Ltd. East Manley Hall

Leadwork, sponsored by Radmat Building Products - NRA Roofing & Flooring Services Ltd, Derby Museum Clock Tower

Mastic Asphalt, sponsored by MAC (Mastic Asphalt Council) - BriggsAmasco Ltd—Sumburgh Head Lighthouse Visitors Centre

Multi-discipline Project over £250k, sponsored by Harrowden - EJ Roberts Roofing Ltd, Lucent W1

Rainscreen Façades, sponsored by Protektor Wemico - Thornton Roofing (Ireland) Ltd, Templemore Baths, Belfast

Reinforced Bitumen Membranes, sponsored by Sika Ltd - Inspire Contract Services Ltd working with Bauder (UK) Ltd, Lloyd’s of London

Roof Slating, sponsored by CUPA PIZARRAS, S.A. - Martin-Brooks (Roofing Specialists) Ltd. The Roundhouse, Leeds

Roof Tiling, sponsored by MarleyClarke Roofing Southern Ltd, Heatherfield

Sheeting & Cladding, sponsored by Euroclad Group Ltd - Lindner Prater Ltd, Aviva Studios (Factory International)

Single Ply Roofing, sponsored by Recticel Insulation (UK) Ltd - Invictus Roofing Ltd, Bellingham Commercial

Small Scale Project (Under £25k, sponsored by Keylite Roof Windows - Matt Timby Ltd, St Andrews Bell Tower

Solar Roofing, sponsored by Sandtoft - MAC Roofing & Contracting Ltd, DLS Synchrotron

Industry Choice Award, sponsored by Radmat Building Products - Inspire Contract Services Ltd working with Bauder (UK) Ltd, Lloyd’s of London

Project of the Year Award, sponsored by SIG Roofing - MAC Roofing & Contracting Ltd, DLS Synchrotron

Three individuals were also recognised for their contributions to the industry.

Young Roofer of the Year, sponsored by BMI - Frankie Storrie, Oxley Asphalte Roofing Services Ltd

Local Hero Award, managed by SIG Roofing - Josh Morrison, J R Roofing Lancs Ltd

Health and Safety Individual of the Year Award, sponsored by ROCKWOOL - Mark Cardnell, H&S Manager, Inspire Contract Services Ltd

MEADFLEET TO BE HONOURED AT INTERNATIONAL CSR EXCELLENCE AWARDS 2024

Leading open space management provider Meadfleet is thrilled to announce its success against more than 500 other nominations in the campaign to find the companies with the best social responsibility initiatives. The company will be presented with their trophy and certificate at a glittering presentation ceremony in the world-famous St Paul’s Cathedral, London on 1st July.

Meadfleet’s success in the International CSR Excellence Awards recognises its commitment to corporate social responsibility whilst providing housebuilders with a sustainable and innovative open space management solution.

David King, Managing Director of Meadfleet commented: “We are delighted our efforts as a socially responsible organisation have been recognised in the International CSR Excellence Awards. Meadfleet aim to promote best practice across our operations, from being Carbon Neutral, initiating industry leading biodiversity campaigns and leading community engagement projects. We are looking forward to celebrating with our fellow winners in July”.

The CSR Excellence Awards are run by The Green Organisation - an international, independent, non-profit, non-political environment group that began in 1994 to recognise, reward and promote social responsibility best practice around the world.

22 Events & Awards News Construction UK Magazine - July 2024

WILLMOTT DIXON RECOGNISED FOR CREATING INCLUSIVE OPPORTUNITIES

Willmott Dixon’s activities to help young people with neurodiversity get important work experience in the construction industry has been recognised by one of the UK’s largest providers of education and care for young people with special educational needs.

The company is one of the first to receive a Future Employers Award from Witherslack Group, which operates 35 SEN schools nationally for children and young people aged from four to 19. Presented in collaboration with the ADHD Foundation Neurodiversity Charity, it recognises Willmott Dixon’s support over the past year organising site visits and workshops that offered employability skills, careers training and mentoring for 134 students.

As a Future Employers Award winner, Willmott Dixon employees can now access training from the ADHD Foundation, where they can participate in awareness sessions aimed at

enhancing understanding and support for neurodiverse individuals.

The project demonstrates Willmott Dixon’s commitment to ensure that alongside their customer’s buildings it leaves a lasting legacy for local people and communities.

Winner of a King’s Award for Promoting Opportunity in 2023, the company delivered over 300 community

programmes nationally, positively impacting 5,565 lives and creating a £577m social return on investment over the course of the year.

BELOW: Celebrating being a Future Employers Award winner; from left to right: Alison Gibney – Witherslack Group, Brian Hall – Willmott Dixon, Vickie Thornton –Willmott Dixon, Nicola Tyson-Lightfoot – Willmott Dixon, Chris Yates – Willmott Dixon, Fiona Kain – Witherslack Group.

23 Construction UK Magazine - July 2024

BUILDING THE MARKET FOR IN-ROOF SOLAR

In-roof solar may still be a relatively new technology, but the market is building quickly. Suppliers such as Wienerberger are helping to upskill contractors through specialist training, providing essential skills and knowledge for the growing solar energy market. Simon Garbett, Category Manager for Roofing Systems, Wienerberger, explains more.

While Wienerberger only introduced its Sandtoft in-roof solar panels a year ago, demand for the technology has been increasing ever since. Popular with roofing contractors, these interlocking panels install directly onto roof battens, mimicking traditional tiled roofs and fitting both clay and concrete tiles. Each panel weighs just 8.95 kg and mounting directly to battens cuts installation costs. The panels are part of a full roofing package that includes inverters and batteries, integrating fabric, solar, and storage technologies.

While making products and technology available is important, encouraging their adoption is a different challenge. This is especially true given that the Spring Budget did not address the industry’s need for a skilled workforce. By leveraging recent technologies, we can upskill the existing workforce through targeted, effective product training, building the market for in-roof solar.

Equipping tradespeople

In-roof solar training covers more than installation; it is also important that contractors understand the importance of the technology, particularly in relation to the Future Homes Standard and lowering carbon emissions from a building.

Wienerberger’s core in-roof solar training is an interactive, half-day, in-person session designed for those seeking an overview of its in-roof solar PV system. The training takes place at

Wienerberger’s Centre of Excellence, located at its dedicated Sandtoft facility. For flexible, self-paced learning, the free on-demand online training offers comprehensive installation demonstrations with detailed instructions and helpful tips. Taking about an hour to complete, the training is designed for roofers and installers but is also useful for other construction professionals.

A UK first

Such is the appeal and significance of in-roof solar that contractors can now access an Electrotechnical Certification Scheme Test, a first in the UK. Delivered by Wienerberger and energy training provider GTEC Training, the programme covers key topics like navigating UK building regulations, understanding local grid requirements, and implementing the latest solar innovations. By participating, installers enhance their technical skills and business capabilities while gaining a thorough understanding of the regulatory landscape for UK solar installations. The course includes handson training on in-roof solar panel and inverter installation, as well as electrical safety.

Through a combination of training courses, manufacturer insights, and new technological breakthroughs, the building sector is rapidly adapting to more sustainable production techniques. By leveraging in-roof solar technology, homes can now be built with the capability to generate and store their own energy, paving the way for a more self-sufficient and eco-friendly future.

As the market embraces these innovative solutions, it becomes evident that the old adage rings true: if you build it, they will come. The sector’s proactive approach to upskilling professionals and integrating cutting-edge technologies is driving the widespread adoption of sustainable practices, shaping the way we construct and power our living spaces for generations to come.

To learn more about Sandtoft in-roof solar PV systems and its training portfolio, visit Advanced Solar Training | Wienerberger UK.

24 Solar

Construction UK Magazine - July 2024

Energy

Project Oak CASE STUDY

Fassa augment listed building with its thermal render solution

Fassa Bortolo, the forefront Italian render manufacturer, has recently provided its expertise to the completion of Project Oak, the new four-storey global headquarters for Spirax Sarco Engineering in Cheltenham.

Tasked with augmenting the existing listed building, Charlton House, which has served as the headquarters for over eight decades, Fassa Bortolo undertook the construction of a curved extension to complement the historic structure. This innovative addition boasts 180 workstations, a gym, and an auditorium, embodying modern functionality within a heritage context.

For the external rendering, Fassa Bortolo deployed its state-of-the-art Fassatherm system, specifically the Fassatherm Frame Plus system, certified by Kiwa BDA. This system, renowned for its efficiency, utilises A 96 adhesive along with mineral wool insulation, ensuring both thermal performance and structural integrity.

The finishing coat, was the application of RX 561 acrylic-siloxane top coat. This not only ensures a flawless finish, but also provides essential protection against environmental elements.

Designed by Roberts Limbrick, the project’s architectural finesse is paralleled by its commitment to sustainability, achieving an esteemed BREEAM ‘Outstanding’ accreditation, a testament to its positioning among the top 0.5% of sustainable new builds worldwide.

In alignment with the project’s ethos of efficiency and sustainability, Fassa Bortolo’s involvement exemplified their commitment to delivering bespoke solutions that seamlessly integrate cutting-edge technology with architectural brilliance.

Fassatherm Frame Plus system, certified by Kiwa BDA

Utilises A 96 adhesive along with mineral wool insulation

RX 561 acrylic-siloxane top coat

BDA Agrément

FASSA NATIONAL SPECIFICATION MANAGER: Stephen Gore

PROJECT: Project Oak, Cheltenham

ARCHITECT: Roberts Limbrick

SYSTEM: Fassatherm Frame Plus

White and grey fibrereinforced cementitious adhesive, grading < 1.4 mm.

Thermal insulation panels, manufactured by melting and spinning stone materials.

TO FIND OUT MORE about Fassa Bortolo and its range of render systems and building products. Visit www.fassabortolo.co.uk or call 01684 218 305

160 g/m² alkali-resistant fibreglass reinforcing mesh, 4.15x3.8 mm mesh size.

Universal pigmented primer-undercoat.

Rustic acrylic-siloxane coating with high water repellency and broad-spectrum protection against growth of algae and mould species.

A 96 FX 526

RX 561

MINERAL WOOL

FASSANET 160

UVAC WARNS OF THREAT TO CONSTRUCTION SKILLS GAP POSED BY APPRENTICESHIP LEVY REFORM

A new report by the University Vocational Awards Council (UVAC) has today warned that drastic reform or the abolishment of the government’s Apprenticeship Levy scheme will have a hugely detrimental impact on the skills gap across the construction sector.

Cuts to funding of higher and degree apprenticeships, that are so critical to training core sectors and occupations such as construction to a senior level, will lead to a decline in skilled professionals.

The warnings come from UVAC, which is the voice for over 90 universities that deliver higher and degree apprenticeships and has just produced a white paper setting out the future of the

apprenticeship levy and what a future government should consider to maintain the volume and quality of delivery of higher-level skills.

The levy was first introduced in 2017 and is funded by a 0.5% compulsory contribution by employers with payroll costs of over £3m. It was met with some concerns especially from levy-paying organisations, regarded as another form of business taxation and has recently come under heavy scrutiny.

One possible reform UVAC has recommended in its new report is the ring fencing of public sector levy payments. This would ensure that employers, such as the NHS, would

The warnings come from UVAC, which is the voice for over 90 universities that deliver higher and degree apprenticeships and has just produced a white paper setting out the future of the apprenticeship levy and what a future government should consider to maintain the volume and quality of delivery of higher-level skills.

have far greater control over where it spends its payments, regardless of whether restrictions were introduced for employers in the private sector.

Other proposed reforms to the levy opposed by UVAC could include a graduate ban which would prevent funding being spent on young people and adults pursuing a construction-based higher or degree apprenticeship.

The new report on the future of the Apprenticeship Levy will be freely available to view online from June when published on www.uvac.ac.uk.

TALENT- ctct CONCRETE QUALIFICATIONS FOR ALL On-line training leading to Institute of Concrete Technology qualifications Concrete Technology & Construction • General Principles • Practical Applications Courses approved by The Institute of Concrete Technology Enrolments now invited! FURTHER INFORMATION: info@talentconcretetraining.org.uk 01723 567432 www.talentconcretetraining.org.uk

28 Training

Construction UK Magazine - July 2024

& Education News

THE RETROFIT HUB LAUNCHES TRAINING CENTRE TO MEET GROWING DEMAND FOR DECARBONISING HOMES

As the demand to decarbonise homes intensifies, The Retrofit Hub is proud to announce the launch of its new training centre. This initiative aims to support the construction workforce by providing access to essential training and qualifications in retrofit practices. Currently offering in-person sessions, the training centre plans to expand to online courses in the near future.

At the core of The Retrofit Hub is a dedicated team of retrofit-led builders. Serving clients across South Manchester and East Cheshire, we are committed to improving the energy efficiency of homes through high-quality retrofit solutions. Our deep understanding of retrofit methodologies has inspired us to establish this training centre, with the goal of sharing our knowledge, enhancing competence within the sector, and ensuring that superior retrofit practices become standard.

“Our team possesses extensive expertise in retrofit, and we believe in the importance of sharing that knowledge to elevate the entire industry,” said Richard Shears, Director at The Retrofit Hub. “By opening this training centre, we aim to foster competence and uphold the highest standards in retrofit practices.”

The Retrofit Hub’s training programmes are practical and immersive, specifically developed by retrofit professionals for professionals. The curriculum addresses real-life challenges and offers practical solutions, grounding participants in both fundamental principles and advanced techniques.

Looking ahead, The Retrofit Hub plans to offer online training modules, making it even easier for professionals to access the knowledge and skills required to excel in the retrofit sector.

For more information about The Retrofit Hub’s training centre, or to inquire about custom training solutions, please visit our website at theretrofithub.co.uk or visit our training profile on Eventbrite at www.eventbrite.co.uk/o/the-retrofithub-78340399803

CARPENTRY STUDENTS CREATE BUG HOTEL FOR RHS CANCERAWARENESS GARDEN

For the second consecutive year, students at Leeds College of Building are using their skills to help create a poignant RHS show garden.

The Level 1 Diploma Carpentry & Joinery students have crafted two five-foot triangular wooden bug hotels. The structures will feature at the main entrance of a garden going on display at RHS Tatton Flower Show 2024 (17 – 21 July).

Led by garden designer Carolyn Hardern and landscape construction manager Jon Jarvis, the project will raise awareness about melanoma skin cancer in the construction industry. The ‘1804 Garden’ is named after the date melanoma was first referred to in the medical world.

Research shows that working outdoors in the sun leads to around five melanoma cases and one death a week in the UK. Last year, construction workers accounted for 44% of occupational skin cancer diagnoses and 42% of occupational skin cancer deaths each year – despite construction workers making up only 8% of the workforce.

At just over 300m², the garden will be the largest at the Tatton Flower Show this year and promote the charities Band of Builders and Melanoma UK. The garden is shaped like an equilateral triangle, inspired by the yellow and black radiation symbol often found in hospital cancer centres.

The Leeds College of Building students recycled waste timber from previous

projects to make the bug hotels. Wood was glued and planed to required sizes and drilled, screwed, glued, and dowel jointed together. They finished off the hotels by adding a wooden beetle shape and each will be filled with natural materials collected by pupils at Wrenbury County and Bickerton primary schools in Cheshire.

Inspired by the theme of wellbeing and mental health, the garden included over 700 wooden hearts spray painted the colour of hard hats by Leeds College of Building painting and decorating apprentices. Each represented a life taken by suicide in the construction sector in just one year.

The 1804 Garden will go on to feature on a smaller scale at the Southport Flower Show in August before being donated to a worthy, permanent local home. The project will cost in the region of £30k and donations towards the build and garden relocation are now being asked via the project’s Just Giving page.

29

Education News Construction UK Magazine - July 2024

Training &

Training & Education

HOW TO BUILD A LEARNING AND DEVELOPMENT PROGRAMME FOR THE CONSTRUCTION SECTOR

The Construction Industry Training Board predicts the UK will need an extra 251,500 construction workers by 2028 to meet the expected levels of work. That means over the next few years there will be thousands of individuals eager to develop their skills in the sector.

Most organisations know the importance of training their staff, but the best businesses implement an adaptable Learning and Development (L&D) strategy to harness their workforce’s desire to succeed. Capitalising on the unearthed talent pool within an organisation not only benefits the individual, but also boosts business performance.

The Acivico way

We invest more than £100,000 into our own employee learning and development programme annually, which is much higher than similar sized SMEs in our field. In return, we’ve seen an annualised voluntary turnover rate drop from 15.1% in February 2023 to 9.1% in February 2024, as well as a substantial increase in employee satisfaction through our Employee Net Promoter Score.

We’ve also used the opportunity to develop our own talent, attracting the young generation through graduates, apprenticeships, and trainees, and utilised the apprenticeship levy for the first time to the value of 26K.

Marina Robertson, Managing Director at Acivico Group, said: “Our vision at Acivico Group is to use our expertise to

Marina Robertson

Marina Robertson

promote public wellbeing and sustainable development. Investing in learning and development is central to our viability, as expertise is the raw material of all our production activities. Some may say that this investment is wasted if the employee chooses to then leave the business but as a purpose led business our investment benefits the industry as a whole as it increases skills capacity in the sector.”

But if you’re struggling where to start in revamping your L&D strategy, here are some things to consider.

• Establish objectives

A successful L&D strategy should define objectives from the beginning. Objectives will vary and should take into account your business goals and the types of skills your workforce will benefit from having. For example, recent changes

to the Building Safety Act, which saw individuals required to register towards a new regulator and demonstrate the highest level of competence in their field, presents a perfect opportunity to set an attainable training goal for new trainees and existing employees.

• Know what works

How will you give your staff an environment to learn? How will you ensure the training adds value? At Acivico Group, we’ve had success creating in-house compliance and softskills training tailored towards the Built Environment industry. But, training isn’t a one size fits all and you may want to consider external training packages or professional memberships as well as coaching and partnering with experts.

• Anaylse the metrics

Think about your key performance indicators and what you want to get out of an L&D programme. This could be anything from customer satisfaction, profitability or employee retention. Track the progress of these metrics before and after implementing the programme because it will allow for easy evaluation of how well the plan is working.

• Never stop improving

An effective L&D program is powered by continuous refinement and willingness to change in the response to feedback. The annual Learning At Work week, which takes place each May, presents an opportunity to sit down with your team to discuss ways of working and employee learning that can evolve in the ever changing construction landscape. The benefits of a successful learning and development programme and positive learning culture include a boost in staff morale, better customer service, and reduced turnover.

By Marcus Passant, Group Director of People and Governance, Acivico Group

30

Construction UK Magazine - July 2024

Training & Education News

NOCN GROUP FIRST AWARDING ORGANISATION TO BE APPROVED TO DELIVER EPA FOR NEW LOW CARBON HEATING TECHNICIAN APPRENTICESHIP

NOCN Group is the first Awarding Organisation to be approved to deliver End Point Assessment for the new Low Carbon Heating Technician Apprenticeship Standard.

Training Providers and employers offering the new apprenticeship to their learners and employees will be able to choose NOCN as the approved independent End Point Assessment Organisation on the Government’s online Apprenticeship portal.

The 36 month-long Low Carbon Heating Technician programme is a designated ‘Royal Apprenticeship’ hand-picked by industry experts to celebrate the King’s Coronation due to its green credentials. The broad purpose of the occupation is to plan, select and size, install, commission, service and maintain (including fault finding, diagnosis and repair) zero carbon central heating and hot water systems in buildings including dwellings and industrial and commercial premises.